Page 1

ALWAYS READ INSTRUCTIONS

BEFORE USING POWER TOOLS

ALWAYS WEAR

SAFETY GOGGLES

WEAR HEARING

PROTECTION

AVOID PROLONGED

EXPOSURE TO VIBRATION

4912CAH & 4920CAH 1 rev. 12/19/06

Operating Instructions • Warning Information • Parts Breakdown

Capacity 12 Tons 20 Tons

Minimum Height 10.44" 10.44"

Maximum Height 20.09" 20.09"

Ram Travel 6.5" 6.5"

Extension Screw 3.6" 3.6"

Shipping Weight 28.0 lbs. 40.2 lbs.

4912CAH &

4920CAH

12 & 20 TON

CAPACITY

AIR/HYDRAULIC

BOTTLE JACK

THIS JACK IS DESIGNED FOR LIFTING PURPOSES ONLY.

AFTER LIFTING VEHICLE, ALWAYS USE SAFETY STANDS TO

SUPPORT THE LOAD BEFORE MAKING ANY REPAIRS. NEVER CRAWL

UNDER VEHICLE TO PLACE STANDS.

DO NOT OVERLOAD THIS JACK BEYOND THE RATED CAPACITY.

SET PARKING BRAKES AND BLOCK TIRES.

USE JACK ONLY ON HARD, LEVEL SURFACES CAPABLE OF

SUSTAINING THE LOAD.

CENTER LOAD ON THE SADDLE AND BE SURE THE SETUP

IS STABLE.

LOWER VEHICLE SLOWLY.

DO NOT EXCEED 120 PSI (OPERATING PRESSURE 90-120 PSI).

USING BRAKE OR TRANSMISSION FLUIDS WILL DAMAGE JACK.

OWNER AND/OR OPERATOR SHALL HAVE AN UNDERSTANDING

OF ALL OPERATING INSTRUCTIONS AND WARNINGS BEFORE

OPERATING THE JACK.

FAILURE TO HEED THESE WARNINGS MAY RESULT IN PERSONAL

INJURY AND/OR PROPERTY DAMAGE.

THIS OPERATING MANUAL CONTAINS IMPORTANT SAFETY

INFORMATION.

READ CAREFULLY AND UNDERSTAND ALL INFORMATION BEFORE

OPERATING THIS TOOL.

SAVE THIS MANUAL FOR FUTURE USE.

4912CAH 4920CAH

SPECIFICATIONS

4912CAH4920CAH_121906.indd 1 12/19/06 1:32:24 PM

Page 2

4912CAH & 4920CAH 2 rev. 12/19/06

▲WARNING!

FAILURE TO OBSERVE THESE WARNINGS COULD RESULT IN INJURY.

Important: Read these instructions carefully. Note the safe

operational requirements, warnings and cautions. Use this

tool correctly and with care for the purpose for which it was

intended. Failure to do so may cause property damage or

personal injury, and will invalidate the warranty.

• Ensure the jack is in sound condition and good working

order. Take action for immediate repair or replacement of

damaged parts. Use recommended accessories only. (The

use of improper accessories may be dangerous and will

invalidate the warranty.)

• Keep the jack clean for safest performance.

• Locate the jack in an adequate working area for its

function. Keep working area clean, tidy and free from

unrelated materials. Ensure the working area has

adequate lighting.

• Use the jack only on level and solid ground. Place blocks

under the wheels of the vehicle. Make sure engine is off.

Allow minimum distance of 0.5 meter between vehicle tilt

and static objects such as doors, walls, etc. Ensure all

non-essential persons keep a safe distance while the jack

is in use. Make sure there are no passengers in the

vehicle when the vehicle is raised.

• Place the jack under the vehicle manufacturer’s

recommended lifting points. (Check vehicle handbook.)

• Make sure the vehicle is stable and centered on the jack

saddle at the recommended lifting points. DANGER: Use

the jack for lifting only. (Not for supporting the lifted load.)

Use correct jack stands under the vehicle before

proceeding with any task.

• Use a qualified person to check and lubricate the jack.

Confirm that the recommended hydraulic oil is used

during maintenance.

• Do not use the jack if damaged.

• Untrained persons should not operate the jack.

• Do not exceed the rated capacity of the jack.

• Do not allow the vehicle to move while being lifted.

DANGER: Avoid lifting a vehicle if it may result in the

spilling of fuel, battery acid or other dangerous substances.

Do not allow anyone inside the vehicle while it is being

lifted. Do not work under the vehicle until jack stands

have been correctly positioned.

• Use the jack only for the purpose for which it

was intended.

• Store the jack in a dry, childproof area when not in use.

The owner and/or user must have a thorough understanding of the

manufacturer’s operating instructions and warnings before using

this bottle jack. Personnel involved in the use and operation of

equipment shall be careful, competent, trained, and qualified in the

safe operation of the equipment and its proper use when servicing

motor vehicles and their components. Warning information should be

emphasized and understood. If the operator is not fluent in English,

the manufacturer’s instructions and warnings shall be read to and

discussed with the operator in the operator’s native

language by the purchaser/owner, making sure that the operator

comprehends its contents.

Owner and/or user must study and maintain for future reference the

manufacturer’s instructions. Owner and/or user is responsible for

keeping all warning labels and instruction manuals legible and intact.

• Designed for operating either manually or pneumatically.

• The air hose can swivel in any direction.

• Fitted with safety valve against overloading.

• Extension screw gives added height when necessary.

• Minimum air pressure required is 90 PSI, 6.2 Bar.

• Two piece handle allows for easy pumping.

• Double spring return.

OWNER/USER RESPONSIBILITY FEATURES

!

4912CAH4920CAH_121906.indd 2 12/19/06 1:32:25 PM

Page 3

4912CAH & 4920CAH 3 rev. 12/19/06

OPERATING INSTRUCTIONS

BEFORE USE: Before using this product, read the owner’s manual

completely and familiarize yourself thoroughly with the product and

the hazards associated with its improper use. Open the release valve

counterclockwise (no more than 2 full turns). With ram fully

retracted, locate and remove the oil filler plug. Insert the handle into

the handle sleeve, then pump 6 to 8 strokes. This will help release

any pressurized air which may be trapped within the reservoir.

Ensure the oil level is just below the oil filler plug hole. Re-install the

oil filler plug. Pour a teaspoon of good quality, air tool lubricant into

the air supply inlet of the lift control valve. Connect to air supply and

operate for 3 seconds to evenly distribute lubricant. Check to ensure

that jack rolls freely (if so equipped) and that the pump operates

smoothly before putting into service. Replace worn or damaged parts

and assemblies as needed with manufacturer’s authorized

replacement parts. This product is fitted to accept the popular 1/4"

NPT nipple of your choice; ensure that thread tape or compound is

used when servicing connections. Inspect before each use. Do not

use if bent, broken or cracked components are noted.

OPERATION

MAINTENANCE

Lifting: Assemble two piece handle. Secure the load to

prevent inadvertent shifting and movement. Position the jack near

desired lift point. Close the release valve by turning it clockwise until

it is firmly closed.

Insert handle into handle sleeve. Pump handle or squeeze the lift

control valve until saddle contacts load. To end air operation, simply

release the grip on the lift control valve. NEVER WIRE, CLAMP OR

OTHERWISE DISABLE THE LIFT CONTROL VALVE TO FUNCTION BY

ANY MEANS OTHER THAN BY USING THE OPERATOR’S HAND. Raise

load to desired height, then immediately transfer the load to

appropriately rated support devices such as jack stands.

CAUTION: Use the handle provided with this product or

an authorized replacement handle to ensure proper release valve

operation. Do not use an extender on the air hose nor the operating

handle. When using to lift vehicle, lift only on the manufacturer’s

recommended lift point and in accordance with the published

guidelines in your vehicle owners manual. Always use jack stands to

support the load immediately after lifting.

WARNING:

This is a lifting device only. It is designed to lift part of the

total vehicle (one wheel or axle). Always wear safety glasses when

using this equipment. Center load on saddle before lifting. Never

work on, under or around load until it is properly supported. Transfer

the load immediately to appropriately rated jack stands. Do no use

this product for any purpose other than that for which it was

intended. It is owner’s responsibility to keep labels and instructional

material legible and available. Replacement labels and manuals are

available from the manufacturer. Failure to heed these and all other

warnings pertaining to this product can result in sudden loss of lifted

load resulting in death, personal injury or property damage.

Important: Use only a good grade hydraulic jack oil. Avoid mixing

different types of fluid and NEVER use brake fluid, turbine oil,

transmission fluid, motor oil or glycerin. Improper fluid can cause

premature failure of the jack and the potential for sudden and

immediate loss of load.

Adding Oil: With saddle fully lowered and pump position fully

depressed, set jack in its upright, level position. Remove oil filler plug.

Fill until oil is level with the filler plug hole, re-install oil filler plug.

Lubrication: A coating of light lubricating oil to pivot points, axles

and hinges will help to prevent rust and ensure that wheels, casters

and pump assemblies move freely. Periodically check the pump

piston and ram for signs of rust or corrosion. Clean as needed and

wipe with any oily cloth. NEVER USE SANDPAPER OR ABRASIVE

MATERIAL ON THESE SURFACES! When not in use, store the jack

with pump piston and ram fully retracted.

Lowering:

Raise load enough to carefully remove jack stands. Insert

handle onto release valve and slowly turn handle counterclockwise,

but no more than 1/2 turn. If load fails to lower, carefully transfer

the load to another lifting device and jack stands. Carefully remove

affected jack, and then the jack stands. Lower the load, again by

slowly turning the release valve no more than 1/2 turn. After removing

jack from under the load, push ram and handle sleeve down to reduce

exposure to rust and contamination.

WARNING: Be sure all tools and personnel are clear before

lowering load. Dangerous dynamic shock loads are created by

quickly opening and closing the release valve as the load is being

lowered. The resulting overload may cause hydraulic system failure

which could cause severe personal injury and/or property damage.

4912CAH4920CAH_121906.indd 3 12/19/06 1:32:25 PM

Page 4

4912CAH & 4920CAH 4 rev. 12/19/06

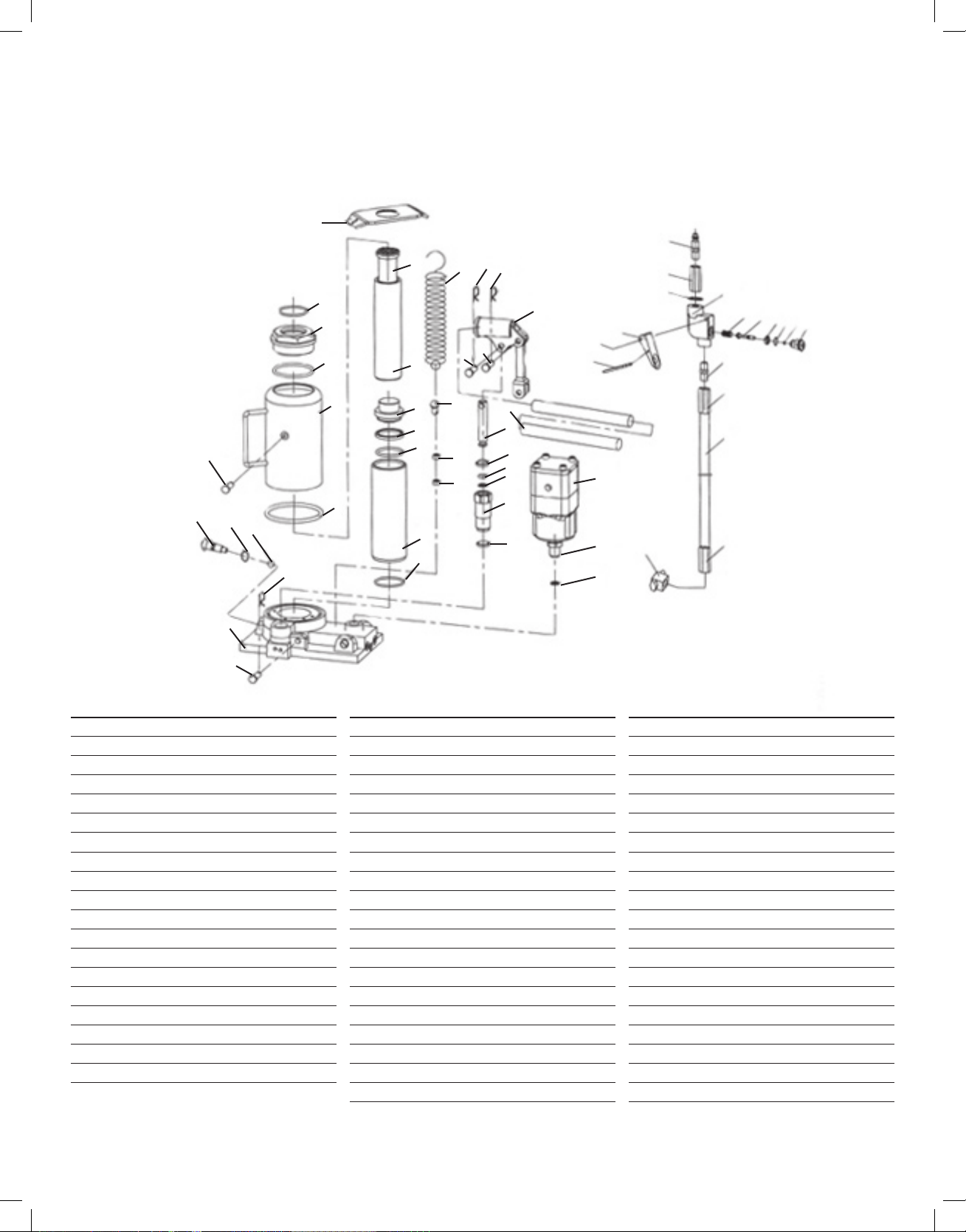

ITEM NO. DESCRIPTION QTY.

1 BASE 1

2 * BALL 1/4" 1

3 * SEAL

1

4 RELEASE VALVE 1

5 * O-RING 1

6 CYLINDER 1

7 * WASHER 1

07-1 * SEAL 1

07-2 RSAMPC

AIR MOTOR PUMP CYLINDER

(INCL. # 07-1) 1

8 PUMP CYLINDER

1

9 * O-RING

1

10 RS49HDL12 HANDLE 1

11 *

CUP SEAL 1

12 * BACK UP RING

1

13 PUMP PLUNGER

1

14 HANDLE SLEEVE 1

15 COTTER PIN

3

16

PIN 1

ITEM NO. DESCRIPTION QTY.

17 PIN 2

18 * PACKING 1

19 RESERVOIR 1

20 *RS49

FP FILLER PLUG 1

21 EXTENSION SCREW 1

22 RAM 1

23 CUP SEAL 1

24 * CAP WASHER 1

25 *

SNAP RING-G 1

26 * PACKING 1

27 TOP NUT 1

28 * O-RING 1

29 SPRING

2

30 SPRING PLATE 1

31 NUT 1

32 O-RING 1

33 O-RING

1

34 PACKING 1

35 THROTTLE 1

36 SPRING

1

ITEM NO. DESCRIPTION QTY.

37 RS12CAHVB VALVE BODY 1

(INCL. # 31-44)

38 HOSE CONNECTOR 1

39 SPRING 1

40 AIR FILTER 1

41 LEVEL 1

42 LOCK LEVER

1

43 LEVER PIN 1

44 HOSE CONNECTOR 1

45 HOSEBAND

2

(INCL. W/ #4

6)

46 RS12CAHHA AIR HOSE ASSY.

1

(INCL. #45 & 47)

47 PUMP ELBOW 1

(INCL. W/ #46)

48 RS12CAHAM AIR MOTOR

1

(INCL. # 07-1 & 07-2)

49 SPRING WASHER 2

50 NUT

2

51 EYE BOLT 2

4912CAH &

4920CAH

12 & 20 TON CAPACITY

AIR/HYDRAULIC

BOTTLE JACK

38

39

40

41

43

42

37

36

35

34

33

31

32

44

45

46

45

47

07-1

17

01

02

03

04

20

18

19

26

27

28

30

21

22

23

24

25

06

05

07

08

09

11

12

13

17

16

15

15

14

10

48

29

51

50

49

15

*Also Available- RS12CAHSK seal kit for 4912CAH and RS20CAHSK seal kit for 4920CAH (items identified by *).

NOTE: Only seal kits and items identified by a part number are available for purchase.

07-2

4912CAH4920CAH_121906.indd 4 12/19/06 1:32:25 PM

Page 5

4912CAH & 4920CAH 5 rev. 12/19/06

SUNEX INTERNATIONAL, INC. WARRANTS TO ITS CUSTOMERS THAT THE COMPANY’S SUNEX TOOLS

®

BRANDED

PRODUCTS ARE FREE FROM DEFECTS IN WORKMANSHIP AND MATERIALS.

Sunex International, Inc. will repair or replace its Sunex Tools® branded products which fail to give satisfactory service due to defective

workmanship or materials, based upon the terms and conditions of the following described warranty plans attributed to that specific product.

This product carries a ONE YEAR warranty. During this warranty period, Sunex Tools will repair or replace at our option any part or unit which

proves to be defective in material or workmanship.

Other important warranty information...

This warranty does not cover damage to equipment or tools arising from alteration, abuse, misuse, damage and does not cover any repairs or

replacement made by anyone other than Sunex Tools or its authorized warranty service centers. The foregoing obligation is Sunex Tools’ sole

liability under this or any implied warranty and under no circumstances shall we be liable for any incidental or consequential damages.

Note: Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may

not apply to you. Please contact your local Sunex distributor for proper warranty handling procedures.

If you have any questions about warranty service, please write to Sunex Tools. This warranty gives you specific legal rights and you may also

have other rights which vary from state to state. Repair kits and replacement parts are available for many of Sunex Tools products regardless

of whether or not the product is still covered by a warranty plan.

Shipping Address: Sunex Tools • 315 Hawkins Rd. • Travelers Rest, SC 29690

Mailing Address: Sunex Tools • P.O. Box 4215 • Greenville, SC 29608

POSSIBLE CAUSESSYMPTOM CORRECTIVE ACTION

Jack will not lift load

Release valve not tightly closed

Overload condition

Air supply inadequate

Ensure release valve tightly closed

Remedy overload condition

Ensure adequate air supply

Jack bleeds off after lift

Release valve not tightly closed

Overload condition

Hydraulic unit manlfunction

Ensure release valve tightly closed

Remedy overload condition

Contact Seller

Jack will not lower after

unloading

Reservoir overfilled

Linkages binding

Drain fluid to proper level

Clean and lubricate moving parts

Poor lift performance

Fluid level low

Air trapped in system

Ensure proper fluid level

With ram fully retracted, remove

oil filler plug to let pressurized air

escape, re-install oil filter plug

Will not lift to full extension

Fluid level low

Ensure proper fluid level

TROUBLESHOOTING

LIMITED WARRANTY...

4912CAH4920CAH_121906.indd 5 12/19/06 1:32:26 PM

Page 6

4912CAH & 4920CAH 6 rev. 12/19/06

LEER SIEMPRE LAS INSTRUCCIONES

ANTES DE USAR LAS HERRAMIENTAS

NUEMÁTICAS

USAR SIEMPRE ANTEOJOS

PROTECTORES

USAR PROTECCIÓN PARA

LOS OÍDOS

EVITAR EXPOSICIÓN PROLONGADA A

LAS VIBRACIONES

Instrucciones de operación • Información de advertencia • Desglose de partes

Capacidad 12 toneladas 20 toneladas

Altura mínima 10.44" 10.44"

Altura máxima 20.09" 20.09"

Viaje del pistón 6.5" 6.5"

Tornillo de extensión 3.6" 3.6"

Peso de embarque 28.0 lbs. 40.2 lbs.

4912CAH &

4920CAH

GATO NEUMÁTICO/

HIDRÁULICO TIPO

BOTELLA CAPACIDAD

12 & 20 TONELADAS

ESTE GATO ESTÁ DISEÑADO PARA EL TRABAJO DE LEVANTAMIENTO

SOLAMENTE. DESPUÉS DE LEVANTAR EL VEHÍCULO, SIEMPRE USE

SOPORTES DE SEGURIDAD PARA SOSTENER LA CARGA ANTES DE

HACER CUALQUIER REPARACIÓN. NUNCA MÉTASE DEBAJO DEL

VEHÍCULO PARA COLOCAR LOS SOPORTES. NO SOBRECARGUE ESTE

GATO MÁS ALLÁ DE SU CAPACIDAD NOMINAL. AJUSTE LOS FRENOS

DE ESTACIONAMIENTO Y BLOQUEE LAS LLANTAS.

USE EL GATO SÓLO EN LAS SUPERIFICIES DURAS Y NIVELADAS, LAS

QUE SEAN CAPACES DE SOSTENER LA CARGA.

CENTRE LA CARGA EN LA SILLA Y ASEGÚRESE QUE EL MONTAJE

ESTÉ ESTABLE.

BAJE EL VEHÍCULO LENTAMENTE.

NO EXCEDA LAS 120 PSI (PRESIÓN DE OPERACIÓN DE 90-120 PSI).

EL USO DE LÍQUIDOS PARA FRENOS O TRANSMISIÓN DAÑARÁ EL

GATO.

ANTES DE OPERAR EL GATO, EL PROPIERTARIO Y/O OPERADOR

DEBE TENER PLENA COMPRENSIÓN DE TODAS LAS INSTRUCCIONES

DE OPERACIÓN Y ADVERTENCIAS.

HACER CASO OMISO A ESTAS ADVERTENCIAS PUEDE OCASIONAR

LESIONES PERSONALES Y/O DAÑOS A LA PROPIEDAD.

ESTE MANUAL DE OPERACIÓN CONTIENE INFORMACIÓN IMPORTANTE

DE SEGURIDAD.

LEA CUIDADOSAMENTE Y COMPRENDA TODA LA INFORMACIÓN

CONTENIDA ANTES DE OPERAR ESTA HERRAMIENTA.

CONSERVE ESTE MANUAL PARA USO FUTURO.

4912CAH 4920CAH

ESPECIFICACIONES

4912CAH4920CAH_121906.indd 6 12/19/06 1:32:27 PM

Page 7

4912CAH & 4920CAH 7 rev. 12/19/06

▲AVERTENCIA

EL INCUMPLIMIENTO DE OBSERVAR ESTAS ADVERTENCIAS

PUEDEN RESULTAR EN ALGUNA LESIÓN

Importante: Lea estas instrucciones cuidadosamente. Nótese

los requerimientos, advertencias y precauciones para la

operación segura. Use esta herramienta correctamente y

con cuidado para el fin para el cual ésta está destinada. La

negligencia de hacer esto puede causar daños a la propiedad

o lesiones personales y anulará la garantía.

• Asegúrese que el gato esté en buenas condiciones y de

buen funcionamiento. Tome las medidas necesarias para

inmediatamente reparar o reponer las partes dañadas. Use

los accesorios recomendados solamente. (El uso de

accesorios inadecuados puede ser peligroso y anulará la

garantía)

• Mantenga limpio el gato para el desempeño seguro

del mismo.

• Mantenga el gato en una área adecuada de trabajo para su

funcionamiento. Mantenga limpio y ordenado el área de

trabajo y libre de materiales no relacionados. Asegúrese

que el área de trabajo cuente con iluminación adecuada.

• Use el gato sólo en superficies duras y planas. Coloque

unos bloques debajo de las llantas del vehículo. Asegúrese

que esté apagado el motor. Deje una distancia mínima de

0.5 metros entre la inclinación del vehículo y los objetos

inmóviles, tales como puertas, paredes, etc. Asegúrese que

todas las personas no esenciales mantengan una distancia

segura mientras el gato está en uso. Asegúrese que no

haya pasajeros en el vehículo cuando esté levantado el

vehículo.

• Coloque el gato debajo de los puntos de levantamiento

recomendados por el fabricante (Revise el manual del

vehículo).

• Asegúrese que el vehículo esté estable y centrado

sobre la silla del gato en los puntos recomendados de

levantamiento. PELIGRO: Use el gato para el trabajo de

levantamiento solamente. (No lo use para el sostenimiento

de la carga levantada.)

• Use los soportes adecuados para gato debajo del vehículo

antes de proceder con cualquier tarea.

• Emplee a una persona calificada para revisar y lubricar

el gato. Durante el mantenimiento, confirme que se use

del aceite hidráulico recomendado.

• No use el gato si está dañado.

• Las personas no capacitadas no deben operar el gato.

• No exceda la capacidad nominal del gato.

• No permita que se mueva el vehículo mientras esté en

proceso de elevación. PELIGRO: Evite levantar el vehículo

si esto pueda ocasionar el derrame de combustible,

ácido de batería o sustancias peligrosas. Durante el

levantamiento, no permita que nadie esté adentro del

vehículo. No trabaje debajo del vehículo hasta que los

soportes de gato hayan sido correctamente posicionados.

• Use el gato sólo para los fines para los cuales éste está

destinado.

• Cuando no está en uso, almacene el gato en un área seca

y a prueba de niños.

El propietario y/o usuario debe tener un amplio conocimiento de las

instrucciones de operación y advertencias del fabricante antes de

emplear el gato de botella. El personal involucrado en el uso y la

operación del equipo debe ser cuidadoso, competente ycalificado

para la operación segura del equipo y su uso adecuado al llevar

a cabo el mantenimiento de los vehículos motorizados y sus

componentes. La información de advertencia debe ser enfatizada

y comprendida. Si el operador no domina el idioma inglés, las

instrucciones y advertencias del manufacturero le deben ser leídas y

discutidas con el operador en su idioma maternal por el comprador/

propietario, así asegurando que el operador comprenda su contenido.

El propietario y/o usuario debe estudiar y conservar las instrucciones

del fabricante, para consultas futuras. El propietario y/o usuario es

responsable de asegurarse que las etiquetas de advertencia y los

manuales de instrucciones estén conservados legiblemente e

intactos. Las etiquetas de reemplazo y la documentación están

disponibles con el fabricante.

• Diseñado para la operación manual o neumática

• La manguera de aire puede girar en cualquier dirección

• Viene con una válvula de seguridad contra la sobrecarga.

• Tornillo de extensión proporciona altura adicional cuando

sea necesario

• La mínima presión de aire requerida es de 90 PSI, 6.2 Bar.

• Mango de dos piezas permite un bombeo fácil

• Mecanismo de doble resorte

CARACTERÍSTICAS

!

RESPOSABILIDAD DEL

PROPRIETARIO/USUARIO

4912CAH4920CAH_121906.indd 7 12/19/06 1:32:27 PM

Page 8

4912CAH & 4920CAH 8 rev. 12/19/06

INSTRUCCIONES DEL FUNCIONAMIENTO

ANTES DEL USO: Antes de usar este producto, lea el manual entero

del propietario y familiarícese completamente con el producto y

con los peligros asociados con su uso indebido. Abra la válvula de

liberación en el contrasentido de las agujas del reloj (no más de 2

vueltas completas). Con el pistón retraído completamente, ubique

y quite el tapón de rellenado de aceite. Inserte el mango en el forro

del mango, luego bombéelo de 6 a 8 golpes. Esto ayudará a liberar

cualquier aire a presión la cual haya sido atrapada en el depósito.

Asegúrese que el nivel de aceite llegue justo debajo del agujero

del tapón de rellenado de aceite. Reponga el tapón de rellenado

de aceite. Vierta una cucharada de lubricante para herramientas

neumáticas de buena calidad en la entrada del suministro de aire

de la válvula de control de levantamiento. Conéctelo al suministro

de aire y opérelo por 3 segundos para distribuir equitativamente el

lubricante. Revíselo para asegurar que el gato se mueva libremente

(si es que así viene equipado) y que la bomba opere suavemente

antes de ponerlos a trabajar. Reponga las piezas y montajes desgastados o dañados, según sea necesario, con piezas de reposición

autorizadas por el fabricante. Este producto está ajustado para

aceptar el latiguillo NPT 1/4” popular de su preferencia; asegúrese

que se use su cinta o compuesto de rosca al momento de dar

servicio a las conexiones. Inspecciónelo antes de cada uso. No lo

use si está doblado, roto, o si se notan componentes agrietados.

LA OPERACIÓN

MANTENIMIENTO

Levantamiento: Ensamble el mango de dos piezas. Asegure la

carga para prevenir el desplazamiento y movimientos involuntarios.

Posicione el gato cerca del punto deseado de levantamiento. Cierre

la válvula de liberación al girarla en el sentido de las agujas del reloj

hasta que esté firmemente cerrado.

Inserte el mango en el forro del mango. Bombee el mango o apriete

la válvula de control de levantamiento hasta que la silla tenga

contacto con la carga. Para terminar la operación neumática,

simplemente libere el agarre en la válvula de control de levantamiento.

NUNCA CONECTE, RETENGA CON ABRAZADERA, NI DE OTRA FORMA

IMPOSIBILITE EL FUNCIONAMIENTO DE LA VÁLVULA DE CONTROL DE

LEVANTAMIENTO POR CUALQUIER OTRA MEDIDA QUE NO SEA POR

MANO DEL OPERADOR. Levante la carga a la altura deseada, luego

inmediatamente transfiera la carga a los aparatos de sostenimiento

de especificación adecuada, tales como los soportes de gato.

PRECAUCIÓN: Use el mango provisto con este producto o algún mango

de repuesto autorizado para asegurar la operación adecuada de la

válvula de operación. No ocupe ninguna extensión con la manguera de

aire ni con el mango de operación. Cuando se usa una para levantar el

vehículo, levántelo sólo en el punto de levantamiento recomendado por

el fabricante y de acuerdo con las directrices publicadas en su manual

de propietario del vehículo. Inmediatamente después de levantarlo,

siempre use soportes de gato para sostener la carga

ADVERTENCIA: Este aparato está destinado para el levantamiento

solamente. Está diseñado para levantar una parte del vehículo entero

(una llanta o eje). Siempre use gafas de seguridad al usar este equipo.

Centre la carga en la silla antes de levantarla. Nunca trabaje en,

Importante: Sólo use un aceite de gato hidráulico de buena calidad.

Evite mezclar diferentes tipos de lubricantes y NUNCA use lubricante

de frenos, aceite de turbina o líquido para transmisiones, aceite

motor o glicerina. El lubricante inadecuado puede ocasionar fallas

prematuras del gato y potenciales pérdidas repentinas e inmediatas

de la carga.

Agregando aceite: Con la silla completamente bajada y la posición

de la bomba íntegramente presionada, coloque el gato en su posición

vertical plana. Quite el tapón de rellenado de aceite. Rellene hasta

que el aceite esté a nivel con el agujero de rellenado, luego reponga

el tapón de rellenado.

Lubricación: Una capa de aceite ligero de lubricación en los puntos

de pivote, ejes y bisagras ayudará en la prevención de oxidación y

asegurará que las llantas, rodajas y montajes de bomba cuenten

con un libre movimiento. Revise el pistón y cilindro de la bomba

periódicamente por señas de corrosión u oxidación. Límpielos según

sea necesario con un trapo aceitado. ¡NUNCA USE PAPEL DE LIJA

NI MATERIAL ABRASIVO EN ESTAS SUPERFICIES! Cuando no está

en uso, almacene el gato con el pistón de la bomba y el cilindro

completamente retraídos.

debajo de, o cerca de la carga hasta que ésta esté adecuadamente

sostenida. Inmediatamente transfiera la carga a los soportes de gato

de la especificación adecuada. No use este producto para ningún otro

fin excepto para él que fue destinado. Es la responsabilidad del

propietario mantener legibles y disponibles las etiquetas y el

material de instrucción. Las etiquetas y material de reposición están

disponibles por parte del fabricante. Hacer caso omiso a estas y

todas las demás advertencias pertenecientes a este producto pueden

ocasionar la pérdida repentina de la carga levantada, así causando la

muerte, lesión personal o daños a la propiedad.

Bajada: Levante la carga lo suficiente para cuidadosamente quitar los

soportes de gato. Inserte el mango en la válvula de liberación y gire

el mango lentamente en el contrasentido de las agujas del reloj,

pero no más allá de una1/2 vuelta. Si la carga no baja, transfiera

cuidadosamente la carga a otro aparato de levantamiento y a otros

soportes de gato. Quite cuidadosamente el gato afectado, y

posteriormente los soportes de gato. Baje la carga, nuevamente al

girar la válvula de liberación no más allá de una 1/2 vuelta. Después

de quitar el gato de debajo de la carga, empuje el pistón y el forro

de mango hacia abajo para reducir exposición a la corrosión y contaminación.

ADVERTENCIA: Asegúrese que todas las herramientas y personal estén

libres del área antes de bajar la carga. Se crean cargas de choque

dinámico peligrosas al abrir y cerrar rápidamente la válvula de

liberación, mientras que se baje la carga. La sobrecarga resultante

puede causar la falla del sistema hidráulico lo cual podría ocasionar

lesiones personales severas y/o daños a la propiedad.

4912CAH4920CAH_121906.indd 8 12/19/06 1:32:28 PM

Page 9

4912CAH & 4920CAH 9 rev. 12/19/06

SUNEX INTERNATIONAL, INC., LE GARANTIZA A SUS CLIENTES QUE LAS HERRAMIENTAS Y PRODUCTOS

CON LA MARCA DE LA EMPRESA SUNEX TOOLS NO CONTIENEN DEFECTOS EN SU MANO DE OBRA NI

MATERIAS PRIMAS

.

Sunex International, Inc., reparará o sustituirá sus productos con la marca Sunex Tools® que reflejen fallas en el funcionamiento satisfactorio

debido a que la mano de obra o las materias primas estén defectuosas, tomando como base las cláusulas y condiciones de los planes de

garantía descritos a continuación y asignados a ese producto específico. Este producto tiene una garantía de UN AñO. Durante ese periodo

de garantía, Sunex Tools reparará o sustituirá, como así opte por hacerlo, cualquier componente o unidad que se compruebe tener decectos

en su materia prima o mano de obra.

Otra importante información de la garantía...

Esta garantía no cubre ningún daño al equipo o herramientas, si este surge como resultado de su alteración, abuso, o mal uso o daños ni

tampoco cubre las reparaciones o reposiciones hechas por cualquier persona ajena a los centros de servicio de garantía autorizados y que

no sean de Sunex Tools. La obligación antes mancionada queda bajo la responsabilidad exclusiva de Sunex Tools® según se menciona o

de cualquier garantía implícita y bajo ninguna circunstancia quedará bajo su responsabilidad cualquier garantía implícita ya bajo ninguna

circunstancia quedará bajo su responsabilidad cualquier daño incidental o consecuencial.

Note: Algunos estados no permiten la exclusión o limitación de los daños incidentales o consecuenciales, por lo tanto la limitación o

exclusión arriba mencionada quizá no pudiera serle pertinente a usted. Devuelva el equipo o componentes a Sunex Tools, un centro de

servicio de garantía autorizado, con elflete pagado. Asegúres haber incluido su nimbre y dirección, la evidencia de la fecha de adquisición

y la descripción del defecto que se sospeche tener.

Si usted tiene cualquier duda acerca del servicio de garantía, escriba por favor a Sunex Tools. Esta garantía le proporciona derechos legales

específicos y usted también podrá contar con derechos adicionales, los cuales varían de estado a estado. Las cajas de reparación y las

piezas de repuesto están disponibles para un gran número de productos de Sunex Tools, independientemente de que si algún producto aún

esté cubierto o no por el plan de garantía.

DIRECCIÓN A EMBARCARSE: Sunex Tools • 315 Hawkins Rd. • Travelers Rest, South Carolina 29690

DIRECCIÓN DE CORREOS: Sunex Tools • P.O. Box 4215 • Greenville, South Carolina 29608

CAUSAS POTENCIALESSÍNTOMA ACCIÓN CORRECTIVA

El gato no levantará la carga

La válvula de liberación no está

apretadamente cerrada

Condición de sobrecarga

Surtimiento de aire inadecuado

Asegúrese que la válvula de liberación esté bien cerrada

Remedie la condición de sobrecarga

Asegure el surtimiento adecuado de aire

El gato se purga después

del levantamiento

La válvula de liberación no está

apretadamente cerrada

Condición de sobrecarga

Mal funcionamiento de la unidad

hidráulica

Asegúrese que la válvula de liberación esté bien cerrada

Remedie la condición de sobrecarga

Contacte al vendedor

El gato no se baja después

de la descarga

Sobre-rellenado del depósito

Atascamiento de vinculaciones

Vacíe el aceite hasta el nivel adecuado

Limpie y lubrique las partes móviles

Rendimiento pobre de

levantamiento

Nivel bajo de líquido

Aire entrapado en el sistema

Asegúrese del nivel adecuado de fluidos

Con el pistón completamente retraído, quite el tapón de

rellenado de aceite para dejar escapar el aire a presión,

reponga el tapón de rellenado de aceite

No se levantará a su

plena extensión

Bajo nivel de fluidos

Asegúrese del nivel adecuado de fluidos

DIAGNÓSTICO DE AVERÍAS

GARANTÍA LIMITADA...

4912CAH4920CAH_121906.indd 9 12/19/06 1:32:28 PM

Page 10

4912CAH & 4920CAH 10 rev. 12/19/06

LEER SIEMPRE LAS INSTRUCCIONES

ANTES DE USAR LAS HERRAMIENTAS

NUEMÁTICAS

USAR SIEMPRE ANTEOJOS

PROTECTORES

USAR PROTECCIÓN PARA

LOS OÍDOS

EVITAR EXPOSICIÓN PROLONGADA

A LAS VIBRACIONES

Instrucciones de operación • Información de advertencia • Desglose de partes

Capacité 12 Tonnes 20 Tonnes

Hauteur minimum 10,44" 10,44"

Hauteur maximum 20,09" 20,09"

Course du vérin 6,5" 6,5"

Vis de rallonge 3,6" 3,6"

Poids à l’expédition 28,0 lbs 40,2 lbs

4912CAH &

4920CAH

CRIC BOUTEILLE

D’UNE CAPACITÉ DE

12 & 20 TONNES

PNEUMATIQUE/

HYDRAULIQUE

CE CRIC EST CONÇU POUR LE LEVAGE SEULEMENT.

APRÈS LE LEVAGE DU VÉHICULE, UTILISEZ TOUJOURS LES SUPPORTS

DE SÉCURITÉ POUR SOUTENIR LA CHARGE AVANT D’EFFECTUER

DES RÉPARATIONS. NE JAMAIS RAMPER SOUS LE VÉHICULE POUR

PLACER LES SUPPORTS.

NE SURCHARGEZ PAS CE CRIC AU DELÀ DE LA CAPACITÉ ÉVALUÉE.

PLACEZ LE FREINS DE STATIONNEMENT ET BLOQUER LES ROUES.

UTILISEZ LE CRIC SEULEMENT SUR DES SURFACES RIGIDES ET DE

NIVEAU, CAPABLES DE SOUTENIR LA CHARGE.

CENTREZ LA CHARGE SUR LA SELLE ET ASUREZ-VOUS QUE

L’INSTALLATION EST STABLE.

ABAISSEZ LE VÉHICULE LENTEMENT.

N’EXCÉDEZ PAS 120 PSI (PRESSION DE FONCTIONNEMENT 90-120

PSI).

UTILISEZ DES FLUIDES DE FREIN OU DE TRANSMISSION

ENDOMMAGERA LE CRIC.

LE PROPRIÉTAIRE ET/OU L’OPÉRATEUR DOIT AVOIR UNE

COMPRÉHENSION DE TOUTES LES CONSIGNES D’UTILISATION ET

AVERTISSEMENTS AVANT D’UTILISER LE CRIC.

LE MANQUE D’OBSERVER CES AVERTISSEMENTS PEUT AVOIR COMME

CONSÉQUENCE DES BLESSURES ET/OU DES DÉGATS MATÉRIELS.

CE MANUEL D’OPÉRATION CONTIENT DE L’INFORMATION

IMPORTANTE DE SÉCURITÉ.

LISEZ SOIGNEUSEMENT ET COMPRENEZ TOUTE L’INFORMATION

AVANT D’UTILISER CET OUTIL.

CONSERVEZ SE MANUEL POUR RÉFÉRENCE FUTURE.

4912CAH 4920CAH

SPÉCIFICATIONS

4912CAH4920CAH_121906.indd 10 12/19/06 1:32:29 PM

Page 11

4912CAH & 4920CAH 11 rev. 12/19/06

▲AVERTISSEMENT

LE NON-RESPECT DE CES AVERTISSEMENTS POURRAIT ENTRAÎNER DES BLESSURES.

Important : Lisez ces instructions soigneusement. Prenez note

des conditions, avertissements et indications de prudence.

Utilisez cet outil correctement et avec soin pour l’usage pour

lequel il a été conçu seulement. Le manquement à faire ainsi

peut causer des dégâts matériels ou des blessures et annulera

la garantie.

• Assurez-vous que le cric est en bonne condition et en bon

état de fonctionnement. Réagissez rapidement si le besoin

d’une réparation ou d’un remplacement de pièces

endommagées se fait sentir. Utilisez que les accessoires

recommandés uniquement. (L’utilisation des accessoires

non recommandées peut être dangereuse et annulera la

garantie.)

• Maintenez le cric propre pour une utilisation plus

sécuritaire.

• Gardez le cric dans un emplacement de travail approprié

pour sa fonction. Maintenez l’emplacement de travail

propre, rangé et libre de matériaux étrangers. Assurez-vous

que l’emplacement de travail possède un éclairage

adéquat.

• Utilisez le cric uniquement sur une surface rigide et de

niveau. Placez des cales sous les roues du véhicule.

Assurez-vous que le moteur est éteint. Laissez une

distance minimale de 0,5 mètre entre l’inclinaison du

véhicule et les objets statiques tels que portes, murs, etc.

Assurez-vous que toutes les personnes non essentielles

gardent une distance sécuritaire tandis que le cric est en

fonction. Assurez-vous qu’il n’y a aucun passager dans le

véhicule lorsque le véhicule est soulevé.

• Placez le cric sous les points de levage recommandés par

le fabricant du véhicule. (Manuel du véhicule.) Assurez-vous

que le véhicule est stable et centré sur la selle du cric aux

points de levage recommandés. DANGER : Utilisez le cric

pour soulever seulement. (Pas pour soutenir la charge

soulevée.) Utilisez des supports de véhicule adéquats sous

le véhicule avant d’effectuer une tâche.

• Utilisez une personne qualifiée pour faire la vérification et

lubrifier le cric.

• Confirmez que l’huile hydraulique recommandée est utilisée

pendant l’entretien.

• N’utilisez pas le cric si endommagé.

• Les personnes non formées ne devraient pas actionner

le cric.

• N’excédez pas la capacité évaluée du cric.

• Ne laissez pas le véhicule se déplacer tout en étant

soulevé. DANGER : Évitez de soulever un véhicule s’il y a

risque de déversement de carburant, d’acide de batterie

ou d’autres substances dangereuses. Ne permettez pas

à quiconque d’être à l’intérieur du véhicule tandis qu’il est

soulevé. Ne travaillez pas sous le véhicule jusqu’à ce que

des supports de véhicule soient correctement en place.

• Utilisez le cric seulement pour l’usage pour lequel il a

été conçu.

• Entreposez le cric dans un endroit sec, et hors de la porté

des enfants lorsqu’il il n’est pas utilisé.

Le propriétaire et/ou l’utilisateur doit avoir une compréhension

approfondie des consignes d’utilisation et des avertissements du

fabricant avant d’utiliser le cric bouteille. Le personnel impliqué

dans l’utilisation et le fonctionnement de l’équipement doit être

prudent, compétent, bien entraîné et qualifié dans le fonctionnement

sécuritaire de l’équipement et de son utilisation adéquate en faisant

l’entretien des véhicules à moteur et leurs composants. L’information

concernant les avertissements doit être soulignée et comprise.

Si l’opérateur n’est pas à l’aise en anglais, les instructions et les

avertissements du fabricant doivent lui être lus et discutés avec

l’opérateur dans la langue maternelle de l’opérateur par l’acheteur/

le propriétaire, s’assurant que l’opérateur comprend son contenu.

Le propriétaire et/ou l’utilisateur doit étudier et conserver les

directives du manufacturier, pour référence éventuelle. Relativement

aux étiquettes de mises en garde et aux manuels de directives, le

propriétaire et/ou l’utilisateur est responsable de s’assurer qu’ils

soient maintenus lisibles et intacts. Les étiquettes de remplacement

et la littérature sont disponibles auprès du manufacturier.

• Conçu pour fonctionner manuellement ou de manière

pneumatique.

• Les boyaux d’air peuvent pivoter dans n’importe quelle direction.

• Équipé d’une soupape de sécurité contre la surcharge.

• La vis de rallonge donne une hauteur supplémentaire si

nécessaire.

• La pression d’air minimum exigée est de 90 psi, 6,2 Bar

• Poignée de deux pièces pour un pompage facile.

• Ressort de retour double

CARACTÉRISTIQUES

!

RESPOSABILITÉ DU

PROPRIÉTAIRE/UTILISATEUR

4912CAH4920CAH_121906.indd 11 12/19/06 1:32:30 PM

Page 12

4912CAH & 4920CAH 12 rev. 12/19/06

INSTRUCCIONES DEL FUNCIONAMIENTO

AVANT L’UTILISATION : Avant d’utiliser ce produit, lisez attentivement le manuel du propriétaire et familiarisez-vous complètement

avec le produit et les risques liés à une mauvaise utilisation. Tournez

la valve de relâchement dans le sens contraire des aiguilles d’une

montre (pas plus de 2 tours complets). Le vérin entièrement rétracté,

localisez et enlevez le bouchon de remplissage d’huile. Insérez la

poignée dans la douille de poignée, puis pompez de 6 à 8 courses.

Ceci aidera à libérer l’air pressurisé qui peut être emprisonné dans le

réservoir. Assurez-vous que le niveau d’huile est juste au-dessous du

trou du bouchon de remplissage d’huile. Réinstallez le bouchon de

remplissage d’huile. Versez une cuillère à thé de lubrifiant pour outil

pneumatique de bonne qualité, dans l’admission d’air de la soupape

de commande. Reliez à l’air et faites fonctionnez pendant 3 secondes

pour distribuer également le lubrifiant. Vérifiez pour s’assurer que

le cric tourne librement (si ainsi équipé) et que la pompe fonctionne

sans à-coup avant la mise en service. Remplacez les pièces et les

assemblages usées ou endommagées avec les pièces de rechange

autorisées par le fabricant dès que nécessaire. Ce produit est adapté

pour accepter le populaire mamelon de 1/4”NPT de votre choix ;

assurez-vous que la bande filetée ou un abrasif est utilisé pour

l’entretien des raccordements. Inspectez avant chaque utilisation.

Ne pas utiliser si plié, cassé ou fendu.

FONCTIONNEMENT

MANTENIMIENTO

Levage : Assemblez les deux pièces de la poignée. Fixez la charge

pour empêcher le décalage latéral et le mouvement du véhicule par

inadvertance. Placez le cric près du point de levage désiré. Fermez la

valve de relâchement en la tournant dans le sens des aiguilles d’une

montre jusqu’à ce qu’elle soit fermement fermée.

Insérez la poignée dans la douille de poignée. Pompez la poignée ou

serrez la soupape de commande de levage jusqu’à ce que la selle

entre en contact avec la charge. Pour terminer l’utilisation d’air,

relâcher simplement la poignée sur la soupape de commande de

levage. NE JAMAIS BROCHER, FIXER OU NEUTRALISER LA SOUPAPE

DE COMMANDE DE LEVAGE PAR QUELQUES MOYENS QUE CE SOIT,

AUTRE QUE PAR L’UTILISATION DE LA MAIN DE L’OPÉRATEUR.

Soulevez la charge à la hauteur désirée, puis transférez

immédiatement la charge aux dispositifs de soutien convenablement

évalués, tels que des supports de véhicule.

ATTENTION : Utilisez la poignée fournit avec ce produit ou une

poignée de rechange autorisée pour assurer l’opération appropriée

de la valve de relâchement. N’utilisez pas une unité d’extension

sur les boyaux d’air ainsi que sur la poignée. Lorsque utilisé pour

soulever un véhicule, soulevez seulement sur les points de levage

recommandés par le fabricant et selon les directives du manuel du

propriétaire du véhicule. Utilisez toujours des supports de véhicule

pour soutenir la charge juste après le levage.

AVERTISSEMENT : Ceci est un dispositif de levage seulement. Il est

conçu pour soulever une partie de n’importe quel véhicule (une roue

ou un axe). Portez toujours une protection oculaire lorsque vous

utilisez cet équipement. Centrez la charge sur la selle avant le levage.

Ne travaillez jamais sous ou autour de la charge avant qu’elle ne soit

correctement soutenue. Transférez la charge immédiatement aux

supports de véhicule appropriés.

Important : Utilisez seulement une huile de qualité pour cric

hydraulique. Évitez de mélanger différents types de fluide et

n’utilisez jamais le liquide des freins, l’huile de turbine, le fluide de

transmission, l’huile à moteur ou la glycérine. Un fluide inapproprié

peut entraîner la défaillance prématurée du cric et potentiellement

la perte soudaine et immédiate de la charge.

L’ajout d’huile : La selle entièrement rétractées et la position de

la pompe entièrement abaissée, placez le cric en position droite et

de niveau. Enlevez le bouchon de remplissage d’huile. Remplissez

jusqu’à ce que l’huile soit de niveau avec le trou du bouchon de

remplissage d’huile, réinstallez le bouchon de remplissage d’huile.

Lubrification: Un enduit d’huile de graissage légère aux points de

pivots, aux axes et charnières aidera à empêcher la rouille et à

assurer que les roues, les roulettes et les pompes bougent librement.

Examinez périodiquement le piston et le vérin de pompe pour

détecter les signes de rouille ou de corrosion. Nettoyez tant

que nécessaire avec un chiffon ou n’importe quel tissu huileux.

N’EMPLOYEZ JAMAIS DE PAPIER SABLÉ OU D’ABRASIF SUR CES

SURFACES ! Lorsqu’il n’est pas utilisé, entreposez le cric avec le

piston de pompe et le vérin entièrement rétractée.

N’utilisez ce produit que pour l’usage pour lequel il a été conçu

seulement Il est de la responsabilité du propriétaire de maintenir

les étiquettes et le matériel didactique lisibles et disponibles. Les

étiquettes et les manuels de rechange sont fournis par le fabricant.

Le manque d’observer ces derniers et tous autres avertissements

qui concernent ce produit peut avoir comme conséquence la perte

soudaine de la charge soulevée pouvant entraîner des dégâts

matériels, des blessures graves et même la mort.

Abaissement : Soulevez la charge suffisamment pour enlever

prudemment les supports de véhicule. Insérez la poignée sur la

valve de relâchement et tournez lentement la poignée dans le sens

contraire des aiguilles d’une montre, mais pas plus de 1⁄2 tour. Si

la charge ne s’abaisse pas, transférez soigneusement la charge à

un autre dispositif de levage et supports de véhicule. Enlevez

soigneusement le cric défectueux, ensuite les supports de

véhicule. Abaissez la charge, encore en tournant lentement la

valve de relâchement pas plus de 1⁄2 tour. Après l’enlèvement

du cric de sous la charge, poussez le vérin et la douille vers le bas

pour réduire l’exposition à la rouille et à la contamination.

AVERTISSEMENT : Assurez-vous que toutes les personnes et

instruments sont à une distance sécuritaire avant d’abaisser la

charge. Des charges dynamiques de choc dangereuses sont créées

en ouvrant et fermant rapidement la valve de relâchement pendant

que la charge est abaissée. La surcharge qui s’en suit pourrait

causer la défaillance du circuit hydraulique et entraîner des

blessures graves et/ou des dégâts matériels.

4912CAH4920CAH_121906.indd 12 12/19/06 1:32:30 PM

Page 13

4912CAH & 4920CAH 13 rev. 12/19/06

SUNEX INTERNATIONAL, INC. GARANTI À SES CLIENTS QUE LES PRODUITS DE L’ENTREPRISE SUNEX

TOOLS® SONT EXEMPTS DES DÉFAUTS DE MAIN-D’ŒUVRE ET DE MATÉRIAUX.

Sunex International, Inc. réparera ou remplacera ses outils de marque Sunex Tools

®

qui ne donnent pas un service satisfaisant à cause

d’un défaut de main d’œuvre ou de matériau, selon les termes et conditions décrits ci-dessous dans les plans de garantie correspondant à

ce produit spécifique. Ce produit a une garantie de UN AN. Pendant la période de garantie, Sunex Tools réparera ou remplacera, à sa seule

discrétion, toute pièce ou tout appareil dont il a été déterminé qu’il comporte un défaut de matériau ou de main d’œuvre.

Autres informations importantes sur la garantie...

Cette garantie ne couvre pas les dommages à de l’équipement ou à des outils modifiés, sujets à des abus ou à une utilisation incorrecte, ou

encore endommagés; elle ne couvre pas les réparations ou le remplacement effectué par quiconque autre que Sunex Tools ou ses centres

de services de garantie autorisés. L’obligation qui précède constitue la seule responsabilité de Sunex Tools en vertu de cette garantie ou de

toute garantie implicite; et en aucun cas Sunex Tools ne pourra être responsable pour des dommages indirects ou consécutifs.

Remarque : Certaines juridictions ne permettent pas l’exclusion ou la limitation des dommages indirects ou consécutifs; la limitation ou

l’exclusion ci-dessus pourrait donc ne pas s’appliquer à votre cas.

Retourner l’équipement ou les pièces à Sunex Tools, ou à un centre de service de garantie autorisé, port prépayé. S’assurer d’inclure votre

nom, votre adresse, une preuve de la date d’achat et la description de la défaillance présumée. Pour toutes questions concernant le service

de garantie, communiquez avec les « Outils Sunex ». Cette garantie vous donne des droits légaux spécifiques et vous pouvez également avoir

d’autres droits qui varient d’un état à l’autre. Les trousses de réparation et les pièces de rechange sont disponibles pour plusieurs des outils

Sunex, peu importe si les produits sont toujours couverts par un plan de garantie

.

Adresse d'expédition : Sunex Tools • 315 Hawkins Rd. • Travelers Rest, SC 29690

Adresse postale : Sunex Tools • P.O. Box 4215 • Greenville, SC 29608

CAUSES POSSIBLESSYMPTÔME ACTION CORRECTIVE

Le cric ne soulève pas

la charge

La valve de relâchement n’est pas

fermée correctement

Condition de surcharge

Alimentation en air inadéquate

Assurez-vous que la valve de relâchement est

bien fermée

Remède à la condition de surcharge

Assurez-vous d’une alimentation en air adéquate

Le cric fuit après le levage

La valve de relâchement n’est pas

bien fermée

Condition de surcharge

Mauvais fonctionnement de l’unité

hydraulique

Assurez-vous que la valve de relâchement est

bien fermée

Remède à la condition de surcharge

Communiquez avec le vendeur

Le cric ne s’abaisse pas après

le déchargement

Trop plein du réservoir

Grippage du mécanisme articulé

Vidangez le fluide au niveau approprié

Nettoyez et lubrifiez les pièces mobiles

Faible performance de levage

Niveau du fluide bas

Air emprisonné dans le système

Assurez un niveau de fluide approprié

Avec le vérin entièrement rétracté, retirez le bouchon de

remplissage d’huile pour laisser l’air s’échapper, ensuite

réinstallez le bouchon de remplissage d’huile

Ne se soulève pas à pleine

hauteur

Niveau du fluide bas

Assurez un niveau de fluide approprié

DÉPANNAGE

GARANTIE LIMITÉE...

4912CAH4920CAH_121906.indd 13 12/19/06 1:32:30 PM

Loading...

Loading...