TM-8085000709

DIGITAL AUTOMATIC

ANTENNA COUPLER

CU-9125

OPERATION AND MAINTENANCE

MANUAL

SUNAIR 3005 SW Third Avenue, Ft. Lauderdale, FL 33315-3389

WARRANTY POLICY

GROUND AND MARINE PRODUCTS

Sunair Electronics warrants equipment manufactured by it to be free from

defects in material or workmanship, under normal use for the lesser of one (1)

year from the date of installation or 15 months from date of shipment by Sunair.

Sunair will repair or replace, at its option, any defective equipment or component

of the equipment returned to it at its factory, transportation prepaid, within such

warranty period. No reimbursement will be made for non-factory repair charges.

This warranty is void if equipment is modified or repaired without authorization,

subject to misuse, abuse, accident, water damage or other neglect, or has its

serial number defaced or removed.

THIS WARRANTY IS ESPECIALLY IN LIEU OF ANY AND ALL OTHER

WARRANTIES EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. The obligation and responsibility of Sunair shall be limited to that

expressly provided herein and Sunair shall not be liable for consequential or

other damage or expense whatsoever therefore or by any reason thereof.

Sunair reserves the right to make changes in design or additions to or

improvements in its equipment without obligation to install such additions or

improvements in equipment theretofore manufactured.

SUNAIR ELECTRONICS, INC.

CU-9125

DIGITAL AUTOMATIC

ANTENNA COUPLER

SUNAIR

OPERATION

AND

MAINTENANCE MANUAL

FIRST EDITION, AUGUST 1, 1990

SECOND REVISION, JULY 1993

Page changes 1: 3/15/00

PRODUCT SERVICE:

PRODUCT SERVICE:

In case of difficulty please contact the Sunair

In case of difficulty please contact the Sunair

Product Service Department, between the hours

Product Service Department, between the hours

of 8:00 AM and 5:00 PM or write to:

of 8:00 AM and 5:00 PM or write to:

Product Service Dept.

Product Service Dept.

Sunair Electronics, Inc.

Sunair Electronics, Inc.

3101 SW Third Avenue

3101 SW Third Avenue

Ft. Lauderdale, FL 33315-3389

Ft. Lauderdale, FL 33315-3389

U.S.A.

U.S.A.

Telephone: (954) 525-1505

Telephone: (954) 525-1505

Fax: (954) 765-1322

Fax: (954) 765-1322

TRAINING:

TRAINING:

Sunair offers training programs of varying lengths

Sunair offers training programs of varying lengths

covering operation, service, and maintenance

covering operation, service, and maintenance

of all Sunair manufactured equipment. For

of all Sunair manufactured equipment. For

details please contact the Product Service

details please contact the Product Service

Department.

Department.

SUNAIR CU-9125

TABLE of CONTENTS

Section Description Page

I GENERAL INFORMATION

1.1 Scope

1.2 Description

1.2.1 General

1.2.2 Assemblies

1.2.2.1 Chassis Assembly 2A1

1.2.2.2 RF Assembly 2A2

1.2.2.3 Computer Board 2A3

1.2.2.4 Detector/Pad Assembly 2A4

1.3 Specifications

1.3.1 General

1.3.2 Environmental

1.4 Equipment Supplied

1.5 Equipment Required But Not Supplied

1.6 Optional Equipment Not Supplied

1-1

1-1

1-1

1-1

1-1

1-1

1-1

1-1

1-3

1-3

1-4

1-4

1-4

1-5

II INSTALLATION

2.1 General

2.2 Unpacking and Inspection

2.3 Return of Equipment to Factory

2.4 Power Requirements

2.5 Installation Considerations and Mounting Information

2.5.1 General Installation Procedures and Requirements

2.5.2 Mounting Considerations

2.5.2.1 Base Station Installation

2.5.2.2 Vehicular Installation

2.5.2.3 Marine Installation

2-1

2-1

2-1

2-2

2-2

2-2

2-3

2-3

2-3

2-3

i

SUNAIR CU-9125

TABLE of CONTENTS (Cont...)

Section Description Page

2.6 Antenna and Ground Systems

2.6.1 General

2.6.2 Narrow Band 50 Ohm Antennas

2.6.3 Random Length Non-resonant Antennas

2.7 Construction of Control Cable Assembly 8076004195

2.8 Checks After Installation

III OPERATION

3.1 Antenna Coupler Tuning

IV THEORY OF OPERATION

4.1 General

4.2 Antenna Tuning Network

4.3 Detector/Pad Assembly 2A4

4.3.1 General

2-9

2-9

2-9

2-10

2-12

2-14

3-1

4-1

4-1

4-1

4-3

4.3.2 Magnitude Discriminator

4.3.3 Phase Discriminator

4.3.4 Forward and Reflected Power Detector

4.3.5 6 dB Attenuator Pad Assembly

4.3.6 Tune Relay

4.4 Computer Board Assembly with Sleep Circuit

4.4.1 General

4.4.2 Phase Discriminator Interface

4.4.3 Magnitude Discriminator Interface

4.4.4 ‘RF Present’ Detector

4.4.5 VSWR Comparator

4.4.6 Reflected Power Meter Driver

4.4.7 Reference Voltage Sources

4.4.8 Tune Relay Latch

4-3

4-3

4-3

4-4

4-4

4-4

4-4

4-5

4-5

4-5

4-5

4-6

4-6

4-6

ii

SUNAIR CU-9125

TABLE of CONTENTS (Cont...)

Section Description Page

4.4.9 Microprocessor Circuits

4.4.9.1 General

4.4.9.2 Microprocessor U1

4.4.9.3 Address Decoder U2

4.4.9.4 Address Latch U3

4.4.9.5 Erasable Programmable Read Only Memory

(EPROM) U4

4.4.9.6 Input Port

4.4.9.7 Output Ports

4.4.9.8 Timer

4.4.9.9 Random Access Memory (RAM)

4.4.9.10 Electrically Erasable Programmable Read

Only Memory (EEPROM) U14

4.5 Chassis Assembly 2A1

4.5.1 General

4-6

4-6

4-6

4-7

4-7

4-7

4-8

4-9

4-10

4-10

4-10

4-10

4-10

4.5.2 RF Assembly 2A2

4.5.3 Motherboard 2A1A1

V ALIGNMENT

5.1 General

5.2 Preventive Maintenance

5.3 Inspection

5.4 Repair or Replacement

5.4.1 General Precautions

5.4.2 Circuit Card Assembly, Two-Lead Component

4.5.2.1 General

4.5.2.2 Theory of Operation

Removal

4-10

4-10

4-11

4-11

5-1

5-1

5-1

5-3

5-3

5-3

iii

SUNAIR CU-9125

TABLE of CONTENTS (Cont...)

Section Description Page

5.4.3 Circuit Card Assembly, Multi-lead Component

Removal

5.4.4 Removal of Components of Doubtful Condition

5.5 Performance Test

5.5.1 Test Equipment

5.5.2 Preliminary

5.5.3 CU-9125 Alignment Procedure for Computer

Board Assembly 2A3

5.5.4 Alignment Procedure for Detector/Relay Pad

Assembly 2A4

5.6 Schematics and Parts Lists

5-3

5-4

5-4

5-4

5-5

5-6

5-9

5-44

iv

SUNAIR CU-9125

LISTING of FIGURES

Section Description Page

I GENERAL INFORMATION

1.1 CU-9125 Major Assembly Locations. 1-2

II INSTALLATION

2.1 Outline Mounting Details CU-9125. 2-4

2.2 Shockmount Installation. 2-5

2.3 Typical Base Station Installation

Using Non-Resonant Antennas. 2-6

2.4 Typical Vehicular Installation. 2-7

2.5 Coupler Grounding. 2-8

2.6 Whip Antenna. 2-10

2.7 Inverted “V” Antenna. 2-11

2.8 Longwire Antenna. 2-11

2.9 Wiring Diagram, Control Cable (8076004195). 2-13

IV THEORY OF OPERATION

4.1 CU-9125 Block Diagram. 4-2

V ALIGNMENT

5.1 Antenna Coupler Cover Removal. 5-2

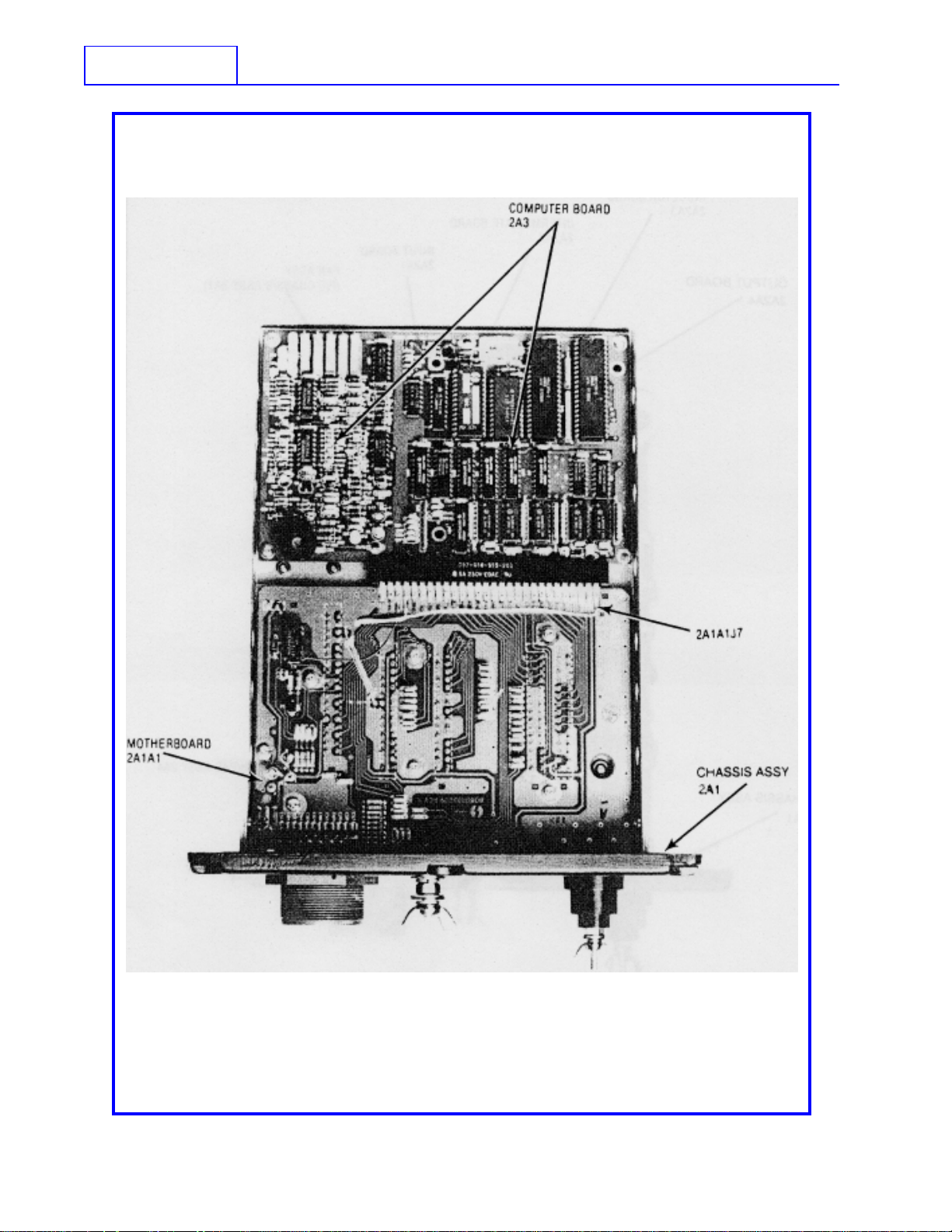

5.2 Computer Board Test Point and Adjustment Locations. 5-6

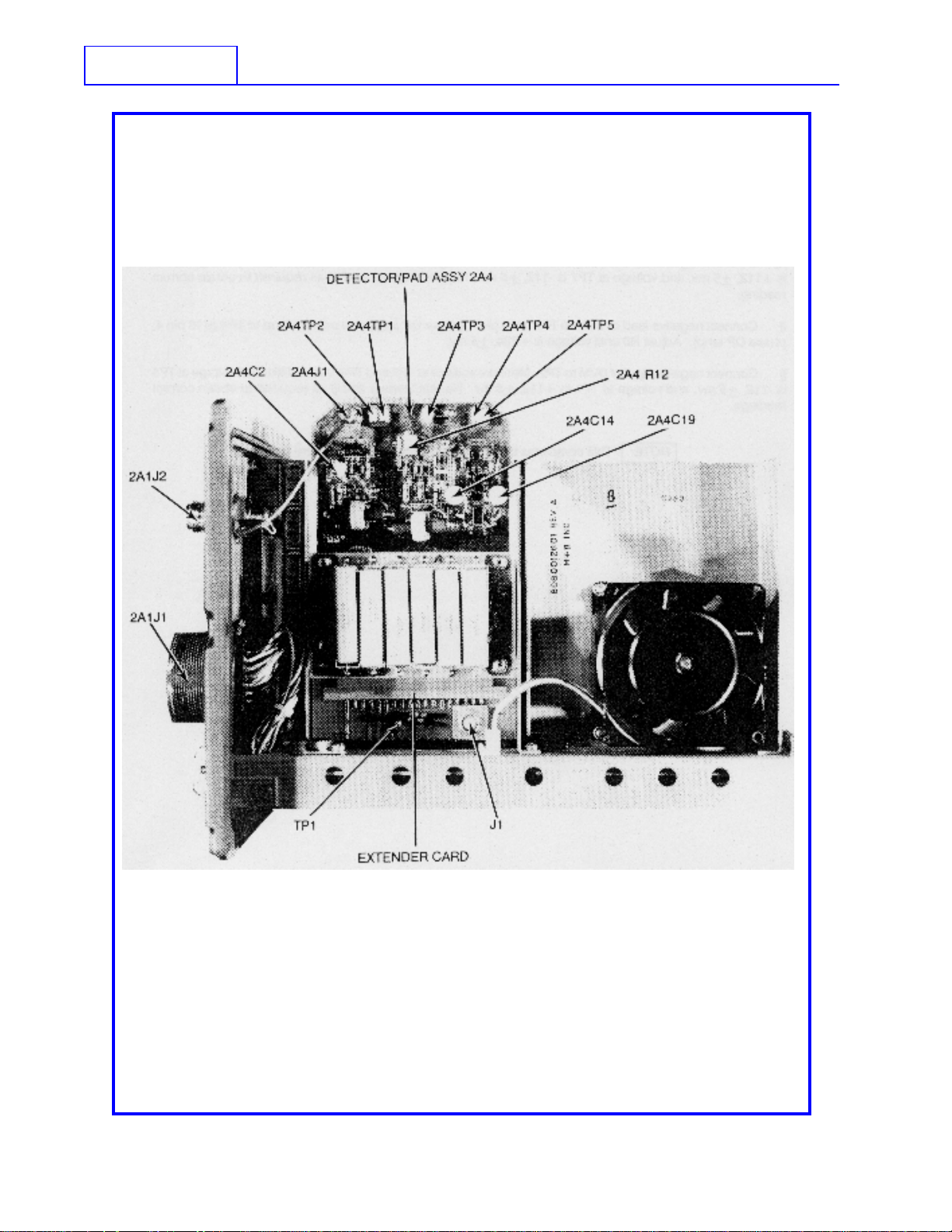

5.3 Detector Pad (2A4) and Extender Card Test Point

and Adjustment Locations. 5-8

5.4 Coupler Test. 5-10

5.5 Major Assembly and Component Locations

(Front View). 5-12

5.6 Major Assembly and Component Locations

(Top View). 5-13

5.7 Major Assembly and Component Locations

(Bottom View). 5-14

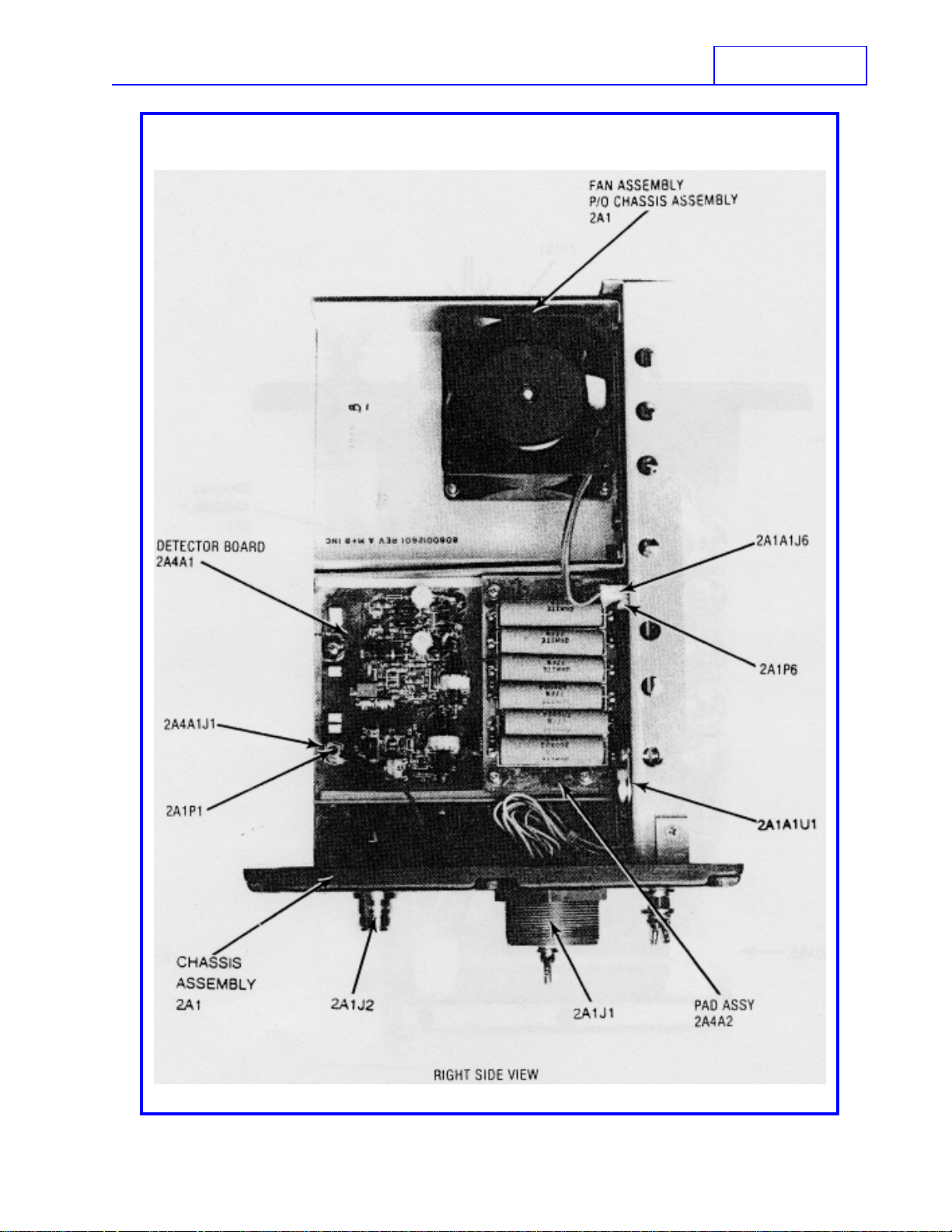

5.8 Major Assembly and Component Locations

(Right Side View). 5-15

v

SUNAIR CU-9125

LISTING of FIGURES (Cont...)

Section Description Page

5.9 Major Assembly and Component Locations

(Left Side View). 5-16

5.10 Front Panel Wiring Diagram. 5-17

5.11 Motherboard Assembly 2A1A1, page 1 of 3. 5-47

5.11 Motherboard Assembly 2A1A1, page 2 of 3. 5-48

5.11 Motherboard Assembly 2A1A1, page 3 of 3. 5-49

5.12 Input Board 2A2A1, page 1 of 2. 5-50

5.12 Input Board 2A2A1, page 2 of 2. 5-51

5.13 Intermediate Board 2A2A2, page 1 of 2. 5-52

5.13 Intermediate Board 2A2A2, page 2 of 2. 5-53

5.14 Inductor Board 2A2A3, page 1 of 2. 5-54

5.14 Inductor Board 2A2A3, page 2 of 2. 5-55

5.15 Output Board 2A2A4, page 1 of 2. 5-56

5.15 Output Board 2A2A4, page 2 of 2. 5-57

5.16 Computer Board Assembly 2A3, page 1 of 6. 5-58

5.16 Computer Board Assembly 2A3, page 2 of 6. 5-59

5.16 Computer Board Assembly 2A3, page 3 of 6. 5-60

5.16 Computer Board Assembly 2A3, page 4 of 6. 5-61

5.16 Computer Board Assembly 2A3, page 5 of 6. 5-62

5.16 Computer Board Assembly 2A3, page 6 of 6. 5-63

5.17 Detector/Relay Pad Assembly 2A4, page 1 of 2. 5-64

5.17 Detector/Relay Pad Assembly 2A4, page 2 of 2. 5-65

5.18 TS-100 Antenna Simulator Schematic. 5-66

vi

SUNAIR CU-9125

LISTING of TABLES

Section Description Page

IV THEORY OF OPERATION

4.1 Magnitude Discriminator Truth Table 4-8

4.2 Phase Discriminator Truth Table 4-8

4.3 Truth Table BCD Channels 00-09 4-9

V ALIGNMENT

5.1 Fault Analysis 5-11

5.2 Fault Analysis and Troubleshooting Computer Board 2A3 5-19

5.3 Table of Assemblies 5-44

5.4 Parts List of CU-9125 Major Assemblies 5-45

vii

SUNAIR CU-9125

TABLE of ABBREVIATIONS

ADDR Address

AGC Automatic Gain Control

ALC Automatic Level Control

AM Amplitude Modulation

AME Amplitude Modulation Equivalent

AMP/AMPL Amplifier

ARQ Automatic Request

AUD Audio

AUTO Automatic

AUX Auxiliary

BAUD A variable unit of data transmission speed (bits

per second)

BELL U.S. Telephone standards

BFO Beat Frequency Oscillator

BITE Built In Test Equipment

BRD Board

CH /CHAN /CHL/CHN Channel

CLR Clear

CMOS Complementary Metal Oxide Semiconductor

CPLR Coupler

CPU Computer

CW Carrier Wave

dB Decibel

dBm Decibels referred to 1 milliwatt across 600 ohms

DSBSC Double Sideband Suppressed Carrier

DSP Display

DUART Dual Asynchronous Receive/Transmit

EEPROM Electrically Erasable and Programmable Read

Only Memory

EPROM Electrically Programmable Read Only Memory

EMI Electromagnetic Radiation Interference

ENTR Enter

FAX Facsimile

FEC Forward Error Correction

FREQ Frequency

FSK Frequency Shift Keying

FWD Forward

GRP Group

HF High Frequency

Hz Hertz

IC Integrated Circuit

IF Intermediate Frequency

I/O Input/Output

IONCAP Ionospheric Communications Analysis

and Prediction

kHz Kilohertz

kW Kilowatt

ISB Independent Sideband

LCD Liquid Crystal Display

LCL Local

LED Light Emitting Diode

LK Link

LO Local Oscillator

LP/LPX Lincompex

LRU Lowest Repairable Unit

LSB Lower Sideband

LT Light

LVL Level

MAN Manual

M CH Manual Channel

MED Medium

MHz Megahertz

MIC Microphone

MIL-STD Military Standard

MNL Manual

ms Millisecond

MTTR Mean Time To Repair

MTR Meter

NAR Narrow

O.D. Olive Drab

PA Power Amplifier

PC Printed Circuit

PEP Peak Envelope Power

PLL Phase-Locked Loop

P/N Part Number

PNL Panel

POSTSL Post-Selector

PRESEL Pre-Selector

PTT Push-To-Talk

PWR Power

RCV/RX Receive

REFL Reflected

REV Revision

RF Radio Frequency

RFI Radio Frequency Interference

RFL Reflected

RMT Remote

RS232 Computer control, hardwired up to 50 feet maximum

RS422 Computer control, hardwired up to 4000 feet

maximum

RS485 Computer control, hardwired for multiple users

RTTY Radio Teletype

SEL Select

SLO Slow

S MTR Signal Strength Meter

SPKR Speaker

SPLX Simplex

SRAM Static Random Access Memory

SSB Single Sideband

TCXO Temperature Controlled Crystal Oscillator

TGC Transmit Gain Control

THD Total Harmonic Distortion

TTL Transistor Transistor Logic

TX/XMT Transmit

USB Upper Sideband

UTC Universal Time

VCO Voltage Controlled Oscillator

VHF Very High Frequency

VRMS Volts Root Mean Square

VSWR Voltage Standing Wave Ratio

W Watt

WPM Words Per Minute

* Asterisk indicates function selected

SUNAIR CU-9125

SECTION I

GENERAL INFORMATION

1.1 SCOPE

This manual contains information necessary to install, operate, maintain and repair the CU-9125 Automatic Digital

Antenna Coupler.

1.2 DESCRIPTION

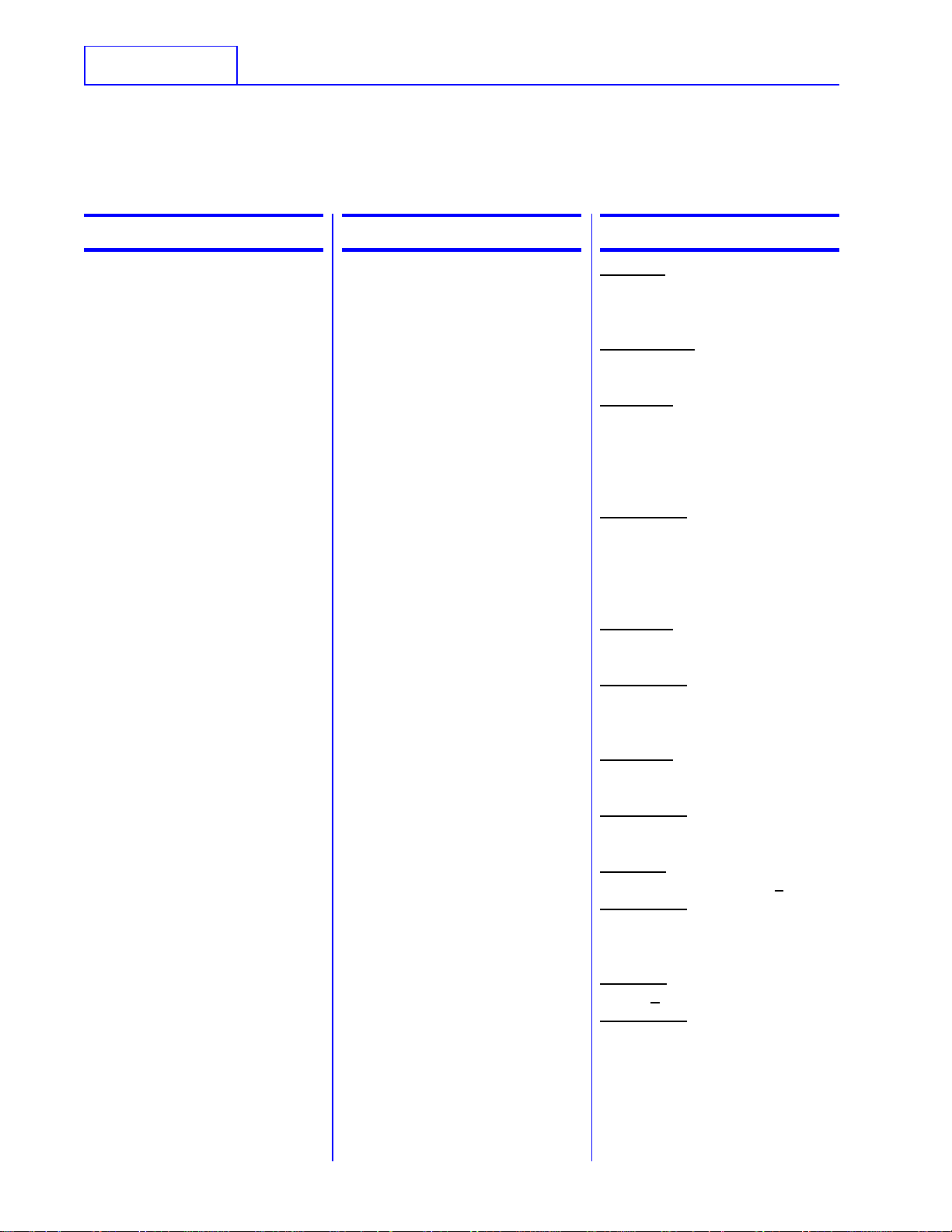

See Figure 1.1

1.2.1 GENERAL

The CU-9125 is a high quality remotely controlled antenna coupler capable of matching a wide variety of

antennas ranging from 9 ft. whips to 150 ft. longwires over the frequency range of 1.6000 to 29.9999 MHz. In

addition, the coupler may be used as a “line flattener” to correct the VSWR of resonant antennas.

The CU-9125 is designed to operate in conjunction with the Sunair 9000 Series Equipment utilizing Cable

Assembly p/n 8076004098 at separations of up to 250 feet. Manual tuning cycles are initiated by depressing

the “CPLR TUNE” pushbutton on the 9000 Series Transceiver or Exciter. Tuning status metering for indicating

forward and reflected power are located on the radio equipment. The coupler is mounted in a sturdy, fully

gasketed case designed for outside mounting near the antenna.

1.2.2 ASSEMBLIES

1.2.2.1 CHASSIS ASSEMBLY 2A1

The Chassis Assembly provides the required mounting surfaces for the various electrical and mechanical

components. The Motherboard 2A1A1 serves as the interconnect for all assemblies.

1.2.2.2 RF ASSEMBLY 2A2

The four (4) boards comprising the RF Assembly are the Input Board 2A2A1, the Intermediate Board 2A2A2,

the Inductor Board 2A2A3 and the Output Board 2A2A4. The boards contain all of the variable binary elements

in the antenna matching network.

1.2.2.3 COMPUTER BOARD 2A3

This assembly contains the microprocessor responsible for the operation and functions of the CU-9125.

1.2.2.4 DETECTOR/PAD ASSEMBLY 2A4

The Detector Assembly 2A4A1 contains the magnitude, phase and VSWR detectors. The Pad Assembly

2A4A2 plugs into the Detector Assembly and protects the Transceiver/Exciter from impedance variations during

the tuning cycle.

1-1

SUNAIR CU-9125

OUTPUT BOARD

2A2A4

INDUCTOR BOARD

2A2A3

DETECTOR/PAD ASSEMBLY

2A4

TOP VIEW W/O COVER

INTERMEDIATE BOARD

2A2A2

INPUT BOARD

2A2A1

FAN ASSEMBLY

P/0 CHASSIS ASSEMBLY

2A1

1-2

MOTHERBOARD

2A1A1

COMPUTER BOARD

2A3

BOTTOM VIEW W/O COVER

Figure 1.1 CU-9125 Major Assembly Locations.

SUNAIR CU-9125

1.3 SPECIFICATIONS

1.3.1 GENERAL

FREQUENCY RANGE: 1.6 to 30 MHz.

TUNING CAPABILITIES: 9 ft. whips

16 ft. whips

23 ft. whips

35 ft. whips

50 ft. to 150 ft. longwires

suitable as a line flattener for broadband antennas

RF INPUT POWER: 150 Watts PEP and AVERAGE.

INPUT IMPEDANCE: 50 Ohms, non-reactive.

DUTY CYCLE: Continuous for antennas 23 feet and longer. Fifty percent (maximum 5 minutes

continuous key down time) for 9 and 16 ft. antennas.

TUNING TIME: Memory Tuning - 10 milliseconds or less.

Non-Memory Tuning: - Typical: 1 second.

Maximum: 10 seconds.

Memory: Non volatile, 128 channels (00 - 127).

TUNE POWER REQUIRED: 25 Watts RF delivered.

TUNE ACCURACY: 1.5:1 VSWR maximum.

REMOTE CAPABILITY: Up to 250 ft. from Transceiver/Exciter.

POWER INPUT: +28 VDC from Transceiver/Exciter, 1 Amp maximum.

WEIGHT: 23 lbs (10.35 kgs).

DIMENSIONS: (Inches) 9.1H X 9.6W X 11.4D.

(CM) 23.1H X 24.4W X 28.96D.

1-3

SUNAIR CU-9125

1.3.2 ENVIRONMENTAL

TEMPERATURE: Operating: -30oC to +65oC.

Storage: -50oC to +85oC.

HUMIDITY: MIL-STD 810C, Method 507.1, Procedure II.

SHOCK: MIL-STD-810C, Method 516.2, Proc I, Figure 516.2-2, Ampl. b (20 g.), Dur.d.

VIBRATION:MIL-STD-810C, Method 514.2 equipment category f, Table 514.2-VI for wheeled vehicles, Figure

514.2-6, curve V.

DUST: MIL-STD-810C, Method 510.1, Procedure I.

RAIN: MIL-STD-810C, Method 506.1, Procedure I.

PACKAGING: Rain tight, for exposed installations.

1.4 EQUIPMENT SUPPLIED

Automatic Digital Antenna Coupler, CU-9125,

Connector Kit,

Operation and Maintenance Manual,

1.5 EQUIPMENT REQUIRED BUT NOT SUPPLIED

Control Cable Assembly:

Order by length desired. The Coupler will operate with up

to 250 ft. of remote control cable.

Cable, Control. Specify length.

Cable, Coaxial, RG-58A/U:

Recommended where separation between Transceiver/

Exciter and Coupler is less than 100 ft. Specify length.

Cable, Coaxial, RG-8/U:

Recommended where separation between Transceiver/

Exciter and Coupler exceeds 100 ft. Specify length.

SUNAIR PART NUMBER

8085000253 Grey

8085000296 Olive Drab

6035002099

8085000709

8076004195

0588680001

0588130001

0588640000

1-4

Cable, Coaxial, RG-213:

Same as RG-8/U.

Connector, RF, PL-259:

Mates with antenna connector J4 on 9000 Series.

1010770021

0742190005

1.6 OPTIONAL EQUIPMENT NOT SUPPLIED

SUNAIR CU-9125

Transceiver/Exciter

Shockmount Kit - CU-9125

PC Assy, Extender CU-9125

Depot Spare Parts Kit

Field Module Kit

PC Assy, Detector Extender Board

Antenna Simulator Model TS-100

Consult Sunair Marketing Dept.

8080000492

8080002096

8085900092

8085902095

8085165091

8084001094

1-5

SUNAIR CU-9125

THIS PAGE INTENTIONALLY LEFT BLANK.

1-6

SUNAIR CU-9125

SECTION II

INSTALLATION

2.1 GENERAL

Section II contains all necessary instructions for the unpacking, inspection, and if necessary, reshipping of

damaged equipment or parts. In addition, further information regarding location and mounting considerations,

power requirements, antenna and ground system hook-ups and final checkouts after installation is also provided.

2.2 UNPACKING AND INSPECTION

As soon as you have received your unit(s), unpack and inspect all components and accessories. Check the packing

list to be sure you have received all items ordered and that all items necessary for operation have been ordered.

NOTE: Be sure to retain the carton and its associated packing materials

should it be necessary to reship damaged equipment.

Do not accept a shipment when there are visible signs of damage to the cartons until a complete inspection is made.

If there is a shortage of items or any evidence of damage, insist on a notation to that effect on the shipping papers

before signing the receipt from the carrier. If concealed damage is discovered after the shipment has been

accepted, notify the carrier immediately in writing and await his inspection before making any disposition of the

shipment. A full report of the damage should also be forwarded to Sunair’s Product Services Department. Include

the following:

a) Order Number

b) Model and Serial Number

c) Name of Transportation Agency

d) Applicable dates.

When Sunair receives this information, arrangements will be made for repair or replacement.

2.3 RETURN OF EQUIPMENT TO FACTORY

The shipping container for the CU-9125 has been carefully designed to protect the equipment during shipment. The

container and its associated packing materials should be used to reship the unit. When necessary to return

equipment to Sunair for warranty or non-warranty repair, an authorization number is required. This number can

be obtained from our Product Services Department, Telephone: (954)-525-1505, FAX: (954)-765-1322.

If the original shipping carton is not available, be sure to carefully pack each unit separately, using suitable

cushioning material where necessary. Very special attention should be given to providing enough packing material

around connectors and other protrusions from the coupler. Rigid cardboard should be placed at the corners of the

equipment to protect against denting.

When returning subassemblies or components for repair or replacement, be sure to pack each item separately,

using suitable cushioning material.

2-1

SUNAIR CU-9125

Shipment to be made prepaid consigned to:

Sunair Electronics, Inc.

Product Services Department

3101 SW Third Avenue

Ft. Lauderdale, Florida 33315-3389

U.S.A.

Plainly mark with indelible ink all mailing documents as follows:

U.S. Goods Returned For Repair

Value For Customs - $100.00

Mark ALL SIDES of the package:

FRAGILE - ELECTRONIC EQUIPMENT!

NOTE: Before shipping, carefully inspect the package to be sure it is marked

properly and is securely wrapped.

2.4 POWER REQUIREMENTS

All power necessary to operate the CU-9125 Automatic Digital Antenna Coupler is supplied from a companion

Exciter/Transceiver via the Control Cable Assembly. See Figure 2.8 for control cable connections. If an Exciter/

Transceiver other than a Sunair model is used, an external power source of +28VDC at 1.0 amp is required to power

the CU-9125.

2.5 INSTALLATION CONSIDERATIONS AND MOUNTING INFORMATION

The satisfactory operation of the equipment will depend upon the care and thoroughness taken during the

installation.

IMPORTANT INSTRUCTIONS

2.5.1 GENERAL INSTALLATION PROCEDURES AND REQUIREMENTS

1. Carefully plan radio/coupler/antenna locations, observing the following requirements before starting

installation.

2. Provide best possible RF ground for radio and coupler. Use flat copper strap 1" wide or #6 (or larger) wire

and connect to the ground terminal at rear of radio. Leads to ground system should be as short as possible.

3. Provide the maximum separation between coupler output and the radio with its associated wiring. Coupler

may be mounted up to 100 feet from radio when RG-58 is used, and up to 250 feet from radio when RG-8 or

RG-213 is used.

4. The antenna lead from the coupler to antenna must be insulated for at least 10 kv potential. The lead should

not run parallel to metal objects that are bonded to the system ground. The coupler should be as close to the

antenna as possible, and never more than three (3) feet away as this will decrease antenna efficiency.

5. If the coupler is installed on a wood or fiberglass boat, a 12 square foot minimum area of metal surface

area in contact with the water should be provided for use as an RF ground.

2-2

SUNAIR CU-9125

6. If operating the coupler on external DC power, check for correct polarity before applying power.

7. The installation should be carefully planned beforehand in accordance with drawings on the following

pages.

8. Linear amplifiers with low level modulation such as used in Sunair Exciters/Transceivers will oscillate if the

RF power output is radiated or conducted into the low level stages. Evidence of this situation is erratic or

excessive power output. This is caused by too close proximity of the coupler output and antenna to the

Transceiver/Exciter and/or inadequate RF grounds. Carefully following the above procedures will prevent this

from occurring.

2.5.2 MOUNTING CONSIDERATIONS

See Figure 2.1 for Coupler dimensions.

2.5.2.1 BASE STATION INSTALLATION

A typical base installation consisting of an RT-9000 and a CU-9125 is shown in Figure 2.3. (Consult the RT-

9000 Operation and Maintenance Manual, p/n 8076000505, for installation details for the Transceiver.) The

CU-9125 can also be used with the T-9400 HF/ISB Exciter. (Consult the T-9400 HF/ISB Exciter Operation

and Maintenance Manual, p/n 8103000507, for installation details.) Refer to Section 2.6 for recommendations

for suitable antennas.

2.5.2.2 VEHICULAR INSTALLATION

Figure 2.4 shows a typical vehicular installation with an RT-9000 Transceiver and shockmount assembly.

NOTE: Shockmounting is required only in severe shock or vibration

environments exceeding those noted in Section 1.3.2. See

Figure 2.2 for installation.

See Section 2.6 for specific antenna recommendations. In order to minimize RF pickup, it is important that the

ground straps supplied with the shockmount, if used, be securely fastened between the ground post on the radio

and the bottom of the right rear shock isolator. (Consult the RT-9000 manual for further details.)

2.5.2.3 MARINE INSTALLATION

In marine installations, follow the same recommendations as outlined in paragraph 2.5.2.2 above. If the radio

is installed in a wood or fiberglass boat, a ground plate of 12 square foot minimum area in contact with the water

should be installed. A heavy ground lead such as 1 inch wide strap or braid should be connected between the

ground post on the radio and the ground plate. The length of this ground lead should be held to an absolute

minimum commensurate with a neat installation.

2-3

SUNAIR CU-9125

2-4

Figure 2.1 Outline Mounting Details CU-9125.

SUNAIR CU-9125

Figure 2.2 Shockmount Installation.

2-5

SUNAIR CU-9125

2-6

Figure 2.3 Typical Base Station Installation Using Non-Resonant Antennas.

SUNAIR CU-9125

Figure 2.4 Typical Vehicular Installation.

2-7

SUNAIR CU-9125

2-8

IMPORTANT NOTE:

In some installations, it may be necessary to install the CU-9125 adjacent to the

radio. Grounding is extremely important to prevent RF from feeding back into the

radio. The CU-9125 should be grounded to the front ground strap, as shown

above. In addition, the ground braid used on the rear of the radio should be as

short as possible. The interconnecting cable from the radio to the CU-9125

should be as short as possible and should not be routed under the antenna feed

wire.

Figure 2.5 Coupler Grounding.

SUNAIR CU-9125

2.6 ANTENNAS AND GROUND SYSTEMS

2.6.1 GENERAL

Sunair Exciters/Transceivers are designed to operate into a 50 Ohm resistive antenna system with a maximum

voltage standing wave ratio (VSWR) of 2:1. When used with the CU-9125 Automatic Digital Antenna Coupler

the system will match antennas ranging from 9 foot whips to 150 foot longwires. Although the CU-9125 will match

9 foot whips down to 1.6 MHz, use of a 9 foot whip is not recommended for low frequency use due to poor

radiation efficiency. The CU-9125 is unique in that it can be placed close to the antenna and controlled from the

front panel of the Exciter/Transceiver. This optimizes both operator convenience and electrical performance.

As there are numerous types of antennas, a complete discussion is beyond the scope of this manual. Antennas

requiring an antenna coupler for use in the 1.6 to 30 MHz spectrum generally fall into two categories:

a) Narrow Band 50 Ohm Antennas

b) Random length non-resonant Antennas.

Antennas falling into each of the above mentioned categories are discussed in this section. For specific

recommendations, consult our Marketing and Product Support Departments.

Some general DOs and DON'Ts of antenna installation are listed below:

a) The antenna should be clear of all large objects such as trees and buildings.

b) Although the coupler will match electrically short antennas (i.e. those under 1/8 wavelength), such

antennas are not efficient radiators. If the installation permits, antennas over 1/8 wavelength long at the lowest

operating frequency should be used. Antenna length generally limits system performance in vehicular

applications at frequencies below 10 MHz as the size would be prohibitive.

c) When using whip antennas, the ground system actually forms part of the radiating system. Where space

permits (such as in a base station installation) a good ground plane or radial system should be installed at the

base of the antenna. (See Figure 2.6)

NOTE: An inadequate ground system is most often responsible for

disappointing performance when using a whip antenna.

2.6.2 NARROW BAND 50 OHM ANTENNAS

Typical of this type of antenna is the Inverted V illustrated in Figure 2.7. This type of antenna may be assembled

from the Sunair Doublet Antenna Kit (p/n 0996240004). Its operation is efficient for only a narrow band of

frequencies within approximately 2½% of their center frequency. The antenna coupler is NOT generally

required if the above frequency span is not exceeded. Separate antennas must be erected for each small band

of frequencies to be used. The antenna exhibits somewhat directional characteristics. The direction of

maximum radiation is perpendicular to the antenna wire. This antenna is particularly suitable for communication

with nearby mobile stations (with vertical antennas) since a portion of the radiation is in a vertical direction.

2-9

SUNAIR CU-9125

2.6.3 RANDOM LENGTH NON-RESONANT ANTENNAS

Whips and longwires are popular non-resonant antennas. The whip antenna (illustrated in Figure 2.6), is often

used in mobile, marine, portable or semi-portable installations because it is rugged and self- supporting. The

antenna impedance is strongly dependent on the operating frequency, and an antenna coupler, therefore, must

be used to match the antenna to the Transceiver/Exciter. Best radiation efficiency will be obtained if the antenna

is at least 1/8 wavelength long at the lowest operating frequency; however, this requirement does not result in

a practical size antenna for low frequency operation. Thirty-five foot whip antennas offer a good compromise

between practical height and good electrical performance at low frequencies. The antenna coupler is designed

to efficiently match whip antennas of 15 foot length or greater. An efficient match may also be obtained for a

9 foot whip above 4 MHz. The whip’s performance is greatly influenced by its ground system. For temporary

base station installations, a minimum of four six-foot long ground rods should be driven into the ground

symmetrically placed around the antenna base. The rods should be bonded together with heavy strap and then

connected to the antenna coupler ground by another short heavy strap. If the antenna is mounted on the roof

of a building where a short ground lead to coupler cannot be obtained, a minimum of four symmetrically placed

ground radials should be installed at the base of the antenna, bonded together, and connected to the antenna

coupler ground post. The radials should be made of number 12 gauge wire or larger and should be at least ¼

wave long at the lowest operating frequency. (Radial length in feet = 246/frequency in MHz.) The whip’s

radiation pattern is omni-directional in the azimuthal plane.

The longwire antenna, illustrated in Figure 2.8, is a popular base station antenna where a wide range of operating

frequencies are used. The antenna impedance varies greatly with frequency and, therefore, must be matched

to the transmitter with the antenna coupler. The CU-9125 Antenna Coupler will efficiently match longwire

antennas up to 150 foot in length. The radiation pattern of the longwire antenna is also a strong function of

operating frequency. The two most popular longwire antennas, (75 and 150 foot) available from Sunair, exhibit

excellent low frequency radiation efficiency.

2-10

Figure 2.6 Whip Antenna.

SUNAIR CU-9125

Figure 2.7 Inverted ‘V’ Antenna.

Figure 2.8 Long Wire Antenna.

2-11

SUNAIR CU-9125

2.7 CONSTRUCTION OF CONTROL CABLE ASSEMBLY 8076004195

It is recommended that the control cable assembly be procured from Sunair. However, if necessary, the cable may

be made from individual wires of #20 AWG with an overall braided shield and PVC jacket.

The control cable assembly may be shipped from the factory without connectors attached to facilitate the routing

of this cable through walls, bulkheads, conduit, etc. After installing the cable, follow the procedure outlined below.

NOTE: The connector with the male pins (1011130009) should be wired at

the transceiver end of the cable.

The connector with female pins (0747690008) should be wired at the

coupler end of the cable. Refer to Figure 2.8

1. Loosen both screws on one of the cable clamps.

2. Insert the rubber telescoping bushing (boot) through the rubber grommet on the inside of the cable clamp

and push through until the lip on the boot bottoms on the rubber grommet. The boot should extend beyond the

cable clamp.

3. Insert the cable (0588680001) into the open end of the boot and cable clamp and pull through until

approximately six inches of cable extends from the inside of the cable clamp.

4. Carefully remove approximately 1½ inches of the plastic outer jacket of the remote control cable using a

knife or razor blade. Use care so as not to damage the shield or inner conductors.

5. Carefully unbraid the cable shield to within approximately ¼ inch of the outer jacket. Carefully cut the

unbraided shield wires at this point using a pair of small wire cutters.

6. Remove approximately one inch of insulation from the end of a three-inch piece of #22 gauge hook-up wire.

Wrap the wire around the outer jacket and solder the connection using a medium-size soldering iron. Attach

a #8 solder lug to the other end of the wire, after pulling the wire back through the telescoping bushing.

7. Note the mylar sleeve over the wire bundle. Carefully cut this sleeve, being careful not to nick the wires

in the bundle, until the wire bundle is exposed back to the end of the shield.

8. Flare out the bundle of wires and separate the individual wires. Strip approximately 1/8 inch of insulation

from each wire.

9. Choose one of the wires and carefully tin it. Solder the wire to one of the cups of the connector. Make a

chart showing the wire color code and pin connection.

10. Proceed in a similar manner until all required wires are installed.

11. When all connections are completed, screw the rear shell and cable clamp assembly on the connector and

tighten. Push a small additional amount of cable into the connector to ensure some slack. Remove one cable

clamp screw and insert the lug on the #22 shield wire. Reinsert screw into cable clamp. Tighten the two screws

on the cable clamp.

12. Follow an identical procedure to connect the other end of the cable to the proper pin as shown in Figure

2.9.

2-12

SUNAIR CU-9125

WARNING: Connectors installed by the customer must be wired in accordance

with the instructions provided in this section. The cable MUST BE continuity

checked after connector installation and prior to system power up.

Figure 2.9 Wiring Diagram, Control Cable Assembly (8076004195).

2-13

SUNAIR CU-9125

2.8 CHECKS AFTER INSTALLATION

9000 Series Exciters/Transceivers

1. Select a frequency in the 2 to 3 MHz range (or a frequency you are allowed to use).

2. Upon initial power on, the LCD will display function and status of the radio. An alternating ‘Coupler Untuned’

message will appear on the screen.

3. Depress the ‘CPLR TUNE’ pushbutton.

4. While coupler is tuning, screen will display ‘Coupler Tuning’.

5. When a successful tune has been completed (1-2 seconds), screen will display ‘System Ready’ and then

return to normal display status. If a ‘System Fault’ or ‘Coupler Fault’ message is displayed see section 3.1.

2-14

SUNAIR CU-9125

SECTION III

OPERATION

3.1 ANTENNA COUPLER TUNING

Once an operating frequency has been selected the exciter or transmitter section of the Transceiver is

automatically tuned to the same frequency (Simplex Operation). If the Transceiver/Exciter output is fed to an

Antenna Coupler (CU-9125), depression of the ‘CPLR TUNE’ key, will initiate the tune cycle. During this time

(a few seconds or less), the message

’COUPLER TUNING‘

will appear on the Status Display Screen. When coupler tuning has been completed, the message

‘SYSTEM READY’

will appear on the Status Display Screen.

THE TRANSCEIVER/EXCITER IS NOW FULLY OPERATIONAL

NOTE: If there is no antenna coupler in the system, depression of the ‘CPLR

TUNE’ key will produce the message

‘NO ANTENNA COUPLER’

on the Operational Display Screen.

NOTE: If the coupler is unable to tune the antenna within 10 seconds, the

message

‘SYSTEM FAULT’

will appear on the Status Display Screen. If this occurs, check the

installation and the antenna. If all appears in order, proceed to the

troubleshooting section of the coupler manual.

NOTE: If the coupler remains in the tune mode for longer than 10 seconds

the message

‘COUPLER FAULT’

will appear on the Status Display Screen. If this occurs, proceed to

the troubleshooting section of the coupler manual.

3-1

SUNAIR CU-9125

THIS PAGE INTENTIONALLY LEFT BLANK.

3-2

SUNAIR CU-9125

SECTION IV

THEORY OF OPERATION

4.1 GENERAL

The CU-9125 is a fully automatic digital antenna coupler designed for use with Sunair 9000 series equipment or

their equivalent. The coupler is rated for 125 Watts PEP or average power, and will tune all common vehicular and

ground based antenna systems 9 feet and longer. (For antennas shorter than 23 feet, duty cycle is limited to 5

minutes transmit, 5 minutes receive.) The tune command is generated by the Sunair 9000 series equipment with

the depression of the ‘CPLR TUNE’ pushbutton. Completion of a successful tune is indicated by an LCD message

on the front panel of the Sunair 9000 series equipment.

Memory is provided within the coupler for 128 channels to use with Transceivers/Exciters such as the RT-9000

Transceiver or the T-9400 Exciter that provide channel information to the coupler. This memory will be retained

in the coupler for a minimum power off period of ten years.

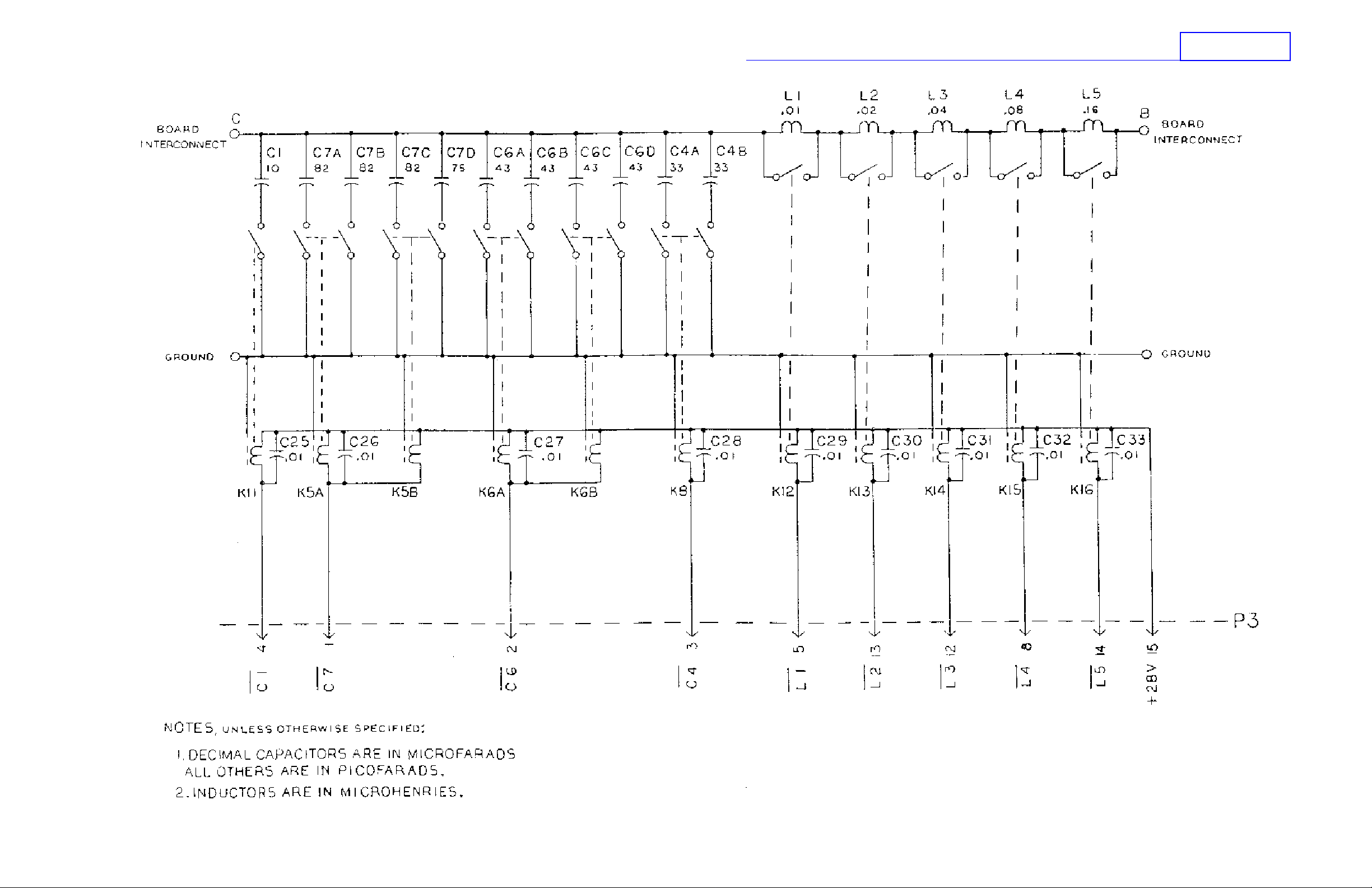

4.2 ANTENNA TUNING NETWORK

The antenna tuning network is basically an ‘L’ low pass circuit with additional shunt output capacitance, where

required, to transform the network into a ‘PI’. An additional capacitor is provided at the output of the network to allow

tuning of inductive antennas. A block diagram of the CU-9125 is shown in Figure 4.1.

The input capacitor bank, located on the Input Board 2A2A1, Figure 5.12, and the Intermediate Board 2A2A2,

Figure 5.13, consists of C1 through C11, and provides binary stepped values from 0 to 10293 picofarad (pF) steps.

The series inductor bank, located on the Intermediate Board, Inductor Board 2A2A3, Figure 5.14, and the Output

Board 2A2A4, Figure 5.15, and consisting of L1 through L11 and C12, provides binary stepped values from 0 to

21.8 microhenry (µH) steps. C12 is used at the higher frequencies to cancel out the coupler stray inductance. The

output capacitor bank, located on the Output Board 2A2A4, consisting of C13 through C16, provides binary stepped

values from 0 through 750 pF. The series phase correcting capacitor C17, is located on the Output Board.

Refer to page 4-2 for Figure 4.1; CU-9125, Antenna Coupler, Block Diagram.

4.3 DETECTOR/PAD ASSEMBLY (2A4)

Refer to Figure 5.17 Detector/Relay Pad Assembly (2A4) Schematic.

4-1

SUNAIR CU-9125

4-2

Figure 4.1 CU-9125, Antenna Coupler, Block Diagram.

SUNAIR CU-9125

4.3.1 GENERAL

The Detector/Pad Assembly contains the magnitude discriminator, the phase discriminator, the forward and

reflected power detectors, the resistive pad network, the pad relay, and the tune relay.

4.3.2 MAGNITUDE DISCRIMINATOR

The magnitude discriminator consists of T1 and its associated components. It provides a means of measuring

the relative magnitude of the transformed antenna impedance relative to 50 Ohms. For a magnitude greater

than 50 Ohms, the magnitude discriminator produces an output voltage less than the +5 VDC reference

voltage. For a magnitude less than 50 Ohms, an output greater than +5 VDC reference is produced. A voltage

sample is provided from the transmission line by L1, C2, C3 and is rectified by CR2 to give a DC voltage

proportional to the RF voltage on the line. A voltage proportional to the current in the transmission line is

generated by transformer T1 and is rectified by CR3. Capacitor C2 is adjusted so that the voltage sample is

exactly equal to the current sample when the transmission line is terminated with 50 Ohms resistance. The

output of this discriminator is fed to differential amplifier U17B on the Computer Board Assembly 2A3, Figure

5.16. Note that the output of the magnitude discriminator is floating and is referenced to +5 VDC, not ground.

So all measurements of the magnitude detector must be referenced to +5 VDC.

4.3.3 PHASE DISCRIMINATOR

The phase discriminator consists of transformer T2 and its associated components. It provides a means of

measuring the relative phase angle at the input to the tuning network by comparing the phase of the line voltage

with that of the line current. The discriminator output is zero when the transmission line voltage and current

samples are in phase (pure resistance terminating the transmission line). The voltage sample is derived by C13,

R10, C7, which shifts it in phase by 90o. The current sample is generated by transformer T2 and is in phase

with the line current. The voltage sample is fed to T2 center tap, and the resulting output is detected by CR4,

CR5 to produce a DC voltage proportional to the phase difference between the voltage on the transmission line

and the current in the line. R12 is the phase discriminator balance control and is adjusted so the phase output

is nulled (relative to +5 VDC) when the transmission line is terminated with a 50 Ohm non-inductive load.

The sensing of the phase discriminator is established to provide a positive output for inductive loads (positive

phase angle) and a negative output for capacitive loads (negative phase angle). The output of this discriminator

is fed to differential amplifier U17A on the Computer Board Assembly 2A3.

4.3.4 FORWARD AND REFLECTED POWER DETECTOR

The forward and reflected power detector consists of T3 and its associated components. The reflected power

voltage sample obtained from C14, C15 is combined with the current sample obtained from T3, at CR6 to

provide a DC voltage proportional to reflected RF power on the transmission line. This detector compares both

phase and magnitude of the voltage and current samples. Its output is always one polarity, i.e., positive with

respect to ground, and is a minimum when the coupler network has tuned the antenna to provide a 50

Ohm resistive load to the transceiver/exciter. C14 provides an adjustment to null the output when the

transmission line is terminated with a 50 Ohm, non-reactive load.

4-3

SUNAIR CU-9125

The forward power voltage sample from C19, C17 is combined with the current sample from T3 at CR7 to

provide a DC voltage proportional to forward power on the transmission line. It operates in much the same

way as the reflected power detector, and its output is also positive with respect to ground, but maximum when

the transmission line is terminated with a 50 Ohm, non-reactive load.

This output is used for (2) two functions:

1 - to tell the microprocessor when RF energy is present, and

2 - to provide a reference against which the reflected power is compared for the calculation of VSWR. The

VSWR is used as an indication of the quality of the tune, and is acceptable for values of 2:1 or better.

4.3.5 6 dB ATTENUATOR PAD ASSEMBLY

The 6 dB attenuator consists of R1 through R6 and relay K1 and associated circuitry. It is switched between

the coupler tuning network and the Transceiver/Exciter whenever the VSWR is greater than 2:1, and the

Transceiver/Exciter is keyed. The pad provides protection for the Transceiver/Exciter by limiting the impedance

variations placed on the Transceiver/Exciter during the tuning cycle. When a satisfactory tune has been

accomplished, the pad is switched out of the circuit, allowing full transmit power to reach the antenna.

The Resistive Pad Subassembly 2A4A2, resistors R1 through R6, plugs into the Detector Board 2A4A1 to make

up the Detector/Pad Assembly 2A4.

4.3.6 TUNE RELAY

The tune relay K2, is energized by the microprocessor following receipt of a tune command from the

Transceiver/Exciter, and supplies a +28 VDC signal to the Transceiver/Exciter. This ‘Tune Enable’ signal is

used in the transceiver/exciter to supply AM carrier for coupler tuning. When the tune cycle has been terminated,

the tune relay is de-energized allowing normal keyline operation.

4.4 COMPUTER BOARD ASSEMBLY WITH SLEEP CIRCUIT

Refer to Figure 5.16.

4.4.1 GENERAL

The Computer Board 2A3 combines the analog interface circuitry used to process the detector outputs for use

by the microprocessor U1, with the microprocessor computer circuitry. The analog circuits are located on the

left side of the board and consist of integrated circuits U17 through U22, U27, Q1, Q2, and their associated

circuitry.

4-4

SUNAIR CU-9125

4.4.2 PHASE DISCRIMINATOR INTERFACE

The phase discriminator interface consists of U17A, U18A, U18B, U20A and U20B. The phase discriminator

output is compared with the +5 VDC reference voltage for magnitude and polarity in U17A. Potentiometer R6

and R61 determine the width of the output threshold ‘window’. This window is adjusted to provide an output

whenever the phase exceeds plus or minus 20 degrees. If the phase is positive and greater than 20

degrees, the discriminator output is positive, U17A output is positive, U18A output is positive, and U20A output

is negative (ground), so a Low signal is sent to U5, RAM/IO/TIMER, on the PHASE > +20o line. Similarly, if the

phase is negative and less than 20 degrees, an output from U17A, U18B, and U20B sends a Low signal to U5

on the PHASE < -20o line. Comparators U18A and U18B are used in conjunction with Schmitt triggers U20A

and U20B to provide a toggle action to the phase commands, stabilizing the threshold limits. When the detected

phase angle is within ± 20o of 0o, both the PHASE > +20o and PHASE < -20o lines are High, indicating to the

microprocessor that the phase angle is within an acceptable ‘window’.

4.4.3 MAGNITUDE DISCRIMINATOR INTERFACE

The magnitude discriminator interface consists of U17B, U18C, U18D, U20C and U20D. The discriminator

output is compared with the +5 VDC reference for magnitude and polarity, in U17B. Potentiometer R19 and

R66 set the width of the magnitude window relative to 50 Ohms. The window is set to provide an output whenever

the magnitude is greater than 60 Ohms or less than 40 Ohms. If the magnitude is greater than 60 Ohms,

the discriminator output is negative, U17B output is negative, U18D output is positive and U20D output is

negative, giving a Low on the MAG >60 Ohm line to U5. The unaffected comparator, U18C in this case, provides

a Low output to U20C, which in turn supplies a High to the MAG <40 Ohm line. This way, only one output at

a time may be Low, but both may be High, indicating to U5 that the magnitude is within an acceptable ‘window’.

For magnitudes less than 40 Ohms, operation is similar to that described above, supplying a Low from U20C

to the MAG <40 Ohm line to U5.

4.4.4 ‘RF PRESENT’ DETECTOR

Transistor Q2 acts as a switch to provide a Low to microprocessor U1 on pin 5, whenever RF power is present

at the coupler input. The transistor is turned on by a DC voltage from the forward RF power detector on the

Detector/Pad Assembly 2A4. In order for U1 to continue its tuning program, the RF line must be held at a Low.

4.4.5 VSWR COMPARATOR

Comparator U19A compares the relative magnitude of the forward and reflected power detectors to compute

the VSWR. Potentiometer R43 will make this occur whenever the VSWR exceeds 2:1. Diode CR7 provides

a reference to keep the VSWR line High between transmit speech pauses. Diode CR8 isolates the base circuit

of Q2 from the voltage supplied by CR7. Diode CR16 isolates the reflected power detector on the Detector/Pad

Assembly 2A4 from voltages generated by U19A circuitry.

U19C, U20F, U27C and U27D provide a High to microprocessor U1 on pin 9 when VSWR exceeds 2:1, U1 pin

9 is an interrupt input. This High awakens U1, permitting it to initiate a tune cycle to reduce the VSWR to an

acceptable level. Normally U1 sleeps, keeping its DATA BUS and ADDRESS BUS quiet to eliminate any

possible radiated BUS noise.

4-5

SUNAIR CU-9125

4.4.6 REFLECTED POWER METER DRIVER

U19B is used as a current source with a voltage gain of one to drive the Transceiver/Exciter meter proportionally

to reflected power level.

4.4.7 REFERENCE VOLTAGE SOURCES

Voltage regulator U22 provides +10 VDC at TP1. Voltage divider R28 & R29 provides +5 VDC at TP2. These

two voltages are used by the operational amplifiers and voltage comparators. Since plus and minus sensing

is required, the reference ‘ground’ for U17A and U17B is established at +5 VDC. U18A, U18B, U18C, and U18D

can compare the outputs of U17A and U17B to voltage thresholds set just above and below +5 VDC.

Zener Diode CR10 drops the voltage to the regulator from the supplied +28 VDC, to minimize power dissipation

in the regulator.

4.4.8 TUNE RELAY LATCH

Transistor Q1 is used to provide a ground to the tune relay K2 on the Detector/Pad Assembly 2A4, energizing

the relay and starting the tune cycle. A positive pulse turns Q1 on, pulling in the tune relay, and awakening

microprocessor U1 to begin a tuning cycle. The microprocessor then sends a positive voltage back called TUNE

LATCH to the base of Q1, keeping it on and the tune relay latched during the tune cycle. When the tune cycle

is terminated, the voltage from the base is removed, Q1 no longer conducts, and the tune relay is deenergized.

4.4.9 MICROPROCESSOR CIRCUITS

4.4.9.1 GENERAL

The microprocessor circuit portion of the Computer Board is the ‘brain’ of the CU-9125. Here, all appropriate

signals are monitored, decisions are made, and control commands are generated for controlling the capacitor

and inductor steps. An algorithm, which determines the process by which the coupler elements are

manipulated, to achieve the proper transformation of the antenna impedance to 50 Ohms resistive, is resident

in the EPROM memory. Included in this section are the microprocessor U1, the address decoder U2 and U8,

the address latch U3, the EPROM U4, the RAM/IO/TIMER U5, the output ports U6, U7, and U15, element drivers

U9, U10, U11, U12, U13, storage memory EEPROM U14 and input buffer U16.

4.4.9.2 MICROPROCESSOR U1

The microprocessor U1 performs all of the required calculations from the information it receives from the

discriminator and detectors, interrogates the program memory to determine the next logical step to take, and

tells the element drivers which elements to connect in the RF circuit. When an acceptable tune condition has

been found, i.e., both phase and magnitude signals are in their respective ‘windows’, U1 tells the pad and tune

relays to drop out. U1 then stops all BUS activity and goes to sleep to eliminate any possible radiated BUS noise.

U1, while sleeping, continuously monitors the ‘CPLR TUNE’ pushbutton, a channel change, and a VSWR fault

condition. Any one of these conditions awakens U1 to take the proper action before going back to sleep. If a

load cannot be tuned or a coupler failure occurs, a ‘CPLR FAULT’ indication will be displayed on the front panel

of the Transceiver/Exciter. The coupler is also placed in a bypass mode (straight connection between input and

the antenna), thus preventing loss of the receive path.

4-6

SUNAIR CU-9125

U23 establishes the clock frequency for U1 through a built-in oscillator circuit. Q5, R65, CR9, R63 and R64 form

a power-on reset network to assure correct initialization of U1 upon application of power.

4.4.9.3 ADDRESS DECODER U2

The address decoder consists of U2 and OR gates U8A, U8B, U8C, and U8D. These circuits take address

codes supplied by U1 on A8-A15 and use them to enable the EPROM U4, the RAM/IO/TIMER U5, the storage

memory unit U14, the output latches U6, U7 and U15, the channel update latch U25 and the input buffer U16.

U1 uses the address decoder circuit to enable the proper device when it needs to transfer information.

EXAMPLE: The software in U4 requires the channel information to be sampled periodically. In order to do this

U16, U25 and OR gate U8C must be addressed. U1 places an address on A8-A15 which causes Y5 pin 10

of U2 to go Low. With Y5 Low, U1 issues a Low read pulse on the RD line. At this time OR gate U8D has two

Lows at its inputs, causing its output pin 11 to be a Low. This Low enables the transfer to channel information

from the inputs of U16 to the DATA BUS. Once on the bus, U1 will proceed to process the information.

4.4.9.4 ADDRESS LATCH U3

The address latch U3, separates the address information from the data on bus lines AD0 through AD7 from

microprocessor U1. U3 is employed to produce continuous address information to U4 and U14. Each time U1

produces address information to the inputs of U3 via DATA BUS, U1 also produces a positive going pulse called

ALE (Address Latch Enable). The ALE pulse latches the address information on the DATA BUS inputs to U3

through to U3’s outputs. The address information is then latched on the output lines (ADDRESS BUS) and sent

to the EPROM U4 to call up a specific memory location where the data requested by U1 is stored. This latching/

information gathering sequence is repeated every time U1 needs to know the next step in the algorithm.

4.4.9.5 ERASABLE PROGRAMMABLE READ ONLY MEMORY (EPROM) U4

The EPROM U4, contains the data bits which make up the program algorithm used by the microprocessor U1

to adjust the network elements which tune the antenna. Address information from AD0, AD7, and A8-A11 is

sent to the EPROM U4, when U1 requires information for the execution of the next algorithm instruction stored

in U4. U4 responds by placing the instruction from its internal memory onto the DATA BUS when U1 issues

a brief LOW going read pulse on the RD line pin 32. U1 collects the instruction from the DATA BUS, analyzes

it, then acts on the directions provided.

4-7

SUNAIR CU-9125

4.4.9.6 INPUT PORT

Integrated circuit U5 contains the input port (Port C) to the microprocessor system. Through this port, the

microprocessor U1 can call up information, giving it the status of the phase and magnitude discriminators and

the VSWR detector.

U5, Magnitude and Phase Inputs:

There are six signals coming into integrated circuit U5, PHASE >+20o, PHASE <-20o, MAG >60 Ohm,

MAG <40 Ohm, VSWR and TUNE command. Signals PHASE >+20o, PHASE <-20o are the phase

discriminator interface outputs, and MAG >60 Ohm, MAG <40 Ohm, are the magnitude discriminator interface

outputs (refer to sections 4.3.2 and 4.3.3). See Truth Tables below. These four signals direct U1 through the

tuning algorithm program stored in the EPROM, U4. Truth tables for these signals follow:

U5 Pin 1

MAG > 60 OHM

* Illegal

>60

<40

In the window

Table 4.1 Magnitude Discriminator Truth Table.

* Note that a Low indication in both signals is not

possible as the magnitude cannot be both greater than

60 Ohms and less than 40 Ohms simultaneously.

0

0

1

1

U5 Pin 39

MAG < 40 OHM

0

1

0

1

U5 Pin 38

PHASE > +20

** Illegal

o

>+20

o

<-20

In the window

Table 4.2 Phase Discriminator Truth Table.

** Note that a Low indication in both signals is not

possible as the phase cannot be both positive and

negative simultaneously. A Low on any of these signals

indicates the true state.

0

0

1

1

U5 Pin 37

o

PHASE < -20

o

0

1

0

1

The VSWR signal coming into U5 pin 2 is a product of the VSWR comparator (refer to section 4.4.5) and is

used by U1 to determine a tune ready condition (High on VSWR line), once the magnitude and phase

discriminators fall in the window during a tune cycle.

4-8

SUNAIR CU-9125

Channel Lines: Input Port U16:

There are eight channel lines coming into the CU-9125 in the form of inverted binary coded decimal (BCD)

numbers representing channels 00 thru 127. Table 4.3 shows the Truth Table for channels 00-09.

Channel

Number

00

01

02

03

04

05

06

07

08

09

CH

2

1

1

1

1

1

1

1

1

1

1

CH

7

6

2

1

1

1

1

1

1

1

1

1

1

CH

2

1

1

1

1

1

1

1

1

1

1

5

CH

2

1

1

1

1

1

1

1

1

1

1

4

CH

2

1

1

1

1

1

1

1

1

0

0

3

CH

2

1

1

1

1

0

0

0

0

1

1

2

CH

2

1

1

0

0

1

1

0

0

1

1

1

CH

2

1

0

1

0

1

0

1

0

1

0

0

Table 4.3 Truth Table BCD Channels.

The Truth Tables are utilized by the Coupler when the Transceiver/Exciter supplying channel

information. Each one of the channels is then assigned a memory location. These memory locations

will contain the tune settings (i.e. the relay settings in the coupler network) for the channels and a code

indicating that particular channel has valid settings. If a channel change occurs, U26 detects this

function and awakens U1. U1 then fetches the new tune combination from its channel memory

location and configures the coupler network accordingly before returning to sleep.

4.4.9.7 OUTPUT PORTS

The Output Ports U5 (Port A and B), U6, U7, and U15, are used in conjunction with element drivers U9, U10,

U11, U12, and U13 to energize the appropriate relays or generate command signals.

To understand how U1 performs an output operation, consider what is involved in enabling the ‘READY’ line.

U1 issues an address on lines A8-A15, causing U2 output Y2 pin 13 to go Low. With Y2 Low, U1 issues a code

onto the DATA BUS, placing a High on line AD5 pin 17. U1 also issues a short duration Low going write pulse

on the WR line pin 31. OR gate U8A´s Low inputs cause it to have a Low out on pin 3 to pin 11 of U6. The Low

on U6 pin 11 clocks the information from the DATA BUS through U6 into Relay Driver U11, thus initiating the

‘READY’ line out of CU-9125.

4-9

SUNAIR CU-9125

4.4.9.8 TIMER

The timer resides within U5 and, in conjunction with U1, acts as a stopwatch beginning at the initiation of the

TUNE command. It is programmed to stop the microprocessor program and turn on the ‘FAULT’ line if a

satisfactory tune is not accomplished within ten seconds. The timer is reset whenever a new tune command

is received. If a proper tune is achieved, the timer is disabled, and the ‘READY’ line is enabled.

The timer is programmed at power up and receives its basic timing information from microprocessor U1. U1

continuously issues a signal called CLK OUT on pin 37. The timer in turn issues a brief Low going pulse on

TIMER OUT pin 6 of U5, which clocks U1. As a tune cycle is initiated, U1 keeps sampling this line and uses

it to stop the tune cycle if a satisfactory tune is not achieved within 10 seconds, then activates the ‘FAULT’ line.

If a proper tune is achieved, U1 stops sampling the TIMER OUT signal which is continuously issued by U5, and

sends the READY line enable.

4.4.9.9 RANDOM ACCESS MEMORY (RAM)

The RAM, also a part of U5, provides an area of temporary storage which U1 uses as a ‘scratch pad’ when

making its calculations. When the microprocessor needs to store information in RAM, U1 issues a code on lines

A8-A15. This code makes output Y1 pin 14 of U2 go Low. While Y1 is Low, U1 will issue a Low on the IO/M

line, the code it wants stored in RAM on the AD0-AD7 lines and a Low going write pulse on the WR line.

4.4.9.10 ELECTRICALLY ERASABLE PROGRAMMABLE READ ONLY MEMORY (EEPROM) U14

Long term storage of coupler element settings by channel is handled by the non-volatile memory in U14. If the

Transceiver/Exciter has the capability of supplying channel number (in BCD format) to the coupler, the coupler

element settings, when tuned, will be stored in this memory in a location corresponding to the selected channel.

Memory capacity is 128 channels. This provides extremely fast tuning, on the order of 10 ms, or less.

4.5 CHASSIS ASSEMBLY (2A1)

4.5.1 GENERAL

The Chassis Assembly contains the RF Assembly 2A2 and the Motherboard 2A1A1.

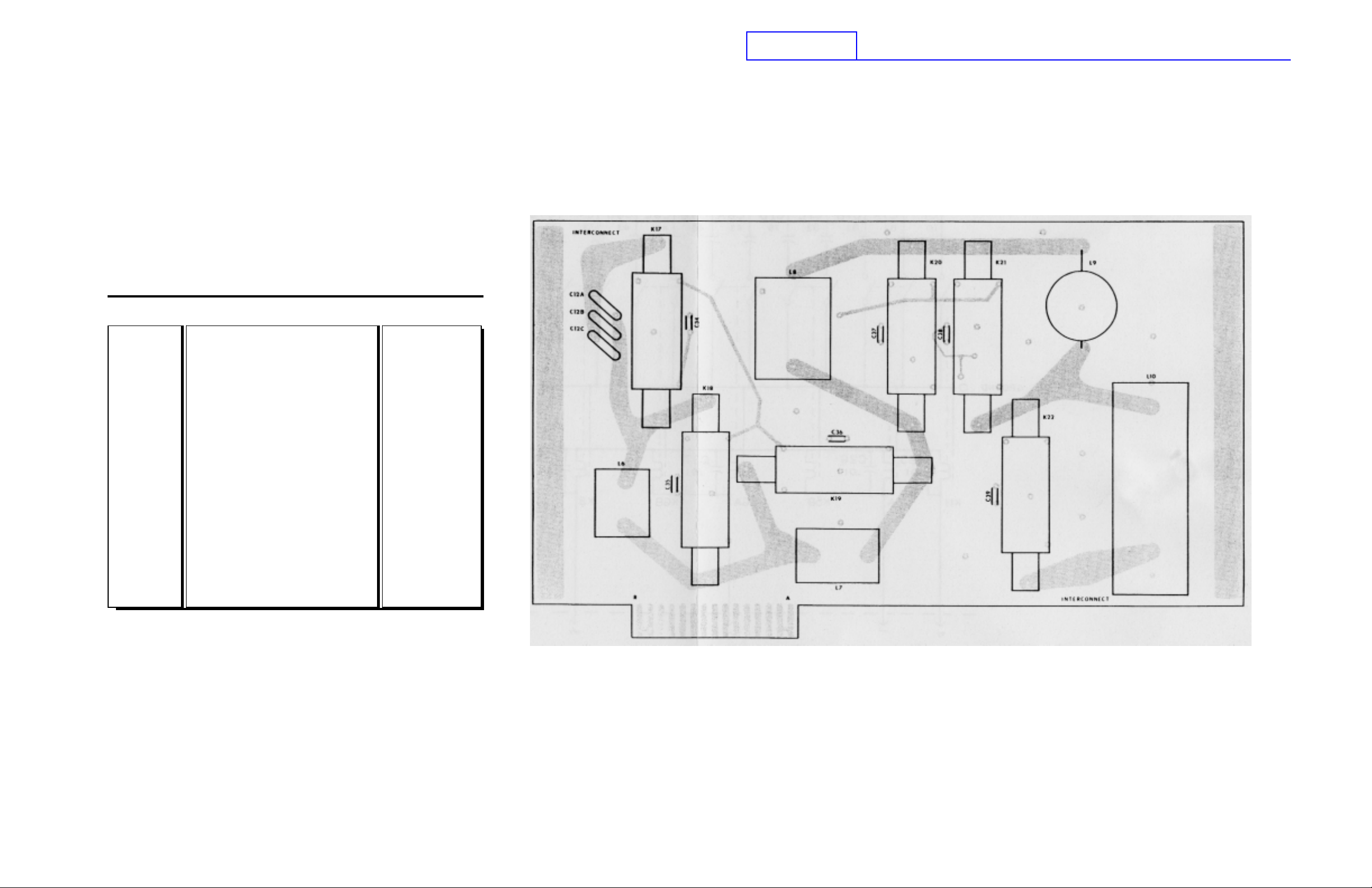

4.5.2 RF ASSEMBLY (2A2)

4.5.2.1 GENERAL (Refer to Figures 5.12, 5.13, 5.14, and 5.15)

a). Input Board 2A2A1 (Figure 5.12).

The Input Board contains input capacitors C2, C3, C5, C8, C9, C10, C11 and their

respective switching relays.

4-10

b). Intermediate Board 2A2A2 (Figure 5.13).

The Intermediate Board contains input capacitors C1, C4, C6, and C7, inductors L1,

L2, L3, L4, L5 and their respective switching relays.

SUNAIR CU-9125

c). Inductor Board 2A2A3 (Figure 5.14).

The Inductor Board contains inductors L6, L7, L8, L9, L10, stray inductance cancelling

capacitor C12, and their respective switching relays.

d). Output Board 2A2A4 (Figure 5.15).

The Output Board contains inductor L11, output capacitors C13, C14, C15, and C16,

series phase-cancelling capacitor C17, and their respective switching relays.

4.5.2.2 THEORY OF OPERATION

The four boards comprising the RF assembly contain all of the variable elements in the antenna matching

network. The basic network is a low pass ‘L’ with the capability of adding shunt output capacitance, transforming

the network to a low pass ‘P’. In addition, a series capacitor is available at the output of the network to aid in

tuning inductive antennas. Input capacitance is available in approximately 10 pF steps from 0 to 10293 pF (C1

through C11), selected in a binary progression. The series inductance, L1 through L11, is also binary

progression, and is available in .01 µH steps from 0 to 21.8 µH. The output capacitance, C13 through C16, is

also a binary progression and furnishes values from 0 to 750 pF in 50 pF steps. The output series capacitor,

C17, is selected whenever the initial load phase angle is positive. Capacitor C12 is used at the higher

frequencies to cancel out the stray coupler inductance, allowing full use of the small inductance steps available.

The switching relays are high speed, where on or off transitions are made in approximately one millisecond. This

allows the microprocessor 2A3U1 to make decisions very rapidly, providing extremely fast tuning time, typically

less than one second.

4.5.3 MOTHERBOARD (2A1A1)

Refer to Figure 5.11.

The Motherboard serves as an interconnection plane between the RF Assembly 2A2, the Computer Board 2A3,

the Detector/Pad Assembly 2A4 and the coupler front panel. Transistor Q1 grounds the TUNING line during

a coupler tune sequence. U1 is the primary +5 VDC regulator supplying power to the Computer Board 2A3.

It is mounted on the coupler sheet metal chassis for heat sinking, and plugs into the motherboard. Figure 5.10

shows the Front Panel wiring diagram.

4-11

SUNAIR CU-9125

THIS PAGE INTENTIONALLY LEFT BLANK.

4-12

SUNAIR CU-9125

SECTION V

ALIGNMENT

GENERAL

5.1

This section provides test procedures and evaluation of overall performance for the CU-9125 Automatic Digital

Antenna Coupler. A Fault Analysis Table is included to aid the repairman in isolating a fault to the defective module

or subassembly.

5.2 PREVENTIVE MAINTENANCE

Reduce the effects of salt air and salt water to the front panel and case of the CU-9125.

When CU-9125 Coupler is installed in a harsh environment (i.e. salt air/salt water), the following preventive

maintenance procedures should be accomplished:

1. The complete outside of the coupler unit should be washed with fresh water every two (2) weeks.

2. Once a year open the coupler unit and remove the old gasket. Clean the metal surface and groove in

the front panel. Clean the metal mating surface on the case. Install a new "O" Ring Gasket P/N 1006320032

into the front panel groove and reassemble coupler unit. See Figure 5.1.

3. Anytime the coupler unit is opened a new "O" Ring Gasket should be installed prior to reassembling the

coupler unit.

5.3 INSPECTION

If the CU-9125 has the case removed for maintenance, a visual inspection should be performed and the resultant

corrective action should be taken as follows:

1. Inspect chassis for loose or missing mounting hardware, deformation, damaged fasteners, or damaged

connectors. Replace all damaged parts.

2. Inspect connectors for broken parts; check insulation for cracks; and check the pins for damage,

misalignment, or bad plating. Carefully realign pins when possible; or, if connectors are otherwise severely

damaged, replace connector. Check for loose, or poorly soldered connections to terminals or connectors.

Tighten or solder as required.

3. Inspect wiring of chassis and subassemblies for any signs of physical damage or charring. Any damaged

wires must be replaced.

4. Inspect for leaky, blistered, charred, or cracked capacitors, resistors, or diodes. Check for loose or

corroded terminal connections. Obviously damaged components should be replaced.

5-1

SUNAIR CU-9125

5. Inspect for cold soldered or resin joints. Bad joints can be recognized by a dull, porous appearance.

Resolder.

6. Antenna coupler cover removal:

a. Remove the 8 Phillips’ head screws.

b. Slide the unit out of the case.

5-2

Figure 5.1 CU-9125 Antenna Coupler Cover Removal.

SUNAIR CU-9125

5.4 REPAIR OR REPLACEMENT

The repair or replacement of damaged and defective parts usually involves standard service techniques.

Carefully examine the equipment to determine the correct technique required to effect the repair.

5.4.1 GENERAL PRECAUTIONS

a) Perform repairs and replace components with power disconnected from unit.

b) Replace connectors, shielded conductors, and twisted pairs only with identical items.

c) Reference to component side of a printed circuit board means the side on which the majority of

components are located; solder or circuit side refers to the other side.

d) When repairing circuits, carefully observe lead dress and component orientation. Keep leads as short

as possible and observe correct repair techniques.

e) Observe cable routing prior to disassembly to enable the proper reinstallation of cabling during

reassembly procedures.

f) If component is defective beyond any reasonable doubt, remove and replace according to the procedures

given in paragraph 5.4.4. If there is some doubt about the condition of a component, or if it is being removed

for troubleshooting, remove it according to the procedures in paragraph 5.4.4.

5.4.2 CIRCUIT CARD ASSEMBLY, TWO-LEAD COMPONENT REMOVAL

(RESISTORS, CAPACITORS, DIODES, ETC.)

a) Inspect solder side of component to determine if the leads were bent over prior to soldering. If they weren’t,

proceed to Step b. If they were, melt the solder and remove it with a desoldering tool, then straighten the leads

and remove the component.

b) Heat one lead from component side of board until solder flows and lift one lead from board; repeat for

other lead and remove component (note orientation).

c ) Melt solder in each hole and using desoldering tool, remove solder from each hole.

d) Dress and form leads of replacement component; insert leads into correct holes.

e) Solder in place and clip leads on solder side of board.

5.4.3 CIRCUIT CARD ASSEMBLY, MULTI-LEAD COMPONENT REMOVAL

(IC’s, etc.)

a) Remove component by clipping each lead along both sides. Clip off leads as close to component as

possible. Discard component.

b) Heat hole from solder side and remove clipped lead from each hole.

c ) Melt solder in each hole and using a desoldering suction tool, remove solder from each hole.

5-3

SUNAIR CU-9125

d) Insert replacement component, observing correct orientation.

e) Solder component in place from solder side of board. Avoid solder runs. No solder is required on contacts

where no track exists.

5.4.4 REMOVAL OF COMPONENTS OF DOUBTFUL CONDITION

a) To remove components that are not heat sensitive melt the solder and remove it with a desoldering tool,

then remove the component.

b) To remove components that are heat sensitive, such as diodes, transistors, and IC’s, connect a heat

sink to the lead between the body of the component and the solder joint, melt and remove the solder. Repeat

for all leads of the component, then remove the component. Apply heat to the lead for the minimum amount

of time necessary to remove the solder. When working with IC’s, start at one corner, then go to the lead farthest

away, then back to where you started, etc....(Example: pins 1, 8, 14, 7,...) This is to keep heat buildup to

a minimum. Remember that some solid state devices are extremely heat sensitive; and even though maximum

care is exercised during their removal, they may still be destroyed by the removal procedure.

c) To install a heat sensitive component, use a heat sink and the sequence outlined above to prevent heat

from destroying the component.

5.5 PERFORMANCE TEST

The following tests will aid in determining specific problems.

5.5.1 TEST EQUIPMENT

The following test equipment or equivalent is required to perform the test procedures outlined in this section.

1. Exciter/Transceiver

2. 35 ft. Whip Antenna Simulator, Model TS-100 Sunair P/N 8084001094

3. ‘THRULINE’ Wattmeter: Bird Model 43 with 100 Watt 2-30 MHz element

4. VOM: Simpson 260 (20k Ohm/Volts)

5. Digital Multimeter: H.P. Model 3476A

6. Oscilloscope: Tektronix 2445

7. Frequency Counter: Systron Donner Model 6242A

8. PC Assy, Detector Extender Board Sunair P/N 8085165091

9. Coaxial Resistor: Bird Model 8135, 50 Ohm, 150 Watt

5-4

SUNAIR CU-9125

5.5.2 PRELIMINARY

Connect Transceiver/Exciter, Antenna Coupler, and Test Equipment as shown in Figure 5.4, Antenna Coupler

Test Set Up.

a) Set the Transceiver/Exciter´s switches and controls to the positions shown below and turn on.

SWITCH OR CONTROL POSITION

‘FREQUENCY’ 1.60000 MHz

‘VOLUME’ Control/On/Off On

‘SQUELCH’ Control Off

b) The Transceiver/Exciter display will alternately display ‘COUPLER UNTUNED’. Depress the ‘CPLR

TUNE’ pushbutton. The Thruline Wattmeter should indicate 30 to 35 Watts of forward RF power while the

coupler is tuning. The Transceiver/Exciter will display ‘COUPLER TUNING’ and then ‘SYSTEM READY’ and

the coupler should be tuned. The Thruline Wattmeter should show no forward RF power after the tune cycle

is completed.

c) Set mode to CW and key the Transceiver/Exciter with CW key switch. Check the forward and reflected

power on the Thruline Wattmeter. An acceptable tune should show 70 to 125 forward Watts and 2.8 to 5.1

reflected Watts maximum. See chart below:

FORWARD WATTS REFLECTED WATTS MAXIMUM

70 2.8

80 3.2

100 4.0

110 4.4

125 5.1

Acceptable Reflected Power Chart for VSWR 1.5:1.

d) Set the Transceiver/Exciter to the following frequencies and tune the coupler. Using the CW key switch

check the forward and reflected power of each frequency to see if they fall within the parameters given in the

preceding paragraph.

1.9900 MHz 4.6000 MHz 12.6000 MHz

2.6000 MHz 6.6000 MHz 25.6000 MHz

3.6000 MHz 9.6000 MHz 29.9900 MHz

NOTE: If upon completion of the Performance Test Procedures, the CU-9125

is not operating properly, accomplish the following alignment

procedures. Remove Antenna Coupler from case, see Figure 5.1.

5-5

SUNAIR CU-9125

Figure 5.2 CU-9125, Computer Board Test Points and Adjustment Locations.

5.5.3 CU-9125, ALIGNMENT PROCEDURE for COMPUTER BOARD ASSEMBLY (2A3)

NOTE: All measurements and adjustments are accomplished on the Computer

Board (2A3). (See Figure 5.2).

a) Turn on the Exciter/Transceiver. (It is necessary to supply power to the coupler).

b) Connect negative lead of DVM to ground. Set meter scale to read +10 VDC.

c ) Measure voltage at TP1 (U22 pin 3+10VDC regulator); should read +10.5,

5-6

+.5 VDC.

d) Connect negative lead of DVM to ground. Set meter scale to read +5 VDC.

SUNAIR CU-9125

e) Measure voltage at TP2 (junction of voltage divider R28 and R29) should read +5.25,

f) Measure voltage at TP3 (U19 pin 4, VSWR OP amp). Adjust R43 until voltage is +1.75,

g) Connect negative lead of DVM to TP7 (U18 pin 11 magnitude OP amp). Set meter scale to read 200 mv.

Connect positive lead to TP6 (U18 pin 8 magnitude OP amp). Adjust R19 until voltage is +224,

h) Connect negative lead of DVM to TP2. Measure voltage at TP6 and TP7. Adjust R66 until voltage at

TP6 is +112,

reading.

i) Connect negative lead of DVM to TP5 (U18 pin 7, phase OP amp) and positive lead to TP4 (U18 pin 4,

phase OP amp). Adjust R6 until voltage is +224,

j) Connect negative lead of DVM to TP2. Measure voltage at TP5 and TP4. Adjust R61 until voltage at

TP5 is -112,

readings.

+5 mv, and voltage at TP7 is -112, +5 mv. Repeat steps g) and h) as required to obtain correct

+5 mv.

+5 mv, and voltage at TP4 is +112, +5 mv. Repeat steps i) and j) as required to obtain correct

NOTE: This completes the alignment of the Computer Board Assembly.

+.5 VDC.

+.05 VDC.

+5 mv.

5-7

SUNAIR CU-9125

Figure 5.3 CU-9125 Detector/Pad (2A4) and Extender Card Test Points and Adjustment Locations.

5-8

SUNAIR CU-9125

5.5.4 ALIGNMENT PROCEDURE for DETECTOR/RELAY PAD ASSEMBLY (2A4)

Connect Transceiver/Exciter, Antenna Coupler and Test Equipment as shown in Figure 5.4 Detector/Relay

Pad Alignment Set Up. Install Detector/Relay Pad Assembly (2A4) on card extender (Sunair P/N 8085165091).

(See Figure 5.3).

NOTE: All measurements and adjustments are accomplished on the 2A4

board. See Figure 5.3 for Test Point and Adjustment Locations.

a) Turn on Transceiver/Exciter (it is necessary to supply power to the coupler). Set Transceiver/Exciter

frequency to 29.6050 MHz and select ‘AM’ mode.

b) Key the Transceiver/Exciter with the microphone PTT key switch. Power shown on Thruline Wattmeter

connected to Transceiver/Exciter output will display 40 to 50 Watts. Thruline Wattmeter connected to J1 on

Detector/Relay Pad extender card output will display 40 to 50 Watts. Ground TP1 on extender card,