Sun Microsystems ULTRA ENTERPRISE 6000, ULTRA ENTERPRISE 5000, ULTRA ENTERPRISE 4000 User Manual

Page 1

Ultra™Enterprise™6000/5000/4000 SystemsInstallationGuide

The Network Is the Computer

Sun Microsystems Computer Company

2550 Garcia Avenue

Mountain View, CA 94043 USA

415 960-1300 fax 415 969-9131

Part No.: 802-3844-11

Revision A, November 1996

™

Page 2

Copyright 1996 Sun Microsystems,Inc.2550GarciaAvenue,MountainView, California 94043-1100U.S.A.

All rights reserved.Thisproductordocumentisprotectedbycopyrightanddistributedunderlicensesrestrictingitsuse,copying,distribution,

and decompilation. No part of this productordocumentmaybereproducedinanyformbyanymeanswithoutpriorwrittenauthorizationof

Sun and its licensors, if any.

Portions of this productmaybederivedfromtheUNIX®system and fromtheBerkeley4.3BSDsystem,licensedfromtheUniversityof

California. UNIX is a registeredtrademarkintheUnitedStatesandinothercountriesandisexclusivelylicensedbyX/OpenCompanyLtd.

Third-partysoftware,includingfonttechnologyinthisproduct,isprotectedbycopyrightandlicensedfrom Sun’s suppliers.

RESTRICTED RIGHTS LEGEND: Use, duplication, or disclosurebytheU.S.GovernmentissubjecttorestrictionsofFAR52.227-14(g)(2)(6/87)

and FAR52.227-19(6/87),orDFAR252.227-7015(b)(6/95)andDFAR227.7202-3(a).

Sun, Sun Microsystems,theSunlogo,Solaris,Enterprise,Ultra,UltraComputing,UltraServer, and UltraSPARC aretrademarksorregistered

trademarks of Sun Microsystems,Inc.intheUnitedStatesandinothercountries.AllSPARCtrademarksareusedunderlicenseandare

trademarks or registeredtrademarksofSPARCInternational,Inc.intheUnitedStatesandinothercountries.ProductsbearingSPARC

trademarks arebaseduponanarchitecturedevelopedbySunMicrosystems,Inc.

The OPEN LOOK®and Sun™ Graphical User Interfaces weredevelopedbySunMicrosystems,Inc.foritsusersandlicensees.Sun

acknowledges thepioneeringeffortsofXeroxCorporationinresearchinganddevelopingtheconceptofvisualorgraphicaluserinterfacesforthe

computer industry.SunholdsanonexclusivelicensefromXeroxtotheXeroxGraphicalUserInterface,whichlicensealsocoversSun’slicensees

who implement OPEN LOOK GUIs and otherwise comply with Sun’s written license agreements.

THIS PUBLICATION IS PROVIDED “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING,

BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, OR

NON-INFRINGEMENT.

Copyright 1996 Sun Microsystems,Inc.,2550GarciaAvenue,MountainView, Californie 94043-1100U.S.A.

Tous droitsréservés.Ceproduitoudocumentestprotégéparuncopyrightetdistribuéavecdeslicencesquienrestreignent l’utilisation, la copie

et ladécompilation.Aucunepartiedeceproduitoudesadocumentationassociéenepeutêtrereproduite sous aucune forme, par quelque moyen

que ce soit, sans l’autorisation préalable et écrite de Sun et de ses bailleurs de licence, s’il y en a.

Des parties de ce produitpourront être derivées du système UNIX®et du système Berkeley 4.3 BSD licencié par l’Université de Californie. UNIX

est une marque enregistrée aux Etats-Unis et dans d’autres pays, et licenciéeexclusivement par X/Open Company Ltd. Le logiciel détenu par des

tiers, et qui comprendla technologie relative aux polices de caractères, est protégé par un copyright et licencié par des fournisseurs de Sun.

Sun, Sun Microsystems,le logo Sun, Solaris, Enterprise, Ultra, UltraComputing, UltraServer,et UltraSPARCsont des marques déposées ou

enregistréesde Sun Microsystems, Inc. aux Etats-Unis et dans d’autres pays. Toutesles marques SPARC, utilisées sous licence, sont des marques

déposées ou enregistréesde SPARCInternational, Inc. aux Etats-Unis et dans d’autres pays. Les produits portant les marques SPARC sont basés

sur une architecturedéveloppée par Sun Microsystems, Inc.

Les utilisateurs d’interfaces graphiques OPEN LOOK®et Sun™ ont été développés de Sun Microsystems, Inc. pour ses utilisateurs et licenciés.

Sun reconnaîtles efforts de pionniers de Xerox Corporation pour la rechercheet le développement du concept des interfaces d’utilisation visuelle

ou graphique pour l’industrie de l’informatique. Sun détient une licence non exclusive de Xerox sur l’interface d’utilisation graphique, cette

licencecouvrant aussi les licenciés de Sun qui mettent en place lesutilisateurs d’interfaces graphiques OPEN LOOK et qui en outrese conforment

aux licences écrites de Sun.

CETTE PUBLICATION EST FOURNIE “EN L’ETAT” SANS GARANTIE D’AUCUNE SORTE, NI EXPRESSE NI IMPLICITE, Y COMPRIS, ET

SANS QUE CETTE LISTE NE SOIT LIMITATIVE, DES GARANTIES CONCERNANT LA VALEUR MARCHANDE, L’APTITUDE DES

PRODUITS A REPONDRE A UNE UTILISATIONPARTICULIERE OU LE FAIT QU’ILS NE SOIENT PAS CONTREFAISANTS DE PRODUITS

DE TIERS.

Please

Recycle

Page 3

Contents

1. Preparing for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 Unpacking the Enterprise 6000/5000 Cabinet Systems. . 1-3

1.2 Shipping and Storing the System . . . . . . . . . . . . . . . . . . . . 1-4

1.3 Preparing the Electrical Circuits. . . . . . . . . . . . . . . . . . . . . 1-5

1.3.1 Enterprise 6000/5000 Cabinet Systems . . . . . . . . . . 1-5

1.3.2 Enterprise 4000 System. . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.4 Preparing the Air Conditioning . . . . . . . . . . . . . . . . . . . . . 1-7

1.5 Preparing the Ethernet Network . . . . . . . . . . . . . . . . . . . . 1-7

1.6 Preparing the Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.6.1 Floorspace for the Enterprise 6000/5000

Cabinet Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.6.2 Surface for the Enterprise 4000 System . . . . . . . . . . 1-10

1.7 Preparing the Enterprise 6000/5000 Cabinet Systems. . . 1-11

1.7.1 Moving the Server. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1.7.2 Adjusting the Levelling Pads. . . . . . . . . . . . . . . . . . . 1-12

1.8 Preparing the Enterprise 4000 System . . . . . . . . . . . . . . . . 1-14

iii

Page 4

1.9 Using the User Naming Area . . . . . . . . . . . . . . . . . . . . . . . 1-15

2. Cabling the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 Preparing the System for Cabling. . . . . . . . . . . . . . . . . . . . 2-1

2.2 Removing and Replacing the Enterprise 6000/5000

Cabinet Rear Screen and Kick Panel . . . . . . . . . . . . . . . . . 2-1

2.3 Connecting the Power Cords . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.3.1 Connecting the Enterprise 6000/5000 System

Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.3.2 Connecting the Enterprise 4000 System

Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.4 Connecting the Network Cable to the System . . . . . . . . . 2-6

2.5 Connecting the System to the Network. . . . . . . . . . . . . . . 2-7

2.6 Connecting an ASCII Terminal. . . . . . . . . . . . . . . . . . . . . . 2-10

2.7 Connecting the Fiber Cable to the I/O Board. . . . . . . . . . 2-11

2.8 Connecting External SCSI Devices. . . . . . . . . . . . . . . . . . . 2-12

3. Powering the System On and Off . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1 Using JumpStart Automatic Installation . . . . . . . . . . . . . . 3-1

3.2 Enterprise 6000/5000 Cabinet Systems . . . . . . . . . . . . . . . 3-2

3.2.1 Powering On the System . . . . . . . . . . . . . . . . . . . . . . 3-2

3.2.2 Reading Boot Messages . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.2.3 Interpreting Status LED Patterns . . . . . . . . . . . . . . . 3-8

3.2.4 Powering Off the System . . . . . . . . . . . . . . . . . . . . . . 3-9

3.3 Enterprise 4000 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.3.1 Powering On the System . . . . . . . . . . . . . . . . . . . . . . 3-10

3.3.2 Reading Boot Messages . . . . . . . . . . . . . . . . . . . . . . . 3-13

iv Ultra Enterprise 6000/5000/4000 Systems Installation Guide—November 1996

Page 5

3.3.3 Interpreting Status LED Patterns . . . . . . . . . . . . . . . 3-13

3.3.4 Powering Off the System . . . . . . . . . . . . . . . . . . . . . . 3-15

3.4 Failure of Network Communications . . . . . . . . . . . . . . . . 3-16

4. Using the Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 Operating System Software. . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Solstice SyMON Software . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Index-1

Contents v

Page 6

vi Ultra Enterprise 6000/5000/4000 Systems Installation Guide—November 1996

Page 7

Figures

Figure 1-1 Ultra Enterprise 6000/5000/4000 Systems . . . . . . . . . . . . . . . . 1-2

Figure 1-2 Attaching the Ramps to the Shipping Pallet . . . . . . . . . . . . . . . 1-4

Figure 1-3 NEMA L6-30P Electrical Connector . . . . . . . . . . . . . . . . . . . . . . 1-5

Figure 1-4 IEC 309 Electrical Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Figure 1-5 Types of Network Cables Used. . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Figure 1-6 Example of 10/100BASE-T (Twisted-Pair) Ethernet . . . . . . . . 1-8

Figure 1-7 Cabinet Server Access Areas — Top View . . . . . . . . . . . . . . . . 1-10

Figure 1-8 Standalone Server Access Areas — Top View . . . . . . . . . . . . . 1-11

Figure 1-9 Moving the Server Safely Down the Ramps . . . . . . . . . . . . . . . 1-12

Figure 1-10 Rear Screen, Levelling Wrench, Kick Panel, and

Levelling Pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Figure 1-11 Stabilizer Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Figure 2-1 Keyswitch Standby Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Figure 2-2 AC Power Sequencer Power Switch and Rear Screen . . . . . . . 2-3

Figure 2-3 Routing Cables Under the Kick Panel . . . . . . . . . . . . . . . . . . . . 2-4

Figure 2-4 Key Switch Positions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Figure 2-5 AC Power Switch and Power Receptacle. . . . . . . . . . . . . . . . . . 2-6

vii

Page 8

Figure 2-6 Network Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Figure 2-7 10/100BASE-T Ethernet Connection . . . . . . . . . . . . . . . . . . . . . 2-7

Figure 2-8 Connecting Twisted Pair Ethernet to N-type Coaxial

Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Figure 2-9 Ethernet Cabling Length — Example Using N-type

Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Figure 2-10 Clock Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Figure 2-11 Fiber Cable and Fibre Card Connectors and Ports

on the I/O Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Figure 2-12 Onboard Single-ended SCSI Connector on the I/O Board . . . 2-14

Figure 3-1 Key Switch Positions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Figure 3-2 The AC Power Sequencer Power Switch . . . . . . . . . . . . . . . . . . 3-4

Figure 3-3 Local/Remote Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Figure 3-4 CPU Reset Switch on the Clock Board . . . . . . . . . . . . . . . . . . . 3-7

Figure 3-5 System Status LEDs (Cabinet Server). . . . . . . . . . . . . . . . . . . . . 3-8

Figure 3-6 Key Switch Positions and AC Power Switch. . . . . . . . . . . . . . . 3-11

Figure 3-7 CPU Reset Switch on Clock Board . . . . . . . . . . . . . . . . . . . . . . . 3-12

Figure 3-8 System Status LEDs (Standalone Server). . . . . . . . . . . . . . . . . . 3-14

viii Ultra Enterprise 6000/5000/4000 Systems Installation Guide—November 1996

Page 9

Tables

Table 2-1 Ethernet Cabling Limitations for N-type Coaxial Cable . . . . . 2-9

Table 2-2 Internal SCSI Lengths (Approximate) . . . . . . . . . . . . . . . . . . . . 2-13

Table 3-1 Front Panel LED Status Indicators . . . . . . . . . . . . . . . . . . . . . . . 3-8

Table 3-2 Front Panel LED System Status. . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

ix

Page 10

x Ultra Enterprise 6000/5000/4000 Systems Installation Guide—November 1996

Page 11

UNIX Commands

Preface

The Ultra™ Enterprise™ 6000/5000/4000 Systems Installation Guide provides

installation instructions for factory-configured 16-slot and 8-slot cabinet and

standalone server systems. These instructions are for an experienced system

administrator with networking knowledge.

This document may not include specific software commands or procedures.

Instead, it may name software tasks and refer you to operating system

documentation or the handbook that was shipped with your new hardware.

The types of tasks that you might need to use references for includes:

• Shutting down the system

• Booting the system

• Configuring devices

• Other basic software procedures

The references you can use include:

• Solaris 2.x Handbook for SMCC Peripherals contains Solaris™ 2.x software

commands.

• On-line AnswerBook™ for the complete set of documentation supporting

the Solaris 2.x software environment.

• Other software documentation and Platform Notes that you received with

your system.

xi

Page 12

TypographicConventions

The following table describes the typographic changes used in this book.

Typeface or

Symbol Meaning Example

Shell Prompts

AaBbCc123 The names of commands,

files, and directories;

on-screen computer output

AaBbCc123 What you type, contrasted

with on-screen computer

output

AaBbCc123 Command-line placeholder:

replace with a real name or

value

AaBbCc123 Book titles, new words or

terms, or words to be

emphasized

Edit your .login file.

Use ls -a to list all files.

machine_name% You have mail.

machine_name% su

Password:

To delete a file, type rm filename.

Read Chapter 6 in the User’s Guide.

These are called class options.

You must be root to do this.

The following table shows the default system prompt and superuser prompt

for the C shell, Bourne shell, and Korn shell.

Shell Prompt

C shell machine_name%

C shell superuser machine_name#

Bourne shell and Korn shell $

Bourne shell and Korn shell

superuser

xii Ultra Enterprise 6000/5000/4000 SystemsInstallation Guide—November 1996

#

Page 13

Related Documents

The following documents contain topics that relate to the information

in the Ultra Enterprise 6000/5000/4000 Systems Installation Guide.

Application Title Part Number

Safety/EMI Ultra Enterprise Server Regulatory Compliance Manual 802-3846

Service Ultra Enterprise 6000/5000/4000 Systems Manual 802-3845

Software SMCC SPARC Hardware Platform Guide 802-5341

Solstice SyMON User’s Guide 802-5355

Options Expansion Cabinet Installation and Service Manual 802-6084

Enterprise Systems Boards Installation Guide 802-5030

UltraSPARC Module Installation Guide 802-5031

Enterprise Systems Memory Modules Installation Guide 802-5032

Enterprise Systems Peripheral Power Supply Installation Guide 802-5033

Enterprise Systems Power/Cooling Module Installation Guide 802-6244

Ultra Enterprise Cabinet Floor Brackets Mounting Guide 802-7543

Ultra Enterprise Caster Base Installation Guide 802-5034

Ordering Sun Documents

The SunDocs Order Desk is a distribution center for Sun Microsystems

technical documents. You can use major credit cards and company purchase

orders. You can order documents in the following ways:

Country Telephone Fax

United States 1-800-873-7869 1-800-944-0661

United Kingdom 0-800-89-88-88 0-800-89-88-87

France 05-90-61-57 05-90-61-58

Belgium 02-720-09-09 02-725-88-50

Luxembourg 32-2-720-09-09 32-2-725-88-50

Preface xiii

Page 14

Germany 01-30-81-61-91 01-30-81-61-92

The Netherlands 06-022-34-45 06-022-34-46

Sweden 020-79-57-26 020-79-57-27

Switzerland 155-19-26 155-19-27

Japan 0120-33-9096 0120-33-9097

World Wide Web: http://www.sun.com/sunexpress/

Sun Welcomes YourComments

Please use the Reader Comment Card that accompanies this document. We are

interested in improving our documentation and welcome your comments and

suggestions.

If a card is not available, you can email or fax your comments to us. Please

include the part number of your document in the subject line of your email or

fax message.

• Email: smcc-docs@sun.com

• Fax: SMCC Document Feedback

1-415-786-6443

Notes, Cautions, and Warnings

Warning – This equipment contains lethal voltage. Accidental contact with

centerplane, card cage, and drive areas can result in serious injury or death.

Caution – Improper handling by unqualified personnel can cause serious

!

xiv Ultra Enterprise 6000/5000/4000 SystemsInstallation Guide—November 1996

damage to this equipment. Unqualified personnel who tamper with this

equipment may be held liable for any resultant damage to the equipment.

Individuals who remove any outer panels or open covers to access this

equipment must observe all safety precautions and ensure compliance with

skill level requirements, certification, and all applicable local and national

laws.

Page 15

Procedures contained in this document must be performed by qualified

service-trained maintenance providers.

Note – Before you begin, carefully read each of the procedures in this manual.

If you have not performed similar operations on comparable equipment, do

not attempt to perform these procedures.

Preface xv

Page 16

xvi Ultra Enterprise 6000/5000/4000 SystemsInstallation Guide—November 1996

Page 17

PreparingforInstallation

This chapter describes how to prepare your site for these systems:

1

• Ultra Enterprise 6000 system — 16-slot cabinet server

• Ultra Enterprise 5000 system — 8-slot cabinet server

• Ultra Enterprise 4000 system — 8-slot standalone server

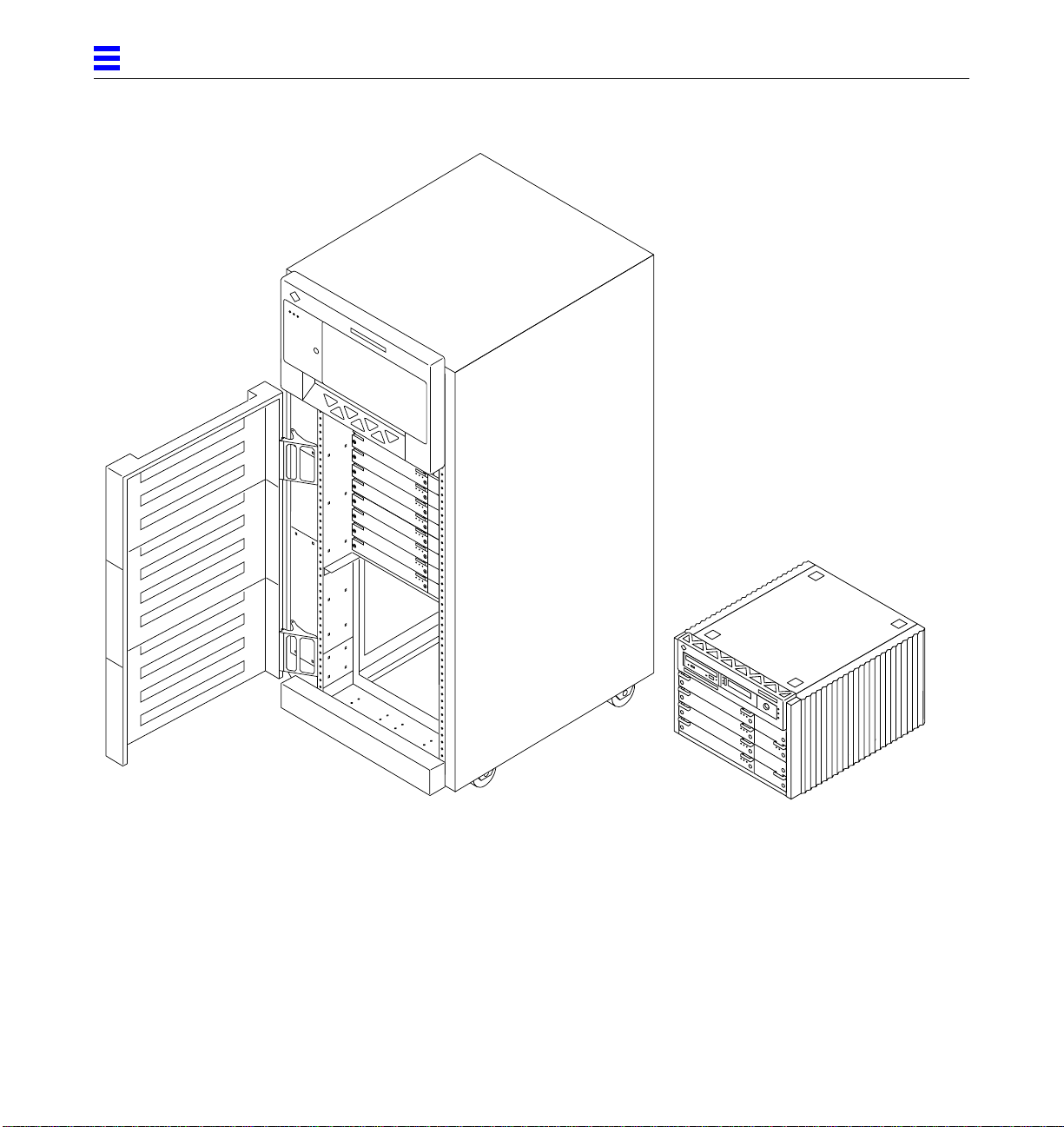

See Figure 1-1 on page 1-2 for diagrams of the cabinet and standalone servers.

The tasks for installing the systems are:

1. Unpacking the cabinet server — Chapter 1

2. Preparing the site — Chapter 1

3. Preparing the servers — Chapter 1

4. Cabling — Chapter 2

5. Powering on — Chapter 3

6. Using the software — Chapter 4

Note – For information about physical specifications, electrical specifications,

and environmental requirements, refer to Appendix A, “Specifications,” in the

Ultra Enterprise 6000/5000/4000 Systems Manual.

1-1

Page 18

1

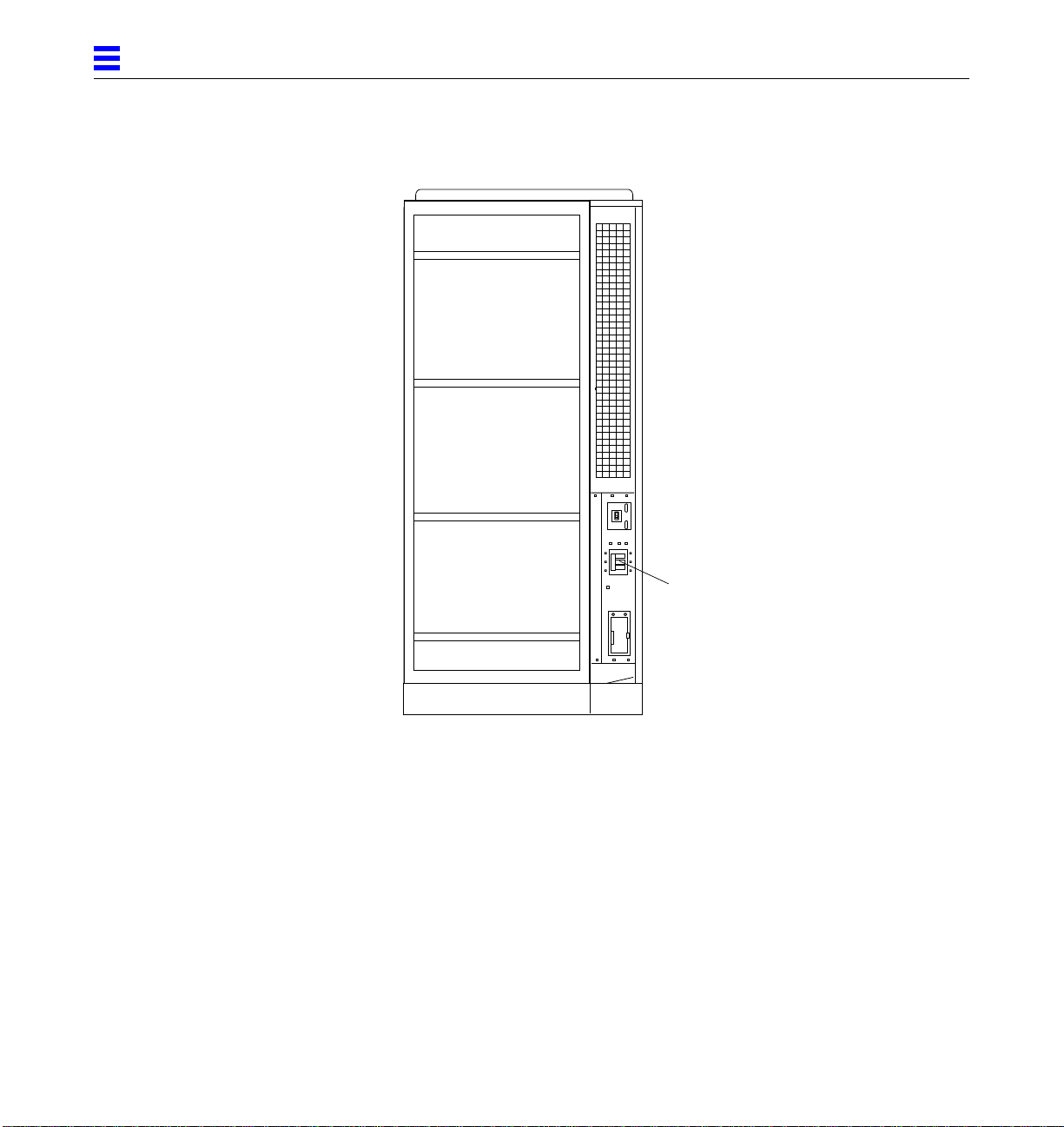

Enterprise 6000/5000 systems — 16-slot and

8-slot servers in data center system cabinets

Figure 1-1 Ultra Enterprise 6000/5000/4000 Systems

1-2 Ultra Enterprise 6000/5000/4000Systems Installation Guide—November1996

Enterprise 4000 system —

8-slot standalone server

Page 19

1.1 Unpacking the Enterprise 6000/5000 Cabinet Systems

Note – Inspect all shipping cartons for evidence of physical damage. If a

shipping carton is damaged, request that the carrier's agent be present when

the carton is opened. Keep all contents and packing material for the agent's

inspection.

If you have a standalone Enterprise 4000 system, or the cabinet is already

unpacked, go to Section 1.3, “Preparing the Electrical Circuits.”

Note – Any unpacking instructions printed on the outside of the shipping

carton take precedence over instructions in this section.

Caution – If your cabinet system is on a wooden pallet, extend the cabinet

!

levelling pads so that the cabinet cannot roll. If the original shipping pallet has

side rails, it is not necessary to lower the levelling pads.

1. Cut the plastic or metal straps that are around the shipping container and

lift off the corrugated top.

Store the shipping materials for future shipments.

1

2. Remove the sides of the container.

The container is held together by six plastic clips. To unlock a clip, press the

two inner tabs together and pull out the entire clip.

3. Remove inner packing materials from the top and corners of the cabinet.

4. At the front of the pallet, lift the Velcro™ strip at each end of the wooden

bar to detach the bar, then set it aside.

5. Slide out the two wooden ramps from under the cabinet.

6. Attach the wooden ramps to the pallet using the Velcro strip that is

attached to each ramp.

Ensure both wheel guides (wooden strips) are to the outside. See Figure 1-2.

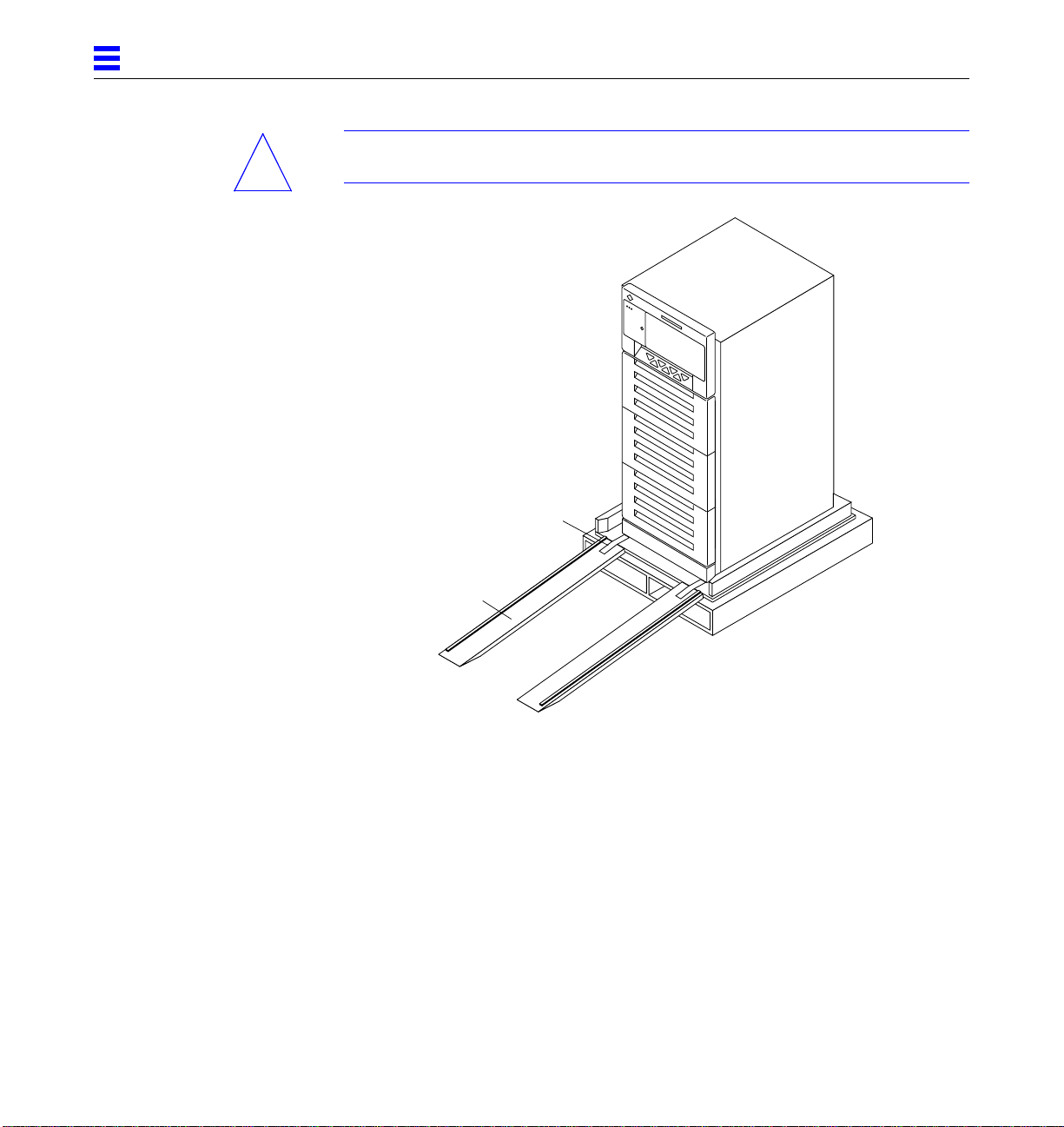

Caution – Three or more people are needed to move the server cabinet safely.

!

Two people must push at the front of the cabinet to control the movement of

the cabinet.

Preparingfor Installation 1-3

Page 20

1

Caution – To prevent the cabinet from tipping over, push or pull only on the

!

upper half of the cabinet.

Adhesive strip

Wheel guide

Figure 1-2 Attaching the Ramps to the Shipping Pallet

1.2 Shipping and Storing the System

Save the original shipping containers and packing materials in case you need

to store or ship your system.

If you cannot store the shipping materials, recycle or dispose of the materials

properly. Consult your local recycling authority for information.

1-4 Ultra Enterprise 6000/5000/4000Systems Installation Guide—November1996

Page 21

1.3 Preparing the Electrical Circuits

In planning where to place your equipment, remember that each of the

following items require access (by way of a separate power cord) to a power

outlet:

• Ultra Enterprise 6000/5000/4000 system

• External peripherals

• Monitor used for diagnostics

1.3.1 Enterprise 6000/5000 Cabinet Systems

The 16-slot and 8-slot system cabinets require a 30A circuit and a detachable

cable.

The equipment relies on the protective device in the building installation; thus

it requires a 30A circuit breaker.

Caution – Do not attach other electrical equipment to the server AC circuit;

!

server reliability may be affected.

1

Two AC connector plug types are available.

• The AC input power cable for 200-240V North American operation has a

NEMA L6-30P connector that plugs into the AC source on one end

(Figure 1-3). The other end, with metal housing, plugs into the sequencer.

• The AC input power cable for 200-240V international operation has a 32A,

single-phase, IEC 309 connector that plugs into the AC source on one end

(Figure 1-4). The other end, with metal housing, plugs into the sequencer.

Figure 1-3 NEMA L6-30P Electrical Connector

Preparingfor Installation 1-5

Page 22

1

Figure 1-4 IEC 309 Electrical Connector

Note – If the appropriate mating receptacle is not available in your country, the

plug may be removed from the cord. The cord can then be permanently

connected to a dedicated branch circuit by a qualified electrician. Check local

electrical codes for proper installation requirements.

Warning – The system cabinet has a high leakage current to ground. Strictly

observe the following instructions to reduce the risk of electric shock.

The system requires an electrical circuit that is grounded to earth. The UL1950,

CSA950, and EN60950 specify:

An insulated earthing conductor that is identical in size, insulation

material, and thickness to the earthed and unearthed branch-circuit

supply conductors, except that it is green with or without one or

more yellow stripes, is to be installed as part of the branch circuit

that supplies the unit or system. The earthing conductor described

is to be connected to earth at the service equipment or, if supplied

by a separately derived system, at the supply transformer or

motor-generator set.

The attachment-plug receptacles in the vicinity of the unit or

system are all to be of an earthing type, and the earthing

conductors serving these receptacles are to be connected to earth at

the service equipment.

The power cord provides a ground path that will protect the drives and boards

in the cabinet from static electricity damage.

1. Information TechnologyEquipment — UL 1950, copyright 1989, 1991 by Underwriters Laboratories, Inc.

1-6 Ultra Enterprise 6000/5000/4000Systems Installation Guide—November1996

1

Page 23

Caution – Do not make mechanical or electrical modifications to the server

!

cabinet. Sun Microsystems® is not responsible for the regulatory compliance if

the cabinet is modified.

1.3.2 Enterprise 4000 System

The 8-slot Enterprise 4000 system uses nominal input voltages of 100-120 VAC

or 200-240 VAC. Sun products are designed to work with single-phase power

systems having a grounded neutral conductor.

To reduce the risk of electrical shock, do not plug Sun products into another

type of power source. Contact your facilities manager or a qualified electrician

if you are unsure what type of power is supplied to your building.

1.4 Preparing the Air Conditioning

For the most reliable system operation:

• The room should have sufficient air-conditioning capacity to support the

cooling needs of the entire system.

• The air-conditioning system should have controls that prevent excessive

temperature changes.

1

1.5 Preparing the Ethernet Network

The Enterprise 6000/5000/4000 systems follow the IEEE standard for

10/100BASE-T Ethernet (twisted-pair) or MII (Media Independent Interface).

Twisted-pair cables used with Sun Microsystems products have RJ-45

connectors that resemble the smaller RJ-11 connectors used for modular

telephone cables. For twisted-pair cable length, see Chapter 2, Table 2-1 on

page 2-9.

A MII to AUI converter cable, available from Sun, enables the 10/100 Mbps

Ethernet interface to run over 10 Mbps coaxial Ethernet networks. Other MII

Ethernet connectivity products are available from third parties.

Figure 1-5 and Figure 1-6 illustrate types of network cables and possible

implementations of 10/100BASE-T Ethernet.

Preparingfor Installation 1-7

Page 24

1

Set up the network using Sun or third-party components. To obtain the best

results, read any applicable manufacturer instructions. Be aware that Sun

Microsystems cannot guarantee the performance of any components that are

not purchased from Sun.

Ethernet cable

Transceiver drop cable

(coaxial or optical fiber)

Figure 1-5 Types of Network Cables Used

Coaxialcableor

optical fiber

Tap

Workstation

Vampire tap or N-type connectors

Transceiver

Hardware interface

10/100BASE-T

twisted-pair cable

Network cable

Concentrator hub

Server

Tap

Concentrator hub

Server

Twisted-pair cable

Figure 1-6 Example of 10/100BASE-T (Twisted-Pair) Ethernet

1-8 Ultra Enterprise 6000/5000/4000Systems Installation Guide—November1996

Page 25

Note – Multiplexer boxes require a transceiver when used with the Ethernet

applications described in this manual. Although these transceivers are

compatible with Sun equipment, Sun Microsystems does not guarantee the

performance of any component that was not purchased from Sun.

Many transceivers are compatible with both level-1 and level-2 Ethernet. To

operate these transceivers with Sun equipment, set the device for level-2

operation following the manufacturer’s instructions.

Sun equipment conforms to the Ethernet 10/100BASE-T standard, which states

that the 10/100BASE-T Link Integrity Test function should always be enabled

on both the host and the hub. If you have problems verifying connection

between Sun equipment and your hub, verify that your hub also has the link

test function enabled. See Section 3.4, “Failure of Network Communications,”

and refer to the manual provided with your hub.

1.6 Preparing the Area

1.6.1 Floorspace for the Enterprise 6000/5000 Cabinet Systems

1

•

The server cabinets require approximately four feet (122 cm) of space in

front and three feet (92 cm) in back for access by service personnel. See

Figure 1-7.

• Allow two inches (5 cm) of space on the left for adequate air flow.

• Allow two inches (5 cm) of space on the right for adequate air flow.

• The server system (including expansion cabinets) should have a dedicated

AC breaker panel. The server system should not share this breaker panel

with other, unrelated equipment.

• Keep power and interface cables out of the way of foot traffic. Cables can be

routed inside walls, floors, ceilings, or in protective channels. Interface

cables should be routed away from motors and other sources of

electric/magnetic or radio frequency interference.

Preparingfor Installation 1-9

Page 26

1

3 feet access at rear

2 inches, left

and right sides

System

Tape/disk

EXP

Tape/disk

EXP

Tape/disk

EXP

Figure 1-7 Cabinet Server Access Areas — Top View

cabinet

4 feet access at front

1.6.2 Surface for the Enterprise 4000 System

Tape/disk

EXP

Tape/disk

EXP

Tape/disk

EXP

The Enterprise 4000 system is designed to sit on the floor, on a caster base, or

on a desk or table.

Note – Do not stack multiple Enterprise 4000 systems so that they sit directly

on top of each other, resting on the top cover of the system below.

Use the following guidelines to prepare a location for your server.

• The server unit requires approximately 1.5 feet (47 cm) of space in the front

and back for access by service personnel. See Figure 1-8.

• A minimum space of 6 inches (16 cm) is required on both sides of the server

to afford adequate air flow.

• A minimum space of 3 feet (92 cm) is recommended to avoid exhaust air

recirculation if systems are placed next to each other.

Warning – To avoid exhaust air recirculation, do not put systems or

!

1-10 Ultra Enterprise 6000/5000/4000 SystemsInstallation Guide—November 1996

peripherals side by side with less than 3 feet of space between them.

Page 27

• Keep power and interface cables clear of foot traffic. Route cables inside

walls, under the floor, through the ceiling, or in protective channels. Route

interface cables away from motors and other sources of magnetic or radio

frequency interference.

on each side

* 3 feet on each side if systems or peripherals

are placed next to each other, side by side

Figure 1-8 Standalone Server Access Areas — Top View

1

1.5 feet access at rear

6 inches*

Standalone

system

1.5 feet access at front

1.7 Preparing the Enterprise 6000/5000 Cabinet Systems

You need the following tools:

• #1 Phillips screwdriver

• Levelling wrench (packed inside the system cabinet)

• Front panel key (packed in a bag in the accessory box)

1.7.1 Moving the Server

The server may weigh1/2-ton/500 kilograms, or more, and can be unstable

when rolling down ramps.

Caution – Three or more people are needed to move the server cabinet safely.

!

Two people must push at the front of the cabinet to control the movement of

the cabinet.

Preparingfor Installation 1-11

Page 28

1

Caution – To prevent the cabinet from tipping over, push or pull only on the

!

upper half of the cabinet.

Figure 1-9 Moving the Server Safely Down the Ramps

1.7.2 Adjusting the Levelling Pads

After moving the cabinet to its operating location, adjust the levelling pads.

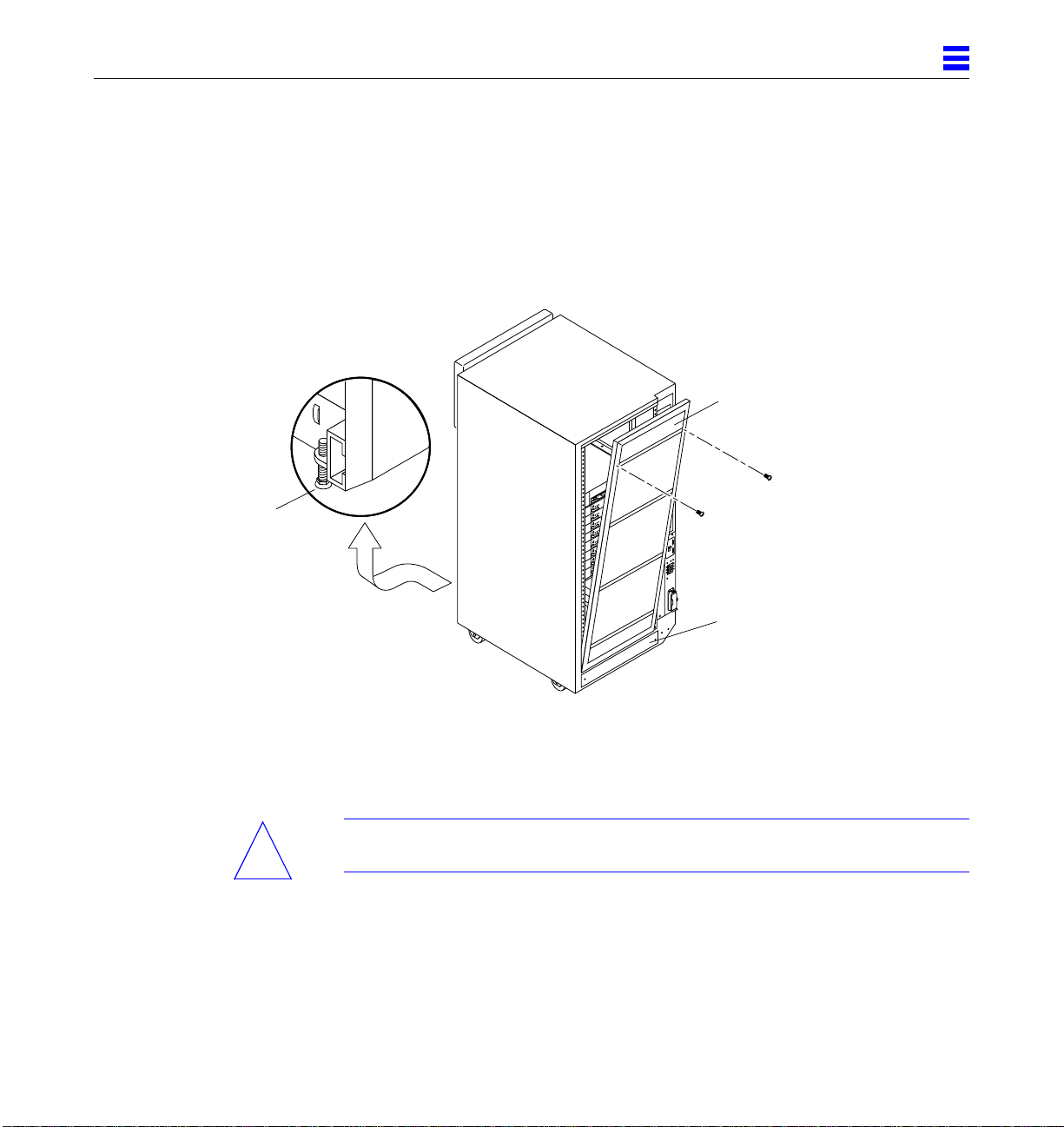

1. Take off the rear screen by removing the two screws shown in Figure 1-10.

Note – If your system cabinet has a hinged rear door, use the sliding door latch

to open the door.

2. Remove the levelling wrench from inside the server cabinet.

Press the plastic tab to unlock the plastic strap around the wrench, then

slide part of the strap through the lock to loosen the wrench. Do not cut the

strap.

1-12 Ultra Enterprise 6000/5000/4000 SystemsInstallation Guide—November 1996

Page 29

Levelling pad

(1 of 6)

1

3. Extend the stabilizer bar fully from the bottom of the cabinet.

See Figure 1-11.

4. Screw the two stabilizer bar levelling pads down until they are 1/8- to

1/4-inch (three to six millimeters) above the floor.

Make sure both pads are at equal heights above the floor. This clearance

allows an extended stabilizer bar to stop the cabinet if it should begin to tilt.

Rear screen

Kick panel

Figure 1-10 Rear Screen, Levelling Wrench, Kick Panel, and Levelling Pad

5. Slide the stabilizer bar into the cabinet.

Warning – Always extend the stabilizer bar before pulling the disk drive trays

!

out for servicing.

6. Adjust the four levelling pads on the cabinet frame. The four pads should

press against the floor so that the cabinet does not move.

To adjust levelling pads on the cabinet rear, you may have to remove the

kick panel. Two captive screws attach the panel to the cabinet (Figure 1-10).

Preparingfor Installation 1-13

Page 30

1

This completes the first part of the system installation. If you are unable to

continue the installation at this time, close the cabinet:

1. Secure the levelling wrench inside the cabinet.

2. Replace the kick panel if the panel was removed.

3. Attach the rear screen.

Stabilizer bar

Figure 1-11 Stabilizer Bar

1.8 Preparing the Enterprise 4000 System

Warning – The server weighs more than 150 lbs (68 kg). To prevent personal

!

1-14 Ultra Enterprise 6000/5000/4000 SystemsInstallation Guide—November 1996

injury, two people are needed to lift the server safely.

You need the following tools:

• #1 Phillips screwdriver

Page 31

• Front panel key (packed in a bag in the accessory box)

Follow the graphic instructions on the shipping container to remove the server

from the container. Remove the front panel key and the power cord from the

shipping container. These are needed to power on the system.

1.9 Using the User Naming Area

To display the name of the server, IP address, owner, or other important

information on the front of the machine:

1. Remove the top front bezel.

Refer to Chapter 13, “Preparing for Service,” in the Ultra Enterprise

6000/5000/4000 Systems Manual.

• Enterprise 6000/5000 systems: refer to Section 13.3.3, “Top Front Bezel.”

• Enterprise 4000 system: refer to Section 13.4.1, “Top Bezel.”

2. Snap out the narrow transparent window.

From the rear side of the bezel, gently squeeze the top and bottom edges

together as you simultaneously push the transparent window out through

the front of the bezel.

1

3. Choose the information that will appear on the label.

Common items include the name of the server, IP address, name and contact

information for the system administrator, and the group of users that the

machine services.

4. Use the colored paper provided with the system to make a label.

The available area for the paper label is 12 mm x 150 mm (0.5 in x 5.9 in).

Print or write the desired information in an area this size and cut the label to

fit the transparent window.

5. Place the paper label inside the window, and snap the window back in

place from the front side of the bezel.

Preparingfor Installation 1-15

Page 32

1

1-16 Ultra Enterprise 6000/5000/4000 SystemsInstallation Guide—November 1996

Page 33

CablingtheSystem

This chapter contains procedures for connecting the power cord to the AC

power supply and instructions for cabling the system to the network.

2

2.1 Preparing the System for Cabling

Make sure the server is in an area that allows access to both the front and rear

of the chassis. This site should conform to site preparation guidelines and

specifications covered in Chapter 1.

2.2 Removing and Replacing the Enterprise 6000/5000 Cabinet Rear Screen and Kick Panel

Removing the Rear Screenand Kick Panel

1. Locate the plastic key that is in the accessory box.

2. Open the door on the left side of the top bezel to access the key switch.

The door opens when you press on the recessed area.

3. Turn the system key switch to (the Standby position).

See Figure 2-1.

4. Ensure that the AC power sequencer switch is set to Off.

This switch is at the rear of the cabinet. See Figure 2-2.

2-1

Page 34

2

Standby position

Figure 2-1 Keyswitch Standby Position

5. If the rear screen is still in place, remove it.

Note – If your system cabinet has a hinged rear door, use the sliding door latch

to open the door, and proceed to Step 6 and Step 7.

a. Remove two screws near the top of the screen.

See Figure 2-2.

b. Tilt the screen out and lift it free of the chassis.

Set the screen aside.

6. Remove the AC power cord that is coiled inside the server cabinet.

Set the power cord aside.

7. Remove the kick panel by loosening the two screws.

See Figure 2-3. Set the panel aside.

2-2 Ultra Enterprise 6000/5000/4000Systems Installation Guide—November1996

Page 35

2

AC

power

sequencer

Figure 2-2 AC Power Sequencer Power Switch and Rear Screen

Rear

screen

Replacing the Rear Screenand Kick Panel

1. Tighten the two screws to secure the kick panel to the cabinet.

If cables are to be routed under the floor, the cables should be between the

bottom panel and the kick panel. See Figure 2-3.

2. Place the bottom of the rear screen on the flanges near the cabinet bottom.

3. Tilt the rear screen against the frame and install two screws to secure the screen in place.

See Figure 2-2.

4. After all the cables are connected and the screen and panel have been

replaced, power on the system.

Cabling the System 2-3

Page 36

2

Bottom panel

Cable

Kick panel

Figure 2-3 Routing Cables Under the Kick Panel

2.3 Connecting the Power Cords

2.3.1 Connecting the Enterprise 6000/5000 System Power Cord

1. Remove the rear screen and the kick panel.

See Section 2.2, “Removing and Replacing the Enterprise 6000/5000 Cabinet

Rear Screen and Kick Panel.”

2. Route the AC power cord and external interface cables along the bottom

panel of the cabinet and over the edge of the bottom panel.

See Figure 2-3. The cables should be between the bottom panel and the kick

panel when you replace the kick panel.

3. Uncoil the AC power cord and plug it into a grounded wall outlet.

The outlet must be a 200-240 VAC 30A circuit, dedicated solely to the server

cabinet, as described in the site preparation instructions in Chapter 1.

2-4 Ultra Enterprise 6000/5000/4000Systems Installation Guide—November1996

Page 37

Warning – Risk of electric shock. Do NOT turn on AC power to the unit yet.

4. Continue with Section 2.4 through Section 2.7 for further cabling

instructions, and then see Section 2.2 to replace the rear screen and kick

panel.

2.3.2 Connecting the Enterprise 4000 System Power Cord

1. Insert the key provided with your system into the front panel key switch.

Turn it to the Standby position (fully counterclockwise).

See Figure 2-4.

Standby

2

Figure 2-4 Key Switch Positions

2. Turn the AC power switch to Off.

This switch is in the upper left corner of the system rear. See Figure 2-5.

3. Connect the female end of the power cord into the AC connector.

This connector is to the left of the AC power switch on the system rear.

See Figure 2-5.

4. Connect the male end of the power cord into a grounded wall outlet.

The outlet must be a 100-240 VAC 15A circuit.

Cabling the System 2-5

Page 38

2

AC connector

AC power switch

Figure 2-5 AC Power Switch and Power Receptacle

Caution – Do NOT turn on power to the unit yet. Doing so could cause system

!

damage to occur.

5. Continue with Section 2.4 through Section 2.7 for further cabling instructions.

6. After all the cables are connected, power on the system.

2.4 Connecting the Network Cable to the System

The locations specified in the following instructions assume the use of twistedpair 10BASE-T or 100BASE-T Ethernet.

1. Locate the network cable.

Figure 2-6 shows the twisted-pair Ethernet network cable.

Figure 2-6 Network Cable

2-6 Ultra Enterprise 6000/5000/4000Systems Installation Guide—November1996

Page 39

2

2. Connect one end of the network cable into the RJ-45 twisted-pair network port.

For 10/100BASE-T Ethernet, the default interface port is the onboard

connector on the I/O board in slot 1. See Figure 2-7.

Ethernet port

Figure 2-7 10/100BASE-T Ethernet Connection

3. Enterprise 6000/5000 systems only: route the cable down along the right

mounting rail of the chassis.

Use tie wraps to secure the cable to the rail.

2.5 Connecting the System to the Network

1. Connect the network cable to a twisted-pair-to-transceiver interface box.

2. Connect the interface box with an appropriate cable to a network transceiver.

Figure 2-8 shows a typical arrangement for connecting the system to an

Ethernet network.

3. For Ethernet cables, determine if the cable has N-type screw-on

connectors at the ends.

Cabling the System 2-7

Page 40

2

• If the Ethernet cable lacks N-type connectors at the ends, use a “vampire”

tap to connect the cable to the transceiver. See Figure 2-8. To connect the

cable to the transceiver, use instructions provided with the vampire tap.

• If the Ethernet cable has N-type connectors, connect the Ethernet cable to

the transceiver:

a. Screw the Ethernet coaxial cable into one of the round screw-on type

connectors on the transceiver.

Use either one of the transceiver connectors.

b. Screw the other Ethernet coaxial cable into the other round screw-on

type connector on the transceiver.

4. Determine if a terminator should be installed. Table 2-1 lists the cabling

limitations for Ethernet.

5. If termination is required, install a 50-ohm terminator in the unused

transceiver N connector or at the end of the coaxial cable. Use a female

double N-type connector.

Figure 2-8 shows the elements used in the installation process.

Ethernet cable

Transceiver drop cable

(coaxial or optical fiber)

Figure 2-8 Connecting Twisted Pair Ethernet to N-type Coaxial Cable

2-8 Ultra Enterprise 6000/5000/4000Systems Installation Guide—November1996

Hardware interface

Vampire tap or N-type connectors

Transceiver

10/100BASE-T

twisted-pair cable

Server

Page 41

2

Table 2-1 lists the cabling limitations for Ethernet.

Table 2-1 Ethernet Cabling Limitations for N-type Coaxial Cable

Cable Segment Length in Meters

Allowed contiguous length of cable segments 23.4

70.2

117.0

1

500.0

Distance between transceivers (multiples-of) 2.5

Minimum length of Ethernet coaxial cable segments 23.4

Maximum length of transceiver “drop” cable 50.0

Minimum length of twisted pair cable no minimum

Maximum length of twisted pair cable 110

1. Finite lengths (as constrained by transmission line phenomena). Minimum length =23.4M; maximum = 500M.

If cable falls shorter than one of these values, add cable to achieve next-highest value.

2. Transceiversare placed at intervals of 2.5 meters, or multiples of 2.5 meters along the Ethernet cable.

Example: transceivers are connected 2.5 meters apart, not 2.0 meters.

Example: transceivers are connected 15 meters apart (6 multiples of 2.5 meters), not 14.0 meters.

2

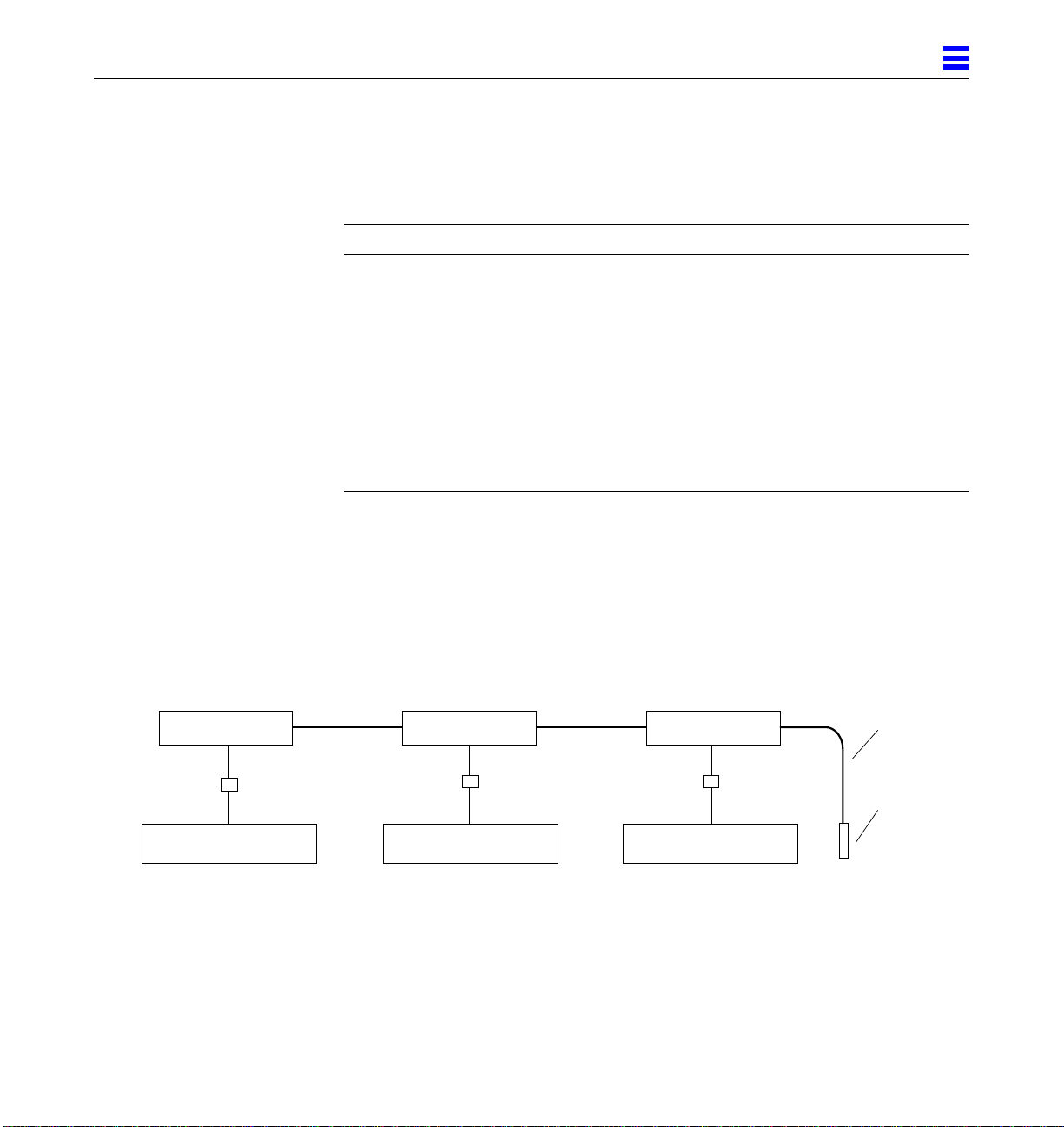

Figure 2-9 shows an example of a typical network setup. The Ultra Enterprise

6000/5000/4000 systems can be any server shown in this figure.

Transceiver

Transceiver drop cable

Twisted pair cable

Server or workstation

Note: 5 Meters + 15 Meters + 3.4 Meter Extension = 23.4 Meters minimum length allowed.

5 Meters

Figure 2-9 Ethernet Cabling Length — Example Using N-type Cable

Cabling the System 2-9

Transceiver Transceiver

Server or workstation Server or workstation

15 Meters

3.4 Meter

Extension

Terminator

Page 42

2

Note – Sun equipment conforms to the Ethernet 10/100BASE-T standard,

which states that the 10/100BASE-T Link Integrity Test function should always

be enabled on both the host and the hub. If you have problems verifying

connection between Sun equipment and your hub, verify that your hub also

has the link test function enabled. See Section 3.4, “Failure of Network

Communications,” and refer to the manual provided with your hub for more

information about the Link Integrity Test function.

2.6 Connecting an ASCII Terminal

An ASCII terminal (or workstation) must be attached to the server to display

diagnostic messages produced by the firmware (power-on self test/POST or

OpenBoot PROM/OBP) program. A terminal is not required for normal server

operations, so it may be necessary to locate a terminal to connect to the server.

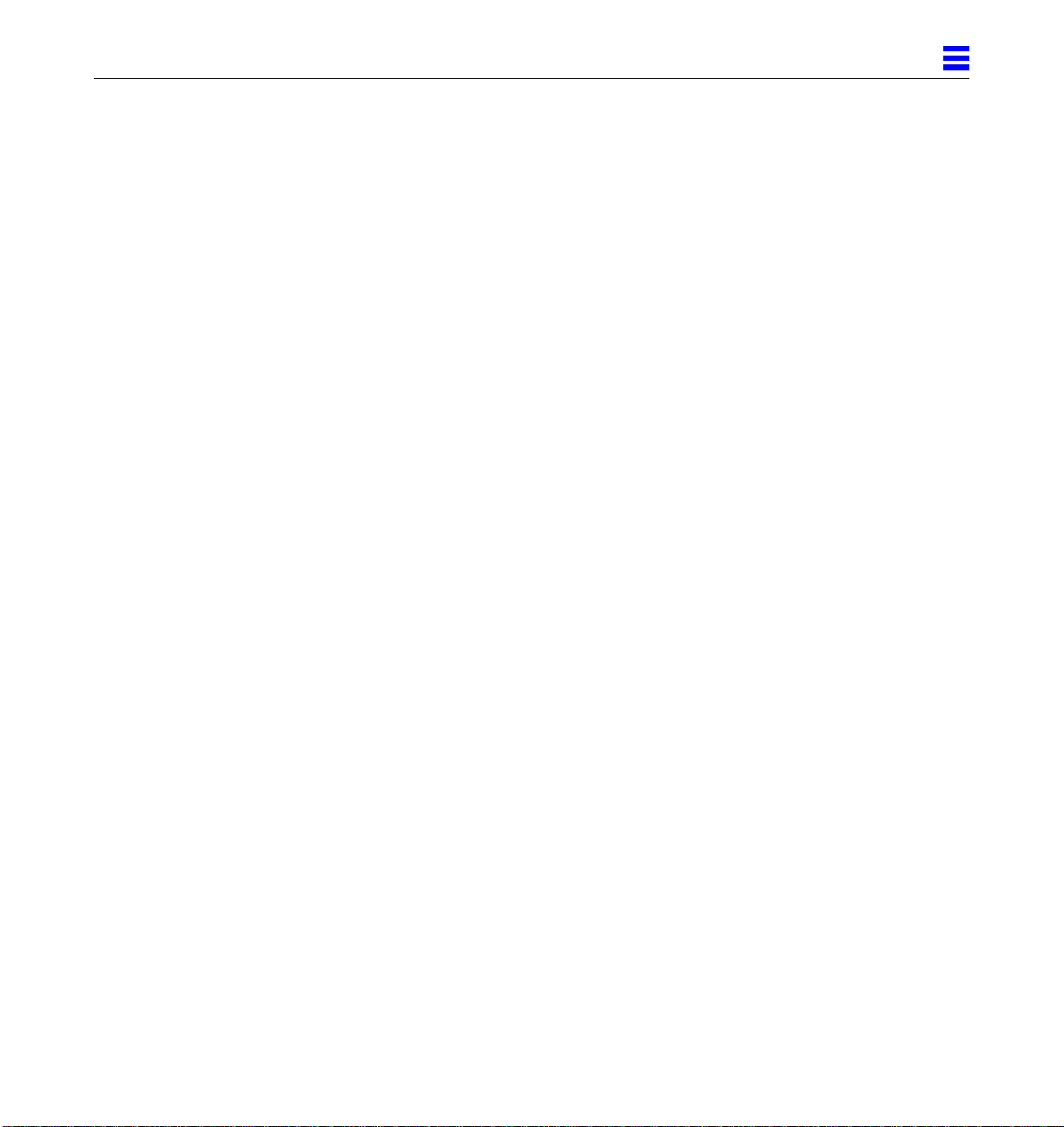

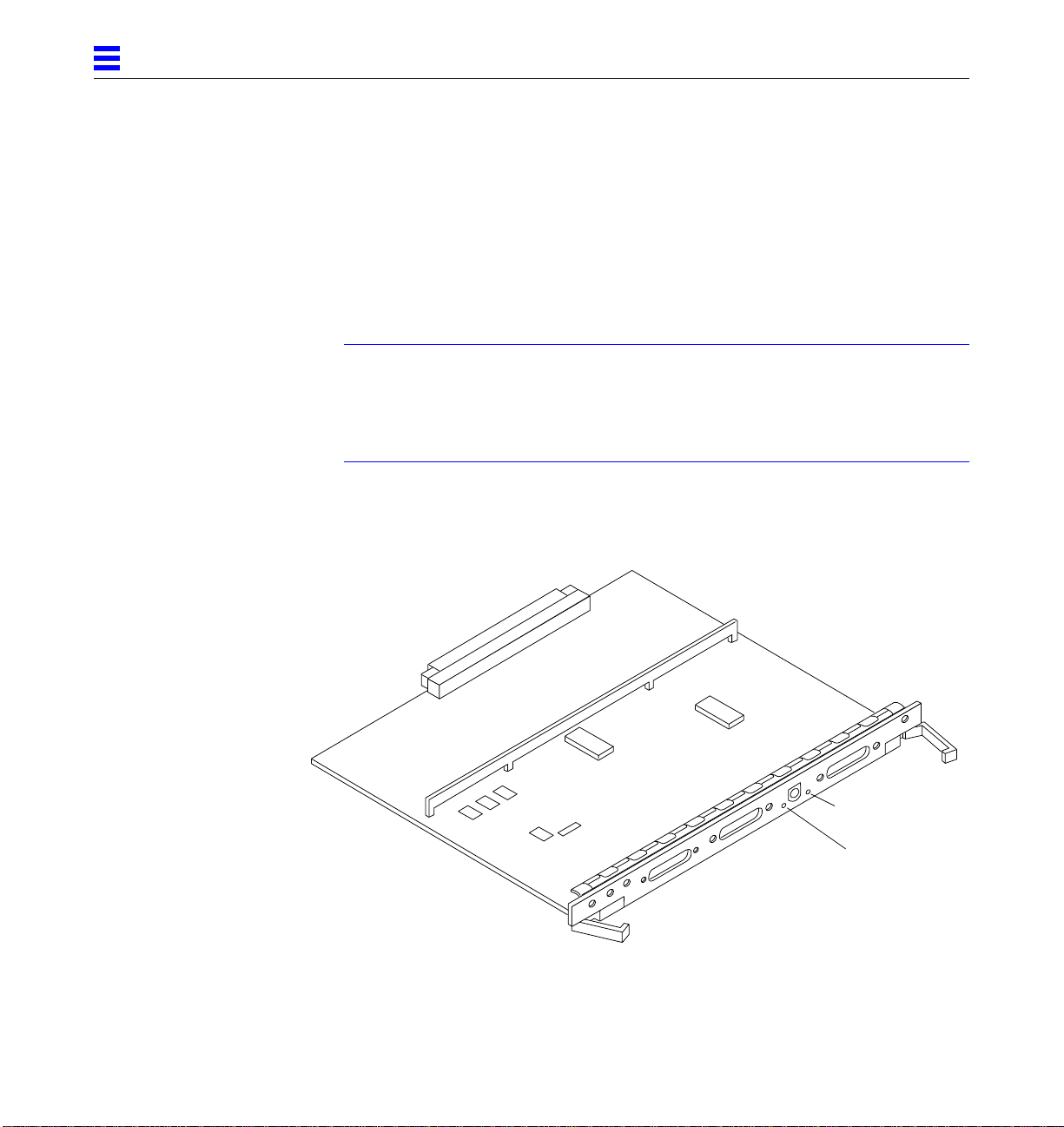

1. Connect the terminal cable into serial port A on the clock board.

See Figure 2-10.

Serial port A

Figure 2-10 Clock Board

2-10 Ultra Enterprise 6000/5000/4000 SystemsInstallation Guide—November 1996

Page 43

2

2. Enterprise 6000/5000 systems only: route the terminal cable from the clock

board down along the right mounting rail of the cabinet.

Use tie wraps to secure the terminal cable to the mounting rail.

3. Connect the terminal power cord into an AC wall outlet.

4. Configure the ASCII terminal as follows:

• 9600 bps

• 1 stop bit

• 8 data bits

• Parity off

• Full duplex

Refer to the instruction manual shipped with the terminal for specific

configuration instructions.

Note – The setup parameters listed in Step 4 may differ from the setup at the

customer site. These parameters can be changed in the NVRAM. Refer to the

set-defaults and printenv commands in the OpenBoot Command Reference

manual, part number 802-3242.

2.7 Connecting the Fiber Cable to the I/O Board

1. Remove the two plastic caps that cover the cable connector on the FC/OM

module.

2. Remove the plastic cap covering the ends of the fiber cable.

3. Connect one end of the fiber cable into the FC/OM module installed on

the I/O board.

Align the notch in the cable connector with the key notch in the module

connector. See Figure 2-11.

4. Connect the other end of the fiber cable into the FC/OM connector on the

SPARCstorage Array (or other storage device with fiber optics interface)

rear panel.

Align the notch in the cable connector with the notch in the connector on the

storage device rear panel.

Cabling the System 2-11

Page 44

2

Key notch

in module

connector

Notch on

fiber cable

Fibre card connector

Fiber

0

Fiber

1

B

Connect cable through

Port A (Fiber 0) or

Port B (Fiber 1)

Figure 2-11 Fiber Cable and Fibre Card Connectors and Ports on the I/O Board

A

2.8 Connecting External SCSI Devices

External SCSI-2 devices connect to your system through the built-in singleended Fast/Wide SCSI-2 port on I/O boards (except for the board in slot 1), or

through FSBE/S, DSBE/S, SWIS/S, or DWIS/S SBus cards installed on I/O

boards.

Note – The onboard SCSI-2 bus on the I/O board in slot 1 controls internal

SCSI tray devices. Therefore, the external SCSI connector on the I/O board in

slot 1 must always have a terminator installed.

Note – The maximum combined length for a string of SCSI cables is six meters

for non-differential cables. For differential SCSI cables, the maximum is 25

meters.

When calculating the total length of a SCSI string, include external cables,

internal cables, and printed traces. Table 2-2 lists internal measurements for the

Enterprise servers.

2-12 Ultra Enterprise 6000/5000/4000 SystemsInstallation Guide—November 1996

Page 45

Table 2-2 Internal SCSI Lengths (Approximate)

Location Internal Length Comments

Enterprise 6000 slot 1 3.7 meters Includes I/O board traces and cables to SCSI tray

Enterprise 5000 slot 1 3.7 meters Includes I/O board traces and cables to SCSI tray

Enterprise 4000 slot 1 1.4 meters Includes I/O board traces and cables to SCSI tray

SBus I/O board 0.43 meter Includes board traces only

Graphics I/O board 0.43 meter Includes board traces only

Disk board 0.64 meter Includes board traces only

For information on device addressing, priorities, and slot assignments, refer to

Appendix D, “Rules for System Configuration” in the Ultra Enterprise

6000/5000/4000 Systems Manual, part number 802-3845.

Caution – Risk of equipment damage. Do not assign the same SCSI address to

!

two devices sharing the same SCSI bus or SBus card.

2

To connect an external SCSI device to your system:

1. Connect a SCSI cable to the appropriate SCSI-2 host on the I/O board.

• For the I/O board in slot 1, this is an SBus card installed in an appropriate

SBus slot.

• For I/O boards in slots 2 through 15, use the onboard SCSI-2 port or an

SBus card installed in an appropriate SBus slot.

Figure 2-12 shows the location of the onboard single-ended SCSI connector

on the I/O board.

Cabling the System 2-13

Page 46

2

Fast/wide onboard SCSI-2,

68-pin connector

Figure 2-12 Onboard Single-ended SCSI Connector on the I/O Board

2. Enterprise 6000/5000 systems only: route the cable from the I/O board

down along the left mounting rail inside the cabinet.

Use tie wraps to secure the cable to the left mounting rail.

3. Connect the other end of the SCSI cable to the external SCSI-2 device.

4. Enterprise 6000/5000 systems only: return to Section 2.2, “Removing and

Replacing the Enterprise 6000/5000 Cabinet Rear Screen and Kick Panel”

to replace the screen and panel. Then power on and test the server.

This concludes the hardware installation for the standalone server. You can

now power on the system and test the server.

2-14 Ultra Enterprise 6000/5000/4000 SystemsInstallation Guide—November 1996

Page 47

PoweringtheSystemOnandOff

This chapter contains information about powering the system on and off,

reading boot messages, and interpreting system status by viewing the LEDs.

3.1 Using JumpStart Automatic Installation

The Ultra Enterprise 6000/5000/4000 systems can use the JumpStart™

automatic installation feature that is described in installation documents for

Solaris software. The software that enables this feature is present on a hard

disk in your system if the system was built at the factory with internal disk

boards or disk trays. JumpStart software is not installed on SPARCstorage

Array disks.

JumpStart will run only when the system is powered on for the first time.

Caution – JumpStart may incorrectly install the system as a standalone

!

workstation. You should prevent JumpStart automatic installation from

proceeding if the appropriate server-specific configuration information is not

in place. Information about the JumpStart feature is on a card titled “JumpStart

Installation Instructions” that is provided with the system documentation.

3

To prevent JumpStart installation from occurring unintentionally:

• Do not connect the system to a network when you power it on initially.

• Do not place a Solaris release CD-ROM in a drive when you first power on

the machine.

3-1

Page 48

3

Note – If JumpStart automatic installation begins unintentionally, interrupt it

by pressing “L1-A” (Stop-A) or “Break” (on ttya). Perform a manual

installation when you are ready.

If JumpStart completes the installation incorrectly, you may need to reinstall

Solaris 2.x manually.

3.2 Enterprise 6000/5000 Cabinet Systems

3.2.1 Powering On the System

Note – It is advisable to connect an ASCII terminal to the system during

installation. See Section 2.6, “Connecting an ASCII Terminal,” for terminal

settings and connections.

Observe the yellow (middle) LED on the front panel. It should go off when

boot completes. If it remains lit, observe the terminal screen for boot messages

produced by the firmware diagnostic program during power on.

To power on the cabinet system:

1. Begin with a safety inspection of the system:

a. Turn the system key switch to (the Standby position).

See Figure 3-1.

Note – The standby position ()does not turn off any AC-powered drive trays

in the lower part of the system cabinet. The key switch controls only the DC

power supply and DC-powered devices in the main cabinet.

b. Turn the AC power sequencer power switch to Off.

The AC power sequencer is at the rear of the cabinet. See Figure 3-2.

c. Verify that the cabinet AC power cord is plugged into a wall socket.

3-2 Ultra Enterprise 6000/5000/4000Systems Installation Guide—November1996

Page 49

3

Standby

On

!

Legend:

Diagnostics

Locked

Figure 3-1 Key Switch Positions

Caution – The outlet must be a 200-240 VAC 30A circuit intended solely for use

by the server cabinet. The electrical receptacles must be grounded, and the

grounding conductors serving these receptacles must be connected to the earth

ground at the service equipment.

Caution – Do not disconnect the AC power cord from the wall socket when

you work on or in the server cabinet. This connection provides a ground path

that prevents damage from electrostatic discharge.

Standby = OFF; no DC power

On = Normal power ON

Diagnostics = Normal power ON with full

diagnostics

Locked= Normal power ON in secure mode

Warning – Never move the system or expansion cabinets when system power

!

is on. Excessive movement can cause catastrophic disk drive failure. Always

power the system OFF before moving it.

2. Turn on power to any expansion cabinets.

Read the documentation supplied with each type of expansion cabinet for

specific instructions.

Powering the System Onand Off 3-3

Page 50

3

AC power switch

Figure 3-2 The AC Power Sequencer Power Switch

3. Turn on power to the terminal (if applicable).

4. Set the system cabinet Local/Remote switch to Local.

See Figure 3-3.

5. Turn the AC power sequencer power switch to On.

See Figure 3-2. Listen for the sound of AC-powered devices such as disk

drives and fans in the disk drive tray(s).

3-4 Ultra Enterprise 6000/5000/4000Systems Installation Guide—November1996

Page 51

3

Note – The front panel keys for this switch are packed in the accessory box.

Local/remote switch

Figure 3-3 Local/Remote Switch

6. Turn the key switch to the On position.

The system will run firmware diagnostics for about one minute and then

boot.

You should see and hear several things happen:

• The fans in the power supplies begin turning.

• The left LED (green) on the front of the cabinet turns on immediately to

indicate the DC power supply is functioning.

• The middle LED (yellow) begins flashing.

Powering the System Onand Off 3-5

Page 52

3

• The right LED (green) flashes after firmware completes to denote that the

operating system is running.

• The terminal screen lights up upon completion of the internal self test.

7. Watch the terminal screen for any firmware error messages.

Note – If the middle front panel LED remains lit after the system has booted,

firmware has found (and deconfigured) failing hardware in the main cabinet.

POST (power-on-self test) tests subassemblies and some interface paths

between subassemblies.

At the conclusion of testing, firmware automatically attempts to reconfigure

the system, omitting any parts of the system that have failed diagnostics.

If there are no faults, or if firmware completes a successful reconfiguration

in response to detected faults, the system boots.

If the system is unable to communicate with the network, see Section 3.4,

“Failure of Network Communications.”

Note – POST does not test drives or internal parts of SBus cards. To test these

devices, run OpenBoot PROM (OBP) diagnostics manually after the system has

booted. Refer to the OpenBoot Command Reference for instructions.

Note – If faulty parts are detected and configured out of the working system,

you and the system manager must decide whether to operate the system until

replacement parts arrive, or to halt operation. Also, if a faulty component

cannot be replaced in the field, the entire subassembly (like the system board)

must be replaced.

8. To restart firmware, or if the system hangs, press the CPU reset switch on

the clock board.

See Figure 3-4.

3-6 Ultra Enterprise 6000/5000/4000Systems Installation Guide—November1996

Page 53

Figure 3-4 CPU Reset Switch on the Clock Board

3.2.2 Reading Boot Messages

3

System

reset switch

CPU

reset switch

Use the boot software messages to verify that all options are installed and

recognized by the system. After firmware completes the system self test, a

message similar to the following will appear on your screen. The message lists

hardware detected in the system.

Note – This screen display is an example only. The actual message displayed

on the screen will vary with the software running on the system.

16-slot Ultra Enterprise 6000, Keyboard Present

OpenBoot -.- FCS, --- MB memory installed, Serial #---.

Ethernet address -:-:--:-:--:--, Host ID: ------.

If firmware indicates a hardware problem at this time, refer to the

Ultra Enterprise 6000/5000/4000 Systems Manual, Part 3, “Troubleshooting,” for

further instructions.

Powering the System Onand Off 3-7

Page 54

3

Note – When the system finishes booting for the first time — if there is no

appropriate server configuration file on the disk drive — it may be necessary

to prevent the JumpStart automatic configuration program from running. See

the caution in Section 3.1, “Using JumpStart Automatic Installation.”

3.2.3 Interpreting Status LED Patterns

If there is no terminal on the system, basic system status information is

available on the front panel LEDs, as shown in Figure 3-5.

DC power

(green)

Fault (yellow)

System running

(green)

Figure 3-5 System Status LEDs (Cabinet Server)

Table 3-1 summarizes LED status indications.

Table 3-1 Front Panel LED Status Indicators

LED Position Condition

Left LED (green) On — DC power supply is receiving AC current.

Off — There is no DC power.

Middle LED

(yellow)

Right LED (green) Off — (first 60 seconds) Self tests are running.

3-8 Ultra Enterprise 6000/5000/4000Systems Installation Guide—November1996

On Flashing — (first 60 seconds) Self tests are running.

Off — (after self tests end) No hardware failures.

On — (after self tests end) Hardware failure was detected.

On Flashing — (after self tests end) System is running.

Off — (after self tests end) System cannot run; repair is needed.

Page 55

3.2.4 Powering Off the System

Before turning off the system power, you must halt the operating system. See

the Preface, “UNIX Commands,” to find references if you need help with the

commands for this task or other system administration procedures.

Note – Failure to halt the operating system properly can cause the loss of disk

drive data.

Note – Do not disconnect the terminal while the system is running.

Caution – To avoid damaging internal circuits, do not disconnect or connect

any cable while power is applied to the system.

To shut down the system:

1. Notify users that the system is going down.

2. Back up the system files and data to tape, if necessary.

3

3. Halt the system using the appropriate commands. Refer to the Solaris

Handbook for SMCC Peripherals that corresponds to your operating system.

4. Wait for the system-halted message and the boot monitor prompt.

5. Turn the key switch on the front panel of the server to the Standby

position (fully counterclockwise).

6. Turn off the system power in this order:

a. External drives and expansion cabinets (if any)

b. System cabinet AC power switch

c. Terminal

For more system administration information on methods for shut-down and

backup, see the Preface, “UNIX Commands,” for references to documentation

that describes these procedures.

Powering the System Onand Off 3-9

Page 56

3

3.3 Enterprise 4000 System

3.3.1 Powering On the System

Note – It is advisable to connect an ASCII terminal to the system during

installation. See Section 2.6, “Connecting an ASCII Terminal,” for terminal

settings and connections.

Observe the yellow (middle) LED on the front panel. It should go off when

boot completes. If it remains on, observe the terminal screen for boot messages

produced by the firmware diagnostic program during power-on.

To power on the Enterprise 4000 system:

1. Begin with a safety inspection of the system.

a. Turn the system key switch to (the Standby position).

See Figure 3-6.

b. Turn the AC power sequencer power switch to Off.

The AC power sequencer is at the rear of the enclosure. See Figure 3-6.

c. Verify that the AC power cord is plugged into a wall socket.

Caution – Do not disconnect the power cord from the wall socket when

working on the server. This connection provides a ground path that prevents

damage from uncontrolled electrostatic discharge.

2. Turn on power to any expansion cabinets.

Read the documentation supplied with each type of expansion cabinet for

specific instructions.

3. Turn on the terminal (if applicable).

4. Turn the AC power sequencer power switch to On.

See Figure 3-6.

5. Turn the key switch on the front panel to the On position.

See Figure 3-6. You should see and hear several things happen:

3-10 Ultra Enterprise 6000/5000/4000 SystemsInstallation Guide—November 1996

Page 57

Legend:

Standby = OFF; no DC power

On = Normal power ON

Diagnostics = Normal power ON with full

diagnostics

Locked= Normal power ON in secure mode

Standby

3

On

Diagnostics

Locked

AC connector

AC power switch

Figure 3-6 Key Switch Positions and AC Power Switch

• The fans in the power supplies begin turning.

• The top front panel LED (green) turns on immediately denoting the power

supply is delivering DC power.

• The middle front panel LED (yellow) flashes while POST runs for

approximately 60 seconds. After 60 seconds, this LED turns off if the tests

pass. If the LED remains lighted after 60 seconds, a test has failed.

• The bottom front panel LED (green) flashes to show that booting is

successful and the operating system is running. If this LED fails to turn on

and the middle LED is on, a severe hardware fault exists.

Warning – Never move the system when the power is on. Failure to heed this

!

warning may result in catastrophic disk drive failure. Always power the

system off before moving it.

Powering the System Onand Off 3-11

Page 58

3

6. Watch the terminal screen for error messages from the firmware diagnostic

program.

POST (power-on-self test) tests subassemblies and some interface paths

between subassemblies.

At the conclusion of testing, firmware automatically attempts to reconfigure

the system, omitting any parts of the system that have failed diagnostics.

If there are no faults, or if firmware completes a successful reconfiguration

in response to detected faults, the system boots.

Note – If faulty parts are detected and configured out of the working system,

you and the system manager must decide whether to operate the system until

replacement parts arrive, or to halt operation. Also, if a faulty component

cannot be replaced in the field, the entire subassembly (like the system board)

must be replaced.

7. To restart firmware, or if the system hangs, press the CPU reset switch on

the clock board. See Figure 3-7.

CPU

reset switch

Figure 3-7 CPU Reset Switch on Clock Board

3-12 Ultra Enterprise 6000/5000/4000 SystemsInstallation Guide—November 1996

System

reset switch

Page 59

3.3.2 Reading Boot Messages

Use the boot software messages to verify that all options are installed and

recognized by the system. After firmware completes the system self test, a

message similar to the following will appear on your screen. The message lists

hardware detected in the system.

Note – This screen display is an example only. The actual message displayed

on the screen will depend on the software running on your system.

8-slot Ultra Enterprise 5000/4000, Keyboard Present

OpenBoot -.- FCS, --- MB memory installed, Serial #---.

Ethernet address -:-:--:-:--:--, Host ID: ------.

If firmware indicates a hardware problem at this time, refer to the

Ultra Enterprise 6000/5000/4000 Systems Manual, Part 3, “Troubleshooting,” for

further instructions.

3

Boot the system using the procedure that is appropriate for your operating

system. See the Preface, “UNIX Commands,” for a reference to documentation

that describes this procedure.

3.3.3 Interpreting Status LED Patterns

If there is no terminal on the system, basic system status information is

available on the front panel LEDs, as shown in Figure 3-8.

Powering the System Onand Off 3-13

Page 60

3

DC power (green)

Fault (yellow)

System running

(green)

Figure 3-8 System Status LEDs (Standalone Server)

Table 3-2 summarizes LED status indications.

After boot, check the status of the system by inspecting system status LEDs on

the front panel. See Table 3-2 and Figure 3-8.

Table 3-2 Front Panel LED System Status

LED Position Condition

Top LED (green) On — The power supply is delivering DC power.

Middle LED

(yellow)

Bottom LED

(green)

Flashing — (first 60 seconds of AC power) Self tests are running.

Off — (after self tests end) No hardware failures detected.

On — (after self tests end) Hardware failure was detected.

Off — (first 60 seconds of AC power) Self tests are running.

Flashing — (after self tests end) System is running.

Off — (after self tests end) System cannot run; repair is needed.

Ideally, when self test completes, both top and bottom LEDs are on. Less ideal

is if all LEDs are on (system needs service, but is able to run). The worst

condition is if the top and middle LEDs are on (system cannot boot), or if no

LED is on.

3-14 Ultra Enterprise 6000/5000/4000 SystemsInstallation Guide—November 1996

Page 61

3.3.4 Powering Off the System

Before turning off the system power, you must halt the operating system. See

the Preface, “UNIX Commands,” to find references if you need help with the

commands for this task or other system administration procedures.

Note – Failure to halt the operating system properly can cause the loss of disk

drive data.

Note – Do not disconnect the terminal while the system is running.

Caution – To avoid damaging internal circuits, do not disconnect or plug in

any cable while power is applied to the system.

To shut down the system:

1. Notify users that the system is going down.

2. Back up the system files and data to tape, if necessary.

3

3. Halt the system using the appropriate commands. Refer to the Solaris

Handbook for SMCC Peripherals that corresponds to your operating system.

4. Wait for the system-halted message and the boot monitor prompt.

5. Turn the key switch on the front panel of the server to the Standby

position (fully counterclockwise).

6. Turn off the system power in this order:

a. External drives and expansion cabinets (if any)

b. System AC power switch

c. Terminal

For more system administration information on methods for shut-down and

backup, see the Preface, “UNIX Commands,” for references to documentation

that describes these procedures.

Powering the System Onand Off 3-15

Page 62

3

3.4 Failure of Network Communications

Description of the Problem

The system cannot communicate with a network if the system and the network

hub are not set in the same way for the Ethernet link integrity test. This

problem particularly applies to 10BASE-T network hubs, where the Ethernet

link integrity test is optional. This is not a problem for 100BASE-T networks,

where the test is enabled by default.

If you connect the system to a network and the network does not respond, use

the OpenBoot command watch-net-all to display conditions for all network

connections:

ok watch-net-all

For SBus Ethernet cards, the test can be enabled or disabled with a hardware

jumper, which you must set manually. For the TPE and MII onboard ports on

the I/O board, the link test is enabled or disabled through software, as shown

below.

Remember also that the TPE and MII ports are not independent circuits and as

a result, both ports cannot be used at the same time.

Note – Some hub designs do not use a software command to enable/disable

the test, but instead permanently enable (or disable) the test through a

hardware jumper. Refer to the hub installation or user manual for details of

how the test is implemented.

Determining the Device Namesof the I/OBoards

To enable or disable the link test for an onboard TPE (hme) port, you must first

know the device name for the I/O board. To list the device names:

1. Shut down the system and take the system into OpenBoot.

2. Determine the device names of the I/O boards:

3-16 Ultra Enterprise 6000/5000/4000 SystemsInstallation Guide—November 1996

Page 63

a. Type:

ok show-devs

b. In the show-devs listing, find the node names.

Node names take the general form /sbus@3,0/SUNW,hme@3,8c00000.

Solution 1

Use this method while the operating system is running:

1. Become superuser.

2. Type:

# eeprom nvramrc=”probe-all install-console banner apply disable-link-pulse device-name “

(Repeat for any additional device names.)

# eeprom “use-nvramrc?”=true

3. Reboot the system (when convenient) to make the changes effective.

3

Solution 2

Use this alternate method when the system is already in OpenBoot:

1. At the monitor OpenBoot prompt, type:

ok nvedit

0: probe-all install-console banner

1: apply disable-link-pulse device-name

(Repeat this step for other device names as needed.)

(Press CONTROL-C to exit nvedit.)

ok nvstore

ok setenv use-nvramrc? true

2. Reboot to make the changes effective.

Powering the System Onand Off 3-17

Page 64

3

3-18 Ultra Enterprise 6000/5000/4000 SystemsInstallation Guide—November 1996

Page 65

UsingtheSoftware

This chapter contains information about software for your Enterprise

6000/5000/4000 systems.

4.1 Operating System Software

Refer to the operating system documentation that came with your system.

4.2 Solstice SyMON Software

Solstice™ SyMON™ features a graphical user interface (GUI) display that

shows various graphs reflecting system status.

Solstice SyMON, intended to complement network-wide and enterprise-wide

system management tools, is accessible through an SNMP interface from

network tools such as Solstice SunNet Manager™.

Refer to the online Solstice SyMON User’s Guide, part number 802-5355, for

starting and operating instructions.

4

4-1

Page 66

4

4-2 Ultra Enterprise 6000/5000/4000Systems Installation Guide—November1996

Page 67

Index

A

AC switch, 2-6, 3-2, 3-10

adjust, levelling pads, 1-12

air conditioning needs, 1-7

ASCII terminal

cabling and setup, 2-10

removal, 3-9, 3-15

automatic installation, JumpStart, 3-1

B

bar, stabilizer, 1-13

boot messages, 3-7, 3-13

C

cabling

ASCII terminal, 2-10

ethernet, length, 2-9

fiber, 2-11

network, 2-6

power, 2-4

preparing for, 2-1

SCSI, 2-12

twisted-pair, 1-7

cautions

notes, warnings, xiv

SCSI bus, SBus, 2-13

clearance, system, 1-10

connecting, power cord, 2-5

cord, power, 1-15

D

disk drive

tray, use stabilizer bar, 1-13

drive

disk, caution

improper shutdown, 3-9

moving with power on, 3-3

test, 3-6

tray, safety, 1-13

duplicate addresses, caution, 2-13

E

error messages

POST, 3-2, 3-10

terminal, 3-2, 3-10

ethernet

cable

length, 2-9

limitations, 2-9

F

fiber cable, 2-11

Index-1

Page 68

floorspace, 1-9

H

halting the system, 3-9, 3-15

I

installation, preparing for, 1-1

J

JumpStart installation program, 3-1

K

key

location in container, 1-15

switch

positions, 2-5

kick panel

replace, 2-1

L

LEDs

interpretation, 3-6

status, 3-14

leveling

wrench, 1-14

levelling

pads, adjust, 1-12

lifting the server, 1-14

limitations, cable, ethernet, 2-9

link test function, 1-9, 2-10

local/remote switch, 3-4

M

messages

boot, 3-7, 3-13

error, 3-2, 3-10

MII connector, 1-7

N

network

cabling, 2-6 to 2-7

site preparation, 1-7

transceiver, 1-9

notes, cautions, warnings, xiv

P

panel

replace

kick, 2-1

rear screen, 2-1

POST

error messages, 3-2, 3-10

LED interpretation, 3-6

program, 2-10

reconfiguration of system, 3-6, 3-12

restart, 3-6

SBus card, 3-6

power

cabling, 2-4

cord, location, 1-15

off the system, 3-9, 3-15

on the system, 3-2 to 3-7

power-on self-test See POST

precaution, automatic installation

JumpStart, 3-1

preparing

for cabling, 2-1

for installation, 1-1

R

rear screen

replace, 2-1

reconfiguration, system, POST, 3-12

remove

ASCII terminal, 3-9, 3-15

replace

panel

kick, 2-1

rear screen, 2-1

reset switch, 3-6

Index-2 Ultra Enterprise 6000/5000/4000 SystemsInstallation Guide—November 1996

Page 69

usage of, 3-12

restart, POST, 3-6

S

SBus

card

POST, 3-6

test, 3-6

caution, 2-13

SCSI