Page 1

subzero.com 800.222.7820

BBQ

Service Manual

General Information 2

Controls & Operation 6

Installation Information 13

Component Access & Removal 18

Troubleshooting Guide 39

Technical Data 43

Page 2

OOUUTTDDOOOORR BBBBQQ GGRRIILLLLSS

General Information

1-2

TECHNICAL ASSISTANCE

If you should have any questions regarding a Wolf

appliance and/or this manual, please contact:

Wolf Appliance, Inc.

ATTN: Service Department

P.O. Box 44988

Madison, WI 53744-4988

Customer Service

Phone #: (800) 222-7820

Technical Assistance

Phone #: (800) 919 - 8324

Parts / Warranty Claims

Phone #: (800) 332 - 9513

Customer Service E-Mail Address

customerservice@wolfappliance.com

Customer Service & Technical Assistance

Facsimile #: (608) 441 - 5887

Parts / Warranty Claims

Facsimile #: (608) 441 - 5886

Office Hours:

7:00 AM to 7:00 PM Central Standard Time

Monday through Friday

This manual is designed to be used by Authorized Service Personnel only. Wolf Appliance, Inc. assumes

no responsibility for any repairs made to Wolf appliances by anyone other than Authorized Service

Technicians.

IMPORTANT SAFETY INFORMATION

Below are the Product Safety Labels used in this manual. The "Signal Words" used are WARNING and

CAUTION.

Please note that these safety labels are placed in areas

where awareness of personal safety and product safety

should be taken and lists the precautions to be taken

when the signal word is observed.

INTRODUCTION

This Wolf Outdoor BBQ Grills Technical Service/Parts Manual, Part #803332, has been compiled to provide the most

recent technical service information about the Wolf Appliance, Inc. BBQ Grills. This information will enable the service technician to troubleshoot and diagnose malfunctions, perform necessary repairs, and return a Wolf Outdoor

BBQ Grill to proper operational condition.

The service technician should read the complete instructions contained in this Training/Service Manual before initiating any repairs on a Wolf Appliance.

* Some information in section 2 (Theory of Operation) has been provided by the American Gas Association

and reprinted with their approval.

INDICATES THAT HAZARDOUS OR UNSAFE PRACTICES COULD RESULT IN SEVERE PERSONAL

INJURY OR DEATH

Indicates that hazardous or unsafe practices could

result in minor personal injury or product and/or

property damage

In addition, please pay attention to the signal word

“NOTE”, which highlights especially important information within each section.

The information and images are the copyright property of Wolf Appliance, Inc., an affiliate of Sub-Zero, Inc. Neither

this manual nor any information or images contained herein may be copied or used in whole or in part without the

express written permission of Wolf Appliance, Inc., an affiliate of Sub-Zero, Inc. © Wolf Appliance, Inc., all rights

reserved.

Page 3

General Information

1-5

OOUUTTDDOOOORR BBBBQQ GGRRIILLLLSS

WARRANTY INFORMATION

This page contains a summary of the 2 & 5 Year

Warranty that is supplied with every Wolf product, fol-

lowed by details and notes about the warranties.

TWO & FIVE YEAR Warranty Summary

• Two year TOTAL PRODUCT warranty, parts and

labor.

• Limited Parts Only Warranty for the 3rd through 5th

year on the following parts only:

Gas Burners (excluding appearance)

LIMITED LIFETIME WARRANTY SUMMARY

• Repair or Replace any BBQ body which rust

through due to defective material or workmanship.

• Repair or replace any BBQ hood which rust

through due to defective material or workmanship.

• Labor to remove or replace defective parts is not

covered.

Warranty Details:

The warranty applies only to products installed for

normal residential use. The warranty applies only

to products installed in the United States or

Canada.

Warranty Notes:

• All warranties begin at the time of the units initial

installation.

• All Warranty and Service information collected by

Wolf Appliance, Inc. is arranged and

stored under the unit serial number and/or the customer’s name. Please note that Wolf Appliance,

Inc. requests that you have the model

and serial number available whenever contacting

the factory or parts distributor.

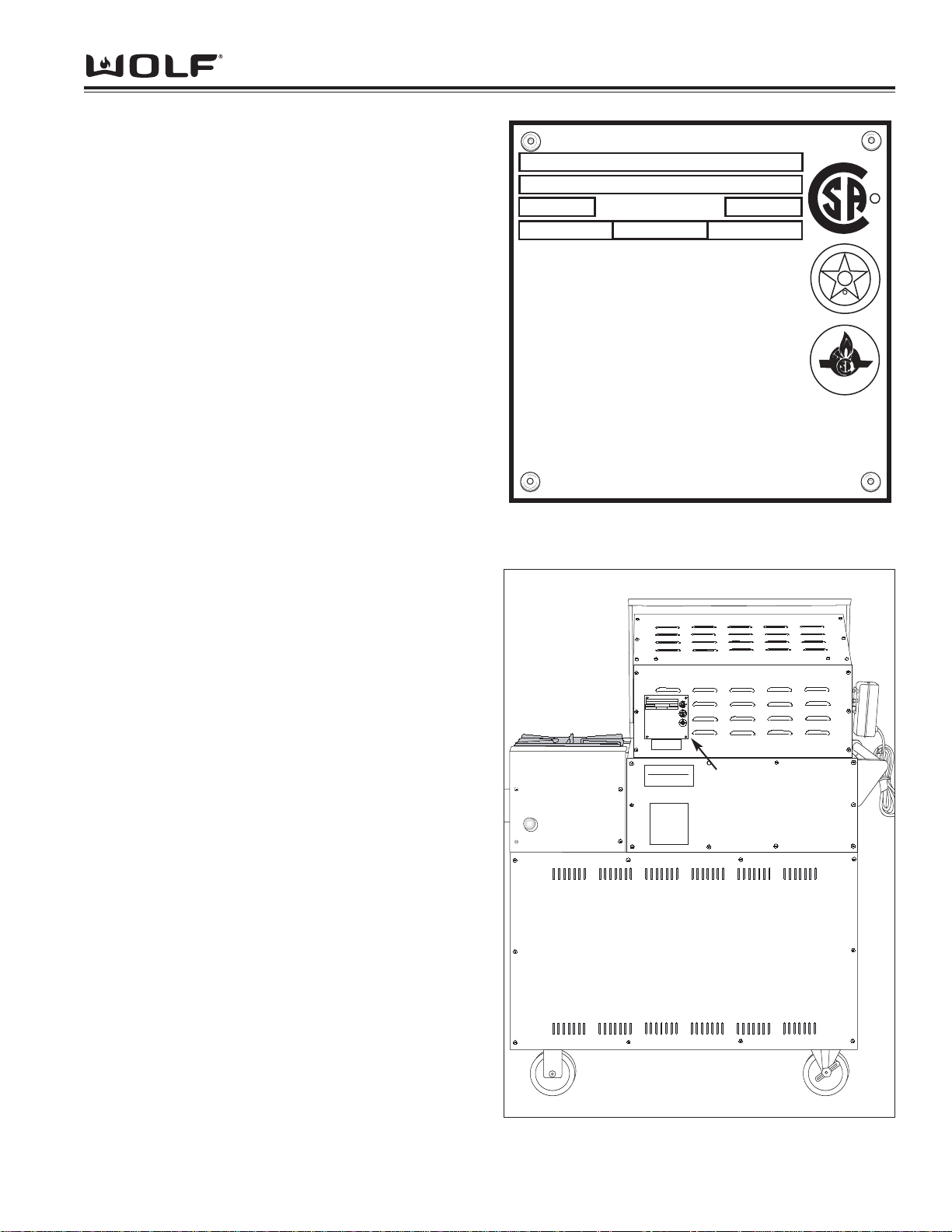

• See Figure 1-1 for serial plate layout.

• See Figure 1-2 for serial plate location.

CERTIFIED

D

E

S

I

G

N

A

M

E

R

I

C

A

N

A

S

S

O

C

I

A

T

I

O

N

R

G S

A

C

E

R

T

I

F

I

E

D

R

WOLF

APPLIANCE CO. LLC FITCHBURG, WI

MODEL

BBQ-

SERIAL

NO.

GAS

GRILL

ROTISSERIE

MAN.

PRESS.

OPEN

BURNER

INPUT RATING EACH

BURNER-BTU / HR.

ROTISSERIE MOTOR ELECTRICAL RATING

120V, 60 Hz, 0.58A

MINIMUM CLEARANCE FROM SIDES AND BACK OF UNIT TO ADJACENT

COMBUSTIBLE CONSTRUCTION BELOW TOP OF UNIT, 8 INCHES FROM

SIDES AND BACK. MINIMUM HORIZONTAL CLEARANCE FROM SIDES

AND BACK OF UNIT TO ADJACENT VERTICAL COMBUSTABLE

CONSTRUCTION EXTENDING ABOVE TOP OF UNIT, 6 INCHES FROM SIDES

ANS 12 INCHES FROM BACK. DO NOT LOCATE THIS UNIT UNDER

OVERHEAD UNPROTECTED COMBUSTIBLE SURFACES.

FOR OUTDOOR USE ONLY.

CAUTION:

1. DO NOT STORE A SPARE LP-GAS CYLINDER UNDER THIS

APPLIANCE.

2. NEVER FILL THE CYLINDER BEYOND 80 PERCENT FULL..

3. IF THE INFORMATION IN (1) AND (2) IS NOT FOLLOWED EXACTLY

A FIRE CAUSING DEATH OR SERIOUOS INJURY MAY OCCUR.

"ANSIZ21.58A CAN/CGA-1.6A-1998 OUTDOOR COOKING APPL.,"

"FOR INSTALLATION IN NON-COMBUSTIBLE LOCATIONS UNLESS

USED WITH APPROVED INSULATING JACKET"

800116

Figure 1-1 Typical Serial Plate Layout

FOR USE WITH A GAS PRESSURE REGULATOR. THE REGULATOR SUPPLIED

MUST BE USED WITH THIS UNIT.

CET APPARIEL REQUIERT L' INSTALLATION D' UN DETENDEUR DE PRESSION.

LE DETENDEUR FOURNI DOIT Y ENTRE

INSTALLE.

WARNING: Improper installation

adjustment, alteration, service, or

maintenance can cause property

damage, injury or death. Read the

maintenance instructions thoroughly

before installing or servicing this

equipment.

MISE EN GARDE: Une mauvaise

installation, un mauvais entretien,

une reparation, un ajustement ou

une alteration inappropiee peuvent

causer des dommages a lappariel,

des blessures corporels ou la mort.

Lire les instructions d'installation,

de fonctionnement et d'entretien

avant l'installation ou lentretien de

cet appareil.

For Wolf Authorized Service

CALL

888-904-9653

CERTIFIED

D

E

S

I

G

N

A

M

E

R

I

C

A

N

A

S

S

O

C

I

A

T

I

O

N

R

G S

A

C

E

R

T

I

F

I

E

D

R

WOLF

APPLIANCE CO. LLC FITCHBURG, WI

MODEL

BBQ-

SERIAL

NO.

GAS

GRILL

ROTISSERIE

MAN.

PRESS.

OPEN

BURNER

INPUT RATING EACH

BURNER-BTU / HR.

ROTISSERIE MOTOR ELECTRICAL RATING

120V, 60 Hz, 0.58A

MINIMUM CLEARANCE FROM SIDES AND BACK OF UNIT TO ADJACENT

COMBUSTIBLE CONSTRUCTION BELOW TOP OF UNIT, 8 INCHES FROM

SIDES AND BACK. MINIMUM HORIZONTAL CLEARANCE FROM SIDES

AND BACK OF UNIT TO ADJACENT VERTICAL COMBUSTABLE

CONSTRUCTION EXTENDING ABOVE TOP OF UNIT, 6 INCHES FROM SIDES

ANS 12 INCHES FROM BACK. DO NOT LOCATE THIS UNIT UNDER

OVERHEAD UNPROTECTED COMBUSTIBLE SURFACES.

FOR OUTDOOR USE ONLY.

CAUTION:

1. DO NOT STORE A SPARE LP-GAS CYLINDER UNDER THIS

APPLIANCE.

2. NEVER FILL THE CYLINDER BEYOND 80 PERCENT FULL..

3. IF THE INFORMATION IN (1) AND (2) IS NOT FOLLOWED EXACTLY

A FIRE CAUSING DEATH OR SERIOUOS INJURY MAY OCCUR.

"ANS Z21.58A CAN/CGA-1.6A-1998 OUTDOOR COOKING APPL.,"

"FOR INSTALLATION IN NON-COMBUSTIBLE LOCATIONS UNLESS

USED WITH APPROVED INSULATING JACKET"

800116

Figure 1-2 The serial plate is located on the backside of

the Rear Hood Top.

Serial Plate

Page 4

OUTDOOR BBBQ GGRILLS

General Information

1-6

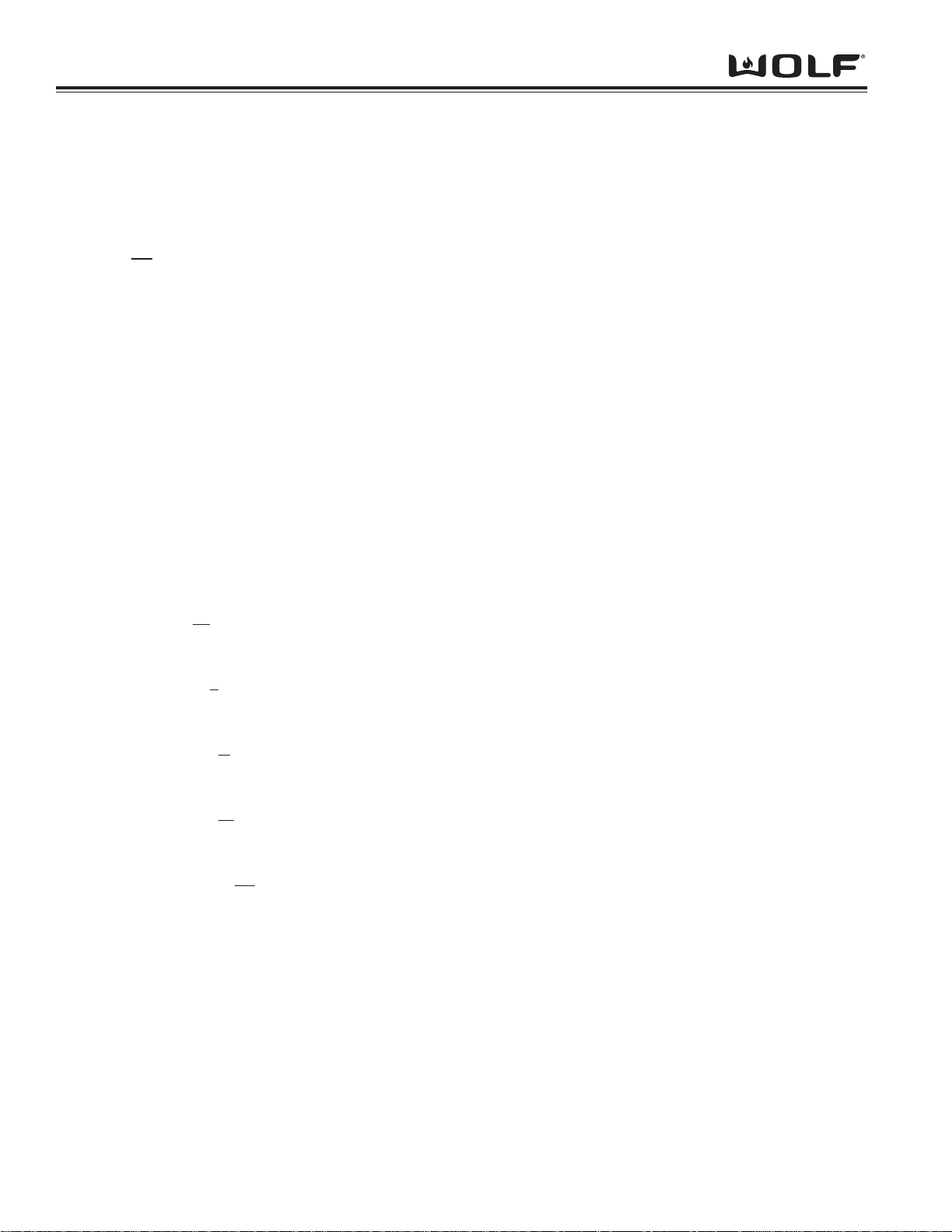

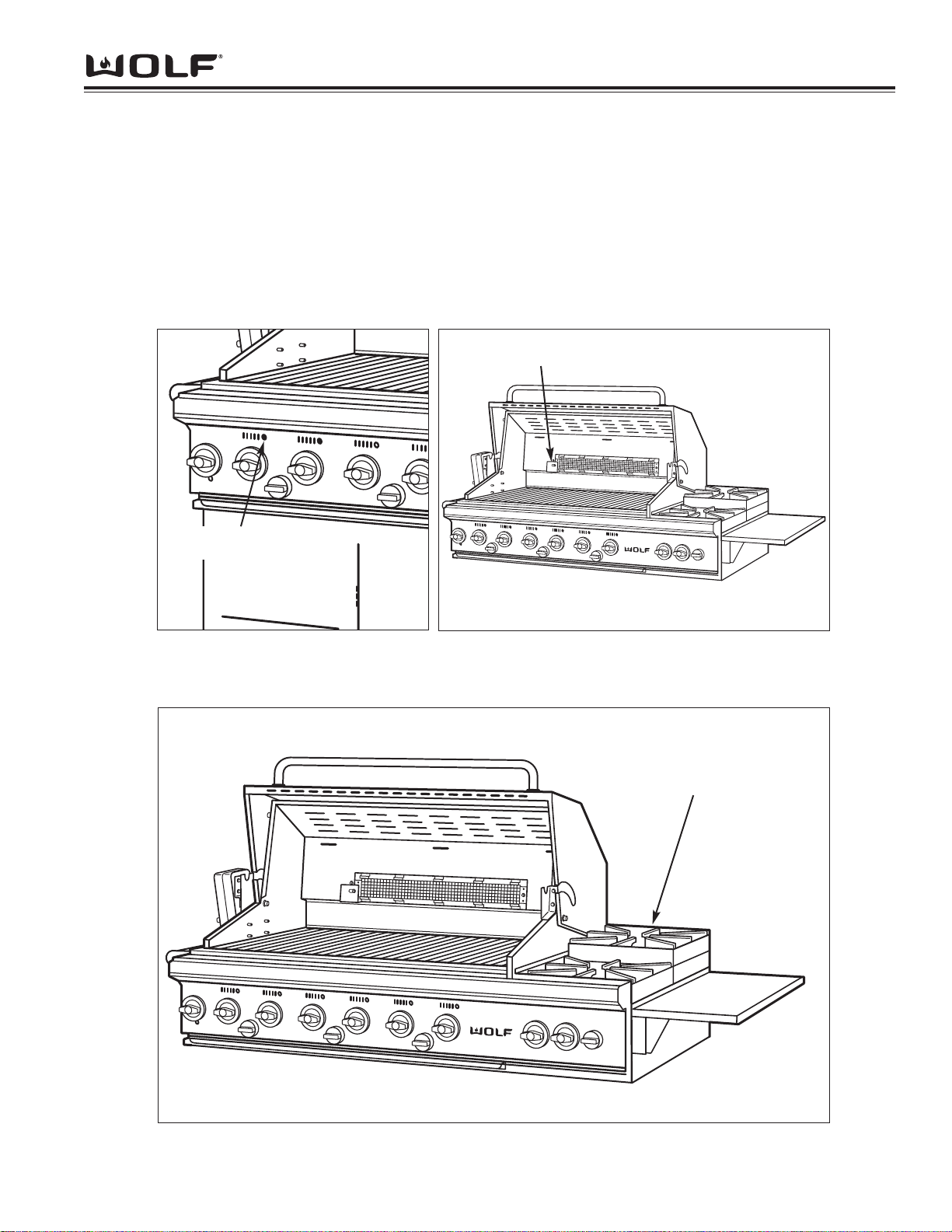

MODEL FEATURES:

All Models:

Wolf BBQ grills are constructed with heavy duty 18-gauge stainless steel. The hood is a two piece stainless steel

design with a handle. All grates are made from porcelainized cast iron. A grill scraper and protective cover is provided with each unit.

Wolf BBQ grills are assembled to either work with natural gas or LP gas. Converting a unit from one gas type to

another is not possible. There are built-in models and freestanding cart models. Cart models are currently equipped

with 5” locking swivel casters at both ends, with older models having non-swivel wheels at one end. The grill burner

tubes are made of stainless steel and have a 10,000 BTU (British Thermal Unit) rating. Every Wolf BBQ grill is also

equipped with a rotisserie burner, rated at 9,000 BTU’s, with a 115 volt rotisserie motor for turning the rotisserie rod.

Side Burner Models:

Some models are equipped with two porcelain cast iron side step-up burners. These burners have a 16,000 BTU

rating.

LP Gas Models:

LP gas units include a regulator, hose and 5-gallon LP tank.

MODEL NUMBER DESCRIPTIONS

This section briefly describes the reason for different model numbers. The BBQ’s are manufactured as either natural

gas or LP gas, built-in or on a free standing cart.

• The two digits “24”, “36”, “48” following the letters BBQ indicate the width of the grill chassis in inches.

Example: BBQ24

2C = 24” chassis.

• An additional number such as “2”, after the first two digits indicates there are two side step-up burners.

Example: BBQ242

C = Two side step-up burners.

• The letter “C” which appears in some of the models is for cart.

Example: BBQ242C

= Cart model.

• When there is “BI” in the model number, it indicates that the unit will be built in.

Example: BBQ242BI

= Built in unit.

• The “-LP” at the end of the model number indicates the unit is manufactured to operate on LP gas.

Example: BBQ242C-LP = LP gas.

BBQ MODEL NUMBERS IN SUMMARY:

• BBQ = Grill

• 24, 36, 48 = Indicates the width in inches of the grill chassis.

• 2 = This number following the first two digits indicates two side step-up burners.

• C = Cart

• BI = Built in.

• -LP = Indicates LP gas. When -LP is not at the end of the model number it indicates the unit is manufactured

for Natural gas.

Page 5

General Information

OUTDOOR BBBQ GGRILLS

MODEL NUMBER KEY

Refer to this key for an example of the model numbers.

Model: BBQ362BI-LP

Product Type

Size

Side Burners

Features

Fuel

Product T

ype

BBQ

Size

24 24 - Grill Space

36 30 - Grill Space

48 36 - Grill Space

Side Burners

2

Features

Built In

Cart

Fuel

LP Propane Gas

* No -LP indicates the unit is manufactured for Natural gas.

Page 6

OUTDOOR BBBQ GGRILLS

General Information Notes

1-8

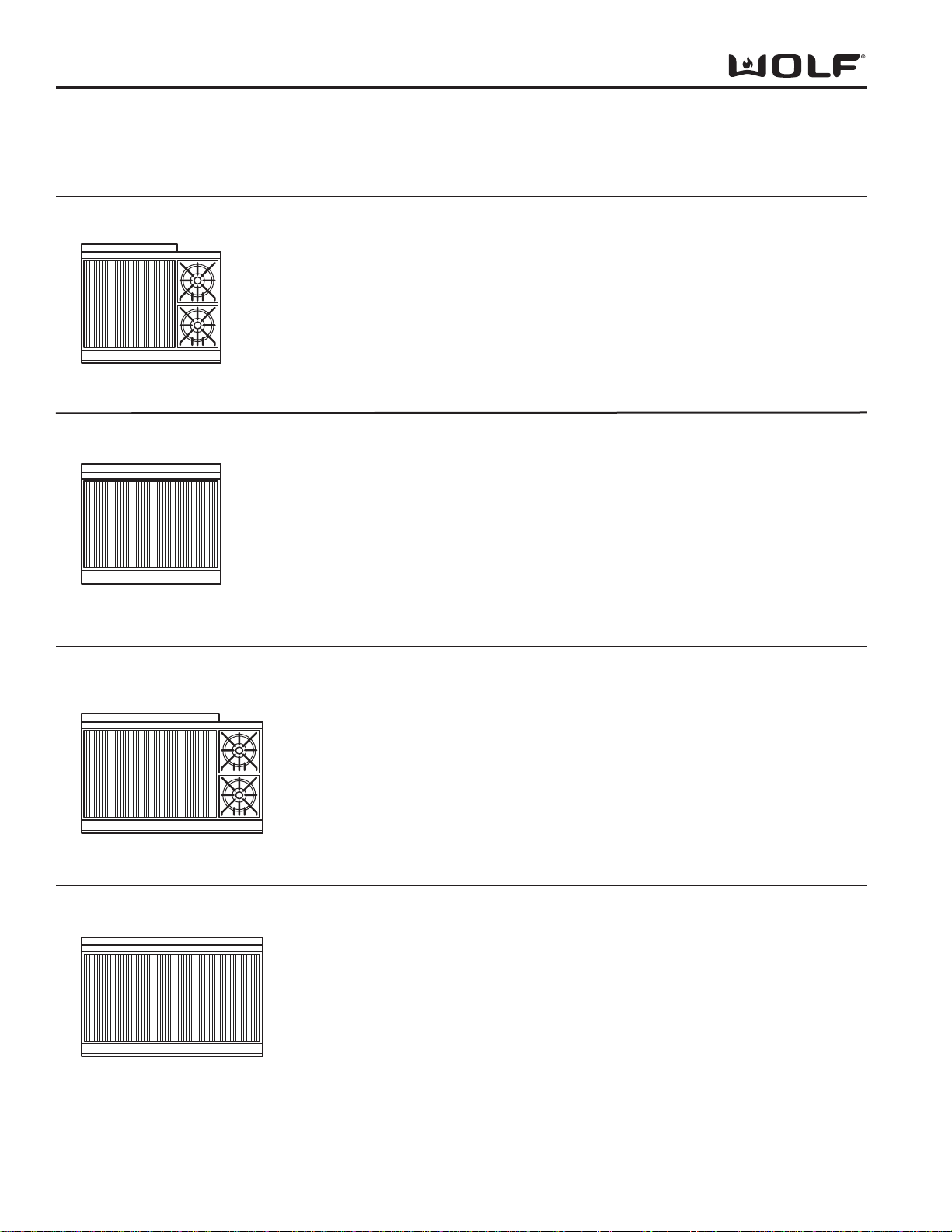

TOP CONFIGURATIONS FOR OUTDOOR BBQ GRILLS

Configuration

Model #

Description

BBQ242BI

BBQ242BI-LP

BBQ242C

BBQ242C-LP

24” Grill with Two Open Burners, Built-In (Nat. Gas)

24” Grill with Two Open Burners, Built-In (LP)

24” Grill with Two Open Burners on 36” Cart (Nat. Gas)

24” Grill with Two Open Burners on 36” Cart (LP)

All 24” Grills have Four Grill Burners

BBQ36BI

BBQ36BI-LP

BBQ36C

BBQ36C-LP

36” Grill, Built-In (Nat. Gas)

36” Grill, Built-In (LP)

36” Grill on 36” Cart (Nat. Gas)

36” Grill on 36” Cart (LP)

All 36” Grills have Six Grill Burners

BBQ362BI

BBQ362BI-LP

BBQ362C

BBQ362C-LP

BBQ48BI

BBQ48BI-LP

BBQ48C

BBQ48C-LP

36” Grill with Two Open Burners, Built-In (Nat. Gas)

36” Grill with Two Open Burners, Built-In (LP)

36” Grill with Two Open Burners on 48” Cart (Nat. Gas)

36” Grill with Two Open Burners on 48” Cart (LP)

All 36” Grills have Six Grill Burners

48” Grill, Built-In (Nat. Gas)

48” Grill, Built-In (LP)

48” Grill on 48” Cart (Nat. Gas)

48” Grill on 48” Cart (LP)

All 48” Grills have Eight Grill Burners

Page 7

OUTDOOR BBBQ GGRILLS

Theory of Operation

2-2

THEORY OF OPERATION

A service technician should understand how a gas appliance operates before attempting to service the appliance.

This section provides descriptions of the different types of fuel gases and explains gas heating values. A definition

of specific gravity of gas is given along with its characteristics and effects. Gas combustion principles are explained

and gas burner components are described and illustrated. The end of this section contains illustrations which

demonstrate basic cooking appliance theory of operation.

Types of Fuel Gas:

Gases used to supply heat energy are called fuel gases. Common fuel gases are not simply one kind of hydrocarbon, they are mixtures of hydrocarbon gases. They contain other gases as well, such as free hydrogen, carbon

dioxide and nitrogen. As an example, natural gas might contain 85% methane, 12% ethane and 3% of other gases.

The presence of each of these gases in the fuel gas has some effect on the nature of the gas.

Some common fuel gasses are methane [CH

4], ethane [C2H6], Propane [C3H8] and butane [C4H10]. Propane and

butane are nearly odorless. Natural gas that is processed to remove condensables and moisture, has little or no

odor and no color. Odorants are added to natural gas before distribution to aid in leak detection. A common odorant

used is a colorless liquid containing sulfur compounds.

Heating Value of Gas:

Heat energy produced when burning a fuel gas is commonly expressed in British Thermal Units (BTU). One BTU of

heat will raise the temperature of one pound of water one degree Fahrenheit.

The more carbon and hydrogen atoms in each molecule of a fuel gas, the higher its heating value. Natural gas

which is high in methane has a heating value of about 950 to 1150 BTU per cubic foot. The variance is due to the

various other substances found in natural gases. The more ethane, propane or butane in the gas raises the heating

value. Propane, or LP gas, has a heating value of about 2500-2800 BTU per cubic foot, and butane about 3200

BTU per cubic foot.

Specific Gravity of Gas:

The specific gravity of a gas is the weight of one cubic foot, or the gas compared to one cubic foot of dry air. When

stating the specific gravity of a gas, a pressure and temperature must be clearly stated. In the gas industry, the

standard conditions of pressure and temperature are 30.0 inches of mercury and 60° F. A pressure of 30.0 inches of

mercury will sustain a column of mercury 30 inches high in a tube with a vacuum on top of the column. Since air is

used as the reference, its specific gravity is always 1.0. This value of 1.0 has no direct physical meaning with

regard to air, such as its density. It is only a relative number or ratio used to express specific gravity of other gases.

The specific gravity of a gas will determine if the gas will rise or fall when released into the air. Natural gas will rise

since its specific gravity is less than 1.0 at 0.4 to 0.8. Propane has a specific gravity of 1.5 and butane 2.0. These

gases will fall when released into the air. They sometimes collect in low spots into pools which become a hazard if

open flames are present.

In addition, specific gravity has two other characteristics. It has an important effect on the flow of gases through orifices, and hence the rating of the burners. Gas flow through an orifice is dependent upon the orifice size and the

gas pressure upstream of the orifice. More of a lighter gas will flow through a given orifice size than a heavier gas

at the same gas pressure. This effect is taken into account in tables and calculators used to select orifice sizes for

burners.

Specific gravity also affects gas flow in pipes. A given driving pressure at a pipe inlet will move more lighter gas

than heavier gas through that pipe.

Page 8

Theory of Operation

2-3

OUTDOOR BBBQ GGRILLS

Principles of Gas Combustion:

Combustion - When oxygen acts with a substance to produce large amounts of heat rapidly.

Requirements for Combustion - There are three required elements for combustion to occur; Fuel (Gas), Oxygen

(Air) and Heat (Ignition Temperature, which for gas is between 1100°F/593°C and 1200°F/649°C). All must be present. Removing any one of the three and combustion will cease.

Chemistry of Combustion - Combustion of gas is a chemical reaction between fuel gas and oxygen. The basic

elements of common fuel gasses are hydrogen [H] and carbon [C]. When hydrogen burns, water vapor [H

2O] is pro-

duced. Complete burning of carbon in fuel gases form carbon dioxide [CO2] and water vapor [H2

O].

Controlled Combustion - Controlled combustion takes place when gas and air are supplied at proper rates to

assure complete combustion of the gas in a steady flame. When a gas appliance is operating properly, burning

starts at the burner ports. Gas flow is controlled by gas orifice size and gas pressure upstream of the orifice. Air is

mixed with the gas before it passes through the burner ports. This added air is called “Primary Air”. The remaining

air required for complete combustion is supplied to the burner at the point of combustion and is called “Secondary

Air”.

Adjustments of the gas-to-air ratio and the secondary air supply is the key to obtaining stable blue flames at a burner. Proper amounts of primary and secondary air are required for quiet and efficient burner operation and for complete combustion of the gas. Air Shutters or other devices provide control of primary air. Inlet opening and flue outlets control Secondary Air flow.

Total air - In an ideal situation, primary and secondary air is all that is needed (for the oxygen required) to burn the

gas, but some additional air is required to assure complete burning of the gas. The total air, “primary”, “secondary”

and “excess” are expressed as percentages of the amount needed. About ten cubic feet of air is required to completely burn one cubic foot of gas. For this reason an appliance should not be operated in an air tight home.

Limits of Flammability - Not all air-to-gas mixtures will burn. Mixtures with 0% - 4% natural gas in air are too lean

to burn. Mixtures of 4% - 14% natural gas in air can burn with a controlled flame. Flammability limits come into play

when primary air adjustments are made on burners. If too much primary air is used, the mixture may become too

lean and fall below flammability limits, thus preventing combustion.

Incomplete Combustion (Causes and Effects) - To obtain complete combustion, sufficient amounts of air must be

supplied to the process. This air must have a reasonably normal oxygen content. Complete burning of gas produces harmless carbon dioxide gas and water vapor. If the air supply is insufficient, incomplete combustion occurs

resulting in the formation of toxic by-products, such as carbon monoxide [CO] or aldehydes.

Carbon monoxide is colorless and odorless. Inhaling carbon monoxide in sufficient quantities could cause death by

reducing oxygen levels in the blood.

Aldehydes, which are equally dangerous, have a sharp and penetrating odor which is easily detected by smell at

very low concentrations. The odor caused by aldehydes should not be confused with odorants added to natural gas.

The absence of aldehydes does not assure that carbon monoxide is not present. However, if the odor of aldehydes

is present, then carbon monoxide is virtually always present.

Gas Burner Operation - A gas burner is a device to burn gas under control in order to produce useful heat.

Primary air is brought into the burner from outside of the appliance at atmospheric pressure. The gas jet streaming

from the orifice draws primary air with it into the burner.

The gas/air mixture, combined with a spark at the burner port(s) and the secondary air creates a controlled burn.

Page 9

OUTDOOR BBBQ GGRILLS

Theory of Operation

2-4

Burner Components:

Gas Orifice - An opening or hole which regulates or limits the amount of gas flowing to a burner. Gas flow rate (vol-

ume) depends on the size of the orifice (hole) and the gas pressure at the inlet of the orifice.

Air Shutter - This is used to adjust the size of the primary air inlet area and therefore controls primary air flow.

Venturi Tube - A section of pipe at the inlet of the burner body that narrows and then flares out again. This tube

helps maintain a proper and constant primary air injection.

Mixing Tube/Throat - Serves to carry the gas/air mixture from the venturi tube to the burner body.

Burner Body - The accumulation chamber below the burner base which allows the gas and air to mix together fully.

Burner Head - The component containing the burner ports where the gas/air mixture ignites. The burner ports are

distributed in a useful pattern to optimize heat transfer. The flames should be spread so they can be easily reached

by secondary air and provide a stable blue flame.

Air Shutter

Air Shutter

Burner Head

Mixing Tube/Throat

Burner Body

Venturi Tube

Venturi Tube

The Gas Orifice or hole

regulates or limits the amount

of gas flowing to a burner.

The part which contains the orifice

should be referred to as an orifice

Spud, Hood or Cap.

Fig. 2-1

Fig. 2-2

Fig. 2-3

Page 10

Theory of Operation

2-5

OUTDOOR BBBQ GGRILLS

Types of Burners:

Blue Flame Burners - All Wolf BBQ burners are blue flame burners. With this type of burner, primary air is mixed

with the fuel gas before the gas reaches the burner ports. An orifice is used to regulate gas flow to the burner. Air

which is mixed with the gas inside of the burner body enters through openings in the burner body. A shutter or venturi tube is used to adjust the size of these openings and control the primary air. Gas and air mix in the mixing tube

or throat, which then exits the burner ports where it is ignited. Secondary air is air from around the flames. The

flame produced has several zones, each represents a stage in burning of the gas. The burner tip has a thin dark

blue cone called the inner or primary cone. A lighter cone called the outer cone, surrounds the inner cone. Air

around the flame diffuses into the flame to burn at the outer cone. If conditions are perfect, products from the inner

cone burn here. The final products of burning are carbon dioxide and water vapor. An outer mantle surrounds the

outer cone where burning is usually completed. It is nearly invisible and glows only because of the high temperature

of the final combustion.

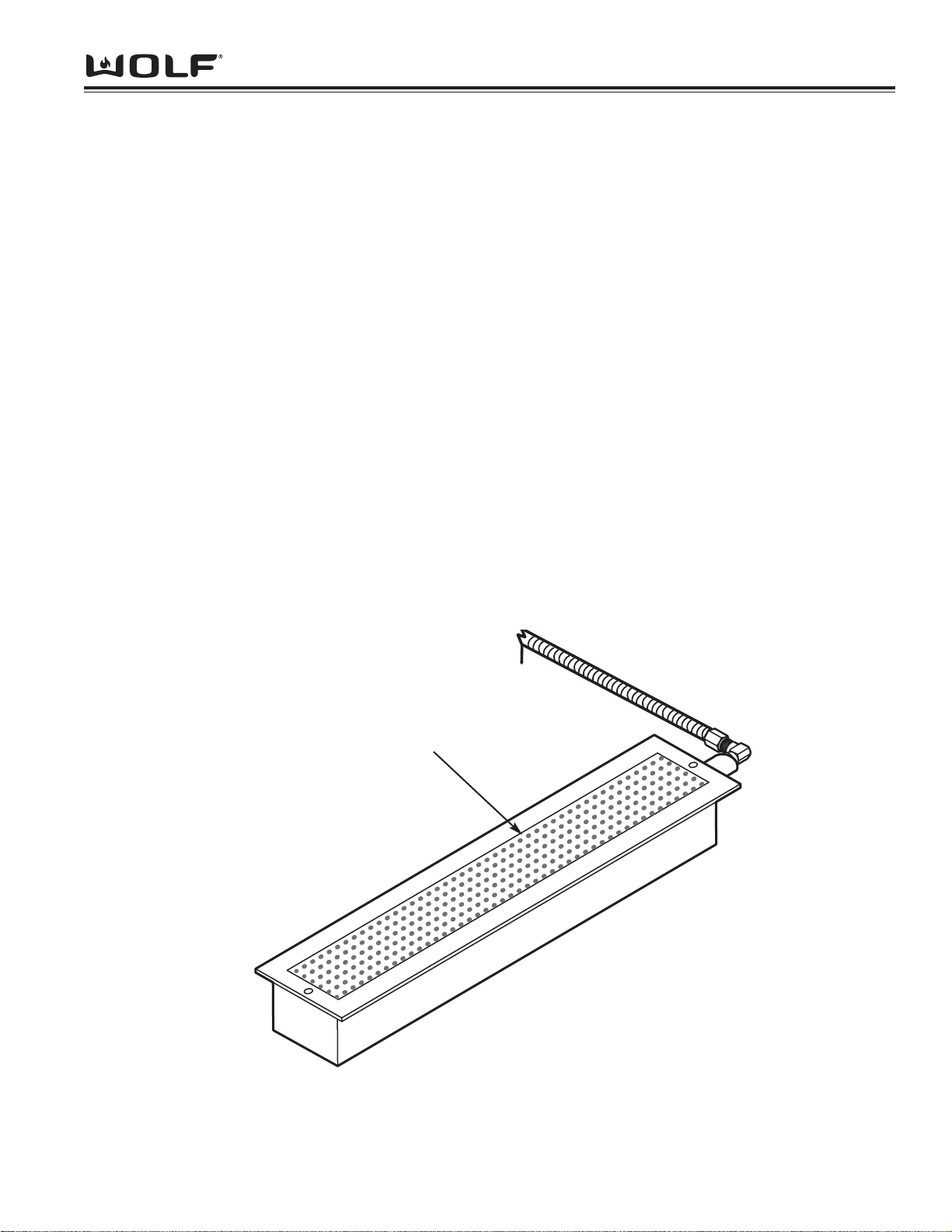

Infrared Burner - All Wolf gas BBQ’s use an infrared burner for the rotisserie. This infrared burner is a porous

refractory ceramic tile burner, similar to the infrared burner used in the ranges and cooktops. (See Figure 2-4) With

infrared heat, thermal energy is transmitted through space without heating the medium through which it travels.

Infrared energy is usually not affected by air flowing between the burners and heated surfaces because of the burner’s numerous and tiny flames. This type of heat is very efficient and compact. The refractory ceramic infrared

burner requires 100 percent primary air and is designed to have a hot glowing burner surface. The flame burns

close to the burner surface at a high temperature.

NOTE: There is not a shutter on infrared burners for adjusting the primary air.

Fig.2-4

Porous Ceramic Surface

Page 11

OUTDOOR BBBQ GGRILLS

Theory of Operation

2-6

Operation of the Wolf BBQ Grill

About the Wolf BBQ

The grill grates are composed of five-inch heavy duty porcelain cast iron and are designed for easy handling and

cleaning. Just below the grill surface are the stainless steel heat radiants which concentrate the heat. The Wolf

BBQ design eliminates the use of briquettes or lava rock. BBQ burners produce 10,000 BTU/hr and are located

every five inches across the bottom of the unit. The optional open top side burners are rated at 16,00BTU/hr and

have a spark igniter for rotary knob lighting.

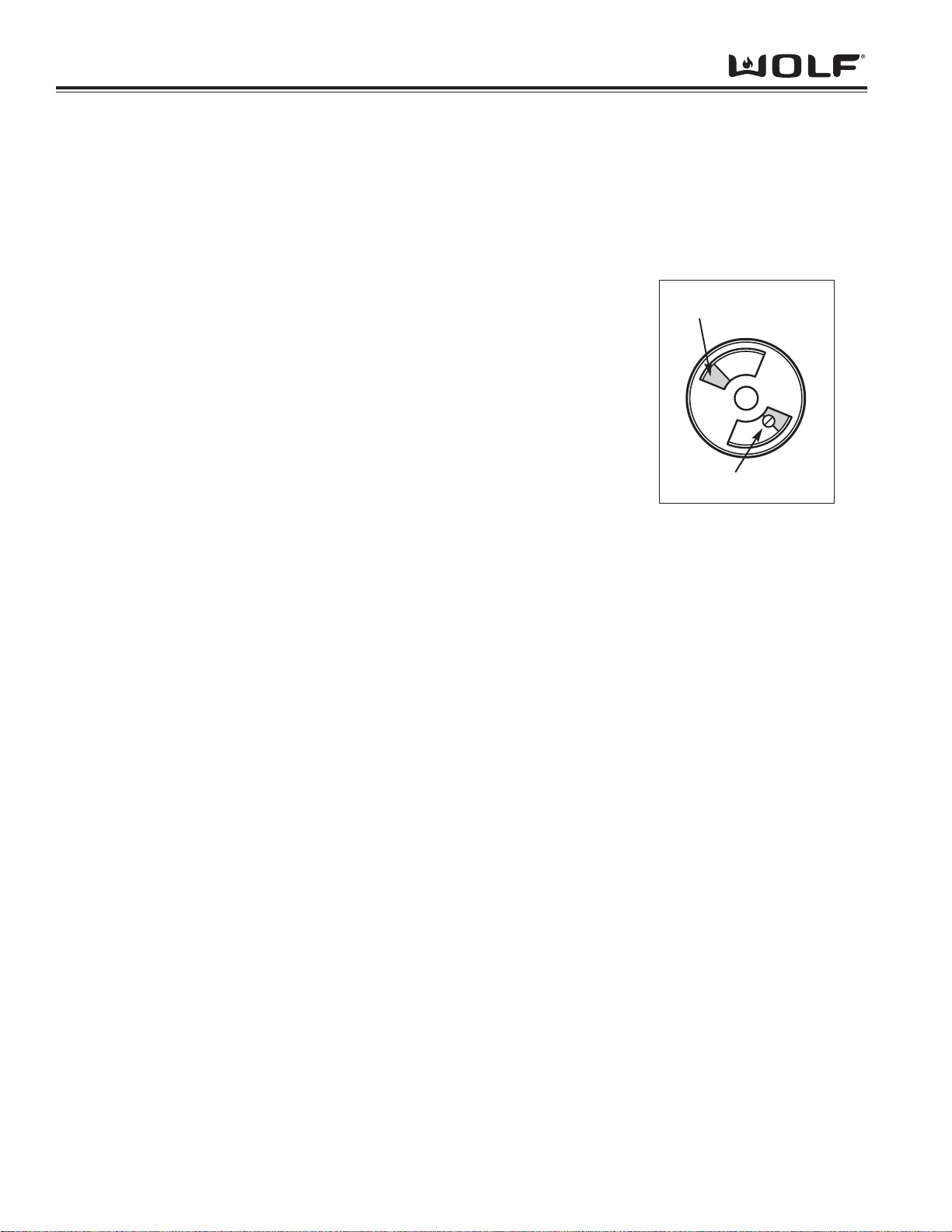

Lighting Instructions

The Wolf BBQ Grill is pre-set for the gas specified when the unit is purchased,

either natural or LP gas. The properly adjusted flame should have a bluish-green

inner cone and a dark blue outer mantle. The flame should be clean and soft

with no yellow tips. Blowing or lifting of the flame should not occur. If the air

shutters are not visible as in Fig. 2-5, the shutter adjustment is

made by loosening the air shutter screw, setting then retightening.

(This should give you proper mixture of the air and gas.)

Before Lighting

Prior to lighting, inspect the gas supply piping or hose. Look for evidence of

abrasion, cuts, wear and tear, or other damage which would require replacement

prior to use. Make sure all burner control knobs are in the OFF position. Do not

attempt to light the burners if the smell of gas is present. Make sure there is

gas in the cylinder and the cylinder is upright. Make sure all radiants are positioned

properly over the grill burners.

Lighting the Grill

1. Open the hood.

2. Push in the gas control knob for the grill and turn counter clockwise to HIGH.

3. Keep your face as far away from the burners as possible.

4. Turn the black igniter knob clockwise which corresponds with the gas control knob you have turned on until you

hear a loud click. Repeat immediately if the burner does not light on the first try.

5. Listen for a “whoosh” sound. If the burner does not light by the fourth attempt with the igniter, turn the control

knob to the OFF position. Wait five minutes until the gas clears.

6. Repeat the procedure or refer to the Manual Lighting Procedure.

7. If the burner is lit, you can see flames by looking through a series of holes just above the control knob of

the corresponding burner.

8. Upon successful lighting, repeat the process on the other burners as needed

Lighting the Open Burners

1. Remove the open burner cover or any utensils from the grate.

2. Follow the steps as above in lighting the grill.

NOTE: The front and rear open burners are lit by a single electrode. The igniter knob is the same for the front and

rear open burners.

Lighting the Rotisserie Burner

The position of the infrared rotisserie burner makes it more susceptible to be blown out and should not be used if

windy conditions prevail or in an unprotected area. For this reason the burner is equipped with a safety valve which

will not allow the burner to operate unless the pilot is lit.

1. Open the hood and remove the rotisserie burner cover.

2. Push in and turn the rotisserie gas control knob to HIGH.

3. After 15 to 30 seconds, turn the rotary igniter knob clockwise until a clicking sound is heard. (This will give the

gas enough time to travel through the tubing to the pilot at the left corner of the burner.)

4. Once the pilot is lit, the burner will light in approximately 30 seconds. The flame is not visible but will give off

heat and a red-orange glow after a few minutes.

Fig. 2-5

1/16” for Natural

1/4” for LP

Air Shutter Screw

Page 12

Theory of Operation

2-7

OUTDOOR BBBQ GGRILLS

Manual Lighting Procedure

You may manually light the grill burners by inserting the match/lanyard holder or a butane lighter into the 1/2” diameter hole above the grill valve knob (Fig. 2-6). Position the match or the lighter tip near the burner ports, push and

turn the knob counter clockwise to HIGH and light the burner. Repeat for the other burners.

The open burners can be lit directly from the top along the orifice holes around the burner heads. (Fig. 2-8)

The rotisserie burner must be lit at the pilot. Once the pilot is lit, the burner will light within 30 seconds. (Fig. 2-7)

Fig. 2-7Fig. 2-6

Position the Match/Lanyard with a lit

match over the Open Burner Head.

Push and turn Burner Valve Knob

counter clockwise to HIGH and light

burner.

Fig. 2-8

Use Match/Lanyard to

light Rotisserie at Pilot

Insert Match/Lanyard

to manually light Grill

Page 13

OUTDOOR BBBQ GGRILLS

Theory of Operation

2-8

Cleaning and Maintenance

Burner Grates

The grates are composed of durable cast iron with a

porcelain enamel finish. Operating the grill on High for

a few minutes after cooking will help to burn off any

excess food. The wire brush included with the BBQ

can be used to clean the grill grates. Once the grates

have cooled, they can be lifted off and sprayed with a

commercial grill and stainless cleaner. They must be

rinsed and dried before they are put back into place.

Open Burner Grates

These grates are porcelain cast iron and can be wiped

clean while in place. They can also be removed when

cool and cleaned with warm soapy water.

Open Burner Heads

Simply lift the removable porcelain cast iron burner

heads straight up. Clean clogged gas holes with an

open paper clip or wire. Wash with soapy water, dry

and replace.

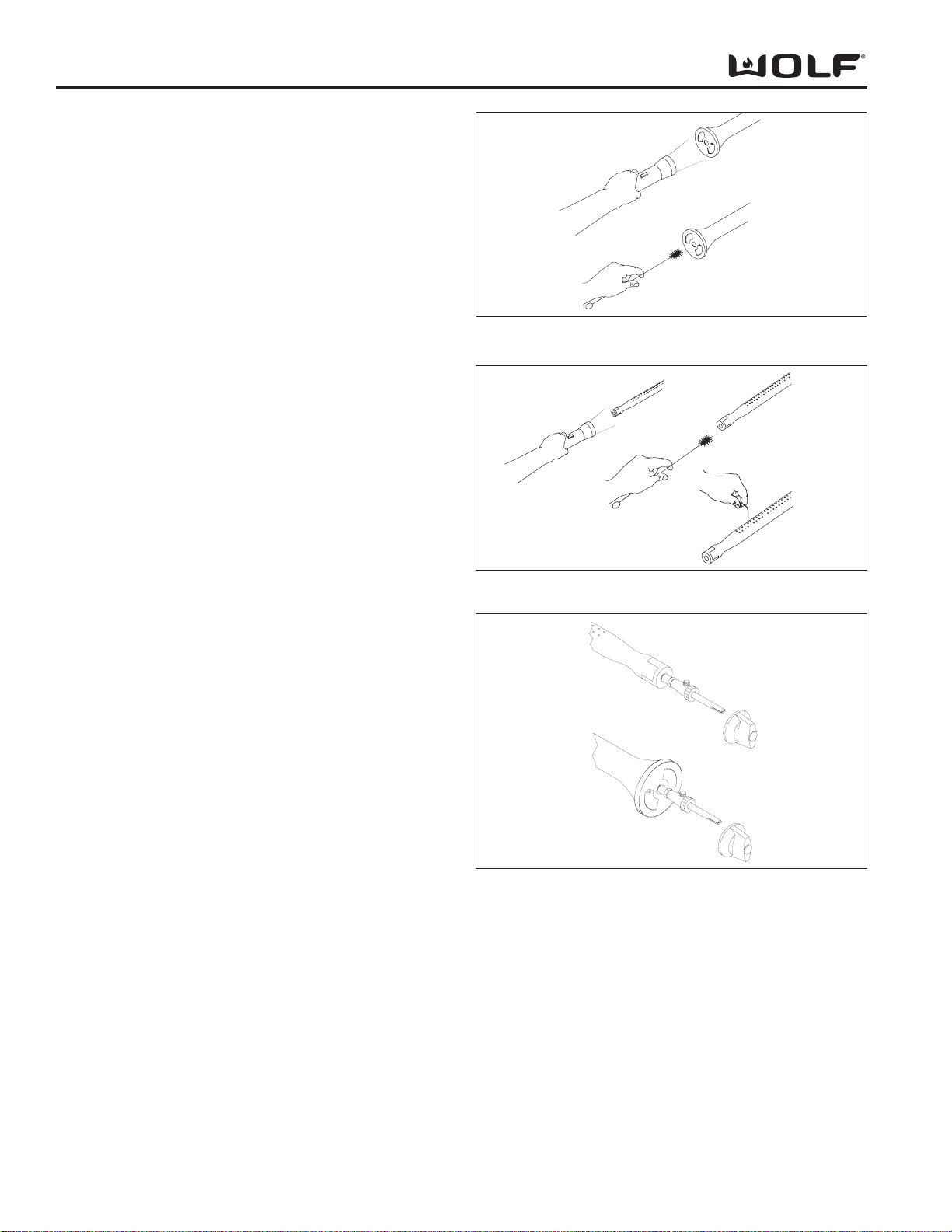

Venturis

Spiders or small insects may spin webs or build nests

inside of the venturis. This especially occurs in late

summer and fall when spiders are most active. These

nests can obstruct gas flow and cause a fire in and

around the valve. Such a fire can cause operator injury

and serious damage to the grill.

To help prevent a blockage and ensure full heat output,

follow these steps to clean and inspect the venturis

once or twice a month.

1. Using a flashlight, look inside of the end of the burners for webs or mud nests. See Fig. 2-9

2. Use the special venturi brush provided and push the

brush through the full length of each burner several

times. See Fig. 2-9

3. For the grill venturis, clean the gas holes with a

paper clip if blocked. See Fig. 2-10

4. Replace the venturis and make sure the bell shaped

or cylindrical end is located over the valve orifices.

See Fig. 2-11

5. Test light to see if it is burning properly.

Grill Tank Bottom

If there is an accumulation of carbon or burned food on the bottom of the grill, use a spatula or scraper to push all

of the carbon and food to the front and into the drip pan to collect and dispose.

Drip Trays and Grease Cans

After cooling, the drip trays and grease cans may be removed and cleaned. The grease can should be cleaned after

each use.

Fig. 2-9

Fig. 2-10

Fig. 2-11

Page 14

OUTDOOR BBBQ GGRILLS

Installation Information

3-2

Insulated Jacket

The optional insulated jacket is necessary when the non cart grill is to be installed into a combustible enclosure.

Use only the Wolf approved insulated jacket which has been specifically designed and tested for this purpose.

See Fig. 3-2

Clearance to Combustible Construction

A minimum of 12” from the sides and 12” from the back is required above and below the cooking surface to adjacent

vertical combustible surfaces as shown on page 3-3. A minimum of 4-1/2” from the back is required for the hood to

open and 6” to the side is required for the rotisserie motor. Refer to the illustrations and chart on page 3-3.

INSTALLATION INFORMATION

This section of the manual covers some of the installation issues that a service technician may need to know when

servicing a Wolf BBQ. If additional installation information is needed after reviewing this section of the manual,

please refer to the Installation Guide or contact the Wolf Appliance Customer Service Department.

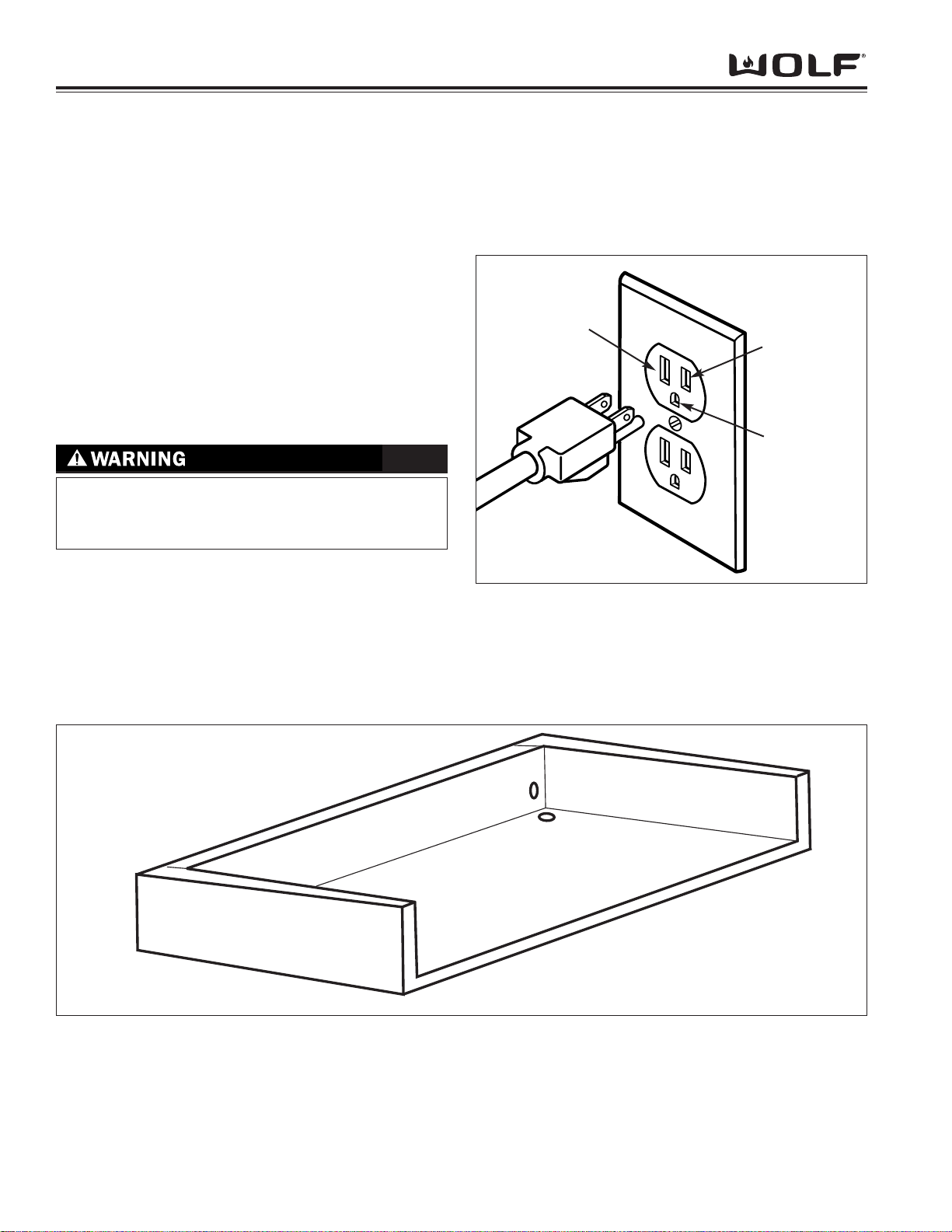

Electrical Requirements:

A Wolf BBQ rotisserie motor requires 110-120 volts AC to

operate. The power supply cord on the rotisserie motor is

equipped with a 3-prong (grounding) plug. The installation

site must be equipped with a properly grounded 3-prong

receptacle. If the electric receptacle or the power cord are

not properly grounded and polarized, a shock hazard could

exist and the rotisserie motor may experience problems.

(See Figure 3-1)

Neutral

Line

Voltage

(Power)

Ground

Fig. 3-1. Proper Polarity at Electric Receptacle

TO AVOID SHOCK HAZARD, NEVER REMOVE THE

GROUNDING PRONG FROM THE PLUG OF THE

POWER SUPPLY CORD.

Note: Keep electrical supply cords and the fuel supply

hose away from heated surfaces.

Fig. 3-2 Insulated Jacket

Page 15

Installation Information

3-3

OUTDOOR BBBQ GGRILLS

Pre-Installation Specifications

Overall / Pre-Installation Dimensions Model BBQ242 Model BBQ36 Model BBQ362 Model BBQ48

A Overall Width of Grill 36” 36” 48” 48”

B Width of Hood 24” 36” 36” 48”

C Rough Opening Width (Combustible Enclosure) 38 1/4” 38 1/4” 50 1/4” 50 1/4”

D Rough Opening Width (Non-Combustible Enclosure) 36 1/4” 36 1/4” 48 1/4” 48 1/4”

Pre-Installation Dimensions Combustible Enclosure Non-Combustible Enclosure

E Rough Opening Depth 27 3/4” 26 3/4”

F Rough Opening Height 10 1/2” 9 1/2”

G Minimum Clearance to Side Walls 12” 6”

H Minimum Clearance to Back Wall 12” 4 1/2”

I Gas Supply Location (Back Wall/Bottom Location) 3 1/8” 2 1/8”

J Gas Supply Location (Back Wall Location) 3 3/4” 2 3/4”

K Gas Supply Location (Bottom Location) 2 7/8” 1 7/8”

Page 16

OUTDOOR BBBQ GGRILLS

3-4

Installation Information

Gas Requirements

Gas Pressure:

NOTE: All Wolf BBQ’s are manufactured as either natural gas or LP gas.

Natural Gas Manifold Pressure

Standard natural gas orifices on the BBQ are set for 5” WC (Water Column Pressure). A natural gas regulator is

provided.

Liquid Propane (LP) Manifold Pressure

Standard LP gas orifices on the BBQ are set for 10” WC (Water Column Pressure). An LP gas regulator is provided.

Gas Supply Pressure

• Maximum line pressure for natural gas and LP is 14” WC; 1/2 psi (3.5 kPa).

• Minimum line pressure for natural gas is 7” WC.

• Minimum line pressure for LP gas is 11” WC.

Gas Pressure Regulator

To control and maintain a uniform gas pressure in the gas manifold, Wolf gas appliances must be connected to the

gas supply line through a pressure regulator. The burner orifices are sized for the pressure delivered by the regulator. Never attempt to operate a Wolf gas appliance without the use of the proper pressure regulator.

The maximum gas supply pressure to the regulator is 14” WC (Water Column Pressure); 1/2 psi (3.5kPa) and

should not be exceeded.

Natural Gas Hook-Up

Hook-up to a natural gas supply is made from the rear right side with fittings and a regulator. The coupling, pipe,

nipple, street elbow and regulator are provided. To hook up the fittings refer to Fig. 3-3. Make sure the flow arrow

on the regulator points in the direction of the gas flow from the gas supply to the grill. See Fig. 3-4

Fig. 3-3 Fig. 3-4

3/4" Coupling

To Grill

3/4" x 3" Pipe Nipple

3/4" x 3/4" Street Elbow

Regulator

Manifold Pipe

3/4" x 1/2" Adapter*

1/2" Close Nipple*

Vent

Shut Off Valve*

(must be easily accessible)

* Indicates parts not included

From Gas Supply

Page 17

Installation Information

3-5

OUTDOOR BBBQ GGRILLS

LP Gas Hook Up

An LP Wolf BBQ is equipped with a five foot hose, regulator and unfilled 20 pound gas cylinder. This connection is

done with the cylinder located inside of the cart. See Fig. 3-5 and Fig. 3-6

Cylinder Specifications

The LP gas supply cylinder used with this grill must be approximately 12” in diameter and 18” high. The maximum

fuel capacity is 20 lbs. of propane or 5 gallons. Full cylinder weight should be approximately 38 lbs. (43.7 lbs. nominal water capacity). The LP gas supply cylinder must be provided with a listed over-filling prevention device. (DPD)

Approximate running time for a 20 pound LP tank:

BBQ Model #

BTU Rating Running Time

BBQ36 / BBQ36C 69,000 BTU 6-1/2 hours

BBQ242 / BBQ242C 80,000 BTU 5-1/2 hours

BBQ48 / BBQ48C 89,000 BTU 5 hours

BBQ362 / BBQ362C 101,000 BTU 4-1/2 hours

Fig. 3-5

VENT HOLE ON REGULATOR MUST POINT DOWN TO

PREVENT FREEZE UP DURING OPERATION OF GRILL

Vent Hole

NOTE: When connecting the regulator

with hose, you must coil excess hose

around LP Cylinder. Failure to do so could

result in pulsating flames or partial flame.

Fig. 3-6

VENT

To LP

Cylinder

To Grill

VENT

Vent

Manifold Pipe

Coupling Nut

VENT

Regulator with 5' Hose

LP Gas Cylinder

(Use in upright position only)

Page 18

OUTDOOR BBBQ GGRILLS

Installation Information

3-6

Installation Checklist

- All internal packaging has been removed.

- All shipping restraints have been removed from the burners.

- Specified clearances to any combustible materials have been maintained.

- All burners light properly, individually and simultaneously.

- All flames appear normal

- The drip pan slides freely. The grease can is properly placed.

- The pressure regulator is connected.

- The LP cylinder is in an upright position and the hose is not kinked.

- The unit has been tested and is free of leaks.

- The customer has been informed of the gas supply shut off valve locations.

- Radiants are located properly over the grill burners.

Leak Testing

A leak test should be performed every time the gas cylinder is connected to the regulator, and whenever part of the

gas system is disconnected or replaced. This applies to both natural and LP gas.

Test for leaks at the cylinder valve, cylinder welds, regulator (especially attached to cylinder valves), hose and connections.

NOTE: DO NOT use a flame, such as a lighted match to test for leaks. Use only a leak testing solution of soapy

water or an electronic leak detector.

Leak Testing Procedure

1. Check that all control knobs are in the OFF position.

2. Mix a one-part soap/one-part water solution. (If not using an electronic detector.)

3. Turn the cylinder valve knob counter-clockwise one turn to open.

4. Apply the soap/water solution on the joints of the gas delivery system.

5. The appearance of blowing bubbles in the soap solution indicates that a leak is present.

6. Stop the leak by tightening the loose connection or replacing the faulty part.

DO NOT attempt to repair the cylinder valve if it should become damaged. The cylinder must be replaced.

NOTE: It is important that there are no leaking connections on the BBQ grill. Refer to the Leak Testing Procedure.

Page 19

OUTDOOR BBBQ GGRILLS

Component Removal

COMPONENT ACCESS AND REMOVAL

This section explains how to access and remove components from a Wolf Outdoor BBQ Grill. Depending on which

component you are going to access or remove in the following sections, you may have to remove some components

first. Refer to the appropriate section in this manual that explains how to access and remove those various components. When reassembling, just reverse the steps that were used to acces and remove the components.

NOTE: Before attempting to access or remove any components from a Wolf Appliance, take note of the following

warnings.

- TO AVOID SERIOUS BURNS AND/OR EXPLOSIONS, KEEP COMBUSTIBLES AWAY FROM THE APPLIANCE

WHENEVER A FLAME IS PRESENT. KEEP IN MIND THAT SURFACES AND COMPONENTS GET HOT

DURING THE USE OF THE APPLIANCE.

- TO AVOID ELECTRICAL SHOCK, POWER TO THE UNIT MUST BE DISCONNECTED WHENEVER ACCESS

ING AND/OR REMOVING COMPONENTS POWERED BY ELECTRICITY OR COMPONENTS NEAR OTHER

ELECTRICAL COMPONENTS.

- IF IT IS NECESSARY TO REMOVE A UNIT FROM ITS INSTALLATION, REMEMBER THAT THE UNIT COULD

TIP FORWARD WHEN PULLED FORWARD, RESULTING IN SERIOUS INJURY OR DEATH. PULLING A

UNIT FROM ITS INSTALLATION SHOULD ONLY BE DONE BY AN AUTHORIZED SERVICE TECHNICIAN OR

INSTALLER.

Page 20

Component Removal

OUTDOOR BBBQ GGRILLS

OPEN BURNER COMPONENTS:

Components include; Open Burner Cover, Open Top

Grates, Step Up Frame, Burner Head, Front & Rear

Venturi, Spark Ground Strap, Spark Electrode, Spark

Electrode Mounting Bracket and Pilot Tube Bracket,

Burner Support Bracket

Open Burner Cover

The stainless steel open burner cover protects the open

burners from the weather when the open burners are

not is use. To remove the open burner cover, lift the

cover off. See Fig. 4-1

Fig. 4-1

Fig. 4-2

Fig. 4-3

Open Top Grates

The open top grates are used to place pots and pans

on the open top burners for cooking. To remove the

open top grates, lift them off of the open top frame.

See Fig. 4-2

Step-Up Frame

The step-up frame is stainless steel and is used to elevate the rear open top burner. To remove the step-up

frame you will need to extract the screws at the back of

the frame which mount it to the BBQ chassis. Now, lift

off the step-up frame from the chassis. See Fig. 4-3

Fig. 4-4

Burner Head

The burner head is made of cast iron and consists of

numerous holes that the gas and flame come out of. To

remove the burner head, lift the burner head off of the

burner venturi. See Fig. 4-4

Page 21

OUTDOOR BBBQ GGRILLS

Component Removal

Rear Venturi

The burner head sits on top of the rear venturi. The

rear venturi sits on the burner support bracket and

slides over the burner valve orifice. To remove the rear

venturi you must remove the open top grate. Now lift

the venturi up off of the burner support bracket and

slide it off of the burner valve orifice. Lift the rear venturi out through the burner support bracket.

See Fig. 4-6

Spark Ground Strap

The spark ground strap is mounted over the spark electrode and is secured to the spark electrode mounting

bracket. To remove the spark electrode ground strap

you will first need to remove the open top grates. Now

extract the screw that mounts the ground strap to the

spark electrode mounting bracket and remove the

ground strap. See Fig. 4-7

Front Venturi

The burner head sits on top of the front venturi. The

front venturi sits on the burner support bracket and

slides over the burner valve orifice. To remove the front

venturi you must remove the open top grate. Now lift

the venturi up and off of the burner support bracket and

slide it off of the burner valve orifice. Now lift the front

venturi out through the burner support bracket.

See Fig. 4-5

Fig. 4-5

Fig. 4-6

Fig. 4-7

Fig. 4-8

Spark Electrode

The spark electrode emits the spark produced by the

rotary igniter to the open top burners. To remove the

spark electrode you will need to remove the open top

burner grates. Now unplug the spark electrode from the

rotary igniter by reaching down along the open top

burner valve and unplugging it from the rotary igniter.

Cut any wire ties that secure the electrode wire. Now

extract the screw from the ground strap and remove the

ground strap. Now remove the spark electrode by

pulling it through the hole in the burner support bracket.

See Fig. 4-8

Page 22

Component Removal

OUTDOOR BBBQ GGRILLS

Spark Electrode Mounting Bracket

The spark electrode mounting bracket is used to mount

the spark electrode to the pilot burner tube. To remove

the spark electrode mounting bracket you will need to

remove the open top burner grates, spark electrode

ground strap and spark electrode. Now extract the

screw for the spark electrode mounting bracket and

remove the spark electrode mounting bracket from the

pilot tube and the burner support bracket.

See Fig. 4-9

Pilot Tube and Bracket

The pilot tube bracket allows gas to flow from the front

and rear open top burners to the spark electrode, which

will produce the flame for the burners once a spark has

been produced from the rotary igniters. To remove the

pilot tube bracket you will need to remove the open top

burner grates and the spark electrode with mounting

bracket. Now extract the screw that mounts the pilot

tube to the support bracket and remove the pilot tube.

See Fig. 4-10

Burner Support Bracket

The burner support bracket is used to support the open

top burners. To remove the burner support bracket you

will need to remove the open top grates, the front and

rear venturi and the step-up frame. Now unplug the

spark electrode from the rotary igniter by reaching down

along the open top burner valve and unplugging it from

the rotary igniter. Cut any wire ties that secure the

electrode wire and extract the two screws at the front of

the burner support bracket and remove. Now lift the

bracket up while pulling the bracket forward to disengage the tab of the support bracket from slot in the

open top frame. See Fig. 4-11

Fig. 4-9

Fig. 4-10

Fig. 4-11

Page 23

OUTDOOR BBBQ GGRILLS

Component Removal

GRILL COMPONENTS:

Components include; Broiler Grates, Radiant, Stainless

Steel Burner, Spark Electrode Ground Strap, Spark

Electrode Mounting Bracket and Spark Electrode.

NOTE: To remove the following components, you must

first raise the front hood.

Stainless Steel Burner

The stainless steel burner tubes are located under the

broiler grates and the radiant. They are long stainless

steel tubes with various holes along the entire length of

the tube.

NOTE: The size of the BBQ unit will determine the

number of burner tubes.

The burner tube fits into a slot on the rear of the grill

chassis. The front of the burner tubes slides over the

orifice on the burner valve. To remove the stainless

steel burner tubes you need to first remove the broiler

grates and the radiant. Then lift the back of burner tube

out of the slot and slide the burner tube off of the burner

valve orifice and out. See Fig. 4-14

Radiant

The radiant is placed on pins that are welded to the grill

chassis, at both the front and back. When the radiant is

placed on top of the holding pins, it is raised just above

the burner tube. The flame from the burner tube is

directed onto the underside of the radiant, distributing

the heat to the sides, rather than directly onto the food

being prepared. To remove the radiant you need to

remove the broiler grates from the grill chassis and then

lift the radiant off of the radiant pin holders.

See Fig. 4-13

Fig. 4-12

Fig. 4-13

Broiler Grates

The grilling surface is composed of numerous broiler

grates. To remove the broiler grates, lift them from the

grill chassis. See Fig.4-12

Page 24

Component Removal

OUTDOOR BBBQ GGRILLS

Spark Electrode Mounting Bracket

The spark electrode mounting bracket holds the spark

electrode and ground strap. To remove the spark electrode mounting bracket you will need to remove the

broiler grates and radiant. Lower the control panel and

unplug the spark electrode from the rotary igniter and

cut any wire ties that secure the electrode wire. Pull

the electrode wire with sleeve through the hole in the

BBQ chassis. Then remove the ground strap and spark

electrode. Now extract the screws that secure the

mounting bracket to the BBQ chassis and remove the

spark electrode mounting bracket. See Fig. 4-16

Spark Electrode Ground Strap

The spark electrode ground strap secures the spark

electrode to the spark electrode mounting bracket. To

remove the spark electrode ground strap you will need

to remove the broiler grates and radiant. Now extract

the screw that secures the ground strap to the mounting bracket and remove ground strap. See Fig. 4-15

Spark Electrode

The spark electrode emits the spark supplied from the

rotary igniter to light the gas in the burner tube. To

remove the spark electrode you will need to remove the

front control panel. Once the control panel has been

removed, unplug the spark electrode wire from the

rotary igniter. Remove the broiler grates, radiant,

ground strap and spark electrode mounting bracket.

Now pull the spark electrode and sleeve through the

hole and out of the grill chassis. See Fig. 4-17

Fig. 4-15

Fig. 4-16

Fig. 4-17

Page 25

OUTDOOR BBBQ GGRILLS

Component Removal

FRONT CONTROL PANEL COMPONENTS:

Components include; Control Knob, Igniter Knob,

Control Panel, Rotary Igniter and Match Holder with

Lanyard.

Control Knob

To remove, pull the knob straight off of the burner valve

shaft. See Fig. 4-18

Igniter Knob

To remove, pull the knob straight off of the rotary igniter

shaft. See Fig. 4-18

Fig. 4-18

Fig. 4-20

Fig. 4-21Fig. 4-19

Match Holder with Lanyard

The match holder is used to secure a lighted match to

light the burner if the rotary igniter fails to produce a

spark. It is riveted to the bottom of the control panel.

To replace it, you will have to drill out the rivet.

See Fig. 4-21

Rotary Igniter

To remove the rotary igniter, first remove the rotary

igniter knobs and the control knobs. Remove the control panel and unplug the electrode wire from the rotary

igniter. Next extract the two screws that mount the

rotary igniter to the control panel. Then pull the rotary

igniter from the control panel. See Fig. 4-20

Control Panel

Begin by removing all of the control panel knobs.

Extract the screws from the bottom left and right corners of the panel. Pull the bottom of the panel out

about 30 degrees and lift slightly to disengage the top

flange of the panel from its mounting. Then lift the top

forward. See Fig. 4-19

Page 26

Component Removal

OUTDOOR BBBQ GGRILLS

COMPONENTS BELOW THE BULL NOSE:

Components include; Bull Nose, Burner Valve, Burner Valve Orifice Hood, Valve Adapter, Tee, Nipple, Connector,

Pilot Valve and the Manifold Pipe.

Bull Nose Removal

To remove the bull nose, extract the two screws from the left and right legs of the bull nose and lift the bull nose

from the unit. See Fig. 4-22

Fig. 4-22

Fig. 4-23

Burner Valve

The burner valves are threaded into the underside of

the manifold assembly. To remove a burner valve, you

will need to turn off the gas supply, remove the broiler

grates, radiant, stainless steel burner tube, control

knobs, control panel and unplug the spark electrode

wires from the rotary igniters. Now using a wrench,

loosen and remove the burner valve. See Fig. 4-23

Burner Valve Orifice Hood

The burner valve orifice is threaded onto the end of the

burner valve. To remove the burner valve orifice you

will need to turn off the gas supply, remove the broiler

grates, radiant, stainless steel burner tube, control

knobs, control panel and unplug the spark. Now using

a wrench, loosen and remove the burner valve orifices

hood. See Fig. 4-23

Page 27

OUTDOOR BBBQ GGRILLS

Component Removal

Valve Adapter and Tee

The valve adapter is threaded onto the end of the infrared rotisserie burner valve. It allows the tee adapter to be

threaded on, so the rotisserie burner valve can supply gas to the pilot valve and the safety valve for the infrared

burner. To remove the valve adapter you will need to turn off the gas supply, remove the control knobs, control

panel and unplug the spark electrode wires from the rotary igniter. Now, loosen and remove the pilot valve gas tubing from the pilot valve and loosen and remove the gas tubing from the safety valve to the connector on the tee

adapter. Then loosen and remove the entire valve adapter/tee assembly as one unit. Once the assembly has been

removed from the unit, remove the valve adapter from the tee. See Fig. 4-24

Nipple and Connector

The nipple is threaded on the end of the tee, which allows the connector for the flexible gas tubing to be threaded

on. This flexible gas tubing goes to the safety valve which supplies gas to the infrared burner. To remove the nipple

you will need to turn off the gas supply, remove the control knobs, control panel and unplug the spark electrode

wires from the rotary igniter. Now you will need to loosen and remove the pilot valve gas tubing from the pilot valve

and loosen and remove the gas tubing from the safety valve to the connector on the tee adapter. Now loosen and

remove the entire valve adapter/tee assembly as one unit. Once the assembly is removed from the unit, you can

remove the nipple from the connector and the tee. See Fig. 4-24

Pilot Valve

The pilot valve is threaded into the bottom of the tee. It allows for a separate gas supply to go to the pilot light for

the infrared burner. To remove the pilot valve you need to turn off the gas supply, remove the control knobs, control

panel and unplug the spark electrode wires from the rotary igniter. Now you will need to loosen and remove the pilot

valve gas tubing from the pilot valve and loosen and remove the flexible gas tubing from the safety valve to the connector on the tee adapter. Now loosen and remove the entire valve adapter/tee assembly as one unit. You can now

loosen and remove the pilot valve from the tee. See Fig. 4-24

Manifold Pipe

The manifold pipe is connected to the gas source at one end and is sealed at the other end. It supplies gas to the

burner valves, pilot valve and safety valve. To remove the manifold you need to turn off the gas supply, remove the

control knobs, control panel and unplug the spark electrode wires from the rotary igniter. Now you will need to

loosen and remove the pilot valve gas tubing from the pilot valve and loosen and remove the flexible gas tubing from

the safety valve to the connector on the tee adapter. Now disconnect the manifold from the gas source. Extract the

screws that secure the manifold to the grill chassis and remove the manifold by pulling straight out of the grill chassis. See Fig. 4-24

Fig. 4-24

Manifold Pipe

Tee

Connector

Nipple

Grill Burner Valve

Pilot Valve

Rotisserie Burner Valve

Valve Adapter

Page 28

Component Removal

OUTDOOR BBBQ GGRILLS

Fig. 4-26

Fig. 4-25

Fig. 4-27

HOOD COMPONENTS:

Components include; Rotisserie Rod with Fork,

Rotisserie Motor, Motor/Rod Support, Hood Handle,

Front Hood, Rear Hood Top, Rear Hood Left and Right,

IR Burner Cover with Handle, Pilot Shield, Infrared

Burner, Pilot Burner, Spark Electrode, Rear Splash

Panel, Side Plate Shelf, Side Plate Shelf Brackets and

Belly Bar with Brackets.

Rotisserie Rod with Fork

The rod for the rotisserie system is assembled into the

motor by placing the pointed end into the motor and

resting the threaded end on the support at the right side

of the grill. Once the rod is pushed as far as possible

into the motor, the grooved end of the rod should rest

on the right side bracket. The removable rotisserie

handle should be removed when using the open burners. To remove the rotisserie rod with fork, lift the rod

out of the support bracket on the right side. Now pull

the rod out of the rotisserie motor. See Fig. 4-25

Rotisserie Motor

The rotisserie motor is equipped with metal gears and

is capable of turning a balanced 25 lb. cut of meat or

poultry. The motor is mounted to a metal bracket,

which attaches to the sides of the grill and must be

electrically grounded. To remove the rotisserie motor

you first need to unplug the rotisserie motor from the

electrical source. Remove the rotisserie rod with fork,

now lift the rotisserie motor straight up and out of the

motor support bracket. See Fig. 4-26

Rotisserie Motor/Rod Support

The motor support holds the rotisserie motor in place

and is mounted to the left side hood. To remove the

motor support bracket you need to extract the acorn

nuts from screws. Then extract the mounting screws

from the bracket. Now lift the bracket off of the left side

of the hood.

The rod support bracket holds one end of the rotisserie

rod and is mounted on the right side hood. To remove

the rod support, extract the mounting screws and lift

bracket off right side hood. See Fig. 4-27

Page 29

OUTDOOR BBBQ GGRILLS

Component Removal

Fig. 4-28

Fig. 4-29

Fig. 4-30

Hood Handle

The hood handle is attached to the hood from the

inside. To remove the hood handle you need to remove

the plug buttons from the inner hood liner to gain

access to the mounting bolts for the handle. Now

extract the bolts from the handle and lift the handle from

the front hood. See Fig. 4-28

Front Hood

The hood is used to provide an even temperature, conserve fuel, lessen flare-up and improve food flavor. To

remove the hood you will first need to remove the rotary

motor rod support bracket. Now extract the shoulder

screw and nut from the flanged bushing on the left and

right side of the hood. Lift off the front hood.

See Fig. 4-29

Rear Hood Top

The rear hood top is connected to the right and left side

hood, and is slotted for ventilation. It covers the

infrared burner and gas tubing. In order to remove the

rear hood, the front hood will need to be removed. To

remove the rear hood, remove the screws along the

right and left side hood. Remove the screws along the

middle of the rear hood. The middle screws mount the

rear hood to the rear splash panel. Now lift off the rear

hood. See Fig. 4-30

Rear Hood Right and Left

The rear hood right and left makes-up the side of the

hood. In order to remove the rear hood right and left,

the front hood and rear top hood need to be removed.

Remove the screws that are located inside the grill

chassis for each side hood. Once that is done, lift out

the side hoods. See Fig. 4-31

Fig. 4-31

Page 30

Component Removal

OUTDOOR BBBQ GGRILLS

Fig. 4-32

Fig. 4-33

Infrared (IR) Burner Cover with Pull

The infrared burner has a stainless steel cover that protects it when not in use. The cover has two tabs that fit

into grooves which are cut into the rear splash panel.

When the tabs are inserted into the grooves the cover

hangs onto the rear splash panel. To remove the

infrared burner cover, just lift off and remove.

The cover also has a handle, known as a pull. To

remove the pull, lift the infrared burner cover off of the

rear splash panel, then remove the screws that mount

the pull to the cover. See Fig. 4-32

Pilot Shield

The pilot shield protects the pilot burner assembly for

the infrared burner. To remove the pilot shield, extract

the screw that mounts the shield to the rear splash

panel and lift the pilot shield off. See Fig. 4-33

Infrared Burner

The infrared burner is used for rotisserie cooking. The

intensity of this radiant heat is preferred over other

methods because of its ability to sear the natural juices

and nutrients into the food. The location of the burner

allows for the placement of a basting pan beneath the

food to collect all juices and drippings. To remove the

infrared burner, make sure you have the gas supply

turned off. If the rotisserie motor and rod are in place,

remove them. Now remove the rear hood top. Now that

the rear hood top is removed, disconnect the flexible

gas tubing from the infrared burner. Disconnect the gas

tubing that is connected to the pilot burner (See Fig. 4-

34). Then remove the screw that mounts the sparker to

the pilot burner and remove the sparker and pilot burner

from the mounting bracket . Now you can extract the

two screws that secure the infrared burner to the rear

splash panel and pull the infrared burner towards the

front of the unit to remove. See Fig. 4-33

sconnect

Gas

e

Disconnect Gas Line

Fig. 4-34

Di

Flexible

Lin

Page 31

OUTDOOR BBBQ GGRILLS

Component Removal

Fig. 4-37

Fig. 4-36

Fig. 4-35

Pilot Burner

The pilot burner is lit by a sparker and maintains a

standing pilot light for the infrared burner and flame

sensor as long as the infrared burner valve is in the on

position. The pilot burner must maintain a standing pilot

light on the flame sensor in order to keep the safety

valve open and allow gas to flow to the infrared burner.

To remove the pilot burner, make sure the gas supply is

turned off. If the rotisserie motor and rod are in place,

remove them. Remove the infrared cover. Remove the

pilot shield from the rear splash panel. Loosen the

screw that holds the flame sensor in place on the pilot

burner. Slide the flame sensor down and out of the

pilot burner. Remove the rear hood top. Disconnect

the gas line to the pilot burner. Remove the screw that

mounts the sparker and pilot burner to the mounting

bracket. Now move the sparker out of the way and

slide the pilot burner through the slot in the rear splash

panel towards the back of the unit and out.

See Fig. 4-35

Spark Electrode

The spark electrode provides the spark for the pilot

burner, which in turn allows the safety valve to open

and supply gas to the infrared burner for the rotisserie.

The spark electrode is a one-piece electrode with a

wire, which is plugged into the rotary igniter on the control panel. When you turn the rotary igniter, you create

a spark from the electrode, which lights the gas to the

pilot burner supplied from the pilot valve. To remove

the spark electrode, remove the rear hood top.

Disconnect the nut from the screw that mounts the

sparker to the pilot burner on the mounting bracket.

Now remove the control panel and disconnect the

sparker wire from the rotary igniter. Remove the spark

electrode and wire from the unit out the rear of the grill.

See Fig.4-36

Rear Splash Panel

The rear splash panel is located at the back of the grill.

The infrared burner, pilot shield, pilot valve and sparker

are mounted to it as well as the rear hood top. To

remove the rear splash panel you need to make sure

the gas supply is turned off. Remove the rear hood top.

Disconnect the gas line to the pilot burner and infrared

burner. Remove the pilot shield. Remove the spark

electrode and pilot burner from the mounting bracket.

Remove the infrared burner. Now extract the screws

from the bottom of the rear splash panel from the grill

chassis and lift the rear splash panel off.

See Fig. 4-37

Page 32

Component Removal

OUTDOOR BBBQ GGRILLS

Fig. 4-38

Fig. 4-39

Fig. 4-40

Belly Bar and Brackets

The belly bar is a stainless steel tube that is mounted to

the side of the unit with two mounting brackets. It can

be used to push or pull the unit from one position to

another. To remove the belly bar you will need to

remove one of the mounting brackets first. To remove

the mounting bracket, extract the two screws that

mount the bracket to the unit. Now lift the bracket off

and slide the belly bar from its mounting position on the

other bracket. Now you can remove the other belly bar

bracket by extracting the two screws that mount the

bracket to the unit. See Fig. 4-40

Side Plate Shelf Brackets

These brackets provide the support for mounting the

side plate shelf. To remove the brackets, first remove

the plate shelf. Now extract the two screws from the

bracket and remove the bracket. Repeat this process

for each bracket. See Fig. 4-39

Side Plate Shelf

The Side Plate Shelf is a stainless steel fold down shelf

that is mounted to the side of the unit. It can be lifted

up for holding a variety of items during cooking or it can

be folded down when not in use. To remove the side

plate shelf you will need to have it in the folded position.

Now push the side of the shelf in slightly, along the

oblong mounting holes on the sides. Lift the shelf off of

the mounting pin brackets. See Fig. 4-38

Page 33

4-16

OUTDOOR BBBQ GGRILLS

Component Removal

REAR PANEL COMPONENTS:

Components include; Rear Panel, Safety Valve and

Gas Tubing

Rear Panel

The rear panel is on the back of the grill chassis. Once

the rear panel is removed you have access to the safety valve and related gas tubing. If the grill is in a built in

installation, it will have to be pulled out to gain access

to the rear panel screws. To remove the rear panel,

extract the screws around the rear and lift the panel off.

See Fig. 4-41

Safety Valve

The safety valve allows the gas to flow to the infrared

burner via the gas tubing. The safety valve has a flame

sensor attached to it, which is mounted on the pilot

burner. Once the pilot is lit, the flame goes over the

flame sensor. When the flame sensor gets hot enough

it opens the safety valve and the gas is allowed to flow

through the tubing and to the infrared burner. The flame

at the pilot burner then lights the infrared burner. If the

flame on the pilot light goes out for any reason, the

safety valve closes and shuts off the gas supply to the

infrared burner. To remove the safety valve you need to

turn off the gas supply and remove the rear panel. If

the grill is in a built-in installation, it will have to be

pulled forward to gain access to the rear panel and

screws. Disconnect the flexible gas tubing from the

safety valve. Now remove the two screws that secure

the safety valve to the bracket and lift out the safety

valve. See Fig. 4-42

Safety Valve Gas Tubing

This is a flexible gas line that goes between the Tee

connector at the manifold and the safety valve. It supplies gas to the safety valve. To remove this flexible

gas tube you will have to turn off the gas supply. If the

unit is in a built-in installation, it will have to be pulled

out. Remove the rear panel. Then disconnect the flexible gas line on the side of the safety valve and at the

Tee connector at the manifold. In order to do this you

will have to remove the control panel and disconnect

the spark electrodes from the rotary igniters. Now

remove the flexible gas tube from the unit.

See Fig. 4-43

Fig. 4-41

Fig. 4-42

Fig. 4-43

WOLF

APPLIANCE CO. LLC FITCHBURG, WI

MODEL

BBQ-

SERIAL

NO.

R

MAN.

GAS

INPUT RATING EACH

PRESS.

BURNER-BTU / HR.

OPEN

GRILL

ROTISSERIE

BURNER

I

G

S

N

E

ROTISSERIE MOTOR ELECTRICAL RATING

D

R

I

E

C

M

A

120V, 60 Hz, 0.58A

A

N

G S

A

MINIMUM CLEARANCE FROM SIDES AND BACK OF UNIT TO ADJACENT

A

S

R

N

S

COMBUSTIBLE CONSTRUCTION BELOW TOP OF UNIT, 8 INCHES FROM

O

O

I

C

T

I

A

C

SIDES AND BACK. MINIMUM HORIZONTAL CLEARANCE FROM SIDES

E

D

R

E

I

T

I

F

AND BACK OF UNIT TO ADJACENT VERTICAL COMBUSTABLE

CONSTRUCTION EXTENDING ABOVE TOP OF UNIT, 6 INCHES FROM SIDES

ANS 12 INCHES FROM BACK. DO NOT LOCATE THIS UNIT UNDER

OVERHEAD UNPROTECTED COMBUSTIBLE SURFACES.

FOR OUTDOOR USE ONLY.

CERTIFIED

CAUTION:

1. DO NOT STORE A SPARE LP-GAS CYLINDER UNDER THIS

APPLIANCE.

2. NEVER FILL THE CYLINDER BEYOND 80 PERCENT FULL..

3. IF THE INFORMATION IN (1) AND (2) IS NOT FOLLOWED EXACTLY

A FIRE CAUSING DEATH OR SERIOUOS INJURY MAY OCCUR.

"ANS Z21.58A CAN/CGA-1.6A-1998 OUTDOOR COOKING APPL.,"

"FOR INSTALLATION IN NON-COMBUSTIBLE LOCATIONS UNLESS

800116

USED WITH APPROVED INSULATING JACKET"

For Wolf Authorized Service

CALL

888-904-9653

FOR USE WITH A GAS PRESSURE REGULATOR. THE REGULATOR SUPPLIED

MUST BE USED WITH THIS UNIT.

CET APPARIEL REQUIERT L' INSTALLATION D' UN DETENDEUR DE PRESSION.

LE DETENDEUR FOURNI DOIT Y ENTRE

INSTALLE.

WARNING: Improper installation

adjustment, alteration, service, or

maintenance can cause property

damage, injury or death. Read the

maintenance instructions thoroughly

before installing or servicing this

equipment.

MISE EN GARDE: Une mauvaise

installation, un mauvais entretien,

une reparation, un ajustement ou

une alteration inappropiee peuvent

causer des dommages a lappariel,

des blessures corporels ou la mort.

Lire les instructions d'installation,

de fonctionnement et d'entretien

avant l'installation ou lentretien de

cet appareil.

Safety Valve Gas Tubing

Page 34

4-17

Component Removal

OUTDOOR BBBQ GGRILLS

Infrared Gas Tubing

This is a flexible gas line that goes between the safety valve and the infrared burner. Once the flame sensor on the

pilot burner is hot enough to open the safety valve, it will supply the gas from the safety valve to the infrared burner.

To remove this flexible gas tube you will have to turn off the gas supply. If the unit is in a built-in installation, it will

have to be pulled out. Extract the screws and remove the rear hood top. Disconnect the flexible gas tube from the

infrared burner and the top of the safety valve and remove the flexible gas tube from the unit. See Fig. 4-44

Pilot Valve Gas Tubing

This is a gas tube that goes between the pilot valve at

the Tee connector on the manifold and to the pilot burner at the infrared burner. Once the infrared burner

valve is turned on, it supplies gas for the pilot light at

the pilot burner. To remove this gas tube you will have

to turn off the gas supply. If the unit is in a built-in installation, it will have to be pulled out. Extract the screws

and remove the rear hood top. Disconnect the gas

tube at the pilot burner. Remove the control panel and

disconnect the gas tube from the pilot valve. Now

remove the gas tubing from the unit. See Fig. 4-45

sconnect

Gas

e

Fig. 4-45

Fig. 4-44

Di

Flexible

Lin

Pilot Valve Gas Tubing

Page 35

OUTDOOR BBBQ GGRILLS

Component Removal

CART COMPONENTS:

Components include; BBQ Chassis, Door Handles,

Door Assembly, Doorstops, Top Catch Holder, Magnetic

Catch, Bottom Panel, Rear Panel, Side Panel, Top Trim,

Swivel Caster w/Brake, Caster Locking Bracket, NonSwivel Caster, 48" Cart Shelf, 48" Cart Partition and

Cart Frame Assembly

BBQ Chassis

To remove the entire BBQ chassis from the cart you will

need to turn off and disconnect the gas supply. Then

remove the control panel, rear panel and extract the

mounting bolts from the cart frame to the BBQ chassis.

Now lift the BBQ chassis from the cart assembly.

See Fig. 4-46

Door Handles

To remove the stainless steel cart door handles you will

need to open the door and extract the two screws from

the inside of the door that mount the handle to the door.

See Fig. 4-47

Door Assembly

To remove the stainless steel door assembly you will

need to open the door and extract the two screws that

mount the door hinge to the inside of the cart frame.

NOTE: If replacing the door, the door handles will have

to be removed and reinstalled on the new door.

NOTE: The door hinges are not replaceable. They are

welded to the door assembly and to replace them you

will replace the entire door assembly.

See Fig. 4-48

Doorstops with Screw and Spacer

The doorstops are located inside of the cart, behind the

doors, at the bottom front. They are to keep the door

from closing too far into the cart. The doorstop is simply a screw inserted into a spacer, then screwed as one

piece to the bottom panel. To remove the doorstop you

will need to open the door, extract the screw and then

remove the screw from the spacer. See Fig. 4-49

Fig. 4-49

Fig. 4-48

Fig. 4-47

Fig. 4-46

Page 36

Component Removal

OUTDOOR BBBQ GGRILLS

Top Catch Holder

The top catch holder is located behind the cart doors

and centered at the top of the cart frame. It is a bracket

that houses the magnetic catch for the doors. To

remove this you will need to open the doors. Now

extract the two screws that mount the top catch holder

to the cart frame and remove the top catch holder.

See Fig. 4-50

Magnetic Catch

The magnetic catch is a round plastic grommet with

locking tabs that contain a magnet. The magnetic catch

is installed into the top catch holder. To remove the

magnetic catch you need to open the cart door. Reach

around the back of top catch holder and push in the two

locking tabs on each side of the magnetic catch. Now

push the magnetic catch towards the front and out of

the top catch holder and remove. See Fig. 4-51

Bottom Panel

To remove the bottom panel inside the cart you will first

need to open the cart doors. Now extract the doorstops

and extract the screws around the perimeter of the bottom panel. Reach under the cart frame on one side

and push up on the bottom panel at an angle. Now

you can remove the bottom panel from the inside of the

cart by angling the bottom panel as you lift the panel

out of the cart.

NOTE: For the 48" cart you will need to remove the left

cart door, the cart shelf and the cart partition before you

remove the bottom panel.

Fig. 4-52

Fig. 4-51

Fig. 4-50

Page 37

4-20

OUTDOOR BBBQ GGRILLS

Component Removal

Rear Panel

To remove the rear panel you will need to pull the cart

out so you have access to the rear of the unit. Now

extract the screw from the rear panel and lift the rear

panel off of the cart. See Fig. 4-53

Side Panel

To remove the side panels you will need to remove the

rear panel and the control panel. Now extract and

remove the mounting bolts from the cart frame that

mount the BBQ chassis to the cart both front and back

on one side. Now prop the BBQ chassis up from the

cart slightly. Using a putty knife, separate the doublesided tape from the bottom of the side panel to the cart

frame. Now lift the back flange of the side panel off of