Page 1

INSTALLATION GUIDE

PRO 48 Refrigeration

Page 2

Contents

Important Note

PRO 48 Refrigeration ............................ 3

PRO 48 Specifications ........................... 4

PRO 48 Site Preparation .......................... 5

PRO 48 Installation .............................. 8

Service Information ............................. 18

Features and specifications are subject to change at any time

without notice. Visit subzero.com/specs for the most up-todate information.

IMPORTANT NOTE: Throughout this guide, dimensions in

parentheses are millimeters unless otherwise specified.

To ensure the safe and efficient installation of Sub-Zero

equipment, please take note of the following types of

highlighted information throughout this guide:

IMPORTANT NOTE highlights information that is especially

relevant to a problem-free installation.

CAUTION signals a situation where minor injury or product

damage may occur if instructions are not followed.

WARNING states a hazard that may cause serious injury or

death if precautions are not followed.

Page 3

PRO 48 Refrigeration 3

subzero.com/specs

Sub-Zero PRO 48 Refrigeration

The importance of the installation of the Sub-Zero

PRO 48 unit cannot be overemphasized. Installation

should be done by a qualified installer.

Before you begin the installation process, it is recommended that you read this entire installation guide. There

are key details that you should take special care to

observe during the installation. By reading these instructions carefully, you will make the installation process

easier, problem-free and most importantly, safe.

The installation process is identical for both the model

648PROG which features a glass door on the upper refrigerator compartment and model 648PRO with a solid door.

Any questions or problems regarding the installation

should be directed to your authorized Sub-Zero dealer or

Sub-Zero customer service at 800-222-7820. You may

also check the contact & support section of our website,

subzero.com.

Important product information, including the model and

serial number of your unit are listed on the product rating

plate. The rating plate is located on the left side of the top

freezer drawer compartment (drawer must be open).

Refer to the illustration below.

Before You Start

Make sure the opening dimensions, door and drawer

clearances, electrical service and plumbing are correct for

the model you are about to install. Refer to specifications

on the following pages.

TOOLS AND MATERIALS REQUIRED

• Appliance dolly able to support 1000 lbs (454 kg) and

adequate manpower to handle the weight of the unit.

• Phillips and slotted screwdrivers.

• Torx drive screwdriver set

• Allen, standard and crescent wrenches.

• Various sized pliers.

•7/16" hex bolt nut driver.

• Cordless drill and assorted drill bits.

• Level—2' (.6 m) and 4' (1.2 m) recommended.

• 4' (1.2 m) of1/4" copper tubing and saddle valve for

water line (do not use self-piercing valves).

• Copper tubing cutter.

• Masonite, plywood, pressed fiberboard, cardboard or

other suitable material to protect finished flooring.

RATING

PLATE

Location of rating plate

(open drawer).

• Appropriate materials to cover and protect the home

and furnishings during installation.

Page 4

PRO 48 Specifications 4

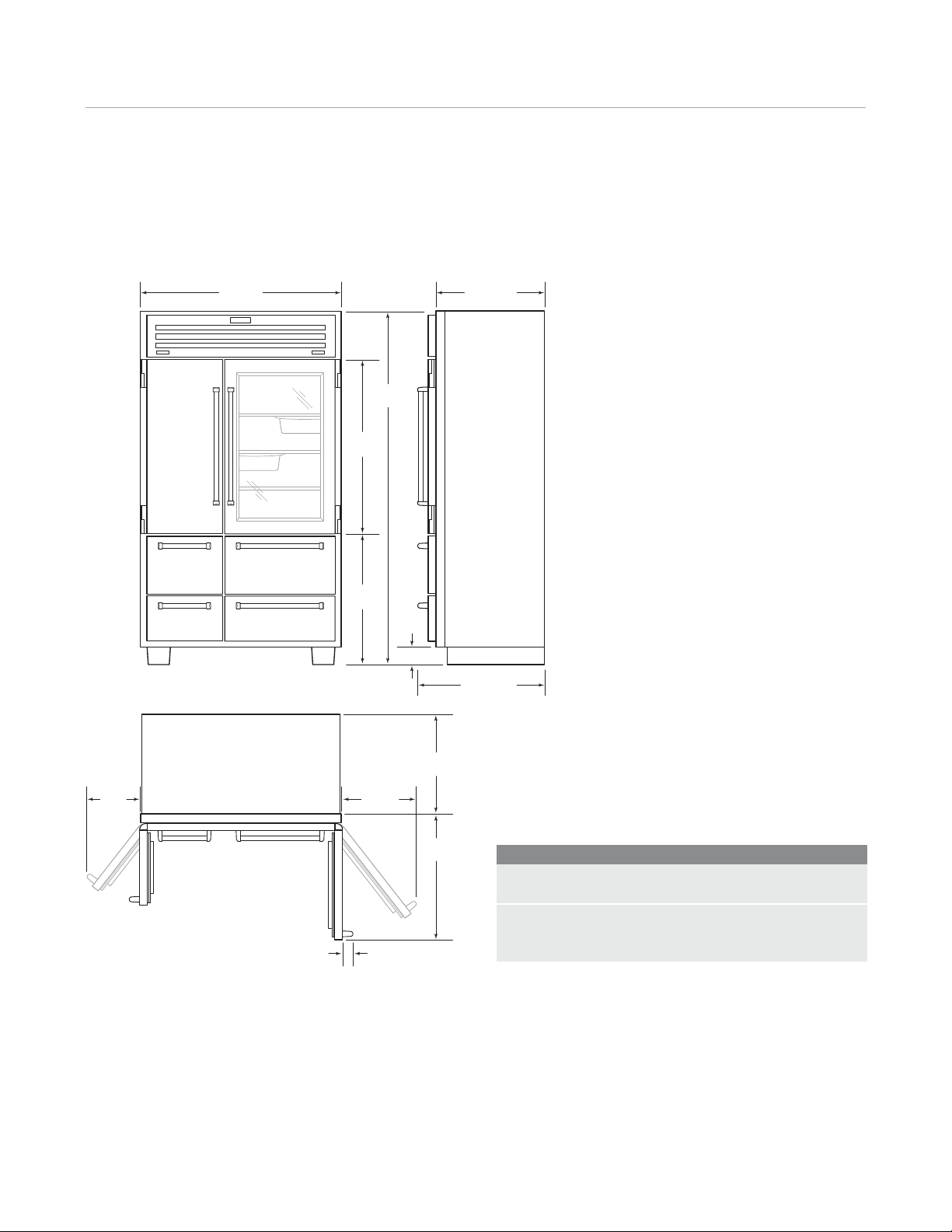

Overall Dimensions

MODELS 648PRO AND 648PROG

48" (1219)

HEIGHT DIMENSIONS ±

1

/2" (13)

421/8"

(1070)

301/2"

(775)

84"

(2134)

257/8" (657)

4" (102)

303/16" (767)

141/2"

(368)

21" (533)

23/8" (60)

237/8"

(606)

303/4"

(781)

SPECIFICATIONS

Capacity / Weight

INTERIOR CAPACITY R CU FT (L) FCUFT(L)

648PRO and 648PROG 18.4 (521) 11.7 (331)

SHIPPING WEIGHT LBS (KG)

648PRO 860 (390)

648PROG 875 (397)

Page 5

PRO 48 Site Preparation 5

subzero.com/specs

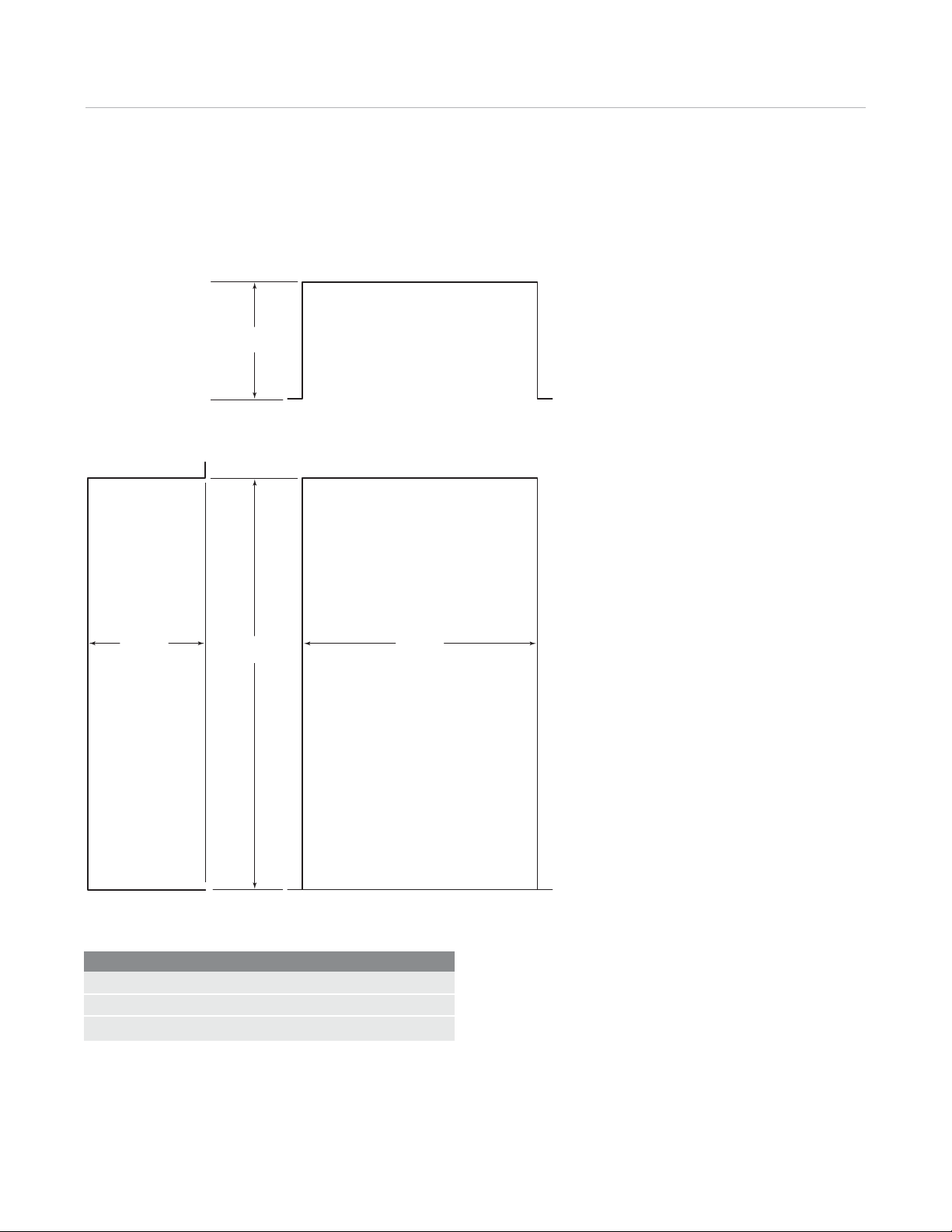

Opening Dimensions

STANDARD AND FLUSH BUILT-IN INSTALLATIONS

TOP VIEW

OPENING

DEPTH

OPENING

DEPTH

OPENING

HEIGHT

OPENING

WIDTH

FRONT VIEWSIDE VIEW

Opening Dimensions Standard Flush

Opening Width 471/2" (1206) 48" (1219)

Opening Height 833/4" (2127) 841/8" (2137)

Opening Depth 24" (610) 26" (660)

IMPORTANT NOTE: For standard built-in installations, the

face frame of the unit will extend 2" (51) beyond cabinetry.

In flush built-in installations, the front of the face frame will be

flush with surrounding cabinetry.

Page 6

PRO 48 Site Preparation 6

Electrical Requirements

For PRO 48 models, the electrical supply should be

located within the shaded area shown in the illustration

below. Follow the National Electrical Code and local codes

and ordinances when installing the receptacle. A separate

circuit, servicing only this appliance is required. A ground

fault circuit interrupter (GFCI) is not recommended and

may cause interruption of operation.

Electrical Requirements

Power Supply 115 V AC, 60 Hz

Circuit Breaker 15 amp

Receptacle 3-prong grounding-type

The outlet must be checked by a qualified electrician to

be sure that it is wired with the correct polarity. Verify

that the outlet is properly grounded.

Do not use an extension cord or two-prong adapter.

Do not remove the power supply cord ground prong.

Always shut power off at the circuit breaker before

performing any installation, service or maintenance.

FRONT VIEW

7"

E

(178)

6"

(152)

751/2"

(1918)

FROM

FLOOR

Location of electrical supply.

Page 7

PRO 48 Site Preparation 7

subzero.com/specs

Plumbing Requirements

The PRO 48 has an automatic ice maker with an integrated

water filtration system. The water supply line should be

located within the shaded area shown in the illustrations.

The water line must not interfere with installation of the

anti-tip bracket.

The water supply line should be connected to the house

supply with an easily accessible shut-off valve between

the supply and the unit. Do not use self-piercing valves.

A saddle valve kit is available through your authorized

Sub-Zero dealer.

A reverse osmosis system can be used, provided there

is constant water pressure of 20 psi (1.4 bar) to 120 psi

(8.3 bar) supplied to the unit at all times. In this application, the water filtration system must be bypassed. Refer

to water filter bypass mode on page 16.

IMPORTANT NOTE: All installations must meet local

plumbing code requirements.

It is not recommended that the ice maker be connected to

a softened water supply. Water softener chemicals, such

as salt from a malfunctioning softener, can damage the ice

maker and lead to poor ice quality. If a softened water

supply cannot be avoided, make sure that the water

softener is well maintained and operating properly.

Plumbing Requirements

Water Supply Line

Water Pressure 35–120 psi (2.4–8.3 bar)

Excess Water Line for Connection 36" (914)

18"

(457)

FLOOR

FRONT VIEW

Location of water supply—

rear.

(152)

3"

6"

(76)

Location of water supply—

bottom.

1

/4" OD copper line

BACK WALL

18"

(457)

TOP VI EW

1

/2"

13)

(

6"

(152 )

IMPORTANT NOTE: Do not use with water that is microbi-

ologically unsafe or of unknown water quality without

adequate disinfection before or after the system. Systems

certified for cyst reduction may be used on disinfected

waters that may contain filterable cysts.

Page 8

PRO 48 Installation 8

Anti-Tip Bracket Installation

IMPORTANT NOTE: For either wood or concrete floor

To prevent the PRO 48 from tipping forward and

provide a stable installation, the unit must be secured

in place with the anti-tip bracket provided with the unit.

IMPORTANT NOTE: Placement of the anti-tip bracket is

critical to a stable installation. Failure to properly position

the anti-tip bracket will prevent it from engaging the unit.

The anti-tip bracket must be installed exactly 26" (660)

from the front of the face frame of the unit to the back of

the anti-tip bracket. Also, the centering line on the lower

flange of the anti-tip bracket must be centered in the

rough opening. Make sure the anti-tip bracket is installed

on a solid base. Refer to the illustration below.

To properly secure the anti-tip bracket for a stable installation, use all anti-tip bracket hardware as instructed for

wood or concrete floors.

applications, if the wood screws do not hit a wall stud in

any of the upper holes on the anti-tip bracket, use the

1

provided #8–18 x 1

/4" wood screw, #12 flat washer and

nylon zip-it wall anchor in its place.

IMPORTANT NOTE: In some installations the subflooring

or finished floor may necessitate angling the screws used

to fasten the anti-tip bracket to the back wall.

Make sure there are no electrical wires or plumbing in

the area which the screws could penetrate.

Anti-Tip Bracket Hardware

1 Anti-tip bracket

12 #12 x 21/2" PN HD wood screws

33/8"x33/4" Trubolt anchors

12 #12 flat washers

3 #8–18 x 11/4"ABPHHDscrews

3 Nylon zip-it wall anchors

Anti-tip bracket.

Page 9

PRO 48 Installation 9

subzero.com/specs

Anti-Tip Bracket Installation

WOOD FLOOR APPLICATIONS

Use the twelve #12 x 21/2" wood screws and the twelve

#12 flat washers provided. Drill pilot holes

3

/16" (5)

diameter maximum and make sure the screws penetrate

through the flooring material and into the wall plate a

3

minimum of

/4" (19). Make sure the screws hold tight.

Refer to the illustration below.

CONCRETE FLOOR APPLICATIONS

Use the three3/8"x33/4" concrete wedge anchors, six

#12x2

provided. Drill pilot holes

1

/2" wood screws and six #12 flat washers

3

/16" (5) diameter maximum and

make sure the screws penetrate through the flooring

material and into the wall plate a minimum of

Then drill

minimum of 1

3

/8" (10) diameter holes into the concrete a

1

/2" (38) deep. Make sure the anchors and

3

/4" (19).

screws hold tight. Refer to the illustration below.

INSTALL CONCRETE WEDGE ANCHORS:

1) Drill a3/8" (10) diameter hole any depth exceeding the

minimum embedment. Clean the hole or continue

drilling additional depth to accommodate drill fines.

Use a carbide drill bit manufactured within ANSI

B94.12-77.

2) Assemble the washer and nut flush with the end of

anchor to protect threads. Drive the anchor through the

material to be fastened until the washer is flush with

the surface material.

3) Expand the anchor by tightening the nut 3–5 turns past

hand-tight position or to 25 foot-pounds of torque.

Always wear safety glasses and use other necessary

protective devices or apparel when installing or

working with anchors.

Anchors are not recommended for use in lightweight

masonry material such as block or brick, or for use in

new concrete which has not had sufficient time to cure.

The use of core drills is not recommended to drill holes

for the anchors.

233/4"

233/4"

(603)

WALL PLATE

SUBFLOORING

WOOD FLOOR

(603)

FINISHED

FLOORING

233/4"

(603)

WALL PLATE

SUBFLOORING

CONCRETE

FLOOR

Wood floor. Concrete floor.

233/4"

(603)

FINISHED

FLOORING

11/2"(38)

min

Page 10

PRO 48 Installation 10

Unpack the Unit

Uncrate the PRO 48 unit and inspect for any damages.

Remove the wood base and discard the shipping bolts

and brackets that hold the wood base to the bottom of the

unit. Remove and discard all packing materials.

IMPORTANT NOTE: Do not discard the kickplate, anti-tip

bracket and hardware or corner protectors. These items

will be needed for installation.

Retract the front leveling legs all the way up to allow the

unit to be moved into position more easily. You will extend

the front leveling legs down and make adjustments once

the unit is in position.

Remove the drain pan from the base of the unit to avoid

damage to the drain pan, and allow for proper placement

of the appliance dolly.

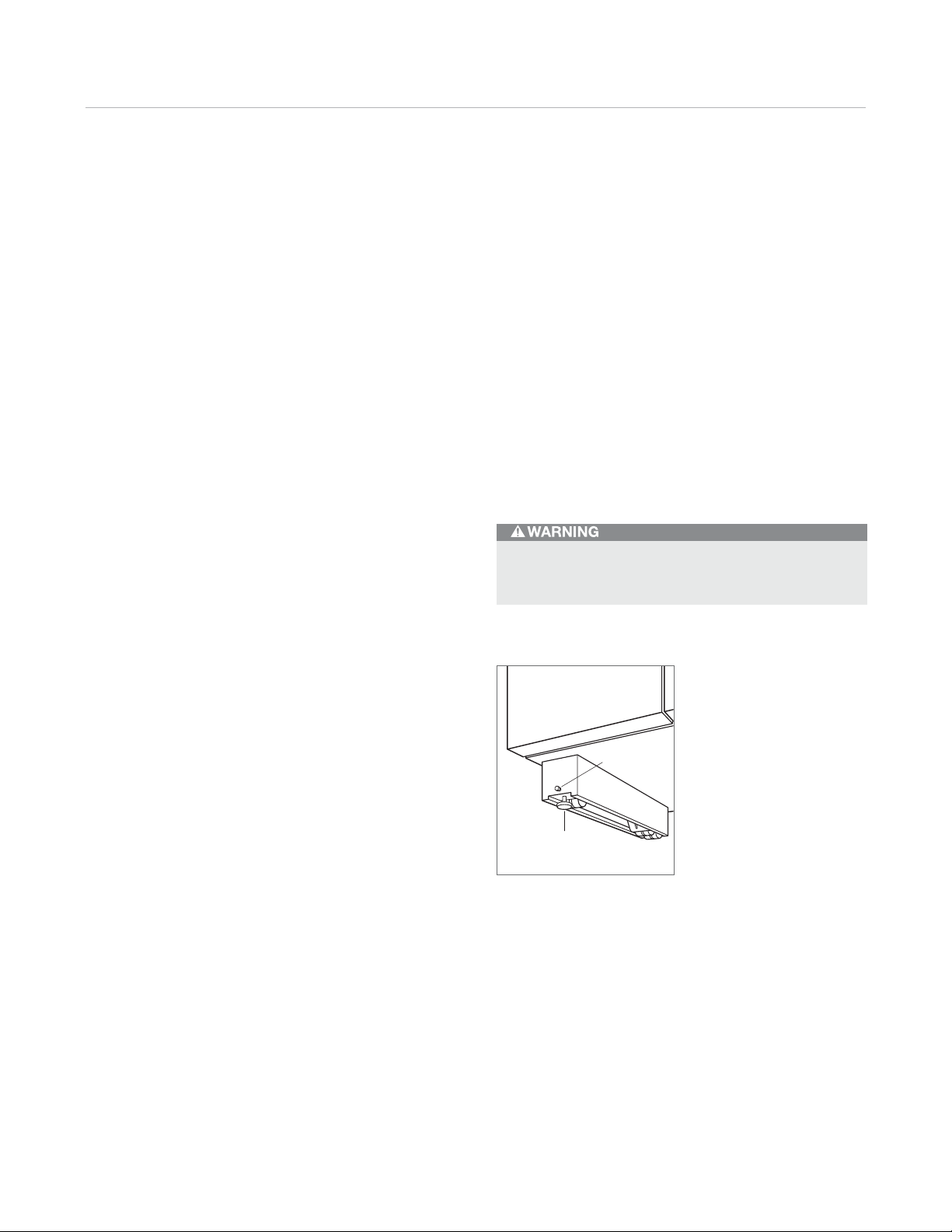

Grille Removal

In order to prevent damage to the PRO 48 grille, the top

grille assembly should be removed prior to moving the

unit.

To remove the grille assembly, pull out on the bottom edge

of the grille and tilt the grille frame forward. Disconnect the

network cables which connect the exterior temperature

displays on the grille to the display module. Cut the two

white cable ties which attach the network cables to the

right grille support and disconnect the cables. The cable

ties should be replaced with the extra cable ties provided,

once the unit is properly installed. Remove the three grille

bolts from base of the grille and the upper grille screw.

Remove the grille assembly. Refer to the illustrations

below.

Reverse this procedure to reinstall the grille assembly.

GRILLE

SCREW

NETWORK

CABLES

GRILLE BOLT

Lift grille assembly. Grille removal.

Page 11

PRO 48 Installation 11

subzero.com/specs

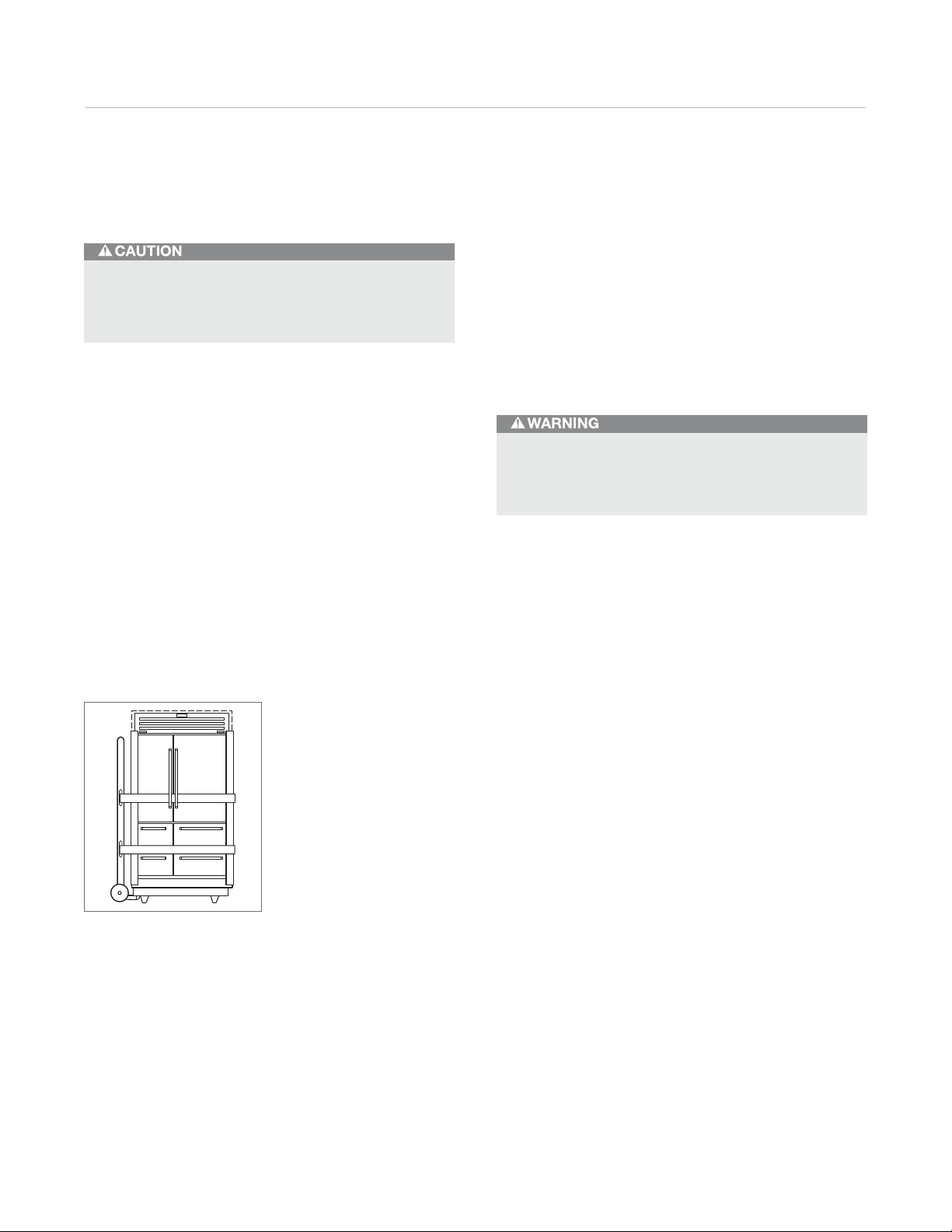

Position the Unit

IMPORTANT NOTE: If for any reason the unit has been

Before moving the PRO 48 unit into position, secure

doors and drawers closed and protect any finished

flooring.

Use an appliance dolly to move the unit near the rough

opening. The PRO 48 is equipped with rollers, so it can be

moved into position more easily.

laid on its back or side, you must allow the unit to stand

upright for a minimum of 24 hours before connecting

power.

Shut off power to the electrical outlet. Plug the power cord

into the grounded outlet and roll the unit into position.

Make sure the anti-tip bracket is properly engaged.

When securing the unit on the appliance dolly, use the

corner protectors (retained from the packing materials)

under the strapping to avoid damage to the stainless steel

exterior. Also, secure the doors and drawers closed with

the strapping. Refer to the illustration below for proper

placement of the appliance dolly.

IMPORTANT NOTE: The rear levelers must be in their

lowest position in order to roll the unit back into the rough

opening. Leveling cannot be completed until the unit is in

position.

The PRO 48 is very heavy—885 lbs (401 kg) or 900 lbs

(408 kg). Be sure to have adequate manpower when

moving and positioning the unit.

Moving the PRO 48.

Page 12

PRO 48 Installation 12

Water Line Connection

Approximately 3' (.9 m) of1/4" plastic tubing is connected

1

to the ice maker with a preassembled

connection at the end. This tubing is located under the

unit.

The water line fitting connection kit, provided with the unit,

contains a

1

/4" compression sleeve and nut for connection

to the household water line. Place the sleeve and nut on

the water line and fasten to the connection at the end of

the tubing under the unit. Do not over tighten. Check all

water line fittings for leaks. Make sure the drain pan can

be removed without water line interference.

Purge the water line prior to final connection to the unit.

This will remove any debris that may be present in the

tubing from installing the new water line.

IMPORTANT NOTE: If a reverse osmosis system is used,

it is recommended that the water filtration system be

bypassed. Refer to water filter bypass mode on page 16.

IMPORTANT NOTE: Let your customer know that the ice

maker will not produce ice immediately, and that the first

few batches of ice produced should be discarded. Allow

24 hours for proper ice production.

/4" compression

Level the Unit

Once the unit is in position, extend the front leveling legs

down by tur ning the legs counterclockwise and adjust the

height. The rear height adjustment can be made from the

5

front of the base. Use a

rollers. Turn the

5

/16" hex bolt clockwise to raise the unit or

counterclockwise to lower it. Refer to the illustration below

for location of the rear roller base adjustment.

When the unit is properly leveled, door and drawer adjustments are less likely to be necessary.

IMPORTANT NOTE: Be sure to reference leveling of the

unit to the floor and not surrounding cabinetry. This could

affect the operation of the unit, such as door closing.

To reduce the possibility of the unit tipping forward,

the front leveling legs must be in contact with the floor.

/16" socket to adjust the rear

IMPORTANT NOTE: Water lines must not be exposed to

freezing temperatures. Exposure could cause damage to

the unit and home.

REAR

ADJUSTMENT

FRONT

LEVELING LEG

Rear roller base adjustment.

Page 13

PRO 48 Installation 13

subzero.com/specs

Door Adjustment

Make sure both doors of the PRO 48 are properly aligned

for function and appearance. If not, adjustments can be

made to the cabinet hinges.

IMPORTANT NOTE: The unit must be properly leveled

before adjusting hinges.

If the PRO 48 is properly installed and leveled, it may still

be necessary to adjust doors left to right. Adjustments are

performed at the top and / or bottom cabinet hinges.

HINGE ADJUSTMENT

1) Lift up the vent portion of the top grille.

2) Remove the door by opening to approximately 90° and

lifting the door off cabinet hinges. Refer to the illustration below.

The doors of the PRO 48 are very heavy. Use care when

removing them.

IMPORTANT NOTE: When adjusting hinges, it is important

to keep hinges parallel to the face of the door and side of

the cabinet. Excessive misalignment will result in door

light switch malfunction. If the switch is not activated, the

fan will not operate and lights will remain on. This will

result in elevated cabinet temperatures. After hinge adjustments are made, check for proper functioning of door light

switch. Refer to the illustration below.

3) Remove hinge pins.

4) Loosen the two cabinet hinge screws

1

/4 to1/2 turn.

Refer to the illustration below.

5) Reinstall hinge pins and door. With the door open,

using the Allen wrench provided, turn the adjustment

screw to adjust the cabinet hinge. Refer to the illustration below.

6) Close the door and check alignment. If additional

adjustment is required, repeat these steps until the

door is properly aligned.

HINGE

SCREW

HINGE

PIN

CABINET

HINGE

ADJUSTMENT

SCREW

LIGHT

SWITCH

Door light switch.

Door removal. Hinge adjustment.

Page 14

PRO 48 Installation 14

Drawer Adjustment

Make sure all drawers of the PRO 48 are properly aligned

for function and appearance. If not, vertical and horizontal

adjustments can be made to the drawers.

The drawer must be removed to make vertical and horizontal adjustments. To remove the drawer, pull the drawer

all the way out until it stops, lift up evenly on both sides of

the drawer front and pull out.

To reinstall the drawer, raise the front of the drawer and

place onto the drawer slide tracks. Be sure to engage the

front of the drawer slide with the drawer assembly. Make

sure the drawer is fully engaged onto the tracks. Check

alignment of the drawer closer. If the closer catch does

not align with closer pin, adjust the position of drawer

closer.

VERTICAL ADJUSTMENT

1) Loosen the drawer slide mounting screws.

2) Using a

7

/16" open-end wrench, turn the adjustment

screw until proper alignment is achieved. Refer to the

illustration below.

HORIZONTAL ADJUSTMENT

1) Loosen the two front drawer slide screws. Refer to the

illustration below.

2) Move adjustment blocks to desired position and

tighten screws.

3) Release the rear adjustment block by disengaging the

snaps.

4) Move the block forward to shift drawer to the right, and

back to shift drawer to the left. Each position will move

the drawer .030" (.8). Both sides should be moved in

the same direction.

5) Snap the block over the pins located on the rear

adjuster. Refer to the illustration below.

6) After adjustment, tighten all screws and reinstall the

drawer. Check the drawer seal for proper gasket

seating.

3) After adjustment, tighten all screws and reinstall the

drawer. Check the drawer seal for proper gasket

seating.

MOUNTING

ADJUSTMENT

SCREW

Vertical adjustment.

SCREW

REAR

ADJUSTMENT

BLOCK

SLIDE

SCREW

Horizontal adjustment.

Page 15

PRO 48 Installation 15

subzero.com/specs

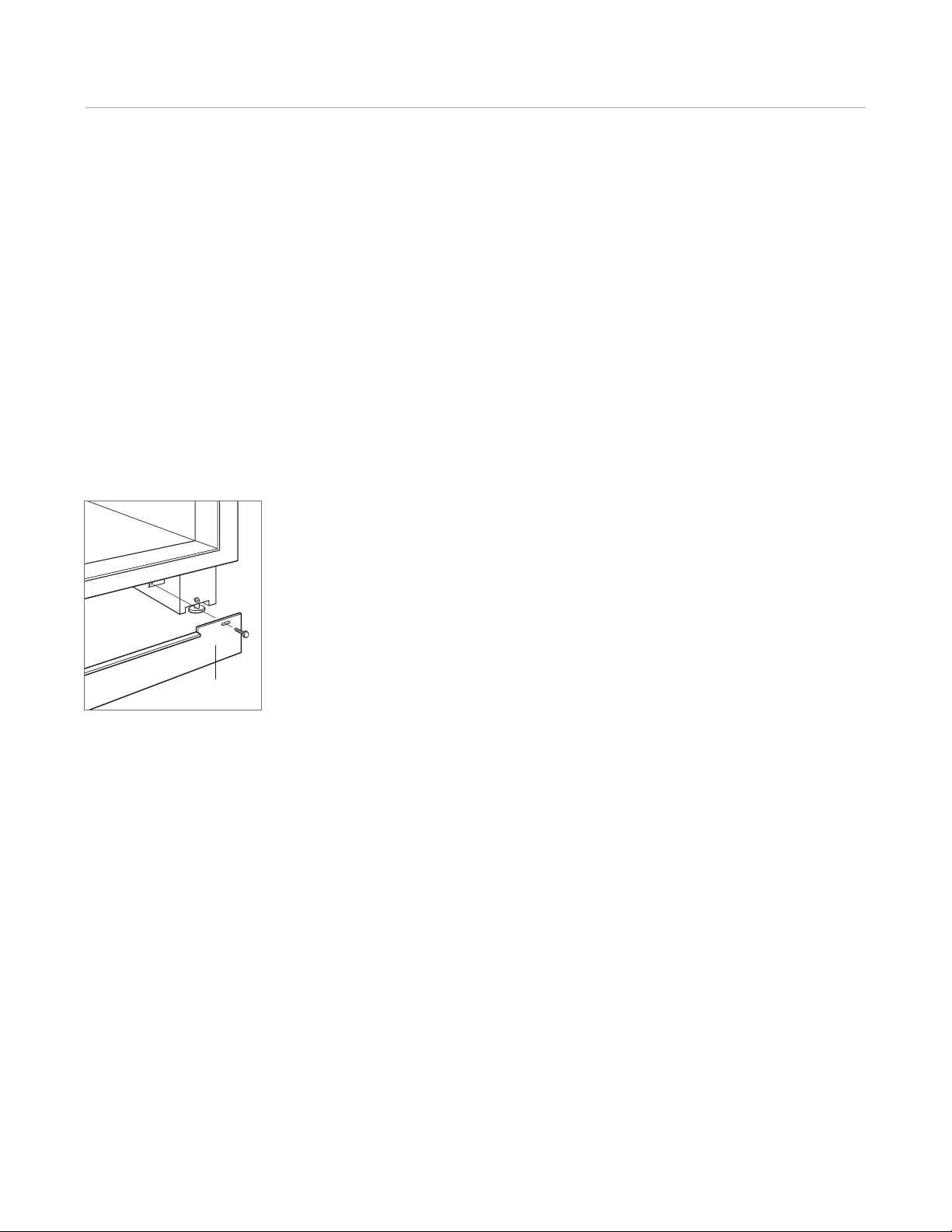

Complete the Installation

INSTALL KICKPLATE

Make sure the drain pan is in the proper position before

installing the kickplate. To install, screw the kickplate to

brackets attached to the inside surface of each roller

base. Refer to the illustration below.

IMPORTANT NOTE: The kickplate must be removable for

service. The floor cannot interfere with removal.

Reinstall the grille by reversing the procedure outlined on

page 10. Turn power back on to the electrical outlet.

Optional Accessories

90°DOORSTOP

The doors of PRO 48 models open to 135°. For installations where the door opening must be limited, an optional

90° door stop kit is available through your authorized

Sub-Zero dealer. To obtain local dealer information, visit

the find a showroom section of our website, subzero.com.

SIDE AND TOP PANELS

For freestanding applications, stainless steel side and top

panels are available through your authorized Sub-Zero

dealer. Installation instructions are provided with the

panels. To obtain local dealer information, visit the find a

showroom section of our website, subzero.com.

KICKPLATE

Kickplate installation.

Page 16

PRO 48 Installation 16

Water Filtration System

WATER FILTER BYPASS MODE

If you choose not to use the water filtration system, the

system can be placed in water filter bypass mode by

removing the water filter cartridge. In this mode, the water

supplied to the ice maker will not be filtered and the water

filter monitor will be deactivated.

Lift the top grille assembly to access the water filter

cartridge. To lift the grille, pull out on the bottom edge of

the grille and tilt the grille frame forward. Refer to the

illustration.

WATER FILTER

Slowly rotate the water filter cartridge one-quarter tur n

counterclockwise to disengage. Gently twist until the cartridge is free from the base. DO NOT pull. There will be

water in the filter cartridge, so it is normal for a small

amount of water to spill out. Refer to the illustration.

The water filtration system automatically goes into bypass

mode when the filter cartridge is removed.

Lift grille assembly. Water filter removal.

Page 17

PRO 48 Installation 17

subzero.com/specs

Installation Checklist

To ensure a safe and proper installation, the following

checklist should be completed by the installer to ensure

that no part of the installation has been overlooked.

INSTALLATION CHECKLIST

Have all packing materials been removed?

Turn the unit on. Is it operating properly?

If not, is the unit plugged in? Is the control turned on?

Is the water supply line connected and not leaking? Is

the water supply turned on and ice maker control on?

Has the anti-tip bracket been installed securely and

properly engaging the unit?

Is the unit leveled properly on a solid, level floor? Has

the drain pan and kickplate been installed?

Has the top grille assembly been reinstalled?

Are doors and drawers aligned for proper appearance

and operation? Is a 90° door stop required?

Has the water filter cartridge been removed (for homes

with a reverse osmosis system)?

Does the customer understand the unit's operation?

Does the customer have the warranty package?

Have any installation or service problems been noted

on the product registration card? Has the registration

card been mailed in?

Have stainless steel surfaces been inspected for any

imperfections? This is to be done by the authorized

Sub-Zero dealer or installer with the customer, upon

completion of installation. Stainless steel surfaces are

covered by a limited 60-day warranty for cosmetic

defects.

Page 18

Service Information 18

Service Information

If service is necessary, maintain the quality built into your

PRO 48 unit by calling Sub-Zero factory certified service.

For the name and number of Sub-Zero factory certified

service nearest you, check the contact & support section

of our website, subzero.com or call Sub-Zero customer

service at 800-222-7820.

When calling for service, you will need the model and

serial number of your unit. Both numbers are listed on the

product rating plate, located on the left side of the top

freezer drawer compartment (drawer must be open).

Refer to the illustration below.

If you are storing or disposing of your old refrigerator or

freezer, please do it

safely. Remove the

doors or tightly secure

the doors closed.

Child entrapment

accidents can be tragic.

RATING

PLATE

Location of rating plate

(open drawer).

Page 19

The information and images in this guide are the copyright property of Sub-Zero, Inc. Neither this guide nor any information or images contained herein may be

copied or used in whole or in part without the express written permission of Sub-Zero, Inc. ©Sub-Zero, Inc. all rights reserved.

Wolf, Wolf & Design, Wolf Gourmet, W & Design and the color red as applied to knobs are registered trademarks and service marks of Wolf Appliance, Inc.

Sub-Zero, Sub-Zero & Design, Dual Refrigeration, Constant Care and The Living Kitchen are registered trademarks and service marks of Sub-Zero, Inc.

(collectively,the “Company Marks.”) All other trademarks or registered trademarks are property of their respective owners in the United States and other countries.

Page 20

SUB-ZERO, INC. P. O. BOX 44848 MADISON, WI 53744 SUBZERO.COM 800.222.7820

7020379 REV-A 10/2010

Loading...

Loading...