SUMMIT

MICROELECTRONICS, Inc.

SML2108

Dual Loop Laser Diode Adaptive Power Controller

with Look Up Table

FEATURES

!!

! Dual Closed-loop Control of Laser Diode Mean

!!

Power and Extinction Ratio

!!

! Automatic Power Control (APC) with Integrated

!!

10-Bit Programmable Offset

""

" Automatic Initial Bias Optimization

""

!!

! Integrated Bias Current Monitor

!!

""

" Monitors & Measures Laser Temperature

""

Directly

""

" Eliminates Need for External Thermistor &

""

Thermal Coupling Issues

""

" Alarm Output on Over-temperature Condition

""

!!

! Adaptive Modulation Control (AMC)

!!

""

" Adjusts Modulation Current as a Function of

""

the Laser Temperature

""

" 256 Independent Compensation Values

""

""

" Integrated 8-Bit Modulation Control DAC

""

!!

! Current Available: 0 to 100mA Sink or Source

!!

!!

! Electronic Calibration Through 2-wire Interface

!!

!!

! 3V or 5V Operation

!!

!!

! Typical Applications: 2.5GHz Transceivers;

!!

200 pin/300 pin 10GIG Sonet MSA Compliant;

10GbE XENPAK-compliant Transponders

DESCRIPTION

The SML2108 is an adaptive power controller for laser

diodes. It is the industry's first integrated device that can

directly monitor and measure a laser diode's temperature,

and provide a variable modulation current. The

SML2108's integrated active feedback loop is used to

calibrate and control the mean and modulation power of

high speed, high power laser diodes.

Inherent manufacturing tolerances introduce variations

of performance in laser diodes. These variations, combined with parametric changes over the laser’s extreme

temperature range and laser aging, call for an efficient

temperature compensation scheme. Using an internal

digital control loop and a programmable nonvolatile compensation lookup table, the SML2108 provides the most

optimum adaptive power control with a minimum number

of external components.

The SML2108 removes the need for any manual calibration of the laser control circuit, which is currently the

industry standard practice. All calibration values are

programmed through the 2-wire communication interface,

which can be controlled by most production ATE equipment.

Programming of configuration, control and calibration

values by the user can be simplified with the interface

adapter and Windows GUI software obtainable from Summit Microelectronics.

PRELIMINARY

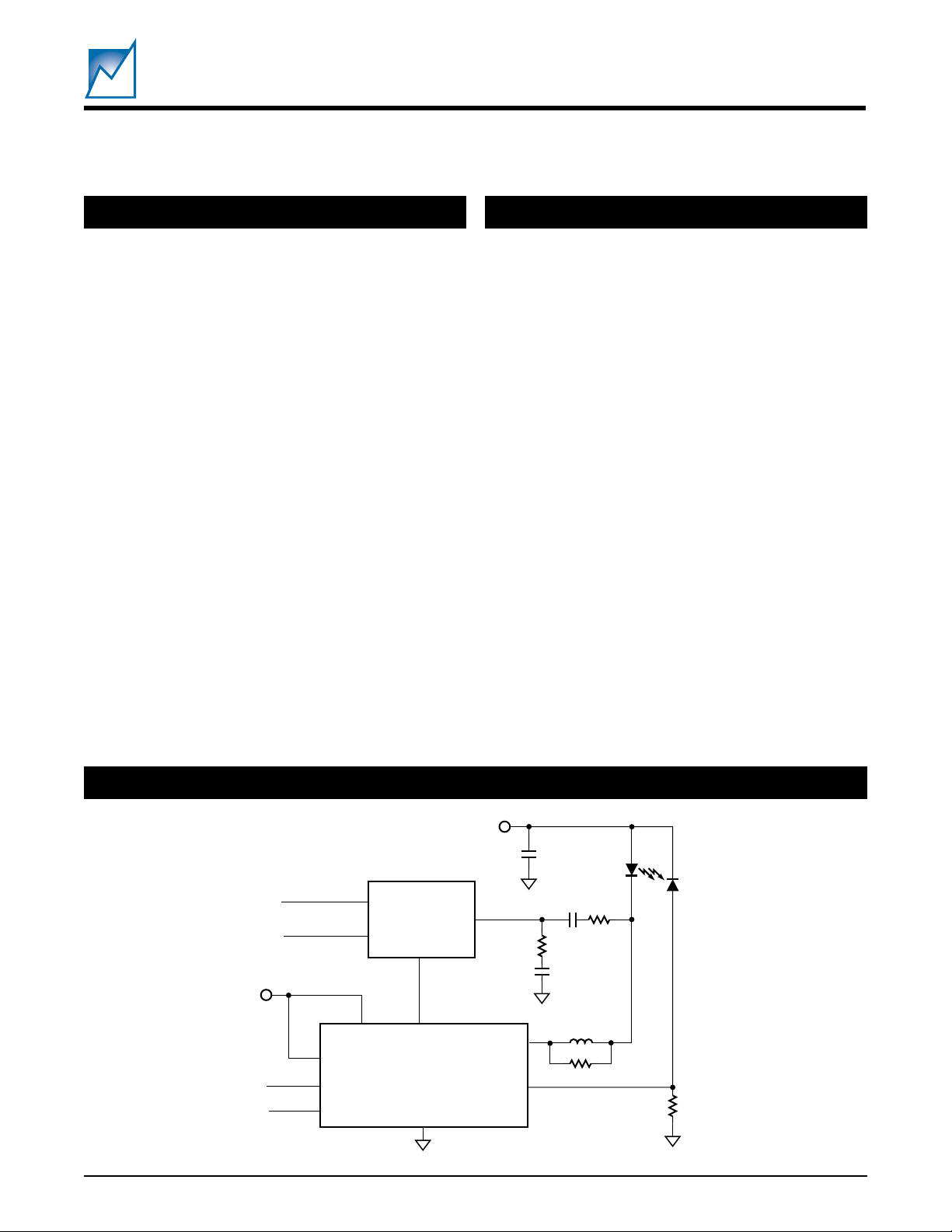

SIMPLIFIED APPLICATION DIAGRAM

V

DD

LASER

IN+

IN–

V

DD

V

AUTOMON

Interface

©SUMMIT MICROELECTRONICS, Inc., 2001 • 300 Orchard City Dr., Suite 131 • Campbell, CA 95008 • Phone 408-378-6461 • FAX 408-378-6586 • www.summitmicro.com

Characteristics subject to change without notice

SDA

SCL

LASER

MODULATION

DRIVER

MODN

DD

SML2108

IMOD

MODSET

BIASN

DETECT

V

SS

2053 3.0 10/03/01

DIODE

MONITOR

DIODE

2053 SAD

1

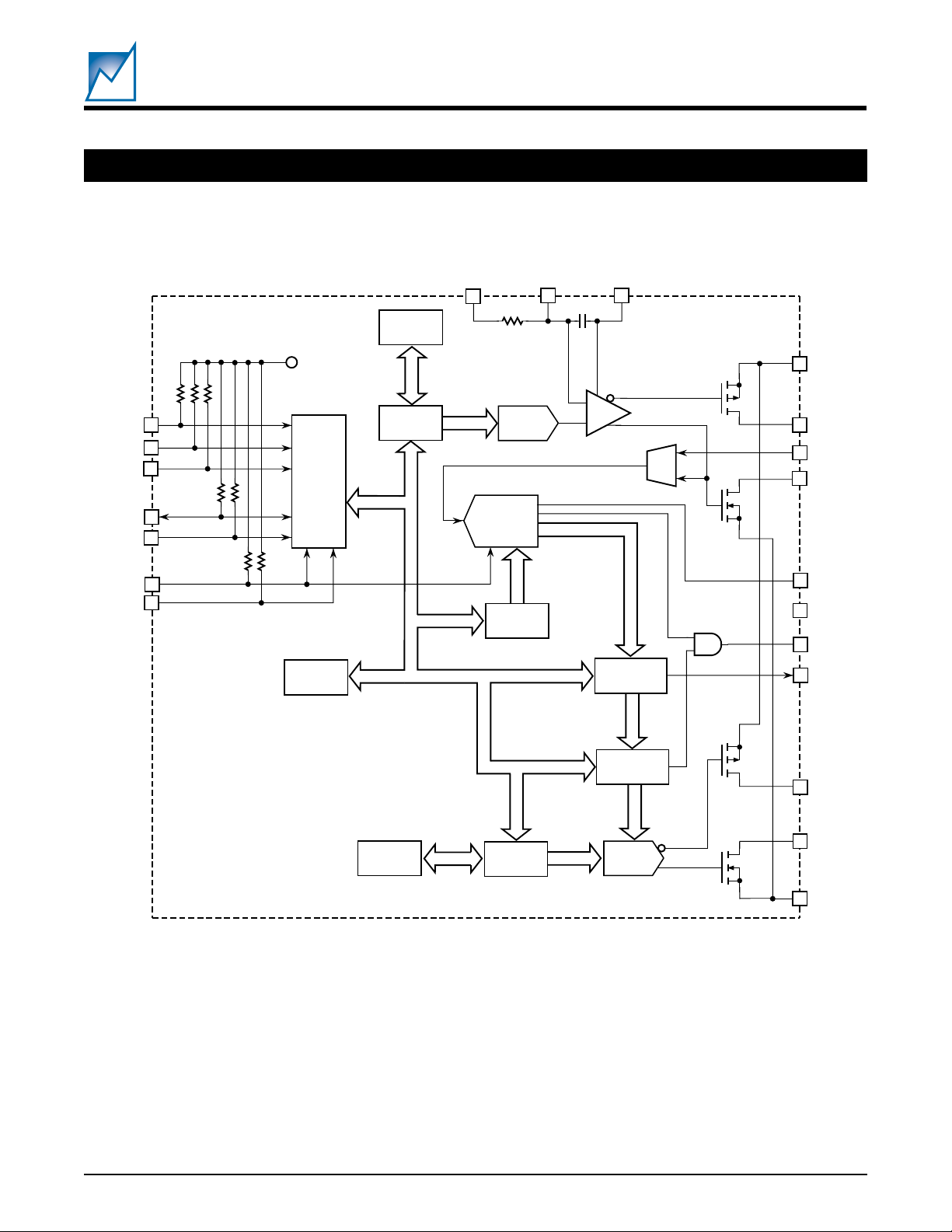

FUNCTIONAL BLOCK DIAGRAM

SML2108

PRELIMINARY

A0

A2

SDA

SCL

AUTOMON

CE#

A1

48

1

2

3

4

5

(All Rs 100kΩ)

6

V

CC

Config

10-Bit

NV Reg

10-Bit

DAC Reg

DETECT

12

10-Bit

DAC

8-Bit

ADC

NV Scaling

& Offset

CAP1

11

CAP2

10

–

+

ADC Read &

Alarm Reg

BIAS P

EXT TEMP

5

BIAS N

13

VSS A

14

VSS D

7

RDY

ALERT#

8

V

DD

NV Look-up

Table

8-Bit

NV Reg

2

2053 3.0 10/03/01

8-Bit

DAC Reg

8-Bit

DAC

2053 BD 2.2

SUMMIT MICROELECTRONICS, Inc.

MOD P

MOD N

V

SS

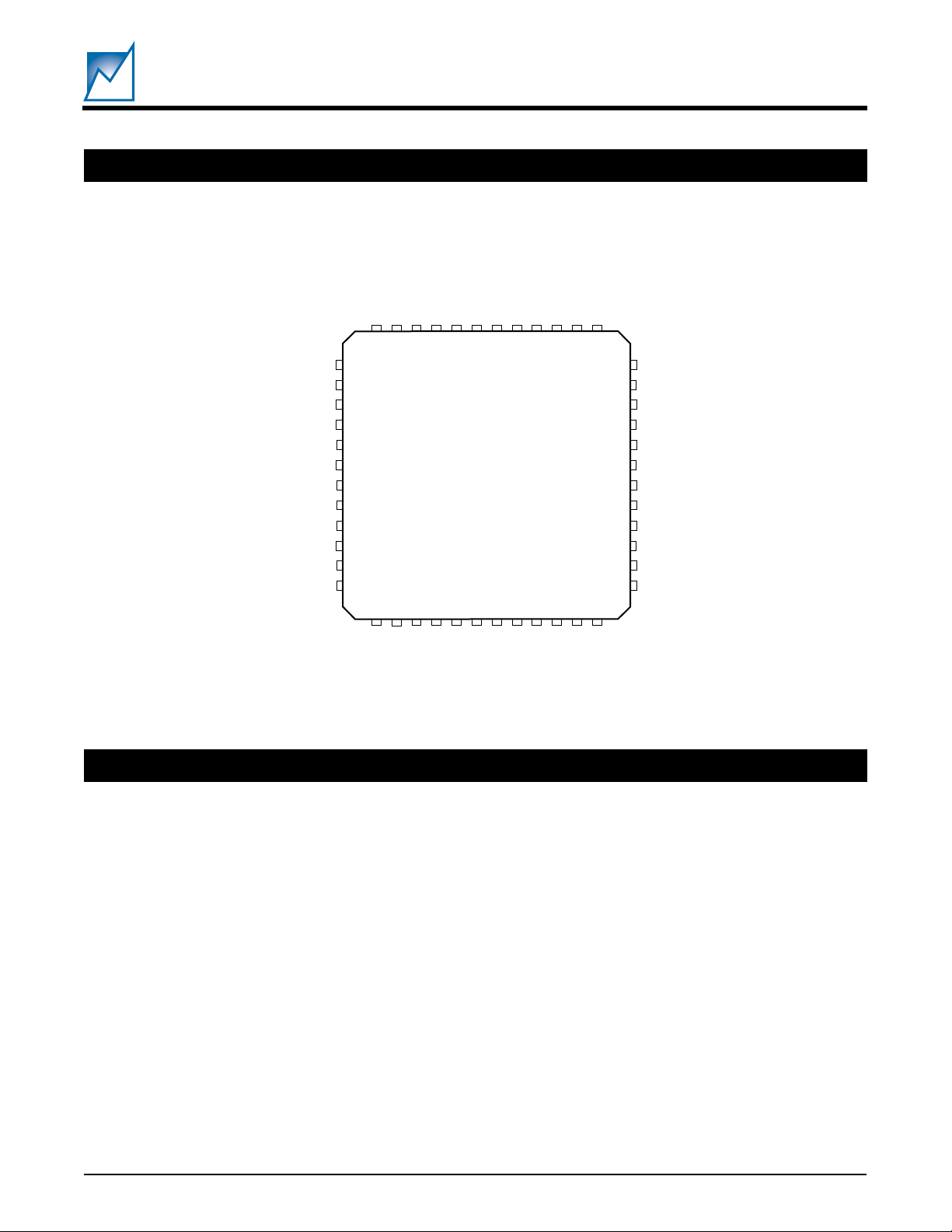

PIN CONFIGURATION

SML2108

PRELIMINARY

48-Pin TQFP

A0

A1

A2

SDA

SCL

AUTOMON

RDY#

ALERT#

EXT TEMP

CAP2

CAP1

DETECT

CE#

VDDVDDVDDBIASP

BIASP

MODP

MODP

4847464544434241403938

1

2

3

4

5

6

7

8

9

10

11

12

1314151617181920212223

A

D

DDVDD

SS

SS

V

V

V

BIASP

BIASP

MODP

MODP

VDDVDDVSSV

DDVDD

VSSV

V

SS

37

36

35

34

33

32

31

30

29

28

27

26

25

24

SS

MODN

MODN

BIASN

BIASN

V

SS

V

SS

V

SS

V

SS

BIASN

BIASN

MODN

MODN

2053 PCon 2.1

PIN DESCRIPTIONS

DETECT (12)

This is the analog input from the laser monitor photodiode

for the integrator circuit. There is an on-board resistance

of 2MΩ between the DETECT input and CAP1 pin.

CAP1 and CAP2 (11 & 10)

Capacitor inputs for an external capacitor in the feedback

loop of the Mean Power Control Integrator. There is an onboard capacitance of 500pF.

AUTOMON (6)

Active high input used to enable the internal auto-monitor

function, which provides automatic adjustments to the

modulation output currents (MODP and MODN) based on

the internal A/D output and the values stored in the

nonvolatile lookup table. This pin has an internal 100kΩ

pull-up.

SUMMIT MICROELECTRONICS, Inc.

2053 3.0 10/03/01

ALERT# (8)

Active low, open-drain output. This pin is driven low

whenever the bias current increases beyond a predefined

nonvolatile threshold. This can be used to predict laser

failure.

SDA, SCL (4 & 5)

Data and Clock lines, respectively, whose function and

use are based on the industry standard I2C interface.

Lookup table values, configuration data, and D/A and A/D

registers may all be accessed via these two pins of the

SML2108. These pins have internal 100kΩ pull-ups.

A0, A1, A2 (1, 2, & 3)

Address Pins for the interface provided to allow multiple

devices on a single bus. These pins have internal 100kΩ

pull-ups.

3

SML2108

PRELIMINARY

RDY# (7)

Active low, open-drain output. This pin is driven low

whenever the internal A/D is performing a conversion, or

while the on-board EEPROM is being programmed.

EXT TEMP (9)

Temperature input (or no connection). This pin can be

programmed as an input to the ADC and can interface a

temperature sensor. The EXT TEMP pin is multiplexed

with the bias current to provide a means of configuring the

input to the ADC. When EXT TEMP is programmed as the

input to the ADC using bit 5 of Register 1, the converted

value of the current entering this pin is used as the

address of the EEPROM lookup table. In this configuration the modulation current can be controlled by temperature rather than the bias current. Refer to the application

example on using the EXT TEMP pin. If this option is not

used the pin should be left floating.

V

A, VSSD (13 & 14)

SS

Analog and digital low-side supplies for on-board circuitry. Must be at same potential as all other VSS pins.

V

(15, 16, 21, 22, 39, 40, 45, 46, & 47)

DD

High-side supply for the Bias and Modulation currents and

power supply input for the chip.

(23, 24, 29, 30, 31, 32, 37, & 38)

V

SS

Power supply return.

CE# (48)

The chip enable input is active low and provides an

additional method of enabling the serial interface. The

state of this pin has no effect on the auto-monitor function.

This pin has an internal 100kΩ pull-up.

BIASP (17, 18, 43, & 44)

High-side mean bias control current. Current source

output range is programmable, with the optional ranges of

0 to 100mA or 0 to 10mA.

BIASN (27, 28, 33, & 34)

Low-side mean bias control current. Current sink input

range is 0 to 100mA.

MODP (19, 20, 41, &42)

High-side modulation control current. Current source

output range is programmable, with optional ranges of 0 to

100mA or 0 to 10mA.

MODN (25, 26, 35, &36)

Low-side modulation control current. Current sink input

range is 0 to 100mA.

4

2053 3.0 10/03/01

SUMMIT MICROELECTRONICS, Inc.

ABSOLUTE MAXIMUM RATINGS*

SML2108

PRELIMINARY

Temperature Under Bias ...................... –55°C to 125°C

Storage Temperature ........................... –65°C to 150°C

Lead Solder Temperature (10 secs) ................... 300 °C

*COMMENT

Stresses listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions

outside those listed in the operational sections of this specification is not

implied. Exposure to any absolute maximum rating for extended

periods may affect device performance and reliability.

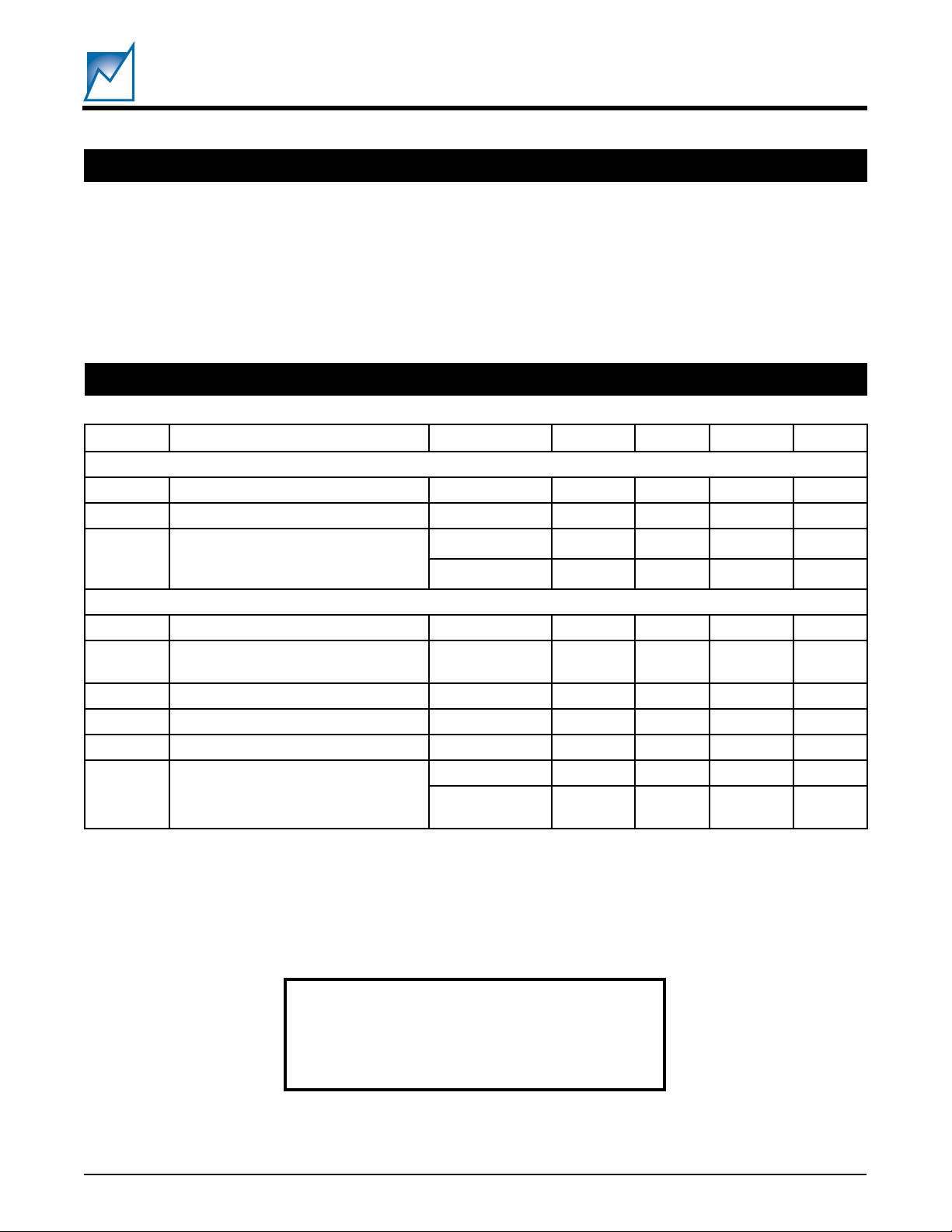

ELECTRICAL TABLES

(Over Recommended Operating Conditions; Voltages are relative to GND)

lobmySretemaraPsnoitidnoC.niM.pyT.xaMstinU

ecnamrofrePCDAlacipyT

º

N/SoitaresioNotlangiST

DHTnoitrotsidcinomrahlatoT08– Bd

noitaludomretnicinomrahkaeP

noitrotsid

ycaruccACD

noituloseR8stiB

gnissimonhcihwrofnoituloeR

deetnaraugerasedoc

ycaruccaevitaleR ½±BSL

LND 1±BSL

rorreelacsllufevitisoP2±BSL

V

rorretesfforalopinU

V

º

Cº52= 07Bd

A

redrOdn208– Bd

redrOdr308– Bd

8stiB

V5=2±BSL

SS

SS

V6.3

otV7.2=

2±BSL

2053 Elect Table A

SUMMIT MICROELECTRONICS, Inc.

RECOMMENDED OPERATING CONDITIONS

Temperature –40ºC to 85ºC.

Voltage 3.0V to 5.5V

2053 3.0 10/03/01

5

ELECTRICAL TABLES (Continued)

lobmySretemaraPsnoitidnoC.niM.pyT.xaMstinU

V

DD

I

D

I

OL

I

IL

V

LO

V

HO

V

LI

V

HI

f

TNI

t

SUP

emit

TCETEDCDAottupniTCETED05.1V

I

PMETTXE

I

NDOM

I

PDOM

I

NSAIB

I

PSAIB

V

CAD

tnerruc

tnerruc

TRELAtuptuoTRELA

egatlovylppuS

tnerrucylppuS

tnerrucegakaeltupnIV

NI

tnerrucegakaeltuptuOV

egatlovwoltuptuOI

egatlovhgihtuptuO

LO

V

DD

V

DD

egatlovwoltupnI1.0– 3.0 × V

egatlovhgihtupnI7.0 × V

poolrotargetnI

ycneuqerf

noitazilibatspurewoP

stupnIgolanA

tupnitnerrucelacslluF 6.093Aµ

stuptuOgolanA

noitaludomlennahc-N

noitaludomlennahc-P

tnerrucsaiblennahc-N0001– Am

tnerrucsaiblennahc-P0001Am

tuptuoCADtiB-0105.1V

stuptuOlatigiD

SML2108

PRELIMINARY

noitaludomdnasaibmumixaM

tnerruc

-tuotnerrucnoitaludomdnasaiB

nepostup

VotV0=

DD

TUO

VotV0=

DD

Am2=4.0V

I,V5=

LO

I,V5.4<

LO

Aµ004–=4.2V

Aµ001–=V

sselsitnatsnocemitrotargetnI

sm01naht

situptuoTRELAniardnepO

evitca

35.5V

2Am

1Aµ

01Aµ

2.0– V

DD

V

DD

DD

5.0V

1zHk

01sm

0001– Am

0001Am

5Am

2053 Elect Table B

6

2053 3.0 10/03/01

SUMMIT MICROELECTRONICS, Inc.

DEVICE OPERATION

SML2108

PRELIMINARY

General Description

The SML2108 is an adaptive power controller for laser

diodes with an active feedback loop used to calibrate and

control the mean and modulation power of high speed,

high power laser diodes. Inherent manufacturing tolerances introduce variations of performance in laser diodes.

These variations, combined with parametric changes over

the laser’s extreme temperature range and laser aging,

call for an efficient compensation solution. The SML2108,

with a minimum number of external components, is designed to compensate for these tolerances using a digital

control loop and a programmable nonvolatile calibration

lookup table.

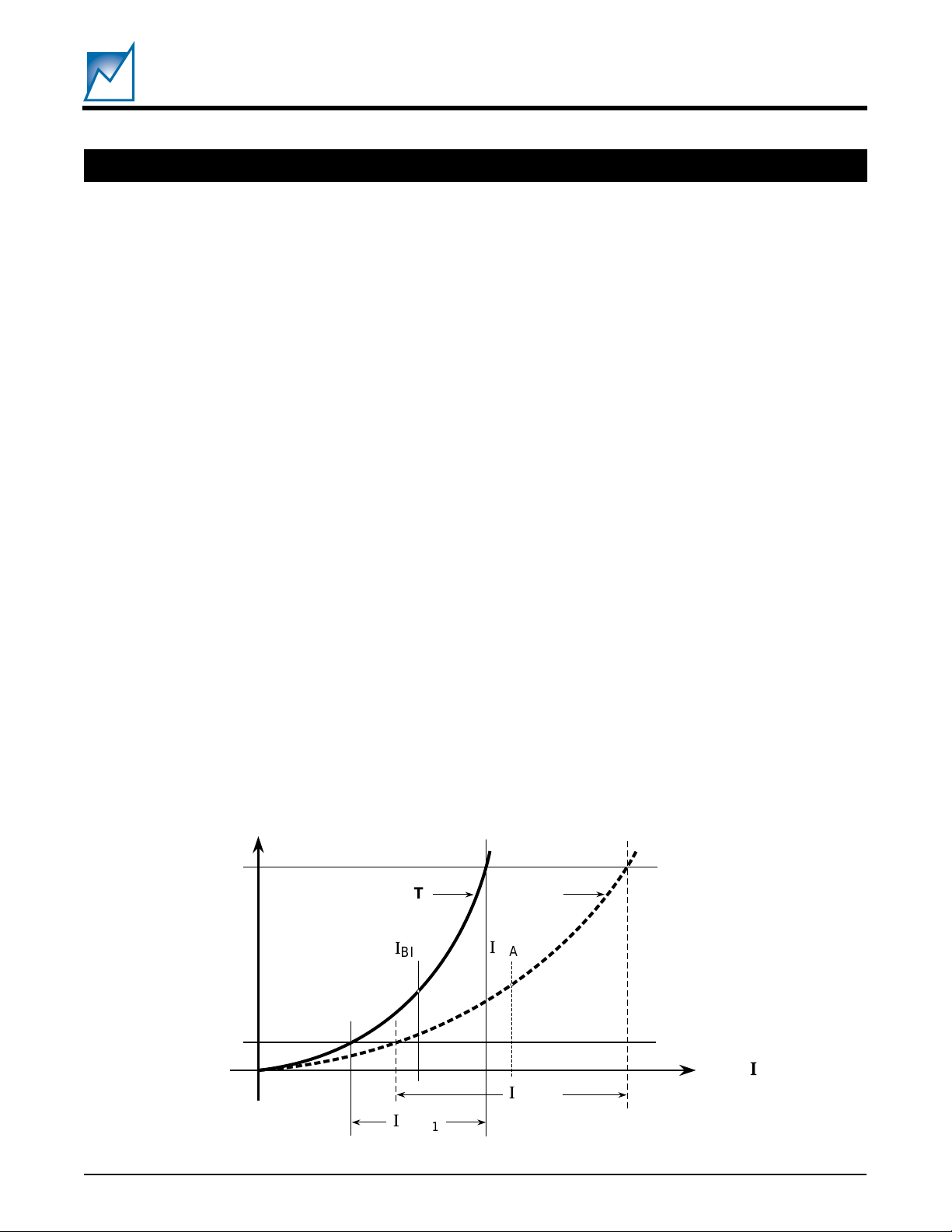

Figure 1 illustrates the usefulness of the SML2108. The

figure shows the output light power of a laser diode versus

its operating current. Depicted in the graph are typical

laser diode characteristics at two different temperatures.

At the first temperature (T

), the laser requires an average

1

bias current of IBIAS1. The modulation current needed to

switch the laser between its on and off state is labeled

IMOD1. The ratio of light power of its on state divided by

the light power of its off state is referred to as the extinction

ratio. Ideally the laser will maintain a constant extinction

ratio over its entire operating temperature range, as the

receiver module is calibrated to this level. Running the

laser driver at a higher extinction ratio indicates that power

is being wasted, whereas operating at a lower extinction

ratio indicates that data may possibly be lost.

The required bias current increases to IBIAS

when the

2

laser is operated at a second temperature (T2). The laser

requires a modulation of IMOD2 to maintain a constant

extinction ratio as in the T1 curve. The SML2108 is the

industry’s first integrated device capable of providing a

variable modulation current based on a function of either

the bias current or an external temperature. This ability

to compensate the modulation output current enables the

system designer to optimize the extinction ratio of the

laser driver module.

The SML2108 has been specified to remove the need for

any manual calibration of the laser control circuit. All

calibration values are programmed through an industry

standard 2-wire communication interface, whose protocol

and function can be controlled by most production ATE

equipment.

Bias Current — Mean Power Control

The SML2108 bias current output (BIASP or BIASN)

establishes the average power being delivered to an

external laser diode. The output of the laser diode is

separately monitored using a local back-face diode, the

output of which is tied to the DETECT pin of the SML2108.

This feedback loop becomes the mean power control for

the laser diode when coupled with the internal integrator.

The output block of the mean power control is shown in

Figure 2.

(On) 1

(Off) 0

Figure 1. Laser Current Increase Caused by Temperature Increase, Constant Light Power Out

SUMMIT MICROELECTRONICS, Inc.

Light

Power

I

BIAS

I

MOD

T1

I

1

1

2053 3.0 10/03/01

BIAS

I

MOD

T2

2

Total

2

2053 Fig01

I

7

Loading...

Loading...