Sun Fire™15K/12K Systems

Service Manual

Sun Microsystems, Inc.

www.sun.com

Part No. 806-3512-13

May 2006, Revision A

Submit comments about this document at: http://www.sun.com/hwdocs/feedback

Copyright 2006Sun Microsystems,Inc., 4150Network Circle, SantaClara, California95054, U.S.A.All rightsreserved.

Sun Microsystems,Inc. hasintellectual property rightsrelating totechnology embodiedin theproduct that is described inthis document.In

particular,and withoutlimitation, theseintellectual property rightsmay includeone ormore ofthe U.S.patents listedat

http://www.sun.com/patents andone ormore additionalpatents orpending patentapplications inthe U.S.and inother countries.

This documentand theproduct towhich itpertains are distributedunder licensesrestricting theiruse, copying,distribution, and

decompilation. Nopart ofthe productor ofthis documentmay bereproducedin anyform byany meanswithout priorwritten authorizationof

Sun andits licensors,if any.

Third-party software, includingfont technology,is copyrightedand licensedfrom Sun suppliers.

Parts ofthe productmay bederived from BerkeleyBSD systems,licensed fromthe Universityof California.UNIX isa registered trademarkin

the U.S.and inother countries,exclusively licensedthrough X/OpenCompany, Ltd.

Sun, SunMicrosystems, theSun logo,AnswerBook2, docs.sun.com,Sun Fire, OpenBoot,SunVTS, SunFireplane interconnect, andSolaris are

trademarks orregistered trademarks of Sun Microsystems,Inc. inthe U.S.and inother countries.

All SPARCtrademarks areused underlicense andare trademarks or registered trademarksof SPARCInternational, Inc.in theU.S. andin other

countries. Productsbearing SPARCtrademarks are basedupon anarchitecture developed by Sun Microsystems,Inc.

The OPENLOOK andSun™ GraphicalUser Interfacewas developedby SunMicrosystems, Inc.for itsusers andlicensees. Sunacknowledges

the pioneeringefforts ofXerox in researchingand developingthe conceptof visualor graphicaluser interfacesfor thecomputer industry.Sun

holds anon-exclusive licensefrom Xerox tothe XeroxGraphical UserInterface, whichlicense alsocovers Sun’slicensees whoimplement OPEN

LOOK GUIsand otherwisecomply withSun’s writtenlicense agreements.

U.S. GovernmentRights-Commercial use.Government usersare subject to the Sun Microsystems, Inc.standard licenseagreement and

applicable provisionsof theFAR andits supplements.

DOCUMENTATION IS PROVIDED "AS IS" AND ALL EXPRESS OR IMPLIED CONDITIONS, REPRESENTATIONS AND WARRANTIES,

INCLUDING ANYIMPLIED WARRANTY OFMERCHANTABILITY, FITNESSFOR A PARTICULAR PURPOSEOR NON-INFRINGEMENT,

ARE DISCLAIMED, EXCEPT TO THE EXTENT THAT SUCH DISCLAIMERS ARE HELD TO BE LEGALLY INVALID.

Copyright 2006Sun Microsystems,Inc., 4150Network Circle, SantaClara, Californie95054, Etats-Unis.Tous droitsréservés.

Sun Microsystems,Inc. ales droits depropriété intellectuelsrelatants à la technologie incorporée dans leproduit quiest décritdans ce

document. Enparticulier,et sansla limitation,ces droits depropriété intellectuelspeuvent inclure unou plusdes brevetsaméricains énumérés

à http://www.sun.com/patents et unou lesbrevets plus supplémentairesou lesapplications debrevet enattente dansles Etats-Uniset dans

les autrespays.

Ce produitou documentest protégé parun copyrightet distribuéavec deslicences quien restreignent l’utilisation,la copie,la distribution,et la

décompilation. Aucunepartie dece produitou documentne peutêtre reproduite sousaucune forme,parquelque moyen que ce soit, sans

l’autorisation préalableet écritede Sunet deses bailleursde licence,s’il yena.

Le logicieldétenu pardes tiers,et quicomprend latechnologie relative auxpolices decaractères, estprotégépar uncopyright etlicencié pardes

fournisseurs deSun.

Des partiesde ceproduit pourront êtredérivées dessystèmes BerkeleyBSD licenciéspar l’Universitéde Californie.UNIX estune marque

déposée auxEtats-Unis etdans d’autrespays etlicenciée exclusivementpar X/OpenCompany, Ltd.

Sun, SunMicrosystems, lelogo Sun,AnswerBook2, docs.sun.com,Sun Fire, OpenBoot,SunVTS, SunFireplane interconnect, etSolaris sontdes

marques defabrique oudes marques déposéesde SunMicrosystems, Inc.aux Etats-Uniset dansd’autres pays.

Toutes lesmarques SPARC sont utilisées sous licence et sont des marques defabrique oudes marquesdéposées deSPARC International,Inc.

aux Etats-Uniset dansd’autres pays.Les produits protantles marques SPARC sont baséssur unearchitecturedéveloppée parSun

Microsystems, Inc.

L’interfaced’utilisation graphiqueOPEN LOOKet Sun™a étédéveloppée parSun Microsystems, Inc.pour sesutilisateurs etlicenciés. Sun

reconnaît lesefforts de pionniers de Xeroxpour larecherche et le développment du concept des interfaces d’utilisation visuelle ou graphique

pour l’industriede l’informatique.Sun détientune licensenon exclusivedo Xeroxsur l’interfaced’utilisation graphiqueXerox,cette licence

couvrant égalementles licenciéesde Sunqui mettenten placel’interface d’utilisation graphiqueOPEN LOOKet quien outrese conforment

aux licencesécrites deSun.

LA DOCUMENTATION EST FOURNIE "EN L’ÉTAT" ET TOUTES AUTRES CONDITIONS, DECLARATIONS ET GARANTIES EXPRESSES

OU TACITES SONT FORMELLEMENTEXCLUES, DANSLA MESUREAUTORISEE PARLA LOIAPPLICABLE, YCOMPRIS NOTAMMENT

TOUTE GARANTIE IMPLICITE RELATIVE A LA QUALITE MARCHANDE, A L’APTITUDE A UNE UTILISATION PARTICULIERE OU A

L’ABSENCE DE CONTREFAÇON.

Contents

Declaration of Conformity xxiii

Preface xxv

1. Guidelines, Indicators, and Nomenclature 1–1

1.1 System Component Hot-Swap Guidelines 1–1

1.2 Configuration Rules 1–2

1.3 Testing the System 1–3

1.4 Reviewing System Temperatures 1–4

1.5 Reviewing System Power 1–5

1.6 Hardware Indicators 1–6

1.7 Field-Replaceable Units (FRU)—Mean Time to Repair (MTTR) 1–7

1.8 Safety Precautions 1–12

1.9 Special Tools and Shipping Kit Items 1–13

1.10 System Block Diagrams 1–14

2. FrameManager and Extension, and TopCap and Extension Replacement

Procedures 2–1

2.1 FrameManager Replacement 2–2

2.1.1 Removing the FrameManager 2–2

2.1.2 Installing the FrameManager 2–2

iii

2.2 FrameManager Extension Replacement 2–2

2.2.1 Removing the FrameManager Extension 2–2

2.2.2 Installing the FrameManager Extension 2–3

2.3 TopCap Replacement 2–3

2.3.1 Removing the TopCap 2–3

2.3.2 Installing the TopCap 2–3

2.4 TopCap Extension Replacement 2–4

2.4.1 Removing the TopCap Extension 2–4

2.4.2 Installing the TopCap Extension 2–4

3. System Power 3–1

3.1 Power Module Replacement Procedures 3–2

3.1.1 Power Module Replacement 3–2

3.1.2 Powering Off for Power Module Removal 3–2

3.1.3 Removing a Power Module 3–4

3.1.4 Installing a Power Module 3–6

3.1.5 Powering On After Power Module Installation 3–7

3.2 4 kW Dual AC–DC Power Supply Replacement Procedures 3–8

3.2.1 4 kW Dual AC–DC Power Supply LEDs 3–9

3.2.2 4 kW Dual AC–DC Power Supply Replacement 3–10

4. Fan Trays 4–1

4.1 Fan Tray LEDs 4–2

iv Undefined BookTitle • May 2006

3.2.2.1 Isolating a Failed Power Supply 3–10

3.2.2.2 Powering Off a 4 kW Dual AC–DC Power Supply 3–11

3.2.2.3 Removing a 4 kW Dual AC–DC Power Supply 3–11

3.2.2.4 Installing a 4 kW Dual AC–DC Power Supply 3–12

3.2.2.5 Powering On a 4 kW Dual AC–DC Power Supply 3–13

3.2.2.6 Verifying a 4 kW Dual AC–DC Power Supply 3–13

4.2 Fan Tray Replacement Procedures 4–3

4.2.1 Isolating a Failed Fan Tray 4–3

4.2.2 Powering Off a Fan Tray 4–4

4.2.3 Removing a Fan Tray 4–4

4.2.4 Installing a Fan Tray 4–5

4.2.5 Verifying a Fan Tray 4–6

5. System Control (SC) CPU Board and cPCI Memory Board 5–1

5.1 System Control (SC) CPU Board Replacement Procedures 5–2

5.1.1 Powering Off the SC Board 5–2

5.1.2 Removing the SC Board 5–2

5.1.3 Removing the System Control (SC) CPU Board 5–2

5.2 System Control (SC) Board cPCI Memory Board Installation Procedures

5–3

5.2.1 Installing cPCI Memory Boards on the SC CPU 5–3

5.2.2 Installing the System Control (SC) CPU Board 5–5

5.2.3 Installing the System Control (SC) Board 5–5

5.2.4 Verifying the cPCI Memory Boards on the SC CPU 5–6

6. System Control (SC) Board 6–1

6.1 System Control (SC) Board Replacement 6–2

6.1.1 System Control Board LEDs 6–2

6.1.2 System Control Board (SC) Replacement Procedures 6–4

6.1.2.1 Isolating a Failed System Control Board 6–4

6.1.2.2 Powering Off a System Control (SC) Board 6–4

6.1.2.3 Removing a System Control (SC) Board 6–7

6.1.2.4 Installing a System Control (SC) Board 6–8

6.1.2.5 Verifying a System Control (SC) Board 6–10

7. System Control (SC) Peripheral Board 7–1

Contents v

7.1 System Control Peripheral Board LEDs 7–2

7.2 System Control Peripheral Board Replacement Procedures 7–5

7.2.1 Isolating a Failed System Control (SC) Peripheral Board 7–5

7.2.2 Powering Off a System Control (SC) Peripheral Board 7–5

7.2.3 Removing a System Control (SC) Peripheral Board 7–5

7.2.4 Installing a System Control (SC) Peripheral Board 7–7

7.2.5 Powering On a System Control (SC) Peripheral Board 7–7

7.2.6 Verifying a System Control (SC) Peripheral Board 7–8

7.3 DVD-ROM Peripheral Replacement Procedures 7–8

7.3.1 Removing the Failed DVD-ROM Peripheral From the System

Control (SC) Peripheral Board 7–8

7.3.2 Installing the DVD-ROM Peripheral on the System Control (SC)

Peripheral Board 7–10

7.3.3 Powering On a DVD-ROM Peripheral 7–10

7.3.4 Verifying a DVD-ROMDVD-ROM Peripheral 7–10

7.4 Hard Drive Peripheral Replacement Procedures 7–11

7.4.1 Removing the Failed Hard Drive Peripheral From the System

Control (SC) Peripheral Board 7–11

7.4.2 Installing the Hard Drive Peripheral on the System Control (SC)

7.4.3 Powering On a Hard Drive Peripheral 7–13

7.4.4 Verifying a Hard Drive Peripheral 7–13

7.5 Digital Audio Tape (DAT) Peripheral Replacement Procedures 7–14

7.5.1 Removing the FailedDATPeripheral Fromthe SystemControl (SC)

7.5.2 Installing the DAT Peripheral on the System Control (SC)

7.5.3 Powering On a Digital Audio Tape (DAT) Peripheral 7–16

7.5.4 Verifying a Digital Audio Tape (DAT) Peripheral 7–16

8. CPU (Slot 0) Board 8–1

vi Undefined BookTitle • May 2006

Peripheral Board 7–13

Peripheral Board 7–14

Peripheral Board 7–15

8.1 CPU (Slot 0) Board LEDs 8–2

8.2 CPU (Slot 0) Board Replacement Procedures 8–3

8.2.1 Isolating a Failed CPU (Slot 0) Board 8–3

8.2.2 Powering Off a CPU (Slot 0) Board 8–4

8.2.3 Removing a CPU (Slot 0) Board 8–5

8.2.4 Installing a CPU (Slot 0) Board 8–7

8.2.5 Verifying a CPU (Slot 0) Board 8–8

8.3 CPU (Slot 0) Board DIMM Replacement Procedures 8–9

8.3.1 Removing the CPU DIMMs 8–9

8.3.2 Installing the CPU DIMMs 8–11

8.4 CPU (Slot 0) Filler Panel Replacement Procedures 8–12

8.4.1 Removing a CPU (Slot 0) Filler Panel 8–12

8.4.2 Installing a CPU (Slot 0) Filler Panel 8–12

9. I/O (Slot 1) Assemblies 9–1

9.1 hsPCI (Slot 1) Assembly 9–2

9.1.1 hsPCI (Slot 1) Assembly LEDs 9–2

9.1.2 hsPCI I/O (Slot 1) Assembly Replacement Procedures 9–3

9.1.2.1 Isolating a Failed hsPCI (Slot 1) Assembly 9–3

9.1.2.2 Powering Off an hsPCI (Slot 1) Assembly 9–4

9.1.2.3 Removing an hsPCI (Slot 1) Assembly 9–5

9.1.2.4 Installing an hsPCI (slot 1) Assembly 9–6

9.1.2.5 Powering On an hsPCI (Slot 1) Assembly 9–7

9.1.2.6 Verifying an hsPCI (Slot 1) Assembly 9–7

9.2 PCI Cassette Replacement Procedures 9–8

9.2.1 PCI Cassette Replacement 9–8

9.2.1.1 Removing the PCI Cassette 9–8

9.2.1.2 Installing the PCI Cassette 9–9

9.3 PCI Cassette Card Replacement Procedures 9–10

Contents vii

9.3.1 PCI Cassette Card Replacement 9–10

9.3.1.1 Removing the PCI Card from the Cassette 9–10

9.3.1.2 Installing the PCI Card into the Cassette 9–10

9.4 MaxCPU (Slot 1) Board Replacement Procedures 9–11

9.4.1 MaxCPU (Slot 1) Board LEDs 9–11

9.4.2 MaxCPU (Slot 1) Board Replacement 9–12

9.4.2.1 Isolating a Failed MaxCPU (Slot 1) Board 9–12

9.4.2.2 Powering Off a MaxCPU (Slot 1) Board 9–13

9.4.2.3 Removing a MaxCPU (Slot 1) Board 9–13

9.4.2.4 Installing a MaxCPU (Slot 1) Board 9–14

9.4.2.5 Powering On a MaxCPU (Slot 1) Board 9–15

9.4.2.6 Verifying a MaxCPU (Slot 1) Board 9–15

9.5 I/O (Slot 1) Filler Panel Replacement Procedures 9–17

9.5.1 Removing an I/O (Slot 1) Filler Panel 9–17

9.5.2 Installing an I/O (Slot 1) Filler Panel 9–17

10. Board Set Carrier Plates 10–1

10.1 Inserting a Board Set Carrier Plate 10–2

10.2 Carrier Plate Replacement and Modifications 10–5

10.2.1 Carrier Plate FRU Modification Contents 10–6

10.2.2 Carrier PlateReplacement forStandard Configurations of Slots 1, 2,

10.2.3 Carrier Plate Replacement for Configuration of Slots 0 and 9 10–7

10.2.4 Carrier Plate Replacement for Configuration of Slots 4, 5, 13, and

10.3 Carrier Plate (With Air Dam) Replacement 10–10

10.3.1 Carrier Plate (With Air Dam) Replacement for Standard

11. System Control Expander Board Set 11–1

viii Undefined BookTitle • May 2006

3, 6, 7, 8, 10, 11, 12, 15, 16, and 17 10–6

14 10–8

Configurations of Slots 4, 5, 13, and 14 10–11

11.1 Centerplane Support Board Replacement 11–2

11.1.1 Centerplane Support Board LEDs 11–2

11.2 Centerplane Support Board Replacement Procedures 11–3

11.2.1 Isolating a Failed Centerplane Support Board 11–4

11.2.2 Powering Off a Centerplane Support Board 11–4

11.2.3 Removing a Centerplane Support Board 11–4

11.2.4 Installing a Centerplane Support Board 11–6

11.2.5 Powering On a Centerplane Support Board 11–7

11.2.6 Verifying a Centerplane Support Board 11–7

12. System Expander Board Set 12–1

12.1 System Expander Board LEDs 12–2

12.2 Expander Board Replacement Procedures 12–3

12.2.1 Isolating a Failed Expander Board 12–3

12.2.2 Powering Off an Expander Board 12–4

12.2.3 Removing an Expander Board 12–5

12.2.4 Installing an Expander Board 12–7

12.2.5 Powering On an Expander Board 12–8

12.2.6 Verifying an Expander Board 12–8

13. Sun Fireplane Interconnect Replacement Procedure 13–1

13.1 Isolating a Failed Sun Fireplane Interconnect 13–2

13.2 Setting Up the System Prior to Replacing the Sun Fireplane Interconnect

13–2

13.3 Powering Off the System for Sun Fireplane Interconnect Replacement 13–

4

13.4 Removing the Sun Fireplane Interconnect From the Chassis 13–5

13.5 Installing the Sun Fireplane Interconnect into the Chassis 13–8

13.6 Powering On the System After the Sun Fireplane Interconnect

Installation 13–9

Contents ix

14. Fan Backplane Replacement Procedure 14–1

14.1 Powering Off for Fan Backplane Removal 14–2

14.2 Removing a Fan Backplane 14–3

14.3 Installing a Fan Backplane 14–5

14.4 Powering On After Fan Backplane Installation 14–6

15. Power Centerplane Replacement Procedure 15–1

15.1 Powering Off the System for Power Centerplane Replacement 15–2

15.2 Removing the Power Centerplane 15–3

15.3 Installing the Power Centerplane Assembly into the Chassis 15–6

15.4 Powering On the System After Power Centerplane Installation 15–9

16. Cable Replacement Procedures 16–1

16.1 AC Power Cord 16–8

16.2 Internal Cabinet Cable Replacement Procedures 16–8

16.2.1 Powering Off the System for Cable Replacement 16–8

16.2.2 48 VDC Power Cable Replacement 16–10

16.2.3 Power Shelf I2C or FrameManager and TopCap Cable

16.2.4 Power Crossover Cable Replacement 16–12

16.2.5 Fan Tray Power Cable Replacement 16–13

x Undefined BookTitle • May 2006

16.2.2.1 Removing the 48 VDC Power Cable 16–10

16.2.2.2 Installing the 48 VDC Power Cable 16–11

Replacement 16–11

16.2.3.1 Removing the Power Shelf I2C or FrameManager and

TopCap Cable 16–11

16.2.3.2 Installing the Power Shelf I2C or FrameManager and

TopCap Cable 16–12

16.2.4.1 Removing the Power Crossover Cable 16–12

16.2.4.2 Installing the Power Crossover Cable 16–13

16.2.5.1 Removing the Fan Tray Power Cable 16–13

16.2.5.2 Installing the Fan Tray Power Cable 16–15

16.2.6 Internal Cable Harness Set Replacement 16–16

16.2.6.1 Removing the Internal Cable Harness Set 16–16

16.2.6.2 Installing the Internal Cable Harness Set 16–17

16.2.7 FrameManager Cable Replacement 16–18

16.2.7.1 Removing the FrameManager Cable 16–18

16.2.7.2 Installing the FrameManager Cable 16–19

16.2.8 TopCap Cable Replacement 16–20

16.2.8.1 Removing the TopCap Cable 16–20

16.2.8.2 Installing the TopCap Cable 16–21

16.3 Powering On the System 16–22

17. Mechanical Components Replacement Procedures 17–1

17.1 Side Panel Replacement 17–2

17.1.1 Removing a Side Panel 17–2

17.1.2 Installing a Side Panel 17–2

17.2 Access Door Replacement 17–2

17.2.1 Removing an Access Door 17–3

17.2.2 Installing an Access Door 17–3

17.3 Kick Plate Assembly Replacement 17–3

17.3.1 Removing a Kick Plate Assembly 17–3

17.3.2 Installing a Kick Plate Assembly 17–4

18. Periodic Maintenance 18–1

18.1 Cleaning the Air Plenum Panel Air-Intake Screens 18–2

18.1.1 Air Plenum Panel Air-Intake Screen for Sun Fire 15K/12K

Systems 18–2

18.1.2 Cleaning the Air Plenum Air-Intake Screens 18–3

18.2 Air Filter Replacement 18–3

18.2.1 Replacing an Air Filter 18–3

Contents xi

A. Component Serial Number Worksheet 19–1

B. System Labels 20–1

B.1 ESD GROUND and Top Fan Tray Component Number Labels 20–1

B.2 System Chassis and Carrier Plate Labels 20–2

B.3 Fan Tray Labels 20–3

B.3.1 Fan Tray Removal Label 20–3

B.3.2 Bottom Fan Tray Component Number Labels 20–4

B.4 Board Carrier Slot Component Number Labels 20–4

2.4.1 Front Component Number Labels 20–4

2.4.2 Rear Component Number Labels 20–5

B.5 Expander Label 20–5

B.6 Centerplane Support Label 20–5

B.7 Sun Fireplane Interconnect Label 20–6

B.8 Power Supply Labels 20–6

2.8.1 Power Supply Component Labels 20–6

2.8.2 External Power Supply Handle-Instruction Label 20–7

2.8.3 Power Supply Weight-Information Label 20–7

2.8.4 Power Supply CAUTION Label 20–7

C. Sun Fire 15K/12K Systems Field-Replaceable Units (FRU) 21–1

C.1 Access Doors and Side Panels 21–2

3.2 FrameManager Assembly and TopCap Assembly 21–3

3.2.1 FrameManager Assembly 21–3

3.2.2 TopCap Assembly 21–3

3.3 Kick Plate Assembly 21–4

3.4 System Board Assemblies and Carrier Plates 21–5

3.5 Fan Tray Cooling Components 21–14

3.6 Power Supplies and Air Filters 21–15

xii Undefined BookTitle • May 2006

3.7 System Cables 21–17

Index Index–1

Contents xiii

xiv Undefined BookTitle • May 2006

Figures

FIGURE 1-1 Sun Fire 15K/12K Systems Component Numbering—Front 1–8

FIGURE 1-2 Sun Fire 15K System Component Numbering—Rear 1–9

FIGURE 1-3 Sun Fire 12K System Component Numbering—Rear 1–10

FIGURE 1-4 Cassette Component Numbering—Sun Fire 15K Front and Rear, and Sun Fire 12K Front 1–

11

FIGURE 1-5 System Architecture Block Diagram 1–14

FIGURE 1-6 Control Distribution Block Diagram 1–15

FIGURE 1-7 Power Distribution Block Diagram 1–16

FIGURE 3-1 Air-Plenum Cover 3–4

FIGURE 3-2 Power Module 3–6

FIGURE 3-3 Sun Fire 15K/12K Systems Power Supply 3–8

FIGURE 3-4 4 kW Dual AC–DC Power Supply LEDs 3–10

FIGURE 3-5 AC Power Cord Installation 3–13

FIGURE 4-1 Fan Tray 4–1

FIGURE 4-2 Fan Tray LEDs 4–3

FIGURE 5-1 System Control (SC) CPU cPCI Memory Board Installation 5–4

FIGURE 6-1 System Control Board LEDs (3U to 6U Conversion Board Option) 6–3

FIGURE 6-2 System Control Board 6–8

FIGURE 7-1 System Control Peripheral Board LEDs 7–3

FIGURE 7-2 SC Peripheral Board and Center Access Panel—Exploded 7–6

FIGURE 7-3 SC Peripheral Board DVD Removal and Access Panel—Exploded 7–9

xv

FIGURE 7-4 SC Peripheral Board Hard Drive Removal and Access Panel—Exploded 7–12

FIGURE 7-5 SC Peripheral Board DAT Removal and Access Panel—Exploded 7–15

FIGURE 8-1 CPU Board LEDs 8–3

FIGURE 8-2 CPU Board Components 8–6

FIGURE 8-3 CPU Board Memory DIMM Locations 8–10

FIGURE 8-4 CPU DIMM Removal 8–11

FIGURE 9-1 hsPCI Board LEDs 9–3

FIGURE 9-2 PCI Cassette Removal 9–9

FIGURE 9-3 MaxCPU Board LEDs 9–12

FIGURE 10-1 System Carrier Plates 10–3

FIGURE 10-2 Standard Configuration Carrier Plate 10–5

FIGURE 10-3 Removing the T Rail Guide 10–7

FIGURE 10-4 Securing the Center Guide Bracket After the T Rail Guide Removal 10–8

FIGURE 10-5 Removing the Card Cage Filler Panel 10–9

FIGURE 10-6 Installing the EMI Metal Gasket 10–10

FIGURE 10-7 Air-Dam Configuration Carrier Plate 10–11

FIGURE 11-1 Centerplane Support Board LEDs 11–3

FIGURE 11-2 Centerplane Support Board and Carrier Plate 11–6

FIGURE 12-1 System Expander Board LEDs 12–3

FIGURE 12-2 Expander Board and Carrier Plate—Exploded 12–6

FIGURE 13-1 Sun Fireplane Interconnect—Front and Rear View 13–7

FIGURE 14-1 Fan Backplane Locations—Front 14–4

FIGURE 14-2 Fan Backplane Connections 14–5

FIGURE 15-1 Power Centerplane Power Control Connections 15–4

FIGURE 15-2 Voltage-and-Return Reference Designation Labels—Front and Rear 15–7

FIGURE 16-1 Sun Fire 15K/12K Systems Internal Cable Connections 16–2

FIGURE 16-2 System Cable Layout Diagram—Typical for Front (Side 0) and Rear (Side 1) 16–3

FIGURE 16-3 Fan Tray Backplane FRU Cable Diagram—Top Front, Side 0 16–4

FIGURE 16-4 Power Centerplane Cable Diagram—Bottom Front, Side 0 16–4

FIGURE 16-5 Fan Tray Backplane FRU Cable Diagram—Top Front, Side 1 16–5

xvi Undefined BookTitle • May 2006

FIGURE 16-6 Power Centerplane Cable Diagram—Bottom Rear, Side 1 16–5

FIGURE 16-7 Cable Schematic Diagram for Interface Connectors—Side 0 16–6

FIGURE 16-8 Cable Schematic Diagram for Interface Connectors—Side 1 16–6

FIGURE 16-9 DC Power Distribution Cables—Side 0 and Side 1 16–6

FIGURE 16-10 48 VDC Power Cables 16–10

FIGURE 16-11 Fan Tray Power Cable 16–14

FIGURE 16-12 Internal Cable Harness Set 16–17

FIGURE 16-13 FrameManager Cable 16–19

FIGURE 16-14 TopCap Cable 16–21

FIGURE 17-1 Kick Plate Assembly 17–4

FIGURE 18-1 Air Plenum Panel and Air-Intake Screen for the Sun Fire 15K/12K Systems 18–2

FIGURE 18-2 Filter Replacement—Front and Rear 18–4

FIGURE B-1 ESD GROUND and Top Fan Tray Component Number Labels 20–1

FIGURE B-2 System Chassis and Carrier Plate Label—Carrier Plate Installation Procedures 20–2

FIGURE 2-3 Carrier Plate Warning Label 20–3

FIGURE B-4 Fan Tray Removal Label 20–3

FIGURE 2-5 Bottom Fan Tray Component Number Labels 20–4

FIGURE 2-6 Front Component Number Labels 20–4

FIGURE 2-7 Rear Component Number Labels 20–5

FIGURE 2-8 Expander Label 20–5

FIGURE 2-9 Centerplane Support Label 20–5

FIGURE 2-10 Sun Fireplane Interconnect Label 20–6

FIGURE 2-11 Power Supply Component Labels 20–6

FIGURE 2-12 External Power Supply Label 20–7

FIGURE 2-13 Power Supply Weight-Information Label 20–7

FIGURE 2-14 Power Supply CAUTION Label 20–7

FIGURE C-1 System FRU Component Categories 21–1

FIGURE 3-2 Access Doors and Side Panels 21–2

FIGURE 3-3 FrameManager Assembly Components 21–3

FIGURE 3-4 TopCap Assembly Components 21–4

Figures xvii

FIGURE 3-5 Kick Plate Assembly Components 21–4

FIGURE 3-6 Centerplane Support Board 21–6

FIGURE 3-7 System Controller Carrier Plate 21–6

FIGURE 3-8 System Expander Carrier Plate (With Air Dam) 21–7

FIGURE 3-9 System Control Board—3U to 6U Conversion Board Option 21–7

FIGURE 3-10 System Control Peripheral Board 21–8

FIGURE 3-11 System Expander Board 21–8

FIGURE 3-12 System Expander Carrier Plate (with or without air dam) 21–9

FIGURE 3-13 CPU Board 21–9

FIGURE 3-14 Hot-swap PCI (hsPCI-X/hsPCI+) I/O Board 21–10

FIGURE 3-15 MaxCPU Board 21–10

FIGURE 3-16 I/O Filler Panel (used as required) 21–11

FIGURE 3-17 CPU Filler Panel (used as required) 21–11

FIGURE 3-18 Sun Fireplane Interconnect 21–12

FIGURE 3-19 Power Centerplane 21–12

FIGURE 3-20 Fan Backplane 21–13

FIGURE 3-21 Fan Tray Cooling Component 21–14

FIGURE 3-22 Power Supply 21–15

FIGURE 3-23 Power Module 21–16

FIGURE 3-24 Air Filter 21–16

FIGURE 3-25 AC Power Cable, Domestic 21–18

FIGURE 3-26 AC Power Cable, Domestic 2 21–18

FIGURE 3-27 AC Power Cable, International 21–19

FIGURE 3-28 AC Power Cable, International 2 21–19

FIGURE 3-29 Fan Power Cable 21–20

FIGURE 3-30 Fan I2C Cable, Front Upper 21–21

FIGURE 3-31 Fan I2C Cable, Front Lower 21–21

FIGURE 3-32 Fan I2C Cable, Rear Upper 21–22

FIGURE 3-33 Fan I2C Cable, Rear Lower 21–22

FIGURE 3-34 Power Module to Connector Bulkhead, 48 VDC Power 21–23

xviii Undefined BookTitle • May 2006

FIGURE 3-35 Connector Bulkhead to Connector Bulkhead, 48 VDC Crossover 21–24

FIGURE 3-36 Power Module to Connector Bulkhead, I2C Signals 21–24

FIGURE 3-37 Control 0 Cable, Front 21–25

FIGURE 3-38 Control 1 Cable, Front 21–25

FIGURE 3-39 Control 0 Cable, Rear 21–26

FIGURE 3-40 Control 1 Cable, Rear 21–26

FIGURE 3-41 Power Control Cable, Front 21–27

FIGURE 3-42 Power Control Cable, Rear 21–27

FIGURE 3-43 FrameManager and TopCap Power Cable, Internal 21–27

FIGURE 3-44 FrameManager and TopCap Power Cable, External 21–28

FIGURE 3-45 RS-232 Cable, Internal 21–29

FIGURE 3-46 RS-232 Cable, External 21–29

FIGURE 3-47 SC-CPU Cable 21–30

Figures xix

xx Undefined BookTitle • May 2006

Tables

TABLE 1-1 Temperature Levels 1–4

TABLE 1-2 Ambient Thermal Levels 1–4

TABLE 1-3 Voltage and Current Limits 1–5

TABLE 1-4 LEDs 1–6

TABLE 1-5 Customer Availability and Mean Time to Repair 1–7

TABLE 1-6 Safety Precautions 1–12

TABLE 3-1 4 kW Dual AC–DC Power Supply Components 3–9

TABLE 3-2 4 kW Dual AC–DC Power Supply Valid LED Status 3–9

TABLE 4-1 Fan Tray Components 4–2

TABLE 4-2 Fan Tray Valid LED Status 4–2

TABLE 6-1 System Control Board Components 6–2

TABLE 6-2 System Control Board Valid LED Status 6–2

TABLE 6-3 System Control CPU Board Indicator Function Descriptions 6–2

TABLE 7-1 System Control (SC) Peripheral Board Components 7–2

TABLE 7-2 System Control (SC) Peripheral Board Valid LED Status 7–2

TABLE 7-3 System Control DVD Peripheral Indicator Function Descriptions 7–3

TABLE 7-4 System Control Tape Peripheral Indicator Function Descriptions 7–4

TABLE 8-1 CPU Board Components 8–2

TABLE 8-2 CPU Board Valid LED Status 8–2

TABLE 9-1 hsPCI Assembly Components 9–2

xxi

TABLE 9-2 hsPCI Assembly Valid LED Status 9–2

TABLE 9-3 MaxCPU (Slot 1) Board Components 9–11

TABLE 9-4 MaxCPU (Slot 1) Board Valid LED Status 9–11

TABLE 10-1 Carrier Plate FRU Modification Contents 10–6

TABLE 11-1 Centerplane Support Board Components 11–2

TABLE 11-2 Centerplane Support Board Valid LED Status 11–2

TABLE 12-1 Expander Board Components 12–2

TABLE 12-2 Expander Board Valid LED Status 12–2

TABLE 13-1 Component Serial Numbers Worksheet 13–3

TABLE 16-1 Cable Termination Table 16–7

TABLE C-1 Access Doors and Side Panels 21–2

TABLE 3-2 FrameManager Assembly Components 21–3

TABLE 3-3 TopCap Assembly Components 21–3

TABLE 3-4 Kick Plate Assembly Components 21–4

TABLE 3-5 System Board Assemblies 21–5

TABLE 3-6 System Board Carrier Plates 21–5

TABLE 3-7 Fan Tray Cooling Components 21–14

TABLE 3-8 Power Supplies and Air Filters 21–15

TABLE 3-9 System Cables 21–17

TABLE 3-10 AC Power Cable, Domestic, Wire List 21–18

TABLE 3-11 AC Power Cable, Domestic 2, Wire List 21–18

TABLE 3-12 AC Power Cable, International, Wire List 21–19

TABLE 3-13 AC Power Cable, International 2, Wire List 21–19

TABLE 3-14 Fan Power Cable (Side 0) Termination Table 0 21–20

TABLE 3-15 Fan Power Cable (Side 1) Termination Table 1 21–20

TABLE 3-16 Power Module to Connector Bulkhead Cable, 48 VDC Power, Termination Table 21–23

TABLE 3-17 Connector Bulkhead to Connector Bulkhead, 48 VDC Crossover, Termination Table 21–24

TABLE 3-18 FrameManager and TopCap Power Cable, External, Termination Specifications 21–28

TABLE 3-19 RS-232 Cable, External, Termination Specifications 21–29

TABLE 3-20 SC-CPU Cable Termination Specifications 21–30

xxii Undefined BookTitle • May 2006

Declaration of Conformity

Compliance Model Number: 2080

Product Name: Sun Fire 15K/12K Systems

EMC

European Union

This equipment complies with the following requirements of the EMC Directive 89/336/EEC:

EN55022:1995/CISPR22:1997 Class A

EN550024:1998 EN61000-4-2 4 kV (Direct), 8 kV (Air)

EN61000-4-3 3 V/m

EN61000-4-4 1.0 kV Power Lines, 0.5 kV Signal Lines

EN61000-4-5 1 kV Line-Line, 2 kV Line-Gnd Power Lines

EN61000-4-6 3 V

EN61000-4-8 3 A/m

EN61000-4-11 Pass

EN61000-3-2:1995 Pass

EN61000-3-3:1995 Pass

Safety

This equipment complies with the following requirements of the Low Voltage Directive 73/23/EEC:

EC Type Examination Certificates:

EN60950:1992, 2nd Edition, Amendments 1,2,3,4,11 TÜV Product Service Certificate No.

IEC 950:1991, 2nd Edition, Amendments 1,2,3,4

Evaluated to all CB Countries CB Scheme Certificate No. CB 01 07 17641 014

Z1A 01 07 17641 013

Supplementary Information

This product was tested and complies with all the requirements for the CE Mark.

Dennis P. Symanski DATE

Manager, Compliance Engineering

Sun Microsystems, Inc.

4150 Network Circle

Santa Clara, CA 95054, USA

Tel: 650-786-3255

Fax: 650-786-3723

Peter Arkless DATE

Quality Manager

Sun Microsystems Scotland, Limited

Springfield, Linlithgow

West Lothian, EH49 7LR

Scotland, United Kingdom

Tel: 0506-670000

Fax: 0506 760011

xxiii

xxiv Sun Fire 15K/12K Systems Service Manual • May 2006

Preface

The Sun Fire 15K/12K Systems Service Manual provides guidelines and detailed

instructions for replacing field-replaceable components on the Sun™ Fire 15K/12K

Systems.

How This Book Is Organized

Chapter 1 provides component replacement guidelines, indicator descriptions, and

hardware nomenclature.

Chapter 2 details the replacement procedures for the FrameManager assembly and

the FrameManager extension.

Chapter 3 details the replacement procedures for the system power module and the

4 kW dual AC–DC power supplies.

Chapter 4 details the replacement procedures for the system fan trays.

Chapter 5 details the replacement procedures for the System Control (SC) CPU

board and installation of the cPCI memory.

Chapter 6 details the replacement procedures for the System Control (SC) board.

Chapter 7 details the replacement procedures for the System Control peripheral

board containing the DVD-ROM, hard drive, and audio tape peripherals.

Chapter 8 details the replacement procedures for the CPU (slot 0) board.

Chapter 9 details the replacement procedures for the I/O (slot 1) assemblies.

Chapter 10 details the replacement procedures for the board set carrier plate and

identifies the carrier-plate configurations.

Chapter 11 details the replacement procedures for the centerplane support board of

the system control expander board set.

xxv

Chapter 12 details the replacement procedures for the expander board of the system

expander board set.

Chapter 13 details the replacement procedures for the Sun Fireplane interconnect

assembly.

Chapter 14 details the replacement procedures for the fan backplane.

Chapter 15 details the replacement procedures for the power centerplane.

Chapter 16 details the replacement procedures for the system cables.

Chapter 17 details the replacement procedures for the mechanical components.

Chapter 18 provides procedures for the system components requiring periodic

maintenance.

Appendix A provides a component serial number worksheet.

Appendix B details the information and safety labels used in the Sun Fire 15K/12K

systems.

Appendix C provides a pictorial review of the Sun Fire 15K/12K systems

components.

Using UNIX Commands

This document may not contain information on basic UNIX®commands and

procedures such as shutting down the system, booting the system, and configuring

devices.

See the following for this information:

■ Documentation for the Solaris™ operating environment, which is at:

http://docs.sun.com

■ Other software documentation that you received with your system

xxvi Sun Fire 15K/12K Systems Service Manual • May 2006

Typographic Conventions

TABLE P-1 Typographic Conventions

Typeface Meaning Examples

AaBbCc123 The names of commands, files,

and directories; on-screen

computer output

AaBbCc123

AaBbCc123 Book titles, new words or

What you type, when

contrasted with on-screen

computer output

terms, words to be emphasized

Command-line variable;

replace with a real name or

value

Edit your .login file.

Use ls -a to list all files.

% You have mail.

% su

Password:

Read Chapter 6 in the User’s Guide.

These are called class options.

Yo u must be superuser to do this.

To delete a file, type rm filename.

Preface xxvii

Shell Prompts

TABLE P-2 Shell Prompts

Shell Prompt

System Control (SC) Command sc%

SC superuser, main SC sc#

Domain superuser domain_name#

SC superuser, spare SC sc_spare#

Related Documentation

TABLE P-3 Related Documentation

Application Title

Service Sun Fire 15K/12K Systems Read Me First

Service Sun Fire 15K/12K Systems Getting Started

Service Sun Fire 15K/12K Systems Unpacking Guide

Service Sun Fire 15K/12K Systems Site Planning Guide

Service Sun Fire 15K/12K Systems Hardware Installation and

De-Installation Guide

Service Sun Fire 15K/12K Systems Service Manual

Service Sun Fire 15K/12K Systems Service Reference I–Nomenclature

Service Sun Fire 15K/12K Systems Service Reference II–Component Numbering

Service Sun Fire 15K/12K Systems Carrier Plate Configurations

Accessing Sun Documentation

You can view, print, or purchase a broad selection of Sun documentation, including

localized versions, at:

xxviii Sun Fire 15K/12K Systems Service Manual • May 2006

http://www.sun.com/documentation

Contacting Sun Technical Support

If you have technical questions about this product that are not answered in this

document, go to:

http://www.sun.com/service/contacting

Sun Welcomes Your Comments

Sun is interested in improving its documentation and welcomes your comments and

suggestions. You can submit your comments by going to:

http://www.sun.com/hwdocs/feedback

Please include the title and part number of your document with your feedback:

Sun Fire 15K/12K Systems Service Manual, part number 806-3512-13

Preface xxix

United States Export Control Laws

Notice

Products covered by and information contained in this service manual are controlled

by U.S. Export Control laws and may be subject to the export or import laws in other

countries. Nuclear, missile, chemical biological weapons, or nuclear maritime end

uses or end users, whether direct or indirect, are strictly prohibited. Export or reexport to countries subject to U.S. embargo or to entities identified on U.S. export

exclusion lists, including but not limited to the denied persons and specially

designated nationals lists, is strictly prohibited. Use of any spare or replacement

CPUs is limited to repair or one-for-one replacement of CPUs in products exported

in compliance with U.S. export laws. Use of CPUs as product upgrades unless

authorized by the U.S. Government is strictly prohibited.

xxx Sun Fire 15K/12K Systems Service Manual • May 2006

CHAPTER

1

Guidelines, Indicators, and Nomenclature

This chapter provides the following introductory information for the Sun Fire

15K/12K systems:

■ Section 1.1, “System Component Hot-Swap Guidelines” on page 1-1

■ Section 1.2, “Configuration Rules” on page 1-2

■ Section 1.3, “Testing the System” on page 1-3

■ Section 1.4, “Reviewing System Temperatures” on page 1-4

■ Section 1.5, “Reviewing System Power” on page 1-5

■ Section 1.6, “Hardware Indicators” on page 1-6

■ Section 1.7, “Field-Replaceable Units (FRU)—Mean Time to Repair (MTTR)” on

page 1-7

■ Section 1.8, “Safety Precautions” on page 1-12

■ Section 1.9, “Special Tools and Shipping Kit Items” on page 1-13

■ Section 1.10, “System Block Diagrams” on page 1-14

1.1 System Component Hot-Swap Guidelines

In the Sun Fire 15K/12K systems, hot-swapping a component refers to physically

removing and replacing a component while the remaining system components are

operational.

Note – The System Management Software (SMS) requires 30 seconds to recognize

the removal of a hot-swappable component. The user should wait for a system

response before installing a new replacement board.

1-1

The hot-swappable components in the system are listed as follows.

■ System Control board

■ Centerplane support board

■ CPU board

■ MaxCPU board

■ hsPCI assembly

■ System expander board

■ Fan trays

■ Power supplies

■ System control peripheral board

1.2 Configuration Rules

The following rules apply when configuring components of the Sun Fire 15K/12K

systems:

■ Every system must be equipped with two centerplane support boards (CSB) in

order to utilize full-width data, address, and response paths. If one CSB fails,

there is an interruption in service. However, SMS recovers the domains and the

remaining CSB runs in a degraded mode.

■ Every system must be equipped with two System Control (SC) boards.

■ Every system must be equipped with two SC peripheral boards.

■ Every system must be equipped with eight fan trays.

■ Every system must be equipped with six power supplies.

The following rules apply when configuring components on the CPU board:

Note – The CPU/Memory board field-replaceable unit (FRU) is for maintenance use

only. FRUs must not be used to upgrade CPU performance in systems. Usage as

such can violate United States export regulations.

The United States government sets limits as to the server configuration exportable to

certain destinations or certain customers. Server CPU upgrades must be ordered as

standalone CPU upgrade options rather than spares. All upgrades must first be

approved by Sun International Trade Services to ensure the system does not exceed

1-2 Sun Fire 15K/12K Systems Service Manual • May 2006

the legal limit for the destination (customer). The following message appears on the

label on all CPU FRUs to alert all concerned that this FRU is for maintenance of the

system only and should not be used to upgrade a system:

This assembly is for maintenance use only.

Not to be used to upgrade systems.

Use as system upgrades could violate

United States export regulations.

■ All CPU modules must be the same speed.

■ All external cache modules must be the same size.

■ When configuring memory:

■ All sockets within a bank must be fully populated.

■ All DIMM sizes within a bank must be equal.

1.3 Testing the System

The Sun Fire 15K/12K systems use setkeyswitch to diagnose system problems by

running hpost(1M) when posting a domain. The hpost(1M) diagnostic probes,

configure and test the domain hardware, preparing the system to run OpenBoot™

PROM and subsequently the Solaris operating environment.

The Sun VTS™ diagnostics suite can be used as a verification of a dynamic system

domain or an SC. To use the sunvts(1M) command, you must be logged into the

host as superuser. Information about sunvts(1M) is located in

/opt/share/man/man1m.

Verify the SMS is up and running by typing:

sc% showfailover -r

MAIN

This command explains the role of the SC. The value returned should be MAIN

indicating that this SC is providing all resources for the Sun Fire 15K/12K systems.

If you do not get this value, consult the SMS Administration Guide.

Chapter 1 Guidelines, Indicators, and Nomenclature 1-3

1.4 Reviewing System Temperatures

The temperature status can be checked at any time by using Sun™ Management

Center software or the

sc% showenvironment -p temps

See the showenvironment(1M) man page for further details.

TABLE 1-1 Temperature Levels

Component Optimum High Warning High Critical Overlimit

ASICs

Category I: AR, SDC, DX, SBBC,

Category II: PROC < 80

Category III: SDI, AXQ, RMX, AMX,

TABLE 1-2 Ambient Thermal Levels

showenvironment command. At the command line type:

o

<80

C>85oCto95oC>95oC to 105oC > 105oC

CBH: IOA

o

C>85oCto90oC>90oCto 95oC>95oC

o

<65

C>70oCto80oC>80oCto 85oC>85oC

DMX, WCI, DARB

Power supplies < 65

Proximity sensors < 40

o

C>70oCto75oC>75oCto 80oC>80oC

o

C>45oCto50oC>50oCto 55oC>55oC

Component

Low

Critical

Low

Warning Optimum

Ambient ≤ 5oC>5oCto15oC>20oCto25oC

* Fan reset point

1-4 Sun Fire 15K/12K Systems Service Manual • May 2006

High

Warning

*

>25oCto35oC>35oC>40oC

High

Critical Overlimit

1.5 Reviewing System Power

■ Check the power status by using Sun™ Management Center software or the

showenvironment command. To review, at the command line type:

sc% showenvironment -p volts

See the showenvironment(1M) man page for further details.

TABLE 1-3 Voltage and Current Limits

Voltage and Current Low–Minimum Acceptable Range High–Maximum

PROC Core -5% Core voltage

+1.5 V x ≤ +1.4 +1.4 < x < +1.6 +1.6 ≤ x

+2.5 V x ≤ +2.3 +2.3 < x < +2.7 +2.7 ≤ x

+3.3 V x ≤ +3.0 +3.0 < x < +3.5 +3.5 ≤ x

+3.3 HK x ≤ +3.0 +3.0 < x < +3.5 +3.5 ≤ x

+5.0 V x ≤ +4.75 +4.75 < x < +5.25 +5.25 ≤ x

+12 V x ≤ +11.4 +11.4 < x < +12.6 +12.6 ≤ x

-12 V x ≤ -12.6 -12.6 < x < -11.4 -11.4 ≤ x

+5 V current Each component must

be within

average of all

components in the

group.

+3.3 V current Each component must

be within

average of all

components in the

group.

+1.5 V converter Each component must

be within

average of all

components in the

group.

* Core voltage is processor-version dependent.

*

+ 50% of the

+ 50% of the

+ 50% of the

+5%

Chapter 1 Guidelines, Indicators, and Nomenclature 1-5

1.6 Hardware Indicators

The LED indicators provide current status information about the component directly

associated with the indicator array. Indicators are arranged in a straight line,

horizontal or vertical, with the green LED on the left or top (

TABLE 1-4 LEDs

Symbol LED Color Indication Operation

Green Activation indicator Component is powered on.

Amber Service indicator Service indicator is only used during

Amber Removal indicator Component may be removed.

TABLE 1-4).

initial startup.

1-6 Sun Fire 15K/12K Systems Service Manual • May 2006

1.7 Field-Replaceable Units (FRU)—Mean

Time to Repair (MTTR)

TABLE 1-5 lists the estimated time required for replacement of the FRUs in the Sun

Fire 15K/12K systems. These times assume the new component is on site and

properly configured. They do not include any time required by software for system

reconfiguration or the shutdown and bring-up time required for the non-concurrent

service items.

TABLE 1-5 Customer Availability and Mean Time to Repair

FRU MTTR Online Service

4 kW dual AC–DC power supply 10 min Yes

Fan tray 10 min Yes

Centerplane support board 30 min Yes

System Control board 10 min Yes

SC CPU board 10 min Yes

SC peripheral board 10 min Yes

Expander board 30 min Yes

Dual in-line memory module (DIMM) 10 min Yes

CPU board 10 min Yes

hsPCI I/O assembly (hsPCI-X/hsPCI+) 10 min Yes

MaxCPU board 10 min Yes

Sun Fireplane interconnect 90 min No

Power centerplane 180 min No

Fan backplane 70 min No

I/O cables 15 min Yes

Power module 60 min No

FrameManager or TopCap 10 min Yes

Side panel 5 min Yes

Access doors 5 min Yes

Air filter 5 min Yes

AC power cord 5 min Yes

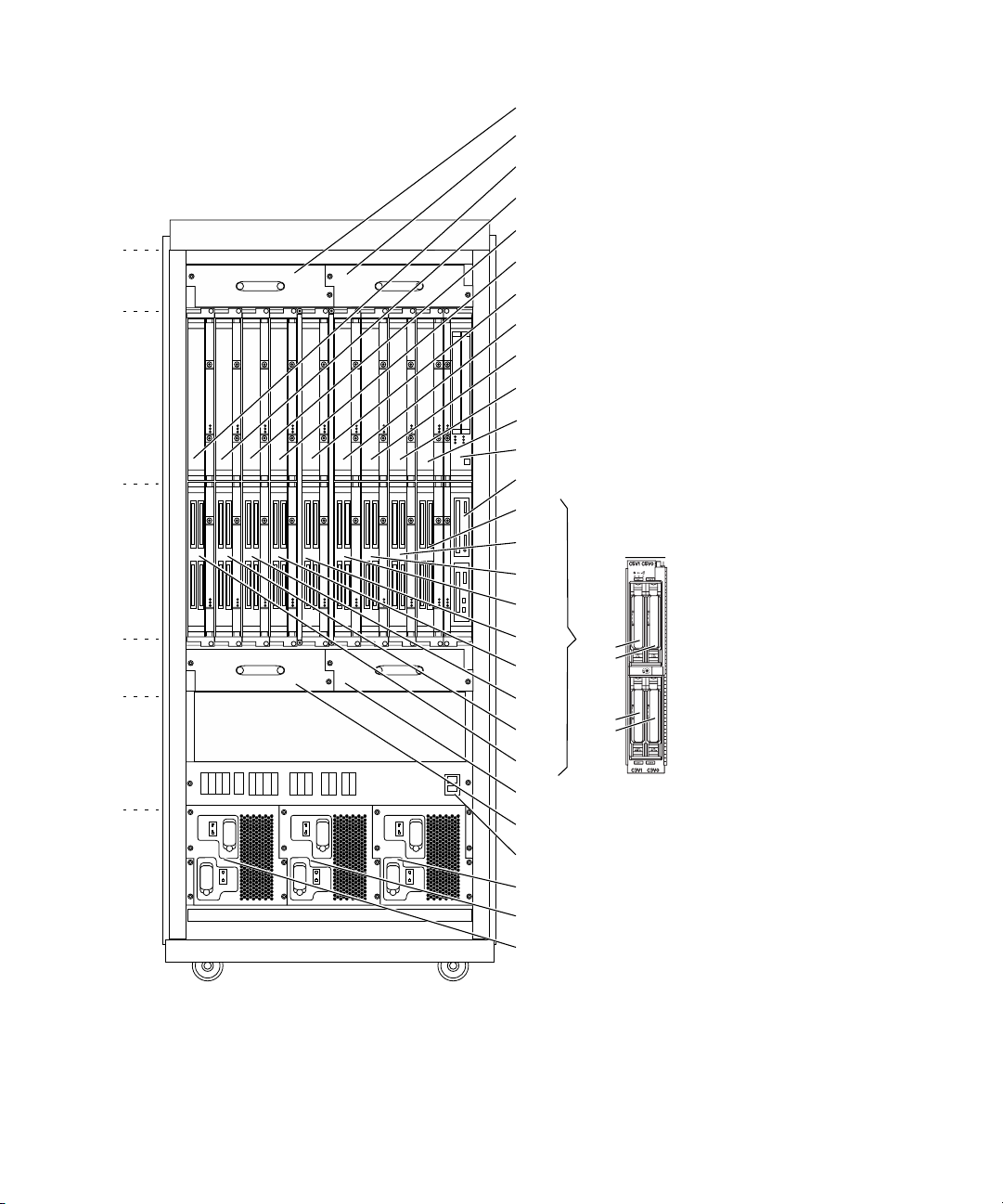

See the front and rear system component numbering (

FIGURE 1-3). See FIGURE 1-4 for cassette component numbering.

Chapter 1 Guidelines, Indicators, and Nomenclature 1-7

FIGURE 1-1, FIGURE 1-2 and

or TopCap

FrameManager

Fan

Tr ay s

Slot 0

Slot 1

Fan

Tr ay s

Air

Vent

Powe r

Supplies

FT1, fan tray

FT0, fan tray

SB8, standard CPU or CPU filler panel

SB7, standard CPU or CPU filler panel

SB6, standard CPU or CPU filler panel

SB5, standard CPU or CPU filler panel

SB4, standard CPU or CPU filler panel

SB3, standard CPU or CPU filler panel

SB2, standard CPU or CPU filler panel

SB1, standard CPU or CPU filler panel

SB0, standard CPU or CPU filler panel

SC0, System Control CPU and spare cPCI port

SCPER0, DVD-ROM, hard drive, tape drive peripherals

IO options: hsPCI+/hsPCI-X, MaxCPU, I/O filler panel

IO0

IO1

IO2

Cassette Numbering

hsPCI

(See additional hsPCI diagrams in

this document for further detail.)

IO3

IO4

IO5

C5V1

C5V0

IO6

C3V1

IO7

C3V0

IO8

FT2, fan trays

FT3, fan trays

LINK (0, 1), remote power to I/O expansion racks

(not used)

PS0 (AC0, AC1), power supplies

PS1 (AC0, AC1), power supplies

PS2 (AC0, AC1), power supplies

FIGURE 1-1 Sun Fire 15K/12K Systems Component Numbering—Front

1-8 Sun Fire 15K/12K Systems Service Manual • May 2006

Fan

Tr ay s

Slot 0

Slot 1

Fan

Tr ay s

Air

Vent

Powe r

Supplies

FT5, fan tray

FT4, fan tray

SB17, standard CPU or CPU filler panel

SB16, standard CPU or CPU filler panel

SB15, standard CPU or CPU filler panel

SB14, standard CPU or CPU filler panel

SB13, standard CPU or CPU filler panel

SB12, standard CPU or CPU filler panel

SB11, standard CPU or CPU filler panel

SB10, standard CPU or CPU filler panel

SB9, standard CPU or CPU filler panel

SC1, System Control CPU and spare cPCI port

SCPER1, DVD-ROM, hard drive, tape drive peripherals

IO9

IO10

IO11

IO options: hsPCI-X/hsPCI+, MaxCPU, I/O filler panel

Cassette Numbering

hsPCI

(See additional hsPCI diagram in

this document for further detail.)

IO12

IO13

IO14

C5V1

C5V0

IO15

C3V1

IO16

C3V0

IO17

FT6, fan trays

C3V1C3V0

FT7, fan trays

LINK (2, 3), remote power to I/O expansion racks

(not used)

PS3 (AC0, AC1), power supplies

PS4 (AC0, AC1), power supplies

PS5 (AC0, AC1), power supplies

FIGURE 1-2 Sun Fire 15K System Component Numbering—Rear

Chapter 1 Guidelines, Indicators, and Nomenclature 1-9

Fan

Tr ay s

Slot 0

Slot 1

Fan

Tr ay s

Air

Vent

Powe r

Supplies

FT5, fan tray

FT4, fan tray

SB17, CPU filler panel

SB16, CPU filler panel

SB15, CPU filler panel

SB14, CPU filler panel

SB13, CPU filler panel

SB12, CPU filler panel

SB11, CPU filler panel

SB10, CPU filler panel

SB9, CPU filler panel

SC1, System Control CPU and spare cPCI port

SCPER1, DVD-ROM, hard drive, tape drive peripherals

IO9

IO10

IO11

IO12

IO13

I/O Filler panels

IO14

IO15

IO16

IO17

FT6, fan trays

FT7, fan trays

LINK (2, 3), remote power to I/O expansion racks

(not used)

PS3 (AC0, AC1), power supplies

PS4 (AC0, AC1), power supplies

PS5 (AC0, AC1), power supplies

FIGURE 1-3 Sun Fire 12K System Component Numbering—Rear

1-10 Sun Fire 15K/12K Systems Service Manual • May 2006

hsPCI+

Cassette interchange diagram

C5V1, hsPCI 33 MHz, yellow

C5V0, hsPCI 33 MHz, blue

C3V1, hsPCI 66 or 33 MHz, yellow

C3V0, hsPCI 66 or 33 MHz, yellow

C3V2, hsPCI-X 90, 66, or 33 MHz, yellow

C5V0, hsPCI-X 33 MHz, blue

Actual I/Os

3.3V and 5.0V

cassettes

3.3V cassettes

3.3V and 5.0V

cassettes

hsPCI-X

C3V1, hsPCI-X 90, 66, or 33 MHz, yellow

C3V0, hsPCI-X 90, 66, or 33 MHz, yellow

3.3V cassettes

FIGURE 1-4 Cassette Component Numbering—Sun Fire 15K Front and Rear, and Sun Fire

12K Front

Note – The 3.3V cassette positions are interchangeable and the 5.0V cassette

positions are interchangeable.

Chapter 1 Guidelines, Indicators, and Nomenclature 1-11

1.8 Safety Precautions

For your protection, observe the following safety precautions when setting up your

equipment:

■ Follow all cautions and instructions marked on the equipment.

■ Never push objects of any kind through openings in the equipment as they might

touch dangerous voltage points or short out components that could result in fire

or electric shock.

■ Refer servicing of equipment to qualified personnel.

To protect both yourself and the equipment, observe the safety precautions outlined

in

TABLE 1-6.

TABLE 1-6 Safety Precautions

Item Problem Precaution

ESD wrist

strap

ESD mat ESD An approved ESD mat provides protection from static

Electro-Static

Discharge

(ESD)

There are four ground points on the system cabinet, two at

the front top left and top right, and two at the rear top left

and top right.

damage when used with a wrist strap. The mat also cushions

and protects parts that are attached to the printed circuit

boards.

1-12 Sun Fire 15K/12K Systems Service Manual • May 2006

1.9 Special Tools and Shipping Kit Items

The following list represents the special tools and items supplied in the shipping kit

box at the time of system delivery:

Special Tools and Shipping Kit Items

Special Tools in Right-Front Door

Two (2) preset 18 in.-lbs (2.2 Nm) torque screwdrivers

Special Tools in Shipping Kit:

Two (2) system control console cables

One (1) 11 in. (27.9 cm) magnetic, replaceable-tip screwdriver

One (1) No. 1 Phillips head bit

One (1) No. 2 Phillips head bit

Other Shipping Kit Items:

I/O cable labels

Power cable labels

Velcro straps for I/O cables

ESD Kit with large mat:

Wrist strap

Static mat, 24 in. (61.0 cm) x 24 in. (61.0 cm)

Envelope, plastic bag

ESD kit instructions

Chapter 1 Guidelines, Indicators, and Nomenclature 1-13

1.10 System Block Diagrams

FIGURE 1-5 defines the Sun Fire 15K/12K systems architecture.

FIGURE 1-6 defines the power control system circuitry from the System Control

boards to the individual power supplies and the fan trays.

FIGURE 1-7 defines the power distribution circuitry. This diagram represents the

48 VDC power distribution from the individual power supplies to the various

boards through the designated circuit breakers.

18 x 18 addresses,

responses, and

data crossbars

on Logic Centerplane

Full-width

board

Half-width

board

Full bandwidth (4.8 Gbps) board type

• 4 CPU / 4 memory banks

FIGURE 1-5 System Architecture Block Diagram

Expander

board

Address

Response

Data

3 half bandwidth (2.4 Gbps) board types

Full-width

Expander

board

• 4 PCI adapters

• 2 CPU / 0 memory banks

• 2 PCI adapters / 3 WCI links

board

Half-width

board

1-14 Sun Fire 15K/12K Systems Service Manual • May 2006

TopCap

FrameManager

12V

12V

12V

RS-232

SC0_I2C (54)

side 0side 1

Present (18)

Interrupt (6)

System Control board

12V

RS-232

2

C (54)

SC1_I

Present (18)

Interrupt (6)

RS-232

RS-232

RS-232

Powe r

Centerplane

To remote frame

(connectors located on

front power module)

To remote frame

(connectors located on

rear power module)

SC0 I2C (8)

SC1 I

Present (4)

SC0 I2C (9)

SC1 I

Present (3)

Interrupt (3)

2

2

C (8)

C (9)

48 Volts

48 Volts

48 Volts

48 Volts

Fan Tray

FT0

Fan Tray

FT1

Fan Tray

FT2

Fan Tray

FT3

Power Supply

PS0

Power Supply

PS1

Power Supply

PS2

Fan Tray

FT4

Fan Tray

FT5

Fan backplaneFan backplane

bottom front top front

top rear

Fan backplaneFan backplane

System Control board

48 Volts

2

C (8)

SC0 I

2

C (8)

SC1 I

Present (4)

2

SC0 I

C (9)

SC1 I2C (9)

Present (3)

Interrupt (3)

FIGURE 1-6 Control Distribution Block Diagram

Chapter 1 Guidelines, Indicators, and Nomenclature 1-15

48 Volts

Fan Tray

FT6

Fan Tray

FT7

Power Supply

PS3

Power Supply

PS4

Power Supply

PS5

bottom rear

Front

Rear

Power Supply

PS0

Power Supply

PS1

Power Supply

PS2

Power Supply

PS3

Power Supply

PS4

Power Supply

PS5

+48 volt

return

+48 volt

return

+48 Volts

+48 Volts

+48 Volts

+48 Volts

+48 Volts

+48 Volts

Fan Bottom Side1

Fan Top Side1

Fan Bottom Side0

Fan Top Side0

System Control Peripheral 0

System Control Board 0

Centerplane Support Board 0

System Expander 0

System Expander 1

System Expander 2

System Expander 3

System Expander 4

System Expander 5

System Expander 6

System Expander 7

System Expander 8

System Expander 8

System Expander 7

System Expander 6

System Expander 5

System Expander 4

System Expander 3

System Expander 2

System Expander 1

System Expander 0

Centerplane Support 0

System Control Board 0

System Control Peripheral 0

Fan Backplane 0.0

Fan Backplane 0.1

Fan Bottom Side 1

Fan Top Side 1

Fan Bottom Side 0

Fan Top Side 0

System Control Peripheral 1

System Control 1

Centerplane Support Board 1

System Expander 9

System Expander 10

System Expander 11

System Expander 12

System Expander 13

System Expander 14

System Expander 15

System Expander 16

System Expander 17

System Expander 17

System Expander 16

System Expander 15

System Expander 14

System Expander 13

System Expander 12

System Expander 11

System Expander 10

System Expander 9

Centerplane Support 1

System Control Board 1

System Control Peripheral 1

Fan Backplane 1.0

Fan Backplane 1.1

BreakersSystem ComponentSystem Component Breakers

FIGURE 1-7 Power Distribution Block Diagram

1-16 Sun Fire 15K/12K Systems Service Manual • May 2006

CHAPTER

2

FrameManager and Extension, and TopCap and Extension Replacement Procedures

The FrameManager assembly and FrameManager extension appear on some of the

Sun Fire 15K/12K systems and the TopCap assembly and TopCap extension appear

on other Sun Fire 15K/12K systems. For those systems, this chapter contains the

replacement procedures for both assemblies and their extensions.

The chapter contains the following sections:

■ Section 2.1, “FrameManager Replacement” on page 2-2

■ Section 2.1.1, “Removing the FrameManager” on page 2-2

■ Section 2.1.2, “Installing the FrameManager” on page 2-2

■ Section 2.2, “FrameManager Extension Replacement” on page 2-2

■ Section 2.2.1, “Removing the FrameManager Extension” on page 2-2

■ Section 2.2.2, “Installing the FrameManager Extension” on page 2-3

■ Section 2.3, “TopCap Replacement” on page 2-3

■ Section 2.3.1, “Removing the TopCap” on page 2-3

■ Section 2.3.2, “Installing the TopCap” on page 2-3

■ Section 2.4, “TopCap Extension Replacement” on page 2-4

■ Section 2.4.1, “Removing the TopCap Extension” on page 2-4

■ Section 2.4.2, “Installing the TopCap Extension” on page 2-4

For your protection, also observe the following safety precautions when setting up

your equipment:

■ Follow all cautions and instructions marked on the equipment.

■ Always use proper ESD equipment and procedures when handling boards and

components.

■ Never push objects of any kind through openings in the equipment as they might

touch dangerous voltage points or short out components that can result in fire or

electric shock.

■ Refer servicing of equipment to qualified personnel.

2-1

2.1 FrameManager Replacement

2.1.1 Removing the FrameManager

Caution – Be sure you are properly grounded before you begin the hardware

removal and installation. There are four ground points on the system cabinet, two at

the front top left and top right, and two at the rear top left and top right.

1. Remove the four (4) M4x12 panhead screws attaching the FrameManager assembly

to the chassis.

2. Disconnect the four (4) cable connectors from the rear of the FrameManager

assembly.

3. Remove the FrameManager assembly.

2.1.2 Installing the FrameManager

1. Install a new FrameManager assembly.

2. Connect the four (4) cable connectors to the rear of the FrameManager assembly.

3. Secure the FrameManager assembly with four (4) M4x12 panhead screws.

2.2 FrameManager Extension Replacement

2.2.1 Removing the FrameManager Extension

1. Remove the two (2) M4x12 panhead screws attaching the FrameManager extension

to the chassis.

2. Remove the FrameManager extension.

2-2 Sun Fire 15K/12K Systems Service Manual • May 2006

2.2.2 Installing the FrameManager Extension

1. Install a new FrameManager extension.

2. Secure the FrameManager extension with two (2) M4x12 panhead screws.

2.3 TopCap Replacement

2.3.1 Removing the TopCap

Caution – Be sure you are properly grounded before you begin the hardware

removal and installation. There are four ground points on the system cabinet, two at

the front top left and top right, and two at the rear top left and top right.

1. Remove the four (4) M4x12 panhead screws attaching the TopCap assembly to the

chassis.

2. Disconnect the 12V cable connector from the rear of the TopCap assembly.

3. Remove the TopCap assembly.

2.3.2 Installing the TopCap

If you are removing a FrameManager assembly prior to installing a replacement

TopCap assembly, see Section 2.1.1, “Removing the FrameManager” on page 2-2.

Note – If you are replacing a FrameManager assembly with a TopCap, follow the

procedure outlined in the documentation that accompanies the TopCap FRU

package.

1. Install a new TopCap assembly.

2. Connect the 12V cable connector to the rear of the TopCap assembly.

3. Secure the TopCap assembly with four (4) M4x12 panhead screws.

Chapter 2 FrameManager and Extension, and TopCap and Extension Replacement Procedures 2-3

2.4 TopCap Extension Replacement

2.4.1 Removing the TopCap Extension

1. Remove the two (2) M4x12 panhead screws attaching the TopCap extension to the

chassis.

2. Remove the TopCap extension.

2.4.2 Installing the TopCap Extension

1. Install the new TopCap extension.

2. Secure the TopCap extension with two (2) M4x12 panhead screws.

2-4 Sun Fire 15K/12K Systems Service Manual • May 2006

CHAPTER

3

System Power

The Sun Fire 15K/12K systems have two power modules, each holding three hotswappable power supplies. One module is on the front of the system and the other

module is on the rear of the system. This chapter contains the replacement

procedures for the power modules and the 4 kW dual AC–DC power supplies.

This chapter contains the following sections:

■ Section 3.1, “Power Module Replacement Procedures” on page 3-2

■ Section 3.1.1, “Power Module Replacement” on page 3-2

■ Section 3.1.2, “Powering Off for Power Module Removal” on page 3-2

■ Section 3.1.3, “Removing a Power Module” on page 3-4

■ Section 3.1.4, “Installing a Power Module” on page 3-6

■ Section 3.1.5, “Powering On After Power Module Installation” on page 3-7

■ Section 3.2, “4 kW Dual AC–DC Power Supply Replacement Procedures” on

page 3-8

■ Section 3.2.1, “4 kW Dual AC–DC Power Supply LEDs” on page 3-9

■ Section 3.2.2, “4 kW Dual AC–DC Power Supply Replacement” on page 3-10

For your protection, also observe the following safety precautions when setting up

your equipment:

■ Follow all cautions and instructions marked on the equipment.

■ Always use proper ESD equipment and procedures when handling boards and

components.

■ Never push objects of any kind through openings in the equipment as they might

touch dangerous voltage points or short out components that can result in fire or

electric shock.

■ Refer servicing of equipment to qualified personnel.

3-1

3.1 Power Module Replacement Procedures

3.1.1 Power Module Replacement

The Sun Fire 15K/12K systems have two power modules, each holding three power

supplies. One module is on the front of the system and the other module is on the

rear of the system. See

3.1.2 Powering Off for Power Module Removal

Caution – The power module is NOT a hot-swappable component. This procedure

requires a complete shutdown of the domains and SCs, and disconnection of all AC

power to the system.

There are four ground points on the system cabinet, two at the front top left and top

right, and two at the rear top left and top right.

Caution – The seven (7) power cables and the three (3) control cables MUST BE

REMOVED from the side of the system where the power module is being removed.

FIGURE 3-2.

1. As a superuser on the domains, systematically shut down all running domains

by typing:

domain_name# shutdown -y -g seconds -i 0

where seconds = amount of time before shutdown.

2. On the main SC, power off the domain hardware by typing:

sc% poweroff

This command powers off the entire system with the exception of the power

supplies, fans, and the SCs. Refer to poweroff(1M) for more information.

3-2 Sun Fire 15K/12K Systems Service Manual • May 2006

3. Shut down the System Control boards by doing the following:

■ As a superuser on the spare SC, shut down the spare SC by typing:

sc_spare# shutdown -y -g seconds -i 0

where seconds = amount of time before shutdown.

■ On the main SC, power off the spare SC by typing:

sc% poweroff SCx

where x = 0-1, dependent upon which SC is the spare.

■ As a superuser on the main SC, shutdown the main SC by typing:

sc# shutdown -y -g seconds -i 0

where seconds = amount of time before shutdown.

4. Open the Sun Fire 15K/12K system cabinet access doors.

Note – All DC circuit breakers are to remain in the on position at all times.

5. Power off the AC0 and AC1 circuit breakers for all power supplies in the system.

Note – Observe the following warning message displayed at the right side of the

circuit breakers on the circuit breaker panel above the AC power supplies:

WARNING

FAN TRAYS HAVE REDUNDANT DC POWER SOURCES.

CIRCUIT BREAKERS ON BOTH SIDES, FRONT AND REAR,

MUST BE OPERATED TO TURN OFF FAN TRAYS.

POWER SUPPLIES HAVE DUAL AC INPUTS.

BOTH CIRCUIT BREAKERS, AC0 AND AC1 MUST BE

OPERATED TO TURN OFF A POWER SUPPLY.

Chapter 3 System Power 3-3

3.1.3 Removing a Power Module

Caution – Be sure you are properly grounded before you begin the hardware

removal and installation of the board.

There are four ground points on the system cabinet, two at the front top left and top

right, and two at the rear top left and top right.

1. Label and disconnect the twelve (12, six per side) AC power cords with the labels

provided in the shipping kit.

2. Remove the power supplies from the power module.

See Section 3.2.2.3, “Removing a 4 kW Dual AC–DC Power Supply” on page 3-11.

3. Remove the air-plenum cover by removing the eighteen (18) M4x35 panhead

screws from the top, sides, and bottom of the air-inlet screen (

4. Remove the four (4) M4x8 panhead screws from the side and bottom of the air

plenum panel, at the circuit breaker level.

FIGURE 3-1).

Air plenum cover

M4x35 panhead

screws (18)

M4x8 panhead

screws (4)

Cover cutout for system

circuit breakers

Air-inlet screen

FIGURE 3-1 Air-Plenum Cover

Caution – Handle the EMI honeycomb panel carefully to prevent damage to the

screen.

3-4 Sun Fire 15K/12K Systems Service Manual • May 2006

Air plenum

filter (back

of cover)

5. Remove the air plenum cover and its air-inlet EMI honeycomb panel and air filter.

Place on a flat sturdy surface.

Caution – The seven (7) power cables and the three (3) control cables MUST BE

REMOVED from the system chassis on both the front and rear sides of the system

prior to removing the power module.

6. With a flat-blade screwdriver (if needed), loosen the jackscrews on the seven (7)

8W8 Combo-D 8-pin DC power connectors (on the left side) and the three (3)

DB-25 control connectors (on the right side).

7. Disconnect the cables from the mounting bulkhead of the system chassis.

8. Remove the four (4) M4x10 panhead screws attaching the power module front

flanges to the system chassis, as shown in

FIGURE 3-2.

Caution – The power module weighs 48 lb (21.82 kg). Although the unit can be

lifted by one person, it is suggested that two people, one on each side, maneuver the

power module into position. Use proper heavy-lifting procedures when removing

this unit.

9. With one person on each side of the power module, grasp the front (at the power

supply opening) and the bottom and slide the power module outward from the

cabinet.

10. Place the power module on a flat sturdy surface.

11. From the top rear of the power module, loosen the seven (7) 8W8 Combo-D 8-pin

DC power connectors (on the left side) and the three (3) DB-25 control connectors

(on the right side).

12. Disconnect the cables, and set aside.

Chapter 3 System Power 3-5

DB-9 control connector

to side wall for the

FrameManager

P13 to J13 cable (front)

P12 to J12 cable (rear)

Power module

DC circuit breakers (16)

AC circuit breakers

(2 per power supply)

8W8 Combo-D 8-pin

power connectors (7)

to connector bulkhead

DB-25 control

connectors (2)

to connector bulkhead

DB-25 control connector

to side wall for the

FrameManager

and TopCap

P10 to J10 cable (front)

P11 to J11 cable (rear)

M4x8 panhead screws (4)

Power supplies

(removed prior to power module replacement)

FIGURE 3-2 Power Module

3.1.4 Installing a Power Module

1. At the top rear of the power module, connect and hand tighten the jackscrews of

the seven (7) 8W8 Combo-D 8-pin DC power connectors on the left side and the

three (3) DB-25 control connectors on the right side.

Note – The power module weighs 48 lb (21.82 kg). Although the unit can be lifted

by one person, it is suggested that two people, on each side, maneuver the power

module into position. Use proper heavy-lifting procedures when installing this unit.

2. With one person on each side of the power module, grasp the front (at the power

supply opening) and the bottom and slide the power module into the system

chassis.

3. Secure the power module to the system chassis with the four (4) M4x10 panhead

module-to-system mounting screws, as shown in

M4x10 panhead module-to-system

mounting screws (4)

FIGURE 3-2.

3-6 Sun Fire 15K/12K Systems Service Manual • May 2006

4. Connect the seven (7) 8W8 Combo-D 8-pin DC power connectors (on the left side)

and the three (3) DB-25 control connectors (on the right side) to the mounting

bulkhead of the system chassis, as shown in

jackscrews.

FIGURE 3-2, and hand tighten the

Caution – Handle the EMI honeycomb panel carefully to prevent damage to the

screen.

5. Install the air-plenum cover and its air-inlet EMI honeycomb panel and air filter.

6. Secure with the eighteen (18) M4x35 panhead screws at the top, sides, and bottom

around the air-inlet screen, and the four (4) M4x8 panhead screws at the side and

bottom of the air plenum panel, at the circuit breaker level.

Note – All power supply units are fully interchangeable.

7. Install the 4 kW dual AC input power supplies.

See Section 3.2.2.4, “Installing a 4 kW Dual AC–DC Power Supply” on page 3-12.

8. Ensure that all DC circuit breakers are in the on position.

9. Ensure that all AC circuit breakers are in the off position.

3.1.5 Powering On After Power Module Installation

1. Connect the AC power cords to the 4 kW dual AC–DC power supplies.

2. Power on the AC0 and AC1 circuit breakers for all power supplies in the system.

3. Close the Sun Fire 15K/12K system cabinet access doors.

4. Once the main SC is booted, start the domain(s) by typing:

sc% setkeyswitch -d domain_id on

where domain_id is the domain letter A-R. Execute one setkeyswitch command

for each domain to be started.

Chapter 3 System Power 3-7

3.2 4 kW Dual AC–DC Power Supply

Replacement Procedures

The Sun Fire 15K/12K systems have three 4 kW dual AC–DC hot-swappable power

supplies at the front of the system and three at the rear of the system. See

Top view

Activation indicator (green)

Service indicator (amber)

Removal indicator (amber)

AC0

200-240 VAC

47-63 Hz, 24A

FIGURE 3-3.

AC1

200-240 VAC

47-63 Hz, 24A

FIGURE 3-3 Sun Fire 15K/12K Systems Power Supply

3-8 Sun Fire 15K/12K Systems Service Manual • May 2006

Right-side viewFront view Rear view

3.2.1 4 kW Dual AC–DC Power Supply LEDs

4 kW Dual AC–DC power supply components and LEDs are listed in TABLE 3-1 and

TABLE 3-2.

TABLE 3-1 4 kW Dual AC–DC Power Supply Components

Total Number of Power Supplies

Per System

Total Number of LEDs Per

Power Supply

63

TABLE 3-2 4 kW Dual AC–DC Power Supply Valid LED Status

LEDs after Insertion

or Initial System Power On

Active Service Remove Active Service Remove Active Service Remove Active Service Remove

LEDs After PRESENCE

is Detected Component Powered On

*

Component Powered Off

on off off off off on on off off off off on

* ON = AC0_FAIL_L = H or AC1_FAIL_L = H

\ OFF = AC0_FAIL_L = L and AC1_FAIL_L = L

Failure of the active LED to transition from ON to OFF within 60 seconds after

insertion indicates a power-status control fault.

FIGURE 3-4 illustrates the power supply and the LED locations.

\

Chapter 3 System Power 3-9

AC0

Activation indicator (green)

Service indicator (amber)

Removal indicator (amber)

AC1

FIGURE 3-4 4 kW Dual AC–DC Power Supply LEDs

3.2.2 4 kW Dual AC–DC Power Supply Replacement

3.2.2.1 Isolating a Failed Power Supply

1. Check that the power supply fans are on.

2. Verify the status of the LEDs.

3. Confirm that the power supply is properly seated.

4. Check the power status by using the Sun Management Center or by typing the

following SMS command:

sc% showenvironment -p powers

5. On the SC, check for error messages in

/var/opt/SUNWSMS/adm/platform/messages.

3-10 Sun Fire 15K/12K Systems Service Manual • May 2006

3.2.2.2 Powering Off a 4 kW Dual AC–DC Power Supply

● Power off the AC–DC power supply by using the Sun Management Center or by

typing the following SMS command:

sc% poweroff psx

where x is the power supply 0-5. Refer to poweroff(1M) for more information.

This should cause the AC0 and AC1 circuit breakers to go into the off position.

3.2.2.3 Removing a 4 kW Dual AC–DC Power Supply

Caution – Be sure you are properly grounded before you begin the hardware

removal and installation. There are four ground points on the system cabinet, two at

the front top left and top right, and two at the rear top left and top right.

1. Open the Sun Fire 15K/12K system cabinet access doors.

Caution – Before removing the power supply from the system, the green activation

LED must be off and the amber removal OK LED must be on. See Section 3.2.2.2,

“Powering Off a 4 kW Dual AC–DC Power Supply” on page 3-11.

Note – Observe the following warning message displayed at the right of the circuit

breakers on the circuit breaker panel above the AC power supplies.

WARNING

FAN TRAYS HAVE REDUNDANT DC POWER SOURCES.

CIRCUIT BREAKERS ON BOTH SIDES, FRONT AND REAR,

MUST BE OPERATED TO TURN OFF FAN TRAYS.

POWER SUPPLIES HAVE DUAL AC INPUTS.

BOTH CIRCUIT BREAKERS, AC0 AND AC1 MUST BE

OPERATED TO TURN OFF A POWER SUPPLY.

2. Ensure power is off at the circuit breakers, AC0 (top breaker) and AC1 (bottom

breaker), on the front panel of the power supply.

Note – Ensure all AC power cords are labeled before removing.

Chapter 3 System Power 3-11

3. Label and remove both AC power cords from the front panel of the power supply.

Caution – The power supply unit weighs 43.0 lb (19.5 kg). Use proper heavy-lifting

procedures when removing this unit.

4. Use a Phillips No. 2 screwdriver to release the four (4) front panel captive

fasteners.

5. To pull out the 4 kW dual AC–DC power supply, use the power connector insertejector bracket as a handle and slide the power supply forward until the handle

on the top of the power supply is exposed.

6. Use one hand to hold the power supply by the handle as you pull it the rest of the

way out of the power module.

7. Place the power supply on a flat, sturdy, ESD-protected surface.

3.2.2.4 Installing a 4 kW Dual AC–DC Power Supply

Caution – The power supply unit weighs 43.0 lb (19.5 kg). Use proper heavy-lifting

procedures when removing this unit.

1. Insert the 4 kW dual

AC–DC power supply into its appropriate location in the

power module.

2. Slide the power supply smoothly inward to a point where contact is made with

the power module connector.

3. Secure the power supply with the four (4) front panel captive fasteners.

Note – Failure of the active LED to transition from on to off within 60 seconds after

insertion indicates a power-status control fault.

4. Verify the LED status per

TABLE 3-2.

5. Connect the AC power cords into their appropriate AC connectors on the front

panel of the power supply.

See

FIGURE 3-5 to determine the proper part number and orientation for connection.