Page 1

Electronic Control System

3-2

#7019014 - Revision A - October, 2010

Built-In (BI) Series

Built-In (BI) Series

Term/Component

Definition / Description

Main Control Board ..………….… (Also referred to as the Main “Controller” Board), is the printed-circuit board (PC Board)

which contains a microprocessor, relays, triacs and electrical connections that monitor

and control all functions of the appliance.

Microprocessor ……….…….…... An electrical component on the control board which receives electrical signals from

other components, processes the information, then sends electrical signals to relays and

triacs on the board to open or close, switching components in the appliance ON or OFF.

Relay ……………………….……. An electrical component on the control board which switches other components in the

appliance ON or OFF when instructed to do so by the microprocessor.

Triac ………………………....…… Similar in function to a relay, the triac is a three terminal semiconductor for controlling

current in either direction.

Control Panel Assembly ……..… (Also referred to as the User Interface Module, or User Interface), is that part of the

electronic control system where all manual input operations are performed.

Function Keys …….….................. The keys or buttons on the control panel assembly used for manual input operations.

The words on the function keys are: “LIGHTS”, “ICE MAKER”, “MAX ICE”, “PURE AIR”,

“COLDER”, “WARMER”, “ALARM” and “POWER”.

Capacitance Touch Sensitive ..… The ability of the keys on the control panel to detect the natural capacitance of the

human body when in close proximity causing a change in electrons state or quantity

which signals the electronic control to perform a function.

LCD (Liquid Crystal Display) …... A semi-liquid substance sandwiched between glass in the control panel assembly. The

molecules of this semi-liquid substance have no specific orientation. However, when

electricity is applied to them, they react predictably, aligning and straightening in such a

way as to control light passage. In doing so, they can be manipulated and arranged to

form the indicators that appear in the LCD.

Indicators .....………………...…... The words, numbers and icons that appear at the LCD.

Fault Codes (Error Codes) ......... The code number indicators that may appear in the LCD when accessing Fault Code

History during Fault and Sensor Recall Mode. This coded data represents current

and/or historical problematic events that specific electronic components may have expe-

rienced.

Temperature Units of Measure…. Temperature readings observed at the LCD may be in Fahrenheit units of measure (°F)

or Celsius units of measure (°C). A series of key strokes allows the temperature units of

measure to be switched to display as either °F or °C.

Set-Point ……………………….... The desired zone temperature, established by pressing the COLDER or WARMER

keys.

High Offset (Cut-in) …………...... As the zone air temperature cycles up and down, the high offset is the maximum zone

temperature that the electronic control system will allow before calling for cooling.

Low Offset (Cut-out)…………...... As the zone air temperature cycles up and down, the low offset is the minimum zone air

temperature that the electronic control system will allow before interrupting cooling.

Thermistor …………………….…. (Also Referred to as a Temperature Sensor), is a resistor with which resistance changes

as the temperature around it changes. For electronic control system purposes, the

microprocessor detects, monitors and processes this resistance value in order to control

the appliance’s cooling functions as well as displays it as a temperature reading in the

LCD.

Variable Speed Compressor …... A compressor designed to run at varying speeds depending on the temperature detect-

ed in the corresponding zone of the appliance.

Variable Speed Fan Motor ...…... A fan motor that is deigned to runs at varying speeds depending on the temperature

detected in the corresponding zone, or the temperature of a specific component.

ELECTRONIC CONTROL TERMINOLOGY & COMPONENT DESCRIPTIONS

The Built-In Series utilizes an electronic control system which monitors, regulates, controls and displays a variety of

functions and operations in the appliance.

The table below defines some of the basic electronic control system terminology.

Previous Page

Next Page

Main Menu

Built-In Series Menu

Built-In Series Menu

Previous Page

Main Menu

Table of Contents

Next Page

Page 2

Electronic Control System

3-3

#7019014 - Revision A - October, 2010

Built-In (BI) Series

Built-In (BI) Series

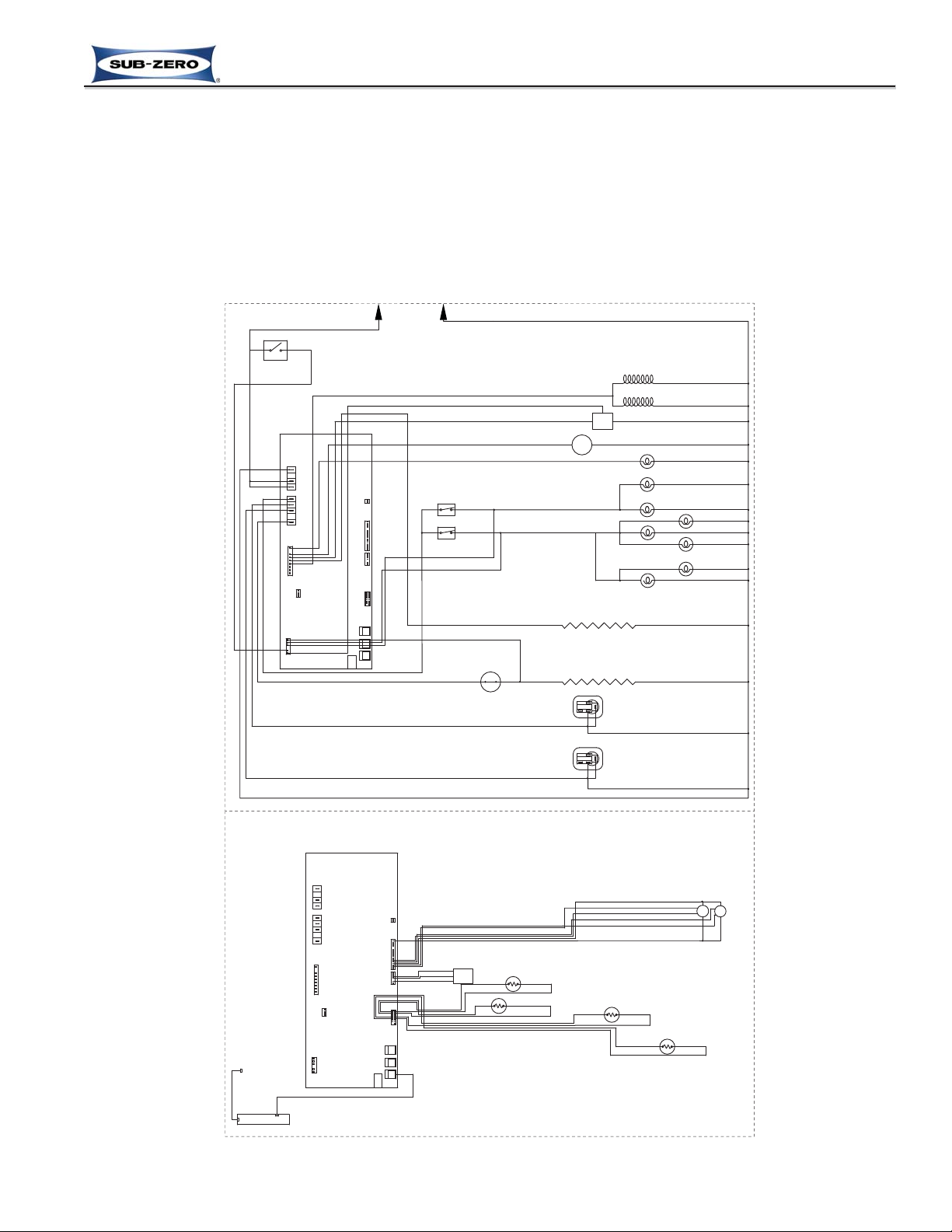

Figure 3-1. Electronic Control System Overview (BI-36UG Wiring Schematic)

115 VOLTS

60 CYCLES

L1

NEUTRAL

N.O.

WATER FILTER SWITCH

P16

MAIN

CONTROL

BOARD

P1

3

P14

L1

L1

NEUTRAL

1164

P2

P15

85

P3

P6

P5

P6

P9

P8

P7

P18

DEFROST HTR

COMP2

COMP1

MAIN LIGHTS

N.C.

N.C.

FZ DOOR SWITCH

REF DOOR SWITCH

ISOLATION VALVE

660 Ω

WATER VALVE

160 Ω

M

IM

CONDENSER FAN MOTOR

CRISPER LIGHTS

REF LIGHTS

AIR FILTER LIGHT

FREEZER LIGHTS

FILL-TUBE HEATER

2300-2900 Ω

DEF HEATER

27.9-30.9 Ω

DEFROST TERMINATOR

REFRIGERATOR COMPRESSOR

STARTING RELAY

FREEZER COMPRESSOR

STARTING RELAY

PURPLE

WHITE

WHITE/BLUE

WHITE/BLUE

BLUE

WHITE

PURPLE

GRAY

RED

PINK

YELLOW

BLACK

RED

WHITE/BLUE

TAN

BLUE

ORANGE

YELLOW

YELLOW

ORANGE/BLACK

GRAY/WHITE

ORANGE/BLACK

WHITE

RED/WHITE

WHITE/RED

TAN

PINK

GRAY

ORANGE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

TAN/WHITE

TAN/WHITE

BROWN

YELLOW

WHITE

REF

EVAPORATOR FAN

FREEZER

EVAPORATOR FAN

M

M

FLOW

METER

THERMISTER FREEZER EVAP

THERMISTER FREEZER CABINET

THERMISTER REF CABINET

THERMISTER REF EVAP

BROWN

BLACK/WHITE

WHITE/BLACK

BLUE

BROWN

BLUE

BROWN

YELLOW

RED

YELLOW/BROWN

BLUE/WHITE

BROWN

BLUE

BLUE

BROWN

BLUE

WHITE

MAIN CONTROL

BOARD

16

1

17

1

P18

3

P6

P15

P16

85

P14

1164

P6

P9

P8 P7

P5

P2

P3

P1

DEFROST HTR

COMP2

COMP1

MAIN LIGHTS

L1

NEUTRAL

L1

EXERNAL

DEVICE

KEYPAD

LOW VOLTAGE

HIGH VOLTAGE

ELECTRONIC CONTROL SYSTEM OVERVIEW

Figure 3-1 is the wiring schematic for the model BI-36UG showing the components of the electronic control system.

• Manual input operations are performed at the Control Panel Assembly (Keypad).

• Monitoring, regulating and controlling functions take place at the Main Control Board.

• Temperatures, icons and function/diagnostic codes are displayed in the LCD (part of Keypad).

The entire electronic control system is described in greater detail on the following pages.

NOTE: For more detailed electrical diagrams refer to the wiring diagram and schematic supplied with the appliance.

Previous Page

Next Page

Main Menu

Built-In Series Menu

Built-In Series Menu

Previous Page

Main Menu

Table of Contents

Next Page

Page 3

Electronic Control System

3-4

#7019014 - Revision A - October, 2010

Built-In (BI) Series

Built-In (BI) Series

MAIN CONTROL

BOARD

P18

3

P6

P15

P16

85

P14

1164

P6

P9

P8 P7

P5

P2

P3

P1

DEFROST HTR

COMP2

COMP1

MAIN LIGHTSL1NEUTRAL

L1

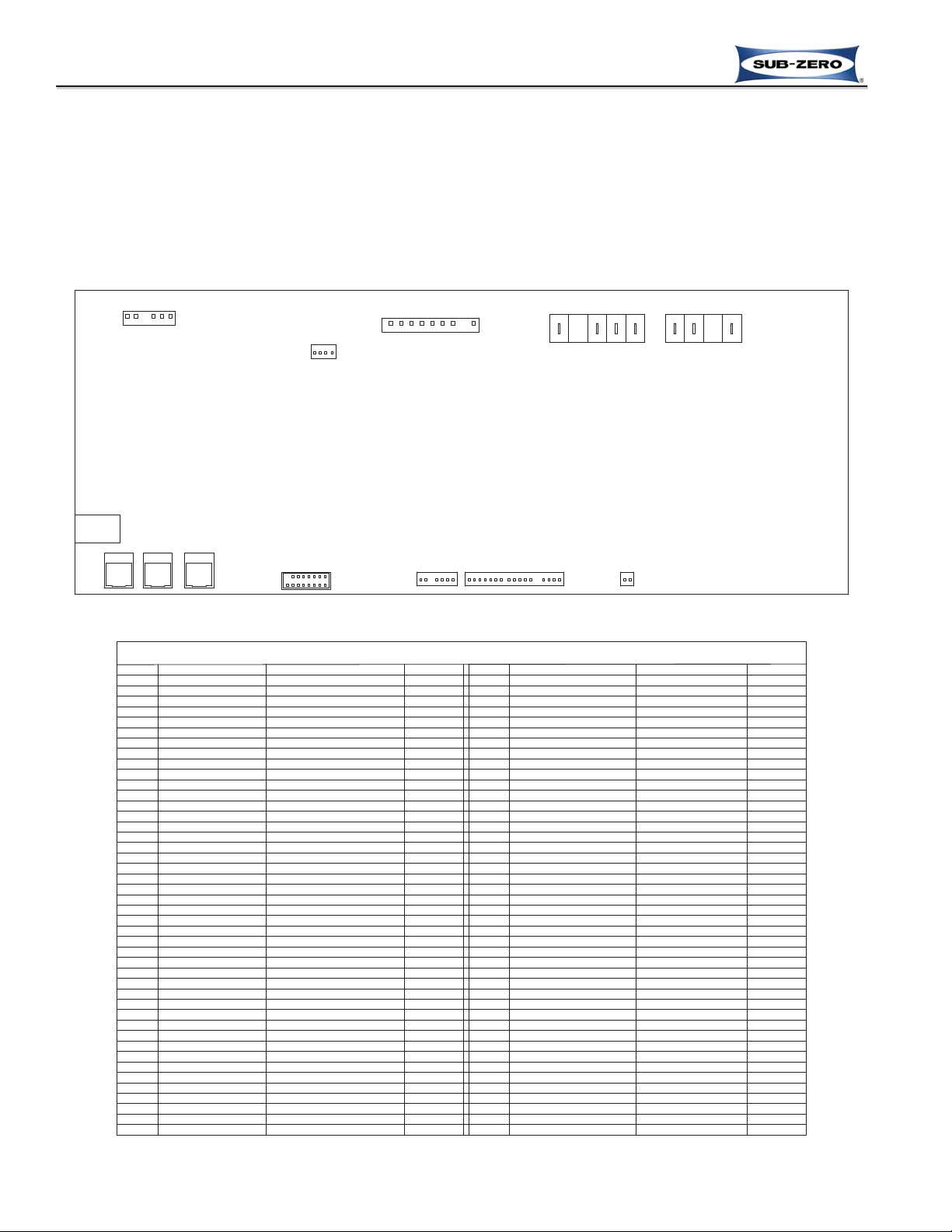

Figure 3-2. Control Board Layout

Figure 3-3. Control Board Summary Table

CONTROL BOARD LAYOUT AND SUMMARY TABLE

The electrical connection points on the main control board are labeled alphanumerically (See Figure 3-2). These

labels correspond with the alphanumeric control board summary table, located on wiring diagrams (See Figure 3-3).

By referencing the summary table, it is possible to identify which components are connected at which connection

points on the main control board.

NOTE: All components on control board are non-replaceable. If problems with control board are identified, the

complete control board must be replaced.

P16-5

P16-6

P16-7

P16-8

P16-9

P18-1

P18-2

P18-3

P18-4

P18-5

P18-6

P14-5

P14-6

P14-1

P14-2

P14-3

P14-4

P15-8

P15-7

P15-6

P15-5

P15-4

P15-3

P15-1

P15-2

CIRCUIT

P16-1

P16-2

P16-3

P16-4

ICE MAKER ACCESSORIES

WATER VALVE INPUT

REFRIGERATOR DOOR INPUT

WATER FILTER RESET SWITCH

FREEZER DOOR INPUT

UNUSED

ICE MAKER

CONDENSER FAN

AIR FILTER LIGHT

UNUSED

REF BI-METAL

UNUSED

UNUSED

ICE MAKER WATER VALVE

120 VOLT CIRCUITS

POWER IN (L1)

UNUSED

POWER IN (L1)

NEUTRAL

UNUSED

UNUSED

DEFROST HEATER

MAIN LIGHTS

UNUSED

COMPRESSOR #2

COMPRESSOR #1

UNUSED

UNUSED

UNUSED

WATER VALVE

DESCRIPTION

POWERS FILL TUBE AND ACCESSORIES

---

---

SENSES IF REF DOOR IS OPEN

SENSES WATER VALVE ACTIVATION

SENSES WHEN DEF HEATER SHUTS OFF

SENSES IF FREEZER DOOR IS OPEN

POWERS ICE MAKER

CONDENSER FAN

AIR FILTER LIGHT

SENSES WATER FILTER

UNUSED

UNUSED

POWER INTO BOARD

NEUTRAL INTO BOARD

POWER INTO BOARD

POWERS MAIN LIGHTS

POWERS COMPRESSOR

POWERS REF COMPRESSOR

POWERS OFF HEATER

POWERS WATER VALVE

POWERS IM WATER VALVE

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

FUNCTION

WHITE/BLUE

ORANGE/RED

GRAY/WHITE

ORANGE/BLACK

-

PINK

WHITE/RED

RED

TAN

-

ORANGE

BLACK

-

-

WHITE

-

BLACK

BLUE

YELLOW

PURPLE

GRA

Y

-

-

-

-

COLOR

---

-

--

TAN/WHITE

EVAPORATOR FAN RETURN

CRISPER LIGHT POWER

CRISPER LIGHT RETURN

AIR FILTER FAN OUTPUT

AIR FILTER FAN RETURN

AIR FILTER LIGHT OUTPUT

AIR FILTER LIGHT RETURN

PWM DRIVE OUTPUT

PWM DRIVE OUTPUT

EVAPORATOR FAN POWER

TACHOMETER INPUT

TACHOMETER INPUT

WATER FLOW SENSOR INPUT

FLOW METER POWER

FLOW METER RETURN

---

---

SENSES TEMPERATURE

SENSES TEMPERATURE

SENSES TEMPERATURE

SENSES TEMPERATURE

---

---

SENSES TEMPERATURE

SENSES TEMPERATURE

SENSES TEMPERATURE

SENSES TEMPERATURE

---

---

---

---

---

---

CRISPER LIGHT 12 VDC POWER

CRISPER LIGHT GROUND RETURN

AIR FILTER LIGHT

AIR FILTER LIGHT

FREEZER EVAPORATOR FAN

REF EVAPORATOR FAN

EVAPORATOR FAN 12 VDC POWER

FREEZER EVAPORATOR FAN

LOW VOLTAGE CIRCUITS

REF EVAPORATOR FAN

UNUSED

FLOW METER 12V DC POWER

UNUSED

REFRIGERATOR EVAPORATOR

FREEZER CABINET

FREEZER EVAPORATOR

UNUSED

UNUSED

FREEZER EVAPORATOR

FREEZER CABINET

UNUSED

REFRIGERATOR EVAPORATOR

UNUSED

THERMISTER CIRCUITS

EVAPORATOR FAN GROUND RETURN

FLOW METER

P3-3

P3-7

P3-6

P3-4

P3-5

P5-9

P5-8

P5-7

P5-6

P5-5

P5-16

P5-15

P5-14

P5-13

P5-12

P5-11

P5-10

P5-4

P5-3

P5-2

P5-1

CIRCUIT

UNUSED

FLOW METER

UNUSED

UNUSED

UNUSED

REF CABINET

REF CABINET

UNUSED

UNUSED

DESCRIPTION

P2-1

P2-2

P2-3

P2-4

P2-5

P2-6

P2-7

P2-8

P2-9

P2-10

P2-1

1

P2-12

P2-13

P2-14

P2-15

CIRCUIT

P2-16

P2-17

CIRCUIT

P3-2

P3-1

UNUSED

AIR FILTER FAN

AIR FILTER FAN

UNUSED

DESCRIPTION

UNUSED

DESCRIPTION

UNUSED

UNUSED

FUNCTION

UNUSED

UNUSED

FUNCTION

UNUSED

FUNCTION

WHITE/BROWN

YELLOW/BROWN

WHITE/BLACK

-

BROWN

BLACK/WHITE

BROWN

BLUE/BLACK

BROWN

BLUE

BROWN

BLUE/WHITE

BROWN

BLUE/YELLOW

BROWN

BLUE/ORANGE

BROWN

BLUE/RED

----

---

----

----

COLOR

-

-

-

-

-

-

WHITE

RED/BLACK

YELLOW

RED

BLUE/WHITE

COLOR

-

-

-

BLUE

COLOR

UNUSED

UNUSED

-

UNUSED

UNUSED

-

-

S x S CONTROL BOARD SUMMARY

Previous Page

Next Page

Main Menu

Previous Page

Next Page

Main Menu

Table of Contents

Built-In Series Menu

Built-In Series Menu

Page 4

Electronic Control System

3-5

#7019014 - Revision A - October, 2010

Built-In (BI) Series

Built-In (BI) Series

PURE AIR WARMER COLDER WARMER COLDER ALARM POWER MAX ICE ICE MAKER LIGHTS

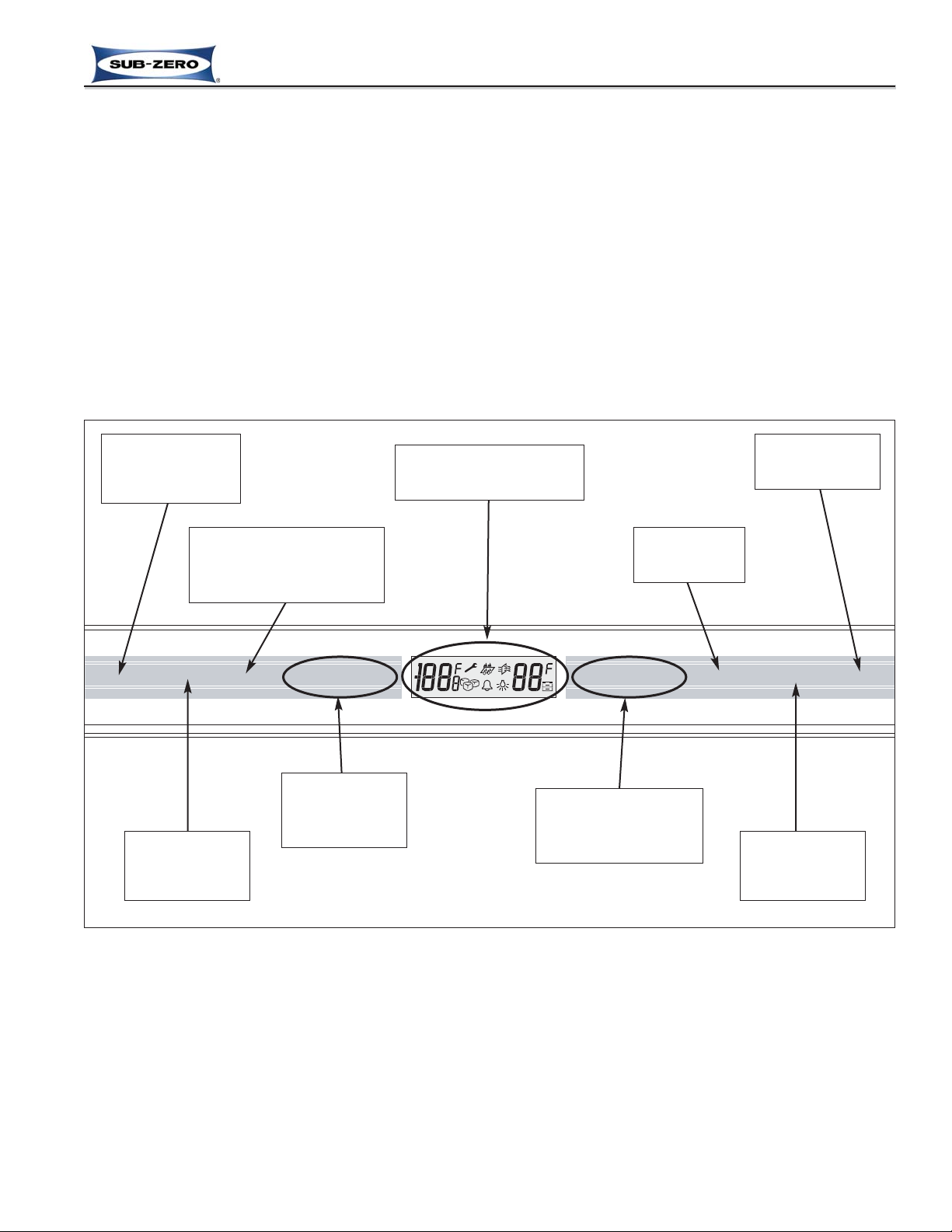

CONTROL PANEL LAYOUT (AKA USER INTERFACE MODULE)

Figure 3-4 below shows the layout of the control panel assembly.

NOTES:

• Not all keys are present on all models:

- If the unit does not have a glass refrigerator door, the control panel will not have the accent LIGHTS on/off key.

- The control panel in an all-refrigerator model does not have the freezer zone COLDER and WARMER keys, nor

the ICE MAKER and MAX ICE keys.

- The control panel in an all-freezer model does not have the refrigerator zone COLDER and WARMER keys, nor

the PURE AIR key.

• The control panel keys are “capacitance touch sensitive”, so even though the words “press” is used throughout

this section to indicate what to do to the keys, they actually only need to be “touched” to operate.

• Whenever a key is touched the electronic control will emit a beep.

Figure 3-4. Control Panel Layout

UNIT / POWER

ON/OFF KEY

DOOR AJAR

ALARM ON/OFF

KEY

ACCENT LIGHTS

ON/OFF KEY

units with glass

doors only

ICE MAKER

SYSTEM ON/OFF

KEY

FREEZER ZONE

SET-POINT

ADJUSTMENT

KEYS

LCD

(Liquid Crystal ‘Display)

MAXIMUM ICE

PRODUCTION ON/OFF KEY

speeds ice production

by up to 40%

REFRIGERATOR ZONE

SET-POINT

ADJUSTMENT

KEYS

AIR PURIFIER

ON/OFF KEY

Previous Page

Next Page

Main Menu

Built-In Series Menu

Built-In Series Menu

Previous Page

Main Menu

Table of Contents

Next Page

Page 5

Electronic Control System

3-6

#7019014 - Revision A - October, 2010

Built-In (BI) Series

Built-In (BI) Series

PURE AIR WARMER COLDER WARMER COLDER ALARM POWER MAX ICE ICE MAKER LIGHTS

Figure 3-5. Power Supplied to Unit, but Unit in OFF Mode

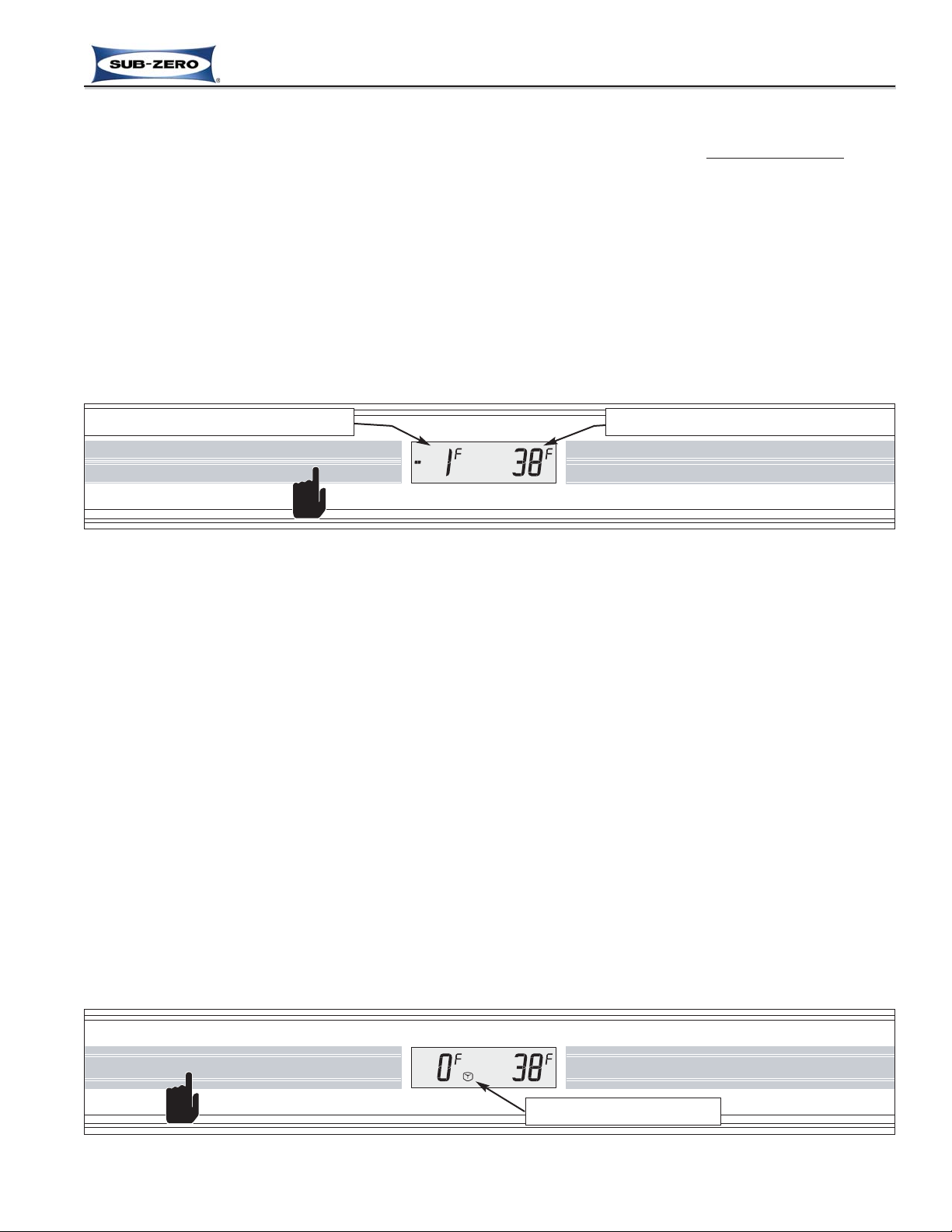

BASIC ELECTRONIC CONTROL INPUT OPERATIONS

The following pages describe the basic input operations performed at the control panel (switching unit ON and OFF;

adjusting set-point (temperature adjustment); switching ice maker system ON and OFF; activate and deactivate

maximize ice production feature; enabling and disabling door ajar alarm feature; activate and deactivate air purification feature; and in models with glass doors only, switching accent lighting system ON and OFF). Please note that

though possible to display temperatures in Fahrenheit or Celsius, in most cases Fahrenheit readings are shown in

this manual.

Unit ON/OFF

All units are shipped in OFF Mode. When electricity is supplied to the appliance, a short power up diagnostics test

is initiated where the lights are energized, “- -” (double-dashes) appear in the LCD, followed by the model code, then

all components are switched OFF and the word “OFF” appears in the LCD (See Figure 3-5). By pressing the

POWER key for one (1) second, electricity is allowed past the control board to the rest of the unit (See Figure 3-6),

indicated by two audible beeps, the lights energizing and temperature readings appearing in the LCD.

NOTES:

• Whenever the unit is switched OFF using the POWER key, the word “OFF” will be visible in the LCD as long as

there is electricity supplied to the appliance.

• Whenever the unit is switched ON using the POWER key, the model code will appear in the LCD for approximately two (2) seconds, then temperature readings will appear.

• If the unit experiences any problems during the power up diagnostic test, then the appropriate Fault Codes will be

logged.

PURE AIR WARMER COLDER WARMER COLDER ALARM POWER MAX ICE ICE MAKER LIGHTS

Figure 3-6. Switching Unit ON (or OFF) - Press POWER Key, Actual Temperatures will be Displayed

WHEN IN “OFF” MODE, AC LINE VOLTAGE IS STILL PRESENT AT CONTROL BOARD!

Previous Page

Next Page

Main Menu

Built-In Series Menu

Built-In Series Menu

Previous Page

Main Menu

Table of Contents

Next Page

Page 6

Electronic Control System

3-7

#7019014 - Revision A - October, 2010

Built-In (BI) Series

Built-In (BI) Series

Adjusting Set-Point (Temperature Adjustment)

To adjust set-points, press the appropriate WARMER or COLDER key on control panel in multiple key strokes

until

the desired set-point is achieved (See Figure 3-7). Each key stroke equals a one degree change and is accompanied by an audible beep. When the desired set-point is reached and the keys are no longer being pressed, the setpoint will flash ON and OFF at two (2) second intervals for ten (10) seconds, then the current zone temperature will

be displayed.

NOTES:

• During initial pull-down the real-time compartment temperatures will be displayed, then once set-point tempera-

tures are achieved, the temperature shown in the LCD can change by no more than one (1) degree per minute.

• The temperature range in a freezer zone is -5°F (-20°C) to +5°F (-15°C).

• The temperature range in a refrigerator zone is +34°F (+1°C) to +45°F (+7°C).

• Initial factory set-points are 0°F (-18°C) in a freezer zone and 38°F (3°C) in a refrigerator zone.

• The initial stroke of the WARMER or COLDER key will change the previous set-point by one degree.

PURE AIR WARMER COLDER WARMER COLDER ALARM POWER MAX ICE ICE MAKER LIGHTS

Figure 3-7. Adjusting Set-Point - Press Desired WARMER or COLDER Key In Multiple Key Strokes

Freezer Set-Point/Temperature Display

Refrigerator Set-Point/Temperature Display

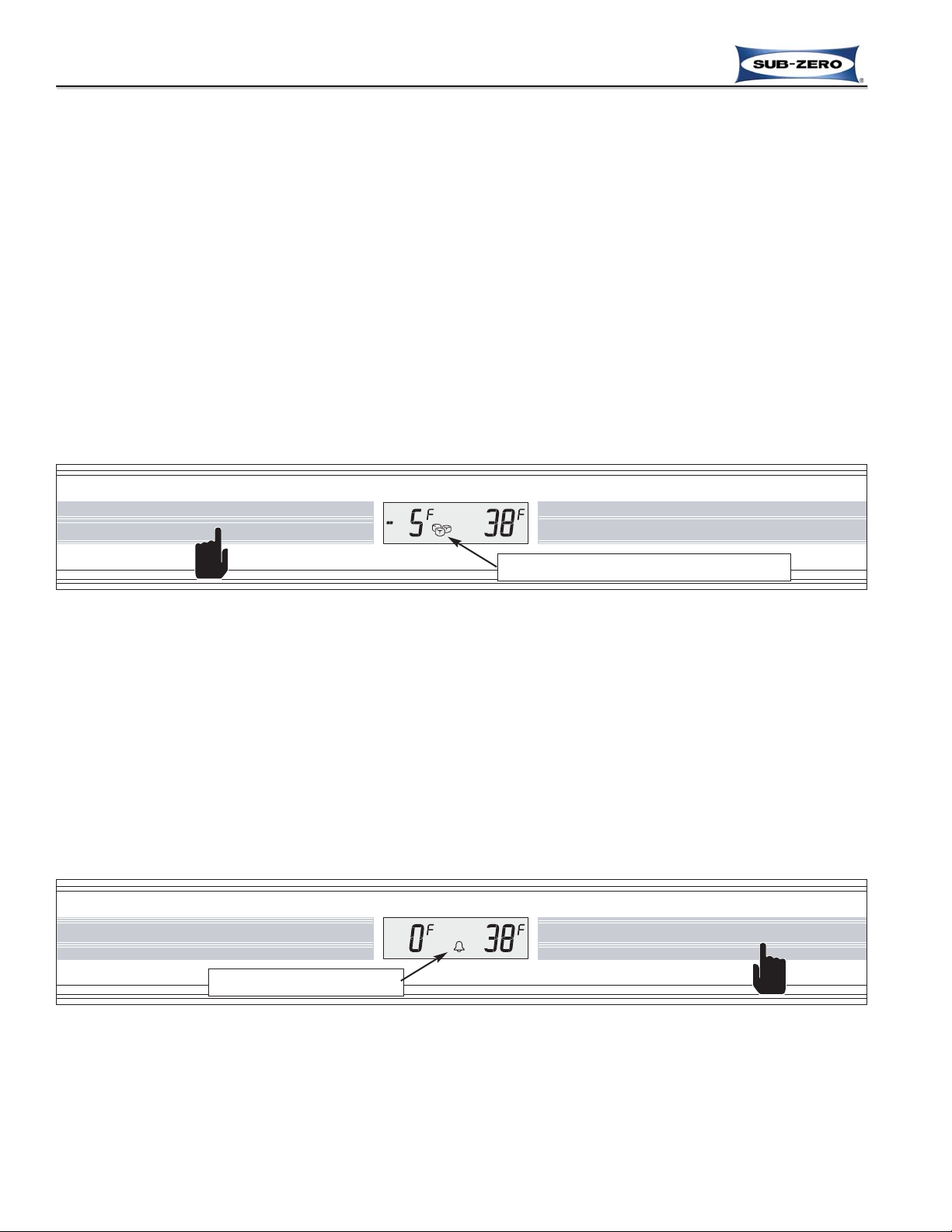

Ice Maker System ON/OFF

All units are shipped with the ice maker system switched OFF. By pressing the ICE MAKER key on the control

panel, power is allowed to the ice maker system and the single ice cube icon appears in the LCD (See Figure 3-8).

To switch the ice maker system OFF, press the ICE MAKER key again and the single ice cube icon disappears.

NOTES:

• Power to the freezer lights is monitored to help control icemaker operation. If the freezer door is open, power to

the ice maker system is interrupted, unless the icemaker is filling with water at that time. After the door is closed,

power is not allowed to the ice maker system for an additional three (3) minutes, unless the Maximum Ice

Production feature has been initiated.

• The ice maker system will continue to produce ice if the ice bucket is not in the correct position. However, to help

prevent the ice maker system from filling the freezer with ice, the electronic control will not allow twenty (20) consecutive ice harvests between any two door openings.

• To allow ice to freeze fully and reduce effects of low water pressure, power to the ice maker system is interrupted

for forty-five (45) minutes after each ice harvest. This can be bypassed for service purposes by switching the icemaker system OFF, then back ON with the ICE MAKER key.

• The fill tube heater is energized 100% of the time whenever the ice maker system is ON.

• When in Sabbath Mode, the icemaker system is disabled. Sabbath Mode will be explained later.

• The ice maker system is disabled whenever the water filter or water filter plug is removed.

Figure 3-8. Switch Ice Maker System ON or OFF - Press ICE MAKER Key, Single Ice Cube Appears when ON

PURE AIRWARMERCOLDER WARMERCOLDER ALARM POWERMAX ICEICE MAKERLIGHTS

Ice Maker System is ON

Previous Page

Next Page

Main Menu

Built-In Series Menu

Built-In Series Menu

Previous Page

Main Menu

Table of Contents

Next Page

Page 7

Electronic Control System

3-8

#7019014 - Revision A - October, 2010

Built-In (BI) Series

Built-In (BI) Series

Figure 3-10. Switching Door Ajar Alarm ON or OFF - Press ALARM Key, Bell Appears when Activated

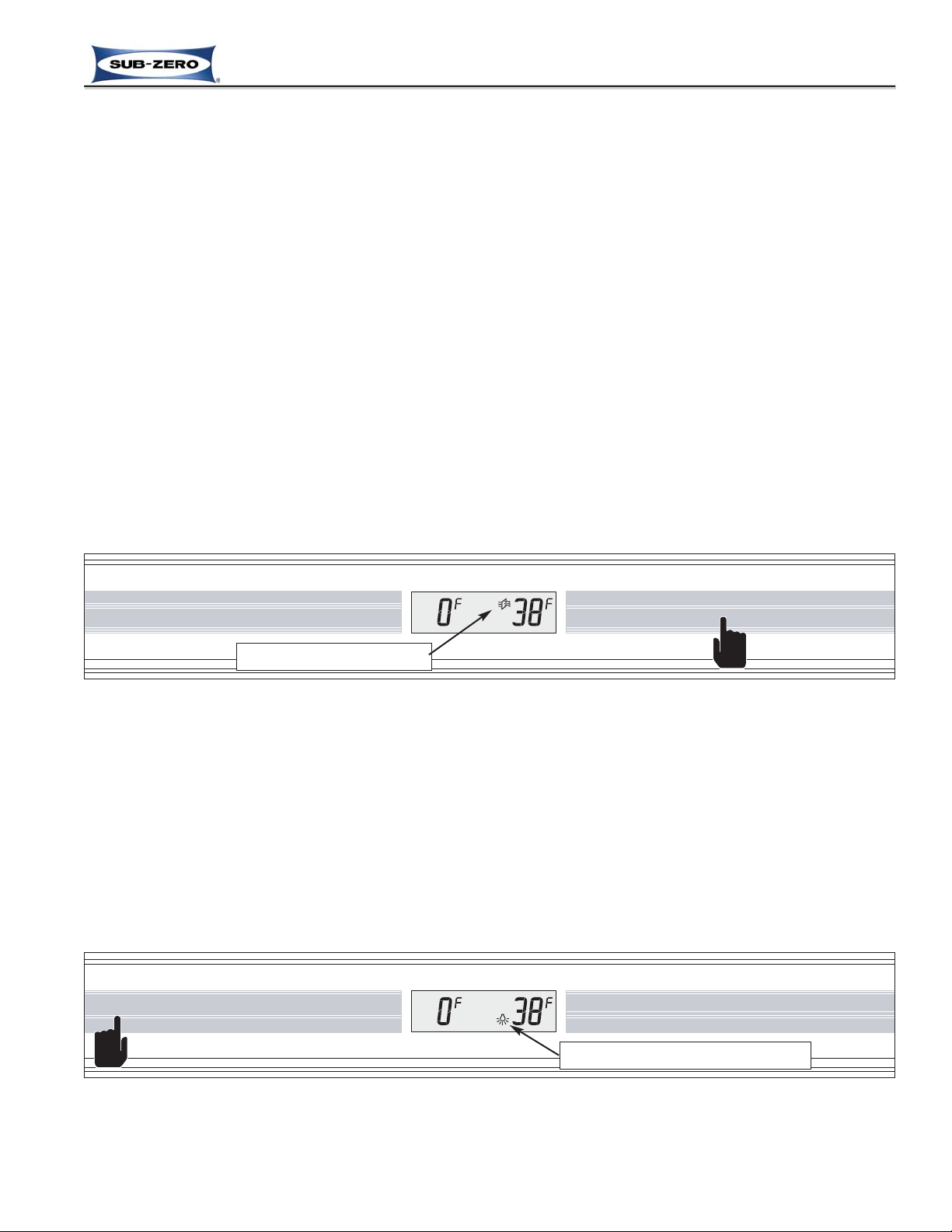

Door Ajar Alarm Feature ON/OFF

All BI Series units are equipped with a door ajar alarm feature. To enable the door ajar alarm, press the ALARM key

on the control panel and the bell icon will appear in the LCD indicating the alarm is enabled (See Figure 3-10). With

the alarm enabled, the bell icon will flash and an audible alarm will chime at two (2) second intervals whenever a

door is left open for more then thirty or sixty (30 or 60) seconds, depending on vintage. To disable the door ajar

alarm, press the ALARM key again and the bell icon disappears from the LCD.

Maximize Ice Production Feature

These appliances are equipped with a feature that can boost ice production up to 40% above normal. By pressing

the MAX ICE key on the control panel, the ice maker system is switched ON (if OFF); multiple ice cube icons appear

in the LCD (See Figure 3-9); the freezer set-point is automatically set to -5°F (-21°C) for twenty-four (24) hours, and

the freezer evaporator fan is switched to 100% run for twenty-four (24) hours, switching off only when the door is

opened.

After twenty-four (24) hours, the freezer set-point reverts to the last manually input set-point, the freezer evaporator

fan resumes its normal operation (cycling with the compressor); and two of the three ice cube icons disappear from

the LCD, indicating normal ice production has resumed.

NOTES:

• When the maximize ice production feature is active, power to the icemaker system is NOT interrupted after ice

harvest, so the icemaker will initiate a harvest as soon as the thermostat reaches 10°F (-12°C).

• Switching the unit OFF, then back ON with the POWER key, or pressing the MAX ICE key during the twenty-four

(24) hour production period will switch the maximize ice production feature OFF.

• When in Sabbath Mode, the icemaker system is disabled. Sabbath Mode will be explained later.

• The ice maker system is disabled whenever the water filter or water filter plug is removed.

Figure 3-9. Maximize Ice Production Feature ON or OFF - Press MAX ICE Key,

Multiple Ice Cubes Appear when Activated

PURE AIRWARMERCOLDER WARMERCOLDER ALARM POWERMAX ICEICE MAKERLIGHTS

Maximize Ice Production Feature Activated

PURE AIR WARMER COLDER WARMER COLDER ALARM POWER MAX ICE ICE MAKER LIGHTS

Alarm Feature is ON

Previous Page

Next Page

Main Menu

Built-In Series Menu

Built-In Series Menu

Previous Page

Main Menu

Table of Contents

Next Page

Page 8

Electronic Control System

3-9

#7019014 - Revision A - October, 2010

Built-In (BI) Series

Built-In (BI) Series

Accent Lighting System ON/OFF (Models Produced with Glass Doors Only)

Models produced with glass refrigerator doors are equipped with an accent lighting system in the refrigerator compartment. To energize the accent lighting system, press the LIGHTS key, and the bulb icon will appear in the LCD

indicating the accent lights are enabled (See Figure 3-12). With the accent lighting system energized, the accent

LED strip will be energized and stay illuminated when the door is closed. To disable the accent lights, press the

LIGHTS key again.

Figure 3-12. Accent Lighting System ON or OFF - Press the LIGHT Key, Bulb Appears when Activated

PURE AIR WARMER COLDER WARMER COLDER ALARM POWER MAX ICE ICE MAKER LIGHTS

Accent Lighting System is Activated

Air Purification Feature ON/OFF

An air purification feature has been incorporated into these appliances to remove bacteria and ethylene gas (byproducts of ripening fruits and vegetables). The two main parts of this air purifier are a replaceable cartridge consisting of a small light and a filter medium, and a small low DC Voltage fan below the cartridge. The fan drives the

refrigerator compartment air through the cartridge, over the light induced chemical filtering system which converts

these harmful airborne food storage by-products into water vapor and carbon dioxide. Please note that this is not

intended to be an “air deodorizer”, but rather a devise that helps to preserve foods for longer storage life by removing these food storage by-products.

To activate the air purification feature, press the PURE AIR key, and the Pure Air Icon appears in the LCD indicating

the air purification feature has been activated (See Figure 3-11). When activated, the UV light in the filter cartridge

and the fan motor under the cartridge are energized 100% of the time, unless the refrigerator door is opened or the

unit is in Showroom Mode.

After approximately eight-thousand (8000) hours of use, the Pure Air Icon will flash, indicating it is time to change

the air purifier cartridge. To stop the Pure Air Icon from flashing and reset the timer after the cartridge is replaced,

the PURE AIR key must be pressed and held for five (5) seconds.

NOTES:

• If the unit is in Sabbath Mode, the air purifier fan will not switch OFF when the refrigerator door is opened.

• If in Showroom Mode, the air purifier will operate for thirty (30) seconds whenever the door is open or the PURE

AIR key is pressed. Pressing the PURE AIR key again will force the air purifier ON for another thirty (30) seconds.

• If the light bulb in the cartridge should fail, the Pure Air Icon will flash and the appropriate fault code will be logged.

Figure 3-11. Air Purification ON or OFF - Press PURE AIR Key, Pure Air Icon Appears when ON

PURE AIR WARMER COLDER WARMER COLDER ALARM POWER MAX ICE ICE MAKER LIGHTS

Air Purifier Feature is ON

Previous Page

Next Page

Main Menu

Built-In Series Menu

Built-In Series Menu

Previous Page

Main Menu

Table of Contents

Next Page

Page 9

Electronic Control System

3-10

#7019014 - Revision A - October, 2010

Built-In (BI) Series

Built-In (BI) Series

UNIQUE ELECTRONIC CONTROL INPUT OPERATIONS

The following pages illustrate unique customer input operations performed at the control panel. The input operations

described are: Temperature Unit Selection Mode, Contrast Adjust Mode, Tone Adjust Mode, Showroom Mode,

Sabbath Mode, Manual Zone Disable and Manual Freezer Evaporator Defrost.

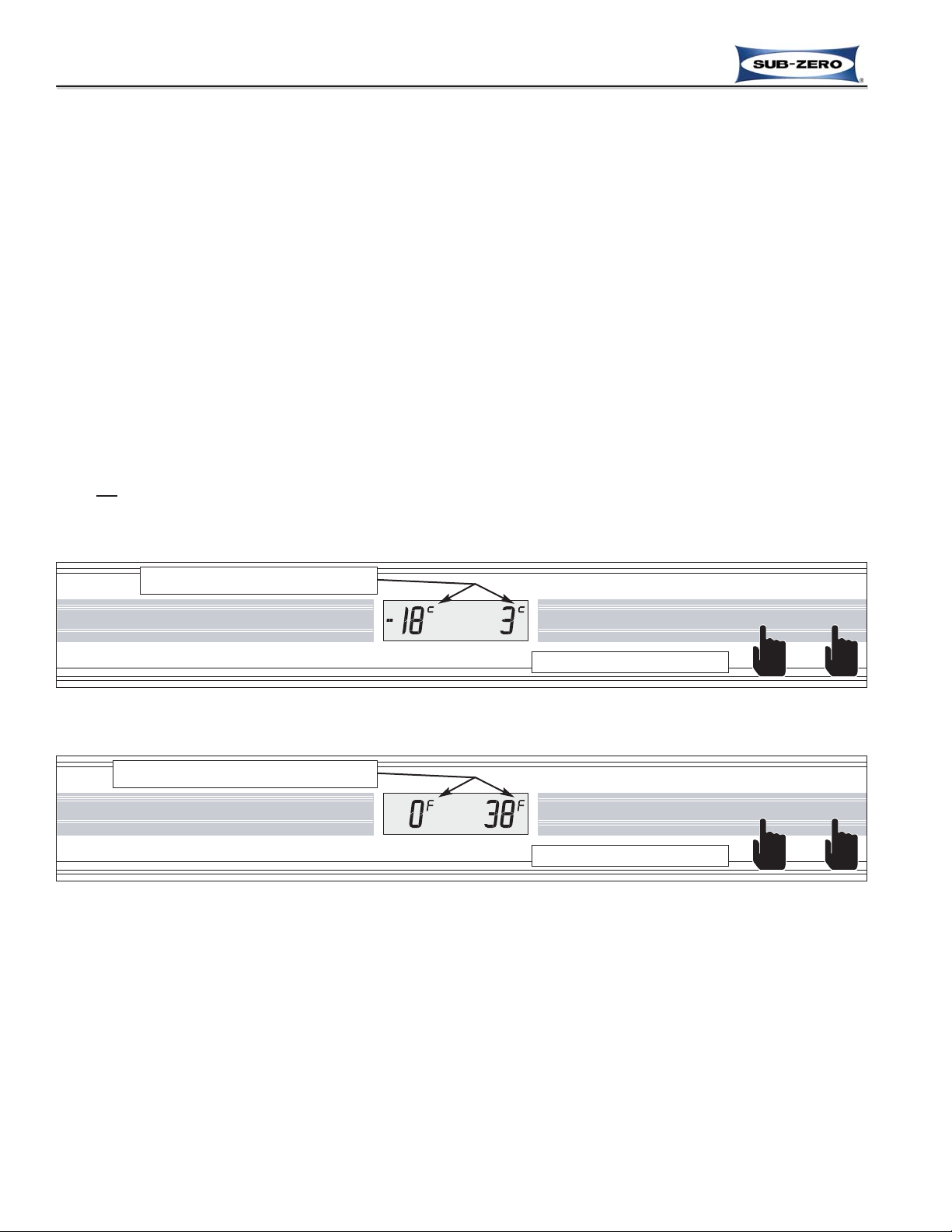

Temperature Units Selection Mode (Selecting Degrees Fahrenheit or Degrees Celsius Display)

The appliance is initially set to display temperatures in Fahrenheit temperature units of measure, indicated by the “F”

at the upper right of the temperature readings in the LCD. This can be changed so Celsius units of measure are displayed by initiating Temperature Units Selection Mode.

NOTE: Temperature Units Selection Mode must be initiated within the first (1) minute after switching the unit ON.

To convert Fahrenheit (°F) temperature units of measure to Celsius (°C) within the first minute after switching the

unit ON, press and hold the ALARM key and the POWER key simultaneously for five (5) seconds, then release the

keys (See Figure 3-13); a “c“ will appear at the upper right of the temperature readings in the LCD, indicating that

temperatures will now be displayed in Celsius units of measure. Please note that changing from Celsius temperature units of measure to Fahrenheit is the same procedure (See Figure 3-14).

NOTES:

• Do not

press and hold the POWER key first, that will simply switch the unit OFF.

• Temperature Units Selection Mode will end ten (10) seconds after the last key stroke, or the ALARM key can be

pressed to exit this mode before the ten (10) seconds has elapsed.

PURE AIR WARMER COLDER WARMER COLDER ALARM POWER MAX ICE ICE MAKER LIGHTS

Figure 3-13. Converting Temperature Units of Measure to °C (within first minute after switching unit ON) -

Press and Hold ALARM Key and POWER Key for 5 Seconds

Press and hold for 5 seconds

Figure 3-14. Converting Temperature Units of Measure to °F (within first minute after switching unit ON) -

Press and Hold ALARM Key and POWER Key for 5 Seconds

Indicates Celsius Units of Measure

PURE AIR WARMER COLDER WARMER COLDER ALARM POWER MAX ICE ICE MAKER LIGHTS

Press and hold for 5 seconds

Indicates Fahrenheit Units of Measure

Previous Page

Next Page

Main Menu

Built-In Series Menu

Built-In Series Menu

Previous Page

Main Menu

Table of Contents

Next Page

Page 10

Electronic Control System

3-11

#7019014 - Revision A - October, 2010

Built-In (BI) Series

Built-In (BI) Series

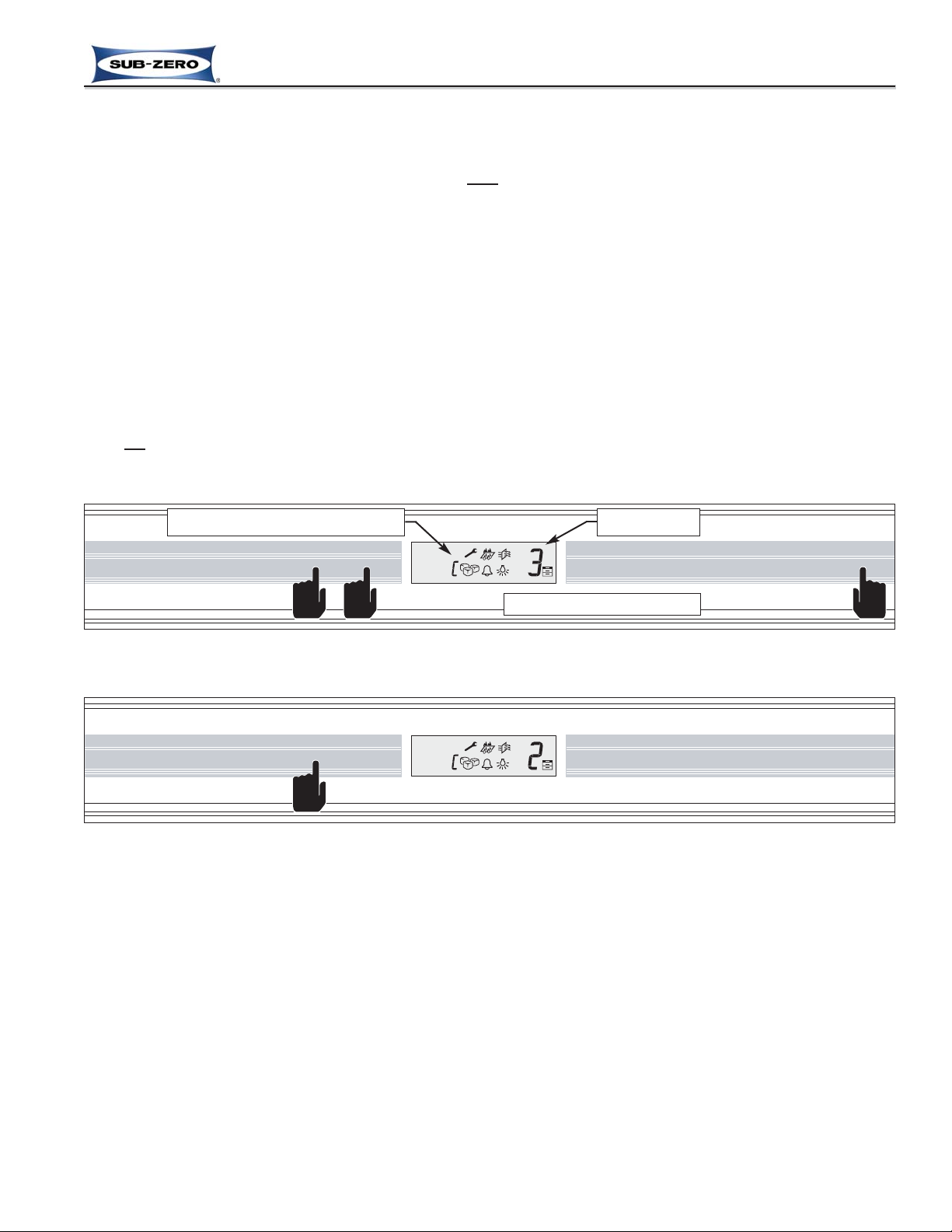

Contrast Adjust Mode (Adjusting the LCD Contrast Level)

The contrast level of the LCD can be manually adjusted to one of five levels through Contrast Adjust mode.

NOTE: Contrast Adjust Mode can be initiated anytime af

ter the first (1) minute of switching the unit ON.

To adjust the LCD contrast level anytime after the first minute of switching the unit ON, press and hold either set of

COLDER and WARMER keys and the POWER key simultaneously for five (5) seconds, then release the keys (See

Figure 3-15). The letter “C” will appear at the small digit location in the LCD indicating the control is now in Contrast

Adjust Mode and a number 1, 2, 3, 4, or 5 will appear at the right side of the LCD, indicating the last contrast level

setting. Pressing a COLDER key at this time will decrease the number; pressing a WARMER key will increase the

number (See Figure 3-16).

Please note that what is actually happening here is the segments and icons in the LCD are slanting at slightly different angles for each level adjustment. This means that the lower numbers will not always indicate less contrast and

the higher numbers will not always indicate more contrast, as it depends on the line of sight of the user. In fact a tall

person and a short person standing side-by-side during the adjustment may see the contrast level move in totally

opposite directions; one seeing it increase, the other seeing it decrease.

NOTES:

• Do not

press and hold the POWER key first, that will simply switch the unit OFF.

• Contrast Adjust Mode will end ten (10) seconds after the last key stroke, or press ALARM key to exit.

PURE AIR WARMER COLDER WARMER COLDER ALARM POWER MAX ICE ICE MAKER LIGHTS

Figure 3-15. Adjusting LCD Contrast Level (any time after first minute of switching unit ON) -

Press and Hold COLDER, WARMER and POWER Keys for 5 Seconds

Press and hold for 5 seconds

Figure 3-16. Press COLDER or WARMER Key to Change Contrast Level

(Pressing COLDER Shown - Decrease Number)

“C” Indicates Contrast Adjust Mode

Contrast Level

PURE AIR WARMER COLDER WARMER COLDER ALARM POWER MAX ICE ICE MAKER LIGHTS

Previous Page

Next Page

Main Menu

Built-In Series Menu

Built-In Series Menu

Previous Page

Main Menu

Table of Contents

Next Page

Page 11

Electronic Control System

3-12

#7019014 - Revision A - October, 2010

Built-In (BI) Series

Built-In (BI) Series

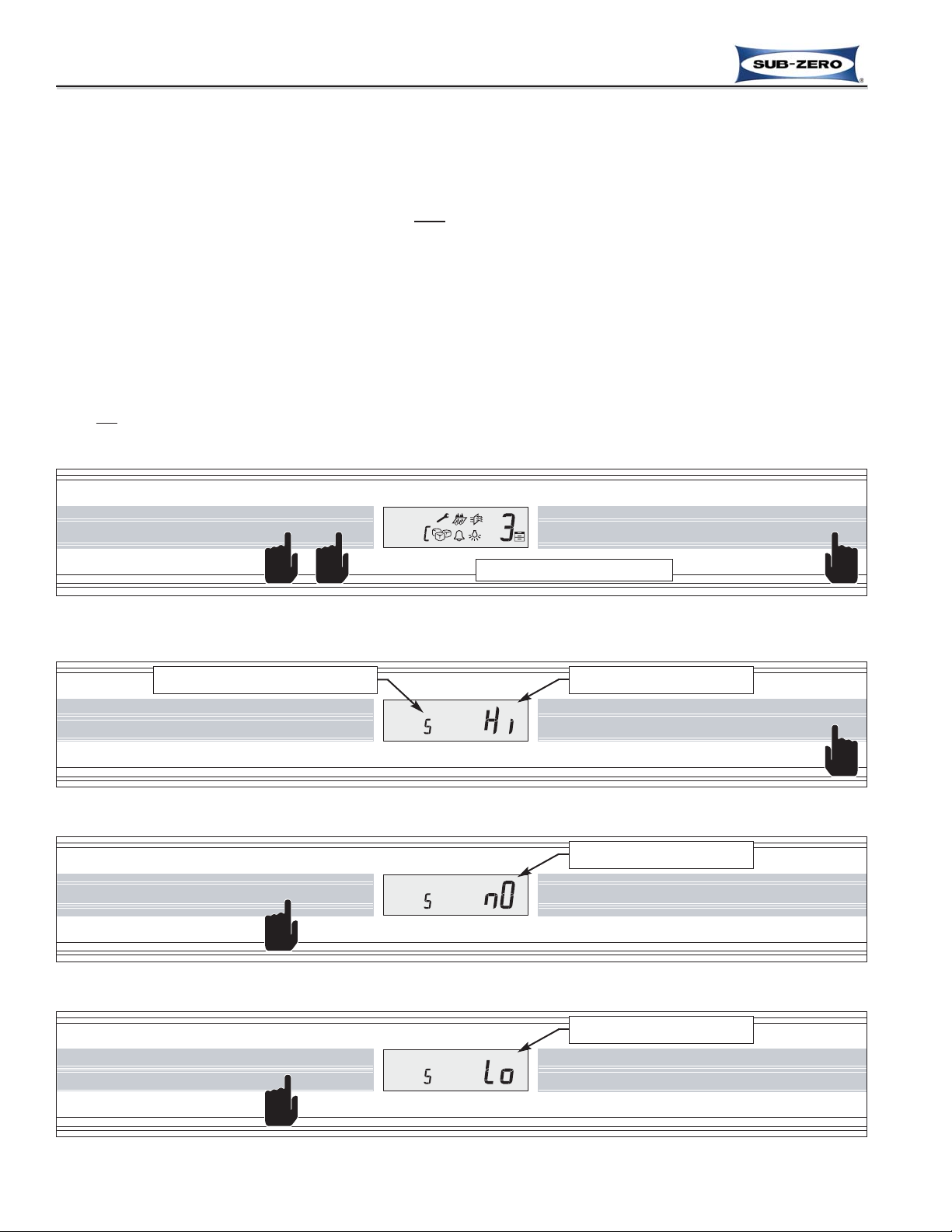

Tone Adjust Mode (Adjusting the Audible Chime Tone)

The tone of the electronic control audible chime is preset at the factory. This preset level is referred to as the “normal” tone, but it can be manually adjusted down to low, or up to high, for a total of three possible settings. This is

possible through Tone Adjust Mode.

NOTE: Tone Adjust Mode can be initiated anytime af

ter the first (1) minute of switching the unit ON.

To adjust the chime tone, first initiate Contrast Adjust Mode by pressing and holding either set of COLDER and

WARMER keys and the POWER key simultaneously for five (5) seconds, then release the keys (See Figure 3-17).

While in Contrast Adjust Mode, press the POWER key, and the letter “S” (for “Sound”) will appear at the small digit

location in the LCD indicating the control is now in Tone Adjust Mode. At the right side of the LCD will be the letters

“Hi” (for High), or “nO” (for Normal), or “Lo” (for Low), indicating the last tone setting (See Figure 3-18). Pressing a

COLDER key at this time will decrease the tone setting and the chime will sound in the lower/softer tone; while

pressing a WARMER key will increase the tone setting and the chime will sound in the higher/louder tone (See

Figures 3-19 and 3-20).

NOTES:

• Do not

press and hold the POWER key first, that will simply switch the unit OFF.

• Tone Adjust Mode will end ten (10) seconds after the last key stroke, or press ALARM key to exit.

PURE AIR WARMER COLDER WARMER COLDER ALARM POWER MAX ICE ICE MAKER LIGHTS

Figure 3-17. Adjusting Chime Tone (any time after first minute of switching unit ON) - Initiate Contrast

Adjust Mode First; Press and Hold COLDER, WARMER and POWER Keys for 5 Seconds

Press and hold for 5 seconds

Figure 3-18. While in Contrast Adjust Mode, Press POWER Key to Initiate Tone Adjust Mode

PURE AIR WARMER COLDER WARMER COLDER ALARM POWER MAX ICE ICE MAKER LIGHTS

“S” Indicates Tone Adjust Mode

Tone Level. “Hi” = High

Figure 3-19. Press COLDER Key to Decrease Tone; Press WARMER Key to Increase Tone

PURE AIR WARMER COLDER WARMER COLDER ALARM POWER MAX ICE ICE MAKER LIGHTS

Tone Level. “nO” =Norman

Figure 3-20. Press COLDER Key to Decrease Tone; Press WARMER Key to Increase Tone

PURE AIR WARMER COLDER WARMER COLDER ALARM POWER MAX ICE ICE MAKER LIGHTS

Tone Level. “nO” =Norman

Previous Page

Next Page

Main Menu

Built-In Series Menu

Built-In Series Menu

Previous Page

Main Menu

Table of Contents

Next Page

Page 12

Electronic Control System

3-13

#7019014 - Revision A - October, 2010

Built-In (BI) Series

Built-In (BI) Series

PURE AIR WARMER COLDER WARMER COLDER ALARM POWER MAX ICE ICE MAKER LIGHTS

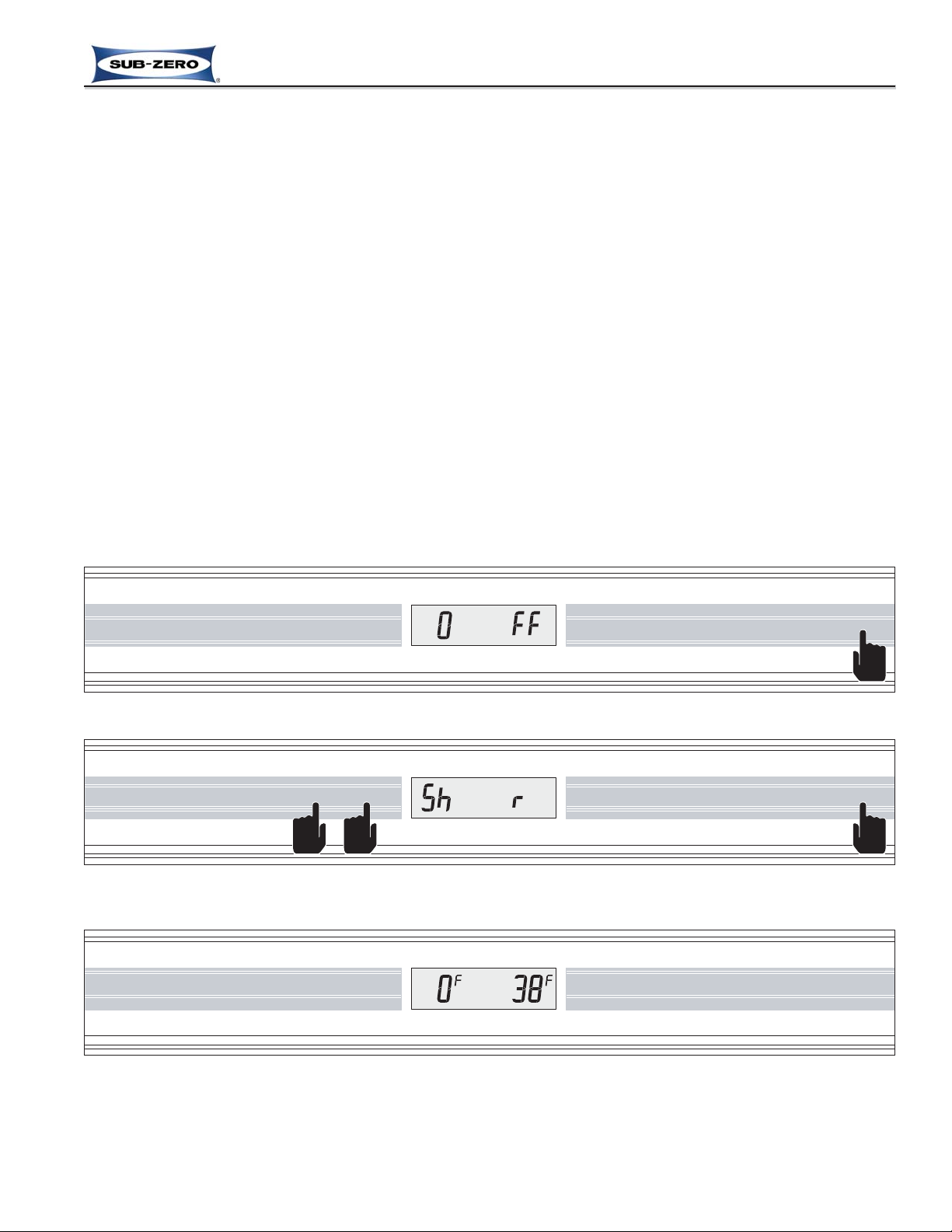

Showroom Mode

Showroom Mode was incorporated into the electronic control system so that these appliances could be displayed in

a showroom setting. When in Showroom Mode all cooling, defrosting, ice making and dispensing (if applicable)

functions are disabled, but the lighting system and door ajar alarm system remain operational, and the LCD will

show the set-points.

To initiate Showroom Mode, the unit must first be switched OFF using the POWER key (See Figure 3-21). Then,

press and hold either pair of WARMER and COLDER keys, then the POWER key, at which point three (3) beeps will

be emitted and “Sh” and “r” will appear in the LCD for five (5) seconds indicating the appliance is now is showroom

mode (See Figure 3-22). After the initial five seconds, set-points will appear in the LCD (See Figure 3-23).

To return the unit to normal operation, repeat the steps above.

NOTES:

• The air purifier will be energized for thirty (30) seconds any time the door is opened or the PURE AIR key is

pressed.

• The lighting system will be disabled for twenty (20) minutes if the lights stay ON more than 90% of the time in any

given fifteen (15) minutes, or if a compartment thermistor reports a temperature greater than ambient plus thirty

(30) degrees, or if an evaporator thermistor reports a temperature greater than ambient plus twenty (20) degrees.

• For demonstration purposes, the water filter icon can be forced ON during Showroom Mode by pressing the ICE

MAKER key for five (5) seconds. To switch it OFF, press the filter reset button behind the unit grille for five (5)

seconds.

• Units with glass refrigerator doors contain a glass door heater, which is disabled while in Showroom mode.

• Always check set-points after returning unit to normal operation.

Figure 3-22. Then Press and Hold Either Pair of WARMER and COLDER Keys, Then the POWER Key -

“Sh” and “r” appear for 5 Seconds

Figure 3-21. To Enter (or Exit) Showroom Mode, Switch Unit OFF First

PURE AIR WARMER COLDER WARMER COLDER ALARM POWER MAX ICE ICE MAKER LIGHTS

PURE AIR WARMER COLDER WARMER COLDER ALARM POWER MAX ICE ICE MAKER LIGHTS

Figure 3-23. Set-points Appear in LCD 5 seconds after Showroom Mode is Initiated

Previous Page

Next Page

Main Menu

Built-In Series Menu

Built-In Series Menu

Previous Page

Main Menu

Table of Contents

Next Page

Page 13

Electronic Control System

3-14

#7019014 - Revision A - October, 2010

Built-In (BI) Series

Built-In (BI) Series

Figure 3-25. Then Press and Hold POWER Key for 10 seconds

PURE AIR WARMER COLDER WARMER COLDER ALARM POWER MAX ICE ICE MAKER LIGHTS

Sabbath Mode

Sabbath Mode was incorporated into the electronic control system for the observance of certain religious days.

When Sabbath Mode is initiated the lighting systems, ice making system, dispensing system (if applicable), alarm

system and the air purification feature are disabled, plus the letters “SA” and “b” will appear in the LCD.

To initiate Sabbath Mode, the unit must first be switched OFF using the POWER key (See Figure 3-24). Then,

press and hold the POWER key for ten (10) seconds, at which time the alarm will chime, and “SA” and “b” will

appear in the LCD (See Figure 3-25).

To return to normal operation, press the POWER key, the lights will be energized accompanied by two beeps and

current zone temperature will appear in the LCD.

NOTES:

• Set-points cannot be changed and manual defrost cannot be initiated.

• The following holds true in accordance with Star-K requirements:

- Freezer defrosting functions will convert to a fixed time base sequence instead of adaptive defrosting, which is

usage based.

- The compartment/zone thermistors will still detect high off-set, which is the determining factor to start the cooling

process, but there will be a random fifteen (15) to twenty-five (25) second delay before cooling begins.

- The “SA” and “b” in the LCD remain energized when the door is closed.

• When Sabbath Mode is exited, the accent lights, door alarm, icemaker and air purification system will return to the

ON or OFF state they were in prior to initiating Sabbath Mode.

Figure 3-24. To Enter Sabbath Mode, Switch Unit OFF First

PURE AIR WARMER COLDER WARMER COLDER ALARM POWER MAX ICE ICE MAKER LIGHTS

Press and hold for 10 seconds

Previous Page

Next Page

Main Menu

Built-In Series Menu

Built-In Series Menu

Previous Page

Main Menu

Table of Contents

Next Page

Page 14

Electronic Control System

3-15

#7019014 - Revision A - October, 2010

Built-In (BI) Series

Built-In (BI) Series

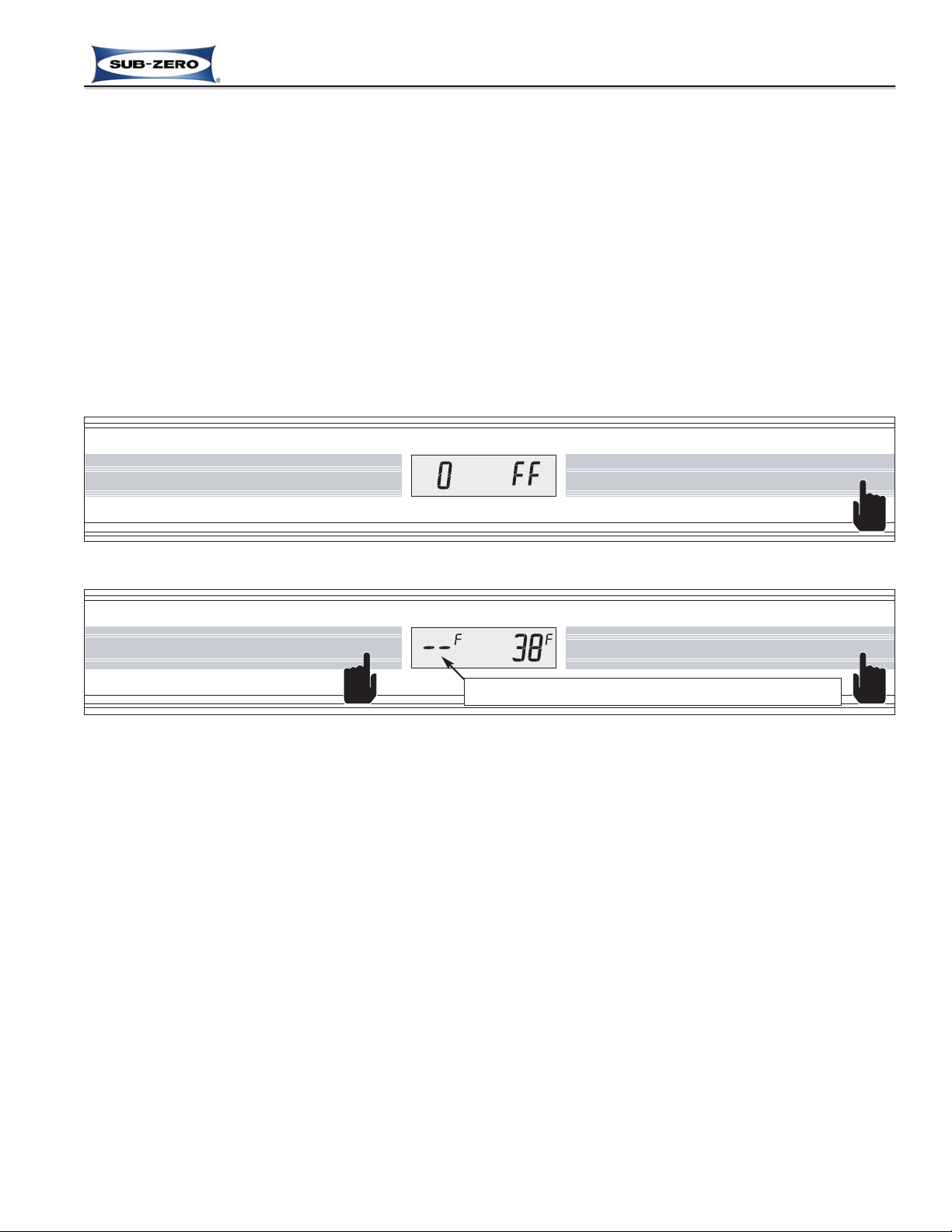

Manual Zone Disable Mode

Manual Zone Disable Mode allows a customer or Service Technician to switch one zone, or “compartment” OFF for

defrosting, interior cleaning, or diagnostic purposes, while allowing the other zones to continue cooling.

To initiate Manual Zone Disable Mode, the unit must first be switched OFF using the POWER key (See Figure 3-26).

Now, press and hold the WARMER key for the zone being disabled, then the POWER key, then release both keys,

at which time “- -” (double-dashes) will appear in place of temperature readings for the chosen zone (See Figure 3-

27).

To return the disabled zone to operational state, repeat the steps above.

NOTE:

• If switched OFF then back ON, the electronic control stores this mode-set in non-volatile memory, so the disabled

zone will remain disabled until the proper key sequence is performed to reenable the zone.

• The alarm system for the disabled zone is inactive during this mode.

• Always check set-points after returning unit to normal operation.

Figure 3-27. Then Press and Desired Zone WARMER Key along with the POWER Key

PURE AIR WARMER COLDER WARMER COLDER ALARM POWER MAX ICE ICE MAKER LIGHTS

Figure 3-26. To Disable a Zone, Switch Unit OFF First by Pressing the POWER Key

PURE AIR WARMER COLDER WARMER COLDER ALARM POWER MAX ICE ICE MAKER LIGHTS

Indicates Cooling Functions for Zone Have Been Disabled

Previous Page

Next Page

Main Menu

Built-In Series Menu

Built-In Series Menu

Previous Page

Main Menu

Table of Contents

Next Page

Page 15

Electronic Control System

3-16

#7019014 - Revision A - October, 2010

Built-In (BI) Series

Built-In (BI) Series

Manual Freezer Evaporator Defrost

Manual Freezer Evaporator Defrost was incorporated into the electronic control to assist a customer that may inadvertently leave the freezer door ajar, causing a heavily frosted evaporator, and may also be utilized by a Service

Technician for servicing and diagnostics.

To initiate manual freezer evaporator defrost the unit must be ON, then press and hold the ICE MAKER key for five

(5) seconds, at this time the freezer evaporator temperature will be displayed at left in the LCD with the refrigerator

evaporator temperature displayed at right for five (5) seconds (See Figure 3-28), then compartment temperatures

will be displayed (See Figure 3-29).

NOTES:

• Though the refrigerator evaporator temperature is also shown when manual defrost is initiated, only the freezer

evaporator is affected.

• Manual Freezer Evaporator Defrost will not operate if unit is in Sabbath Mode.

• The defrost terminator will not allow power to the defrost heater if the evaporator is above 30°F (1°C).

PURE AIRWARMERCOLDER WARMERCOLDER ALARM POWERMAX ICEICE MAKERLIGHTS

Figure 3-28. Initiate Manual Freezer Evaporator Defrost - Press and Hold ICE MAKER Key for 5 Seconds

Press and hold for 5 seconds

Evaporator Temperatures Displayed for 5 Seconds when Initiated

PURE AIR WARMER COLDER WARMER COLDER ALARM POWER MAX ICE ICE MAKER LIGHTS

Figure 3-29. Compartment Temperatures Displayed 5 Seconds after Manual Defrost is Initiated

Previous Page

Next Page

Main Menu

Built-In Series Menu

Built-In Series Menu

Previous Page

Main Menu

Table of Contents

Next Page

Page 16

Changing the Dispenser Lighting States

There are three possible lighting states at the dispenser assembly:

• All Lights ON (blue keys and white glasswell)

• Key Lights ON only

• All Lights OFF

Press the LIGHT key in multiple key strokes until the desired lighting

state is achieved (See Figure 3-30).

NOTE: During water or ice dispensing, all lights will illuminate until dis-

pensing is complete, then lights will return to their previous state.

Dispensing Water

To operate the water dispenser, set a glass on the grille of the glasswell, then press and hold the WATER key until the desired amount of

water is received (See Figure 3-31).

NOTE: Before the water dispenser is used for the first time, or after

servicing the water dispensing system, the water reservoir tank, water

lines and plumbing connection must be purged of air by pressing the

WATER key for approximately three (3) minutes. This will clear any air

from the system, along with any foreign materials that may be present

in the plumbing connection.

Dispensing Ice

The ice dispenser in these models uses a delay, or metering feature to

limit the amount of ice dispensed each time the ICE key is pressed in

approximately two (2) second intervals.

To dispense ice, set a glass on the grille of the glasswell, then press

and hold the ICE key for approximately two (2) seconds, and the dispenser will meter out the ice, collect it in the cylinder valve directly

above the glass, then turn the cylinder valve to drop the ice into the

glass (See Figure 3-32).

If less ice is desired, hold the ICE key for less than two (2) seconds; if

more ice is desired, hold the ICE key until the dispensing cycle repeats.

NOTE: The ice dispenser can be reprogrammed to deactivate the delayed dispense feature, which would allow the

dispenser cylinder valve and ice auger motor to remain energized continuous whenever the ICE key is pressed and

held. This is referred to as Delayed Dispense Reset, and is covered on the next page.

Electronic Control System

3-17

#7019014 - Revision A - October, 2010

Built-In (BI) Series

Built-In (BI) Series

DOOR DISPENSER CONTROL INPUT OPERATIONS (MODELS BI42SD AND BI48SD ONLY)

Models equipped with an ice and water dispenser through the refrigerator door utilize a capacitance touch control

panel similar to the main control panel. Below are the input operations a customer or Service Technician may perform at the door dispenser control panel.

Figure 3-31. Dispense Water - Press

and Hold WATER Key

Figure 3-32. Water Dispense - Press

and Hold ICE Key

Figure 3-30. Choose Light State -

Press LIGHT Key in Multiple Strokes

The dispenser assembly operates on low DC voltage. Never apply AC line voltage to the dispenser components, doing so will damage the appliance.

Previous Page

Next Page

Main Menu

Built-In Series Menu

Built-In Series Menu

Previous Page

Main Menu

Table of Contents

Next Page

Page 17

Electronic Control System

3-18

#7019014 - Revision A - October, 2010

Built-In (BI) Series

Built-In (BI) Series

Locking the Dispenser

The dispenser assembly is equipped with a Lock feature which deactivates all keys on the dispenser control panel to prevent unintended ice

and water dispensing while cleaning and/or to prevent small children

from using the dispenser.

To activate the lock feature, press and hold the LIGHT key for approximately five (5) seconds (See Figure 3-33), until the dispenser lights

flash once and the key ( ) icon illuminates red. The dispenser lights

will remain in the state they were in before the lock feature was activated.

To deactivate the lock feature, press and hold the LIGHT key again for approximately five (5) seconds, until the dispenser lights flash once and the red key icon is no longer illuminated. The lights will remain in the state they were in

before the lock feature was deactivated.

Delayed Dispense Reset Mode (Deactivating/Reactivating Delayed Dispense Feature)

The ice dispenser is initially set with the delayed dispense feature active. Delayed Dispense Reset Mode allows the

Service Technician to deactivate (or reactivate) the ice delayed dispense feature. If deactivated, the ice dispenser

cylinder valve and ice auger motor will remain energized continuous whenever the ICE key is pressed and held.

NOTE: Delayed Dispense Reset Mode must be initiated within the first (1) minute after switching the unit ON. If the

unit has been running more than one (1) minute, use the POWER key on the main control panel to switch the unit

OFF then back ON.

To deactivate or reactivate this feature within the first minute after switching the unit ON:

1. Press the LIGHT key on the dispenser control panel for approxi-

mately five (5) seconds, until the dispenser lights flash once and the

key ( ) icon illuminates red. (See Figure 3-34).

2. Press and hold ICE key on dispenser control panel (See Figure 3-

35).

3. While holding ICE key, press and release the LIGHT key five con-

secutive times in rapid succession (See Figure 3-36). The key icon

will flash five times, then switch off indicating successful feature

manipulation. This can be double-checked by pressing and holding

the ICE key.

To switch back, repeat the steps above, starting with switching the unit

OFF first.

ADDITIONAL DISPENSER NOTES:

• For dispensing large quantities of ice into an ice container, open the

refrigerator door, place the container under the dispenser chute, then

press the BULK ICE key pad located above the dispenser chute.

• If any part of the dispenser system should fail, the appropriate fault

code will be logged.

• Because of the capacitance touch functionality of the dispenser keys,

they must be kept clean and dry to insure proper operation.

• When in Sabbath Mode, the dispenser is disabled.

• The ice maker system and water dispensing system are disabled whenever the water filter or water filter plug is

removed.

Figure 3-33. Lock Dispenser - Press

& Hold LIGHT Key for 5 Seconds

Figure 3-34. Press & Hold LIGHT

Key for 5 Seconds

Figure 3-35. Press & Hold ICE Key

Figure 3-36. Press LIGHT Key 5

Times While Holding ICE Key

Previous Page

Next Page

Main Menu

Built-In Series Menu

Built-In Series Menu

Previous Page

Main Menu

Table of Contents

Next Page

Page 18

Electronic Control System

3-19

#7019014 - Revision A - October, 2010

Built-In (BI) Series

Built-In (BI) Series

FUNCTIONS OF THE ELECTRONIC CONTROL SYSTEM

The following pages explain monitoring, regulating and controlling functions of the electronic control system. In most

cases signal traces on a model BI36U wiring schematic are used to show current flow for functions being explained.

Supply Power to the Lighting System

Power is supplied to the lighting system through the control board when the unit is switched ON by pressing the

POWER key. When a door is open, the corresponding normally closed light switch allows power to the lights in the

compartment (See Figure 3-37).

NOTES:

• Power to the light is monitored by the microprocessor to control the door ajar alarm feature.

• Power to the refrigerator lights is also monitored to help control the refrigerator evaporator fan and air purifier fan

operation. When the refrigerator door is open, power to the evaporator fan is interrupted.

• Power to the freezer lights is also monitored to help control the freezer evaporator fan and icemaker operation. If

the freezer door (or drawer) is open, power to the freezer evaporator fan and the icemaker is interrupted.

• If in Sabbath Mode, the lighting system is disabled.

Figure 3-37. Signal Trace Schematic: Lighting System

115 VOLTS

60 CYCLES

L1

NEUTRAL

N.O.

WATER FILTER SWITCH

P16

MAIN

CONTROL

BOARD

P1

3

P14

L1

L1

NEUTRAL

1164

P2

P15

85

P3

P6

P5

P6

P9

P8

P7

P18

DEFROST HTR

COMP2

COMP1

MAIN LIGHTS

N.C.

N.C.

FZ DOOR SWITCH

REF DOOR SWITCH

ISOLATION VALVE

660 Ω

WATER VALVE

160 Ω

M

IM

CONDENSER FAN MOTOR

CRISPER LIGHTS

REF LIGHTS

AIR FILTER LIGHT

FREEZER LIGHTS

FILL-TUBE HEATER

2300-2900 Ω

DEF HEATER

27.9-30.9 Ω

DEFROST TERMINATOR

REFRIGERATOR COMPRESSOR

STARTING RELAY

FREEZER COMPRESSOR

STARTING RELAY

PURPLE

WHITE

WHITE/BLUE

WHITE/BLUE

BLUE

WHITE

PURPLE

GRAY

RED

PINK

YELLOW

BLACK

RED

WHITE/BLUE

TAN

BLUE

ORANGE

YELLOW

YELLOW

ORANGE/BLACK

GRAY/WHITE

ORANGE/BLACK

WHITE

RED/WHITE

WHITE/RED

TAN

PINK

GRAY

ORANGE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

TAN/WHITE

TAN/ WHI TE

BROWN

YELLOW

WHITE

HIGH VOLTAGE

1. Power supplied to

lighting system

unless unit is

switched OFF, or in

Sabbath Mode.

2. Power to the lights

is monitored to help

control alarm, evaporator fan, air purifier fan and icemaker

operation.

Previous Page

Next Page

Main Menu

Built-In Series Menu

Built-In Series Menu

Previous Page

Main Menu

Table of Contents

Next Page

Page 19

Electronic Control System

3-20

#7019014 - Revision A - October, 2010

Built-In (BI) Series

Built-In (BI) Series

Control Condenser Fan Operation

The microprocessor observes the power output to both compressors; if power is being supplied to either compressor, a signal is sent to the condenser fan relay on the control board to close, supplying power to the condenser fan

motor (See Figure 3-38). If both compressors are OFF, the condenser fan will be OFF.

Figure 3-38. Signal Trace Schematic: Condenser Fan Operation

115 VOLTS

60 CYCLES

L1

NEUTRAL

N.O.

WATER FILTER SWITCH

P16

MAIN

CONTROL

BOARD

P1

3

P14

L1

L1

NEUTRAL

1164

P2

P15

85

P3

P6

P5

P6

P9

P8

P7

P18

DEFROST HTR

COMP2

COMP1

MAIN LIGHTS

N.C.

N.C.

FZ DOOR SWITCH

REF DOOR SWITCH

ISOLATION VALVE

660 Ω

WATER VALVE

160 Ω

M

IM

CONDENSER FAN MOTOR

CRISPER LIGHTS

REF LIGHTS

AIR FILTER LIGHT

FREEZER LIGHTS

FILL-TUBE HEATER

2300-2900 Ω

DEF HEATER

27.9-30.9 Ω

DEFROST TERMINATOR

REFRIGERATOR COMPRESSOR

STARTING RELAY

FREEZER COMPRESSOR

STARTING RELAY

PURPLE

WHITE

WHITE/BLUE

WHITE/BLUE

BLUE

WHITE

PURPLE

GRAY

RED

PINK

YELLOW

BLACK

RED

WHITE/BLUE

TAN

BLUE

ORANGE

YELLOW

YELLOW

ORANGE/BLACK

GRAY/WHITE

ORANGE/BLACK

WHITE

RED/WHITE

WHITE/RED

TAN

PINK

GRAY

ORANGE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

TAN/WHITE

TAN/ WHI TE

BROWN

YELLOW

WHITE

HIGH VOLTAGE

1. Power output to

compressors

observed by

microprocessor

2. If power is supplied to

either compressor, the

condenser fan is energized

Previous Page

Next Page

Main Menu

Built-In Series Menu

Built-In Series Menu

Previous Page

Main Menu

Table of Contents

Next Page

Page 20

Electronic Control System

3-21

#7019014 - Revision A - October, 2010

Built-In (BI) Series

Built-In (BI) Series

Monitor, Regulate and Display Refrigerator Compartment Temperatures

The temperature signal from the refrigerator compartment thermistor is monitored by the microprocessor. When

high offset temperature is detected, calling for cooling, a high-speed run command is sent to the refrigerator evaporator fan, switching it ON, and when the evaporator temperature climbs to 38°F (3°C) the compressor is also energized, beginning the cooling cycle. When the compartment reaches low offset temperature, the compressor and fan

are switched OFF. Though compartment air temperature fluctuates from OFF and ON cycles, it is the refrigerator

compartment’s “average” temperature that is displayed at the right side of the LCD. (See Figure 3-39)

NOTES:

• Refrigerator zone temperature range is +34°F (+1°C) to

+45°F (+7°C).

• If average compartment temperature changes, the display

will change by one degree

per minute.

• If the refrigerator compartment thermistor is faulty, the

refrigerator compressor

defaults to 20 minutes ON,

40 minutes OFF cycling, EE

appears at right in LCD, the

service icon flashes and the

appropriate fault code is

logged.

• If the refrigerator evaporator

thermistor is faulty, the refrigerator compressor will not

energize until compartment

air temperature exceeds high

offset by 5°F (3°C); the service icon flashes and the

appropriate fault code is

logged.

• If in Sabbath Mode, the compartment thermistor still controls compressor operation,

except that when high offset

is reached, there is a random

15 to 25 second delay before

the cooling cycle is started.

• The condenser fan is energized whenever a compressor is energized.

Figure 3-39. Signal Trace Schematic: Regulating Refrigerator Temperature

Average temp.

displayed at

right of LCD

2. Run command

sent to evaporator fan

1. High offset temperature detected

3. Ref. evaporator above 38°F

(3°C)

4. Compressor energized

5. Condenser fan

energized

Previous Page

Next Page

Main Menu

Built-In Series Menu

Built-In Series Menu

Previous Page

Main Menu

Table of Contents

Next Page

HIGH VOLTAGE

BLACK

WATER FILTER SWITCH

N.O.

RED

TAN/WHITE

P14

1164

NEUTRAL

L1

L1

MAIN LIGHTS

COMP1

3

COMP2

85

DEFROST HTR

P15

P16

MAIN

P6

YELLOW

P18

CONTROL

BOARD

WHITE

GRAY

RED

PURPLE

BLUE

L1

115 VOLTS

60 CYCLES

WHITE/BLUE

TAN

PINK

P1

P2

P3

P5

P7

P9

FZ DOOR SWITCH

WHITE/BLUE

P6

P8

NEUTRAL

N.C.

YELLOW

YELLOW

N.C.

YELLOW

BROWN

REF DOOR SWITCH

ORANGE/BLACK

ORANGE

GRAY/WHITE

BLUE

DEFROST TERMINATOR

WHITE/BLUE

WHITE

TAN/WHITE

TAN

PINK

WHITE/RED

RED/WHITE

ORANGE/BLACK

ORANGE

FILL-TUBE HEATER

GRAY

PURPLE

ISOLATION VALVE

660 Ω

WATER VALVE

160 Ω

IM

CONDENSER FAN MOTOR

M

AIR FILTER LIGHT

FREEZER LIGHTS

REF LIGHTS

CRISPER LIGHTS

2300-2900 Ω

DEF HEATER

27.9-30.9 Ω

REFRIGERATOR COMPRESSOR

STARTING RELAY

FREEZER COMPRESSOR

STARTING RELAY

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

LOW VOLTAGE

EXERNAL

DEVICE

KEYPAD

P14

1164

3

85

P15

P16

P6

P18

NEUTRAL

L1

L1

MAIN LIGHTS

COMP1

COMP2

DEFROST HTR

MAIN CONTROL

BOARD

FREEZER

EVAPORATOR FAN

REF

RED

BLUE/WHITE

YELLOW/BROWN

P1

1

P2

WHITE/BLACK

17

P3

1

P5

16

P6

P8 P7

P9

BLACK/WHITE

BROWN

FLOW

METER

THERMISTER FREEZER EVAP

BLUE

BROWN

THERMISTER FREEZER CABINET

BLUE

BROWN

THERMISTER REF EVAP

BLUE

BROWN

YELLOW

BLUE

WHITE

THERMISTER REF CABINET

BLUE

BROWN

EVAPORATOR FAN

M

M

Page 21

Electronic Control System

3-22

#7019014 - Revision A - October, 2010

Built-In (BI) Series

Built-In (BI) Series

Additional Regulating of Refrigerator Compartment Temperatures:

Details of Controlling the Refrigerator Variable Speed Evaporator Fan Motor

The evaporator fan in the refrigerator zone uses a low DC voltage variable speed motor. During normal operation

and when the door is closed, the motor is supplied with 12V DC at all times from P2-14 off of the control board, with

the neutral or ground return to P2-1. When high offset temperature is detected a command is sent to the evaporator

fan motor from P2-13 to run at high-speed, and the RPM is monitored via P2-16. On some models, the refrigerator

evaporator fan will always run at high speed when energized, while on others a command will be sent to the fan

after approximately thirty (30) seconds of high-speed operation to ramp down to low-speed. This will vary by model.

If the compartment thermistor in those models where the fan speed is normally ramped down after thirty (30) seconds detects temperatures above high offset, the fan will remain at high-speed until the temperature falls below high

offset, then ramp down to low-speed. And, in all models, if the refrigerator door is opened while the evaporator fan

is operating, the microprocessor will detect the power signal to the lights and interrupts the 12V DC power to the fan.

(See Figure 3-40)

NOTE:

• During Sabbath Mode the lighting system is disabled and the 12V DC supplied to the evaporator fan cannot be

interrupted, thus the evaporator fan may be observed running when the door is open.

• If improper RPM signals are detected from the evaporator fan, the appropriate fault code will be logged.

REF

EVAPORATOR FAN

FREEZER

EVAPORATOR FAN

M

M

FLOW

METER

THERMISTER FREEZER EVAP

THERMISTER FREEZER CABINET

THERMISTER REF CABINET

THERMISTER REF EVAP

BROWN

BLACK/WHITE

WHITE/BLACK

BLUE

BROWN

BLUE

BROWN

YELLOW

RED

YELLOW/BROWN

BLUE/WHITE

BROWN

BLUE

BLUE

BROWN

BLUE

WHITE

MAIN CONTROL

BOARD

16

1

17

1

P18

3

P6

P15

P16

85

P14

1164

P6

P9

P8 P7

P5

P2

P3

P1

DEFROST HTR

COMP2

COMP1

MAIN LIGHTS

L1

NEUTRAL

L1

EXERNAL

DEVICE

KEYPAD

LOW VOLTAGE

2. High offset temperature

detected in refrigerator

1. 12VDC supplied to

motor (P2-14)

3. High-speed

command

sent to motor

(P2-13), after

30 seconds,

low-speed

command

sent to motor

(depending

on model)

Motor RPM

monitored at

all time (P2-16)

Figure 3-40. Signal Trace Schematic: Low DC Voltage Variable Speed Refrigerator Fan Operation

Previous Page

Next Page

Main Menu

Built-In Series Menu

Built-In Series Menu

Previous Page

Main Menu

Table of Contents

Next Page

Page 22

Electronic Control System

3-23

#7019014 - Revision A - October, 2010

Built-In (BI) Series

Built-In (BI) Series

Additional Regulating of Refrigerator Compartment Temperatures:

Details of Controlling the Refrigerator Drawers Temperature

The refrigerator zone contains a diverter behind the evaporator cover, below the evaporator and just above the

refrigerator drawers. At the bottom of the evaporator cover is a series of holes and an air diverter near the location

of the diverter. The refrigerator air is drawn from the compartment and pushed down through the evaporator, some

air is diverted through the holes in the evaporator cover to the upper refrigerator compartment and some is allowed

past the diverter. Since cold air sinks, this cooling method allows for the drawers to remain approximately 2°F (1°C)

colder than the rest of the compartment. However, if the compartment thermistor detects

temperatures below 35°F (2°C),

the defrost time is extended

slightly to avoid freezing temperatures in the drawer area.

NOTES:

• During Sabbath Mode the

lighting system is disabled

so the evaporator fan may be

observed running when the

door is open.

Figure 3-41. Signal Trace Schematic: Drawer Area Temperature Control

1. Fan cycles on and off during normal operation, but if

temperatures fall below 35°F

(2°C), fan switches off

2. Defrost is initiated, with an

extended “ON” time

Previous Page

Next Page

Main Menu

Built-In Series Menu

Built-In Series Menu

Previous Page

Main Menu

Table of Contents

Next Page

HIGH VOLTAGE

BLACK

WATER FILTER SWITCH

N.O.

RED

TAN/WHITE

P14

1164

NEUTRAL

L1

L1

MAIN LIGHTS

COMP1

3

COMP2

85

DEFROST HTR

P15

P16

MAIN

P6

YELLOW

P18

CONTROL

BOARD

WHITE

GRAY

RED

PURPLE

BLUE

L1

115 VOLTS

60 CYCLES

WHITE/BLUE

TAN

PINK

P1

P2

P3

P5

P6

P7

P8

P9

NEUTRAL

FZ DOOR SWITCH

N.C.

YELLOW

YELLOW

N.C.

YELLOW

BROWN

REF DOOR SWITCH

ORANGE/BLACK

ORANGE

WHITE/BLUE

GRAY/WHITE

BLUE

DEFROST TERMINATOR

WHITE

ISOLATION VALVE

660 Ω

TAN/WHITE

PINK

WHITE/RED

RED/WHITE

TAN

ORANGE/BLACK

ORANGE

WATER VALVE

160 Ω

IM

CONDENSER FAN MOTOR

M

FREEZER LIGHTS

REF LIGHTS

CRISPER LIGHTS

FILL-TUBE HEATER

WHITE/BLUE

2300-2900 Ω

DEF HEATER

27.9-30.9 Ω

REFRIGERATOR COMPRESSOR

STARTING RELAY

GRAY

FREEZER COMPRESSOR

STARTING RELAY

PURPLE

AIR FILTER LIGHT

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

LOW VOLTAGE

P14

1164

EXERNAL

DEVICE

3

85

P15

P16

P6

P18

NEUTRAL

L1

L1

MAIN LIGHTS

COMP1

COMP2

DEFROST HTR

MAIN CONTROL

BOARD

P1

1

P2

WHITE/BLACK

17

P3

1

P5

16

P6

P8 P7

P9

BLACK/WHITE

BROWN

FLOW

METER

THERMISTER FREEZER EVAP

BLUE

BROWN

THERMISTER FREEZER CABINET

BLUE

BROWN

THERMISTER REF EVAP

BLUE

BROWN

THERMISTER REF CABINET

BLUE

BROWN

BLUE/WHITE

YELLOW/BROWN

YELLOW

WHITE

RED

BLUE

FREEZER

EVAPORATOR FAN

M

KEYPAD

REF

M

EVAPORATOR FAN

Page 23

Electronic Control System

3-24

#7019014 - Revision A - October, 2010

Built-In (BI) Series

Built-In (BI) Series

Monitor and Control Refrigerator Fan-Assisted, Off-Cycle Defrost

Temperature signals from the refrigerator compartment and evaporator thermistor’s are observed by the microprocessor. During the off cycle defrost, if the refrigerator compartment temperature reaches high offset (calling for

cooling) before the evaporator temperature rises to 38°F (3°C), no power will be supplied to the compressor, but the

evaporator fan will be switched ON. Only after the evaporator temperature reaches 38°F (3°C) will the compressor

be energized. (See Figure 3-42).

NOTES:

• if the compartment thermistor

detects temperatures below

35°F (2°C), the defrost time

is extended slightly to avoid

freezing temperatures in the

drawer area.

• If the refrigerator compartment thermistor is faulty, the

refrigerator compressor

defaults to 20 minutes ON,

40 minutes OFF cycling, EE

appears at right in LCD, the

service icon flashes and the

appropriate fault code is

logged.

• If the refrigerator evaporator

thermistor is faulty, the refrigerator compressor will not

energize until compartment

air temperature exceeds high

offset by 5°F (3°C); the service icon flashes and the

appropriate fault code is

logged.

• If in Sabbath Mode, the compartment thermistor still controls compressor operation,

except that when high offset

is reached, there is a random

15 to 25 second delay before

the cooling cycle is started.

Figure 3-42. Signal Trace Schematic: Refrigerator Off-Cycle Defrost

2. Run command sent

to evaporator fan

1. High offset temperature detected in refrigerator

3. Ref. evap.below

38°F (3°C)

4. Compressor not energized until

evaporator temp climbs to 38°F (3°C)

Previous Page

Next Page

Main Menu

Built-In Series Menu

Built-In Series Menu

Previous Page

Main Menu

Table of Contents

Next Page

HIGH VOLTAGE

BLACK

WATER FILTER SWITCH

N.O.

RED

TAN/WHITE

P14

1164

NEUTRAL

L1

L1

MAIN LIGHTS

COMP1

3

COMP2

85

DEFROST HTR

P15

P16

MAIN

P6

YELLOW

P18

CONTROL

BOARD

WHITE

GRAY

RED

PURPLE

BLUE

L1

115 VOLTS

60 CYCLES

WHITE/BLUE

TAN

PINK

P1

P2

P3

P5

P7

P9

FZ DOOR SWITCH

WHITE/BLUE

P6

P8

NEUTRAL

N.C.

YELLOW

YELLOW

N.C.

YELLOW

BROWN

REF DOOR SWITCH

ORANGE/BLACK

ORANGE

GRAY/WHITE

BLUE

DEFROST TERMINATOR

WHITE/BLUE

WHITE

TAN/WHITE

TAN

PINK

WHITE/RED

RED/WHITE

ORANGE/BLACK

ORANGE

FILL-TUBE HEATER

GRAY

PURPLE

ISOLATION VALVE

660 Ω

WATER VALVE

160 Ω

IM

CONDENSER FAN MOTOR

M

AIR FILTER LIGHT

FREEZER LIGHTS

REF LIGHTS

CRISPER LIGHTS

2300-2900 Ω

DEF HEATER

27.9-30.9 Ω

REFRIGERATOR COMPRESSOR

STARTING RELAY

FREEZER COMPRESSOR

STARTING RELAY

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

LOW VOLTAGE

P16

EXERNAL

DEVICE

P18

P14

P15

P6

1164

NEUTRAL

L1

L1

MAIN LIGHTS

3

COMP1

COMP2

DEFROST HTR

85

P1

1

P2

17

P3

1

P5

BOARD

P9

16

P6

P8 P7

MAIN CONTROL

FREEZER

EVAPORATOR FAN

REF

RED

BLUE/WHITE

M

WHITE/BLACK

BLACK/WHITE

BROWN

FLOW

METER

THERMISTER FREEZER EVAP

BLUE

BROWN

THERMISTER FREEZER CABINET

BLUE

BROWN

THERMISTER REF EVAP

BLUE

BROWN

YELLOW/BROWN

YELLOW

THERMISTER REF CABINET

BLUE

BROWN

WHITE

M

BLUE

EVAPORATOR FAN

KEYPAD

Page 24

Electronic Control System

3-25

#7019014 - Revision A - October, 2010

Built-In (BI) Series

Built-In (BI) Series

Minimize Condensation on Refrigerator Door Glass (Models Produced with Glass Doors Only)

On models with glass refrigerator doors a low DC voltage, five (5) watt braided wire heater is foamed into the door

around the glass perimeter. This heater helps to minimize the formation of condensation on the glass and/or door

frame by energizing in ten (10) to forty (40) second ON/OFF cycles, depending on the compartment temperatures;

colder temperatures equal longer cycles. (See Figure 3-43).

To help minimize condensation

further, the microprocessor

detects when the refrigerator

door is opened, via the light

switch, and when the door closes the evaporator fan is energized for five (5) minutes,

regardless of the refrigerator

compressor operational state,

drawing any warmer moist air

away from the door glass.

(See Figure 3-43)

115 VOLTS

60 CYCLES

L1

NEUTRAL

N.O.

WATER FILTER SWITCH

P16

MAIN

CONTROL

BOARD

P1

3

P14

L1

L1

NEUTRAL

1164

P2

P15

85

P3

P6

P5

P6

P9

P8

P7

P18

DEFROST HTR

COMP2

COMP1

MAIN LIGHTS

N.C.

N.C.

FZ DOOR SWITCH

REF DOOR SWITCH

ISOLATION VALVE

660 Ω

WATE R VALV E

160 Ω

M

IM

CONDENSER FAN MOTOR

CRISPER LIGHTS

REF LIGHTS

AIR FILTER LIGHT

FREEZER LIGHTS

FILL-TUBE HEATER

2300-2900 Ω

DEF HEATER

27.9-30.9 Ω

DEFROST TERMINATOR

REFRIGERATOR COMPRESSOR

STARTING RELAY

FREEZER COMPRESSOR

STARTING RELAY

PURPLE

WHITE

WHITE/BLUE

WHITE/BLUE

BLUE

WHITE

PURPLE

GRAY

RED

PINK

YELLOW

BLACK

RED

WHITE/BLUE

TAN

BLUE

ORANGE

YELLOW

YELLOW

ORANGE/BLACK

GRAY/WHITE

ORANGE/BLACK

WHITE

RED/WHITE

WHITE/RED

TAN

PINK

GRAY

ORANGE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

TAN/WHITE

TAN/WHITE

BROWN

YELLOW

WHITE

REF

EVAPORATOR FAN

FREEZER

EVAPORATOR FAN

M

M

FLOW

METER

THERMISTER FREEZER EVAP

THERMISTER FREEZER CABINET

THERMISTER REF CABINET

THERMISTER REF EVAP

BROWN

BLACK/WHITE

WHITE/BLACK

BLUE

BROWN

BLUE

BROWN

YELLOW

RED

YELLOW/BROWN

BLUE/WHITE

BROWN

BLUE

BLUE

BROWN

BLUE

WHITE

MAIN CONTROL

BOARD

16

1

17

1

P18

3

P6

P15

P16

85

P14

1164

P6

P9

P8 P7

P5

P2

P3

P1

DEFROST HTR

COMP2

COMP1

MAIN LIGHTS

L1

NEUTRAL

L1

EXERNAL

DEVICE

KEYPAD

LOW VOLTAGE

HIGH VOLTAGE

LED

GLASS DOOR HEATER

24.9 Ω - 31.7 Ω

WHITE/PURPLE

BLUE/PURPLE

WHITE/PURPLE

BLUE/PURPLE

BLACK/YELLOW

WHITE/YELLOW

Figure 3-43. Signal Trace Schematic: Glass Door Unit Door Heater &

Evaporator Fan Operation

3. Evaporator

fan energized

1. Power supplied to door heater in

10 - 40 second ON/OFF cycles at

all times. Cycle length depends on

compartment temperature. Colder

temperatures = longer time on.

2. Signal that ref. door

opened and closed

Previous Page

Main Menu

Built-In Series Menu

Built-In Series Menu

Previous Page