Page 1

4930A/4950B 1 7/19/06

Operating Instructions • Warning Information • Parts Break down

THIS IS A LIFTING DEVICE ONLY. IMMEDIATELY AFTER LIFTING, SUPPORT THE

VEHICLE WITH APPROPRIATE MEANS.

THE JACK.

CENTER LOAD ON AREAS OF THE VEHICLE AS SPECIFIED BY THE VEHICLE

THIS JACK IS DESIGNED FOR USE ONLY ON HARD, LEVEL SURFACES CAPABLE

OF SUSTAINING THE LOAD. USE ON OTHER THAN HARD, LEVEL SURFACES CAN

THIS JACK BEFORE OPERATING. FAILURE TO HEED THESE WARNINGS

THIS OPERATING MANUAL

SAFETY INFORMATION. READ

ALL INFORMATION BEFORE

SPECIFICATIONS

The jack must be removed from service

shock or load.

SHIPPING WEIGHT

4930A

4950B

Always support

vehicle with

jack stands

© 2006 Sunex Tools

4930A-4950B_opman.indd 1 8/7/06 4:54:10 PM

Page 2

4930A/4950B 2 7/19/06

INSPECTION

The owner and/or user must have a thorough understanding

trained, and qualified in the safe operation of the equipment

the manufacturer’s instructions and warnings shall be

that the operator comprehends its contents. Owner and/

the manufacturer’s instructions and pertinent warning

the manufacturer.

Visual inspection should be made be fore each use

warning labels be replaced with man u fac tur er’s specified

A list of authorized repair facilities is avail able from the

coun ter clock wise one full turn.

2. Place the handle in the handle sock et and pump

about 6 full strokes to purge the air from the pump

and valving.

3. Close the release valve. Pump the han dle until the jack

has reached full ex ten sion. Continue to pump several

times to purge air from un der the ram.

4. Open the release valve and push ram into its lowest

position. Close the release valve and op er ate nor mal ly.

If the jack responds im me di ate ly to pump

OPERATING INSTRUCTION

MAINTENANCE

OWNER RESPONSIBILITY

To use the jack:

To raise a load,

close release valve by ro tat ing the

handle firmly in a clock wise direction (do not

over tight en). Care ful ly position the jack under the load

and pump the jack handle to raise the load to the

desired height.

2. If raising a vehicle, always support it with vehicle

3.

To lower the load,

slowly rotate the jack handle

valve. Open ing the release valve more per mits the load

to de scend faster.

As with any hydraulic unit, this unit

plunger down. Re move filler plug and add

hydraulic jack oil to level of filler hole. Be sure oil is

clean and be careful to keep dirt out of jack.

TRANS MIS SION FLU ID.

2. Periodically lubricate the points in di cat ed with SAE 30

oil. Keep jack clean.

3. Occasionally check extension screw and pump

plung er for corrosion. Keep these parts lubricated to

pre vent cor ro sion.

4. When not in use, store jack in up right position in a dry

location with pump plung er and extension screw in

lowest position and release valve closed.

4930A-4950B_opman.indd 2 8/7/06 4:54:11 PM

Page 3

4930A/4950B 3 7/19/06

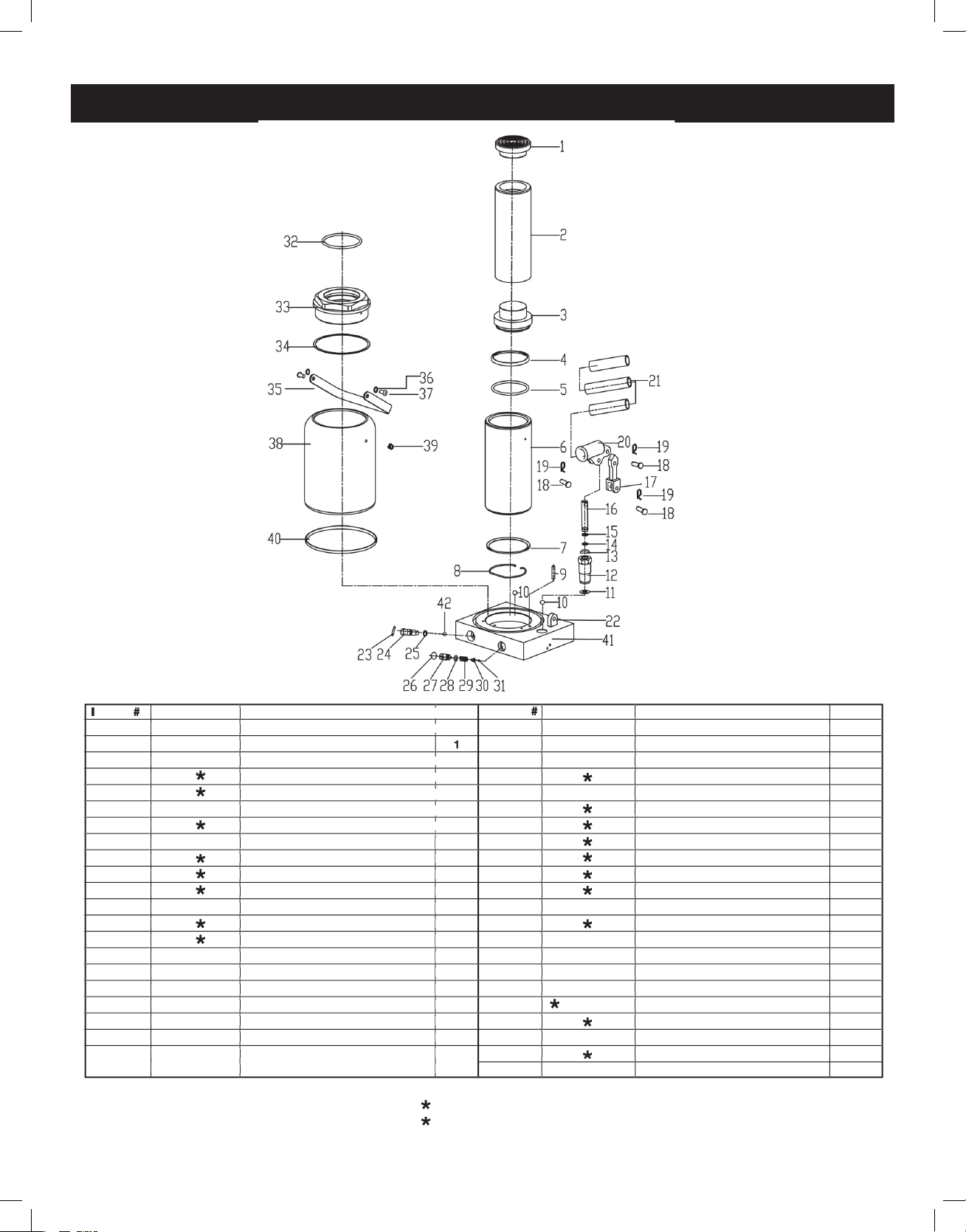

4930A & 4950B PARTS LIST AND BREAKDOWN

tem

Part # Description Qty

1 Saddle 1

2 Ram

3 Ram Head 1

4 Washer 1

5 O-Ring 1

6 Cylinder 1

7 Washer 1

8 Retaining Ring 1

9 Filter Net 1

10 Steel Ball 2

11 Washer 1

12 Pump 1

13 Seal 1

14 O-Ring 1

15 Retaining Ring 1

16 Piston 1

17 Linkage 1

18 Pin 3

19 Pin for Yoke 3

20 Yoke 1

21 RS49HDL30 Handle for 4930A 1

I

tem

Part # Description Qty

22 Connect

23 Pin 1

24 Release Valve Rod 1

25 O-Ring 1

26 Screw 1

27 Bypass 1

28 O-Ring 1

29 Spring 1

30 Spring Set 1

31 Steel Ball 1

32 O-Ring 1

33 Nut 1

34 O-Ring 1

35 Handle 1

36 Washer 1

37 Rivet 1

38 Tank 1

39 RS49FP Oil Fill Plug 1

40 O-Ring 1

41 Base 1

42 Steel Ball 1

When ordering seal kits please specify:

21 RS49HDL50 Handle for 4950B 1

4930A-4950B_opman.indd 3 8/7/06 4:54:13 PM

Page 4

4930A/4950B 4 7/19/06

TROUBLESHOOTING

WARRANTY

SUNEX INTERNATIONAL, INC. WARRANTS TO ITS CUSTOMERS THAT THE COMPANY’S SUNEX TOOLS®

warranty plans attributed to that specific product.

This product carries a ONE-YEAR warranty. During this warranty period, Sunex Tools will repair or replace at our option

This warranty does not cover damage to equipment or tools arising from alteration, abuse, misuse,

damage and does not cover any repairs or replacement made by anyone other than Sunex Tools or

its authorized warranty service centers.

The foregoing obligation is Sunex Tools’ sole liability under this or any implied warranty and under no

circumstances shall we be liable for any incidental or consequential damages.

limitation or exclusion may not apply to you.

service center, transportation prepaid. Be certain to

Travelers Rest, South Carolina 29690

4930A-4950B_opman.indd 4 8/7/06 4:54:16 PM

Page 5

4930A/4950B 5 7/19/06

CONTIENE INFORMACIONES IMPORTANTES,

Y ASEGÚRESE DE COMPRENDER TODAS

APARATO. CONSERVE ESTE MANUAL PARA

UNA REFERENCIA EVENTUAL.

ESTE ES SOLAMENTE UN MECANISMO DE LEVANTAMIENTO. DESPUÉS DE HABER LEVANTADO

EL VEHÍCULO INMEDIATAMENTE, SOSTENGALO UTILIZANDO MÉTODOS APROPIADOS.

QUE FALLE.

LEVANTE EL VEHÍCULO SOLAMENTE EN LOS LUGARES DISEÑADOS POR EL FABRICANTE.

CENTRE LA CARGA SOBRE EL ASIENTO, ANTES DE LEVANTARLA. CARGAS DESCENTRADAS

PUEDEN CAUSAR DAÑOS AL GATO, PROVOCAR UNA PÉRDIDA DE LA CARGA, DAÑOS

ESTE GATO ESTÁ DISEÑADO PARA SER UTLIZADO SOLAMENTE SOBRE SUPERFICIES DURAS

Y PLANAS, QUE PUEDAN SOSTENER LA CARGA. AL UTILIZARLO EN OTROS LUGARES QUE NO

SEAN SUPERFICIES DURAS, PUEDE PROVOCAR LA INESTABILIDAD DEL GATO Y EL FALLO DE

SU CARGA.

NUNCA HAGA MODIFICACIONES O ADAPTACIONES SOBRE EL GATO.

LEA, ESTUDIE Y COMPRENDA EL MANUEL DE FUNCIONAMIENTO INCLUIDO DENTRO DEL

EMBALAJE DEL GATO, ANTES DE UTILIZARLO. YA QUE AL NO SEGUIR ESTAS ADVERTENCIAS

PUEDE CAUSAR UNA PÉRDIDA DE LA CARGA, PROVOCAR DAÑOS AL GATO Y/O DAÑOS

SOLAMENTE.

SOPORTE SIEMPRE EL

VEHÍCULO CON

CAPACIDAD

EXTENSIÓN EJE PARA

SOPORTE

ALTURA MÍNIMA

ALTURA MÁXIMA

TAMAÑO DE LA BASE

PESO PARA TRANSPORTE

4930A

27.22 T.M.

7.07"

11.2"

18.27"

7.75" X 6"

47.74 lbs

4950B

45.36 T.M.

7.07"

11.79"

18.86"

8.75" X 7"

67.54 lbs

ESPECIFICACIONES

Instrucciones de Operación • Información de Advertencia • Revisión de Refacciones

Si el gato está expuesto a una choque eléctrico o

una carga anormal, el usuario debe inmediatamente

suspender su uso y levarlo a que sea inspeccionado por un centro de reparación del fabricante.

GATOS DE BOTELLA

45.36 Toneladas Métricas

© 2006 Sunex Tools

4930A-4950B_opman.indd 5 8/7/06 4:54:19 PM

Page 6

4930A/4950B 6 7/19/06

Al utilizar el gato

Cierre la válvula de aflojamiento girando

firmemente la manija en el sentido del reloj (no la apriete

2. Al levantar un vehículo, sostengalo siempre con soportes para

vehículos antes de trabajar sobre el vehículo o al deslizarse Ud.

3. Para bajar la carga:

Gire lentamente el mango del gato en el

sentido contrario del reloj, suficientemente para abrir la válvula

Como para todas las unidades hidráulicas, es

Quite el tapón del orificio para llenar y añada el aceite

hidráulico para gatos hasta el nivel del orificio. Asegúrese de

que el aceite esté limpio e im

de suciedades dentro del gato.

2. Lubrique periódicamente los puntos indicados con aceite SAE

30. Mantenga limpio el gato.

3. Ocasionalmente, verifique la extensión del eje para soporte y

4. Cuando no lo utilice, guarde el gato en posición

y la extensión del eje para soporte en posición baja y la válvula

ESPONSABILIDAD DEL

PROPRIETARIO / USUARIO

y las advertencias del fabricante deben ser leidas y explicadas por

faltantes o flojas. Cada uno de los gatos debe estar verificado

servicio del fabricante, si accidentalmente el producto ha sufrido

verificación anual del gato y sea realizada por un

Antes de utilizar el gato hidráulico

2. Coloque el mango dentro del casquillo para mango y

3. Cierre la válvula de aflojamiento. Bombee el mango hasta que

4. Abra la válvula de aflojamiento y empuje el eje para soporte

y hagala funcionar normalmente.

Si el gato hidráulico responde inmediatamente a la acción

VERIFICACIÓN

INSTRUCCIONES PARA EL

FUNCIONAMIENTO

MANTENIMIENTO

4930A-4950B_opman.indd 6 8/7/06 4:54:20 PM

Page 7

4930A/4950B 7 7/19/06

SUNEX INTERNATIONAL, INC., LE GARANTIZA A SUS CLIENTES QUE LAS HERRAMIENTAS Y PRODUCTOS CON LA

Sunex International, Inc., reparará o sustituirá sus productos con la marca Sunex Tools® que reflejen fallas en el funcionamiento satisfactorio debido a que la

mano

de obra o las materias primas estén defectuosas, tomando como base las cláusulas y condiciones de los planes de garantía descritos a continuación y

asignados a ese producto específico. Este producto tiene una garantía de UN AñO. Durante ese periodo de garantía, Sunex Toolsreparará o sustituirá, como así

opte por hacerlo, cualquier componente o unidad que se compruebe tener decectos en su materia prima o mano de obra.

Esta garantía no cubre ningún daño al equipo o herramientas, si este surge como resultado de su alteración, abuso, o mal uso o daños ni tampoco cubre las

antes mancionada queda bajo la responsabilidad exclusiva de Sunex Tools® según se menciona o de cualquier garantía implícita y bajo ninguna circunstancia

quedará bajo su responsabilidad cualquier garantía implícita ya bajo ninguna circunstancia quedará bajo su responsabilidad cualquier daño incidental o

consecuencial.

Algunos estados no permiten la exclusión o limitación de los daños incidentales o consecuenciales, por lo tanto la limitación o exclusión arriba

mencionada quizá no pudiera serle pertinente a usted.

dirección, la evidencia de la fecha de adquisición y la descripción del defecto que se sospeche tener. Si tiene alguna duda relacionada con elservicio de

garantEia, por favor escríbale a Sunex Tools. Esta garantía le concede derechos jurídicos específicos y quizá otros derechos que varían de un estado a otro,

Sunex Tools tiene a su disposición los juegos de reparación y refacciones de repuesto para muchos de sus productos, sin importar si el producto continúe o no

bajo el plan de la garantía.

GARANTÍA LIMITADA

Travelers Rest, South Carolina 29690

CONSEJOS DE DIAGNÓSTICO DE AVERÍAS

4930A-4950B_opman.indd 7 8/7/06 4:54:24 PM

Page 8

4930A/4950B 8 7/19/06

CECI EST UN MÉCANISME DE LEVAGE SEULEMENT. IMMÉDIATEMENT APRÈS AVOIR SOULEVÉ

LE VÉHICULE, SUPPORTEZ-LE EN UTILISANT UNE MÉTHODE APPROPRIÉE.

NE PAS SURCHARGER, LA SURCHARGE PEUT ENDOMMAGER OU PRODUIRE UN AFFAISSEMENT

SOULEVEZ SEULEMENT AUX ENDROITS DU VÉHICULE, TEL QUE DÉSIGNÉS PAR LE

CENTREZ LA CHARGE SUR LA SELLE AVANT DE SOULEVER. DES CHARGES DÉCENTRÉES

POURRAIENT CAUSER DES DOMMAGES AU CRIC, PROVOQUER UNE PERTE DE LA CHARGE,

CE CRIC EST CONÇU POUR ÊTRE UTILISÉ SUR DES SURFACES DURES ET PLANES, CAPABLES

ET PLANES, PEUT RÉSULTER EN UNE INSTABILITÉ DU CRIC ET LA POSSIBILITÉ DE LA PERTE

VOUS NE DEVEZ FAIRE AUCUNE MODIFICATION AU CRIC.

LISEZ, ÉTUDIEZ ET COMPRENEZ LE MANUEL DE FONCTIONNEMENT, INCLUS DANS

L’EMBALLAGE DU CRIC, AVANT DE LE FAIRE FONCTIONNER. NE PAS TENIR COMPTE DE CES

LA CHARGE, DES DOMMAGES À LA PROPRIÉTÉ, DES BLESSURES OU LA MORT.

À LA SÉCURITÉ. LISEZ ATTENTIVEMENT ET

ASSUREZ-VOUS DE COMPRENDRE TOUS CES

Si le cric est soumis à un choc ou une charge

anormale, veuillez cesser immédiatement son

CAPACITÉ

EXTENSION-ARBRE DE

SUPPORT

HAUTEUR MINIMALE

HAUTEUR MAXIMALE

DIMENSION DE LA BASE

POIDS POUR TRANSPORT

4930A

27.22 t.m

7.07 po

11.2 po

18.27 po

7.75 X 6 po

47.74 lbs

4950B

45.36 t.m.

7.07 po

11.79 po

18.86 po

8.75 X 7 po

67.54 lbs

véhicule à l’aide de sup-

véhicules

S P É C I F I C A T I O N S

• Instructions de fonctionnement • Avertissement • Pièces

CRICS BOUTEILLE

45.36 Tonnes Métriques

© 2006 Sunex Tools

4930A-4950B_opman.indd 8 8/7/06 4:54:28 PM

Page 9

4930A/4950B 9 7/19/06

sécuritaire et à l’utilisation adéquate de l’équipement, au moment

touchant les mises en garde. Si l’utilisateur ne parle pas couramment

jusqu’à ce que les réparations nécessaires aient été

service reconnu par le manufacturier, afin de remplacer

toutes pièces défectueuses, autocollants ou étiquettes

spécifiées par le manufacturier. Une liste des centres de service

Avant l’utilisation du cric

tournant dans le sens contraire des aiguilles d’une montre,

2. Placez le manche dans l’orifice du manche et pompez

3. Refermez la valve de relâchement. Pompez le manche jusqu’à

sous l’arbre de support.

4. Ouvrez la valve de relâchement et poussez l’arbre de support

faites fonctionner normalement.

Si le cric répond immédiatement à l’action

RESPONSABILITÉ DU

PROPRIÉTAIRE/UTILISATEUR

TILISATION

C

Pour soulever la charge:

Fermez la valve de relâchement en

tournant la poignée fermement dans le sens des aiguilles

2. Si vous soulevez un véhicule, il faut toujours le supporter à

vous glisser sous le véhicule pour quelque raison.

3.

Pour abaisser la charge:

Tournez lentement la poignée du cric

suffisamment pour ouvrir la valve de relâchement. Ouvrir la

valve de relâchement un peu plus permet d’abaisser plus

Tout comme pour tout appareil hydraulique, il est

système hydraulique, lors d’un renversement durant le transport. Pour

l’air des passages d’huile, ouvrez la valve et pompez

AMORTISSEURS OU TRANSMISSION.

2. Lubrifiez périodiquement les points indiqués avec de l’huile

3. Occasionnellement vérifiez la vis d’extension et le piston de la

4. Lorsqu’il n’est utilisé, rangez le cric en position droite dans

VÉRIFICATION

DIRECTIVES DE

FONCTIONNEMENT

INSTRUCCIONES PARA EL FUNCIONA-

DIRECTIVES D’ENTRETIEN

DIRECTIVES D’ENTRETIEN

4930A-4950B_opman.indd 9 8/7/06 4:54:29 PM

Page 10

4930A/4950B 10

7/19/06

SUNEX INTERNATIONAL, INC. GARANTIT À SES CLIENTS QUE LES OUTILS DE MARQUE

SUNEX TOOLS SONT EXEMPTS DE DÉFAUTS DE MAIN D'(UVRE ET DE MATÉRIAU

satisfaisant à cause d'un défaut de main d'œuvre ou de matériau, selon les termes et conditions décrits ci-dessous

Autres informations importantes sur la garantie

Cette garantie ne couvre pas les dommages à de l'équipement ou à des outils modifiés, sujets à des abus ou à une utilisation

la seule responsabilité de Sunex Tools en vertu de cette garantie ou de toute garantie implicite; et en aucun cas

Sunex Tools ne pourra être responsable pour des dommages indirects ou consécutifs.

juridictions ne permettent pas l'exclusion ou la limitation des dommages indirects ou consécutifs;

juridiques spécifiques ainsi que certains autres droits qui peuvent varier selon la juridiction. Les trousses de réparation et de

GARANTIE LIMITÉE

ADRESSE POSTALE:

ADRESSE D'EXPÉDITION

Travelers Rest, South Carolina 29690

CONSEILS DE DÉPANNAGE

4930A-4950B_opman.indd 10 8/7/06 4:54:33 PM

Loading...

Loading...