TM-8129000504

REMOTE CONTROL UNIT

for

RT-90008 HF/SSB

TRANSCEIVER

RCU-93108

OPERATION AND MAINTENANCE

MANUAL

fj®

SUNAIR 3005 Southwest Third Avenue, Fort Lauderdale, Florida 33315-3312

WARRANTY POLICY

GROUND AND MARINE PRODUCTS

(

Sunair Electronics warrants each equipment manufactured by

material or workmanship, under normal use for the lesser of one

installation or

Sunair will repair or replace, at its option, any defective equipment or component of the

equipment returned to

No

reimbursement will

This warranty

misuse, abuse, accident, water damage or other neglect, or has its serial number defaced

or removed. (

THIS WARRANTY

EXPRESSED

ABILITY

of Sunair

consequential or other damage or expense whatsoever therefore or by any reason thereof.

15 months from date of shipment

it

at its factory, transportation prepaid, within such warranty period.

be

made for non-factory repair charges.

is

void

if

OR

FITNESS

shall

equipment

IS

ESPECIALLY

OR

IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MERCHANT-

FOR

A PARTICULAR PURPOSE. The obligation and responsibility

be

limited to that expressly provided herein and Sunair shall not

is

modified or repaired without authorization, subject to

IN

LIEU OF ANY AND ALL OTHER WARRANTIES

by

Sunair.

it

to be free from defects

(1)

year from the date of

be

liable for

in

Sunair reserves the right

equipment without obligation

theretofore manufactured.

,,®

to

make changes

SUNAIR ELECTRONICS, INC.

in

design or additions to or improvements

to

install such additions or improvements

in

equipment

in

its

(

0

Ql

~

Mtc/AUX

~I

e

Oo

e

K!Y

~

@

P:AI.A.T

I

I

QJ

[!]

0

000

000

I I

~~~

II:U:-11

I

0

I I

D

D

0

~~o

OFFo

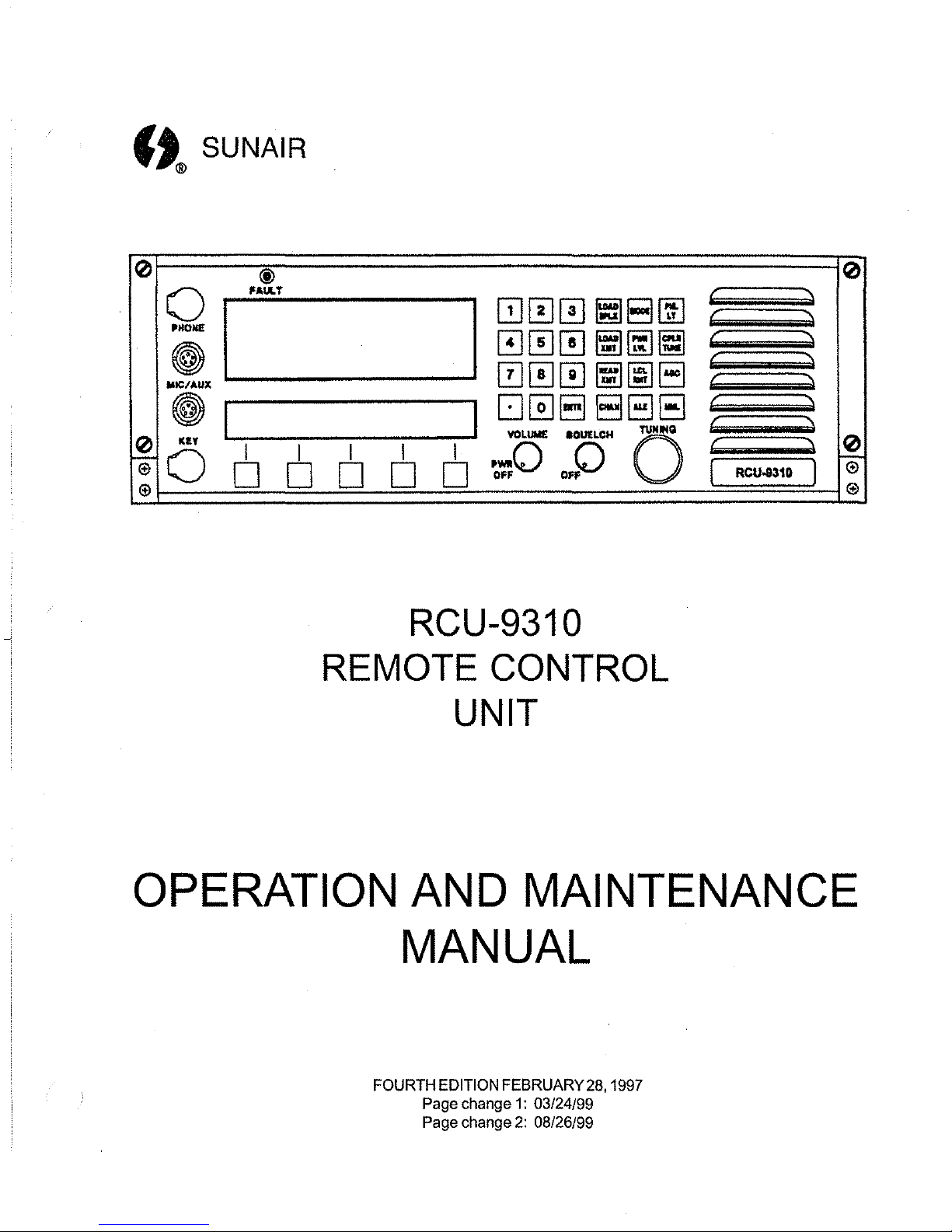

RCU-9310

REMOTE CONTROL

UNIT

f;i\jj

El

~

[';ij@J~

"

"

rrm[;JEJ

~.l:'

0

I

RCU-8310

l

0

~

e

e

OPERATION

AND

MAINTENANCE

MANUAL

FOURTHEDITIONFEBRUARY28, 1997

Page change

Page change

1:

03/24/99

2:

08/26/99

PRODUCT SERVICE:

In case of difficulty please contact the Sunair

Product SeNice Department, between the hours

of

8:00 AM and 5:00

Product SeNice Dept.

Sunair Electronics,

3101

Ft.

Lauderdale, FL 33315-3389

PM

or write to:

Inc.

SW Third Avenue

U.S.A.

Telephone:

Fax:

E-Mail:

(954) 525-1505

(954) 765-1322

techsupport@ sunairhf.com

TRAINING:

Sunair offers training programs of varying

lengths

maintenance

equipment. For details please contact the

Product Support Department.

covering

of all

operation, service, and

Sunair

manufactured

(

(

I SUNAIR RCU-9310 I

f

I

r

, I

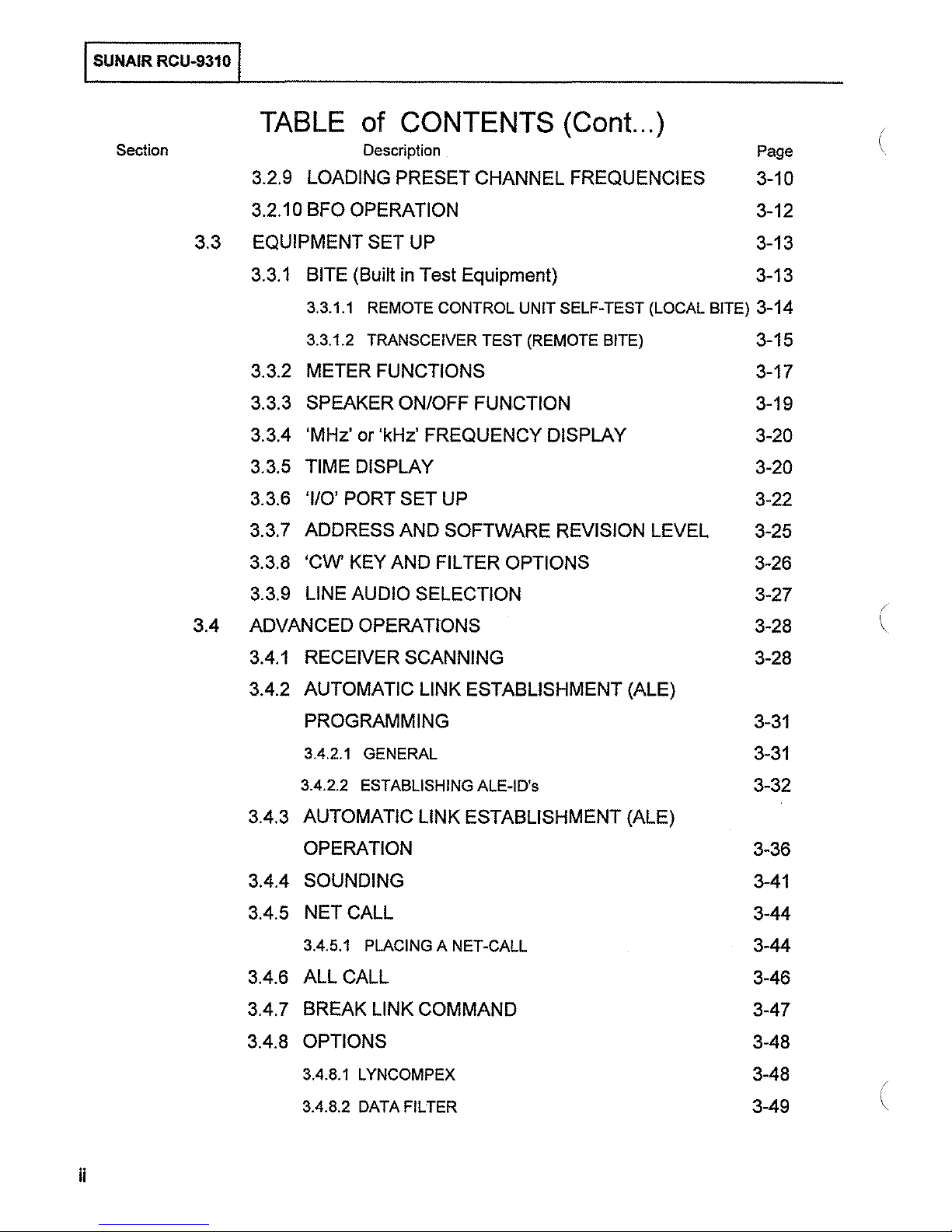

Section

II

TABLE

GENERAL INFORMATION

1.1

1.2

1.3 GENERAL DESCRIPTION

1.4 TECHNICAL SPECIFICATIONS

1.5 ENVIRONMENTAL SPECIFICATIONS

1.6 EQUIPMENT SUPPLIED

1.7 OPTIONS AVAILABLE

INSTALLATION

2.1

2.2

2.3 RETURN OF EQUIPMENT TO FACTORY

SCOPE OF MANUAL

PURPOSE OF EQUIPMENT

GENERAL

UNPACKING

of

Description

AND

INSPECTION

CONTENTS

Page

1-1

1-1

1-1

1-2

1-2

1-3

1-3

2-1

2-1

2-1

2.4 GENERAL INSTALLATION

INFORMATION

2.4.1

2.4.2 BASE STATION INSTALLATION

2.4.3 RACK INSTALLATIONS

Ill OPERATION

3.1

3.2

GENERAL

PRIMARY OPERATIONS

3.2.1

3.2.2

3.2.3

3.2.4 ANTENNA

3.2.5 MANUAL

3.2.6

AND

MOUNTING

2-2

GENERAL INSTALLATION

REMOTE TRANSCEIVER SET

AND

TRANSMIT POWER 3-3

ESTABLISHING

TRANSMIT TUNING 3-6

TUNING 3-6

PANEL LIGHTING 3-7

AN

OPERATING FREQUENCY 3-5

COUPLER TUNING 3-6

UP

FOR

MODE,

2-2

2-9

2-9

3-1

3-3

AGC

3.2.7

3.2.8 MANUAL CHANNEL

OPERATING WITH PRESET CHANNELS 3-7

SCANNING 3-8

I SUNAIR RCU-9310 I

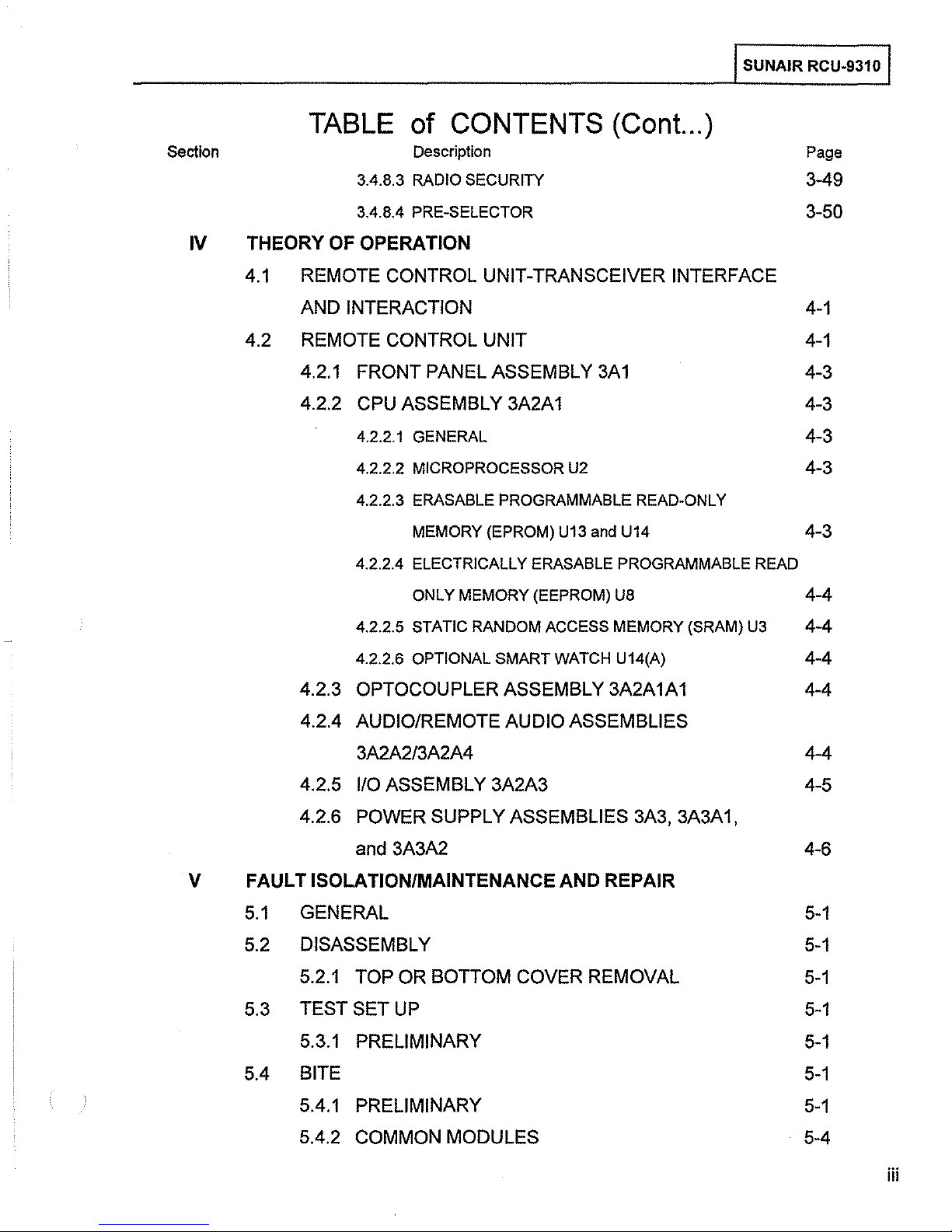

Section

3.3

TABLE

3.2.9 LOADING PRESET CHANNEL FREQUENCIES

3.2.10 BFO OPERATION

EQUIPMENT SET UP

3.3.1

3.3.2

3.3.3

3.3.4

3.3.5 TIME DISPLAY

3.3.6 'I/O' PORT SET UP

3.3.7

3.3.8

BITE (Built in Test Equipment)

3.3.1.1

3.3.1.2

METER FUNCTIONS

SPEAKER ON/OFF FUNCTION

'MHz' or 'kHz' FREQUENCY DISPLAY

ADDRESS AND SOFTWARE REVISION LEVEL

'CW

of

CONTENTS

Description

REMOTE

TRANSCEIVER

KEY AND FILTER OPTIONS

CONTROL

TEST

(Cont.

UNIT

SELF-TEST

(REMOTE

BITE)

..

)

(LOCAL

BITE)

Page

3-10

3-12

3-13

3-13

3-14

3-15

3-17

3-19

3-20

3-20

3-22

3-25

3-26

(

\

3.4

3.3.9

ADVANCED OPERATIONS

3.4.1

3.4.2

3.4.3

3.4.4

3.4.5

3.4.6

3.4.7

3.4.8

LINE AUDIO SELECTION

RECEIVER SCANNING

AUTOMATIC LINK ESTABLISHMENT (ALE)

PROGRAMMING

3.4.2.1

3.4.2.2

AUTOMATIC LINK ESTABLISHMENT (ALE)

OPERATION

SOUNDING

NET

3.4.5.1

ALL CALL

BREAK LINK COMMAND

OPTIONS

GENERAL

ESTABLISHING

CALL

PLACING A NET-CALL

ALE-I

D's

3-27

3-28

3-28

3-31

3-31

3-32

3-36

3-41

3-44

3-44

3-46

3-47

3-48

(

3.4.8.1 L

3.4.8.2

ii

YNCOMPEX

DATA

FILTER

3-48

3-49

(

I SUNAIR RCU-9310 I

Section

IV

TABLE

3.4.8.3 RADIO SECURITY

3.4.8.4 PRE-SELECTOR

THEORY

4.1

4.2 REMOTE CONTROL UNIT

OF

OPERATION

REMOTE CONTROL UNIT-TRANSCEIVER INTERFACE

AND INTERACTION

4.2.1 FRONT PANEL ASSEMBLY

4.2.2

CPU ASSEMBLY 3A2A1 4-3

4.2.2.1 GENERAL

4.2.2.2 MICROPROCESSOR U2

4.2.2.3 ERASABLE PROGRAMMABLE READ-ONLY

4.2.2.4 ELECTRICALLY ERASABLE PROGRAMMABLE READ

of

CONTENTS (Cont...)

Description

MEMORY (EPROM)

3A1

U13 and U14

Page

3-49

3-50

4-1

4-1

4-3

4-3

4-3

4-3

v

FAULT

5.1

5.2

5.3

ONLY MEMORY (EEPROM)

4.2.2.5 STATIC RANDOM ACCESS MEMORY (SRAM) U3

4.2.2.6 OPTIONAL SMART WATCH U14(A)

4.2.3 OPTOCOUPLER ASSEMBLY 3A2A

4.2.4

4.2.5 1/0 ASSEMBLY 3A2A3

4.2.6 POWER SUPPLY ASSEMBLIES 3A3, 3A3A

GENERAL

DISASSEMBLY

5.2.1 TOP

TEST

5.3.1 PRELIMINARY

AUDIO/REMOTE AUDIO ASSEMBLIES

3A2A2/3A2A4

and 3A3A2

ISOLATION/MAINTENANCE

OR

BOTTOM COVER REMOVAL

SETUP

AND

US

1A

REPAIR

1

4-4

4-4

4-4

4-4

4-4

4-5

1,

4-6

5-1

5-1

5-1

5-1

5-1

5.4

BITE

5.4.1 PRELIMINARY

5.4.2 COMMON MODULES

5-1

5-1

5-4

iii

I SUNAIR

RCU-9310

I

Section

5.5

5.6

5.7

TABLE

5.4.2.1

5.4.2.2 CPU FAULT 5-4

5.4.2.3

5.4.2.4 AUDIO FAULT 5-5

5.4.2.5 POWER SUPPLY FAULT 5-6

TROUBLESHOOTING WITH SELF-SURVEILLANCE BITE 5-6

5.5.1

5.5.2

TEST EQUIPMENT REQUIRED OR EQUIVALENT 5-16

TEST AND ALIGNMENT 5-16

5.7.1

5.7.2

AC POWER SUPPLY 5-6

INSTALLATION OF NEW BACKLIGHTING DEVICES

FOR

TRANSMIT REMOTE AUDIO 5-16

RECEIVE REMOTE AUDIO 5-20

of CONTENTS (Cont...)

Description Page

FRONT PANEL FAULT 5-4

110

FAULT 5-5

FRONT PANEL LCD'S 5-12

(

5.8

5.7.3 SOFTWARE SWITCH SETTING CHECKS

SCHEMATICS AND PARTS LISTS 5-25

5-23

(

iv

(

I SUNAIR RCU-9310 I

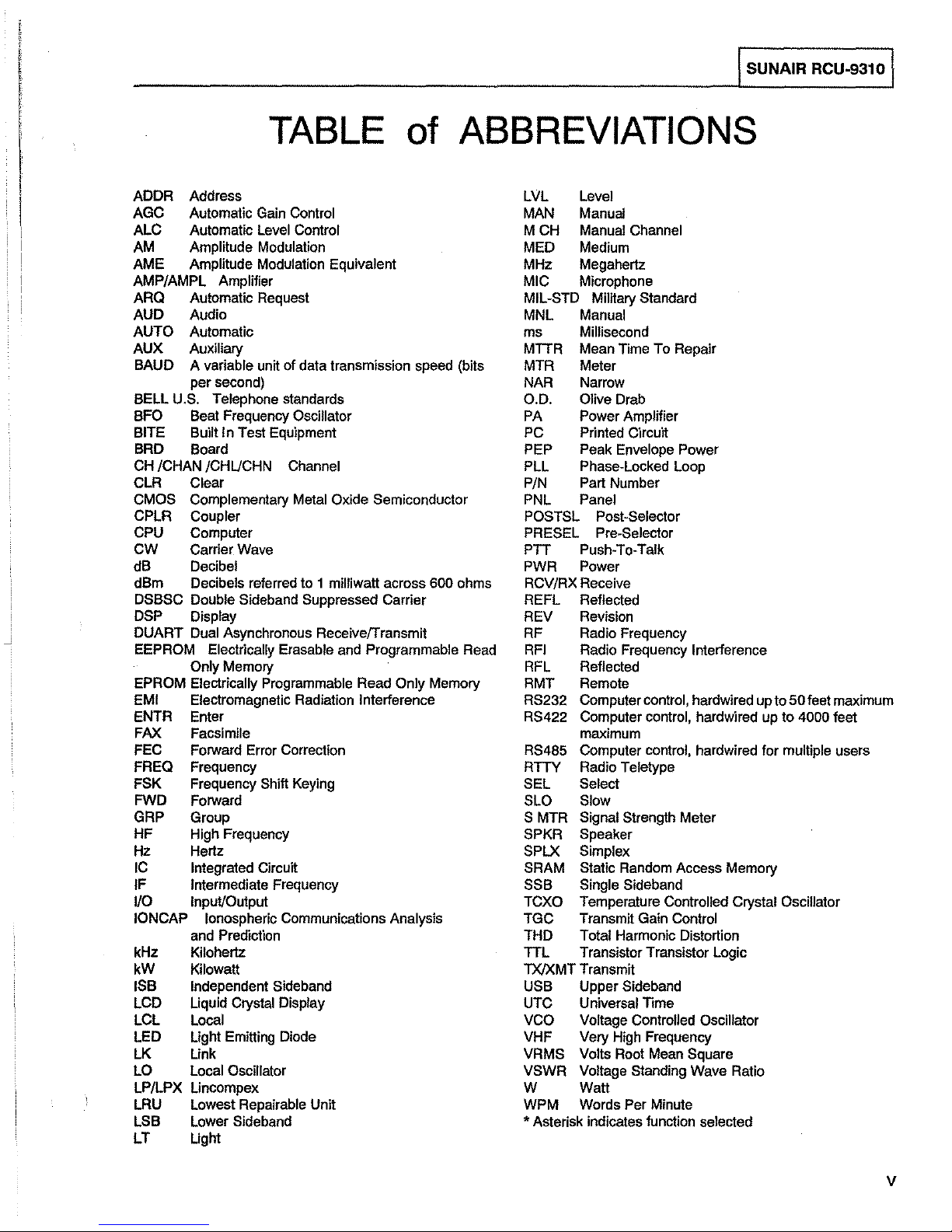

ADDR

AGC

ALC

AM

AME

AMP/AMPL Amplifier

ARQ

AUD

AUTO Automatic

AUX

BAUD

BELL

BFO

BITE

BAD

CH

CLR

CMOS

CPLR

CPU

CW

dB

dBm

DSBSC

DSP

DUART

EEPROM

EPROM

EMI

ENTR

FAX

FEC

FREQ

FSK

FWD

GAP Group

HF

Hz

IC

IF

1/0

IONCAP

kHz

kW

ISB

LCD

LCL

LED

LK

LO

LP/LPX Lincompex

LRU

LSB

LT Light

Address

Automatic

Automatic

Amplitude

Amplitude

Automatic

Audio

Auxiliary

A variable unij of data transmission

per

U.S.

Beat

Built In Test Equipment

Board

/CHAN

/CHLJCHN

Clear

Complementary

Coupler

Computer

Carrier

Decibel

Decibels

Double

Display

Dual

Electrically

Only

Electrically

Electromagnetic

Enter

Facsimile

Forward

Frequency

Frequency Shift

Forward

High

Hertz

Integrated Circuit

Intermediate Frequency

lnpui/Output

Ionospheric Communications Analysis

and

Kilohertz

Kilowatt

Independent

Liquid

Local

Light Emitting

Link

Local

Lowest

Lower

Gain

Level

Modulation

Modulation

Request

second)

Telephone standards

Frequency

Wave

referred

Sideband

Asynchronous

Memory

Programmable

Error

Frequency

Prediction

Crystal

Oscillator

Repairable

Sideband

TABLE

Control

Control

Equivalent

Oscillator

Channel

Metal

Oxide

Semiconductor

to 1 milliwatt across

Suppressed Carrier

Receive/Transmit

Erasable

Correction

Sideband

Display

Diode

and

Radiation

Keying

Unit

Programmable

Read

Interference

of

speed

Only

ABBREVIATIONS

(bits

600

ohms

Read

Memory

LVL

MAN

M

MED

MHz

MIC

MIL-STD

MNL

ms

MTTR

MTR

NAR

0.0.

PA

PC

PEP

PLL

P/N

PNL

POSTSL

PRESEL

PTT Push-To-Talk

PWR

RCV/RX

REFL

REV

RF

RFI

RFL

RMT

RS232

RS422

RS485

RlTY

SEL

SLO

S

SPKR

SPLX

SRAM

SSB

TCXO

TGC

THO

TTL Transistor Transistor Logic

TX/XMT Transmit

USB

UTC

VCO

VHF

VRMS

VSWR

W Watt

WPM

• Asterisk indicates function selected

Level

Manual

CH

Manual

Medium

Megahertz

Microphone

Manual

Millisecond

Mean

Meter

Narrow

Olive

Power

Printed

Peak

Phase-Locked

Part

Panel

Power

Receive

Reflected

Revision

Radio

Radio

Reflected

Remote

Computer

Computer

maximum

Computer control, hardwired for multiple users

Radio

Select

Slow

MTR

Signal Strength Meter

Speaker

Simplex

Static

Single

Temperature Controlled Crystal Oscillator

Transmit

Total

Upper

Universal

Voltage Controlled Oscillator

Very

Volts

Voltage standing

Words

Channel

Milijary Standard

Time

To

Repair

Drab

Amplifier

Circuit

Envelope

Number

Post-Selector

Pre-Selector

Frequency

Frequency

Teletype

Random

Sideband

Harmonic

Sideband

High

Root

Per

Power

Loop

control,

control,

Access Memory

Gain

Control

Distortion

Time

Frequency

Mean

Minute

Interference

hardwired upto50feetmaximum

Square

Wave

hardwired

Ratio

up

to

4000

feet

v

I SUNAIR RCU-9310 I

Section

II

LISTING

Description Page

INSTALLATION

Figure 2.4.1.1 RCU-9310 Outline Dimensions and Connector

Locations. 2-4

Figure 2.4.1.2 Interconnection

Unit and RT-9000 Transceiver. 2-5

Figure 2.4.1.3

Wiring Diagrams.

Figure 2.4 .1.4

Wiring Diagram. 2-7

Figure 2.4.1.5

Diagram. 2-8

Figure 2.4.3

FSK, RS-232, RS-422,

RCU-9310 Remote Audio to RT-9000 Audio

RCU-9310 Audio to External Data Modems Wiring

Installation

of

of

of

RCU-9310

FIGURES

RCU-931 0 Remote Control

or

RS-485

in

Equipment Rack.

(

2-6

2-9

Ill

OPERATION

Figure 3.1.1 Front Panel Controls for the RCU-9310.

Figure 3.1.2

Figure

Figure 3.2.2

Figure 3.2.5

Figure 3.2. 7

Figure 3.2.8 RCU-931

Figure 3.2.9.1

Figure 3.2.9.2

Figure 3.2.10

Figure 3.3.1.1

Figure 3.3.1.2

Figure 3.3.2.1

Figure 3.3.2.2

3.2.1

Operational Display Information Location.

RCU-9310 Remote Control Display Screens. 3-4

RCU-9310 Operating Controls. 3-5

RCU-9310 Operating Controls. 3-7

RCU-9310 Operating Controls. 3-8

0 Operational Controls. 3-9

RCU-9310 Channel Loading Controls.

RCU-931

RCU-9310 Displays,

RCU-9310 Feature Menu, BITE Selection. 3-13

RCU-9310 BITE Submenu. 3-14

RCU-931 0 Operational Displays.

RCU-9310 Feature Menu Select Display. 3-17

0 'Feature Display'.

with BFO Enabled. 3-12

3-1

(

3-2

3-10

3-11

3-17

Figure 3.3.2.3

Figure 3.3.2.4

Figure 3.3.3

vi

RCU-9310 Feature Menu Select Display.

RCU-9310 Feature Menu Select Display.

RCU-9310 Feature Menu Select Display. 3-19

3-18

3-18

(

I SUNAIR RCU-9310 I

Section

LISTING

Figure 3.3.4 RCU-931 0 Operating Controls. 3-20

Figure 3.3.5.1 Feature Menu Display. 3-20

Figure 3.3.5.2 Time Display

Figure 3.3.5.3 Time Display.

Figure 3.3.5.4 'Set-Time' Display. 3-22

Figure 3.3.6.1 RCU-931 0

Figure 3.3.6.2 Feature Menu

Figure 3.3.6.4 Port 'A' Conditioning Menu. 3-24

Figure 3.3.6.5 Baud Rate

Figure 3.3.6.6 Baud Rate Selection Menu

Figure 3.3.6.7 Baud Rate

Figure

3.3.7.1

Address

of

FIGURES (Cont.

Description Page

and

Time Set Display.

110

Port Connector. 3-22

Display

Display. 3-24

Selection Menu

and

Revision Level Display. 3-25

of

Port 'A' Selection Menu. 3-23

1.

2.

..

)

3-21

3-21

3-24

3-25

Figure 3.3.7.2 Feature Menu for

Figure 3.3.8 Feature

Figure 3.3.9.1 RCU-9310 Feature Menu Select Display. 3-28

Figure 3.3.9.2 Line Audio Selection Menu Display. 3-28

Figure 3.4.1.1 Operational Display for Channelized Mode. 3-29

Figure 3.4.1.2 Feature Menu

Figure 3.4.1.3 Feature Menu

Figure 3.4.1.4 Feature Menu Display for 'SCAN LOAD' Select

Figure 3.4.2.2.1 RCU-9310 Feature Menu Display. 3-32

Figure 3.4.2.2.2 Feature Menu

Figure 3.4.2.2.3 RCU-9310 Display for 'SLOT

Figure 3.4.2.2.4 RCU-9310 Display for 'SELF ID' Programming.

Figure 3.4.2.2.5 Feature Display for 'CALL ID' Select

Figure 3.4.3.1 Operational Display for 'ALE' Function.

Figure 3.4.3.2 ALE

Menu

Calling Menu.

Selection of Address. 3-26

Display for Selection

Display for 'SCAN' Select

Display for 'SCAN' Function. 3-30

Display for 'ALE-ID' Select

of

'CW' Options. 3-27

Key.

Key.

PS'

Programming.

Key.

Key.

3-29

3-30

3-33

3-33

3-34

3-35

3-37

3-37

Figure 3.4.3.3 Feature Display for 'Select Group'.

Figure 3.4.3.4 Operational Display for 'CALL ID' Selection.

Figure 3.4.3.5 Operational Display of the Station Being Called.

3-38

3-39

3-39

vii

I SUNAIR RCU-9310 I

Section

LISTING of FIGURES (Cont.

Description

Figure 3.4.3.6 Operational Display of

Figure 3.4.3.7 Operational Display

Figure

Figure 3.4.4.2 Sounding

Figure 3.4.4.3 Operational Display at Sounding Station.

Figure 3.4.4.4

Figure 3.4.4.5 Sounding Timer Menu.

Figure

Figure

Figure 3.4.8.

Figure 3.4.8. 1.2 Lycompex

3.4.4.1

Sound.

3.4.7.1

3.4.8.1

ALE

Calling Menu.

Menu.

Operational Display

Break Link Keys. 3-48

'SECURE' Feature

1.1

Lycompex Feature

Control Feature

Link

with

Station

on

Called Station after a

on

Network Stations Receiving

Menu.

Menu

Display. 3-48

Menu

..

)

Being

Display. 3-49

Called.

Link.

Page

3-40

3-41

3-41

3-42

3-42

3-43

3-43

3-48

IV

v

Figure 3.4.8.5. 1 Feature

THEORY

Figure

FAULT

Figure

Figure

Figure

Figure

Figure

Figure 5.4.2.2

Figure 5.4.2.3

Figure 5.4.2.4 Removal/Replacement of 1/0 3A2A3 or

OF OPERATION

4.1

RCU-9310 Remote Control Unit Block Diagram.

ISOLATION/MAINTENANCE AND REPAIR

5.2.

1.1

Top/Bottom

5.4.1.1

5.4.

5.4.1

5.4.2.1

Assemblies Locations. 5-9

1/0 3A2A3. 5-10

FSK 3A2A3A

RCU-9310 Feature Menu, BITE Selection.

1.2

RCU-931

.3

Top View

Major Assembly Locations. 5-8

Removal of Front and Rear Panel and Major

Removal/Replacement

Menu

0 BITE Submenu.

RCU-931 0 LRU

1.

Display for Pre-selector Selection. 3-50

and

Card Cage Covers Removal.

'Fault Indicators'. 5-5

of

CPU

3A2A 1 and

(

4-2

5-2

5-3

5-3

5-11

Figure 5.5.2. 1 Removal

Assembly. 5-13

Figure 5.5.2.2

viii

Removal

and

Installation of Front Panel

and

Installation of

LCD

PC

(

Assembly. 5-14

I SUNAIR RCU-9310 I

LISTING of FIGURES (Cont.

Section Description

Figure 5.5.2.3 Installation of Backlighting Devices. 5-15

Figure 5.7.1.1

5.

Figure

Figure

Figure

Figure 5.7.2.2 Receive Path Audio

Figure

Figure

Figure 5.8.2

Figure 5.8.3

7.1.2 Top View RCU-931 0 Alignment Adjustment

Locations. 5-18

5.

7.1.3 Transmit Path Audio

5.

7.2.1

5.8

5.8.1

and Connector

RCU-931

RCU-931

RCU-9310 Assemblies and Subassemblies. 5-25

Final Tested RCU-931

PC

Assembly, Front Panel 3A 1A

PC

Assembly, Mother Board 3A2A5, page 1 of

0 Stand Alone Audio Test Set

0 Stand Alone Audio Test Set

Kit.

A.

A.

0,

Chassis Assembly

1,

page 1 of

..

)

Up.

Up.

3A3,

6.

4.

Page

5-18

5-19

5-21

5-22

5-27

5-28

5-34

Figure 5.8.4

Figure 5.8.5

page 1

Figure 5.8.6

Figure

Figure 5.8.8

Figure 5.8.9

Figure

Figure

Figure 5.8.12

Figure 5.8.13

5.8. 7 PC

5.8.1

0 AC/DC Power Supply Chassis and Interconnect

Diagram, page 1 of

5.8.11

page 1 of

page 1 of

page 1 of

PC

Assembly, CPU 3A2A

PC

Assembly, OPTOCOUPLER 3A2A1A1,

of

3.

PC

Assembly, Audio 3A2A2, page 1

Assembly, Audio Remote 3A2A4, page 1 of

PC

Assembly, 1/0 Board 3A2A3, page 1 of

PC

Assembly, FSK Modem 3A2A3A1, page 1 of

1.

PC

Assembly, 28V Regulator, 5 Amp 3A3A

2.

PC

Assembly, 5/12V Regulators 3A3A2,

2.

PC

Assembly, Audio Connectors 3A3A3,

2.

1,

page 1 of

of

8.

9.

4.

1,

2.

2.

5-38

5-46

5-49

5-58

5-60

5-64

5-67

5-68

5-70

5-72

ix

(

ITHIS

PAGE

INTENTIONALLY

LEFr

BLANK.I

(

(

I SUNAIR RCU-9310 I

SECTION I

GENERAL INFORMATION

1.1

SCOPE

This manual contains information necessary to install, operate, and maintain the RCU-931 0 Remote Control Unit.

Installation information is

Maintenance and Repair Procedures are in Section

IV.

configurations,

1.2 PURPOSE OF EQUIPMENT

OF

MANUAL

in

Section

unless otherwise stated in the text or illustrations.

II.

Operating Instructions are in Section Ill. Theory

V.

Information in this manual applies to all equipment

of

Operation is in Section

The RCU-931 o Remote Control Unit is designed to provide complete operational control

RT-9000

The RCU-9310

selecting the transmission mode and power level; establishing operating frequencies; automatically tuning the

transmitter and associated antenna

frequency

The RCU-9310 also enables the remote operator to perform several non-operational, periodic, functions related

to equipment setup and maintenance. Diagnostic tests--to the lowest repairable unit (LRU) -- can be selectively

executed

keying speed and filtering options; connection of external devices to the transceiver's audio input and output lines;

local I/O

metering at the remote

In

addition, the RCU-931 o allows the remote operator to access and use the transceiver's advanced automated

functions: receiver scanning

Establishment (ALE) operations; "sounding" (broadcasting to selected stations in a predefined network); and

"network call" (broadcasting to all stations in a network).

Transceiver.

allows

channels.

on

both the transceiver and the remote control unit itself. Other functions include: selection

port conditioning; transceiver memory dump (i.e., clearing all preprogrammed channels); and transceiver

an

operator at a remote site to access and perform all transceiver primary functions:

coupler; manual tuning; and loading, scanning, and operating with preset

control panel.

of

preprogrammed channels; programming and execution of Automatic Link

of

a remotely-located

of

CW

1.3 GENERAL DESCRIPTION

The RCU-931 o

package makes the

the service technician in mind.

modularized plug-in assemblies

located on the assemblies allow the technician to pinpoint faulty modules immediately. The RCU-931 0 is

lightweight for its capability, weighing only 20 pounds. Available in Olive Drab (OD)

compatible with most radio station color schemes. (If a particular color other than

Sunair Marketing Department for information concerning changes

the

is

intended for use on table tops

RCU-9310 adaptable to various environments. Internally, the RCU-9310 is designed with

Built-in test equipment (BITE), with descriptive front-panel readouts, and .

rnake the MTTR (Mean Time To Repair) less than fifteen (15) minutes. LEDs

or

in base station 19-inch rack installations. However, its rugged

or

Grey, the RCU-931 0 is

ODor

Grey is required, contact

to

the standard colors.)

The RCU-9310 has a simple, easily understood, front panel that duplicates the functions

Transceiver. Firsttime users can operate the equipment without extensive training. The wide screen liquid crystal

display

Channel, Mode, BFO, AGC, Power, Local

selectively indicates signal strength, forward RF power, reverse RF power and Remote transmit and receive audio

(LCD)

is

continuously updated by the microprocessor with operational status such as Frequency,

of

the RT-9000

or

Remote Control. The LCD also contains a bar graph meter which

1-1

I SUNAIR RCU-9310 I

The built-in-test routines include power amplifier and antenna coupler status in plain English messages which

appear in the

The softkeys

operating features not found on the front

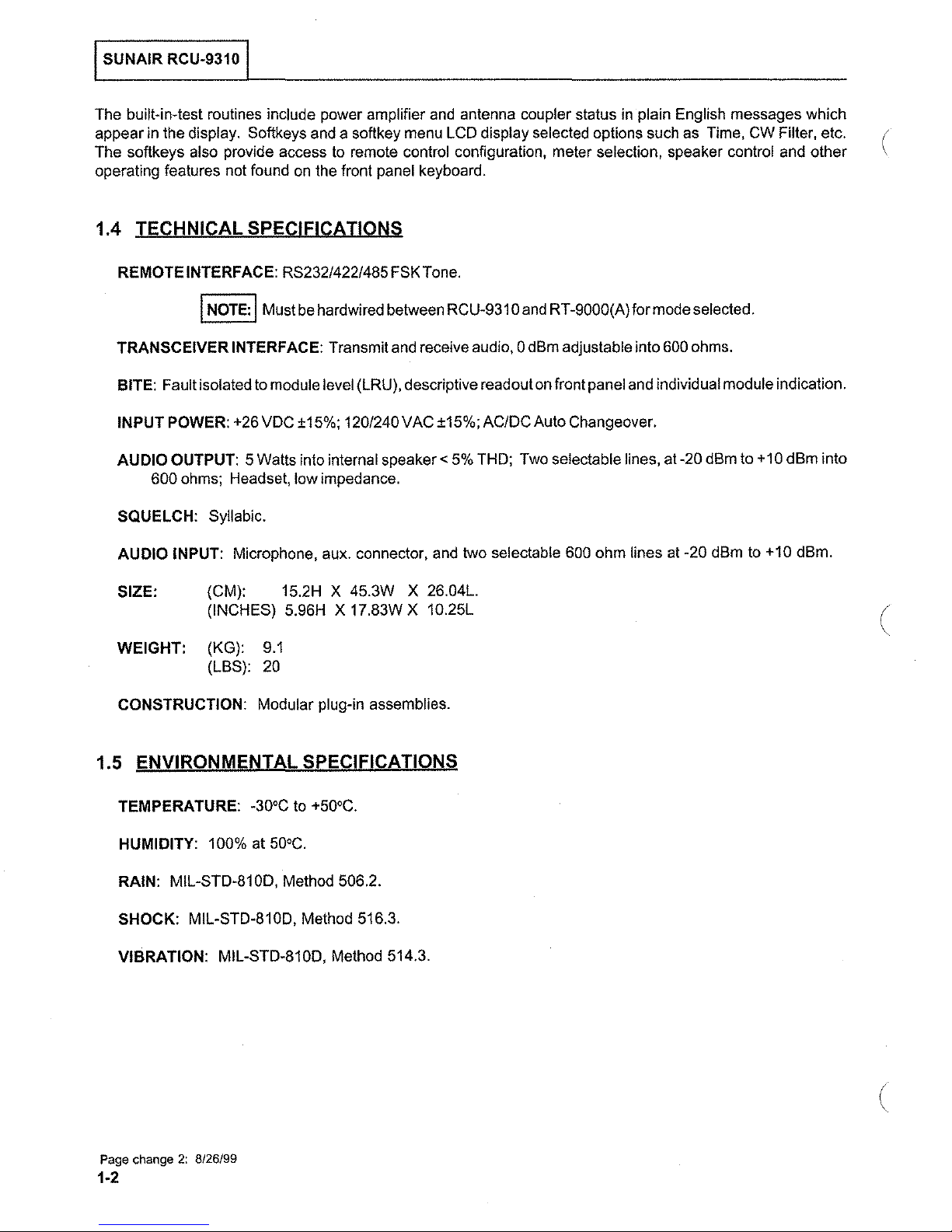

1.4 TECHNICAL SPECIFICATIONS

REMOTE INTERFACE: RS232/422/485 FSKTone.

TRANSCEIVER INTERFACE: Transmit and receive audio, 0 dBm adjustable into 600 ohms.

BITE: Fault isolated to module level (LRU), descriptive readout on front panel and individual module indication.

display. Softkeys and a softkey menu LCD display selected options such as Time,

also provide access to remote control configuration, meter selection, speaker control and other

panel keyboard.

I

NOTE:

I Must be hardwired between RCU-931 0 and RT -9000(A) for mode selected.

CW

Filter, etc.

(

INPUT POWER: +26

AUDIO OUTPUT: 5 Watts into internal speaker< 5% THO; Two selectable lines, at

600 ohms; Headset, low impedance.

SQUELCH: Syllabic.

AUDIO INPUT: Microphone, aux. connector, and two selectable 600 ohm lines at -20 dBm to +10 dBm.

SIZE:

WEIGHT: (KG):

CONSTRUCTION: Modular plug-in

(CM):

(INCHES) 5.96H X 17.83W X 10.25L

(LBS): 20

VDC ±15%; 120/240VAC ±15%;

15.2H X 45.3W X 26.04L.

9.1

assemblies.

AC/DCAuto

Changeover.

·20

dBm to

+1

0 dBm into

1.5 ENVIRONMENTAL SPECIFICATIONS

TEMPERATURE:

HUMIDITY: 100%

-30'C

to +50'C.

at 50'C.

(

RAIN: MIL-STD-8100, Method 506.2.

SHOCK: MIL-STD-8100, Method 516.3.

VIBRATION: MIL-STD-8100, Method 514.3.

Page change

1-2

2:

8/26/99

(

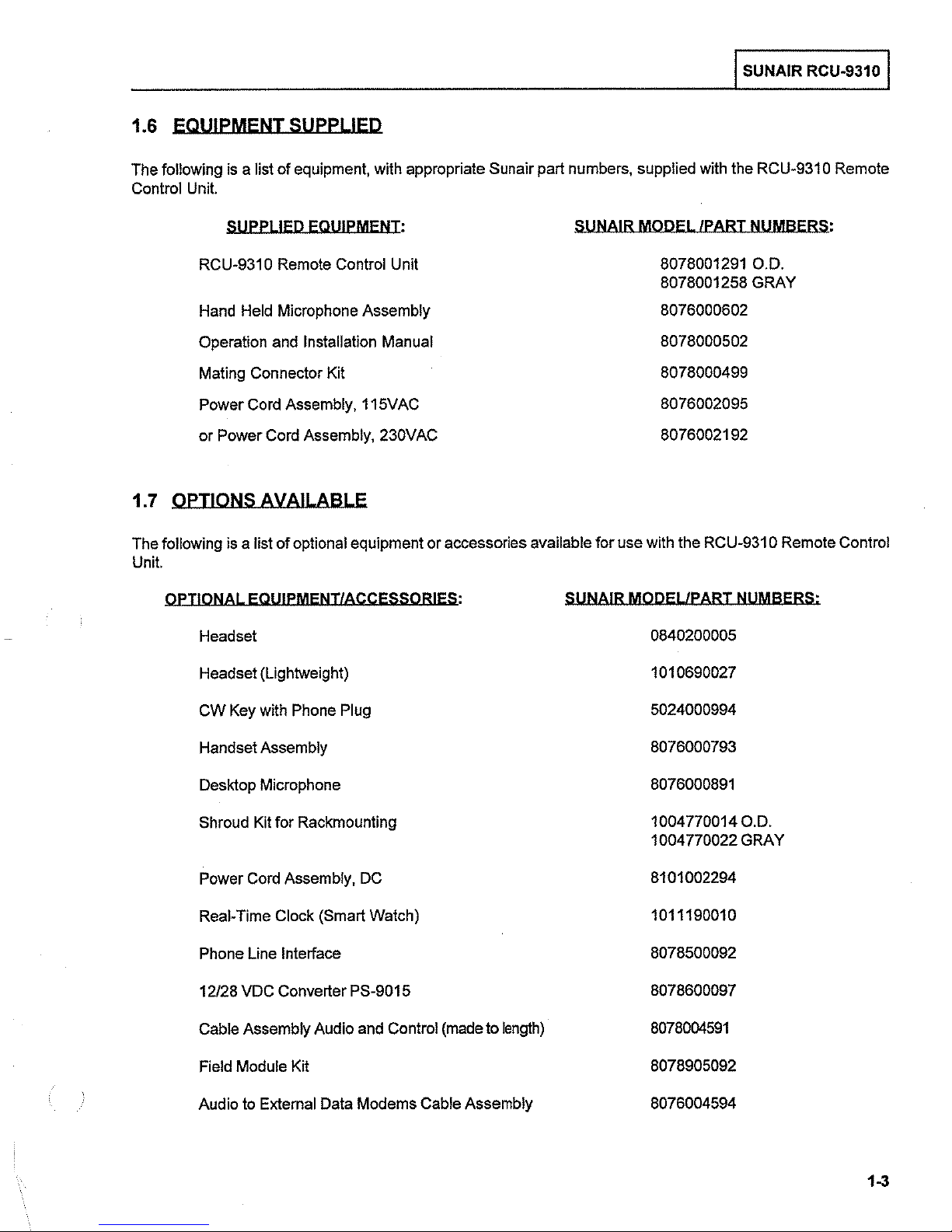

1.6 EQUIPMENT SUPPLIED

I SUNAIR RCU-9310 I

The following

Control

is a Jist

Unit.

SUPPLIED EQUIPMENT:

RCU-931

Hand

Operation

Mating Connector Kit

Power

or Power

of equipment, with appropriate Sunair part numbers, supplied

0 Remote Control Unit

Held

Microphone Assembly

and

Installation Manual

Cord

Assembly, 115VAC

Cord

Assembly, 230VAC

with

the

SUNAIR MODEL /PART NUMBERS:

8078001291

8078001258 GRAY

8076000602

8078000502

8078000499

8076002095

8076002192

1.7 OPTIONS AVAILABLE

following

The

Unit.

OPTIONAL EQUIPMENT/ACCESSORIES: SUNAIR MODEL/PART NUMBERS:

is

a list of optional equipment or accessories available for use with the

RCU-931

RCU-931

O.D.

0 Remote Control

0 Remote

Headset 0840200005

Headset (Lightweight) 1010690027

Key

with

CW

Handset Assembly 8076000793

Desktop Microphone

Shroud

Power

Real-Time Clock (Smart Watch) 1011190010

Phone Line Interface 8078500092

12/28

VDC

Assembly Audio

Cable

Field Module Kit 8078905092

Phone

Kit

for Rackmounting 1004770014

Cord

Assembly,

Converter PS-9015 8078600097

Plug

DC

and

Control

(made

to

length)

5024000994

8076000891

1004 770022 GRAY

8101002294

8078004591

O.D.

to

Audio

External

Data

Modems Cable Assembly 8076004594

1-3

I SUNAIR RCU-9310 I

(

lrHIS

PAGE INTENTIONALLY LEFT BLANK.!

(

1-4

(

I

I

SUNAIR

RCU-9310 I

SECTION

II

INSTALLATION

2.1

GENERAL

Section

equipment

system hookups, and cabling considerations is also provided.

II

contains all necessary instructions for unpacking, inspection, and,

or

parts. Information regarding location and mounting considerations, power requirements, ground

if

required, reshipment

of

the

2.2 UNPACKING AND INSPECTION

As soon as you have received your unit(s), unpack and inspect all components and accessories. Check the

packing list to be sure you have received

ordered.

I NOTE: I

Do not accept a shipment when there are visible signs

made.

papers before signing the receipt from the carrier.

accepted, notify the carrier immediately in writing and await his inspection before making any disposition of the

shipment. A

be sure to include the

If there is a shortage ofitems or any evidence

full report ofthe damage should also be forwarded to Sunair's Product Services Department. Please

following information for prompt service:

Be sure to retain the carton(s) and associated packing materials

should it

all items ordered, and that all items necessary for operation have been

be

necessary to reship the equipment.

of

damage to the cartons until a complete inspection is

of

damage, insist

If concealed damage

on

a notation

is

discovered after the shipment has been

to

that effect on the shipping

a)

ORDER NUMBER.

MODEL AND SERIAL NUMBER.

b)

c) NAME

d) APPLICABLE

Upon receipt of this information, Sunair will make arrangements for repair

OF TRANSPORTATION AGENCY.

DATES.

or

replacement.

2.3 RETURN OF EQUIPMENT TO FACTORY

The shipping carton for the RCU-931 0 has been designed to protect the equipment during shipment. The

be

used

to

container and its associated packing materials should

When necessary to return equipment to

required. This number can be obtained from our Product Services Department: TELEPHONE: (954) 525-1505,

FACSIMILE:

If

the original shipping carton is not available, be sure to carefully pack each unit separately, using suitable

cushioning material where necessary. Very special attention should

material around connectors and other protrusions from the unit. Rigid cardboard should be placed at the corners

of

the equipment to protect against denting. DO NOT USE DUNNAGE (e.g., STYROFOAM PEANUTS) FOR

PACKING PROTECTION;

(954) 765-1322.

it may allow the unit

Sunair for warranty or non-warranty repair,

to

shift while being shipped, and, therefore, become damaged.

reship the equipment.

an

authorization number

be

given to providing enough packing

is

2-1

I SUNAIR RCU-9310 I

When returning subassemblies or components for repair

suitable cushioning

Shipment

to

be

material. (

made PREPAID consigned to:

or

replacement, be sure to pack each separately, using

Sunair Electronics, Inc.

Product Services Department

3101

SW

Third Avenue

Fort Lauderdale, Florida 33315-3389

U.S.A

Plainly mark with indelible ink all mailing documents as follows:

US Goods Returned For Repair

Mark ALL SIDES

of

the package:

I NOTE: I

Value For

FRAGILE - ELECTRONIC EQUIPMENT!

Before shipping, carefully inspect the package

properly and is securely wrapped.

Customs-

$(Amt.)

to

be

sure it is marked

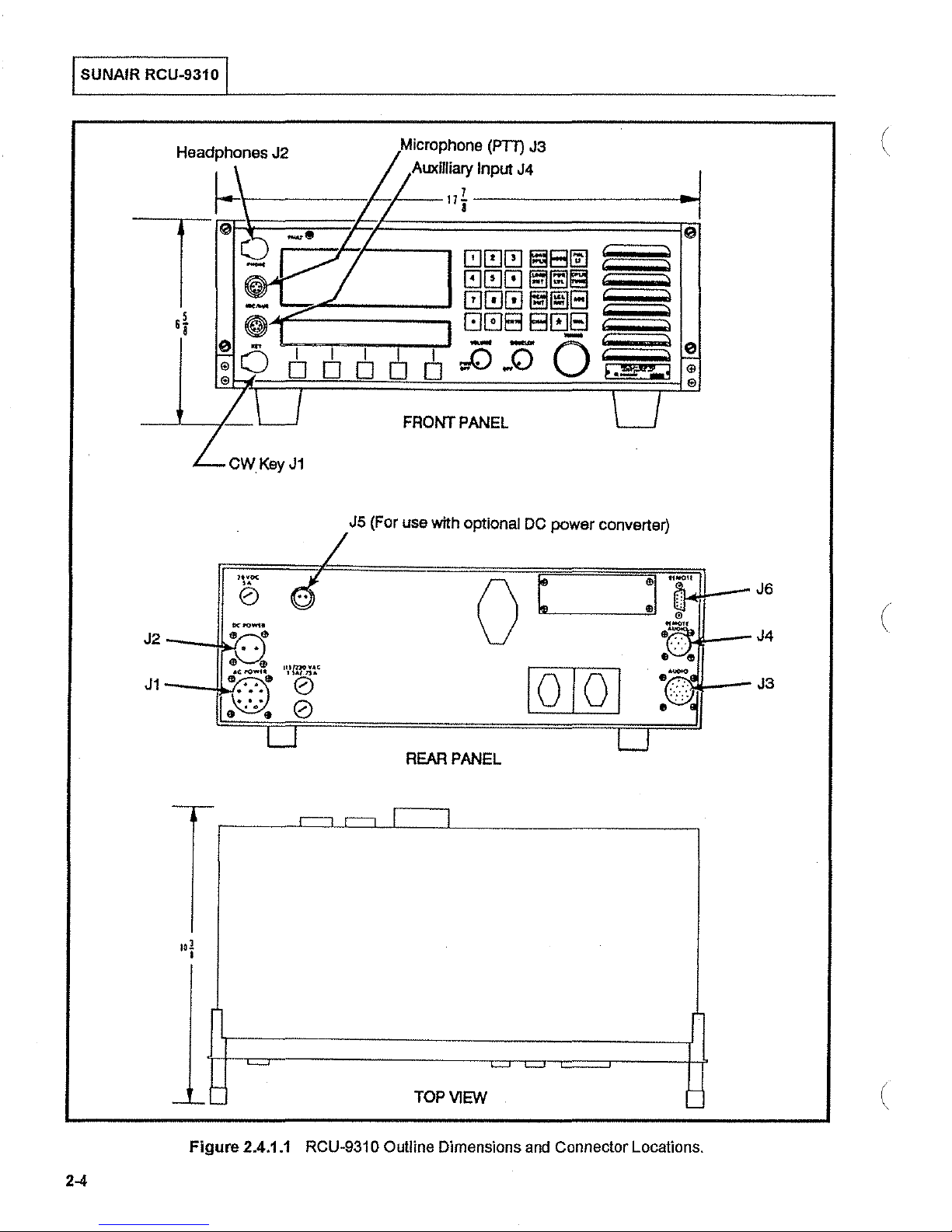

2.4 GENERAL INSTALLATION AND MOUNTING INFORMATION

Satisfactory operation

of

this equipment will depend upon the care and thoroughness taken during installation.

12.4.1 GENERAL INSTALLATION I

For

installation and operation with

conjunction with their respective operating manuals

Before starting installation, carefully

suitable and that adequate access for maintenance is provided.

If

operated

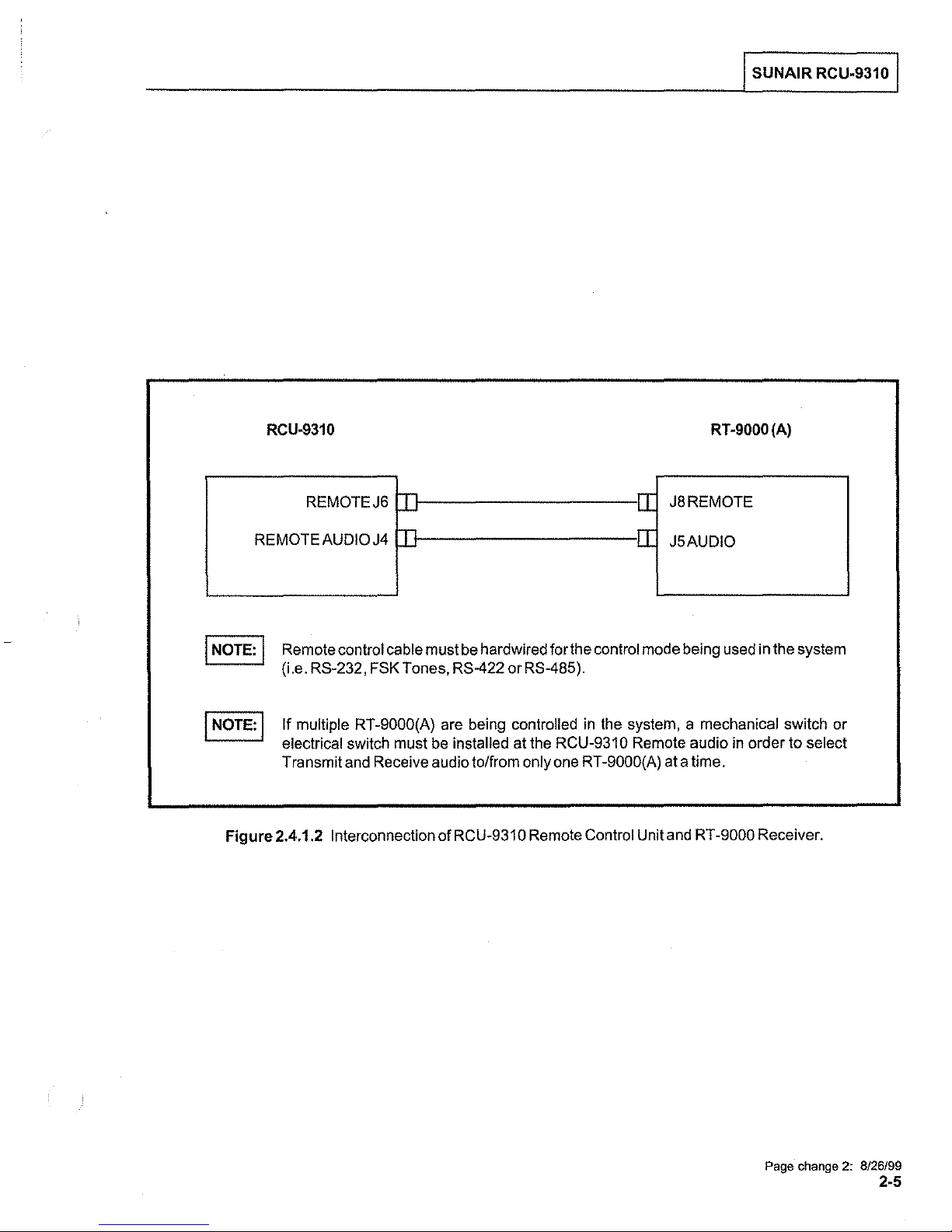

RCU-931 0 Remote Control Unit and RT-9000 Transceiver are interconnected as shown in Figure 2.4.1.2.

The

on

DC power, check

I NOTE: I

Figure 2.4.1.2 illustrates the direct cabling method for interconnecting

the remote

methods may

unit and transceiver signals must be maintained.

KW

equipment, modems, and other peripherals, use this manual in

for

complete installation information.

plan equipment locations to ensure that the operating environment is

for

correct polarity before applying power.

control unit and transceiver. While other interface

be

employed, the relationship between remote control

(

2-2

(

I SUNAIR RCU-9310 I

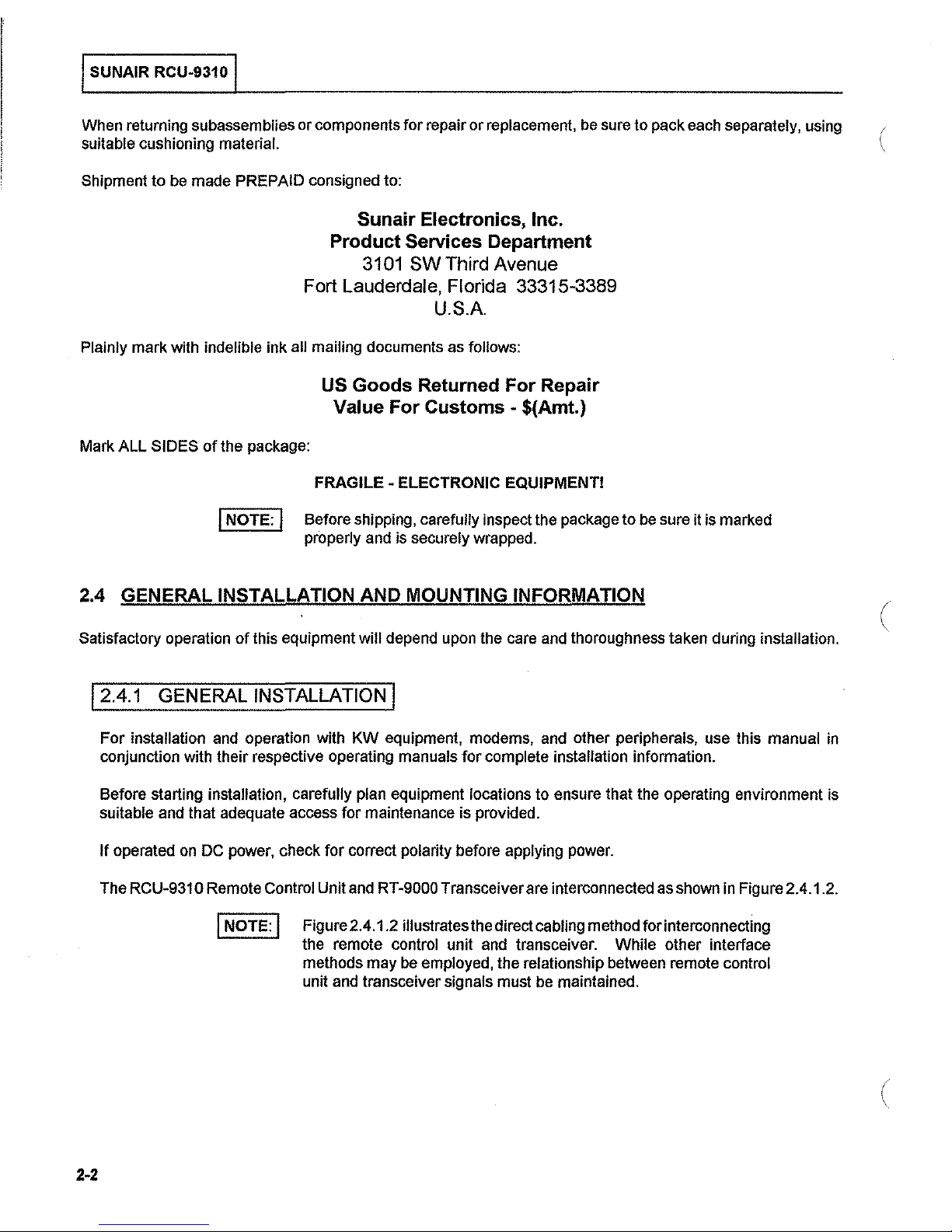

Connection

AC Power

DC Power

Microphone

Headphones

CW Key

Transceiver (RT

of

the RCU-931 0 to power sources and other equipment may be accomplished as follows:

TO

ADD

(option)

-9000)

RCU-9310

AC

DC

Microphone to J3 on front panel.

Headphones

CW Key to J 1

Control Lines from J6 on rear

panel

rear panel of

CONNECTIVITY GUIDE.

CONNECTION(s)

source to

source

to

J1

on rear panel.

to

J2

on

rear panel.

to

J2

on

front panel.

on

front panel.

remote connector J8 on

RT-9000.

NOTE

See Figure 2.4.1.1.

See Figure 2.4.1.1.

See Figure 2.4.1.1.

See Figure 2.4.1.1.

See Figure 2.4.1.1.

See Figures 2.4.1.1, 2.4.1.2,

2.4.1.3, and consult

manual. Must be hardwired for

mode that the system will use

(i.e. RS-232, etc.)

RT-9000

External Data Modems (Direct

connection RCU-931

0)

Audio lines from J4 on rear panel

to Audio connector J5 on rear

panel

of

RT-9000.

Connect

keyline to J3

RCU-9310.

modem

on

audio

rear panel

and

of

See Figures 2.4.1.1, 2.4.1.2,

2.4.1.4, and consult RT

manual.

See Figures 2.4.1.1 and 2.4.1.5.

-9000

Page change

2:

8/26/99

2-3

I SUNAIR RCU-9310 I

Headphones J2

r-------/--/---111-----------l-~·

CWKeyJ1

1h'OC

6

I I I I

DODO

J5 (For use with optional

Microphone

Auxllliary Input J4

(PTT)

I

Ol

FRONT PANEL

J3

DC

power converter)

..

(

,

(

2-4

-'-'-

Figure

REAR PANEL

.r----1

-

2.4.1.1 RCU-9310 Outline Dimensions and Connector Locations.

,.....,

I

TOP

I

VIEW

-

(

I

SUNAIR

RCU-9310 I

RCU-9310

REMOTEJ6

REMOTE

AUDIO

J4

n

n

I NOTE: I Remote control cable must

RS-232,

(i.e.

If multiple RT-9000(A)

electrical switch must

Transmit

Figure 2.4.1.2 Interconnection of

FSK

Tones, RS-422 or RS-485).

are

be

and

Receive audio to/from only

be

hardwired for

being controlled

installed at

RCU-931 0 Remote

the

RCU-931 0 Remote

one

-IT

-IT

the

control

in

RT

Control Unit

mode

the

system, a mechanical switch or

-9000(A) at a time.

RT-9000(A)

J8REMOTE

J5AUDIO

being

used

audio

in

and

RT

-9000 Receiver.

in

the

system

order to select

Page change 2: 8/26/99

2-5

I SUNAIR RCU-9310 I

822981

(

ACU-93!0

8

PIN

CONNECTOR

DB-9

FEMALE

)-~X~M~T--------------~R~S~-=2~3=2

_!R~C~V~------------~A~S~-=2~3=2--------------------~XM~T~

2 1

>

5 5

AS-232

)-----------------~F~S~K_T~O~N~E~----------------------<2

________________

>

2

XMT

XMT

RCV

ACV

RS-422

HIGH

LOW

HIGH

LOW

6

7

8

9

CONTROL INTERCONNECT 150

_!F~S~K_T~O~N~E~----------------------<

TONE

MODEM

CONTROL

CONTROL

INTERCONNECT

_____________________

GROUND

INTERCONNECT

-

AS

422

RS-422

AS-422

RS-422

RCV

RCV

XMT

XMT

\4000

FT.

FT.

HIGH

LOW

HIGH

LOW

MAX.)

MAX.!

AT-9000

15

PIN

DB-15

9

PIN

DB-9

R~C~v~

!AJ

CONNECTOR

FEMALE

OR

CONNECTOR

FEMALE

2

8

9

6

7

8

1----<

9

6

MULTIPLE

RT-9000

7

B

,~----<

9

'

6

'

7

!AI

(

----------------~R~S~-4~8~5~H~l~GH~--------------~----~

'>

8 8

9 9

Page change

2:

AS-485

8/26/99

Figure

CONTROL

2.4.1.3 FSK, RS232, RS-422,

2-6

AS-485

INTERCONNECT

LOW

\4000

FT.

MAX.!

H--<8

f-< 9

Hi--<

~9

or

RS485 Wiring Diagrams.

MULTIPLE

RT-9000

8

IAJ

(

RCU-9310

10

PIN

P/N

1010650025

l

PW06A-12-

CONNECTOR

lOP)

A>--

-------'T_:.:Rc::_ANSMJ

T

AUD,_,l_:=O

__

I SUNAIR RCU-9310 I

RT

-9000

PIN

(A)

CONNECTOR

19

P/NJQ1 1 l40004

(PW06A-14-l9P)

REMOTE

AUO!O

c

>-----

E )

F >

G)

H)

J >

----·

TRANSMl

T _

_::AcoU::_D.cl

Dc:_·c_

__

_

AUDIO

JS

Figure 2.4.1.4 RCU-9310 Remote Audio to RT-9000

(A)

Audio Wiring Diagram.

2-7

~

::!!

co

c:

til

~

-

"'

~

c

12

-

0

~

5"

5

~

3

!!!.

~

;::

g_

~

"'

§;

:::!.

::>

co

0

&"

ii)

?

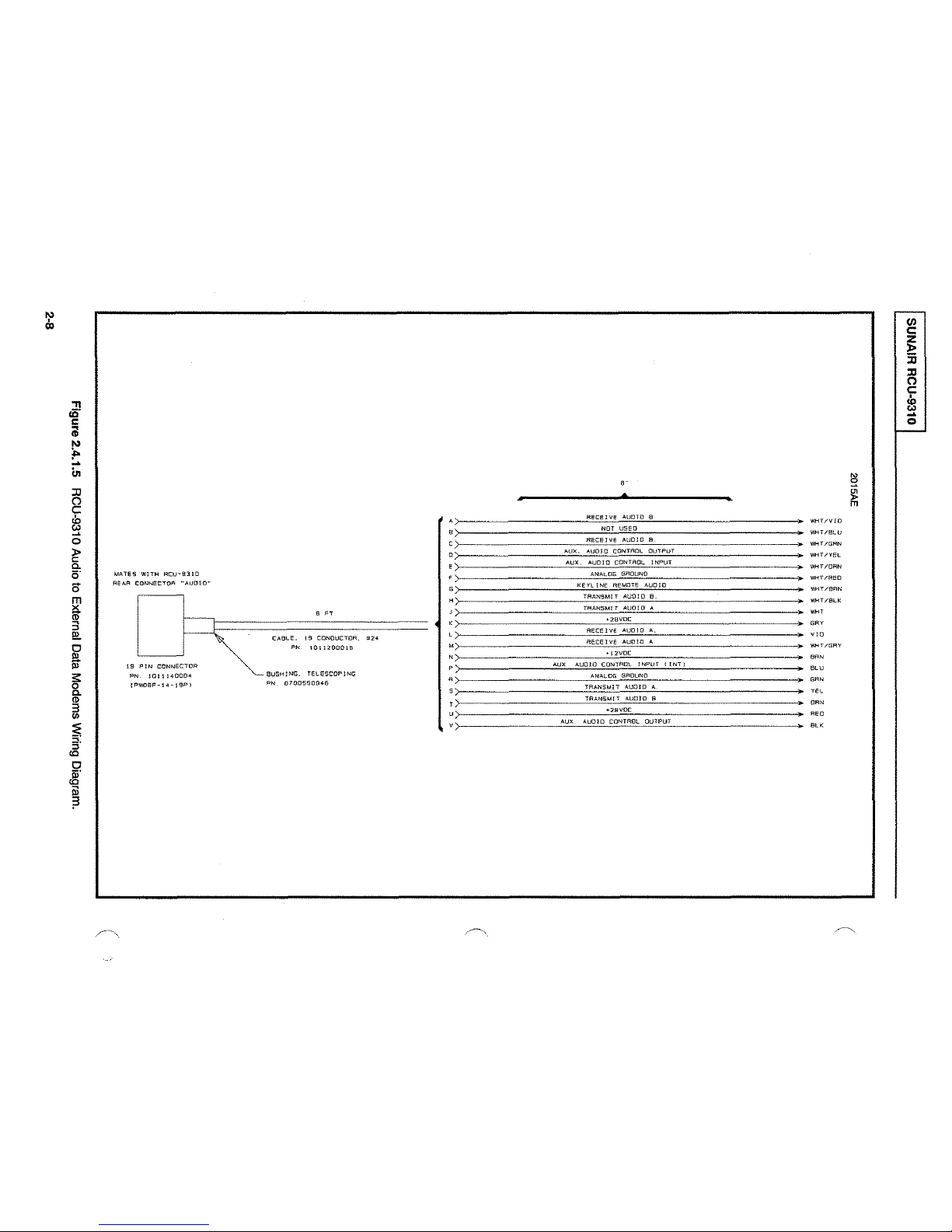

MATES

WITH

RCU-9310

REAR

CONNECTQF'i

'"AUDIO""

/----,_

19

PlN

CONNECTOR

PN_

1011140004

[PI'/OSF-14-!SP)

'"

CABLE,

!9

CONDUCTOR.

U24

PN

!011200015

BUSHING. TELESCOPING

PN

0700550046

a·

-

~

~

~

m

VIHT

/V

IO

1'/HT/BLU

\'IHT/GRN

v.HT/YE!...

\\IHT/ORN

WHT

/REO

WHT/SAF-.:

I'IHT

/BLK

~'

GR'

'<0

1'/HT/GAY

BAN

acu

GRN

m

ORN

RGO

ee<

~

en

c:

~

Si

:II

0

c:

;

0

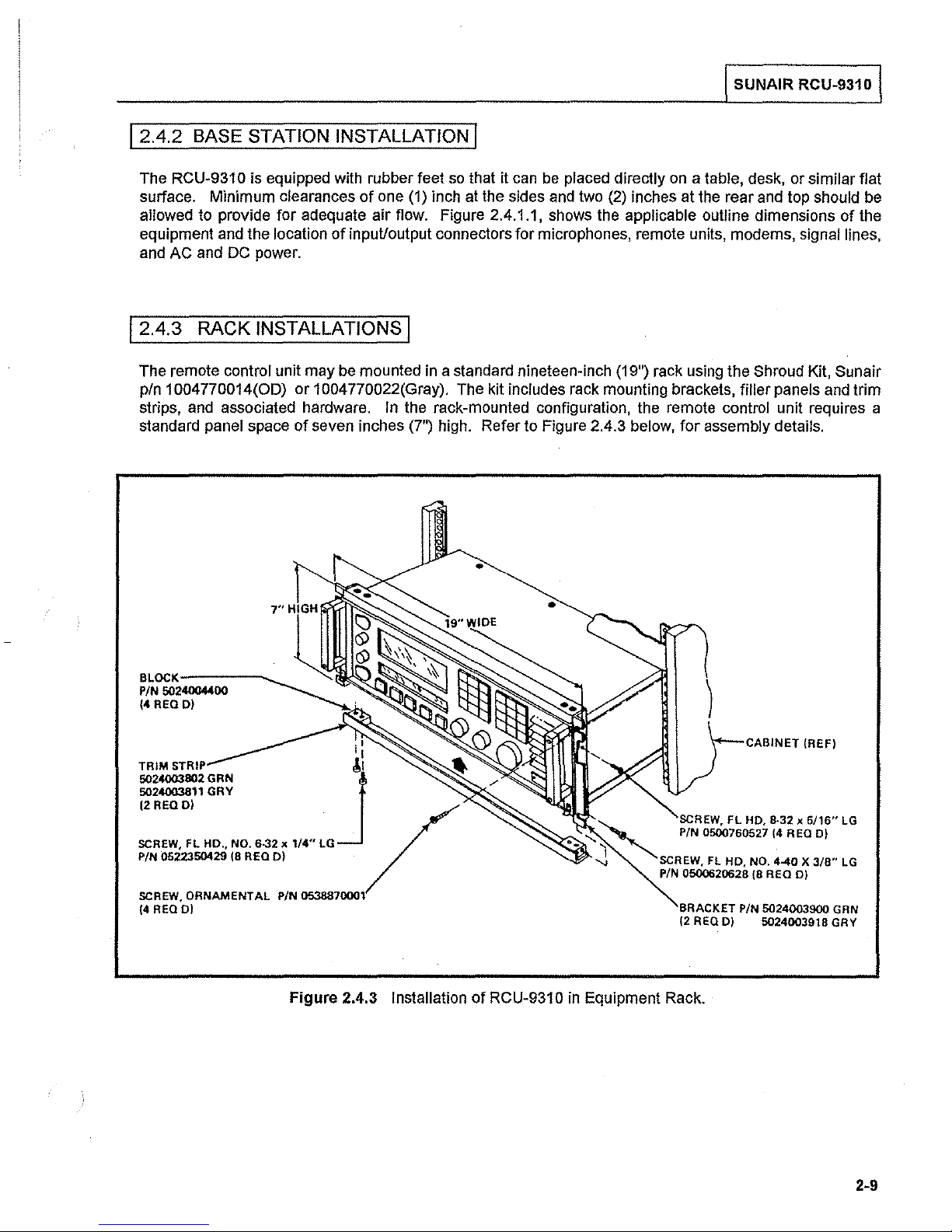

12.4.2 BASE STATION INSTALLATION I

I SUNAIR RCU-9310 I

The RCU-931 o is equipped with rubber feet

surface. Minimum clearances

allowed to provide for adequate

equipment and the location

and

AC and DC power.

of

one (1) inch at the sides and two (2) inches at the rear and top should be

air

flow. Figure 2.4.1.1, shows the applicable outline dimensions

of

input/output connectors

12.4.3 RACK INSTALLATIONS I

The remote control unit may

p/n 1 004

strips, and associated hardware.

standard panel space

770014(00)

be

mounted

or

1004 770022(Gray). The kit includes rack mounting brackets, filler panels and trim

In

the rack-mounted configuration, the remote control unit requires a

of

seven inches (7") high. Refer to Figure 2.4.3 below,

so

that it can be placed directly

for

microphones, remote units, modems, signal lines,

in

a standard nineteen-inch (19") rack using the Shroud Kit, Sunair

on

a table, desk,

for

assembly details .

or

similar flat

of

•

the

5024003811 GRY

12REQD)

PIN

0522350429

SCREW.

(4 REOD)

ORNAMENTAL PiN 0538870001

(8

REO

D)

Figure

,.

.!\

2.4.3 Installation

~

0

of

RCU-931 0

in

Equipment Rack.

)

CABINET (REF)

BRACKET P/N

(2

REO

D)

5024003900

5024003918 GRV

GRN

2-9

I SUNAIR RCU-9310 I

(

ITHIS PAGE INTENTIONALLy LEFT

BLANK.!

(

2-10

(

(

RCU-93108

Remote Control Unit

(

\

Please refer to Section

manual for RCU-931

OB

VI

Supplement of this

Operating Instructions.

/

\

(

(

I SUNAIR RCU-9310 I

SECTION IV

THEORY OF OPERATION

4.1 REMOTE CONTROL UNIT-TRANSCEIVER INTERFACE AND INTERACTION

The RCU-931 0 Remote Control Unit and its companion RT-9000 Transceiver interconnect and communicate

means

--provide

110

Receive audio input and transmit audio output are applied, respectively, to the remote unit from the transceiver

and to the transceiver from the remote unit over separate pairs

Transmit Audio Output connections are provided by the 'Remote Audio' connector (J4) on the remote control unit's

rear

From an operational standpoint, the RCU-931 o can

duplicates the primary operator functions

the transceiver, the transceiver's primary operator controls are inoperative. The reverse is true when the

transceiver has

Both the RCU-931 0 and the RT-9000 are software-controlled, microprocessor-based units, using similar devices

and technology. The remote unit's software provides the control and interface capability forthe front

processes incoming and outgoing messages, and

transceiver.

of

two

110

ports and two sets

the communications path

port connections are provided by the 'Remote' connector (J6) on the remote control unit's rear panel.

panel.

control.

of

audio lines. The

for

all operational,

a)

channel number and frequency information

b)

mode selection and tuning commands

c) transmit and receive commands

d) automatic scan and ALE setup and activation

e)

operator messages

of

the RT-9000 Transceiver. When the RCU-931 0 assumes control

110

or

be

--when

ports-- one each on the remote unit and transceiver

control, data:

of

audio lines. The Receive Audio Input and the

viewed as a remote control panel that essentially

in control -- generates functional commands to the

panel display,

by

of

4.2 REMOTE CONTROL UNIT

The RCU-931 0 Remote Control Unit contains the circuitry to allow the remote operatorto control all

of

the

RT

functions

The major functional assemblies

follwing paragraphs.

Figure 4.1, the

assemblies; schematic diagrams are included in Section V

-9000 Transceiver.

overall block diagram

of

the RCU-931 0 Remote Control Unit are listed below and described

(1) Front Panel Assembly

(2) CPU Assembly 3A2A 1

(3) Audio/Remote Audio Assembly 3A2A2/3A2A4

110

(4)

(5)

Assembly 3A2A3

AC and DC Power Supplies 3A3A 1/3A3A2

of

the RCU-9310, illustrates the functional relationship between these

3A1

of

this manual.

ofthe

primary

in

the

4-1

SUNAIR RCU-9310

AEMI

'"

PANEl

~EMCHE

AUOIO

H

XMtr

A~~--~-,,

3A:lA~

"

REMOTE

ASSEMSL

AUDIO

Y

3A2A2 AUDIO ASSY.

501,0il(H

00</llF>

-.~

='~

AOJI'.UD

""

SGUHCH

((ltol>b);

PC~R

f'OJ!iR

0!<1(1f

Sll'l'l1

I~

;uoiO <<l

IHIOOfiO

REMIP•>*L

AU>:

<<lIN

~~~>.<!Ill

~

..

•UI)IO

(

3A1

FRONT

PANEL

ASSY

MICROPROCESSOR

3A3

POWER

SUPPLY

ASSEMBLY

ASSEMBLY

3A:.!Al

t--++-

.---1-+-

L_------~====~

::'

":']

~·

A$l!!ol!O.r

•26

voc

(

Figure

4.1

4·2

(

RCU-9310 Remote Control Unit Block Diagram.

I SUNAIR RCU-9310 I

14.2.1 FRONT PANEL ASSEMBLY

The front

appropriate subassemblies.

the microprocessor assembly

indicates

power

display

transmit/receive

Built-In

the transceiver's

messages

unit

Selecting the

unit's microprocessor

If a fault

a

message

will activate the test routines

monitor

A 'soft-key'

functions,

Day,

speaker control.

panel

assembly contains the circuitry necessary

(Transceiver)

level,

and

which

can

Test

Equipment

are

displayed

or

the transceiver.

'Local

is

detected,

on

the

the

testing the transceiver's

menu

such

as

etc.

The

soft

It also provides

with

the

various other assemblies. A

operating status

local/remote control

selectively indicate receive

audio

levels.

(BITE)

BITE

can

BITE' function exercises a comprehensive test

software)

the 'FAULT' Light Emitting

LCD

will indicate

LCD

located directly below the primary display permits

Scan,

keys

monitors the status ofthe remote control unit's plug-in assemblies.

be

activated

on

the

LCD,

that

in

the transceiver's microprocessor software

Sounding,

also

provide access

such

as

selected

and

providing assurance ofthe continuing functionality of

checks

which

LRU

LRU's.

Automatic

3A11

to

provide

and

accepts digital information through the control/data bus

as

frequency, channel,

by

a front panel

signal

strength, transmit forward/reflected

monitored

all

plug-in

to

from

the

remote

subassemblies

Diode

(LED)

in

is

inoperative. Similarly, selecting the 'Remote BITE' function

Link

Establishment

meter selection, 1/0 port configuration, remote

analog

wide

keypad.

control

routine

to

the

upper left corner of the

(ALE),

and

screen

mode,

The

unitfront

(contained

the

the Lowest

and

the

Local

Liquid Crystal

BFO,

the

selection of

and

control interfacing

Display

AGC

release

LCD

contains a

power,

panel.

in

Repairable

remote

Remote

and

Plain

the

remote

the remote control

panel

control unit

several

BITE,

with

(LCD)

time,

bar

graph

600-ohm

In

addition,

language

control

Unit

(LRU).

will light

LCD

enhanced

Time-of-

audio,

the

via

RF

and

will

and

14.2.2 CPU ASSEMBLY 3A2A

4.2.2.1 GENERAL

The

CPU

Assembly

status indications

of transceiver operations, the microprocessor

transceiver.

software

Communications

provided

4.2.2.2 MICROPROCESSOR U2

The 8-bit

instructions

on

4.2.2.3 ERASABLE PROGRAMMABLE READ-ONLY MEMORY (EPROM)

The

the

routines

by

80C85

the

CPU

EPROM'S,

RCU-931

the control/data

(software)

Assembly

provides overall control of

and

executes the

These

0 functions.

commands

and

perform

between

microprocessor,

U13

and

the

stored

by

means of a multiplexed address/data

U14,

bus.

in

stores the program(s) or software executed

11

RCU-931

RCU-931

are

decoded

the designated function(s).

Microprocessor Assembly

U2,

EPROM'S

is

O's

the

U13

internal

provides

by

primary

and

0 functions. It

BITE

message control

the transceiver

control for all

U14.

U2

enables

routines.

and

controls

When

to

execute the appropriate (transceiver)

the other major functional assemblies

RCU-931

and

communicates

bus.

by

most Front

the

RCU-931 0 assumes

and

generates

0 functions. It executes the

U13

the microprocessor U2to control

with

AND

Panel

controls

control

commands

the other circuits

U14

to

and

the

are

4-3

I SUNAIR RCU-9310 I

4.2.2.4 ELECTRICALLY

Long term storage of the RCU-9310 ALE functions is handled by the non-volatile memory in

BK

X 8 bit CMOS EEPROM in which each byte may be reliably written 10,000 times without degrading device

The

operation.

applied.

4.2.2.5 STATIC RANDOM ACCESS MEMORY (SRAM) U3

The SRAM provides temporary storage that is used as a "scratch pad" by microprocessor U2 during the

execution of its program with U13 and U14.

4.2.2.6

Watch is

Smart

seconds, seconds, minutes, hours, days of the week, days

lithium energy cell maintains time information when the equipment is turned off. The above information is

available to microprocessor U2 for selective display on the Front Panel LCD as time-of-day clock.

data in the byte will remain valid after its last write operation for ten years with or without power

OPTIONAL SMART WATCH U14(A)

an

optional device that is "piggy-backed" into socket U14. It keeps track of: hundreths of

I NOTE: I

ERASABLE

The Smart Watch in the remote control unit is completely independent

of

the Smart Watch in the transceiver.

PROGRAMMABLE READ ONLY MEMORY (EEPROM)

of

the month, months, and years. An embedded

US.

US

US

is an

(

14.2.3 OPTOCOUPLER ASSEMBLY 3A2A 1 A

The Optocoupler, a subassembly that plugs onto

Optocoupler electronically isolates the CPU's multiplexed address/data bus from the control/data bus

prevent noise transfer to/from the microprocessor (U2).

the

11

CPU Assembly, contains optically-coupled isolators. The

14.2.4 AUDIO/REMOTE AUDIO ASSEMBLIES 3A2A2/3A2A4I

The Audio/Remote Audio Assemblies process the Remote Receive Audio input signal from the transceiver

the

to drive

modems.

Audio inputfrom a microphone,

Assemblies

over the transmit audio

After converting the receive 600 ohm audio to single ended output in the Remote Audio Assembly, the

Receive Audio

to the connected

3.3.9).

bypassed-switched to the Syllabic Squelch and Electronic Volume Control circuits. The output of the

Electronic Volume Control is amplified and switched (controlled by a designed-in Mute function

ON/OFF)

for headphone audio. Full power audio is routed through an energized relay

front panel speaker, headphones, and to provide two selectable 600-ohm audio outputs to external

CW

key, or selected external device is processed by the Audio/Remote Audio

to

produce an amplified 600 ohm Transmit Audio output signal that is applied

lines.

signal is amplified and routed

external device ('A'

The

amplified input signal can be electronically switched through a

and routed to

the

Speaker Driver.

or

to

the 600-ohm line drivers to provide a balanced 600-ohm output

'B',

as

determined by the

The

output is dropped through

'Une

Audio' selection described in Section

CW

Narrowband Audio Filter

R111

and routed to

(K3)

to the front panel speaker.

to

the transceiver

or

Squelch

the

front panel

(

to

or

I NOTE: I

4-4

When headphones are

de-energized,

plugged into the front panel, relay K3 is

disabling the audio to

the

speaker.

(

The

Squelch

received

and --if it

Driver.

poises

The Syllabic

or

circuit is a true syllabic type that operates

audio,

has

short

such

as

noise,

voice

characteristics-- turns

Squelch

fades,

I

NOTE:

minimizing

I

data,

etc.

The

on

circuit

is

designed

the effects of nuisance interruptions.

This

is

a function

transceiver into

squelch

Receive

the

Receive

to

remain

in

the

on

voice

Audio input

Audio

inactive

RCU-9310

operation.

characteristics

is

sampled

switch

(i.e.,

and

and

audio

does

passes

I

SUNAIR

and

rejects other types

in the Syllabic

through

unsquelched)

not

put

the

remote

RCU-9310 I

of

Squelch

to the Speaker

during

circuit

voice

During

The

electronically

controlled

or

and

Transceiver.

The

buffered

can

ohm

Keying

Audio Amplifier. A

Transmit

microphone

by

switched

applied

600-ohm

and

also

be

audio

the

operation,

input

switched

an

internal

to

bypass

to

a line driver

balanced

electronically

internally

signal

CW

then

key

them.

switched

enables

second

input

signal

from

to

the

Microphone/600-ohm

adjustment.

The

microphone

on

the

audio

from

switched

to

follows the

the

CW

buffer

to

the Audio Assembly originates

the front

Remote

external

through the Microphone/600-ohmAudio

pass

same

Sidetone

and

14.2.5 1/0 ASSEMBLY 3A2A3I

a)

Microphone,

b)

600-ohm

c)

CW

The

output

Audio

through, or

path

internal level control

balanced

key.

panel

is

routed

Audio

may

be

audio

is

then

Assembly

input

level

bypass,

as

the microphone

Switch.

lines,

to

the

Switch

fed

through

amplified,

to

provide a

is

controlled

the Transmit

The

CW

provides

from

or

Audio

circuits. This

the Transmit

switched

600-ohm

by

an

Audio

signal.

tone

is

buffered

sidetone

one

of three

Assembly

microphone

Audio

to

the

Transmit Audio

internal

Switch

Compressor

and

to

sources:

where

Transmit

adjustment.

circuits.

the

it

is

Compressor

Audio

This

circuits.

coupled

Speaker

amplified

output

signal

This

audio signal

to the Transmit

Driver.

and

level

is

circuits,

Amplifier,

to

the

signal

is

The

600-

The

1/0

Assembly

is

dedicated

remote

or

1/0

(U9)

special instructions

commands

The organization of the

simultaneously.

control

RS-485

Port

functions

under

formats

to

be

used

unit

control

from

contains

for

and

its

at

speeds

I

NOTE:

are

implemented

ofthe 1/0 Assembly's microprocessor

(software

the

Front

two

independent

future

specific

companion

of

300,

Port A may

I

FSK

Line

contained

Panel

or Microprocessor Assembly.

1/0

Assembly

1/0

ports,

predetermined

transceiver.

600,

1200,

be

used

Tone

Modem

Select

by a

(3A2A6)

Dual

in

EPROM

hardware

designated

operations.

This

port

is

configurable

2400,

4800,

9600,

for communications

(3A2A3A1)

and

Phone

Universal

Asynchronous Receiver/Transmitter

(U1

U20)

in

and

software

'A:

and

'B'.

Port A provides

from

19200

baud

over

and

optional

Interface

0).

The 1/0

response

is

such

Port B is

the

control

or

FSK

telephone

PC

(3A3A4).

Assembly

to

messages

that

an

RS-232,

the

control

Assemblies

interface

panel

tones

at

lines

mic,roprocessor

from

both

ports

9600-baud

for

RS-232,

300

with

Phone

(DUART)

the transceiver or

can

between

baud

the

be

port

that

RS-422,

only.

circuit

executes

active

the

4-5

I SUNAIR RCU-9310 I

14.2.6 POWER SUPPLY ASSEMBLIES 3A3, 3A3A

The

RCU-931 0 operates

are

connected,

source.

source.

The

3A3A

before

to

regulated output for

When

AC

power

1.

This

being

produce

The

the+

the

supply

AC

supply

+28

VDC

routed

12

from

RCU-9310

will

sense

line

returns,

assembly

is

routed

to

the

circuitry

VDC

regulated

the

RCU-931

either a

operates

AC

line

the

unit

(3A3)

produces

to

PC

in

the

output

0 circuitry.

+26

VDC

from

the

reductions

will

automatically

assembly

RCU-9310.

routed

to

or

120/220

AC

line

input,

or failure

switch

unregulated

3A3A2

RCU-931

The

where

+28

VAC

and

DC

0 circuitry

1,

and 3A3A21

power

using

the

automatically

back

to

AC

that

is

regulated

the

+28

VDC

is

also

and

source.

+26

VDC

line

VDC

is

sentthru

to

3A3A2

When

input

switch

power.

to

+28

fuse

R1

U2

both

power

as a backup

to

the

backup

VDC

in

(3A3A2

and

producing

F1)

R2

PC

assembly

protected

to

3A3A2

the

sources

power

voltage

U1

+5

VDC

(

(

(

I SUNAIR RCU-9310 I

SECTION V

FAULT ISOLATION/MAINTENANCE AND REPAIR

5.1

GENERAL

This

section provides the procedures for Fault Isolation, maintenance and repair

to

the

Lowest Repairable Unit

(LRU)

level.

5.2

DISASSEMBLY

Disassembly should be only to the extent necessary to accomplish the repair or replacement

of

the defective LRU.

Procedures for the disassembly

of

major modules and assemblies are given in the following paragraph.

15.2.1 TOP OR BOTTOM COVER REMOVAL I

Refer to Figure 5.2.1.1

a)

Remove the three screws

at

the rear

of

the cover.

b)

Pull the cover up and back from the front panel.

5.3

TEST SET UP

js.3.1

PRELIMINARY!

5.4

§Jig

a)

Connect RCU-931 0

to

AC or DC power and turn ON.

WARNING: For personal safety and to prevent damage to voltage

sensitive components in the remote control unit, always

turn OFF the RCU-931 o whenever resealing printed circuit

cards

(PC), LRU'S and when replacing fuses.

ls.4.1

PRELIMINARY I

The

BITE

of

the RCU-931 0 provides immediate LRU faults. The Surveillance BITE is controlled by the

microprocessor on

CPU Assembly 3A2A 1. It checks the operational status

of

the LRU's with the exception

of

the +28 V Regulator 3A3A 1. This LRU has a self-surveillance BITE non-dependent upon CPU Assembly

3A2A1. The front panel "LCD" will display a plain language "FAULT MESSAGE", the "FAULT" Red LED will

illuminate

on the front panel (See Figure 5.4.1.1 and on the faulty LRU (see Figure 5.4.1.3)).

The

RCU-9310

Remote Control Unit can be tested independently, with or without a transceiver connected. With RCU-931 0

connected to selected input power turn ON remote unit and refer to figure 5.4.1.1 and perform the following

steps

to

access the BITE menu.

5-1

I SUNAIR RCU-9310 I

5-2

'l

..

I

(

TOP

COVER

(

(

Figure 5.2.1.1 Top/Bottom and Card Cage Covers Removal.

0

~

®

®

I SUNAIR RCU-9310 I

4 5

I

-~

0

0

FAULT

RCV 9.16717

MHZ

CH

26

QJ00

~

J•oofjl

PNLI

LT

PHONE

S3

S6

S9

+20 +40 +60

000

~

METER········

[;B

I

PWR

IICPLRI

LVL

TUNE

,_

:\'~SEL

REMOTE OR

LOCAL

000

~~EJ

MIC/AUX

'"'

~

BFCl-

BITE

MCH-

ALE-10 MORE

008

jcHANJI

ALE

JJ

MIL

j

VOLUME

SQUELCH

TUNING

KEY

0

~

0

I

cb

I I

cb

PWRO

OFP

I I

0

0

0

OFF

RCU-9310

®

®

2

3

1

Figure

5.4.1.1 RCU-931 0 Feature Menu, BITE Selection.

Depress the 'MORE' key 1 successively until the feature menu 2 shown

in

Figure 5.4.1.2 appears.

Depress the

'BITE' key 3 . The message:

'SEL REMOTE

OR

LOCAL'

will appear on the status display screen 4 , and the BITE submenu shown

in

Figure 5.4.1.2 will

be

displayed

on the 'Feature' screen.

II

REM·BITE

LOCBITE

END

II

I

I I I

I

~

D

~

D

~

2

1 3

Figure

5.4.1.2 RCU-9310 BITE Submenu.

Depress the 'LOC BITE' key 1 . The RCU-931 0 will initiate a self-test routine and will display messages

and/or

results on the status screen. The initial message will

be:

'BITE IN PROGRESS'

As each modules tested, a corresponding message will appear briefly on the screen in the following order.

'FRONT PANEL O.K.'

'CPU O.K.'

'POWER SUPPLY O.K.'

5·3

I SUNAIR RCU-9310 I

'1/0

O.K.'

1000

Hz

Audio Tone heard in speaker at this point.

'AUDIO O.K.'

If

any

of

the modules (LRUs) are faulty, the BITE program will halt, the front panel 'FAULT' indicator 5 will

light,

and the status screen will display a message indicating the faulty module:

!s.4.2

COMMON

MODULES I

'FRONT PANEL FAULT'

'CPU FAULT'

'POWER SUPPLY FAULT'

'1/0

FAULT'

'AUDIO FAULT'

!NOTE: I

Refer to Figures 5.2.1.1, 5.4.2.1 and 5.4.2.2 for module cover removal

and

assembly locations.

5.4.2.1 FRONT PANEL FAULT

This is an indication

of

a failure on the Front Panel PC Board Assembly

3A

1 A

1.

a)

Turn RCU-9310

OFF

and remove Front Panel Module 3A1. See Figure 5.4.2.2 on the following page.

b)

Remove and replace Front Panel PC Board Assembly 3A1A1. See Figure 5.4.2.2.

c)

Reinstall Front Panel Module 3A1. Turn RCU-9310 ON.

d)

Repeat "BITE TEST''. Upon completion

of

successful test, return RCU-931 0 to operational status and

return

failed

3A

1 A 1 PC

to

factory for repair.

e)

If

in

step d) above, test fails the Front Panel test again, turn

OFF

RCU-9310 and remove

3A1

Module;

replace

with original

3A1

A 1 PC Assembly. Return the failed

3A

1 Module to factory for repair.

5.4.2.2

CPU

FAULT

This is an indication

of

a failure on the PC Assembly CPU 3A2A1. Check position of DIP Switch S1. (See

Figures 5.8.4 and 5.7.3.1).

a)

Turn the RCU-9310 OFF and remove and replace PC Assembly 3A2A1. See Figures 5.4.2.1 thru 5.4.2.4.

b)

Turn ON RCU-9310 and repeat "BITE TEST". Upon completion of a successful test, return RCU-9310

to

operational status.

c)

Return failed PC Assembly 3A2A 1 to factory for repair.

(

(

(

I SUNAIR RCU-9310 I

5.4.2.3 1/0 FAULT

This is an indication of a failure on PC Assembly

1/0

3A2A3.

a) Turn the

RCU-931 0 OFF and remove and replace PC Assembly 3A2A3. See Figures 5.4.2.1 thru 5.4.2.4.

b) Turn

ON RCU-9310 and repeat "BITE

TEST'.

Upon completion of a successful test return RCU-9310 to

operational status.

c)

Return failed PC Assembly 3A2A3 to factory for repair.

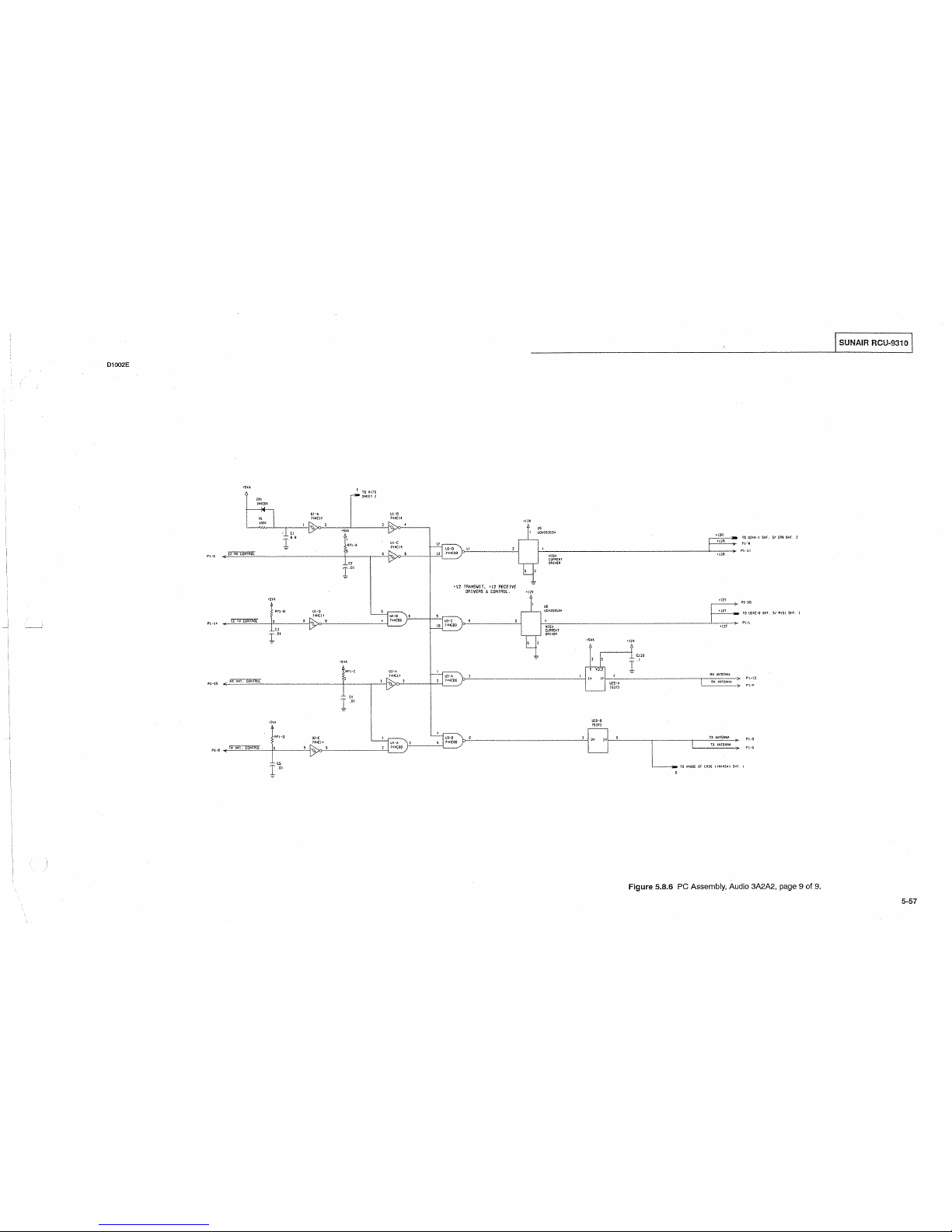

5.4.2.4 AUDIO FAULT

This is an indication of a failure on the Audio PC Board Assembly 3A2A2. Check DIP Switch S1. See Figure

5.8.6.

a) Turn RCU-9310 OFF and remove and replace 3A2A2. See Figure 5.4.2.1.

b)

Turn RCU-931 0 ON. Repeat "BITE

TEST'.

Upon completion of successful test, return RCU-931 0 to

operational status. Return failed 3A2A2

to

factory for repair.

OVER

VOLTAGE

(RED

LED)

\

UNDER

VOLTAGE

(RED

LED)

READY

(GR\

LED)

I I

/OVER

CURRENT

(RED

LED)

I

0

'\

/~

/

0

I

""

.

•

•u•~

(

)

1(

~

'if

!?

NOT

USED

110110Nf

()t

19

"

KV

""''

OSC

Uf'lol

"""'"'

'"""'

•v:o

(B

®

I

I

IUC

UNI

OUKIO«

.,,.,.,

•

•

•••••

•

•

I

'IM:Jif.•f(,.~~

I

llMOTE

AUDIO

"

""'

FAUU

""'0

c•u

•

llil

MU~

110

®

~~·:-;

Or-t

Jill

111

.,;;:iL

'--'

'--'

'-

~

!-

..._

FAULT

LED

(RED

LED)

FRONT

PANEL

FAULT

(RED

LED)

NOT

SHOWN

Figure 5.4.1.3 Top View RCU-9310 LRU "Fault Indicators".

5-5

I SUNAIR RCU-9310 I

5.4.2.5 POWER SUPPLY FAULT

This indicates a failure of the +28VDC out of PC Assembly 3A3A2 usually 3A3A2-F1.

a)

Turn OFF RCU-931 0 and check 3A3A2-F1, replace as required.

b)

If 3A3A2-F1 is not blown, use normal troubleshooting procedures and check the +28VDC lines

on

Mother

Board

assembly 3A2A5-J2 pins 23 and 24. If this is correct, the fault is on the CPU assembly 3A2A 1.

1)

Turn RCU-931 0 Off and remove and replace PC assembly 3A2A

1.

See Figures 5.4.2.1 thru 5.4.2.4.

2)

Turn ON RCU-931 0 and repeat "BITE TEST". Upon completion of a successful test, return RCU-931 0

to operational status.

3) Return

failed PC Assembly 3A2A 1 to factory for repair.

5.5 TROUBLESHOOTING WITH SELF-SURVEILLANCE

BITE

Refer to Figure 5.4.1.3.

ls.s.1

AC POWER SUPPLY I

The Self-Surveillance Bite for the AC power supply consists of the following LED's (See Figure 5.4.1.3)

SYMPTOM(s)

AC PQWER ONLY:

a)

GREEN=

READY (3A3A1-CR8)

b)

RED=

OVER VOLTAGE (3A3A1-CR7)

c)

RED=

UNDER VOLTAGE (3A3A1-CR6)

d)

RED=

OVER CURRENT (3A3A1-CR3)

TROUBLESHOOTING

GUIDE.

POSSIBLE

TROUBLE(s)

CHECKS

& CORRECTIVE

ACTION(s)

UnabletoturnunitON.

NoLED'slit

1.

NoACPower.

on 3A3A1.

1.

Check AC power input and take

appropriate action.

2.

Open AC fuses 3A3F1

or

F2.

5-6

2.

Replace

F1

or

F2. If fuse opens

again

use

normal

troubleshooting procedures, locate and

repair short

in

AC power supply.

(

(

(

I SUNAIR RCU-9310 I

TROUBLESHOOTING

GUIDE

(CoNT

...

)

SYMPTOM(s)

POSSIBLE

TROUBLE(s)

CHECKS

& CORRECTIVE

ACTION(s)

Unable

to

turn unit

ON

and

GREEN

t.

3A3A2-K2 or associated circuitry

t.

Troubleshoot and repair or

READY

LED

on

3A3A t lit. 3A3A2-Q2 or

03

faulty. replace faulty component.

Unable to

turn

unit

ON

and

RED

UNDER

VOLTAGE

LED

on

3A3At

lit.

AC

or

DC POWER:

Unit turns

ON,

unable to turn

ON

Front

Panel

LCD

back lite.

Run

local

BITE.

Unit displays "POWER

SUPPLY FAULT'.

No

audio tone

during audio test and

displays

"AUDIO FAULT"

and

Front

Panel

FAULT

LED

is

lit.

Unit

turns

on,

Front Panel LCD

glows, but no information

is

displayed. Unit has

no

RED

FAULT

LED's

lit.

GREEN READY

LED

on

3A3A t

is

lit.

Unit

turns

on,

Front Panel

LCD

glows,

but

no information is

displayed. Unit has

no

RED

FAULT

LED's

lit.

With

AC

power applied

GREEN READY

LED

ON

3A3A t

is

lit.

With

DC

only READY

LED

will

not be

lit.

DC PQWER ONLY:

Unable to turn unit

on.

t.

3A3At-Qt faulty.

2.

Faulty component(s)

on

3A3A

t.

2. Remove and replace

PC

Assembly 3A3A2.

t.

Replace

Qt.

2.

Troubleshoot

and

replace faulty

components, or remove and

replace

PC

Assembly 3A3A

t.

t.

3A3A2-Ft open.

t.

Replace

Ft,

if fuse opens again

use

normal troubleshooting

procedures,

locate

and

repair

short

on

+28VDC lines

in

unit.

t.

3A3A2-Ut or associated circuitry

t.

Replace

Ut.

faulty.

2.

Troubleshoot

and

replace faulty

components or remove and

replace

PC

Assembly 3A3A2.

t.

3A3A2-U2

or

associated circuitry

t.

Replace

U2.

faulty.

t.

No

DC

power.

2.

3A3A-F3 open.

3.

3A3A2-Kt,

K2

or associated

circuitry

faulty.

2.

Troubleshoot

and

replace faulty

components or remove and

replace 3A3A2.

t.

Check

DC

power input

and

take

appropriate action.

2.

Replace

F3,

if fuse opens again,

use

normal troubleshooting

procedures,

locate and repair

short

in

DC

circuitry.

3.

Troubleshoot

and

replace faulty

component(s) or remove and

replace

PC

Assembly 3A3A2.

5-7

~

::n

CQ

c

iil

"'

~

-

s:

-5·

~

~

(/)

CD

3

CT

-<

b

~

::>

?'

~.

3A2A 1 PC

ASSEMBLY CPU

3A1

FRONTPANELASSEMBLY

~

~~~

3A2A4

PC

ASSEMBLY

REMOTE

AUDIO

BOARD

3A3

REAR

CHASSIS ASSEMBLY

/'.

3A 1 A 1

PC

ASSEMBLY

FRONT

PANEL

31>2/>2

PC

ASSEMBLY AUDIO

~

(/)

c:

~

:s

::0

(')

c:

~

-

0

I SUNAIR RCU-9310 I

3A1

FRONT PANEL ASSEMBLY

3A2A1

PC ASSEMBLY

CPU

3A2M.

PC ASSEMBLY AUDIO

3A2A5

MOTHER

{Bottom

of

Main

Chassis)

•

•

3A3A3

PC

ASSEMBLY AUDIO CONNECTORS

3A3/>2

PC ASSEMBLY 5/12V REGULATORS

3A3A1 PC ASSEMBLY28V REGULATOR

3A3 REAR

CHASSIS ASSEMBLY

Figure 5.4.2.2 Removal of Front and Rear Panel and Major Assemblies Locations.

5-9

j

I

r

I SUNAIR RCU-9310 I

5-10

8078073291

8078072295

U13

U14

Ribbon cable connections

\

'1\:JQ'a~~~

naaa~~

!.""=:!====~

aaaaaa