Page 1

StorageTek™

L40

Tape Library

Installation Manual

96053

Revision: L

Page 2

Page 3

L40

Tape Library

Installation Manual

Page 4

Copyright 2006 Sun Microsystems, Inc., 4150 Network Circle, Santa Clara, California 95054, U.S.A. Al l rights reserved.

Sun Microsystems, Inc. has intellectual property rights relating to technology that is described in this document. In particular, and without

limitation, these intellectual property rights may include one or more of the U.S. patents listed at http://www.sun.com/patents and one

or more additional patents or pending patent applications in the U.S. and in other countries.

This document and the product to which it pertains are distributed under licenses restricting their use, copying, distribution, and

decompilation. No part of the product or of this document may be reproduced in any form by any means without prior written

authorization of Sun and its licensors, if any.

Third-party software, including font technology, is copyrighted and licensed from Sun suppliers.

Parts of the product may be derived from Berkeley BSD systems, licensed from the University of California. UNIX is a registered

trademark in the U.S. and in other countries, exclusively licensed through X/Open Company, Ltd.

Sun, Sun Microsystems, the Sun logo, Java, AnswerBook2, docs.sun.com, and Solaris, StorageTek, VolSafe, TimberWolf, TimberLine, and

RedWood are trademarks or registered trademarks of Sun Microsystems, Inc. in the U.S. and in other countries.

All SPARC trademarks are used under license and are trademarks or registered trademarks of SPARC International, Inc. in the U.S. and in

other countries. Products bearing SPARC trademarks are based upon an architecture developed by Sun Microsystems, Inc.

The OPEN LOOK and Sun™ Graphical User Interface was developed by Sun Microsystems, Inc. for its users and licensees. Sun

acknowledges the pioneering efforts of Xerox in researching and developing the concept of visual or graphical user interfaces for the

computer industry. Sun holds a non-exclusive license from Xerox to the Xerox Graphical User Interface, which license also covers Sun’s

licensees who implement OPEN LOOK GUIs and otherwise comply with Sun’s written license agreements.

U.S. Government Rights—Commercial use. Government users are subject to the Sun Microsystems, Inc. standard license agreement and

applicable provisions of the FAR and its supplements.

DOCUMENTATION IS PROVIDED "AS IS" AND ALL EXPRESS OR IMPLIED CONDITIONS, REPRESENTATIONS AND

WARRANTIES, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR

NON-INFRINGEMENT, ARE DISCLAIMED, EXCEPT TO THE EXTENT THAT SUCH DISCLAIMERS ARE HELD TO BE LEGALLY

INVALID.

Copyright 2006 Sun Microsystems, Inc., 4150 Network Circle, Santa Clara, Californie 95054, Etats-Unis. Tous droits réservés.

Sun Microsystems, Inc. a les droits de propriété intellectuels relatants à la technologie qui est décrit dans ce document. En particulier, et

sans la limitation, ces droits de propriété intellectuels peuvent inclure un ou plus des brevets américains énumérés à http://

www.sun.com/patents et un ou les brevets plus supplémentaires ou les applications de brevet en attente dans les Etats-Unis et dans les

autres pays.

Ce produit ou document est protégé par un copyright et distribué avec des licences qui en restreignent l’utilisation, la copie, la

distribution, et la décompilation. Aucune partie de ce produit ou document ne peut êt re reproduite s ous aucune forme, par quelque

moyen que ce soit, sans l’autorisation préalable et écrite de Sun et de ses bailleurs de licence, s’il y en a.

Le logiciel détenu par des tiers, et qui comprend la technologie relative aux polices de caractères, est protégé par un copyright et licencié

par des fournisseurs de Sun.

Des parties de ce produit pourront être dérivées des systèmes Berkeley BSD licenciés par l’Université de Californie. UNIX est une marque

déposée aux Etats-Unis et dans d’autres pays et licenciée exclusivement par X/Open Company, Ltd.

Sun, Sun Microsystems, le logo Sun, Java, AnswerBook2, docs.sun .com, et Solaris, StorageTek, VolSafe, TimberWolf, TimberLine, and

RedWood sont des marques de fabrique ou des marques déposées de Sun Microsystems, Inc. aux Etats-Unis et dans d’autres pays.

Toutes les marques SPARC sont utilisées sous licence et sont des marques de fabrique ou des marques déposées de SPARC International,

Inc. aux Etats-Unis et dans d’autres pays. Les produits portant les marques SPARC sont basés sur une architecture développée par Sun

Microsystems, Inc.

L’interface d’utilisation graphique OPEN LOOK et Sun™ a été développée par Sun Microsystems, Inc. pour ses utilisateurs et licenciés.

Sun reconnaît les efforts de pionniers de Xerox pour la recherche et le développement du concept des interfaces d’utilisation visuelle ou

graphique pour l’industrie de l’informatique. Sun détient une license non exclusive de Xerox sur l’interface d’utilisation graphique Xerox,

cette licence couvrant également les licenciées de Sun qui mettent en place l’interface d ’utilisation graphique OPEN LOOK et qui en outre

se conforment aux licences écrites de Sun.

LA DOCUMENTATION EST FOURNIE "EN L’ÉTAT" ET TOUTES AUTRES CONDITIONS, DECLARATIONS ET GARANTIES

EXPRESSES OU TACITES SONT FORMELLEMENT EXCLUES, DANS LA MESURE AUTORISEE PAR LA LOI APPLICABLE, Y

COMPRIS NOTAMMENT TOUTE GARANTIE IMPLICITE RELATIVE A LA QUALITE MARCHANDE, A L’APTITUDE A UNE

UTILISATION PARTICULIERE OU A L’ABSENCE DE CONTREFAÇON.

We welcome your feedback. Please contact the Sun Learning Services Feedback System at:

SLSFS@Sun.com

or

Sun Learning Services

Sun Microsystems, Inc.

One StorageTek Drive

Louisville, CO 80028-3256

USA

Please include the publication name, part number, and edition number in your correspondence if they are

available. This will expedite our response.

ii Revision L 96053

Page 5

Summary of Changes

EC Date Edition Description

111666 August 2001 First Initial release

111717 January 2002 Second Refer to this edition for a description of the changes.

111732 March 2002 Third Refer to this edition for a description of the changes.

111784 August 2002 Fourth Refer to this edition for a description of the changes.

111828 February 2003 Fifth Refer to this edition for a description of the changes.

111854 June 2003 Sixth Refer to this edition for a description of the changes.

111875 November 2003 Seventh Refer to this edition for a description of the changes.

111923 July 2004 Eighth Refer to this edition for a description of the changes.

111948 January 2005 Ninth Refer to this edition for a description of the changes.

111976 May 2005 Tenth Refer to this edition for a description of the changes.

114172 October 2006 L Cover, Copyright, Preface: Added Sun verbiage and

branding.

Chapter 2: Updated Table 2-5, Table 2-6 and

Table 2-7.

96053 Revision L iii

Page 6

Summary of Changes

This page intentionally left blank.

iv Revision L 96053

Page 7

Contents

Summary of Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

Alert Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Mensajes de alerta . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiii

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiv

Additional Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Sun’s External Web Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Customer Resource Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Partners Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Global Services Support Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xvi

Documents on CD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xvi

Hardcopy Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xvi

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Lifting Techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xviii

Shoulder, Elbow, Wrist, and Hand Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xviii

Rack Safety and Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xix

Fiber-optic Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xix

Laser Product Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

Fiber-optic Cable Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

Fiber-optic Cable Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xxi

Electrostatic Discharge (ESD) Damage Prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

ESD Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

ESD-Protection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xxiii

Prepare the Work Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xxiii

Access the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xxiii

Replace Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xxiii

Clean Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xxiv

96053 Revision L v

Page 8

Contents

Seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxv

Precauciones de seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxv

Técnicas de levantamiento de objetos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xxvi

Seguridad de hombros, codos, muñecas y manos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xxvi

Seguridad y precauciones del bastidor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvii

Seguridad de fibras ópticas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvii

Etiqueta del producto láser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xxviii

Instalación de cables de fibra óptica . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xxix

Manipulación de cables de fibra óptica . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xxix

Prevención de daños por descargas electrostáticas (DES) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxx

Precauciones contra descargas electrostáticas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxx

Procedimiento de protección contra descargas electrostáticas . . . . . . . . . . . . . . . . . . . . . . . . . .xxxi

Prepare el área de trabajo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xxxi

Acceda al equipo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxxii

Sustituya los componentes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxxii

Limpie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxxii

1: Hardware Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Quick Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Standard Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Preparing for the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Unpacking the Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Inspecting the Library and Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Preparing the Installation Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Positioning the Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Desktop Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Rack Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Choosing SCSI HVD or LVD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

SCSI Cable Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Host Bus Adapter Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

SCSI Device/Bus Type Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Installing the External Fibre Channel Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Connecting the External SCSI Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Connecting Fiber and SCSI Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Attaching the Personality Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Attaching the Cell Barrier Clip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Inserting the Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Drive Compatibility Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Installing the Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

Powering-on the Library and Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

Recording the Configuration Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

vi Revision L 96053

Page 9

Contents

2: Locations, Specifications, and Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Library Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Library Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Drive and Cartridge Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Drive Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Power Cord Numbers and Receptacles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

External Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

A: SNMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

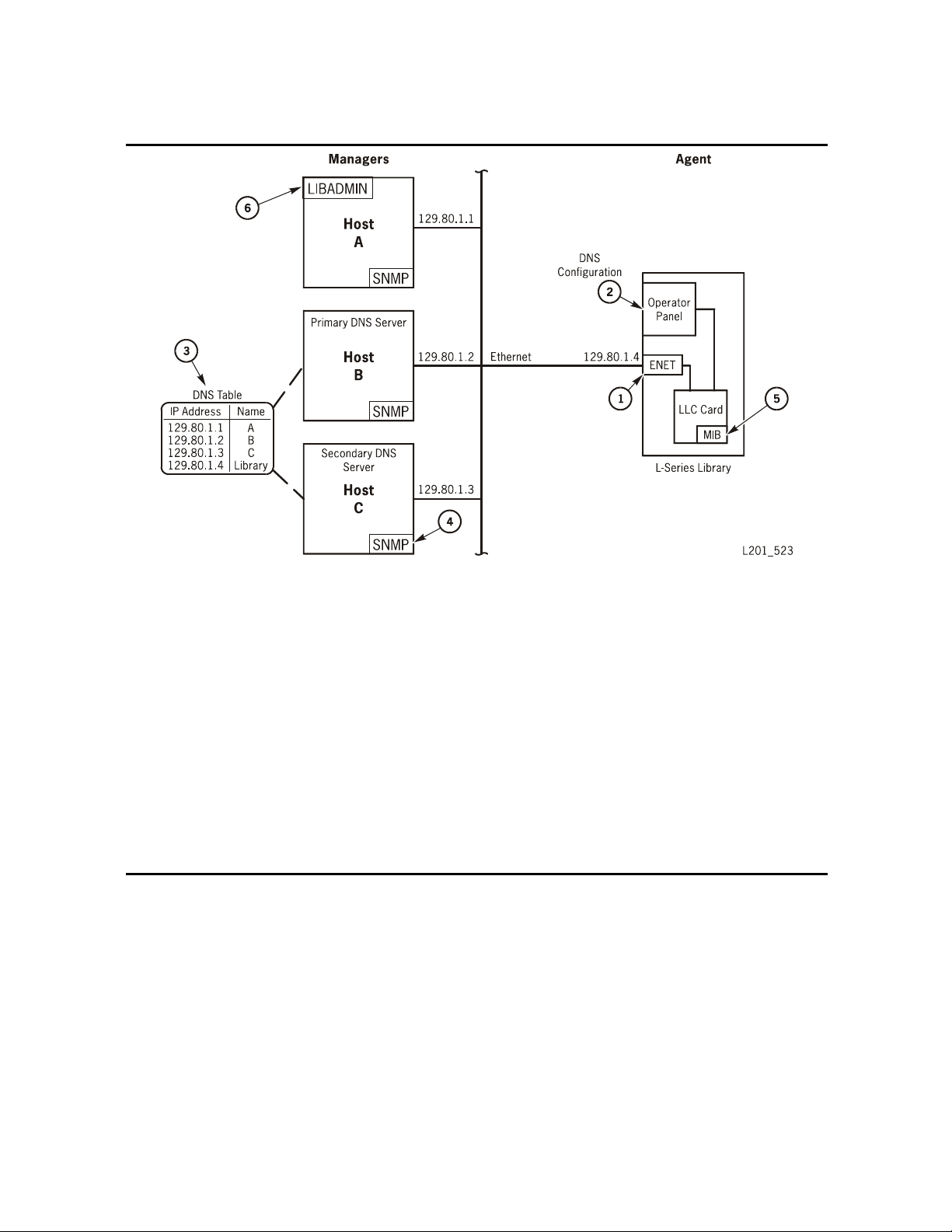

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

SNMP Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

SNMP Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Access Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Management Information Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Starting SNMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Index-1

96053 Revision L vii

Page 10

Figures

Figure 1-1. Unpacking the Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Figure 1-2. Attaching the Cell Barrier Clip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

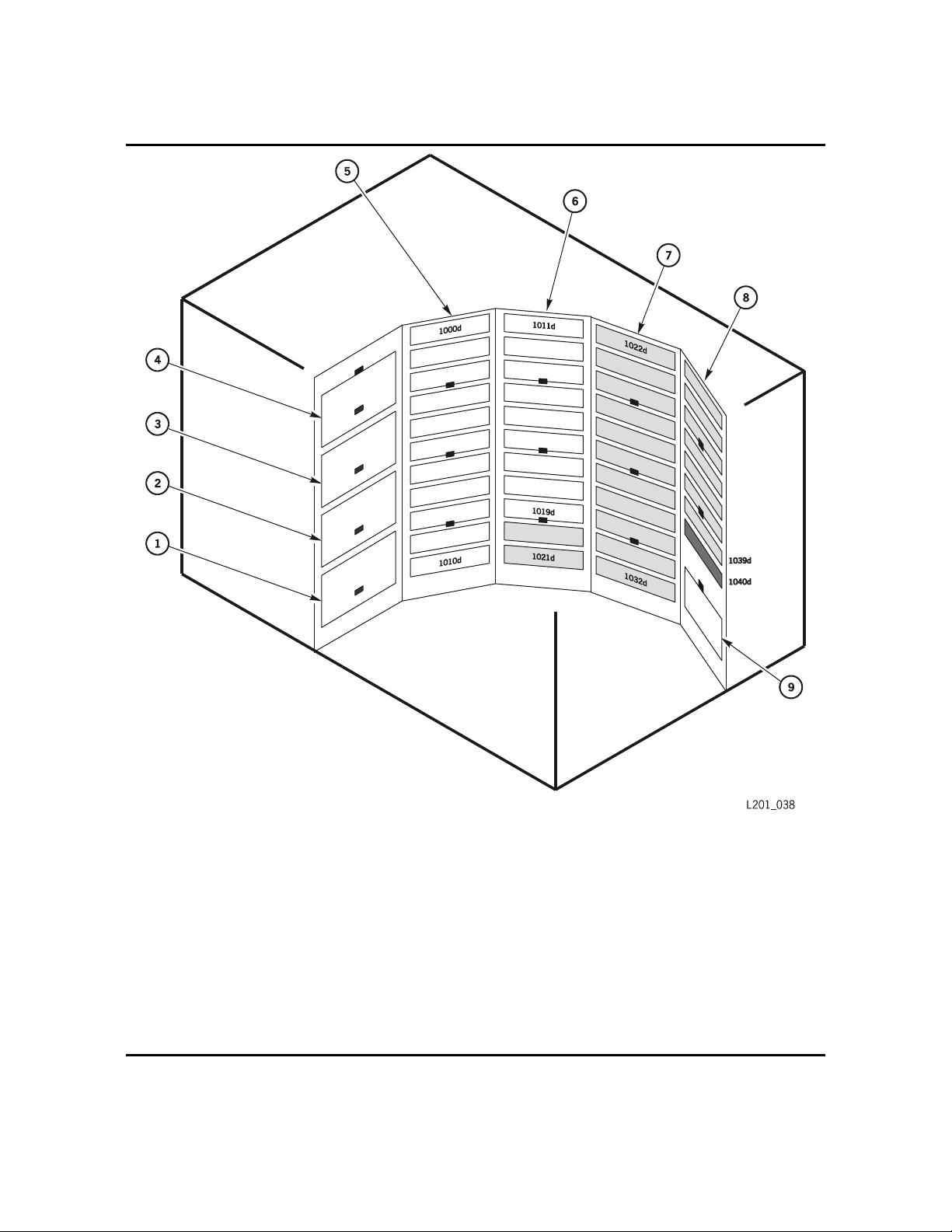

Figure 1-3. Determining the Valid Storage Cells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

Figure 1-4. Inserting the Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

Figure 2-1. Front View of Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Figure 2-2. Rear View of Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Figure 2-3. Internal View of Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Figure 2-4. Robotic Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Figure 2-5. DLT Drive Label Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Figure 2-6. Ultrium Drive Label Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Figure 2-7. L40 Desktop Version Dimensions and Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Figure 2-8. L40 Rack Version Dimensions and Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

96053 Revision L viii

Page 11

Tables

Tables

Table 1-1. SCSI Cable Length Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Table 1-2. SCSI Device/Bus Types: Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Table 1-3. LTO Drive Backward Readability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Table 1-4. SCSI Device/Bus Types: Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Table 1-5. Compatible Drives and Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

Table 1-6. L40 Tape Library Configuration Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

Table 2-1. Library Environment Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Table 2-2. Library Power Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Table 2-3. Drive and Cartridge Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Table 2-4. Drive Power Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Table 2-5. Country-specific Power Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Table 2-6. Non-country-specific Power Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Table 2-7. External Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

96053 Revision L ix

Page 12

Tables

x Revision L 96053

Page 13

Preface

This manual is for either customers or service representatives, depending upon the

service contract. When you have completed the procedures in this manual, refer to the

user’s guide to configure your library. See

Most of the information pertains to library hardware. For specific drive information or

for client-generated software commands and console messages, refer to your drive or

software documentation.

■ Organization

This manual has two chapters, an appendix, and an index:

Chapter 1 “Hardware Installation” tells you how to install the hardware portions

Chapter 2 “Locations, Specifications, and Cables” identifies library components,

“Related Publications” on page xiv.

of the library. It contains a “Quick Installation Procedure” for

experienced users and a “Standard Installation Procedure” that guides

you through each step of the installation.

drive label locations, specifications, and external cable part numbers.

Appendix A “SNMP” provides the implementation of the Simple Network

Management Protocol (SNMP).

Index The Index helps you locate information.

96053 Revision L xi

Page 14

■ Alert Messages

Alert messages call your attention to information that is especially important or that has a

unique relationship to the main text or graphic.

Note: A note provides additional information that is of special interest. A note might

point out exceptions to rules or procedures. A note usually, but not always,

follows the information to which it pertains.

CAUTION:

A caution informs you of conditions that might result in damage to

hardware, corruption of data, or corruption of application software.

A

caution always precedes the information to which it pertains.

WARNING:

A warning alerts you to conditions that might result in long-term health

problems, injury, or death. A warning always precedes the information

which it pertains.

to

■ Mensajes de alerta

Los mensajes de alerta llaman la atención hacia información de especial importancia

que tiene una relación específica con el texto principal o los gráficos.

o

Nota: Una nota expone información adicional que es de interés especial. Una nota

puede señalar excepciones a las normas o procedimientos. Por lo general, aunque

no siempre, las notas van después de la información a la que hacen referencia.

PRECAUCIÓN:

Una precaución informa sobre situaciones que podrían conllevar

daños

Las

hacen

ADVERTENCIA:

Una advertencia llama la atención sobre condiciones que podrían

conllevar problemas de salud crónicos, lesiones o muerte.

Las

hacen

del hardware, de los datos o del software de aplicación.

precauciones van siempre antes de la información a la que

referencia.

advertencias van siempre antes de la información a la que

referencia.

xii Revision L 96053

Page 15

■ Conventions

Typographical conventions highlight special words, phrases, and actions in this

publication.

Item Example Description of Convention

Buttons

Commands Mode Select Initial cap

Document titles System Assurance Guide Italic font

Emphasis not or must Italic font

File names fsc.txt Monospace font

Hypertext links Figure 2-1 on page 2-5 Blue (prints black in hardcopy

Indicators Open Font and capitalization follows label

Jumper names TERMPWR All uppercase

Keyboard keys

Menu names Configuration Menu Capitalization follows label on

Parameters and variables Device = xx Italic font

Path names c:/mydirectory Monospace font

MENU

<Y>

<Enter> or

<Ctrl+Alt+Delete>

Font and capitalization follows label

on product

publications)

on product

Font and capitalization follows label

on product; enclosed within angle

brackets

product

Port or connector names SER1 Font and capitalization follows label

on product; otherwise, all uppercase

Positions for circuit breakers,

jumpers, and switches

Screen text (including screen

captures, screen messages, and

user input)

Switch names

URLs http://www.sun.com Blue (prints black in hardcopy

96053 Revision L xiii

ON Font and capitalization follows label

on product; otherwise, all uppercase

downloading Monospace font

Power

Font and capitalization follows label

on product

publications)

Page 16

■ Related Publications

Refer to the following publications for additional information:

Library Documentation Part Number

L40 Tape Library Ordering Guide MT5011

L40 Tape Library Service Manual 96026

L40 Tape Library User’s Guide 96005

L40/80 Tape Library CRU Instructions 96031

L40/80 Tape Library Drives CRU Instructions 96006

Tape Drive Documentation Part

DLT 7000 Tape Drive Product Manual 31313450x

DLT 8000 Tape Drive Product Manual Quantum: 81-60118-0x

DLT1 Installation and Operations Guide Benchmark: 000826-0x

DLT1 Product Specification Benchmark: 000827-0x

SDLT 220, 320 and 600 Product Manual CD included with drive

Hewlett Packard LTO Ultrium Publication CD included with drive

IBM LTO Ultrium Publication CD included with drive

Quantum’s Certance LTO Ultrium Publication CD included with drive

Other Publications Part Number

American National Standard Dictionary for Information

Processing Systems

American National Standard Magnetic Tape and Cartridge

for Information Interchange

Crossroads Fibre Router User’s Manual DS30110

StorageNet 3300 Fibre Channel Router User Manual 461273-01

Fiber Optic User’s Guide 9433

Magnetic Tape Labels and File Structure for Information

Interchange

SCSI-3 Parallel Interface (SPI) ANSI X3T9.2/91-010R7

Small Computer System Interface ISO 9316:1989

ANSI X3/TR-1-82

ANSI X3B5/87-009

ANSI X3.27-1978

xiv Revision L 96053

Page 17

■ Additional Information

Sun Microsystems, Inc. (Sun) offers several methods for you to obtain additional

information.

Sun’s External Web Site

Sun’s external Web site provides marketing, product, event, corporate, and service

information. The external Web site is accessible to anyone with a Web browser and an

Internet connection.

The URL for the external Web site is: http://www.sun.com

The URL for StorageTek™ brand-specific information is:

http://www.sun.com/storagetek/

Customer Resource Center

The Sun StorageTek product Customer Resource Center (CRC) is a Web site that enables

members to resolve technical issues by searching code fixes and technical documentation

for StorageTek brand products. CRC membership entitles you to other proactive services,

such as HIPER subscriptions, technical tips, answers to frequently asked questions,

addenda to product documentation books, and online product support contact

information. Customers who have a current warranty or a current maintenance service

agreement may apply for membership by clicking on the

on the CRC home page. Sun employees may enter the CRC through the SunWeb

PowerPort.

Request Password button

The URL for the CRC is http://www.support.storagetek.com

Partners Site

The StorageTek Partners site is a Web site for partners with a StorageTek Partner

Agreement. This site provides information about products, services, customer support,

upcoming events, training programs, and sales tools to support StorageTek Partners.

Access to this site, beyond the Partners Login page, is restricted. On the Partners Login

page, employees and current partners who do not have access can request a login ID and

password and prospective partners can apply to become StorageTek resellers.

The URL for the StorageTek Partners site is:

http://members.storagetek.com

The URL for partners with a Sun Partner Agreement is:

http://www.sun.com/partners/

96053 Revision L xv

Page 18

Global Services Support Tools

Global Services Support Tools site (also called Field Tools) provides tools that aid in the

sales and support of Sun StorageTek brand products and services. This is an internal Web

site for employees.

The URL for the Global Services Support Tools is http://sunsolve.central.sun.com/

handbook_internal/FieldTools

Documents on CD

Documents on CD (3106600xx) contains portable document format (PDF) files of Sun

StorageTek brand product publications. To order Documents on CD, contact your local

Customer Services Logistics Depot. Documents on CD is only for employees.

Hardcopy Publications

You may order paper copies of publications listed on the CRC or included on the

Documents on CD.

Service publications have numeric part numbers. To order paper copies of service

publications, contact your local Customer Services Logistics Depot.

xvi Revision L 96053

Page 19

Safety

The following pages describe common practices concerning electrical safety, ergonomics,

rack installation, fiber optics, and electrostatic discharge.

■ Safety Precautions

WARNING:

Potential injury: On-the-job safety is important; therefore, observe the

following safety precautions while you are engaging in any maintenance

activity. Failing to follow these precautions could result in serious injury.

Remove all conductive jewelry, such as watches and rings, before you

service powered-on equipment.

• Avoid electrical shock. Be careful when you work near power connectors and

supplies.

• Power-off the equipment that is being serviced before you remove a field replaceable

unit (FRU) or other component. Remember that dangerous voltages could still be

present in some areas even though power is off.

• Ground all test equipment and power tools.

• Lift objects properly; read the information in “Lifting Techniques” on page -xviii.

• Do not remove, cut, or relocate any floor tiles indiscriminately. Before you

manipulate floor tiles, be sure that you understand the customer’s environment and

receive the customer’s approval. Remember, each situation is different.

• Enforce good housekeeping practices in the equipment area to help prevent fire and

accidents.

Note: Important things to investigate and to be aware of include the use of Halon®

gas, under-the-floor smoke detectors, and cables to other equipment installed

nearby.

96053 Revision L xvii

Page 20

■ Lifting Techniques

Lifting, regardless of how much or how little, can create serious back stress. If you follow

these guidelines, you can reduce the risk of back injury:

• Do not twist your body to pick up something or to put it down. Twisting puts

extreme pressure on your back, especially when you lift or carry objects. Instead of

twisting, make the task two separate moves; first lift, and then use your feet to turn

your body.

• Plan the lift: first examine the object and then determine how it will be lifted and

where it will be placed.

• Choose the appropriate lifting technique. Examine the weight, size, location,

frequency, and direction of the lift. Plan to avoid awkward postures, and determine if

material-handling aids are needed.

• Place your feet shoulder-width apart, and place one foot a little behind the other.

Keep your back straight because even light loads can significantly increase pressure

on your spine when you lean forward.

• Whenever you can, grip the load with your whole hand, and use two hands.

• Carry objects at elbow height and close to your body. The farther away you hold an

object, the more force it puts on your lower back.

• Lift with your legs instead of your back. Leg muscles are some of the strongest in the

body. When you squat and lift with your legs, you can lift more weight safely.

• Alternate lifting tasks with tasks that are less stressful to the same muscles. This

technique ensures that your muscles have some recovery time.

Shoulder, Elbow, Wrist, and Hand Safety

Follow these guidelines to minimize the possibility of injury to your shoulders, elbows,

wrists, and hands.

• Work within your safety zone—the area between shoulder level and knuckle level of

your lowered hands. You face less chance of injury when you work or lift in this area.

• Keep your elbows bent to keep loads close to your body and to decrease the amount

of force necessary to do the job. If you use this posture, you will put less weight and

pressure on your shoulder.

• Be sure to keep your wrists straight. Avoid bending, extending, or twisting your

wrists for long periods of time.

• Do not use a pinch grip to lift large or heavy loads because the way you lift also can

affect the tendons in your hand. When you grasp an object between your thumb and

fingers, you put a lot of tension on hand and wrist tendons. Use both hands—use

one for a while, and then use the other—to give them rest.

xviii Revision L 96053

Page 21

■ Rack Safety and Precautions

WARNING:

Possible personal injury:

• Lifting hazard: The library weighs 44.45 kg (98 lb) plus the weight of

the drives. Use at least two people and a mechanical device to lift and

position the library. Make sure you read the information in

“Lifting Techniques” on page xviii before beginning.

• Also consider the library’s total weight when you are placing other

equipment into the rack. To prevent an unbalanced situation, install

the heaviest equipment on the bottom and the lightest equipment on

the top. Failure to do so might cause the rack to become unstable

and tip over.

Observe the following safety precautions when you are installing the library into a rack:

• If the rack has front or rear doors, do not allow the doors to interfere with the

library’s ventilation. The rack’s internal ambient temperature should not exceed the

recommended operating temperature range of the library. The maximum rack air

ambient temperature is 40°C (104°F).

• Ensure that rack doors provide adequate clearance to the library.

• Ensure that the combination of the library with other equipment in the rack does not

create an overcurrent condition, whether the equipment is connected directly to the

branch circuit or to a power distribution strip.

• Ensure that all equipment in the rack has reliable earth ground, whether the

equipment is connected directly to the branch circuit or to a power distribution strip.

Note: The library relies on the ground pin of the power cord for its earth ground.

■ Fiber-optic Safety

WARNING:

Eye hazard. Never look directly into a fiber-optic cable, a fiber-optic

connector, or a laser transceiver module. Hazardous conditions might

exist from laser power levels that are capable of causing injury to the

eye.

Be especially careful when using optical instruments with this

equipment. Such instruments might increase the likelihood of eye injury.

The laser transceivers in fiber-optic equipment can pose dangers to personal safety.

Ensure that anyone who works with this Sun StorageTek equipment understands these

dangers and follows safety procedures. Ensure that the optical ports of every laser

transceiver module are terminated with an optical connector, a dust plug, or a cover.

96053 Revision L xix

Page 22

Each fiber-optic interface in this Sun StorageTek Fibre Channel equipment contains a

laser transceiver that is a Class 1 Laser Product. Each laser transceiver has an output of

less than 70 μW and a wavelength of 850 nm. Sun StorageTek’s Class 1 Laser Products

comply with EN60825-1(+A-11) and with sections 21 CFR 1040.10 and 1040.11 of the

Food and Drug Administration (FDA) regulations.

The following translations are for users in Finland and Sweden who wish to identify laser

safety and classification:

CLASS 1 LASER

LUOKAN 1 LASERLAITE

KLASSE 1 LASER APPARAT

Laser Product Label

In accordance with safety regulations, a label on each Sun StorageTek Fibre Channel

product identifies the laser class of the product and the place and date of the

manufacturer. The label appears on top of a Fibre Channel tape drive and near the Fibre

Channel connectors on a Fibre Channel tape library. A copy of the label is shown here:

COMPLIES WITH 21 CFR 1040.10 AND 1040.11

CLASS 1 LASER PRODUCT

LASER KLASSE 1

APPAREIL A LASER DE CLASSE 1

Fiber-optic Cable Installation

Follow these guidelines when you install fiber-optic cables:

1. Cable routing:

• Raised floor: You may install fiber-optic cables under a raised floor. Route them

away from any obstruction, such as existing cables or other equipment.

• Cable tray or raceway: Place the cables in position; do not pull them through

the cable tray. Route the cables away from sharp corners, ceiling hangers, pipes,

and construction activity.

• Vertical rise len g t h : Leave the cables on the shipping spool, and lower them

from above; do not pull the cables up from below. Use proper cable ties to

secure the cable.

• General: Do not install fiber-optic cables on top of smoke detectors.

xx Revision L 96053

Page 23

2. Cable management:

• Leave at least 4.6 m (15 ft) of cable at each end for future growth.

• Use strain reliefs to prevent the weight of the cable from damaging the

connector.

• Review all information in this manual and in any related manuals about safely

handling fiber-optic cables.

3. Connector protection:

• Insert connectors carefully to prevent damage to the connector or fiber.

• Leave the connector’s protective cover in place until you are ready to make

connections.

• Replace the connector’s protective cover when the connector is disconnected.

• Clean the connector before making a connection. Make sure that there are no

obstructions and that keyways are aligned.

Fiber-optic Cable Handling

Observe these precautions when you handle fiber-optic cables:

• Do not coil the cable to less than 96 mm (3.75 in.) in diameter.

• Do not bend the cable to less than 12 mm (0.5 in.) in radius. It is most important that

a cable’s bend radius be no less than 20 times the diameter of the cable.

• Do not pull on the cables; carefully place them into position.

• Do not grasp the cables with pliers, grippers, or side cutters; do not attach pulling

devices to the cables or connectors.

• Keep cables away from sharp edges or sharp protrusions that could cut or wear

through the cable; make sure that cutouts in the equipment have protective edging.

• Protect the cable from extreme temperature conditions.

• Install the connector’s protective cover whenever the connector is not connected.

96053 Revision L xxi

Page 24

■ Electrostatic Discharge (ESD) Damage Prevention

Anyone who handles ESD-sensitive components must be aware of the damage that ESD

can cause to electronic components and must take the proper precautions to prevent it.

Also, anyone who performs maintenance on Sun StorageTek equipment must complete

an ESD-basics course.

CAUTION:

Potential damage to equipment: Handle ESD-sensitive components only

under ESD-protected conditions. To meet this requirement, always use

the Field Service Grounding Kit (PN 4711) and always follow these ESD

precautions and procedures when you are servicing Sun StorageTek

equipment or handling ESD-sensitive components.

ESD Precautions

Always take the following general precautions when you work with ESD-sensitive

components:

• Wear ESD protection whenever you install, remove, maintain, or repair Sun

StorageTek equipment.

• Keep ESD-sensitive printed-circuit components in their ESD-protective packages

until you have taken all ESD-preventive steps and you are ready to install the

component.

• Do not allow anyone to touch or handle an unprotected ESD-sensitive component

unless that person has taken all ESD precautions.

• Reinstall all equipment covers and close all equipment doors after you have

completed the work.

• If the grounding-kit work surface has been exposed to temperatures above 66ºC

(150ºF) or below 4.5ºC (40ºF), acclimate the work surface to room temperature

before you unroll it.

• Immediately place any component that you have removed into an ESD-protective

package.

• Keep the grounding-kit work surface clean.

Note: To clean the work surface, use a mild detergent and water, and make sure

that the surface is completely dry before you use it.

• Periodically check the electrical resistance of the ground cord and the wrist-strap coil

cord.

Note: The ground cord should measure less than 1.2 MΩ, and the coil cord

should measure between 0.8 and 1.2 MΩ. Repair or replace the cords if they

no longer meet these requirements.

xxii Revision L 96053

Page 25

ESD-Protection Procedure

Remember that each customer environment is different. Address all the customer’s

concerns before you work on any equipment.

Prepare the Work Area

1. Before you service the equipment, unfold the grounding-kit work surface completely

and place it on a convenient surface.

2. Attach one end of the ground cord to the work surface; secure the snap fastener.

Note: You will attach the free end in a later step.

3. Slip on an ESD wrist strap. Make sure that the strap is comfortable and makes

contact with the entire circumference of your wrist.

4. Snap one end of the coil cord to the wrist band.

Access the Equipment

5. Carefully open the doors to the equipment or remove the covers from the

equipment. Do not touch any internal components.

CAUTION:

Be sure that you are properly grounded before you touch any internal

components.

6. Attach the free end of the coil cord to the most appropriate place:

a. If you are working on components from a small piece of equipment, attach the

free end of the coil cord to the grounding-kit work surface. In addition, be sure

that you touch an unpainted metal surface on the equipment before you touch an

internal component.

b. If you are working on components from a large piece of equipment, attach the

free end of the coil cord to a grounding jack or to an unpainted metal surface

inside the equipment.

Replace Components

7. Remove the defective component and place it on the work surface.

8. Remove the replacement component from its ESD-protective package, and install

the component in the equipment.

9. Place the defective component in the ESD-protective package.

96053 Revision L xxiii

Page 26

Clean Up

10. Disconnect the ground cords from the equipment.

11. Reinstall all equipment covers and close all equipment doors.

12. Disconnect the coil cord from your wrist, and, if necessary, disconnect the ground

13. Properly store the work surface and the other Field Service Grounding Kit items.

cord from the work surface.

xxiv Revision L 96053

Page 27

Seguridad

Las siguientes páginas describen prácticas habituales sobre seguridad eléctrica,

ergonomía, instalación en bastidor, fibras ópticas y descargas electrostáticas.

■ Precauciones de seguridad

ADVERTENCIA:

Posibles lesiones: la seguridad durante el trabajo es importante; por

ello, atienda a las siguientes precauciones de seguridad mientras esté

realizando alguna actividad de mantenimiento. El incumplimiento de

dichas precauciones puede conllevar graves lesiones.

Antes de realizar cualquier tarea en equipos eléctricos conectados,

quítese las joyas y accesorios conductores de electricidad, como relojes

y anillos.

• Evite las descargas eléctricas. Tenga cuidado al trabajar en la proximidades de

conectores y alimentaciones eléctricas.

• Antes de extraer unidad sustituible in situ u otro componente, apague el equipo y

desconéctelo de la red eléctrica. Recuerde que, incluso si están apagados, en algunas

áreas pueden quedar tensiones peligrosas.

• Ponga a tierra todos los equipos de prueba y herramientas eléctricas.

• Para levantar objetos, consulte la información de “Técnicas de levantamiento de

objetos” (véase a continuación).

• No quite, corte ni cambie de lugar indiscriminadamente las baldosas. Antes de

manipular baldosas, asegúrese de conocer el entorno del cliente y de recibir su

autorización. Recuerde que cada situación es diferente.

• Aplique las prácticas adecuadas de limpieza en el área del equipo para prevenir

incendios y accidentes.

Nota: Entre los factores importantes que deben tenerse en cuenta es la presencia de gas

Halón®, detectores de humo subterráneos y cables conductores a otros equipos

instalados en las proximidades.

96053 Revision L xxv

Page 28

Técnicas de levantamiento de objetos

El levantar equipos o componentes, independientemente de su peso o tamaño, puede

provocar serias lesiones lumbares. Siguiendo estas directrices podrá reducir los riesgos

de

lesiones.

• No incline el cuerpo para levantar o bajar algo. Esta posición supone una tensión

extrema para la espalda, en especial al levantar o transportar objetos. En lugar de

inclinarse, efectúe dos movimientos: primero levante el componente y, a

continuación, utilice los pies para girar el cuerpo.

• Planifique el levantamiento: primero examine el objeto y, a continuación, determine

cómo lo levantará y dónde lo colocará.

• Seleccione la técnica de levantamiento adecuada. Examine el peso y tamaño del

objeto, su ubicación y frecuencia y dirección en que vaya a levantarlo. La planificación

debe hacerse de tal modo que se eviten posturas incómodas. Determine si son

necesarios accesorios para la manipulación de materiales.

• Separe bien las piernas y coloque una ligeramente detrás de la otra. Mantenga la

espalda recta, porque incluso pesos ligeros pueden incrementar significativamente

la

presión sobre la espina dorsal al inclinarse hacia adelante.

• En la medida de lo posible, sostenga la carga con toda la mano, y utilice ambas

manos.

• Transporte los objetos a la altura del codo y próximos a su cuerpo. Cuanto más lejos

tenga que transportar un objeto, más presión aplicará sobre la zona lumbar.

• Levante el objeto haciendo fuerza con las piernas, y no con la espalda. Los músculos

de las piernas se cuentan entre los más fuertes del cuerpo. Al acuclillarse y levantar un

peso con las piernas, tendrá mayor tolerancia al peso.

• Alterne estas tareas con otras menos pesadas para los mismos músculos. De este

modo, los músculos dispondrán de un cierto tiempo de recuperación.

Seguridad de hombros, codos, muñecas y manos

Siga estas instrucciones para reducir al mínimo las posibilidades de lesionarse los

hombros, codos, muñecas y manos.

• Trabaje dentro de su zona de seguridad, el área entre el nivel de los hombros y el nivel

de los nudillos. Trabajando o levantando objetos dentro de esta área se expondrá a

menos probabilidades de lesiones.

• Mantenga los codos inclinados para mantener las cargas próximas a su cuerpo y

reducir la fuerza necesaria para realizar la tarea. Con esta postura, aplicará menos

peso y presión sobre los hombros.

• Asegúrese de mantener las muñecas rectas. Evite doblarlas, extenderlas o torcerlas

durante períodos de tiempo prolongados.

xxvi Revision L 96053

Page 29

• No levante cargas grandes o pesadas con el puño cerrado, porque el modo de

levantarlas también afecta a los tendones de la mano. Al tomar un objeto entre el

pulgar y los dedos se aplica mucha tensión a las manos y tendones de las muñecas.

Utilice ambas manos alternativamente, para permitir que descansen.

■ Seguridad y precauciones del bastidor

ADVERTENCIA:

Posibilidad de lesiones físicas:

• Peligro de levantamiento: La biblioteca pesa 44,45 kg (98 lb), a lo que

hay que añadir el peso de las unidades. Para levantar la biblioteca y

colocarla en su posición se requieren como mínimo dos personas.

Antes de poner manos a la obra, asegúrese de leer la información

presentada en

página xxvi.

• Al colocar otros equipos en el bastidor, considere también el peso

total de la biblioteca. Para evitar un desequilibrio de la carga,

coloque los equipos más pesados abajo y los más ligeros arriba.

De

lo contrario, el bastidor podría desestabilizarse y caerse.

“Técnicas de levantamiento de objetos” en la

Al instalar la biblioteca en el bastidor, adopte las siguientes precauciones de seguridad:

• Si el bastidor tiene puertas delanteras o traseras, no permita que las puertas interfieran

con la ventilación de la biblioteca. La temperatura ambiente en el interior del bastidor

no debe ser superior a la temperatura de servicio recomendada de la biblioteca.

La

temperatura ambiente máxima del interior del bastidor es de 40 °C (104 °F).

• Asegúrese de que las puertas del bastidor permitan el acceso adecuado a la biblioteca.

• Asegúrese de que la combinación de la biblioteca con otros equipos instalados en el

bastidor no provoque situaciones de sobretensión, tanto si el equipo está conectado

directamente al circuito derivado o a una regleta de distribución.

• Asegúrese de que todos los equipos del bastidor dispongan de una puesta a tierra

fiable, tanto si el equipo está directamente conectado al circuito derivado o a una

regleta de distribución

Nota: La puesta a tierra de la biblioteca se conecta a través de la patilla de puesta

tierra del enchufe.

a

■ Seguridad de fibras ópticas

ADVERTENCIA:

Riesgo para la vista. Nunca mire directamente el interior de un cable de

fibra óptica, un conector de fibra óptica o un módulo transceptor de

láser. Los niveles de potencia del láser pueden conllevar situaciones de

riesgo, susceptibles de lesionar la vista.

96053 Revision L xxvii

Page 30

Tenga especial cuidado al utilizar instrumentos ópticos con estos

equipos. Dichos instrumentos pueden incrementar las probabilidades

de lesiones oculares.

Los transceptores de láser de los equipos de fibra óptica pueden suponer un peligro

para

la seguridad física. Asegúrese de que toda persona que trabaje con estos equipos de

Sun StorageTek entienda los peligros y siga los procedimientos de seguridad. Asegúrese

de que todos los puertos ópticos de los módulos transceptores de láser estén terminados

con un conector óptico, una cubierta o un tapón de protección contra el polvo.

Todas las interfaces de fibra óptica de estos equipos de canal de fibra de Sun StorageTek

contienen un transceptor de láser, categorizado como Producto láser de Clase 1. Cada

transceptor láser tiene una salida de menos de 70 μW y una longitud de onda de 850 nm.

Los productos de láser de clase 1 de Sun StorageTek cumplen las normas EN608251(+A-11) y las secciones 21 CFR 1040.10 y 1040.11 de las normas de la Administración

para la Calidad de Alimentos y Medicamentos (FDA).

Las siguientes traducciones están dirigidas a usuarios de Finlandia y Suecia que deseen

identificar la categoría y clasificación de seguridad de los dispositivos láser:

LÁSER DE CLASE 1

LUOKAN 1 LASERLAITE

KLASSE 1 LASER APPARAT

Etiqueta del producto láser

De conformidad con las normas de seguridad, cada producto de canal de fibra de Sun

StorageTek lleva una etiqueta que identifica la clase de láser del producto, y el lugar y

fecha de fabricación. Esta etiqueta aparece sobre la unidad de cinta de canal de fibra, así

como en las proximidades de los conectores de las bibliotecas de cintas de canal de fibra.

A continuación puede verse una copia de dicha etiqueta:

CLASS 1 LASER PRODUCT

APPAREIL A LASER DE CLASSE 1

CUMPLE LAS NORMAS 21 CFR 1040.10 Y 1040.11

LASER KLASSE 1

xxviii Revision L 96053

Page 31

Instalación de cables de fibra óptica

Para instalar cables de fibra óptica, efectúe este procedimiento:

1. Tendido del cable:

• Tarima : Los cables de fibra óptica pueden instalarse debajo de tarimas.

Al

tenderlos, manténgalos apartados de cualquier obstrucción, como por

ejemplo otros cables o equipos.

• Escalerilla portacables o canaleta de cables: Sitúe los cables en su

posición. No tire de ellos a través de la escalerilla portacables. Al tender los

cables, manténgalos apartados de esquinas afiladas, colgadores de techo,

conductos, tuberías y actividades de construcción.

• Longitud de elevación vertical: Deje los cables en la bobina original y

bájelos desde arriba. No tire de ellos desde abajo. Utilice los fijadores adecuados

para inmovilizarlos.

• General: No instale cables de fibra óptica encima de detectores de humo:

2. Instalación de los cables:

• Deje como mínimo 4,6 m (15 pies) de cable en cada extremo, en previsión

de

futuras extensiones.

• Utilice protectores contra tirones para evitar que el peso del cable dañe el

conector.

• Repase en el presente manual, así como de manuales afines, toda la información

relativa a la manipulación segura de cables de fibra óptica.

3. Protección de los conectores:

• Inserte los conectores con todo cuidado para evitar dañar éstos o la fibra.

• No quite la cubierta de protección del conector hasta que esté preparado para

realizar las conexiones.

• Al desconectar el conector, vuelva a colocar la cubierta de protección.

• Antes de realizar una conexión, limpie el conector. Asegúrese de que no haya

obstrucciones y de que las ranuras de chavetas estén alineadas.

Manipulación de cables de fibra óptica

Al manipular cables de fibra óptica, tenga en cuenta las siguientes precauciones:

• No enrolle el cable a menos de 96 mm (3,75") de diámetro.

• No curve el cable a menos de 12 mm (0,5") de radio. Sun recomienda que el radio de

curvatura de un cable no sea inferior a 20 veces el diámetro del cable.

• No tire de los cables: colóquelos con cuidado en su posición.

96053 Revision L xxix

Page 32

• No aferre los cables con alicates, pinzas ni fresas. No una los cables ni los conectores

a dispositivos de tracción.

• Mantenga los cables apartados de bordes y salientes afilados que pudieran cortarlos

o

desgastarlos. Asegúrese de que los orificios del equipo dispongan de bordes

protectores.

• Proteja los cables contra temperaturas extremas.

• En toda ocasión en que el conector no esté conectado, colóquele su cubierta de

protección.

■ Prevención de daños por descargas

electrostáticas (DES)

Quienes manipulan componentes sensibles a las descargas electrostáticas (DES) deben

ser conscientes de los daños que éstas pueden provocar en los componentes electrónicos,

con el objeto de adoptar las precauciones adecuadas para evitarlas. Asimismo, las

personas que realicen tareas de mantenimiento en equipos de Sun StorageTek deben

pasar un

PRECAUCIÓN:

Posibles daños a los equipos: Manipule los componentes sensibles a

las descargas electrostáticas sólo en las condiciones de protección

adecuadas. Para cumplir este requisito, utilice siempre el Kit de puesta a

tierra del servicio de campo (NP 4711) y cumpla en todo momento estas

precauciones y procedimientos al realizar tareas de mantenimiento

o

componentes sensibles a las descargas electrostáticas.

curso de fundamentos de las descargas electrostáticas.

servicio técnico de equipos de Sun StorageTek, así como al manipular

Precauciones contra descargas electrostáticas

Al trabajar con componentes sensibles a las descargas electrostáticas (DES), adopte

siempre las siguientes precauciones generales:

• Utilice protección contra descargas electrostáticas a realizar tareas de instalación,

desinstalación, mantenimiento o reparación de equipos de Sun StorageTek.

• Mantenga los circuitos impresos sensibles a las descargas electrostáticas dentro

de

sus embalajes de protección hasta haber adoptado las medidas de prevención

adecuadas y esté preparado para instalar el componente.

• No permita que nadie toque o manipule un componente sensible a las descargas

electrostáticas no protegido, salvo que dicha persona haya adoptado las precauciones

pertinentes.

xxx Revision L 96053

Page 33

• Una vez concluido el trabajo, vuelva a colocar todas las cubiertas del equipo y cierre

todas las puertas.

• Si la superficie de trabajo del kit de puesta a tierra ha estado sometida a temperaturas

superiores a los 66 ºC (150 ºF) o inferiores a los 4,5 ºC (40 ºF), deje que la superficie

se aclimate a la temperatura ambiente antes de desenrollarla.

• Coloque inmediatamente sobre esta superficie todo componente que haya retirado

de su embalaje de protección contra descargas electrostáticas.

• Mantenga limpia la superficie de trabajo del kit de puesta a tierra.

Nota: Para limpiarla, utilice agua y un detergente suave, asegurándose de que esté

completamente seca antes de utilizarla.

• Compruebe periódicamente la resistencia eléctrica del cable de puesta a tierra y del

cable en espiral de la muñequera.

Nota: Al medir la resistencia del cable de puesta a tierra, debe ser inferior a 1,2

MΩ,; la del cable en espiral debe situarse entre 0,8 y 1,2 MΩ. Repare o

sustituya los cables si no cumplen estos requisitos.

Procedimiento de protección contra descargas electrostáticas

Recuerde que cada entorno de cliente es diferente. Responda a todas las dudas e

inquietudes del cliente antes de proceder a trabajar en un equipo.

Prepare el área de trabajo

1. Antes de reparar el equipo, desenrolle completamente la superficie de trabajo del kit

de puesta a tierra y colóquela sobre una superficie adecuada.

2. Conecte un extremo del cable de puesta a tierra a la superficie de trabajo y ajuste el

broche de presión.

Nota: El otro extremo se conectará posteriormente.

3. Colóquese una muñequera antiestática. Asegúrese de que le resulte cómoda y que

haga contacto con toda la circunferencia de la muñeca.

4. Conecte a la muñequera un extremo del cable en espiral.

96053 Revision L xxxi

Page 34

Acceda al equipo

5. Con todo cuidado, abra las puertas o retire las cubiertas del equipo. No toque ningún

componente interno.

PRECAUCIÓN:

Antes de tocar cualquier componente interno, asegúrese de estar

correctamente conectado a tierra.

6. Conecte el extremo libre del cable en espiral al lugar más adecuado:

a. Si está trabajando con componentes de un equipo de pequeñas dimensiones,

conecte el extremo libre del cable a la superficie de trabajo del kit de puesta

a

tierra. Asimismo, asegúrese de tocar una superficie metálica no pintada del

equipo antes de tocar cualquier componente interno.

b. Si está trabajando con componentes de un equipo de amplias dimensiones,

conecte el extremo libre del cable en espiral a un conector de puesta a tierra

o

a una superficie metálica no pintada del interior del equipo.

Sustituya los componentes

7. Sustituya el componente defectuoso y colóquelo sobre la superficie de trabajo.

8. Extraiga el componente de recambio de su embalaje de protección contra descargas

eléctricas e instálelo en el equipo.

Limpie

9. Coloque el componente defectuoso dentro del embalaje de protección.

10. Desconecte los cables de puesta a tierra del equipo.

11. Vuelva a instalar todas las cubiertas y cierre todas las puertas del equipo.

12. Desconecte el cable en espiral de la muñeca. Si fuese necesario, desconecte el cable

de puesta a tierra de la superficie de trabajo.

13. Pliegue correctamente la superficie de trabajo, y guárdela. Guarde también los demás

componentes del Kit de puesta a tierra del servicio de campo.

xxxii Revision L 96053

Page 35

Hardware Installation

This chapter tells you how to install the L40 Tape Library. Two methods are available:

• “Quick Installation Procedure” for users who have installed other L40 Tape Libraries

• “Standard Installation Procedure” on page 1-4 for first-time installers who want help

with each step of the process

You might need to ask your system administrator for some of the configuration

information, such as the network entries.

See Chapter 2 to become familiar with the component locations, specifications, and

cables.

■ Quick Installation Procedure

If you are experienced with computer equipment and want to install this library with the

minimum number of steps, use the following procedure. If you encounter problems,

follow the detailed instructions in

WARNING:

Safety first: Make sure you read the information in “Safety” on page xvii

before beginning. Use at least two people and a mechanical device to lift

and position the library. The library weighs 44.45 kg (98 lb) plus the

weight of the drives.

“Standard Installation Procedure” on page 1-4.

1

ADVERTENCIA:

La seguridad es lo primero: Antes de poner manos a la obra, asegúrese

de leer la información presentada en

levantar la biblioteca y colocarla en su posición se requieren como

mínimo dos personas. La biblioteca pesa 44,45 kg (98 lb), a lo que hay

que añadir el peso de las unidades.

Note: Rack installation requires special procedures.

See “Rack Installation” on page 1-9.

Save all the packing material in case you want to relocate or return the library in

the future.

1. Remove the library from its shipping container and place the library on a firm,

horizontal surface.

2. Obtain the door key from the accessory container, and unlock and open the front

door.

96053 Revision L 1-1

“Seguridad” en la página xxv. Para

Page 36

Quick Installation Procedure

3. Remove the packing cushion and foam.

4. Visually inspect the library and drives, using a flashlight if necessary:

CAUTION:

Possible component damage: Make sure you follow the ESD procedure

described in

5. Obtain the personality module from the bag taped to the power supply handle and

insert it into its connector at the rear of the library. The library will not initialize properly

unless the personality module is installed.

• A 20-cell version uses part 31363270x.

• A 40-cell version uses part 31363300x.

6. If your library is a 20-cell version, attach the cell barrier clip

(Figure 1-2 on page 1-19) onto the next to the bottom cell of Column 1. This clip

identifies the cells that you may use for your data cartridges.

7. Connect one end of the power cable into the rear of the library.

8. Connect the other end of the power cable into the wall socket.

“ESD-Protection Procedure” on page xxiii for the next step.

9. Power-on the library and drives. The library will begin its initialization routine.

10. When initialization is complete, use the operator panel to configure the library and

drives.

Note: Refer to the user’s guide for any field values that you do not understand.

11. When the configuration is complete, power-off the library and drives.

12. Connect the SCSI cables to the rear of the library.

13. Attach the HVD or LVD label to the SCSI cable connector.

14. Terminate the last drive in the string:

• HVD uses terminator part 10187075.

• LVD/SE uses terminator part 10148031.

Note: If your library includes an optional Fibre Channel router, attach cables according

to the figures under

“Connecting Fiber and SCSI Cables” on page 1-16.

15. Power-on the library to activate the firmware.

16. Wait for the library to complete initialization.

17. Press the MENU button.

1-2 Revision L 96053

Page 37

Quick Installation Procedure

18. Press the SELECT button.

The > sign appears to the left of Door Operations. The DOOR MENU:

Push Select to Prepare Library for Opening Door message

appears.

19. Press the SELECT button.

CAUTION:

Possible hand damage: Always wait for the operator panel to display the

OK To Open Door message before opening the door. This ensures that

the hand assembly is safely seated.

20. Insert the key into the lock, and unlock and open the door.

21. Insert the labeled cartridges into the library.

Make sure that the cartridge hub is down and the volume label is facing the robot.

22. Close and lock the door, and remove the key.

The library will initialize and audit the cartridges.

23. Configure your tape management software at the console.

24. Place the library online.

25. Record your library configuration information in Table 1-6 on page 1-30.

26. Make a copy of the table and give it to the customer. The customer will refer to it

when making a service call or ordering features and upgrades.

96053 Revision L 1-3

Page 38

Standard Installation Procedure

■ Standard Installation Procedure

The procedure for the standard installation of the library takes you through each step of

the installation process.

Check off the tasks in this list as you complete them:

❑

❑

❑

❑

❑

❑

❑

❑

❑

❑

❑

1. “Preparing for the Installation” on page 1-5

2. “Unpacking the Library” on page 1-5

3. “Inspecting the Library and Drives” on page 1-8

4. “Preparing the Installation Location” on page 1-8

5. “Positioning the Library” on page 1-9

6. “Installing the External Fibre Channel Router” on page 1-14

7. “Connecting the External SCSI Cables” on page 1-14

8. “Connecting Fiber and SCSI Cables” on page 1-16

9. “Attaching the Personality Module” on page 1-18

10. “Attaching the Cell Barrier Clip” on page 1-19

11. “Inserting the Cartridges” on page 1-20

❑

❑

1-4 Revision L 96053

12. “Installing the Drives” on page 1-26

13. “Powering-on the Library and Drives” on page 1-29

Page 39

Preparing for the Installation

Read “Safety” on page xvii before beginning.

In general, for a successful installation you should be familiar with:

• SCSI principles (bus termination, terminating power, addressing)

• The SCSI cable plan for your installation

• The SCSI addresses (IDs) already in use by your system

• The SCSI IDs chosen for the devices to be installed (library and drives)

• Fibre Channel principles (termination, cabling, addressing) if your library includes an

optional Fibre Channel router

Unpacking the Library

Note: Save all the packing material in case you want to relocate or return the library in

the future.

Become familiar with the components in Figure 1-1 on page 1-6, and:

1. Cut any packing tape, bands, and seals, and remove the outer container.

Standard Installation Procedure

2. Remove the container locks.

3. Remove the container cap.

4. Remove the accessory container.

5. Remove the sleeve.

6. Remove the top cushion.

7. Remove the plastic bag.

8. Remove the front and rear rail of the bottom cushion. Do not remove the library from the

pallet.

9. Obtain the door key, part 419712101, from the accessory container, and unlock and

open the door.

96053 Revision L 1-5

Page 40

Standard Installation Procedure

Figure 1-1. Unpacking the Library (L201_158)

1-6 Revision L 96053

Page 41

Figure 1-1. Unpacking the Library (L201_158)

Standard Installation Procedure

1. Outer Container

2. Container cap

3. Logo label, used for repacking

4. Container locks (Hold so the protruding part is

on top. Squeeze the ears and lift the locks to

secure them into the openings.)

5. Accessory container

6. Sleeve

10. Cut the tie wraps and remove the packing cushion from the Z shaft.

7. Bar code label, used for repacking

8. Top cusion

9. Plastic bag

10. Library

11. Internal bracing items

12. Bottom cushion

13. Front and rear rail

14. Pallet

1. Tie Wraps

2. Packing cushion around the rear Z shaft

3. Z carriage

4. Hand foam

11. Carefully raise the Z carriage and remove the foam securing the hand assembly.

96053 Revision L 1-7

Page 42

Standard Installation Procedure

Inspecting the Library and Drives

Visually inspect the library and drives, using a flashlight if necessary:

1. Check the library’s exterior and interior for any obvious physical damage or loose

parts.

2. Make sure that the cables and accessories you require are present. Refer to your

shipping bill. Some items might be shipped in a separate package.

____ SCSI cables

____ SCSI terminators

____ SCSI adapters

____ Fibre Channel cables

____ AC power cable

____ Cartridges and labels

____ Personality module (in a bag taped to the power supply handle)

3. Report any damaged, missing, or incorrect items to your sales representative.

Preparing the Installation Location

Prepare the installation location:

1. Make sure that the location is clean, dry, level, and adequately ventilated.

2. Allow sufficient space to service the library from the front, right side, and rear. Each

of these areas should have a service clearance of 610 mm (2 ft).

3. Make sure that the AC power outlet is near the library and is easily accessible to the

library’s power cable.

4. If you are installing the library in a 483-mm (19-in.) standard-width rack, you must

have either brackets or a tray measuring at least 711 mm (28

the brackets or tray is installed within the rack before you install the library.

See Figure 2-7 on page 2-9 or Figure 2-8 on page 2-10 to make sure your installation area

meets the required dimensions and weight.

in.) deep. Make sure that

1-8 Revision L 96053

Page 43

Positioning the Library

The library can be ordered for either desktop or rack installation.

Desktop Installation

WARNING:

Possible personal injury: Check the path to the intended location and

clear it of obstructions before you move the library. Use at least two

people and a mechanical device to lift and position the library. The

library weighs 44.45 kg (98 lb) plus the weight of the drives. Depending

upon the drive type, each drive weighs between 5.0 kg (11 lb) and 5.5 kg

(12 lb).

ADVERTENCIA:

Posibilidad de lesiones físicas: Antes de mover la biblioteca, verifique el

trayecto hasta la ubicación de instalación prevista y retire cualquier

obstáculo. Para levantar la biblioteca y colocarla en su posición se

requieren como mínimo dos personas. La biblioteca pesa 44,45 kg (98

lb), a lo que hay que añadir el peso de las unidades. En función del tipo

de unidad, cada unidad pesa entre 5,0 kg (11 lb) y 5,5 kg (12 lb).

Standard Installation Procedure

CAUTION:

Equipment damage: Do not grip the library by the power supply handles

or by the fans.

To install the desktop library:

1. Place the library on any sturdy desk or table within cabling distance to your clientserver computer.

2. Install the drive trays, if they were not shipped with the library.

See “Installing the Drives” on page 1-26.

Rack Installation

Use a standard 483-mm (19-in.) rack with 10 rack units of space to accommodate the

library, which sits on brackets or a tray provided by the customer. The library is secured

to the rack with screws and nut clips to prevent anyone from pulling the library off the

rack.

The rack can have a rear door. The door must extend at least 102 mm (4 in.) beyond the

library to allow proper air flow for the library’s cooling fans and for cable routing. The

maximum rack air ambient temperature is 40ºC (104ºF).

To allow easy access to the CAP and operator panel, the rack should not have a front

door. If you install a front door, make sure that the door provides proper ventilation.

96053 Revision L 1-9

Page 44

Standard Installation Procedure

The library uses the power cable’s ground point for its earth-ground connection. All