Page 1

Sun Fire™ 15K/12K Systems Unpacking Guide

Page 2

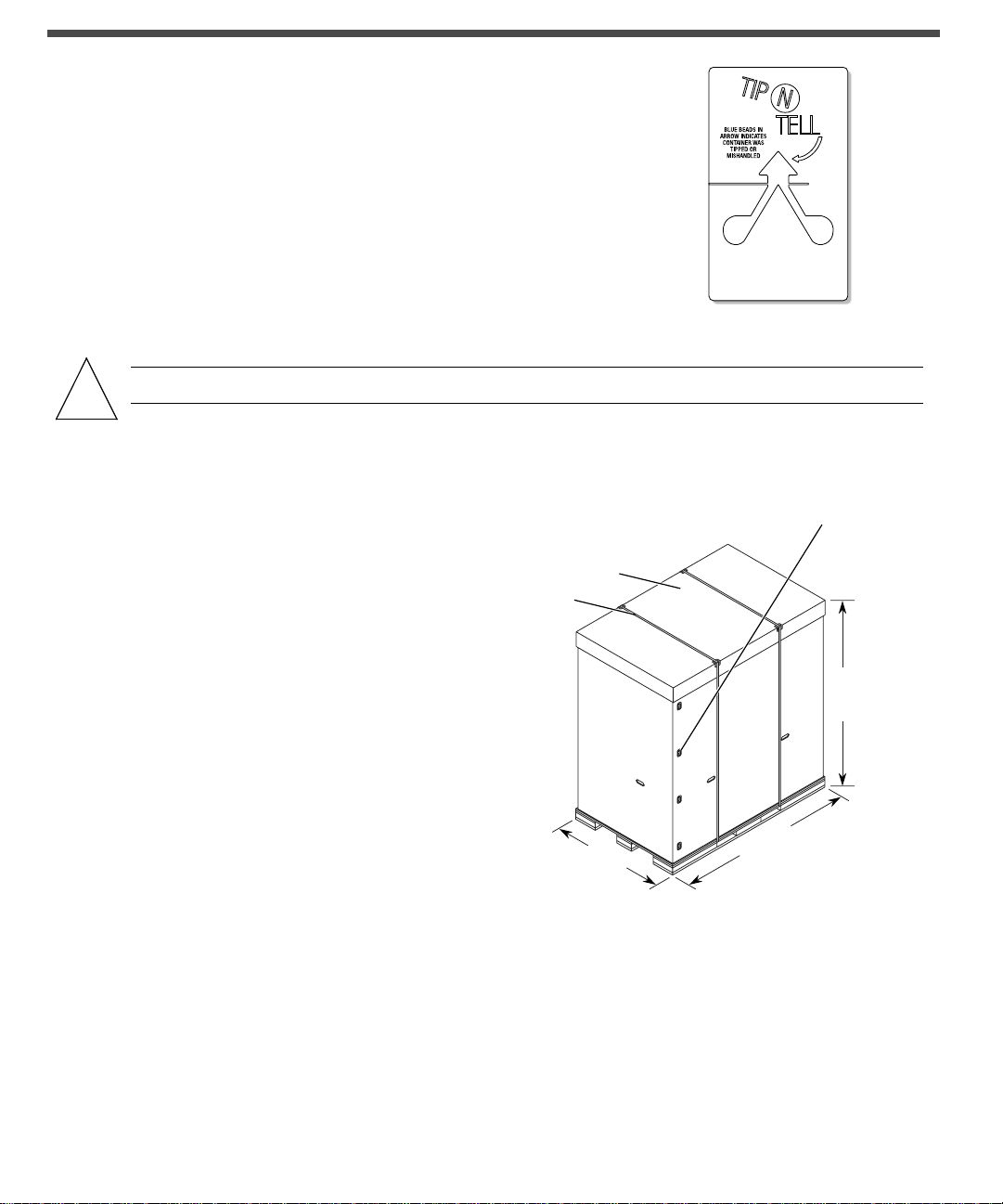

1. Verify the container was not damaged during shipment. Review

the

TIP N TELL device and all packaging components for

indications of rough treatment. If damage is evident, note on

airbill or bill of lading. Failure to note damage may invalidate

future claims. Noting possible damage allows the claimant time

to file a claim with the shipping carrier.

Caution – Use a 60-inch pallet jack (suggested) to transport the container.

!

2. Prepare cutting pliers, or equivalent, to remove

plastic banding on outside of shipping

container. A minimum of 18 ft [5.49 meters] of

floor space is required to unload the cabinet.

The cabinet may be unloaded from either end

of the pallet. Ramps are attach to either end of

the pallet. Note the “RAMPS ATTACH THIS

END” markings and image on the outside of

the shipping carton when considering its

permanent location. The shipping label on the

carton indicates the front of the unit.

Carton

top cap

Banding

Locking

clips

Height:

80.75 inches

(2051.1 mm)

3. Position the shipping container as close as

possible to the final installation site. Access to

all sides of the cabinet is needed with a

minimum of 18 ft (5.49 m) to move the cabinet

from the pallet, down the ramp, and onto the

floor.

4. Cut the outer banding and remove the carton

top cap. Remove the eight plastic locking clips

(four per side) by squeezing the center flanges

together while pulling outward.

5. Remove outer cartons. Remove the hardware box located at the front or rear of the system and the two

shipping kit boxes located on the sides of the pallet deck. Take out the 9/16-inch open-end wrench from

the hardware box, and retain the remaining items for later use as needed.

48 inches

(1219.2 mm)

Front

Side

75.5 inches

(1917.7 mm)

Page 3

6. Remove internal top cap. Remove the two ramps from each side of the pallet deck and set aside for

later use.

External

carton top

Internal

top cap

Plastic

bag

Ramps

Hardware

box

7. Remove the customer service documentation from the shipping kit box. Customer service

documentation consists of the system overview, site planning guide, hardware installation and deinstallation guide, service manual, and additional configuration information.

Caution – To prevent damage during installation, remove the four doors from the cabinet before

you remove the unit from the pallet. Use the edges of the cabinet frame to maneuver the cabinet.

!

Do not use the internal system board handles to move the cabinet.

Shipping kit boxes

Outer cartons

8. Remove the front and rear chocks. Remove the outer plastic bag. Remove the doors from the front and

rear of the cabinet by pulling down on the top spring-loaded hinge pins, and then lift the doors upward

to remove from the pins on the bottom hinge brackets of the cabinet. Set the four doors aside.

Caution – To prevent damage to the kick plate mounting bracket assembly, remove the kick plate

from both ends of the cabinet prior to unloading. The cabinet cannot be moved at an angle of more

than 10 degrees maximum.

!

9. Remove the kick plate assemblies at the front and rear of the cabinet. Use a pull-turn motion to release

the spring-loaded captive locking pin and pull the kick plate and mounting tube outward from the

mounting bracket and set aside. Loosen the two captive panel fasteners of the kick plate mounting

bracket assembly. Remove by pulling forward and tipping downward to release the support tabs from

their mounting holes.

Page 4

10. Return a chock to the pallet end used for unloading.

11. At the end of the pallet not used for unloading,

use the 9/16-inch open-end wrench to remove

the four bolts from the two zinc-plated

shipping brackets. Retain the parts for later

use.

12. Return the remaining chock to its original position on the pallet deck.

Chock

Kick plate

assembly

Caution – Ensure Step 12 is completed before proceeding. Both chocks should be installed at

!

this time.

13. Align the tines of the ramps with corresponding holes at the unloading side of the pallet. Verify the

ramps are firmly in position by pressing or standing on the back side of the tines.

14. At the unloading side of the pallet where the ramps are attached, remove the chock. Using the 9/16 inch

open-end wrench, remove the four bolts from the two zinc-plated shipping brackets. Retain the parts

for later use.

15. Move the cabinet off the pallet. One or

two persons should push while two

others slowly guide the cabinet down the

ramps. Maneuver the cabinet using the

edges of the cabinet frame. Do not use the

internal handles to move the cabinet.

Shipping bolts

and brackets

!

Caution – Refer to the Sun Fire 15K/12K Systems Site Planning Guide for air-cooling requirements for

raised-floor computer room environments.

Page 5

16. Move the cabinet to the position where it will

be installed. Fully extend the four leveling feet

at the base of each corner of the cabinet. Make

an additional 1/4 turn of the leveling feet to

ensure stability.

17. After the cabinet has been positioned in its

permanent location, re-install the two kick plate

assemblies. Insert the inner support tabs of the

kick plate mounting bracket. Align the two

outer tabs at the front mounting holes of the

cabinet frame and slide the bracket inward to

align the inner support tabs into the two

mounting holes of the horizontal support

structure under the cabinet. Secure with the two

captive panel fasteners. Re-insert the square

mounting tube of the kick plate mounting

bracket assembly until it is flush with the

cabinet. Secure with the spring-loaded captivelocking pin.

18. Use a Phillips No. 2 screwdriver to loosen the

four captive screws on the front handle bar and

the four captive screws on the rear handle bar.

Remove and retain these parts for later use.

19. Reinstall the front and rear cabinet doors by

inserting each door onto the bottom peg for

each bottom-hinge bracket of the cabinet. At the

top of each door, pull down the spring-loaded

pin and insert the peg of the door into the tophinge bracket of the cabinet.

Note – Shipping materials cannot be reused due to foam compression. These materials can be disposed of per

the customer’s instructions. Reduce and recycle whenever possible.

20. Refer to the Sun Fire 15K/12K Systems Hardware Installation and De-Installation Guide and the other

customer service documentation that was removed in Step 7.

Page 6

Accessing Sun Documentation

You can view, print, or purchase a broad selection of Sun documentation, including localized versions, at:

http://www.sun.com/documentation

Contacting Sun Technical Support

If you have technical questions about this product that are not answered in this document, go to:

http://www.sun.com/service/contacting

Sun Welcomes Your Comments

Sun is interested in improving its documentation and welcomes your comments and suggestions. You can

submit your comments by going to:

http://www.sun.com/hwdocs/feedback

Please include the title and part number of your document with your feedback:

Sun Fire 15K/12K Systems Unpacking Guide, part number 806-3508-12

Copyright2003 SunMicrosystems,Inc. Allrights reserved.Use is subjectto licenseterms. Third-partysoftware, including fonttechnology,is copyrighted andlicensed from Sun

suppliers.Portions may be derivedfrom Berkeley BSD systems,licensed fromU.of CA. Sun,Sun Microsystems,the Sun logo,SunFire, and Solaris are trademarksor registered

trademarks of SunMicrosystems, Inc. inthe U.S. andin other countries.All SPARCtrademarks areused under licenseand are trademarksor registeredtrademarks of SPARC

International, Inc. inthe U.S.andin othercountries. Government users aresubject to theSunMicrosystems, Inc. standardlicenseagreement and applicableprovisionsof the FAR and

itssupplements.

Copyright 2003 SunMicrosystems, Inc.Tous droitsréservés. Distr ibué pardes licences quien restreignentl’utilisation. Le logicieldétenu par destiers, et quicomprend la

technologie relative auxpolices de caractères,est protégé parun copyright etlicencié par desfournisseurs deSun. Des parties de ceproduit pourront êtredérivées dessystèmes

BerkeleyBSD licenciéspar l’Université deCalifornie.Sun, SunMicrosystems,le logoSun, Sun Fire,et Solaris sontdes marquesde fabrique oudes marques déposéesde Sun

Microsystems,Inc. auxEtats-Unis et dansd’autres pays. Toutes les marquesSPARC sont utiliséessous licenceet sont desmarques de fabriqueou desmarques déposées de

SPARC International,Inc. aux Etats-Uniset dansd’autres pays.

Sun Microsystems, Inc.

4150 Network Circle

Santa Clara, CA 95054 USA

www.sun.com

Part No. 806-3508-12, Rev.A

June 2003

Loading...

Loading...