Page 1

SPARCstation 5 Service Manual

Sun Microsystems Computer Company

A Sun Microsystems, Inc. Business

901 San Antonio Road Palo Alto, CA 94303-4900 USA

650 960-1300

fax 650 969-9131

Part No.: 801-6396-11

Revision A, August 1994

Page 2

1994 Sun Microsystems,Inc.,901SanAntonioRoad,PaloAlto,California94303-4900U.S.A.

All rights reserved.

This productordocumentisprotectedbycopyrightanddistributedunderlicensesrestrictingitsuse,copying,distribution,anddecompilation.

No part of this productordocumentmaybereproducedinanyformbyanymeanswithoutpriorwrittenauthorizationofSunanditslicensors,

if any.

Portions of this productmaybederivedfromtheUNIX®system,licensedfromNovell,Inc.,andfromtheBerkeley4.3BSDsystem,licensed

fromtheUniversityofCalifornia.UNIXisaregisteredtrademarkintheUnitedStatesandinothercountriesandisexclusivelylicensedby

X/Open Company Ltd. Third-partysoftware,includingfonttechnologyinthisproduct,isprotectedbycopyrightandlicensedfrom Sun’s

suppliers. RESTRICTED RIGHTS: Use, duplication, or disclosurebytheU.S.GovernmentissubjecttorestrictionsofFAR 52.227-14(g)(2)(6/87)

and FAR52.227-19(6/87),orDFAR252.227-7015(b)(6/95)andDFAR 227.7202-3(a).

Sun, Sun Microsystems,theSunlogo,andSolarisaretrademarksorregisteredtrademarksofSunMicrosystems, Inc. in the United States and in

other countries. All SPARC trademarks are used under licenseandaretrademarksorregisteredtrademarksofSPARCInternational,Inc.inthe

United States and in other countries. ProductsbearingSPARC trademarks arebaseduponanarchitecturedevelopedbySunMicrosystems,Inc.

The OPEN LOOK® and Sun™ Graphical User Interfaces weredevelopedbySunMicrosystems,Inc.foritsusersandlicensees.Sun

acknowledges the pioneering effortsofXeroxCorporationinresearchinganddevelopingtheconceptofvisualorgraphicaluserinterfacesfor

the computer industry. Sun holds a nonexclusive licensefromXeroxtotheXeroxGraphicalUserInterface,whichlicensealsocoversSun’s

licensees who implement OPEN LOOK GUIs and otherwise comply with Sun’s writtenlicenseagreements.

THIS PUBLICATIONISPROVIDED“ASIS”WITHOUTWARRANTYOFANYKIND,EITHEREXPRESSORIMPLIED,INCLUDING,BUT

NOT LIMITED TO,THEIMPLIEDWARRANTIES OF MERCHANTABILITY,FITNESSFORAPARTICULAR PURPOSE, OR NONINFRINGEMENT.

Copyright 1994 Sun Microsystems,Inc.,901SanAntonioRoad,PaloAlto,Californie94303-4900U.S.A.Tousdroitsréservés.

Ce produitoudocumentestprotégéparuncopyrightetdistribuéavecdeslicencesquienrestreignentl’utilisation,lacopieetladécompilation.

Aucune partie de ce produitoudesadocumentationassociéenepeutêtrereproduitesousaucuneforme,parquelquemoyenquecesoit,sans

l’autorisation préalable et écrite de Sun et desesbailleursdelicence,s’ilyena.

Des parties de ce produitpourrontêtrederivéesdusystèmeUNIX®licenciéparNovell,Inc.etdusystèmeBerkeley4.3BSDlicenciépar

l’Université de Californie. UNIX est une marqueenregistréeauxEtats-Unisetdansd’autrespays,etlicenciéeexclusivementparX/Open

Company Ltd. Le logiciel détenu par des tiers, et quicomprendlatechnologierelativeauxpolicesdecaractères,estprotégéparuncopyrightet

licencié par des fournisseurs de Sun.

Sun, Sun Microsystems,lelogoSun,etSolarissontdesmarquesdéposéesouenregistréesdeSunMicrosystems,Inc.auxEtats-Unisetdans

d’autrespays.Toutes les marquesSPARC, utilisées sous licence, sont des marquesdéposéesouenregistréesdeSPARCInternational,Inc.aux

Etats-Unis et dans d’autrespays.LesproduitsportantlesmarquesSPARCsontbaséssurunearchitecturedéveloppéeparSunMicrosystems,

Inc.

Les utilisateurs d’interfaces graphiques OPEN LOOK® et Sun™ont étédéveloppésdeSunMicrosystems,Inc.poursesutilisateursetlicenciés.

Sun reconnaîtleseffortsdepionniersdeXeroxCorporationpourlarecherche et le développement du concept des interfaces d’utilisation

visuelle ou graphique pour l’industrie de l’informatique. Sun détientunelicencenonexclusivedeXeroxsurl’interfaced’utilisationgraphique,

cette licence couvrant aussi les licenciés deSun quimettentenplacelesutilisateursd’interfacesgraphiquesOPENLOOKetquienoutrese

conforment aux licences écrites de Sun.

CETTE PUBLICATIONESTFOURNIE"ENL’ETAT"SANSGARANTIED’AUCUNESORTE, NI EXPRESSENIIMPLICITE,YCOMPRIS,ET

SANS QUE CETTE LISTE NE SOIT LIMITATIVE,DESGARANTIESCONCERNANTLAVALEURMARCHANDE,L’APTITUDE DES

PRODUITS A REPONDRE A UNE UTILISATIONPARTICULIERE OU LE FAITQU’ILSNESOIENTPASCONTREFAISANTSDEPRODUITS

DE TIERS.

Please

Recycle

Page 3

Contents

1. Product Description 1-1

1.1 Standard Features 1-1

1.1.1 Subassemblies, Boards, and Components 1-2

1.1.2 Interior View 1-2

1.1.3 Rear View of SPARCstation 5 System 1-3

1.2 Internal Options 1-4

1.3 External Options 1-5

2. Troubleshooting Overview 2-1

2.1 Factory-Defined Boot Mode 2-1

2.2 After Power Is Switched On 2-4

2.3 Diagnostic Tools and When to Use Them 2-7

2.4 Power-On Self-Test 2-7

2.5 FORTH-Based PROM Diagnostics 2-8

2.6 FORTH Monitor 2-11

2.7 SunDiag System Exerciser 2-11

2.8 SunDiagnostic Executive 2-11

3. Power-On Self-Test (POST) 3-1

3.1 Power-On Self-Test (POST) 3-1

3.2 Normal Mode 3-4

Contents iii

Page 4

3.3 Full Diagnostic Mode 3-4

3.4 Abbreviated Diagnostic Mode 3-5

3.4.1 Setting Up a tip Connection to Another System 3-5

3.5 Tests the POST Runs 3-6

3.6 POST Error Messages 3-8

3.7 Status Lights (LEDs) and Indicators 3-8

4. Troubleshooting Procedures 4-1

4.1 No Video Output on the System Monitor 4-2

4.2 Power-On Does Not Succeed 4-2

4.2.1 Power Supply Test 4-3

4.2.2 System Board Test 4-5

4.3 Disk Drive Errors 4-6

4.3.1 Verifying the Built-In SCSI Controller 4-6

4.4 Determining Faulty DSIMM Locations 4-7

5. Safety and Tools Requirements 5-1

5.1 Safety Requirements 5-1

5.2 Symbols 5-2

5.3 System Precautions 5-3

5.4 Tools Required 5-4

5.5 Electrostatic Discharge (ESD) Precautions 5-4

6. Power On and Off 6-1

6.1 Powering Off the System 6-1

6.1.1 When the System Is Working Normally 6-1

6.1.2 When the System Does Not Respond Normally 6-2

6.2 Powering On the System 6-4

7. Internal Access 7-1

7.1 Removing the Cover 7-1

iv SPARCstation 5 Service Manual • August 1994

Page 5

7.2 Attaching the Wrist Strap 7-3

7.3 Replacing the Cover 7-4

8. Major Subassemblies 8-1

8.1 Power Supply 8-1

8.1.1 Removing the Power Supply 8-1

8.1.2 Replacing the Power Supply 8-3

8.2 Power LED 8-4

8.2.1 Removing the Power LED 8-4

8.2.2 Replacing the Power LED 8-5

8.3 Internal Speaker 8-7

8.3.1 Removing the Internal Speaker 8-7

8.3.2 Replacing the Internal Speaker 8-10

8.4 SCSI Backplane 8-11

8.4.1 Removing the SCSI Backplane 8-11

8.4.2 Replacing the SCSI Backplane 8-13

9. Storage Devices 9-1

9.1 Hard Disk Drive 9-1

9.1.1 Removing a Hard Disk Drive 9-2

9.1.2 Replacing a Hard Disk Drive 9-3

9.2 CD-ROM Drive 9-5

9.2.1 Removing the CD-ROM Drive 9-5

9.2.2 Replacing the CD-ROM Drive 9-6

9.3 Diskette Drive 9-8

9.3.1 Removing the Diskette Drive 9-9

9.3.2 Replacing the Diskette Drive 9-12

9.4 Internal SCSI Data Cable 9-15

9.4.1 Removing the Internal SCSI Cable 9-15

9.4.2 Replacing the Internal SCSI Data Cable 9-17

9.5 DC Power Harness 9-20

Contents v

Page 6

9.5.1 Removing the DC Power Harness 9-20

9.5.2 Replacing the DC Power Harness 9-23

9.6 Diskette Data Cable 9-26

9.6.1 Removing the Diskette Data Cable 9-26

9.6.2 Replacing the Diskette Data Cable 9-27

9.7 CD-ROM Audio Cable 9-28

9.7.1 Removing the CD-ROM Audio Cable 9-28

9.7.2 Replacing the CD-ROM Audio Cable 9-29

10. System Board Overview 10-1

10.1 Damage Prevention 10-1

10.2 Handling System Boards and Assemblies 10-1

10.3 System Board Layout 10-2

10.4 Replaceable System Board Components 10-3

11. System Board and Component Replacement 11-1

11.1 SBus Cards 11-1

11.1.1 Removing an SBus Card 11-2

11.1.2 Replacing an SBus Card 11-5

11.2 S24 Frame Buffer Card 11-7

11.2.1 Removing an S24 Frame Buffer Card 11-8

11.2.2 Replacing an S24 Frame Buffer Card 11-10

11.3 DSIMMs 11-12

11.3.1 Removing a DSIMM 11-13

11.3.2 Replacing a DSIMM 11-15

11.4 System Board 11-17

11.4.1 Removing the System Board 11-17

11.4.2 Replacing the System Board 11-19

11.4.3 Setting Jumpers 11-21

11.5 NVRAM 11-23

11.5.1 Removing the NVRAM Chip 11-23

vi SPARCstation 5 Service Manual • August 1994

Page 7

11.5.2 Replacing the NVRAM Chip 11-24

12. Illustrated Parts Breakdown 12-1

12.1 Illustrations of Selected CRUs 12-1

12.2 Replacement Parts List 12-4

A. System Specifications A-1

A.1 Physical Specifications A-1

A.2 Input Power Requirements A-2

A.3 Environmental Requirements A-2

B. SPARCstation 5 Input/Output Connectors B-1

B.1 SCSI Connector (External) B-1

B.2 Parallel Port Micro-D Connector B-2

B.3 Attachment Unit Interface (AUI) Micro-D Connector B-3

B.4 Twisted-Pair Ethernet Connector B-4

B.5 Serial Connector Ports A and B B-5

B.6 Keyboard/Mouse Connector B-6

B.7 Audio Ports B-6

B.7.1 Headphone Connector B-7

B.7.2 Audio Line-out Connector B-7

B.7.3 Audio Line-in Connector B-8

B.7.4 Microphone Connector B-8

B.8 13W3 Video Connector B-8

C. SCSI Targeting C-1

D. FORTH Diagnostics D-1

D.1 Running the FORTH Diagnostics D-1

D.1.1 test <alias name>, test <device path> D-3

D.1.2 test-all D-4

D.1.3 watch-clock D-4

Contents vii

Page 8

D.1.4 watch-net, watch-aui, watch-tpe, and watch-net-all D-4

D.1.5 probe-scsi, probe-scsi-all D-7

D.1.6 module-info D-7

D.1.7 test-memory D-8

D.2 Returning to the Old-Style Sunmon Compatibility Mode Prompt D-8

Glossary Glossary-1

viii SPARCstation 5 Service Manual • August 1994

Page 9

Figures

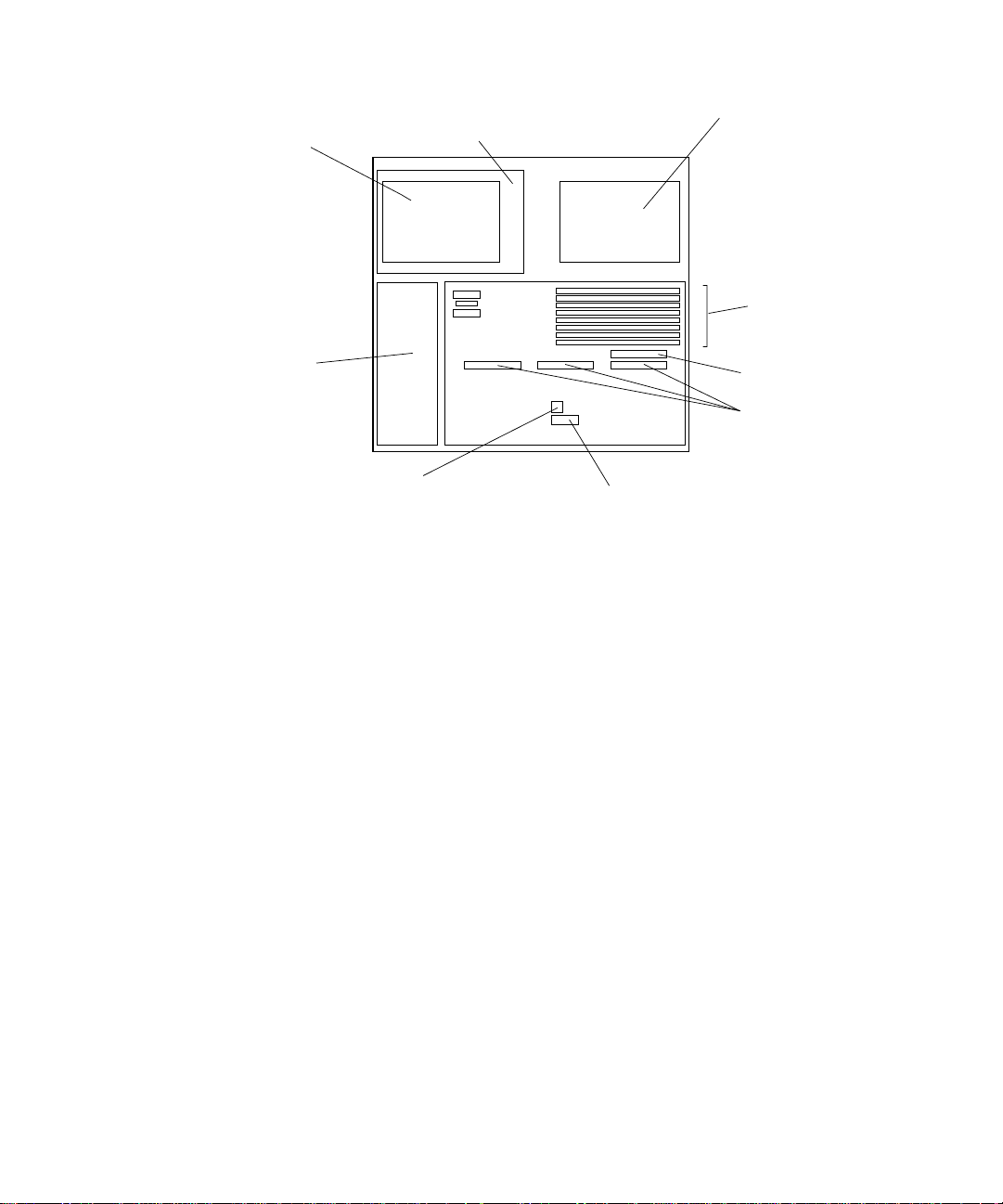

FIGURE 1-1 Basic SPARCstation 5 System 1-2

FIGURE 1-2 Interior View of SPARCstation 5 System 1-3

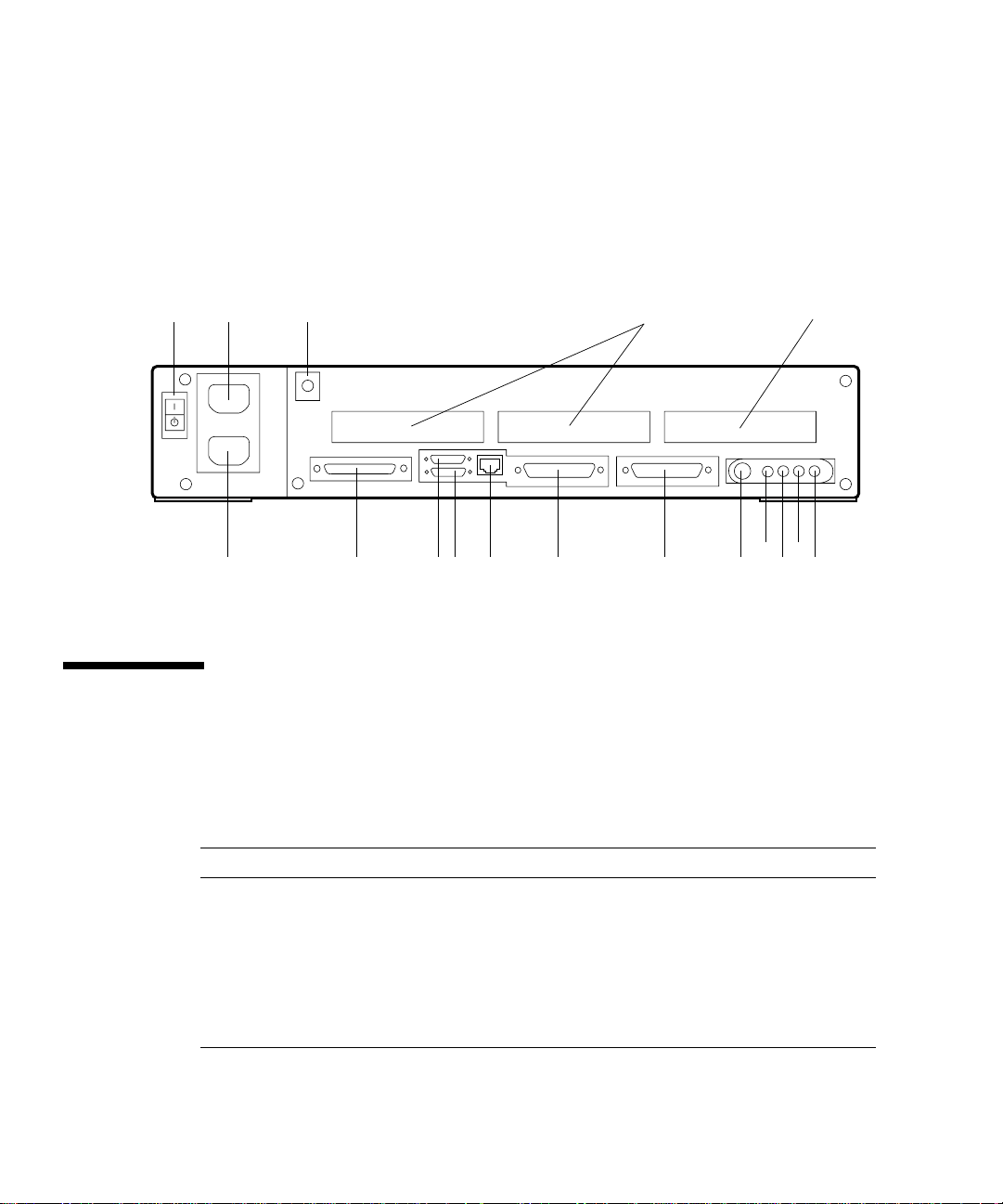

FIGURE 1-3 Rear View of SPARCstation 5 System 1-4

FIGURE 2-1 Factory-Defined Boot Sequence—POST Phase Settings and Tests 2-2

FIGURE 2-2 Factory-Defined Boot Sequence—OpenBoot PROM Phase Settings and Tests 2-3

FIGURE 3-1 Arrangement of Sun Type-5 Keyboard Diagnostic LEDs 3-2

FIGURE 3-2 Sun Type-4 Keyboard 3-2

FIGURE 3-3 Sun Compact 1 Keyboard 3-3

FIGURE 3-4 SPARCstation System Banner 3-4

FIGURE 3-5 Location of System Power LED 3-8

FIGURE 4-1 Power Supply Connector 4-4

FIGURE 4-2 DSIMM Slot Locations 4-8

FIGURE 7-1 Removing the Rear Panel Cover Screws 7-2

FIGURE 7-2 Removing the Cover 7-3

FIGURE 7-3 Grounding the Wrist Strap to the Power Supply 7-4

FIGURE 7-4 Replacing the Cover 7-5

FIGURE 7-5 Securing the System Unit Cover 7-6

FIGURE 8-1 Removing the Power Supply 8-2

FIGURE 8-2 Connecting the DC Power Harness to the Power Supply 8-3

Figures ix

Page 10

FIGURE 8-3 Power LED and In-line Connector 8-5

FIGURE 8-4 Positioning the LED Cable 8-6

FIGURE 8-5 Removing the Speaker Cover 8-8

FIGURE 8-6 Removing the Speaker 8-9

FIGURE 8-7 Speaker Connections 8-10

FIGURE 8-8 Removing the SCSI Backplane 8-12

FIGURE 9-1 Drive Locations 9-2

FIGURE 9-2 Removing a Hard Disk Drive 9-3

FIGURE 9-3 Replacing a Disk Drive 9-5

FIGURE 9-4 Removing the CD-ROM Drive 9-6

FIGURE 9-5 Jumper Settings for SPARCstation 5 CD-ROM Drive 9-7

FIGURE 9-6 Replacing the CD-ROM Drive 9-8

FIGURE 9-7 Diskette Drive Location 9-9

FIGURE 9-8 Removing the CD-ROM Filler Panel 9-10

FIGURE 9-9 Disengaging the Diskette Drive 9-11

FIGURE 9-10 Removing the Diskette Drive 9-12

FIGURE 9-11 Diskette Drive Switch and Grommets 9-13

FIGURE 9-12 Replacing the Diskette Drive 9-14

FIGURE 9-13 System Board Cable Connections 9-16

FIGURE 9-14 Rear Panel Captive Screws 9-16

FIGURE 9-15 Removing the System Board 9-17

FIGURE 9-16 Internal Cable Routing 9-18

FIGURE 9-17 Replacing the System Board 9-19

FIGURE 9-18 Backpanel Captive Screws 9-19

FIGURE 9-19 System Board Cable Connections 9-21

FIGURE 9-20 1 Panel Captive Screws 9-21

FIGURE 9-21 Removing the System Board 9-22

FIGURE 9-22 Internal Cable Routing 9-23

x SPARCstation 5 Service Manual • August 1994

Page 11

FIGURE 9-23 Replacing the System Board 9-24

FIGURE 9-24 Backpanel Captive Screws 9-25

FIGURE 9-25 System Board Cable Routing 9-27

FIGURE 9-26 Audio Connector on the CD-ROM Drive 9-28

FIGURE 9-27 CD-ROM Audio Connector on the System Board 9-29

FIGURE 10-1 SPARCstation 5 System Board 10-2

FIGURE 11-1 SBus Slot Locations 11-1

FIGURE 11-2 Opening the SBus Card Retainers 11-2

FIGURE 11-3 Removing the Extractor From the SBus Card 11-3

FIGURE 11-4 Installing the SBus Card Extractor 11-3

FIGURE 11-5 Removing a Single-Width SBus Card 11-4

FIGURE 11-6 Removing a Double-Width SBus Card 11-4

FIGURE 11-7 Inserting the SBus Card 11-6

FIGURE 11-8 Closing the SBus Card Retainers 11-7

FIGURE 11-9 AFX Bus Slot 11-8

FIGURE 11-10 Opening the Card Retainers 11-9

FIGURE 11-11 Removing an S24 Frame Buffer Card 11-10

FIGURE 11-12 Inserting the S24 Frame Buffer Card 11-11

FIGURE 11-13 Closing the Card Retainers 11-12

FIGURE 11-14 DSIMM Slot Locations on the System Board 11-14

FIGURE 11-15 Ejecting a DSIMM 11-14

FIGURE 11-16 Orienting a DSIMM 11-15

FIGURE 11-17 Installing a DSIMM 11-16

FIGURE 11-18 System Board Cable Connections 11-18

FIGURE 11-19 System Board Captive Screws 11-18

FIGURE 11-20 Removing the System Board 11-19

FIGURE 11-21 Installing the System Board 11-20

FIGURE 11-22 System Board Captive Screws 11-20

Figures xi

Page 12

FIGURE 11-23 Setting the Serial Port Jumpers 11-22

FIGURE 11-24 Locating the NVRAM 11-23

FIGURE 12-1 Selected CRUs—System Unit 12-1

FIGURE 12-2 Standard External Cables 12-2

FIGURE 12-3 Optional External Cables 12-3

FIGURE 12-4 Microphone and Cable 12-3

FIGURE B-1 External SCSI Connector B-1

FIGURE B-2 Parallel Port Micro-D Connector B-2

FIGURE B-3 Attachment Unit Interface (AUI) Micro-D Connector B-3

FIGURE B-4 Twisted-Pair Ethernet Connector B-4

FIGURE B-5 Serial Connector B-5

FIGURE B-6 Keyboard/Mouse Connector B-6

FIGURE B-7 SPARCstation 5 Audio Ports B-6

FIGURE B-8 Headphone Connector B-7

FIGURE B-9 Audio Line-out Connector B-7

FIGURE B-10 Audio Line-in Connector B-8

FIGURE B-11 Microphone Connector B-8

FIGURE B-12 SPARCstation 5 13W3 Video Connector B-9

xii SPARCstation 5 Service Manual • August 1994

Page 13

Tables

TABLE 1-1 Internal Options 1-4

TABLE 1-2 Selected External SCSI Peripheral Options 1-5

TABLE 2-1 NVRAM Parameters Used During POST and Boot Sequence 2-5

TABLE 2-2 Summary of Autoboot and Diagnostic Switch Parameter Settings 2-6

TABLE 2-3 Diagnostic Tools 2-7

TABLE 2-4 Selected FORTH Diagnostic Tests 2-8

TABLE 3-1 Interpreting the Keyboard Diagnostic LEDs 3-3

TABLE 4-1 Troubleshooting Tips 4-1

TABLE 4-2 Power Supply Connector Pin Assignments 4-4

TABLE 4-3 Troubleshooting Disk Drive Errors 4-6

TABLE 4-4 Physical Memory Address Ranges for Slots 0 Through 7 4-8

TABLE 5-1 Safety Precautions 5-2

TABLE 12-1 Part Number List—Customer Replaceable Units 12-4

TABLE 12-2 Part Number List—Miscellaneous Items 12-5

TABLE A-1 Physical Specifications A-1

TABLE A-2 Input Power Requirements and Power Dissipation A-2

TABLE A-3 Environmental Requirements A-2

TABLE B-1 Pinout Signals for External SCSI Connector B-1

TABLE B-2 Pinout for Parallel Port Micro-D Connector B-2

TABLE B-3 Pinout for Attachment Unit Interface (AUI) Micro-D Connector B-3

Tables xiii

Page 14

TABLE B-4 Pinout for Twisted-Pair Ethernet Connector B-4

TABLE B-5 Pinout for Serial Connector Ports A and B B-5

TABLE B-6 Pinout for Keyboard/Mouse Connector B-6

TABLE B-7 Signals for the SPARCstation 5 Audio Ports B-7

TABLE B-8 13W3 Video Connector Pin Assignments B-9

TABLE C-1 SCSI Targeting—Solaris 1.x (SunOS 4.x) Operating Systems C-1

TABLE C-2 SCSI Targeting—Solaris 2.x (SunOS 5.x) Operating Systems C-2

xiv SPARCstation 5 Service Manual • August 1994

Page 15

Preface

This service manual describes how to troubleshoot problems and replace parts in the

SPARCstation™ 5 computer system. Technicians, advanced computer system endusers (with experience replacing hardware and troubleshooting), system

administrators, or qualified service providers should use this book.

Document Organization

This book is divided into seven parts. A table, at the beginning of each part, lists the

chapters, sections, and page numbers.

■ Part 1, “System Information,” provides an overview of the SPARCstation 5

standard features, internal options, and external options.

■ Part 2, “Troubleshooting,” provides a troubleshooting overview, describes how to

run and troubleshoot errors displayed during the Power-On Self-Test (POST), and

presents symptoms and corrective actions.

■ Part 3, “Preparing for Service,” explains safety requirements, symbols used in this

book, tools required, and how to shut down, power off, and power on the system.

■ Part 4, “Subassembly Removal and Replacement,” describes how to open and

close the system, attach and remove a wrist strap, and remove and replace

subassemblies.

■ Part 5, “System Board,” provides an overview of the system board, describes how

to remove and replace the system board and replaceable parts and components on

the system board.

■ Part 6, “Illustrated Parts Breakdown,” provides illustrations of the major

replaceable parts and lists part numbers.

xv

Page 16

■ Part 7, “Appendixes, Glossary, Index,” provides physical, electrical, and

environmental specifications, connector pinouts and signal descriptions,

information on SCSI targeting, a glossary of technical terms, and an index.

Related Documentation

The following manuals describe software troubleshooting procedures:

■ OpenBoot Command Reference

■ SunDiag User’s Guide

■ System administration manual for the computer system

■ Operating system documentation

Typographic Conventions

The following table describes the type changes and symbols used in this book.

TABLEP-1 Typographic Conventions

Typeface or

Symbol Meaning Example

AaBbCc123 The names of commands, files,

and directories; on-screen

computer output

AaBbCc123 What you type, contrasted with

on-screen computer output

AaBbCc123 Command-line placeholder:

replace with a real name or value

AaBbCc123 Book titles, new words or terms,

or words to be emphasized

Code samples are included in boxes and may display the following:

xvi SPARCstation 5 Service Manual • August 1994

Edit your .login file.

Use ls -a to list all files.

system% You have mail.

system% suPassword:

To delete a file, type rm filename.

Read Chapter 6 in Owner’s Guide.

These are called class options.

You must be root to do this.

Page 17

TABLEP-1 Typographic Conventions

Typeface or

Symbol Meaning Example

% UNIX C shell prompt system%

$ UNIX Bourne and Korn shell

$

prompt

# Superuser prompt, all shells #

Preface xvii

Page 18

xviii SPARCstation 5 Service Manual • August 1994

Page 19

CHAPTER

1

Product Description

This chapter presents a brief overview of the major components of the

SPARCstation 5 system. Please acquaint yourself with the overview before servicing

and maintaining the hardware for this product.

1.1 Standard Features

The SPARCstation 5 system accommodates the following storage devices:

■ 535-Mbyte single-connector hard disk drive

■ 1.05-Gbyte single-connector hard disk drive

■ Diskette drive

■ Internal CD-ROM drive

It also accommodates up to 256 Mbytes of memory using dynamic single in-line

memory modules (DSIMMs). The system has four audio ports on the back panel and

includes an internal speaker. FIGURE 1-1 shows a typical SPARCstation 5 system.

1-1

Page 20

FIGURE 1-1 Basic SPARCstation 5 System

1.1.1 Subassemblies, Boards, and Components

The SPARCstation 5 system unit accommodates the following subassemblies, boards,

and components:

■ System board

■ DSIMMs (up to 8)

■ S24 graphics card

■ SBus cards (up to 3)

■ Hard disk drives, 3.5-inch, 88.0-mm, single-connector (up to 2)

■ CD-ROM drive

■ Diskette drive (3.5-inch)

■ Power supply (150-watt with 2 fans)

1.1.2 Interior View

FIGURE 1-2 shows an interior view of the major subassemblies and the system

board for the SPARCstation 5 system.

1-2 SPARCstation 5 Service Manual • August 1994

Page 21

Diskette drive

t

(bottom unit)

CD-ROM drive

(top unit)

Hard drives

(stacked)

DSIMMs

Power

supply

PROM

FIGURE 1-2 Interior View of SPARCstation 5 System

NVRAM

1.1.3 Rear View of SPARCstation 5 System

FIGURE 1-3 shows the rear view of the system.

AFX Bus slo

SBus slots

Chapter 1 Product Description 1-3

Page 22

Legend:

1—AC On/Standby switch 7—SCSI 13—Keyboard

2—AC power outlet 8—Parallel 14—Audio, headphone

3—Lock block 9—AUI Ethernet 15—Audio, line-out

4—SBus 10—Twisted-pair Ethernet 16—Audio, line-in

5—SBus or AFX Bus 11—Serial port B 17—Audio, microphone

6—AC power receptacle 12—Serial port A

23 41

687

FIGURE 1-3 Rear View of SPARCstation 5 System

1.2 Internal Options

TABLE 1-1 lists the internal options.

TABLE1-1 Internal Options

5

14

13121110915

16

17

Option Quantity Comments

S24 card 1 Provides accelerated 24-bit color graphics on

SBus cards Up to 3 System board provides up to three SBus slots

Hard disk drives 1 or 2 System supports up to two disk drives of

1-4 SPARCstation 5 Service Manual • August 1994

the system AFX Bus.

for additional system functionality.

varying capacities. See Chapter 9 for more

information.

Page 23

TABLE1-1 Internal Options

Option Quantity Comments

CD-ROM drive 1 Internal CD-ROM drive.

Diskette drive 1 Internal diskette drive for diskette I/O.

DSIMMs Up to 8 System supports up to 256 Mbytes of dynamic

1.3 External Options

TABLE 1-2 lists selected external small computer system interface (SCSI) options.

TABLE1-2 Selected External SCSI Peripheral Options

Unit Description

Desktop Backup Pack 150-Mbyte tape drive or DAT tape drive.

Desktop Disk Pack Disk expansion unit with a variety of SCSI disk drive

capacities.

Desktop SunCD™ Pack Compact CD-ROM disc drive.

Desktop Storage Module 1.3-Gbyte disk drive or 5.0-Gbyte tape drive.

SCSI Expansion Pedestal Up to seven SCSI disks, compact CD-ROM drive, tape

drive, other non-disk units.

Multi-Disk Pack Desktop enclosure containing a disk array of SCSI disk

drives.

20-Gbyte 4-mm Desktop Tape

Auto-Loader

SCSI Expansion Pedestal Holds up to eight disk drives and two or three

Desktop enclosure containing a tape drive with

multiple magazine cartridges; provides up to 20 Gbytes

of tape backup storage.

removable media in the upper tray. Requires a

minimum of two SCSI controllers if all three trays are

used. You cannot have more than seven SCSI devices

on each SCSI bus.

single in-line memory modules (DSIMMs).

Chapter 1 Product Description 1-5

Page 24

1-6 SPARCstation 5 Service Manual • August 1994

Page 25

CHAPTER

2

Troubleshooting Overview

This chapter describes the factory-defined boot sequence. It also describes the

different types of SPARCstation 5 diagnostic firmware and software tools that are

available to you for troubleshooting; the chapter explains how the tools are related

and when to use them.

2.1 Factory-Defined Boot Mode

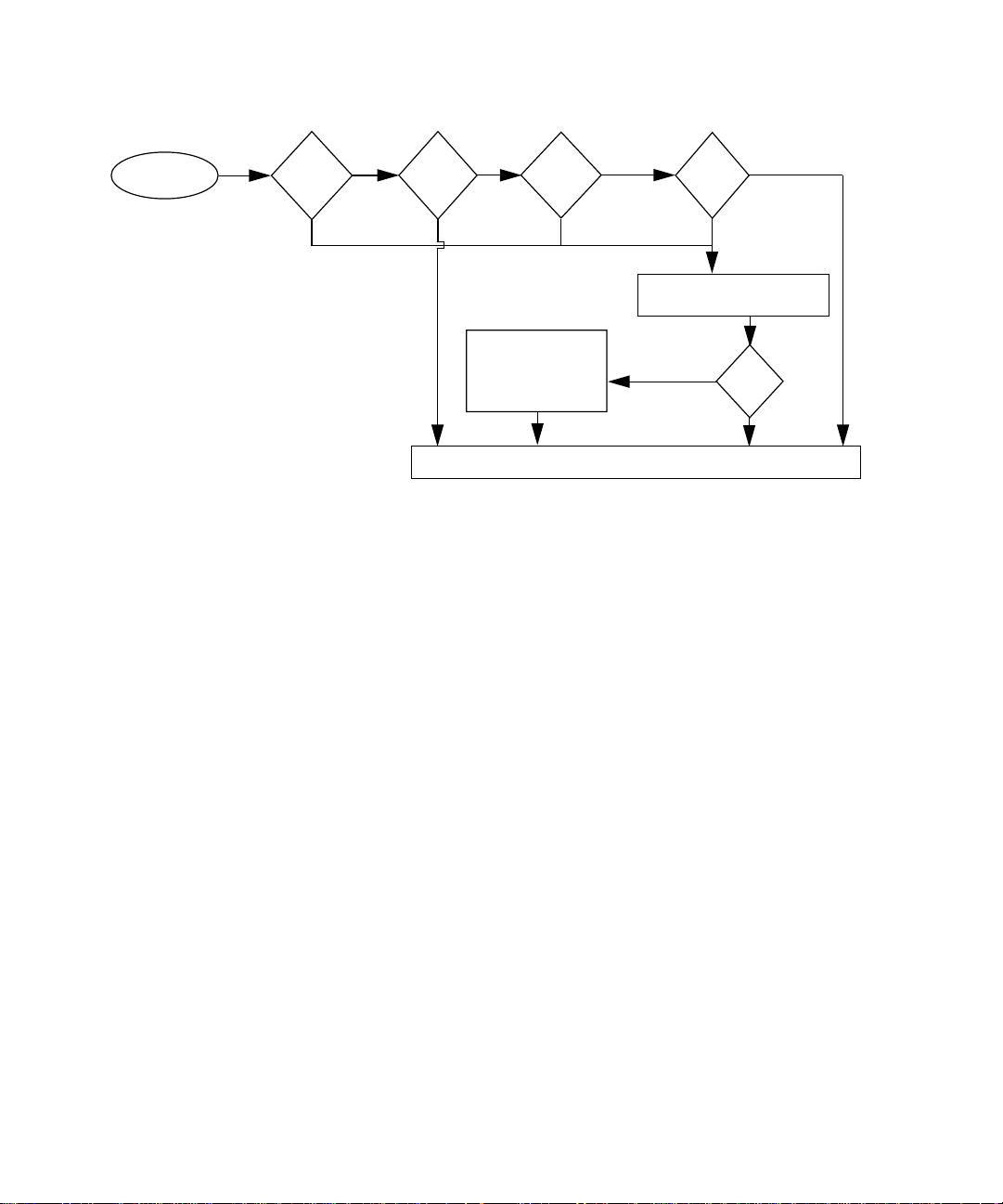

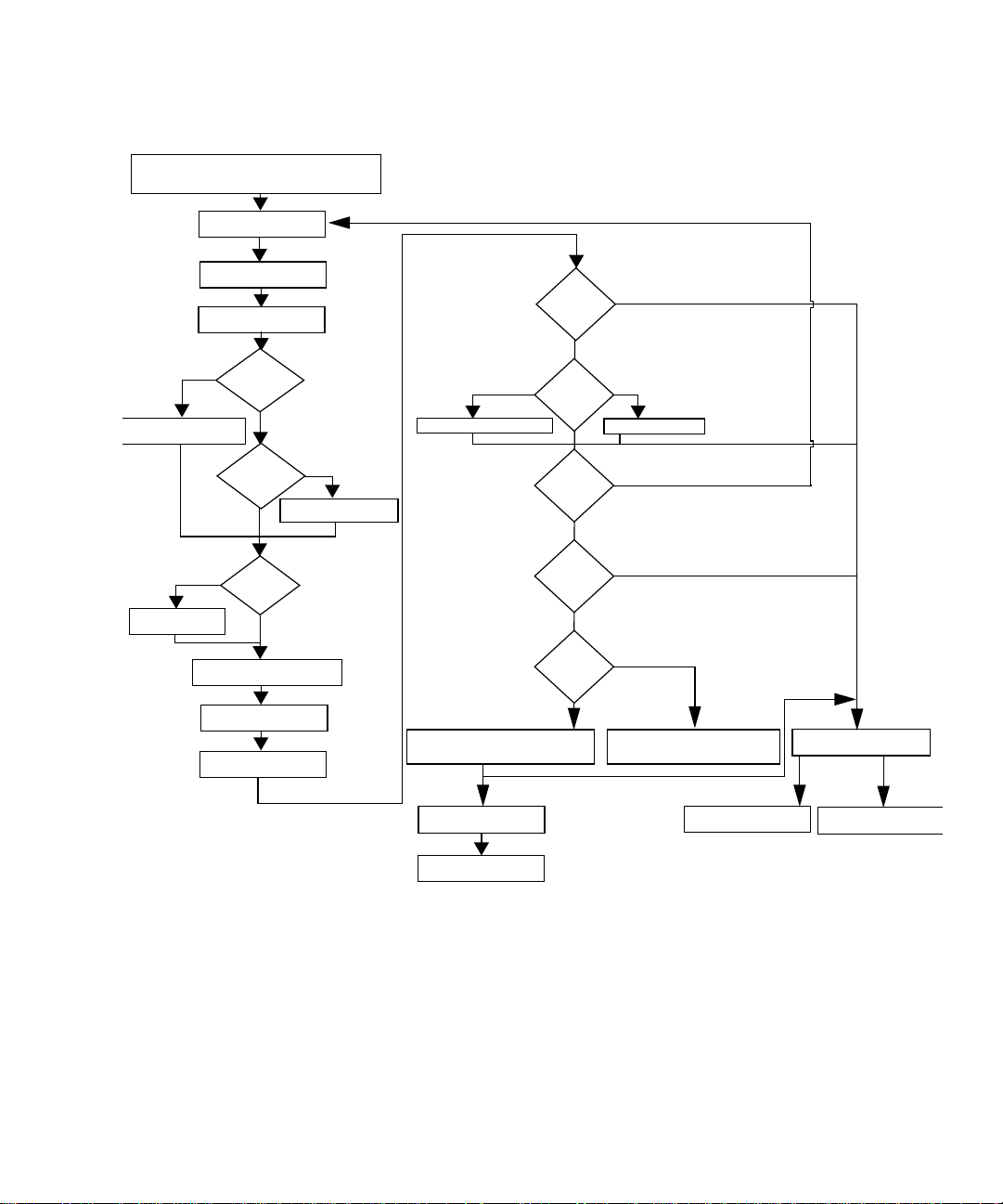

The flowcharts in FIGURE 2-1 and FIGURE 2-2 outline the roles played by various

diagnostics during a factory-defined boot operation under the control of the

OpenBoot™ PROM (OBP) firmware.

The following sections describe the relationship between the various diagnostic

tools, and the role each tool plays during the SPARCstation 5 factory-defined boot

sequence. The descriptions in the following sections assume you are using a

graphics monitor to view test results.

FIGURE 2-1 (POST phase) and FIGURE 2-2 (OBP phase) graphically depict the flow

of OBP processing control, after power is switched on. Each figure depicts the

possible paths for processing control, and the switch settings for the factory-defined

boot sequence. By examining the two flowcharts you can see where in the processing

sequence other diagnostic tests are available or are encountered.

2-1

Page 26

Power-on switch

POST phase

FIGURE 2-1 Factory-Defined Boot Sequence—POST Phase Settings and Tests

If you need to run extended FORTH Diagnostics to take advantage of more extensive

tests, see Appendix D.

Keyboard

attached

?

No

Yes

Stop

key

pressed?

Yes—Skip POST

No

Stop-d

keys

pressed?

Display errors on

keyboard LEDs

and console

OpenBoot PROM firmware takes control

No

Yes—Set

diag-switch? to true

false (default)

diag-

switch?

true

Low-level diagnostic:

POST phase

No

POST

passed

Yes

2-2 SPARCstation 5 Service Manual • August 1994

Page 27

OpenBoot PROM firmware takes control

After POST phase,

System initialization

OpenBoot PROM Phase

Probe memory

Probe CPU

Yes

etting nvram defaults

true

nvramrc?

Evaluate the

script

Probe SBus devices and

interpret their drivers

Install console

System banner

displayed on screen

Stop-n

keys

pressed?

No

Stop-d

keys

pressed?

No

use-

Yes

Set diag-switch?

false

Stop-a

keys

pressed?

No

diag-

false

switch?

Tests selftest-#megs

mfg-

switch?

false

autoboot?

true

diag-

switch?

true

Booting from diag-device=net

and diag-file

Press Stop-a to go to ok prompt

Normal

operating system

Yes

true

Tests all memory

true

false

false

Booting from boot-dev=disk

and boot-file

Press Stop-a

to go to ok prompt

Boot <boot-device>

<boot-file>

ok prompt

On-board

diagnostics

SunDiag System

Exerciser

FIGURE 2-2 Factory-Defined Boot Sequence—OpenBoot PROM Phase Settings and Tests

Chapter 2 Troubleshooting Overview 2-3

Page 28

2.2 After Power Is Switched On

When you turn on the system power, the low-level POST phase is initiated if any of

the following circumstances apply:

■ diag-switch? NVRAM parameter is set to true.

■ Stop-d keys are held down when you turn on the power.

■ Keyboard is disconnected, and diag-switch? is set to false.

The low-level POST code, which is stored in the boot PROM, is designed to test the

most basic functions of the system hardware. The status of the POST is conveyed by

four LEDs on the Sun Type-4, Type-5, and Compact 1 keyboards. The Caps Lock

LED blinks to indicate that the tests are in progress. If a failure is detected during

low-level POST, one of the other three LEDs will light to indicate the nature of the

failure. See Chapter 3 for more information.

Note – You can skip the POST phase by turning on the system while holding down

the Stop key.

At the successful completion of the low-level POST phase, the OpenBoot PROM

firmware takes control and performs the following initialization sequence:

■ Initialize system

■ Probe memory, then CPU

■ Evaluate Script (if use-nvramrc? is set to true)

■ Probe SBus devices and interpret their drivers

■ Install the console (see FIGURE 2-2)

After initialization, a system banner appears on the screen, and the high-level testing

begins. When the high-level tests are finished, the system checks parameters stored

in the NVRAM to determine the next step. Depending on the following parameter

settings, the system will:

■ Boot the operating system from a specified location, if auto-boot?

is set to true

■ Suppress the boot sequence and enter the FORTH Monitor (ok prompt), if auto-

boot? is set to false

■ Continually cycle through the OpenBoot PROM sequence, if mfg-switch? is set

to true

Note – If you are in the Sunmon compatibility mode (prompt is >) type n to return

to the OBP monitor (prompt is ok).

2-4 SPARCstation 5 Service Manual • August 1994

Page 29

TABLE 2-1TABLE 2-1 contains a list of NVRAM parameters and explains their effect

on the power-up sequence. For more detailed information about NVRAM

parameters, see the OpenBoot Command Summary.

Note – At any point during the high-level OBP execution, you can abort the OBP

sequence and access the FORTH Monitor by pressing the Stop and “a” keys

simultaneously.

TABLE2-1 NVRAM Parameters Used During POST and Boot Sequence

NVRAM Parameter Description

selftest-#megs

Default = 1

diag-switch?

Default = false

auto-boot?

Default = true

This parameter determines how many megabytes of

memory to test during high-level OBP testing if diag-

switch? is concurrently set to false. The minimum is

zero; the maximum is the amount actually installed in the

system. The default is a 1-megabyte test.

When set to true, this parameter forces the system to test

automatically all available memory. It also enables

diagnostic message output to serial port A. If a properly

configured terminal or “tip window” is connected,

diagnostic progress can be monitored through this port.

When auto-boot? is set to true and diag-switch? is set

to false, diag-switch? forces the system to boot from

the device and file specified in boot-dev and boot-file.

If auto-boot? is set to true and diag-switch? is set to

true, the system boots the operating system from the

device and file specified in the diag-device and diag-

file NVRAM parameter fields. When set to false, this

will suppress the boot sequence. The system halts with the

ok prompt.

At the FORTH Monitor prompt, you can direct the system to boot the operating

system from a location that you specify, or you can execute a variety of additional

FORTH-based tests. See the OpenBoot Command Reference for a complete description

of the FORTH Monitor.

Chapter 2 Troubleshooting Overview 2-5

Page 30

If the auto-boot? parameter is set to true (the default), the system boots a

standalone program. To determine which program and device to boot from, the

system checks the diag-switch? NVRAM parameter. TABLE 2-2 summarizes the

effect of the auto-boot? and diag-switch? parameters.

TABLE2-2 Summary of Autoboot and Diagnostic Switch Parameter

auto-boot? diag-switch? Result

false false or true > or ok prompt

true false Boot operating system from

device alias “disk” or

“net” for SPARCstation 5

system

true true Boot operating system from

device alias “net”

1. The boot parameters represented here are default settings. The defaults may be changed by following

the procedures listed in the OpenBoot Command Summary.

1

Settings

Once the operating system is running, you can invoke the SunDiag™ System

Exerciser if further diagnostic testing is warranted. Refer to Section 2.7, “SunDiag

System Exerciser,” for additional information.

Another standalone diagnostic program you can run is the SunDiagnostic Executive.

Refer to Section 2.8, “SunDiagnostic Executive,” for further information.

To boot user-specified programs, such as the SunDiagnostic Executive, you must be

at the > prompt or ok prompt. See Appendix D for a detailed procedure on how to

access the > or the ok prompt.

2-6 SPARCstation 5 Service Manual • August 1994

Page 31

2.3 Diagnostic Tools and When to Use Them

TABLE 2-3 provides a summary of the available diagnostic tools and describes when

to use each tool.

TABLE2-3 Diagnostic Tools

Diagnostic Tool When or Why to Use the Tool

Power-On Self-Test

(POST)

FORTH Diagnostics Tests functions such as the Ethernet and SCSI interfaces, system memory, and the

FORTH Monitor Allows input to the system at the boot PROM level. Supports functions such as

SunDiag System Exerciser Runs under the operating system. It displays real-time use of the system

SunDiagnostic Executive Runs extensive, configurable subsystem tests that are independent of the

Executes automatically at power-on when Stop-d keys are pressed or when the

diag-switch? parameter is set to true. The POST code resides in the boot

PROM and is driven by the POK signal from the power supply. POST tells you if

there is a problem with the system board, the NVRAM, or the DSIMMs. See

Section 3.1, “Power-On Self-Test (POST).”

diskette drive controller. You must be at the ok prompt (the FORTH Monitor) to

run the FORTH Diagnostics. The FORTH Diagnostics reside in the boot PROM.

changing NVRAM parameters, resetting the system, running diagnostic tests,

displaying system information, and redirecting input and output. See the

OpenBoot Command Reference for more information.

resources and peripherals. The SunDiag System Exerciser tells you if your

system is functioning correctly. If SunDiag fails, run the Power-On Self-Test. If all

Power-On Self-Tests pass, then run the SunDiagnostic Executive to identify the

problem. See the SunDiag User ’s Guide for more information.

operating system. Run the SunDiagnostic Executive if all tests pass when you

run the POST. Running the SunDiagnostic Executive allows you to determine

which customer replaceable unit needs to be replaced. See the latest version of

SunDiagnostic Executive User’s Guide for the SPARCstations for more information.

2.4 Power-On Self-Test

For information about the POST, see Chapter 3.

Chapter 2 Troubleshooting Overview 2-7

Page 32

2.5 FORTH-Based PROM Diagnostics

For information about how to run the FORTH Diagnostics, see Appendix D.

TABLE 2-4 lists specific on-board diagnostic tests for SPARCstation 5 systems.

TABLE2-4 Selected FORTH Diagnostic Tests

Type of Test Description Preparation When to Use

test screen Tests the system video graphics

hardware and monitor.

test floppy Tests the floppy drive response to

commands.

test scsi Tests the SCSI interface logic on

the system board.

test net-aui Performs an internal and an

external loopback test on the AUI

(Thick) Ethernet interface.

test net-tpe Performs an internal and an

external loopback test on the

twisted-pair Ethernet (TPE)

interface.

test net Performs an internal and an

external loopback test on the

auto-selected system Ethernet

interface.

test disk

test disk0

test disk1

test disk2

test disk3

test cdrom Performs a self-test diagnostic on

Tests internal or external SCSI

disks that have a self-diagnostic

program contained in the drive

controller (disk0 = SCSI address

0, disk1 = SCSI address 1,

disk2 = SCSI address 2, disk

and disk3 = SCSI address 3).

the CD-ROM drive.

The diag-switch? NVRAM

parameter must be set to true.

Insert a formatted diskette into the

drive.

The diag-switch? NVRAM

parameter must be set to true.

A cable must be connected to the

system AUI Ethernet port and to

an Ethernet tap or the test will fail

the external loopback phase.

A cable must be connected to the

system TPE port and to a TPE hub

or the test will fail the external

loopback phase. If the tpe-

link-test? parameter is false

(disabled), the external loopback

test will appear to pass even if a

cable is not connected.

A cable must be attached to the

system and to an Ethernet tap or

hub or the external loopback test

will fail.

The drive must be spinning before

this test is executed or the test will

fail. Enter a boot <disk alias>

command to cause the drive to

spin up.

The CD-ROM must be set to SCSI

target 6 and have a CD inserted in

the drive or the test will fail.

See

description.

See

description.

See

description.

See

description.

See

description.

See

description.

Disk drive

does not

function

properly.

See

description.

2-8 SPARCstation 5 Service Manual • August 1994

Page 33

TABLE2-4 Selected FORTH Diagnostic Tests (Continued)

Type of Test Description Preparation When to Use

test tape

test tape0

test tape1

Tests the SCSI tape drive by

executing the drive self-test

program. tape and tape 0 are

Connect the tape drive to the

system and then turn on the

power.

See

description.

the first tape drive. tape 1 is the

second tape drive.

test ttya

test ttyb

Outputs an alphanumeric test

pattern on the system serial ports

Attach a terminal to the serial port

to observe the output.

Tests serial

ports.

(ttya = serial port A, ttyb =

serial port B).

test keyboard This test executes the keyboard

self- test. The four LEDs on the

Keyboard must be connected. See

description.

keyboard should flash on once,

and the message Keyboard

Present is displayed.

test-memory Tests all of the system main

memory if the diag-switch is

None. See

description.

true.Ifdiag-switch is set to

false, it tests the memory

according to the number

specified in selftest-#megs.

test-all Tests all devices in the system

(such as SBus cards) that have a

built-in test program. Hard disks,

tapes, and

CD-ROMs are not tested.

Set the diag-switch? NVRAM

parameter to true.

When a

device driven

by an SBus

card is not

functioning

properly.

watch-clock Displays seconds from the

system’s Time-of-Day chip.

None. See

description.

watch-net Monitors broadcast Ethernet

packets on the Ethernet cable(s)

connected to the system.

watch-aui Monitors broadcast Ethernet

packets (10Base5—Thicknet) on

the Ethernet cable(s) connected to

the system.

watch-tpe Monitors broadcast Ethernet

packets (10BaseT—Twisted Pair

Ethernet) on the Ethernet cable(s)

connected to the system.

Connect the system to the

network via the desired

Ethernet port.

Connect the system to the

network via the desired

Ethernet port.

Connect the system to the

network via the desired

Ethernet port.

Chapter 2 Troubleshooting Overview 2-9

See

description.

See

description.

See

description.

Page 34

TABLE2-4 Selected FORTH Diagnostic Tests (Continued)

Type of Test Description Preparation When to Use

watch-net-all Monitors broadcast Ethernet

packets on all Ethernet interfaces

installed in the system, one at a

time.

Connect the system to the

network via the desired

Ethernet port.

When an

SBus card

network

controller

card is

installed.

probe-scsi Returns the SCSI devices

(internal and external) and their

SCSI targets connected to the

built-in SCSI port.

Connect external SCSI devices to

the system and turn on

their power.

To determine

if a SCSI

peripheral is

talking to the

system.

To determine

the SCSI

targets

(addresses) of

a SCSI device.

To determine

if more than

one SCSI

peripheral is

assigned the

same SCSI

address.

To determine

if the built-in

SCSI

controller is

defective.

probe-scsi-all Returns to the display the SCSI

devices and their SCSI targets

connected to all SCSI ports (both

the built-in SCSI port and any

additional SCSI host adapter

cards).

Connect external SCSI devices to

the system and turn on

their power.

See probe-

scsi.

To determine

if a SCSI host

adapter

controller is

defective.

power-off Powers off the system. You must have a Sun Type-5

keyboard in order to use this

command.

To power off

the system

with a Sun

Type-5

keyboard.

2-10 SPARCstation 5 Service Manual • August 1994

Page 35

2.6 FORTH Monitor

The FORTH Monitor is a basic diagnostic utility and system interface. If there is any

problem with your operating system, the FORTH Monitor automatically starts, as

indicated by the appearance of the ok prompt (the Monitor also starts if auto-

boot? is set to false).

You can also choose to access the FORTH Monitor by halting the system. For

information on how to access the FORTH Monitor, see Appendix D. For extensive

information about tests you can run from the FORTH Monitor, see OpenBoot

Command Reference.

2.7 SunDiag System Exerciser

Use the SunDiag System Exerciser to determine real-time use of system resources

and peripheral equipment such as Desktop Storage Modules and External Storage

Modules. The SunDiag System Exerciser verifies that the system is functioning

properly. For information about how to use the SunDiag System Exerciser, see the

SunDiag User’s Guide.

If SunDiag passes, the system is operating properly. If SunDiag fails, the error

messages should indicate the part of the system that has failed. If the error messages

are not descriptive enough, you may need to run POST or the SunDiagnostic

Executive.

2.8 SunDiagnostic Executive

The SunDiagnostic Executive is an independent operating system. It runs exhaustive

subsystem tests that are independent of the normal operating system. Run the

SunDiagnostic Executive if all POSTs pass, but your system still has a problem. For

information about POST, see Section 3.1, “Power-On Self-Test (POST).” The

SunDiagnostic Executive is described in the SunDiagnostic Executive User’s Guide for

the SPARCstations.

Chapter 2 Troubleshooting Overview 2-11

Page 36

2-12 SPARCstation 5 Service Manual • August 1994

Page 37

CHAPTER

3

Power-On Self-Test (POST)

This chapter describes the Power-On Self-Test (POST) for Normal, Full, and

Abbreviated modes, available with your SPARCstation 5 system.

The Power-On Self-Test (POST) diagnostics reside in the OpenBoot PROM located

on the system board. There are two POST modes: Normal and Diagnostic.

3.1 Power-On Self-Test (POST)

The Power-On Self-Test (POST) runs when you turn on the system unit power

switch and any of the following conditions apply:

■ diag-switch? NVRAM parameter is set to true.

■ Stop-d keys are held down when you turn on the power.

■ Keyboard is disconnected, and diag-switch? is set to false.

The POST comprises a sequence of tests designed to evaluate the major hardware

components of the main logic board in the short time before the OpenBoot PROM

firmware takes control. The POST does not perform extensive testing on any

component of the main logic board. Only major failures can be detected by the

POST.

Four different LEDs on the keyboards are used to indicate the progress and results of

the POST. These LEDs are on the Caps Lock, Compose, Scroll Lock, and Num Lock

keys, as shown in FIGURE 3-1, FIGURE 3-2, and FIGURE 3-3. To indicate the

beginning of the POSTs, the four LEDs briefly light all at once. The monitor screen

remains blank, and the Caps Lock LED blinks for the duration of the POST.

3-1

Page 38

Scroll Lock LED Num Lock LED

Caps Lock LED

(UNIX Keyboard)

FIGURE 3-1 Arrangement of Sun Type-5 Keyboard Diagnostic LEDs

Caps Lock LED

U.S Keyboard

Caps Lock

LED

FIGURE 3-2 Sun Type-4 Keyboard

Compose

LED

Compose

LED

Scroll Lock

LED

Num Lock

LED

3-2 SPARCstation 5 Service Manual • August 1994

Page 39

Scroll Lock LED

Caps Lock LED

(UNIX Keyboard)

FIGURE 3-3 Sun Compact 1 Keyboard

Caps Lock LED

U.S Keyboard

Compose

LED

Num Lock

LED

If the system fails any POST, one of the LEDs will light to indicate the nature of the

problem. The LED may be lit continuously, or for just a few seconds. TABLE 3-1

provides the meaning of each diagnostic LED.

TABLE3-1 Interpreting the Keyboard Diagnostic LEDs

Diagnostic LED Failed Part

Num Lock LED is lit. Main logic board

Scroll Lock LED is lit. NVRAM

Compose LED is lit DSIMMs (see Section 4.4, “Determining Faulty

DSIMM Locations”)

Note – The Caps Lock LED is not used as a failure indicator; it blinks on and off to

indicate that the POSTs are running. The keyboard LED diagnostics feature

described here applies only to a SPARCstation 5 system with a Sun Type-4, Type-5,

or Compact 1 keyboard connected to its keyboard port. The LED diagnostics do not

apply if a different Sun-supported keyboard is connected to the keyboard port, or if

a terminal and its keyboard are used as a main console instead of a monitor and a

Type-4, Type-5, or Compact 1 keyboard.

Chapter 3 Power-On Self-Test (POST) 3-3

Page 40

If the system passes all the POSTs, all four LEDs light again and then go off. Next,

the OBP firmware performs its initialization sequence and the system banner

appears on the screen. A generic SPARCstation banner is shown as an example.

From this point on, the keyboard LEDs assume their normal functions (that is, you

should no longer interpret the LEDs as diagnostic error indicators).

SPARCstation XXX, Keyboard Present

ROM Rev. X.XY, XX MB memory installed, Serial #XXX

Ethernet address X:X:YY:Z:A:BB, Host ID: XXXXXXXX.

FIGURE 3-4 SPARCstation System Banner

Following the system’s successful initialization, the operating system is booted

automatically—unless the NVRAM configuration options specify otherwise.

You can retrieve more detailed POST failure information by connecting a terminal to

the ttya serial port. If you connect a terminal, you must set the NVRAM parameter

diag-switch? to true. For more information about the NVRAM parameters, see

TABLE 2-1. Test failure messages are displayed on the system monitor or console,

whether or not the system is in Diagnostic Mode. However, it may be easier to

understand the failure message output when it is accompanied by more detailed

POST progress messages available via the ttya serial port.

3.2 Normal Mode

Under Normal Mode, when the system is turned on, control is sent to the OpenBoot

PROM. Depending on the options set in the OpenBoot PROM, for example if auto-

boot? is enabled (set to true), the operating system will load. Diagnostic testing is

not run.

3.3 Full Diagnostic Mode

Full Diagnostic Mode tests the major hardware system board components and, if the

POST is successful, control is transferred to the OBP firmware that probes the

installed SBus modules. Full Diagnostic Mode runs if one of these conditions is met:

■ You press and hold the Stop-d keys while you turn on the power.

3-4 SPARCstation 5 Service Manual • August 1994

Page 41

■ You set the diag-switch? NVRAM parameter to true in the OpenBoot PROM.

■ You disconnect the keyboard and you set the diag-switch? NVRAM parameter

to true in the OpenBoot PROM.

Note – POST does not perform extensive testing on any system board component.

POST detects only major failures.

To view error messages returned by POST, connect a terminal to serial port A or use

a tip connection to another workstation.

If you do not connect a terminal to serial port A or use a tip connection, the screen

will be blank during the POST diagnostics. In this case, use the keyboard LEDs to

display error conditions. See Section 3.7, “Status Lights (LEDs) and Indicators.”

3.4 Abbreviated Diagnostic Mode

A silent Power-On Self-Test (POST) is run if you disconnect the keyboard and you

set the diag-switch? NVRAM parameter to false in the OpenBoot PROM. This

Power-On Self-Test is silent (no progressive test messages are printed out). If an

error or errors occur during the abbreviated Power-On Self-Test, all error messages

are displayed on the TTY or tip window.

3.4.1 Setting Up a tip Connection to Another System

You can use the serial port on your SPARCstation 5 system to connect to another Sun

workstation (either the same type of SPARC“ system or a different type of Sun

workstation or server system). This connection lets you use a shell window on the

Sun workstation as a terminal to the SPARCstation 5 being tested.

The tip method is recommended, because it lets you use SunOS™ windowing and

operating system features to help you work with the boot PROM.

To make a tip connection, follow these steps:

1. Connect the system’s serial port ( ttya) to another Sun workstation ttya serial

port using a serial connection cable. This connection is made with a 3-wire null

modem cable. Connect wires 3-2, 2-3, and 7-7.

Chapter 3 Power-On Self-Test (POST) 3-5

Page 42

2. At the other Sun workstation, add the following lines to the file /etc/remote:

hardware:\

:dv=/dev/ttya:br#9600:el=^C^S^Q^U^D:ie=%$:oe=^D:

3. In a Shell Tool window on the Sun workstation, type tip hardwire. (Some

commands will not work properly in a Command Tool window.)

The system will reply connected.

hostname% tip hardwire

connected

The Shell Tool window is now a tip window directed to the Sun workstation serial

port.

4. When you are finished running POST and want to disconnect the tip window,

either type ~. (tilde period) in the tip window, or type kill -9 and the process

ID number of the tip hardwire process.

hostname% ~.

or

hostname% kill -9 PID# of tip hardwire process

3.5 Tests the POST Runs

Following is a sample listing of the Full Diagnostic Mode tests completed by POST.

CODE EXAMPLE 3-1 POST Tests

MMU Context Table Reg Test

MMU Context Register Test

MMU TLB Replace Ctrl Reg Tst

MMU Sync Fault Stat Reg Test

MMU Sync Fault Addr Reg Test

MMU TLB RAM NTA Pattern Test

MMU TLB CAM NTA Pattern Test

MMU TLB LCAM NTA Pattern Test

IOMMU SBUS Config Regs Test

IOMMU Control Reg Test

IOMMU Base Address Reg Test

3-6 SPARCstation 5 Service Manual • August 1994

Page 43

CODE EXAMPLE 3-1 POST Tests

IOMMU TLB Flush Entry Test

IOMMU TLB Flush All Test

SBus Read Time-out Test

EBus Read Time-out Test

D-Cache RAM NTA Test

D-Cache TAG NTA Test

I-Cache RAM NTA Test

I-Cache TAG NTA Test

Memory Address Pattern Test

FPU Register File Test

FPU Misaligned Reg Pair Test

FPU Single-precision Tests

FPU Double-precision Tests

FPU SP Invalid CEXC Test

FPU SP Overflow CEXC Test

FPU SP Divide-by-0 CEXC Test

FPU SP Inexact CEXC Test

FPU SP Trap Priority > Test

FPU SP Trap Priority < Test

FPU DP Invalid CEXC Test

FPU DP Overflow CEXC Test

FPU DP Divide-by-0 CEXC Test

FPU DP Inexact CEXC Test

FPU DP Trap Priority > Test

FPU DP Trap Priority < Test

PROC0 Interrupt Regs Tests

Soft Interrupts OFF Test

Soft Interrupts ON Test

PROC0 User Timer Test

PROC0 Counter/Timer Test

DMA2 E_CSR Register Test

LANCE Address Port Tests

LANCE Data Port Tests

DMA2 D_CSR Register Test

DMA2 D_ADDR Register Test

DMA2 D_BCNT Register Test

DMA2 D_NADDR Register Test

ESP Registers Tests

DMA2 P_CSR Register Test

DMA2 P_ADDR Register Test

DMA2 P_BCNT Register Test

PPORT Registers Tests

NVRAM Access Test

TOD Registers Test

Chapter 3 Power-On Self-Test (POST) 3-7

Page 44

3.6 POST Error Messages

The POST error messages returned to the terminal are self-explanatory. For example,

if no DSIMM is installed in the system, the POST will tell you that no DSIMM is

installed and will indicate the slot number of the DSIMM slot. Use the error

messages returned by POST to troubleshoot the system.

3.7 Status Lights (LEDs) and Indicators

The LED at the front of the chassis lights when the system is operating normally.

FIGURE 3-5 shows the location of the system LED. Chapter 4, “ shows flow

diagrams of actions to take when the system LED is not lit.

System Front

FIGURE 3-5 Location of System Power LED

Section 3.1, “Power-On Self-Test (POST), describes the keyboard LED sequences

displayed at power up when POST fails. If a failure occurs in POST, the keyboard

displays a specific LED pattern. See FIGURE 3-1 through FIGURE 3-3 and

TABLE 3-1. During normal system operation, the LEDs should not be interpreted as

diagnostic error indicators.

3-8 SPARCstation 5 Service Manual • August 1994

System Power LED

Page 45

Following the system initialization, the operating system boots automatically, unless

the NVRAM configuration options specify not to do so.

Note – The Caps Lock key LED on some U.S. keyboards, located just above the left-

hand Shift key, is not used as a POST failure indicator, but blinks on and off while

POST is running.

If the Caps Lock key fails to flash on and off after you have pressed and held the

Stop-d keys when you power on the system, POST failed. See Section 4.2.2, “System

Board Test,” for troubleshooting information.

Chapter 3 Power-On Self-Test (POST) 3-9

Page 46

3-10 SPARCstation 5 Service Manual • August 1994

Page 47

CHAPTER

4

Troubleshooting Procedures

This chapter describes how to troubleshoot SPARCstation 5 system problems. Each

problem is described, and a set of procedures is provided as a solution to the

problem.

TABLE 4-1 describes commonly encountered problems, and tips for solving them.

TABLE4-1 Troubleshooting Tips

Problem Action

LED on front of system is not lit. Verify that the power switch is turned on and that the power cord is

connected. If both the power switch and the power cord are connected,

shut down the system and verify that the LED cable is connected. If the

LED cable is connected, the power supply may be defective. Replace the

power supply. See Chapter 8.

Disk drive fails to boot or does not

respond.

Operating system does not

recognize disk drive at boot up.

No video output on monitor. Verify that the power cord is connected. Use a volt-ohmmeter (VOM) to

Slow disk drive response. If many SCSI devices are connected to the same SCSI bus and if some of

Shut down the system. The SCSI controller may be defective. See

Section 4.3.1, “Verifying the Built-In SCSI Controller.” Verify that each

SCSI device is assigned a unique SCSI target address. See Appendix C for

important additional information.

Shut down the system. Verify that each SCSI device is assigned a unique

SCSI target address. See Appendix C for important additional

information.

check voltages. See Section 4.1, “No Video Output on the System

Monitor.”

these devices are “fast SCSI” devices, you can install an FSBE/S SBus

card to the “fast SCSI” devices to speed up performance.

4-1

Page 48

TABLE4-1 Troubleshooting Tips

Problem Action

Read, write, or parity error

reported by the operating system

or applications.

Power on does not succeed. LEDs

on keyboard do not light and

there is no tone from the keyboard

when you turn on the system

power.

Power on does not succeed. The

system fails to initialize but the

LEDs on the keyboard light and

there is a tone from the keyboard.

Replace the disk drive indicated by the failure message. Solaris 1.x

operating systems identify the disk drive installed in the lower bay (SCSI

target ID 3) as sd0 and the disk drive installed in the upper bay (SCSI

target ID 1) as sd1. With Solaris 2.x operating systems, the two drives are

identified as c0t3d0 and c0t1d0, respectively.

The power supply may be defective. See Section 4.2.1, “Power Supply

Test.”

The system board may be defective. See Section 4.2.2, “System Board

Test.”

4.1 No Video Output on the System Monitor

1. Check that the power cord is connected to the monitor and to the wall outlet.

2. Verify that the wall outlet is supplying AC power to the monitor.

Use a volt-ohmmeter (VOM).

3. Verify that the video cable connection is secure between the monitor and the

system video output port.

Use a VOM to perform the continuity test on the video cable.

If the power cord and video cable connection are good and there is still no video

output, reseat the video card for the monitor.

4. If the monitor power supply is internally fused, check the fuse.

The fuse could be blown.

4.2 Power-On Does Not Succeed

1. Turn off the system power switch.

4-2 SPARCstation 5 Service Manual • August 1994

Page 49

2. Check that the system power cord is properly connected to the system rear panel

power receptacle and to the wall outlet.

3. Verify with a VOM that the wall outlet is supplying AC power to the system.

4. Turn the rear panel system power switch on and observe the keyboard.

The LEDs on the keyboard should briefly light. You should hear a tone from the

keyboard. If you have a Sun Type-5 keyboard, there is a Standby power key which

you may also press to see if the system can be powered on or not. Only try the

Standby power key if the rear switch fails to turn on the system.

If you hear no tone or see no lights on the keyboard, the system’s power supply may

be defective. See Section 4.2.1, “Power Supply Test.”

If you hear a tone and see lights on the keyboard, but the system still fails to

initialize, see Section 4.2.2, “System Board Test.“

4.2.1 Power Supply Test

1. Use a VOM (volt-ohmmeter) to check the power supply output voltages.

Place the VOM negative probe on one of the logic ground pins in the connector, and

test the +12V, -12V, and +5V power pins individually with the positive probe (pins 1

through 8). See FIGURE 4-1 and TABLE 4-2.

Note – The power supply must remain connected to the system board during this

test. This allows the power supply to regulate the voltages.

2. Replace the power supply assembly if any of the voltages are not present.

See Section 8.1, “Power Supply.”

Chapter 4 Troubleshooting Procedures 4-3

Page 50

19

2

3456 87

10 18

11 1314 1612 15 17

FIGURE 4-1 Power Supply Connector

TABLE 4-2 shows the pin assignments on the power supply connector.

TABLE4-2 Power Supply Connector Pin Assignments

Pin Color Description

1 Blue +12V 10 Black Ground

2 Brown -12V 11 Black Ground

3 Red +5V 12 Black Ground

4 Red +5V 13 Black Ground

5 Red +5V 14 Black Ground

6 Red +5V 15 Black Ground

7 Red +5V 16 Green AC Outlet

8 Red +5V 17 Purple Fan

9 Grey Power off 18 Yellow Power on

1. All volts are direct current.

1

Pin Color Description

4-4 SPARCstation 5 Service Manual • August 1994

Page 51

4.2.2 System Board Test

1. Connect a terminal to serial port A or use a tip connection to another workstation

to receive additional POST failure information.

To set up a tip connection to another workstation, see Section 3.4.1, “Setting Up a

tip Connection to Another System.”

2. Press and hold the Stop-d keys. While holding the keys down, turn the system

power switch on. Watch the keyboard LEDs.

a. The Caps Lock key on the keyboard should flash on and off, indicating that the

system is running the Power-On Self-Test (POST).

If the Caps Lock key fails to flash on and off after you have pressed and held the

Stop-d keys, POST failed.

b. To further troubleshoot the system board, see Section 4.2.2.1, “Caps Lock Key

Fails to Flash On and Off During POST.”

3. Observe the keyboard LEDs.

If a failure occurs during POST, an LED may light up. See TABLE 3-1 on page 3 to

interpret the keyboard diagnostic LEDs.

4. Replace the defective part indicated.

4.2.2.1 Caps Lock Key Fails to Flash On and Off During POST

1. Remove optional SBus cards and DSIMMs.

Leave one DSIMM in Slot 0 (J0300).

2. Run POST again before replacing the system board.

Remove all other parts to eliminate the possibility that those parts could be causing

the POST failure.

Chapter 4 Troubleshooting Procedures 4-5

Page 52

4.3 Disk Drive Errors

TABLE 4-3 presents disk drive error conditions and corrective actions.

TABLE4-3 Troubleshooting Disk Drive Errors

Symptom Corrective Action

Read, write, or parity error

reported by the operating system

or applications.

Drive fails to boot or does not

respond to commands.

Slow disk drive response. If many SCSI devices are connected to the same SCSI

Replace the disk drive indicated by the failure

message. Solaris 1.x operating systems identify the

disk drive installed in the lower bay (SCSI target ID 3)

as sd0 and the disk drive installed in the upper bay

(SCSI target ID 1) as sd1. With Solaris 2.x operating

systems, the two drives are identified as c0t3d0 and

c0t1d0, respectively.

SCSI controller may be defective. See Section 4.3.1,

“Verifying the Built-In SCSI Controller.” Verify that

each SCSI device is assigned a unique SCSI target

address. See Appendix C for important additional

information.

bus and if some of these devices, such as the 1.05Gbyte disk drive, are “fast SCSI” devices, you may

want to install an FSBE/S SCSI host adapter card to

the “fast SCSI” devices and put these “fast SCSI”

devices on a separate SCSI bus to speed up disk drive

response.

4.3.1 Verifying the Built-In SCSI Controller

To check whether the built-in SCSI controller is defective, test the drive response to

the probe-scsi command. To test additional SCSI host adapters added to the

system, use the probe-scsi-all command. Refer to Section D.1.6, “module-info.”

4-6 SPARCstation 5 Service Manual • August 1994

Page 53

● At the ok prompt, type probe-scsi

See the following example.

ok probe-scsi

Target 1

Unit 0 Disk CONNER CP30548 SUN0535AEBX93081QTT

Target 3

Unit 0 Disk SEAGATE ST3610N SUN0535881200054301

a. If the disk drive responds and a message is displayed, the system SCSI

controller has successfully probed the devices.

This indicates that the system board is working correctly.

b. If a disk doesn’t respond:

c. Make sure that every SCSI disk and other SCSI device on the SCSI bus has a

different SCSI target ID (see Appendix C).

Note – Internal SCSI hard drives are automatically assigned target 3 (lower bay)

and target 1 (upper bay).

d. Verify that all SCSI cables and the SCSI terminator are connected securely.

e. Check the SCSI cables to make sure there are no bent pins.

f. If you still have not found the problem, replace the unresponsive drive.

g. If the problem still occurs after replacing the drive, replace the system board.

h. If the problem persists, replace the internal disk drive cable assembly.

4.4 Determining Faulty DSIMM Locations

The SunDiag System Exerciser, SunDiagnostic Executive, and POST diagnostics can

report memory errors encountered during program execution. For general

information about diagnostics, see Chapter 2, “Troubleshooting Overview.” Memory

error messages on the video monitor usually indicate a physical memory address

where the error was detected.

Depending on the diagnostic program you are running, a DSIMM location number

(“J” number) or a memory address may be displayed.

Chapter 4 Troubleshooting Procedures 4-7

Page 54

If the error message displays the location number, see FIGURE 4-2 for DSIMM

location numbers. If the error message displays a physical memory address, consult

TABLE 4-4 to see which memory slot contains the physical address.

For example, if an error is detected at physical memory address 12fe958, examining

TABLE 4-4 shows that the error occurred in the DSIMM in slot 0.

After you have identified the defective DSIMM, follow the instructions in

Section 11.3.1, “Removing a DSIMM, for removing the defective DSIMM. To replace

the DSIMM, follow the directions in Section 11.3.2, “Replacing a DSIMM.

SIMM slot J0403 Slot 7

SIMM slot J0402

SIMM slot J0401

SIMM slot J0400

SIMM slot J0303

SIMM slot J0302

SIMM slot J0301

Slot 6

Slot 5

Slot 4

Slot 3

Slot 2

Slot 1

SIMM slot J0300 Slot 0

FIGURE 4-2 DSIMM Slot Locations

TABLE4-4 Physical Memory Address Ranges for Slots

Slot SIMM # Physical Memory Address Rang es

0 J0300 0000 0000 through 01FF FFFF

1 J0301 0200 0000 through 03FF FFFF

2 J0302 0400 0000 through 05FF FFFF

3 J0303 0600 0000 through 07FF FFFF

4 J0400 0800 0000 through 09FF FFFF

5 J0401 0A00 0000 through 0BFF FFFF

6 J0402 0C00 0000 through 0DFF FFFF

7 J0403 0E00 0000 through 0FFF FFFF

1. Each memory slot can contain one DSIMM up to 32 megabytes in size. Slot 0 must have a DSIMM present.

4-8 SPARCstation 5 Service Manual • August 1994

1

0 Through 7

Page 55

CHAPTER

5

Safety and Tools Requirements

This chapter describes standards, safety procedures, and precautions you should

follow whenever you need to replace or remove assemblies or subassemblies from

your system.

5.1 Safety Requirements

For your protection, observe the following safety requirements:

■ Follow all cautions, warnings, and instructions marked on the equipment.

■ Ensure that the voltage and frequency rating of the power outlet matches the

electrical rating labels on the system.

■ Use properly grounded power outlets.

5-1

Page 56

To protect both yourself and the equipment, observe the safety precautions listed in

TABLE 5-1.

TABLE5-1 Safety Precautions

Item Problem Precaution

AC power cord Electric shock Unplug the AC cord from the AC wall socket

before working on the power supply.

Grounding Leave the AC power cord plugged into the AC

wall outlet when replacing drives, DSIMMs,

chips, or the system board. Leaving the AC

power cord plugged into the wall outlet

provides a grounding path for the wrist strap,

which must be attached.

Wrist strap Electrostatic

Discharge (ESD)

ESD mat ESD An approved antistatic mat provides protection

Printed circuit

boards

Cover System damage

SBus slot filler

panels

microSPARC chip

heat sink

ESD Handle a printed circuit board by the edges

and overheating

System damage

and overheating

Heat, burns Do not touch the metal heat sink on the

Wear a wrist strap when handling printed

circuit boards, drives, or other components

such as DSIMMs.

from static damage when used with a wrist

strap. The mat also cushions and protects small

parts that are attached to printed circuit boards.

Chapter 12, “,” lists the part number of the mat.

only. Store a board in an antistatic bag.

Replace the cover after performing service on

the system.

Install filler panels in all unused SBus

openings. Openings on the back of the system

board reduce the cooling capability of the

system.

microSPARC chip. The heat sink can be hot

enough to cause personal injury.

5.2 Symbols

The following symbols mean:

5-2 SPARCstation 5 Service Manual • August 1994

Page 57

Caution – This equipment contains lethal voltages. Accidental contact can result in

serious injury or death.

Caution – Physical danger due to a non-electrical hazard or danger of irreversible

damage to data or to the operating system.

Caution – Improper handling by unqualified personnel can cause serious damage

to this equipment. Unqualified personnel who tamper with this equipment may be

held liable for any resulting damage to the equipment.

Caution – Hot surface. Avoid contact. Surfaces are hot and may cause personal

injury if touched.

ACA terminal (power outlet) to which alternating current or voltage may be

applied.

ONThe power switch is in the ON position.

STANDBYThe power switch is in the STANDBY position.

5.3 System Precautions

Individuals who service this equipment must observe all safety precautions and

ensure compliance with skill level requirements, certification, and all applicable local

and national laws.

Procedures contained in this document must be performed by trained maintenance

providers. Only people who have been trained at the Sun Microsystems® training

facilities (or at Sun Microsystems affiliates) and have been certified as required by

local and national laws are considered qualified.

Chapter 5 Safety and Tools Requirements 5-3

Page 58

Caution – Before you begin, carefully read each of the procedures in this manual. If

you have not performed similar operations on comparable equipment, do not attempt

to perform these procedures.

5.4 Tools Required

To remove and replace customer replaceable units (CRUs), you will need the

following tools and materials:

■ Small Phillips-head screwdriver

■ Small flat-blade screwdriver

■ Wrist strap

■ Antistatic surface

■ Volt-ohmmeter (VOM) for checking voltages and continuity

■ Needlenose pliers

■ Conductive foam to store chips

■ Container for screws

5.5 Electrostatic Discharge (ESD) Precautions

Caution – The system chassis power must be turned off, and the AC power cord

must remain plugged in to ensure a proper ground.

To minimize electrostatic discharge, observe the following precautions:

■ Hold the system board, SBus cards, DSIMMs, or system components only by the

edges.

■ When removing a board, card, or module from an antistatic bag, lay it on an

antistatic surface such as a Sun ESD mat, an antistatic bag, or a disposable

antistatic mat.

■ Do not place the boards, cards, or modules on an unprotected surface. Use a

cushioned antistatic mat or antistatic bag. Connectors and components have very

thin pins that bend easily.

■ Do not use an oscilloscope or VOM (volt-ohmmeter) probe on the components.

The soldered pins are easily damaged or shorted by the probe point.

5-4 SPARCstation 5 Service Manual • August 1994

Page 59

■ Transport boards, cards, or modules in an antistatic bag.

■ Always wear an antistatic wrist strap connected to a metal surface on the chassis

when working on system components and parts.

Chapter 5 Safety and Tools Requirements 5-5

Page 60

5-6 SPARCstation 5 Service Manual • August 1994

Page 61

CHAPTER

6

Power On and Off

This chapter explains steps to perform before removing a customer replaceable unit

(CRU).

6.1 Powering Off the System

Before you begin any removal or replacement procedure, you must halt the system

in an orderly manner. The procedure to use depends on whether your system is

working normally or not, as described in the next sections.

Caution – When the operating system or any other standalone program has already

booted, do not use the Stop-a keys to halt the system. Using the Stop-a keys to abort

program execution can damage data files.

6.1.1 When the System Is Working Normally

To halt your system when it is working normally:

1. Save all your work.

Consult your software documentation for instructions on ending a work session and

saving your files. If you do not save your work, you could lose it when you switch

off the power.

2. Return to the operating system environment.

If you are in a windowing environment, exit from it and wait for the system prompt

to appear. See the documentation supplied with your windowing system.

6-1

Page 62

3. Halt the operating system.

See the documentation supplied with your operating system for instructions on how

to halt it.

a. For Solaris® 2.x (SunOS 5.x) systems, type:

% su

Password: superuser password

# /usr/sbin/shutdown -y -g60 -i0

b. For Solaris 1.x (SunOS 4.x) systems, type:

% su

Password: superuser password

# /usr/etc/shutdown -h +1

The operating system warns other users of your system of the impending

shutdown, and then halts itself after a one-minute delay. If you wish to provide a

longer delay, see the man page for shutdown(1).

The system responds with system halt messages followed by an ok prompt. When

the ok prompt appears, you can safely turn off the power in the proper sequence.

4. When the ok prompt appears, turn off the power to the system components in this order:

1. External drive units (if you have any)

2. System unit

3. Monitor

6.1.2 When the System Does Not Respond Normally

To halt a system that is hung, or frozen, and unresponsive to commands:

1. If your system is on a network, wait a few minutes before proceeding.

Your system’s slow response may be due to network problems or delays. Check with

the person in charge of your network. If the response is not due to the network, go

to the next step.

2. Press Stop-a (or Break).

If you use a Wyse® WY-50™, VT-100™, or compatible terminal as the console with

your SPARCstation 5 system unit, press Break instead of Stop-a.

6-2 SPARCstation 5 Service Manual • August 1994

Page 63

Note – If the system does not respond to the mouse and keyboard, pressing Stop-a

will not be effective. You may have to turn the power off, wait at least 10 seconds,

and turn the power on again. Then try pressing Stop-a once more.

3. When the ok prompt appears, boot the operating system.

Enter boot at the ok prompt.

4. When you see the login prompt, log in to the system with your user name and password.

5. Halt the operating system.

See the documentation supplied with your operating system for instructions on how

to halt it.

a. For Solaris 2.x (SunOS 5.x) systems, type:

% su

Password: superuser password

# /usr/sbin/shutdown -y -g60 -i0

b. For Solaris 1.x (SunOS 4.x) systems, type:

% su

Password: superuser password

# /usr/etc/shutdown -h +1

The operating system warns other users of your system of the impending