Page 1

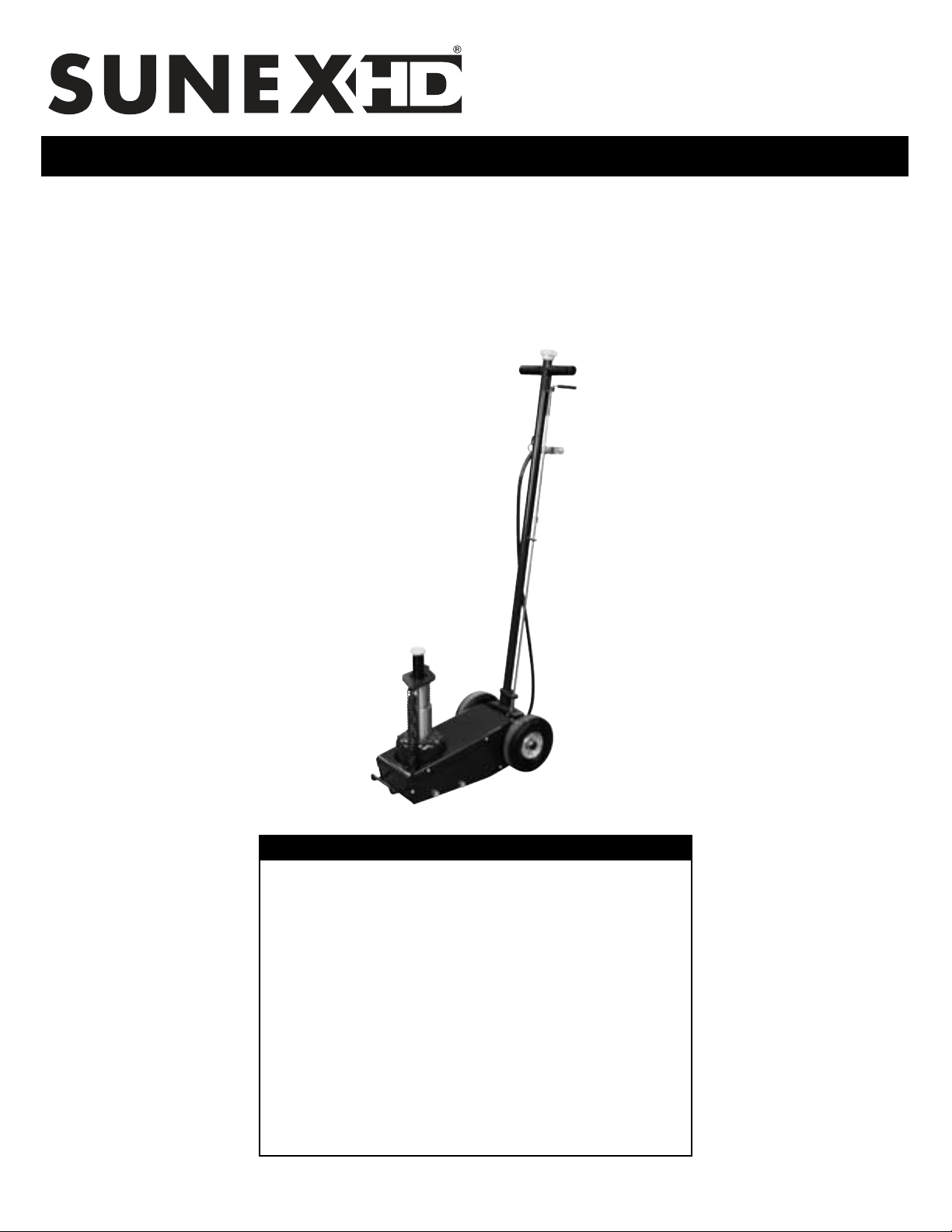

TELESCOPIC TRUCK JACK

OWNER'S MANUAL

CONTENTS:

Page 1 Specifications

2 Warning Information

3 Setup and Operating Instructions

4 Preventative Maintenance, Troubleshooting and Warranty Coverage

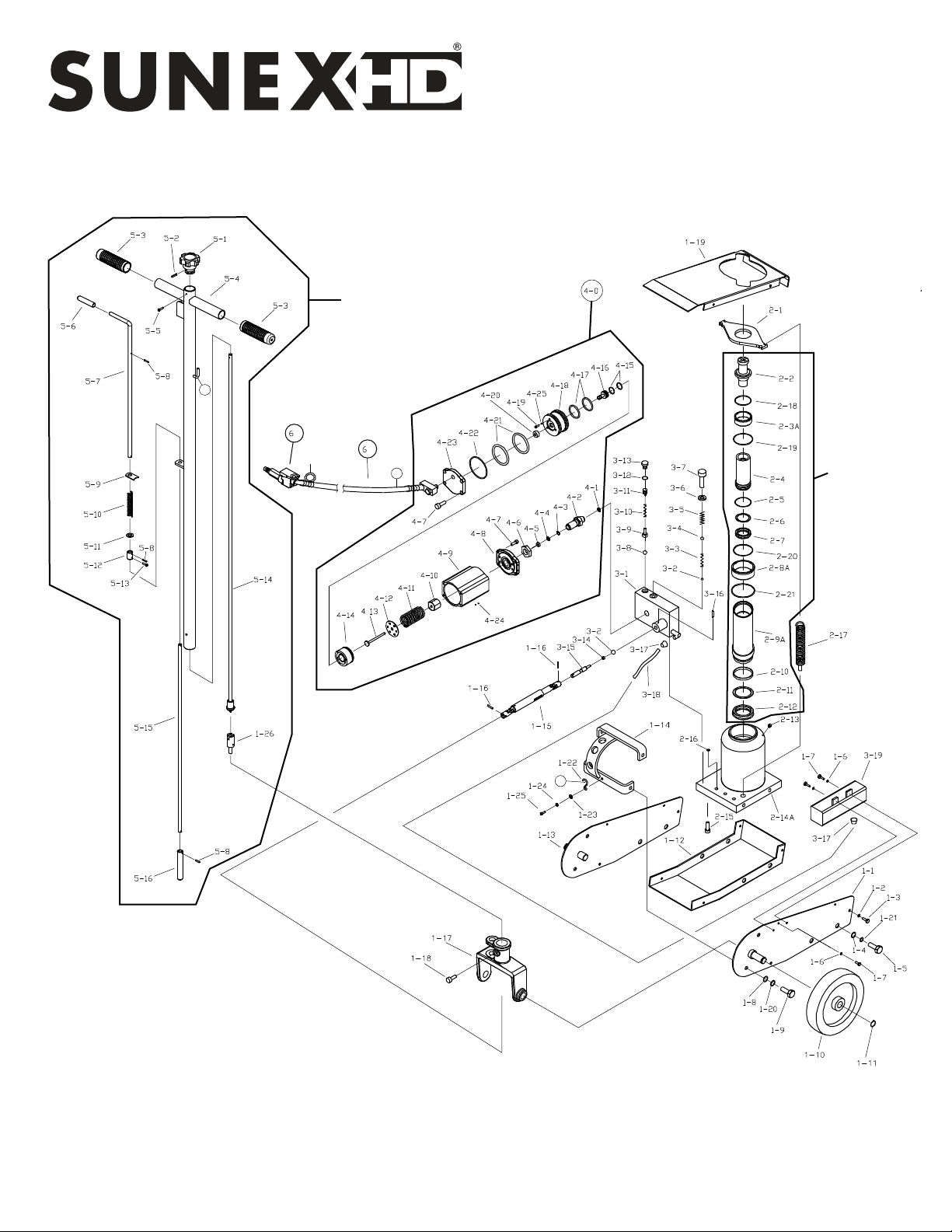

5 Exploded View Drawing

6 Replacement Parts

MODEL 6635A

CAPACITY: 22/35 TON

2-STAGE AIR/HYDRAULIC

SPECIFICATIONS

Capacity ............................................ 22/35 Tons @ 100 PSI

Low Height ..................................................................8-5/8"

Ram Travel ..................................................................7-3/4"

Ext. Screw Adjustment ...............................................3-3/8"

Max. Height with Adapter ........................................19-3/4"

Chassis Length ............................................................... 24"

Overall Width ............................................................13-3/4"

Wheel Diameter ................................................................ 8"

Saddle Diameter ............................................................... 2"

Handle Length ................................................................ 49"

Shipping Weight ......................................................119 lbs.

© Copyright 2013, Sunex Tools

6635A 1 rev. 07/19/13

®

Page 2

WARNINg INFORMATION

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

WARNING

WARNING: Indicates a hazardous situation

which, if not avoided, could result in death

or serious injury.

IMPORTANT: READ THESE INSTRUCTIONS BEFORE OPERATING

BEFORE USING THIS DEVICE, READ THIS MANUAL COMPLETELY AND THOROUGHLY, UNDERSTAND ITS OPERATING

PROCEDURES, SAFETY WARNINGS AND MAINTENANCE REQUIREMENTS.

It is the responsibility of the owner to make sure all personnel read this manual prior to using the device. It is also the responsiblity of

the device owner to keep this manual intact and in a convenient location for all to see and read. If the manual or product labels are lost

or not legible, contact Sunex® for replacements. If the operator is not fluent in English, the product and safety instructions shall be

read to and discussed with the operator in the operator's native language by the purchaser/owner or his designee, making sure that

the operator comprehends its contents.

THE NATURE OF HAZARDOUS SITUATIONS

WARNING

The use of portable automotive lifting devices is subject to certain hazards that cannot be prevented by mechanical means, but only

by the exercise of intelligence, care, and common sense. It is therefore essential to have owners and personnel involved in the use and

operation of the equipment who are careful, competent, trained, and qualified in the safe operation of the equipment and its proper

use. Examples of hazards are dropping, tipping or slipping of loads caused primarily by improperly securing loads, overloading, offcentered loads, use on other than hard level surfaces, and using equipment for a purpose for which it was not designed.

METHODS TO AVOID HAZARDOUS SITUATIONS

WARNING

• Read,study,understandandfollowallinstructionsbeforeoperatingthisdevice.

• Inspectthejackbeforeeachuse.Donotusejackifdamaged,altered,modied,inpoorcondition,leakinghydraulicuid,or

unstable due to loose or missing hardware or parts. Make corrections before using.

• Liftonlyonareasofthevehicleasspeciedbythevehiclemanufacturer.

• WeareyeprotectionthatmeetsANSIZ87.1andOSHAstandards.

• Donotusejackbeyonditsratedcapacity.

• Thisisaliftingdeviceonly.Immediatelyafterlifting,supportthevehiclewithjackstandscapableofsustainingtheloadbefore

working on the vehicle.

• Useonlyonahardlevelsurface.

• Centerloadonsaddle.Besuresetupisstablebeforeworkingonvehicle.

• DonotuseanyadaptersunlessapprovedorsuppliedbySunex®.

• Alwayslowerthejackslowlyandcarefully.

• ThisproductcontainsoneormorechemicalsknowntotheStateofCaliforniatocausecancerandbirthdefectsorother

reproductive harm.

• Failuretoheedthesewarningsmayresultinseriousorfatalpersonalinjuryand/orpropertydamage.

Wash hands thoroughly after handling.

CONSEQUENCES OF NOT AVOIDING HAZARDOUS SITUATIONS

WARNING

Failure to read this manual completely and thoroughly, failure to understand its OPERATING INSTRUCTIONS, SAFETY WARNINGS,

MAINTENANCEINSTRUCTIONSandcomplywiththem,andfailuretocomplywiththeMETHODSTOAVOIDHAZARDOUSSITUATIONS

could cause accidents resulting in serious or fatal personal injury and/or property damage.

6635A 2 rev. 07/19/13

Page 3

SETUP AND OPERATING INSTRUCTIONS

This is the safety alert symbol used for the SETUP and OPERATING INSTRUCTIONS section of this manual to alert you to potential personal

injury hazards. Obey all instructions to avoid possible injury or death.

PLEASE REFER TO THE EXPLODED VIEW DRAWING IN THIS MANUAL IN ORDER TO IDENTIFY PARTS.

1. Remove the bolt from under the handle yoke. Insert the handle tube in the handle yoke while simultaneously inserting the locking rod in the

handle yoke guide holes.

2. Raise the lock lever on the handle assembly up so the locking rod does not have to come in contact with the handle yoke bracket. Rotate the release

knob at the top of the handle back and forth until you feel the bottom of the handle engage the release valve fitting inside and at the bottom

of the handle yoke.

3. Align the handle yoke hole that accepts the bolt with the receiving hole in the bottom of the handle. Once the holes are lined up, secure the handle to the

handle yoke with the bolt provided.

4. Move the handle assembly up and down while simultaneously pushing down on the lock lever until the locking rod engages one of the locating holes

in the handle yoke bracket. There are three holes in the handle yoke bracket that are used to lock the handle in either a horizontal, angular or almost

vertical position.

5. Install the quick disconnect of your choice in the back of the air valve. The air valve and hose are equipped with a loop that secures them to the "L"

shaped hook on the upper portion of the handle.

6. Secure the air valve and hose to the handle and connect a shop air line to the air valve.

7. Sometimes air gets trapped in the hydraulic system during shipment. An air bound hydraulic system feels spongy when pumped.

TO PURGE AIR FROM THE HYDRAULIC SYSTEM

a. Open the release valve by turning the knob at the top of the handle in a counterclockwise direction two full turns

from the closed position.

b. Depress the air valve for about 30 seconds

c. Close the release valve by turning the knob in a clockwise direction until tight.

d. Depress the air valve until the ram raises to maximum height.

e. If the condition remains, repeat steps "a" through "d" until all the air is purged from the system.

OPERATING INSTRUCTIONS

This is the safety alert symbol used for the OPERATING INSTRUCTIONS section of this manual to alert you to potential personal

injury hazards. Obey all instructions to avoid possible injury or death.

IMPORTANT: Before attempting to raise any vehicle, check vehicle service manual for recommended lifting surfaces.

OPERATION:

1. Become familiar with the identification and function of the operating jack components.

a. The telescopic rams come out of the jack in order to lift a load when the air valve is depressed.

b. The secondary (smaller diameter) ram is equipped with an extension screw which can be extended if there is not enough hydraulic ram

stroke to raise the load to the desired height.

2. Chock the vehicle's tires that will not be lifted off the ground prior to lifting the vehicle and if available, apply the emergency brake or any

other method of braking.

3. Position the jack at the designated lift point. Estimate the required ram travel to raise the vehicle to the desired height. If the desired vehicle

height exceeds the entire ram travel, unscrew the extension screw to make up the difference.

4. Turn the knob at the top of the handle all the way in a clockwise direction until tight. Lock the handle in a position that will not interfere with

the vehicle when raised or lowered. Keep the handle in that locked position until the work is completed and you are ready to remove the

jack from use.

5. With the jack in the lowered position, push the jack under the vehicle. IMPORTANT: Use the vehicle manufacturer's recommended lifting

procedures and lifting points before lifting loads.

6. In most cases 100 P.S.I. input air pressure (do not exceed 200 P.S.I.) will lift the maximum capacity load not to exceed 22 tons. Depress the air

valve until the top of the ram comes close to the designated lift point. Make sure the designated lift point is flat, parallel to the ground and free

from grease, any kind of lubricant, and debris. Proceed with pumping the jack in order to lift the vehicle to the desired height. During lifting, inspect

the position of the jack in relation to the ground and the ram in relationship to the load to prevent any unstable conditions from developing.

If conditions look like they are becoming unstable, slowly lower the load and make appropriate setup corrections after the load is fully lowered.

7. When the vehicle or load is lifted to its desired height, immediately place safety support stands (jack stands) in their designated

locations and adjust the stands' support columns up as close to the designated vehicle support points as possible. Although jack stands are

individually rated, they are to be used in a matched pair to support one end of the vehicle only. Stands are not to be used to simultaneously

support both ends or one side of a vehicle. Slowly and carefully turn the release knob in a counterclockwise direction to gently lower the vehicle

onto the safety support stands (jack stands). Make sure the vehicle is safely supported by the safety support stands' (jack stand) saddles and not

the locating lugs of the saddles. Inspect the relationship of the safety support stands (jack stands) with the ground and the safety support stand

(jack stand) columns and saddles with the vehicle to prevent any unstable conditions. If conditions look unstable, close the jack's release knob

and depress the air valve to raise the vehicle off the safety support stands (jack stands). Make the appropriate setup changes and slowly and

carefully lower the vehicle onto the safety support stand saddles.

8. After the work is done, close the release knob and depress the air valve until the jack is high enough to remove the vehicle or load from the

safety support stand saddles. Be sure load is stable. If it is not, lower load back onto safety support stands. Make appropriate setup

corrections and repeat the step again. Remove the safety support stands from under the vehicle, being very careful not to move the vehicle.

9. Turn the release knob in a counterclockwise direction very slowly and carefully to lower the vehicle or load down to the ground.

6635A 3 rev. 07/19/13

Page 4

PREVENTATIVE MAINTENANCE:

This is the safety alert symbol used for the PREVENTATIVE MAINTENANCE section of this manual to alert you to potential personal

injury hazards. Obey all instructions to avoid possible injury or death.

IMPORTANT: Any jack found to be defective as a result of worn parts due to lack of lubrication or air/hydraulic system contaminated

with water, rust and/or foreign materials from the air supply or other outside source is not eligible for warranty consideration.

1. Always store the jack in a well protected area where it will not be exposed to inclement weather, corrosive vapors, abrasive dust, or any

other harmful elements. The jack must be cleaned of water, snow, sand or grit before using.

2. The jack must be lubricated periodically in order to prevent premature wearing of parts. A general purpose grease must be applied to the

threads on the extension screw. Do not lubricate any portion of the lift saddle and make sure the saddle is free from grease, any kind of

lubricant, or debris before using the jack. Jacks found to be defective due to worn parts resulting from inadequate or no lubrication are not

eligible for warranty consideration.

3. It should not be necessary to refill or top off the reservoir with hydraulic fluid unless there is an external leak. An external leak requires

immediate repair which must be preformed in a dirt-free environment by qualified hydraulic repair personnel who are familiar with this

equipment. Authorized Hydraulic Service Centers are required for repairs.

IMPORTANT: In order to prevent seal damage and jack failure, never use alcohol, hydraulic brake fluid, or transmission oil in the jack. Use

Chevron Hydraulic Oil AW ISO 32 or its equivalent Unocal Unax AW 150.

4. Every jack owner is responsible for keeping the jack label clean and readable. Use a mild soap solution to wash external surfaces of the

jack but not any moving hydraulic components.

5. Do not attempt to make any hydraulic repairs unless you are a qualified hydraulic repair person that is familiar with this equipment.

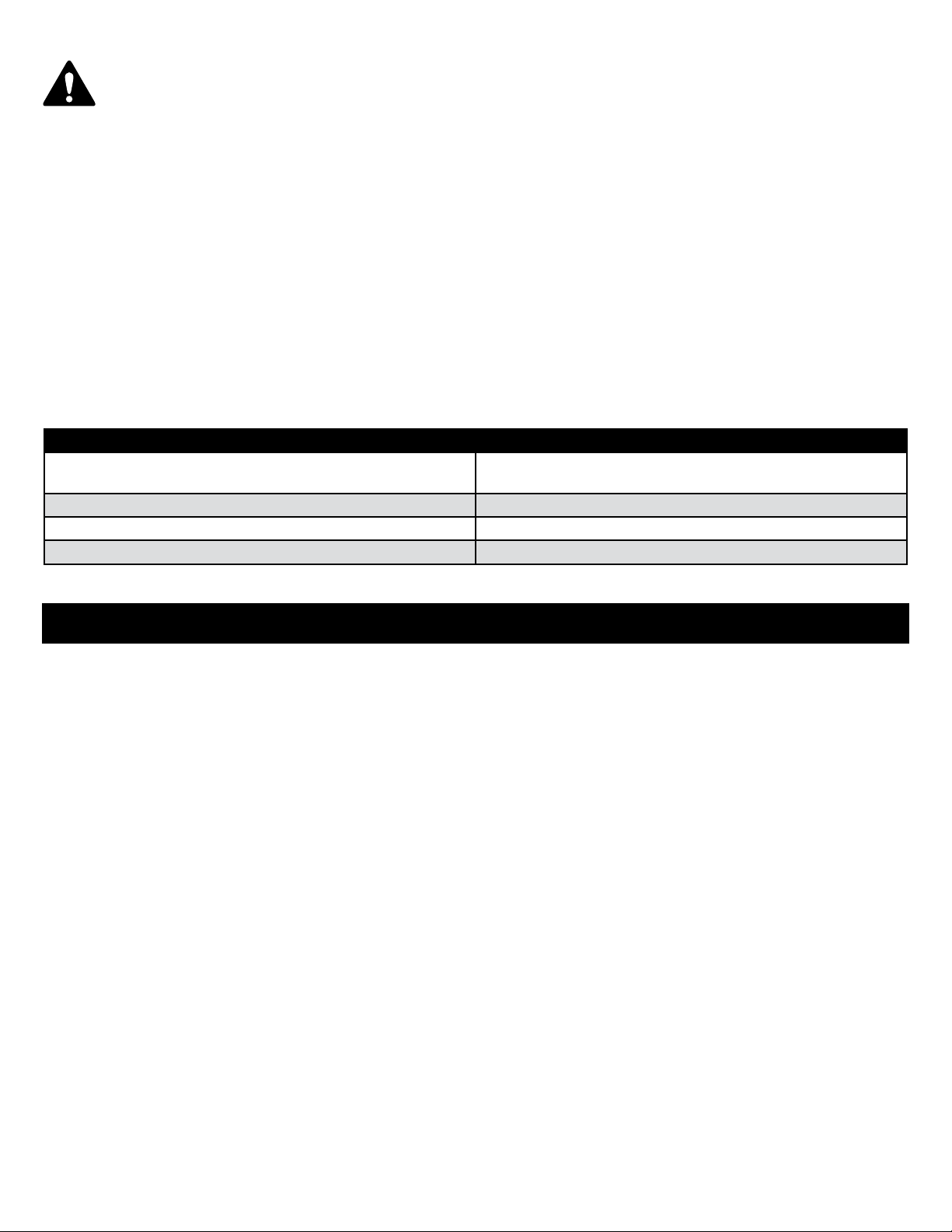

TROUBLESHOOTING

PROBLEM ACTION

1. Unit will not lift load. Purge air from hydraulic system by following procedure

under SETUP and OPERATING INSTRUCTIONS

2. Unit will not sustain load or feels “spongy” under load. Purge air from hydraulic system as above.

3. Unit will not lift to full height. Purge air from hydraulic system as above.

4. Unit still does not operate. Contact an authorized service center from enclosed list.

LIMITED WARRANTY

®

SUNEX INTERNATIONAL, INC. WARRANTS TO ITS CUSTOMERS THAT THE COMPANY’S SUNEX TOOLS

BRANDED

PRODUCTS ARE FREE FROM DEFECTS IN WORKMANSHIP AND MATERIALS.

Sunex International, Inc. will repair or replace its Sunex Tools® branded products which fail to give satisfactory service due to defective workmanship or materials,

based upon the terms and conditions of the following described warranty plans attributed to that specific product. This product carries a ONE-YEAR warranty. During

this warranty period, Sunex Tools

Other important warranty information

This warranty does not cover damage to equipment or tools arising from alteration, abuse, misuse, damage and does not cover any repairs or replacement made by

anyone other than Sunex Tools

and under no circumstances shall we be liable for any incidental or consequential damages.

NOTE:

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

Return equipment or parts to an authorized service center, transportation prepaid. Be certain to include your name and address, evidence of the purchase date, and

description of the suspected defect. If you have any questions about warranty service, please write to Sunex Tools

you may also have other rights which vary from state to state. Repair kits and replacement parts are available for many of Sunex Tools

or not the product is still covered by a warranty plan.

SHIPPING ADDRESS:

Sunex Tools

315 Hawkins Rd.

Travelers Rest, South Carolina 29690

®

will repair or replace at our option any part or unit which proves to be defective in material or workmanship.

®

or its authorized warranty service centers. The foregoing obligation is Sunex Tools’ sole liability under this or any implied warranty

®

. This warranty gives you specific legal rights and

®

products regardless of whether

MAILING ADDRESS:

Sunex Tools

P.O. Box 1233

Travelers Rest, South Carolina 29690

6635A 4 rev. 07/19/13

Page 5

MODEL 6635A

CAPACITY: 22/35 TON

2-STAGE AIR/HYDRAULIC

TELESCOPIC TRUCK JACK

DRAWINg

RS22A40

air PUmP assembly

RS6635A50

Handle assembly

A

A

A

B

B

RS6635A24A

PisTOn rOd

assembly

-

B

Only index numbers identified by part numbers are available separately.

6635A 5 rev. 07/19/13

Page 6

Index Part

No. No. Description Qty.

MODEL 6635A

CAPACITY: 22/35 TON

2-STAGE AIR/HYDRAULIC

TELESCOPIC TRUCK JACK

PARTS LIST

Index Part

No. No. Description Qty.

1-1 Right Frame Assy. 1

1-2 Washer 4

1-3 Screw 4

1-4 Washer 4

1-5 Bolt 4

1-6 Washer 6

1-7 Screw 6

1-8 Washer 4

1-9 Bolt 4

1-10 RS22A110 Wheel 2

1-11 RS6635A111 Washer 2

1-12 Bracket 1

1-13 Left Frame Assy. 1

1-14 Bracket 1

1-15 RS22A115 Universal Joint Assy. 1

(incl. 1-15, (2) 1-16, 3-15)

1-16 Pin 2

1-17 RS22A117 Handle Socket 1

1-18 RS22A118 Screw 1

1-19 RS6635A119 Cover 1

1-20 Washer 4

1-21 Washer 4

1-22 Washer 1

1-23 Washer 1

1-24 Washer 1

1-25 Screw 1

1-26 Rod Joint 1

2-1 RS6635A21 Spring Hanger 1

2-2 Screw Rod Unit 1

2-3A Bushing 1

2-4 RS6635A24A Piston Rod Assy. (incl. 2-2 to 2-21) 1

2-5 * O-ring 1

2-6 * Washer 1

2-7 * Y-ring 1

2-8A Bushing 1

2-9A Inner Cylinder 1

2-10 Bushing 1

2-11 * Washer 1

2-12 * Y-ring 1

2-13 * Oil Filler plug 1

2-14A Oil Cylinder Assy. 1

2-15 Screw 3

2-16 * O-ring 3

2-17 RS6635A217 Spring 2

2-18 * O-ring 1

2-19 * O-ring 1

2-20 * O-ring 1

2-21 * O-ring 1

3-1 Valve Block 1

3-2 * Steel Ball 2

3-3 * Spring 1

3-4 * Steel Ball 1

3-5 * Spring 1

3-6 * Copper Washer 1

3-7 Bolt 1

Only index numbers identified by part numbers are available separately.

* Available in RS6635ARKA hydraulic repair kit.

** Available in RS22APRK air pump repair kit.

6635A 6 rev. 07/19/13

3-8 * Steel Ball 1

3-9 * Ball Seat 1

3-10 * Spring 1

3-11 Bolt 1

3-12 * Sealing Gasket 1

3-13 Bolt 1

3-14A * Sealing Washer 1

3-15 Release Valve Rod (incl. with 1-15) 1

3-16 Pin 1

3-17 Nut 2

3-18 Oil Pipe 1

3-19 Oil Box 1

4-0 RS22A40 Air Pump Assy. 1

4-1 ** Copper Washer 1

4-2 Pump Cylinder 1

4-3 ** Oil Seal 1

4-4 ** Nylon Gasket 1

4-5 ** Copper Bushing 1

4-6 Nut 1

4-7 Screw 8

4-8 Front Cover 1

4-9 Air Pump Housing 1

4-10 Nut 1

4-11 Spring 1

4-12 Washer 1

4-13 Cylinder Pump Plunger 1

4-14 Piston Body "A" 1

4-15 ** O-ring 2

4-16 Air Release Rod 1

4-17 ** O-ring 2

4-18 Piston Body "B" 1

4-19 Screw 3

4-20 ** Air Seal 1

4-21 ** O-ring 2

4-22 ** O-ring 1

4-23 Rear cover 1

4-24 Steel Ball 4

4-25 O-ring 3

5-0 RS6635A50 Handle Assy. 1

5-1 RS22A51 Knob (incl. 5-1, 5-2) 1

5-2 Pin 1

5-3 Sleeve 2

5-4 Handle 1

5-5 Screw 1

5-6 Bushing 1

5-7 Control Rod A 1

5-8 Pin 3

5-9 Strap 1

5-10 Spring 1

5-11 Washer 1

5-12 Bushing 1

5-13 Screw 1

5-14 Convey Rod 1

5-15 Control Rod B 1

5-16 Pin 1

6A RS22A6A Air Valve Assembly 1

6B RS22A6B Hose 1

RS6635ALK Product Label Kit (not shown) 1

Page 7

CAPACIDAD: 22/35 TONELADAS

2 ETAPAS GATO TELESCÓPICO

MANUAL DE OPERATIóN

CONTENIDO:

Página 7 Especificaciones

8 Información de advertencia

9 Ensamble, operación y mantenimiento

10 Montaje, instrucciones de operación y mantenimiento preventivo

MODELO 6635A

HIDRÁULICO/ NEUMÁTICO

PARA CAMIONETA

ESPECIFICACIONES

Capacidad: .......................................22/35 Tons @ 100 PSI

Altura baja

Recorrido del pistón ...................................................7-3/4"

Ajuste del tornillo de extensión .................................3-3/8"

Máx.altura con extensión del tornillo ......................19-3/4"

Longitud del chasis ........................................................ 24"

Anchura global .........................................................13-3/4"

Diámetro de la rueda ...................................................... 8"

Diámetro de la silla

Longitud del mango

Peso de embarque

6635A 7 rev. 07/19/13

..................................................................8-5/8"

......................................................... 2"

..................................................... 49"

................................................119 lbs.

© Copyright 2013, Sunex Tools

®

Page 8

INFORMACIóN DE ADvERTENCIA

Este símbolo indica una alerta de seguridad y se usa para

advertir sobre peligro de accidentes personales. Observe toda

la información de seguridad que sigue a este símbolo para

evitar la posibilidad de que ocurran lesiones o muerte.

ADVERTENCIA

ADVERTENCIA: Indica una situación

peligrosa que si no se evita, puede

provocar la muerte o lesiones graves.

IMPORTANTE: LEA ESTAS INSTRUCCIONES ANTES DE USAR EL DISPOSITIVO

ANTES DE USAR ESTE DISPOSITIVO, LEA ESTE MANUAL DETENIDAMENTE. PROCURE ENTENDER SUS PROCEDIMIENTOS

OPERATIVOS, ADVERTENCIAS DE SEGURIDAD Y FORMA DE MANTENIMIENTO.

El propietario es responsable de asegurarse de que todo el personal lea este manual antes de usar el dispositivo. Asimismo, es

responsabilidad del propietario mantener este manual en buenas condiciones en una ubicación conveniente para su consulta. Si las

etiquetas del manual o producto son ilegibles o no están en su lugar, deberá ponerse en contacto con Sunex

El comprador/propietario o una persona designada deberá leer y comentar el producto y las advertencias de seguridad en la lengua

materna del operario que no hable inglés fluido, a fin de asegurarse de que comprende el contenido.

®

para obtenerlas gratis.

NATURALEZA DE LAS SITUACIONES DE RIESGO

ADVERTENCIA

El uso de dispositivos de elevación de automotores se halla sujeto a ciertos riesgos que no se pueden prever por medios mecánicos,

sino por la información, la diligencia y el sentido común. Por lo tanto, es esencial que el uso del dispositivo quede en manos de los

propietarios y de personal que sea cuidadoso, competente, capacitado y habilitado para realizar una operación segura. Algunos

ejemplos de peligros son dejar caer, inclinar o resbalar las cargas, principalmente como consecuencia de una sujeción incorrecta,

sobrecarga, posición no centrada, uso en superficies no niveladas o firmes, así como usar el dispositivo con un fin para el que no está

diseñado.

METHODS TO AVOID HAZARDOUS SITUATIONS

ADVERTENCIA

• Estudie, comprenda y observe todas las instrucciones antes de operar este dispositivo.

• Inspectthejackbeforeeachuse.Donotusejackifdamaged,altered,modied,inpoorcondition,leakinghydraulicuid,or

unstableduetolooseormissinghardwareorparts.Makecorrectionsbeforeusing.

• Utilice el dispositivo de elevación únicamente en las áreas del vehículo especificadas por su fabricante.

• UseprotecciónparalosojosquecumplaconlasnormasANSIZ87.1yOSHA.

• No use el gato para elevar pesos superiores a su capacidad.

• Este dispositivo se debe utilizar únicamente para levantar cargas. No bien haya elevado la carga, sujete el vehículo con torres

que tengan la capacidad para sostenerlo antes de comenzar a trabajar.

• Useonahardlevelservice.

• Centrelacargaenelasiento.Asegúresedequeelarmadodeldispositivoseaestableantesdecomenzaratrabajar.

• Noutiliceningúntipodeadaptadorniextensiónentreelasientodelgatoylacarga.

• NouseadaptadoresamenosqueSunex® los haya aprobado o suministrado.

• Bajeelgatosiempredespacioyconcuidado.

• EsteproductocontienesustanciasquímicasconsideradasporelEstadodeCaliforniacomocausantesdecáncer,de

malformaciones congénitas u otros daños en el sistema reproductivo. Lávese bien las manos después de manipular el producto.

• Nocumplirconestasindicacionespuedeprovocarlesionesgravesopeligrodemuerte,asícomodañosmateriales.

CONSECUENCIAS DE NO PREVENIR LAS SITUACIONES DE RIESGO

ADVERTENCIA

No leer, comprender u observar todo el contenido de este manual en relación con sus INSTRUCCIONES DE USO, ADVERTENCIAS DE

SEGURIDAD y FORMA DE MANTENIMIENTO, así como desatender las FORMAS DE EVITAR LAS SITUACIONES DE RIESGO, puede

provocar accidentes que tengan como consecuencia lesiones graves, peligro de muerte o daños materiales.

6635A 8 rev. 07/19/13

Page 9

MONTAJE Y MANUAL DE OPERATIÓN

Este es el símbolo de alerta de seguridad usado para las secciones de MONTAJE e INSTRUCCIONES DE OPERACIÓN de este manual para

alertarle a usted de los peligros potenciales de lesión personal. Obedezca todas las instrucciones para evitar lesiones potenciales o la

muerte.

CONSULTE POR FAVOR EL DIBUJO DE VISTA EN DETALLE EN ESTE MANUAL PARA IDENTIFICAR LAS PARTES.

1. Extraiga el perno de debajo de la horquilla de la manivela. Inserte el tubo de la manivela en la horquilla de la manivela mientras que se inserte la varilla

de seguridad simultáneamente en los agujeros de guía de la horquilla de la manivela.

2. Levante la manivela de seguridad en el ensamble de la manivela hacia arriba para que la varilla de seguridad no haga contacto con la ménsula de la

horquilla de la manivela. Gire la perilla de liberación en la parte superior de la manivela hacia adelante y hacia atrás hasta que se sienta que el fondo de

la manivela se encaje con el acoplamiento de la válvula de liberación en el interior y al fondo de la horquilla de la manivela.

3. Alinee el agujero de la horquilla de la manivela, él que acepta el perno con el agujero receptor en el fondo de la manivela. Una vez que los agujeros estén

alineados, asegure la horquilla de la manivela con el perno provisto.

4. Mueva el ensamble de la manivela hacia abajo y hacia arriba al mismo tiempo que se empuje simultáneamente en la manivela de seguridad hasta que

la varilla de seguridad se encaje en uno de los agujeros de ubicación en la ménsula de la horquilla de la manivela. Hay tres agujeros en la ménsula de la

horquilla de la manivela que se usan para bloquear la manivela en una posición horizontal, angular o casi vertical.

5. Instale la desconexión rápida de su preferencia al dorso de la válvula de aire. La válvula de aire y la manguera están equipadas con un aro que las sujete

en el gancho en forma de "L" en la parte superior de la manivela.

6. Asegure la válvula de aire y la manguera a la manivela y conecte una línea de aire de taller a la válvula de aire.

7. A veces se atrapa aire en el sistema hidráulico durante el envío. Un sistema hidráulico con aire atrapado se siente esponjoso al momento de realizar el

bombeo.

PARA PURGAR EL AIRE DEL SISTEMA HIDRÁULICO:

a. Abra la válvula de liberación al girar la manivela en el contrasentido de las agujas del reloj dos vueltas completas desde su posición cerrada.

b. Depress the air valve for about 30 seconds

c. Cierre la válvula de liberación al girar la manivela en el sentido de las agujas del reloj hasta que esté apretada.

d. Presione la válvula de aire hasta que el pistón se levante hasta la altura máxima.

e. Si la condición persista, repita los pasos "a" al "d" hasta que se purgue todo el aire del sistema.

INSTRUCCIONES DE USO

Este símbolo indica una alerta de seguridad y se utiliza en la parte de este manual que versa sobre las INSTRUCCIONES DE USO, con

el fin de advertir sobre los peligros de accidentes personales. Observe todas las instrucciones para evitar lesiones o peligros de muerte.

IMPORTANTE: antes de comenzar a elevar un vehículo, consulte su manual de servicio para conocer las superficies de elevación

recomendadas.

FORMA DE USO:

1. Familiarícese con la identificación y función de los componentes del gato en operación.

a. Los pistones telescópicos salen del gato con el fin de levantar una carga cuando la válvula de aire esté presionada.

b. El pistón secundario (de diámetro más pequeño) viene equipado con un tornillo de extensión el cual puede ser extendido si no hay

suficientes recorridos de pistón hidráulico para levantar la carga hasta la altura deseada.

2. Ponga cuñas en las llantas de vehículo las que no serán levantadas del piso, antes de levantar el vehículo, y si es disponible, aplique el freno de

emergencia o cualquier otro método de frenado.

3. Posicione el gato en el punto de levantamiento designado. Calcule el aproximado recorrido del pistón requerido para levantar el vehículo hasta la

altura deseada. Si la altura deseada exceda el recorrido entero del pistón, desatornille el tornillo de extensión para completar la diferencia y ag

regue una extensión de adaptador si sea necesario.

4. Gire la perilla en la parte superior de la manivela en el sentido de las agujas del reloj hasta que esté completamente apretada. Bloquee la manivela

en una posición la cual no interfiera con el vehículo levantado o bajado. Mantenga la manivela en la posición cerrada hasta que el trabajo esté

completado y usted está listo para retirar el gato del uso.

5. Con el gato en la posición más baja, empuje el gato por debajo del vehículo. IMPORTANTE: Use los procedimientos y puntos de levantamiento

recomendados por el fabricante del vehículo antes de levantar las cargas.

6. En la mayoría de los casos, una presión de entrada de aire de 100 P.S.I. (no exceda 200 P.S.I.) levantará una carga de la máxima capacidad, para

no exceder 22 toneladas. Presione la válvula de aire hasta que la parte superior del pistón se acerque al punto de levantamiento designado.

Asegúrese que el punto de levantamiento esté plano, paralelo al piso, y libre de grasa, cualquier lubricante o escombro. Proceda a bombear el

gato con el fin de levantar el vehículo hasta la altura deseada. Durante el levantamiento, inspeccione la posición del gato en relación al piso y el

pistón en relación a la carga para prevenir el desarrollo de cualquier condición inestable. Si la condición parece que se está volviendo inestable,

baje la carga lentamente y realice las correcciones adecuadas de montaje después de que la carga esté completamente bajada.

7. Cuando el vehículo o carga se levanta hasta la altura deseada, inmediatamente coloque las bases de soporte de seguridad (las bases del gato)

en sus ubicaciones designadas y ajuste las columnas de soporte de las bases lo más cerca posible a los puntos de soporte designados del

vehículo. Aunque las bases del gato estén clasificadas individualmente, ellas deben usarse en pares emparejadas para soportar un extremo del

vehículo solamente. Las bases no deben usarse simultáneamente para soportar ambos extremos o un lado del vehículo. Abra la válvula de

liberación lentamente y cuidadosamente en el contrasentido de las agujas del reloj con el fin de bajar el vehículo sobre las bases de soporte de

seguridad (las bases del gato). Asegúrese que el vehículo esté soportado por las bases de soporte de seguridad (las bases del gato) y no las

tuercas de ubicación de las sillas. Inspeccione la relación entre las bases de soporte de seguridad (las bases del gato) respecto el piso y las

columnas de la base de soporte de seguridad (la base del gato) y las sillas en relación al vehículo, con el fin de prevenir cualquier condición

inestable. Si la condición aparenta ser inestable, cierre la perilla de liberación del gato y presione la válvula de aire para levantar el vehículo de las

bases de soporte de seguridad (las bases del gato). Realice los cambios de montaje adecuados y lentamente y de forma cuidadosa, baje el

vehículo sobre las sillas de la base de soporte de seguridad.

8. Después de que esté completado el trabajo, cierre la perilla de liberación y presione la válvula de aire hasta que el gato esté suficientemente alto

6635A 9 rev. 07/19/13

Page 10

para extraer el vehículo o carga de las sillas de la base de soporte de seguridad. Asegúrese que la carga esté estable. Si no la esté, baje la carga

nuevamente sobre las bases de soporte de seguridad. Realice las correcciones adecuadas de montaje y repita el paso de nuevo. Extraiga las

bases de soporte de seguridad de debajo del vehículo, siendo muy cuidadoso de no mover el vehículo.

9. Gire la perilla de liberación en el contrasentido de las agujas del reloj muy lentamente y de forma cuidadosa para bajar el vehículo o carga hasta el

piso.

MANTENIMIENTO DE SEGURIDAD

Este símbolo indica una alerta de seguridad y se utiliza en la parte de este manual que versa sobre el MANTENIMIENTO DE SEGURIDAD, con el fin

de advertir sobre los peligros de accidentes personales. Observe todas las instrucciones para evitar lesiones o peligros de muerte..

IMPORTANTE: Cualquier gato que se encuentre defectuoso, como resultado de partes desgastadas debido a una falta de lubricación o un

sistema hidráulico/neumático contaminado con agua, corrosión, y/o materiales extraños provenientes del suministro de aire u otra fuente

externo, no es elegible para consideraciones de la garantía.

1. Siempre guarde el gato en un área protegida, en donde no quede expuesto a las condiciones climáticas, gases corrosivos, sustancias abrasivas u

otros materiales perjudiciales. Antes de usar, compruebe que el gato no contenga restos de agua, nieve, arena o arcilla.

2. El gato debe ser lubricado periódicamente con el fin de prevenir el desgaste prematuro de las partes. Un aceite de uso general debe aplicarse a

la roscas en el tornillo de extensión. No lubrique ninguna parte de la silla de levantamiento y asegúrese que la silla está libre de grasa, cualquier

lubricante y escombros antes de usar el gato.

3. No debería ser necesario recargar ni llenar el receptáculo del líquido hidráulico, salvo si existen fugas. Una fuga externa requiere reparación

inmediata la cual debe realizarse en un ambiente libre de suciedad por parte de personal de reparación hidráulica calificado quienes sean

familiarizados con este equipo. Los centros de servicio autorizados son recomendados.

IMPORTANTE: A fin de prevenir daños en las juntas herméticas y fallas en el dispositivo, no use alcohol, líquido de frenos hidráulicos ni aceite de

transmisión en el gato. Use un aceite hidráulico de Chevron AW ISO 32 o su equivalente AW 150 Unocal Unax.

4. El propietario del gato es responsable de mantener sus etiquetas en buen estado de conservación. Use una solución jabonosa suave para lavar el

exterior del gato, sin aplicarla a ninguna de las partes del sistema hidráulico.

5. No intente realizar reparaciones hidráulicas al menos que usted sea un individuo calificado en reparaciones hidráulicas familiarizado con este

equipo.

DIAGNÓSTICO DE AVERíAS

PROBLEMA ACCIÓN

1.El equipo no levantará la carga. Expulsa el aire del sistema hidráulico al seguir el

procedimiento bajo Montaje y LAS INSTRUCCIONES DE

OPERACIÓN

2. El equipo no sostendrá la carga o se siente Expulsa el aire del sistema hidráulico como indicado

anteriormente.esponjoso bajo la carga.

3. El equipo no levantará la carga hasta la altura normal. Expulsa el aire del sistema hidráulico como indicado

anteriormente. Revisa que los niveles de aceite no estén ni

altos ni bajos.

4. El equipo aún no funciona. Contacta al Departamento de Garantía y Refacciones

mencionado a continuación.

gARANTÍA LIMITADA:

SUNEX INTERNATIONAL, INC., LE GARANTIZA A SUS CLIENTES QUE LAS HERRAMIENTAS Y PRODUCTOS CON

LA MARCA DE LA EMPRESA SUNEX TOOLS NO CONTIENEN DEFECTOS EN SU MANO DE OBRA NI MATERIAS

PRIMAS

Sunex International, Inc., reparará o sustituirá sus productos con la marca Sunex Tools® que reflejen fallas en el funcionamiento satisfactorio debido a que la mano de

obra o las materias primas estén defectuosas, tomando como base las cláusulas y condiciones de los planes de garantía descritos a continuación y asignados a ese

producto específico. Este producto tiene una garantía de UN AÑO

o unidad la cual demuestra ser defectuosa en cuanto a material o mano de obra.

Otra importante información de la garantía...

Esta garantía no cubre daños a equipo o herramientas debido a modificaciones, abuso, mal uso o daños y no cubre ninguna reparación o sustitución hecha por ninguna persona que no sea

Sunex Tools o alguno de sus centros de servicio de garantía autorizados.

de cualquier garantía implícita y bajo ninguna circunstancia quedará bajo su responsabilidad cualquier garantía implícita ya bajo ninguna circunstancia quedará bajo su responsabilidad

cualquier daño incidental o consecuencial.

NOTA: Algunos estados no permiten la exclusión ni limitación de daños incidentales ni consecuenciales, por ende la limitación o exclusión anterior puede no ser

aplicable para usted. Si usted tiene preguntas acerca del servicio de garantía, comuníquese por favor con Sunex Tools

específicos y usted puede contar también con derechos adicionales los cuales varían del estado a estado. Los equipos de reparación y las partes de repuesto están

disponibles para muchos de los productos de Sunex Tools, independientemente de que si el producto aún sigue con cobertura bajo un plan de garantía o no.

6635A 10 rev. 07/19/13

.

DIRECCIÓN A EMBARCARSE:

Sunex Tools

315 Hawkins Rd.

Travelers Rest, South Carolina 29690

. Durante este periodo de garantía, Sunex Tools® reparará o repondrá, a nuestra opción, cualquier parte

La obligación antes mancionada queda bajo la responsabilidad exclusiva de Sunex Tools® según se menciona o

®

. Esta garantía le brinda derechos legales

DIRECCIÓN DE CORREOS:

Sunex Tools

P.O. Box 1233

Travelers Rest, South Carolina 29690

Page 11

MANUEL D'OPERATIóN

CONTENU:

Page 11 Spécifications

12 Information d'avertissement

13 Joint, opération et maintien

14 Installation, consignes d'utilisation et entretien préventif

MODÈLE 6635A

CAPACITÉ: 22/35 TONNES

PNEUMATIQUE/HYDRAULIQUE

À DEUX ÉTAGES CRIC

TÉLESCOPIQUE POUR CAMION

SPÉCIFICATIONS

Capacité ............................................ 22/35 Tons @ 100 PSI

Altura baja ...................................................................8-5/8"

Course du piston-plongeur ........................................7-3/4"

Ajustement de la vis de rallonge ...............................3-3/8"

Hauteur maximum avec vis de rallonge déployée .19-3/4"

Longueur du châssis ...................................................24 po

Largeur hors tout .................................................. 13-3/4 po

Diamètre de roue ...........................................................8 po

Diamètre de selle

longueur de poignée ...................................................... 49"

Peso de embarque .................................................. 119 lbs.

6635A 11 rev. 07/19/13

............................................................ 2"

© Copyright 2013, Sunex Tools

®

Page 12

INFORMATION D' AvERTISSEMENT

Ce symbole indique un danger potentiel. Il est utilisé

pour avertir l'utilisateur des risques potentiels de

blessures corporelles. Prière de respecter toutes les

consignes de sécurité qui suivent ce symbole afin

d'éviter les blessures ou la mort potentielles.

AVERTISSEMENT

AVERTISSEMENT : Ce symbole

indique une situation

dangereuse qui pourrait causer

la mort ou des blessures graves

si elle n'est pas évitée.

IMPORTANT : LIRE CES CONSIGNES AVANT L'UTILISATION.

PRIÈRE DE LIRE CES CONSIGNES ATTENTIVEMENT ET DE S'ASSURER DE BIEN COMPRENDRE LES PROCÉDURES D'UTILISATION, LES

AVERTISSEMENTS DE SÉCURITÉ ET LES BESOINS EN MATIÈRE D'ENTRETIEN DE L'OUTIL AVANT DE L'UTILISER.

Le propriétaire doit s'assurer que tous les employés lisent ce manuel avant d'utiliser l'outil. Le propriétaire de l'outil doit aussi maintenir ce

manuel en bon état et le ranger dans un endroit facilement accessible à tous ceux qui doivent le lire. Si le manuel ou les étiquettes de l'outil

sont perdus ou illisibles, communiquer avec Sunex® pour obtenir un remplacement. Si l’utilisateur ne parle pas couramment le français, les

consignes de sécurité et le mode d'emploi de l'outil devront lui être lues à haute voix et être discutées avec l'utilisateur, dans sa langue maternelle, par le propriétaire/acheteur ou une personne désignée, afin d’assurer que l’utilisateur en comprenne les bien le contenu.

LE TYPE DE SITUATIONS DANGEREUSES

AVERTISSEMENT

L'utilisation de dispositifs de levage portatifs pour automobiles expose l'utilisateur à certains dangers qui ne peuvent pas être évités par des

moyens mécaniques, mais seulement en faisant preuve d'intelligence, d'attention et de bon sens. Il est donc essentiel que les propriétaires et

les employés qui utiliseront ce dispositif soient prudents, compétents, qualifiés et formés à l’utilisation sécuritaire de l’équipement. Des exemples de dangers comprennent le renversement, le glissement ou la chute soudaine de la charge. Ces dangers sont principalement imputables

à une charge mal répartie, une utilisation sur une surface meuble ou inclinée, ou une utilisation à des fins autres que celles pour lesquelles le

dispositif a été conçu.

LE TYPE DE SITUATIONS DANGEREUSES

AVERTISSEMENT

•

Lire, étudier, s’assurer de bien comprendre et de suivre les directives avant d’utiliser ce dispositif.

•

Inspecter le cric avant chaque utilisation. Ne pas utiliser le cric s’il est endommagé, altéré, modifié ou en mauvais état, si le liquide

hydraulique fuit ou si le cric est instable en raison de pièces manquantes ou lâches. Apporter les correctifs requis ou les

réparations nécessaires avant l’utilisation

• Soulevez et soutenez seulement les endroits du véhicule comme spécifié par le fabricant de véhicules.

•

Porter des lunettes de protection conformes à la norme ansi z87.1 Et aux normes de l’osha

•

Ne pas utiliser le cric pour soulever une charge supérieure à sa capacité nominale.

• Il y a un seul dispositif de levage. Immédiatement après le levage, maintenir le véhicule avec les plateformes du cric

qui sont capables de supporter la charge avant de travailler sur le véhicule.

•

Utiliser uniquement sur une surface solide et horizontale.

•

Centrer la charge sur la selle. S’assurer de la stabilité du cric et de la charge avant de travailler sur le véhicule.

• Nepasutiliserd’adaptateursautresqueceuxapprouvésoufournisparSunex

.

®

.

• Toujoursabaisserlecriclentementetavecprécaution.

• Ceproduitcontientdesproduitschimiquesreconnusparl’ÉtatdelaCaliforniecommecausantlecancer,desanomaliescongénitales

ou d’autres e_ets nuisibles sur la reproduction. Se laver minutieusement les mains après avoir utilisé le produit.

• Lenon-respectdecesdirectivespeutprovoquerdesdommagesmatérielsoudesblessuresgravesoumortelles.

MÉTHODES POUR ÉVITER LES SITUATIONS DANGEREUSES

AVERTISSEMENT

Le manquement de lire ce manuel complètement et avec attention et l’incompréhension des CONSIGNES D'UTILISATION, AVERTISSEMENTS DE SÉCURITÉ, INSTRUCTIONS D'ENTRETIEN et de se conformer à elles, et en négligeant les MÉTHODES POUR ÉVITER DES

SITUATIONS DANGEREUSES peut causer des accidents ayant comme conséquence des blessures sérieuses ou mortelles et/ou des

6635A 12 rev. 07/19/13

Page 13

INSTALLATION ET MANUEL D'OPERATIÓN

Il s'agit du symbole d'alerte de sécurité utilisé pour l'INSTALLATION et la section de CONSIGNES D'UTILISATION de ce manuel afin de vous

aviser des risques potentiels de blessures corporelles. Conformez-vous à toutes les exigences afin d'éviter des blessures potentielles ou

même la mort.

VEUILLEZ VOUS RÉFÉRER AUX SCHÉMAS DE CE MANUEL POUR IDENTIFIER LES PIÈCES.

1. Enlevez le boulon de dessous la fourche de la poignée. Insérez le tube de poignée dans la fourche de la poignée tout en insérant simultanément la tige de

verrouillage dans les trous guide de la fourche de la poignée.

2. Soulevez le levier de verrouillage de la poignée afin que la tige de verrouillage n'entre pas en contact avec le support de la fourche de la poignée.

Tournez le bouton de dégagement situé au-dessus de la poignée dans les deux sens jusqu'à ce que vous sentiez le fond de la poignée engager l'ajustage

de précision de la soupape de surpression à l'intérieur et au bas de la fourche de la poignée.

3. Alignez le trou de la fourche de la poignée qui reçoit le boulon avec le trou de réception dans le bas de la poignée. Une fois que les trous sont alignés,

fixez la poignée à la fourche de la poignée avec le boulon fourni.

4. Déplacez la poignée de haut et en bas tout en appuyant simultanément sur le levier de verrouillage jusqu'à ce que la tige de verrouillage engage un des

trous de repérage dans le support de la fourche de la poignée. Le support de la fourche de la poignée contient trois trous qui sont utilisés pour verrouiller

la poignée en position horizontale, angulaire ou presque verticale.

5. Installez le raccord rapide de votre choix à l'arrière de la soupape à pneumatique. La soupape pneumatique et le tuyau sont équipés d'une boucle qui les

fixe au crochet en forme de « L » situé sur la partie supérieure de la poignée.

6. Fixez la soupape pneumatique et le tuyau à la poignée et reliez une ligne d'alimentaire en air comprimé à la soupape pneumatique.

7. Parfois une petite quantité d'air peut rester emprisonnée dans le circuit hydraulique pendant l'expédition. Le circuit hydraulique ainsi affecté peut sembler

plus mou au pompage et empêcher le cric de fonctionner convenablement.

PURGER L'AIR DU SYSTÈME HYDRAULIQUE:

a. Ouvrez la soupape de surpression en tournant la poignée dans le sens antihoraire deux tours complets à partir de sa position fermée.

b. Appuyez sur la soupape de surpression pendant environ 30 secondes

c. Fermez la soupape de surpression en tournant la poignée dans le sens horaire jusqu'à ce qu'elle soit bien serrée.

d. Appuyez sur la soupape de surpression en tournant le bouton dans le sens horaire jusqu'à ce qu'il soit bien serré.

e. Si la condition semble s'améliorer, mais est encore perceptible, répétez les étapes « a » à « d » jusqu'à ce que tout l'air soit purgé du système.

DIRECTIVES D'UTILISATION

Voici le symbole utilisé dans la section DIRECTIVES D’UTILISATION du présent manuel pour avertir du risque de

blessure. Suivre toutes les directives pour éviter des blessures pouvant être graves ou mortelles.

IMPORTANT: Avant d'essayer de soulever n'importe quel véhicule, vérifiez le manuel d’entretien du véhicule pour les surfaces

portantes recommandées.

FONCTIONNEMENT:

1. Familiarisez-vous avec l'identification et la fonction des composants du cric d'opération.

a. Les pistons-plongeurs télescopiques sortent du cric afin de soulever une charge lorsque vous appuyez sur la soupape pneumatique.

b. Le piston-plongeur secondaire (de plus petit diamètre) est équipé d'une vis de rallonge qui peut être allongée s'il n'y a pas suffisamment de

courses pour soulever la charge à la hauteur désirée.

2. Mettez des cales sous les roues du véhicule qui ne seront pas soulevées du sol avant de soulever le véhicule et si possible, appliquez le frein à

main ou n'importe quelle autre méthode de freinage.

3. Placez le cric au point de soulèvement indiqué. Estimez la course requise du piston-plongeur afin de soulever le véhicule à la hauteur désirée. Si la

hauteur désirée du véhicule dépasse la course entière du piston-plongeur, dévissez la vis de rallonge pour combler la différence et ajoutez un

adaptateur de rallonge au besoin.

4. Tournez le bouton de dégagement situé au-dessus de la poignée dans le sens horaire jusqu'à ce qu'il soit bien serré. Verrouillez la poignée dans

une position qui n'interfèrera pas avec le véhicule lorsque celui-ci sera soulevé ou abaissé. Maintenez la poignée dans la position verrouillée

jusqu'à ce que le travail soit terminé et que vous soyez prêt à retirer le cric.

5. Avec le cric en position abaissée, poussez le cric sous le véhicule. IMPORTANT : Utilisez les procédures de levage ainsi que les points de

soulèvement recommandés par le fabricant du véhicule avant de soulever des charges.

6. Dans la plupart des cas une entrée d'air de 100 PSI (ne dépassez pas 200 PSI) soulèvera la charge de capacité maximum pour ne pas dépasser

22 tonnes. Appuyez sur la soupape pneumatique jusqu'à ce que le dessus du piston-plongeur se positionne près du point de soulèvement indiqué.

Assurez-vous que le point de soulèvement est plat, parallèle au sol et exempt de graisse, de n'importe quel genre de lubrifiant et de débris.

Continuez de pomper le cric afin de soulever le véhicule à la hauteur désirée. Pendant le levage, inspectez la position du cric par rapport au sol et

du piston-plongeur par rapport à la charge afin d'empêcher toutes conditions instables de se développer. Si les conditions semblent devenir

instables, abaissez lentement la charge et apportez les correctifs nécessaires après que la charge soit entièrement abaissée.

7. Lorsque le véhicule ou la charge est soulevé à la hauteur désirée, placez immédiatement les supports de sécurité (chandelles) aux endroits

indiqués et ajustez les chandelles aussi près des points de soutien indiqués que possible. Bien que les chandelles soient individuellement

évaluées, elles doivent être utilisées en paire afin de soutenir une extrémité du véhicule uniquement. Les chandelles ne doivent pas être utilisées

simultanément pour soutenir les deux extrémités ou un côté d'un véhicule. Tournez lentement et avec précaution le bouton de déverrouillage dans

le sens antihoraire afin de descendre doucement le véhicule sur les supports de soutien (chandelles). Assurez-vous que le véhicule est soutenu

sans risque par les supports de soutien (chandelles) et non sur les oreilles de centrage et de retenue. Inspectez le contact entre les supports de

soutien (chandelles) et le sol ainsi que les supports de soutien (chandelles) et les selles avec le véhicule pour prévenir toutes conditions instables.

Si les conditions semblent instables, fermez le bouton de déverrouillage du cric et appuyez sur la soupape pneumatique afin de soulever le

véhicule et dégager les supports de soutien (chandelles). Apportez les modifications d'installation appropriées puis abaissez lentement et avec

précaution le véhicule sur les supports de soutien (chandelles).

6635A 13 rev. 07/19/13

Page 14

8. Après que le travail soit terminé, fermez le bouton de déverrouillage et appuyez sur la soupape pneumatique jusqu'à ce que le cric soit

suffisamment élevé pour retirer le véhicule ou la charge des selles des supports de soutien (chandelles). Assurez-vous que la charge est stable. Si

elle n'est pas,

9. abaissez la charge à nouveau sur les supports de soutien (chandelles). Apportez les correctifs nécessaires et répétez l'étape. Retirez les supports

de soutien (chandelles) de sous le véhicule en faisant très attention de ne pas déplacer le véhicule.

10. Tournez le bouton de déverrouillage dans le sens antihoraire très lentement et prudemment afin d'abaisser le véhicule ou la charge au sol.

DIRECTIVES D'UTILISATION

Voici le symbole utilisé dans la section DIRECTIVES D’UTILISATION du présent manuel pour avertir du risque de blessure.

Suivre toutes les directives pour éviter des blessures pouvant être graves ou mortelles.

IMPORTANT : Tout cric qui s'avère défectueux en raison de pièces usées dues au manque de lubrification ou d'air/du circuit hydraulique

contaminé avec de l'eau, de la rouille et/ou des corps étrangers provenant de l'entrée d'air ou de toute autre source extérieure n'est pas

admissible à la garantie.

1. Toujours entreposer le grúa dans un endroit où il sera protégé des intempéries, des vapeurs corrosives, de la poussière abrasive ou

d’autres éléments nocifs. Le cric doit être exempt d’eau, de neige, de sable et de particules avant l’utilisation.

2. Le cric doit être lubrifié sur une base régulière afin d'empêcher l'usure prématurée des pièces. Une graisse d'usage universel doit être appliquée

aux filets de la vis de rallonge. Ne lubrifiez pas la selle de soulèvement et assurez que la selle est exempte de la graisse, de n'importe quel genre de

lubrifiant, ou des débris avant d'utiliser le cric.

3. Il n’est pas nécessaire de remplir le haut du réservoir avec du liquide hydraulique à moins qu’il y ait une fuite externe. Une fuite externe exige une

réparation immédiate, laquelle doit être effectuée dans un environnement sans saleté par un personnel qualifié en réparation hydraulique qui soit

familiarisé avec cet équipement. Des centres de service autorisés sont recommandés.

IMPORTANTE: A fin de prevenir daños en las juntas herméticas y fallas en el dispositivo, no use alcohol, líquido de frenos hidráulicos ni aceite de

transmisión en el gato. Utilisez de l'huile hydraulique Chevron AW ISO 32 ou son équivalent Unocal Unax AW 150.

4. Chaque propriétaire est responsable de maintenir l'étiquette du vérin propre et lisible. Contactez Sunex pour une étiquette de rechange si votre

étiquette de vérin n'est pas lisible.

5. N'essayez pas de faire des réparations à moins que vous soyez un réparateur qualifié qui est familiarisé avec cet équipement.

DÉPANNAGE

PROBLÈME ACTION

1. L'unité ne lèvera pas la charge Purger l'air du système hydraulique en suivant la procédure

selon la configuration et manuel d'operation.

2. L'unité ne supportera pas la charge ou est 'spongieuse'

sous la charge.

3. L'unité ne lèvera pas à hauteur complète. Purger l'air du système hydraulique comme mentionné

5. L'unité ne fonctionne toujours pas. Contacter un centre de service expert dans la liste jointe.

gARANTIE LIMITÉE

SUNEX INTERNATIONAL, INC. GARANTIT À SES CLIENTS QUE LES OUTILS DE MARQUE

SUNEX TOOLS

Sunex International, Inc. réparera ou remplacera ses outils de marque Sunex Tools® qui ne donnent pas un service satisfaisant à

cause d'un défaut de main d'œuvre ou de matériau, selon les termes et conditions décrits ci-dessous dans les plans de garantie

correspondant à ce produit spécifique. Ce produit a une garantie de UN AN. Pendant la période de garantie, Sunex Tools

ou remplacera, à sa seule discrétion, toute pièce ou tout appareil dont il a été déterminé qu'il comporte un défaut de matériau ou de

main d'œuvre.

Autres informations importantes sur la garantie...

Cette garantie ne couvre pas les dommages à de l'équipement ou à des outils modifiés, sujets à des abus ou à une utilisation

incorrecte, ou encore endommagés; elle ne couvre pas les réparations ou le remplacement effectué par quiconque autre que Sunex

Tools® ou ses centres de services de garantie autorisés. L'obligation qui précède constitue la seule responsabilité de Sunex Tools® en

vertu de cette garantie ou de toute garantie implicite; et en aucun cas Sunex Tools

indirects ou consécutifs.

REMARQUE : Quelques états ne permettent pas l'exclusion ou la limitation des dommages fortuits ou consécutifs, ainsi la limitation

ou l'exclusion ci-dessus peut ne pas s'appliquer à vous. Si vous avez n'importe quelles questions au sujet du service de garantie,

veuillez contacter les outils

d'autres droits qui varient d'un état à un autre. Les ensembles de réparation et les pièces de rechange sont disponibles pour plusieurs

produits d'outils

®

SONT EXEMPTS DE DÉFAUTS DE MAIN D'ŒUVRE ET DE MATÉRIAU

Sunex Tools® Cette garantie vous donne des droits légaux spécifiques et vous pouvez également avoir

Sunex Tools® indépendamment de si le produit est encore couvert par un plan de garantie.

Purger l'air du système hydraulique comme mentionné

ci-dessus.

ci-dessus ou vérifier le niveau de l'huile dans le réservoir.

®

réparera

®

ne pourra être responsable pour des dommages

ADDRESSE D'EXPÉDITION:

Sunex Tools

315 Hawkins Rd.

Travelers Rest, South Carolina 29690

6635A 14 rev. 07/19/13

ADRESSE POSTALE:

Sunex Tools

P.O. Box 1233

Travelers Rest, South Carolina 29690

Loading...

Loading...