Page 1

Netra™ft 1800

Installation Guide

Sun Microsystems, Inc.

901 San Antonio Road

Palo Alto, CA 94303-4900 USA

650 960-1300 Fax 650 969-9131

Part No.: 805-4533-10

Revision A, February 1999

Send comments about this document to: docfeedback@sun.com

Page 2

Copyright 1999 Sun Microsystems,Inc.,901SanAntonioRoad•PaloAlto,CA94303USA.Allrightsreserved.

This productor document is protected by copyright and distributed under licenses restrictingitsuse, copying, distribution, and

decompilation. No part of this product or document may be reproduced in any form by any meanswithout prior written authorization

of Sun and its licensors, if any.Third-partysoftware,includingfonttechnology, is copyrighted and licensed from Sun suppliers.

Parts of the productmaybederivedfromBerkeleyBSDsystems,licensedfromtheUniversityofCalifornia.UNIXisaregistered trademark in

the U.S. and other countries, exclusivelylicensedthroughX/OpenCompany, Ltd.

Sun, Sun Microsystems,theSunlogo,AnswerBook,Java,theJavaCoffeeCup,NetraandSolarisaretrademarks,registered trademarks, or

service marks of Sun Microsystems,Inc.intheU.S.andothercountries.AllSPARC trademarks are used under licenseandaretrademarksor

registeredtrademarksofSPARC International, Inc. in the U.S. and other countries. ProductsbearingSPARC trademarks are based upon an

architecturedevelopedbySunMicrosystems,Inc.RegisteredExcellence(andDesign)isa certification mark of Bellcore.

The OPEN LOOK and Sun™ Graphical User Interface was developed by Sun Microsystems, Inc. for its users and licensees. Sun acknowledges

the pioneering efforts of Xerox in researching and developing the concept of visual or graphical user interfaces for the computer industry.Sun

holds a non-exclusive license from Xerox to the Xerox Graphical User Interface, which license also covers Sun’s licensees who implement OPEN

LOOK GUIs and otherwise comply with Sun’s written license agreements.

RESTRICTEDRIGHTS: Use, duplication, or disclosureby the U.S. Government is subject to restrictions of FAR 52.227-14(g)(2)(6/87) and

FAR52.227-19(6/87), or DFAR252.227-7015(b)(6/95) and DFAR227.7202-3(a).

DOCUMENTATION IS PROVIDED “AS IS” AND ALL EXPRESS OR IMPLIED CONDITIONS, REPRESENTATIONS AND WARRANTIES,

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NONINFRINGEMENT, ARE DISCLAIMED, EXCEPT TO THE EXTENT THAT SUCH DISCLAIMERS ARE HELD TO BE LEGALLY INVALID.

Copyright 1999 Sun Microsystems, Inc., 901 San Antonio Road • Palo Alto, CA 94303 Etats-Unis. Tousdroits réservés.

Ce produit ou document est protégé par un copyrightet distribué avec des licences qui en restreignent l’utilisation, la copie, la distribution, et la

décompilation. Aucune partie de ce produit ou document ne peut être reproduite sous aucune forme, par quelque moyen que ce soit, sans

l’autorisation préalable et écrite de Sun et de ses bailleurs de licence, s’il y en a. Le logiciel détenu par des tiers, et qui comprend la technologie

relativeaux polices de caractères, est protégé par un copyright et licencié par des fournisseurs de Sun.

Des parties de ce produit pourront être dérivées des systèmes Berkeley BSD licenciés par l’Université de Californie. UNIX est une marque

déposée auxEtats-Unis et dans d’autres pays et licenciée exclusivement par X/Open Company, Ltd.

Sun, Sun Microsystems, le logo Sun, AnswerBook, Java, le logo Jave Coffee Cup, Netra et Solaris sont des marques de fabrique ou des marques

déposées, ou marques de service, de Sun Microsystems, Inc. aux Etats-Unis et dans d’autres pays. Toutesles marquesSPARCsont utilisées sous

licence et sont des marques de fabrique ou des marques déposées de SPARCInternational, Inc. aux Etats-Unis et dans d’autrespays. Les

produitsportant les marques SPARCsont basés sur une architecture développée par Sun Microsystems, Inc.

L’interfaced’utilisation graphique OPEN LOOK et Sun™ a été développée par Sun Microsystems, Inc. pour ses utilisateurs et licenciés. Sun

reconnaîtles efforts de pionniers de Xerox pour la rechercheet le développement du concept des interfaces d’utilisation visuelle ou graphique

pour l’industrie de l’informatique. Sun détient une licence non exclusive de Xerox sur l’interface d’utilisation graphique Xerox, cette licence

couvrant également les licenciés de Sun qui mettent en place l’interface d’utilisation graphique OPEN LOOK et qui en outre se conforment aux

licences écrites de Sun.

CETTE PUBLICATION EST FOURNIE "EN L’ETAT" ET AUCUNE GARANTIE, EXPRESSE OU IMPLICITE, N’EST ACCORDEE, Y

COMPRIS DES GARANTIES CONCERNANT LA VALEUR MARCHANDE, L’APTITUDE DE LA PUBLICATION A REPONDRE A UNE

UTILISATION PARTICULIERE, OU LE FAIT QU’ELLE NE SOIT PAS CONTREFAISANTE DE PRODUIT DE TIERS. CE DENI DE

GARANTIE NE S’APPLIQUERAIT PAS, DANS LA MESURE OU IL SERAIT TENU JURIDIQUEMENT NUL ET NON AVENU.

Please

Recycle

Page 3

Contents

1. Before Installation 1

Electrical Supply Considerations 1

Environmental Considerations 1

Dimensions 2

Airflow Consideration when Mounting in the Equipment Frame 2

Mechanical Considerations when Mounting in the Equipment Frame 6

Mounting Requirements 6

2. Hardware Installation 9

Unshipping and Mounting the System 9

Mounting Flanges 13

19-inch Mountings 13

23-inch, 24-inch and 600mm Mountings 18

Cable Bracket Assemblies 22

Removing and Installing Modules 23

Module Injector/Ejector Mechanisms 23

Replacing an RMM 30

Replacing a Disk Chassis 32

Flexible Module Cabling 35

iii

Page 4

Installing the Filter Trays 36

CAF External I/O Connections 38

System Console Terminal Connections 39

Modem Port Connections 40

Alarms Port Connections 41

3. Electrical Supply Installation 43

System Switch 43

DC Source Site Requirements 44

Overcurrent Protection Requirements 44

Required Connection Materials 48

DC Supply and Ground Conductor 48

Dual Grounding Environment 49

Connecting the Power Leads 51

4. Powering on the System 55

5. Software and Operating Environment Installation 57

Netra ft 1800 Install Media 57

Disk Space Requirement 57

Installation Methods 58

Local Installation 58

Network Installation 59

Before You Start 60

Finishing Installation 63

Setting up Access to

Netra ft 1800 CMS Utilities 63

Setting the MANPATH Variable 63

iv Netra ft 1800 Installation Guide • February 1999

Page 5

6. Installing and Configuring Sun StorEdge Volume Manager 65

Before You Install Sun StorEdge Volume Manager 65

Installing the Volume Manager Software 67

Mounting the CD-ROM Manually 67

Running the Installation 67

Setting up the Volume Manager Environment 68

Initializing the Volume Manager 69

Setting up Boot Disks 70

Setting up Other Disks 71

Configuring Storage 71

Boot Disk Aliases 72

Index 73

Contents v

Page 6

vi Netra ft 1800 Installation Guide • February 1999

Page 7

Figures

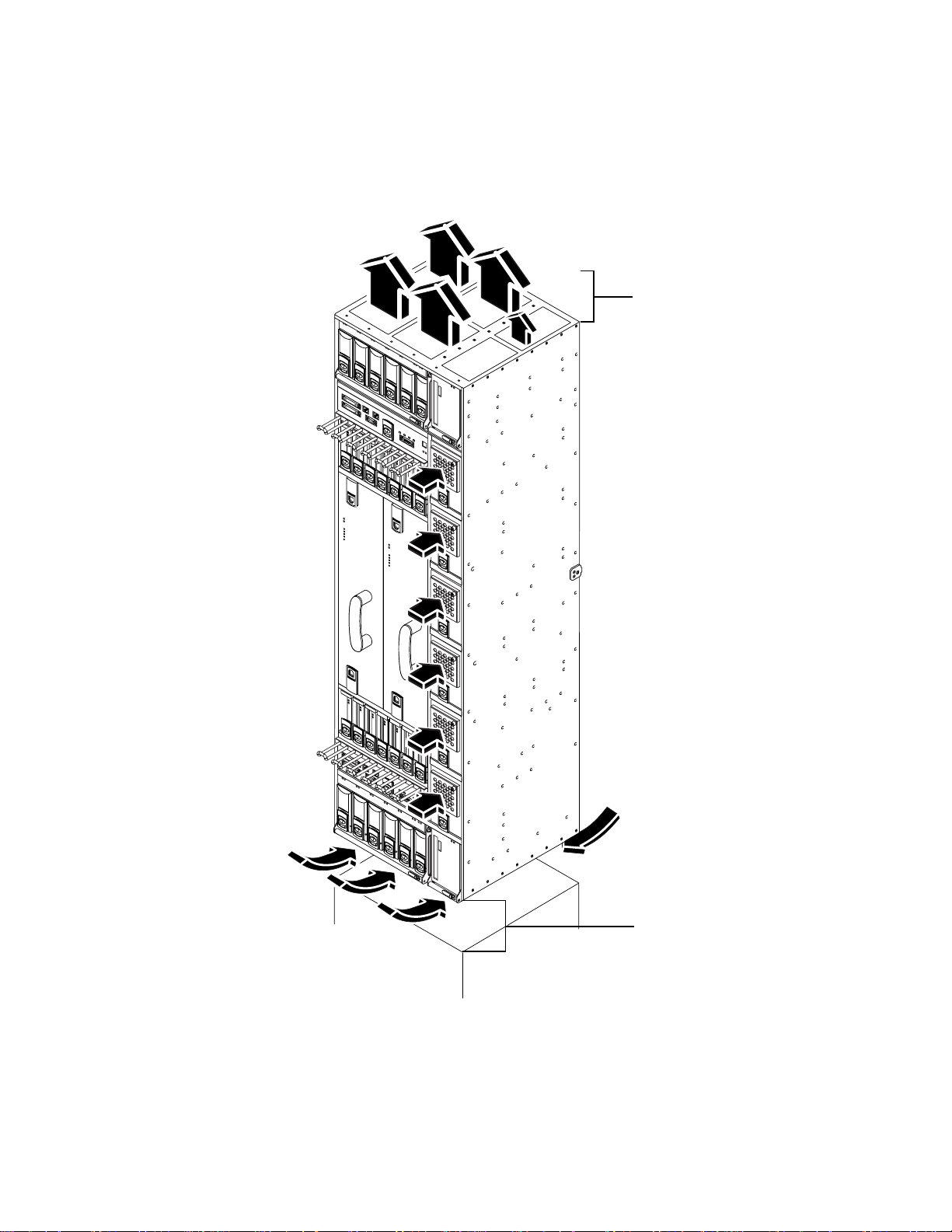

FIGURE 1-1 Netra ft 1800 Airflow Requirements (External) 4

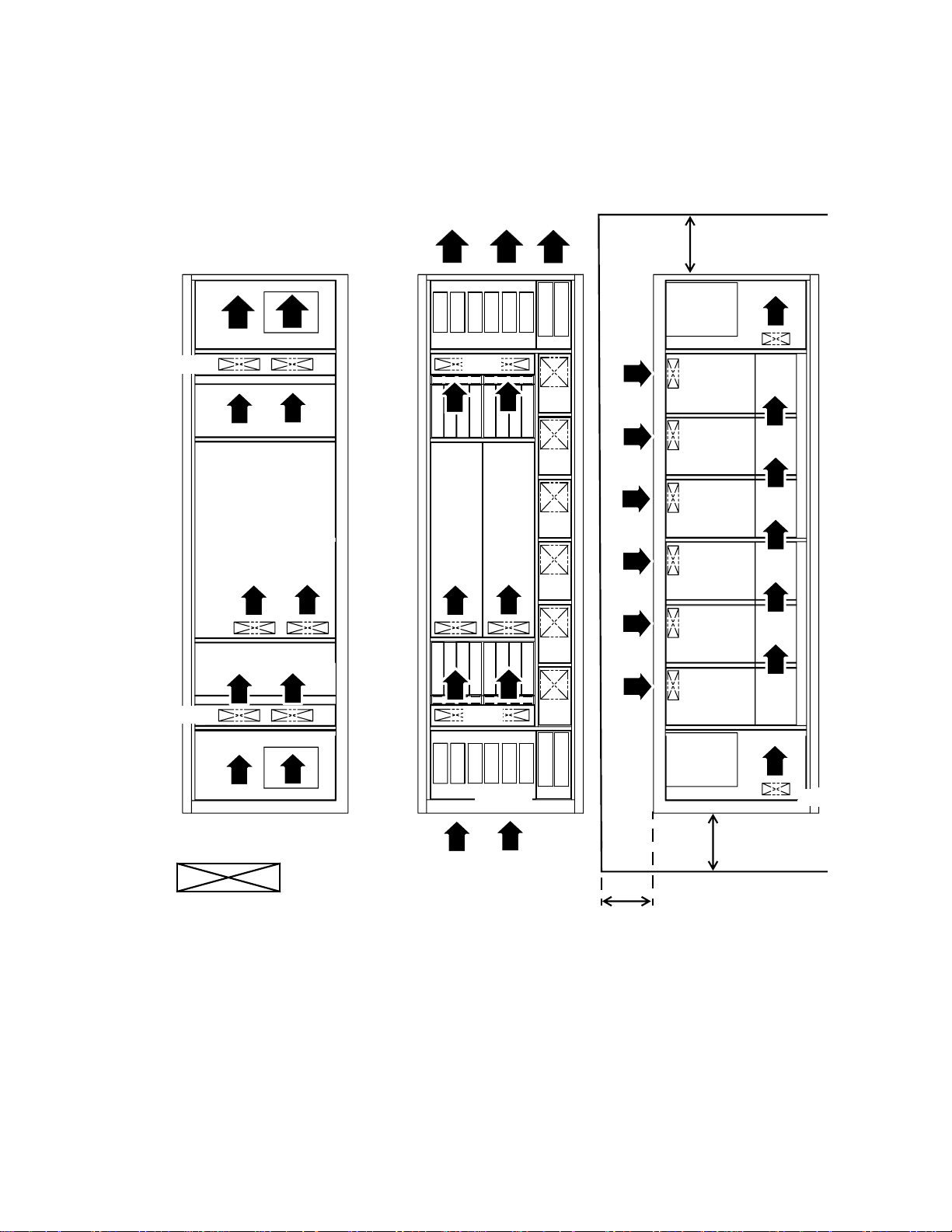

FIGURE 1-2 Netra ft 1800 Airflow Requirements (Internal) 5

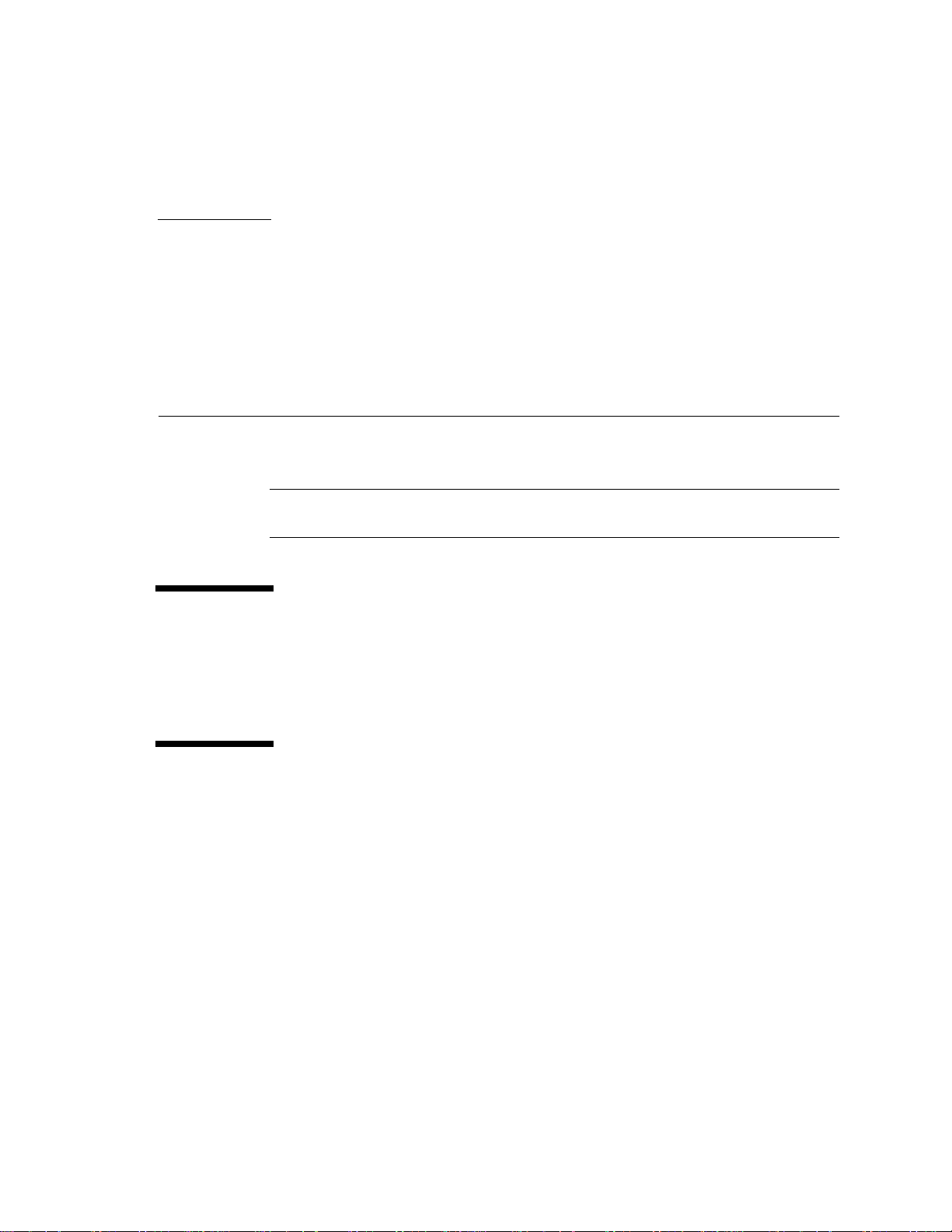

FIGURE 2-1 Shipping Brackets and Sacrificial Plinth 11

FIGURE 2-2 Location Matrix For Mounting Flange Screws (19-inch rack) 14

FIGURE 2-3 Support Rail and Fixings (19-inch Rack) 15

FIGURE 2-4 Orientation of Support Rail Spacers 16

FIGURE 2-5 Rear Rack Mounting (19-inch Rack) 16

FIGURE 2-6 19-inch Rack Mounting Flange Kit 17

FIGURE 2-7 23-inch Rack Mounting Flange Kit 19

FIGURE 2-8 24-inch Rack Mounting Flange Kit 20

FIGURE 2-9 600-mm Rack Mounting Flange Kit 21

FIGURE 2-10 Cable Bracket Assembly 22

FIGURE 2-11 Module Injector/ejector Lever 24

FIGURE 2-12 Removing a CPUset Module 26

FIGURE 2-13 Removing a CAF 27

FIGURE 2-14 Removing a PCI Card Carrier 28

FIGURE 2-15 Removing a Power Supply 29

FIGURE 2-16 Removing an RMM Module 31

FIGURE 2-17 Removing a Disk Drive 33

vii

Page 8

FIGURE 2-18 Removing a DSK Module 34

FIGURE 2-19 Cable Management Shelf 35

FIGURE 2-20 Large Filter Tray 36

FIGURE 2-21 Small Filter Tray 37

FIGURE 2-22 External I/O Connections on CAF Module 38

FIGURE 3-1 Circuit Breakers for Single Power Rails 46

FIGURE 3-2 Circuit Breakers for Dual Power Rails 47

FIGURE 3-3 Location of Chassis-to-Logic-0V Link and Grounding Points, and Wrist Strap Connection

Point 50

FIGURE 3-4 Power Inlet Filter 51

FIGURE 3-5 Power Connector Wiring Polarity and Securing Screws 52

FIGURE 3-6 Power Lead Receptacles 53

FIGURE 3-7 Power Lead Securing Screws 53

FIGURE 3-8 Power Cable Arrangement for Strain Relief 54

FIGURE 4-1 System Switches (Front Panel) 56

viii Netra ft 1800 Installation Guide • Februar y 1999

Page 9

Tables

TABLE 1-1 Mounting Hole Pattern Dimensions 7

TABLE 2-1 19-inch Mounting Flange Kit 13

TABLE 2-2 Support Rail Screw Hole Locations 15

TABLE 2-3 23-inch, 24-inch and 600mm Mounting Flange Kits 18

TABLE 2-4 Console Connector Pinout 39

TABLE 2-5 Console and Modem Port Parameters 39

TABLE 2-6 Modem Port Pinout 40

TABLE 2-7 Alarms Port Pinout 41

TABLE 3-1 Overcurrent Protection Requirements 44

TABLE 5-1 Suggested Disk Layout 62

ix

Page 10

x Netra ft 1800 Installation Guide • Februar y 1999

Page 11

Preface

This document describes the installation procedures for the core hardware and

software used in the Netra

manual, the Netra ft 1800 is fully functional as a fault-tolerant Solaris™ server.

Who Should Use This Book

This guide is intended to be read by installation engineers, software support

personnel and service personnel. It is not intended for the end user of the system.

How This Book Is Organized

This guide is arranged as follows:

™ ft 1800. Upon completion of the procedures in this

Chapter 1 “Before Installation” gives guidelines on site preparation and

environmental considerations.

Chapter 2 “Hardware Installation” describes how to unpack the system, fit the

mounting flanges and install the chassis in a rack.

Chapter 3 “Electrical Supply Installation” provides the information required to

install the electrical supply.

Chapter 4 “Powering on the System” tells you how apply power to the Netra ft 1800.

Chapter 5 “Software and Operating Environment Installation” explains the software

installation procedure.

xi

Page 12

Chapter 6 “Installing and Configuring Sun StorEdge Volume Manager” summarizes

what you need to know in order to use the Volume Manager on the Netra ft 1800.

Related Books

■ Netra ft 1800 Software Release Notes (Part No. 805-4527-10)

■ Netra ft 1800 Hardware Release Notes (Part No. 806-0179-10)

■ Netra ft 1800 CMS API Developer ’s Guide (Part No. 805-5870-10)

■ Netra ft 1800 CMS Developer’s Guide (Part No. 805-7899-10)

■ Netra ft 1800 Developer’s Guide (Part No. 805-4530-10)

■ Netra ft 1800 Hardware Reference Guide (Part No. 805-4531-10)

■ Netra ft 1800 User’s Guide (Part No. 805-4529-10)

■ Netra ft 1800 Reference Manual (Part No. 805-4532-10)

■ Netra ft 1800 Safety and Compliance Manual (Part No. 805-7019-10)

■ Sun StorEdge™ Volume Manager 2.5.4 Installation Guide (Part No. 805-5706-10).

What Typographic Changes Mean

The following table describes the typographic changes used in this book.

TABLEP-1 Typographic conventions

Typeface or

Symbol Meaning Example

AaBbCc123 The names of commands, files,

and directories; on-screen

computer output

AaBbCc123

AaBbCc123 Command-line placeholder:

AaBbCc123 Book titles, new words or terms,

xii Netra ft 1800 Installation Guide • February 1999

What you type, contrasted with

on-screen computer output

replace with a real name or

value

or words to be emphasized

Edit your .login file.

Use ls -a to list all files.

machine_name% You have mail.

machine_name% su

Password:

To delete a file, type rm filename.

Read Chapter 6 in User ’s Guide. These

are called class options.

You must be root to do this.

Page 13

Shell Prompts in Command Examples

The following table shows the default Open Boot PROM (OBP) prompt and the

system prompt and superuser prompt for the C shell, Bourne shell, and Korn shell.

TABLEP-2 Shell prompts

Shell Prompt

Open Boot PROM prompt ok

C shell prompt machine_name%

C shell superuser prompt machine_name#

Bourne shell and Korn shell prompt $

Bourne shell and Korn shell superuser prompt #

Symbols

The following symbols mean:

Note – A note provides information which should be considered by the reader.

Caution – Cautions accompanied by this Attention icon carry information about

!

procedures or events which if not considered may cause damage to the data or

hardware of your system.

Caution – Cautions accompanied by this Hazard icon carry information about

procedures which must be followed to reduce the risk of electric shock and danger

to personal health. Follow all instructions carefully.

Preface xiii

Page 14

Sun Documentation on the Web

The docs.sun.comsmweb site enables you to access Sun technical documentation

on the Web. You can browse the docs.sun.com archive or search for a specific book

title or subject at:

http://docs.sun.com

Sun Welcomes Your Comments

We are interested in improving our documentation and welcome your comments

and suggestions. You can email your comments to us at:

docfeedback@sun.com

Please include the part number of your document in the subject line of your email.

xiv Netra ft 1800 Installation Guide • February 1999

Page 15

CHAPTER

1

Before Installation

This section provides information on what should be considered when choosing a

location for a Netra ft 1800 system.

Note – This equipment is only intended for installation in a Restricted Access

Location as defined by UL1950, 3rd Edition, and EN60950: 1992 / A11: 1997.

Electrical Supply Considerations

Before you install the system, verify that the correct power supply is available. Refer

to “DC Source Site Requirements” on page 44 for further information.

Environmental Considerations

The system can be installed in an environment with the following specific parameter

ranges:

■ Ambient temperature

■ Operating: 0 to 40 degrees Celsius (short term operation up to a temperature of

50 degrees Celsius is possible; however, the operation of removable media

devices cannot be guaranteed.)

■ Storage: –40 to 70 degrees Celsius

1

Page 16

■ Relative humidity

■ Operating: 5 to 85% noncondensing

■ Storage: 10 to 90% noncondensing

■ Elevation

■ Operating: 0 to 3000 meters

■ Storage: 0 to 12000 meters

1

1

Dimensions

■ Height: 1466.85 mm (57.75 inches) 33U NOM

■ Width: 437.60 mm (17.22 inches)

■ Depth: 392.8 mm (15.4 inches)

■ Weight: Maximum 190.5 kg (420 lb) (excluding rack or AC converter items)

■ Maximum rate of heat release for fully configured system: 3000W

(10,200 Btu/hour)

■ GR 63 CORE heat release calculation result: 425.4 W per square foot

[3000 W / (3.25 ft x 2.17 ft)] (4579 W per square meter).

These dimensions are for the product without rack-mount flange adapters; the

overall width of the flanges varies according to the equipment mounting

requirements.

The depth given does not include any I/O or power connectors. The power

connectors add 50 mm (2 inches) to the depth.

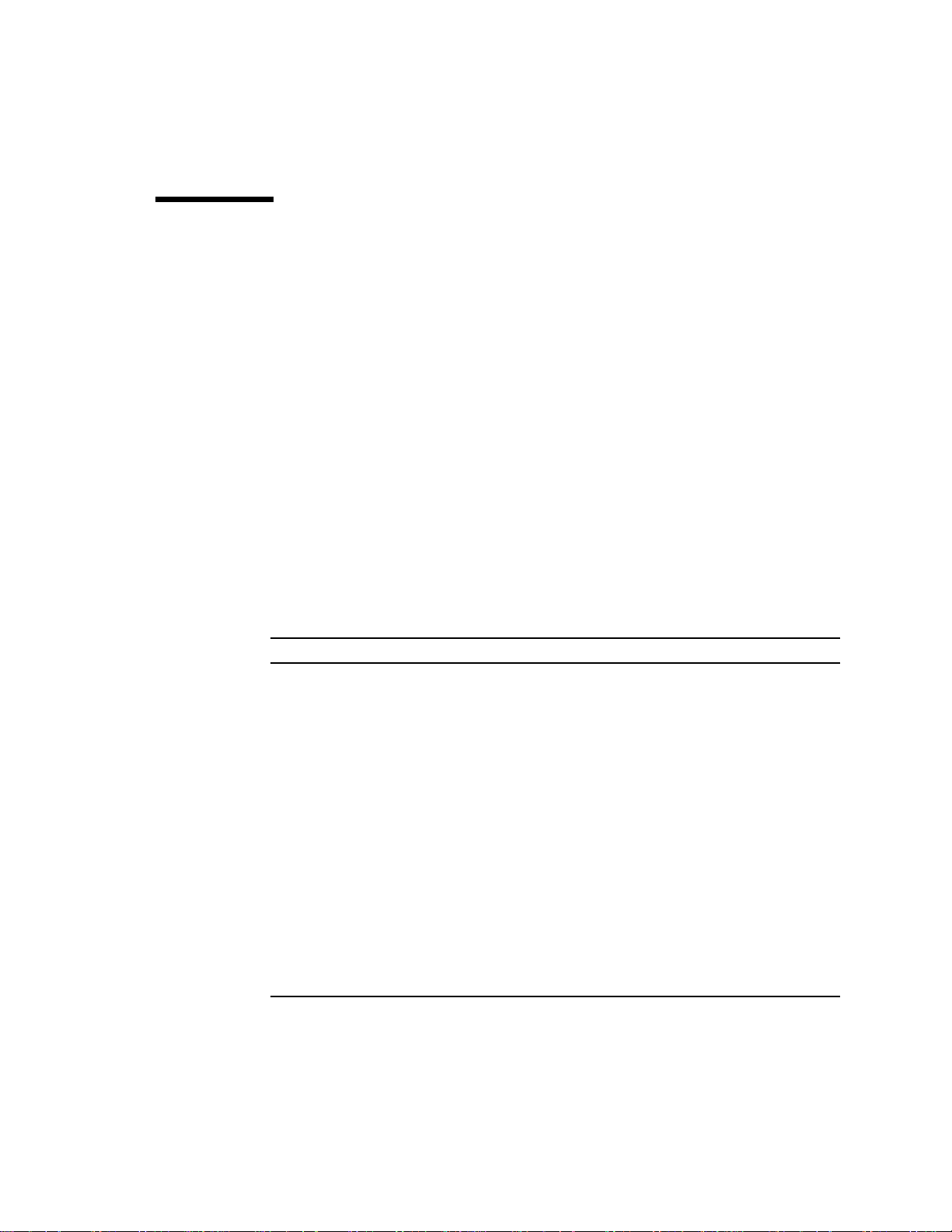

Airflow Consideration when Mounting in the

Equipment Frame

The Netra ft 1800 system has been designed to function while mounted in a natural

convection airflow, but to meet the declared environmental specification the

following rules apply. Refer to

1. Adequate airflow through the equipment frame must be ensured. The

Netra ft 1800 system utilizes internal fans that can achieve a maximum airflow of

840 cfm in free air.

2. The inlet air must enter at the bottom of the Netra ft 1800 cabinet and in front of

the Power Supply Units (PSUs); the airflow exhausts vertically from the top of the

cabinet.

1. Subject to a maximum absolute humidity of 0.024Kg of water per Kg of dry air.

2 Netra ft 1800 Installation Guide • Februar y 1999

FIGURE 1-1 on page 1-4 and FIGURE 1-2 on page 1-5.

Page 17

3. A minimum of 2U (88.9 mm/3.5 inches) clearance must be allowed at both top

and bottom of the Netra ft 1800 cabinet when mounted to allow adequate inlet

and exhaust ventilation.

4. The Netra ft 1800 system must not be mounted above any heat-generating sources

within the same frame unless a heat deflector is used to provide fresh inlet air at

ambient temperature.

5. To maintain adequate airflow, replace the environmental filters every six months

(contact your local support organization for further information). The

environmental filter replacement kit (X-Option No.X6952A) contains six PSU

filters and three base filters.

Chapter 1 Before Installation 3

Page 18

Minimum 2U

(90 mm) gap

FIGURE 1-1 Netra ft 1800 Airflow Requirements (External)

4 Netra ft 1800 Installation Guide • Februar y 1999

Minimum 2U

(90 mm) gap

Page 19

Min.2U (90mm)

gap at top of

system

CAF

CAF

CPU

FrontRear

Fan unit

CAF

CPU CPU

CAF

Front

Front

PSU

PSU

PSU

PSU

PSU

PSU

Rear

Min. 2U (90 mm)

gap at base of

system

Min. 75 mm between

front of system and

rack door (if fitted)

FIGURE 1-2 Netra ft 1800 Airflow Requirements (Internal)

Chapter 1 Before Installation 5

Page 20

Mechanical Considerations when Mounting in the

Equipment Frame

Caution – Mechanical assistance is required if installing a loaded chassis.

If you intend not to use a lifting device for installation, all modules other than the

motherboards must be removed from the system prior to lifting. The empty chassis

weighs approximately 49 kg (108 lb), or 68 kg (150 lb) with the motherboards, plus

the adaptors. The weight of any removable module depends on its configuration.

Weight warning labels are for guidance only.

See “Removing and Installing Modules” on page 23 for information about adding

modules to the motherboard.

The Netra ft 1800 chassis has been designed to accommodate most mounting

configurations. Adaptor flanges to suit 19-inch, 23-inch, 24-inch and 600-mm (ETSI)

rack sizes are available as required.

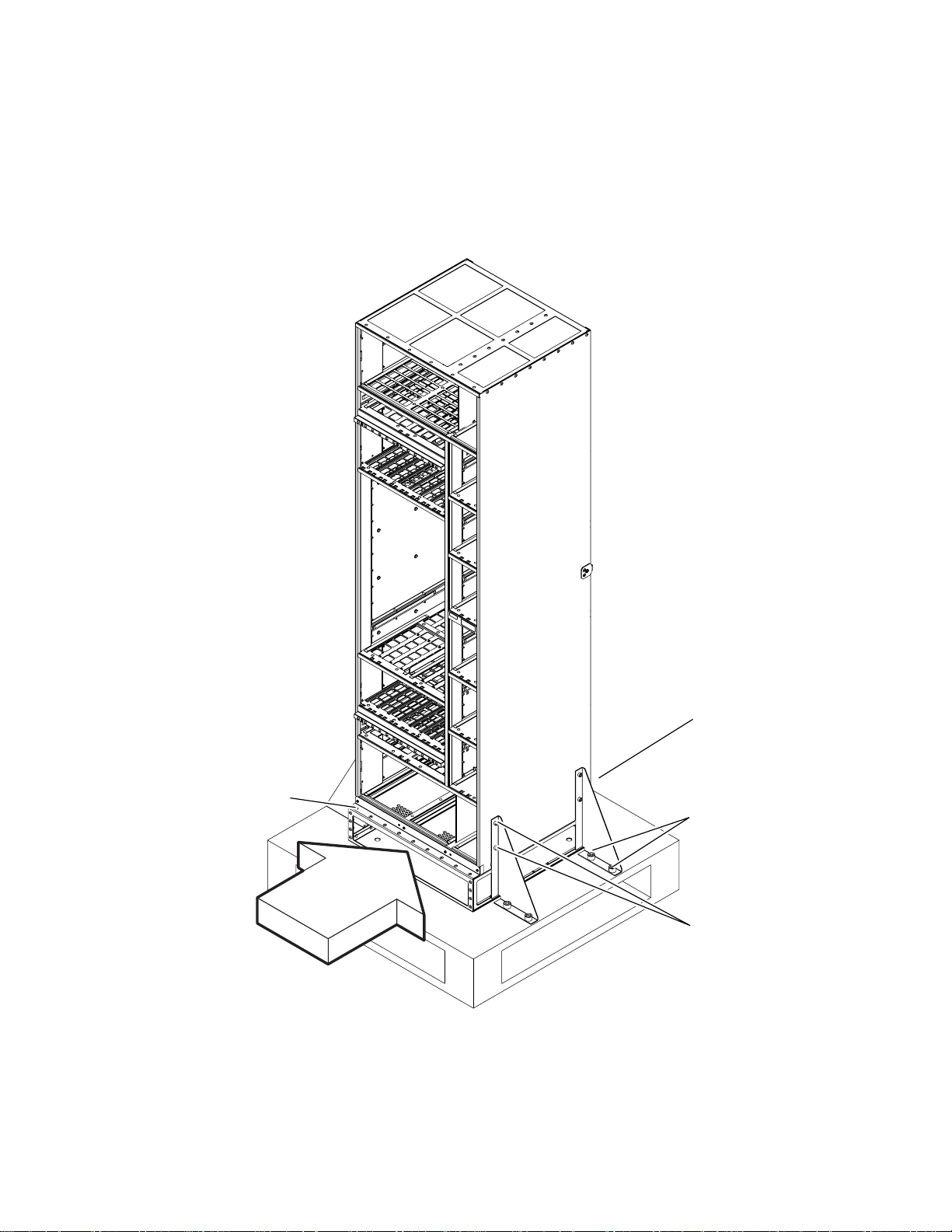

The Netra ft 1800 system is shipped with a plinth, which protects the bottom of the

chassis during transit and handling, and also ensures that the correct airflow inlet

plenum is provided during installation. The plinth must be removed once the

Netra ft 1800 is installed in a rack, then stored in a safe place.

The Netra ft 1800 chassis must be mounted using screws suitable for the equipment

frame. The screws should be M5, M6 or 10-32 UNF. All screws must be fitted. The

recommended tightening torque value for either M5 or 10-32 UNF recess head

screws is 3.8 Nm (2.8 lbf/ft), and that for M6 screws is 6 Nm (4.4 lbf/ft).

Mounting Requirements

The Netra ft 1800 is available with the following removable mounting flanges:

■ 19 inch EIA pattern

■ 23 inch EIA pattern

■ 24 inch EIA pattern

■ 600 mm IEC917 (ETSI) pattern

Any of these flanges can be fitted in the following positions:

■ Flush with the front of the system

■ 65 mm (2.56 inches) from front of system

■ 196.1 mm (7.72 inches) from front of system

The second and third positions are intended for use with 5-inch web open frames

(relay racks).

6 Netra ft 1800 Installation Guide • Februar y 1999

Page 21

Adjustable rear flanges can be fitted. They provide a mounting face anywhere

between 400 mm and 500 mm (15.75 inches and 19.7 inches) from the front of the

system (see “Mounting Flanges” on page 13).

The vertical mounting hole pattern should conform to the standard dimensions

given in

TABLE1-1 Mounting Hole Pattern Dimensions

Standard Pattern

EIA/RETMA (RU) Repeating pattern of 5/8 inch, 5/8 inch, 1/2 inch

IEC917/ETSI (SU) Constant pitch of 25 mm

TABLE 1-1.

Loading

The rack must be capable of supporting 230 kg (500 lbs) for a fully configured and

cabled Netra ft 1800.

In Seismic (Earthquake) Risk Zones 3 and 4, it is recommended that the Netra ft 1800

is installed in an appropriate secured seismic rack or cabinet.

Vertical space

The Netra ft 1800 chassis occupies 33RU (57.75 inches) of vertical height.

To allow adequate airflow, the rack must provide a minimum of 38RU (66 inches) of

rackable height, together with minimum inlet and exhaust vents of 2U gap each. If

the rack provides unobstructed vertical airflow via vents of adequate size in the top

and/or bottom panels, then the minimum rack vertical opening required is 37RU

(64.75 inches).

When you fit the Netra ft 1800 into a rack with its red transit plinth in place, allow

1U (1.75 inches) of clearance beneath the plinth. This space permits removal of the

plinth.

Note – The plinth must be removed to allow fitment of the chassis environmental

filters.

Chapter 1 Before Installation 7

Page 22

Depth

The front door (if fitted) must provide a minimum of 75 mm (3 inches) of clearance

across the entire front surface of the Netra ft 1800 to allow for routing of I/O cables.

As all I/O cables must be routed from the front of the Netra ft 1800 system, due

consideration should be made of the space required within the rack for these cables,

as well as the power cables at the rear of the system.

There must be a minimum of 545 mm (21.5 inches) usable internal depth in the rack/

cabinet. This dimension includes space for connector housings, cabling and the

power inlet filters.

Safety

All racks must be bolted to the floor, to adjacent frames or to both. This must be

done in accordance with the rack manufacturer’s instructions, using the

recommended hardware and fixings.

Free-standing racks with a footprint of less than 600 mm x 600 mm (23.6 inches x

23.6 inches) are likely to be unstable and should be treated with caution.

8 Netra ft 1800 Installation Guide • Februar y 1999

Page 23

CHAPTER

2

Hardware Installation

This chapter provides information on the initial hardware installation procedure,

including installing modules and external I/O connections.

Unshipping and Mounting the System

Once you have removed the packaging from the system, you must then unship the

system from the delivery pallet and brackets before attempting to mount the chassis

in a rack.

Caution – Do not attempt to remove the red plinth before the chassis has been

mounted in the rack.

There is an instruction card attached to the front of the system; the instructions

below are intended to supplement this.

Note – Do not discard the packaging after removing it from the system. It should be

stored in safe, dry place so it can be used in the event that the system requires

moving or returning for repair.

Tools

The tools required to unship the system are contained in a cloth bag attached to the

chassis.

9

Page 24

Note – Do not discard the tools after unshipping and mounting the system. They

can be stored in the cloth bag supplied and attached to the rack adjacent to the

system for easy access when required.

10 Netra ft 1800 Installation Guide • Februar y 1999

Page 25

▼ To Unship and Mount the System

4 x Phillips screws

at front of plinth

FIGURE 2-1 Shipping Brackets and Sacrificial Plinth

3 x Phillips screws

at rear of plinth

2 x Allen bolts

securing bracket to

pallet

Insert lifting

device here

2 x Phillips screws

on each bracket

Chapter 2 Hardware Installation 11

Page 26

1. Remove all modules except the motherboards from the chassis and put them in a

safe place.

Refer to “Removing and Installing Modules” on page 23.

2. Using the Phillips No.2 screwdriver (supplied), remove the two Phillips screws

securing the four red brackets (two on each side) to the chassis (see

FIGURE 2-1).

You may also need to remove the brackets from the pallet. Use the Allen key

supplied to remove the two Allen screws from each bracket. The brackets are not

attached to the red mounting plinth.

3. Install the appropriate mounting flanges.

Refer to “Mounting Flanges” on page 13.

4. Use an appropriate lifting device to lift the chassis by the red mounting plinth,

and install it in the rack.

Caution – If using a fork-lift device, ensure the tines of the lift extend right through

the mounting plinth and beyond the rear of the chassis. The chassis could deform if

you use incorrect lifting techniques.

5. Secure the chassis into the rack using the appropriate mounting points.

See “Mounting Flanges” on page 13.

6. Remove the mounting plinth.

Use the No.2 Phillips screwdriver supplied to remove the four screws from the front

and the three screws from the rear.

Mounting the chassis with the plinth attached ensures that the minimum amount of

clearance for air flow is provided beneath the system.

7. Install the two large and one small filter trays in the spaces immediately beneath

the chassis revealed by the removal of the plinth.

Refer to “To Install the Filter Trays” on page 36. The filter tray thumbscrews are

inserted in the tapped threads exposed by removal of the mounting plinth.

8. Install the modules into their appropriate locations.

Refer to “Removing and Installing Modules” on page 23.

12 Netra ft 1800 Installation Guide • Februar y 1999

Page 27

Mounting Flanges

The system is supplied with the appropriate mounting flanges; other mounting

flanges kits are available, as follows, to enable the system to mounted in different

industry-standard racks:

■ 19-inch racks X-Option No.X6938A

■ 23-inch racks X-Option No.X6939A

■ 24-inch racks X-Option No.X6940A

■ ETSI (600 mm) racks X-Option No. X6941A

Each mounting kit also includes six cable bracket assemblies, which can be fitted to

the mounting flanges to facilitate cable management; see “Cable Bracket

Assemblies” on page 22.

19-inch Mountings

The 19-inch mounting kit consists of the following items:

TABLE2-1 19-inch Mounting Flange Kit

Quantity Item Part number

1 Front left-hand mounting flange 340-4699

1 Front right-hand mounting flange 340-4698

1 Rear top left mounting flange 340-5479

1 Rear top right mounting flange 340-5480

1 Rear bottom left mounting flange 340-5481

1 Rear bottom right mounting flange 340-5482

16 Spacers 340-5483

8 Support rails 340-5484

6 Cable hook bracket with hooks already installed 340-5553

16 M4 10mm panhead screws (for rear flanges) N/A

16 M4 crinkle washers (for M4 screws) N/A

20 M5 8mm countersunk screws (for front flanges) N/A

16 M5 10mm countersunk screws (for support rails) N/A

Refer to

FIGURES 2-3 to 2-6.

Chapter 2 Hardware Installation 13

Page 28

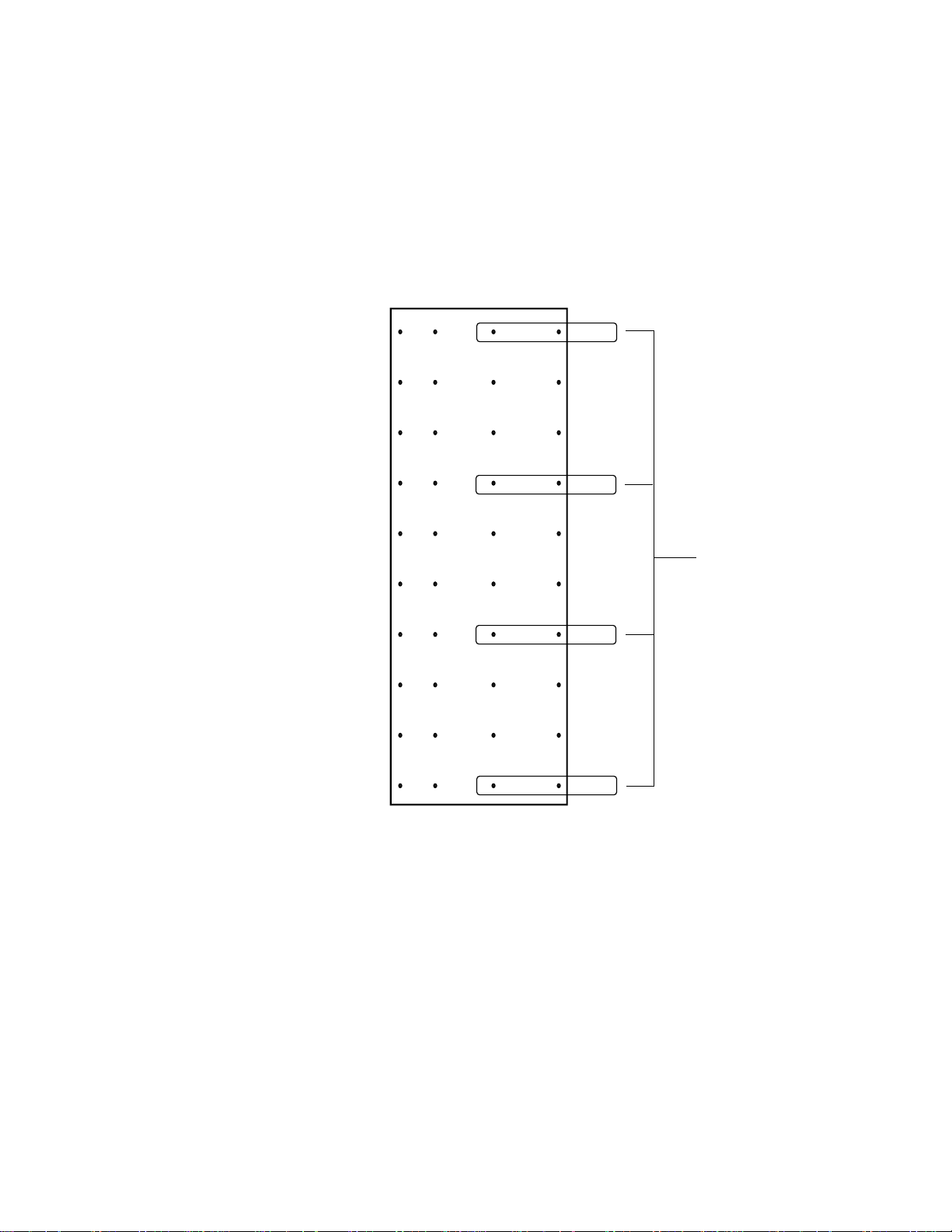

The sides of the system chassis are provided with tapped screwholes as shown in

FIGURE 2-2.

Front of system Rear of system

D

Columns

ABC

1

2

3

4

5

Row numbers

Support rails

(340-5484)

6

7

8

9

10

FIGURE 2-2 Location Matrix For Mounting Flange Screws (19-inch rack)

The front flanges (see FIGURE 2-6 on page 17) are screwed to holes in column C or

column D. Use column B only if the rear flanges are not going to be used.

The support rails (see

FIGURE 2-7 on page 19) are screwed to holes A and B in rows 1,

4, 7 and 10. The spacers provided must be used between the rails and the chassis to

prevent the rails being fouled by the rivets in the chassis metalwork.

14 Netra ft 1800 Installation Guide • Februar y 1999

Page 29

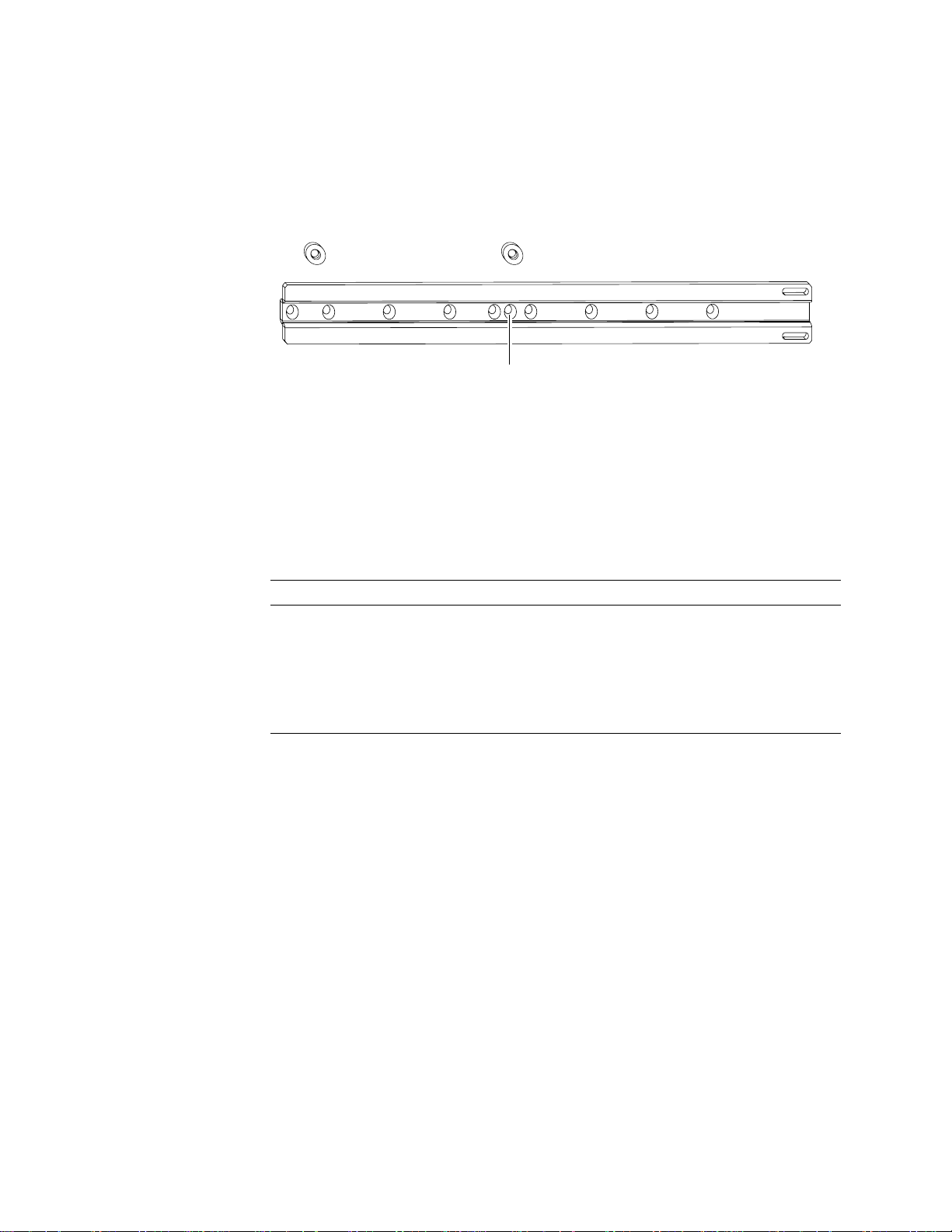

Spacer

F4F3F2F1

Spacer (340-5483)

E5E4E3E2E1

F5

FIGURE 2-3 Support Rail and Fixings (19-inch Rack)

The mounting screws should be placed in position pairs E1 and F1, E2 and F2, E3

and F3, E4 and F4 or E5 and F5. The pair of holes to be used depends on the frontto-back depth of the rack (mounting flange to mounting flange). The holes marked

with the appropriate figure, as shown in

TABLE 2-2, should be closest to the rear of

the chassis.

TABLE2-2 Support Rail Screw Hole Locations

Rack depth Screw holes

480 mm E5 and F5

530 mm E4 and F4

580 mm E3 and F3

630 mm E2 and F2

680 mm E1 and F1

G

G

The slots labeled G are used for mounting the rear flanges (see

FIGURE 2-6 on

page 17). Only one of the vertical pairs of holes in the rear flanges should be used.

The spacers must be placed with the flat side towards the chassis and the

countersink towards the support rail (see

FIGURE 2-4).

Chapter 2 Hardware Installation 15

Page 30

Support rail (340-5484)

Chassis

FIGURE 2-4 Orientation of Support Rail Spacers

The rear flanges are used to mount the chassis in the rear of the rack as shown in

FIGURE 2-5.

M5 10mm countersunk screw

Support rail (340-5484)

Spacer (340-5483)

Screw

Spacer (340-5483)

Chassis

M5 10mm countersunk screw

Rack

Rack rear mounting flange

FIGURE 2-5 Rear Rack Mounting (19-inch Rack)

16 Netra ft 1800 Installation Guide • Februar y 1999

M4 10mm panhead screw

and crinkle washer

Rear flange (340-5479/5480)

Lockable fixing (not supplied)

Page 31

Spacer

(340-5483)

Support rail

(340-5484)

UseM5 10mm

screws

Rear top mounting

flange

(left 340-5479

right 340-5480)

Use M4 10mm

screws

Front mounting flange

(left 340-4699

right 340-4698)

Use M5 8mm screws

FIGURE 2-6 19-inch Rack Mounting Flange Kit

Rear bottom mounting

flange

(left 340-5481

right 340-5482)

Use M4 10mm screws

Chapter 2 Hardware Installation 17

Page 32

23-inch, 24-inch and 600mm Mountings

The 23-inch, 24-inch and 600mm mounting kits consist of the following items:

TABLE2-3 23-inch, 24-inch and 600mm Mounting Flange Kits

Part number

Quantity Item 23-inch 24-inch 600mm

1 Front left-hand mounting flange 340-4592 340-5445 340-5328

1 Front right-hand mounting flange 340-4591 340-5446 340-5329

2 Rear top mounting flange 340-5449 340-5447 340-5331

2 Rear bottom mounting flange 340-5450 340-5448 340-5427

8 Support rails 340-5330 340-5330 340-5330

6 Cable hook bracket with hooks already

installed

40 M5 6mm panhead screws (for front and rear

flanges)

16 M5 8mm countersunk screws (for support

rails)

340-5553 340-5553 340-5553

N/A N/A N/A

N/A N/A N/A

Refer to

and

FIGURE 2-7 on page 19 for 23-inch kits, FIGURE 2-8 on page 20 for 24-inch kits

FIGURE 2-9 on page 21 for 600mm kits.

The sides of the system chassis are provided with tapped screwholes as shown in

FIGURE 2-2 on page 14.

Fit the front brackets using the screwholes in columns C and D, or just column C, or

just column D.

Screw the slide mounts to holes A and B in rows 1, 4, 7 and 10. You can then screw

the rear brackets to the rear of the rack (see

and slide the chassis onto the brackets until the front brackets are flush with the

front of the rack.

18 Netra ft 1800 Installation Guide • Februar y 1999

FIGURE 2-7, FIGURE 2-8 and FIGURE 2-9)

Page 33

Front mounting

flange

(left 340-4592

right 340-4591)

Use M5 6mm

screws

Reartopmounting

flange (340-5449)

Use M5 6mm

screws

Slide support

(340-5330)

Use M5 8mm

screws

Rear bottom mounting

flange (340-5450)

Use M5 6mm screws

FIGURE 2-7 23-inch Rack Mounting Flange Kit

Chapter 2 Hardware Installation 19

Page 34

Front mounting

flange

(left 340-5445

right 340-5446)

Use M5 6mm

screws

Rear top mounting

flange (340-5447)

Use M5 6mm

screws

Slide support

(340-5330)

Use M5 8mm

screws

Rear bottom mounting

flange (340-5448)

Use M5 6mm screws

FIGURE 2-8 24-inch Rack Mounting Flange Kit

20 Netra ft 1800 Installation Guide • Februar y 1999

Page 35

Front mounting

flange

(left 340-5328

right 340-5329)

Use M5 6mm

screws

Rear top mounting

flange (340-5331)

Use M5 6mm screws

Slide support

(340-5330)

Use M5 8mm

screws

Rear bottom mounting

flange (340-5427)

Use M5 6mm screws

FIGURE 2-9 600-mm Rack Mounting Flange Kit

Chapter 2 Hardware Installation 21

Page 36

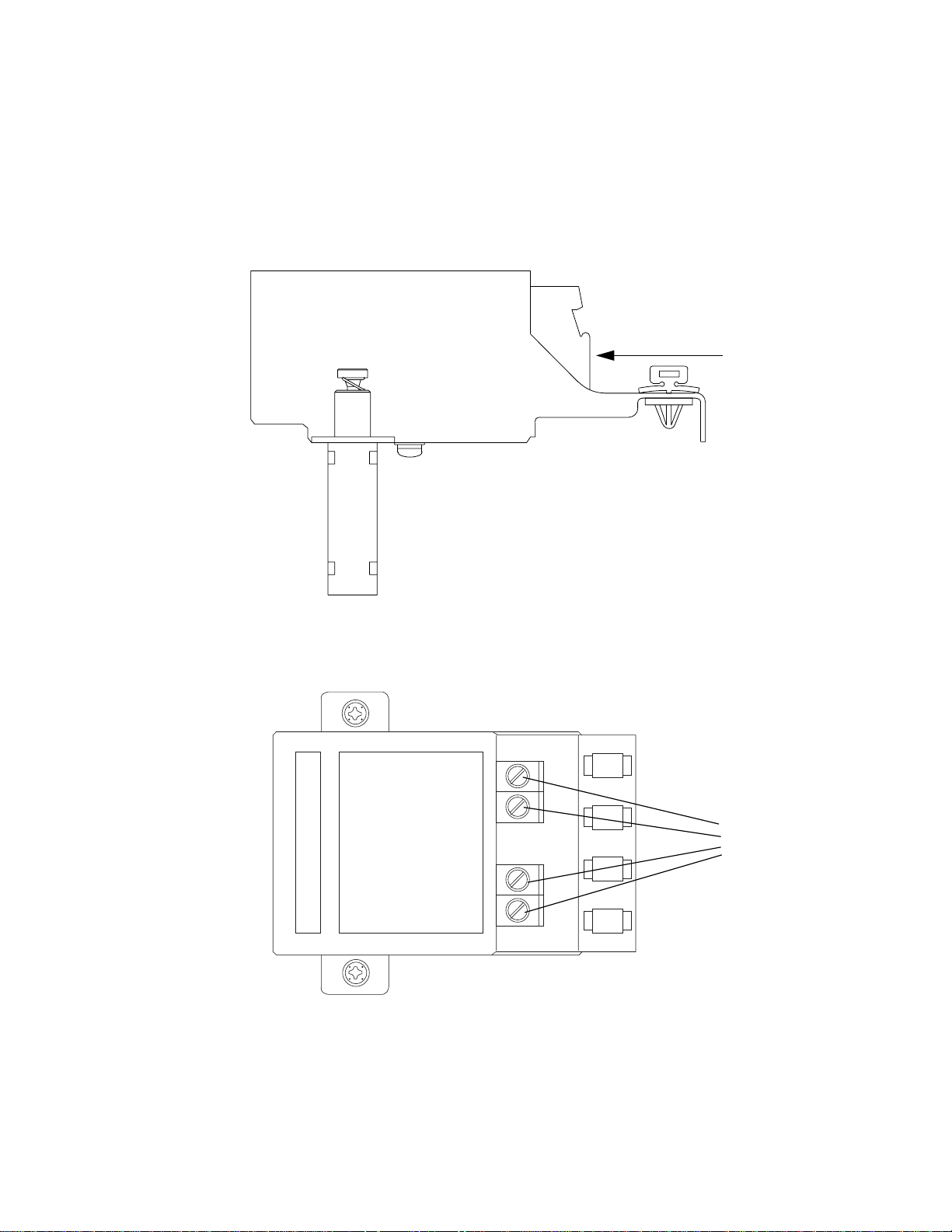

Cable Bracket Assemblies

Six cable bracket mounting assemblies are provided with each mounting flange kit.

These can be fitted to the mounting flanges to facilitate cable management.

FIGURE 2-10 Cable Bracket Assembly

The brackets can be fixed to the mounting flanges in the required position, using the

same screws that fix the flanges to the rack. The hooks can be fitted to the brackets in

one of three positions using the countersunk M3 screws supplied. The hooks must

be fitted before the brackets are fixed to the mounting flange/rack.

22 Netra ft 1800 Installation Guide • Februar y 1999

Page 37

Removing and Installing Modules

This chapter describes how to remove and insert:

■ CPUset, PCI, CAF and PSU modules (“To Remove a Module” on page 24)

■ CPUset modules: “CPUset Modules” on page 25

■ PCI modules: “PCI Modules” on page 28

■ CAF modules: “CAF Modules” on page 27

■ PSU modules: “PSU Modules” on page 29

■ Drive chassis (“Replacing a Disk Chassis” on page 32)

■ Removable media module (“Replacing an RMM” on page 30)

Caution – The wrist-strap provided must be used when replacing modules, or

making cable connections to the rear of the system. The wrist-strap connection point

on the Netra ft 1800 system is located on the panel at the bottom rear of the chassis.

All modules have their own guides in slots in the chassis, into which they fit exactly.

No module will fit into a slot allocated to a different class of module. No module

will fit into its own slot if it is upside down.

Module Injector/Ejector Mechanisms

All the modules except the disk chassis (DSK) and RMM have an injector/ejector

lever (CPUset modules have two). They are all similar in function and usage. A

common feature is a slide which engages and disengages the module’s electrical

connection to the motherboard, and a lever which physically engages and

disengages the module. When the latch is disengaged, a red dot is exposed. This

facilitates the identification of unlatched injectors.

Chapter 2 Hardware Installation 23

Page 38

Open

Closed

FIGURE 2-11 Module Injector/ejector Lever

Red warning dot

The module is disengaged from its electrical connection when the slide is moved

towards the rounded end of the lever, exposing the red warning dot.

The general procedure refers to CPUset, CAF, PCI and PSU modules. For more

specific instructions for the RMM and disk chassis, refer to:

■ “Replacing an RMM” on page 30

■ “Replacing a Disk Chassis” on page 32

▼ To Remove a Module

1. Move the slide in the lever on the module to the disengaged position.

This will expose the red warning dot.

2. Lower the lever.

The module will slide out a small amount when the lever is fully lowered.

3. Slide the module out of its slot, using the handle if there is one.

For specific procedures relating to individual modules, refer to:

■ “CPUset Modules” on page 25

■ “CAF Modules” on page 27

■ “PCI Modules” on page 28

■ “PSU Modules” on page 29

24 Netra ft 1800 Installation Guide • Februar y 1999

Page 39

CPUset Modules

CPUset modules have two injector levers which must be operated simultaneously.

As you pull out the CPUset module, the handle in the top panel pops up and must

be depressed again manually in order to withdraw the module fully from the chassis

(see

FIGURE 2-12). Once the handle is clear of the crossbar and has popped up again,

it can be used to take the weight of the module.

Caution – CPUset modules are very heavy. The weight warning label on the

CPUset is for guidance only. The actual weight of a CPUset depends on its

configuration. Both the front and top handles must be used simultaneously once the

module has been withdrawn as illustrated in FIGURE 2-12.

On inserting the CPUset module the handle must be depressed in order to push the

module fully into the chassis.

Chapter 2 Hardware Installation 25

Page 40

FIGURE 2-12 Removing a CPUset Module

26 Netra ft 1800 Installation Guide • Februar y 1999

Page 41

CAF Modules

FIGURE 2-13 Removing a CAF

Chapter 2 Hardware Installation 27

Page 42

PCI Modules

FIGURE 2-14 Removing a PCI Card Carrier

28 Netra ft 1800 Installation Guide • Februar y 1999

Page 43

PSU Modules

FIGURE 2-15 Removing a Power Supply

Chapter 2 Hardware Installation 29

Page 44

▼ To Replace a Module

1. Slide the module into its slot but not fully home.

A module will not fit into a slot designed for a different class of module.

2. When the lever engages with the chassis, raise it to push the module fully home.

3. Move the slide in the lever into the engaged position.

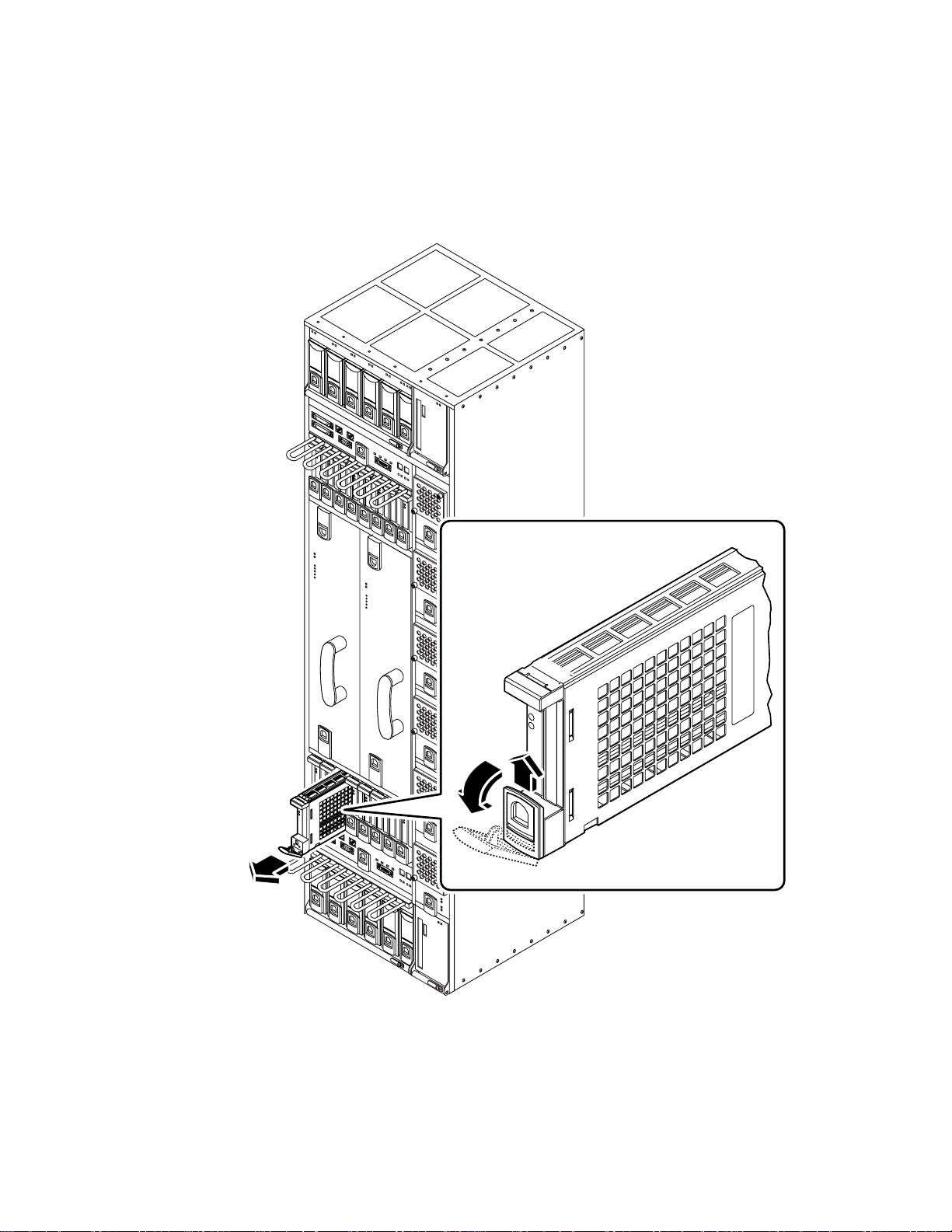

Replacing an RMM

RMM modules have a slide with an actuator microswitch on an ejector handle. The

slide controls the electrical connection to the motherboard. When the slide is closed

(to the right), the electrical connection is engaged; when it is open (to the left), the

electrical connection is disengaged. The handle is lifted to disengage the module

physically, and lowered to engage it.

▼ To Remove the RMM

1. Slide the latch in the handle of the RMM to the left (towards the ‘unlocked’

symbol).

2. Lift the handle.

3. Slide the RMM out of its slot.

30 Netra ft 1800 Installation Guide • Februar y 1999

Page 45

FIGURE 2-16 Removing an RMM Module

Chapter 2 Hardware Installation 31

Page 46

▼ To Replace the RMM

1. Slide the RMM into its slot until it is almost completely home.

A module will not fit into a slot designed for a different class of module.

2. Lower the handle to engage the RMM fully in its slot.

3. Slide the latch in the handle to the right (towards the ‘locked’ symbol).

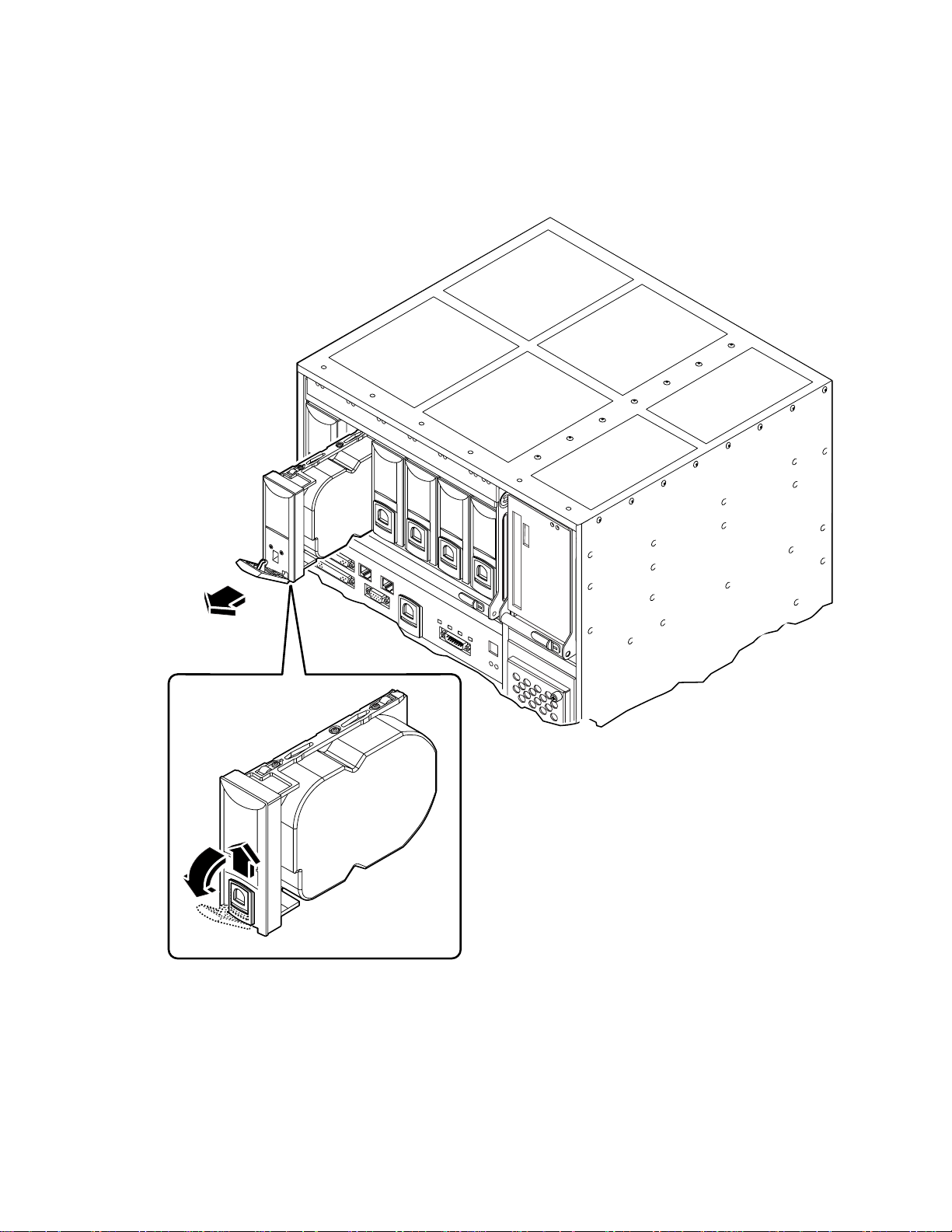

Replacing a Disk Chassis

DSK modules have a slide on an ejector handle. The handle is lifted to disengage the

module physically, and lowered to engage it.

▼ To Remove the Disk Chassis

1. Remove any HDD modules (hard disks) in the disk chassis.

Refer to

Caution – Always remove all hard disk drive modules before removing a disk

chassis. Always put a hard disk back in the same location from which you removed

it.

FIGURE 2-17 on page 33.

2. Slide the latch in the handle of the disk chassis to the left (towards the ‘unlocked’

symbol).

3. Lift the handle.

4. Slide the disk chassis out of its slot.

32 Netra ft 1800 Installation Guide • Februar y 1999

Page 47

FIGURE 2-17 Removing a Disk Drive

NOTE: The injector/ejector lever of a disk drive

module does not switchthe power on and off. If the

chassis is powered on, the disk drive will power off

when it is removed and power on as soon as it is

inserted, regardless of the position of the lever.

Chapter 2 Hardware Installation 33

Page 48

FIGURE 2-18 Removing a DSK Module

▼ To Replace the Disk Chassis

1. Slide the disk chassis into its slot until it is almost completely in.

2. Lower the handle to engage the disk chassis fully in its slot.

3. Slide the latch in the handle to the right (towards the ‘locked’ symbol).

4. Replace the hard disk drives.

34 Netra ft 1800 Installation Guide • Februar y 1999

Page 49

Flexible Module Cabling

The cable management shelf is illustrated in FIGURE 2-19.

FIGURE 2-19 Cable Management Shelf

The cable management shelf adjacent to the PCI card locations is flexible and can be

used in a number of different configurations. The holes are equidistant, and the

hooks can be inserted in whatever position is required. The hooks are a firm push-fit

into the holes.

Chapter 2 Hardware Installation 35

Page 50

Installing the Filter Trays

The Netra ft 1800 has three filter trays, two large and one small.

▼ To Install the Filter Trays

FIGURE 2-20 Large Filter Tray

36 Netra ft 1800 Installation Guide • Februar y 1999

Page 51

FIGURE 2-21 Small Filter Tray

1. Insert the trays into the appropriate apertures at the base of the chassis; the two

large trays are fitted on the left and the small tray on the right.

It is unimportant which way up the trays are fitted.

2. Push the trays securely home and hand-tighten the two thumbscrews on each.

The thumbscrews are inserted into the tapped threads exposed by removal of the

sacrificial mounting plinth.

Chapter 2 Hardware Installation 37

Page 52

Modem

port

(DB-25)

CAF External I/O Connections

The Netra ft 1800 system has the following connectors on each CAF module:

■ Female 25-pole D-type connectors for the system console and modem ports

(RS232).

■ A male 9-pole D-type connector for the Remote Control Processor (RCP) ports.

■ A male 15-pole D-type connector for the alarm relay/reset signals.

■ Two RJ45 Ethernet ports.

Ethernet ports

(RJ45)

CAF

Console

port

(DB-25)

Remote

Control

Processor

port (DB-9)

FIGURE 2-22 External I/O Connections on CAF Module

38 Netra ft 1800 Installation Guide • Februar y 1999

Alarm port

(DB-15)

Page 53

System Console Terminal Connections

The system console and modem connections are provided on separate 25-pole

female D-type connectors.

TABLE2-4 Console Connector Pinout

Pin Function Description

1 GND Chassis ground

2 TxD Output data

3 RxD Input data

7 SREF Signal reference

Shield Chassis ground

Except for pin 1, all pins of the console and modem connectors are isolated from the

frame ground of the Netra ft 1800 system.

The connectors have two screw-threaded mounting pillars with 4-40 UNC threads.

You should secure the cable headshell in place with the screws engaged in these

pillars. If you use a cable headshell without securing the screws, make sure that the

pillars do not prevent full engagement of the connector. This can happen with some

types of cable headshell where screw heads can foul against the mounting pillars.

You must also secure the other end of the cable to the console terminal if the

terminal provides some means of locking.

TABLE 2-4 shows the pin allocation on these connectors.

Note – To ensure EMC compliance always use a high quality screened cable that has

metal connector shells.

TABLE 2-5 shows the console terminal configuration parameters for both console and

modem ports. You can modify these parameters using Solaris utilities.

TABLE2-5 Console and Modem Port Parameters

Parameter Setting

Transmit rate 9600 baud

Receive rate 9600 baud

Data bits 8

Chapter 2 Hardware Installation 39

Page 54

TABLE2-5 Console and Modem Port Parameters (Continued)

Parameter Setting

Stop bits 1

Parity enable/sense off/off

XON/XOFF protocol on

System consoles can be connected only to the CAF module.

Modem Port Connections

The modem port pinout is described in TABLE2-6.

TABLE2-6 Modem Port Pinout

Pin Function Description

1 GND Chassis ground

2 TxD Output data

3 RxD Input data

4 RTS Output handshake

5 CTS Input handshake

7 SREF Signal reference

8 DCD Input status

20 DTR Output status

Shield Chassis ground

40 Netra ft 1800 Installation Guide • Februar y 1999

Page 55

Alarms Port Connections

The alarms port pinout is described in TABLE2-7.

TABLE2-7 Alarms Port Pinout

Pin Description Pin Description

1 RESET0+ 9 ALARM0-NC

2 RESET0- 10 ALARM0-COM

3 RESET1+ 11 ALARM1-NO

4 RESET1- 12 ALARM1-NC

5 SYSTEM-NO 13 ALARM1-COM

6 SYSTEM-NC 14 ALARM2-NO

7 SYSTEM-COM 15 ALARM2-COM

8 ALARM0-NO

Chapter 2 Hardware Installation 41

Page 56

42 Netra ft 1800 Installation Guide • Februar y 1999

Page 57

CHAPTER

3

Electrical Supply Installation

This chapter provides information about the Netra ft 1800 system switches and the

installation of the electrical supply. See the Netra ft 1800 Hardware Reference Manual

for full details of the electrical supply hardware.

The Netra ft 1800 has six power input feed pairs, three for each side, which plug in

to the back of the system. These must be assembled by the user, as described in

“Connecting the Power Leads” on page 51.

Note – This equipment is only intended for installation in a Restricted Access

Location as defined by UL1950, 3rd Edition, and EN60950: 1992 / A11: 1997.

Note – In NORWAY, this requirement does not apply to permanently connected

equipment or pluggable equipment type B, installed in areas where equipotential

bonding has been applied, e.g. a telecommunications Central Office.

System Switch

The Netra ft 1800 in fault tolerant mode consists of two sides: processors and

associated modules which function and are powered as separate systems. The

system switches of the Netra ft 1800 function as standby devices for their respective

sides, enabling and disabling the power supply units (PSU) outputs. The system

switches are push, momentary switches. They are located on the CAF module on

each side of the system.

The system does not contain any integral circuit breakers. The only means of

isolating the system from power is by means of external circuit breakers, to be

provided by the user.

43

Page 58

Note – The system On and Stby switches handle low voltage signals only; the high-

power circuits do not pass through these switches.

DC Source Site Requirements

The DC source site requirements are as follows:

■ Suitable for use in –48 Vdc ((classified SELV) nominal or –60 Vdc (classified

TNV-2) nominal systems.

■ The supply source must be electrically isolated by double or reinforced insulation

from any hazardous AC or DC source.

■ The DC source must be reliably connected to earth (that is, battery room positive

bus is connected to the grounding electrode).

■ The DC source must be capable of providing up to 925W of continuous power per

feed pair. The sum of all three feeds on one side will be less than 1500W for

single-feed and 3000W for dual feed.

Overcurrent Protection Requirements

Overcurrent protection devices must be provided as part of each host equipment

rack.

Circuit breakers meeting the requirements shown in

between the DC source and the Netra ft 1800.

TABLE3-1 Overcurrent Protection Requirements

Current rating 30A maximum

Voltage Maximum 60 Vdc rated in –48 Vdc power systems

Maximum 75 Vdc rated in –60 Vdc power systems

Type Fast trip

Protection Double pole breaking (both grounded and ungrounded conductor

open on fault)

Contact gap Minimum 3 mm

Nuisance tripping Circuit breaker must not operate when presented with an inrush

current of 27 amps and a duration of 2.5 microseconds

Quantity One per feed, up to 12 per system

44 Netra ft 1800 Installation Guide • Februar y 1999

TABLE 3-1 must be fitted

Page 59

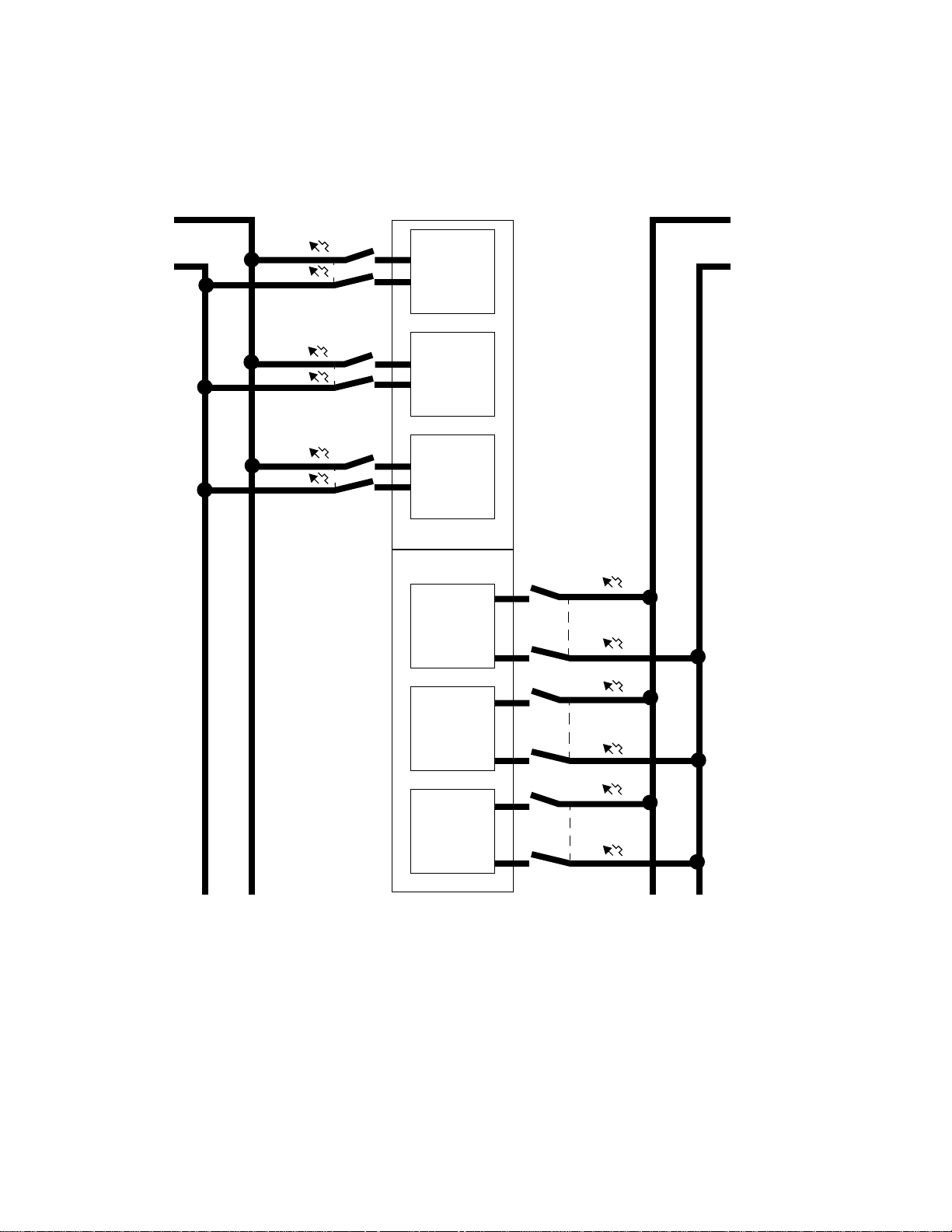

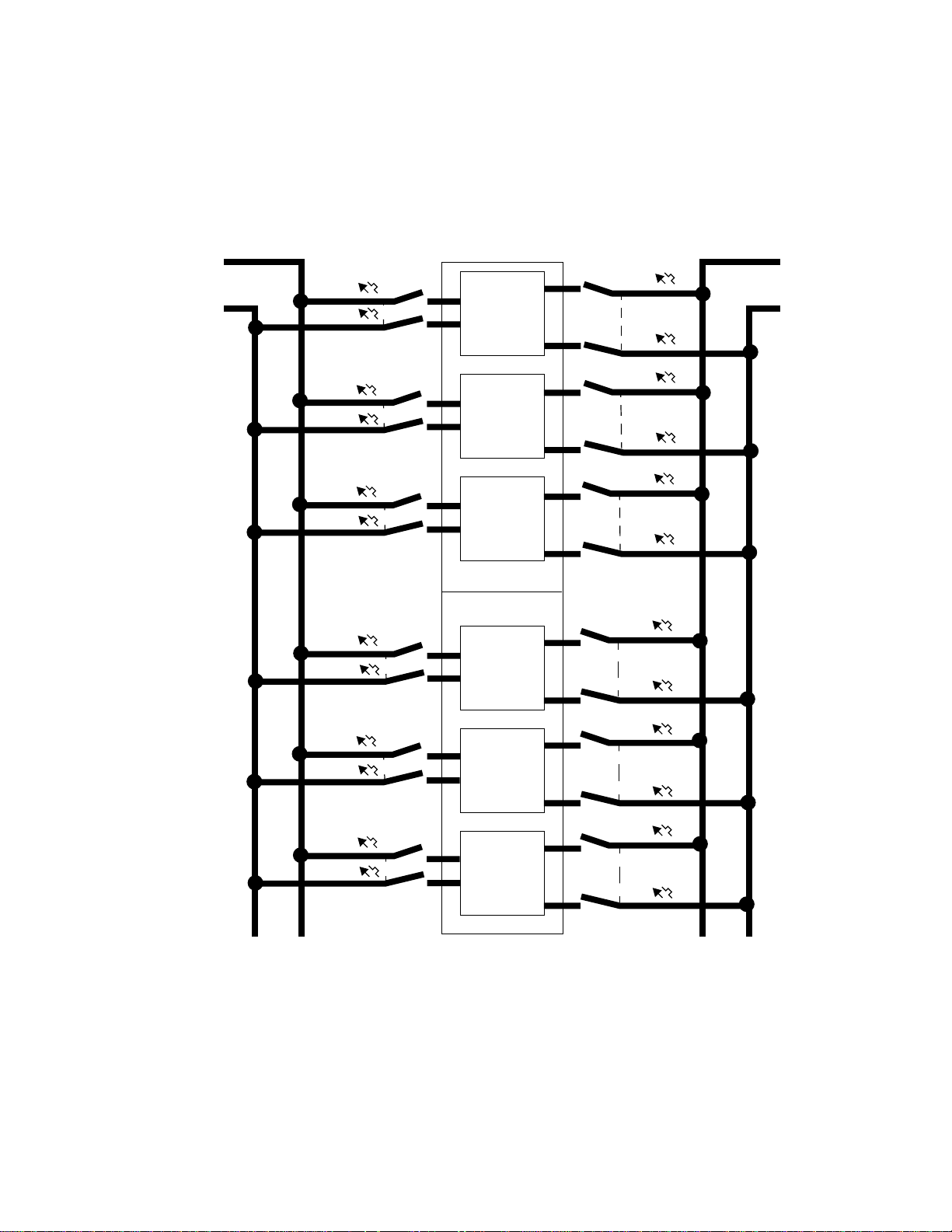

Caution – Double pole circuit breakers are required on each rail for DC

installations. This is necessary because the return path of the current is not isolated

in the PSU.

FIGURE 3-1 on page 3-46 shows the required arrangement for single power rails.

FIGURE 3-2 on page 3-47 shows the required arrangement for dual power rails.

Note – Overcurrent devices must meet applicable national and local electrical safety

codes and be approved for the intended application.

Chapter 3 Electrical Supply Installation 45

Page 60

Return A

–48V supply

A

CB

CB

RTN B

RTN A

–48V A

–48V B

Return B

–48V supply

B

CB

CB

CB

CB

RTN B

RTN BA

–48V A

–48V B

RTN B

RTN A

–48V A

–48V B

RTN B

RTN A

–48V A

–48V B

RTN B

RTN A

–48V A

–48V B

RTN B

RTN A

–48V A

–48V B

CB

CB

CB

CB

CB

CB

FIGURE 3-1 Circuit Breakers for Single Power Rails

46 Netra ft 1800 Installation Guide • Februar y 1999

Page 61

Return A

–48V supply

A

CB

CB

RTN B

RTN A

–48V A

–48V B

CB

CB

Return B

–48V supply

B

CB

CB

CB

CB

CB

CB

CB

CB

RTN B

RTN A

–48V A

–48V B

RTN B

RTN A

–48V A

–48V B

RTN B

RTN A

–48V A

–48V B

RTN B

RTN A

–48V A

–48V B

CB

CB

CB

CB

CB

CB

CB

CB

CB

CB

RTN B

RTN A

–48V A

–48V B

FIGURE 3-2 Circuit Breakers for Dual Power Rails

Chapter 3 Electrical Supply Installation 47

CB

CB

Page 62

Required Connection Materials

DC branch circuits:

■ The required number of field wiring kits are supplied in the shipkit with each

system, according to configuration.

Grounding:

■ One Thomas & Betts two-hole lug (part number: 54204-UB) suitable for 8 AWG

conductor or UL/CSA approved equivalent having 5/8-inch pitch; torque value:

3.5 Nm maximum.

■ A Thomas & Betts crimping tool (part number: TBM 5-S), or approved equivalent

to secure the lug on to the cable.

■ A grounding bus bar that is near the equipment and easily accessible.

Dual Grounding Environment:

■ Additional Thomas & Betts two-hole lug for logic 0V studs.

Caution – External filtering and/or surge suppression devices may be required on

!

the power feeds where branch circuit electromagnetic characteristics are unknown.

DC Supply and Ground Conductor

The requirements are:

■ Suitable conductor material: copper only.

■ Supply conductors: 8 AWG (6 mm

breaker).

■ Ground conductor: 8 AWG.

■ Cable insulation rating: minimum 75 degrees Celsius, Low Smoke Fume (LSF),

Flame Retardant.

■ Cable type must be one of:

■ UL style 1028 or other UL 1581 compliant equivalent.

■ IEEE 383 compliant.

■ IEEE 1202-1991 compliant or classified.

■ Branch circuit cable insulation color: per applicable national electrical codes.

■ Grounding cable insulation color: green/yellow.

48 Netra ft 1800 Installation Guide • Februar y 1999

2

) (between the Netra ft 1800 and the circuit

Page 63

Dual Grounding Environment

Caution – To be compatible with grounding environments requiring isolation

between logic 0V and chassis ground, the fitted grounding bridge plate must be

removed and individual connections made to logic 0V and chassis ground studs.

The grounding bridge plate is located on the middle rear left edge of the unit

between the motherboards. The grounding studs at the base of the chassis are M5

studs with appropriate nuts already installed.

Before installation for dual grounding systems, remove the link from the chassis to

logic 0V. This exposes a 2-hole lug with tapped M5 threads (refer to

Caution – The use of certain PCI cards causes the frame and logic grounds to be

commoned. Refer to the documentation supplied with the PCI card.

▼ To Connect the Ground Lead

1. Strip 9mm of insulation from each end of the grounding lead.

2. Insert the lead into the Thomas & Betts two-hole lug provided (part no. 52024-UB).

Ensure that both the conductor and its insulation are gripped by the lug.

FIGURE 3-3).

3. Position the lug and grounding lead assembly over the grounding studs.

Refer to

provided.

4. Make the connection to the earthing bar at the end of the grounding lead.

Ensure there is adequate strain relief for the cable.

FIGURE 3-3 on page 3-50. Tighten the two M5 nuts over the locking washers

Chapter 3 Electrical Supply Installation 49

Page 64

Chassis to

logic 0V link

Wrist strap

connection

point

Grounding

studs

FIGURE 3-3 Location of Chassis-to-Logic-0V Link and Grounding Points, and Wrist Strap

Connection Point

50 Netra ft 1800 Installation Guide • Februar y 1999

Page 65

Connecting the Power Leads

The inlet power filter must be plugged into the power sockets on the motherboards

at the back of the Netra ft 1800, then the six power leads must be attached to the

input power filter.

Note – Disengage all the PSUs before you insert the power connectors. Inserting the

connectors with the PSUs engaged can damage the connectors.

Top of chassis

Power lead

securing screws

Power lead

receptacles

Captive

spring-loaded

securing screw

(2 off)

Power inlet

sockets

Cable management loops

FIGURE 3-4 Power Inlet Filter

Chapter 3 Electrical Supply Installation 51

Page 66

▼ To Assemble the Power Inlet and Leads

1. Insert the socket in the appropriate slot on the motherboard.

The socket can only be inserted one way round. The label on the front of the filter

indicates the correct orientation.

2. Tighten the captive spring-loaded screws, preferably finger-tight only.

If you use a screwdriver, these screws should be tightened no more than 6 in-lbf

(0.68 Nm). Refer to

FIGURE 3-5.

+ RETURN B

Inlet filter

securing

screws

FIGURE 3-5 Power Connector Wiring Polarity and Securing Screws

3. Strip 9mm of insulation from boths ends of each power lead.

The connectors will not accommodate leads of greater than 8 AWG (6 mm

+ RETURN A

– Negative A

– Negative B

2

).

52 Netra ft 1800 Installation Guide • Februar y 1999

Page 67

4. Insert the leads into the appropriate receptacles in the terminal block.

Refer to

FIGURE 3-6.

Insert power

leads here

FIGURE 3-6 Power Lead Receptacles

5. Tighten the terminal block power lead M4 securing screws to 1.5-1.8 Nm.

Refer to

FIGURE 3-7.

Power lead

securing

screws

FIGURE 3-7 Power Lead Securing Screws

Chapter 3 Electrical Supply Installation 53

Page 68

6. Use cable ties to secure the wires to the swivel loops in the mounting bracket (see

FIGURE 3-8).

The loops can be rotated to a convenient position. This strain relief method must be

implemented.

Caution – Observe correct working practices regarding the termination of cable ties.

FIGURE 3-8 Power Cable Arrangement for Strain Relief

7. Ensure the circuit breakers are open, then connect the other ends of the leads to

the circuit breakers.

Secure the cables using adequate strain relief.

54 Netra ft 1800 Installation Guide • Februar y 1999

Cable tie

Page 69

CHAPTER

4

Powering on the System

This chapter describes the procedure for powering on the Netra ft 1800.

▼ To Power On the System

1. Prior to powering on, inspect the supply conductors for mechanical security.

2. Activate the external circuit breakers.

Note – The power supply units (PSUs) remember their last requested state. They are

shipped in the ON state. Because the external circuit breaker is activated when the

last state of the PSU was ON, the PSU will power up at this point.

3. Push the On system switch on either CAF.

55

Page 70

4. Push the other On system switch (on the other CAF front panel).

On

Standby

switch

FIGURE 4-1 System Switches (Front Panel)

switch

The PSU, CPUset and CAF Power LEDs will successively light, and the terminal will

display the output from the Power On Self Test (POST). The POST sequence may

take some time.

The CPUset LEDs will perform their own test sequence towards the end of the POST

procedure, then the Target LED on one of the CPUsets will flash as the OBP ok

prompt appears.

CAF

56 Netra ft 1800 Installation Guide • February 1999

Page 71

CHAPTER

5

Software and Operating

Environment Installation

This chapter describes all the steps necessary to install a software and operating

environment release for the Netra ft 1800. To perform the steps described here, you

should be familiar with the Solaris operating environment.

Netra ft 1800 Install Media

The release software consists of the following:

■ Netra ft 1800 Full Installation containing Solaris and Netra ft 1800 install software.

■ Sun StorEdge Volume Manager 2.5 media kit and Sun StorEdge Volume Manager

patches.

■ Supplemental CD, which contains PCI card drivers, SunVTS and other utilities.

Disk Space Requirement

Netra ft 1800 release software occupies approximately 540 Mbytes of disk space.

57

Page 72

Installation Methods

The Netra ft 1800 supports two types of installation: local, from a local CD-ROM

drive; or network, from a machine set up as a Solaris installation server. The

requirements for these two types of installation are described in the following

subsections.

You must install the Sun StorEdge Volume Manager package when the Netra ft 1800

installation is complete in order to implement fault tolerant operation. See Chapter 6

“Installing and Configuring Sun StorEdge Volume Manager” for more details.

You should install patches after the Netra ft 1800 software installation.

Recommended Solaris patches are included on the Netra ft 1800 Installation CDROM. Any recommended patches should be installed immediately after the reboot

at the end of the installation.

The local and network installation procedures differ only in their initial steps.

Otherwise, the procedure is the same for both types of installation.

Note – Inadvertent keyboard use during installation can abort installation.

Local Installation

To perform a local installation of the Netra ft 1800 software, you must have an RMM

module that contains a CD-ROM drive in slot

to be installed.

Local installation involves booting the Netra ft 1800 from one of its CD-ROM drives

while an installation CD-ROM is in the drive.

Note – The CD-ROM cannot be loaded into the CD-ROM drive unless the drive is

powered on. Do not attempt to load the CD-ROM unless the module’s Power LED is

lit.

58 Netra ft 1800 Installation Guide • Februar y 1999

A-RMM or B-RMM of the Netra ft 1800

Page 73

Network Installation

To perform a network installation of the Netra ft 1800 software, you must ensure the

following:

■ Access to a SPARC server on which the Netra ft 1800 software can be installed. (A

CD-ROM drive is needed for the initial server installation but need not be present

for the network installation.) In the following instructions, this will simply be

referred to as the server.

■ That the Netra ft 1800 system to be installed is on the same subnet as the server.

In the following instructions, this will be simply referred to as the client.

Chapter 5 Software and Operating Environment Installation 59

Page 74

Before You Start

Caution – Before inserting a CD-ROM disk into your system read “Handling and

!

Taking Care of your CD-ROM Disks” in the Netra ft 1800 Compliance and Safety

Manual. In some circumstances if your CD-ROM disk does not have a clean data

surface your system may fail to boot.

1. Establish the following:

■ The system Ethernet address (displayed in the BOOT PROM messages at system

startup, which you can display with the banner utility, invoked from the ok

prompt).

■ The system IP address (see your system administrator).

■ The machine name (see your system administrator).

■ The netmask (see your system administrator).

■ The name service (for example, NIS or NIS+; see your system administrator).

2. You need to be at the OBP ok prompt in order to perform the installation.

▼ To Install the Software

This section describes the steps necessary to install a Netra ft 1800 system with the

Solaris operating environment and Netra ft 1800 software.

Note – It is recommended that you install Solaris on one hard disk only in order to

optimize the performance of the Volume Manager.

1. Disengage all the hard disk drive modules except the one in the location on which

you wish to install the operating environment.

FIGURE 2-17 on page 2-33. You do not need to remove the modules from their

See

slots completely.

2. If the system is powered down, power on the system.

See “To Power On the System” on page 55.

3. Perform Step a for network installation or Step b for local installation.

a. Set up an install server with the Netra ft 1800 CD-ROM

Follow the procedures outlined in Chapter 7 of the Solaris Advanced Installation

Guide (part number 802-5740-10).

60 Netra ft 1800 Installation Guide • Februar y 1999

Page 75

b. Insert the Netra ft 1800 CD-ROM in the drive on side A, at the top of the

system, or the drive on side B at the bottom of the system.

Check that the Power LED is lit on the RMM that contains the CD-ROM drive.

4. Boot the system.

a. For local installation, type:

ok boot a-cdrom0

if you inserted the CD in the CD-ROM drive on side A, or

ok boot b-cdrom0

if you inserted the CD in the CD-ROM drive on side B.

b. For network installation, go to the OBP ok prompt and type:

ok boot a-net0

The Target LED on one CPUset will flash rapidly, and the Diag LED on the other

CPUset will flash at approximately half the speed.

Wait for booting to complete. The Netra ft 1800 software installation program then

starts.

5. Install the Solaris operating environment.

Refer to the Solaris 2.6 documentation for full details of installing the operating

environment. The following Solaris installation documents are shipped with

Netra ft 1800:

■ “Start Here” (a fold-out card) part number 805-3866-10

■ Solaris 2.6 Hardware: 3/98, Chapter 1, part number 805-3540-10

■ Solaris Advanced Installation Guide, part number 802-5740-10

In the course of Solaris installation, follow the instructions on the screen, using the

following information:

a. Accept the device offered by the system as the default disk.

b. Choose Manual Layout.

Chapter 5 Software and Operating Environment Installation 61

Page 76

You must leave two free slices for Sun StorEdge Volume Manager. The disk layout

should have a maximum of five slices, plus the overlap slice, similar to the

following:

TABLE5-1 Suggested Disk Layout

Slice Size

/

swap 512 (rounds up to 513)

overlap no change

/export 2000

/opt 2000

/var 1050

3000

There will be some rounding differences.

You must also leave 1024 sectors, or 512K, free for Sun StorEdge Volume Manager

within the total space available. This space is required for the allocation of an ondisk database to allow the disk to be encapsulated. See the Sun StorEdge

Volume Manager Release Notes for full details.

6. Select Manual Reboot.

7. After Solaris has finished booting, set the default boot device:

# eeprom boot-device=a-dsk0 diag-device=a-dsk0

This sets the boot device to the disk in location

drive in a different location, replace a-dsk0 with the location that corresponds to

the default device that you set during Solaris installation.

8. Re-engage the HDD modules which you removed before installation, and remove

the CD from the drive if you installed locally.

Eject the CD using vold.

9. Reboot the system by typing:

# reboot

A few minutes after the system has rebooted to the system prompt, the Sync LEDs

on the CPUsets will illuminate and remain steadily lit, indicating that the system is

now running in synchronization.

62 Netra ft 1800 Installation Guide • Februar y 1999

A-DSK0. If you installed on a disk

Page 77

10. Install the appropriate patches.

Refer to the Release Notes accompanying the CD.

11. Install the required PCI drivers and, if desired, SunVTS.

Refer to the Release Notes accompanying the CD.

5.1 Finishing Installation

Finishing installation includes:

■ Appending the path to the Netra ft 1800 CMS utilities to the PATH variable;

■ Setting the MANPATH environment variable to include path to the man pages

shipped with the Netra ft 1800 software.

5.1.1 Setting up Access to

Netra ft 1800 CMS Utilities

To allow access to Netra ft 1800 CMS utilities, append the following path to your

PATH variable in your shell start-up file.

For a C-shell, in your $HOME/.cshrc file type:

setenv PATH ${PATH}:/usr/platform/SUNW,Ultra-4FT/SUNWcms/sbin

For a Bourne or Korn shell, in your $HOME/.profile file type:

PATH=${PATH}:/usr/platform/SUNW,Ultra-4FT/SUNWcms/sbin:

export PATH

5.1.2 Setting the MANPATH Variable

To obtain access to the Netra ft 1800 man pages, you must assign or append

/opt/SUNWsms/mfs/lib to the MANPATH environment variable.

Chapter 5 Software and Operating Environment Installation 63

Page 78

For a C-shell, in your $HOME/.cshrc file type:

setenv MANPATH ${MANPATH}:/opt/SUNWftm

For a Bourne or Korn shell, in your $HOME/.profile file type:

MANPATH=${MANPATH}:/opt/SUNWftm

export MANPATH

64 Netra ft 1800 Installation Guide • Februar y 1999

Page 79

CHAPTER

6

Installing and Configuring

Sun StorEdge Volume Manager

This section contains guidelines for installing Sun StorEdge Volume Manager to

provide fault tolerant mass storage on the Netra ft 1800 system.

The main steps involved are:

1. Using pkgadd to load the Volume Manager packages, and install any required

patches.

2. Configuring the Volume Manager software as described in “Setting up the

Volume Manager Environment” on page 68.

3. Initializing the Volume Manager disk storage as described in “Initializing the

Volume Manager” on page 69.

Refer to the Sun StorEdge Volume Manager documentation for full information

about installing and using the Volume Manager, and to the Netra ft 1800 User’s Guide

for information about using the cmsconfig utility. (You use cmsconfig to obtain

the device name of the root disk when you add disks to your server.)

You perform all of the steps in this chapter as root.

Before You Install Sun StorEdge

Volume Manager

Sun StorEdge Volume Manager is installed on the Netra ft 1800 system in the same

way as other applications.

65

Page 80

In the following procedure, you use cmsconfig to obtain the Disk attribute of the

HDD module and the Funct_0 attribute of the CD-ROM drive (plus Funct_1 if you

have an additional drive).

To identify the device name of the root disk:

1. Start cmsconfig:

# /usr/platform/SUNW,Ultra-4FT/SUNWcms/sbin/cmsconfig

2. Locate the HDD modules in the list.

You can press p to page down to see second and subsequent pages.

3. For each HDD module in the list:

a. Enter the number next to the module.

The attributes of the module are displayed.

b. Note the Disk attribute of the module.

This is a normal Solaris device name.

c. Press q to return to the list of modules

4. For each RMM module in the list:

a. Enter the number next to the module.

The attributes of the module are displayed.

b. Note the Funct_0 attribute of the module.

This is the device name of the CD-ROM drive. It is a normal Solaris device name.

If there is a second CD-ROM drive in the module, note the Funct_1 attribute.

This is the device name of the second CD-ROM drive. It is a normal Solaris device

name.

c. Press q twice to exit cmsconfig.

You will need this information when you initialize the Volume Manager. It can be

useful for other purposes, so you may wish to keep it.

You should install the Volume Manager after the Netra ft 1800 software and any

required patches, and before other applications. You should also configure the

Volume Manager volumes before you install other applications.

Before you install Sun StorEdge Volume Manager, copy the file /etc/vfstab to /

etc/vfstab.prevm. This standard practice helps Sun support engineers to recover

a system in the very rare event of serious system failure.

66 Netra ft 1800 Installation Guide • Februar y 1999

Page 81

Caution – Failures during the Sun StorEdge Volume Manager boot disk

!

!

encapsulation process could result in loss of data on the root file system.

Caution – Encapsulation of the boot disk will require that the installed system is

shutdown and rebooted several times.

Installing the Volume Manager Software

This section describes the special requirements when you install the Volume

Manager on the Netra ft 1800. You must install Sun StorEdge Volume Manager and

patches specified in the Release Notes.

See the Sun StorEdge Volume Manager Installation Guide for full details of the Volume

Manager installation.

Mounting the CD-ROM Manually

If the Solaris daemon vold is running (the default situation), you can simply refer to

the path to the CD-ROM, /cdrom/cdrom0/netra_ft1800. If, for some reason,

vold is not running, mount the CD-ROM with the command:

# mount -F hsfs -r /dev/dsk/drive_id /cdrom

Replace drive_id with the correct value for the CD-ROM drive on your system.

Running the Installation

Follow the instructions in the Sun StorEdge Volume Manager Installation Guide and

any instructions in the Sun StorEdge Volume Manager and Netra ft 1800 Release

Notes to run the installation.

You use pkgadd to load the standard set of packages for Sun StorEdge

Volume Manager. You must also follow any instructions in the Release Notes to

obtain and install Volume Manager patches required for the Netra ft 1800.

Chapter 6 Installing and Configuring Sun StorEdge Volume Manager 67

Page 82

Setting up the Volume Manager Environment

When you have loaded the Volume Manager software, and before you run

vxinstall to initialize it, you must configure the software to run as required on the

Netra ft 1800. This involves the following:

■ Setting default volume creation to mirror disks by default when they are created

■ Configuring the Volume Manager to deal with stale boot disks

■ Configuring the Volume Manager’s recovery behavior when a physical disk fails

■ Enabling boot disk detection

Setting Default Volume Creation

Note – Disk mirroring in Volume Manager provides the fault tolerance for the disk

storage of the Netra ft 1800. This step is essential to ensure that all disks are

mirrored.

To mirror disks by default when they are created, enter the following:

$

echo "mirror=yes" > /etc/default/vxassist

Note – If the vxassist file already exists, resolve any differences between the

contents of the file and the line mirror=yes. The resulting file must contain the line

mirror=yes.

The preceding command creates the /etc/default/vxassist file with the

required line in it. This sets the tunable parameters used by the Volume Manager

vxva GUI. (These parameters can be overriden via the command line.) See the

Sun StorEdge Volume Manager documentation for full details.

Dealing with Stale Boot Disks

To prevent the system from stopping when it encounters a stale boot plex during the

boot sequence, enter the following:

# mkdir -p /etc/vx/sbin

# echo ’/sbin/uadmin 2 1 "stale"’ > /etc/vx/sbin/vxaltstale

# chmod +x /etc/vx/sbin/vxaltstale

68 Netra ft 1800 Installation Guide • Februar y 1999

Page 83

These commands create a startup script that enables the Volume Manager to exit

back to the OBP upon encountering a stale boot plex, allowing the Volume Manager

to try alternative boot disks.

Enabling Recovery Behavior and Boot Disk Detection

To enable correct recovery behavior and boot disk detection, make the following

changes to the startup file /etc/rc2.d/S95vxvm-recover:

# vxrelocd root & commenting out this line enables correct recovery behavior

# start the boot disk utility

/usr/platform/SUNW,Ultra-4FT/SUNWcms/lib/vxbootcheck &

Make the edits exactly as shown, commenting out the vxrelocd line and with the

complete path to vxbootcheck. Be sure to append an ampersand to the

vxbootcheck line.

The default behavior of Sun StorEdge Volume Manager when a physical disk fails is

not compatible with the hot-plug of HDD modules on the Netra ft 1800. By default,

when the Volume Manager detects I/O failure on mirrored volumes, it restores

redundancy by relocating the objects to spare disks. This is called hot relocation.You

need to disable this default behavior. By commenting out the vxrelocd line, as

shown above, you prevent hot relocation.

the following line enables boot disk detection

You must repeat all these modifications after system upgrades.

Initializing the Volume Manager

When you have loaded the Sun StorEdge Volume Manager, run vxinstall as

described in the Sun StorEdge Volume Manager Installation Guide. This section

describes the special actions you must take to initialize the Volume Manager for the

Netra ft 1800.

Note – Volume Manager mirroring provides the fault tolerance for disk storage on

the Netra ft 1800. This is provided by default when you add a disk to the Volume

Manager provided you have added the required line to /etc/default/vxassist

as described in “Setting Default Volume Creation” on page 68.

Chapter 6 Installing and Configuring Sun StorEdge Volume Manager 69

Page 84

Setting up Boot Disks

You must encapsulate the boot disk for Sun StorEdge Volume Manager to be able to

mirror it. You are strongly recommended to do the following to ensure that the boot

disk is configured for the Netra ft 1800:

■ Assuming that A-DSK0 is the Solaris install disk, you should have entered the

command shown below at the end of the Solaris installation. See eeprom (1) for

details on using eeprom command to change the boot device.

# eeprom boot-device=a-dsk0 diag-device=a-dsk0