Page 1

WINE STORAGE

INSTALLATION GUIDE

GUÍA DE INSTALACIÓN

GUIDE D’INSTALLATION

GUIDA ALL’INSTALLAZIONE

INSTALLATIONSANLEITUNG

Page 2

WINE STORAGE

Contents

2 Wine Storage

3 Model ICBUW-24 / ICBUW-24FS Site Preparation

4 Model ICBUW-24 / ICBUW-24FS Installation

7 Model ICBBW-30 Site Preparation

10 Model ICBBW-30 Installation

Features and specifications are subject to change at any

time without notice.

Important Note

To ensure this product is installed and operated as safely

and efficiently as possible, take note of the following types

of highlighted information throughout this guide:

IMPORTANT NOTE highlights information that is especially

important.

CAUTION indicates a situation where minor injury or product

damage may occur if instructions are not followed.

WARNING states a hazard that may cause serious injury or

death if precautions are not followed.

IMPORTANT NOTE: Save these instructions for the local

electrical inspector.

Product Information

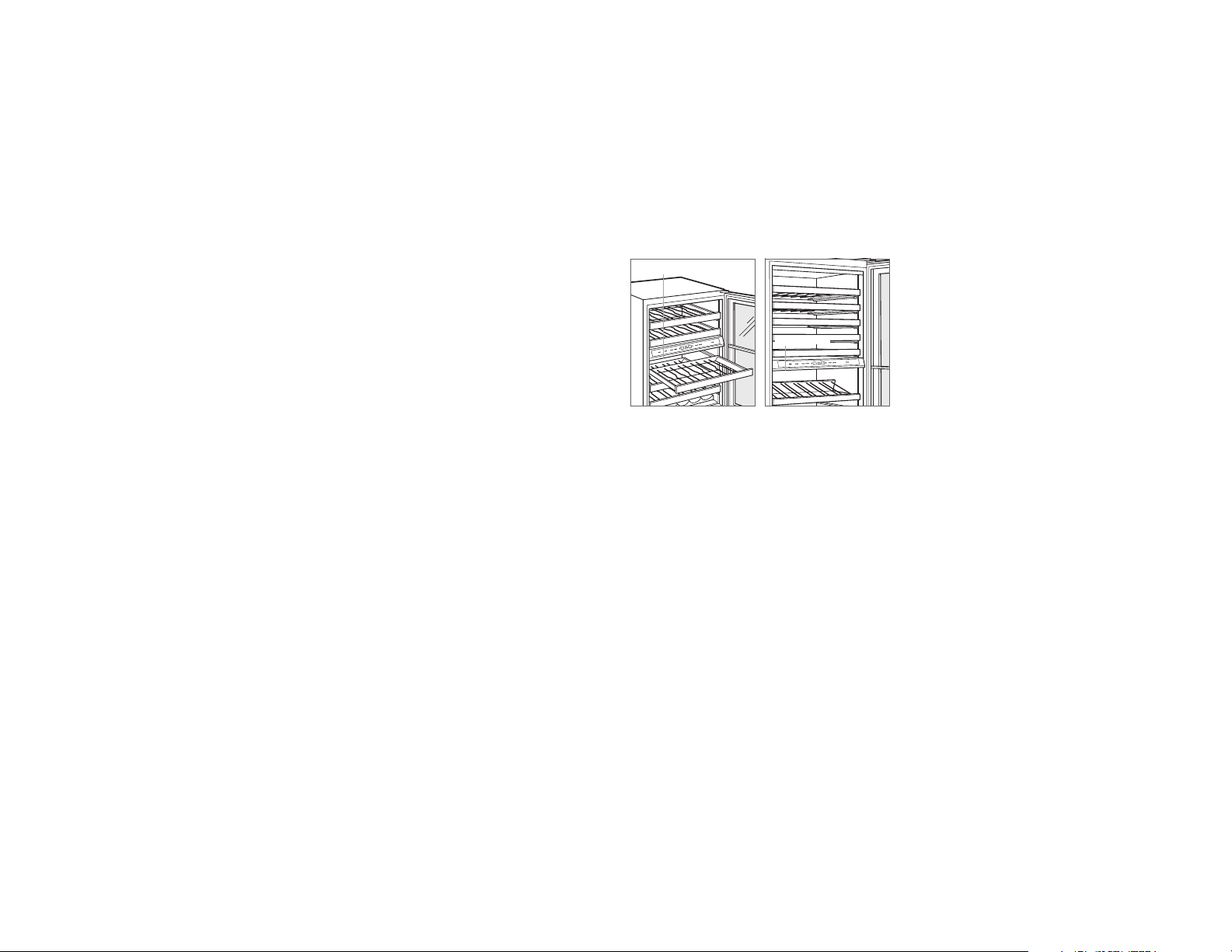

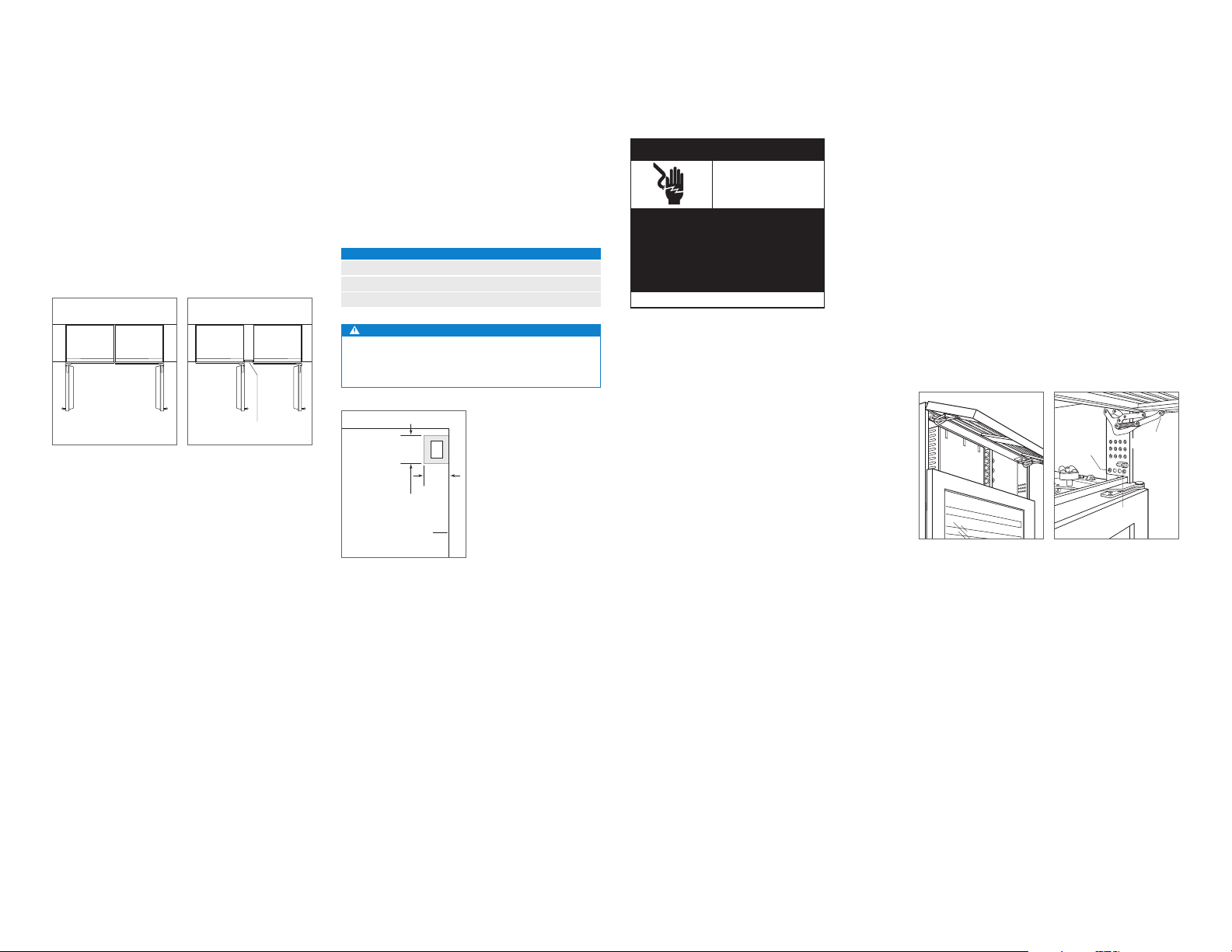

Important product information including the model and

serial number are listed on the product rating plate. The

rating plate is located on the underside of the control panel,

on the left. Refer to the illustrations below.

If service is necessary, contact Sub-Zero factory certified

service with the model and serial number.

RATING PLATE

RATING PLATE

Models ICBUW-24 and

ICBUW-24FS.

Model ICBBW-30.

Tools and Materials

• Screwdrivers—standard, Phillips and Torx.

• Power drill.

• Drill bits (masonry bits required for concrete installation).

• Standard socket and wrench set.

• .6 m and 1.2 m levels.

• Material to protect home, flooring and cabinetry during

installation.

2 | English

Page 3

MODEL ICBUW-24 / ICBUW-24FS SITE PREPARATION

Opening Dimensions

MODEL ICBUW-24

610 mm

OPENING

DEPTH

TOP VIEW

876 mm

OPENING

HEIGHT

SIDE VIEW FRONT VIEW

OPENING WIDTH W

ICBUW-24 610 mm

Two 610 mm Models* 1222 mm

*A dual installation kit will be required for this installation.

W

OPENING WIDTH

DUAL INSTALLATION

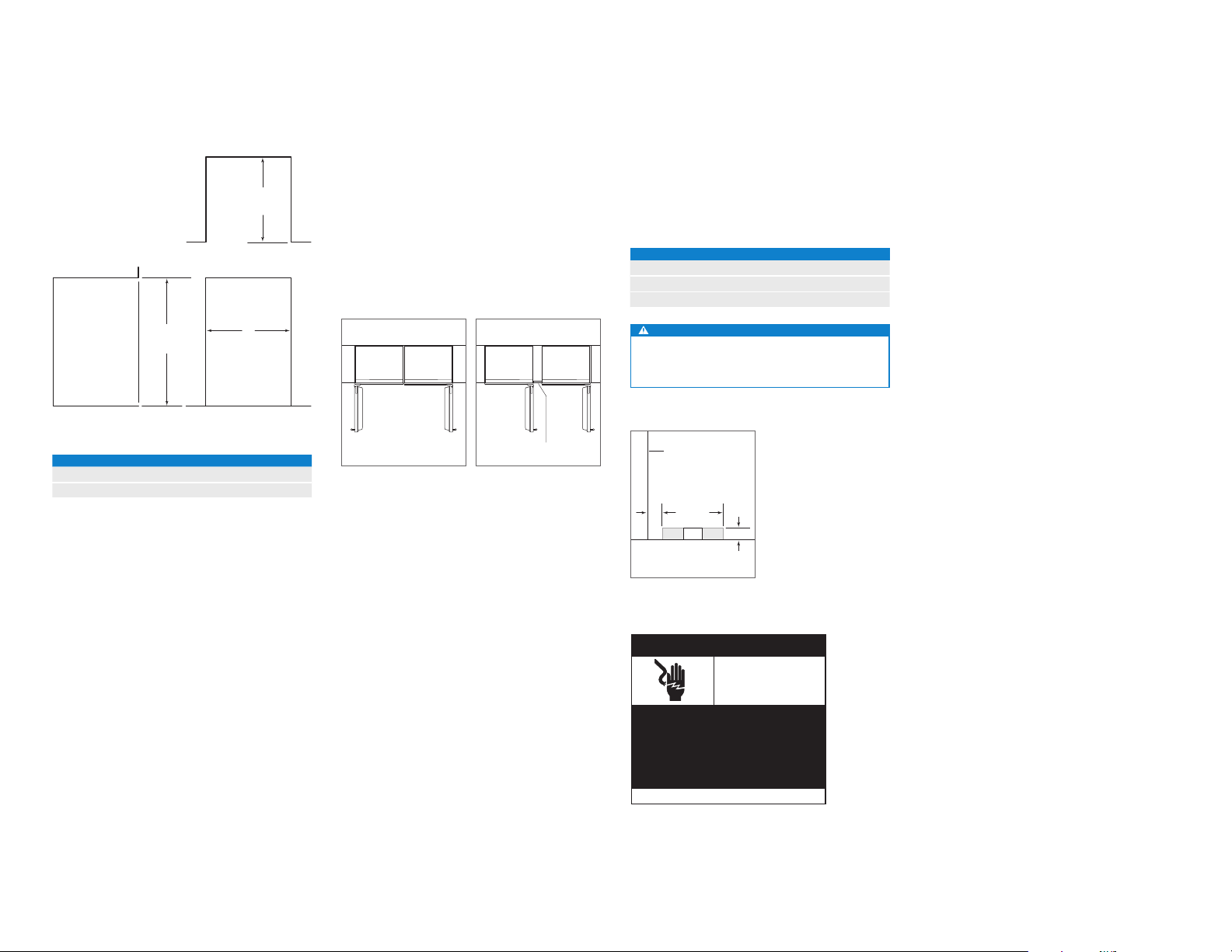

If two units are installed side by side, a dual installation kit

may be required. Installations without a custom filler strip

require a dual installation kit. If a dual installation kit is not

specified, a 51 mm filler strip is recommended between

units. Dual installations without a filler strip can only be

accomplished using two units with opposite hinges. Refer to

the illustrations below.

Dual installation kits are available through an authorized

Sub-Zero dealer.

WITHOUT FILLER STRIP

Opposite hinges.

FILLER STRIP

Same side hinges.

Electrical

Installation must comply with all applicable electrical codes

and be properly grounded (earthed).

The electrical supply should be located within the shaded

area shown in the illustration below. A separate circuit, servicing only this appliance is required. A ground fault circuit

interrupter (GFCI) is not recommended and may cause interruption of operation.

ELECTRICAL REQUIREMENTS

Power Supply 220-240 V AC, 50/60 Hz

Circuit Breaker 10 amp

Receptacle grounding-type (earthed)

CAUTION

The outlet must be checked by a qualied electrician to

be sure that it is wired with the correct polarity. Verify

that the outlet is properly grounded (earthed).

LEFT SIDE

OF OPENING

51

394 mm

mm

E

FLOOR

76 mm

Preparation

To operate properly, the door must open a minimum of 90°.

Use a minimum 76 mm filler in corner installations to assure

a 90° door opening.

Uncrate the unit and inspect for damage. Remove and

recycle packing materials. Do not discard the kickplate, antitip bracket, hardware and the leveling legs which hold the

wood base to the bottom of the unit.

Electrical supply location.

Electrical

Shock

Hazard

Plug power cord directly into a properly

grounded (earthed) outlet.

Do not defeat the grounding (earthing)

nature of the plug.

Do not use adapter or extension cord.

Failure to follow these instructions could

cause serious injury or death.

See installation instructions

subzero.com | 3

Page 4

MODEL ICBUW-24 / ICBUW-24FS SITE PREPARATION MODEL ICBUW-24 / ICBUW-24FS INSTALLATION

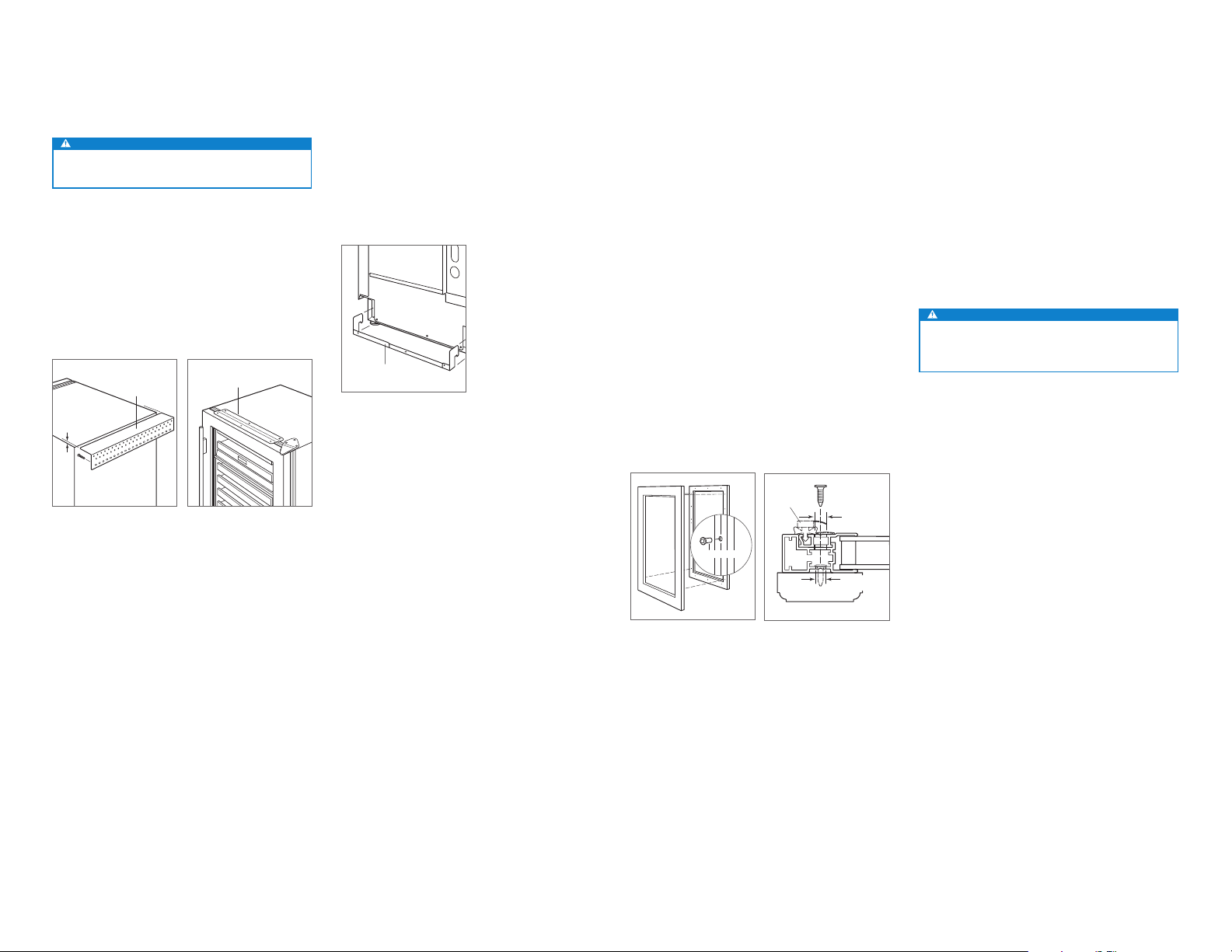

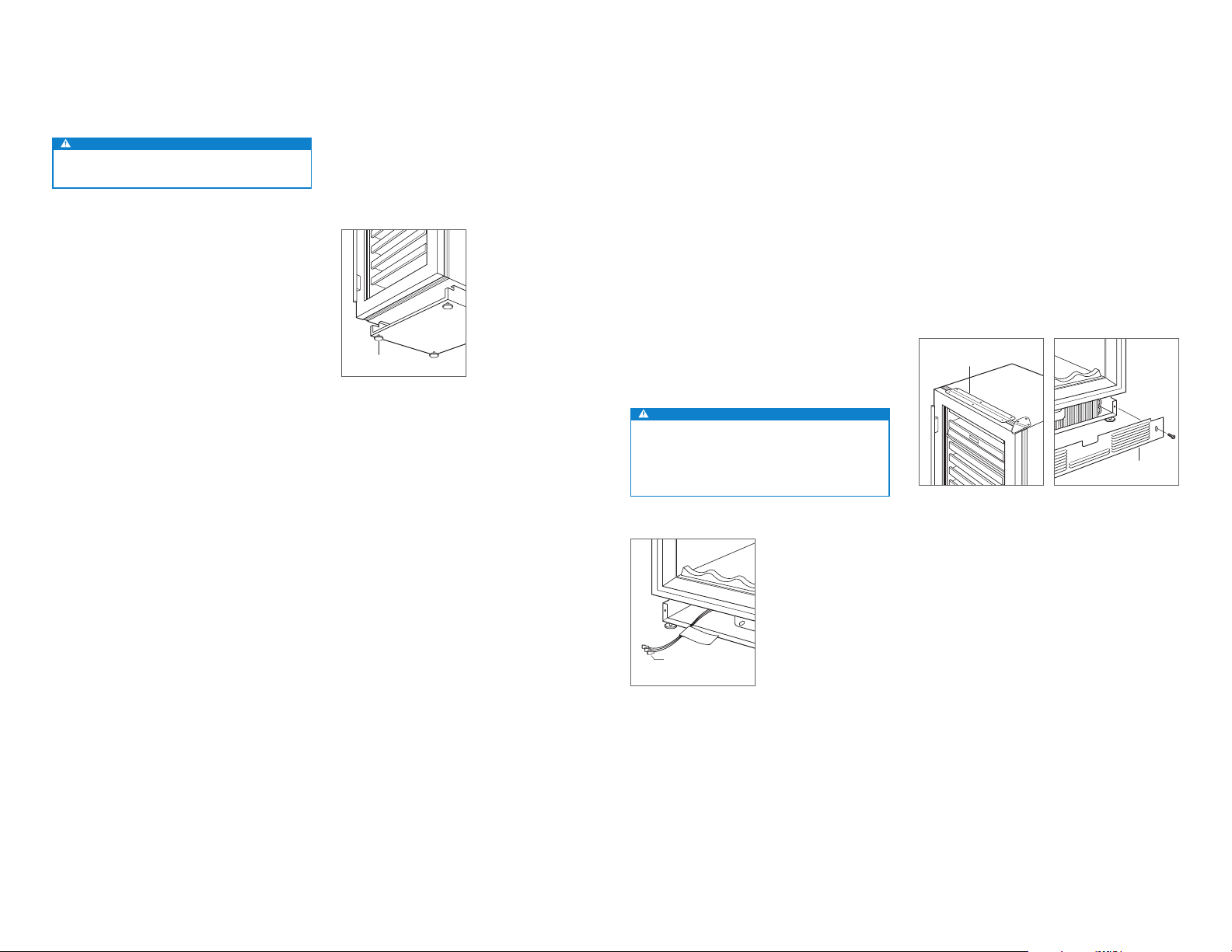

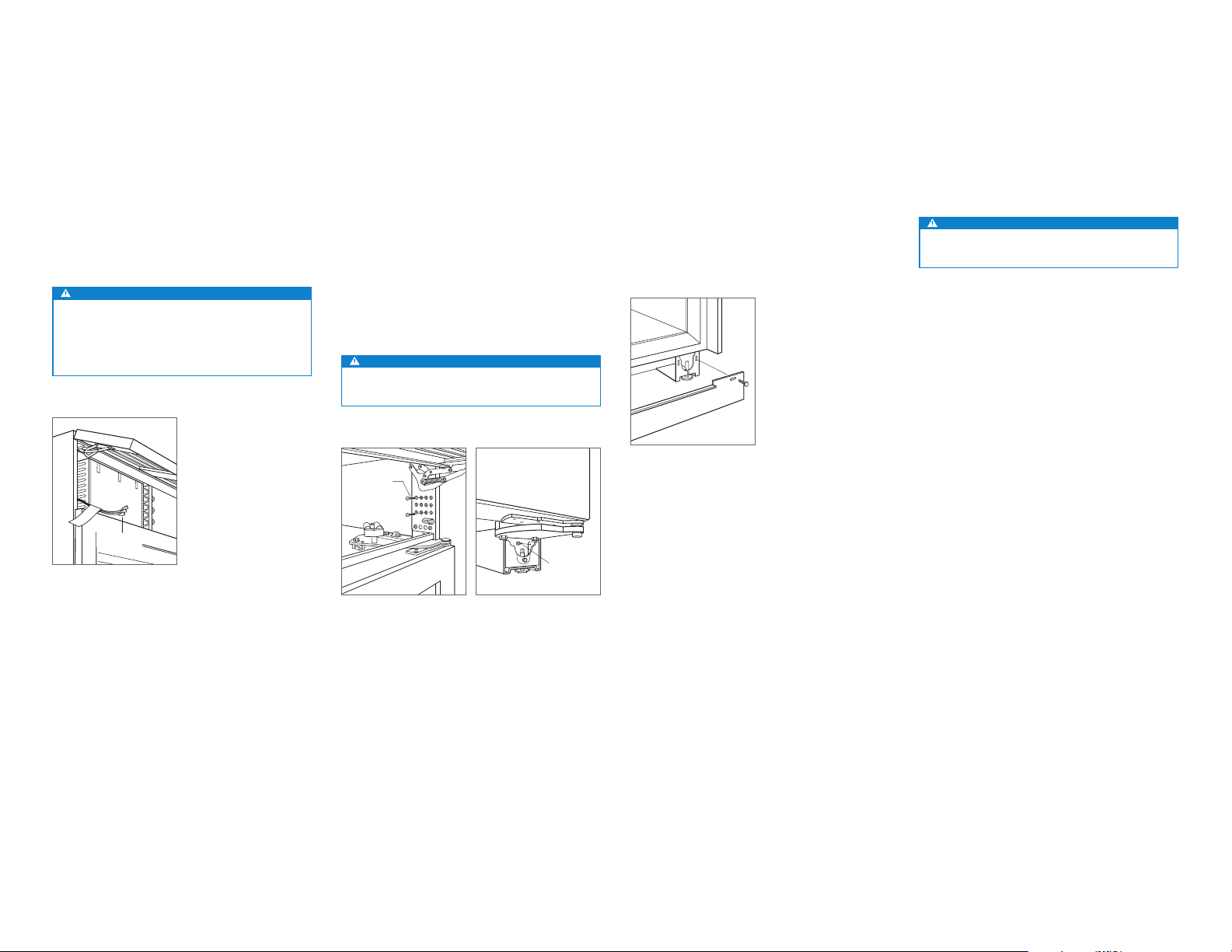

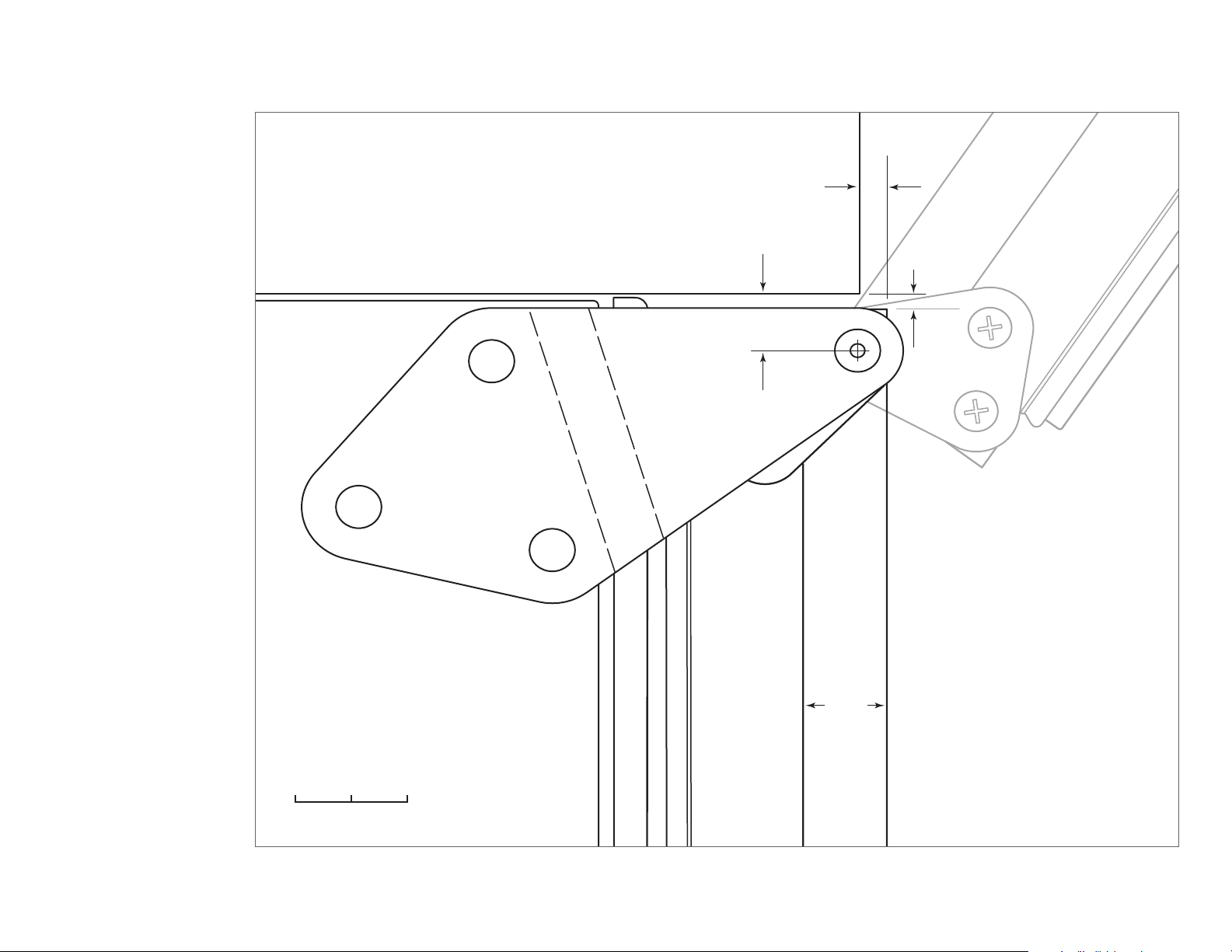

Anti-Tip Bracket

WARNING

To prevent the unit from tipping forward, the anti-tip

bracket must be installed.

MODEL ICBUW-24

The anti-tip bracket should be attached to the wall behind

the unit with the bracket flange located 6 mm above the top

of the unit. Refer to the illustration below. Failure to properly

position the anti-tip bracket will prevent proper engagement.

For installations that cannot accommodate the anti-tip

bracket, a countertop bracket is provided to secure the unit

to the countertop. Refer to the illustration below.

6 mm

Anti-tip bracket (ICBUW-24). Countertop bracket.

COUNTERTOP

BRACKET

MODEL ICBUW-24FS

The back of the anti-tip bracket must be installed 625 mm

from the front and centered behind the unit. Refer to the

illustration below. Refer to page 10 for wood and concrete

floor applications.

ANTI-TIP BRACKET

Anti-tip bracket (ICBUW-24FS).

Custom Panel

MODEL ICBUW-24

For overlay applications, a custom door panel must be

installed. Panel size is critical for a proper fit. To verify panel

requirements and dimensions, refer to the Sub-Zero design

guide.

Finish all sides of the custom panel. They may be visible

when the door is open or through the glass door.

The custom overlay door panel is attached using screws

provided, through the door frame. Screw locations are

marked on the back of the custom panel using tenon centers inserted into holes of the door frame.

With the unit secured and door closed, hold the custom

panel in desired position on the door. Lightly tap the front

of the panel to locate mounting positions. Remove tenon

centers. Refer to the illustration below.

The door frame has mounting holes to accommodate

Sub-Zero accessory handles. If handle mounting holes are

not utilized, the handle should be attached to the custom

panel prior to mounting. Screw heads may need to be countersunk into the panel for proper alignment.

DOOR

FRAMEPANEL

TENON CENTER

GASKET

11 mm

DIAMETER

6 mm

DIAMETER

GLASS

To mount the custom panel, open the door and use predrilled holes to position the panel. Drive screws into the

panel through black tape on the door frame. Screw holes

are hidden behind the door gasket. Use as many screws as

necessary to secure the custom panel. Refer to the illustration below.

Adjustments can be made to the custom panel with a few

mounting screws in place, but not fully tightened. Once the

proper position is achieved, install and secure all screws.

Cover holes on the inside of the door frame with the cover

patches or plugs provided.

CAUTION

A solid panel cannot be installed over the glass door. A

solid door is available through an authorized Sub-Zero

dealer.

4 | English

Tenon center.

Door frame cross section.

Page 5

MODEL ICBUW-24 / ICBUW-24FS INSTALLATION

Placement

CAUTION

Before moving the unit into position, secure the door

closed and protect any nished ooring.

Use an appliance dolly to move the unit near the opening.

If the unit has been on its back or side, it must stand upright

for a minimum of 24 hours before connecting power.

If the unit will be connected to a home security system, run

lead wires through the compressor compartment prior to

positioning the unit. Once the unit is in position, wiring connection can be completed from the front.

Alignment

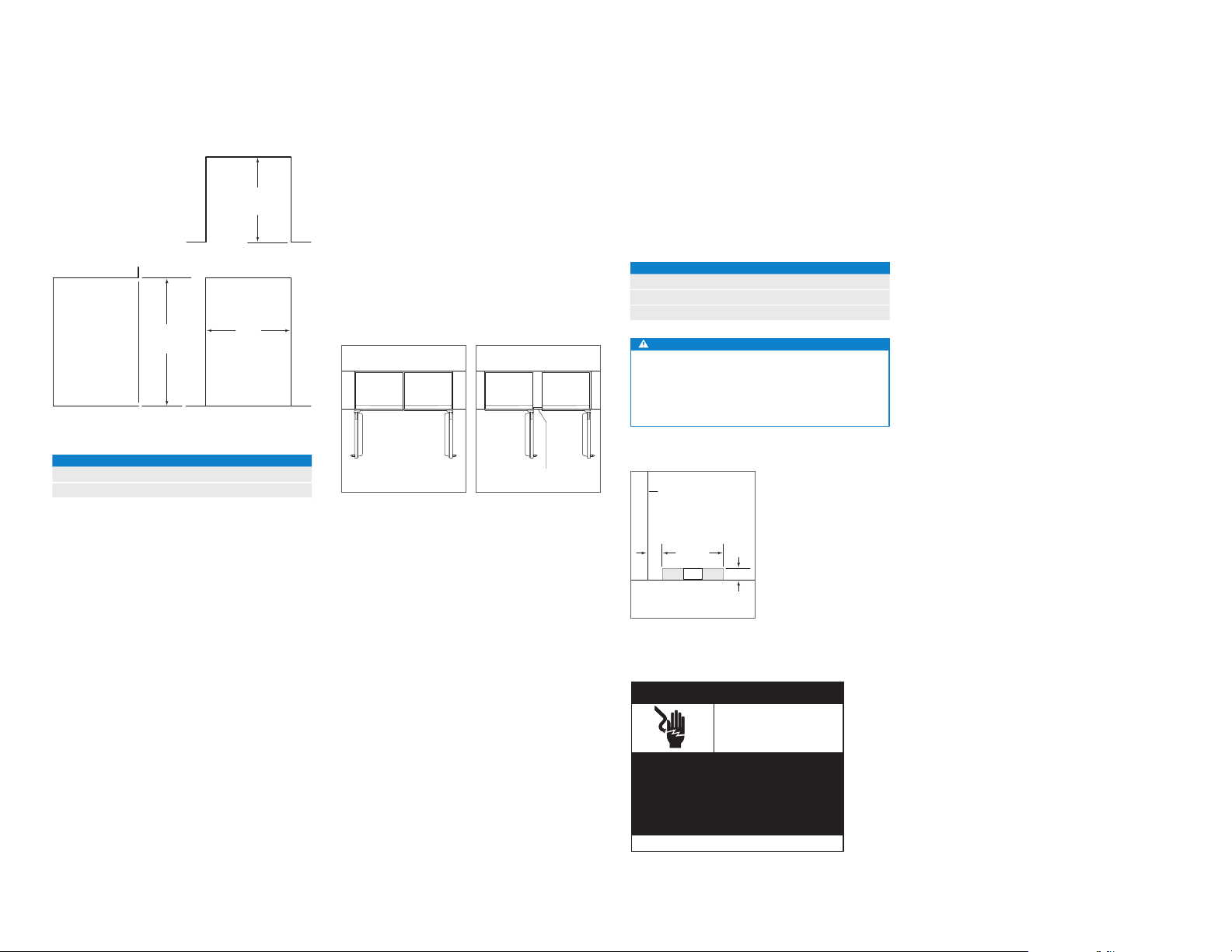

LEVELING

Level the unit before sliding it into position. Turn each of the

four leveling legs clockwise to raise the unit and counterclockwise to lower. Refer to the illustration below.

LEVELING LEGS

Leveling.

Completion

Plug the power cord into the grounded (earthed) outlet,

then slide the unit into position. Verify the anti-tip bracket is

properly engaged.

It may be necessary to install the unit 6 mm beyond the

front surface of adjacent cabinetry, to prevent interference

when the door is opened to 145°. Refer to the full-scale

template on page 6.

HOME SECURITY CONNECTION

If the unit will be connected to a home security system,

make connections to the leads shown in the illustration

below. Refer to the following color codes:

• Normally open contacts—white with red stripe wire.

• Normally closed contacts—white with blue stripe wire.

• Common—gray with white stripe wire.

Use the spade terminals or wire nuts provided to make

proper wiring connections.

CAUTION

The alarm circuit in the unit is intended as a lowvoltage, low-current device only. It should not be used

to switch line power. Any unused terminals should be

completely insulated and all wires should be secured

away from conductive or moving components.

ANCHORING

To anchor, use the countertop bracket provided to secure

the unit to the underside of the countertop. Refer to the

illustration below. If the countertop bracket can not be

utilized, install shims along the top and sides of the unit.

KICKPLATE INSTALLATION

Install the kickplate using the two screws provided. Refer

to the illustration below. The kickplate must be removable

for service. The floor cannot interfere with removal. Do not

cover the louvered section of the kickplate.

COUNTERTOP

BRACKET

KICKPLATE

Anchoring.

Kickplate installation.

HOME SECURITY

LEADS

Home security connection.

subzero.com | 5

Page 6

MODEL ICBUW-24 / ICBUW-24FS INSTALLATION

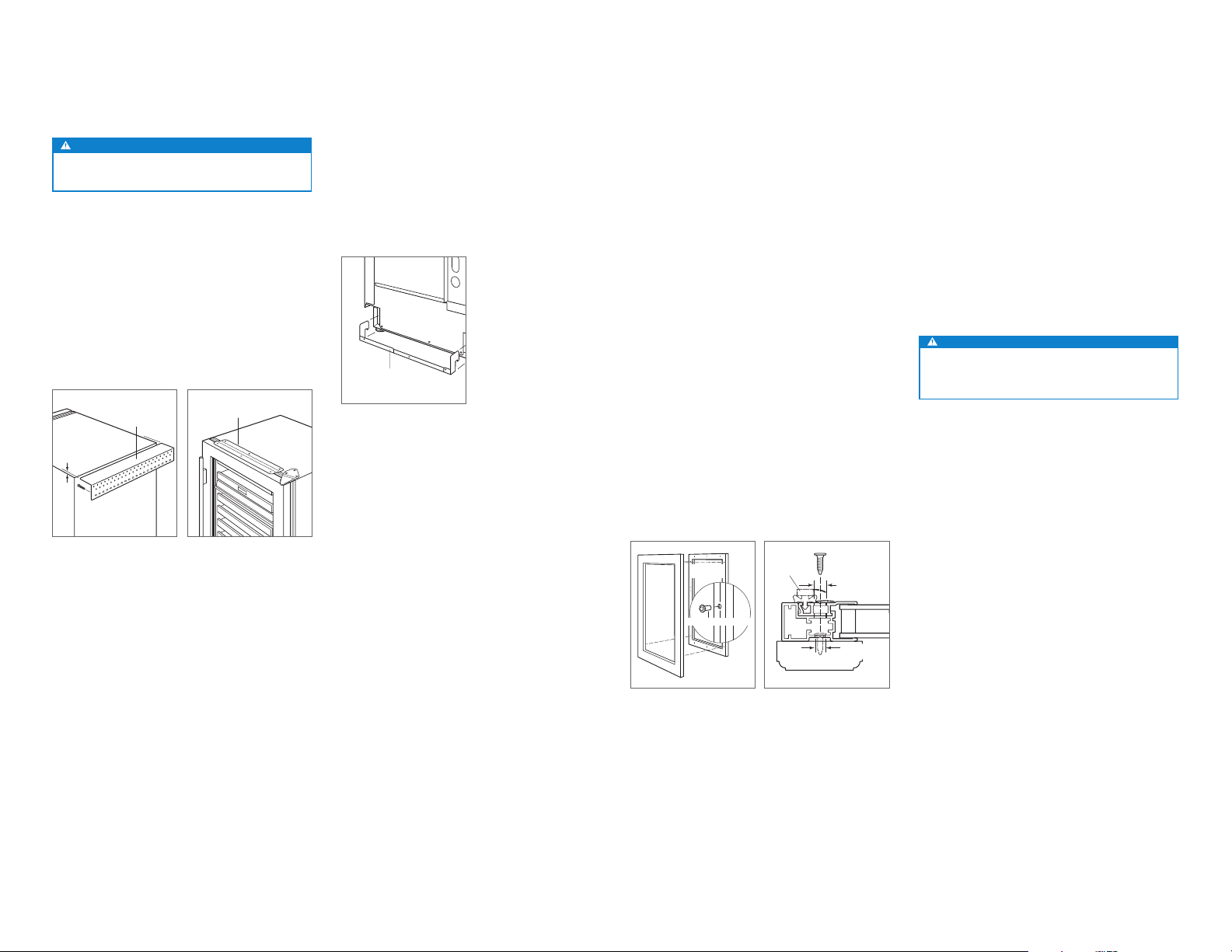

Door Clearance

FULL-SCALE TEMPLATE

To allow for a 145° door opening, the

unit should extend a minimum of 6 mm

beyond the front surface of adjacent

cabinetry. The unit can be installed

flush, however, there is potential for

interference with the panel if the door is

opened past 90°.

ADJACENT

CABINETRY

13 mm

6

mm

3 mm

HINGE AT 145°

OPENING

(DOOR OPENS

PAST 145°)

6 | English

SCALE

145° door opening (top view).

UNDERCOUNTER

UNIT

DOOR CLOSED

19 mm

DOOR PANEL

25 mm0 mm

Page 7

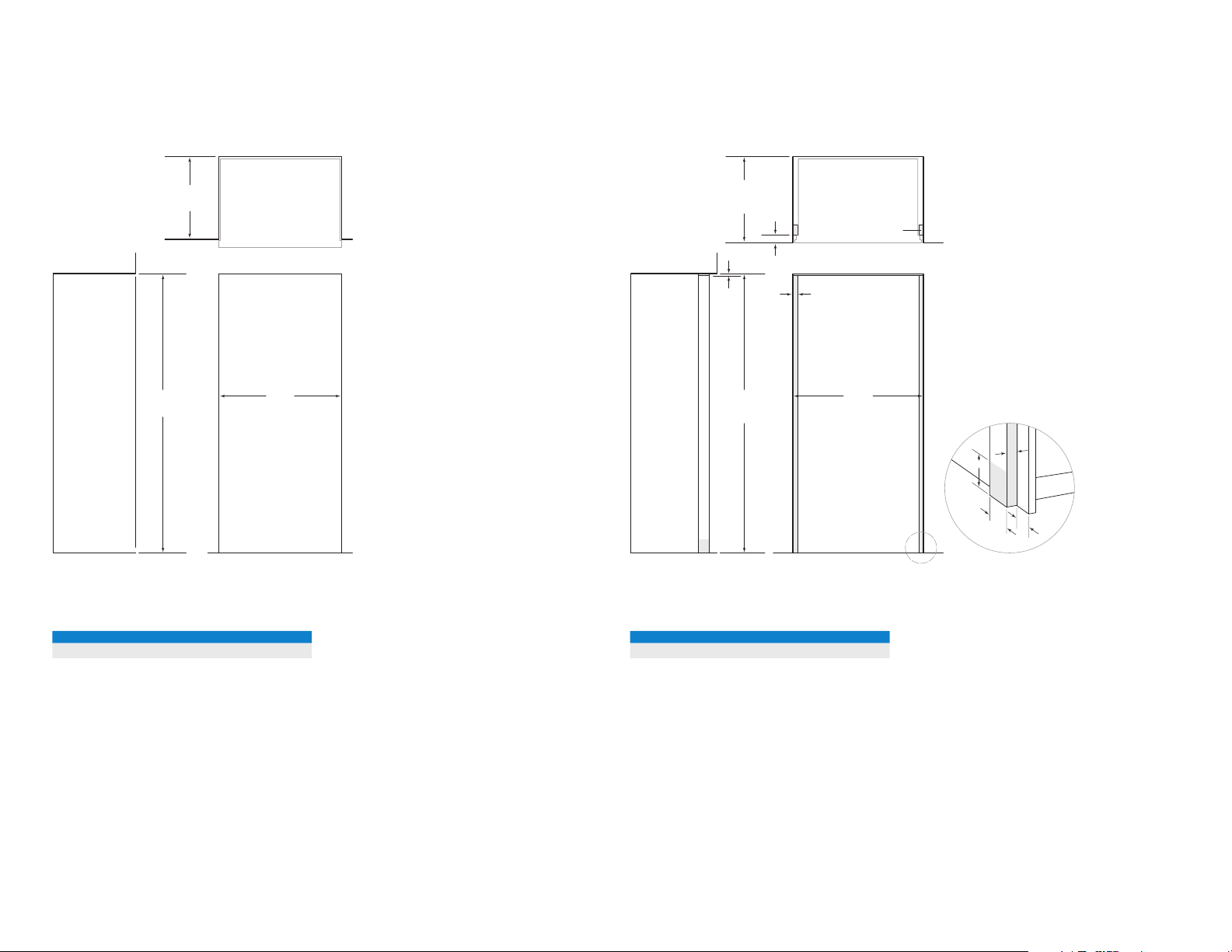

MODEL ICBBW-30 SITE PREPARATION

SIDE

Opening Dimensions

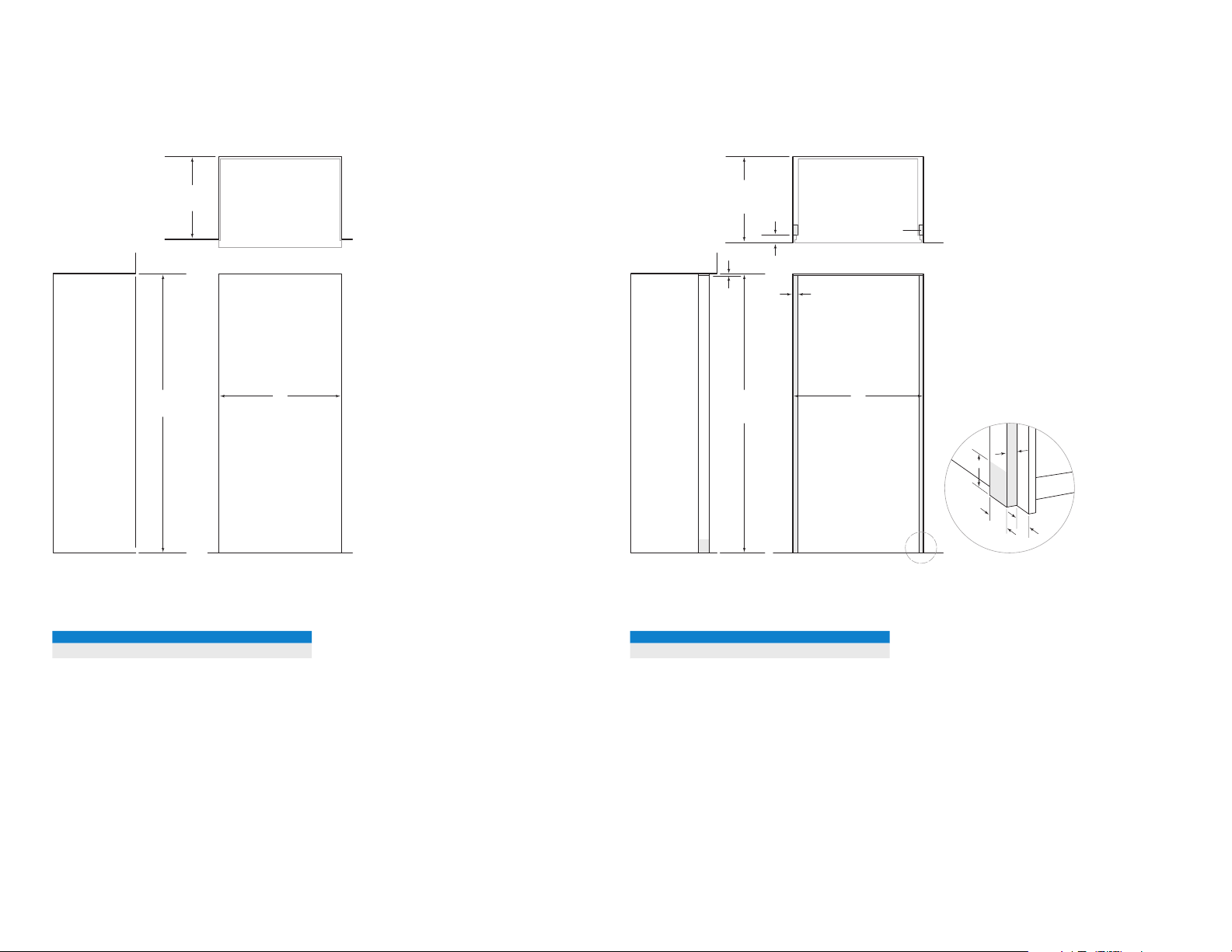

STANDARD INSTALLATION

2127 mm

OPENING

HEIGHT

NOTE: Shaded line represents profile of unit.

610 mm

OPENING

DEPTH

TOP VIEW

W

OPENING WIDTH

FRONT VIEWSIDE VIEW

Opening Dimensions

FLUSH INSET INSTALLATION

665 mm

FLUSH

INSET

DEPTH

56 mm

6 mm

2134 mm

FLUSH

INSET

HEIGHT

VIEW

*76 mm typical depth. Shaded areas will be visible and should be finished to match cabinetry.

NOTE: Shaded line represents profile of unit with 19 mm

32 mm

FLUSH INSET WIDTH

panel.

TOP VIEW

W

FRONT VIEW

FINISHED

CLEATS*

102 mm

32

mm

76

mm*

TYPICAL

mm

56

OPENING WIDTH W

ICBBW-30 749 mm

If two units are installed side by side, refer to page 8.

FLUSH INSET WIDTH W

ICBBW-30 813 mm

Dimensions assume a 19 mm panel thickness. If two units

are installed side by side, refer to page 8.

subzero.com | 7

Page 8

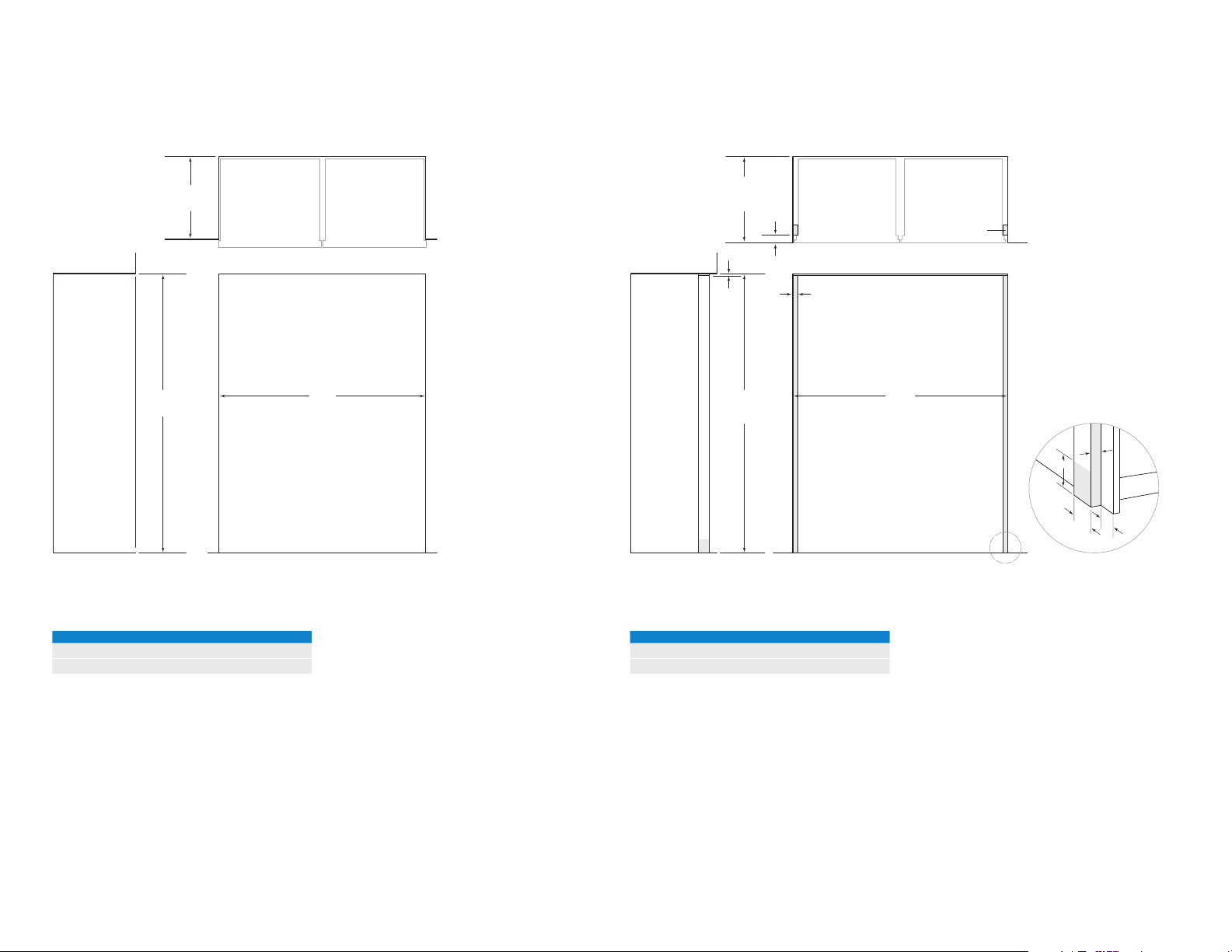

MODEL ICBBW-30 SITE PREPARATION

SIDE

Opening Dimensions

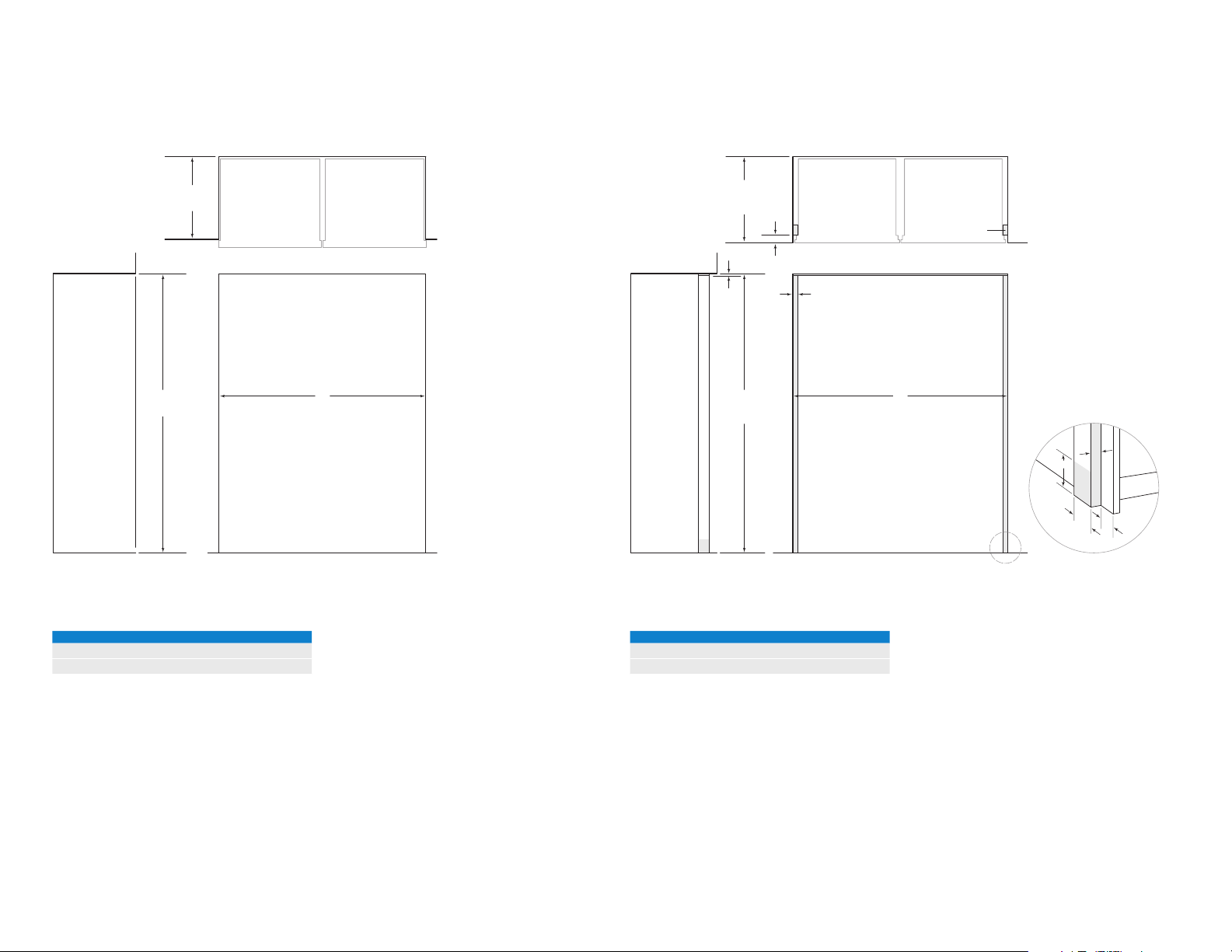

DUAL STANDARD INSTALLATION

610 mm

OPENING

DEPTH

2127 mm

OPENING

HEIGHT

NOTE: Shaded line represents profile of unit.

TOP VIEW

W

OPENING WIDTH

FRONT VIEWSIDE VIEW

Opening Dimensions

DUAL FLUSH INSET INSTALLATION

665 mm

FLUSH

INSET

DEPTH

56 mm

TOP VIEW

6 mm

2134 mm

FLUSH

INSET

HEIGHT

VIEW

*76 mm typical depth. Shaded areas will be visible and should be finished to match cabinetry.

NOTE: Shaded line represents profile of unit with 19 mm

32 mm

FLUSH INSET WIDTH

FRONT VIEW

panel.

FINISHED

CLEATS*

W

32

mm

102 mm

56

76

mm*

TYPICAL

mm

OPENING WIDTH W

ICBBW-30 and 762 mm Built-In Model 1518 mm

ICBBW-30 and 914 mm Built-In Model 1670 mm

8 | English

A dual installation kit will be required for this installation.

FLUSH INSET WIDTH W

ICBBW-30 and 762 mm Built-In Model 1581 mm

ICBBW-30 and 914 mm Built-In Model 1734 mm

Dimensions assume a 19 mm panel thickness. A dual installation kit will be required for this installation.

Page 9

MODEL ICBBW-30 SITE PREPARATION

Dual Installation

If two units are installed side by side, a dual installation kit

may be required. Installations without a custom filler strip

require a dual installation kit. If a dual installation kit is not

specified, a 51 mm filler strip is recommended between

units. Dual installations without a filler strip can only be

accomplished using two units with opposite hinges. Refer to

the illustrations below.

Dual installation kits are available through an authorized

Sub-Zero dealer.

WITHOUT FILLER STRIP

Opposite hinges.

FILLER STRIP

Same side hinges.

Electrical

Installation must comply with all applicable electrical codes

and be properly grounded (earthed).

The electrical supply should be located within the shaded

area shown in the illustration below. A separate circuit, servicing only this appliance is required. A ground fault circuit

interrupter (GFCI) is not recommended and may cause interruption of operation.

ELECTRICAL REQUIREMENTS

Power Supply 220-240 V AC, 50/60 Hz

Circuit Breaker 10 amp

Receptacle grounding-type (earthed)

CAUTION

The outlet must be checked by a qualied electrician to

be sure that it is wired with the correct polarity. Verify

that the outlet is properly grounded (earthed).

178

E

mm

152

mm

1918 mm

FROM FLOOR

RIGHT SIDE

OF OPENING

Electrical supply location.

Electrical

Shock

Hazard

Plug power cord directly into a properly

grounded (earthed) outlet.

Do not defeat the grounding (earthing)

nature of the plug.

Do not use adapter or extension cord.

Failure to follow these instructions could

cause serious injury or death.

See installation instructions

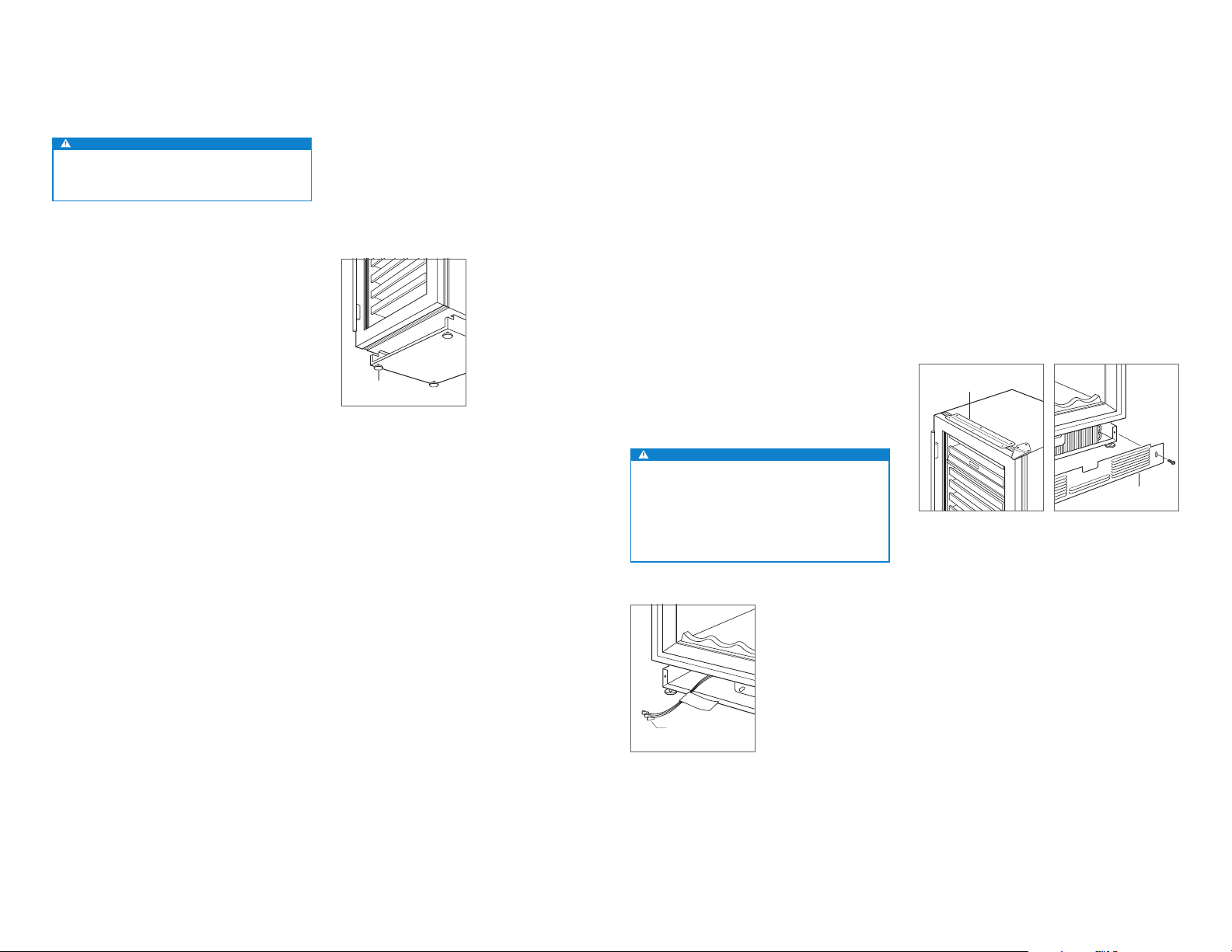

Preparation

Uncrate the unit and inspect for damage. Remove the wood

base and discard shipping bolts and brackets. Remove and

recycle packing materials. Do not discard the kickplate, antitip brackets and hardware.

Completely retract the front leveling legs to allow the unit to

be moved into position. The front and rear leveling legs can

be adjusted from the front once the unit is in position.

Remove the drain pan to avoid damage, and allow for

proper appliance dolly placement.

The grille assembly should be removed prior to moving the

unit. To remove, pull out on the bottom edge of the grille and

rotate upward. Loosen the two back grille mounting screws

and remove the two front grille mounting screws. With the

grille held firmly, pull forward to remove. Refer to the illustrations below.

GRILLE

ADJUSTMENT

FRONT

GRILLE SCREW

SCREWS

Grille removal.

BACK GRILLE

SCREW

Grille mounting screws.

subzero.com | 9

Page 10

MODEL ICBBW-30 INSTALLATION

Anti-Tip Bracket

WARNING

To prevent the unit from tipping forward, the anti-tip

brackets must be installed.

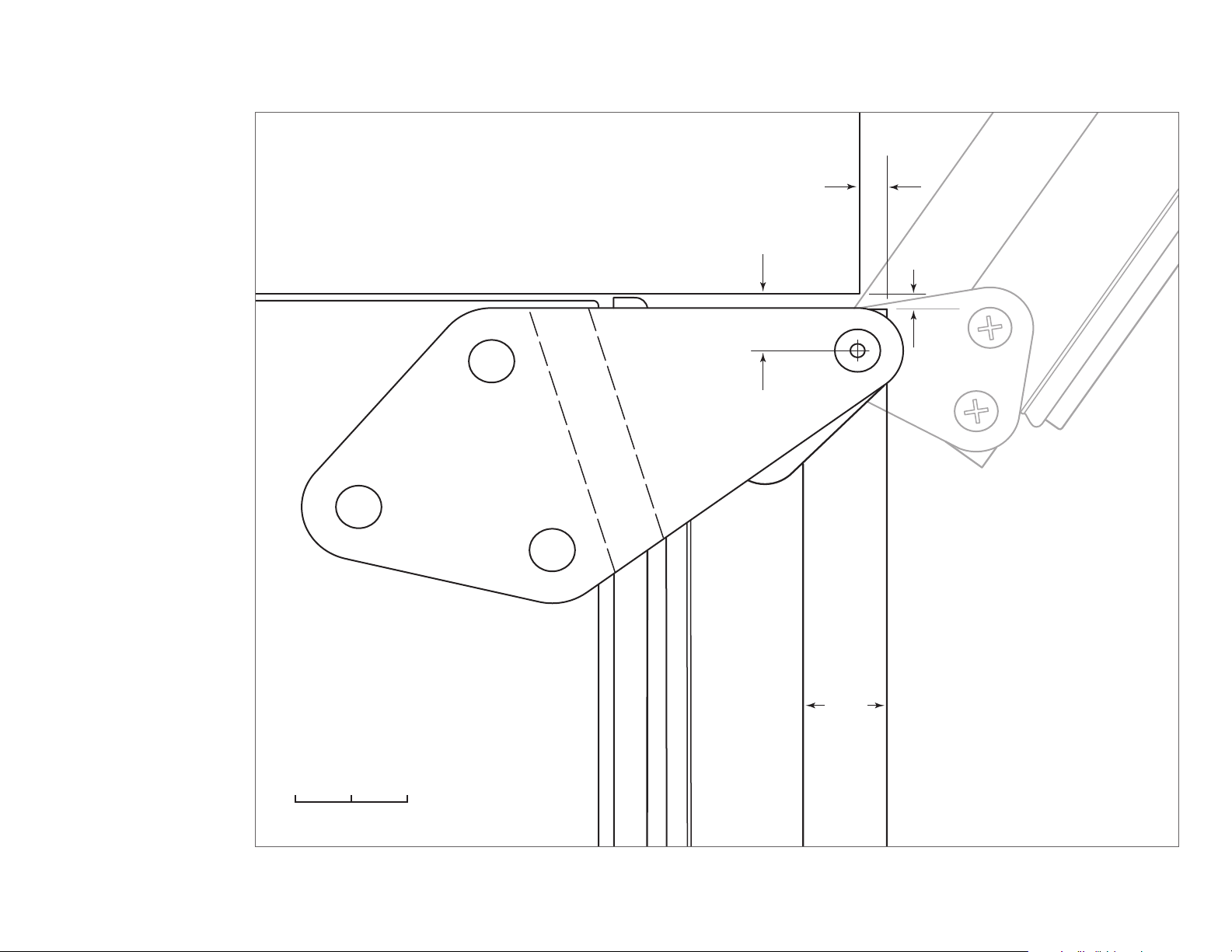

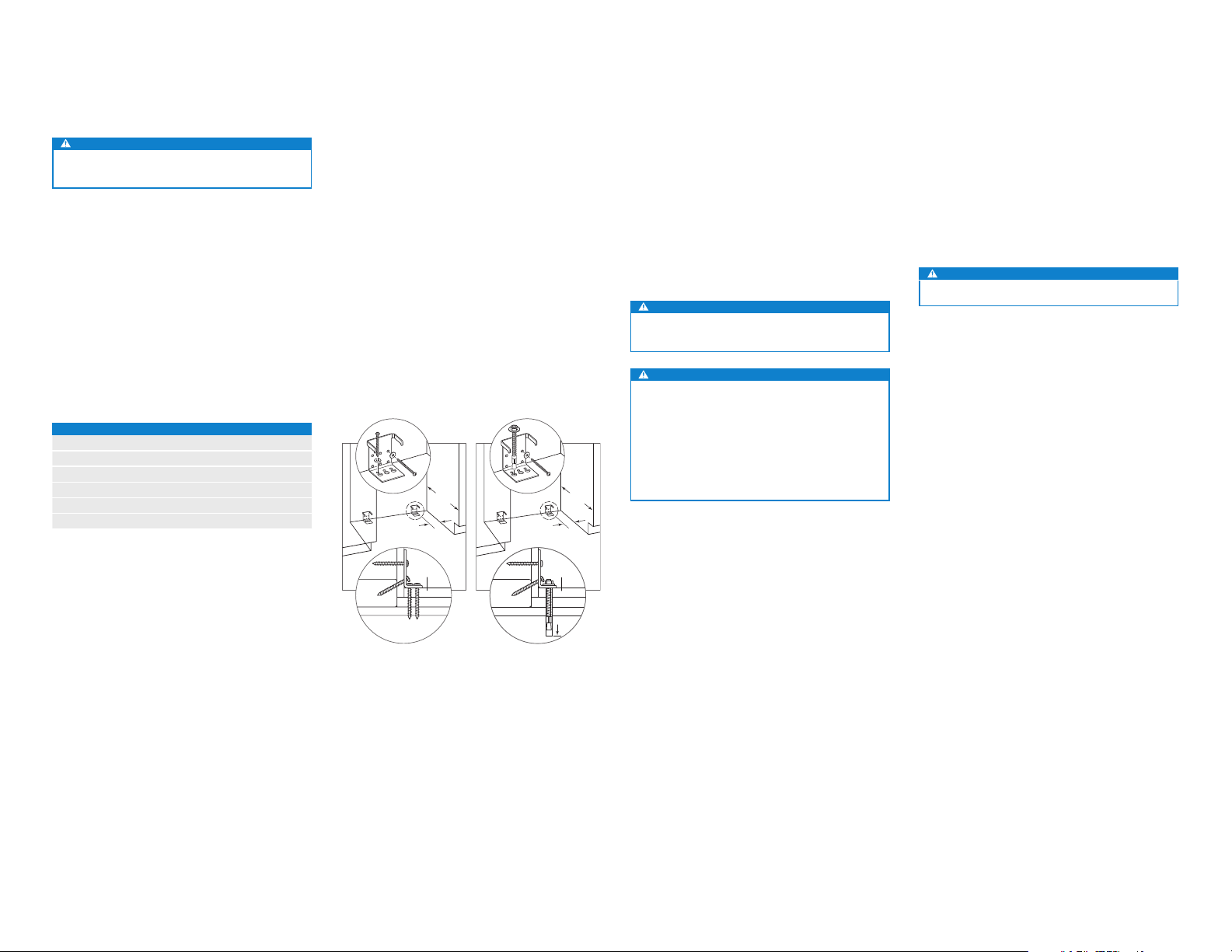

The two anti-tip brackets must be installed exactly 610 mm

from the front of the opening to the back of the brackets

and a minimum of 102 mm from the sides of the opening.

This depth will increase to 665 mm for a flush inset installation, based on 19 mm thick panels. Failure to properly position the anti-tip brackets will prevent proper engagement.

Use all anti-tip bracket hardware as instructed for wood or

concrete floors.

IMPORTANT NOTE: For wood or concrete floor applications,

if the #12 screws do not hit a wall stud or wall plate, use the

#8 screws and #12 washers with the wall anchors.

IMPORTANT NOTE: In some installations the subflooring or

finished floor may necessitate angling the screws used to

fasten the anti-tip brackets to the back wall.

ANTI-TIP HARDWARE

2 Anti-tip brackets

12 #12 x 64 mm pan head screws

3

/8"–16 x 95 mm wedge anchors

4

12 #12 flat washers

4 #8–18 x 32 mm truss head screws

4 Nylon Zip-it

®

wall anchors

WOOD FLOOR

After properly locating the anti-tip brackets in the opening,

drill pilot holes 5 mm diameter maximum in the wall studs or

wall plate. Use the #12 screws and washers to secure the

brackets. Verify the screws penetrate through the flooring

material and into wall studs or wall plate a minimum of 19

mm. Refer to the illustration below.

CONCRETE FLOOR

After properly locating the anti-tip brackets in the opening,

drill pilot holes 5 mm diameter maximum in the wall studs

or wall plate. Drill 10 mm diameter holes into the concrete a

minimum of 38 mm deep. Use the #12 screws and washers

to secure the brackets to the wall, and use the

3

/8" wedge

anchors to secure the brackets to the floor. Verify the screws

penetrate wall studs or wall plate a minimum of 19 mm.

Refer to the illustration below.

102 mm

FINISHED

FLOORING

610

mm

MIN

102 mm

FINISHED

FINISHED

FLOORING

FLOORING

610

mm

MIN

CONCRETE WEDGE ANCHOR INSTALLATION

1 Drill a 10 mm diameter hole any depth exceeding the

minimum embedment. Clean the hole or drill additional

depth to accommodate drill fines.

2 Assemble the washer and nut flush with the end of

anchor to protect threads. Drive the anchor through the

material to be fastened until the washer is flush with the

surface material.

3 Expand the anchor by tightening the nut 3–5 turns past

hand-tight position or to 34 newton-meters of torque.

WARNING

Verify there are no electrical wires or plumbing in the

area which the screws could penetrate.

CAUTION

Always wear safety glasses and use other necessary

protective devices or apparel when installing or working

with anchors.

Anchors are not recommended for use in lightweight

masonry material such as block or brick, or for use in

new concrete which has not had sufcient time to cure.

The use of core drills is not recommended to drill holes

for the anchors.

Custom Panels

For overlay and flush inset applications, custom door and

grille panels must be installed. Panel size is critical for a

proper fit. To verify panel requirements and dimensions,

refer to the Sub-Zero design guide.

IMPORTANT NOTE: Flush inset applications require a

minimum 13 mm reveal on all sides.

Finish all sides of the custom panel. They may be visible

when the door is open or through the glass door.

CAUTION

A solid panel cannot be installed over the glass door.

10 | English

WALL PLATE

SUBFLOORING

Wood oor.

WOOD FLOOR

WALL PLATE

WALL PLATE

SUBFLOORING

SUBFLOORING

CONCRETE

CONCRETE

FLOOR

FLOOR

Concrete oor.

11/2"

38 mm

min

MIN

(38)

Page 11

MODEL ICBBW-30 INSTALLATION

2134

mm

610 mm

OPTIONAL

TOE KICK

CUT-OUT

102 mm

48 mm

25 mm

ROUT TO

3 mm

FRONT

OF SIDE

PANEL

67 mm

MAIN

FRAME

SIDE PANEL

ROUTING

25 mm

48 mm

3 mm

13 mm

Panel Installation

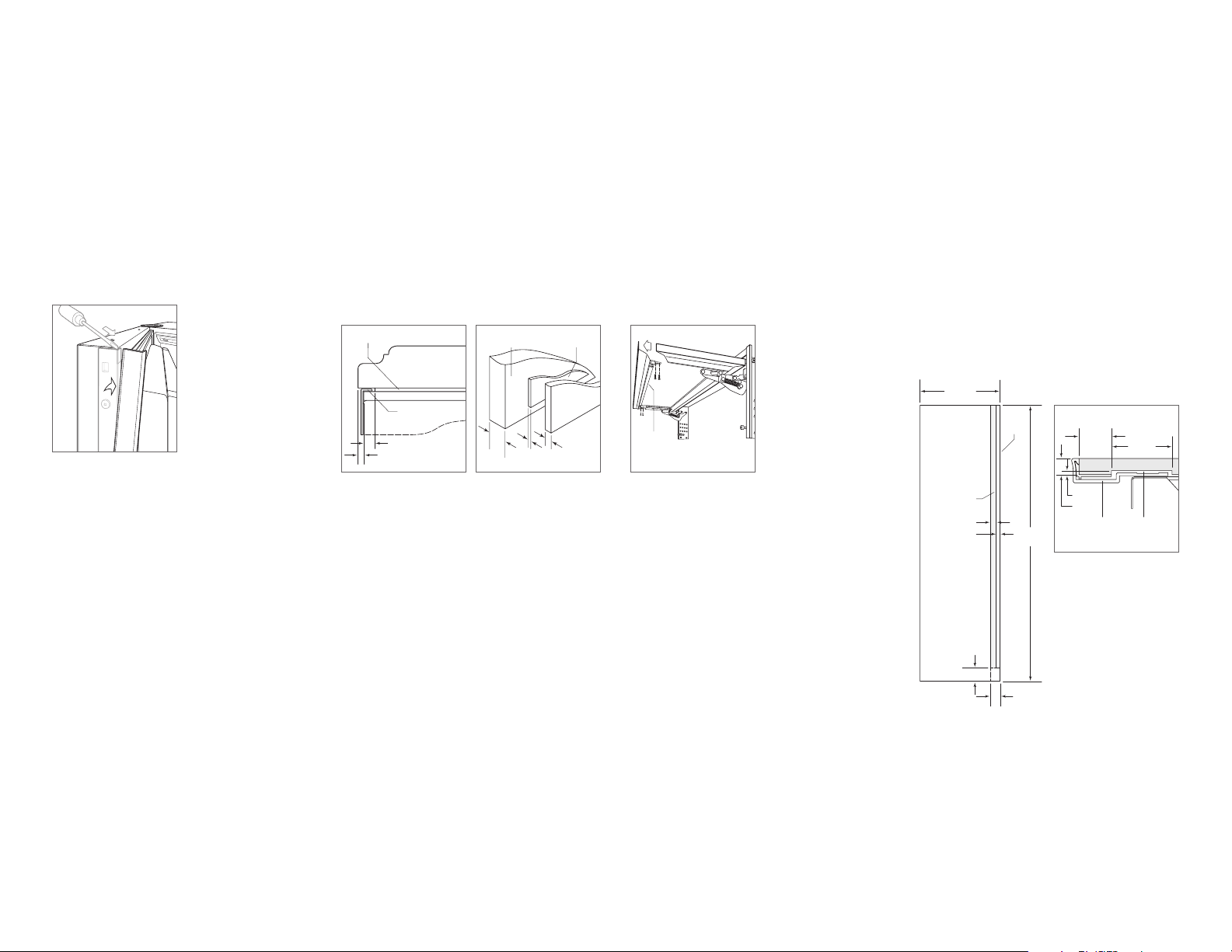

DOOR PANEL

To install the custom door panel, remove the handle side

trim molding. Insert a screwdriver tip into the top corner slot

on the handle side and pop out the trim. Remove the screws

and frame. Refer to the illustration below.

The door has a 6 mm frame for the custom panel to slide

into. If the panel is thicker than a 6 mm, rout an edge around

the panel or mount the panel on a sheet of 6 mm thick

material, then insert into the frame.

Door side trim.

A 3 mm space is required between the backer panel and the

custom panel to allow the panel to slide into the door frame.

Refer to the illustrations below for critical dimensions.

Install handle hardware before inserting the panel. Large

D-style handles are recommend rather than knobs. Screw

heads must be countersunk into the panel.

Slide the panel into the frame.

To reinstall the door trim molding, insert the top of the trim

into grooves at the top of the door and work downward,

snapping the trim into clips on the door frame.

SPACER PANEL

CUSTOM PANEL

BACKER PANEL

TRIM

8 mm min

3 mm (OVERLAY)

Panel assembly cross section

(overlay).

CUSTOM

PANEL

19

mm

typical

Panel assembly rear view.

3 mm

SPACER

PANEL

BACKER

PANEL

6 mm

GRILLE PANEL

Remove the bottom grille frame by extracting the lower

two corner screws from each side of the grille assembly.

Refer to the illustration below.

With the bottom section removed, slide the custom grille

panel into the frame. If the panel is thinner than 6 mm, a

filler material will need to be installed to achieve a proper

fit. Once the panel is installed, reattach the bottom grille

frame by sliding the corner brackets back into position, then

reinstall the four corner screws.

BOTTOM

GRILLE

FRAME

Grille frame assembly.

SIDE PANEL

When installing a custom side panel, an accessory kit is

required and is available through an authorized Sub-Zero

dealer. Stainless steel and white enamel side panels are also

available from an authorized Sub-Zero dealer.

IMPORTANT NOTE: The use of side panels may change the

width of the opening.

A custom side panel must be a minimum of 610 mm deep

and 13 mm thick. Routing will be necessary for the side

panel to fit flush against the side of the unit. Refer to the

illustrations below.

IMPORTANT NOTE: The height of the side panel will vary

with the height of the grille. Verify the finished height before

modifying panels.

Side panel dimensions.

Routing detail.

subzero.com | 11

Page 12

MODEL ICBBW-30 INSTALLATION

Placement

CAUTION

Before moving the unit into position, secure the door

closed and protect any nished ooring.

Use an appliance dolly to move the unit near the opening.

If the unit has been on its back or side, it must stand upright

for a minimum of 24 hours before connecting power.

If the unit will be connected to a home security system, run

lead wires through the compressor compartment prior to

positioning the unit. Refer to page 13. Once the unit is in

position, wiring connection can be completed from the front.

Plug the power cord into the grounded (earthed) outlet, then

roll the unit into position. Verify the anti-tip brackets are

properly engaged.

IMPORTANT NOTE: If used, side panels will need to be

installed before the unit is placed in its final position.

Alignment

LEVELING

Once the unit is in position, turn the front leveling legs

clockwise to adjust the height. The rear height adjustment

can be made from the front of the roller base. Using a

socket, turn the

3

/8" hex bolt clockwise to raise the unit or

counterclockwise to lower. Use the lowest torque setting

when using a power drill. Do not turn the rear leveling legs

by hand. Refer to the illustration below.

When the unit is properly leveled, door adjustments are less

likely to be necessary.

IMPORTANT NOTE: Level the unit to the floor, not sur-

rounding cabinetry. This could affect the operation of the

unit, such as door closing.

WARNING

To reduce the possibility of the unit tipping forward, the

front leveling legs must be in contact with the oor.

FRONT

LEVELING LEG

REAR

ADJUSTMENT

Leveling.

3

/8"

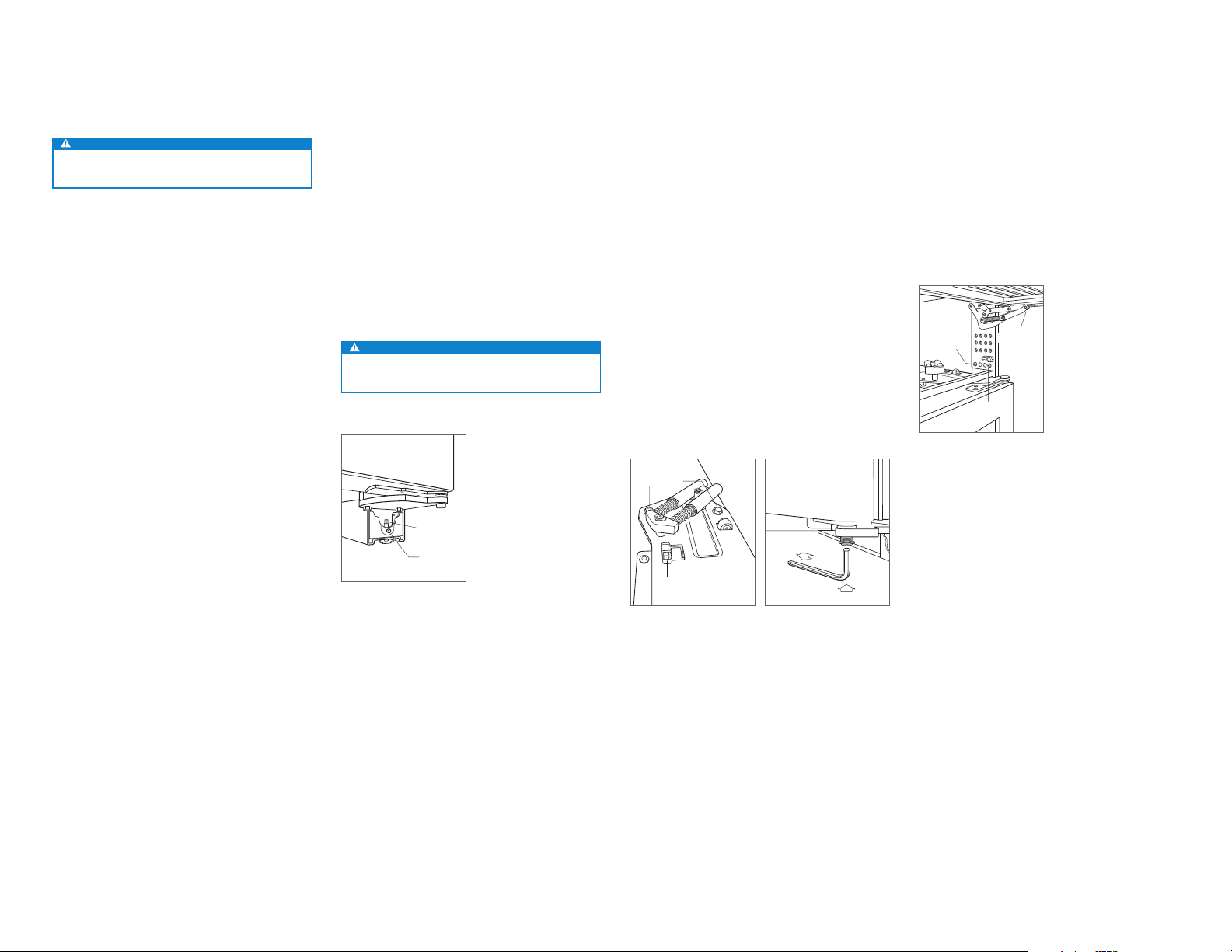

DOOR ADJUSTMENT

The door can be adjusted in and out, side to side tilt and up

and down.

To make adjustments, slightly loosening the two upper hinge

bolts on the upper hinge plate using a

1

/2" wrench. Refer to

the illustration below.

5

In and out adjustment | For a left-hinge door, using a

/32"

allen wrench, turn the adjustment bolt clockwise to bring

the handle side of the door inward, and counterclockwise

to move the handle side outward. Reverse directions for a

right-hinge door.

Side to side tilt adjustment | For a left-hinge door, using a

3

/8" wrench, turn the adjustment bolt clockwise to raise the

handle side of the door, and counterclockwise to lower the

handle side. Reverse directions for a right-hinge door.

Up and down adjustment | For a left-hinge door, using a

1

/4" allen wrench, turn the adjustment bolt clockwise to raise

the door and counterclockwise to lower. Refer to the illustration below. Reverse directions for a right-hinge door.

UPPER

HINGE BOLTS

IN-AND-OUT

ADJUSTMENT

SIDE-TO-SIDE

TILT ADJUSTMENT

Door adjustment bolts.

Up and down door adjustment.

Completion

GRILLE INSTALLATION

Install the grille assembly and check for proper fit. The grille

is designed to rest on the upper door hinge to minimize the

reveal between the top of the door and bottom of the grille.

To eliminate interference, the grille height can be adjusted.

Loosen the four grille adjustment screws (two on each side)

and adjust the grille height as needed. Refer to the illustration below.

GRILLE

BACK GRILLE

SCREW

Grille height adjustment.

ADJUSTMENT

FRONT

GRILLE SCREW

SCREWS

12 | English

Page 13

MODEL ICBBW-30 INSTALLATION

Completion

HOME SECURITY CONNECTION

If the unit will be connected to a home security system,

make connections to the leads shown in the illustration

below. Refer to the following color codes:

• Normally open contacts—white with red stripe wire.

• Normally closed contacts—white with blue stripe wire.

• Common—gray with white stripe wire.

Use the spade terminals or wire nuts provided to make

proper wiring connections.

CAUTION

The alarm circuit in the unit is intended as a lowvoltage, low-current device only. It should not be used

to switch line power. Any unused terminals should be

completely insulated and all wires should be secured

away from conductive or moving components.

ANCHORING

After the unit has been leveled and door adjustment completed, anchor the unit to the opening to ensure a proper fit

and secure installation.

To anchor the top of the unit, open the grille and install the

screws provided, through the grille frame into cabinetry.

There are several hole locations. Refer to the illustration

below. Check for proper door clearance by opening the

door.

To anchor the bottom of the unit, drive a screw through the

side hole inside each roller base assembly. The screw will

need to go in at an angle to attach properly. Refer to the

illustration below. Additional material may be needed behind

the cleat to ensure sufficient anchoring.

CAUTION

If the screws provided are not suitable for the installation, use adequate screws.

KICKPLATE INSTALLATION

Reinstall the drain pan and verify it is in the proper position.

Install the kickplate using screws to attach it to brackets on

the inside of each roller base. Refer to the illustration below.

The kickplate must be removable for service. The floor

cannot interfere with removal. Refer to the label mounted on

the kickplate support for height clearance.

Turn power on by touching POWER on the control panel.

90° DOOR STOP

The door opens to 110°. A 90° door stop is provided with

the unit (located behind the grille). Additional 90° door stop

kits are available through an authorized Sub-Zero dealer.

WARNING

Follow all local laws when storing, recycling or discarding unused refrigerators and freezers.

HOME SECURITY

LEADS

Home security connection.

Kickplate installation.

ANCHORING

SCREWS

Top anchoring.

Bottom anchoring.

ANCHORING

SCREW

Sub-Zero, Sub-Zero & Design, Dual Refrigeration, The Living Kitchen, Great American Kitchens The Fine Art of Kitchen Design, and Ingredients are registered trademarks and

service marks of Sub-Zero, Inc. Wolf, Wolf & Design, Wolf Gourmet, W & Design and the color red as applied to knobs are registered trademarks and service marks of Wolf Appli

ance, Inc. (collectively, the “Company Marks.”) All other trademarks or registered trademarks are property of their respective owners in the United States and other countries.

-

subzero.com | 13

Page 14

CONSERVADORES DE VINO

Contenido

2 Conservador de vino

3 Preparación del sitio del modelo ICBUW-24 /

ICBUW-24FS

4 Instalación del modelo ICBUW-24 / ICBUW-24FS

7 Preparación del sitio del modelo ICBBW-30

10 Instalación del modelo ICBBW-30

Las características y especificaciones están sujetas a cambios sin previo aviso.

Nota importante:

Para garantizar que este producto se instala y funciona de

la forma más eficaz y segura posible, tenga en cuenta la

información que se destaca en esta guía:

NOTA IMPORTANTE se utiliza para resaltar información que

resulta especialmente importante.

PRECAUCIÓN indica una situación en la que se pueden

sufrir heridas leves o provocar daños al producto si no se

siguen las instrucciones.

AVISO indica el peligro de que se produzcan heridas graves

o incluso la muerte si no se respetan las precauciones.

NOTA IMPORTANTE: conserve estas instrucciones para el

inspector eléctrico local.

Información sobre el producto

En la placa de datos del producto encontrará información

importante, incluyendo el modelo y el número de serie. La

placa de datos está ubicada en la parte inferior izquierda del

panel de control. Observe las siguientes ilustraciones.

Si necesita recurrir a un servicio técnico, póngase en contacto con un servicio de Sub-Zero certificado con el modelo

y el número de serie.

PLACA DE DATOS

PLACA DE DATOS

Modelos ICBUW-24 y

ICBUW-24FS.

Modelo ICBBW-30.

Herramientas y materiales

• Destornilladores: estándar, Phillips y Torx.

• Taladro.

• Brocas (se necesitarán brocas de mampostería para la

instalación en hormigón).

• Juego de llaves y llaves de vaso estándar.

• Niveles de 0,6 m y 1,2 m.

• Material para proteger la casa, el suelo y los armarios de

cocina durante la instalación.

2 | Español

Page 15

PREPARACIÓN DEL SITIO DEL MODELO ICBUW-24 / ICBUW-24FS

Medidas de la cavidad

MODELO ICBUW-24

610 mm

DE PROFUNDIDAD

DE LA CAVIDAD

VISTA SUPERIOR

876 mm

ALTURA DE

LA CAVIDAD

VISTA LATERAL VISTA FRONTAL

ANCHURA DE LA CAVIDAD Anch.

ICBUW-24 610 mm

Dos modelos de 610 mm* 1.222 mm

*Para esta instalación se necesita un kit de instalación doble.

Anch.

ANCHURA DE LA CAVIDAD

INSTALACIÓN DOBLE

Si va a instalar dos unidades una junto a la otra, puede

que sea necesario un kit de instalación doble. Asimismo,

las instalaciones que no utilicen un embellecedor a medida

necesitarán un kit de instalación doble. Si no se especifica

el kit de instalación doble, se recomienda utilizar un embellecedor de 51 mm entre las unidades. Las instalaciones

dobles sin embellecedor solamente se pueden llevar a cabo

con dos unidades con las bisagras opuestas. Observe las

siguientes ilustraciones.

Podrá encontrar los kits de instalación doble en un distribuidor de Sub-Zero autorizado.

SIN EMBELLECEDOR

Bisagras opuestas.

EMBELLECEDOR

Bisagras al mismo lado.

Potencia

La instalación debe cumplir con todas las normativas eléctricas aplicables y debe estar correctamente conectada a

tierra.

La toma eléctrica debe situarse en el área sombreada en la

siguiente ilustración. Se necesita un circuito independiente

para esta unidad. No se recomienda utilizar un interruptor

de circuito de fallos de toma de tierra (GFCI), ya que puede

interrumpir el funcionamiento de la unidad.

REQUISITOS ELÉCTRICOS

Alimentación eléctrica 220-240 V CA, 50/60 Hz

Magnetotérmico 10 amperios

Enchufe con toma de tierra

PRECAUCIÓN

La toma de corriente debe ser revisada por un electricista cualicado para comprobar que la conexión se ha

realizado con la polaridad correcta. Compruebe que la

toma de corriente está conectada a tierra de manera

correcta.

LADO IZQUIERDO

DE LA CAVIDAD

51

394 mm

mm

E

SUELO

76 mm

Preparación

Para que funcione correctamente, la puerta debe abrirse un

mínimo de 90°. Utilice un embellecedor de al menos 76 mm

cuando instale el aparato en esquinas, con el fin de que se

pueda abrir la puerta a 90°.

Desembale la unidad y compruebe si tiene algún daño o

desperfecto. Quite y recicle los materiales de embalaje. No

tire el zócalo, el soporte antivuelco, las piezas de montaje ni

las patas de nivelación que sujetan la base de madera a la

parte inferior de la unidad.

Ubicación de la alimentación

eléctrica.

Potencia

Descarga

Eléctrica

Enchufe el cable eléctrico directamente en una

toma con conexión a tierra.

No manipule la conexión a tierra del enchufe.

No utilice adaptadores ni alargadores.

Si no sigue estas instrucciones, existe riesgo de

que se produzcan heridas graves o incluso la

muerte.

Ver instrucciones de instalación

subzero.com | 3

Page 16

PREPARACIÓN DEL SITIO DEL MODELO ICBUW-24 / ICBUW-24FS INSTALACIÓN DEL MODELO ICBUW-24 / ICBUW-24FS

Soporte antivuelco

AVISO

Debe instalarse el soporte antivuelco para evitar que la

unidad se incline hacia adelante.

MODELO ICBUW-24

El soporte antivuelco debe quedar fijado a la pared

situada detrás del aparato con la placa del soporte que

se encuentra a 6 mm por encima del aparato. Observe la

siguiente ilustración. Si no coloca bien el soporte antivuelco,

es posible que no quede bien fijado.

En las instalaciones en las que no se pueda colocar el

soporte antivuelvo, se suministra un soporte bajo la encimera para fijar la unidad a la encimera. Observe la siguiente

ilustración.

6 mm

Soporte antivuelco (ICBUW-24). Soporte de encimera.

SOPORTE

DE ENCIMERA

MODELO ICBUW-24FS

La parte trasera del soporte antivuelco debe instalarse a

625 mm de la parte delantera de la unidad y quedar centrada detrás de esta. Observe la siguiente ilustración. Para

aplicaciones en suelos de madera y de hormigón, consulte

la página 10.

SOPORTE ANTIVUELCO

Soporte antivuelco

(ICBUW-24FS).

Panel fabricado a medida

MODELO ICBUW-24

Para aplicaciones revestibles, se debe instalar un panel de

puerta a medida. El tamaño del panel es fundamental para

que se ajuste correctamente. Para comprobar las medidas

y los requisitos del panel, consulte la guía de diseño de

Sub-Zero.

Realice el acabado de todos los lados del panel a medida,

pues son áreas que pueden resultar muy visibles al abrir la

puerta o a través de los cristales.

El panel de puerta revestible a medida se fija con los tornillos suministrados, en el marco de la puerta. Las ubicaciones de los tornillos están marcadas en la parte posterior

del panel a medida con centros de espiga insertados en

orificios del marco de la puerta.

Con la unidad fijada y la puerta cerrada, coloque el panel

a medida en la posición deseada en la puerta. Golpee con

suavidad la parte frontal del panel para localizar las posiciones de montaje. Retire los centros de espiga. Observe la

siguiente ilustración.

El marco de la puerta tiene orificios de montaje para instalar

los tiradores de Sub-Zero que se distribuyen como accesorios. Si no se utilizan los orificios de montaje para los

tiradores, este debe fijarse al panel a medida antes del montaje. Para una alineación correcta, puede que sea necesario

encastar las cabezas de los tornillos en el panel.

PANEL

MARCO DE

LA PUERTA

JUNTA

11 mm

DE DIÁMETRO

Para montar el panel a medida, abra la puerta y utilice los

orificios ya perforados para colocar el panel. Inserte los tornillos en el panel a través de la cinta negra en el marco de la

puerta. Los orificios de los tornillos quedan ocultos detrás

de la junta de la puerta. Utilice todos los tornillos necesarios para sujetar el panel a medida. Observe la siguiente

ilustración.

Es posible realizar ajustes al panel a medida con unos

pocos tornillos de montaje, colocados pero sin estar completamente apretados. Cuando haya alcanzado la posición

adecuada, instale y fije los tornillos.

Cubra los orificios en el interior del marco de la puerta con

las cubiertas o tapones suministrados.

PRECAUCIÓN

No se puede instalar un panel sólido en una puerta de

cristal. La puerta sólida está disponible en los distribuidores de Sub-Zero autorizados.

4 | Español

CENTRO DE ESPIGA

Centro de espiga.

CRISTAL

6 mm

DE DIÁMETRO

Vista transversal del marco de

la puerta.

Page 17

INSTALACIÓN DEL MODELO ICBUW-24 / ICBUW-24FS

Colocación

PRECAUCIÓN

Antes de desplazar la unidad para colocarla en su sitio,

asegúrese de que la puerta esté cerrada y proteja el

acabado del suelo.

Utilice una plataforma rodante para desplazar la unidad

hasta la cavidad.

Si la unidad ha estado boca abajo o sobre uno de los lados,

debe permanecer en posición vertical como mínimo 24

horas antes de conectarla a la alimentación.

Si se desea conectar la unidad al sistema de seguridad de

la casa, es necesario instalar cables por el compartimiento

del compresor antes de colocar la unidad. Una vez colocada la unidad, la conexión de los cables se puede realizar

desde la parte delantera.

Alineación

NIVELADO

Nivele la unidad antes de desplazarla para colocarlo en su

sitio. Gire cada una de las cuatro patas de nivelación en

el sentido de las agujas del reloj para levantar el aparato y

gírelas en sentido contrario para bajar la unidad. Observe la

siguiente ilustración.

PATAS DE

NIVELACIÓN

Nivelado.

Comprobación

Enchufe el cable eléctrico en la toma de conexión a tierra y

deslice la unidad en la posición adecuada. Compruebe que

el soporte antivuelco esté bien fijado.

Puede que sea necesario instalar la unidad de forma que

sobresalga 6 mm de la superficie frontal de los muebles

circundantes, para evitar la interferencia cuando la puerta

se abre a 145º. Consulte la plantilla a escala real de la

página6.

CONEXIÓN AL SISTEMA DE SEGURIDAD DE LA CASA

Si se desea conectar la unidad al sistema de seguridad de

la casa, conecte los cables conforme a la siguiente ilustración. Consulte los siguientes códigos de color:

• Contactos que suelen estar abiertos: cable blanco con

raya roja.

• Contactos que suelen estar cerrados: cable blanco con

raya azul.

• Común: cable gris con raya blanca.

Utilice los terminales en horquilla o las tuercas incluidas

para realizar las conexiones de cables correctamente.

PRECAUCIÓN

El circuito de alarma en el aparato solo constituye

un dispositivo de bajo voltaje y corriente débil. No se

debe utilizar para encender o apagar la conexión de

la línea. Todos los terminales sin utilizar deben quedar

aislados por completo y todos los cables deben

quedar jados lejos de componentes de conducción o

desplazamiento.

ANCLAJE

Para el anclaje, utilice el soporte de encimera suministrado para fijar la unidad a la parte inferior de la encimera.

Observe la siguiente ilustración. Si el soporte de encimera

no se puede utilizar, instale chapas a lo largo de los lados y

la parte superior de la unidad.

INSTALACIÓN DEL ZÓCALO

Instale el zócalo utilizando los dos tornillos suministrados.

Observe la siguiente ilustración. El zócalo debe ser extraíble

para permitir sacarlo en caso de avería. El suelo no puede

ser un impedimento para llevar a cabo esta operación. No

cubra la parte tipo persiana del zócalo.

SOPORTE

DE ENCIMERA

ZÓCALO

Anclaje.

Instalación del zócalo.

CABLES DEL SISTEMA

DE SEGURIDAD

DE LA CASA

Conexión al sistema de seguridad de la casa.

subzero.com | 5

Page 18

INSTALACIÓN DEL MODELO ICBUW-24 / ICBUW-24FS

Margen de apertura de la puerta

PLANTILLA A ESCALA REAL

Para permitir una apertura de la puerta de

145º, la unidad debe sobresalir un mínimo

de 6 mm de la superficie frontal de los

muebles circundantes. La unidad puede

instalarse empotrada, aunque es posible

que interfiera con el panel si la puerta se

abre más de 90°.

MUEBLES

ADYACENTES

13 mm

6

mm

3 mm

BISAGRA A UNA

APERTURA DE 145º

(LA PUERTA DE

ABRE PASADOS145º)

6 | Español

25 mm0 mm

ESCALA

Apertura de la puerta de 145º (vista superior).

UNIDAD BAJO

LA ENCIMERA

PUERTA CERRADA

19 mm

DE PANEL DE

LA PUERTA

Page 19

PREPARACIÓN DEL SITIO DEL MODELO ICBBW-30

VIST

Medidas de la cavidad

INSTALACIÓN ESTÁNDAR

610 mm

DE PROFUNDIDAD

DE LA CAVIDAD

2127 mm

ALTURA DE

LA CAVIDAD

NOTA: las líneas sombreadas representan el perfil de la unidad.

VISTA SUPERIOR

Anch.

ANCHURA DE LA CAVIDAD

VISTA FRONTALVISTA LATERAL

Medidas de la cavidad

INSTALACIÓN EMPOTRABLE

665 mm

DE

PROFUNDIDAD

EMPOTRABLE

56 mm

6 mm

2134 mm

ALTURA DE

INSTALACIÓN

EMPOTRABLE

A LATERAL

*76 mm de profundidad estándar. las áreas sombreadas serán visibles y deberán acabarse para que coincidan con los muebles.

NOTA: las líneas sombreadas representan el perfil de la unidad con un panel de 19 mm.

32 mm

ANCHURA DE INSTALACIÓN

LISTONES

ACABADOS*

VISTA SUPERIOR

Anch.

EMPOTRABLE

VISTA FRONTAL

102 mm

ESTÁNDAR

mm

mm*

32

56

76

mm

ANCHURA DE LA CAVIDAD Anch.

ICBBW-30 749 mm

Si va a instalar dos unidades una junto a la otra, consulte la

página 8.

ANCHURA DE INSTALACIÓN EMPOTRABLE Anch.

ICBBW-30 813 mm

Las medidas están calculadas con un panel de 19 mm de

grosor. Si va a instalar dos unidades una junto a la otra,

consulte la página 8.

subzero.com | 7

Page 20

PREPARACIÓN DEL SITIO DEL MODELO ICBBW-30

VIST

Medidas de la cavidad

INSTALACIÓN DOBLE ESTÁNDAR

610 mm

DE PROFUNDIDAD

DE LA CAVIDAD

2127 mm

ALTURA DE

LA CAVIDAD

NOTA: las líneas sombreadas representan el perfil de la unidad.

VISTA SUPERIOR

Anch.

ANCHURA DE LA CAVIDAD

VISTA FRONTALVISTA LATERAL

Medidas de la cavidad

INSTALACIÓN DOBLE EMPOTRABLE

665 mm

DE

PROFUNDIDAD

EMPOTRABLE

56 mm

VISTA SUPERIOR

6 mm

2134 mm

ALTURA DE

INSTALACIÓN

EMPOTRABLE

A LATERAL

*76 mm de profundidad estándar. las áreas sombreadas serán visibles y deberán acabarse para que coincidan con los muebles.

NOTA: las líneas sombreadas representan el perfil de la unidad con un panel de 19 mm.

32 mm

ANCHURA DE INSTALACIÓN EMPOTRABLE

Anch.

VISTA FRONTAL

LISTONES

ACABADOS*

102 mm

32

mm

76

mm*

ESTÁNDAR

mm

56

ANCHURA DE LA CAVIDAD Anch.

Modelo empotrable de 762 mm e ICBBW-30 1518 mm

Modelo empotrable de 914 mm e ICBBW-30 1670 mm

8 | Español

Para esta instalación se necesita un kit de instalación doble.

ANCHURA DE INSTALACIÓN EMPOTRABLE Anch.

Modelo empotrable de 762 mm e ICBBW-30 1581 mm

Modelo empotrable de 914 mm e ICBBW-30 1734 mm

Las medidas están calculadas con un panel de 19 mm de

grosor. Para esta instalación se necesita un kit de instalación doble.

Page 21

PREPARACIÓN DEL SITIO DEL MODELO ICBBW-30

Instalación doble

Si va a instalar dos unidades una junto a la otra, puede

que sea necesario un kit de instalación doble. Asimismo,

las instalaciones que no utilicen un embellecedor a medida

necesitarán un kit de instalación doble. Si no se especifica

el kit de instalación doble, se recomienda utilizar un embellecedor de 51 mm entre las unidades. Las instalaciones

dobles sin embellecedor solamente se pueden llevar a cabo

con dos unidades con las bisagras opuestas. Observe las

siguientes ilustraciones.

Podrá encontrar los kits de instalación doble en un distribuidor de Sub-Zero autorizado.

SIN EMBELLECEDOR

Bisagras opuestas.

EMBELLECEDOR

Bisagras al mismo lado.

Potencia

La instalación debe cumplir con todas las normativas eléctricas aplicables y debe estar correctamente conectada a

tierra.

La toma eléctrica debe situarse en el área sombreada en la

siguiente ilustración. Se necesita un circuito independiente

para esta unidad. No se recomienda utilizar un interruptor

de circuito de fallos de toma de tierra (GFCI), ya que puede

interrumpir el funcionamiento de la unidad.

REQUISITOS ELÉCTRICOS

Alimentación eléctrica 220-240 V CA, 50/60 Hz

Magnetotérmico 10 amperios

Enchufe con toma de tierra

PRECAUCIÓN

La toma de corriente debe ser revisada por un electricista cualicado para comprobar que la conexión se ha

realizado con la polaridad correcta. Compruebe que la

toma de corriente está conectada a tierra de manera

correcta.

178

E

mm

152

mm

1918 mm

DESDE EL SUELO

LADO DERECHO

DE LA CAVIDAD

Ubicación de la alimentación

eléctrica.

Potencia

Descarga

Eléctrica

Enchufe el cable eléctrico directamente en una

toma con conexión a tierra.

No manipule la conexión a tierra del enchufe.

No utilice adaptadores ni alargadores.

Si no sigue estas instrucciones, existe riesgo de

que se produzcan heridas graves o incluso la

muerte.

Ver instrucciones de instalación

Preparación

Desembale la unidad y compruebe si tiene algún daño o

desperfecto. Retire la base de madera y extraiga todos los

tornillos y soportes del paquete. Quite y recicle los materiales de embalaje. No tire el zócalo, los soportes antivuelco

ni las piezas de montaje.

Repliegue completamente las patas de nivelación delanteras para permitir que la unidad se pueda colocar en la

posición adecuada. Las patas de nivelación delanteras y

traseras pueden ajustarse desde la parte delantera cuando

la unidad ya esté colocada.

Retire el depósito de desagüe para evitar que se dañe y

para que se pueda colocar bien la plataforma rodante.

Retire la rejilla antes de mover la unidad. Para ello, tire

del borde inferior de la rejilla e incline el marco de la rejilla

hasta sacarlo hacia arriba. Afloje los dos tornillos traseros

de montaje de la rejilla y retire los dos tornillos de montaje

delanteros. Sujete firmemente la rejilla y tire hacia adelante

para extraerla. Observe las siguientes ilustraciones.

TORNILLOS DE

AJUSTE DE

LA REJILLA

TORNILLO DELANTERO

DE LA REJILLA

Extracción de la rejilla.

TORNILLO

TRASERO DE

LA REJILLA

Tornillos de montaje de la rejilla.

subzero.com | 9

Page 22

INSTALACIÓN DEL MODELO ICBBW-30

Soporte antivuelco

AVISO

Deben instalarse soportes antivuelco para evitar que la

unidad se incline hacia adelante.

Los dos soportes antivuelco se deben instalar exactamente

a 610 mm de la parte delantera de la cavidad hasta la parte

trasera de los soportes y con un mínimo de 102 mm desde

los lados de la cavidad. Esta profundidad se incrementará

hasta 665 mm si se trata de una instalación empotrable con

paneles delgados de 19 mm. Si no coloca bien los soportes

antivuelcos, es posible que los soportes no queden bien

fijados.

Utilice todas las piezas del soporte antivuelco tal y como

se indica en las instrucciones para suelos de madera o de

hormigón.

NOTA IMPORTANTE: para aplicaciones en suelos de madera

o de hormigón, en caso de que los tornillos del n.º 12 no

alcancen el montante o la placa de pared, utilice tornillos

del n.º 8 y arandelas del n.º 12 con los anclajes para pared.

NOTA IMPORTANTE: en algunas instalaciones es posible

que debido al tipo de suelo o acabado de éste sea necesario colocar inclinados los tornillos utilizados para sujetar

los soportes antivuelco a la pared trasera.

PIEZAS ANTIVUELCO

2 Soportes antivuelco

12 Tornillos de cabeza plana del n.º 12 (64 mm)

4 Anclajes de expansión de 16 x 95 mm –

12 Arandelas planas del n.º 12

4 Tornillos de cabeza ovalada del n° 8 (18 x 32 mm)

4 Anclajes para pared de nailon Zip-it

3

/8"

®

SUELO DE MADERA

Tras colocar correctamente los soportes antivuelco en la

cavidad, perfore orificios guía de 5 mm de diámetro como

máximo en los montantes de pared o en la placa de pared.

Utilice arandelas y tornillos del n.º 12 para fijar los soportes.

Compruebe que los tornillos penetren en el material del

suelo y en los montantes de pared o en las placas un

mínimo de 19 mm. Consulte la siguiente ilustración.

SUELO DE HORMIGÓN

Tras colocar correctamente los soportes antivuelco en la

cavidad, perfore orificios guía de 5 mm de diámetro como

máximo en los montantes de pared o en la placa de pared.

Realice orificios de 10 mm de diámetro en el hormigón con

una profundidad mínima de 38 mm. Utilice arandelas y tornillos del n.º 12 para fijar los soportes a la pared, y anclajes

de expansión de

3

/8" (9,5 mm) para fijar los soportes al

suelo. Compruebe que los tornillos penetran en los montantes de pared o en las placas un mínimo de 19 mm.

Consulte la siguiente ilustración.

PLACA DE PARED

TIPO DE SUELO

SUELO DE MADERA

Suelo de madera.

102 mm

SUELO

ACABADO

610

mm

MIN

WALL PLATE

PLACA DE PARED

SUBFLOORING

TIPO DE SUELO

CONCRETE

FLOOR

Suelo de hormigón.

102 mm

FINISHED

SUELO

FLOORING

ACABADO

11/2"

38 mm

min

MIN

610

mm

MIN

(38)

INSTALACIÓN DE ANCLAJES DE EXPANSIÓN PARA

HORMIGÓN

1 Haga un agujero de 10 mm de diámetro con una profun-

didad superior al incrustado mínimo. Limpie el orificio o

continúe taladrando para hacer que el orificio sea más

profundo y quepan en él los residuos.

2 Coloque la arandela y la tuerca al nivel del extremo del

anclaje para proteger las roscas. Inserte el anclaje en el

material en el que debe atornillarse hasta que la arandela

quede nivelada con el material de la superficie.

3 Extienda el anclaje mediante una llave que sirva para

apretar la tuerca de 3 a 5 vueltas más de su posición

lograda con el apriete manual o hasta 34 Newton metros

de par.

AVISO

Compruebe que no haya cables eléctricos ni tuberías

en el área en la que se van a introducir los tornillos.

PRECAUCIÓN

Lleve siempre gafas de seguridad y utilice cualquier

otro dispositivo o ropa de protección que sea necesario

cuando esté instalando o trabajando con anclajes.

Se recomienda no utilizar los anclajes en material de

mampostería poco pesado, por ejemplo, bloques o

ladrillos, ni utilizarlo en hormigón fresco que no se haya

secado el tiempo suciente. No se recomienda utilizar

brocas huecas para hacer oricios para los anclajes.

Paneles a medida

En aplicaciones revestibles y empotrables, deben instalarse

paneles de rejilla y puertas a medida. El tamaño del panel

es fundamental para que se ajuste correctamente. Para

comprobar las medidas y los requisitos del panel, consulte

la guía de diseño de Sub-Zero.

NOTA IMPORTANTE: las aplicaciones revestibles necesitan

un margen mínimo de 13mm en todos los lados.

Realice el acabado de todos los lados del panel a medida,

pues son áreas que pueden resultar muy visibles al abrir la

puerta o a través de los cristales.

PRECAUCIÓN

No se puede instalar un panel sólido en una puerta de

cristal.

10 | Español

Page 23

INSTALACIÓN DEL MODELO ICBBW-30

2134

mm

610 mm

CORTE

OPCIONAL PARA

EL RODAPIÉ

102 mm

48 mm

25 mm

FRESAR A

3 mm

67 mm

PARTE DEL

ANTERA

DEL PANEL

LATERAL

MARCO

PRINCIPAL

DISPOSICIÓN DEL

PANEL LATERAL

25 mm

48 mm

3 mm

13 mm

Instalación del panel

PANEL DE PUERTA

Para instalar el panel de puerta a medida, retire la moldura

del borde del lateral del tirador. Introduzca la punta de un

destornillador en la ranura de la esquina superior del lateral

del tirador y extraiga el borde. Retire los tornillos y el marco.

Observe la siguiente ilustración.

La puerta tiene un marco de 6mm para deslizar dentro el

panel a medida. Si el panel posee un grosor inferior a 6mm,

frese el borde del panel o monte el panel en una lámina de

material fino de 6mm, y luego introdúzcalo en el marco.

Borde de la puerta.

Se necesita un espacio de 3 mm entre el panel trasero y

el panel a medida para que el panel pueda deslizarse en

el marco de la puerta. Observe las siguientes ilustraciones

para ver las medidas fundamentales.

Coloque las piezas del tirador antes de insertar el panel. Se

recomienda utilizar tiradores anchos en forma de D en lugar

de pomos. Las cabezas de los tornillos se deben encastar

en el panel.

Deslice el panel en el marco.

Para volver a colocar la moldura del borde de la puerta,

introduzca la parte superior del borde en las ranuras de

la parte superior de la puerta tirando de ellas hacia abajo,

encajándolo en las sujeciones del marco.

PANEL ESPACIADOR

PANEL FABRICADO

A MEDIDA

PANEL TRASERO

JUNTA

8 mm mín.

3 mm (REVESTIBLE)

Vista transversal del conjunto

de panel (revestible).

PANEL FABRICADO

A MEDIDA

19

mm

estándar

Vista trasera del conjunto de

panel.

3 mm

PANEL

ESPACIADOR

PANEL

TRASERO

6 mm

PANEL DE REJILLA

Quite el marco de la rejilla inferior extrayendo los dos tornillos de las esquinas inferiores a cada lado del conjunto de la

rejilla. Observe la siguiente ilustración.

Una vez extraída la sección inferior, deslice el panel de rejilla

a medida en el marco. Si el panel posee menos de 6mm

de grosor, necesitará instalar un material de relleno para

que se ajuste correctamente. Cuando el panel esté instalado, vuelva a fijar el marco inferior de la rejilla deslizando

los soportes de las esquinas a su posición y volviendo a

colocar los cuatro tornillos de los extremos.

MARCO DE

LA REJILLA

INFERIOR

Conjunto del marco de la rejilla.

PANEL LATERAL

En caso de instalar un panel lateral a medida, necesitará un

kit de accesorios, disponible en cualquier distribuidor de

Sub-Zero autorizado. Podrá encontrar los paneles laterales

de acero inoxidable y esmalte blanco en su distribuidor de

Sub-Zero autorizado.

NOTA IMPORTANTE: el uso de paneles laterales puede

afectar a la anchura de la cavidad.

Un panel lateral personalizado debe tener un mínimo de

610 mm de profundidad y 13 mm de grosor. Será necesario

sacarlo un poco para que el panel lateral quede empotrado con el lateral de la unidad. Observe las siguientes

ilustraciones.

NOTA IMPORTANTE: la altura del panel lateral variará en fun-

ción de la altura de la rejilla. Compruebe la altura final antes

de modificar los paneles.

Medidas del panel lateral.

Detalle de disposición.

subzero.com | 11

Page 24

INSTALACIÓN DEL MODELO ICBBW-30

Colocación

PRECAUCIÓN

Antes de desplazar la unidad para colocarla en su sitio,

asegúrese de que la puerta esté cerrada y proteja el

acabado del suelo.

Utilice una plataforma rodante para desplazar la unidad

hasta la cavidad.

Si la unidad ha estado boca abajo o sobre uno de los lados,

debe permanecer en posición vertical como mínimo 24

horas antes de conectarla a la alimentación.

Si se desea conectar la unidad al sistema de seguridad de

la casa, es necesario instalar cables por el compartimiento

del compresor antes de colocar la unidad. Consulte la

página 13. Una vez colocada la unidad, la conexión de los

cables se puede realizar desde la parte delantera.

Enchufe el cable eléctrico en la toma de conexión a tierra y

deslice la unidad en la posición adecuada. Compruebe que

los soportes antivuelcos están bien fijados.

NOTA IMPORTANTE: si se utilizan, los paneles laterales

deben instalarse antes de colocar la unidad en su posición

final.

Alineación

NIVELADO

Una vez que la unidad esté colocada en su sitio, gire las

patas de nivelación delanteras en el sentido de las agujas

del reloj para ajustar la altura. El ajuste de la altura de la

parte trasera se puede realizar desde la parte delantera de

la base de la rueda. Con ayuda de una llave de vaso de

gire el tornillo hexagonal de

3

/8" en el sentido de las agujas

3

del reloj para levantar la unidad y en sentido contrario para

bajarla. Utilice el ajuste de torsión más pequeño si utiliza

un taladro. No gire manualmente las patas de nivelación

trasera. Observe la siguiente ilustración.

Cuando la unidad esté correctamente nivelada, no será tan

necesario realizar los ajustes de las puertas.

NOTA IMPORTANTE: nivele la unidad con el suelo, y no con

los demás muebles. Esto puede afectar al funcionamiento

de la unidad, por ejemplo, es posible que la puerta no se

cierre correctamente.

AVISO

Para evitar que la unidad vuelque hacia delante, las

patas de nivelación delanteras deben llegar hasta el

suelo.

AJUSTE DE LA PUERTA

La puerta puede ajustarse hacia dentro y hacia fuera, inclinación de lado a lado y de arriba a abajo.

Para efectuar ajustes, afloje ligeramente los dos pernos

superiores de las bisagras en la placa de bisagras supe-

/8",

riores con una llave de

1

/2". Observe la siguiente ilustración.

Ajuste hacia dentro y hacia fuera | Para ajustar una puerta

con la bisagra a la izquierda, con ayuda de una llave allen

5

/32", gire el perno en el sentido de las agujas del reloj

de

para que el lado del tirador de la puerta se mueva hacia

dentro, y en sentido contrario para que lo haga hacia fuera.

En caso de que sea una puerta con la bisagra a la derecha,

siga las instrucciones en sentido inverso.

Ajuste de inclinación de lado a lado | Para ajustar una

puerta con la bisagra a la izquierda, con ayuda de una llave

3

/8", gire el perno en el sentido de las agujas del

allen de

reloj para extraer el lado del tirador de la puerta se mueva

hacia arriba, y en sentido contrario para que lo haga hacia

abajo. En caso de que sea una puerta con la bisagra a la

derecha, siga las instrucciones en sentido inverso.

Ajuste hacia arriba y hacia abajo | Para ayudar una puerta

con la bisagra a la izquierda, con ayuda de una llave allen

1

/4", gire el perno en el sentido de las agujas del reloj

de

para levantar la puerta, y en sentido contrario para bajarla.

Observe la siguiente ilustración. En caso de que sea una

puerta con la bisagra a la derecha, siga las instrucciones en

sentido inverso.

Finalización

INSTALACIÓN DE LA REJILLA

Instale el conjunto de la rejilla y compruebe que se ajusta

correctamente. La rejilla está diseñada para que se apoye

sobre la bisagra superior de la puerta con el fin de reducir

al mínimo el margen entre la parte superior de la puerta y la

parte inferior de la rejilla. Para evitar que puedan interferir,

deberá ajustar la altura de la rejilla. Afloje los cuatro tornillos

de ajuste de la rejilla (dos a cada lado) y adapte la altura de

esta según corresponda. Observe la siguiente ilustración.

TORNILLO

TRASERO DE

LA REJILLA

Ajuste de la altura de la rejilla.

TORNILLOS DE

AJUSTE DE

LA REJILLA

TORNILLO DELANTERO

DE LA REJILLA

12 | Español

Nivelado.

PATA DE

NIVELACIÓN

DELANTERA

AJUSTE

TRASERO

PERNOS DE LA

BISAGRA SUPERIOR

AJUSTE DE INCLINACIÓN

Pernos de ajuste de la puerta. Ajuste de la puerta hacia arriba

AJUSTE HACIA

DE LADO A LADO

DENTRO Y

HACIA FUERA

y hacia abajo.

Page 25

INSTALACIÓN DEL MODELO ICBBW-30

Finalización

CONEXIÓN AL SISTEMA DE SEGURIDAD DE LA CASA

Si se desea conectar la unidad al sistema de seguridad de

la casa, conecte los cables conforme a la siguiente ilustración. Consulte los siguientes códigos de color:

• Contactos que suelen estar abiertos: cable blanco con

raya roja.

• Contactos que suelen estar cerrados: cable blanco con

raya azul.

• Común: cable gris con raya blanca.

Utilice los terminales en horquilla o las tuercas incluidas

para realizar las conexiones de cables correctamente.

PRECAUCIÓN

El circuito de alarma en el aparato solo constituye

un dispositivo de bajo voltaje y corriente débil. No se

debe utilizar para encender o apagar la conexión de

la línea. Todos los terminales sin utilizar deben quedar

aislados por completo y todos los cables deben

quedar jados lejos de componentes de conducción o

desplazamiento.

ANCLAJE

Cuando la unidad esté nivelada y se haya ajustado la

puerta, ancle la unidad a la cavidad para garantizar que se

ajusta correctamente y que la instalación es segura.

Para anclar la parte superior de la unidad, abra la rejilla y

coloque los tornillos incluidos a través del marco de la rejilla

hasta que penetren en el mobiliario. Hay varios orificios.

Observe la siguiente ilustración. Compruebe el espacio

adecuado para la apertura de la puerta.

Para anclar la parte inferior de la unidad, coloque un tornillo

en el orificio lateral en el conjunto de la base de cada rueda.

El tornillo se debe colocar en ángulo para que la fijación sea

la correcta. Observe la siguiente ilustración. Es posible que

necesite material adicional por detrás del listón para garantizar que el anclaje sea suficiente.

PRECAUCIÓN

En caso de que los tornillos suministrados no sean

adecuados para la instalación, utilice unos tornillos

adecuados.

INSTALACIÓN DEL ZÓCALO

Vuelva a instalar el depósito de desagüe y compruebe que

está en el lugar adecuado.

Instale el zócalo con tornillos para fijarlo a los soportes

del interior de la base de cada rueda. Observe la siguiente

ilustración. El zócalo debe ser extraíble para permitir sacarlo

en caso de avería. El suelo no puede ser un impedimento

para llevar a cabo esta operación. Consulte la etiqueta que

encontrará en el soporte del zócalo para conocer la separación de la altura.

Encienda la unidad pulsando el botón de “POWER” (encendido) en el panel de control.

TOPE DE PUERTA A 90°

La puerta se abre 110º. Se suministra un tope de puerta a

90º con la unidad (situado detrás de la rejilla). Puede pedir

sistemas de tope de puerta a 90° a través de un distribuidor

autorizado de Sub-Zero.

AVISO

Cumpla con todas las normativas locales para el

almacenamiento, reciclaje o eliminación de frigorícos

y congeladores que no se utilicen.

CABLES DEL SISTEMA DE

SEGURIDAD DE LA CASA

Conexión al sistema de seguridad de la casa.

TORNILLOS

DE ANCLAJE

TORNILLOS

DE ANCLAJE

Anclaje de la parte superior. Anclaje de la parte inferior.

Instalación del zócalo.

Sub-Zero, Sub-Zero & Design, Dual Refrigeration, Constant Care, The Living Kitchen, Great American Kitchens The Fine Art of Kitchen Design, e Ingredients son marcas registradas y

marcas de servicio de Sub-Zero, Inc. Wolf, Wolf & Design, Wolf Gourmet, W & Design y los mandos distintivos de color rojo son marcas registradas y marcas de servicio de Wolf Appliance,

Inc. (en su conjunto, las “Marcas de la Empresa”). Todas las demás marcas o marcas registran son propiedad de sus respectivos propietarios en los Estados Unidos y en otros países.

subzero.com | 13

Page 26

CAVES À VIN

Table des matières

2 Caves à vin

3 Préparation de chantier des modèles ICBUW-24 /

ICBUW-24FS

4 Installation des modèles ICBUW-24 /ICBUW-24FS

7 Préparation de chantier des modèles ICBBW-30

10 Installation des modèles ICBBW-30

Les caractéristiques et spécifications peuvent être modifiées

à tout moment sans préavis.

Remarque importante

Pour garantir une installation de ce produit aussi sûre et efficace que possible, veuillez faire particulièrement attention

aux mentions mises en évidence tout au long de ce guide,

notamment :

REMARQUE IMPORTANTE met l'accent sur un renseigne-

ment particulièrement important.

MISE EN GARDE signale un danger qui pourrait causer une

blessure mineure ou endommager le produit si vous ne

suivez pas les instructions.

AVERTISSEMENT signale un danger qui pourrait causer

des blessures graves voire fatales si vous ne prenez pas

certaines précautions.

REMARQUE IMPORTANTE : Conservez ces instructions pour

l'électricien local chargé des inspections.

Information concernant le produit

Les renseignements importants concernant le produit,

notamment la référence modèle et le numéro de série,

figurent sur la plaque des caractéristiques du produit. La

plaque des caractéristiques se trouve sur le dessous du

panneau de commande, à gauche. Reportez-vous aux illustrations ci-après.

Si vous devez contacter le service après-vente, contactez le

prestataire agréé par l'usine Sub-Zero avec les numéros de

modèle et de série.

PLAQUE DES CARACTÉRISTIQUES

PLAQUE DES

CARACTÉRISTIQUES

Modèles ICBUW-24 et

ICBUW-24FS.

Modèle ICBBW-30.

Outils et matériaux

• Tournevis—normaux, Phillips et Torx.

• Perceuse électrique.

• Mèches (mèches de maçonnerie nécessaires pour l'ins-

tallation dans le béton).

• Jeu de clés et de douilles normales.

• Niveaux de 0,6 m et 1,2 m.

• Matériel pour protéger la maison, le sol et son mobilier

pendant l'installation.

2 | Français

Page 27

MODÈLE ICBUW-24 / PRÉPARATION DE CHANTIER ICBUW-24FS

Cotes d'encastrement

MODÈLE ICBUW-24

610 mm

PROFONDEUR

D'OUVERTURE

VUE EN PLAN

876 mm

HAUTEUR

D'OUVERTURE

VUE LATÉRALE VUE DE FACE

LARGEUR D'OUVERTURE L

ICBUW-24 610 mm

Deux modèles de 610 mm* 1 222 mm

*Il sera nécessaire d’avoir un kit d’installation conjointe pour cette installation.

L

LARGEUR D'OUVERTURE

INSTALLATION CONJOINTE

Si deux appareils sont placés côte à côte, il faudra peut-être

se procurer un kit d'installation conjointe. Les installations

sans filler sur mesure exigent un kit d'installation conjointe.

Si aucun kit d'installation conjointe n'est spécifié, il est

recommandé d'utiliser un filler de 51 mm entre les appareils.

Les installations conjointes sans filler ne sont possibles que

lorsqu'il s'agit de deux appareils dont les charnières sont

opposées. Reportez-vous aux illustrations ci-après.

Ces kits d'installation conjointe sont disponibles chez un

revendeur agréé Sub-Zero.

SANS FILLER

Charnières opposées.

Charnières du même côté.

FILLER

Électricité

L'installation doit se conformer à tous les codes électriques

applicables. Elle doit être correctement mise à la terre.

L'alimentation en électricité doit se trouver dans la zone

ombrée indiquée sur l'illustration ci-dessous. Il est nécessaire d'avoir un circuit indépendant, alimentant uniquement

cet appareil ménager. Il n'est pas recommandé d'avoir

recours à un disjoncteur différentiel (GFCI) qui pourrait provoquer l'interruption du fonctionnement de l'appareil.

CONFIGURATION ÉLECTRIQUE

Alimentation électrique 220-240 V c.a., 50/60 Hz

Disjoncteur 10 A

Prise type mise à la terre

MISE EN GARDE

La prise doit être vériée par un électricien qualié.

Celui-ci doit s'assurer qu'elle est dotée de la polarité

adéquate. Assurez-vous que la prise est correctement

mise à la terre.

CÔTÉ GAUCHE

DE L'OUVERTURE

64

330 mm

mm

6 mm

114

E

mm

SOL

Préparation

Pour fonctionner correctement, l'angle d'ouverture de la

porte doit être de 90 degrés minimum. Dans le cas d'une

installation en coin, prévoyez un filler d'au moins 76 mm

pour que la porte puisse s'ouvrir à 90 degrés.

Dégagez l'appareil du carton et inspectez-le afin de déceler

tout dommage éventuel. Retirez et recyclez les matériaux

d'emballage. Ne jetez pas la plinthe, le support antibasculement, le matériel de fixation, ni les pieds de mise à

niveau qui maintiennent le socle en bois à la partie inférieure

de l'appareil.

Emplacement de l'alimentation

électrique.

Électricité

Danger de

Choc Électrique

Branchez directement le cordon électrique

dans une prise avec mise à la terre adéquate.

N’entravez pas la fonction de mise à la terre

de la prise.

N’utilisez pas d'adaptateur ou de cordon de

rallonge.

Le non-respect de ces instructions pourrait

entraîner des blessures graves voire mortelles.

Voir les instructions d’installation

subzero.com

|

3

Page 28

MODÈLE ICBUW-24 / PRÉPARATION DE CHANTIER ICBUW-24FS INSTALLATION DES MODÈLES ICBUW-24 / ICBUW-24FS

Support antibasculement

AVERTISSEMENT

Le support antibasculement doit être installé pour

empêcher l'appareil de basculer vers l'avant.

MODÈLE ICBUW-24

Le support antibasculement devrait être fixé au mur, derrière

l'appareil, la bride du support se trouvant à 6 mm au-dessus

du dessus de l'appareil. Reportez-vous à l'illustration

ci-après. Si le support antibasculement n'est pas correctement positionné, vous ne pourrez pas bien engager

l'appareil.

Pour les installations qui rendent impossible la fixation du

support antibasculement, un support de plan de travail est

fourni pour fixer l'appareil au plan de travail. Reportez-vous

à l'illustration ci-après.

SUPPORT DE

6 mm

Support antibasculement

(ICBUW-24).

PLAN DE TRAVAIL

Support de plan de travail.

MODÈLE ICBUW-24FS

L'arrière du support antibasculement doit être installé à

625mm mesuré depuis le devant de l'appareil et centré

derrière l'appareil. Reportez-vous à l'illustration ci-après.

Consultez la page 10 pour les installations sur planchers et

sols en béton.

SUPPORT

ANTIBASCULEMENT

Support antibasculement

(ICBUW-24FS).

Panneau sur mesure

MODÈLE ICBUW-24

Pour les installations avec habillage, un panneau de porte

sur mesure doit être installé. Ces dimensions sont essentielles pour que l'installation soit faite correctement. Pour

vérifier les configurations pour les panneaux et les dimensions, consultez le Guide technique Sub-Zero.

Finissez tous les côtés du panneau sur mesure. Ils pourraient être visibles lorsque la porte est ouverte ou par la

porte vitrée.

Le panneau d'habillage de la porte est fixé à l'aide des vis

fournies, par le cadre de la porte. Les emplacements des

vis sont indiqués à l'arrière du panneau sur mesure à l'aide

de centres de tenon insérés dans les trous du cadre de la

porte.

Une fois l'appareil bien fixé et la porte fermée, mettez le

panneau sur mesure à la position désirée sur la porte. Tapez

délicatement sur l'avant du panneau pour identifier les

positions de fixation. Retirez les centres de tenon. Reportez-vous à l'illustration ci-après.

Le cadre de la porte possède des trous de fixation pouvant

accueillir les poignées accessoires Sub-Zero. Si les trous de

fixation de poignée ne servent pas, la poignée doit être fixée

au panneau sur mesure avant de le fixer. Les têtes de vis

devront être fraisées dans le panneau pour obtenir un bon

alignement.

PANNEAU

CADRE DE

PORTE

JOINT

11 mm

DIAMÈTRE

Pour fixer le panneau sur mesure, ouvrez la porte et utilisez

les trous pré-percés pour positionner le panneau. Enfoncez

les vis dans le panneau à travers le ruban noir du cadre de

la porte. Les trous des vis sont dissimulés derrière le joint de

la porte. Utilisez autant de vis que nécessaire pour fixer le

panneau sur mesure. Reportez-vous à l'illustration ci-après.

Les réglages peuvent être faits avec quelques vis de fixation

du panneau sur mesure installées mais pas complètement

serrées. Une fois que la bonne position a été obtenue, installez et serrez toutes les vis.

Recouvrez les trous à l'intérieur du cadre de la porte avec

les pastilles ou les bouchons cache-trou fournis.

MISE EN GARDE

Il est impossible d'installer un panneau massif sur la

porte vitrée. Vous pouvez vous procurer une porte

normale chez un revendeur agréé Sub-Zero.

4 | Français

Centre de tenon.

CENTRE DE

TENON

VITRE

6 mm

DIAMÈTRE

Vue en coupe du cadre de

porte.

Page 29

INSTALLATION DES MODÈLES ICBUW-24 / ICBUW-24FS

Emplacement

MISE EN GARDE

Avant de déplacer l'appareil vers son emplacement

dénitif, maintenez la porte fermée et protégez le plancher ni.

Utilisez un diable spécial appareils ménager pour amener