Page 1

Installation Instructions

Casement Air Conditioners

PTT122606

Page 2

ELECTRICAL REQUIREMENTS

ELECTRICAL SHOCK AND PERSONAL INJURY HAZARD

Electrical ground is required for this air conditioner.

•

DO NOT ground to a gas line.

•

If cold water pop is interrupted by plastic, non-metallic gaskets, or other insulating materials, DO

•

NOT use for grounding.

Check with a qualifi ed electrician if you are in doubt as to whether the air conditioner is properly

•

grounded.

DO NOT modify the power supply cord. If it does not fi t the outlet, have a proper outlet installed

•

by a qualifi ed electrician.

DO NOT have a fuse in the neutral or grounding circuit. A fuse in the neutral or grounding circuit

•

could result in electrical shock.

•

DO NOT use an extension cord with this air conditioner.

RECEPTACLE WIRING

Receptacle wiring should be a minimum of 14 gauge. Use copper wire only. It is your responsibility to

provide proper and adequate receptacle wiring, installed by a qualifi ed electrician.

ELECTRICAL REQUIREMENTS

A 115V (103.5 minimum, 126.5 maximum), 60Hz, AC only, 15 ampere fused electrical supply is

required. A time delay fuse or time delay circuit breaker is also required. A separate circuit, serving

only this air conditioner, must be provided.

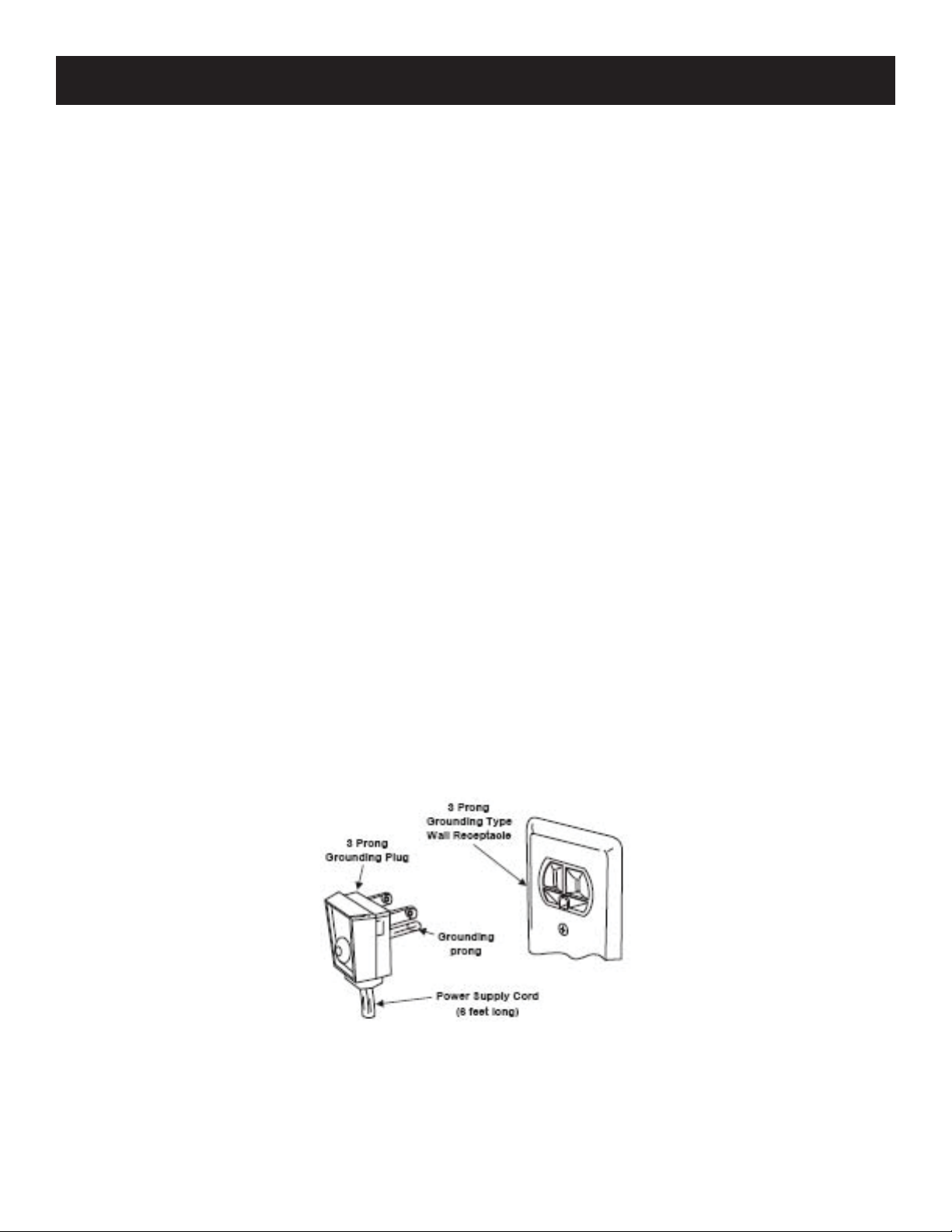

ELECTRICAL CONNECTION

For your personal safety, this air conditioner must be grounded. This unit includes a 3-prong

grounding plug. To minimize possible electrical shock hazard, the cord must be plugged into a mating

3-prong grounding-type outlet and must be grounded according to the National Electrical Code and

all local codes and ordinances. If a mating 3-prong grounding-type outlet is not available, it is your

responsibility to have one installed by a qualifi ed electrician.

2

Page 3

BEFORE INSTALLATION

WARNINGS

Because this unit weights 88-105 lbs., it is recommended that two people install this air conditioner.

•

Inspect the condition of the window where the unit will be installed. Be sure it will support the

weight of the unit.

This appliance must be installed according to all applicable codes and ordinances.

•

Handle the air conditioner with care. Avoid sharp metal fi ns on the front and rear coils.

•

Make sure your air conditioner does not fall during installation.

•

Do not use water collected in the air conditioner for drinking. It is unsanitary.

•

INSTALLATION TIPS

For wood-frame casement windows - it may be necessary to construct a frame using at least 1-inch

•

thick wood with a 15.5-inch wide opening.

For brick or cement building construction - it may be necessary to put a wood stool strip under the

•

air conditioner for mounting purposes.

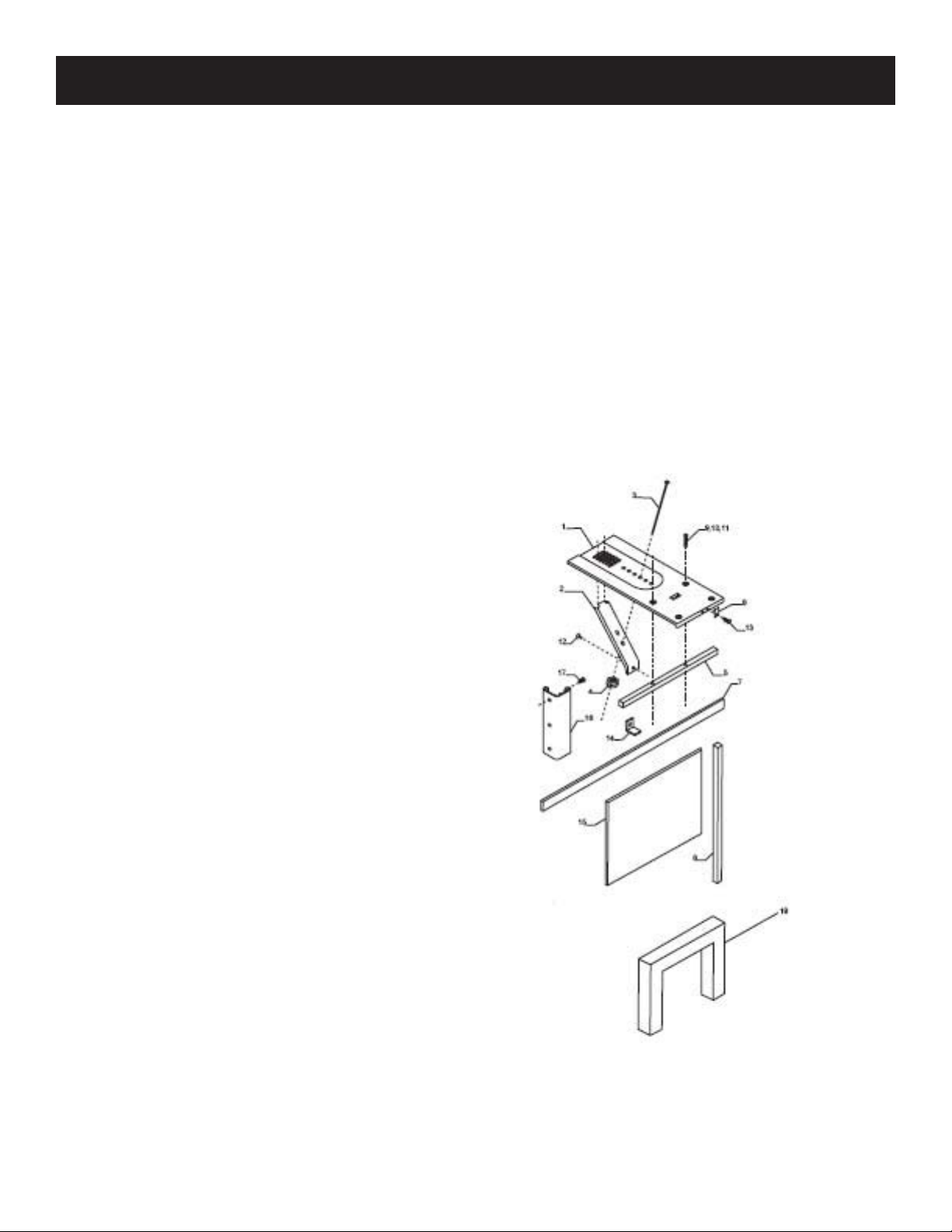

INSTALLATION KIT

Platform (1)

1.

Support brace (1)

2.

Adjustment bolt (1)

3.

Hex fl ange nut - 1/4” (1)

4.

Track seal (1)

5.

Side channel seal (1)

6.

Foam seal strip/Sash seal

7.

Safety bracket (1)

8.

Screw - #10x2-1/2” fl at-head (2) OR

9.

Screw - #10x1-3/4” pan-head (2) OR

10.

Screw - #10x1” pan-head (2)

11.

Screw - #8x3/4” pan-head (6)

12.

Screw - #8-32x3/4” self-threading (7)

13.

Window locking bracket (1)

14.

Plastic window panel (1)

15.

Side channel (2)

16.

Screw - #8x3/8” truss-head (6)

17.

Panel frame/seal assembly (1)

18.

Tools needed: fl at-head screwdriver, Phillips

screwdriver, level, tape measure, fi ne-tooth saw,

electric or hand drill, knife and scissors, pencil

3

Page 4

BEFORE INSTALLATION (cont’d)

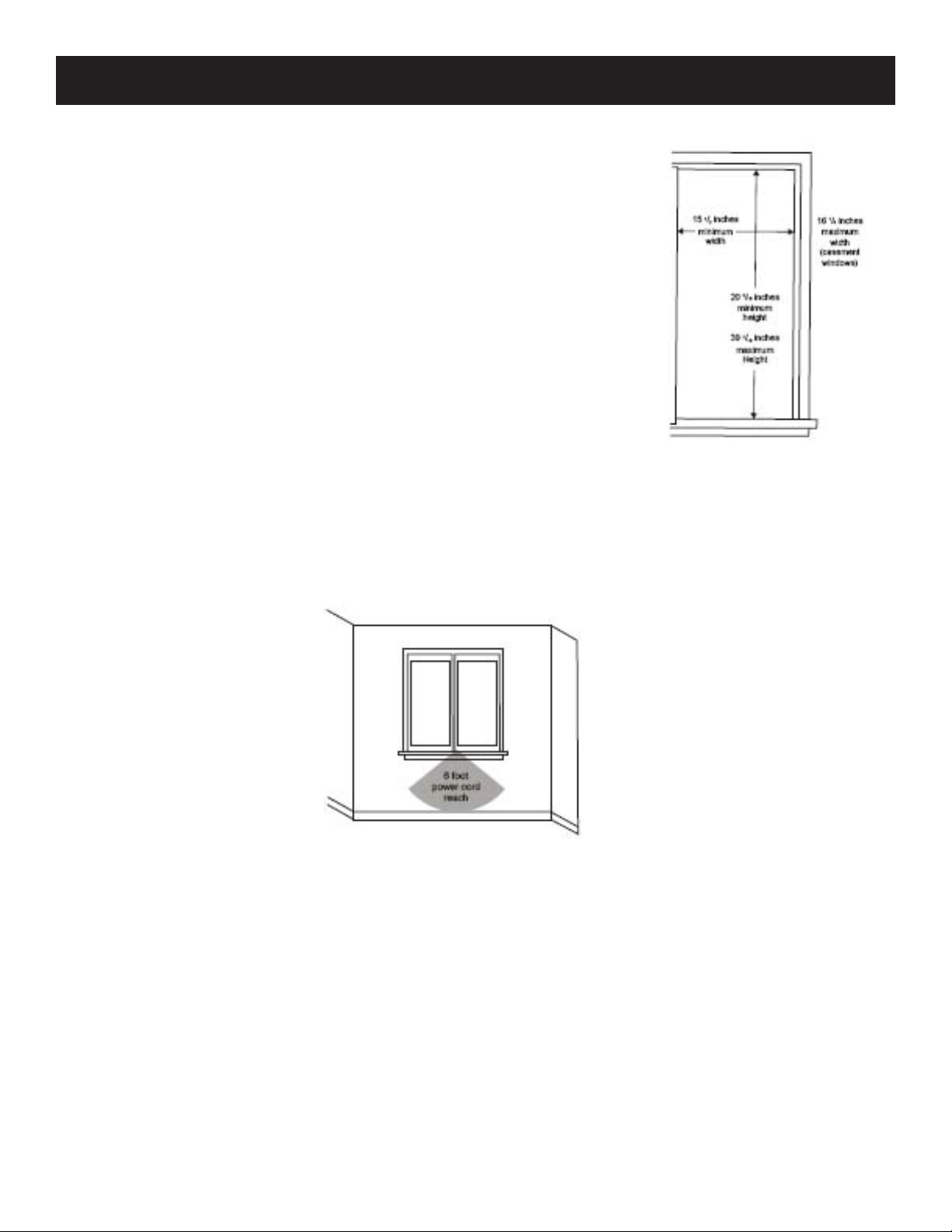

WINDOW SIZE

Be sure your window is the correct size:

15.5” minimum width

•

16.25” maximum width (for casement windows)

•

21.25” minimum height (with window panel retainer)

•

20.3” minimum height (without window panel retainer)

•

39.4” maximum height

•

Note: height measurements must be of a clear opening above mounting

platform. In some cases, due to a variety of stop and track arrangements,

the above dimensions may vary slightly. If necessary, installation can be

made by alternating window jambs.

WINDOW LOCATION

Choose a window that allows the cooled air to fl ow freely and directly into the room you wish to cool.

Remember, it is diffi cult to move air around corners. Also, choose a window that is within 6’ of an

electrical outlet. DO NOT USE AN EXTENSION CORD.

4

Page 5

SLIDING WINDOW INSTALLATION

ATTACH THE SUPPORT BRACE TO THE PLATFORM

Use the adjustment bolt and hex fl ange nut to assemble the

support brace. Choose the slot and adjustment bolt hole that

will create a 45-degree angle between the platform and support

brace. Try to assemble the support brace in the window so

you can determine if the platform will rest properly and at the

correct slope.

MEASURE WINDOW JAMB

Measure and lightly mark a line 8-11/16” from the window

jamb. If any sash stop protrudes more than 1 inch from the side

window jambs, the measurement must be increased accordingly.

Screen and storm window frames may require adjustments.

CENTER PLATFORM

Center the assembled platform on the line with the inside

platform tab pressed against the inside edge of the window

track. Using the platform holes as a guide, mark and drill two

9/64” diameter holes. Drill holes in either the track or the stool.

PROTECTIVE BACKING

Peel off the protective backing from the track seal. Apply seal

to the room side of the window track. The center of the seal

strip should coincide with the previously marked line. The two

previously drilled screw holes should be directly above the seal

strip in the inner track.

SIDING PROTECTION

Securely attach a siding-protection board to the side of the

house. The siding-protection board should be long enough to

span two wall studs.

5

Page 6

SLIDING WINDOW INSTALLATION (cont’d)

PLACE PLATFORM

Place the assembled platform with the platform tab against the

inside window track and attach it to the window jamb. Use the

appropriate length screws.

ADJUST PLATFORM

Adjust the platform so the outside edge is 3/16” lower than the

inside edge. This ensures proper water drainage from the air

conditioner.

LEVEL PLATFORM

Level the platform from side to side. Make sure the window

track is also level. Use the leveling shims, as necessary, to ensure

the air conditioner is level from side to side.

MEASURE WINDOW OPENING HEIGHT

Measure the height of the window opening. Subtract 20.6” and

mark this on the plastic window panel along the longer side.

CLAMP WINDOW PANEL

Clamp the plastic window panel between a board and work

table. Cut around the cutting line with a fi ne tooth saw.

Remove any burrs with a fi le.

FASTEN SIDE CHANNELS

Fasten the side channels to the sides of the air conditioner using

three screws per channel. Make sure the hook ends of the

channels face the back of the unit.

SLIDE PANEL INTO FRAME

Slide the plastic window panel into the panel frame with the

smooth side to the room. Slide the assembled panel frame into

the side channels of the air conditioner cabinet. Make sure

the plastic window panel is fi rmly enclosed on all sides by the

retainer grooves.

6

Page 7

SLIDING WINDOW INSTALLATION (cont’d)

CHANNEL SEAL

Cut the side channel seal into two equal lengths. Remove

protective backing and apply to the read side of the cabinet side

channels, starting just below the assembled panel frame. Pinch

off any excess length so the seal is even with the bottom of the

cabinet side channel.

TO REMOVE THE FRONT

Remove the two front retaining screws from the front frame.

1.

Press fi rmly on each side of the metal case close to the front

2.

of the unit.

While pressing on the sides of the metal case, gently pull the

3.

front out and lift up to release it from the case.

Release the electrical coupler louvers.

4.

Note: DO NOT push or pull on the air direction louvers.

PLACE IN WINDOW

The air conditioner should sit on the assembled platform so the

window panel frame and cabinet side channels are against the

top and side window jambs.

WINDOW SASH

Slide the inner window sash fi rmly against the side of the

cabinet. Make sure not to peel the seal strips from the window

track and cabinet side channels. If the panel frame does not fi t

snugly to the inner window sash, secure the panel frame to the

sash with self-threading screws using the partially plugged holes

in the panel frame.

7

Page 8

SLIDING WINDOW INSTALLATION (cont’d)

SAFETY BRACKET

Hook the safety bracket over the base of the unit and fasten it to

the front of the assembled platform.

Note: the bracket prevents movement after the air conditioner is

in place.

FOAM SEAL

Stuff the foam seal strips/sash seal between the vertical sash and

window glass.

LOCKING BRACKET

Use the window locking bracket to lock the inner window sash

to the base of the outer window sash.

TO REPLACE THE FRONT

Reconnect the coupler plugs and position the exhaust control

through the front. Gently push the front into position on the

cabinet. You will hear it click into place. Replace the retaining

screws to hold the panel in place. DO NOT push or pull the

front panel louvers.

ALTERNATE WINDOW JAMB APPLICATIONS

To install the unit in windows with no fl anges or wood stops on

the top and side jambs, the channels and panel must fi r against

a mating fl ange attached to the window jambs. On each side

of the opening the leading corner of the inner sash becomes the

fl ange. You will need to purchase the angle strip.

8

Page 9

CASEMENT WINDOW INSTALLATION

Open the window the maximum amount to allow cabinet clearance.

•

The crank handle should be removed to allow the platform to be fasted to the jamb.

•

If the window cannot open far enough (more than 15.5”) for the cabinet to clear the window,

•

remove the window entirely by drilling out the rivets. Bolts can serve as the pivots in the future.

To avoid crank handle and window clearance problems, the air conditioner can be installed in a

•

stationary sash section. However, the horizontal mullion and the two glass panels must be removed

before installation.

ATTACH THE SUPPORT BRACE TO THE PLATFORM

Use the adjustment bolt and hex fl ange nut to assemble the

support brace. Choose the slot and adjustment bolt hole that

will create a 45-degree angle between the platform and support

brace. Try to assemble the support brace in the window so

you can determine if the platform will rest properly and at the

correct slope.

PILOT HOLE

Drill a 9/64” diameter pilot hole in the window jamb an equal

distance from each side of the jamb and 3/16” up from the

window sill. If the hole coincides with window lever slot in the

jamb bottom, an additional hole will have to be drilled through

the platform edge and the window jamb to miss this slot.

PROTECTIVE BACKING

Peel off the protective backing from the track seal. Apply seal to

the room side of the window track.

ATTACH PLATFORM TO WINDOW

Screw the assembled platform to the window jamb through the

previously drilled pilot hole using a self-threading screw.

9

Page 10

CASEMENT WINDOW INSTALLATION (cont’d)

ADJUST PLATFORM

Adjust the platform so the outside edge is 3/16” lower than the

inside edge. This ensures proper water drainage from the air

conditioner.

SIDING PROTECTION

Securely attach a siding-protection board to the side of the

house. The siding-protection board should be long enough to

span two wall studs.

MEASURE WINDOW OPENING HEIGHT

Measure the height of the window opening. Subtract 20.6” and

mark this on the plastic window panel along the longer side.

CLAMP WINDOW PANEL

Clamp the plastic window panel between a board and work

table. Cut around the cutting line with a fi ne tooth saw.

Remove any burrs with a fi le.

FASTEN SIDE CHANNELS

Fasten the side channels to the sides of the air conditioner using

three screws per channel. Make sure the hook ends of the

channels face the back of the unit.

SLIDE PANEL INTO FRAME

Slide the plastic window panel into the panel frame with the

smooth side to the room. Slide the assembled panel frame into

the side channels of the air conditioner cabinet. Make sure

the plastic window panel is fi rmly enclosed on all sides by the

retainer grooves.

10

Page 11

CASEMENT WINDOW INSTALLATION (cont’d)

CHANNEL SEAL

Cut the side channel seal into two equal lengths. Remove

protective backing and apply to the read side of the cabinet side

channels, starting just below the assembled panel frame. Pinch

off any excess length so the seal is even with the bottom of the

cabinet side channel.

TO REMOVE THE FRONT

Remove the two front retaining screws from the front frame.

1.

Press fi rmly on each side of the metal case close to the front

2.

of the unit.

While pressing on the sides of the metal case, gently pull the

3.

front out and lift up to release it from the case.

Release the electrical coupler louvers.

4.

Note: DO NOT push or pull on the air direction louvers.

PLACE IN WINDOW

The air conditioner should sit on the assembled platform so the

window panel frame and cabinet side channels are against the

top and side window jambs. The side channels should overlap

the side window jambs equally.

PILOT HOLES

Drill two 9/64” diameter holes in the top window jamb in line with the

partially plugged hole sin the panel frame. Secure the panel frame to the

window jamb with two self-threading screws. If additional holding is

necessary, two screws may be used on the sides of the panel frame.

SCREW-CLEARANCE HOLES

Drill two screw-clearance holes in the cabinet side channels and two 9/64” diameter pilot holes in the

side window jambs. Secure the cabinet side channels to the window jambs with two self-threading

screws. When doing this, be careful not to twist the side channel seals with the screws.

TO REPLACE THE FRONT

Reconnect the coupler plugs and position the exhaust control through the front. Gently push the front

into position on the cabinet. You will hear it click into place. Replace the retaining screws to hold the

panel in place. DO NOT push or pull the front panel louvers.

11

Page 12

© 2006 Sunbeam Products, Inc. doing business as Jarden Consumer Solutions. All rights reserved.

Sunbeam

®

is a registered trademark of Sunbeam Products, Inc. used under license.

Distributed by Petters Consumer Brands, LLC. 4400 Baker Road, Minnetonka, MN 55343.

For service, support and warranty information, visit www.sunbeammajorappliances.com or in the US call 1-866-866-6283.

Loading...

Loading...