Page 1

INTERNATIONAL DESIGN GUIDE

Page 2

Contents

Built-In Refrigeration . . . . . . . . . . . . . . . . . . . . . . . . . . 3

PRO 48 Refrigeration . . . . . . . . . . . . . . . . . . . . . . . . . 34

Integrated Refrigeration . . . . . . . . . . . . . . . . . . . . . . 39

Wine Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Features and specifications are subject to change at any

time without notice. Visit subzero.com/specs for the most

up-to-date information.

Page 3

Built-In Refrigeration 3

subzero.com/specs

Built-In Refrigeration. For the built-in line, Sub-Zero designers and engineers took a fresh look at everything, inside

and out. Exterior refinements include redesigned grilles and lower-profile hinges. Inside, new technology in food preservation makes the built-in line nothing short of revolutionary.

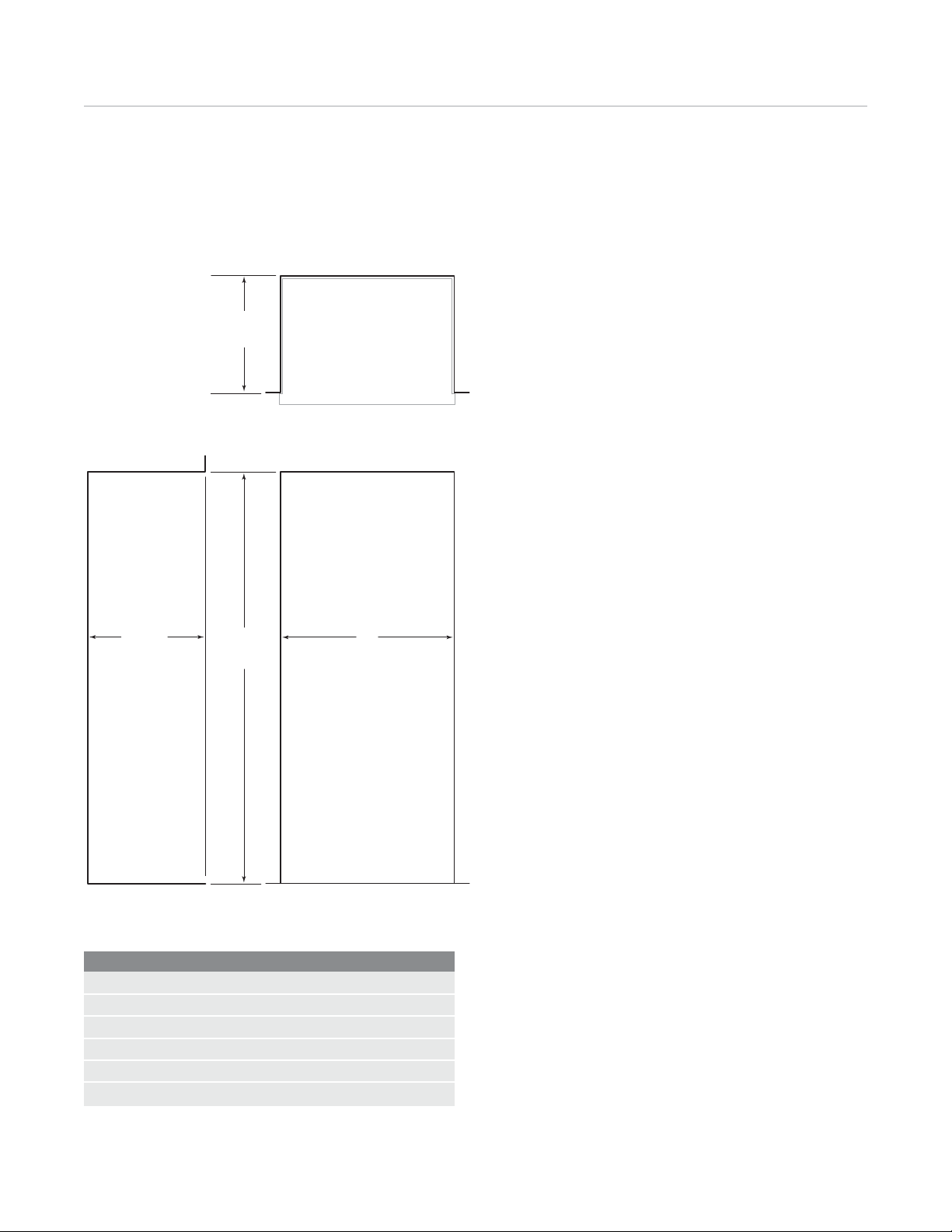

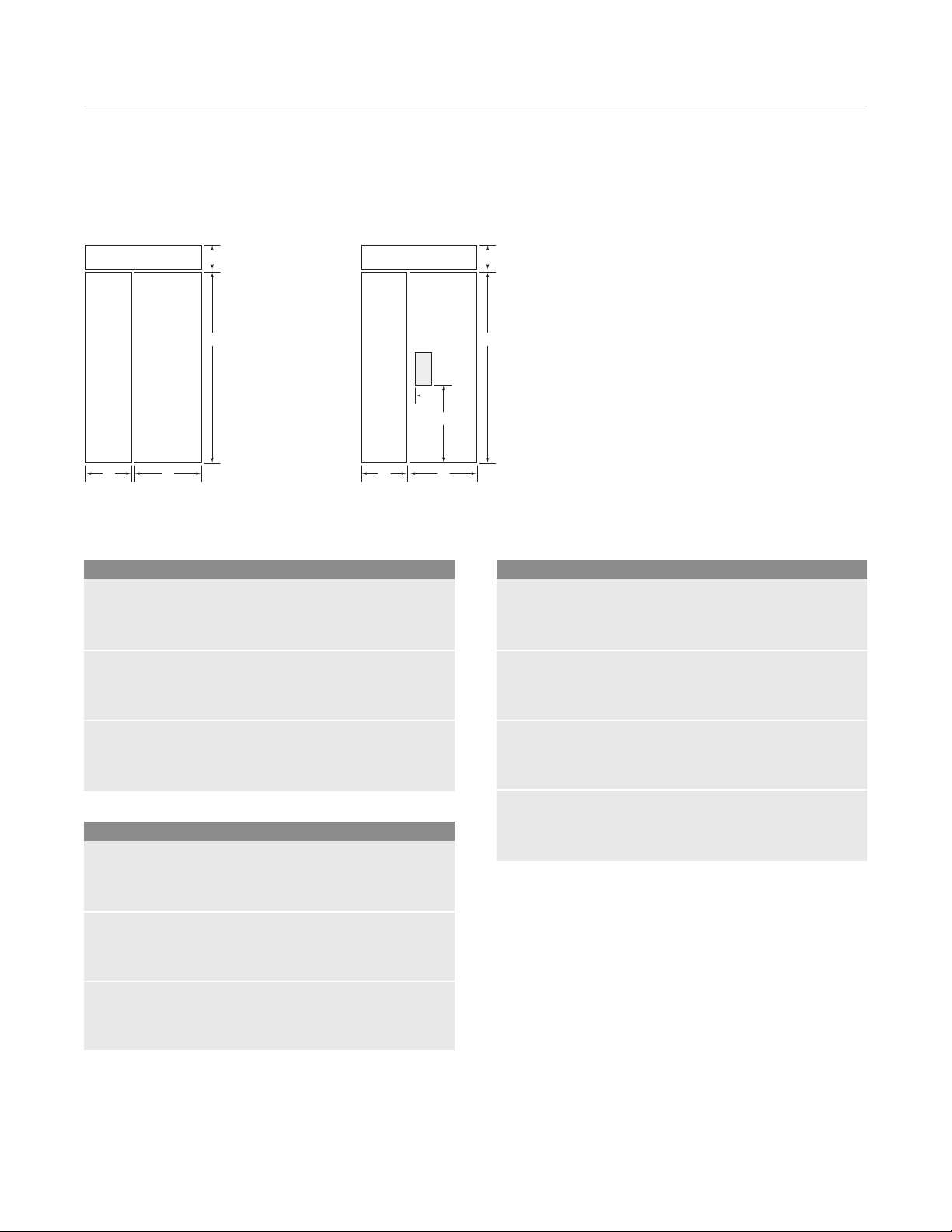

BUILT-IN MODELS

2134

mm

ICBBI-36R

2134

mm

914 mm

914 mm914 mm

2134

mm

762 mm

ICBBI-36F ICBBI-36UICBBI-30U

914 mm

1219 mm 1219 mm1067 mm1067 mm

ICBBI-36S ICBBI-42S ICBBI-42SD ICBBI-48S ICBBI-48SD

KEY FEATURES

• Three distinct design approaches: overlay, flush inset

and stainless steel.

• Handle options coordinate with handles of Wolf

cooking products.

• Dual refrigeration; two compressors preserve food’s

goodness in two sealed compartments.

• Advanced air purification system.

• Crisper and deli drawers form a lower-temperature

zone for produce and meats.

• Flip-up grille provides easy access for quick routine

maintenance.

• All models are Star-K certified.

• Energy efficient.

Page 4

Built-In Refrigeration 4

Built-In Models

SPECIFICATIONS

Interior Capacity R (L) F (L)

ALL REFRIGERATOR / ALL FREEZER MODELS

ICBBI-36R 662

ICBBI-36F 640

OVER-AND-UNDER MODELS

ICBBI-30U 362 116

ICBBI-36U 451 149

SIDE-BY-SIDE MODELS

ICBBI-36S 346 227

ICBBI-42S 455 227

ICBBI-42SD 453 230

ICBBI-48S 533 270

ICBBI-48SD 531 274

Shipping Weight kg

ALL REFRIGERATOR / ALL FREEZER MODELS

ICBBI-36R 191

ICBBI-36F 184

OVER-AND-UNDER MODELS

ICBBI-30U 210

ICBBI-36U 234

SIDE-BY-SIDE MODELS

ICBBI-36S 244

ICBBI-42S 264

ICBBI-42SD 276

ICBBI-48S 286

ICBBI-48SD 298

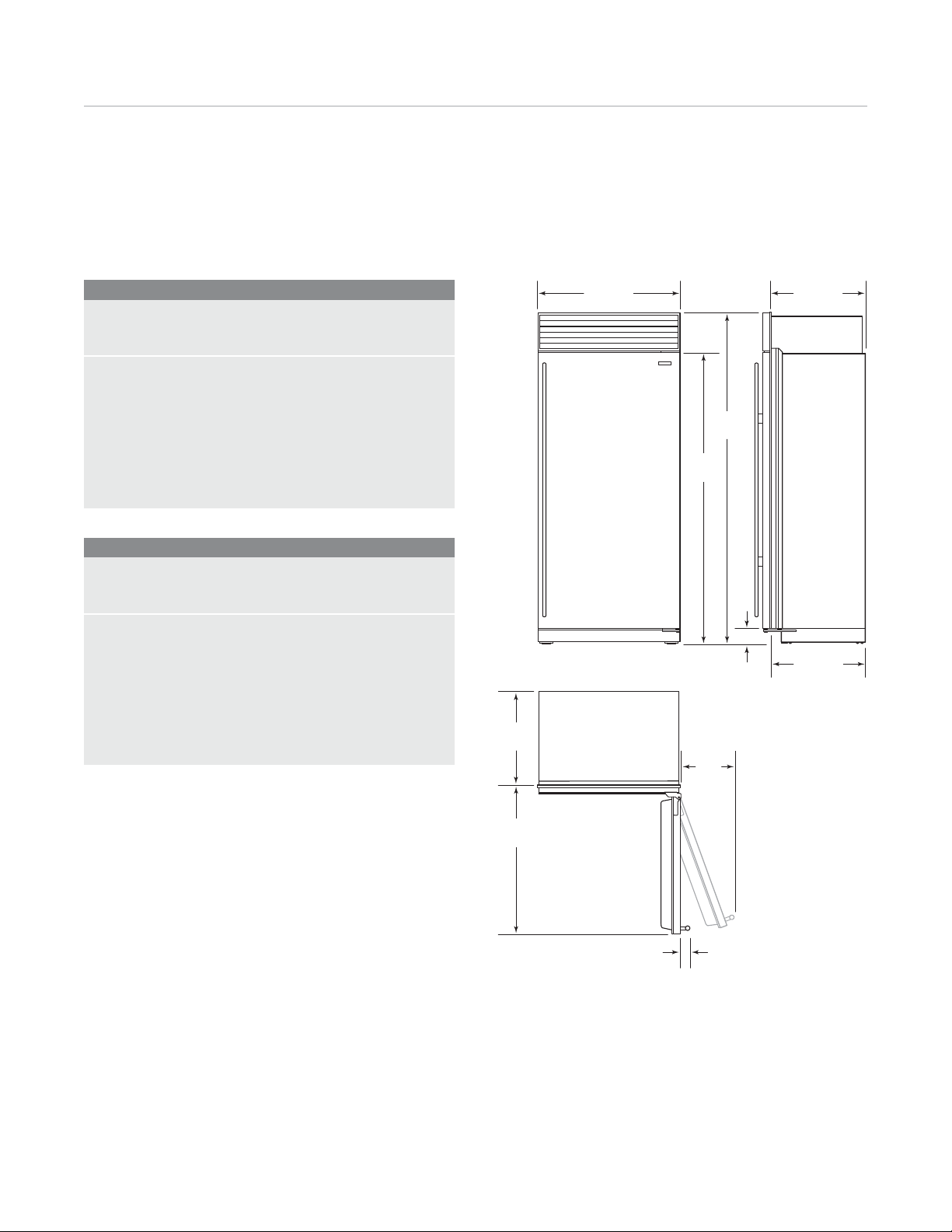

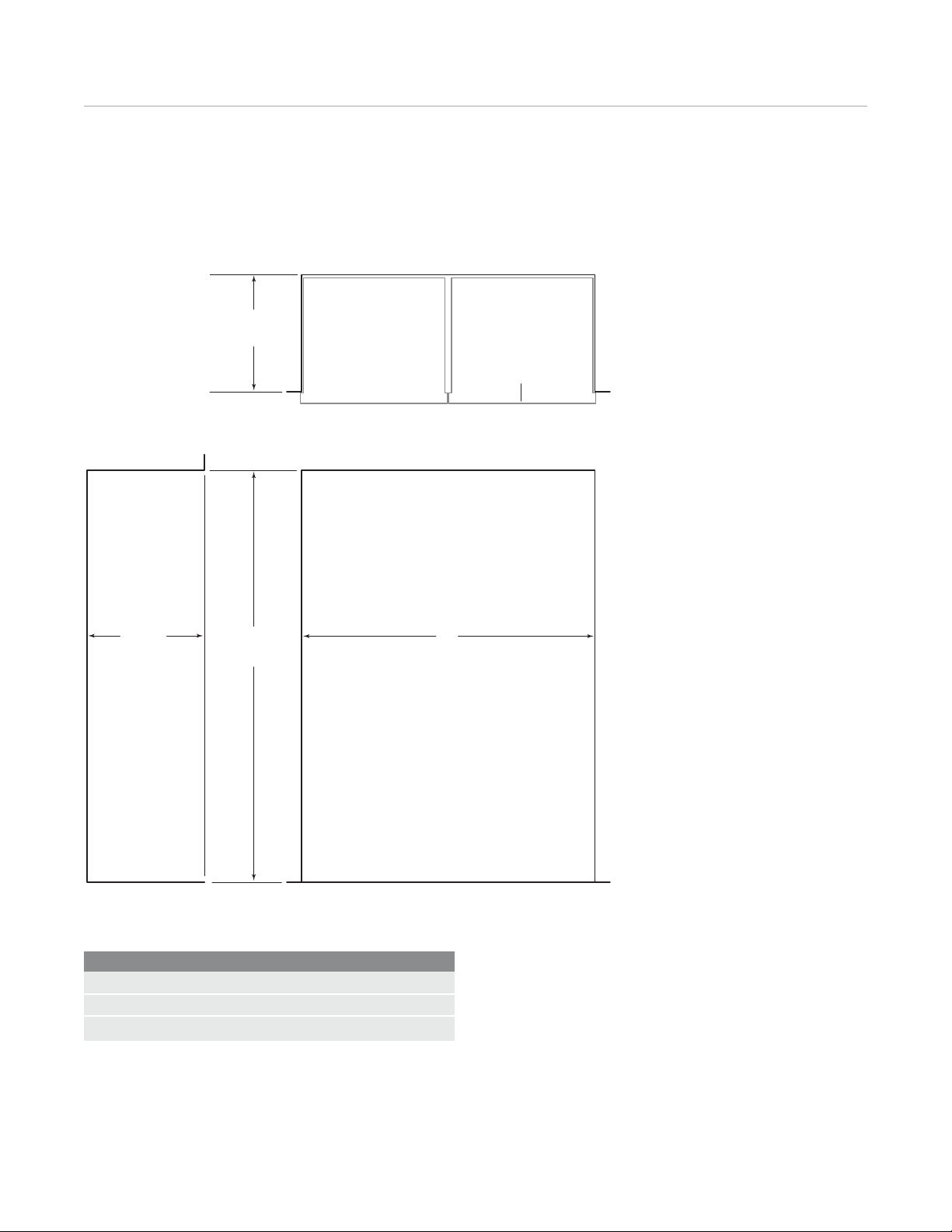

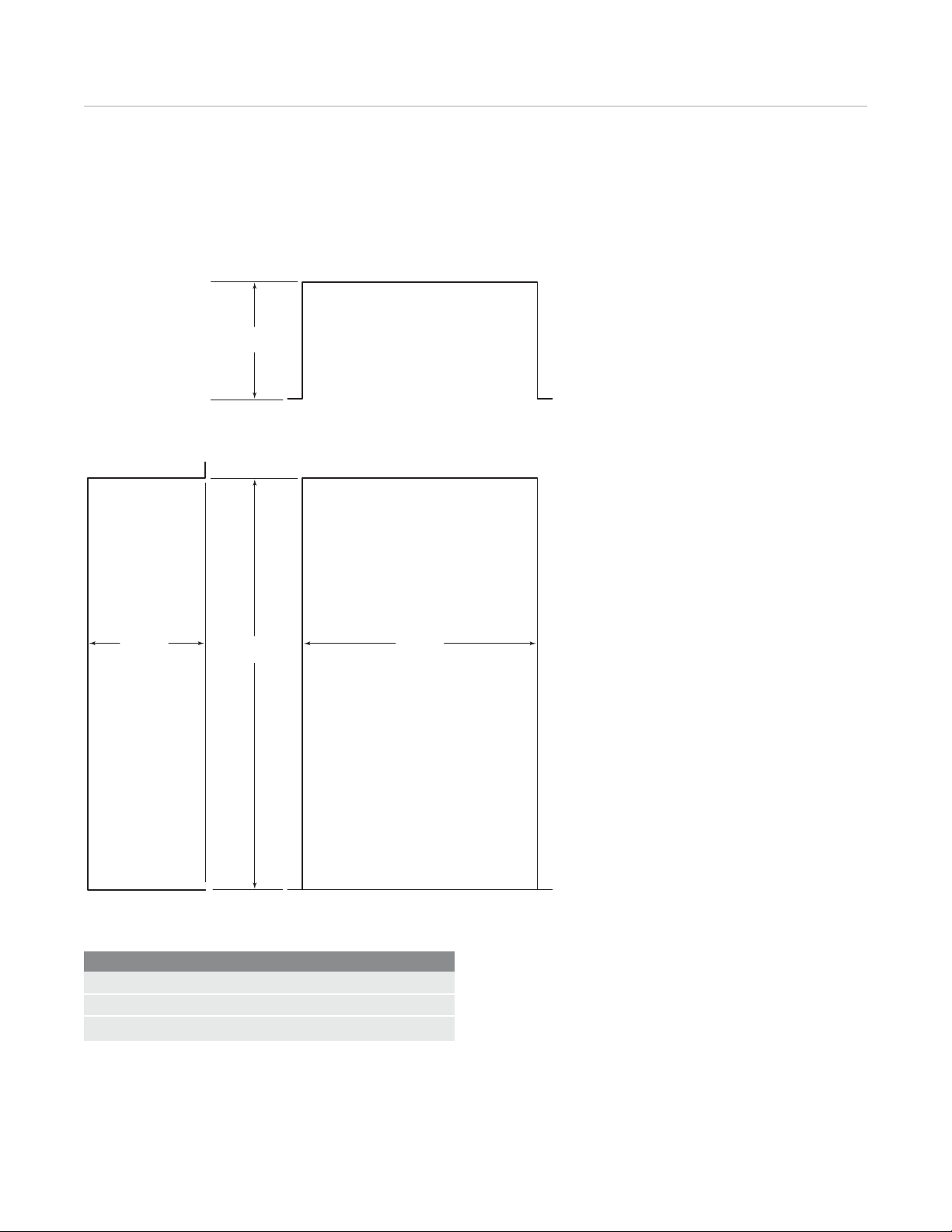

All Refrigerator / All Freezer Models

OVERALL DIMENSIONS

914 mm

2134

mm

1873

mm

HEIGHT DIMENSIONS ± 13 mm

606

mm

432

mm

102 mm

610 mm

606 mm

946

mm

60 mm

MODELS ICBBI-36R AND ICBBI-36F

Shipping weights and overall dimensions are based on

stainless steel models. For flush inset applications, add

13 mm to door clearance dimensions.

Page 5

Built-In Refrigeration 5

subzero.com/specs

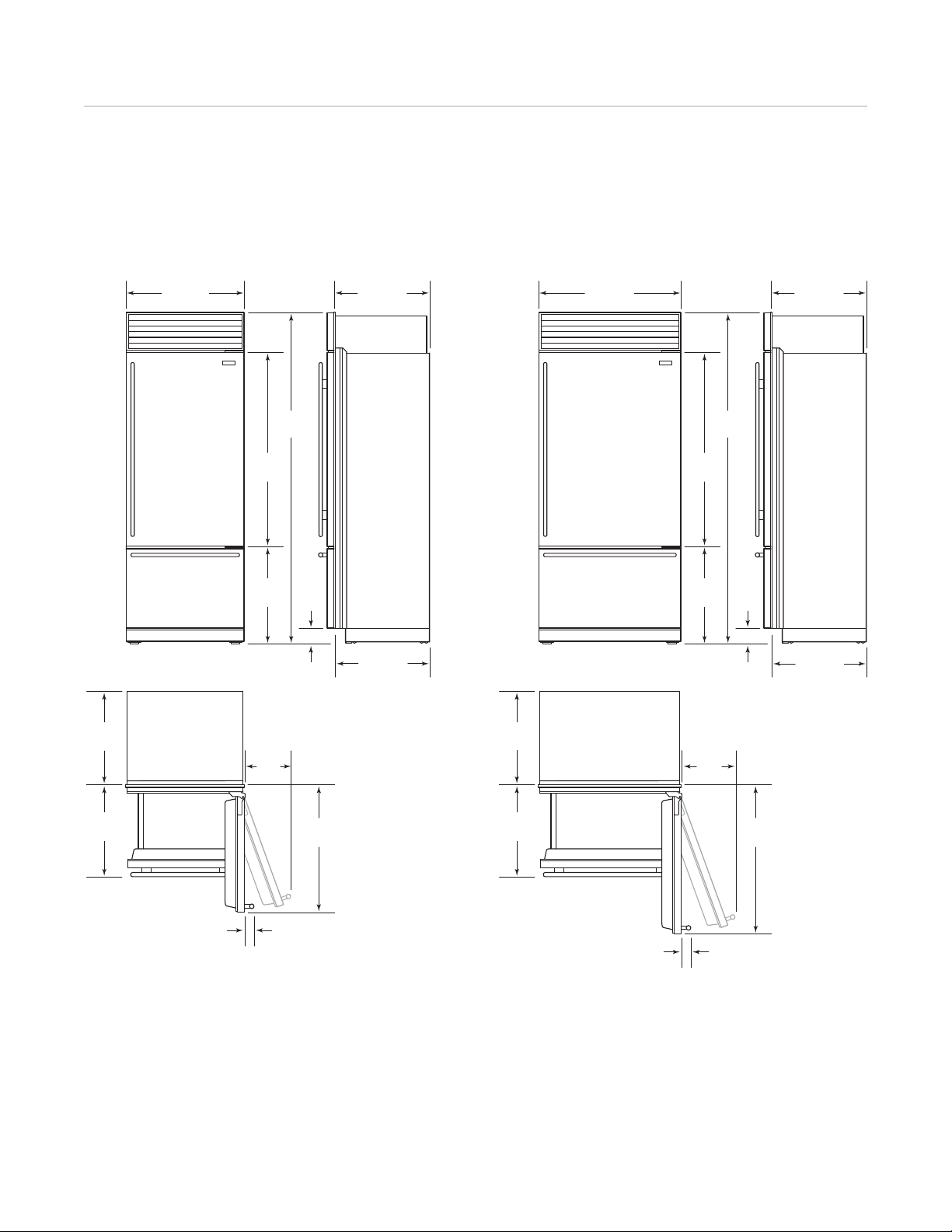

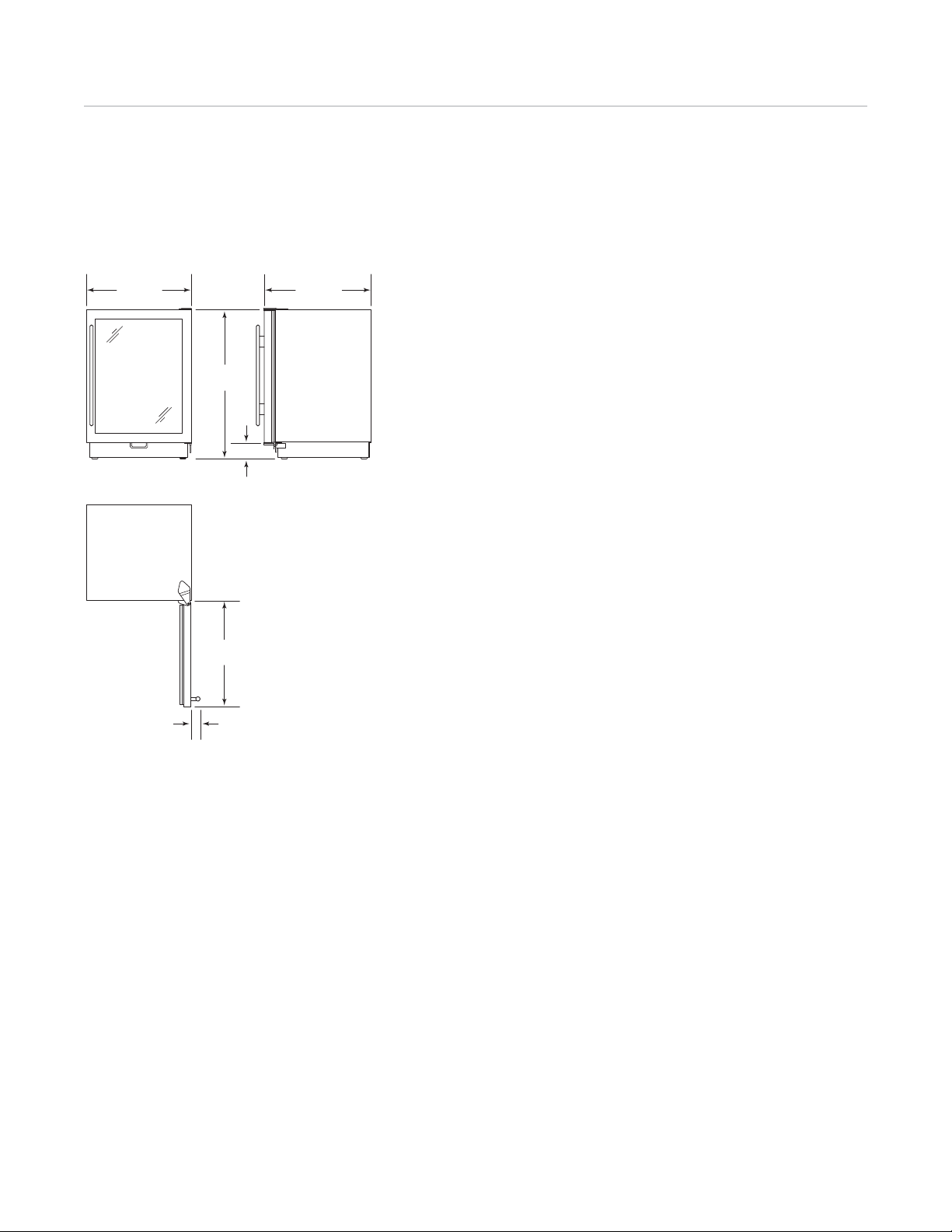

Over-and-Under Models

OVERALL DIMENSIONS

762 mm

HEIGHT DIMENSIONS ± 13 mm

606

mm

1289

mm

584

mm

368

mm

2134

mm

102 mm

610 mm

606 mm

914 mm

HEIGHT DIMENSIONS ± 13 mm

606

mm

1289

mm

584

mm

432

mm

2134

mm

102 mm

610 mm

606 mm

600

mm

MODEL ICBBI-30U

60 mm

796

mm

600

mm

MODEL ICBBI-36U

60 mm

946

mm

Page 6

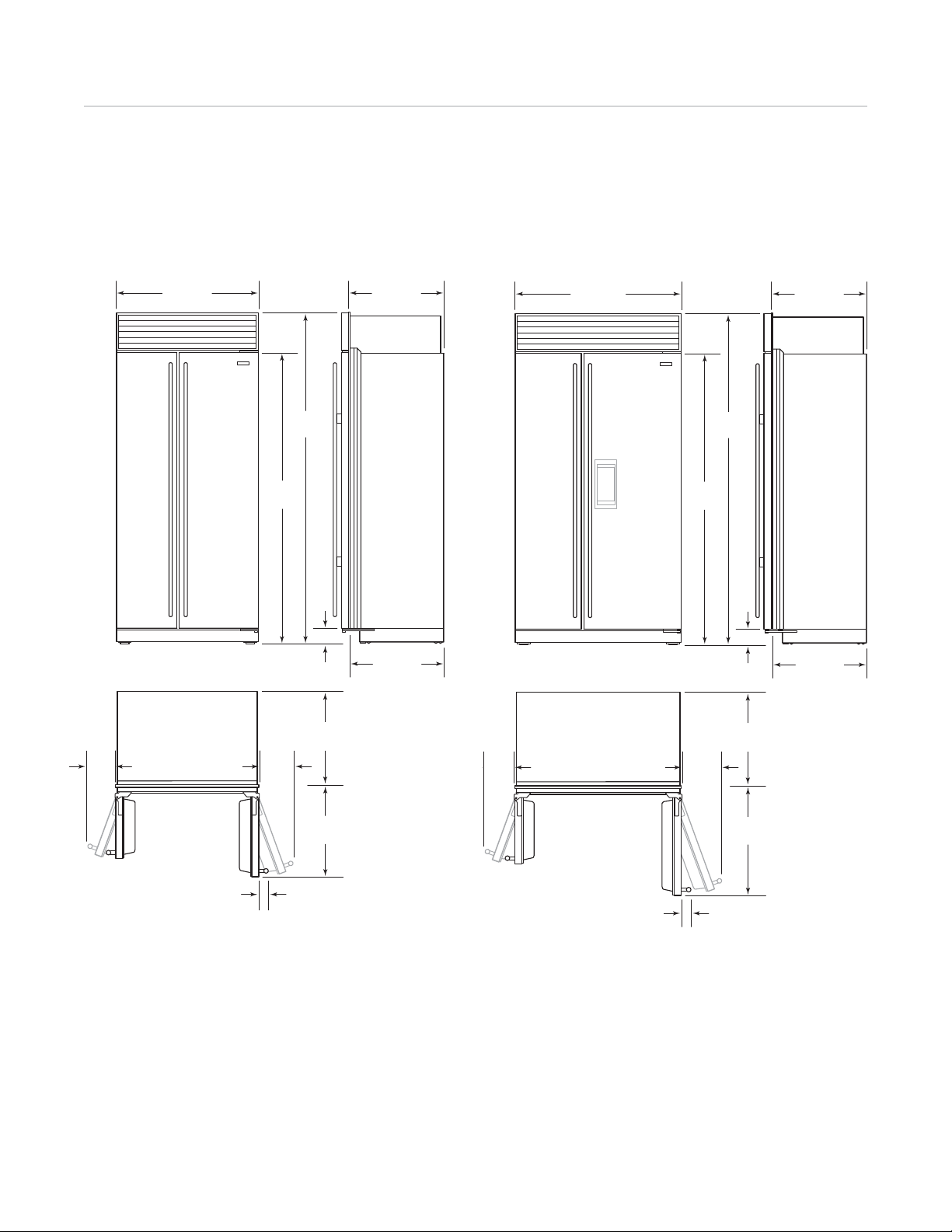

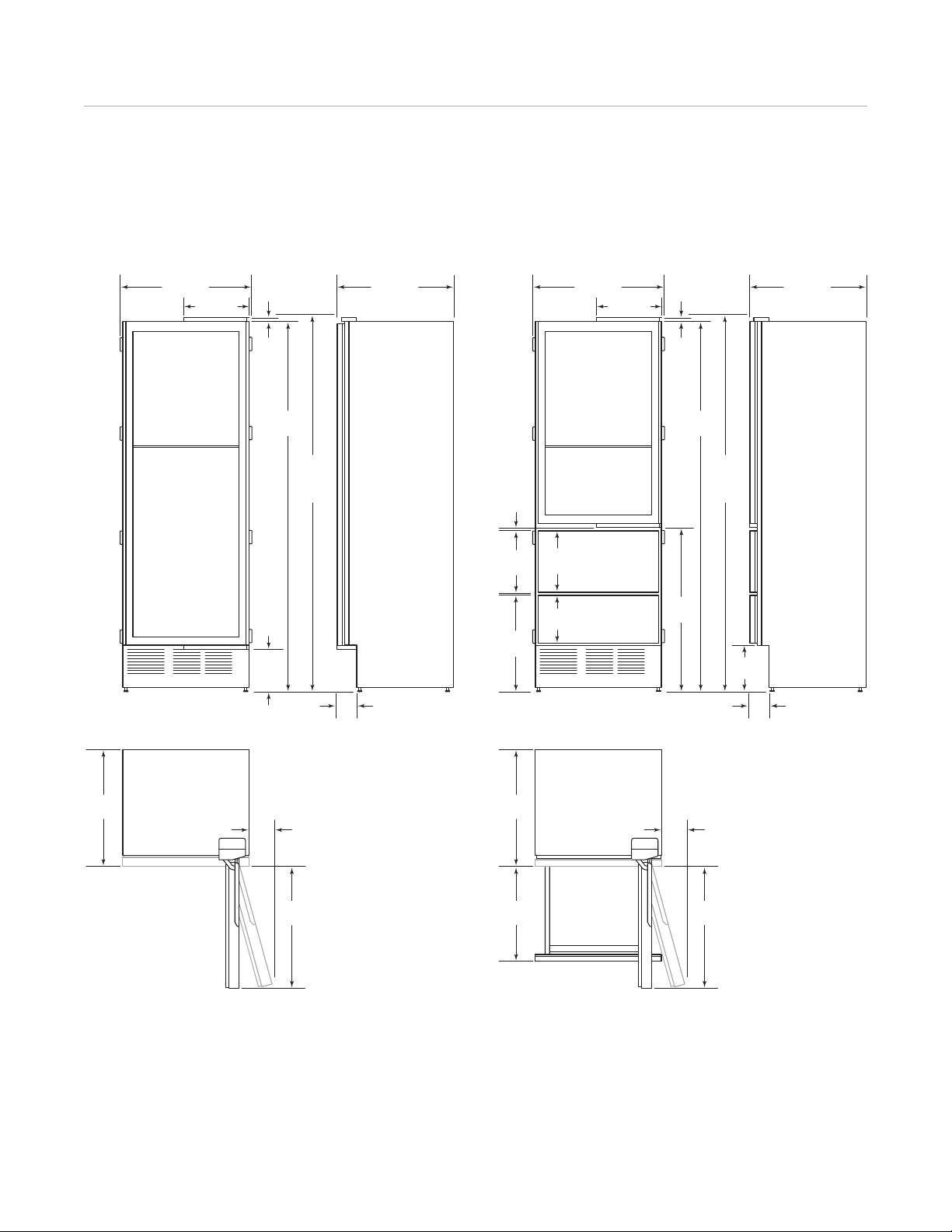

Built-In Refrigeration 6

Side-by-Side Models

OVERALL DIMENSIONS

914 mm

HEIGHT DIMENSIONS ± 13 mm

216

mm

1873

mm

260

mm

2134

mm

102 mm

606

mm

610 mm

606 mm

1067 mm

HEIGHT DIMENSIONS ± 13 mm

222

mm

1873

mm

318

mm

2134

mm

102 mm

606

mm

610 mm

606 mm

565

mm

60 mm

MODEL ICBBI-36S

Overall dimensions are based on stainless steel models.

For flush inset applications, add 13 mm to door clearance

dimensions.

MODELS ICBBI-42S AND ICBBI-42SD

60 mm

668

mm

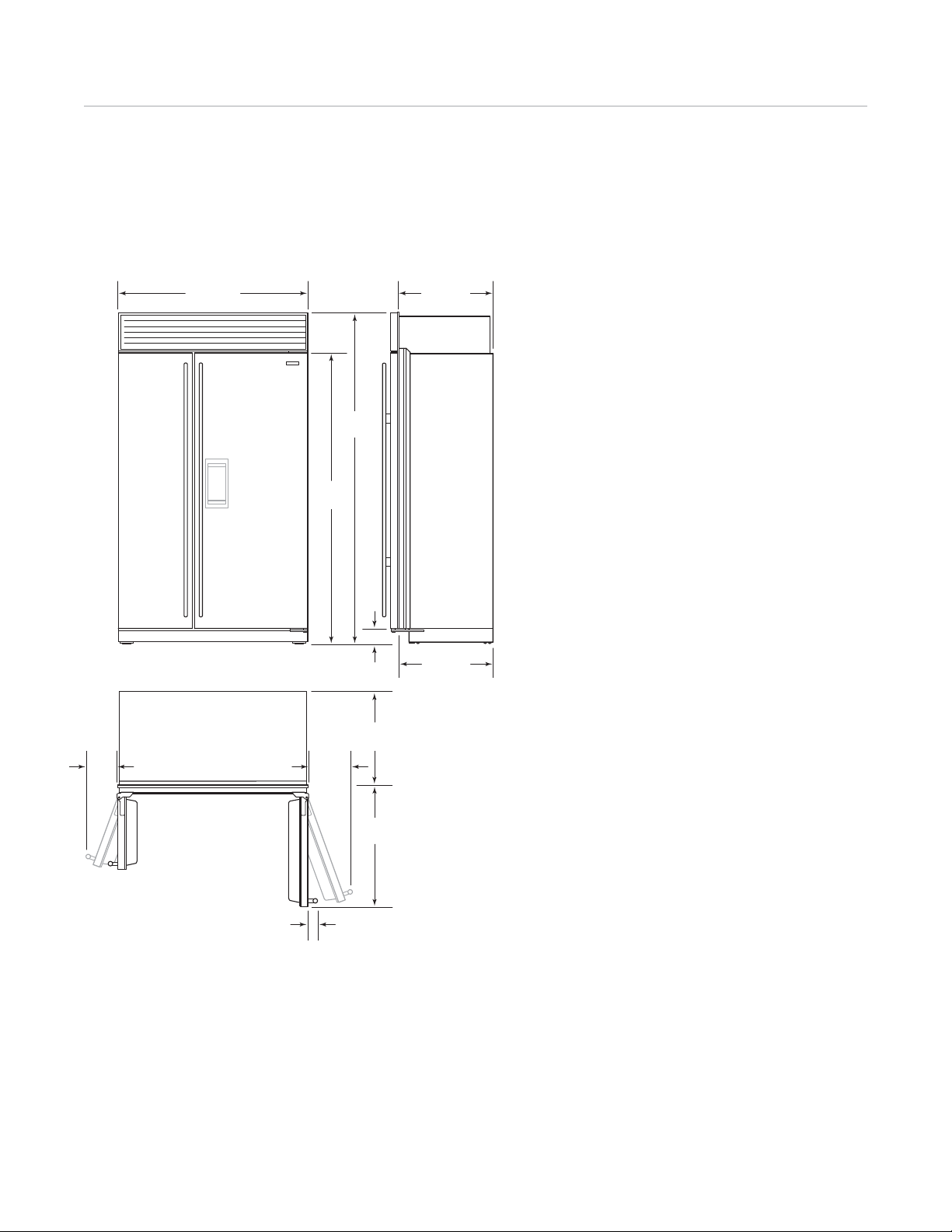

Page 7

Built-In Refrigeration 7

subzero.com/specs

Side-by-Side Models

OVERALL DIMENSIONS

248

mm

1219 mm

HEIGHT DIMENSIONS ± 13 mm

1873

mm

356

mm

2134

mm

102 mm

606

mm

610 mm

606 mm

MODELS ICBBI-48S AND ICBBI-48SD

60 mm

762

mm

Page 8

Built-In Refrigeration 8

Built-In Models

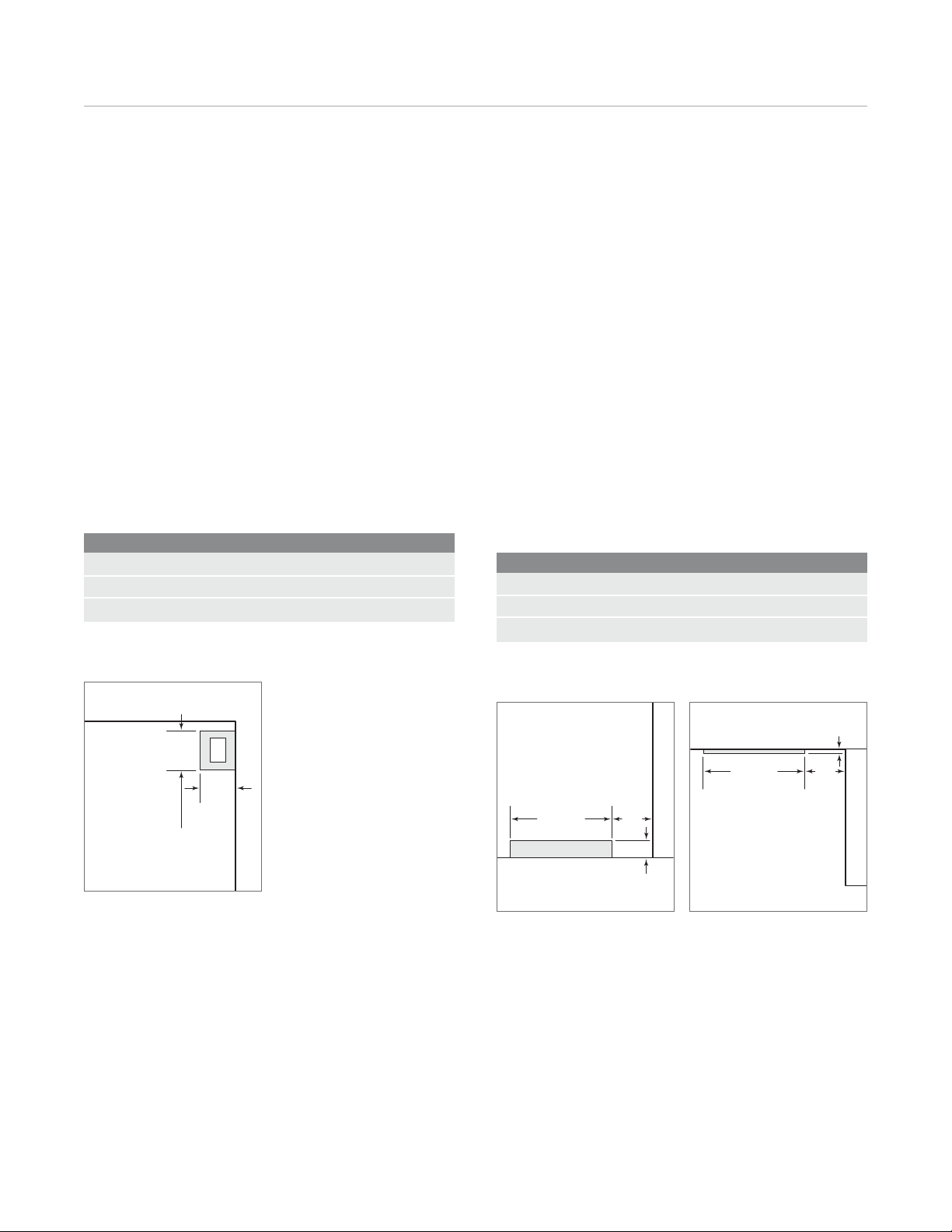

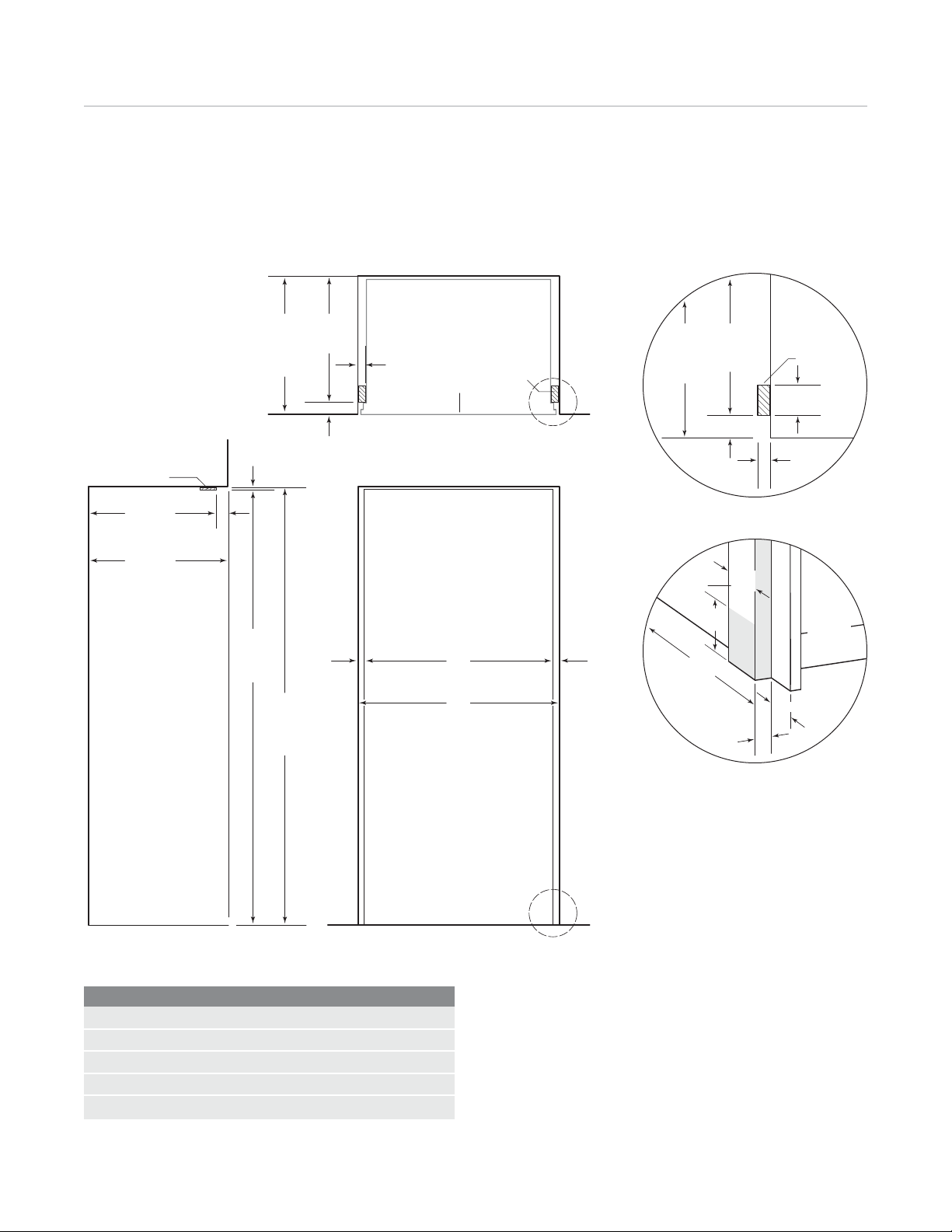

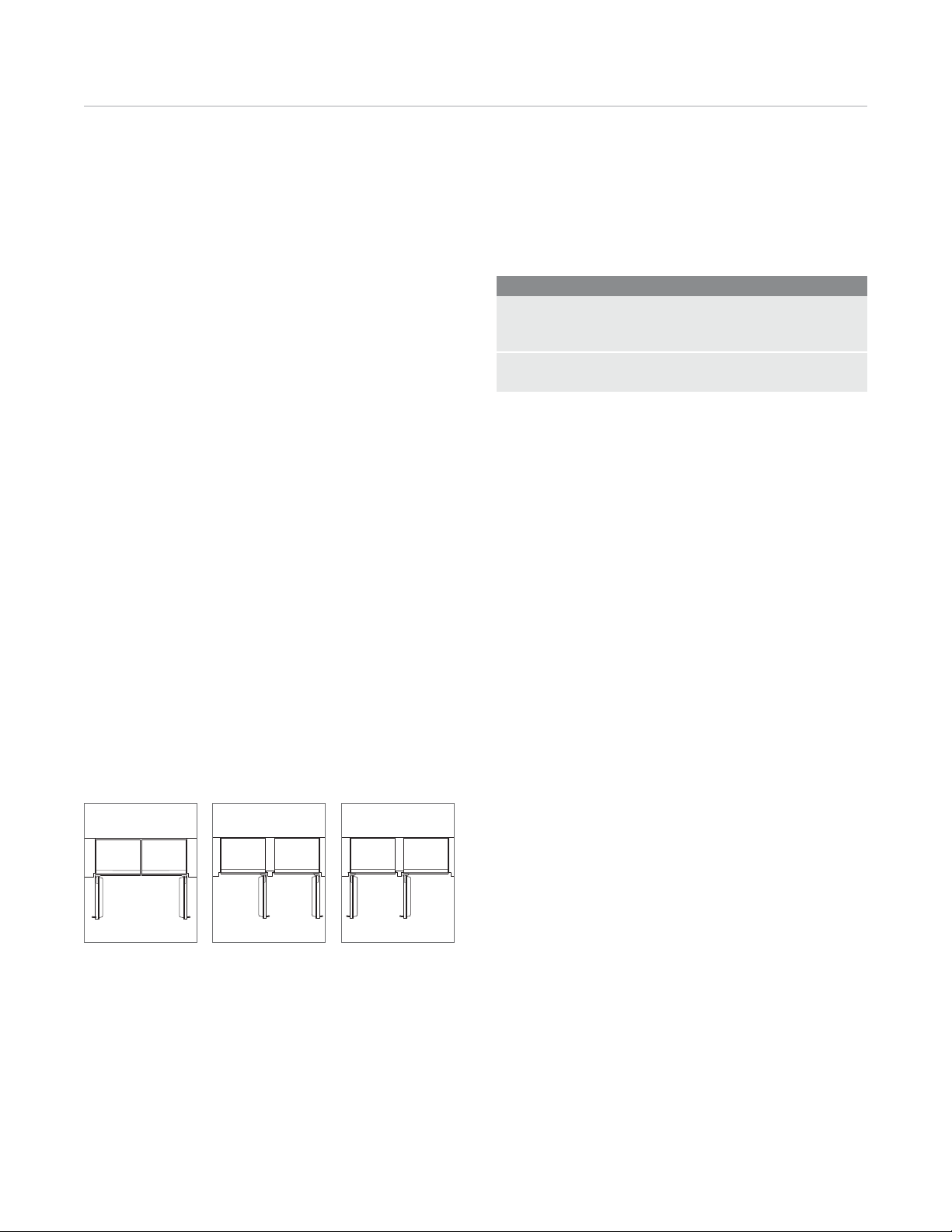

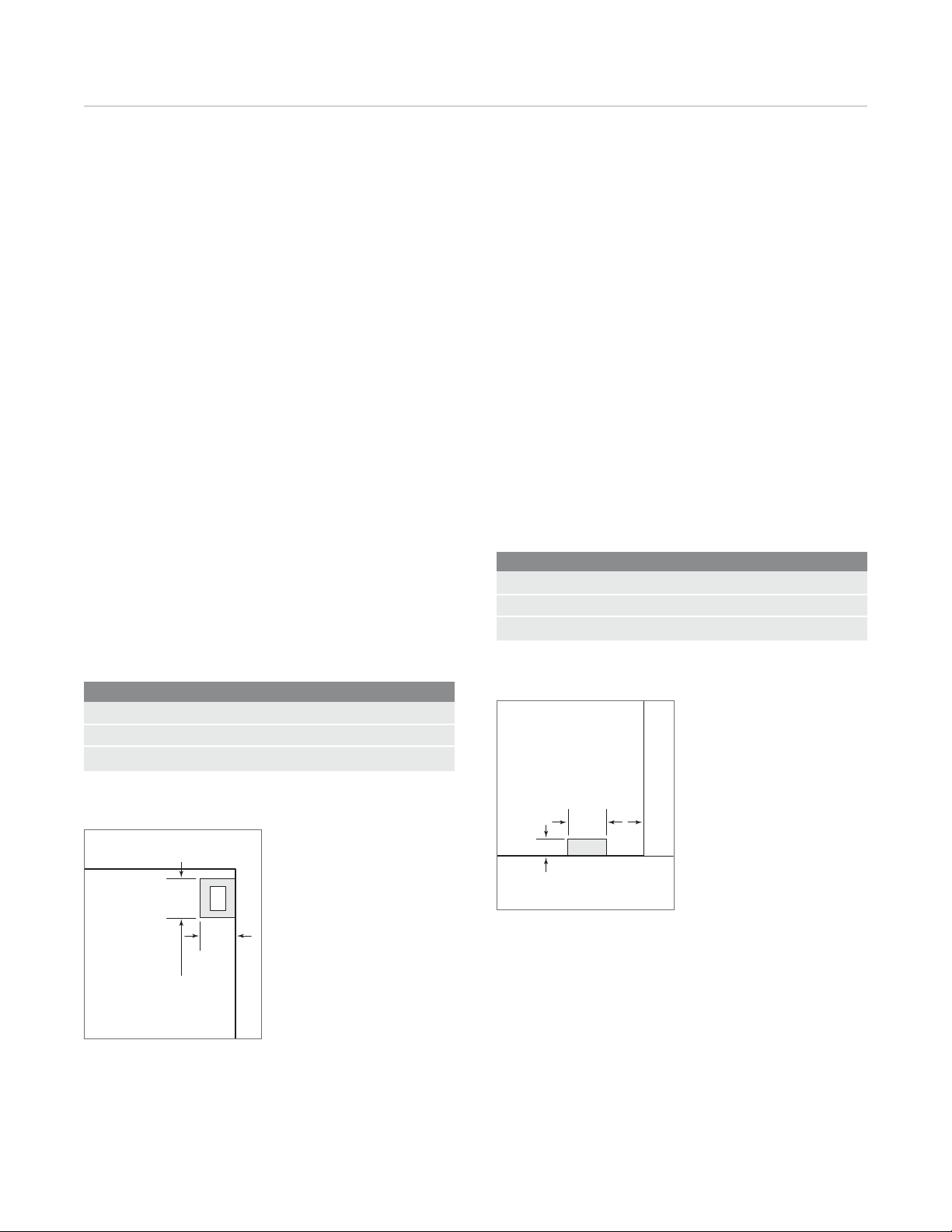

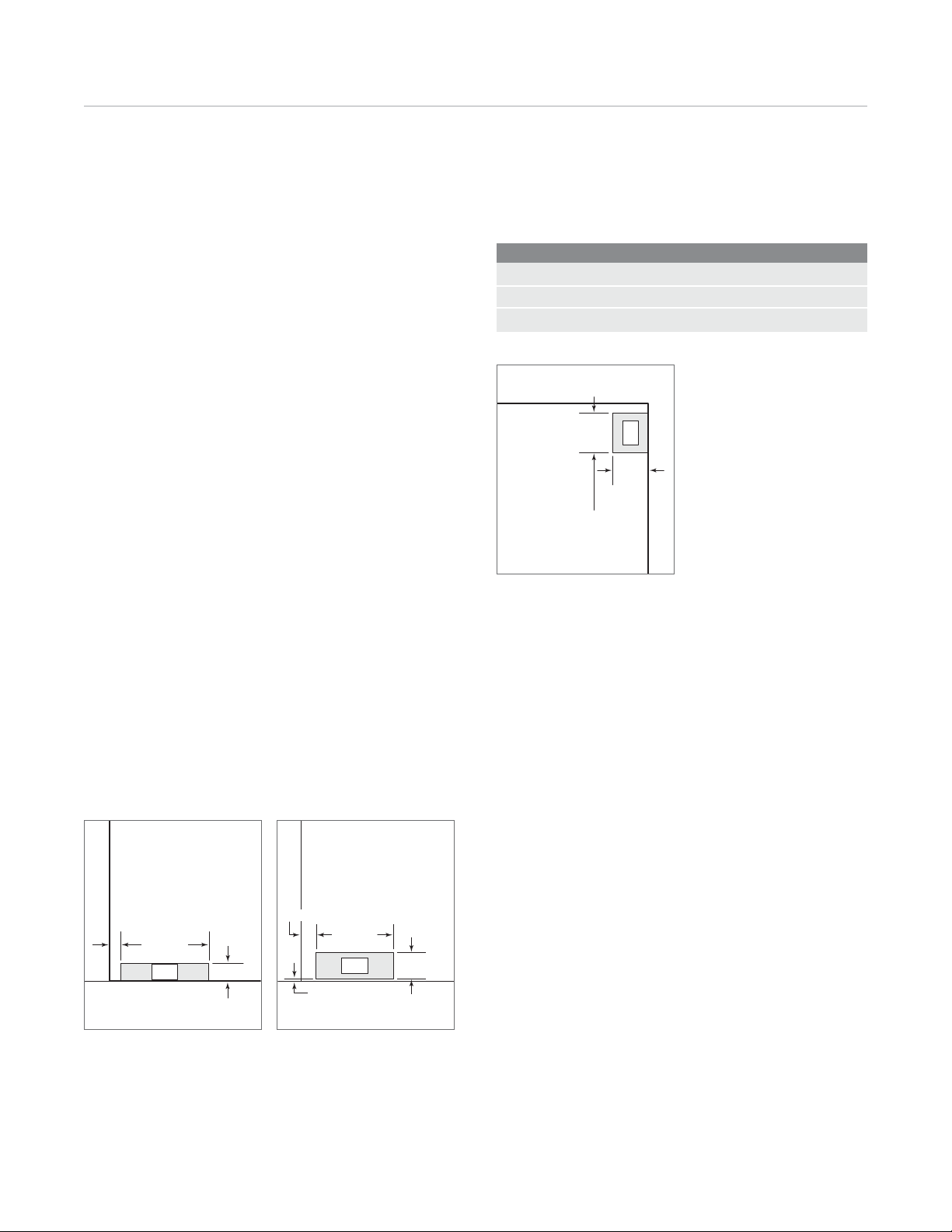

STANDARD INSTALLATION

TOP VIEW

610 mm

OPENING

DEPTH

610 mm

OPENING DEPTH

2127 mm

OPENING

HEIGHT

A

OPENING WIDTH

FRONT VIEWSIDE VIEW

Opening Width A

ICBBI-36R and ICBBI-36F 902 mm

ICBBI-30U 746 mm

ICBBI-36U 902 mm

ICBBI-36S 902 mm

ICBBI-42S and ICBBI-42SD 1054 mm

ICBBI-48S and ICBBI-48SD 1206 mm

IMPORTANT NOTE: If two units are installed side by side,

refer to pages 21–22 for dual standard installations.

Stainless steel models are ready to install out of the box.

Page 9

Built-In Refrigeration 9

subzero.com/specs

Planning Information

ELECTRICAL REQUIREMENTS

International models from the factory designed without a

transformer require a 220-240 V AC, 50/60 Hz electrical

supply, fused at the correct rating for the unit. If required

by local or national codes, the power cord can be easily

replaced using the power inlet device.

For all built-in models, the electrical supply should be

located within the shaded area shown in the illustration.

Follow local codes and ordinances when installing the

receptacle. A separate circuit servicing only this appliance

is required. A ground fault circuit interrupter (GFCI) is not

recommended and may cause interruption of operation.

Electrical Requirements

Power Supply 220-240 V AC, 50/60 Hz

Circuit Breaker 10 amp

Receptacle 3-prong grounding-type

PLUMBING REQUIREMENTS

For built-in models with an automatic ice maker, the water

supply line should be located within the shaded area

shown in the illustrations. The water supply line should be

connected to the house supply with an easily accessible

shut-off valve between the supply and the unit. Do not use

self-piercing valves. A saddle valve kit (4200880) is avail able through your authorized Sub-Zero dealer. The water

line must not interfere with installation of the anti-tip

brackets.

IMPORTANT NOTE: A reverse osmosis system can be

used provided there is constant water pressure of 2.1 bar

to 6.9 bar supplied to the unit at all times.

Plumbing Requirements

Water Supply Line 6.35 mm OD copper line

Water Pressure 2.1–6.9 bar

Excess Water Line for Connection 914 mm

FRONT VIEW

178

E

mm

152

mm

1918 mm

FROM

FLOOR

Location of electrical supply.

457 mm

FLOOR

FRONT VIEW

152

mm

76 mm

Location of water supply—

rear.

BACK WALL

457 mm

TOP VIEW

13 mm

152

mm

Location of water supply—

bottom.

Page 10

Built-In Refrigeration 10

Overlay Panels

If you and your client have ordered an overlay model, you

will be adding panels and handles to give the unit a more

custom look. The overlay panel design option is available

for all built-in overlay models. For exact door panel dimensions, refer to overlay panel specifications on the following

pages.

IMPORTANT NOTE: Overlay models can be used in an

overlay or a flush inset application. Be aware that the

application specified will affect panel sizes, rough opening

dimensions and installation.

The overlay design allows decorative panels to cover the

door trim for a more seamless appearance that blends

with the design of the room. The most common way to

achieve this look is to work with three panels—the decorative overlay panel, which is typically 19 mm, a 3 mm

spacer panel and a 6 mm backer panel. Depending on

your cabinet manufacturer, this could also be one panel

routed for different dimensions.

Regardless of the physical construction of the panels

(three-panel assembly or routed panel), you will need to

follow the overlay panel specifications on the following

pages for exact sizing and panel placement to ensure a

proper fit.

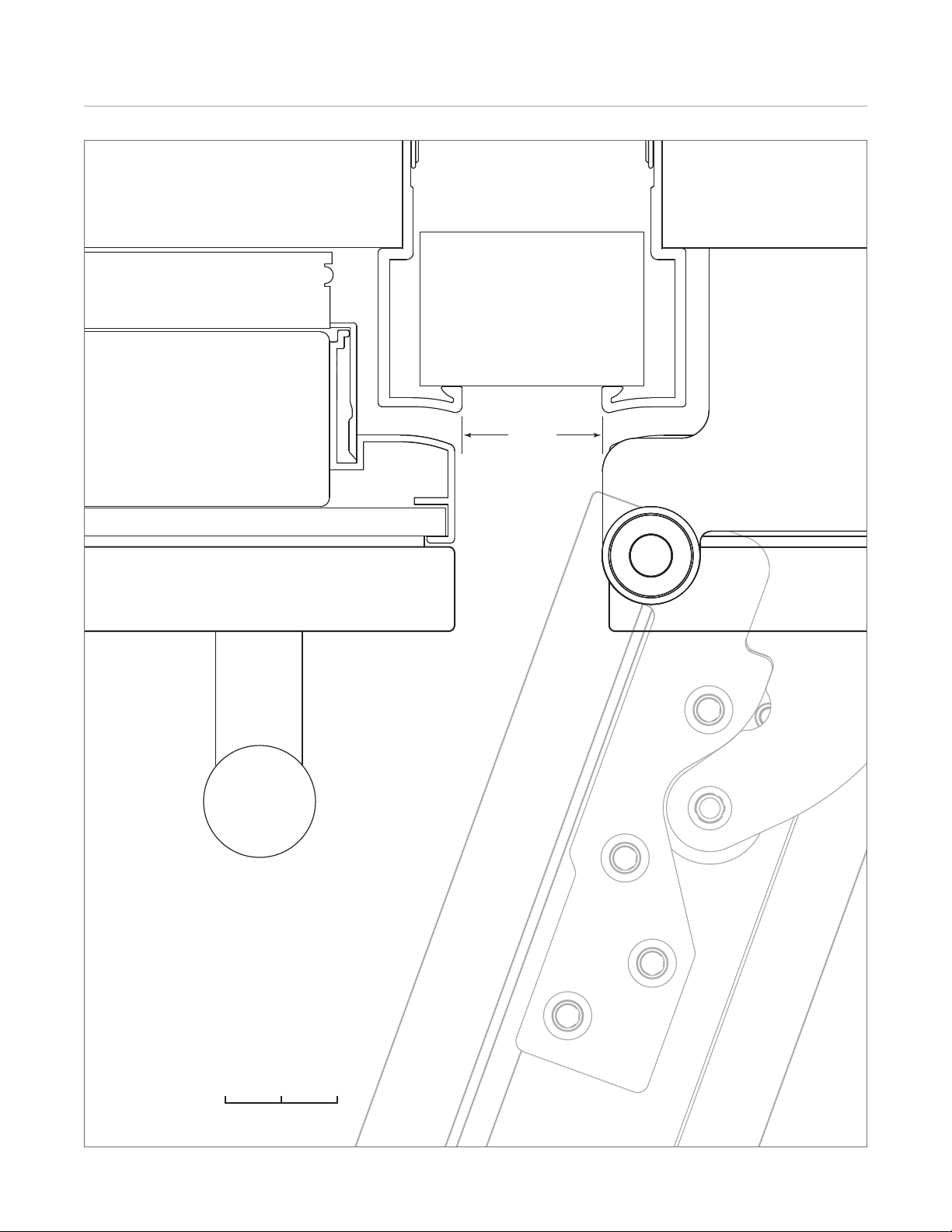

The illustrations provide a cross section view of the threepanel assembly, showing placement of the trim and a rear

view of the three-panel assembly with critical dimensions,

standard for all built-in models.

Overlay grille panels for the panel grille match the design

of the overlay door panels. Dimensions for the grille panel

are listed in the overlay panel specifications on the following pages.

IMPORTANT NOTE: When installing two units in a side-by-

side application, refer to pages 21–22 for dual standard

installations. Be aware that rough opening dimensions are

different for this application.

Do not exceed overlay panel dimensions, as this could

cause damage to panels and the Sub-Zero unit.

SPACER PANEL

OVERLAY PANEL

OVERLAY

PA NE L

SPACER

PA NE L

Overlay Panel Requirements

MAX WEIGHT PER PANEL

All Overlay Models 23 kg

Grille Panel 6 kg

MIN PANEL THICKNESS

All Overlay Panels 16 mm

BACKER PANEL

TRIM

8 mm min

3 mm

19

mm

typical

mm

BACKER

PA NE L

6

3

mm

Panel assembly cross section. Panel assembly rear view.

Page 11

Built-In Refrigeration 11

subzero.com/specs

Overlay Panels

H

H

H

W

ICBBI-30U / ICBBI-36U

Model ICBBI-30U

REFRIGERATOR W H

Overlay Panel 762 mm 1273 mm

Spacer Panel 740 mm 1253 mm

Backer Panel 756 mm 1268 mm

FREEZER W H

Overlay Panel 762 mm 483 mm

Spacer Panel 740 mm 459 mm

Backer Panel 756 mm 475 mm

GRILLE W H

Overlay Panel 762 mm 235 mm*

Spacer Panel 740 mm 211 mm

Backer Panel 756 mm 227 mm

Model ICBBI-36U

REFRIGERATOR W H

Overlay Panel 914 mm 1273 mm

Spacer Panel 892 mm 1253 mm

Backer Panel 908 mm 1268 mm

FREEZER W H

Overlay Panel 914 mm 483 mm

Spacer Panel 892 mm 459 mm

Backer Panel 908 mm 475 mm

GRILLE W H

Overlay Panel 914 mm 235 mm*

Spacer Panel 892 mm 211 mm

Backer Panel 908 mm 227 mm

*Panel height may be increased by 13 mm to hide upper main

frame. For more information, refer to the built-in panel configurator at subzero.com/trade/panels.

Grille panel dimensions listed are for a standard 2134 mm

finished height. For a 2108 mm finished height, subtract 25

mm from grille panel height dimensions. For a 2235 mm

finished height, add 102 mm to height dimensions. A 2108

mm or 2235 mm panel grille must be ordered to accept a

2108 mm or 2235 mm custom panel. Width dimensions do

not vary.

Page 12

Built-In Refrigeration 12

Overlay Panels

H

H

A

WW

ICBBI-36S / ICBBI-42S / ICBBI-48S ICBBI-48SD

Model ICBBI-36S

REFRIGERATOR W H

Overlay Panel 510 mm 1772 mm

Spacer Panel 487 mm 1751 mm

Backer Panel 503 mm 1767 mm

FREEZER W H

Overlay Panel 398 mm 1772 mm

Spacer Panel 376 mm 1751 mm

Backer Panel 392 mm 1767 mm

GRILLE W H

Overlay Panel 914 mm 235 mm*

Spacer Panel 892 mm 211 mm

Backer Panel 908 mm 227 mm

Model ICBBI-42S

REFRIGERATOR W H

Overlay Panel 637 mm 1772 mm

Spacer Panel 614 mm 1751 mm

Backer Panel 630 mm 1767 mm

FREEZER W H

Overlay Panel 424 mm 1772 mm

Spacer Panel 402 mm 1751 mm

Backer Panel 418 mm 1767 mm

GRILLE W H

Overlay Panel 1067 mm 235 mm*

Spacer Panel 1045 mm 211 mm

Backer Panel 1060 mm 227 mm

H

H

B

WW

Models ICBBI-48S and ICBBI-48SD

REFRIGERATOR W H

Overlay Panel 730 mm 1772 mm

Spacer Panel 708 mm 1751 mm

Backer Panel 724 mm 1767 mm

FREEZER W H

Overlay Panel 483 mm 1772 mm

Spacer Panel 460 mm 1751 mm

Backer Panel 476 mm 1767 mm

GRILLE W H

Overlay Panel 1219 mm 235 mm*

Spacer Panel 1197 mm 211 mm

Backer Panel 1213 mm 227 mm

ICBBI-48SD W H

Dispenser Cut-Out 149 mm 316 mm

AB

Cut-Out Location 51 mm 732 mm

*Panel height may be increased by 13 mm to hide upper main

frame. For more information, refer to the built-in panel configurator at subzero.com/trade/panels.

Grille panel dimensions listed are for a standard 2134 mm

finished height. For a 2108 mm finished height, subtract 25

mm from grille panel height dimensions. For a 2235 mm

finished height, add 102 mm to height dimensions. A 2108

mm or 2235 mm panel grille must be ordered to accept a

2108 mm or 2235 mm custom panel. Width dimensions do

not vary.

Page 13

Built-In Refrigeration 13

subzero.com/specs

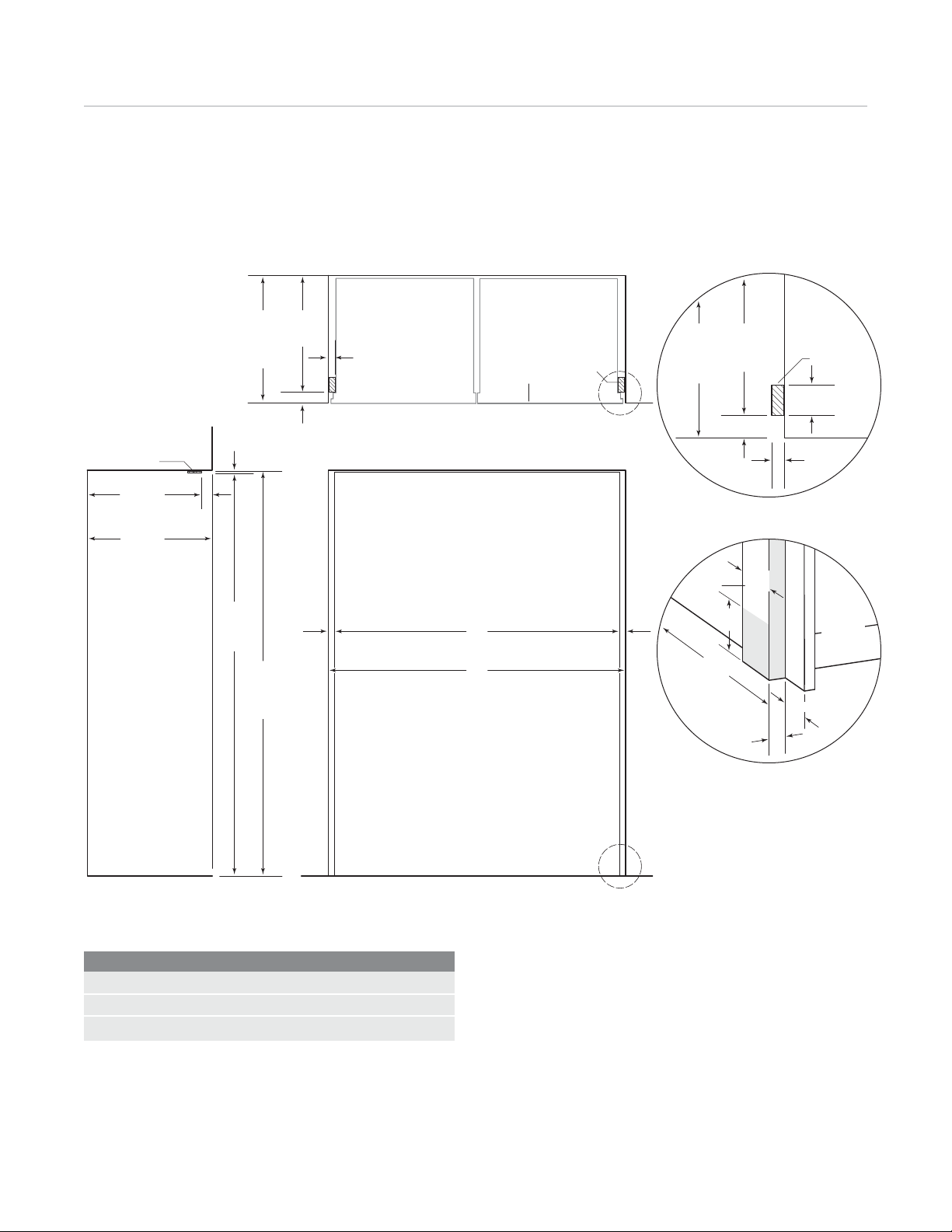

Flush Inset Application

It is necessary to consider the following points when

planning for a flush inset application:

• The flush inset depth is 56 mm deeper than the

standard opening.

• The flush inset width is 64 mm wider than the

standard opening.

• The flush inset height is 6 mm higher than the

standard opening.

• Panel widths increase to achieve the flush inset look.

• You must allow a 13 mm reveal around the perimeter of

the unit and grille to allow for proper door swing and

airflow.

IMPORTANT NOTE: The flush inset application is not a

separate model. This is an overlay unit in a flush installation. The same model is used in an overlay or flush inset

application.

Rough opening dimensions for the flush inset application

assume the use of a 19 mm decorative panel. The illustrations at right show the difference between standard and

flush inset installations.

FLUSH INSET INSTALLATION

19 mm PANEL

STANDARD INSTALLATION

610 mm

OPENING

DEPTH

TOP VIEW

WITH

610 mm

OPENING

DEPTH

56 mm

TOP VIEW

665 mm

FLUSH

INSET

DEPTH

Standard installation. Flush inset installation.

32 mm

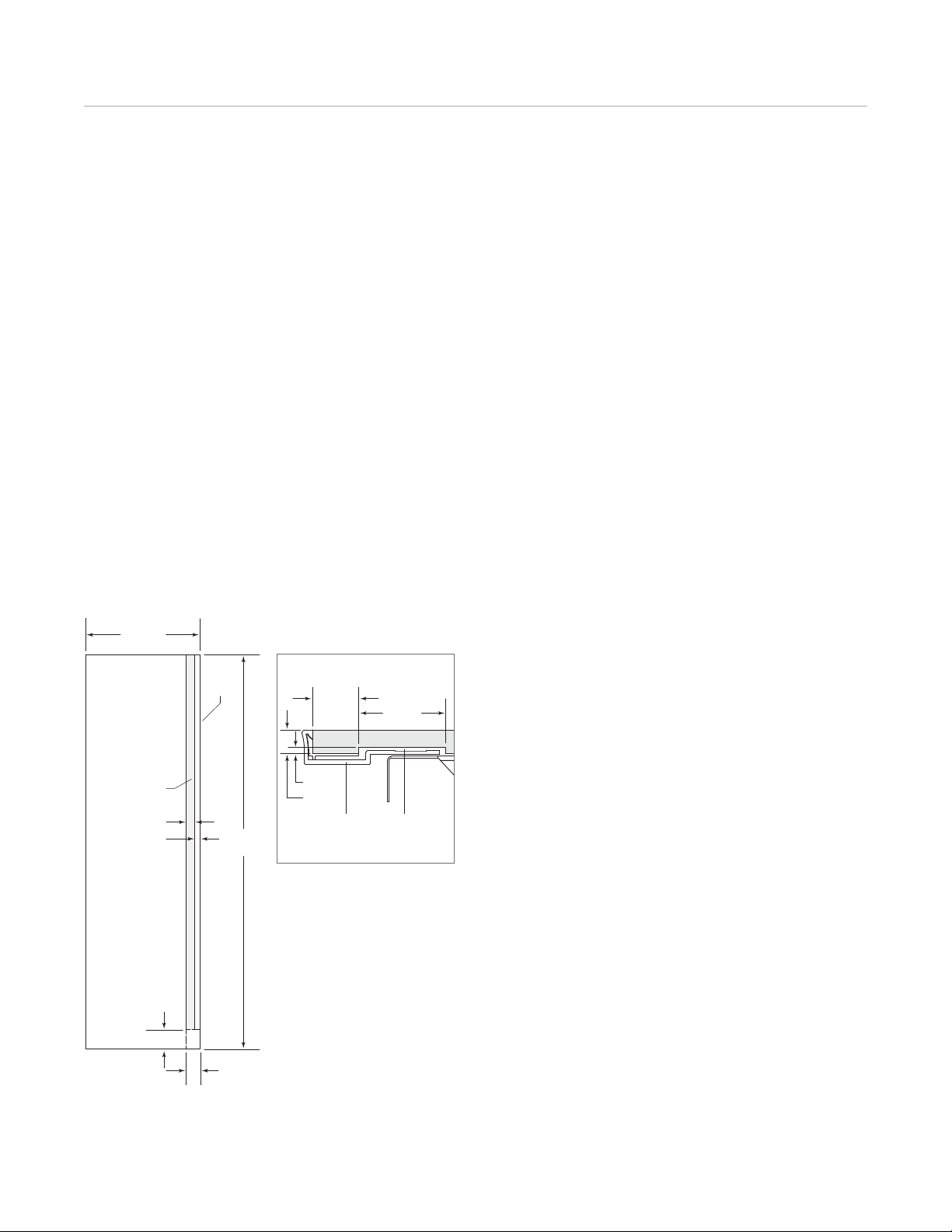

Page 14

32 mm

610 mm

OPENING

DEPTH

TO CLEAT

CLEAT

TOP VIEW

665

mm

FLUSH

INSET

DEPTH

56 mm

76 mm

typical

610 mm

OPENING

DEPTH TO

CLEAT

32 mm

56 mm

CLEAT

SHADED

AREA

MUST BE

FINISHED

76 mm

typical

102

mm

Built-In Refrigeration 14

Built-In Models

FLUSH INSET INSTALLATION

TOP VIEW

610 mm

665

mm

DEPTH

FLUSH

TO CLEAT

CLEAT

6 mm

INSET

DEPTH

56 mm

32

mm

UNIT WITH

19 mm PANEL

CLEAT

DETAIL A

610 mm

DEPTH TO CLEAT

665 mm

FLUSH INSET DEPTH

SIDE VIEW

56

mm

2127

mm

HEIGHT

TO CLEAT

2134

mm

FLUSH

INSET

HEIGHT

32

mm

A

WIDTH TO CLEAT

B

FLUSH INSET WIDTH

DETAIL B

FRONT VIEW

32

mm

Detail A

Detail B

Flush Inset Opening Widths A B

ICBBI-30U 746 mm 813 mm

ICBBI-36U 902 mm 965 mm

ICBBI-36S 902 mm 965 mm

ICBBI-42S 1054 mm 1118 mm

ICBBI-48S and ICBBI-48SD 1206 mm 1270 mm

IMPORTANT NOTE: Dimensions assume a 19 mm panel

thickness.

IMPORTANT NOTE: If two units are installed side by side,

refer to pages 23–27 for dual flush inset installations.

Page 15

Built-In Refrigeration 15

subzero.com/specs

Flush Inset Panels

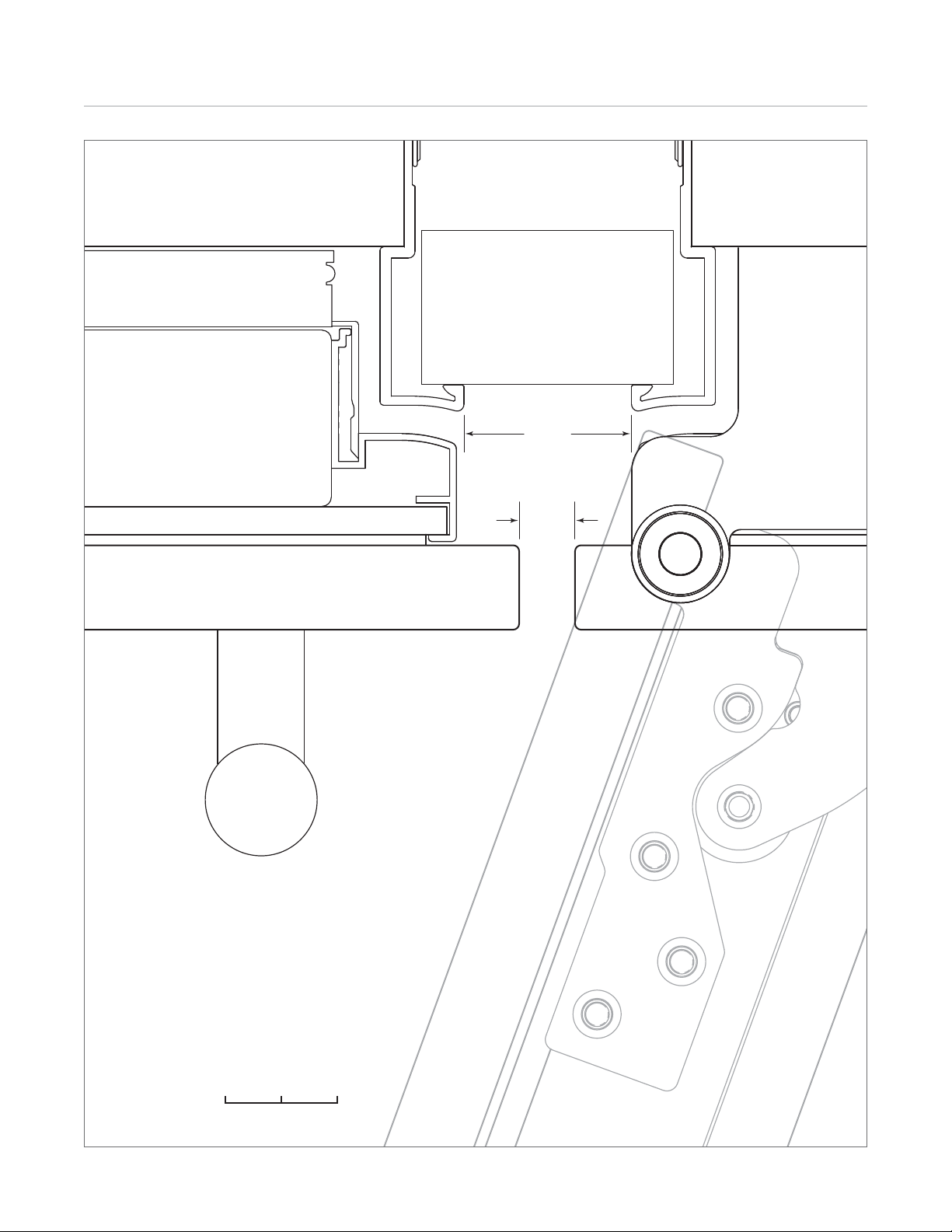

The flush inset application allows decorative panels on the

front of the unit to be flush with surrounding cabinetry and

is available for all built-in overlay models. For exact panel

dimensions, refer to flush inset panel specifications on the

following pages.

The flush inset design allows decorative panels to cover

the door trim for a seamless appearance that blends with

the design of the room. The most common way to achieve

this look is to work with three panels—the decorative flush

inset panel, which is typically 19 mm, a 3 mm spacer

panel and a 6 mm backer panel. Depending on your

cabinet manufacturer, this could also be one panel routed

for different dimensions.

Regardless of the physical construction of the panels

(three-panel assembly or routed panel), you will need to

follow the flush inset panel specifications on the following

pages for exact sizing and panel placement to ensure a

proper fit.

Do not exceed flush inset panel dimensions, as this

could cause damage to panels and the Sub-Zero unit.

The illustration below provides a rear view of the threepanel assembly with critical dimensions, standard for all

built-in models.

IMPORTANT NOTE: The inside edges of the rough opening

as well as the sides and a portion of the back side of the

decorative panels will need to be finished, as they will be

exposed when the doors are open.

IMPORTANT NOTE: For flush inset panels thicker than

19 mm, a 90° door stop may be required to prevent interference with adjacent cabinets. Refer to the full-scale templates at the end of this section.

IMPORTANT NOTE: When installing two units side by side

in a flush inset application, refer to pages 23–27 for dual

flush inset installations. Be aware that rough opening

dimensions, panel sizes and offsets are different for this

application.

FLUSH INSET

PA NE L

SPACER

PANEL

Flush Inset Panel Requirements

MAX WEIGHT PER PANEL

All Flush Inset Models 23 kg

Grille Panel 6 kg

MIN PANEL THICKNESS

All Flush Inset Panels 16 mm

BACKER

PA NE L

19

mm

typical

Three-panel assembly.

3

mm

mm

6

Page 16

Built-In Refrigeration 16

Flush Inset Panels

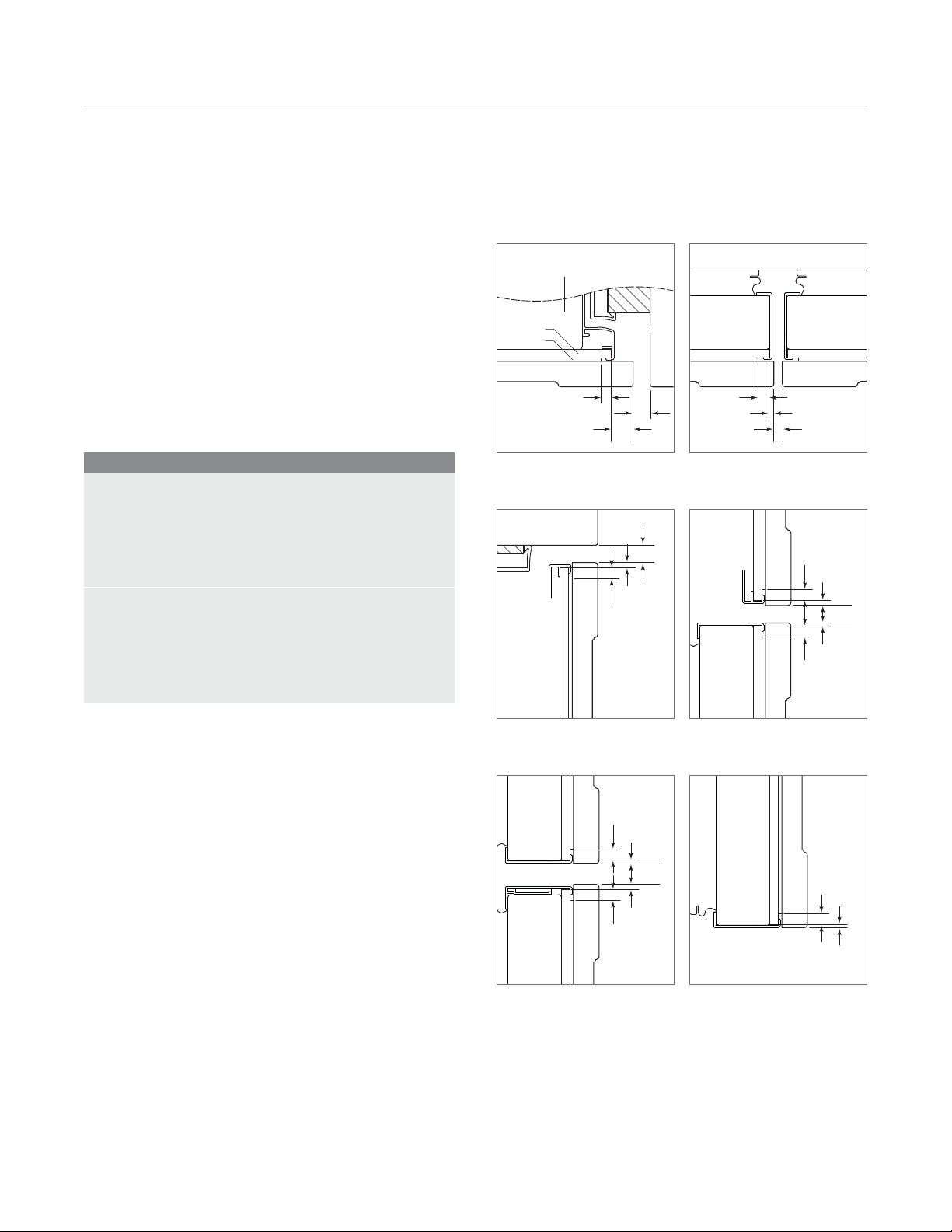

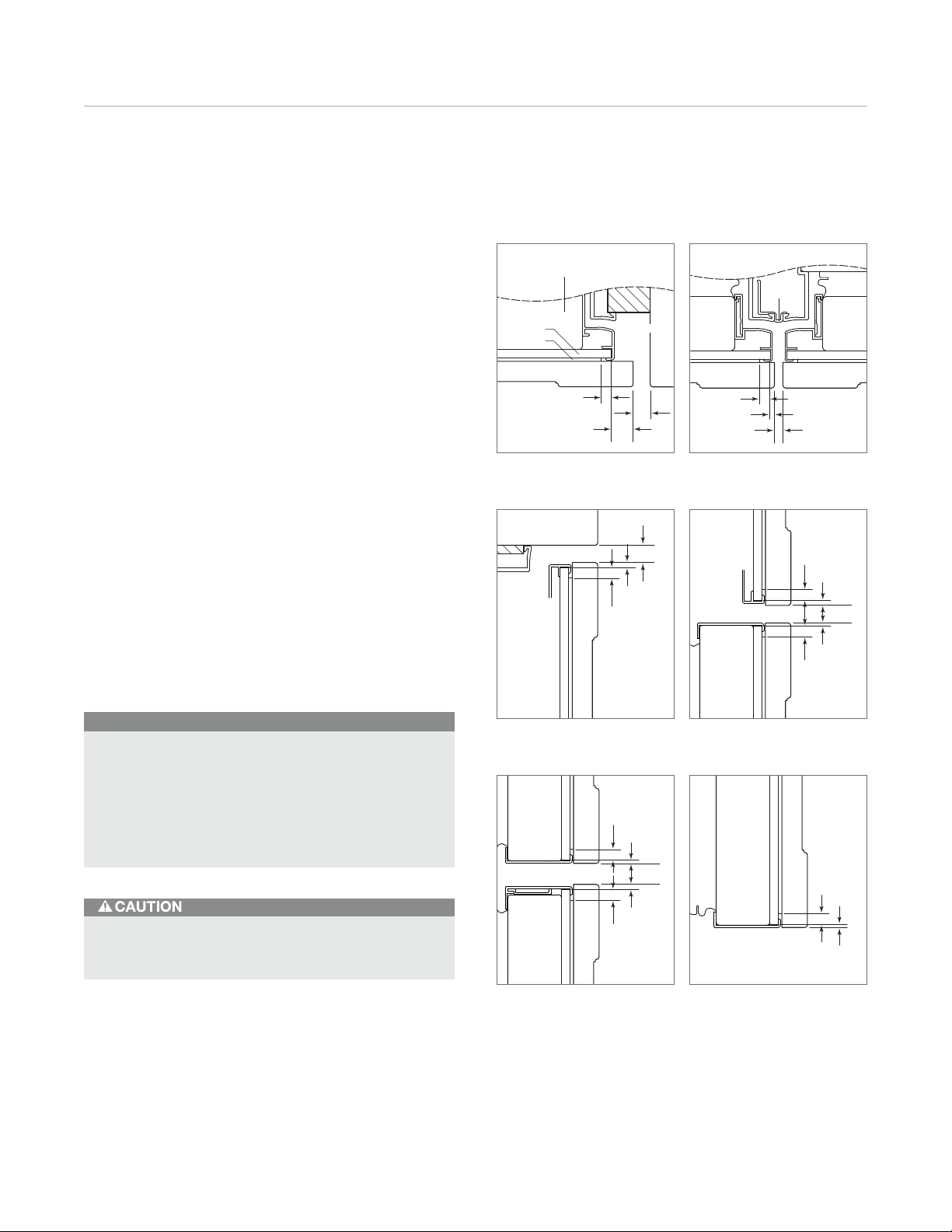

PANEL OFFSETS

Illustrations A–F provide panel offsets and reveals for all

built-in models in a flush inset application. Refer to the

chart below for reference to the illustrations relating to

your specific model.

For additional information on model-specific panel reveals,

visit the specification library section of our website,

subzerotrade.com.

Panel Offsets Illus.

OVER-AND-UNDER

Door / Drawer / Grille Sides A

Grille Top C

Grille Bottom / Door Top D

Door Bottom / Drawer Top E

Drawer Bottom F

SIDE-BY-SIDE

Doors (hinge) / Grille Sides A

Doors (handle) Sides B

Grille Top C

Grille Bottom / Door Top D

Door Bottom F

DOOR / DRAWER / GRILLE

BACKER

SPACER

TOP VIEW

CABINETRY

DOOR DOOR

FLUSH INSET PANEL

8 mm

16

mm

13

mm

Illus. A Illus. B

CABINETRY

13 mm

3

GRILLE

mm

8

mm

SIDE VIEW

8 mm

3 mm

GRILLE

DOOR

TOP VIEW

6 mm

REVEAL

8

mm

mm

mm

8

mm

SIDE VIEW

4

13 mm

2

Illus. C Illus. D

8

mm

2

DOOR

mm

16 mm

DRAWER

mm

8

mm

SIDE VIEW

4

Illus. E Illus. F

DOOR /

DRAWER

SIDE VIEW

8

mm

2

mm

Page 17

Built-In Refrigeration 17

subzero.com/specs

Flush Inset Panels

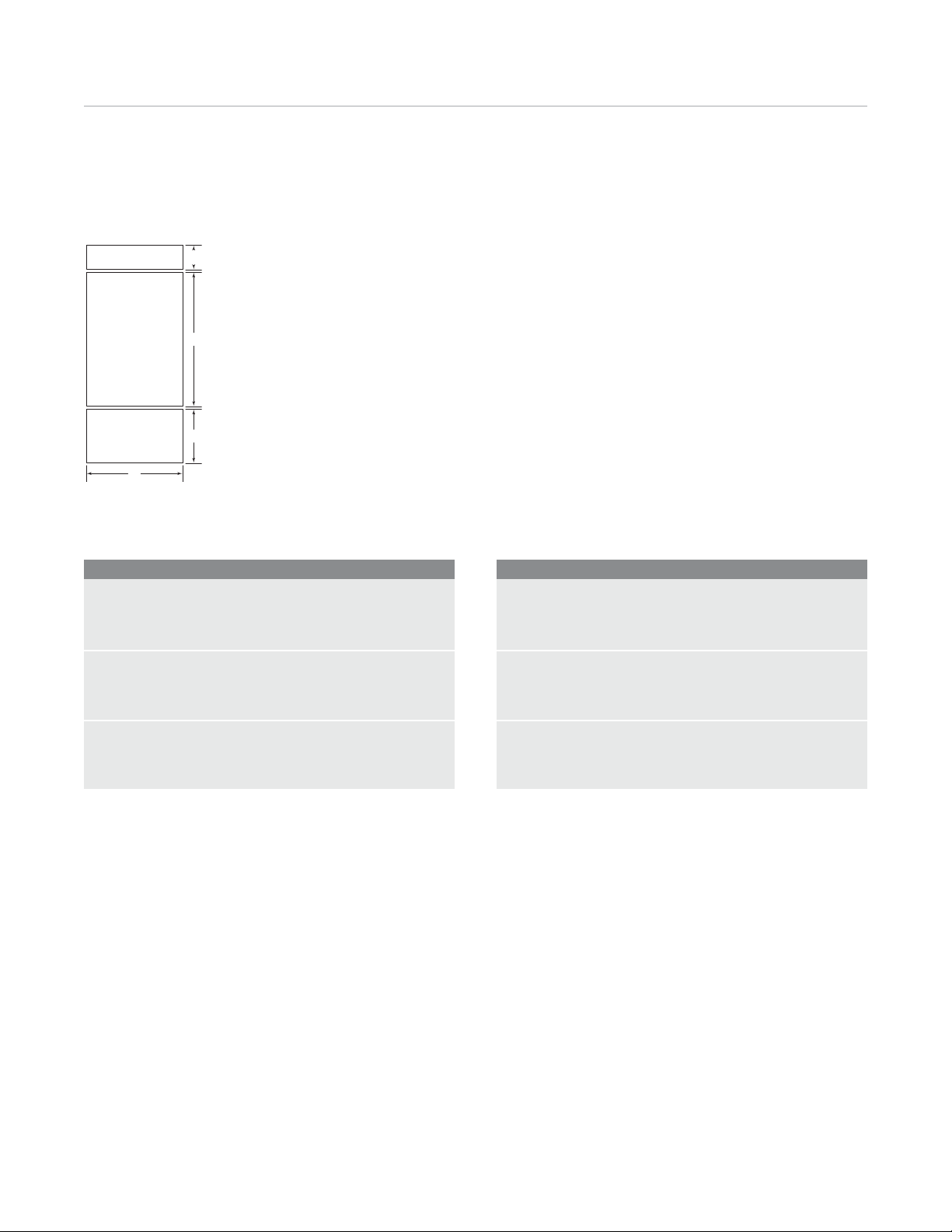

H

H

H

W

ICBBI-30U / ICBBI-36U

Model ICBBI-30U

REFRIGERATOR W H

Flush Inset Panel 787 mm 1273 mm

Spacer Panel 740 mm 1253 mm

Backer Panel 756 mm 1268 mm

FREEZER W H

Flush Inset Panel 787 mm 483 mm

Spacer Panel 740 mm 459 mm

Backer Panel 756 mm 475 mm

GRILLE W H

Flush Inset Panel 787 mm 235 mm

Spacer Panel 740 mm 211 mm

Backer Panel 756 mm 227 mm

Model ICBBI-36U

REFRIGERATOR W H

Flush Inset Panel 940 mm 1273 mm

Spacer Panel 892 mm 1253 mm

Backer Panel 908 mm 1268 mm

FREEZER W H

Flush Inset Panel 940 mm 483 mm

Spacer Panel 892 mm 459 mm

Backer Panel 908 mm 475 mm

GRILLE W H

Flush Inset Panel 940 mm 235 mm

Spacer Panel 892 mm 211 mm

Backer Panel 908 mm 227 mm

Grille panel dimensions listed are for a standard 2134 mm

finished height. For a 2108 mm finished height, subtract 25

mm from grille panel height dimensions. For a 2235 mm

finished height, add 102 mm to height dimensions. A 2108

mm or 2235 mm panel grille must be ordered to accept a

2108 mm or 2235 mm custom panel. Width dimensions do

not vary.

Page 18

Built-In Refrigeration 18

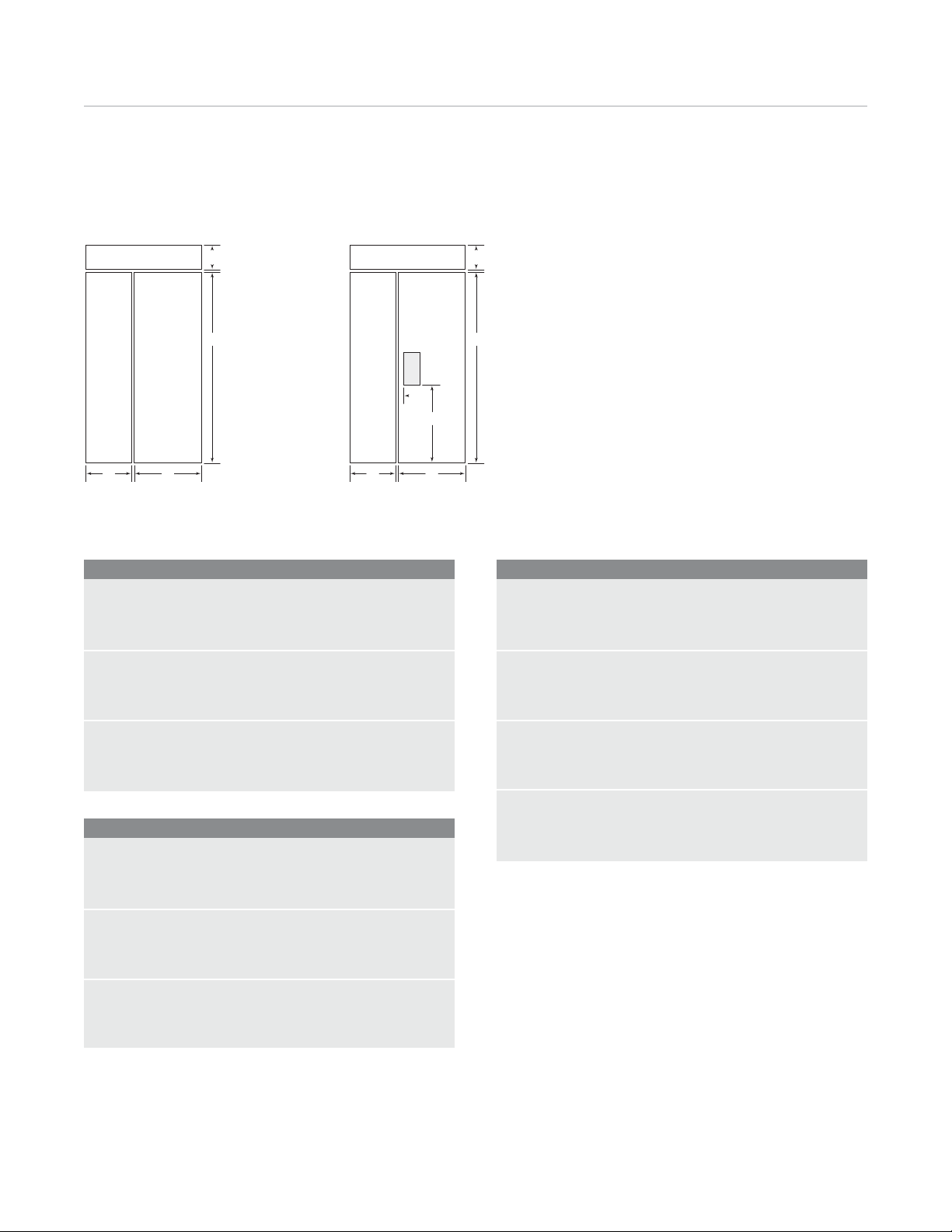

Flush Inset Panels

H

H

A

WW

ICBBI-36S / ICBBI-42S / ICBBI-48S ICBBI-48SD

Model ICBBI-36S

REFRIGERATOR W H

Flush Inset Panel 522 mm 1772 mm

Spacer Panel 487 mm 1751 mm

Backer Panel 503 mm 1767 mm

FREEZER W H

Flush Inset Panel 411 mm 1772 mm

Spacer Panel 376 mm 1751 mm

Backer Panel 392 mm 1767 mm

GRILLE W H

Flush Inset Panel 940 mm 235 mm

Spacer Panel 892 mm 211 mm

Backer Panel 908 mm 227 mm

Model ICBBI-42S

REFRIGERATOR W H

Flush Inset Panel 649 mm 1772 mm

Spacer Panel 614 mm 1751 mm

Backer Panel 630 mm 1767 mm

FREEZER W H

Flush Inset Panel 437 mm 1772 mm

Spacer Panel 402 mm 1751 mm

Backer Panel 418 mm 1767 mm

GRILLE W H

Flush Inset Panel 1092 mm 235 mm

Spacer Panel 1045 mm 211 mm

Backer Panel 1060 mm 227 mm

H

H

B

WW

Models ICBBI-48S and ICBBI-48SD

REFRIGERATOR W H

Flush Inset Panel 743 mm 1772 mm

Spacer Panel 708 mm 1751 mm

Backer Panel 724 mm 1767 mm

FREEZER W H

Flush Inset Panel 495 mm 1772 mm

Spacer Panel 460 mm 1751 mm

Backer Panel 476 mm 1767 mm

GRILLE W H

Flush Inset Panel 1245 mm 235 mm

Spacer Panel 1197 mm 211 mm

Backer Panel 1213 mm 227 mm

DISPENSER (ICBBI-48SD) W H

Cut-Out 149 mm 316 mm

AB

Cut-Out Location 51 mm 732 mm

Grille panel dimensions listed are for a standard 2134 mm

finished height. For a 2108 mm finished height, subtract 25

mm from grille panel height dimensions. For a 2235 mm

finished height, add 102 mm to height dimensions. A 2108

mm or 2235 mm panel grille must be ordered to accept a

2108 mm or 2235 mm custom panel. Width dimensions do

not vary.

Page 19

Built-In Refrigeration 19

subzero.com/specs

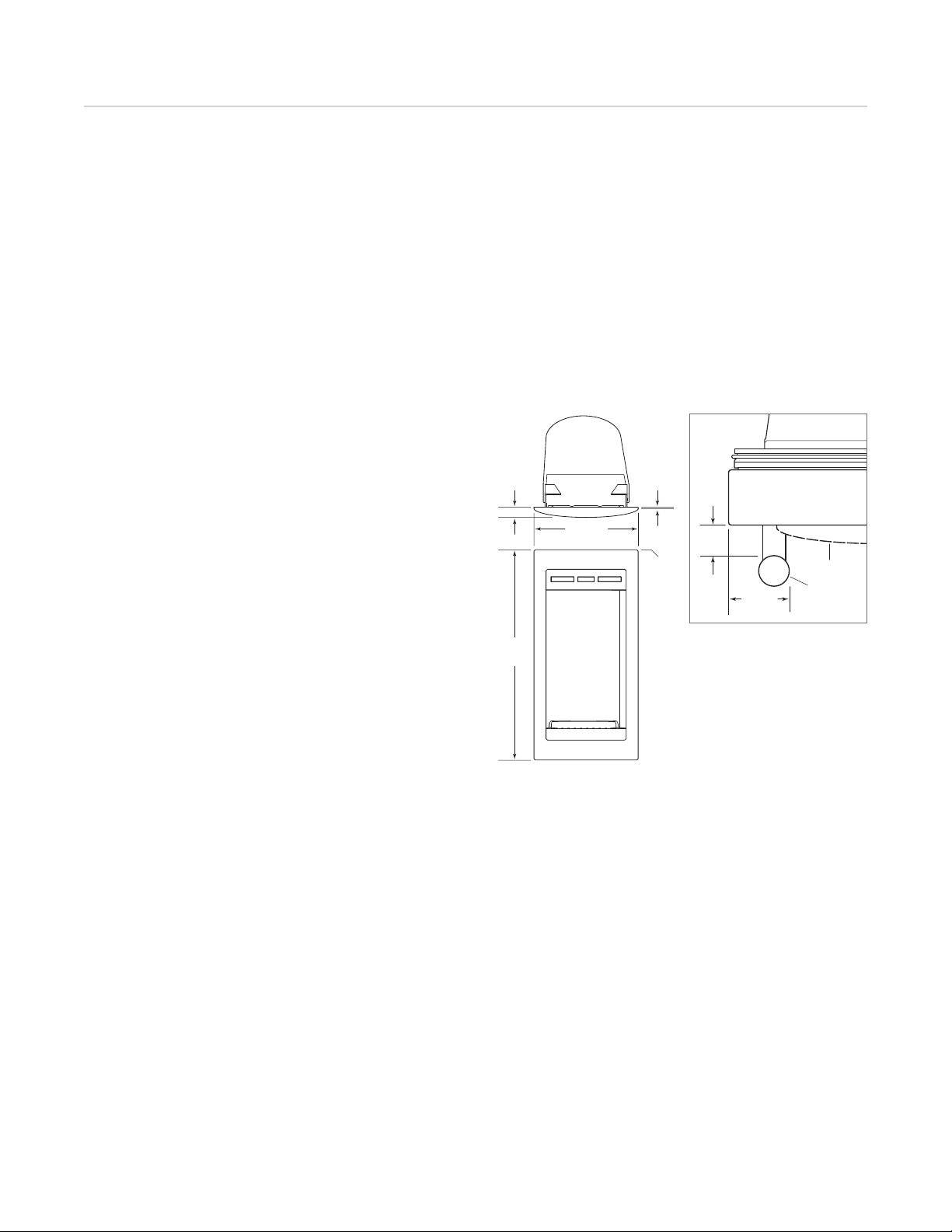

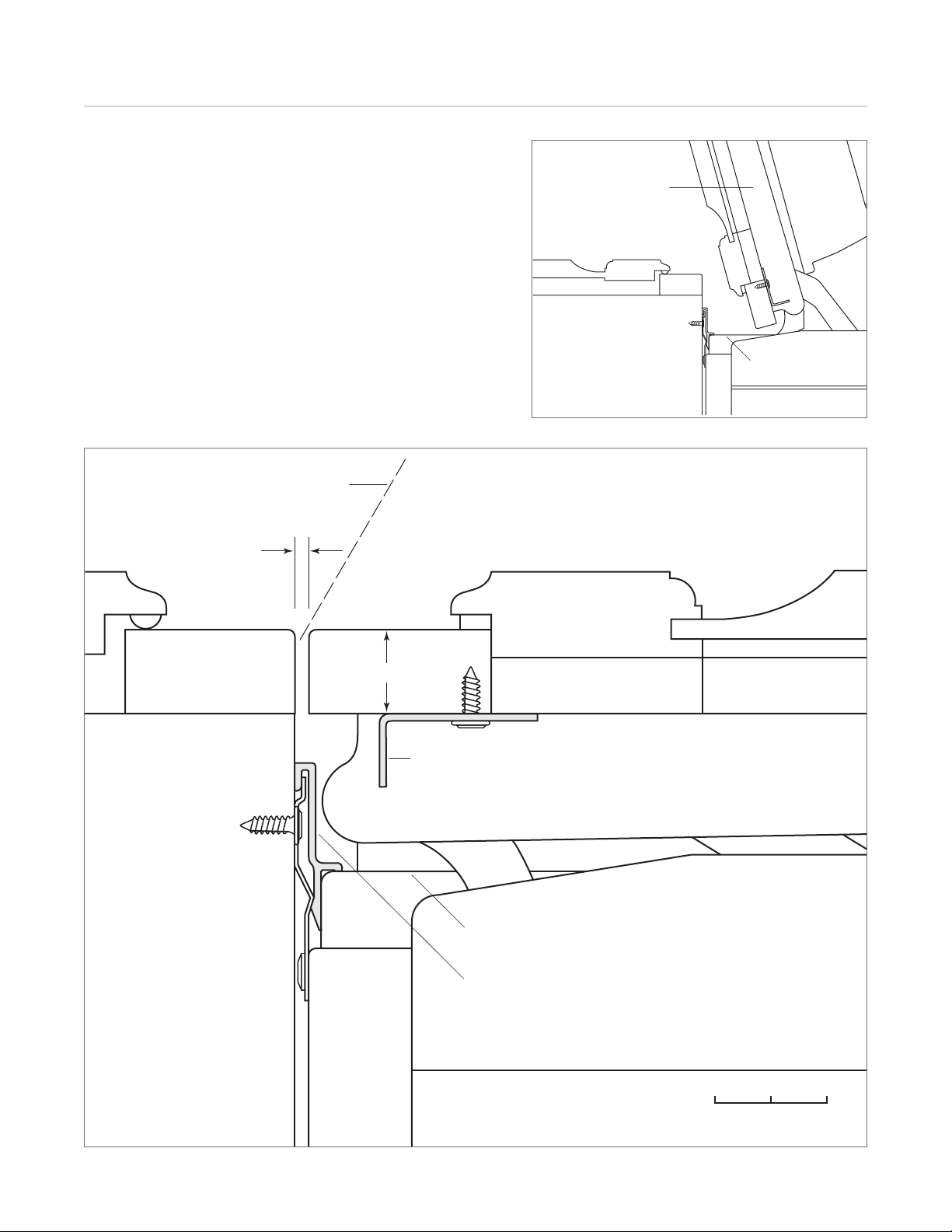

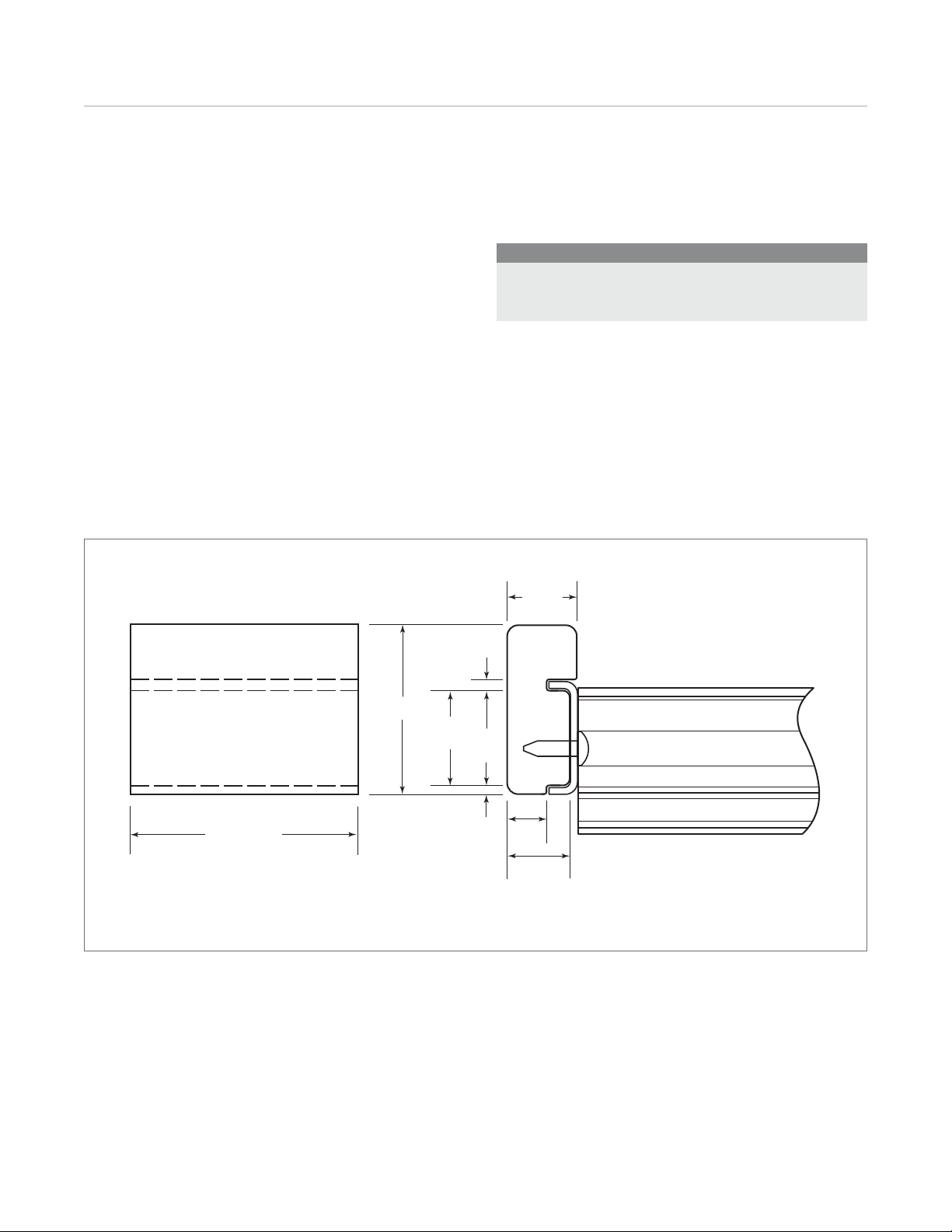

Dispenser

MODEL ICBBI-48SD

The refrigerator door panel must include a cut-out to

accommodate the dispenser glasswell and bezel. The

thickness of the panel in this area can range from 6 mm to

a maximum of 29 mm.

IMPORTANT NOTE: Regardless of the thickness of the

panel for model ICBBI-48SD, you must plan for a flat

landing area for the decorative bezel surrounding the

glasswell area. The illustration to the right provides exact

bezel dimensions. Refer to the appropriate panel specifications page for exact cut-out location. This landing area

can be accomplished in a number of different ways.

One option (flush) is to rout the panel so the bezel will be

flush with rails and stiles. You must rout a space to

accommodate the height and width of the bezel. The

width of the stile immediately to the left of the bezel must

be 44 mm. Do not cut the entire stile to this dimension.

The other option (proud) shows a boxed out landing area

for the bezel using stiles and rails to create this space. In

this application, the bezel will sit proud of the stiles and

rails. The total thickness of the panels at this level must

not exceed 29 mm.

For overlay and flush inset models, mounting placement of

the refrigerator door handle must assure proper access to

the glasswell and adequate clearance under the handle.

The handle placement illustration shows the relation of the

refrigerator door handle to the glasswell bezel on stainless

steel models.

16 mm

327

mm

160 mm

2 mm

3 mm

RADIUS

Handle placement.

25

mm

51 mm

GLASSWELL

HANDLE

Dispenser dimensions.

Page 20

Built-In Refrigeration 20

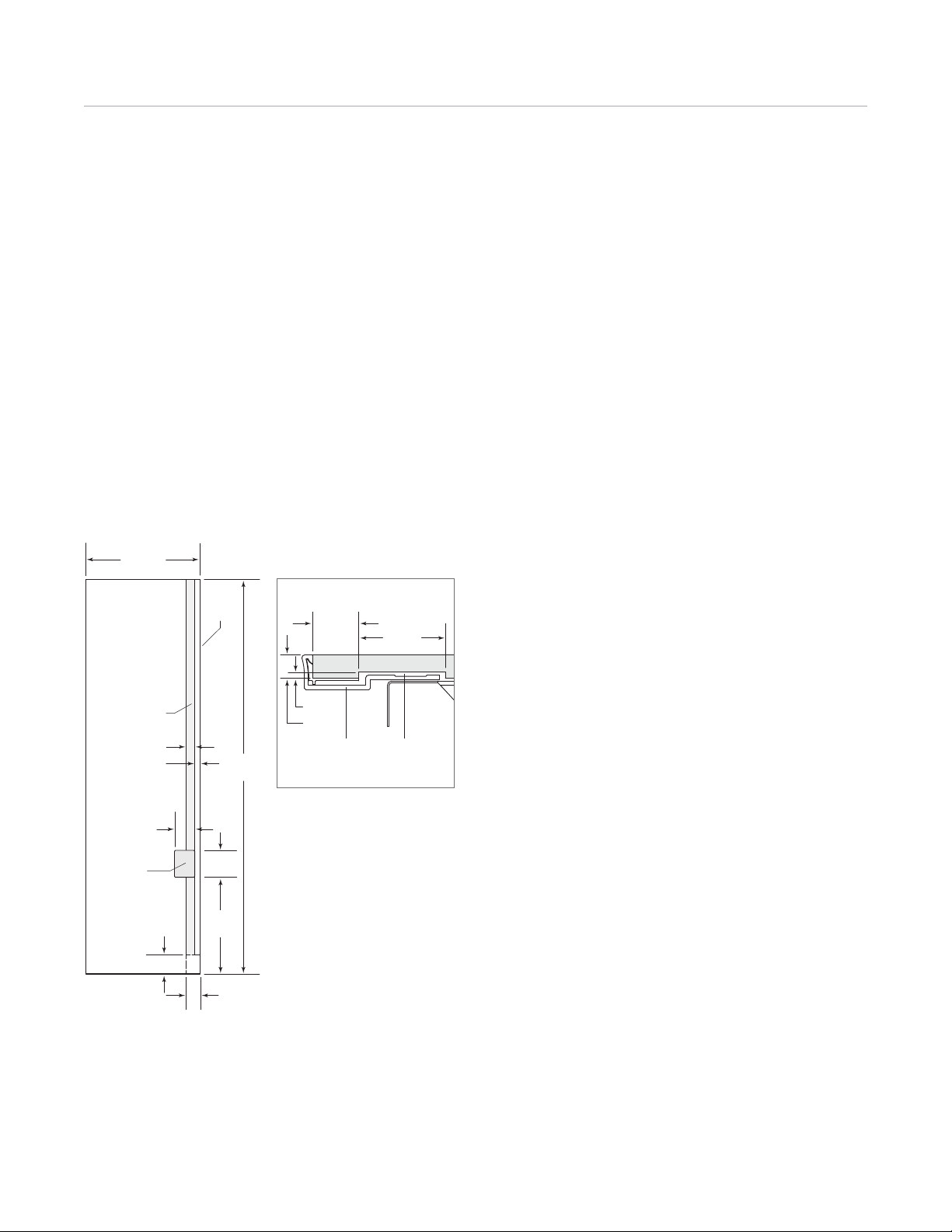

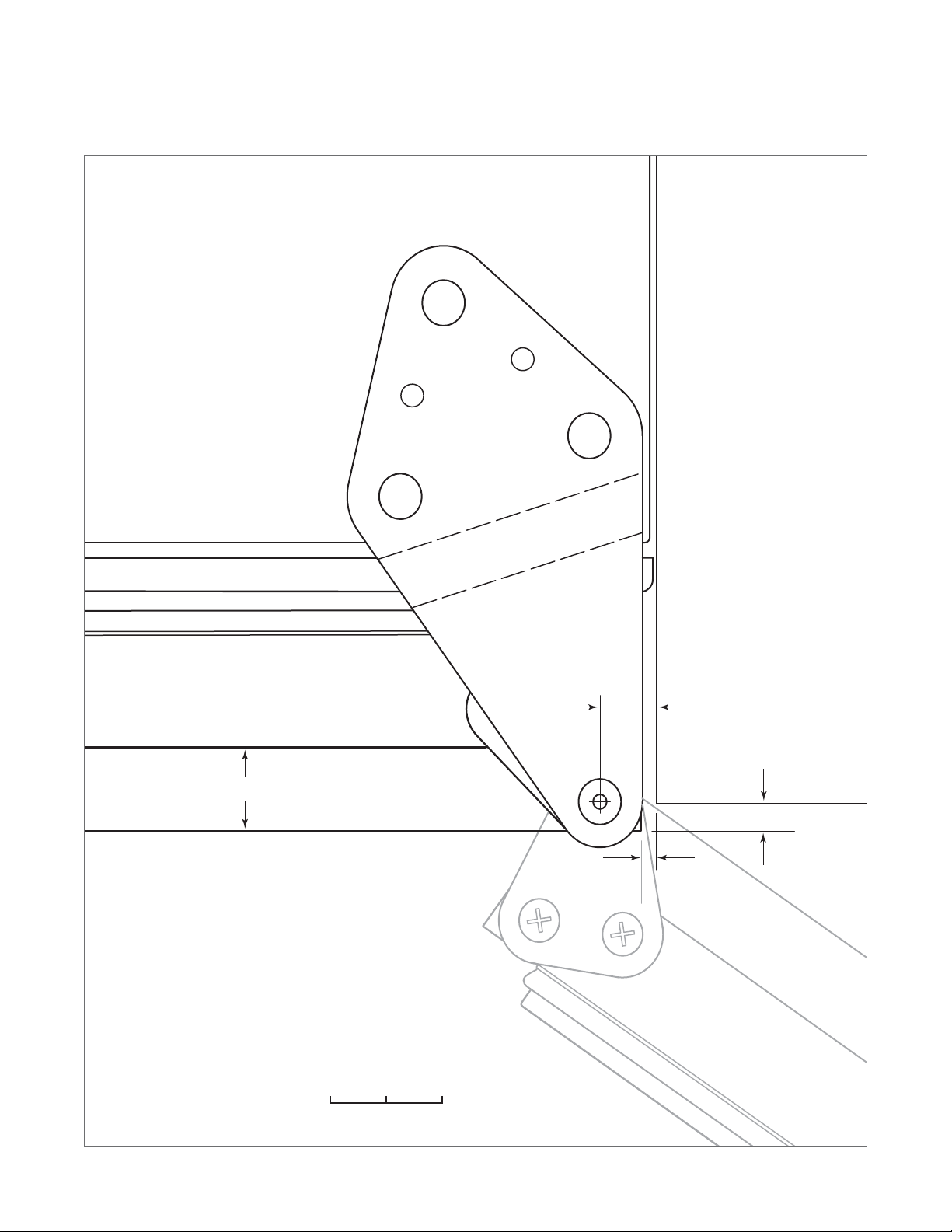

Side Panels

Side panels can be used with every design application.

When planning for side panels with the installation of a

built-in model, you need to be aware of the space configuration to achieve a pleasing fit. Depending on the exact

panel you are using with your unit, the height of the panel

may vary.

IMPORTANT NOTE: The use of side panels may change

the width of your rough opening.

The side panel will need to be a minimum of 610 mm deep

and 13 mm thick. Refer to the illustrations below for side

panel dimensions. Routing will be necessary so that the

side panel fits flush against the side of the unit.

610 mm

FRONT

OF SIDE

PANEL

25 mm

48 mm

IMPORTANT NOTE: If you have a model ICBBI-30U or

ICBBI-36U, extra routing will be necessary to prevent the

panel from hitting the refrigerator lower hinge plate.

When installing a built-in unit with a custom side panel, an

accessory kit (7003407) is required. Stainless steel and

white enamel side panels are also available through your

authorized Sub-Zero dealer.

ROUT TO 3 mm

48 mm

25 mm

108 mm

ROUT TO

5 mm

(OVER-AND-UNDER

MODELS)

102 mm

OPTIONAL

TOE KICK

CUT-OUT

146

mm

521

mm

Side panel dimensions.

2134

mm

67 mm

3 mm

13 mm

MAIN

FRAME

Routing detail.

SIDE PANEL

ROUTING

Page 21

Built-In Refrigeration 21

subzero.com/specs

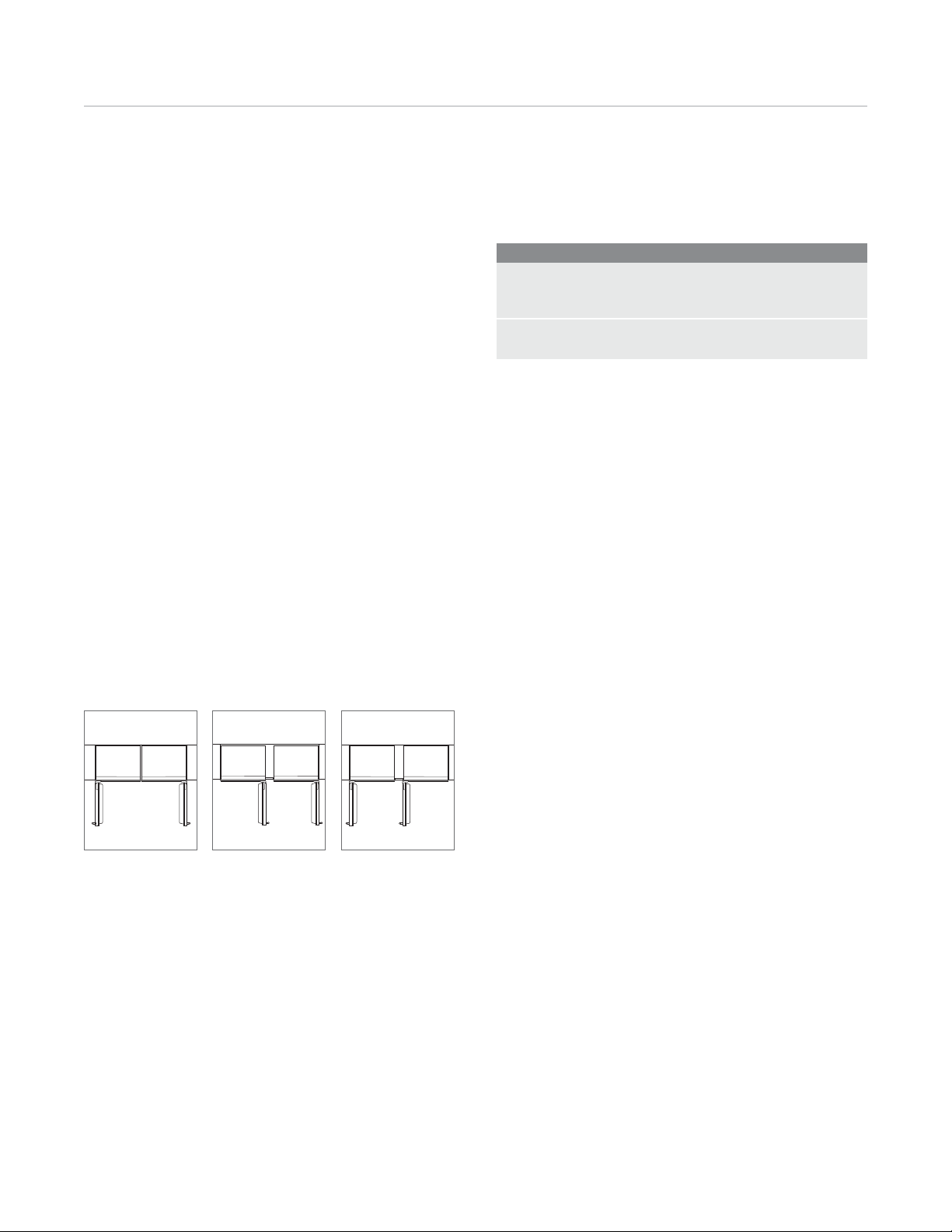

Dual Installation

STANDARD APPLICATION

Two overlay or stainless steel units may be placed side by

side in a dual installation. Some standard applications will

require a dual installation kit, avail able through your

authorized Sub-Zero dealer. If you are installing two units

side by side in a flush inset application, refer to page 23.

A custom filler strip can be used between two units in an

overlay or stainless steel design application. It is recommended that the filler strip be at least 51 mm wide to

prevent condensation between the units. Be sure to add

the filler strip width to your rough opening width. Refer to

the full-scale template on page 32.

Dual installations without a filler strip can only be accomplished using two units with opposite hinges as shown in

illustration A below. The dual installations shown in illustrations B and C require a filler strip.

IMPORTANT NOTE: For the application shown in illustra-

tion A, a dual installation accessory kit is required. Refer to

page 27 for information on dual installation kits.

Dual Installation Panel Requirements

MAX WEIGHT PER PANEL

All Models 23 kg

Dual Wide Grille Panel 12 kg

MIN PANEL THICKNESS

Overlay and Flush Inset Panels 16 mm

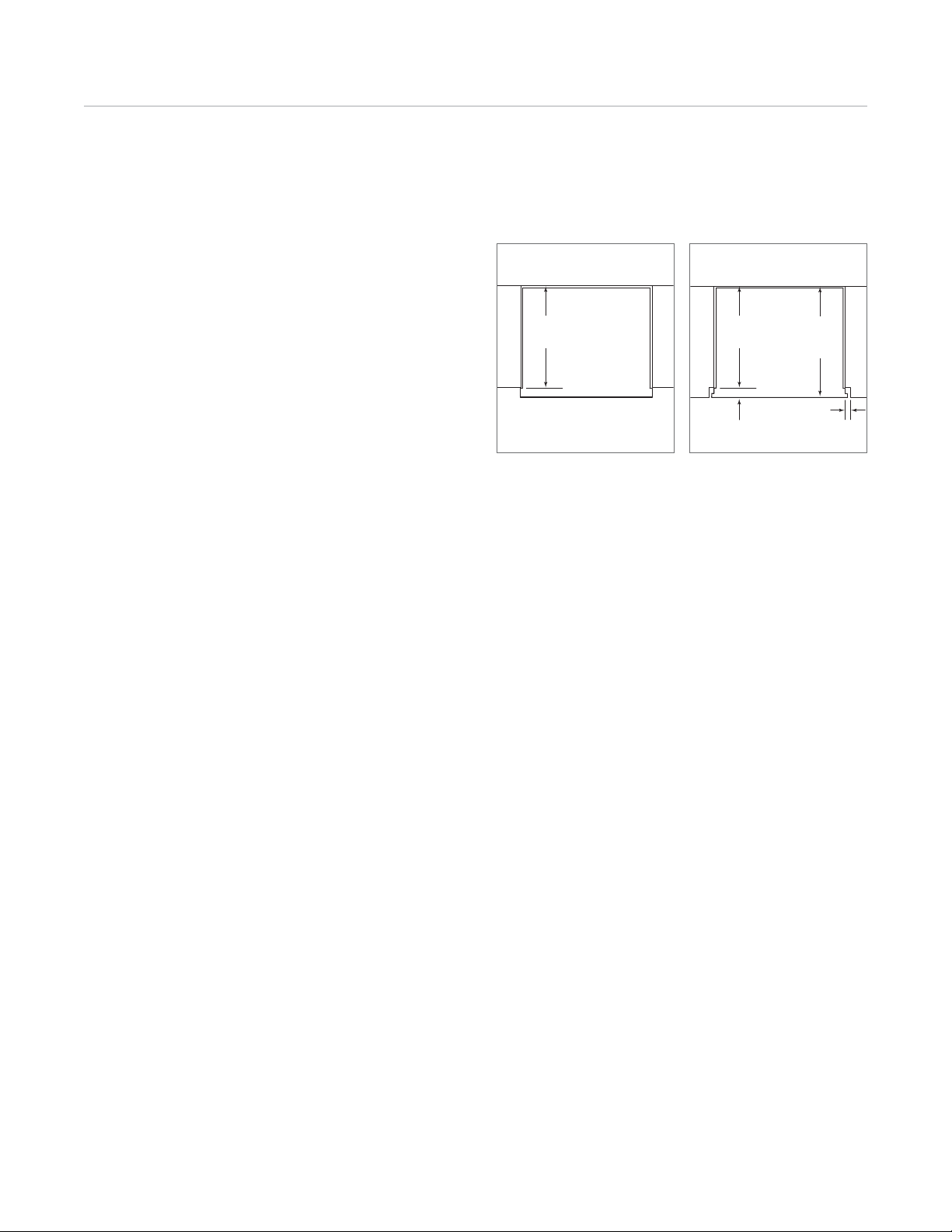

WITHOUT FILLER STRIP

Illus. A

FILLER STRIP REQUIRED

Illus. B Illus. C

FILLER STRIP REQUIRED

Page 22

Built-In Refrigeration 22

Dual Installation

STANDARD INSTALLATION

TOP VIEW

610 mm

OPENING

DEPTH

TWO UNITS WITH

19 mm PA NE L

610 mm

OPENING DEPTH

2127 mm

OPENING

HEIGHT

OPENING WIDTH

FRONT VIEWSIDE VIEW

Opening Widths A

Two 762 mm Models 1518 mm

762 mm and 914 mm Models 1670 mm

Two 914 mm Models 1822 mm

A

IMPORTANT NOTE: A dual installation kit will be required

for this installation.

Stainless steel models are ready to install out of the box.

Page 23

Built-In Refrigeration 23

subzero.com/specs

Dual Installation

FLUSH INSET APPLICATION

Installing two built-in models side by side in a flush inset

application will require adjustments to the dimensions of

your finished rough opening, panel sizes and panel offsets.

It will also require a dual installation kit, avail able through

your authorized Sub-Zero dealer.

Dual installations without a filler strip can only be accomplished using two units with opposite hinges as shown in

illustration A below. The dual installations shown in illustrations B and C require a filler strip. Refer to the full-scale

template on page 33. Illustration A is the only application

that will accommodate the dual wide grille.

IMPORTANT NOTE: The application shown in illustration A

can only be achieved by installing dual flush inset panels.

Failure to install dual flush inset panels will cause the

handle side of the panels to collide when closing. In this

application a dual installation accessory kit is also

required.

Dual flush inset panels and dual installation kits are avail able through your authorized Sub-Zero dealer. Refer to

pages 25–26 for dual flush inset panel specifications and

page 27 for information on dual installation kits.

Dual Installation Panel Requirements

MAX WEIGHT PER PANEL

All Models 23 kg

Dual Wide Grille Panel 12 kg

MIN PANEL THICKNESS

Flush Inset Panels 16 mm

WITHOUT FILLER STRIP

Illus. A

FILLER STRIP REQUIRED FILLER STRIP REQUIRED

Illus. B Illus. C

Page 24

32 mm

610 mm

OPENING

DEPTH

TO CLEAT

CLEAT

TOP VIEW

665

mm

FLUSH

INSET

DEPTH

56 mm

76 mm

typical

610 mm

OPENING

DEPTH TO

CLEAT

32 mm

56 mm

CLEAT

SHADED

AREA

MUST BE

FINISHED

76 mm

typical

102

mm

Built-In Refrigeration 24

Dual Installation

FLUSH INSET INSTALLATION

TOP VIEW

610 mm

665

mm

EPTH

D

FLUSH

TO CLEAT

CLEAT

610 mm

DEPTH TO CLEAT

665 mm

FLUSH INSET DEPTH

56

mm

6 mm

INSET

DEPTH

56 mm

32 mm

TWO UNITS WITH

19 mm PANEL

CLEAT

DETAIL A

Detail A

2127

mm

HEIGHT

SIDE VIEW

TO CLEAT

2134

mm

FLUSH

INSET

HEIGHT

32

mm

Opening Widths A B

Two 762 mm Models 1518 mm 1581 mm

762 mm and 914 mm Models 1670 mm 1734 mm

Two 914 mm Models 1822 mm 1886 mm

A

WIDTH TO CLEAT

B

FLUSH INSET WIDTH

FRONT VIEW

IMPORTANT NOTE: Dimensions assume a 19 mm panel

thickness. A dual installation kit will be required for this

installation.

DETAIL B

32

mm

Detail B

Page 25

Built-In Refrigeration 25

subzero.com/specs

Dual Installation

FLUSH INSET PANEL OFFSETS

When installing two built-in models side by side in a flush

inset application, you must decrease the width of the decorative flush inset panels by 13 mm. Adjustments to the

panel offsets will also need to be made. These adjustments are needed to achieve a proper fit and to ensure the

panels do not collide when closing. Panel dimensions in

the chart below have been adjusted to reflect the

decrease in panel dimensions.

IMPORTANT NOTE: If a filler strip is not used, dual instal-

lations can only be accomplished using two units with

opposite hinges.

Illustrations A–F provide panel offsets and reveals for all

built-in models in a flush inset application. Refer to the

chart below for reference to the illustrations relating to

your specific model. All reveals are 13 mm unless otherwise specified.

For additional information on model-specific panel reveals,

visit the specification library section of our website,

subzerotrade.com.

Panel Offsets Illus.

OVER-AND-UNDER

Doors (hinge) / Drawer / Grille Sides A

Doors (handle) Sides B

Grille Top C

Grille Bottom / Door Top D

Door Bottom / Drawer Top E

Drawer Bottom F

Do not exceed flush inset panel dimensions, as this

could cause damage to panels and the Sub-Zero unit.

DOOR / DRAWER / GRILLE

BACKER

SPACER

TOP VIEW

CABINETRY

DOOR DOOR

FLUSH INSET PANEL

8 mm

16

mm

13

mm

Illus. A Illus. B

CABINETRY

13 mm

3

GRILLE

mm

8

mm

SIDE VIEW

Illus. C Illus. D

8

mm

2

DOOR

DRAWER

mm

mm

8

mm

SIDE VIEW

16 mm

4

8 mm

3 mm

GRILLE

DOOR

DOOR /

DRAWER

TOP VIEW

DUAL

TRIM

SIDE VIEW

6 mm

REVEAL

8

mm

mm

mm

8

mm

SIDE VIEW

8

mm

4

13 mm

2

mm

2

Illus. E Illus. F

Page 26

Built-In Refrigeration 26

Dual Installation—Flush Inset Panels

H

H

H

W

ICBBI-30U / ICBBI-36U

ICBBI-30U

REFRIGERATOR W H

Flush Inset Panel 775 mm 1273 mm

Spacer Panel 740 mm 1253 mm

Backer Panel 756 mm 1268 mm

FREEZER W H

Flush Inset Panel 775 mm 483 mm

Spacer Panel 740 mm 459 mm

Backer Panel 756 mm 475 mm

GRILLE W H

Flush Inset Panel 775 mm 235 mm

Spacer Panel 740 mm 211 mm

Backer Panel 756 mm 227 mm

ICBBI-36U

REFRIGERATOR W H

Flush Inset Panel 927 mm 1273 mm

Spacer Panel 892 mm 1253 mm

Backer Panel 908 mm 1268 mm

FREEZER W H

Flush Inset Panel 927 mm 483 mm

Spacer Panel 892 mm 459 mm

Backer Panel 908 mm 475 mm

GRILLE W H

Flush Inset Panel 927 mm 235 mm

Spacer Panel 892 mm 211 mm

Backer Panel 908 mm 227 mm

Grille panel dimensions listed are for a standard 2134 mm

finished height. For a 2108 mm finished height, subtract 25

mm from grille panel height dimensions. For a 2235 mm

finished height, add 102 mm to height dimensions. Width

dimensions do not vary.

For dual wide grilles, refer to page 27.

Page 27

Built-In Refrigeration 27

subzero.com/specs

Dual Installation Kit

INSTALLATION WITH DUAL WIDE GRILLE

This kit will replace the existing grilles that ship with the

units and span the entire width of both units. The kit

includes a 6 mm center trim strip (required for proper

installation of the dual wide grille), heater, dual kickplate

and mounting hardware. Dual wide grilles are available for

all built-in models and design applications. The overlay

dual installation kit with grille will accept overlay and dual

flush inset panels. For dual wide grille panel dimensions,

refer to the panel specifications below for your design

application. Grille panel dimensions listed are for a

standard 2134 mm finished height.

Dual Wide Grille—Overlay

TWO 762 mm MODELS W H

Overlay Panel 1530 mm 235 mm

Spacer Panel 1508 mm 211 mm

Backer Panel 1524 mm 227 mm

762 mm AND 914 mm MODELS W H

Overlay Panel 1683 mm 235 mm

Spacer Panel 1661 mm 211 mm

Backer Panel 1676 mm 227 mm

TWO 914 mm MODELS W H

Overlay Panel 1835 mm 235 mm

Spacer Panel 1813 mm 211 mm

Backer Panel 1829 mm 227 mm

INSTALLATION WITH INDIVIDUAL GRILLES

This kit is available for those who choose to utilize the

individual grilles that ship with each unit. The kit includes a

6 mm filler strip (which fills the reveal between the units

and grilles), heater and mounting hardware. This dual

installation kit is not required if a custom filler strip is used.

The filler strip should be a minimum of 51 mm wide. Refer

to the full-scale template on page 32 for more information.

Dual Wide Grille—Flush Inset

TWO 762 mm MODELS W H

Flush Inset Panel 1556 mm 235 mm

Spacer Panel 1508 mm 211 mm

Backer Panel 1524 mm 227 mm

762 mm AND 914 mm MODELS W H

Flush Inset Panel 1708 mm 235 mm

Spacer Panel 1661 mm 211 mm

Backer Panel 1676 mm 227 mm

TWO 914 mm MODELS W H

Flush Inset Panel 1861 mm 235 mm

Spacer Panel 1813 mm 211 mm

Backer Panel 1829 mm 227 mm

Page 28

Built-In Refrigeration 28

Accessories

These optional accessories are avail able through your

authorized Sub-Zero dealer. For local dealer information,

visit the find a showroom section of our website,

subzero.com.

• Flush inset front panels in stainless steel with handle

options.

• Side panels in stainless steel and white enamel.

• Grilles for a 2108 mm or 2235 mm finished height.

• Tubular and pro handles to match the style of Wolf

ovens and ranges.

• Dual installation kits with and without dual wide grille.

• Retrofit kits for use with 600 series panels.

STANDARD HANDLES

Refer to the chart below for standard handle lengths

and the stud spacing of tubular and pro handles used on

built-in models.

Standard Handles Length Stud Spacing

FULL-HEIGHT DOOR

Tubular Handle 1622 mm 1114 mm

Pro Handle 1146 mm 1114 mm

ICBBI-30U AND ICBBI-36U DOOR

Tubular Handle 1124 mm 921 mm

Pro Handle 952 mm 921 mm

ICBBI-30U DRAWER

Tubular Handle 633 mm 414 mm

Pro Handle 447 mm 414 mm

ICBBI-36U DRAWER

Tubular Handle 770 mm 567 mm

Pro Handle 597 mm 567 mm

Page 29

Built-In Refrigeration 29

subzero.com/specs

Overlay Panel Thickness

FULL-SCALE TEMPLATE

Overlay and flush inset panels must be a minimum of 16

mm thick to support mounting the handle. Panel thickness

does not include backer and spacer panel. Mount handle

close to the opening edge of the door.

DEPTH OF TUBULAR

AND PRO HANDLES

25

mm

6 mm BACKER PANEL

PANEL THICKNESS

OVERLAY AND FLUSH INSET APPLICATIONS

DOOR

51

mm

76

mm

SPACER PANEL

3 mm

32 mm PANEL

25 mm PANEL

19 mm PANEL

Page 30

Built-In Refrigeration 30

Overlay Application

FULL-SCALE TEMPLATE

0 mm

6 mm

13 mm

19 mm

25 mm

32 mm

38 mm

44 mm

51 mm

57 mm

63 mm

70 mm

76 mm

83 mm

606 mm

TO REAR OF UNIT

OVERALL WIDTH OF UNIT

89 mm

25 mm THICK

PANEL

19 mm THICK

OVERLAY PANEL

(TYPICAL)

6 mm BACKER

DOOR OPENING 90°

TOP VIEW

PANEL

25 mm0 mm

SCALE

Page 31

Built-In Refrigeration 31

subzero.com/specs

Flush Inset Application

FULL-SCALE TEMPLATE

For panels thicker than 19 mm,

a 90° door stop may be required

to prevent interference with

adjacent cabinets.

610 mm

TO BACK WALL

32 mm

56 mm

ASSUMES

19 mm

FLUSH INSET

PA NE L

THICKNESS

25 mm THICK

PANEL

19 mm THICK

FLUSH INSET PANEL

(TYPICAL)

6 mm BACKER

PANEL

DOOR OPENING 110°

TOP VIEW

25 mm0 mm

SCALE

Page 32

Built-In Refrigeration 32

FILLER STRIP

32 mm

APPROX PROFILE OF

STAINLESS STEEL WRAPPED

DOOR AND HANDLE

Dual Installation—Standard

FULL-SCALE TEMPLATE

Typical overlay or stainless steel dual

installation with filler strip at maximum

110° door opening. Depending on panel

thickness, a 90° door stop may be

required.

DOOR

CLOSED

DOOR

OPEN 110°

STANDARD

TOP VIEW

25 mm0 mm

SCALE

Page 33

Built-In Refrigeration 33

subzero.com/specs

FILLER STRIP

38 mm

13 mm

PROFILE OF 19 mm FLUSH INSET PANEL

AND TUBULAR HANDLE

Dual Installation—Flush Inset

FULL-SCALE TEMPLATE

Typical flush inset dual installation with

filler strip at maximum 110° door

opening. Depending on panel thickness,

a 90° door stop may be required.

DOOR

CLOSED

DOOR

OPEN 110°

FLUSH INSET

TOP VIEW

25 mm0 mm

SCALE

Page 34

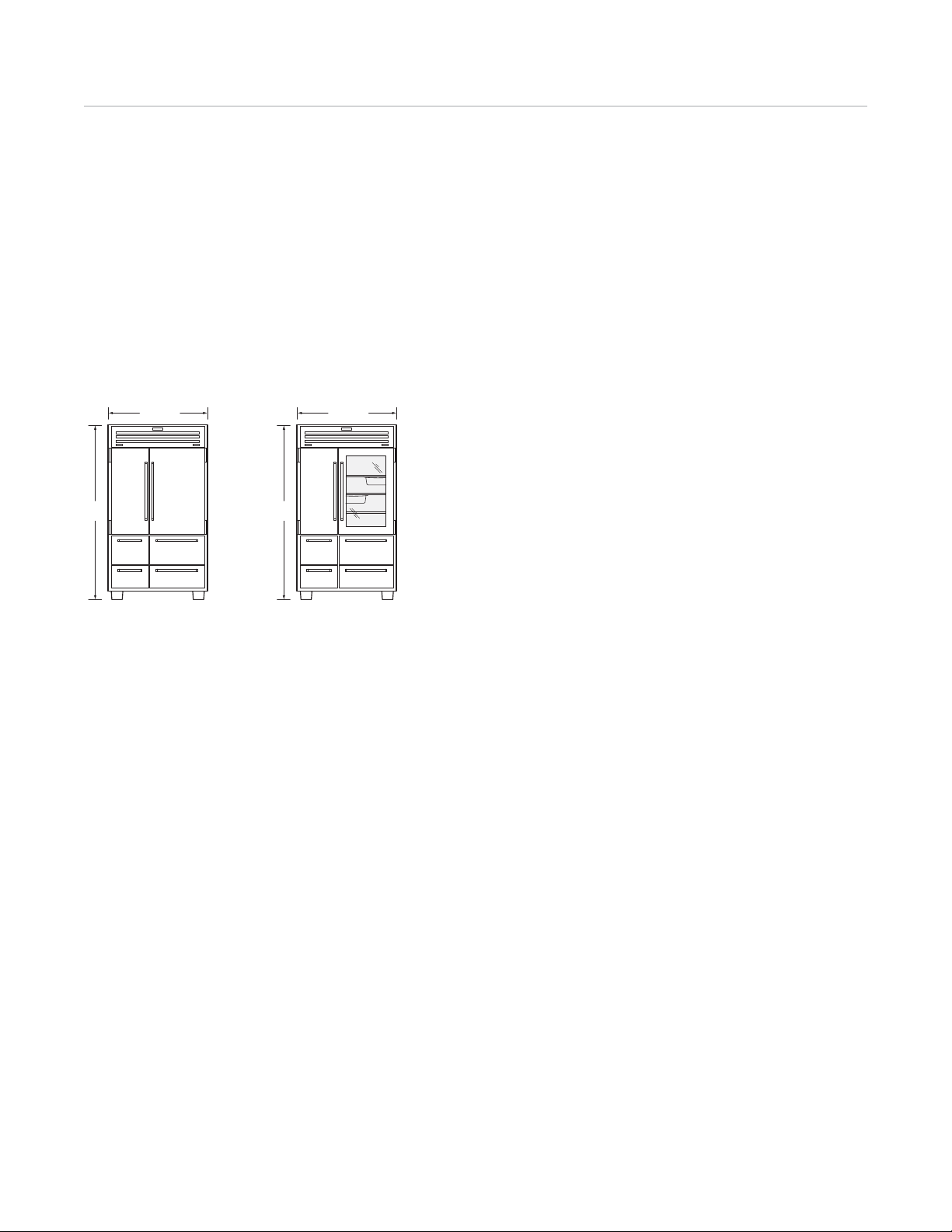

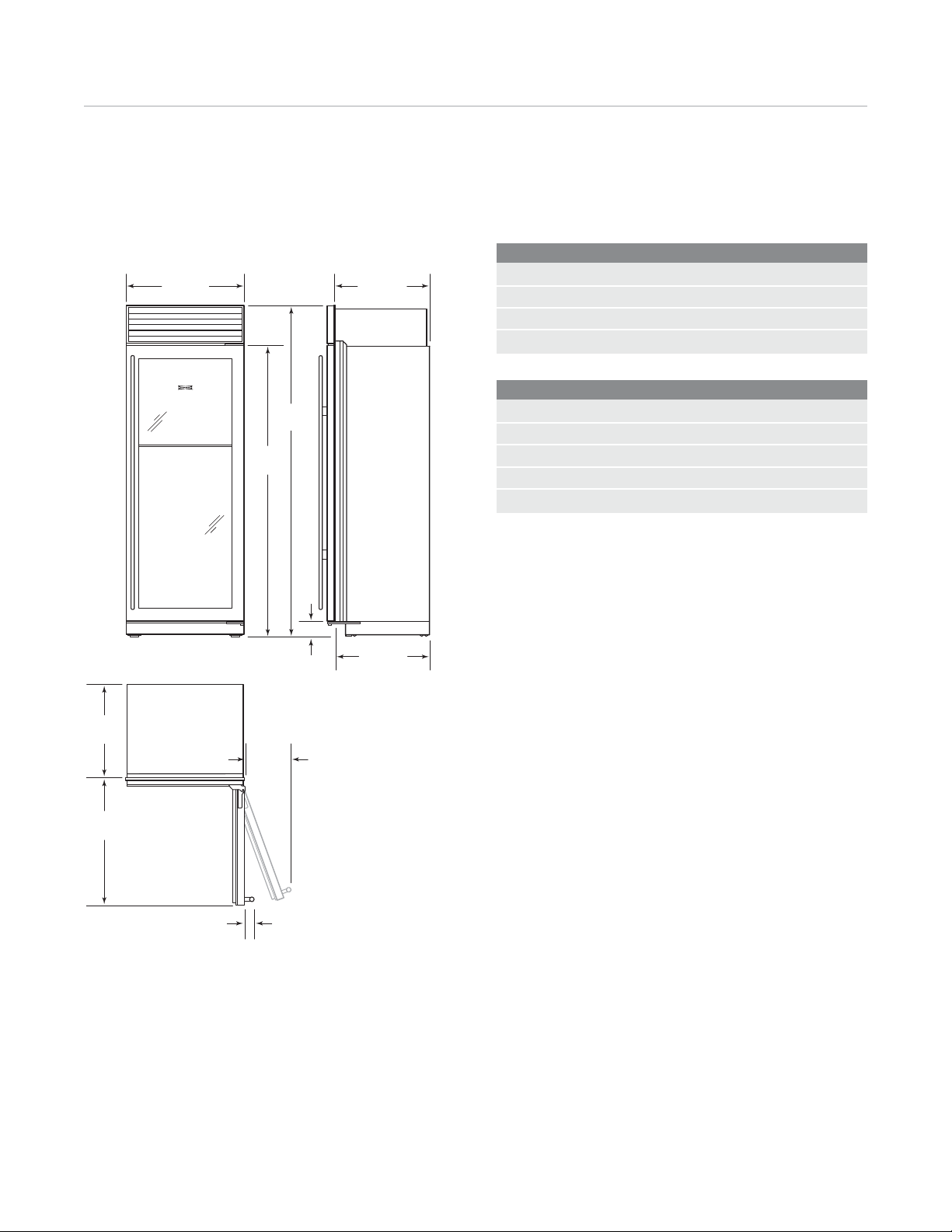

PRO 48 Refrigeration 34

PRO 48 Refrigeration. Freshness finds unmistakable expression in the Sub-Zero PRO 48. A 363 kg monument to

food preservation—equal parts sculpted metal design statement and culinary secret weapon. Its vast interior, like its bold

exterior, is crafted of stainless steel. The PRO 48 is available with or without a glass door and may be either built in or

freestanding.

PRO 48 MODELS KEY FEATURES

• Can be used freestanding or installed as a standard or

1219 mm

1219 mm

flush built-in application.

• Handles coordinate with handles of Wolf ranges.

• Stainless steel interior as well as exterior.

2134

mm

ICB648PRO ICB648PROG

2134

mm

• Dual refrigeration system enhanced with triple evapora-

tors allow independent control of storage conditions in

refrigerator cabinet and drawer compartments.

• Exterior temperature display.

• Flip-up grille provides easy access for quick routine

maintenance.

• Star-K certified.

Page 35

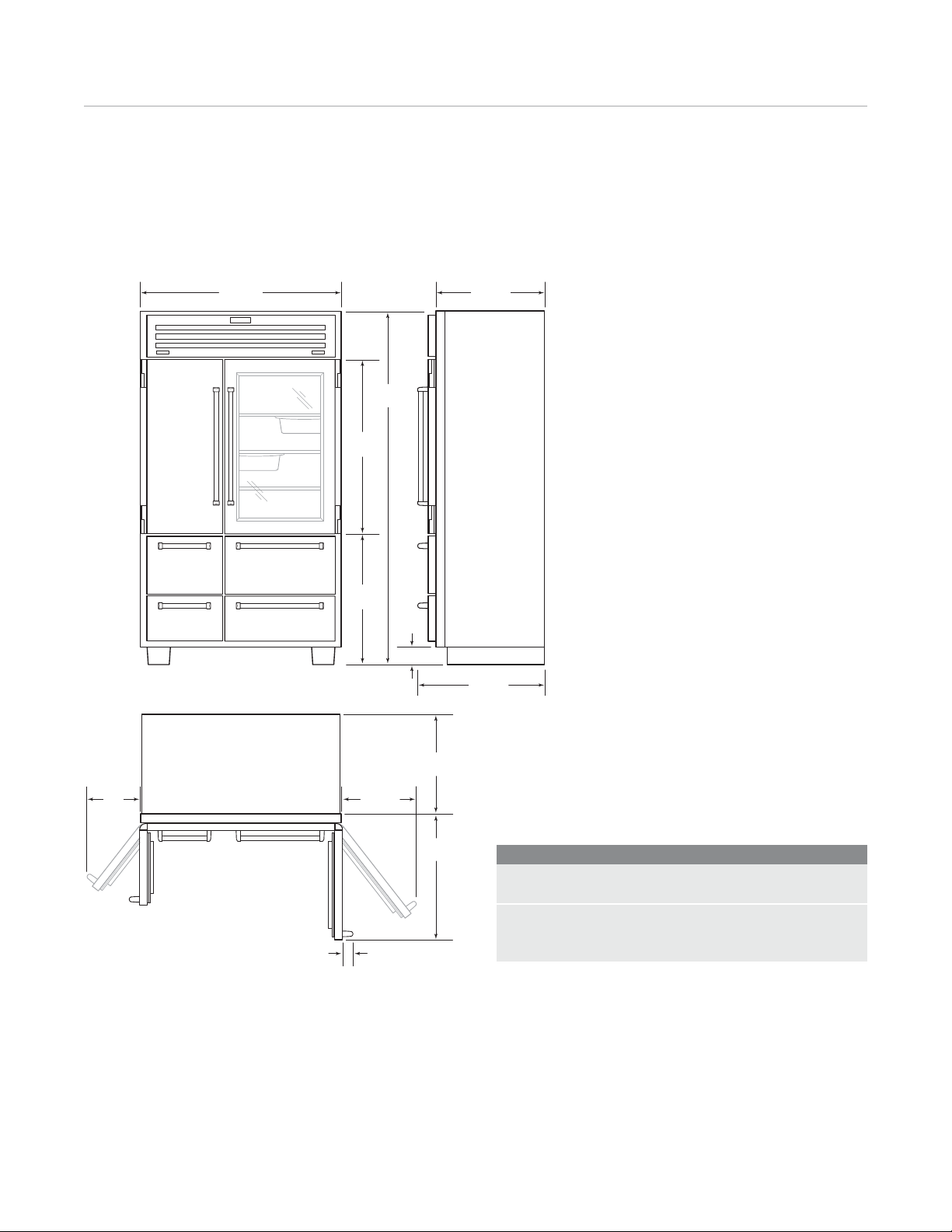

PRO 48 Refrigeration 35

subzero.com/specs

PRO 48 Models

OVERALL DIMENSIONS

1219 mm

HEIGHT DIMENSIONS ± 13 mm

1070

mm

775

mm

2134

mm

657 mm

102 mm

767 mm

368

mm

MODELS ICB648PRO AND ICB648PROG

533 mm

60 mm

606

mm

781

mm

SPECIFICATIONS

Capacity / Weight

INTERIOR CAPACITY R (L) F (L)

ICB648PRO and ICB648PROG 520 332

SHIPPING WEIGHT KG

ICB648PRO 390

ICB648PROG 397

Page 36

PRO 48 Refrigeration 36

PRO 48 Models

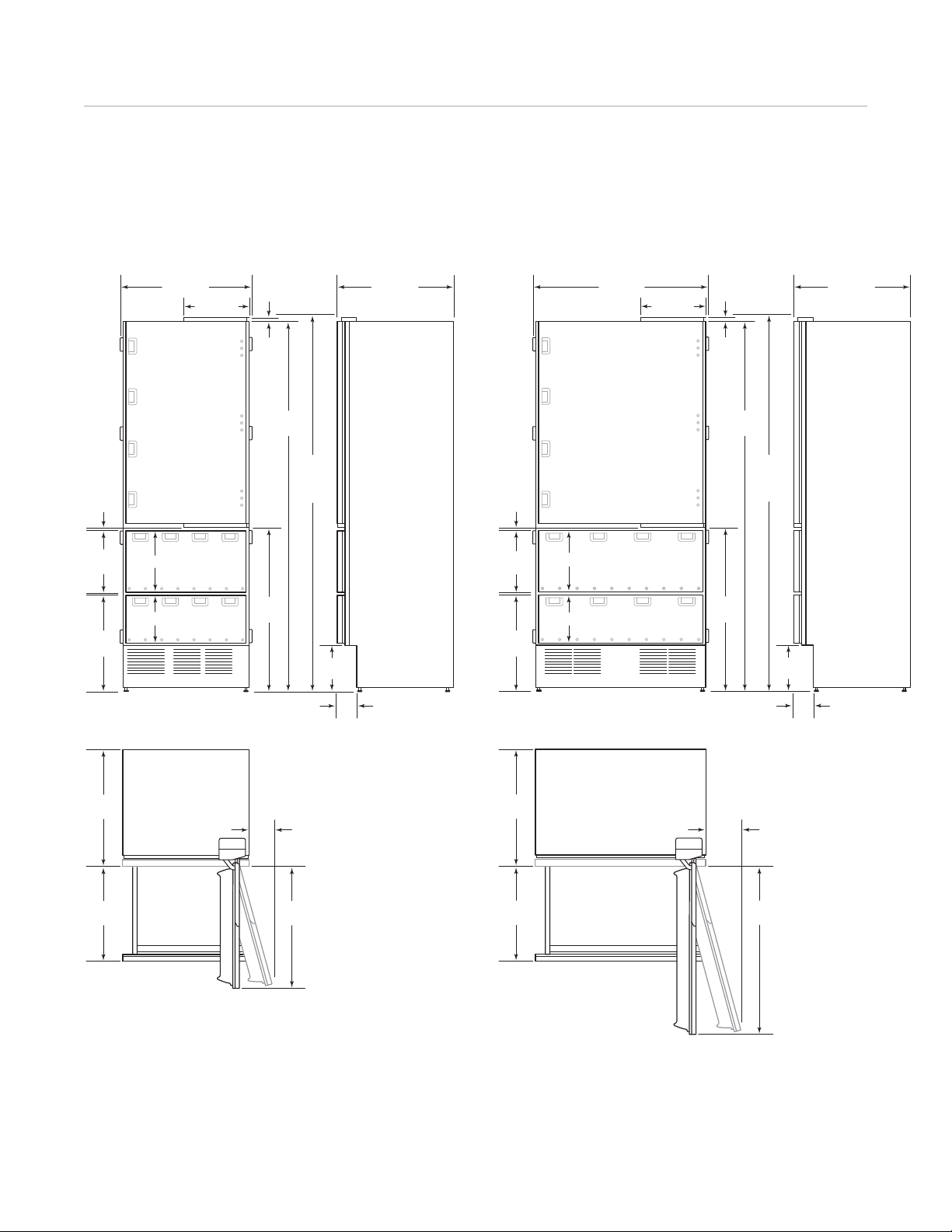

STANDARD AND FLUSH BUILT-IN INSTALLATIONS

TOP VIEW

OPENING

DEPTH

OPENING

DEPTH

OPENING

HEIGHT

OPENING

WIDTH

FRONT VIEWSIDE VIEW

Opening Dimensions Standard Flush

Opening Width 1206 mm 1219 mm

Opening Height 2127 mm 2137 mm

Opening Depth 610 mm 660 mm

IMPORTANT NOTE: For standard built-in installations, the

face frame of the unit will extend 51 mm beyond cabinetry.

In flush built-in installations, the front of the face frame will be

flush with surrounding cabinetry.

Page 37

PRO 48 Refrigeration 37

subzero.com/specs

Planning Information

PRO 48 models can be used freestanding or installed as a

standard or flush built-in application. For standard built-in

installations, the face frame of the unit will extend 51 mm

beyond cabinetry. In flush built-in installations, the front of

the face frame will be flush with surrounding cabinetry.

ELECTRICAL REQUIREMENTS

International models from the factory designed without a

transformer require a 220-240 V AC, 50/60 Hz electrical

supply, fused at the correct rating for the unit. If required

by local or national codes, the power cord can be easily

replaced using the power inlet device.

For PRO 48 models, the electrical supply should be

located within the shaded area shown in the illustration

below. Follow local codes and ordinances when installing

the receptacle. A separate circuit, servicing only this appliance, is required. A ground fault circuit interrupter (GFCI)

is not recommended and may cause interruption of operation.

Electrical Requirements

Power Supply 220-240 V AC, 50/60 Hz

Circuit Breaker 10 amp

Receptacle 3-prong grounding-type

PLUMBING REQUIREMENTS

PRO 48 models come with an automatic ice maker. The

water supply line should be located within the shaded area

shown in the illustration below. The water supply line

should be connected to the house supply with an easily

accessible shut-off valve between the supply and the unit.

Do not use self-piercing valves. A saddle valve kit

(4200880) is avail able through your authorized Sub-Zero

dealer. The water line must not interfere with installation of

the anti-tip brackets.

IMPORTANT NOTE: A reverse osmosis system can be

used provided there is constant water pressure of 2.4 bar

to 8.3 bar supplied to the unit at all times.

Plumbing Requirements

Water Supply Line 6.35 mm OD copper line

Water Pressure 2.4–8.3 bar

Excess Water Line for Connection 914 mm

FRONT VIEW

178

E

mm

152

mm

1918 mm

FROM

FLOOR

Location of electrical supply.

152

mm

132

76 mm

FRONT VIEW

Location of water supply.

mm

FLOOR

Page 38

PRO 48 Refrigeration 38

Accessories

These optional accessories are avail able through your

authorized Sub-Zero dealer. For local dealer information,

visit the find a showroom section of our website,

subzero.com.

• Freestanding kit, which contains two stainless steel

side panels and top lid.

• Stainless steel side panel.

• Refrigerator drawer dividers for compartmentalized

storage.

• Stainless steel slide-out refrigerator bin.

• Dozen egg container.

• 90° door stop.

Page 39

Integrated Refrigeration 39

subzero.com/specs

Integrated Refrigeration. With custom cabinet fronts and hardware, Sub-Zero invented integrated drawers and tall

units that disappear into the decor. Integrated units fit flush with other cabinets, making integrated refrigeration as practical

and beautiful in the master suite, bar or theatre room as in the kitchen.

INTEGRATED MODELS

686 mm

2032

mm

ICB700TR ICB700TCI

914 mm

2032

mm

2032

mm

2032

mm

686 mm

914 mm

876

mm

KEY FEATURES

• Custom cabinet fronts and hardware allow for

infinite design options.

• Point-of-use refrigeration that can be placed

anywhere in the home.

• Dual refrigeration; two compressors preserve

food’s goodness in self-contained compartments.

• Energy efficient.

• Drawer model is Star-K certified.

686 mm

ICB736TR ICB736TCI

ICB700BR

Page 40

Integrated Refrigeration 40

Overall Dimensions

686 mm TALL MODELS

686 mm

356 mm

10

mm

13

337 mm

mm

260 mm

518

mm

21

mm

876

mm

1995

mm

TO TOP OF

2032

mm

OPENNG

248

mm

610 mm

914 mm TALL MODELS

914 mm

10

mm

13

337 mm

mm

260 mm

518

mm

356 mm

33

mm

876

mm

1976

mm

TO TOP OF

2032

mm

OPENNG

248

mm

610 mm

102

HEIGHT DIMENSIONS ± 13 mm

610

mm

117

mm

495

mm

DIMENSIONS WILL VARY WITH PANEL THICKNESS

648

mm

mm

MODELS ICB700TR AND ICB700TCI

Overall dimensions do not include panels or handles.

HEIGHT DIMENSIONS ± 13 mm

610

mm

495

mm

DIMENSIONS WILL VARY WITH PANEL THICKNESS

MODELS ICB736TR AND ICB736TCI

178

mm

876

mm

102

mm

Page 41

Integrated Refrigeration 41

subzero.com/specs

Overall Dimensions

DRAWER MODELS

10

mm

13

mm

518

mm

610

mm

686 mm

337 mm

260 mm

HEIGHT DIMENSIONS ± 13 mm

876

mm

248 mm

102

mm

610 mm

Capacity and Weight

Interior Capacity R (L) F (L)

686 mm TALL MODELS

ICB700TR 439

ICB700TCI 288 143

914 mm TALL MODELS

ICB736TR 590

ICB736TCI 378 200

686 mm DRAWER MODEL

ICB700BR 149

Shipping Weight kg

ICB700TR and ICB700TCI 163

ICB736TR and ICB736TCI 218

ICB700BR 86

495

mm

657 mm

DIMENSIONS WILL VARY WITH PANEL THICKNESS

MODEL ICB700BR

Page 42

Integrated Refrigeration 42

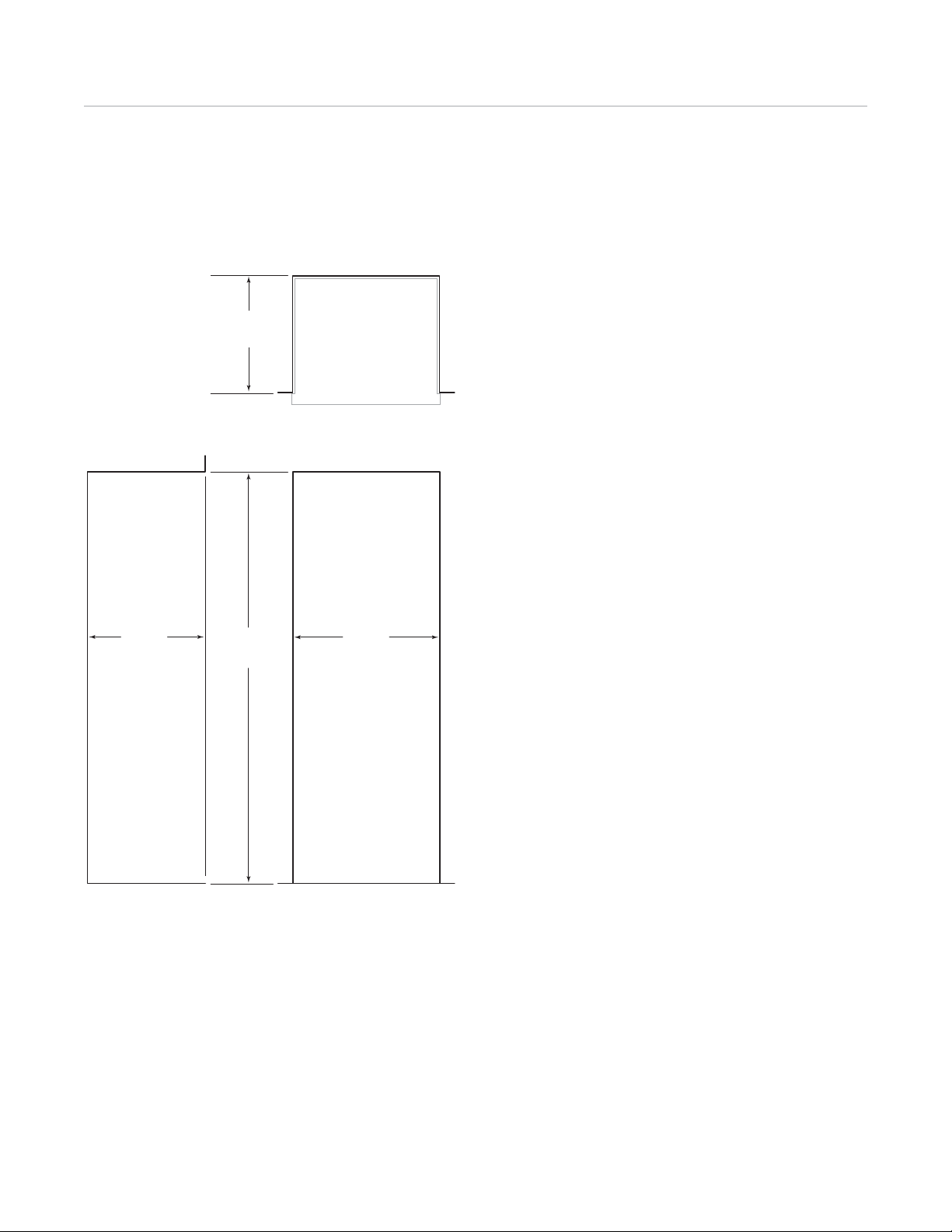

Opening Dimensions

INTEGRATED MODELS

635 mm

OPENING DEPTH

635 mm

OPENING

DEPTH

B

OPENING

HEIGHT

TOP VIEW

A

OPENING WIDTH

IMPORTANT NOTE: The depth of each integrated model is

610 mm from the front of the unit to its back. Your design may

necessitate moving the unit back or cabinets forward to

achieve a flush fit. This will require a minimum rough opening

depth of 635 mm.

FRONT VIEWSIDE VIEW

Opening Dimensions A B

ICB700TR, ICB700TCI 686 mm 2032 mm

ICB736TR, ICB736TCI 914 mm 2032 mm

ICB700BR 686 mm 876 mm

Page 43

Integrated Refrigeration 43

subzero.com/specs

Electrical Requirements

International models from the factory designed without a

transformer require a 220-240 V AC, 50/60 Hz electrical

supply, fused at the correct rating for the unit. If required

by local or national codes, the power cord can be easily

replaced using the power inlet device.

The electrical supply should be located within the shaded

area shown in the illustrations. Follow local codes and

ordinances when installing the receptacle. A separate

circuit, servicing only this appliance, is required. A ground

fault circuit interrupter (GFCI) is not recommended and

may cause interruption of operation.

IMPORTANT NOTE: It is critical that the electrical outlet be

located within the shaded area shown so it does not interfere with installation of the anti-tip bracket. It must be

flush with the back wall and positioned with the grounding

prong to the right of the thinner blades.

POSITION OUTLET WITH

GROUNDING PRONG

TO THE RIGHT

POSITION OUTLET WITH

GROUNDING PRONG

TO THE RIGHT

Electrical Requirements

Power Supply 220-240 V AC, 50/60 Hz

Circuit Breaker 10 amp

Receptacle 3-prong grounding-type

64 mm

mm

6

330 mm

E

FLOOR

FRONT VIEW

114

mm

64 mm

mm

6

445 mm

E

FLOOR

FRONT VIEW

686 mm models. 914 mm models.

114

mm

Page 44

Integrated Refrigeration 44

Plumbing Requirements

For integrated models with an automatic ice maker, the

water supply line should be located through the floor or

back wall, within the shaded area shown in the illustrations. The water supply line should be connected to the

house supply with an easily accessible shut-off valve

between the supply and the unit. Do not use self-piercing

valves. A saddle valve kit (4200880) is avail able through

your authorized Sub-Zero dealer.

IMPORTANT NOTE: It is critical that the water line be

located within the shaded area shown so it does not interfere with installation of the anti-tip bracket.

An in-line filter is required when water conditions have a

high sediment content. The ice maker operates on

constant water pressure between 1.4 bar and 6.9 bar.

IMPORTANT NOTE: In some cases, a reverse osmosis

water filter system may not be able to maintain the

minimum pressure consistently.

ACK

B

WALL

152

mm

64 mm

343 mm

76 mm

FLOOR

FRONT VIEW

1

mm

9

914 mm models.

Plumbing Requirements

Water Supply Line 6.35 mm OD copper line

Water Pressure 1.4–6.9 bar

Excess Water Line for Connection 686 mm

343

mm

64 mm

TOP VIEW

38

mm

76 mm

FLOOR

FRONT VIEW

686 mm models.

229

mm

64 mm

19

mm

BACK

WALL

152

mm

TOP VIEW

229

mm

64 mm

38

mm

Page 45

Integrated Refrigeration 45

subzero.com/specs

Cabinetry Applications

FRAMELESS CABINETRY

679 mm

PANEL WIDTH

2029

mm

A

1153

mm

A

345

mm

A

424

mm

A

1153

mm

A

345

mm

A

424

mm

876

mm

908 mm

PANEL WIDTH

2029

mm

102 mm

686 mm

FINISHED OPENING

ALL REVEALS (A) ARE 3 mm.

686 mm MODELS

TALL AND DRAWER MODELS

4" (102)

914 mm MODELS

TALL MODELS

Typical Panel Dimensions

686 mm MODELS W H

Door 679 mm 1153 mm

Top Drawer 679 mm 345 mm

Bottom Drawer 679 mm 424 mm

914 mm MODELS W H

Door 908 mm 1153 mm

Top Drawer 908 mm 345 mm

Bottom Drawer 908 mm 424 mm

914 mm

FINISHED OPENING

Panel dimensions are based on a 3 mm reveal. A reveal of up

to 6 mm is possible with adjustments to panel dimensions.

Page 46

Integrated Refrigeration 46

Cabinetry Applications

DOOR PANEL HEIGHT

The height of the door panel can extend beyond the

typical panel height, provided you do not exceed the panel

weight limit. The illustration below shows how the panel

may be extended and what you need to consider to finish

the area behind the door panel.

IMPORTANT NOTE: The decorative valance used to finish

the area behind the door panel must stay behind the front

plane of the finished molding.

635 mm

TO WAL L

DECORATIVE VALANCE

CANNOT EXTEND BEYOND

THE FRONT OF THE MOLDING

DECORATIVE VALANCE

OVERALL

HEIGHT

3 mm

3 mm

38

mm

DOOR

PA NE L

TOE KICK CLEARANCE

The toe kick clearance can vary with the height of the

panel. You must keep a minimum space of 102 mm clear

below the bottom edge of the panel for proper venting. In

addition, any decorative base molding must be removable

to clean the condenser and for service.

INTEGRATED UNIT

(SIDE VIEW)

HEIGHT

OF PANEL

KICKPLATE / GRILLE

CAN BE ADJUSTED

F

ORWARD

KICKPLATE / GRILLE

MINIMUM

HEIGHT

TYPICAL

HEIGHT

OF DOOR

PANEL

UPPER VALANCE

TALL MODELS

HINGE

REMOVABLE MOLDING

INTEGRATED UNIT

(SIDE VIEW)

BASE MOLDING

REMOVABLE

102 mm TO 229 mm

FROM FLOOR

67 mm TO 102 mm

KICKPLATE/GRILLE AREA

ALL INTEGRATED MODELS

MUST BE

635 mm TO WALL

Page 47

Integrated Refrigeration 47

subzero.com/specs

Cabinetry Applications

Integrated refrigeration is compatible with virtually any

style and look of cabinetry. These models can be used

with framed as well as frameless cabinetry. Because of the

precise application and the look you may want to achieve,

keep the following considerations in mind:

The thickness of the front panels can vary. A minimum 16

mm thick panel is required, but the thickness can be

increased provided the panel weight limit is not exceeded.

IMPORTANT NOTE: The depth of each integrated model is

610 mm from the front of the unit to its back. You must

allow for the thickness of the panel you are applying when

planning for the finished rough opening depth if you want

the front panel to be flush with surrounding cabinetry. You

may have to move the unit back into drywall or bring the

cabinets forward to achieve a flush fit.

Reveals between panels can vary. A reveal of 3 mm is

typical, but reveals can be increased to up to 6 mm.

As reveals between cabinetry and the unit decrease,

the potential exists for severe finger pinching while the

door is closing.

IMPORTANT NOTE:

The inside edges of the rough opening

as well as the sides and a portion of the backside of the

decorative panels will need to be finished, as they will be

exposed when the doors are open.

D-style handles are recommended. For the cabinet door,

handles must be located near the edge of the panel

opposite the hinge, centered top to bottom. Locate

handles in the top center area of the drawer panels.

Illustrations on the following pages show typical applications of frameless and framed cabinetry. Also refer to the

full-scale illustration at the end of this section for specifics

on door openings.

Panel Requirements

TALL AND DRAWER MODELS MAX WEIGHT

686 mm Door Panel 18 kg

686 mm Drawer Panel 5 kg

914 mm Door Panel 24 kg

914 mm Drawer Panel 7 kg

PANEL THICKNESS MINIMUM

All Panels 16 mm

When 19 mm or thicker panels are used with a reveal of

less than 6 mm, door panels may cause damage to the

unit when the door is opened to the maximum 105°.

Use the built-in 90° door stop.

Page 48

Integrated Refrigeration 48

Cabinetry Applications

The illustrations below show typical applications of framed

and frameless cabinetry. Refer to the full-scale templates

at the end of this section for specifics on door openings.

CABINET

DOOR

3 mm

REVEAL FINISHED

INTEGRATED

UNIT

PANEL

OPENING

CABINET

DOOR

3 mm

REVEAL FINISHED

Framed—full overlay. Framed—standard overlay.

CABINET

DOOR

3 mm

REVEAL

UNIT

PAN E L

FINISHED

OPENING

CABINET

DOOR

3 mm

REVEAL

INTEGRATED

UNIT

PAN E L

OPENING

INTEGRATED

UNIT

PAN E L

FINISHED

OPENING

Dual Installations

Two integrated units may be placed side by side in a dual

installation. Depending on the models specified, opening

widths will be 1372 mm, 1600 mm or 1829 mm. Panel

width dimensions will vary slightly from single installations.

Refer to the chart below for typical panel dimensions. The

dimensions are based on a 3 mm reveal. A reveal of up to

6 mm is possible with adjustments to panel dimensions.

Typical Panel Dimensions

686 mm MODELS W H

Door 681 mm 1153 mm

Top Drawer 681 mm 345 mm

Bottom Drawer 681 mm 424 mm

914 mm MODELS W H

Door 910 mm 1153 mm

Top Drawer 910 mm 345 mm

Bottom Drawer 910 mm 424 mm

A dual installation kit is required for installations with 51

mm or less space between the units. Dual installation kits

are avail able through your authorized Sub-Zero dealer.

IMPORTANT NOTE: If a 686 mm unit is installed next to a

914 mm tall unit, the decorative front panels will align,

however, the face frames will not. This is only apparent

when both doors are open at the same time. Due to a

more robust hinge on 914 mm units, the face frame was

reconfigured to maintain a consistent overall panel height.

Refer to the illustration below.

Framed—beaded inset. Frameless cabinetry.

Face frame alignment.

Page 49

Integrated Refrigeration 49

subzero.com/specs

Accessories

These optional accessories are avail able through your

authorized Sub-Zero dealer. For local dealer information,

visit the find a showroom section of our website,

subzero.com.

• Stainless steel front panels with handles.

• Tubular and pro handles to match the style of Wolf

ovens and ranges.

• Crisper drawer with shelf assembly, deli drawer with

shelf and crisper cover with lid for certain models.

• Dual installation kit.

• Harness kit for Star-K compliance.

STANDARD HANDLES

Refer to the chart below for standard handle lengths

and the stud spacing of tubular and pro handles used on

integrated models.

Standard Handles Length Stud Spacing

DOOR

Tubular Handle 1046 mm 845 mm

Pro Handle 1006 mm 973 mm

686 mm MODEL DRAWERS

Tubular Handle 614 mm 413 mm

Pro Handle 533 mm 500 mm

914 mm MODEL DRAWERS

Tubular Handle 843 mm 641 mm

Pro Handle 762 mm 730 mm

Page 50

Integrated Refrigeration 50

INTEGRATED

DOOR

Maximum Door Opening

FULL-SCALE TEMPLATE

If the panel is thicker than 19 mm, use the built-in 90°

door stop to prevent damage to the panel and face frame

at the maximum door opening.

LINE OF INTERFERENCE

MAXIMUM 105° OPENING

MAXIMUM 105° OPENING

105° OPENING

TOP VIEW—1/4 SCALE

LINE OF

INTERFERENCE

3 mm MINIMUM REVEAL

FRAMED PANEL

19 mm

MOUNTING BRACKET

INTEGRATED DOOR CLOSED

LINE OF INTERFERENCE

SIDE MOLDING AND

INSTALLATION HARDWARE

DOOR CLOSED

TOP VIEW—FULL-SCALE

25 mm0 mm

SCALE

Page 51

Wine Storage 51

subzero.com/specs

Wine Storage. Wine finds a well-deserved place of honor in a Sub-Zero wine storage unit. Every detail is designed to

ensure better wine preservation. Cherrywood-faced shelves, soft lighting, custom cabinetry if desired—Sub-Zero helps

make a wine collection an element of beauty in the home.

WINE STORAGE MODELS

6

86 mm

6

86 mm

762 mm

2032

mm

ICB427G ICB427RG ICBWS-30

864

m

606 mm

m

868

mm

616 mm

ICB424G ICB424FSG

KEY FEATURES

• Integrated, overlay, flush inset and stainless steel

design options.

• Full-view glass door standard on all models.

• Freestanding model ICB424FSG does not require

panels or surrounding cabinetry.

• Discreet interior lighting with illuminated display shelf.

2032

mm

2134

mm

• Two independent storage zones maintain temperature,

humidity and UV protection.

• Cherrywood shelf fronts display the wine beautifully.

• Rust-proof metal shelves accommodate 750 ml

bottles, half-bottles and magnums.

Page 52

Wine Storage 52

Overall Dimensions

UNDERCOUNTER WINE STORAGE

606 mm 610 mm

864

mm

1

02 mm

MODEL ICB424G

645

mm

60 mm

Overall dimensions are based on stainless steel panels

and handles.

Page 53

Wine Storage 53

subzero.com/specs

Overall Dimensions

FULL-SIZE WINE STORAGE

686 mm

356 mm

HEIGHT DIMENSIONS ± 13 mm

21

mm

227

mm

1995

mm

2032

mm

OPENING

HEIGHT

102

mm

610 mm

686 mm

10

mm

337

13

mm

mm

260

mm

518

mm

HEIGHT DIMENSIONS ± 13 mm

356 mm

21

mm

876

mm

1995

mm

2032

mm

OPENING

HEIGHT

248

mm

102

mm

610 mm

610

mm

117

mm

DIMENSIONS WILL VARY WITH PANEL THICKNESS

648

mm

610

mm

495

mm

DIMENSIONS WILL VARY WITH PANEL THICKNESS

MODEL ICB427G MODEL ICB427RG

WITH REFRIGERATOR DRAWERS

Overall dimensions do not include panels or handles.

117

mm

648

mm

Page 54

Wine Storage 54

Overall Dimensions

FULL-SIZE WINE STORAGE

762 mm

HEIGHT DIMENSIONS ± 13 mm

1873

mm

2134

mm

102 mm

610 mm

606 mm

Capacity and Weight

Storage Capacity Bottles (750 ml) R (L)

ICB424G 46

ICB427G 132

ICB427RG 78 150

ICBWS-30 147

Shipping Weight kg

ICB424G 88

ICB424FSG 100

ICB427G 179

ICB427RG 186

ICBWS-30 202

606

mm

432

mm

796

mm

60 mm

MODEL ICBWS-30

Overall dimensions are based on the stainless steel model.

For flush inset applications, add 13 mm to door clearance

dimensions.

Page 55

Wine Storage 55

subzero.com/specs

Opening Dimensions

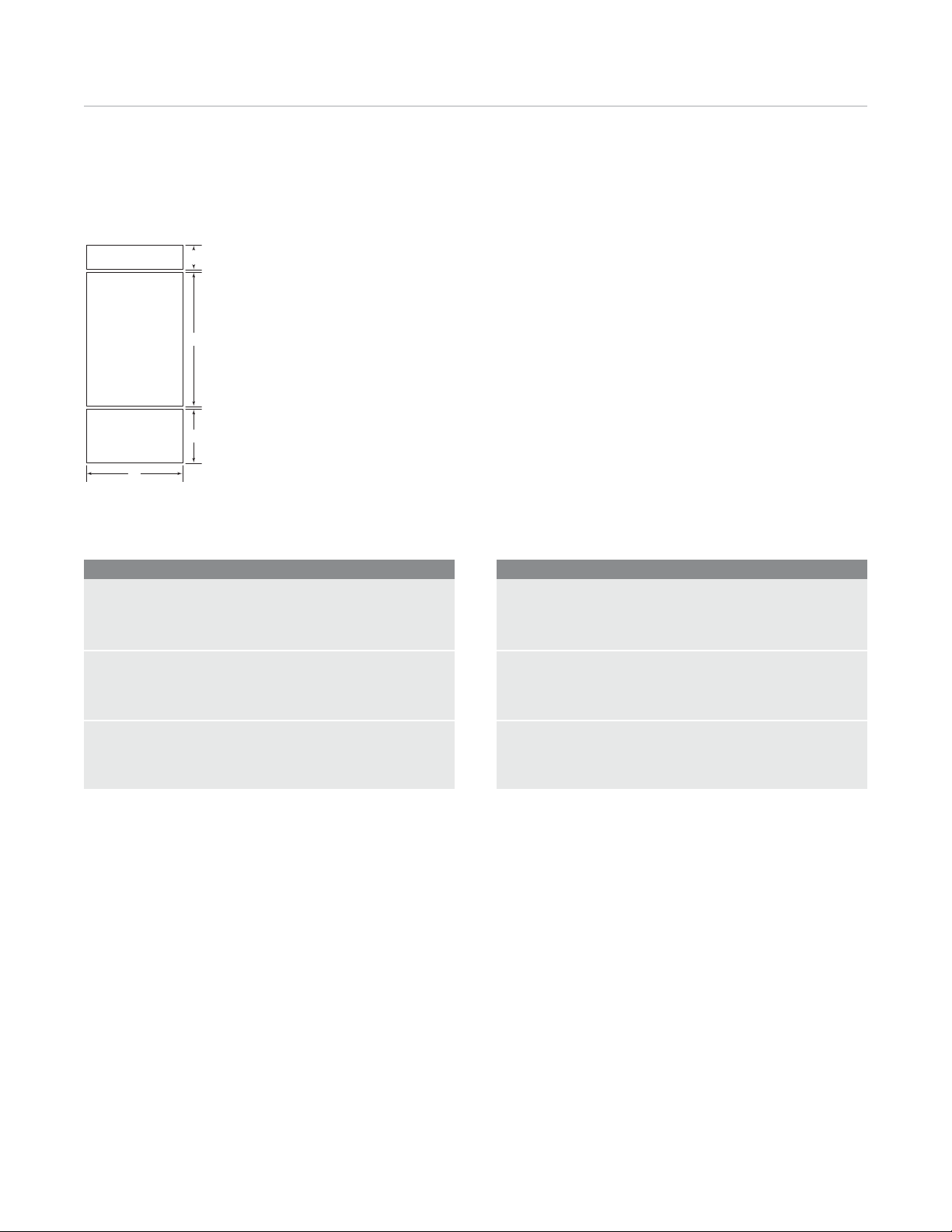

UNDERCOUNTER WINE STORAGE

610 mm

OPENING

DEPTH

610 mm

OPENING DEPTH

MODEL ICB424G

876 mm

OPENING

HEIGHT

TOP VIEW

610 mm

OPENING WIDTH

FRONT VIEWSIDE VIEW

FULL-SIZE WINE STORAGE

635 mm

OPENING

DEPTH

635 mm

OPENING DEPTH

2032 mm

OPENING

HEIGHT

TOP VIEW

686 mm

OPENING WIDTH

FRONT VIEWSIDE VIEW

MODELS ICB427G AND ICB427RG

IMPORTANT NOTE: The depth of each integrated model is

610 mm from the front of the unit to its back. Your design may

necessitate moving the unit back or cabinets forward to

achieve a flush fit. This will require a minimum rough opening

depth of 635 mm.

Page 56

Wine Storage 56

Opening Dimensions

FULL-SIZE WINE STORAGE

610 mm

OPENING

DEPTH

610 mm

OPENING DEPTH

2127 mm

OPENING

HEIGHT

TOP VIEW

746 mm

OPENING WIDTH

Planning Information

All wine storage models must be installed so that the door

can open a minimum of 90° or you will have problems

pulling the wine shelves out. For corner installations, you

need to allow for a minimum 76 mm filler so the door can

open to 90°. If you are using larger-handle hardware, you

will also need to take that into account. Refer to door

clearance specifications.

For a maximum 90° door opening, use the door stop built

into the hinge system of model ICB427G. A 90° door stop

is shipped with model ICBWS-30.

If you will be connecting the unit to a home security

system, you must allow a minimum of 914 mm of the

system’s wiring to be routed in the electrical area designated for your model.

MODEL ICBWS-30

FRONT VIEWSIDE VIEW

Page 57

Wine Storage 57

subzero.com/specs

Planning Information

DUAL INSTALLATIONS

If you are installing a wine storage unit next to an existing

Sub-Zero unit, you may have to allow for a filler strip.

If you are installing a model ICB427G or ICB427RG next to

an existing integrated unit, with 51 mm or less between

the units, an optional heater kit will need to be installed to

prevent moisture from forming between the units. These

optional heater kits are avail able through your authorized

Sub-Zero dealer. For local dealer information, visit the find

a showroom section of our website, subzero.com.

ELECTRICAL REQUIREMENTS

International models from the factory designed without a

transformer require a 220-240 V AC, 50/60 Hz electrical

supply, fused at the correct rating for the unit. If required

by local or national codes, the power cord can be easily

replaced using the power inlet device.

The electrical supply should be located within the shaded

area shown in the illustration for your specific model.

Follow local codes and ordinances when installing the

receptacle. A separate circuit, servicing only this appliance, is required. A ground fault circuit interrupter (GFCI)

is not recommended and may cause interruption of operation.

Electrical Requirements

Power Supply 220-240 V AC, 50/60 Hz

Circuit Breaker 10 amp

Receptacle 3-prong grounding-type

FRONT VIEW

178

E

mm

152

mm

1918 mm

FROM

FLOOR

Model ICBWS-30.

POSITION OUTLET WITH

GROUNDING PRONG

TO THE RIGHT

51 mm

394 mm

E

FRONT VIEW

76 mm

64 mm

mm

6

330 mm

E

FLOOR

FRONT VIEW

Model ICB424G. Models ICB427G and

ICB427RG.

114

mm

Page 58

Wine Storage 58

Door Panels

Unless you are installing a stainless steel model, you will

need to provide a frame for the glass door. If you order a

stainless steel unit, models ICB424G, ICB424FSG and

ICBWS-30 will be shipped with their panels and hardware

installed. For models ICB427G and ICB427RG, optional

stainless steel panels or custom panels will need to be

installed.

The glass door is designed to be exposed to room air circulation. Decorative overlays on the glass should be kept

to a minimum. Also, rails and stiles can be increased in

size but should not exceed the cabinet manufacturers’

standard width and cannot exceed the overall door panel

dimensions listed in the charts.

The back sides of rails and stiles that will be visible

through the glass door will need to be finished. Also, the

inside edges of the frames must be finished to match the

front surface.

FREESTANDING MODEL ICB424FSG

Model ICB424FSG does not require any panels or surrounding cabinetry. It has a beautiful stainless steel

exterior that is designed to be used in a freestanding

application.

Overlay Panels

MODEL ICB424G

The overlay panel applied to model ICB424G should not

be confused with the built-in overlay panel application.

The overlay panel will consist of just a frame and would be

either the 16 mm or 19 mm thick panel you may be using.

It is affixed directly to the door itself with screws through a

series of predrilled holes in the door frame. A backer and

spacer panel is not required.

Model ICB424G can be installed flush with surrounding

cabinetry. Depending on the thickness of the overlay door

panel, it may be necessary to install the unit so that it

extends 6 mm beyond the front surface of surrounding

cabinetry. This will prevent interference between the door

panel and adjoining cabinetry at the maximum 145° door

swing. Refer to the full-scale template at the end of this

section.

Overlay Panels

PANEL DIMENSIONS W H

ICB424G 603 mm 764 mm

MIN WIDTH

Stiles and Rails 57 mm

MAX PANEL WEIGHT

Door Frame 5 kg

MIN PANEL THICKNESS

All Panels 16 mm

Page 59

Wine Storage 59

subzero.com/specs

Integrated Panels

MODELS ICB427G AND ICB427RG

The integrated full panels or frame panels for glass doors

for these models will follow some of the identical planning

processes used with the integrated line. The installation of

the door panels is completely different, however. Rather

than using the mounting hardware we used with the integrated line, door panels for both models ICB427G and

ICB427RG will be applied with screws applied through our

door.

The drawer panels for the model ICB427RG will be applied

using the integrated technique of mounting brackets.

IMPORTANT NOTE: The depth of models ICB427G and

ICB427RG is 610 mm from the front of the unit to its back.

You must allow for the thickness of the panel you are

applying when planning for the finished rough opening

depth if you want the front panel to be flush with surrounding cabinetry. You may have to move the unit back

into the drywall or bring the cabinets forward. Refer to the

integrated section.

Panel dimensions listed in the chart assume the models

finish off at 2032 mm in height overall and have a 102 mm

toe kick for the model ICB427G. If you finish off at 2134

mm, for instance, you must add an additional 102 mm to

the finished height of the panel and 102 mm to the top rail.

Likewise, if you allow for a 152 mm toe kick for the model

ICB427G, you must subtract 51 mm from the bottom rail.

The height of the door panel for models ICB427G and

ICB427RG can extend beyond the typical panel height,

provided you do not exceed the panel weight limit. Refer

to specifications on page 46 of the integrated section.

The toe kick area on model ICB427G cannot be larger

than 152 mm, and on model ICB427RG, no larger than

229 mm. The toe kick area for either model cannot be less

than 102 mm.

If you are installing an optional lock kit on models

ICB427G or ICB427RG, you may have to order door

panels that exceed the 2032 mm finished height. Consult

the lock kit installation instructions and see if your panels

will allow for an adequate installation. These instructions

are available on our website, subzero.com.

Integrated Panels

ICB427G W H

Door 679 mm 1927 mm

ICB427RG W H

Door 679 mm 1153 mm

Top Drawer 679 mm 345 mm

Bottom Drawer 679 mm 424 mm

Panel Requirements

MIN WIDTH

Stiles 57 mm

Top Rail 95 mm

Bottom Rail (ICB427G) 203 mm

Bottom Rail (ICB427RG) 76 mm

MAX PANEL WEIGHT

Door Frame 9 kg

Drawer Panel (ICB427RG) 5 kg

MIN PANEL THICKNESS

All Panels 16 mm

Page 60

Wine Storage 60

Model ICBWS-30

OVERLAY PANEL

Overlay model ICBWS-30 can be used in an overlay or

flush inset application. The specific application will affect

panel sizes, opening dimensions and the installation.

Overlay model ICBWS-30 will be shipped without handle

hardware and with an overlay panel grille as standard

equipment. Along with the door panel, you will need to

provide a panel for the grille and hardware to complement

your surrounding cabinetry.

The overlay design allows the decorative panel to cover

the door trim for a more seamless appearance. The most

common way to achieve this look is to work with three

panels—the decorative overlay panel, which is typically

19 mm, a 3 mm spacer panel and a 6 mm backer panel.

Depending on your cabinet manufacturer, this could be

one panel routed for different dimensions. The illustrations

below will give you a better idea of the panel construction

and how it interacts with our frame. The size of the overlay

panel is critical, it must fit over the door frame.

IMPORTANT NOTE: Do not cover the glass door with a

solid panel. The window cut-out edges of the overlay,

spacer and backer panels will need to be finished, as they

will be exposed.

OVERLAY PANEL SPECIFICATIONS

H

A

AA

H

A

W

ICBWS-30 Overlay

DOOR W H

Overlay Panel 762 mm 1772 mm

Spacer Panel 740 mm 1751 mm

Backer Panel 756 mm 1767 mm

GRILLE WH

Overlay Panel 762 mm 235 mm

Spacer Panel 740 mm 211 mm

Backer Panel 756 mm 227 mm

WINDOW W H

Cut-Out 597 mm 1607 mm

A

Location 83 mm

Overlay Panel Requirements

MODEL ICBWS-30

Max Panel Weight 34 kg

Min Panel Thickness 16 mm

SPACER PANEL

OVERLAY PANEL

BACKER PANEL

DOOR FRAME

3 mm

TRIM

8 mm min

GLASS

OVERLAY

PANEL

19

mm

typical

3

mm

6

mm

SPACER

PA NE L

BACKER

PA NE L

Panel assembly cross section. Panel assembly rear view.

Grille panel dimensions listed are for a standard 2134 mm

overall height of the unit. For a 2108 mm overall height,

subtract 25 mm from grille panel height dimensions. For a

2235 mm overall height, add 102 mm to height dimensions.

Width dimensions do not vary.

Do not exceed overlay panel dimensions, as this could

cause damage to panels and the Sub-Zero unit.

Page 61

Wine Storage 61

subzero.com/specs

Model ICBWS-30

FLUSH INSET PANEL

Overlay model ICBWS-30 used in a flush inset application

allows the decorative panel to cover the door trim for a

seamless appearance. The most common way to achieve