Page 1

BUILT-IN REFRIGERATION

INSTALLATION INSTRUCTIONS

INSTRUCCIONES DE INSTALACIÓN

INSTRUCTIONS D’INSTALLATION

ISTRUZIONI PER L’INSTALLAZIONE

INSTALLATIONSANWEISUNGEN

Page 2

E

NGLISH

E

SPAÑOL

F

RANÇAIS

Installation Recommendations 3

Installation Specifications 4

Installation Instructions 7

Overlay Panel Installation 10

Flush Inset Panel Installation 13

Side Panel Installation 15

C

ompleting the Installation 16

Service Information 17

Features and specifications indicated herein and on

the website are subject to change at any time without

notice. Check our website, subzero.com, for the most

up-to-date specifications.

ITALIANO

Consigli per l’installazione 48

Specifiche per l’installazione 49

Istruzioni per l’installazione 52

Installazione dei pannelli a sovrapposizione 55

Installazione dei pannelli con inserto a filo 58

Installazione dei pannelli laterali 60

Completamento dell’installazione 61

Informazioni sul servizio di assistenza 62

Recomendaciones de instalación 18

E

specificaciones de la instalación 19

Instrucciones de instalación 22

I

nstalación del panel revestible 25

I

nstalación del panel empotrable 28

Instalación del panel lateral 30

Finalización de la instalación 31

Información de mantenimiento 32

Las características y especificaciones que se indican

en esta guía y en la página web están sujetas a

cambios sin previo aviso. Visite nuestra página web,

www.subzero.com, para obtener las especificaciones

más actualizadas.

DEUTSCH

Empfehlungen zur Installation 63

Technische Daten zur Installation 64

Installationsanweisungen 67

Installation von Verkleidungsplatten 70

Installation bündiger/voll integrierter Platten 73

Installation von Seitenplatten 75

Abschluss der Installation 76

Serviceinformationen 77

Recommandations d’installation 33

S

pécifications d’installation 34

Instructions d’installation 37

P

ose des panneaux d’habillage 40

P

ose des panneaux d’affleurement 43

Pose des panneaux de côté 45

Pour terminer l’installation 46

Service après-vente 47

Les caractéristiques et spécifications indiquées dans

ce guide ainsi que sur le site Internet peuvent être

modifiées sans préavis. Pour prendre connaissance

des spécifications les plus récentes, consultez notre

site Internet, subzero.com.

Le funzioni e le caratteristiche indicate in questo

manuale e sul sito Web sono soggette a modifica in

qualsiasi momento senza preavviso. Consultare il sito

Web subzero.com per le specifiche più aggiornate in

merito.

2

Die hier und auf der Website beschriebenen

Leistungsmerkmale und technischen Daten unterliegen jederzeit Änderungen ohne Vorankündigung.

Die aktuellsten technischen Daten finden Sie auf

unserer Website subzero.com.

Page 3

SUB-ZERO B UI LT-I N R EF RIGERATION

BUILT-I N INS TAL LAT IO N

The importance of the installation of the

S

ub-Zero Built-In unit cannot be overemphasized. Installation should be done by a qualified

installer.

Before you begin the installation process, it is

recommended that you read this entire Installat

ion Instructions book. There are key details that

you should take special care to observe during

t

he installation. By reading these instructions

carefully, you will make the installation process

easier, problem-free and, most importantly, safe.

Any questions or problems about the installation

should be directed to your Sub-Zero dealer. You

can also visit our website at

subzero.com

.

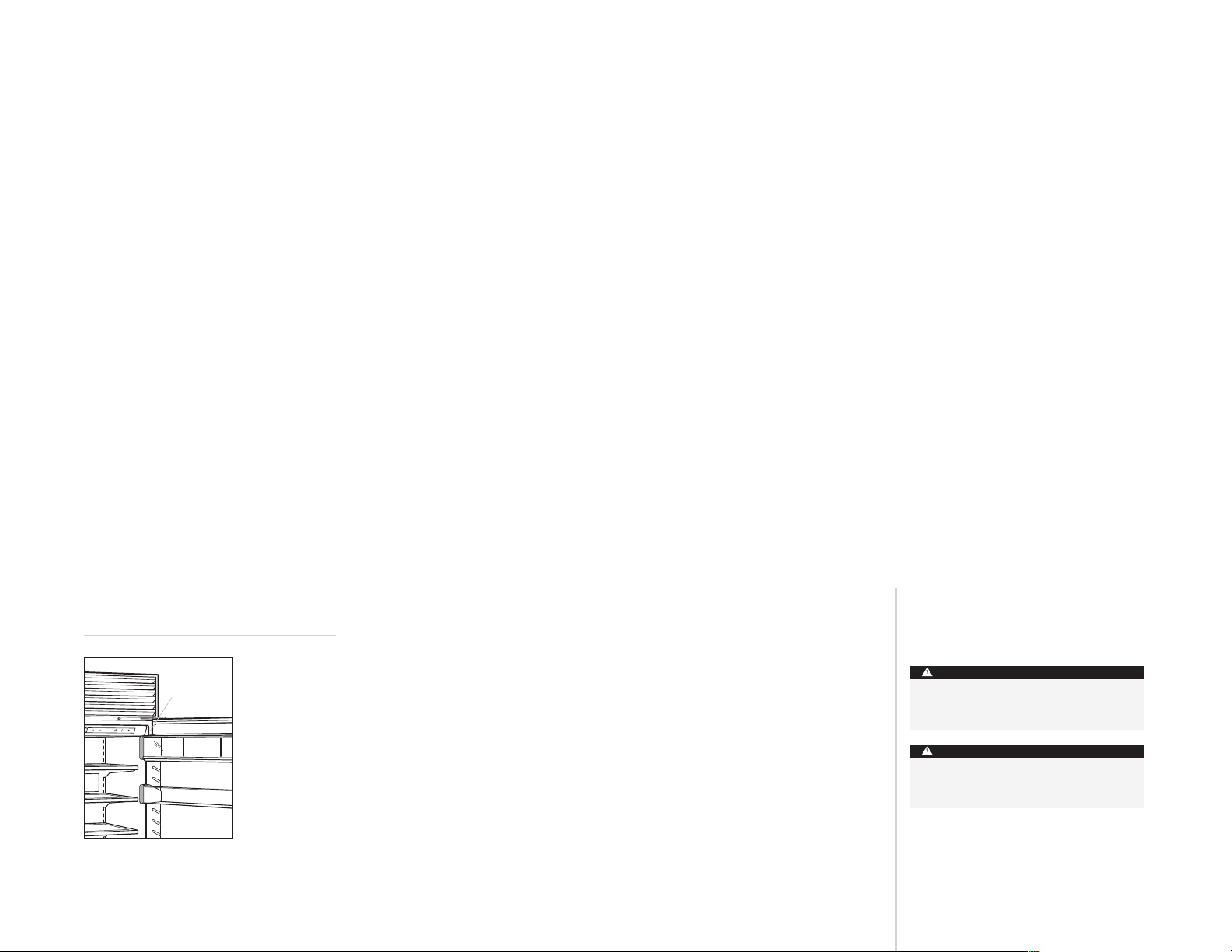

Important product information, including the

model and serial number of your unit are listed

on the product rating plate. The rating plate is

located at the top frame of the unit inside the

door. Refer to the illustration below.

Location of

rating plate

TOOLS AND MA TERIALS REQUIRED

T

he following is a list of tools and materials that

should be available for proper installation.

• Phillips screwdriver set

• Slotted screwdriver set

• Torx drive screwdriver set

• 1.2 m of 6,35 copper tubing and saddle valve

for the water line (4200880)—do not use selfpiercing valves

• Copper tubing cutter

• Level—.6 m and 1.2 m recommended

• Appliance Dolly able to support 317 kg and

adequate manpower to handle the weight of

the unit

• Various sized pliers

• Wrench set

• Allen wrench set

• 8 mm hex bolt nut driver

• Crescent wrenches

• Cordless drill and assorted drill bits

• Masonite, plywood, 3,2 mm pressed fiber-

board, cardboard or other suitable material to

protect finished flooring

• Appropriate materials to cover and protect

the home and its furnishings during installation

Make sure that the actual equipment that was

s

hipped to you matches the design you are

expecting to install. The Sub-Zero Built-In line

offers the following design alternatives—

overlay/flush inset and stainless steel models.

The overlay/flush inset model has two design

applications—overlay and flush inset.

Each of these design options has specific install

ation requirements, which means it is vital that

the unit match your planning and space needs.

Before you begin the installation process, check

the exact model number you need against the

model number on the shipping carton.

If the unit you receive does not match your

requirements, contact your Sub-Zero dealer.

SITE P RE PA RA TI ON

Make sure that the finished rough opening

where the Built-In unit is to be installed is

properly prepared. Refer to the Overall Dimensions and Installation Specifications for your

specific model on the following pages. These

specifications are identical for the overlay/flush

inset and stainless steel applications. The installation specifications are different for the flush

inset application, whether you are using custom

panels or Sub-Zero accessory stainless flush

inset panels. Make sure that the rough opening

dimensions, door swing clearance, electrical

service and plumbing are correct for the model

you are about to install.

If you are installing two Built-In units side by

side in the overlay/flush inset or stainless steel

application, a separating filler strip is recommended. Add the filler strip width to the finished

rough opening dimension. Complete the installation with the Anchoring Kit (7004656). Refer to

page 16.

For installation of two Built-In units side by side

i

n the flush inset application, a dual installation

kit will be necessary. Refer to page 15.

IMPORTANT NOTE:

Built-in units installed side

by side in the flush inset application cannot use

Sub-Zero accessory stainless flush inset panels,

a

nd must have opposing hinges.

IMPORTANT NOTE:

d

oor must open a minimum of 90°. Use a

To operate properly, the

minimum 76 mm filler in corner installations to

assure a 90° door opening. Allow enough clearance in front of the unit for full door swing.

IMPORTANT NOTE:

Make sure the floor under

the unit is level with the surrounding finished

floor.

As you read these Installation Instructions, take

particular note of the CAUTION and WARNING

symbols when they appear. This information is

important for the safe and efficient installation

of Sub-Zero equipment.

CAUTION

signals a situation where minor injury or

product damage may occur if you do not

follow instructions.

Rating plate location

SUB-ZERO®is a registered trademark of Sub-Zero, Inc.

WARNING

states a hazard that may cause serious

injury or death if precautions are not

followed.

In addition, these Installation Instructions may

signal an IMPORTANT NOTE which highlights

information that is especially relevant to a

problem-free installation.

Page 4

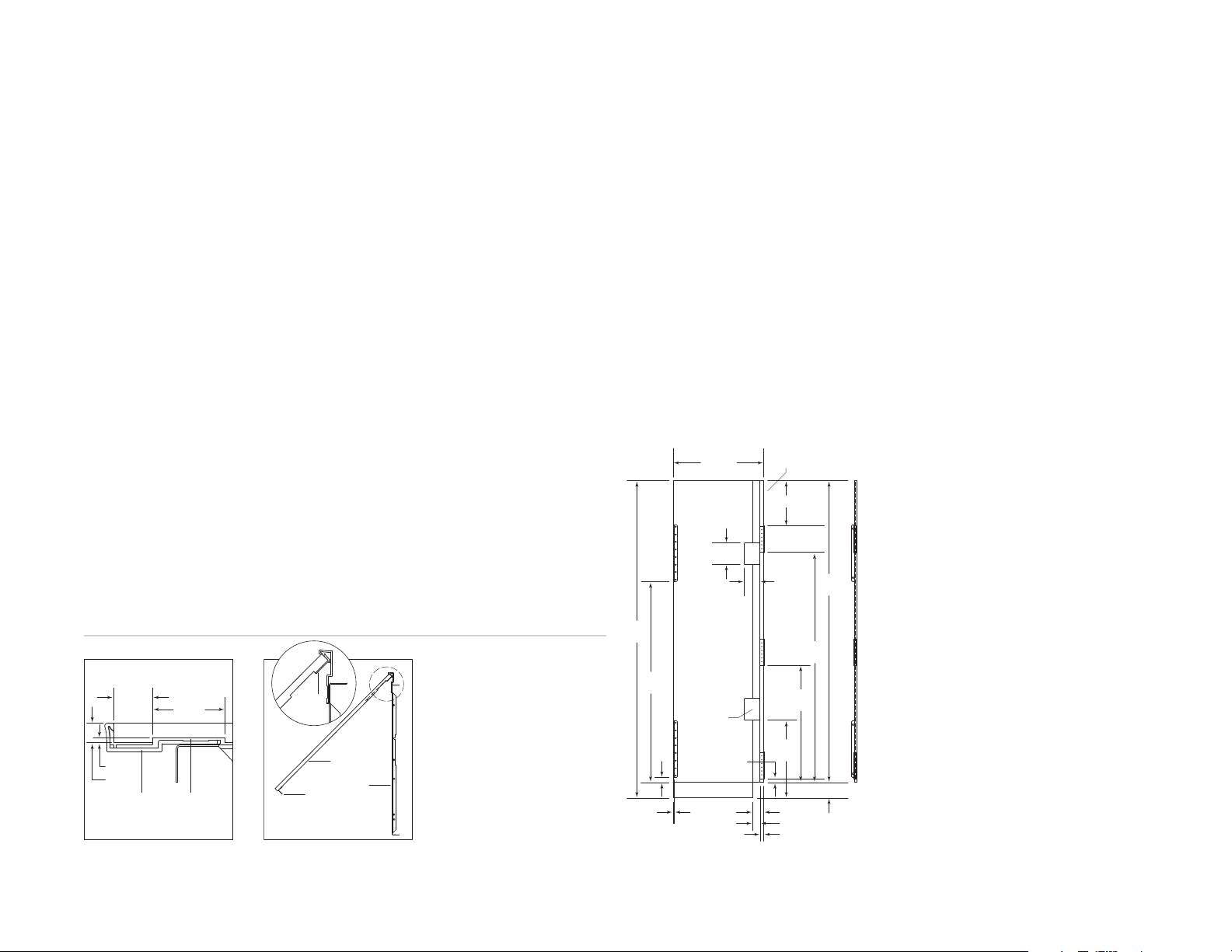

BUILT-I N INS TAL LAT IO N SPECIFI CAT IO NS

606 mm

BEHIND

FRAME

WIDTH

OF UNIT

A

914 mm

2134

mm

914 mm

2134

mm

610 mm

914 mm

2134

mm

610 mm

1

918 mm

178

mm

1

52

mm

E

LOCATE

ELECTRICAL

WITHIN

SHADED AREA

457 mm

W

LOCATEWATER SUPPLY

WITHIN SHADED AREA

1

52

mm

FRONT VIEWSIDE VIEW

2127 mm

OPENING

HEIGHT

A

OPENING WIDTH

7

6 mm

610 mm

OPENING

DEPTH

13 mm

4

57 mm

*

152

mm

610 mm

OPENING

DEPTH

SHUT-OFF

VALVE

OUTLINE OF

OVERLAY

OR STAINLESS

STEEL MODEL

T

OP VIEW

*ANTI-TIP

BRACKET MUST NOT

INTERFERE

WITH WATER LINE.

R

EFER TO INSTALLATION

INSTRUCTIONS FOR COMPLETE

DETAILS.

EXTEND WATER LINE APPROX

914 mm FROM BACK WALL.

WATER LINE

1918 mm

178

mm

152

mm

E

LOCATE

ELECTRICAL

WITHIN

SHADED AREA

13 mm

457 mm

*

152

mm

610 mm

OPENING

DEPTH

665 mm

FLUSH INSET

DEPTH

SHUT-OFF

VALVE

OUTLINE

OF FLUSH INSET

APPLICATION WITH

19 mm PANEL

457 mm

W

LOCATEWATER SUPPLY

WITHIN SHADED AREA

152

mm

FRONT VIEWSIDE VIEW

TOP VIEW

2127 mm

OPENING

HEIGHT

2134

mm

FLUSH

INSET

HEIGHT

6 mm

56 mm**

76 mm

A

OPENING WIDTH

B

FLUSH INSET WIDTH

32

mm

32

mm

56

mm

**

610 mm

OPENING

DEPTH

665 mm

FLUSH INSET

DEPTH

*

ANTI-TIP BRACKET MUST NOT

INTERFERE

WITH WATER LINE.

REFER TO INSTALLATION

I

NSTRUCTIONS FOR COMPLETE

DETAILS.

**ASSUMES 19 mm PANEL

THICKNESS.

EXTEND WATER LINE APPROX

914 mm FROM BACK WALL.

WATER LINE

6

mm

32

mm

FLUSH INSET

DETAIL

56

mm

610 mm

OPENING

DEPTH

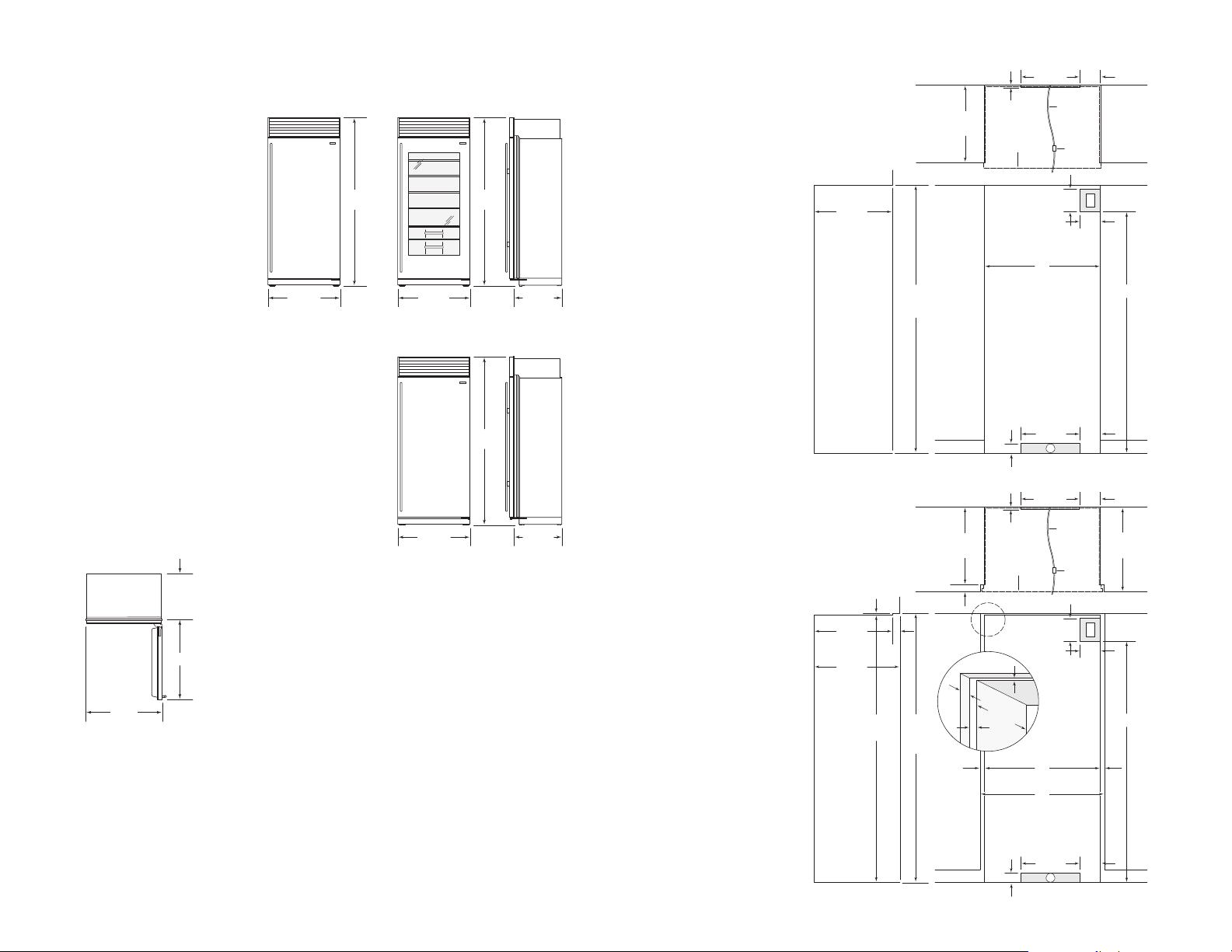

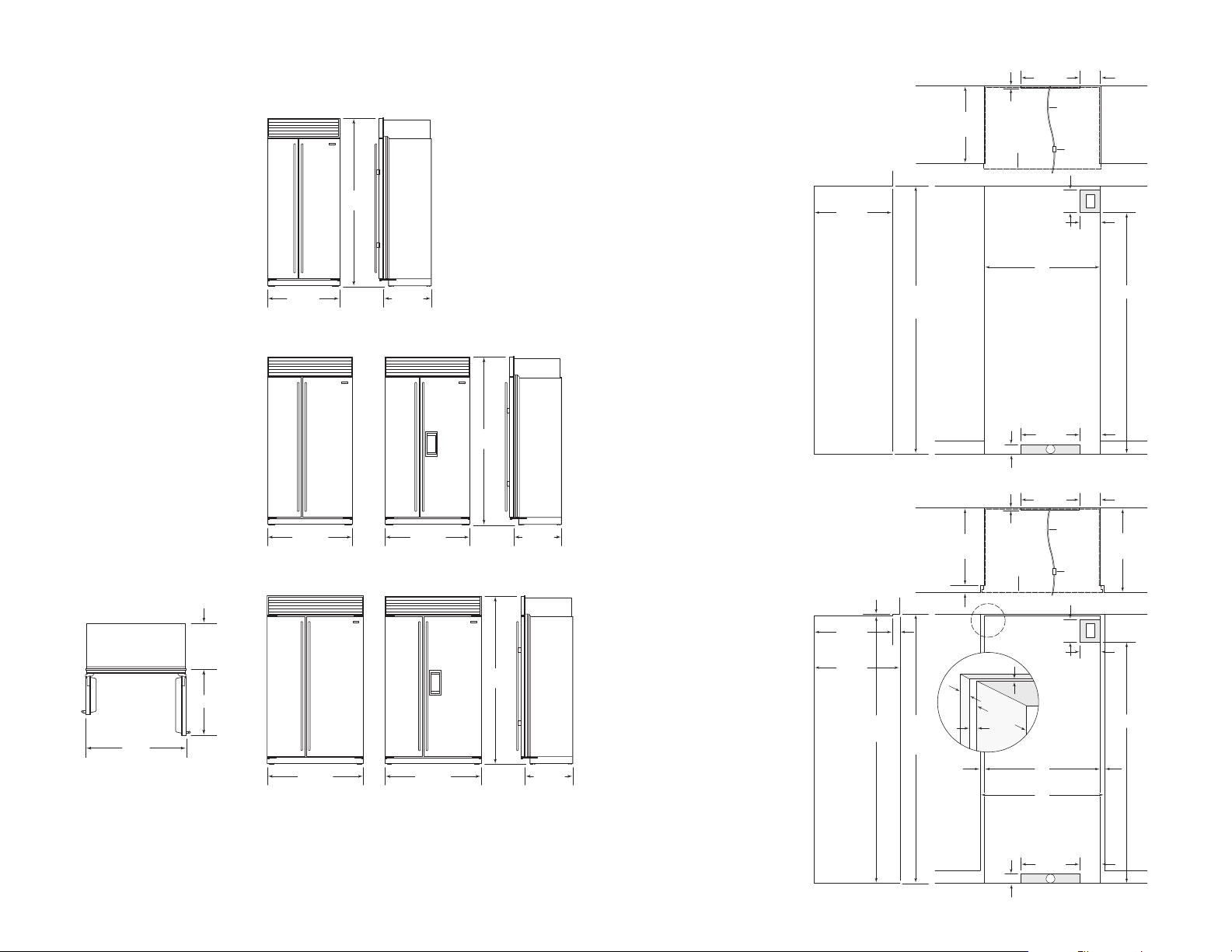

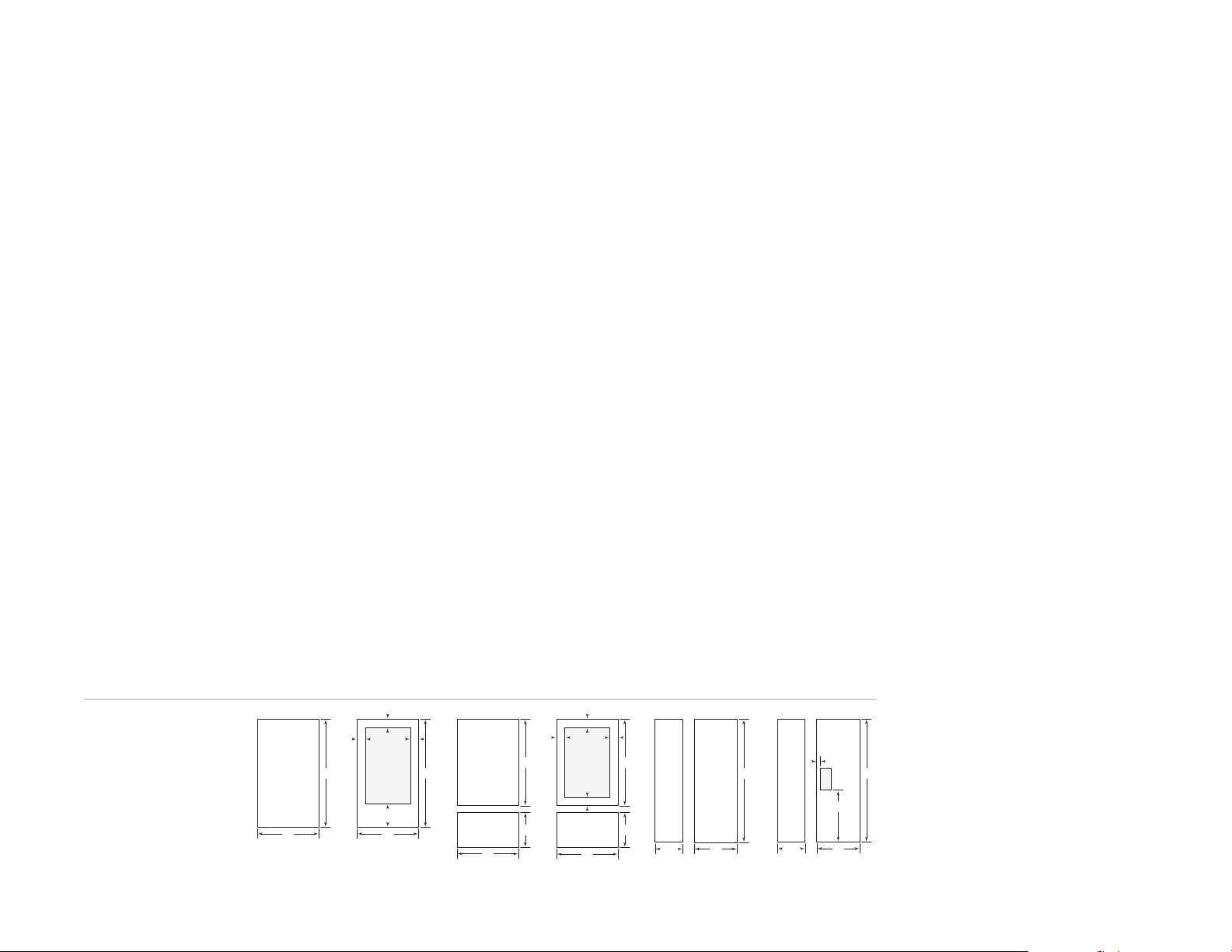

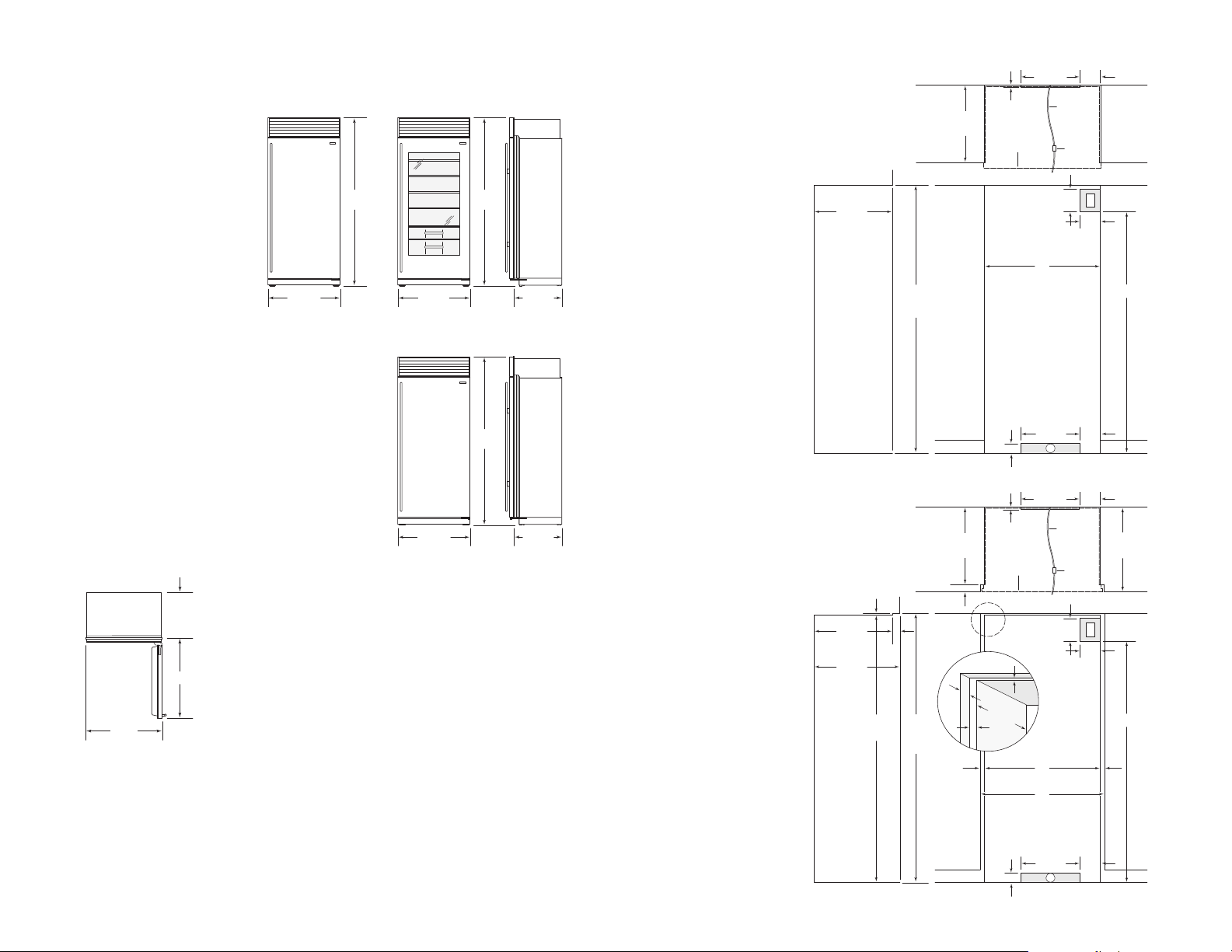

OV ER AL L D IM EN SI ON S

All Refrigerator / All Freezer Models

Model ICBBI-36R

All Refrigerator

WH D

914 mm 2138 mm 610 mm

Model ICBBI-36RG

ll Refrigerator with Glass Door

A

WH D

14 mm 2138 mm 610 mm

9

Model ICBBI-36F

All Freezer

WH D

914 mm 2138 mm 610 mm

Unit dimensions may vary by ± 3 mm.

DO OR C LE AR AN CE

All Refrigerator / All Freezer Models

A

Model ICBBI-36R 946 mm

Model ICBBI-36RG 946 mm

Model ICBBI-36F 946 mm

Door clearance is based on stainless

steel door and handle dimensions.

4

959 mm Flush Inset

959 mm Flush Inset

959 mm Flush Inset

odel ICBBI-36R Model ICBBI-36RG

M

Model ICBBI-36F

Stainless steel design shown.

IN ST AL LA TI ON S PECIFICATIONS

All Refrigerator / All Freezer Models—

Overlay (non-flush inset) and Stainless Steel

A

Model ICBBI-36R 902 mm

odel ICBBI-36RG 902 mm

M

odel ICBBI-36F 902 mm

M

Dimensions are for finished rough openings.

Models ICBBI-36R and ICBB I-36RG will not

equire the water line connection.

r

IN ST AL LA TI ON S PECIFICATIONS

All Refrigerator / All Freezer Models—

Flush Inset Application

Model ICBBI-36R 902 mm 965 mm

Model ICBBI-36RG 902 mm 965 mm

Model ICBBI-36F 902 mm 965 mm

Dimensions are for finished rough openings.

Models ICBBI-36R and ICBB I-36RG will not

require the water line connection.

AB

Page 5

BUILT-I N INS TAL LAT IO N SPECIFI CAT IO NS

606 mm

BEHIND

FRAME

WIDTH

OF UNIT

A

762 mm

2134

m

m

762 mm

2134

m

m

610 mm

914 mm

2134

mm

914 mm

2134

mm

610 mm

1918 mm

178

mm

152

mm

E

LOCATE

ELECTRICAL

WITHIN

SHADED AREA

457 mm

W

LOCATEWATER SUPPLY

WITHIN SHADED AREA

152

mm

FRONT VIEWSIDE VIEW

2127 mm

OPENING

HEIGHT

A

OPENING WIDTH

76 mm

610 mm

OPENING

DEPTH

1

3 mm

457 mm

*

152

m

m

610 mm

OPENING

DEPTH

SHUT-OFF

VALVE

OUTLINE OF

OVERLAY

OR STAINLESS

STEEL MODEL

TOP VIEW

*ANTI-TIP

BRACKET MUST NOT

INTERFERE

WITH WATER LINE.

REFER TO INSTALLATION

I

NSTRUCTIONS FOR COMPLETE

DETAILS.

EXTEND WATER LINE APPROX

914 mm FROM BACK WALL.

WATER LINE

1918 mm

178

mm

152

mm

E

LOCATE

ELECTRICAL

WITHIN

SHADED AREA

13 mm

457 mm

*

152

mm

610 mm

OPENING

DEPTH

665 mm

FLUSH INSET

D

EPTH

SHUT-OFF

VALVE

OUTLINE

OF FLUSH INSET

APPLICATION WITH

19 mm PANEL

457 mm

W

LOCATEWATER SUPPLY

WITHIN SHADED AREA

152

mm

FRONT VIEWSIDE VIEW

TOP VIEW

2127 mm

OPENING

HEIGHT

2134

mm

FLUSH

INSET

HEIGHT

6 mm

56 mm**

76 mm

A

OPENING WIDTH

B

FLUSH INSET WIDTH

32

mm

32

mm

56

mm

**

610 mm

OPENING

DEPTH

665 mm

FLUSH INSET

DEPTH

*ANTI-TIP

BRACKET MUST NOT

I

NTERFERE

W

ITH WATER LINE.

REFER TO INSTALLATION

INSTRUCTIONS FOR COMPLETE

D

ETAILS.

**ASSUMES 19 mm PANEL

THICKNESS.

EXTEND WATER LINE APPROX

914 mm FROM BACK WALL.

WATER LINE

6

mm

32

mm

FLUSH INSET

DETAIL

56

mm

610 mm

OPENING

DEPTH

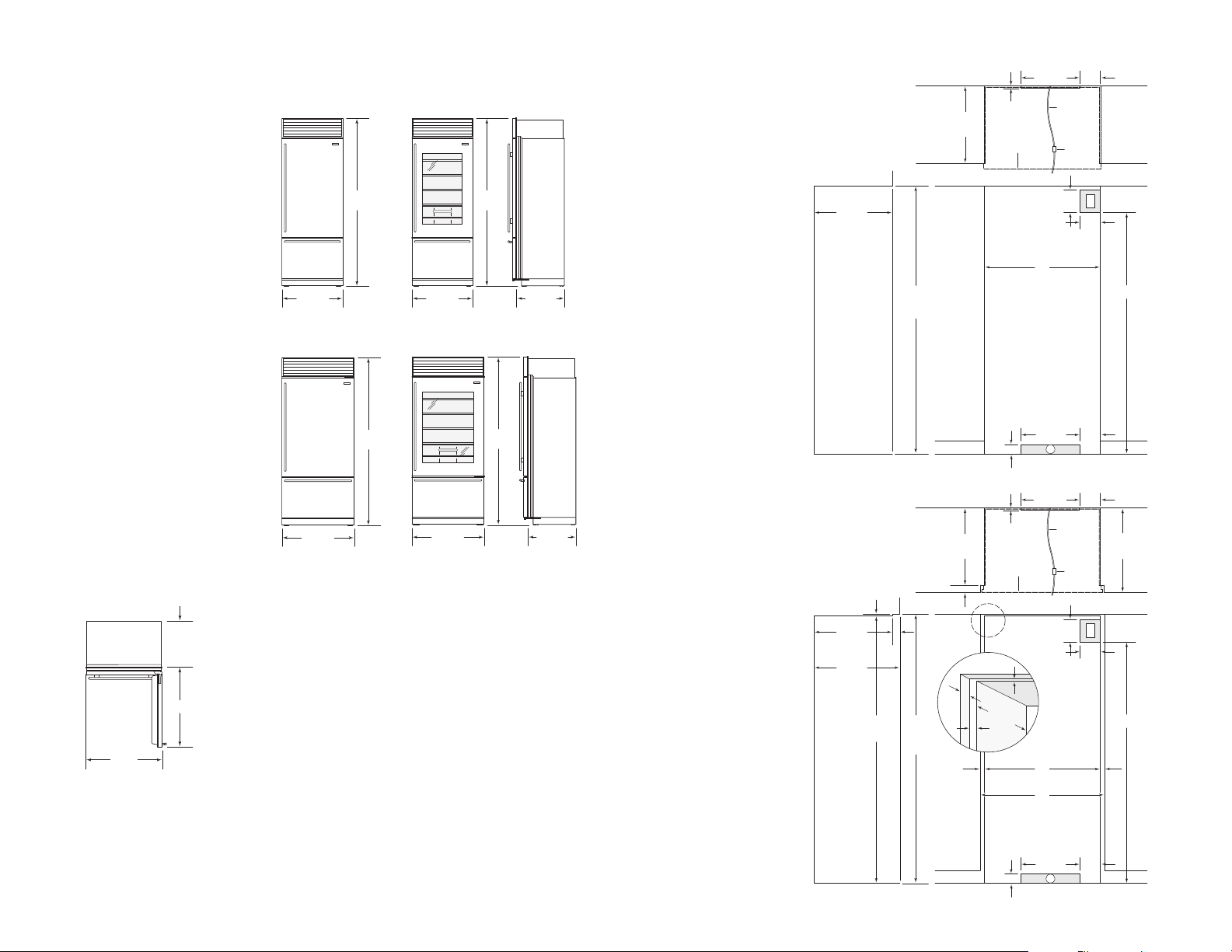

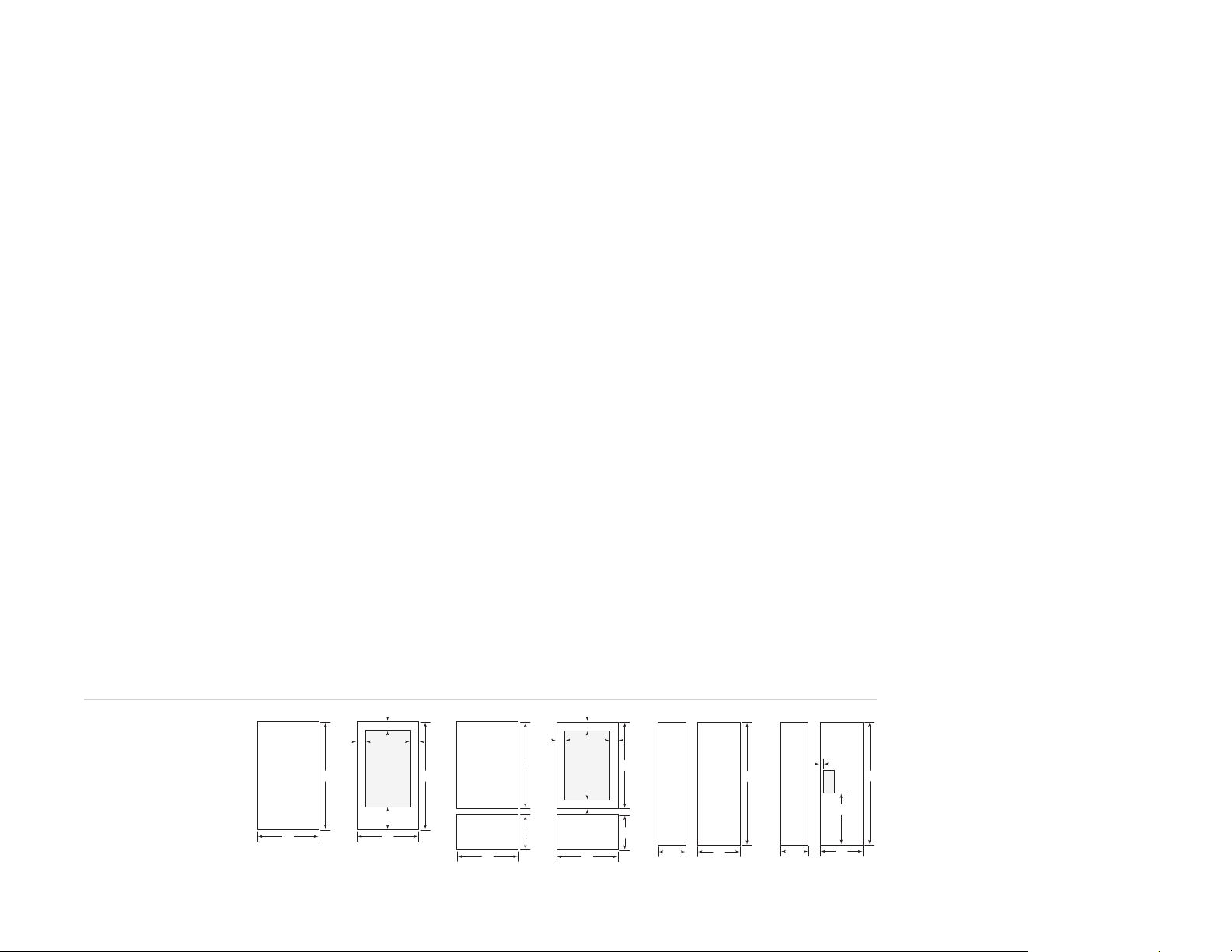

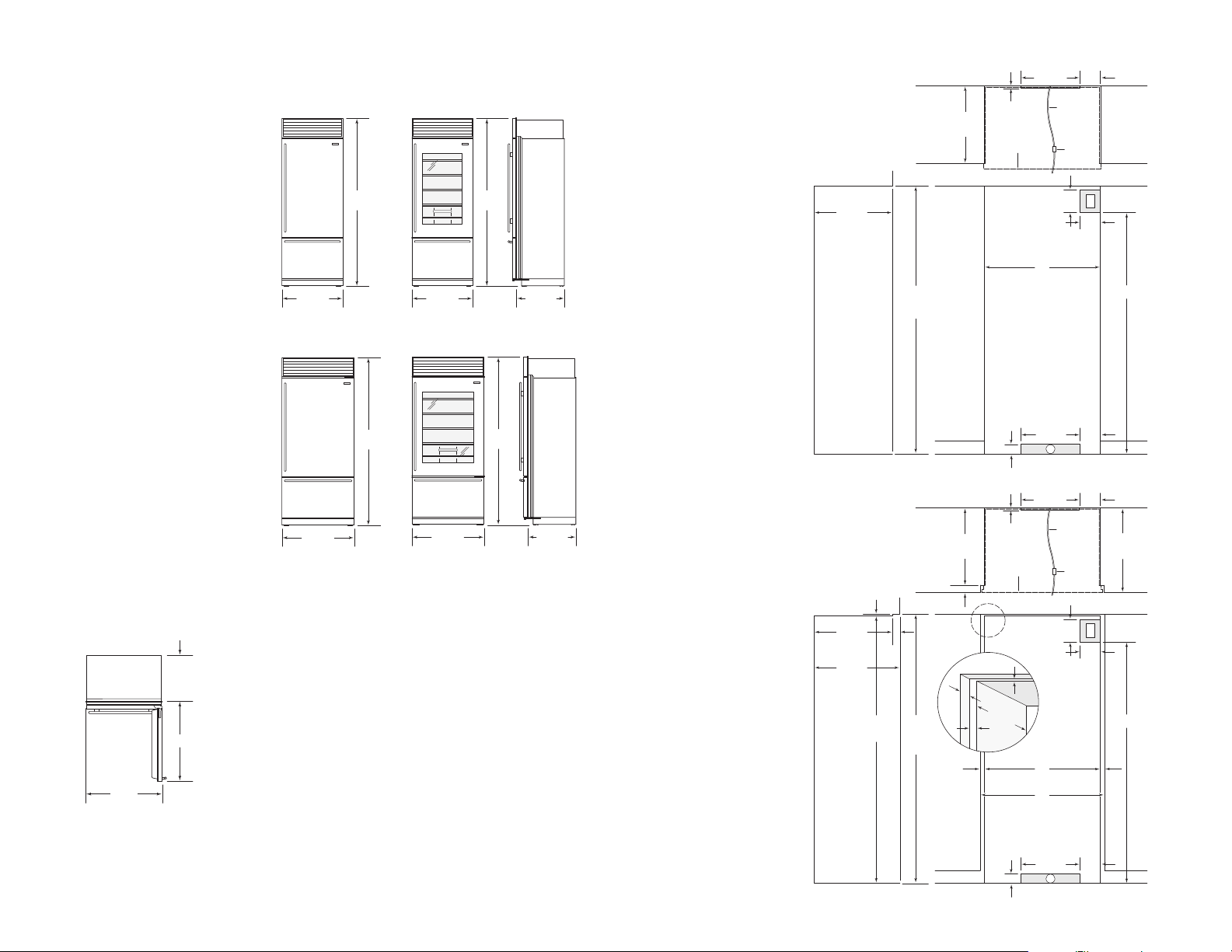

OV ER AL L D IM EN SI ON S

Over-and-Under Models

Model ICBBI-30U

WH D

762 mm 2138 mm 610 mm

Model ICBBI-30UG

with Glass Door

WH D

762 mm 2138 mm 610 mm

Model ICBBI-36U

WH D

914 mm 2138 mm 610 mm

Model ICBBI-36UG

W

with Glass Door

HD

914 mm 2138 mm 610 mm

nit dimensions may vary by ± 3 mm.

U

DO OR C LE AR AN CE

Over-and-Under Models

A

Model ICBBI-30U 794 mm

Model ICBBI-30UG 794 mm

Model ICBBI-36U 946 mm

Model ICBBI-36UG 946 mm

Door clearance is based on stainless

steel door and handle dimensions.

806 mm Flush Inset

806 mm Flush Inset

959 mm Flush Inset

959 mm Flush Inset

odel ICBBI-30U

M

Model ICBBI-36U

Stainless steel design shown.

odel ICBBI-30UG

M

Model ICBBI-36UG

IN ST AL LA TI ON S PECIFICATIONS

Over-and-Under Models —

Overlay (non-flush inset) and Stainless Steel

A

Model ICBBI-30U 749 mm

odel ICBBI-30UG 749 mm

M

odel ICBBI-36U 902 mm

M

Model ICBBI-36UG 902 mm

Dimensions are for finished rough openings.

IN ST AL LA TI ON S PECIFICATIONS

Over-and-Under Models —

Flush Inset Application

Model ICBBI-30U 749 mm 813 mm

Model ICBBI-30UG 749 mm 813 mm

Model ICBBI-36U 902 mm 965 mm

Model ICBBI-36UG 902 mm 965 mm

Dimensions are for finished rough openings.

AB

5

Page 6

BUILT-I N INS TAL LAT IO N SPECIFI CAT IO NS

9

14 mm

2134

mm

6

10 mm

1067 mm

1219 mm

1067 mm

2134

mm

610 mm

606 mm

BEHIND

FRAME

WIDTH

OF UNIT

A

1219 mm

2134

mm

610 mm

1918 mm

178

mm

152

mm

E

LOCATE

ELECTRICAL

WITHIN

SHADED AREA

457 mm

W

LOCATEWATER SUPPLY

WITHIN SHADED AREA

152

mm

FRONT VIEWSIDE VIEW

2127 mm

OPENING

HEIGHT

A

OPENING WIDTH

76 mm

610 mm

OPENING

DEPTH

1

3 mm

457 mm

*

152

m

m

610 mm

OPENING

DEPTH

SHUT-OFF

VALVE

OUTLINE OF

OVERLAY

OR STAINLESS

STEEL MODEL

TOP VIEW

*ANTI-TIP

BRACKET MUST NOT

INTERFERE

WITH WATER LINE.

REFER TO INSTALLATION

I

NSTRUCTIONS FOR COMPLETE

DETAILS.

EXTEND WATER LINE APPROX

914 mm FROM BACK WALL.

WATER LINE

1918 mm

178

mm

152

mm

E

LOCATE

ELECTRICAL

WITHIN

SHADED AREA

13 mm

457 mm

*

152

mm

610 mm

OPENING

DEPTH

665 mm

FLUSH INSET

D

EPTH

SHUT-OFF

VALVE

OUTLINE

OF FLUSH INSET

APPLICATION WITH

19 mm PANEL

457 mm

W

LOCATEWATER SUPPLY

WITHIN SHADED AREA

152

mm

FRONT VIEWSIDE VIEW

TOP VIEW

2127 mm

OPENING

HEIGHT

2134

mm

FLUSH

INSET

HEIGHT

6 mm

56 mm**

76 mm

A

OPENING WIDTH

B

FLUSH INSET WIDTH

32

mm

32

mm

56

mm

**

610 mm

OPENING

DEPTH

665 mm

FLUSH INSET

DEPTH

*ANTI-TIP

BRACKET MUST NOT

I

NTERFERE

W

ITH WATER LINE.

REFER TO INSTALLATION

INSTRUCTIONS FOR COMPLETE

D

ETAILS.

**ASSUMES 19 mm PANEL

THICKNESS.

EXTEND WATER LINE APPROX

914 mm FROM BACK WALL.

WATER LINE

6

mm

32

mm

FLUSH INSET

DETAIL

56

mm

610 mm

OPENING

DEPTH

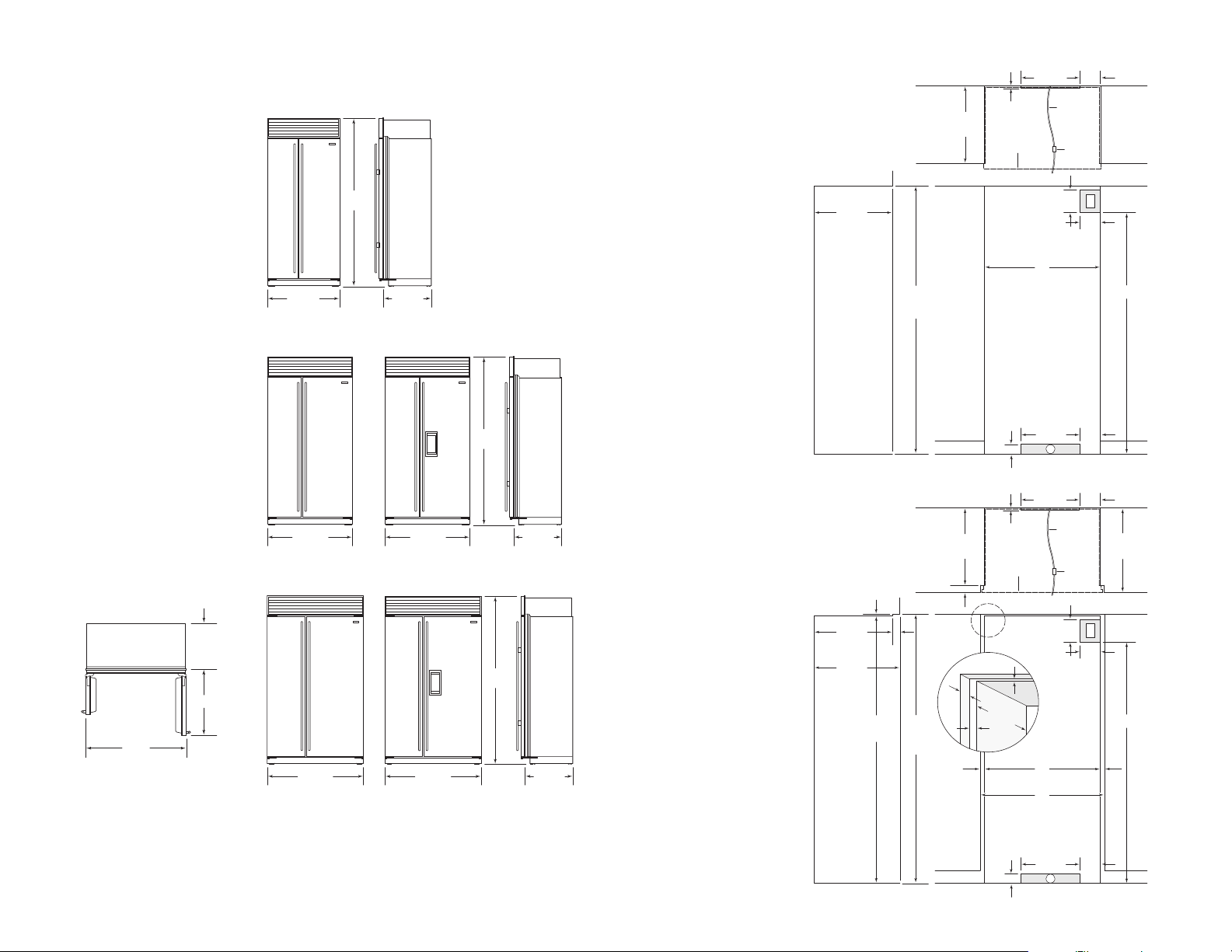

OV ER AL L D IM EN SI ON S

Side-by-Side Models

Model ICBBI-36S

WH D

914 mm 2138 mm 610 mm

Model ICBBI-42S

WH D

1067 mm 2138 mm 610 mm

Model ICBBI-42SD

with Dispenser

WH D

1067 mm 2138 mm 610 mm

Model ICBBI-48S

W

HD

1219 mm 2138 mm 610 mm

Model ICBBI-48SD

W

with Dispenser

HD

1219 mm 2138 mm 610 mm

Unit dimensions may vary by ± 3 mm.

DO OR C LE AR AN CE

Side-by-Side Models

A

Model ICBBI-36S 527 mm

Model ICBBI-42S 649 mm

Model ICBBI-42SD 649 mm

Model ICBBI-48S 743 mm

Model ICBBI-48SD 743 mm

Door clearance is based on stainless

steel door and handle dimensions.

6

odel ICBBI-36S

M

Model ICBBI-42S Model ICBBI-42SD

Model ICBBI-48S Model ICBBI-48SD

Stainless steel design shown.

IN ST AL LA TI ON S PECIFICATIONS

Side-by-Side Models —

Overlay (non-flush inset) and Stainless Steel

A

Model ICBBI-36S 902 mm

odel ICBBI-42S 1054 mm

M

odel ICBBI-42SD 1054 mm

M

Model ICBBI-48S 1207 mm

Model ICBBI-48SD 1207 mm

Dimensions are for finished rough openings.

IN ST AL LA TI ON S PECIFICATIONS

Side-by-Side Models —

Flush Inset Application

Model ICBBI-36S 902 mm 965 mm

Model ICBBI-42S 1054 mm 1118 mm

Model ICBBI-42SD 1054 mm 1118 mm

Model ICBBI-48S 1207 mm 270 mm

Model ICBBI-48SD 1207 mm 1270 mm

Dimensions are for finished rough openings.

AB

Page 7

BUILT-I N INS TAL LAT IO N INSTRUC TI ON S

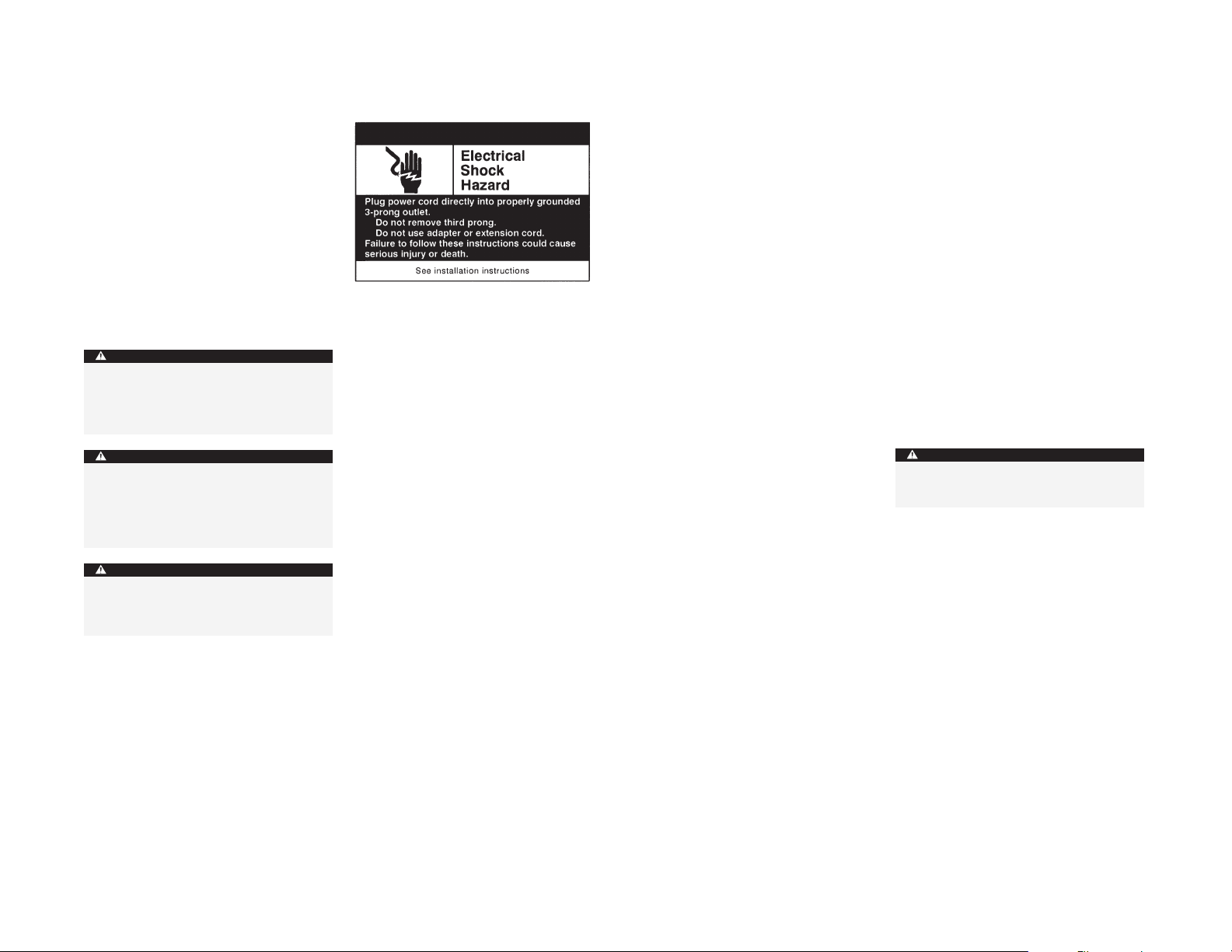

ELECTRICAL R EQ UI RE ME NTS

A 220-240 V AC, 50/60 Hz, 10 amp circuit breaker

a

nd electrical supply are required. A separate

circuit, servicing only this appliance, is required.

All Sub-Zero Built-In models are equipped with a

power supply cord with a 3-prong grounding

plug, which must be plugged into a mating

3

-prong grounding-type wall receptacle. Follow

local codes and ordinances when installing the

r

eceptacle. For location of the electrical supply,

refer to the Installation Specifications illustration

for your specific model on pages 4–6.

IMPORTANT NOTE:

A ground fault circuit

interrupter (GFCI) is not recommended and may

cause interruption of operation.

WARNING

Do not use an extension cord or two-prong

adapter. Electrical ground is required on this

appliance. Do not remove the power supply

cord ground prong.

CAUTION

The outlet must be checked by a qualified

electrician to be sure that it is wired with the

correct polarity. Verify that the outlet

provides 220-240 V AC and is properly

grounded.

WARNING

Always shut power off at the circuit breaker

before performing any installation, service or

maintenance.

IMPORTANT NOTE:

The Built-In line is

equipped with an appliance inlet type device.

This allows easy replacement of the power

cord. The appliance inlet is located on top of

the unit on the compressor shroud. When

replacing the power cord make sure that the

replacement cord is rated HO5VV-F3G1.0 or

equivalent to ensure safe operation of the

appliance.

PLUMBING R EQ UI RE ME NT S

IMPORTANT NOTE:

c

an be used, provided there is constant water

A reverse osmosis system

pressure of 2.1 bar to 6.9 bar supplied to the unit

at all times.

Rough in the cold water supply line using 6 mm

OD copper line. The water line should be routed

u

p through the floor within 13 mm from the back

wall and no higher than 76 mm off the floor. If

y

ou have to come through the wall, make sure

the water line is no more than 76 mm from the

floor.

Regardless of the routing, allow .9 m of excess

copper tubing to remain outside the wall or floor

for easy connection to the unit. Locate the water

supply line within the shaded area indicated in

the Installation Specifications illustration for

your specific model on pages 4–6.

Use an easily accessible shut-off valve between

the water supply and the unit. Do not use

self-piercing valves. A saddle valve kit (4200880)

is available from your Sub-Zero dealer.

It is not recommended that the ice maker be

connected to a softened water supply. Water

softener chemicals, such as salt from a malfunctioning softener, can damage the ice maker and

lead to poor ice quality. If a softened water

supply cannot be avoided, be sure that the water

softener is well maintained and operating

properly.

IMPORTANT NOTE:

All installations must meet

local plumbing code requirements.

IMPORTANT NOTE:

This appliance should be

connected to a potable water supply.

UNPACK THE UNIT

Uncrate the unit and inspect for any damages.

R

emove the wood base and discard the shipping

bolts and brackets that hold the wood base to

the bottom of the unit. Remove and discard all

packing materials.

IMPORTANT NOTE:

p

late, anti-tip bracket and hardware. These items

Do not discard the kick-

will be needed for installation.

R

etract the front leveling legs all the way up to

allow the unit to be moved into position more

easily. You will extend the leveling legs when the

unit is in its final position to reduce the possibility of the unit tipping forward.

IMPORTANT NOTE:

The rear levelers must be in

their lowest position in order to push the unit

back into the rough opening. Therefore, leveling

cannot be completed until the unit is in position.

Remove the drain pan from the base of the unit

to avoid damage to the drain pan, and allow for

proper placement of the appliance dolly.

WARNING

Be sure to secure the door(s) closed before

moving the unit.

7

Page 8

BUILT-I N INS TAL LAT IO N INSTRUC TI ON S

Back Grille

Screw

Front Grille Screw

102 mm

MIN

610 mm

13 mm

MIN

102 mm

MIN

610 mm

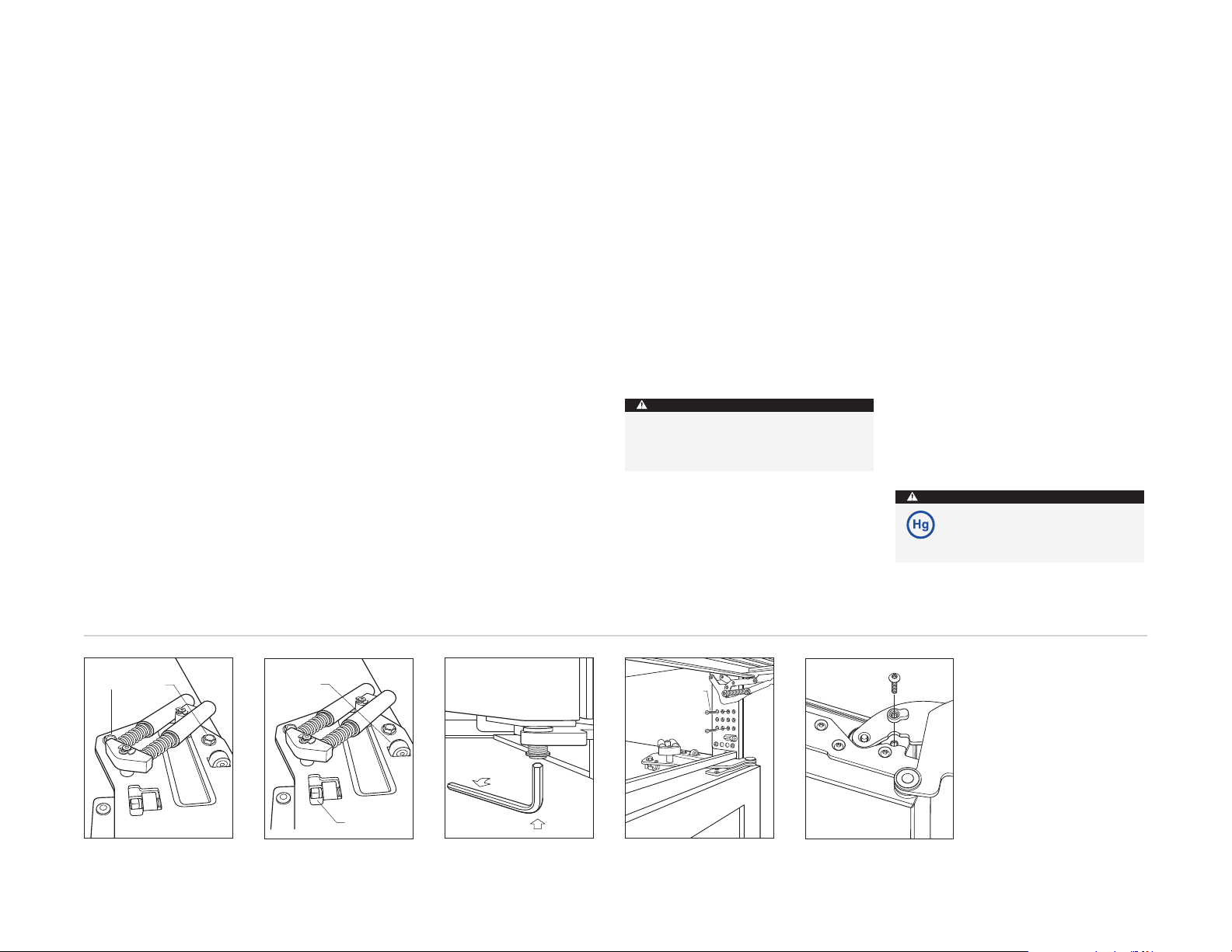

GRILLE R EM OVAL

In order to prevent damage to the grille and to

a

ccess the power cord, the top grille assembly

should be removed prior to moving the unit.

To remove the grille assembly, pull out on the

bottom edge of the grille and tilt it upward.

Loosen the back two grille mounting screws and

r

emove the front two grille mounting screws.

With the grille held firmly, pull forward to

r

emove. Refer to the illustrations below.

To reinstall the grille, insert the grille into

position and be sure that the grille catch tabs are

engaged. Reinstall the front two grille screws,

then retighten the back two grille screws. Check

for proper fit.

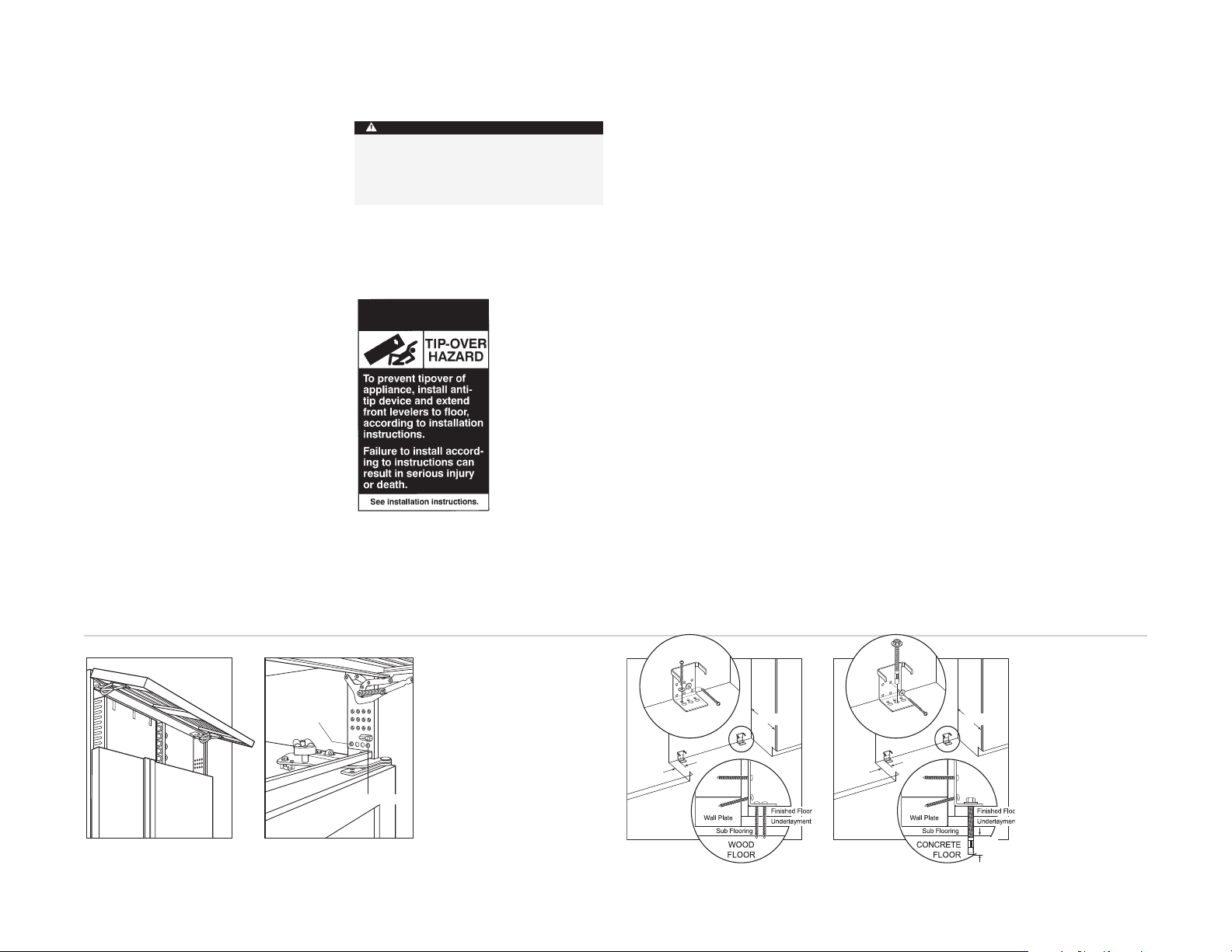

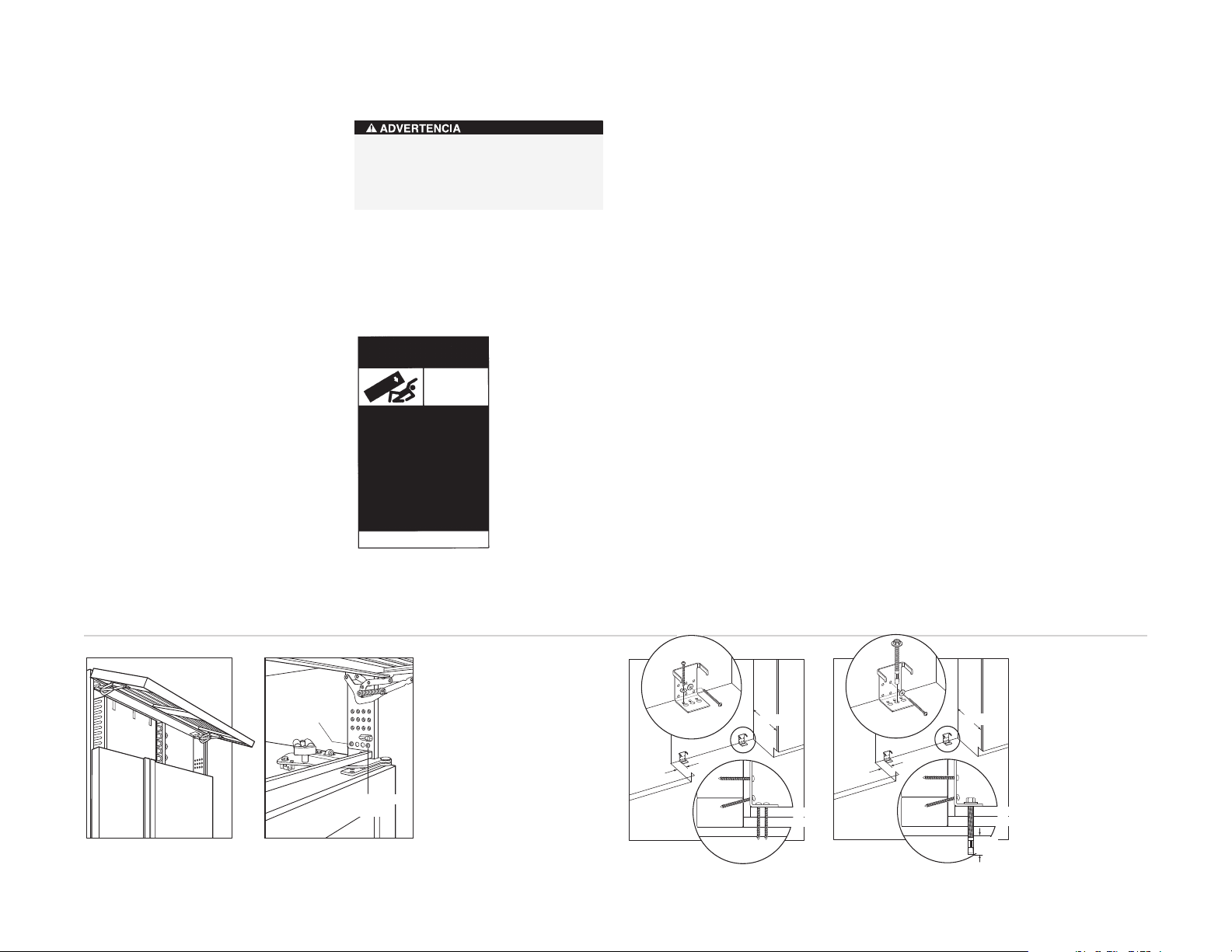

ANTI-TIP B RA CK ET

INSTALLATIO N

WARNING

To prevent the unit from tipping forward and

provide a stable installation, the unit must be

secured in place with the anti-tip brackets

shipped with the unit.

IMPORTANT NOTE:

Placement of the anti-tip

brackets is critical to a stable installation. Failure

to properly position the anti-tip brackets will

prevent them from engaging the unit.

The two anti-tip brackets must be installed

e

xactly 610 mm from the front of the rough

opening to the back of the brackets and a

minimum of 102 mm from the sides of the rough

opening. This depth will increase to 665 mm for

a flush inset installation based on 19 mm deep

decorative panels. Proper placement will ensure

that the anti-tip brackets engage the anti-tip bar

at the back of the unit.

IMPORTANT NOTE:

Both anti-tip brackets

MUST be used.

WOOD F LO OR A PP LI CA TI ON S

After properly locating the anti-tip brackets in the

rough opening, drill pilot holes 5 mm diameter

maximum in the wall studs and/or wall plate.

Use the #12 x 64 mm PH pan HD zinc screws and

#12 flat washers to secure the brackets in place.

Be sure that the screws penetrate through the

flooring material and into wall studs or wall plate

a minimum of 19 mm. Refer to the illustration

below.

CONCRETE F LO OR A PP LI CA TI ON S

A

fter properly locating the anti-tip brackets in the

rough opening, drill pilot holes 5 mm diameter

m

aximum in the wall studs and/or wall plate.

Then drill 10 mm diameter holes into the

concrete a minimum of 13 mm deep. Use the

#12 x 64 mm PH pan HD zinc screws and #12 flat

washers to secure the brackets to the wall and

u

se the 10 mm–16 x 95 mm wedge anchors to

secure the brackets to the floor. Be sure that the

screws penetrate the wall studs or wall plate a

minimum of 19 mm. Refer to the illustration

below.

IMPORTANT NOTE:

For either wood or concrete

floor applications, if the #12 x 64 mm screws do

not hit a wall stud or the wall plate in any of the

back holes of the brackets, use the provided

#8–18 x 32 mm PH truss HD screws and #12 flat

washers with the nylon zip-it wall anchors.

IMPORTANT NOTE:

In some installations the

subflooring or finished floor may necessitate

angling the screws used to fasten the anti-tip

brackets to the back wall.

Grille removal

8

Grille mounting screws

Wood floors

Concrete floors

AC CE SS OR IES

Optional accessories are available

through your

Sub-Zero dealer. To

obtain local dealer

information, visit

our website,

subzero.com.

Page 9

BUILT-I N INS TAL LAT IO N INSTRUC TI ON S

ANTI-TIP B RA CK ET

INSTALLATIO N

WARNING

Make sure that there are no electrical wires

or plumbing in the area which the screws

could penetrate.

ANTI-TIP H AR DW AR E IN CL UD ED

2 Anti-Tip Brackets

12 #12 x 64 mm PH Pan HD Zinc Screws

4 10 mm–16 x 95 mm Wedge Anchors

12 #12 Flat Washers

4 #8–18 x 32 mm PH Truss HD Screws

4 Nylon Zip-It Wall Anchors

INSTALL CONCRETE W ED GE A NC HO RS

1)

Drill a 10 mm diameter hole any depth

exceeding the minimum embedment. Clean

the hole or continue drilling additional depth

t

o accommodate drill fines. Use a carbide drill

bit.

2)

Assemble the washer and nut flush with the

end of anchor to protect threads. Drive the

anchor through the material to be fastened

until the washer is flush with the surface

material.

3)

Expand the anchor by tightening the nut

3–5 turns past hand-tight position or to 34

newton meters of torque.

CAUTION

Always wear safety glasses and use other

necessary protective devices or apparel when

installing or working with anchors.

Anchors are not recommended for use in

lightweight masonry material such as block

or brick, or for use in new concrete which has

not had sufficient time to cure. The use of

core drills is not recommended to drill holes

for the anchors.

POSITION T HE U NI T

CAUTION

Protect any finished flooring before moving

the unit into place. All Built-In models are

equipped with rollers, so you can easily

move the unit into place.

Use an appliance dolly to move the unit near the

rough opening. Carefully move it off of the appliance dolly. Each Built-In unit is equipped with

rollers, so it can be moved into position more

easily.

Shut off power to the electrical outlet. Plug the

power supply cord into the 15 amp grounded

outlet and roll the unit into position. Be sure that

the anti-tip bracket is properly engaged.

IMPORTANT NOTE:

If possible, keep the door(s)

closed until the unit is properly anchored.

IMPORTANT NOTE:

If for any reason the unit

has been laid on its back or side, you must allow

the unit to stand upright for a minimum of 24

hours before connecting power.

WARNING

To reduce the possibility of the unit tipping

forward, the front leveling legs must be in

contact with the floor.

WAT ER LI NE CONNECTION

Approximately .9 m of 6,35 mm plastic tubing is

c

onnected to the unit with a preassembled 6,35

mm compression connection at the end. This

tubing is located under the unit.

The water line fitting connection kit, provided

with the unit, contains a 6,35 mm compression

u

nion fitting for connection to the household

water line. Place the compression nut and sleeve

o

n the water line and fasten to the connection at

the end of the tubing under the unit. Do not over

tighten. Check all water line fittings for leaks.

Make sure that the drain pan can be installed or

removed without any water line interference.

IMPORTANT NOTE:

Be sure to purge the water

line prior to final connection to the unit. This will

remove any debris that may be present in the

tubing from installing the new water line.

IMPORTANT NOTE:

Let your customer know

that the ice maker will not produce ice immediately, and that the first few batches of ice

produced should be discarded. Allow 24 hours

for proper ice production.

IMPORTANT NOTE:

Caution must be taken not

to expose the refrigerator, and/or water lines

leading to the refrigerator, to freezing temperatures. Failure to do so could cause damage to

the product and home.

IMPORTANT NOTE:

This appliance should be

connected to a potable water supply.

9

Page 10

Door/Drawer/

Grille Trim

2 mm

3 mm

6 mm Backer Panel

8 mm min

3

mm

Spacer Panel

Overlay Panel

Spacer Panel

Overlay Panel

6 mm

Backer

Panel

3 mm

~19

mm

REAR

ADJUSTMENT

FRONT

LEVELING LEG

BUILT-I N INS TAL LAT IO N INSTRUC TI ON S

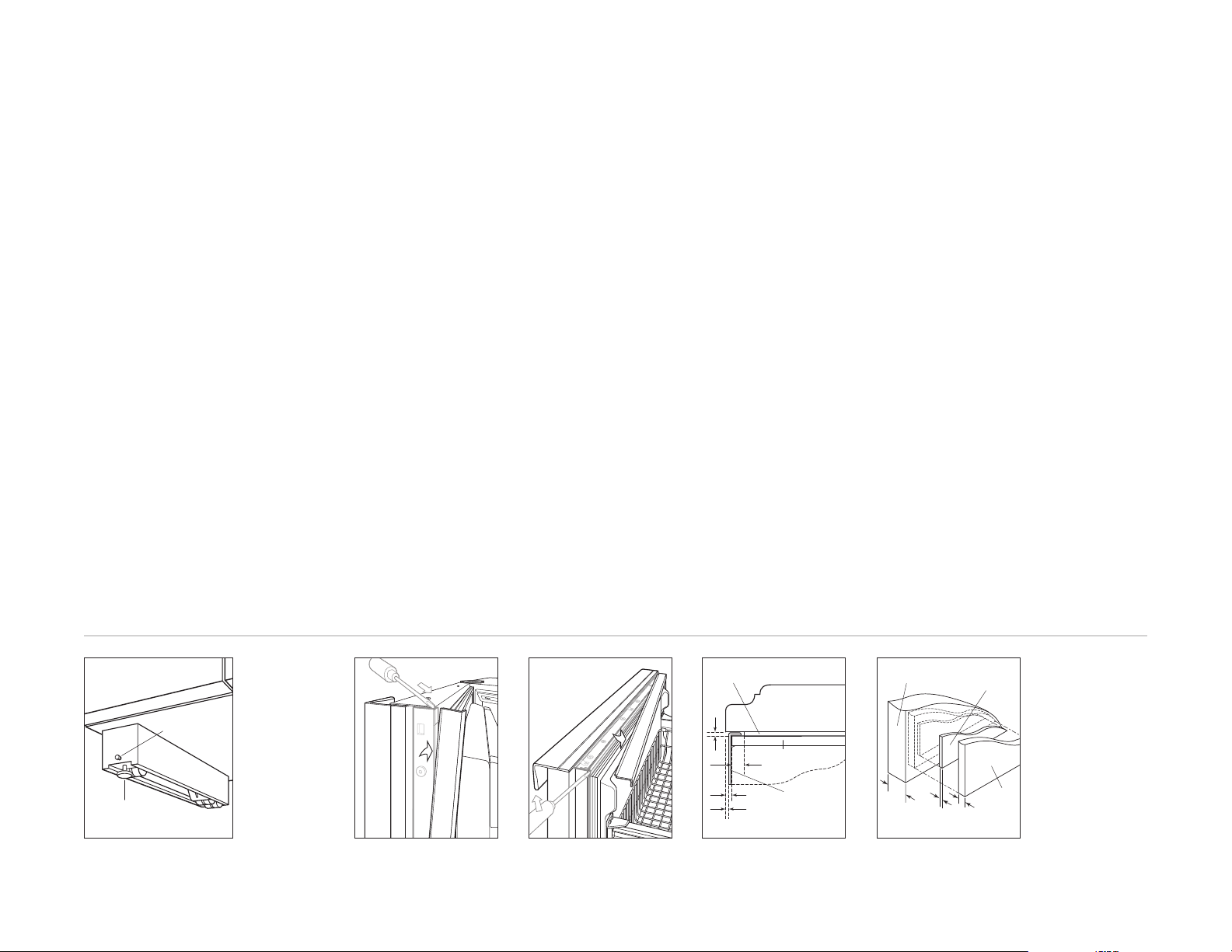

OVERLAY PA NEL I NS TAL LAT ION

LEVEL THE UN IT

Once the unit is in position, extend the front

l

eveling legs down by turning the legs clockwise

and adjust the height. The rear height adjustment can be made from the front of the base.

Use a 8 mm socket to adjust the rear rollers. Turn

the 8 mm hex bolt clockwise to raise the unit or

counterclockwise to lower it.

When the unit is leveled properly, or squared off,

d

oor and/or drawer adjustments are less likely to

be necessary. Refer to the illustration below for

location of the rear roller base adjustment.

IMPORTANT NOTE:

Be sure to reference

leveling of the unit to the floor and not to

surrounding cabinetry. This could affect the

operation of the unit, such as door closing.

INSTALL T HE K IC KP LAT E

To install, screw the kickplate to brackets

attached to the inside surface of each roller base.

IMPORTANT NOTE:

The kickplate must be

removed for servicing. The floor cannot interfere

with removal. Refer to the label mounted on the

kickplate support for height clearance.

Reinstall the grille following the instructions on

page 8. Turn power back on to the electrical

outlet.

OVERLAY PA NELS

If your customer has chosen an overlay design

a

pplication, make sure that the panels you are

about to install match dimensions listed in the

Overlay Panel Specifications on page 12.

IMPORTANT NOTE:

The overlay panel must fit

over the door frame. The weight of each panel

a

ssembly cannot exceed 23 kg, 34 kg for Models

ICBBI-36R, ICBBI-36RG and ICBBI-36F.

O

verlay models are shipped without handle

hardware. The cabinet manufacturer or designer

will need to provide handle hardware to match

the overall decorating scheme.

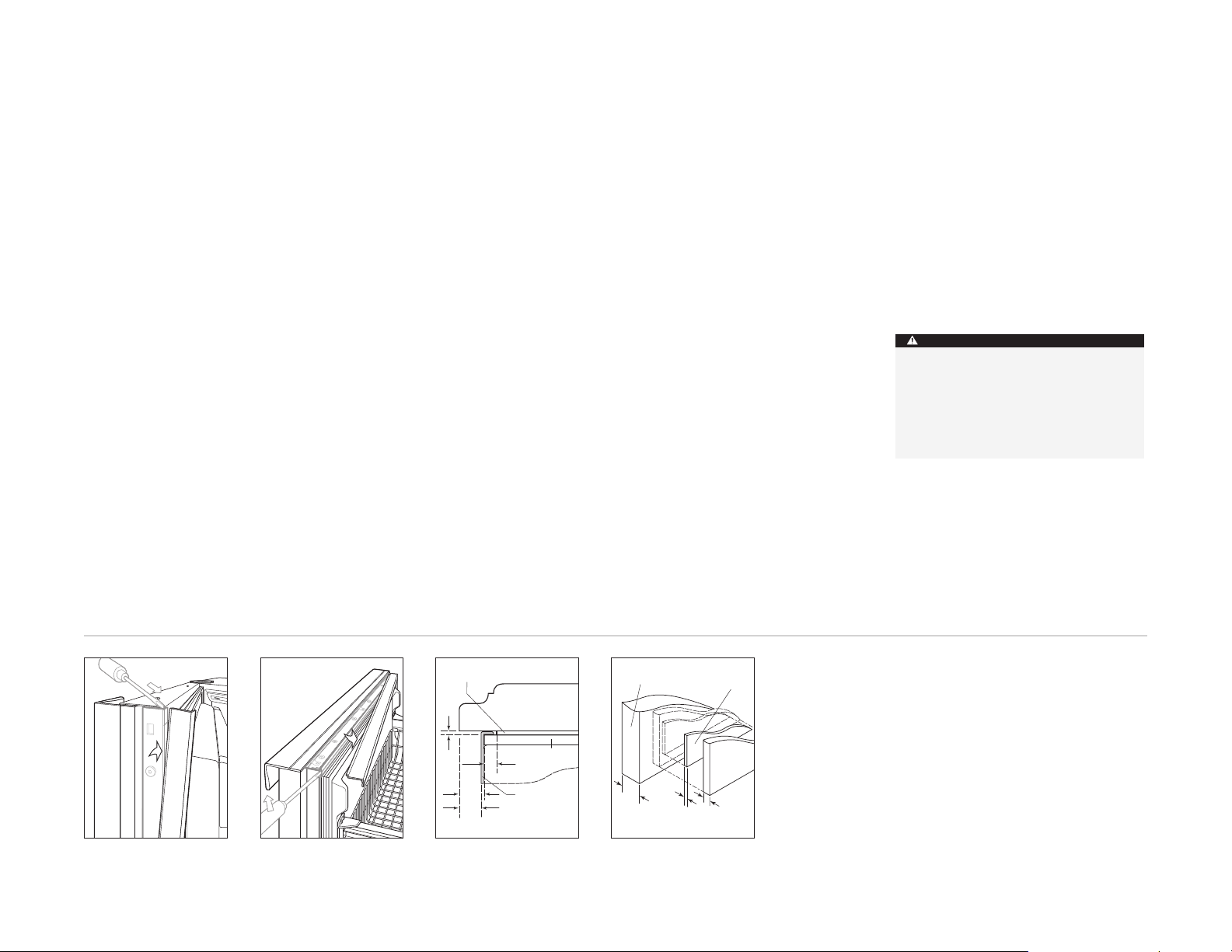

To install overlay panels, first remove the door trim

molding. For side-by-side models and the upper

door for over-and-under models, insert a screwdriver tip into the top corner slot on the handle

side and pop out the trim molding. Remove the

screws and frame. For the drawer on over-andunder models, insert a screwdriver tip into the slot

on either side of the trim molding running along

the top of the drawer and pop out the trim

molding. Remove the screws and frame. Refer to

the illustrations below.

Sub-Zero allows a 6 mm space to slide the

b

acking material into place in the frame. If your

material is thicker than a 6 mm, either rout an

edge around the panel to get a proper fit or

mount the decorative overlay panel on a sheet of

6 mm thick material and insert the backing

material into the channel.

You must allow for 3 mm space between the

b

acker board and the decorative panel, so the

panel will slide easily into the door frame.

The illustrations below provide a cross section

view of the three panel assembly showing placement of the door/drawer/grille trim and a rear

view of the three panel assembly with critical

dimensions, standard for all models.

Install the handle hardware before inserting the

panel. We recommend larger D-style pulls. The

use of small, one-piece knobs is not recommended. If you use screws with thick heads, you

will need to countersink the screws into the

backer panel before sliding the assembly into

place.

Slide the panel into the frame on the door. With

t

he panel in position, replace the frame end. Be

sure the panel is inserted completely into the

channel for proper fit and alignment.

To reinstall the trim molding on side-by-side

models and the upper door for over-and-under

m

odels, insert the top of the trim molding into

the grooves at the top of the door and work

d

ownward, snapping the trim molding into the

clips on the frame.

For the drawer on over-and-under models, start

at one end and move towards the opposite end,

snapping the trim molding into the clips on the

frame.

Rear roller base adjustment

10

Door trim Over-and-under drawer trim

Overlay panels—cross

section

Overlay panels—three panel

assembly

AC CE SS OR IES

Optional accessories are available

through your

Sub-Zero dealer. To

obtain local dealer

information, visit

our website,

subzero.com.

Page 11

Water

Grille

Ice

Key Pad

Light

Key Pad

Water

Key Pad

Touch Pad

Lock

Indicator

Bezel

OVERLAY PA NEL I NS TAL LAT ION

GLASSWELL — DI SP EN SE R MO DE LS

The dispenser area of Models ICBBI-42SD and

I

CBBI-48SD has been engineered to enable the

use of the overlay/flush inset panel application.

Installing overlay/flush inset panels for these

models is the same procedure as for other BuiltIn models. The refrigerator door panel will need

to accommodate a cut-out for the glasswell

bezel.

T

o remove the glasswell bezel for an overlay/

flush inset Model ICBBI-42SD or ICBBI-48SD, the

water grille and touch pad must be removed. Lift

the water grille up and out. Next, remove the

touch pad assembly which is taped in place, by

removing the center plastic mandrel supports.

Carefully tilt the touch pad out and disconnect

the wire harness (blue side up) from the back

side of the touch pad. Remove the bezel by

removing the four screws.

Insert the overlay/flush inset panel into the door

t

rim. Reverse the procedure to install the bezel,

touch pad and water grille. To install the plastic

rivets, insert rivets through the touch pad and

into the control housing and secure by pressing

mandrels into the body of the rivets. Refer to the

illustrations below.

IMPORTANT NOTE:

(

including backer and spacer, if used) in the

The total panel thickness

glasswell bezel area can range from 6 mm to a

maximum of 29 mm. If the panel is thicker, provisions must be made to rout out a space to

accommodate the bezel surrounding the glasswell.

GRILLE PA NE L AS SE MB LY

Remove the inner grille panel assembly as

d

escribed in Grille Removal, page 8. Remove the

top two corner screws and pull away the top

frame. Slide the panel into position in the grille

frame. If you are using a grille panel 6 mm or

thinner, you will need to install a filler.

R

eattach the top frame by reinstalling the two

top corner screws. Install the inner grille panel

a

ssembly onto the unit, by reversing the procedure outlined in Grille Removal, page 8.

Refer to specifications for Overlay Grille Panels

on page 12, and the illustration on page 10, for

the exact sizing of all three panels.

CAUTION

Do not exceed the panel dimensions listed

for the appropriate overlay grille panel you

are specifying. The overlay decorative panel

cannot be any larger or it may restrict the air

flow to the compressor area and cause

problems with the operation of the Sub-Zero

unit.

Glasswell—dispenser models Glasswell bezel removal

11

Page 12

C

C C

H

W

H

D

H

W

H

C

W

H

C C

D

W

H

WW

H

WW

H

E

F

OVERLAY PA NEL S PE CI FI CAT IONS

OV ERLAY DO OR PANELS

ll Refrigerator | All Freezer Overlay (O) Models

A

Model ICBBI-36R WH

Refrigerator Overlay Panel 914 mm 1772 mm

Refrigerator Spacer Panel 892 mm 1751 mm

efrigerator Backer Panel 908 mm 1767 mm

R

odel ICBBI-36RG WH

M

Refrigerator Overlay Panel 914 mm 1772 mm

Refrigerator Spacer Panel 892 mm 1751 mm

efrigerator Backer Panel 908 mm 1767 mm

R

Window Cut-Out Dimensions TBD TBD

indow Cut-Out Location C TBD D TBD

W

Model ICBBI-36F WH

Refrigerator Overlay Panel 914 mm 1772 mm

efrigerator Spacer Panel 892 mm 1751 mm

R

Refrigerator Backer Panel 908 mm 1767 mm

MPORTANT NOTE: Panel specifications are for Built-In

I

verlay/flush inset models in a standard overlay installation.

o

OV ERLAY DO OR PANELS

ver-and-Under Overlay (O) Models

O

Model ICBBI-30U WH

Refrigerator Overlay Panel 762 mm 1273 mm

Refrigerator Spacer Panel 740 mm 1253 mm

efrigerator Backer Panel 756 mm 1268 mm

R

Freezer Overlay Panel 762 mm 483 mm

Freezer Spacer Panel 740 mm 459 mm

reezer Backer Panel 756 mm 475 mm

F

odel ICBBI-30UG WH

M

Refrigerator Overlay Panel 762 mm 1273 mm

efrigerator Spacer Panel 740 mm 1253 mm

R

Refrigerator Backer Panel 756 mm 1268 mm

reezer Overlay Panel 762 mm 483 mm

F

Freezer Spacer Panel 740 mm 459 mm

reezer Backer Panel 756 mm 475 mm

F

Window Cut-Out Dimensions TBD TBD

Window Cut-Out Location C TBD D TBD

odel ICBBI-36U WH

M

Refrigerator Overlay Panel 914 mm 1273 mm

Refrigerator Spacer Panel 892 mm 1253 mm

Refrigerator Backer Panel 908 mm 1268 mm

Freezer Overlay Panel 914 mm 483 mm

Freezer Spacer Panel 892 mm 459 mm

Freezer Backer Panel 908 mm 475 mm

Model ICBBI-36UG WH

Refrigerator Overlay Panel 914 mm 1273 mm

Refrigerator Spacer Panel 892 mm 1253 mm

Refrigerator Backer Panel 908 mm 1268 mm

Freezer Overlay Panel 914 mm 483 mm

Freezer Spacer Panel 892 mm 459 mm

Freezer Backer Panel 908 mm 475 mm

Window Cut-Out Dimensions TBD TBD

Window Cut-Out Location C TBD D TBD

IMPORTANT NOTE: Panel specifications are for Built-In

overlay/ flush inset models in a standard overlay installation.

OV ERLAY DO OR PANELS

ide-by-Side Overlay (O) Models

S

Model ICBBI-36S WH

Refrigerator Overlay Panel 510 mm 1772 mm

Refrigerator Spacer Panel 487 mm 1751 mm

efrigerator Backer Panel 503 mm 1767 mm

R

Freezer Overlay Panel 398 mm 1772 mm

Freezer Spacer Panel 376 mm 1751 mm

reezer Backer Panel 392 mm 1767 mm

F

odels ICBBI-42S and ICBBI-42SD H

M

Refrigerator Overlay Panel 637 mm 1772 mm

efrigerator Spacer Panel 614 mm 1751 mm

R

Refrigerator Backer Panel 630 mm 1767 mm

Freezer Overlay Panel 424 mm 1772 mm

reezer Spacer Panel 402 mm 1751 mm

F

Freezer Backer Panel 418 mm 1767 mm

Models ICBBI-48S and ICBBI-48SD H

Refrigerator Overlay Panel 730 mm 1772 mm

Refrigerator Spacer Panel 708 mm 1751 mm

Refrigerator Backer Panel 724 mm 1767 mm

Freezer Overlay Panel 483 mm 1772 mm

Freezer Spacer Panel 460 mm 1751 mm

Freezer Backer Panel 476 mm 1767 mm

Models ICBBI-42SD and ICBBI-48SD H

Glasswell Cut-Out Dimensions 149 mm 316 mm

Glasswell Location (Overlay) E 51 mm F 732 mm

Glasswell Location (Spacer) E 40 mm F 721 mm

Glasswell Location (Backer) E 48 mm F 729 mm

For M odels ICBBI-42SD and ICBBI-48SD, panel thickness in

the glasswell area can range from 6 mm to a maximum of 29

mm. If the panel is thicker, you must rout out a minimum 6

mm flat landing area to accommodate the bezel surrounding

the glasswell.

IMPORTANT NOTE: Panel specifications are for Built-In

overlay/ flush inset models in a standard overlay installation.

OV ERLAY GR ILL E PANELS

verlay/Flush Inset Models

O

Models ICBBI-30U and ICBBI-30UG

Grille Overlay Panel Width 762 mm

Grille Spacer Panel Width 740 mm

rille Backer Panel Width 756 mm

G

Models ICBBI-36R, ICBBI-36RG, ICBBI-36F, ICBBI-36U,

ICBBI-36UG and ICBBI-36S

Grille Overlay Panel Width 914 mm

Grille Spacer Panel Width 892 mm

Grille Backer Panel Width 908 mm

Model ICBBI-42S and ICBBI-42SD

Grille Overlay Panel Width 1067 mm

Grille Spacer Panel Width 1045 mm

Grille Backer Panel Width 1060 mm

odel ICBBI-48S and ICBBI-48SD

M

Grille Overlay Panel Width 1219 mm

Grille Spacer Panel Width 1197 mm

Grille Backer Panel Width 1213 mm

2108 mm Overall Unit Height

Grille Overlay Panel Height 210 mm

Grille Spacer Panel Height 186 mm

Grille Backer Panel Height 202 mm

2134 mm Overall Unit Height

(standard)

Grille Overlay Panel Height 235 mm

Grille Spacer Panel Height 211 mm

Grille Backer Panel Height 227 mm

2235 mm Overall Unit Height

Grille Overlay Panel Height 337 mm

Grille Spacer Panel Height 313 mm

Grille Backer Panel Height 329 mm

For overlay grille panel sizes, use width dimension listed

for your model and height dimension for overall unit height.

2134 mm overall unit height is standard.

DO UBLE O VERLAY GRILLE PA NE LS

Dual Installation with 2235 mm Overall Height

OV ER LA Y PANELS

Panel specifications

are for B uilt-In

overlay (O) models.

Additional pane l information can be found

in the Built-In Design

Guide. Check our

website at

subzero. com.

12

and ICBBI-36F

Model ICBBI-36RGModels ICBBI-36R

Models ICBBI-30U

and ICBBI-36U

Models ICBBI-30UG

and ICBBI-36UG

Models ICBBI-36S,

ICBBI-42S and

ICBBI-48S

Models ICBBI-42SD

and ICBBI-48SD

Two 762 mm Wide Units WH

Double Grille Overlay Panel 1530 mm 235 mm

Double Grille Spacer Panel 1508 mm 211 mm

Double Grille Backer Panel 1524 mm 227 mm

Two 914 mm Wide Units WH

Double Grille Overlay Panel 1835 mm 235 mm

Double Grille Spacer Panel 1813 mm 211 mm

Double Grille Backer Panel 1829 mm 227 mm

IMPORTANT NOTE: Panel specifications are for Built-In

overlay/ flush inset models in a standard overlay installation.

Page 13

FLUSH INSET PANEL I NS TAL LATION

Door/Drawer/

Grille Trim

14

mm

16

mm

6 mm Backer Panel

8 mm min

3

mm

Spacer Panel

Flush Inset Panel

Spacer Panel

Flush Inset Panel

6 mm

Backer

Panel

3 mm

~19

mm

FLUSH INSET PANELS

If your customer has chosen the flush inset panel

a

pplication, make sure that the panels you are

about to install match dimensions listed in the

Flush Inset Panel Specifications on page 14.

IMPORTANT NOTE:

The size of the flush inset

panel is critical. It must be sized correctly for a

p

roper fit inside the opening.

Overlay/flush inset models are shipped without

h

andle hardware. The cabinet manufacturer or

designer will provide handle hardware at the job

site to match the overall decorating scheme.

To install flush inset panels, first remove the

door trim molding. For side-by-side models and

the upper door for over-and-under models, insert

a screwdriver tip into the top corner slot on the

handle side and pop out the trim molding.

Remove the screws and frame. For the drawer

on over-and-under models, insert a screwdriver

tip into the slot on either side of the trim

molding running along the top of the drawer,

and pop out the trim molding. Remove the

screws and frame. Refer to the illustrations

below.

Sub-Zero allows a 6 mm space to slide the

b

acking material into place in the frame. If your

material is thicker than a 6 mm, either rout an

edge around the panel to get a proper fit or

mount the decorative overlay panel on a sheet of

6 mm thick material and insert the backing

material into the channel.

You must allow for 3 mm space between the

b

acker board and the decorative panel, so the

panel will slide easily into the door frame.

The illustrations below provide a cross section

view of the three panel assembly showing placement of the door/drawer/grille trim and a rear

view of the three panel assembly with critical

dimensions, standard for all models.

IMPORTANT NOTE:

With the panels installed,

13 mm minimum reveals must be kept on all

sides to ensure proper door opening and sufficient cooling of the unit.

Install the handle hardware before inserting the

p

anel. We recommend larger D-style pulls. The

use of small, one-piece knobs is not recommended. If you use screws with thick heads, you

will need to countersink the screws into the

backer panel before sliding the assembly into

p

lace.

Slide the panel into the frame on the door. With

t

he panel in position, replace the frame end. Be

sure the panel is inserted completely into the

channel for proper fit and alignment.

To reinstall the trim molding on side-by-side

models and the upper door for over-and-under

models, insert the top of the trim molding into

the grooves at the top of the door and work

downward, snapping the trim molding into the

clips on the frame.

For the drawer on over-and-under models, start

at one end and move towards the opposite end,

snapping the trim molding into the clips on the

frame.

GRILLE PA NE L AS SE MB LY

Remove the inner grille panel assembly as

d

escribed in Grille Removal, page 8. Remove the

top two corner screws and pull away the top

frame. Slide the panel into position in the grille

frame. If you are using a grille panel 6 mm or

thinner, you will need to install a filler.

R

eattach the top frame by reinstalling the two

top corner screws. Install the inner grille panel

a

ssembly onto the unit, by reversing the proce-

dure outlined in Grille Removal, page 8.

Refer to specifications for Flush Inset Grille

Panels on page 14, and the illustration below for

the exact sizing of all three panels.

CAUTION

Do not exceed the panel dimensions listed

for the appropriate flush inset grille panel

you are specifying. The flush inset decorative

panel cannot be any larger or it may restrict

the air flow to the compressor area and

cause problems with the operation of the

Sub-Zero unit.

Door trim Over-and-under drawer trim

Flush inset panels —cross

section

Flush inset panels —three

panel assembly

13

Page 14

C

C C

H

W

H

D

H

W

H

C

W

H

C C

D

W

H

WW

H

WW

H

E

F

FLUSH INSET PANEL S PE CI FI CATIONS

FL USH IN SET DOOR PA NE LS

ll Refrigerator | All Freezer Models in a Flush Inset Application

A

Model ICBBI-36R WH

Refrigerator Flush Inset Panel 940 mm 1772 mm

Refrigerator Spacer Panel 892 mm 1751 mm

efrigerator Backer Panel 908 mm 1767 mm

R

Refrigerator Panel Offset L 16 mm R 16 mm

Model ICBBI-36RG WH

Refrigerator Flush Inset Panel 940 mm 1772 mm

efrigerator Spacer Panel 892 mm 1751 mm

R

Refrigerator Backer Panel 908 mm 1767 mm

Refrigerator Panel Offset L 16 mm R 16 mm

Window Cut-Out Dimensions TBD TBD

Window Cut-Out Location C TBD D TBD

odel ICBBI-36F WH

M

Freezer Flush I nset Panel 940 mm 1772 mm

Freezer Spacer Panel 892 mm 1751 mm

Freezer Backer Panel 908 mm 1767 mm

reezer Panel Offset L 16 mm R 16 mm

F

IMPORTANT NOTE: Panel specifications are for Built-In

overlay/ flush inset models in a flush inset application.

FL USH IN SET DOOR PA NE LS

ver-and-Under Models in a Flush Inset Application

O

Models ICBBI-30U and ICBBI-30UG H

Refrigerator Flush Inset Panel 787 mm 1273 mm

Refrigerator Spacer Panel 740 mm 1253 mm

efrigerator Backer Panel 756 mm 1268 mm

R

Refrigerator Panel Offset L 16 mm R 16 mm

Freezer Flush I nset Panel 787 mm 483 mm

reezer Spacer Panel 740 mm 459 mm

F

Freezer Backer Panel 756 mm 475 mm

reezer Panel Offset L 16 mm R 16 mm

F

odel ICBBI-30UG WH

M

Window Cut-Out Dimensions TBD TBD

Window Cut-Out Location C TBD D TBD

odels ICBBI-36U and ICBBI-36UG H

M

Refrigerator Flush Inset Panel 940 mm 1273 mm

Refrigerator Spacer Panel 892 mm 1253 mm

Refrigerator Backer Panel 908 mm 1268 mm

efrigerator Panel Offset L 16 mm R 16 mm

R

Freezer Flush I nset Panel 940 mm 483 mm

Freezer Spacer Panel 892 mm 459 mm

Freezer Backer Panel 908 mm 475 mm

Freezer Panel Offset L 16 mm R 16 mm

Model ICBBI-36UG WH

Window Cut-Out Dimensions TBD TBD

Window Cut-Out Location C TBD D TBD

IMPORTANT NOTE: Panel specifications are for Built-In

overlay/ flush inset models in a flush inset application.

FL USH IN SET DOOR PA NE LS

ide-by-Side Models in a Flush Inset Application

S

Model ICBBI-36S WH

Refrigerator Flush Inset Panel 522 mm 1772 mm

Refrigerator Spacer Panel 487 mm 1751 mm

efrigerator Backer Panel 503 mm 1767 mm

R

Refrigerator Panel Offset L 3 mm R 16 mm

Freezer Flush I nset Panel 411 mm 1772 mm

reezer Spacer Panel 376 mm 1751 mm

F

Freezer Backer Panel 392 mm 1767 mm

reezer Panel Offset L 16 mm R 3 mm

F

odels ICBBI-42S and ICBBI-42SD H

M

Refrigerator Flush Inset Panel 649 mm 1772 mm

efrigerator Spacer Panel 614 mm 1751 mm

R

Refrigerator Backer Panel 630 mm 1767 mm

efrigerator Panel Offset L 3 mm R 16 mm

R

Freezer Flush I nset Panel 437 mm 1772 mm

Freezer Spacer Panel 402 mm 1751 mm

Freezer Backer Panel 418 mm 1767 mm

Freezer Panel Offset L 16 mm R 3 mm

Models ICBBI-48S and ICBBI-48SD H

Refrigerator Flush Inset Panel 743 mm 1772 mm

Refrigerator Spacer Panel 708 mm 1751 mm

Refrigerator Backer Panel 724 mm 1767 mm

Refrigerator Panel Offset L 3 mm R 16 mm

Freezer Flush I nset Panel 495 mm 1772 mm

Freezer Spacer Panel 460 mm 1751 mm

Freezer Backer Panel 476 mm 1767 mm

Freezer Panel Offset L 16 mm R 3 mm

Models ICBBI-42SD and ICBBI-48SD H

Glasswell Cut-Out Dimensions 149 mm 316 mm

Glasswell Location (Flush Inse t) E 51 mm F 732 mm

Glasswell Location (Spacer) E 40 mm F 721 mm

Glasswell Location (Backer) E 48 mm F 729 mm

For M odels ICBBI-42SD and ICBBI-48SD, panel thickness in

the glasswell area can range from 6 mm to a maximum of 29

mm. If the panel is thicker, you must rout out a minimum 6

mm flat landing area to accommodate the bezel surrounding

the glasswell.

FL USH IN SET GRIL LE PAN ELS

verlay/Flush Inset Models

O

Models ICBBI-30U and ICBBI-30UG

Grille Flush Inset Panel Width 787 mm

Grille Spacer Panel Width 740 mm

rille Backer Panel Width 756 mm

G

Models ICBBI-36R, ICBBI-36RG, ICBBI-36F, ICBBI-36U,

ICBBI-36UG and ICBBI-36S

Grille Flush Inset Panel Width 940 mm

Grille Spacer Panel Width 892 mm

Grille Backer Panel Width 908 mm

Models ICBBI-42S and ICBBI-42SD

Grille Flush Inset Panel Width 1092 mm

Grille Spacer Panel Width 1045 mm

Grille Backer Panel Width 1060 mm

odels ICBBI-48S and ICBBI-48SD

M

Grille Flush Inset Panel Width 1245 mm

Grille Spacer Panel Width 1197 mm

Grille Backer Panel Width 1213 mm

2108 mm Overall Unit Height

Grille Overlay Panel Height 210 mm

Grille Spacer Panel Height 186 mm

Grille Backer Panel Height 202 mm

2134 mm Overall Unit Height

(standard)

Grille Overlay Panel Height 235 mm

Grille Spacer Panel Height 211 mm

Grille Backer Panel Height 227 mm

2235 mm Overall Unit Height

Grille Overlay Panel Height 337 mm

Grille Spacer Panel Height 313 mm

Grille Backer Panel Height 329 mm

For overlay grille panel sizes, use width dimension listed

for your model and height dimension for overall unit height.

2134 mm overall unit height is standard.

DO UBLE F LUSH IN SE T GRILLE PA NEL S

Dual Installation with 2235 mm Overall Height

FL US H I NSET

PA NE LS

Panel specifications

are for B uilt-In flush

inset applications.

Additional pane l information can be found

in the Built-In Design

Guide. Check our

website at

subzero. com.

14

and ICBBI-36F

Model ICBBI-36RGModels ICBBI-36R

Models ICBBI-30U

and ICBBI-36U

Models ICBBI-30UG

and ICBBI-36UG

Models ICBBI-36S,

ICBBI-42S and

ICBBI-48S

Models ICBBI-42SD

and ICBBI-48SD

Two 762 mm Wide Units WH

Double Grille Flush Inset Panel 1556 mm 235 mm

Double Grille Spacer Panel 1508 mm 211 mm

Double Grille Backer Panel 1524 mm 227 mm

Two 914 mm Wide Units WH

Double Grille Flush Inset Panel 1861 mm 235 mm

Double Grille Spacer Panel 1813 mm 211 mm

Double Grille Backer Panel 1829 mm 227 mm

IMPORTANT NOTE: Panel specifications are for Built-In

overlay/ flush inset models in a flush inset application.

Page 15

SIDE PA NE L IN STA LL ATION

Side Panel

Routing

Main

Frame

25 mm

48 mm

3 mm

13 mm

Side Panel

Rear

Bracket

Front

Bracket

Main

Frame

2134

mm

610 mm

NO SIDE PANEL

5 mm DEEP

HINGE SIDE

POCKET

2032

mm

1353

mm

102 mm

521

mm

305 mm

787

mm

1549

mm

146 mm

67 mm

48 mm

25 mm

32

mm

25 mm

4 mm

108 mm

FRONT OF UNIT

SIDE PA NE L IN STA LL ATION

IMPORTANT NOTE:

i

nstalled before the unit is placed in its final

Side panels will need to be

position.

When installing a Built-In unit with side panels,

an accessory side panel kit is necessary. A kit is

available for installation of stainless steel side

p

anels and one for installing custom wood side

panels. Refer to the instructions with the stainl

ess steel side panel kit when installing stainless

side panels. The following information is in reference to installation of custom wood side panels.

WOOD S ID E P AN EL S

Routing will be necessary on the side panel in

order for it to fit flush against the side of the unit.

Refer to the illustration below for routing detail.

If you have Model ICBBI-30U, ICBBI-30UG, ICBBI36U or ICBBI-36UG, extra routing will be necessary to avoid having the panel hit the refrigerator

lower hinge plate. The illustration on the following page points out the areas where extra

routing is needed for these models.

Install the brackets provided in the kit onto the

s

ide panel in the locations shown in the specifications illustration below. The front brackets are

meant to engage the mainframe and the back

brackets will wrap behind the unit when the

panel is in place. Screws are provided in the kit.

If the provided screws will not work for your

installation, you will need to provide the necessary screws to attach the brackets.

IMPORTANT NOTE:

When a side panel is

mounted on the hinge side of an over-and-under

unit, it will be necessary to move the bottom

front bracket down from the location shown in

the illustration on the following page to avoid

interfering with the hinge plate.

Place the panel at a 75° angle and engage the

front brackets into the mainframe. Swing the

panel inward, being sure that the front brackets

engage the mainframe. With the panel in

position, attach the rear brackets to the rear of

the unit with the screws provided. Check to see

that the panel is secure. Refer to the illustration

below.

IMPORTANT NOTE:

c

hange the width of your rough opening.

IMPORTANT NOTE:

The use of side panels may

The overall height on the

side panel will vary with the height of the grille

being used. Make sure you know your finished

height before cutting any panels.

DUAL INS TAL LAT IO NS

When two Built-in units are installed side-bys

ide, it is necessary to use a Sub-Zero Built-in

dual installation kit. Contact your Sub-Zero

dealer for the proper components and installation instructions.

IMPORTANT NOTE:

d

ual installations are different than those listed

Flush Inset panel sizes for

in this book. Please refer to the Sub-Zero Built-In

R

efrigeration Design Guide.

IMPORTANT NOTE:

Dual installations can only

be accomplished using two units with opposite

hinges.

Routing detail—wood side panel Side panel attachment—

top view

Side panel specifications

15

Page 16

COMPLETING T HE I NS TAL LAT ION

Upper Hinge Bolts

In and Out

Adjustment

Side to Side

Tilt Adjustment

Anchoring Screws

DOOR ADJ US TM EN T

The doors for Built-In side-by-side models and

t

he upper door on over-and-under models can

be adjusted in three ways: In and out, side to

side tilt, and up and down (except over-andunder models).

Regardless of the adjustment being made, start

b

y slightly loosening the two upper hinge bolts

on the upper hinge plate using a 13 mm wrench.

R

efer to the first illustration below.

IN AND OUT ADJUSTM EN T

The second illustration below points out the

proper bolt for the in and out door adjustment.

A 4 mm allen wrench is required.

To adjust a left-hinge door, turn the bolt clockwise to bring the handle side of the door inward,

and counterclockwise to move the handle side of

the door outward. Reverse the directions for a

right-hinge door.

SIDE T O S ID E TI LT A DJ US TM EN T

T

he second illustration below also points out the

proper bolt for the side to side tilt door adjustment. A 9 mm wrench is required.

For a left-hinge door, turn the bolt clockwise to

raise the handle side of the door up and counterclockwise to tilt the handle side of the door

down. Reverse the directions for a right-hinge

d

oor.

DOOR H EI GH T A DJ USTMENT

A 6 mm allen wrench is required.

For a left-hinge door, turn the bolt clockwise to

raise the door and counterclockwise to lower the

door. Refer to the illustration below. Reverse the

directions for a right-hinge door.

ANCHOR T HE UNI T

After door and side panels have been installed,

t

he unit has been leveled and door adjustment

completed, anchor the Built-In unit to the

opening. This will assure a proper fit and a

secure installation.

IMPORTANT NOTE:

t

he unit before anchoring it.

Be sure to level and square

To anchor the unit to cabinetry, open the grille,

a

nd install the screws provided through the grille

frame into the cabinetry. There are several hole

locations provided. Check for proper door clearance by fully opening the door. Refer to the illustration below.

Next, drill a screw through the side hole inside

the roller base assembly. There is one on each

side. The screw will need to go in at an angle in

order to attach properly.

CAUTION

If the screws provided are not suitable for

your application, you must provide adequate

screws.

90° DO OR STOP

The doors of all Built-in models open to 110°.

A

n optional 90° door stop kit is available through

your Sub-Zero dealer.

The 90° door stop will be installed in the top

hinge of the door. To install, open the door to

approximately 90°. At the top of the door, insert

t

he door stop down between the door hinge and

the door closer arm. Insert the screw through the

d

oor stop and into the door as shown in the

illustration below.

AIR PU RIFICATIO N S YS TEM

All Sub-Zero Built-In units, except Model

ICBBI-36F, come with an advanced air purification system. A factory installed air purification

cartridge is located inside the refrigeration

section, on the right-hand side of the back wall.

For information regarding use and removal of

this cartridge, please refer to the Built-In Refrigeration Use & Care Information provided with

the unit.

CAUTION

LAMP CONTAINS MERCURY

Manage in accordance with disposal

laws.

Door adjustment—upper hinge

bolt

16

Door adjustments

Door height adjustment

Top anchoring 90° door stop

AC CE SS OR IES

Optional accessories are available

through your

Sub-Zero dealer. To

obtain local dealer

information, visit

our website,

subzero.com.

Page 17

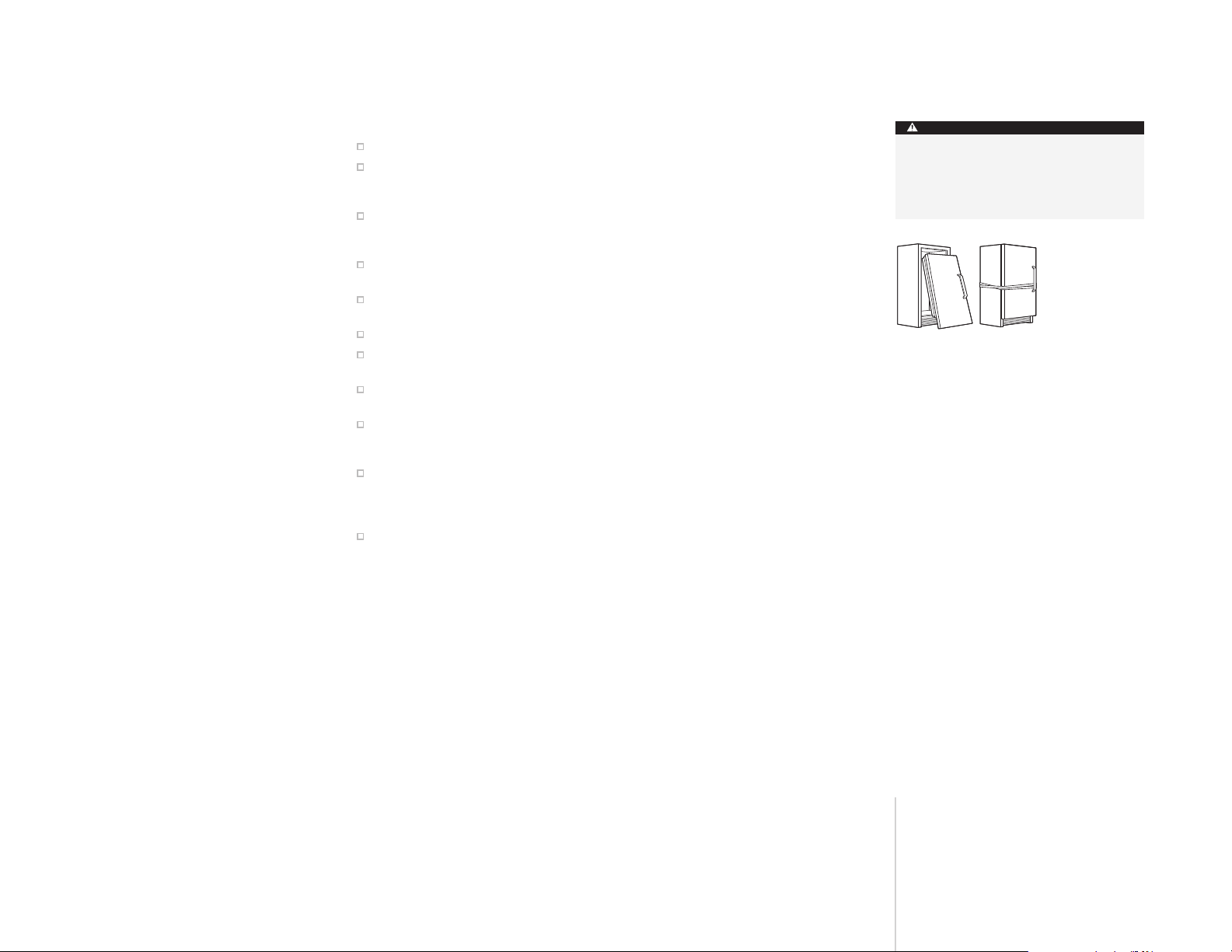

COMPLETING T HE I NS TAL LAT ION

SERV ICE INF OR MAT IO N

INSTALLATIO N C HE CKLIST

The importance of the installation of the

S

ub-Zero Built-In unit cannot be overemphasized. Proper installation is the responsibility

of the selling dealer or installer.

IMPORTANT NOTE:

To ensure a safe and proper

installation, the following checklist should be

c

ompleted by the installer to ensure that no part

of the installation has been overlooked.

A

ny questions or problems about the installation

should be directed to your Sub-Zero dealer. You

can also visit our website,

subzero.com

.

INSTALLATIO N C HE CK LI ST

H

as the packing material been removed?

Turn the unit on. Is it operating properly?

I

f not, is the unit plugged in? Is the control

turned on?

I

s the water supply line connected and not

leaking? Is the water supply turned on and ice

m

aker control on?

Has anti-tip bracket been installed securely

and properly engaging the unit?

Is the unit leveled properly on a solid, level

floor? Is the kickplate installed?

Has the drain pan been installed properly?

Are panels attached securely and properly

aligned?

Have the door(s) been aligned for proper

appearance and operation?

Does your customer understand the unit's

operation? Have you given your customer the

warranty package?

Have any installation or service problems

been noted on the product registration card?

Has the registration card been

mailed in?

Have stainless steel door(s) been inspected

for any imperfections? This is to be done

by the dealer/installer with the customer

upon completion of the installation.

NOTE: Classic, platinum and carbon stainless

steel panels are covered by a limited 60-day

parts and labor warranty for cosmetic defects.

SERV ICE INF OR MAT IO N

If service is necessary, maintain the quality built

i

nto your Sub-Zero unit by calling a Sub-Zero

dealer.

When calling for service, you will need the

model and serial number of your unit. Both

numbers are listed on the product rating plate

l

ocated at the top frame of the unit inside the

door. Refer to the illustration on page 3.

WARNING

If you are storing or disposing of your old

refrigerator or freezer, please do it safely.

Remove the doors or tightly secure the doors

closed. Child entrapment accidents can be

tragic.

The information and images in this guide are the

copyright property of Sub-Zero, Inc. Neither this

book nor any information or images contained

herein may be copied or used in whole or in part

without the express written permission of

Sub-Zero, Inc.

©Sub-Zero, Inc. all rights reserved.

17

Page 18

REFRIGERACIÓN EMPOTRA BL E S UB-ZERO

INSTALACIÓN E MP OT RABLE

Debe tenerse en cuenta la importancia de

la instalación de la unidad empotrable de

Sub-Zero. Sólo un instalador cualificado

d

ebe realizar la instalación.

Antes de comenzar el proceso de instalación,

se recomienda que lea con detenimiento la

guía de instrucciones de instalación. Durante la

i

nstalación, existe información importante a la

que debe prestar especial atención. Si lee estas

instrucciones con detenimiento, podrá llevar a

cabo el proceso de instalación de forma fácil,

sin problemas y, lo que es más importante,

de forma segura.

Si tiene alguna pregunta o problema relacionado

con la instalación, debe ponerse en contacto con

su distribuidor de Sub-Zero. También puede

visitar nuestra página web

www.subzero.com

.

En la placa de datos del producto encontrará

información importante sobre el mismo,

incluyendo el modelo y el número de serie de la

unidad. La placa de datos del producto está situada en el marco superior de la unidad, dentro

de la puerta. Observe la siguiente ilustración.

Ubicación

de la placa

de datos

Ubicación de la placa de datos

SUB-ZERO®es una marca comercial registrada de Sub-Zero, Inc.

HERRAMIENTA S Y M AT ER IA LE S

NECESARIOS

A continuación se especifican las herramientas

y los materiales necesarios para llevar a cabo la

instalación de manera correcta.

• Juego de destornilladores Phillips

• Juego de destornilladores para tornillos

ranurados

• Juego de destornilladores para tornillos de

cabeza torx

• 1,2 m de tubería de cobre de 6,35 y válvula de

montaje para el conducto de agua—N.º de

pieza 4200880 (no utilice válvulas autoperforantes)

• Instrumento especial para cortar el tubo de

cobre

• Se recomienda tener un nivel de —0,6 m y

de 1,2 m

• Unidad rodante para mover el aparato capaz

de soportar 317 kg y personal para manejar

el peso de la unidad

• Alicates de varios tamaños

• Juego de llaves

• Juego de llaves Allen

• Llave para tuercas hexagonales de 8 mm

• Llaves ajustables (inglesas)

• Taladro inalámbrico y varias brocas

• Masonita, madera contrachapada, panel de

fibra prensado de 3,2 mm, cartón u otro

material adecuado para proteger el acabado

del suelo

• Materiales apropiados para cubrir y proteger

el hogar y el mobiliario durante la instalación

Compruebe que el equipo que ha recibido se

corresponda con el diseño que tiene previsto

instalar. La línea de productos empotrables de

S

ub-Zero ofrece las siguientes alternativas

de diseño revestible/empotrable y modelos de

acero inoxidable. El modelo revestible/empotrable presenta dos aplicaciones de diseño:

revestible y empotrable.

Cada una de estas opciones de diseño exige

unos requisitos de instalación específicos, por lo

que es primordial que la unidad se ajuste a sus

necesidades de planificación y de espacio. Antes

de iniciar el proceso de instalación, compruebe

que la referencia exacta del modelo que necesita

se corresponda con la referencia del modelo que

figura en la caja de envío.

Si la unidad que ha recibido no coincide con

sus requisitos, póngase en contacto con su

distribuidor de Sub-Zero.

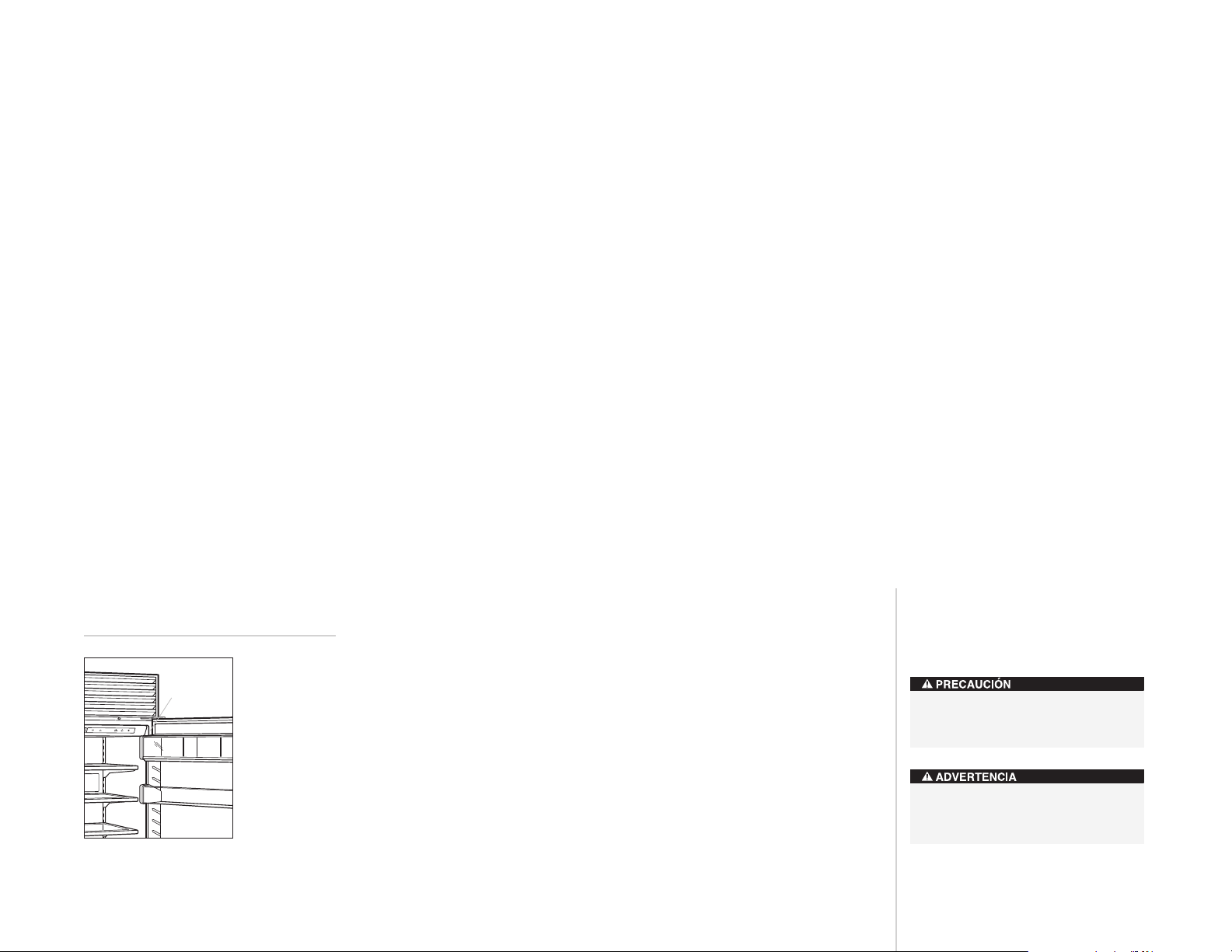

PREPARACIÓN DEL SITIO

Compruebe que la cavidad en la que se va a

instalar la unidad empotrable esté preparada

correctamente. Vea las especificaciones sobre

Medidas totales e Instalación correspondientes

a su modelo concreto en las páginas siguientes.

Estas especificaciones son idénticas para las

aplicaciones revestibles/empotrables y de acero

inoxidable. Las especificaciones de instalación

son distintas para la aplicación empotrable,

tanto si va a utilizar paneles fabricados a medida

como paneles empotrables accesorios inoxidables de Sub-Zero. Asegúrese de que las

medidas de la cavidad, el espacio de apertura de

la puerta, la instalación eléctrica y de fontanería

son correctas para el modelo que va a instalar.

Si va a instalar dos unidades empotrables una al

lado de la otra en la aplicación revestible/empotrable o de acero inoxidable, se recomienda

utilizar un embellecedor de separación. Coloque

el embellecedor del mismo ancho que lo que

mida la cavidad acabada. Finalice la instalación

con el equipo de fijación (pieza n.º 7004656).

Consulte la página 31.

Para instalar dos unidades empotrables de manera contigua con una aplicación empotrable se

necesitará un kit de instalación dual. Consulte la

p

ágina 30.

NOTA IMPORTANTE:

Las unidades empotrables

que se instalan una al lado de la otra en aplicación empotrable no pueden incorporar los

p

aneles empotrables accesorios inoxidables de

Sub-Zero y las bisagras deben instalarse en

sentido opuesto.

NOTA IMPORTANTE:

Para que funcione correctamente, la puerta debe abrirse hasta un mínimo

de 90 grados. Utilice un embellecedor de 76 mm

mínimo cuando coloque el aparato en rincones

con el fin de que se pueda abrir la puerta a 90

grados. Deje suficiente espacio delante de la

unidad para que la puerta pueda abrirse totalmente.

NOTA IMPORTANTE:

Asegúrese de que el suelo

debajo de la unidad está nivelado con respecto

al suelo acabado de alrededor.

Cuando lea estas Instrucciones de instalación,

deberá prestar especial atención cuando aparezcan los símbolos de PRECAUCIÓN y ADVERTENCIA. Esta información es importante para

instalar de forma segura y eficaz el equipo

de Sub-Zero.

indica una situación en la que se pueden

sufrir heridas leves o provocar daños secundarios al producto si no se siguen las instrucciones.

indica peligro de que se produzcan heridas

personales graves o incluso puede provocar

la muerte si no se siguen las precauciones

especificadas.

Además, estas Instrucciones de instalación

pueden incluir una NOTA IMPORTANTE para

resaltar información que es especialmente relevante para una instalación sin problemas.

Page 19

INSTRUCCIONES DE I NS TAL ACIÓN PA RA P RO DU CT OS EM POTRABLES

606 mm

DETRÁS

DEL

MARCO

ANCHURA

DE LA UNIDAD

A

914 mm

2.134

mm

914 mm

2.134

mm

610 mm

914 mm

2.134

mm

610 mm

1.918 mm

178

mm

152

m

m

E

UBICAR TOMA

ELÉCTRICA

EN ÁREA

SOMBREADA

457 mm

W

UBICAR TOMA DE AGUAEN

ÁREA SOMBREADA

152

m

m

VISTA FRONTALVISTA LATERAL

2.127 mm

ALTURA

DE LA

CAVIDAD

A

ANCHURA DE LA CAVIDAD

76 mm

6

10 mm

PROFUNDIDAD

DE LA CAVIDAD

13 mm

457 mm

*

152

mm

6

10 mm

PROFUNDIDAD

DE LA CAVIDAD

VÁLVULA

DE CIERRE

CONTORNO DEL

MODELO REVESTIBLE

O DE ACERO

INOXIDABLE

VISTA

S

UPERIOR

*EL SOPORTE ANTIVUELCO

NO DEBE INTERFERIR CON EL

CONDUCTO DE AGUA.CONSULTE

L

AS INSTRUCCIONES DE INSTALACIÓN

PARAOBTENER LOS DATOS COMPLETOS.

C

ONDUCTO DE AGUAAMPLIADO

914 MM APROX.DESDE PARED TRASERA.

CONDUCTO

DE AGUA

1.918 mm

178

mm

152

mm

E

UBICAR TOMA

ELÉCTRICA

EN ÁREA

SOMBREADA

13 mm

457 mm

*