Page 1

SUB-ZERO FREEZER COMPANY INC. 2005 ALL RIGHTS RESERVED JOB AID #3758424 (Revision B - December, 2005)

Integrated

(700-

3

BASE)

Series

TTeecchhnniiccaall

SSeerrvviiccee MMaannuuaall

Page 2

Page 3

General Information

Integrated

(700-3BASE)

Series

1-1

#3758424 - Revision B - December, 2005

SECTION 1

GENERAL

INFORMATION

Page 4

General Information

Integrated

(700-3BASE)

Series

1-2

#3758424 - Revision B - December, 2005

TECHNICAL ASSISTANCE

If you should have any questions regarding a 7003 Base Unit and/or this manual, please contact:

Sub-Zero Freezer Company, Inc.

ATTN: Service Department

P.O. Box 44988

Madison, WI 53744 - 4988

Customer Service & Parts / Warranty Claims

Phone #: (800) 222 - 7820

Technical Assistance

Phone #: (800) 919 - 8324

Customer Service & Technical Assistance

Facsimile #: (608) 441 - 5887

Parts / Warranty Claims

Facsimile #: (608) 441 - 5886

Service Department E-Mail Address:

customerservice@subzero.com

Office Hours:

7:00 AM to 7:00 PM Central Time

Monday through Friday

This manual is designed to be used by Authorized Service Personnel only. Sub-Zero Freezer Co., Inc.

assumes no responsibility for any repairs made on Sub-Zero refrigeration units by anyone other than

Authorized Service Technicians.

IMPORTANT SAFETY INFORMATION

Below are the Product Safety Labels used in this

manual. The "Signal Words" used are WARNING

or CAUTION.

When reviewing this manual, please note these

different Product Safety Labels placed at the

beginning of certain sections of this manual. You

must follow the instructions given in the boxes

below the Product Safety Labels in order to avoid

personal injury and/or product damage.

The sample Product Safety Labels below illustrate

the precautions that should be taken when the signal word is observed.

INTRODUCTION

This 700-3 Series Base Unit Technical Service Manual, Part #3758424, has been compiled to provide the

most recent information on safety, installation, set-up, design, operation, features, troubleshooting, wiring

diagrams, and repair procedures of the 700-3 Base units. This information will enable the service technician to troubleshoot and diagnose malfunctions, perform necessary repairs, and return a 700-3 Base unit

to proper operational status.

The service technician should read the complete instructions contained in this training/service manual

before initiating any repairs on a 700-3 Base unit.

INDICATES THAT HAZARDOUS OR UNSAFE PRACTICES COULD RESULT IN SEVERE PERSONAL

INJURY OR DEATH

Indicates that hazardous or unsafe practices could

result in minor personal injury or product and/or

property damage

In addition, please pay attention to the signal word

“NOTE”, which highlights information that is espe-

cially important for the topic being covered.

The information and images contained in this manual are the copyright property of Sub-Zero Freezer Company, Inc.

Neither this manual nor any information or images contained herein may be copied or used in whole or in part with-

out the express written consent of Sub-Zero Freezer Company, Inc. © all rights reserved.

Page 5

General Information

Integrated

(700-3BASE)

Series

1-3

#3758424 - Revision B - December, 2005

Section 1 - General Information 1-1

Introduction ....................................................................... 1-2

Important Safety Information ............................................ 1-2

Technical Assistance ........................................................ 1-2

Table of Contents .............................................................. 1-3

Warranty Information ........................................................ 1-5

Model Description ............................................................. 1-6

Section 2 - Installation Information 2-1

Installation Considerations ............................................... 2-2

Unit leveling .................................................................. 2-2

Drawer Adjustment ....................................................... 2-3

Dual Unit Installation ..................................................... 2-3

Section 3 - Electronic Control System Information 3-1

Electronic Control Terminology &

Component Descriptions .................................................. 3-2

Electronic Control System Overview ............................... 3-3

Control Board Layout & Summary Table ....................... 3-4

Control Panel Layout ....................................................... 3-5

Basic Electronic Control Input Operations ...................... 3-6

Unit ON/OFF ................................................................ 3-6

Adjusting Set-Point (Temp. Adjustment) ...................... 3-6

Icemaker System ON/OFF ............................................ 3-7

Door Ajar Alarm ON/OFF ............................................ 3-7

Unique Electronic Control Input Operations .................... 3-8

Temperature Units Selection Mode ............................ 3-8

Sabbath Mode ............................................................. 3-8

Showroom Mode ......................................................... 3-9

Manual Freezer Evaporator Defrost ............................ 3-9

Functions of Electronic Control System ......................... 3-10

Display Zone Temperatures ........................................ 3-10

Supply Power to Lighting System .............................. 3-10

Regulate Freezer Zone Temperature (BC/BF) ............ 3-11

Regulate Refrigerator Zone Temperature (BC) ........... 3-12

Regulate Refrigerator Zone Temperature (BR) ........... 3-13

“Adaptive Defrost” (BC/BF) ......................................... 3-14

Fan-Assisted Off-Cycle Defrost“ (BR) ......................... 3-15

Monitor Compressor Run - Display SERVICE ............ 3-16

Monitor Ice Maker System - Display ICE/SERVICE .... 3-17

Possible Error Indicators ............................................... 3-18

Troubleshooting Input Operations ................................... 3-19

Diagnostic Mode ........................................................ 3-19

Thermistor Location Code Tables .......................... 3-19

Diagnostic Mode Indicators ..................................... 3-20

Error Code Table ..................................................... 3-20

Manual Component Activation Mode .......................... 3-21

Temperature Log Recall Mode .................................... 3-22

Compartment Temperature History Only ................. 3-22

Compartment & Evaporator Temperature History .... 3-23

Temperature Log Event Indicators ........................... 3-24

Temperature Log Index Chart .................................. 3-25

Service Input Operations ................................................. 3-26

Model Configuration Mode .......................................... 3-26

Model Code Table ....................................................... 3-26

Manual Entry Model Configuration Mode .................... 3-27

Section 4 - Sealed System Information 4-1

HFC-134a Refrigerant Service Information ...................... 4-2

General Rules for Working with 134a Refrigerant ........ 4-2

Sealed System Repair Procedures .............................. 4-3

Sealed System Operation ................................................ 4-4

Sealed System Refrigerant Flow Diagrams ..................... 4-6

Section 5 - Air Flow & Fan Blade Spacing 5-1

Model 700BCI-3 ............................................................... 5-2

Model 700BR-3 ................................................................ 5-2

Model 700BFI-3 ............................................................... 5-3

Section 6 - Icemaker Information 6-1

Modular Icemaker ........................................................... 6-2

Modular Icemaker Operation ...................................... 6-2

Additional Icemaker Operation Notes ......................... 6-3

What Happens During Ejector Blade Rotation ............ 6-3

Modular Icemaker Test Procedures ................................ 6-4

Voltage Tests ................................................................ 6-4

Continuity Tests & Thermostat Inspection ................... 6-4

Water Fill Adjustment ...................................................... 6-5

Icemaker Disassembly .................................................... 6-5

Module/Motor Assembly ............................................. 6-5

Mold/Heater Assembly ............................................... 6-5

Ejector Blades and/or Ice Stripper .............................. 6-5

Icemaker Thermostat ................................................. 6-5

TABLE OF CONTENTS

Page #

Page #

Page 6

General Information

Integrated

(700-3BASE)

Series

1-4

#3758424 - Revision B - December, 2005

Section 7 - Component Access and Removal 7-1

Section Table of Contents .............................................. 7-2

WARNINGS & CAUTIONS .............................................. 7-2

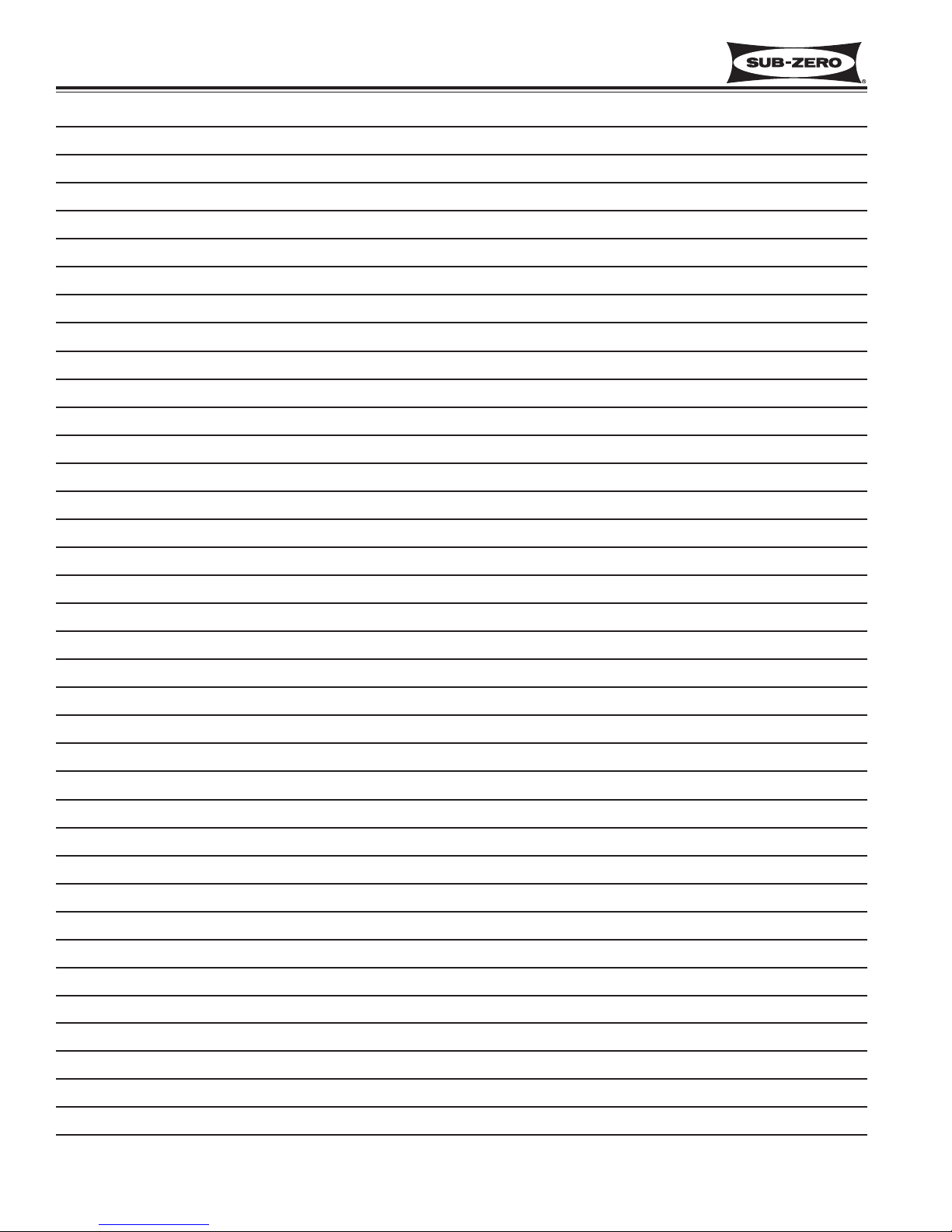

Exterior Cosmetic and Mechanical Components ........ 7-3

Kickplate/Grille (All Base Units) ..................................... 7-3

Drawer Assembly (All Base Units) ................................. 7-3

Top Drawer Assembly................................................ 7-3

Bottom Drawer Assembly........................................... 7-3

Side Trim Molding Strip (All Base Units) ....................... 7-4

Drawer Gasket (All Base Units) .................................. 7-4

Interior Cosmetic, Mechanical Components................ 7-5

Control Panel Assembly (All Base Units) ...................... 7-5

Display Wire Harness (All Base Units) ......................... 7-5

Lighting Bulb & Socket (All Base Units) ....................... 7-5

Mullion Divider (700BC/I-3 ) ......................................... 7-6

Wire Tray (700BR-3, 700BF/I-3) ................................... 7-6

Drawer Closer Assembly (All Base Units) .................... 7-6

Drawer Slide Assembly (All Base Units) ....................... 7-7

Refrigerator Fan Baffle & Shroud (700BC/I-3) .............. 7-7

Refrigerator Light Switch (700BC/I-3) ........................... 7-7

Refrigerator Fan Baffle & Cold Plate(700BR-3) ............ 7-8

Refrigerator Fan Motor (700BC/I-3, 700BR-3)) ............ 7-8

Refrigerator Compartment Thermistor (700BC/I-3) ....... 7-8

Refrigerator Compartment Thermistor (700BR-3) ........ 7-9

Refrigerator Light Switch (700BR-3) ............................. 7-9

Refrigerator Evaporator Thermistor (700BR-3) ............ 7-9

Icemaker Assembly (700BCI-3, 700BFI-3) ................ 7-10

Sump Cover Assembly (700BCI-3, 700BFI-3) ........... 7-10

Lower Air Duct (700BC/I-3) ....................................... 7-11

Air Baffle Control Assembly (700BC/I-3) ..................... 7-11

Freezer Compartment Thermistor (700BC/I-3) .......... 7-11

Freezer Light Switch (700BC/I-3) ............................... 7-11

Freezer Light Switch / Icemaker Switch (700BF/I-3) .. 7-12

Freezer Compartment Thermistor (700BF/I-3) ........... 7-12

Freezer Evap. Thermistor (700BC/I-3,700BF/I-3) ....... 7-13

Defrost Terminator (700BC/I-3, 700BF/I-3) ................. 7-13

Defrost Heater (700BC/I-3, 700BF/I-3) ....................... 7-13

Control Board Assembly (700BC/I-3, 700BF/I-3) ....... 7-14

Evaporator Fan Assembly (700BC/I-3, 700BF/I-3) ..... 7-14

Compressor Area Mechanical Components .............. 7-15

Main Control Board (700BR-3) .................................. 7-15

Icemaker Water Valve Assy

(700BCI-3, 700BFI-3, Prior to Serial #2421189) ......... 7-16

Icemaker Water Valve Assy

(700BCI-3, 700BFI-3, Starting w/Serial #2421189) ..... 7-17

Condenser Fan Assembly (All Base Units) ................. 7-18

Drain Tube Heater (700BC/I-3, 700BF/I-3) ................. 7-19

Sealed System Components ....................................... 7-20

High-Side Filter-Drier (All Base Units) ........................ 7-20

Compressor (All Base Units) ...................................... 7-21

Condenser (All Base Units) ........................................ 7-22

Evap./Heat Exchanger Assy (700BC/I-3, 700BF/I-3) .. 7-23

Evaporator (700BR-3) ................................................. 7-24

Page #

Page #

Section 8 - Troubleshooting Guides 8-1

Troubleshooting Guides .................................................... 8-2

How to Use the Error Code Troubleshooting Guide .......... 8-2

Error Code Table ............................................................ 8-2

Error Code Troubleshooting Guide ................................... 8-3

How to Use the General Troubleshooting Guide .............. 8-6

Temperature Problem Instructions ................................ 8-6

Thermistor Location Code Tables ................................ 8-6

General Troubleshooting Table of Contents ...................... 8-7

General Troubleshooting Guide ......................................... 8-8

Sealed System Troubleshooting / Diagnostic Tables .... 8-16

Normal Operating Pressures Table ............................. 8-16

Pressure Indications Table .......................................... 8-16

Temperature/Pressure Table ....................................... 8-17

Membrane Switch / Ribbon Cable Test .......................... 8-18

Section 9 - Technical Data Tables 9-1

Model 700BC/I-3 .............................................................. 9-2

Model 700BR-3 ................................................................ 9-3

Model 700BF/I-3 .............................................................. 9-4

Section 10 - W

iring Diagrams 10-1

700BC/I-3 Wiring Diagram (PTS #2300444) .................. 10-2

700BC/I-3 Wiring Schematic (PTS #2300444) ............ 10-3

700BC/I-3 Wiring Diagram (SWS #2300444) ................. 10-4

700BC/I-3 Wiring Schematic (SWS #2300444) .......... 10-5

700BR-3 Wiring Diagram ................................................ 10-6

700BR-3 Wiring Schematic......................................... 10-7

700BF/I-3 Wiring Diagram .............................................. 10-8

700BF/I-3 Wiring Schematic........................................ 10-9

Page 7

General Information

Integrated

(700-3BASE)

Series

1-5

#3758424 - Revision B - December, 2005

700BCI 2 0000000

9.0 8.1 R134a

Figure 1-1. Serial Tag Layout

(The serial number tag is located on the left side wall of the upper drawer compartment.)

Jan 2004

Model Number

Serial Number

Manufacture Date

Refrigerant Charge

To ta l Amps Refrigerant Type

REFRIGERATOR FREEZER TOTAL AMPS REFRIGERANT

WARRANTY INFORMATION

This page summarizes the 2, 5 & 12 Year Warranty

supplied with every unit, as well as the two special warranties: The Non-Residential Warranty which applies to

units installed in non-residential applications, and the

Display/Model Home Warranty which applies to distributor or dealer’s display units and units in model homes,

sold three years after date of manufacture. The last

entries on this page are details and notes about the

warranties.

TWO, FIVE & TWELVE YEAR Warranty Summary

• Two year TOTAL PRODUCT warranty, *parts and

labor.

• Five Year SEALED SYSTEM warranty, **parts and

labor.

• Sixth through Twelfth year LIMITED SEALED SYSTEM warranty, sealed system **parts only.

ONE & FIVE YEAR Non-Residential Warranty

Summary (Example: Office, Yacht, etc.)

• One Year TOTAL PRODUCT warranty, *parts and

labor.

• Five year LIMITED SEALED SYSTEM warranty,

sealed system **parts only.

ONE & FIVE YEAR Display/Model Home Warranty

Summary (Display units sold three years after date

of manufacture)

• One Year TOTAL PRODUCT warranty, *parts and

labor.

• Five year LIMITED SEALED SYSTEM warranty,

sealed system **parts only.

Warranty Details:

• * Total Product Parts includes, but is not limited to the

following:

Electronic Control System Components, Fan & Light

Switches, Fan Motors & Blades, Defrost & Drain

Heaters, Defrost Terminators, Drain Pans, Drain Tubes,

Wiring, Light sockets & bulbs, Icemakers, Water

Valves, Door hinges, Door closers & Cams,

Compressor Electricals, etc. . .

• ** Sealed System Parts include the following:

Compressors, Condensers, Evaporators, Filter-Driers,

Heat-exchangers, All Tubing That Carries the Freon.

NOTE: Condenser Fan Motors, Freon, Solder and

compressor electricals are NOT

considered sealed

system parts.

Warranty Notes:

• All warranties begin at the time of the unit's initial

installation.

• All Warranty and Service information collected by SubZero is arranged and stored under the unit serial number. This information is now also stored under the customer's last name.

NOTE: Sub-Zero still requests that you have the

model and serial number available whenever contacting the factory or parts distributor.

• The serial number tag is located on the left side wall of

the upper drawer compartment. (See Figures 1-1, for

serial tag layout)

Page 8

General Information

Integrated

(700-3BASE)

Series

1-6

#3758424 - Revision B - December, 2005

MODEL DESCRIPTIONS

This page briefly describes the Models 700BC-3, 700BCI-3, 700BF-3, 700BFI-3 and 700BR-3.

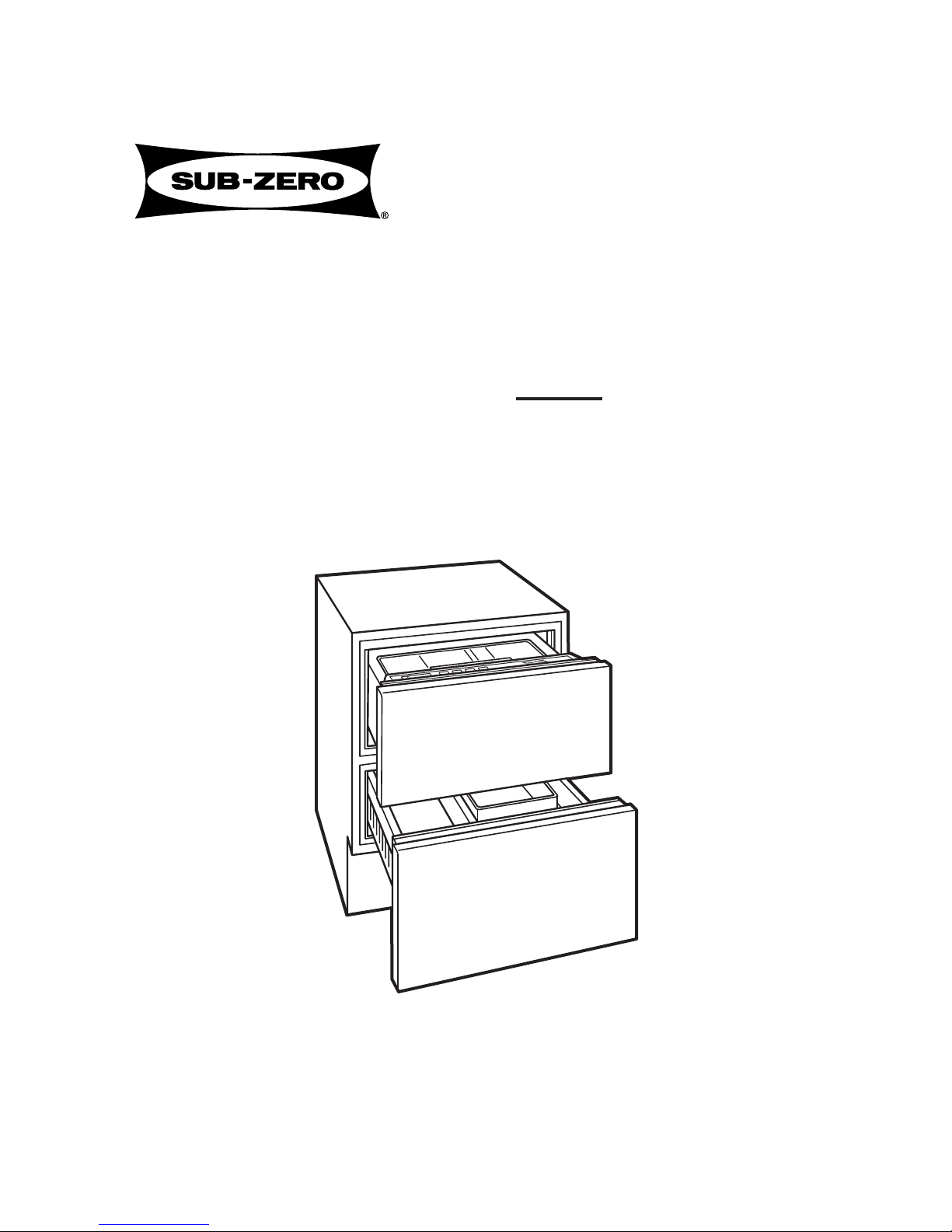

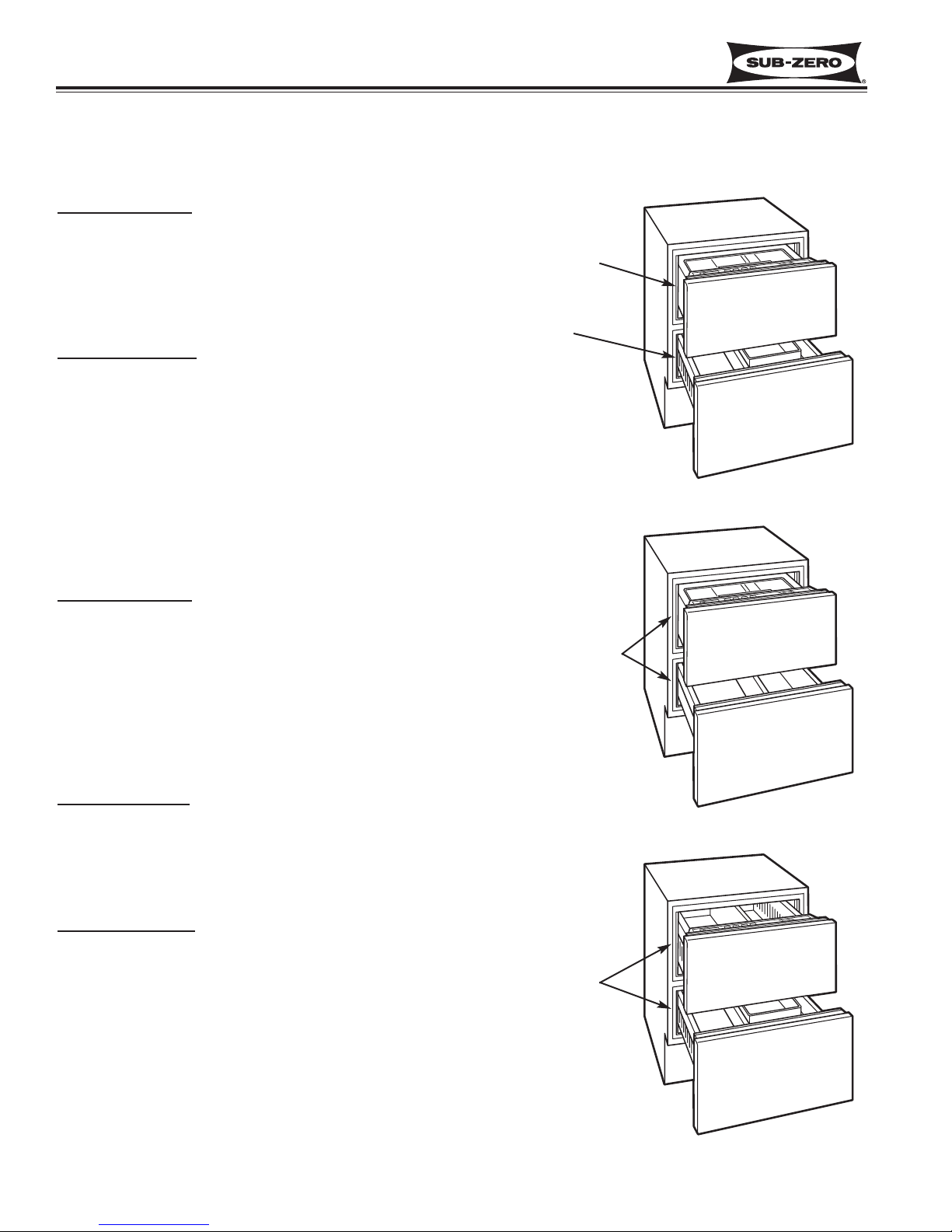

Model 700BC-3 (Figure 1-2)

700 Series, Base Combination, 3rd Design Build

(Combination Refrigerator / Freezer with Two Temperature

Zones - Upper Refrigerator over Freezer)

(Overall Dimensions = 34” H x 27” W x 24” D)

Model 700BCI-3 (Figure 1-7)

700 Series, Base Combination, Icemaker Incl., 3rd

Design Build

(Combination Refrigerator / Freezer with Two Temperature

Zones - Upper Refrigerator over Freezer)

(Overall Dimensions = 34” H x 27” W x 24” D)

Model 700BR-3 (Figure 1-3)

700 Series, Base Refrigerator, 3rd Design Build

(Refrigerator with One Temperature Zone)

(Overall Dimensions = 34” H x 27” W x 24” D)

Model 700BF-3 (Figure 1-4)

700 Series, Base Freezer, 3rd Design Build

(Freezer with One Temperature Zone)

(Overall Dimensions = 34” H x 27” W x 24” D)

Model 700BFI-3 (Figure 1-3)

700 Series, Base Freezer, Icemaker Incl., 3rd Design

Build

(Freezer with One Temperature Zone)

(Overall Dimensions = 34” H x 27” W x 24” D)

Figure 1-2. Model 700BC-3 & 700BCI-3

Upper

Refrigerator

Zone

Lower

Freezer

Zone

Figure 1-3. Model 700BR-3

Two Drawer

All Refrigerator

(One Zone)

Figure 1-4. Model 700BF-3 & 700BFI-3

Two Drawer

All Freezer

(One Zone)

Page 9

Installation Information

Integrated

(700-3BASE)

Series

2-1

#3758424 - Revision B - December, 2005

SECTION 2

INSTALLATION

INFORMATION

Page 10

Installation Information

Integrated

(700-3BASE)

Series

2-2

#3758424 - Revision B - December, 2005

UNIT COULD TIP FORWARD UNDER CERTAIN LOAD CONDITIONS. FAILURE TO INSTALL ANTI-TIP COMPONENTS AND EXTEND LEVELERS TO THE FLOOR ACCORDING TO INSTALLATION MANUAL COULD

RESULT IN SERIOUS PERSONAL INJURY OR DEATH.

INSTALLATION CONSIDERATIONS

This section covers some of the more common installation issues seen by a service technician. An improper installation, though not a valid service issue, has the potential to lead to a customer placing a call for service. Installation

related customer complaints could include, but are not limited to: Unit leveling, unit movement, door misalignment,

drawers not sealing, internal frost or condensation, warm compartment temperatures, exterior condensation, etc.. .

NOTE: If additional installation information is needed, refer to the complete Installation Manual and/or installation

video, or contact the Sub-Zero Technical Assistance Department.

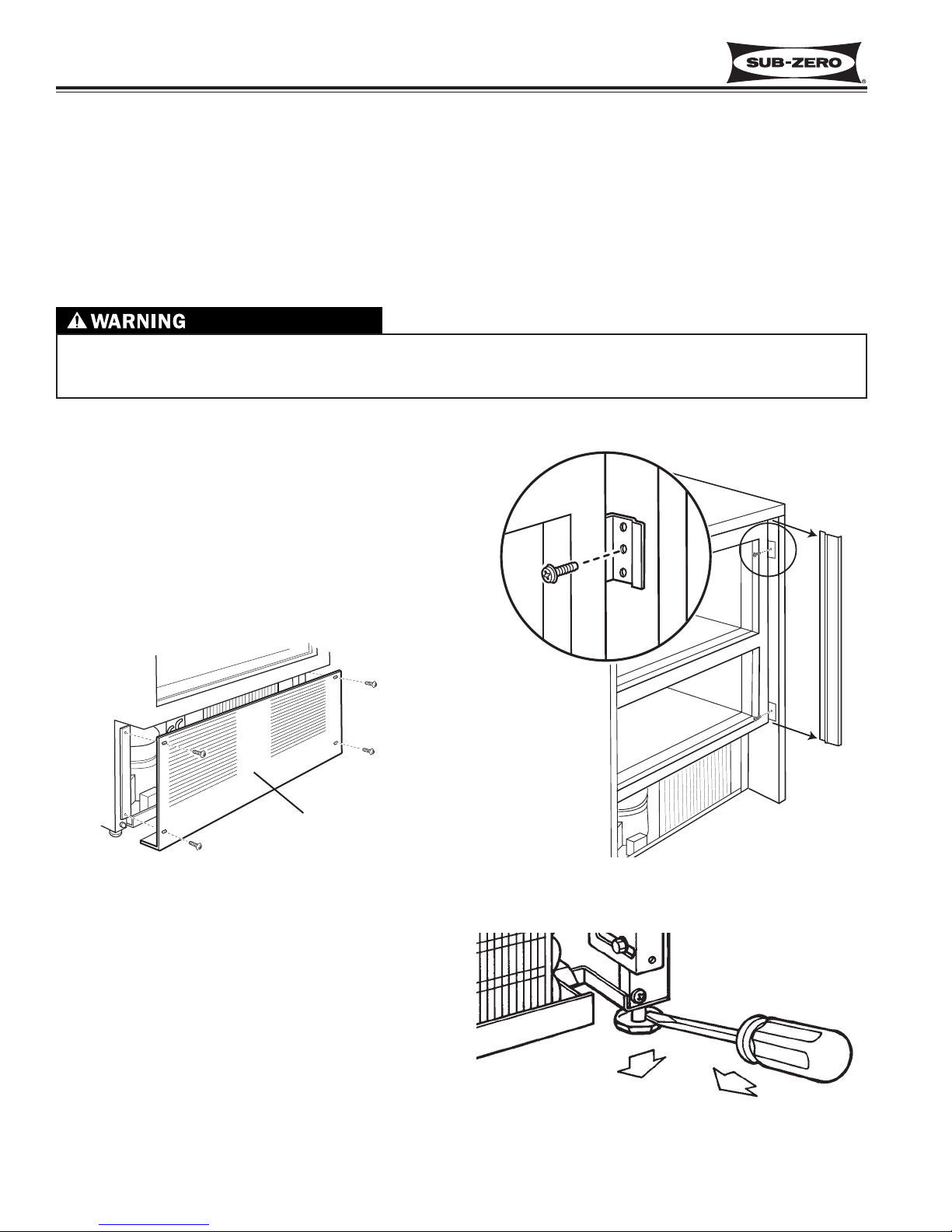

Unit Leveling

NOTE: The kickplate/grille must be removed before

leveling (See Figure 2-1).

If unit has been anchored to cabinets, side molding

strips must be removed and anchor screws extracted

from unit to cabinet brackets before leveling (See

Figure 2-2).

Figure 2-2. Side Molding & Bracket

Figure 2-1. Kickplate/Grille Removal

Figure 2-3. Adjusting Front Levelers

To level unit, turn front leveling legs counterclockwise to

raise front or clockwise to lower it. To assist in turning

front leveling legs, use standard straight-blade screwdriver, placing it in foot of front leg, then rotate leveler

foot (See Figure 2-3).

Kickplate / Grille

Page 11

Installation Information

Integrated

(700-3BASE)

Series

2-3

#3758424 - Revision B - December, 2005

Figure 2-4. Adjusting Rear Levelers

Rear levelers are adjusted at front of base by turning

Phillips head adjusting rod, which engages rear leveler

assembly. Turn rod clockwise to raise rear or counterclockwise to lower it (See Figure 2-4).

NOTE: Rear leveling legs will only move 1/16” for

every 18 revolutions of Phillips head adjusting rod.

Do not over torque. Use lowest torque setting on any

power screwdriver. Do not turn rear leveling legs by

hand, doing so will damage the assembly.

Door and Drawer Adjustment

Doors and drawers on 700-3 Series units are nonadjustable. Instead, door and/or drawer panels must be

adjusted if there are alignment problems. Refer to

Installation Manual and/or installation video for panel

installation and adjustment.

NOTE: Unit must be level before attempting to adjust

door and drawer panels.

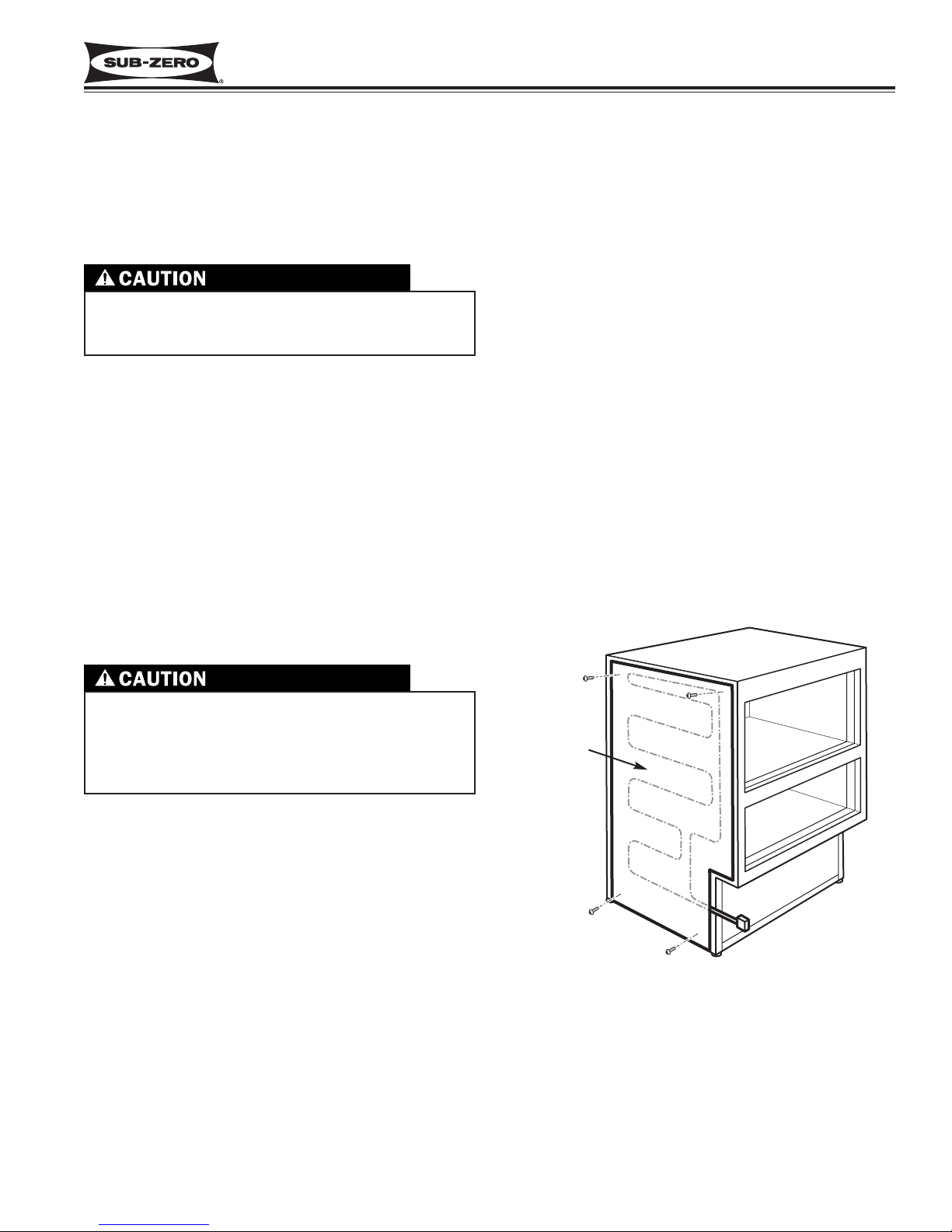

Dual Unit Installations

• If two Base units are installed side by side and are

2” or less apart, use part #BBDUAL.

• If a Tall unit is installed next to a Base unit and they

are 2” or less apart, use part #BBDUAL.

NOTE: Complete installation instructions are supplied

with #BBDUAL and #TTDUAL packages.

If two or more units are placed side by side and are

2” or less apart, a dual unit heater package must be

applied to the left side of the right hand unit. Failure

to install the dual unit heater package could result

in exterior condensation between the units.

Figure 2-5. Dual Unit Heater Installation

Apply heater

to left side

of right hand

unit

Page 12

Installation Information

Integrated

(700-3BASE)

Series

2-4

#3758424 - Revision B - December, 2005

Page 13

Electronic Control System

Integrated

(700-3BASE)

Series

3-1

#3758424 - Revision B - December, 2005

SECTION 3

ELECTRONIC CONTROL

SYSTEM INFORMATION

Page 14

Electronic Control System

Integrated

(700-3BASE)

Series

3-2

#3758424 - Revision B - December, 2005

ELECTRONIC CONTROL TERMINOLOGY & COMPONENT DESCRIPTIONS

All 700-3 Series units utilize an electronic control system which monitors, regulates, controls and displays a variety

of functions and operations in the appliance.

The table below defines some of the basic electronic control system terminology.

Term/Component Definition / Description

Main Control Board ..……....…… The printed-circuit board (PC Board) which contains a microprocessor, relays, triacs and

electrical connections that monitor and control all functions of the appliance.

Microprocessor ……….…....…... An electrical component on the control board which receives electrical signals from

other components, processes the information, then sends electrical signals to relays and

triacs on the board to open or close, switching components in the appliance ON or OFF.

Relay …………………….....……. An electrical component on the control board which switches other components in the

appliance ON or OFF when instructed to do so by the microprocessor.

Triac …………………….......…… Similar in function to the relay, the triac is a three terminal semiconductor for controlling

current in either direction.

Control Panel Assembly ….....… (Also referred to as the Control Keypad Interface), is that part of the electronic control

system where all input operations are performed.

Membrane Switch ……….……... Part of the control panel assembly, which consists of the function keys.

Keys (Function Keys) ……......... The “buttons” on the Membrane Switch used for input operations: “POWER”, “ALARM”,

“ICE MAKER”, “WARMER” and “COLDER”

LCD (Liquid Crystal Display) ..... A semi-liquid substance sandwiched between glass in the display of the control panel

assembly. The molecules of this semi-liquid substance have no specific orientation.

However, when electricity is applied to them, they react predictably, aligning and

straightening in such a way as to control light passage.

Indicators .....……..………….…... The words, numbers and icons that appear on the display of the control panel assembly

through the use of LCD’s.

Error Codes .………...…………... The code numbers that may appear on the display of the control panel assembly when

accessing Error Code History. Error Codes are logged if the unit experienced specific

problems related to electrical signals supplied by electrical components.

Temperature Units of Measure.... Temperature observed on the display of the control panel assembly may be in

Fahrenheit units of measure (°F) or Celsius units of measure (°C). A series of key

strokes allows the temperature units of measure to be switched to display as either °F

or °C.

Set-Point ……………...……….... The desired zone temperature, established by pressing the COLDER or WARMER

keys.

High Offset (Cut-in) ……...…...... As the zone air temperature cycles up and down, the high offset is the maximum zone

temperature that the electronic control system will allow before calling for cooling.

Low Offset (Cut-out)………........ As the zone air temperature cycles up and down, the low offset is the minimum zone air

temperature that the electronic control system will allow before interrupting cooling.

Thermistor ……………..………. (Also Referred to as a Temperature Sensor), is a resistor with which resistance changes

as the temperature around it changes. For electronic control system purposes, the

microprocessor measures the resistance, then displays it as a temperature reading.

Variable Speed Compressor …... A compressor that runs at varying speeds depending on the temperature detected in the

corresponding zone(s) of the appliance.

Page 15

Electronic Control System

Integrated

(700-3BASE)

Series

3-3

#3758424 - Revision B - December, 2005

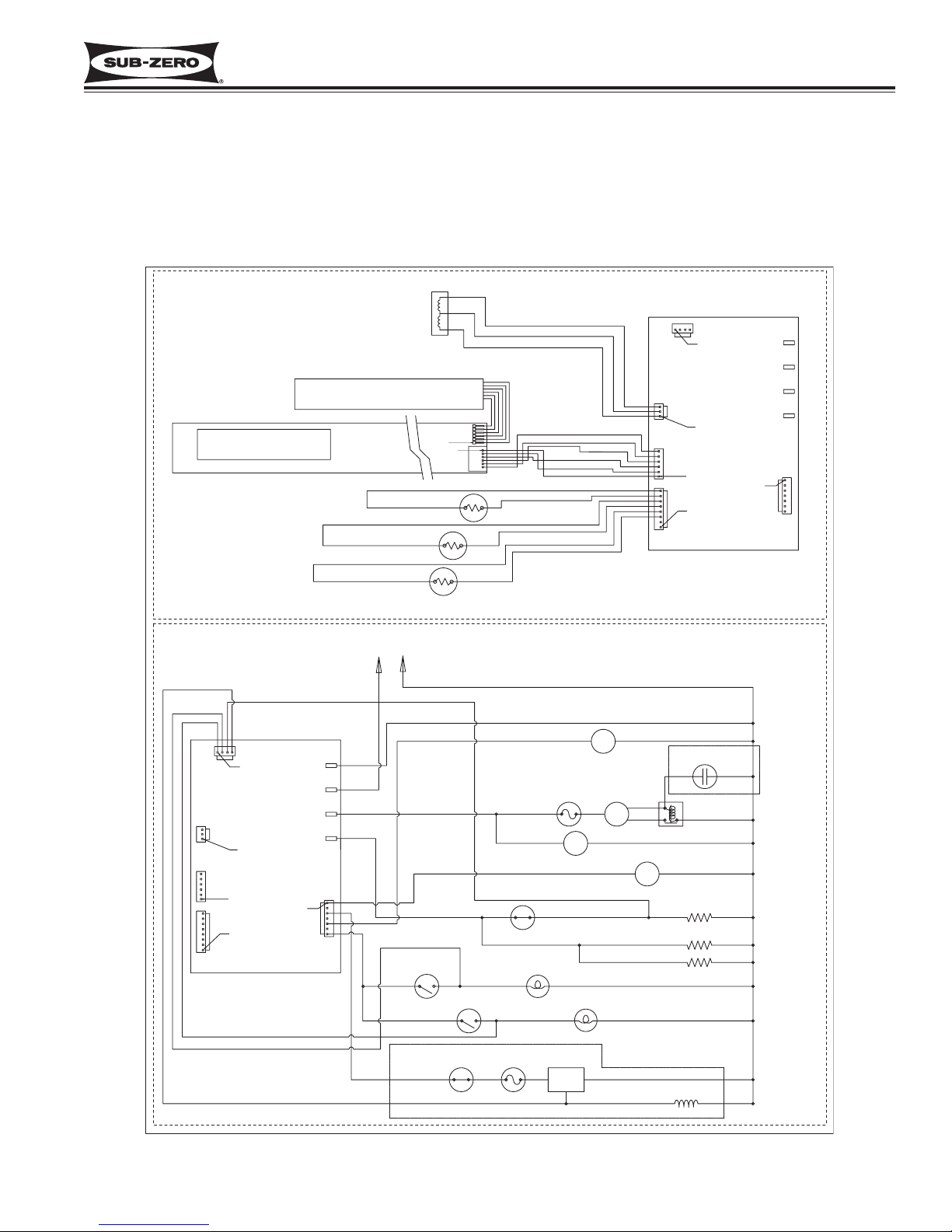

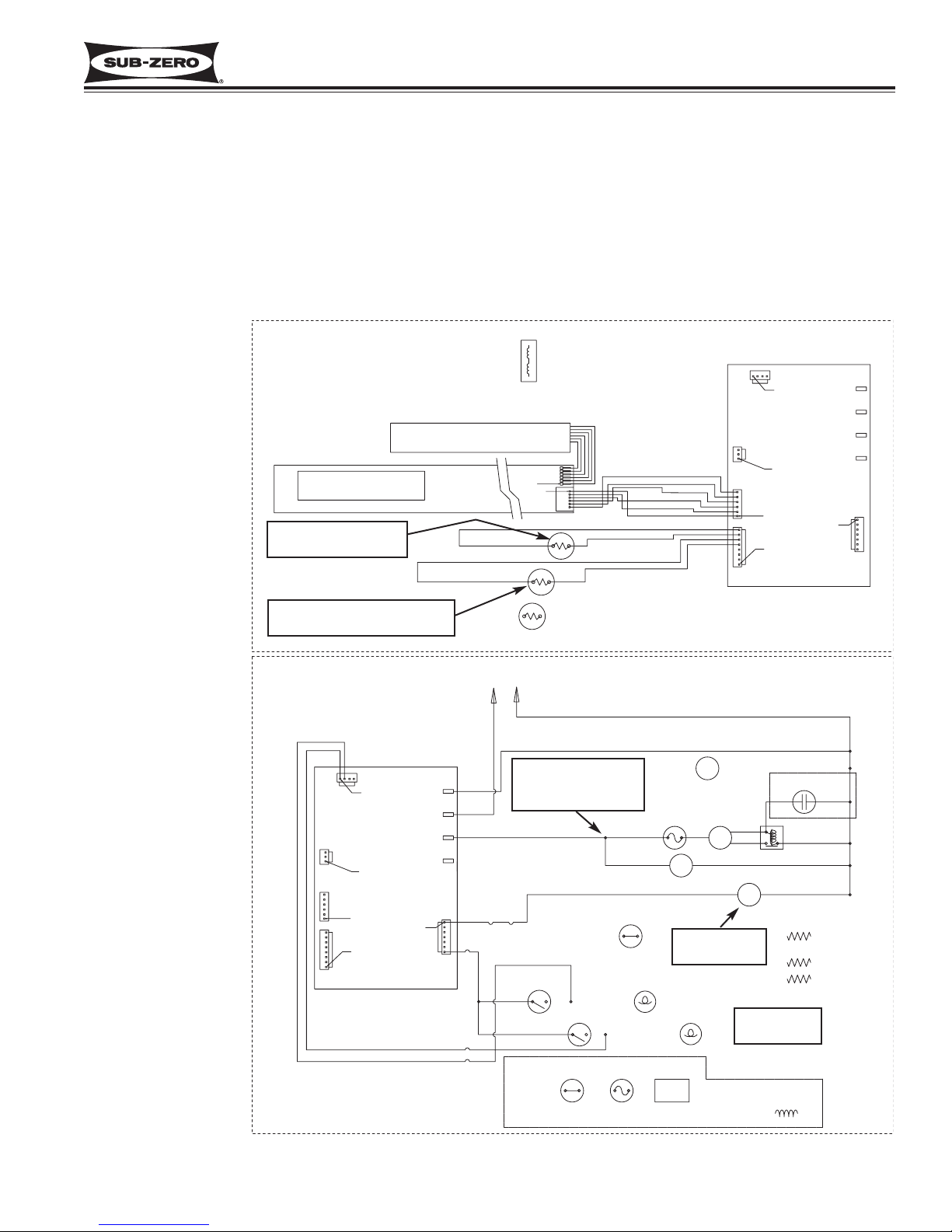

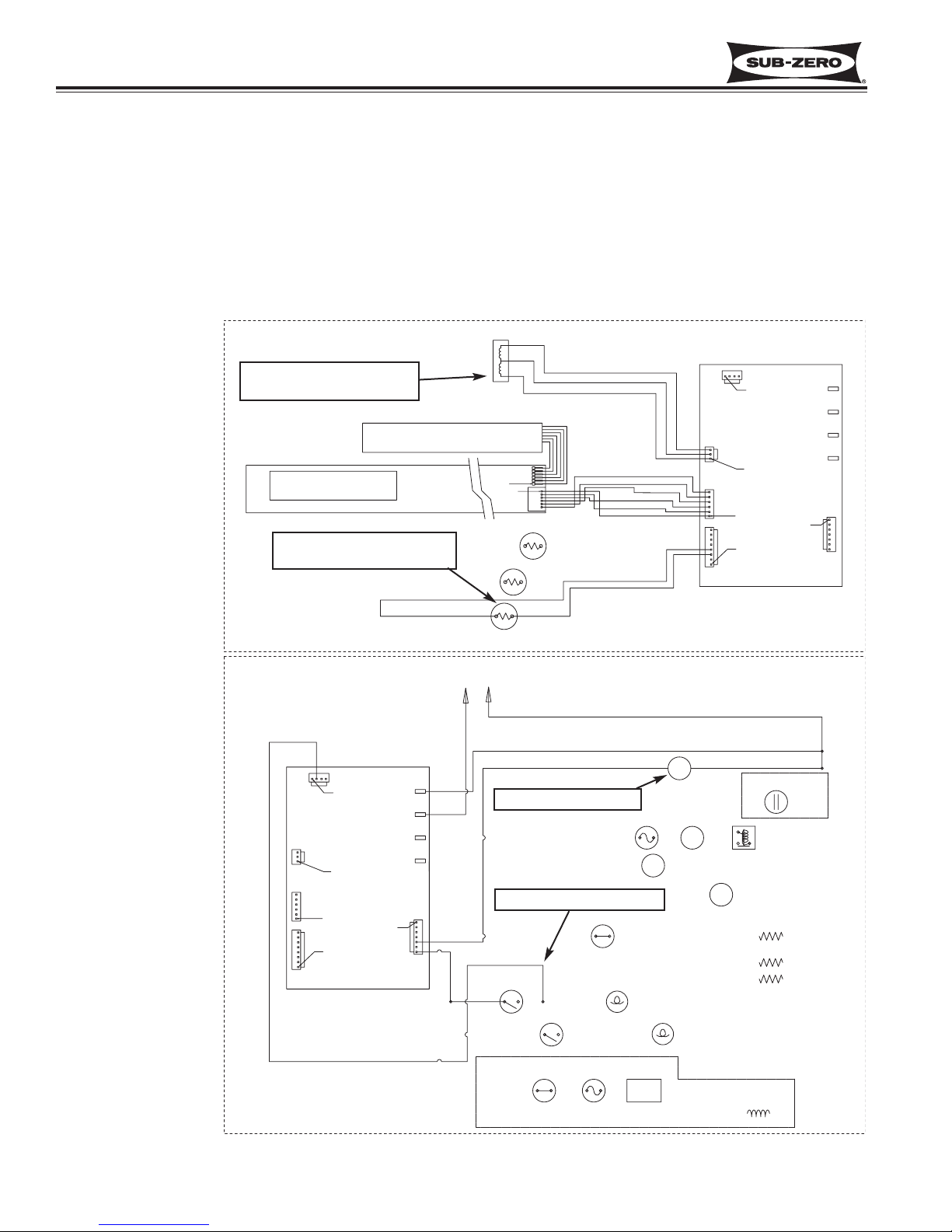

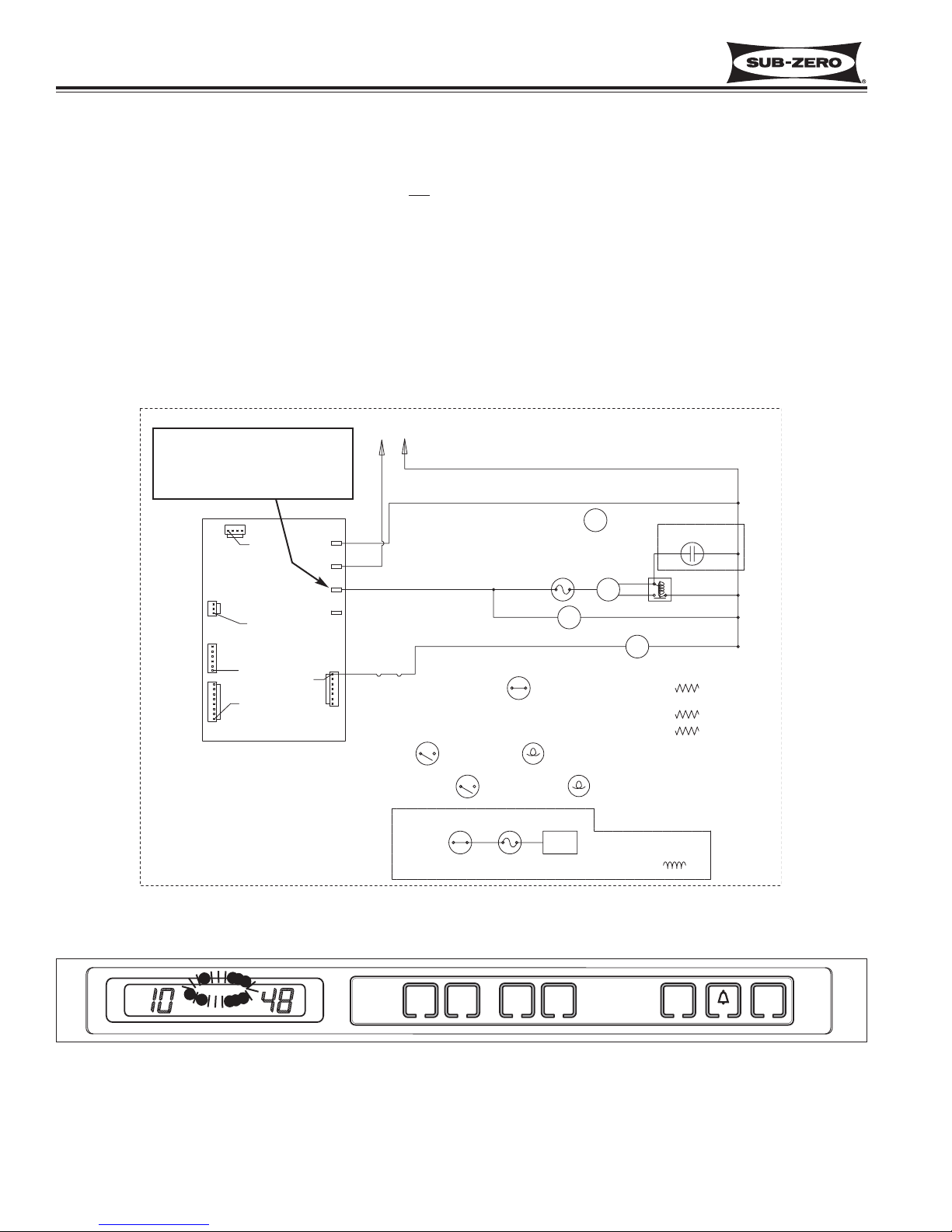

Figure 3-1. 700BCI-3 Wireing Schematic

ELECTRONIC CONTROL SYSTEM OVERVIEW

This page contains the wiring schematic of the model 700BCI-3. Input operations for the electronic control system

are performed at the control panel (located inside the upper drawer), with monitoring, regulating and controlling functions taking place at the main control board. Temperatures and possible problems with the unit are shown in the

control panel display. The entire electronic control system is described in greater detail on the following pages.

NOTE: For more detailed electrical diagrams refer to the wiring diagram and schematic supplied with the unit.

LOW VOLTAGE SCHEMATIC

REF AIR DUCT

DISPLAY

BAFFLE

MEMBRANE KEYPAD

DISPLAY BOARD

THERMISTOR LOWER

DRAWER/FREEZER

PIN 1

PIN 1

THERMISTOR

EVAPORATOR

J2

J3

YELLOW W/WHITE

YELLOW W/BLACK STRIPE

YELLOW W/RED STRIPE

ORANGE W/RED STRIPE

BLUE W/RED STRIPE

BLUE W/BLACK STRIPE

BLUE W/BLACK STRIPE

BLUE W/YELLOW STRIPE

BLUE W/YELLOW STRIPE

RED

WHITE

BLACK

BLUE

ORANGE

YELLOW

J6

J5

J2

PIN 1

MAIN BOARD

PIN 1

J4

PIN 1

PIN 1

P4

P3

P1

P2

PIN 1

J3

HIGH VOLTAGE SCHEMATIC

TAN

ORANGE

GRAY W/WHITE STRIPE

J2

PIN 1

MAIN BOARD

ORANGE W/BLACK STRIPE

PIN 1

J6

J4

PIN 1

PIN 1

J5

P4

P3

P1

P2

PIN 1

THERMISTOR UPPER

DRAWER/REFRIGERATOR

115 VOLTS

60 CYCLES

L1

WHITE

BLACK

BLUE

J3

YELLOW

PINK

NEUTRAL

WHITE

GRAY

PURPLE

ORANGE

REF LIGHT

SWITCH

RED

BLUE

FRZ LIGHT

SWITCH

OVERLOAD

PROTECTOR

CONDENSER FAN

GRAY W/WHITE STRIPE

GRAY W/WHITE STRIPE

DEFROST

TERMINATOR

REF (TOP)

DRAWER LIGHT

M

REF FAN

MOTOR

M

FRZ (BOTTOM)

DRAWER LIGHT

COMPRESSOR

M

FRZ FAN MOTOR

M

FILL TUBE HEATER

RUNNING

CAPACITOR

COMPRESSOR

STARTING

RELAY

DEFROST HEATER

25 - 29 OHMS

DRAIN HEATER

1700 - 2100 OHMS

2800 - 3500 OHMS

WHITE

(WHEN

USED)

ORANGE W/BLACK STRIPE

ORANGE

TAN

ICEMAKER

SWITCH

THERMAL

FUSE

ICEMAKER

(OPTIONAL)

TAN

ICEMAKER

VALVE

3757971 REV A

Page 16

Electronic Control System

Integrated

(700-3BASE)

Series

3-4

#3758424 - Revision B - December, 2005

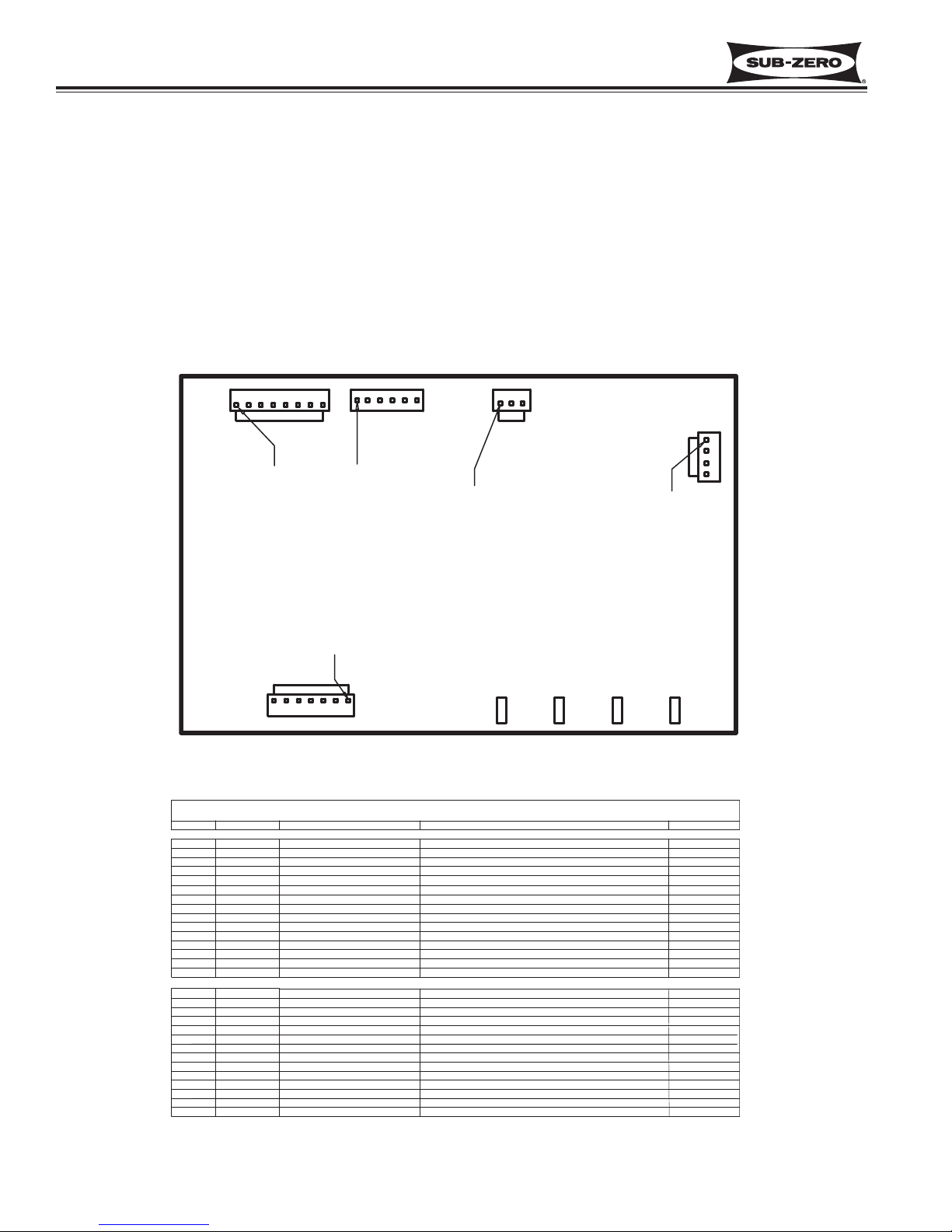

Figure 3-2. Main Control Board Layout

Figure 3-3. Main Control Board Summary Table

MAIN CONTROL BOARD LAYOUT AND SUMMARY TABLE

Electrical connection points on the main control board are labeled alphanumerically. These labels correspond with

the alphanumeric summary table, located on the wiring diagram. By referencing the summary table, it is possible to

identify which components are connected at which points on the main control board. Below is a layout diagram of

the main control board, and a copy of a model 700BCI-3 summary table. (See Figures 3-2 & 3-3)

NOTE: All components on the control board are non-replaceable. If a problem with the control board is identified,

the complete control board must be replaced.

NOTE: There is also a small control board in the control panel assembly (Not Shown). All components in the control panel assembly are non-replaceable. If a problemwith the control panel is identified, the complete control panel

assembly must be replaced.

J5

PIN 1

J3

MAIN CONTROL BOARD SUMMARY

TERMINAL

120 VOLT CIRCUITS

LOW VOLTAGE THERMISTOR CIRCUITS

J5-1,2

J5-3,4

J5-5,6

P4

P3

P1

P2

J3-1

J3-2

J3-3

J3-4

J3-5

J3-6

J3-7

J2-1

J2-2

J2-3

J2-4

J5-7

J5-8

J6-1

J6-2

J6-3

J4-1

J4-2

J4-3

J4-4

J4-5

J4-6

CIRCUIT

COMPRESSOR

DEFROST

FAN 1

FAN 2

LIGHTS

UPPER

LOWER

EVAP

EVAP

DISPLAY

DISPLAY

DISPLAY

DISPLAY

DISPLAY

DESCRIPTION

LN

NEUTRAL

POWER IN

L1

COMPRESSOR

DEFROST HEATER

EVAPORATOR FAN

NOT USED

ICE MAKER

ICE

NOT USED

REFRIGERATOR FAN

NOT USED

LIGHTS

FRZ DRAWER LIGHT SENSE

LWR

REF DRAWER LIGHT SENSE

UPR

DEFROST SENSOR

DEF

ICE MAKER VALVE SENSOR

ICE

NOT USED

REFRIGERATOR COMPARTMENT

FREEZER COMPARMENT

EVAPORATOR

EVAPORATOR

N

BAFFLE NEUTRAL

C

BAFFLE CLOSE

BAFFLE OPEN

O

DISPLAY WIRING

DISPLAY WIRING

DISPLAY WIRING

DISPLAY WIRING

DISPLAY WIRING

DISPLAY WIRINGDISPLAY

J6

J4

PIN 1

PIN 1

PIN 1

P2 P1 P3 P4

NEUTRAL INTO BOARD

POWER INTO BOARD

POWERS COMPRESSOR AND CONDENSER FAN

POWERS DEFROST CIRCUIT AND FILL TUBE HEATER

POWERS EVAPORATOR FAN

POWERS ICE MAKER

POWERS FFAN IN REFRIGERATOR

POWERS LIGHTS

SENSES IF FREEZER DRAWER OPEN

SENSES IF REFRIGERATOR DRAWER OPEN

SENSES WHEN DEF HEATER SHUTS OFF

SENSES WATER VALVE ACTIVATION

SENSES REFRIGERATOR CABINET TEMPERATURE

SENSES FREEZER CABINET TEMPERATURE

SENSES EVAPORATOR TEMPERATURE

SENSES EVAPORATOR TEMPERATURE

BAFFLE NEUTRAL

PULSED TO CLOSE BAFFLE

PULSED TO OPEN BAFFLE

12VDC POWER SUPPLY FOR DISPLAY BOARD

12VDC POWER SUPPLY FOR DISPLAY BOARD

SERIAL DATA RECEIVE

SERIAL DATE TRANSMIT

GROUND FOR DISPLAY BOARD POWER SUPPLY

GROUND FOR DISPLAY BOARD POWER SUPPLY

PIN 1

J2

COLORFUNCTION

WHITE

BLACK

PURPLE

BLUE

RED

PINK

GRAY

YELLOW

ORANGE/BLACK

ORANGE

GRAY/WHITE

TAN

BLUE/YELLOW

BLUE/BLACK

BLUE/RED

ORANGE/RED

YELLOW/RED

YELLOW/BLACK

YELLOW/WHITE

BLACK

WHITE

RED

YELLOW

ORANGE

BLUE

Page 17

Electronic Control System

Integrated

(700-3BASE)

Series

3-5

#3758424 - Revision B - December, 2005

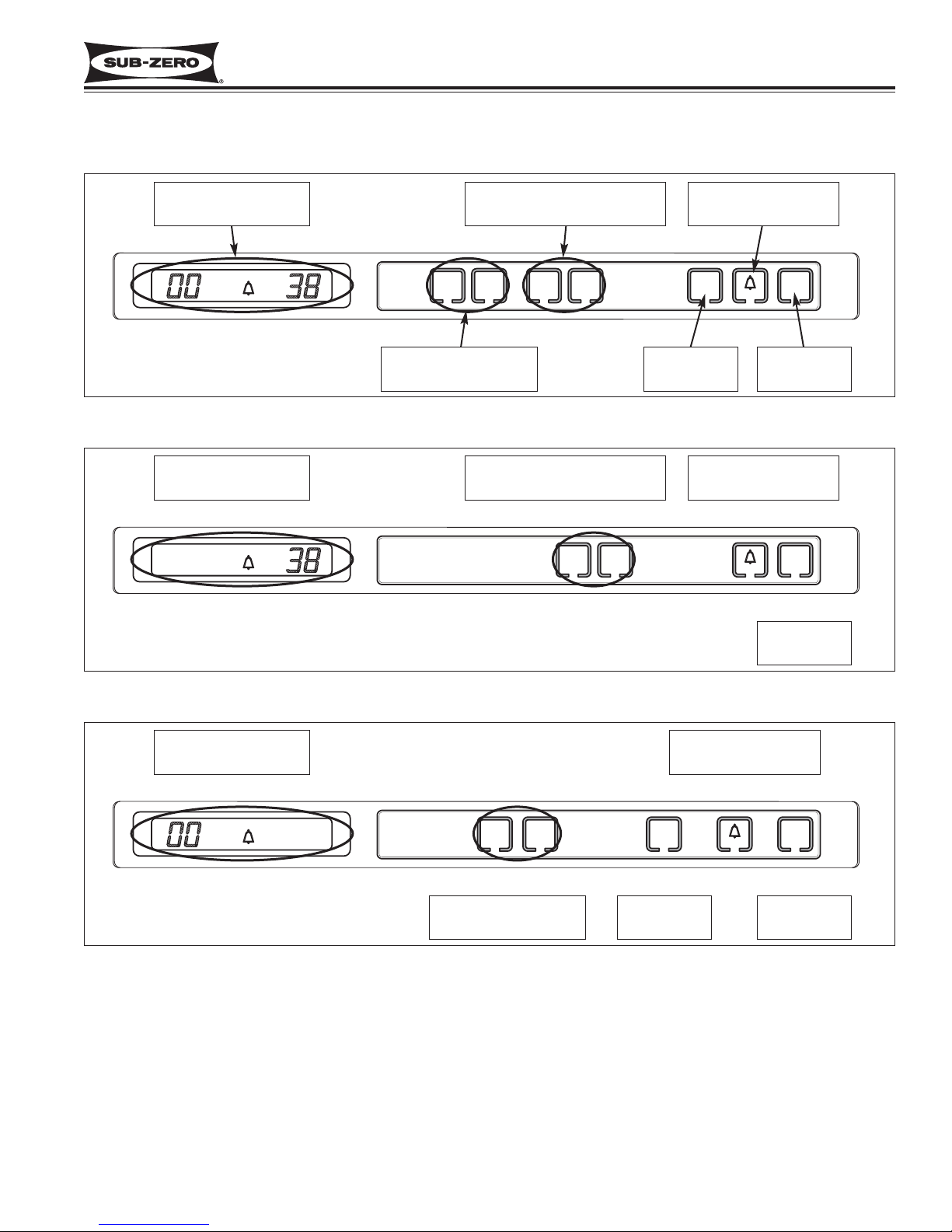

CONTROL PANEL LAYOUT

NOTE: The LCD on the base units is not back lit. It will appear darker than the LCD on tall units.

Figure 3-4. 700BCI-3 Control Panel Layout

FREEZER SET-POINT

ADJUSTMENT KEYS

REFRIGERATOR SET-POINT

ADJUSTMENT KEYS

LCD

(Liquid Crystal Display)

DRAWER AJAR

ALARM ON/OFF KEY

UNIT

ON/OFF KEY

ICE

ON/OFF KEY

Figure 3-5. 700BR-3 Control Panel Layout

REFRIGERATOR SET-POINT

ADJUSTMENT KEYS

LCD

(Liquid Crystal Display)

DRAWER AJAR

ALARM ON/OFF KEY

UNIT

ON/OFF KEY

Figure 3-6. 700BFI-3 Control Panel Layout

FREEZER SET-POINT

ADJUSTMENT KEYS

LCD

(Liquid Crystal Display)

DRAWER AJAR

ALARM ON/OFF KEY

UNIT

ON/OFF KEY

ICE

ON/OFF KEY

SERVICE

ICE

OFF

SERVICE

OFF

FREEZER

WARMERCOLDER

WARMERCOLDER

REFRIGERATOR

REFRIGERATOR

WARMERCOLDER

ON/OFF

UNITICE

ON/OFF

ON/OFF

UNIT

ON/OFF

ON/OFF

SERVICE

ICE

OFF

WARMERCOLDER

FREEZER

ON/OFF

ON/OFF

UNITICE

ON/OFF

Page 18

Electronic Control System

Integrated

(700-3BASE)

Series

3-6

#3758424 - Revision B - December, 2005

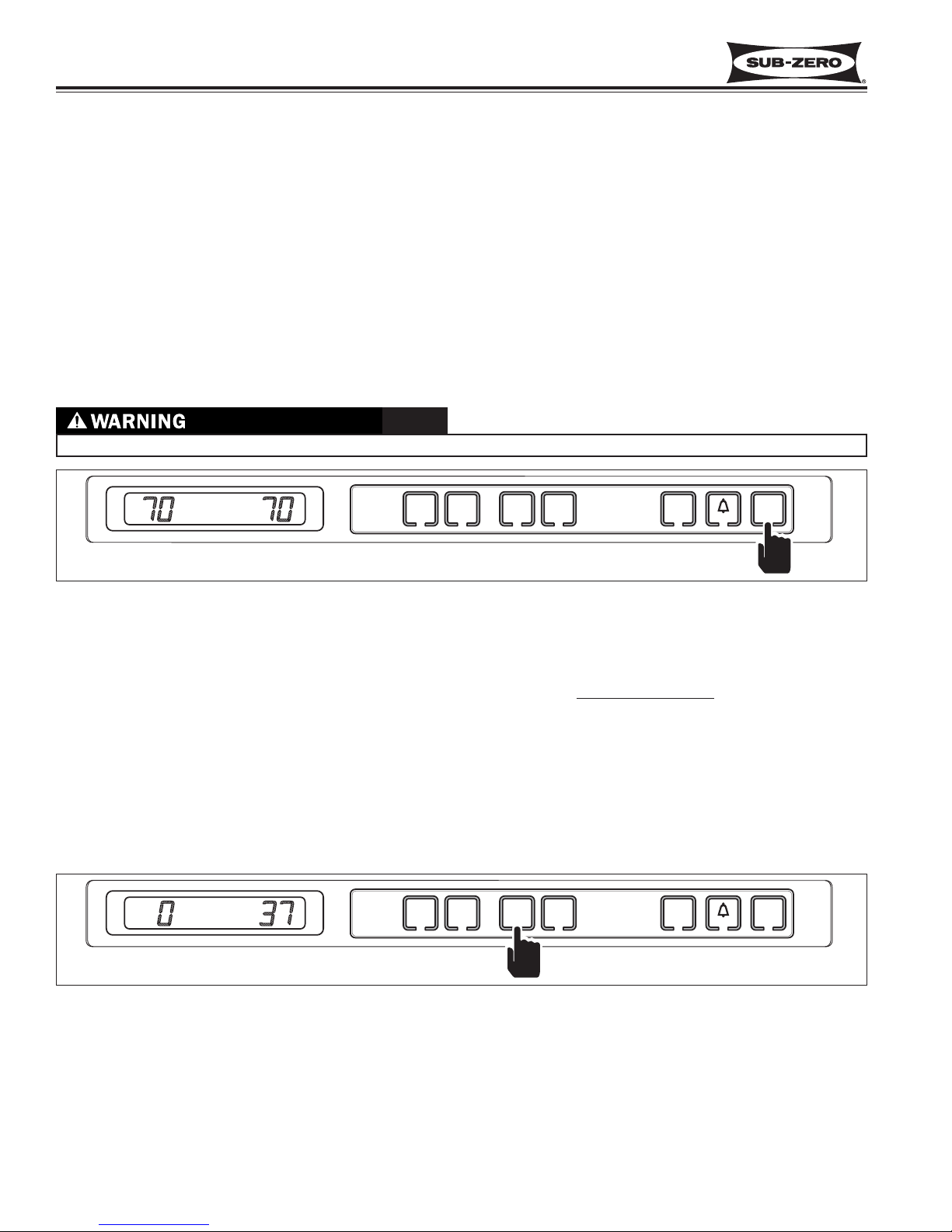

WHEN IN OFF MODE, 115 VOLTS AC IS STILL PRESENT AT CONTROL BOARD.

Figure 3-7. Unit ON/OFF - Press UNIT ON/OFF Key

BASIC ELECTRONIC CONTROL INPUT OPERATIONS

The following pages describe the basic input operations performed at A 700BCI-3 control panel (switching unit ON

and OFF; adjusting set-point (temperature adjustment); switching ice maker system ON and OFF and enabling and

disabling door ajar alarm feature. Please note that though possible to display temperatures in Fahrenheit or Celsius,

in most cases Fahrenheit readings are shown.

Unit ON/OFF

All units are shipped in Off Mode. When power is supplied to the unit, a trace of the word “OFF” is visible on the

LCD. By pressing the UNIT ON/OFF key (See Figure 3-7), power is allowed past the control board to the rest of the

unit. This will be indicated by the unit lights illuminating and the LCD energizing.

NOTE: Whenever the unit is switched OFF using the UNIT ON/OFF key, a trace of the word “OFF” will be visible on

the LCD as long as power is supplied to the unit. This differs in Sabbath Mode, which will be covered later.

Adjusting Set-Point (Temperature Adjustments)

To adjust set-points, press WARMER or COLDER keys on control panel in multiple key strokes

until the desired set-

point is achieved. One key stroke equals one degree change (Fahrenheit or Celsius). (See Figure 3-8)

NOTE: Temperature ranges are -5°F (-21°C) to +5°F (-15°C) in freezer zones, +34°F (+1°C) to +45°F (+7°C) in

refrigerator zones, with initial set-points of 0°F (-18°C) and +38°F (+3°C), respectively.

NOTE: The initial stroke of the WARMER or COLDER keys will change previous set-point by one degree.

NOTE: The set-point will be displayed on the LCD for 10 seconds after the last WARMER or COLDER key stroke.

After the 10 second delay, the zone temperature will be displayed. As the zone temperature changes, the temperature displayed on the LCD will change by no more than one degree per minute.

Figure 3-8. Adjusting Set-Point - Press WARMER or COLDER Key In Multiple Key Strokes

FREEZER

WARMERCOLDER

WARMERCOLDER

REFRIGERATOR

ON/OFF

ON/OFF

UNITICE

ON/OFF

FREEZER

WARMERCOLDER

WARMERCOLDER

REFRIGERATOR

ON/OFF

ON/OFF

UNITICE

ON/OFF

Page 19

Electronic Control System

Integrated

(700-3BASE)

Series

3-7

#3758424 - Revision B - December, 2005

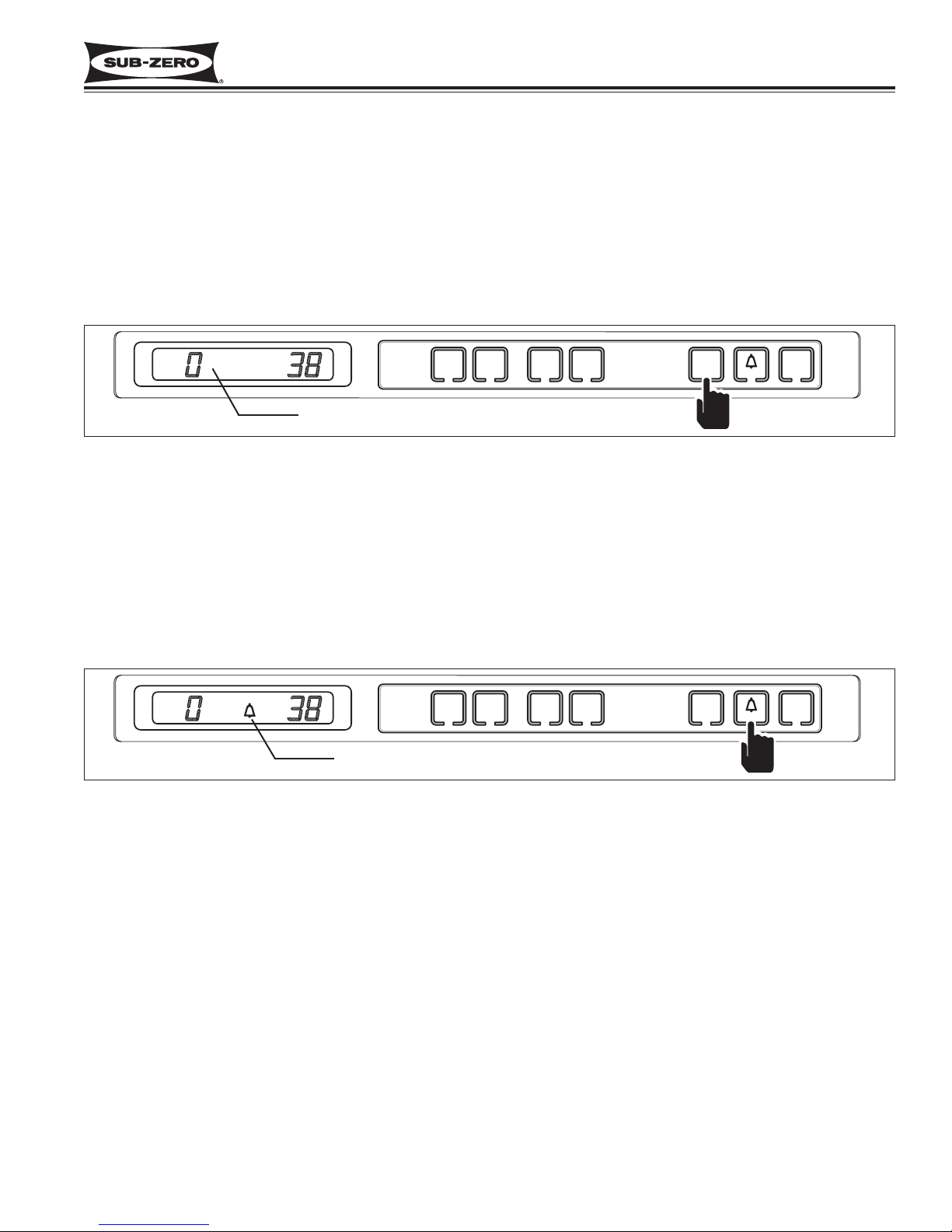

Icemaker System ON/OFF

All units with icemakers are shipped with the icemaker system switched OFF. By pressing the ICE ON/OFF key on

the control panel, power is allowed to the icemaker system, and “ICE” appears on the LCD (See Figure 3-9). To

disable the icemaker system, press the ICE ON/OFF key again and “ICE” will disappear from the LCD indicating the

icemaker system is OFF.

NOTE: When unit is in “Sabbath Mode,” icemaker system is disabled. Sabbath Mode will be covered later.

NOTE: To allow ice to freeze fully and reduce effects of low water pressure, power to the icemaker system is inter-

rupted for 45 minutes after each ice harvest. This can be bypassed for service purposes by pressing the ICE

ON/OFF key to switch the icemaker system OFF, then back ON.

Figure 3-9. Icemaker System ON/OFF - Press ICE ON/OFF Key

Ice system is active if “ICE” is displayed

Drawer Ajar Alarm ON/OFF

All units are equipped with a drawer ajar alarm feature. When activated, the alarm will alert a customer if a drawer

is stuck open or accidentally left open. To enable the drawer ajar alarm feature, press the drawer ajar alarm bell

ON/OFF key on the control panel. A bell icon will appear on the LCD indicating that the alarm feature is active.

(See Figure 3-10) Now, if a drawer is open for 30 seconds, the bell icon will blink and the audible alarm will beep.

To disable the drawer ajar alarm, simply press the drawer ajar alarm bell ON/OFF key and the bell icon on the LCD

will disappear, indicating the alarm feature is OFF.

Figure 3-10. Drawer Ajar Alarm ON/OFF - Press Alarm Bell ON/OFF Key

Alarm is active if bell is displayed

ICE

FREEZER

WARMERCOLDER

WARMERCOLDER

REFRIGERATOR

ON/OFF

ON/OFF

UNITICE

ON/OFF

FREEZER

WARMERCOLDER

WARMERCOLDER

REFRIGERATOR

ON/OFF

ON/OFF

UNITICE

ON/OFF

Page 20

Electronic Control System

Integrated

(700-3BASE)

Series

3-8

#3758424 - Revision B - December, 2005

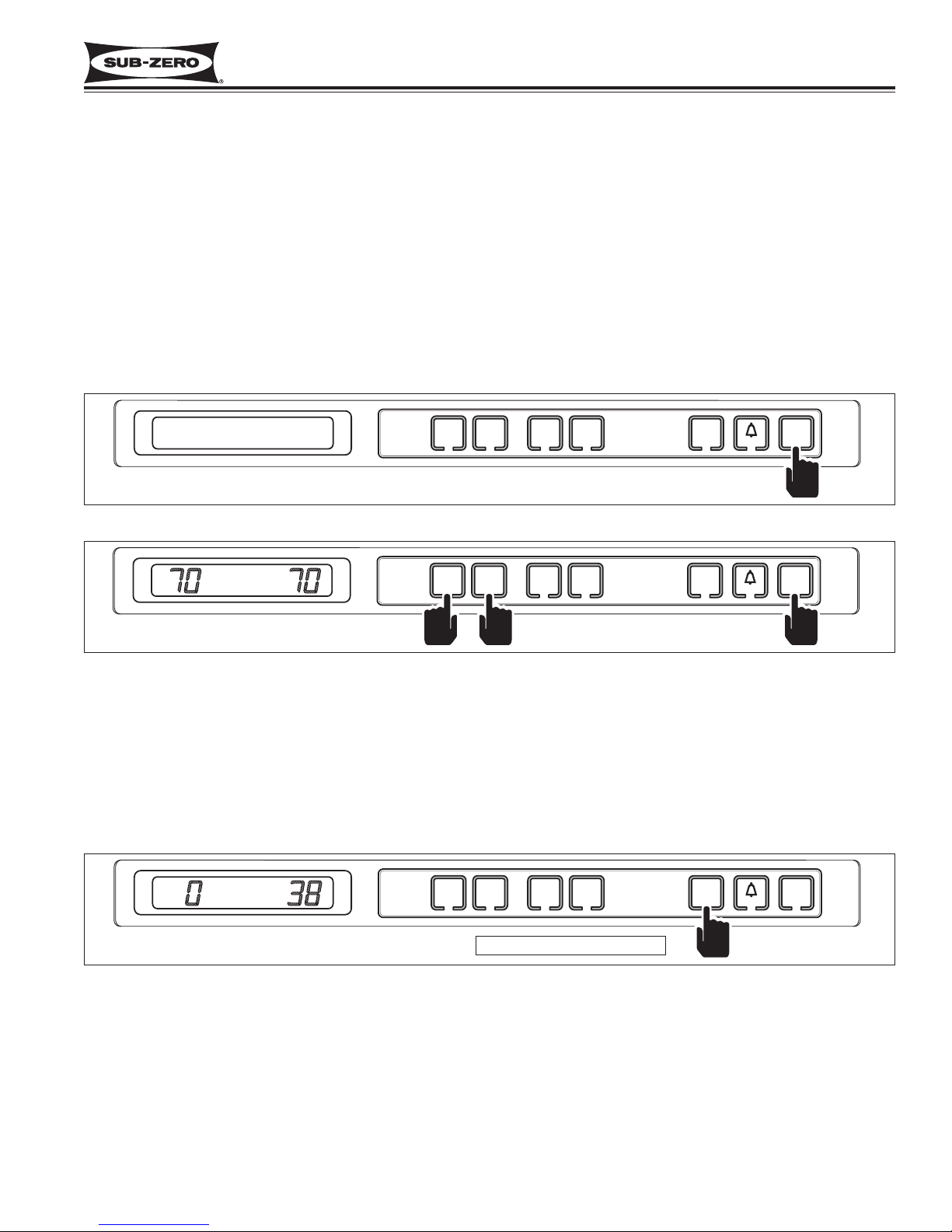

UNIQUE ELECTRONIC CONTROL INPUT OPERATIONS

The following pages describe unique electronic control input operations performed at the control panel that you

would not expect a customer to perform every day. The following input operations described are Temperature Unit

Selection Mode, Sabbath Mode, Showroom Mode, and Manual Freezer Evaporator Defrost.

Temperature Units Selection Mode (Selecting Degrees Fahrenheit or Degrees Celsius Display)

The electronic control is initially set to display temperature in Fahrenheit (°F) units of measure. Units of measure

can be converted from °F to °C (Celsius), and/or back again. This operation is called Temperature Units Selection.

NOTE: Temperature Units Selection must be performed within the first minute after switching the unit ON.

To convert the temperature units of measure from Fahrenheit readings to a Celsius readings, press and hold the

door ajar alarm bell ON/OFF key and the UNIT ON/OFF key simultaneously for 5 seconds, then release the keys.

“ °C “ will appear on the LCD indicating temperatures will now be displayed in Celsius units of measure. (See Figure

3-11) To convert back to Fahrenheit units of measure, repeat the steps above.

NOTE: Bottom Drawer must be closed. If not closed, unit will enter Model Configuration Mode.

NOTE: Temperature Units Selection Mode will end 10 seconds after the last key stroke.

Figure 3-11. Converting Temperature Units of Measure (within first minute after switching unit ON)

Press and Hold the Bell ON/OFF Key and UNIT ON/OFF Key for 5 Seconds

Sabbath Mode

Sabbath Mode was incorporated into the electronic control system for the observance of certain religious days.

Initiating Sabbath Mode disables the LCD, lighting system, icemaker systems and the door ajar alarm feature.

To initiate Sabbath Mode, the unit must first be switched OFF using the UNIT ON/OFF key (See Figure 3-12), then

press and hold the UNIT ON/OFF key for approximately 10 seconds, until the LCD and lights switch OFF (See

Figure 3-13). To return to normal operation, press and release the UNIT ON/OFF key.

NOTE: During Sabbath Mode, the refrigerator fan and evaporator fan may function when drawers are open.

NOTE: During Sabbath Mode, the LCD is disabled and set-points cannot be changed.

Figure 3-13. After Unit is Switched OFF, Press and Hold UNIT ON/OFF Key for 10 Seconds

Figure 3-12. To Enter Sabbath Mode, Switch Unit OFF First

Press and hold for 10 seconds

Press and hold for 5 seconds

FREEZER

WARMERCOLDER

WARMERCOLDER

REFRIGERATOR

ON/OFF

ON/OFF

UNITICE

ON/OFF

OFF

FREEZER

WARMERCOLDER

WARMERCOLDER

REFRIGERATOR

ON/OFF

ON/OFF

UNITICE

ON/OFF

FREEZER

WARMERCOLDER

WARMERCOLDER

REFRIGERATOR

ON/OFF

ON/OFF

UNITICE

ON/OFF

Page 21

Electronic Control System

Integrated

(700-3BASE)

Series

3-9

#3758424 - Revision B - December, 2005

Showroom Mode

Showroom Mode was incorporated into the electronic control system so that units could be displayed in a showroom

setting. When in Showroom Mode, all cooling functions are disabled, but the lighting system and LCD remain

active.

To initiate Showroom Mode, the unit must first be switched OFF using the UNIT ON/OFF key (See Figure 3-14).

With the unit switched OFF, press and hold either pair of WARMER and COLDER keys, then press the UNIT

ON/OFF key, then release all three keys (See Figure 3-15).

To return unit to normal operating condition, repeat the steps above.

NOTE: Always recheck set-points after returning unit to normal operating condition.

NOTE: It is possible to determine if a unit is in Showroom Mode by initiating Diagnostic Mode. If “Sr” is observed in

the left temperature display area during Diagnostic Mode, the unit is in Showroom mode. Initiating Diagnostic Mode

is covered later in this section.

Figure 3-15. After Unit is Switched OFF, Press and Hold the WARMER and COLDER Keys,

Then Press the UNIT ON/OFF Key

Figure 3-14. To Enter (or Exit) Showroom Mode, Switch Unit OFF First

Manual Freezer Evaporator Defrost

Manual Freezer Evaporator Defrost was incorporated into the electronic control to assist in servicing the appliance.

To manually defrost the freezer evaporator, press and hold the ICE ON/OFF key for 5 seconds (See Figure 3-16).

NOTE: Manual Freezer Evaporator Defrost will not operate if unit is in Sabbath Mode.

Figure 3-16. Initiate Manual Freezer Evaporator Defrost - Press and Hold the ICE key for 5 Seconds

Press and hold for 5 seconds

OFF

FREEZER

WARMERCOLDER

WARMERCOLDER

REFRIGERATOR

ON/OFF

ON/OFF

UNITICE

ON/OFF

FREEZER

WARMERCOLDER

WARMERCOLDER

REFRIGERATOR

ON/OFF

ON/OFF

UNITICE

ON/OFF

ICE

FREEZER

WARMERCOLDER

WARMERCOLDER

REFRIGERATOR

ON/OFF

ON/OFF

UNITICE

ON/OFF

Page 22

Electronic Control System

Integrated

(700-3BASE)

Series

3-10

#3758424 - Revision B - December, 2005

FUNCTIONS OF ELECTRONIC CONTROL SYSTEM

The following few pages explain monitoring, regulating and controlling functions of the electronic control system.

Display Zone Temperatures

The temperature signals from the thermistors in the refrigerator and freezer compartments are monitored by the

microprocessor and then displayed on the LCD. Though the compartment air temperature does fluctuate, the LCD

displays the average temperature (See Figure 3-17).

NOTE: If zone temperature changes, temperature display will change by one degree per minute.

Figure 3-17. Display Zone Temperatures

Average temperature displayed

Figure 3-18. 700BCI-3 Signal Trace Schematic (High Voltage) of Lighting System

1. 115 Volts are supplied to

lighting system unless

unit is switched OFF, or

in Sabbath Mode.

2. Light switch position monitored

for alarm and fan operation.

Supply Power to the Lighting System

Power is supplied to the lighting system through the control board when the unit is switched ON by pressing UNIT

ON/OFF key. With a drawer open, the light switch allows power to the light. (See Figure 3-18).

NOTE: Power to the lights is monitored by the microprocessor to control the door ajar alarm feature and to help

control the operation of the evaporator fan and/or refrigerator compartment fan.

NOTE: When in Sabbath Mode, lighting system is disabled. Sabbath Mode will be covered later.

FREEZER

WARMERCOLDER

WARMERCOLDER

REFRIGERATOR

ON/OFF

ON/OFF

UNITICE

ON/OFF

HIGH VOLTAGE SCHEMATIC

ORANGE

J2

PIN 1

MAIN BOARD

ORANGE W/BLACK STRIPE

PIN 1

J6

J4

PIN 1

PIN 1

J5

PIN 1

115 VOLTS

60 CYCLES

L1

NEUTRAL

WHITE

WHITE

P4

BLACK

P3

P1

P2

YELLOW

ORANGE

REF LIGHT

SWITCH

J3

FRZ LIGHT

SWITCH

REF (TOP)

DRAWER LIGHT

M

M

FRZ (BOTTOM)

DRAWER LIGHT

WHITE

M

M

ORANGE W/BLACK STRIPE

ORANGE

Page 23

Electronic Control System

Integrated

(700-3BASE)

Series

3-11

#3758424 - Revision B - December, 2005

Regulate Freezer Zone Temperature (700BCI-3, 700BFI-3)

When the thermistor in the freezer compartment reaches high off-set temperature, calling for cooling, the compressor and condenser fan are energized, but the evaporator fan is not allowed to run until the thermistor on the evaporator reaches 35°F (2°C). (See Figure 3-19)

If either drawer is opened while the evaporator fan is operating, the microprocessor will detect the power signal to

the lights and cut power to the fan.

Though compartment air temperatures will fluctuate, LCD displays average temperature.

NOTE: If compartment temperature exceeds either high or low offset (Ex: drawer is left open), temperature display

will change by one

degree per minute.

NOTE: If freezer

compartment thermistor is faulty, compressor operation defaults

to 20 minutes ON, 20

minutes OFF cycling,

EE appears in left of

LCD, SERVICE will

flash and Error Code

07 will be logged.

NOTE: If evaporator

thermistor is faulty,

the compressor will

be energized after

the dwell time and

the evaporator fan

will be energized 3

minutes later. SERVICE will flash and

Error Code 08 will be

logged.

NOTE: When in

Sabbath Mode, the

freezer compartment

thermistor still controls compressor

operation, except

there is a random 15

to 25 second delay

before the compressor is energized.

Figure 3-19. 700BCI-3 Signal Trace - Regulate Freezer Zone

1. Thermistor at high off-set

temp. calling for cooling.

2. No signal

to lights.

3. Compressor and

condenser fan

energized.

4. Evap Thermistor

below 35°F (2°C).

5. Evap fan

energized.

LOW VOLTAGE SCHEMATIC

J6

J5

J2

PIN 1

MAIN BOARD

PIN 1

J4

PIN 1

PIN 1

P4

P3

P1

P2

PIN 1

J3

DISPLAY

HIGH VOLTAGE SCHEMATIC

MEMBRANE KEYPAD

DISPLAY BOARD

THERMISTOR LOWER

DRAWER/FREEZER

115 VOLTS

60 CYCLES

PIN 1

PIN 1

THERMISTOR

EVAPORATOR

J2

J3

ORANGE W/RED STRIPE

BLUE W/RED STRIPE

BLUE W/BLACK STRIPE

BLUE W/BLACK STRIPE

L1

ORANGE

J2

PIN 1

MAIN BOARD

ORANGE W/BLACK STRIPE

PIN 1

J6

J4

PIN 1

PIN 1

J5

ORANGE W/BLACK STRIPE

ORANGE

PIN 1

NEUTRAL

WHITE

WHITE

P4

BLACK

P3

P1

P2

PURPLE

RED

OVERLOAD

PROTECTOR

CONDENSER FAN

M

COMPRESSOR

M

M

M

FRZ FAN MOTOR

FRZ (BOTTOM)

DRAWER LIGHT

YELLOW

ORANGE

REF LIGHT

SWITCH

FRZ LIGHT

SWITCH

REF (TOP)

DRAWER LIGHT

J3

RUNNING

CAPACITOR

COMPRESSOR

STARTING

RELAY

WHITE

(WHEN

USED)

Page 24

Electronic Control System

Integrated

(700-3BASE)

Series

3-12

#3758424 - Revision B - December, 2005

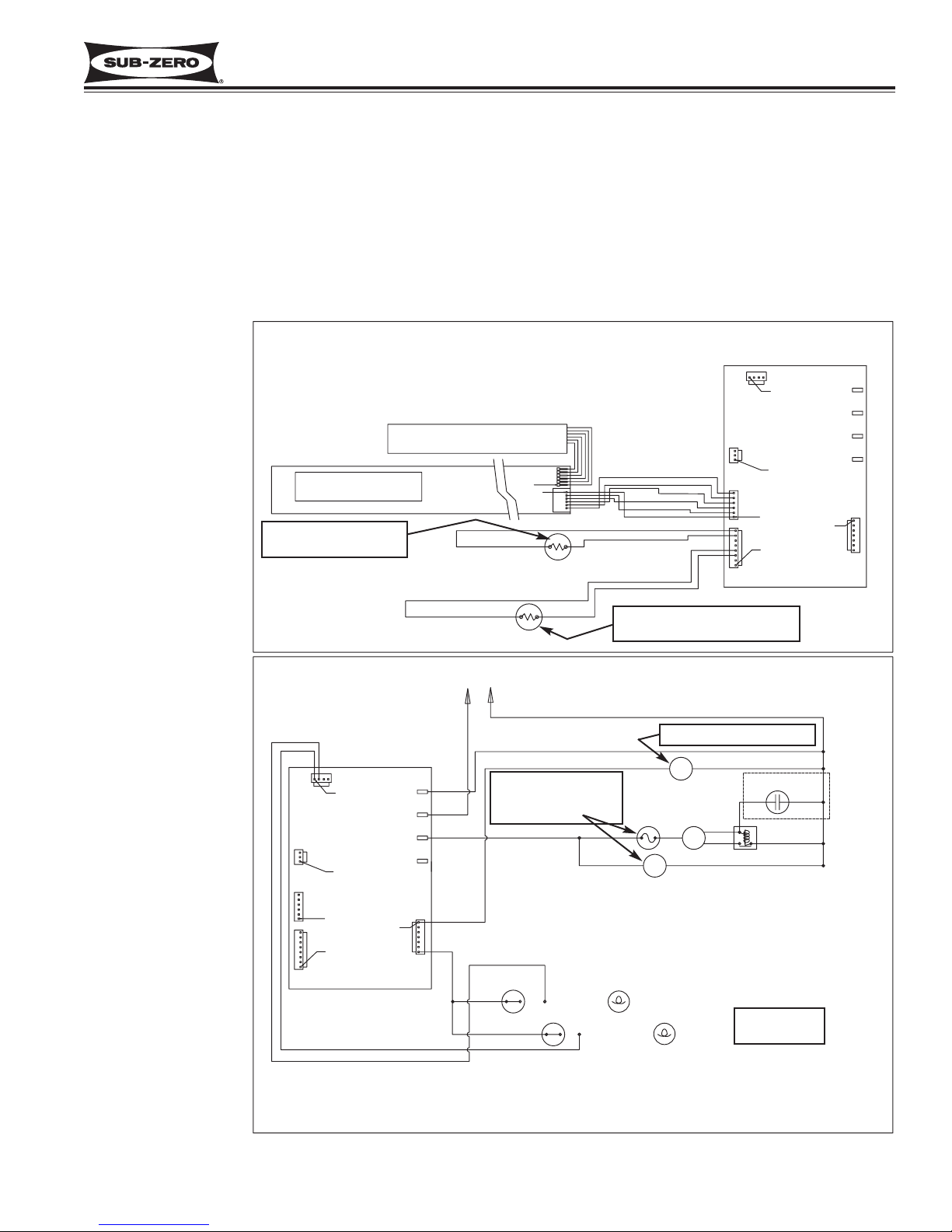

Regulate Refrigerator Zone Temperature (700BCI-3)

When the thermistor in refrigerator compartment reaches high off-set temperature, calling for cooling, the refrigerator

compartment fan is energized and microprocessor sends an 18 Volt pulse signal to the air baffle control to open,

regardless of operational state of the compressor. Whenever the fan is energized, the microprocessor repeats sending a pulse signal every 5 minutes to the air baffle control to open. (See Figure 3-20)

If either drawer is opened while the refrigerator compartment fan is operating, the microprocessor will detect power

to the lights and cut power to the fan.

When thermistor in refrigerator compartment reaches low off-set temperature, power to refrigerator compartment fan

is cut and microprocessor sends an

18 Volt pulse signal

to the air baffle control to close. When

refrigerator compartment fan is off, microprocessor repeats

sending a pulse signal every 5 minutes

to the air baffle control to close.

Though compartment

air temperatures fluctuates, the LCD displays average temperature.

NOTE: If compartment temperature

exceeds either high

or low offset (Ex:

drawer is left open),

temperature display

will change by one

degree per minute.

NOTE: If refrigerator

compartment thermistor is faulty, compartment fan defaults to

20 minutes ON, 40

minutes OFF cycling,

EE appears in right of

LCD, SERVICE will

flash and Error Code

05 will be logged.

NOTE: When in

Sabbath Mode, refrigerator compartment

thermistor still controls fan operation

except there is a random 15 to 25 second

delay before the fan

is energized.

Figure 3-20. 700BCI-3 Signal Trace - Regulate Refrigerator Zone

1. Thermistor at high off-set

temp. calling for cooling.

2. No power to ref. light.

3. Ref. fan energized.

4. Pulse signal to air baffle

control every 5 minutes.

LOW VOLTAGE SCHEMATIC

DISPLAY

REF AIR DUCT

BAFFLE

MEMBRANE KEYPAD

DISPLAY BOARD

THERMISTOR UPPER

DRAWER/REFRIGERATOR

PIN 1

PIN 1

J2

J3

YELLOW W/WHITE

YELLOW W/BLACK STRIPE

YELLOW W/RED STRIPE

BLUE W/YELLOW STRIPE

BLUE W/YELLOW STRIPE

J6

J5

J2

PIN 1

MAIN BOARD

PIN 1

J4

PIN 1

PIN 1

P4

P3

P1

P2

PIN 1

J3

HIGH VOLTAGE SCHEMATIC

115 VOLTS

60 CYCLES

ORANGE

J6

J5

J2

PIN 1

MAIN BOARD

PIN 1

J4

PIN 1

PIN 1

PIN 1

NEUTRAL

WHITE

GRAY

WHITE

P4

BLACK

P3

P1

P2

YELLOW

ORANGE

REF LIGHT

SWITCH

REF (TOP)

DRAWER LIGHT

J3

M

REF FAN

MOTOR

M

M

M

WHITE

L1

ORANGE

Page 25

Electronic Control System

Integrated

(700-3BASE)

Series

3-13

#3758424 - Revision B - December, 2005

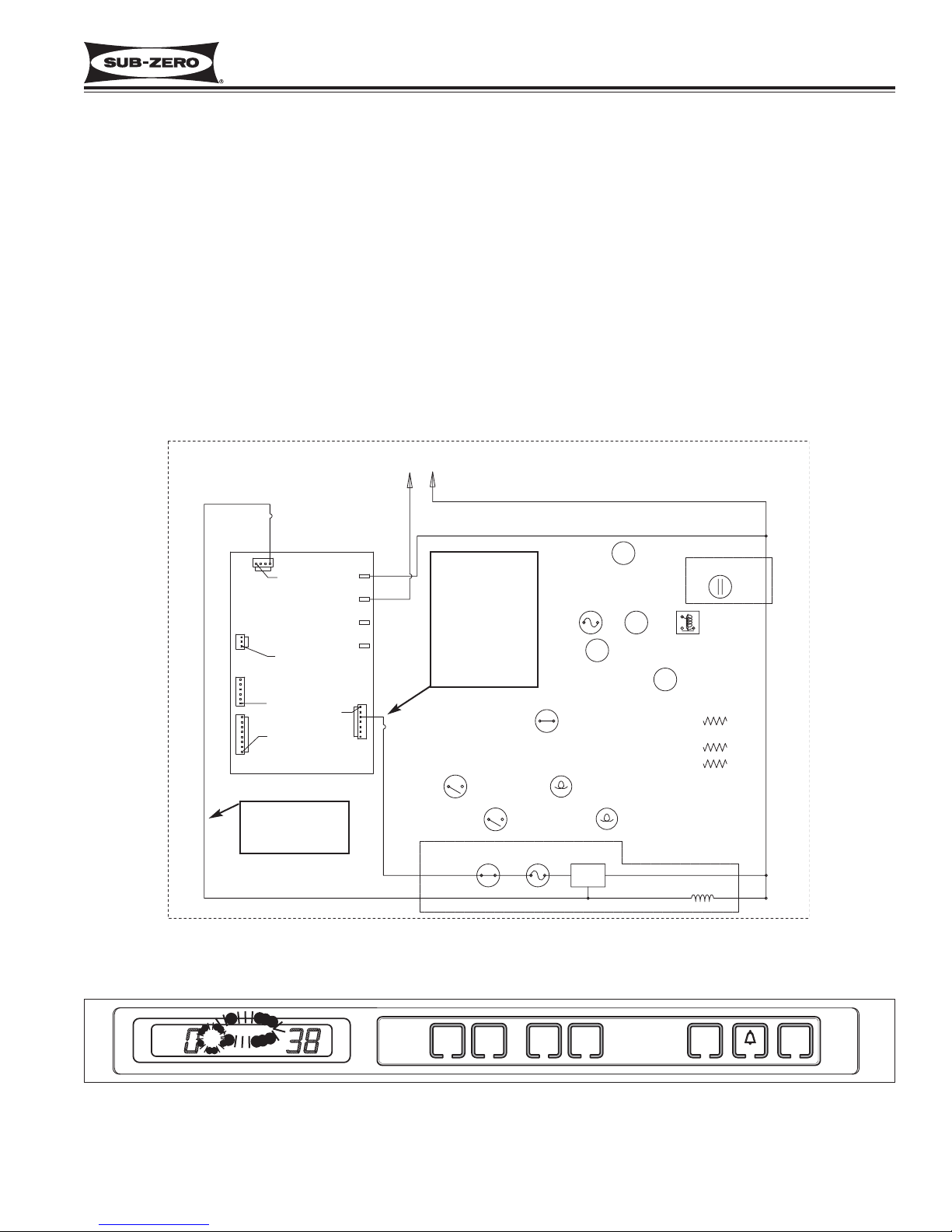

Regulate Refrigerator Zone Temperature (700BR-3)

When the thermistor in the refrigerator compartment reaches high off-set temperature, calling for cooling, the evaporator fan is energized, but the compressor and condenser fan are not allowed to run until the thermistor on the evaporator reaches 38°F (3°C). (See Figure 3-21)

If either drawer is opened while the evaporator fan is operating, the microprocessor will detect the power signal to

the lights and cut power to the fan.

Though compartment air temperatures will fluctuate, LCD displays average temperature.

NOTE: If compartment temperature exceeds either high or low offset (Ex: drawer is left open), temperature display

will change by one

degree per minute.

NOTE: If refrigerator

compartment thermistor is faulty, compressor operation defaults

to 20 minutes ON, 40

minutes OFF cycling,

EE appears in left of

LCD, SERVICE will

flash and Error Code

05 will be logged.

NOTE: If evaporator

thermistor is faulty,

the compressor will

not energize until

zone air temperature

exceeds high offset

by 5°F (3°C). SERVICE flashes and

Error Code 06 is

logged.

NOTE: When in

Sabbath Mode, the

refrigerator compartment thermistor still

controls compressor

operation, except

there is a random 15

to 25 second delay

before the compressor is energized.

Figure 3-21. 700BR-3 Signal Trace - Regulate Refrigerator Zone

1. Thermistor at high off-set

temp. calling for cooling.

2. No Power

to lights.

5. Compressor and

condenser fan

energized.

4. Evap Thermistor

above 38°F (3°C).

3. Evap fan energized.

LOW VOLTAGE SCHEMATIC

J6

J5

J2

PIN 1

MAIN BOARD

PIN 1

J4

PIN 1

PIN 1

P4

P3

P1

P2

PIN 1

J3

DISPLAY

THERMISTOR UPPER DRAWER/REFRIGERATOR

MEMBRANE KEYPAD

DISPLAY BOARD

THERMISTOR EVAPORATOR

PIN 1

PIN 1

J2

J3

ORANGE W/YELLOW STRIPE

BLUE W/YELLOW STRIPE

BLUE W/BLACK STRIPE

BLUE W/BLACK STRIPE

RED

WHITE

BLACK

BLUE

ORANGE

YELLOW

HIGH VOLTAGE SCHEMATIC

ORANGE

J2

PIN 1

MAIN BOARD

ORANGE W/BLACK STRIPE

PIN 1

J6

J4

PIN 1

PIN 1

J5

ORANGE W/BLACK STRIPE

ORANGE

PIN 1

115 VOLTS

60 CYCLES

L1

NEUTRAL

WHITE

RED

WHITE

P4

BLACK

P3

P1

P2

J3

PURPLE

ORANGE

UPPER

LIGHT SWITCH

YELLOW

LOWER

LIGHT SWITCH

UPPER DRAWER LIGHT

M

REF FAN MOTOR

OVERLOAD

PROTECTOR

CONDENSER FAN

LOWER DRAWER LIGHT

COMPRESSOR

M

M

RUNNING

CAPACITOR

COMPRESSOR

STARTING

RELAY

WHITE

(WHEN

USED)

Page 26

Electronic Control System

Integrated

(700-3BASE)

Series

3-14

#3758424 - Revision B - December, 2005

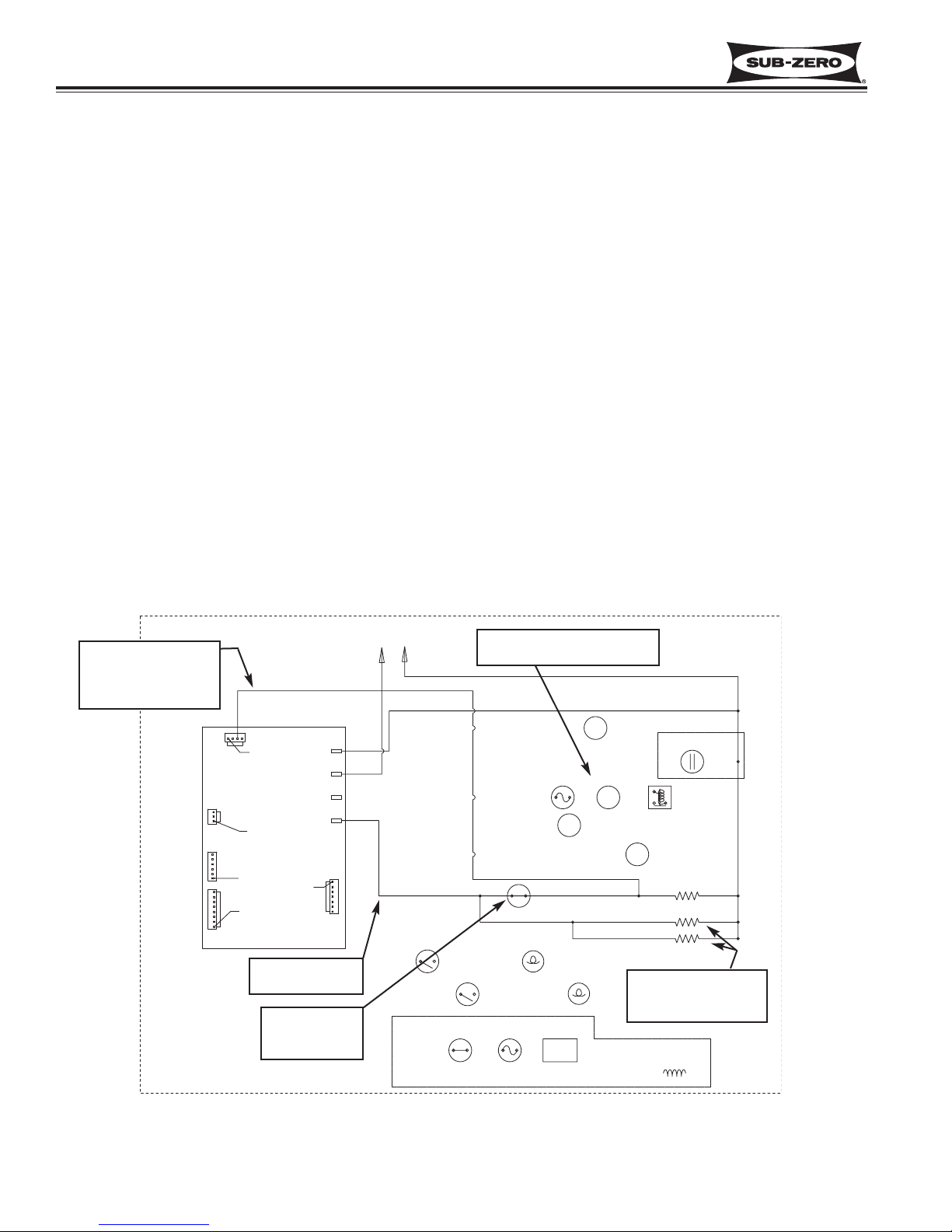

Monitor and Control “Adaptive Defrost” (700BCI-3, 700BFI-3)

Initially, the compressor will cycle-run for 12 hours, after which the microprocessor sends a signal to the defrost relay

on the control board to close. This supplies power to the defrost heater, drain tube heater and fill tube heater. At

the same time the compressor, condenser fan and evaporator fan are switched off.

With the “Adaptive Defrost” technique, the length of time that the defrost heater stays on to open the defrost terminator bimetal (70°F/21°C), is observed by the microprocessor via the grey w/white stripe wire to J2.

The microprocessor then determines the number of hours before the next defrost. If the heater stays on for a shorter time than specified, the microprocessor increases the next defrost interval. If the heater stays on longer than

specified, the electronic control decreases the next defrost interval. (See Figure 3-13) This is an ongoing process

whereby the defrost time and the defrost interval will vary by unit use.

NOTE: A 5 minute time delay/dwell follows all defrosts, during which the drain tube heater and fill tube heater

remain energized. At the end of the 5 minute dwell, the drain tube heater and fill tube heater are switched off, then

the compressor and condenser fan are energized, but the evaporator fan will not be energized until the evaporator

temperature falls below 35°F (2°C).

NOTE: The minimum defrost interval is 6 hours of compressor run time; the maximum defrost interval is 42 hours of

compressor run time; the maximum defrost duration is 25 minutes plus 5 minute dwell.

NOTE: If the grey w/white wire defrost sensing line is open, defrost operation defaults to 25 minute defrost time and

6 hour build time, and Error Code 22 is logged. If the evaporator thermistor detects an underheat or overheat situation at the same time, Error Codes 20 or 23 will be registered, respectively.

NOTE: During defrost, the display temperature is locked.

Figure 3-22. 700BCI-3 Signal Trace Schematic - Adaptive Defrost

5. Drain and fill tube

heaters remain

on during dwell.

2. Defrost circuit

energized.

3. Terminator

opens at

70°F (21°C)

1. Compressor runs 12

hours, then switched off.

4. Defrost duration

observed, interval

between next

defrost adjusted

HIGH VOLTAGE SCHEMATIC

J2

PIN 1

MAIN BOARD

PIN 1

J6

J4

PIN 1

PIN 1

J5

GRAY W/WHITE STRIPE

PIN 1

115 VOLTS

60 CYCLES

L1

NEUTRAL

WHITE

WHITE

P4

BLACK

P3

P1

BLUE

P2

BLUE

J3

M

COMPRESSOR

M

M

CONDENSER FAN

GRAY W/WHITE STRIPE

GRAY W/WHITE STRIPE

DEFROST

TERMINATOR

FRZ FAN MOTOR

WHITE

M

DEFROST HEATER

25 - 29 OHMS

DRAIN HEATER

1700 - 2100 OHMS

FILL TUBE HEATER

2300 -2900 OHMS

Page 27

Electronic Control System

Integrated

(700-3BASE)

Series

3-15

#3758424 - Revision B - December, 2005

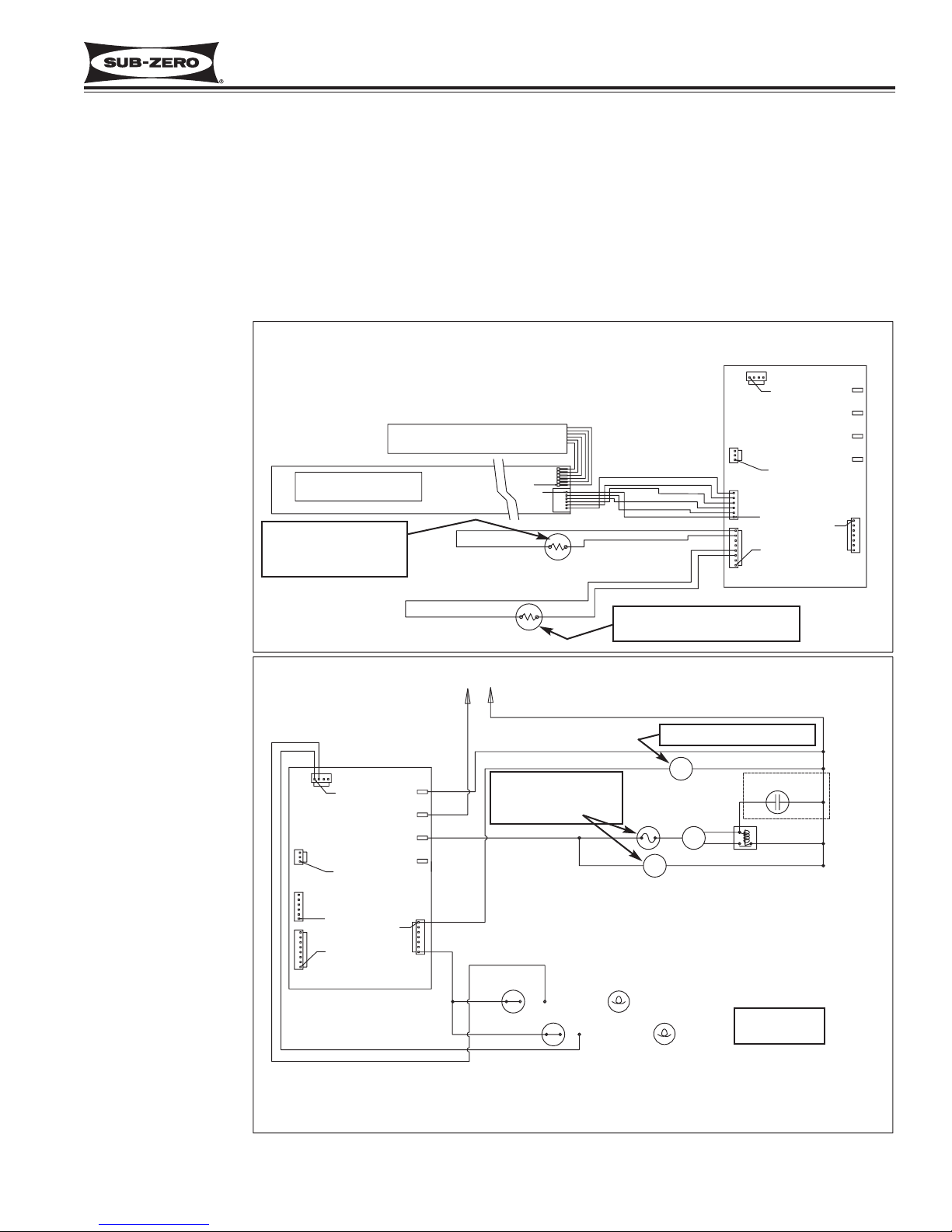

Monitor and Control Refrigerator Fan-Assisted, Off-Cycle Defrost (700BR-3)

Temperature signals from refrigerator evaporator's thermistor’s are observed by the microprocessor. During off cycle

defrost, if a refrigerator zone temperature reaches high offset (calling for cooling) before evaporator temperature

rises to 38°F (3°C), no power will be supplied the the compressor. But, the the zone evaporator fan will switch ON.

Once the evaporator temperatur reaches 38°F (3°C), normal cooling functions begin. (See Figure 3-23).

NOTE: If refrigerator compartment thermistor is faulty, compressor operation defaults to 20 minutes ON, 40 minutes

OFF cycling, EE appears in left of LCD, SERVICE will flash and Error Code 05 will be logged.

NOTE: If evaporator thermistor is faulty, the compressor will not energize until zone air temperature exceeds high

offset by 5°F (3°C). SERVICE flashes and Error Code 06 is logged.

NOTE: When in

Sabbath Mode, the

refrigerator compartment thermistor still

controls compressor

operation, except

there is a random 15

to 25 second delay

before the compressor is energized.

Figure 3-21. 700BR-3 Signal Trace - Regulate Refrigerator Zone

1. Thermistor at high off-set

temp. calling for cooling.

2. No Power

to lights.

5. compressor and

condenser fan

energized.

4. When Evap

Thermistor rises

above 38°F (3°C),

3. Evap fan energized.

LOW VOLTAGE SCHEMATIC

DISPLAY

THERMISTOR UPPER DRAWER/REFRIGERATOR

HIGH VOLTAGE SCHEMATIC

ORANGE

J2

PIN 1

MAIN BOARD

ORANGE W/BLACK STRIPE

PIN 1

J6

J4

PIN 1

PIN 1

J5

ORANGE W/BLACK STRIPE

ORANGE

PIN 1

P4

P3

P1

P2

J3

MEMBRANE KEYPAD

DISPLAY BOARD

THERMISTOR EVAPORATOR

115 VOLTS

60 CYCLES

L1

WHITE

BLACK

YELLOW

J2

PIN 1

PIN 1

J3

BLUE W/YELLOW STRIPE

BLUE W/BLACK STRIPE

BLUE W/BLACK STRIPE

NEUTRAL

WHITE

RED

PURPLE

ORANGE

UPPER

LIGHT SWITCH

LIGHT SWITCH

UPPER DRAWER LIGHT

LOWER

J2

PIN 1

MAIN BOARD

PIN 1

BLUE

ORANGE

YELLOW

RED

WHITE

BLACK

ORANGE W/YELLOW STRIPE

J6

J4

PIN 1

PIN 1

J5

REF FAN MOTOR

OVERLOAD

PROTECTOR

M

CONDENSER FAN

LOWER DRAWER LIGHT

M

COMPRESSOR

M

RUNNING

CAPACITOR

COMPRESSOR

STARTING

RELAY

WHITE

(WHEN

USED)

P4

P3

P1

P2

PIN 1

J3

Page 28

Electronic Control System

Integrated

(700-3BASE)

Series

3-16

#3758424 - Revision B - December, 2005

Monitor Compressor Run Duration, Displays If Service is Needed

The microprocessor observes the state of the compressor relay to determine the length of compressor run time (See

Figure 3-22). If the compressor runs 100% (Freezer = 6 hours, Refrigerator = 4 hours), an error code is logged (EC

40), and defrost will be initiated, but SERVICE will not flash.

If several 100% compressor run periods occur, and a drawer was not opened during the last excessive compressor

run period, and the temperature in the zone is not able to fall half way between the set point and the low off-set,

then SERVICE will flash (See Figure 3-23).

NOTE: To clear a flashing SERVICE and error codes, the problem must be corrected, then the Alarm ON/OFF key

pressed for 15 seconds. Failure to clear an error code will cause SERVICE to display constant.

NOTE: If the unit is ever switched OFF then back ON, the compressor will not energize for at least 3 minutes. This

3 minute minimum OFF time is used to protect the compressor and its electricals.

Figure 3-23. Service Flashing if several 100% compressor run periods occurred, a drawer was not opened

during last excessive run period, and temperature is not able to fall half way between set point & low off-set.

Figure 3-22. 700BCI-3 Signal Trace Schematic - Compressor Run

1. Compressor relay closed,

allowing 115 Volts AC to

compressor. This is

observe by microprocessor.

HIGH VOLTAGE SCHEMATIC

J2

PIN 1

MAIN BOARD

PIN 1

J6

J4

PIN 1

PIN 1

J5

PIN 1

115 VOLTS

60 CYCLES

L1

NEUTRAL

WHITE

M

WHITE

P4

BLACK

P3

P1

BLUE

P2

J3

PURPLE

RED

TERMINATOR

OVERLOAD

PROTECTOR

M

CONDENSER FAN

COMPRESSOR

M

M

FRZ FAN MOTOR

RUNNING

CAPACITOR

COMPRESSOR

STARTING

RELAY

WHITE

(WHEN

USED)

SERVICE

FREEZER

WARMERCOLDER

WARMERCOLDER

REFRIGERATOR

ON/OFF

ON/OFF

UNITICE

ON/OFF

Page 29

Electronic Control System

Integrated

(700-3BASE)

Series

3-17

#3758424 - Revision B - December, 2005

Monitor Icemaker System and Display If Service is Needed

The microprocessor observes the power supplied to the icemaker water valve solenoid. If the solenoid is energized

for more than 15 seconds, power to the icemaker system is disabled for 24 hours and an error code is logged (EC

30). (See Figure 3-24) If this happens five consecutive times, ICE and SERVICE on the LCD will flash and the ICE

ON/OFF key will be disabled (See Figure 3-25).

NOTE: To clear the ICE and SERVICE error indicators, and reactivate the ICE ON/OFF key, the problem must be

corrected, then the unit must be switched OFF and back ON, and the Alarm key must be pressed for 15 seconds to

clear the Error Code.

NOTE: To allow ice to freeze fully and reduce effects of low water pressure, power to the icemaker system is interrupted for 45 minutes after each ice harvest. This can be bypassed for service purposes by switching the icemaker

system OFF, then back ON by pressing the ICE ON/OFF key.

NOTE: When in Sabbath Mode, icemaker system is disabled. Sabbath Mode will be covered later.

Figure 3-25. ICE & SERVICE Flashing if solenoid energized 15 seconds, every 24 hours, 5 consecutive times

Figure 3-24. 700BCI-3 Signal Trace Schematic - Icemaker Operation and Solenoid Monitoring

1. 115 Volts AC

to solenoid

monitored.

2. If solenoid

energized

more then

15 seconds,

power to IM

system

interrupted

for 24 hours.

HIGH VOLTAGE SCHEMATIC

TAN

J2

PIN 1

MAIN BOARD

PIN 1

J6

J4

PIN 1

PIN 1

J5

TAN

PIN 1

115 VOLTS

60 CYCLES

L1

NEUTRAL

WHITE

WHITE

P4

BLACK

P3

P1

P2

J3

PINK

ICEMAKER

SWITCH

THERMAL

FUSE

ICEMAKER

(OPTIONAL)

M

M

M

M

ICEMAKER

TAN

VALVE

WHITE

SERVICE

ICE

FREEZER

WARMERCOLDER

WARMERCOLDER

REFRIGERATOR

ON/OFF

ON/OFF

UNITICE

ON/OFF

Page 30

Electronic Control System

Integrated

(700-3BASE)

Series

3-18

#3758424 - Revision B - December, 2005

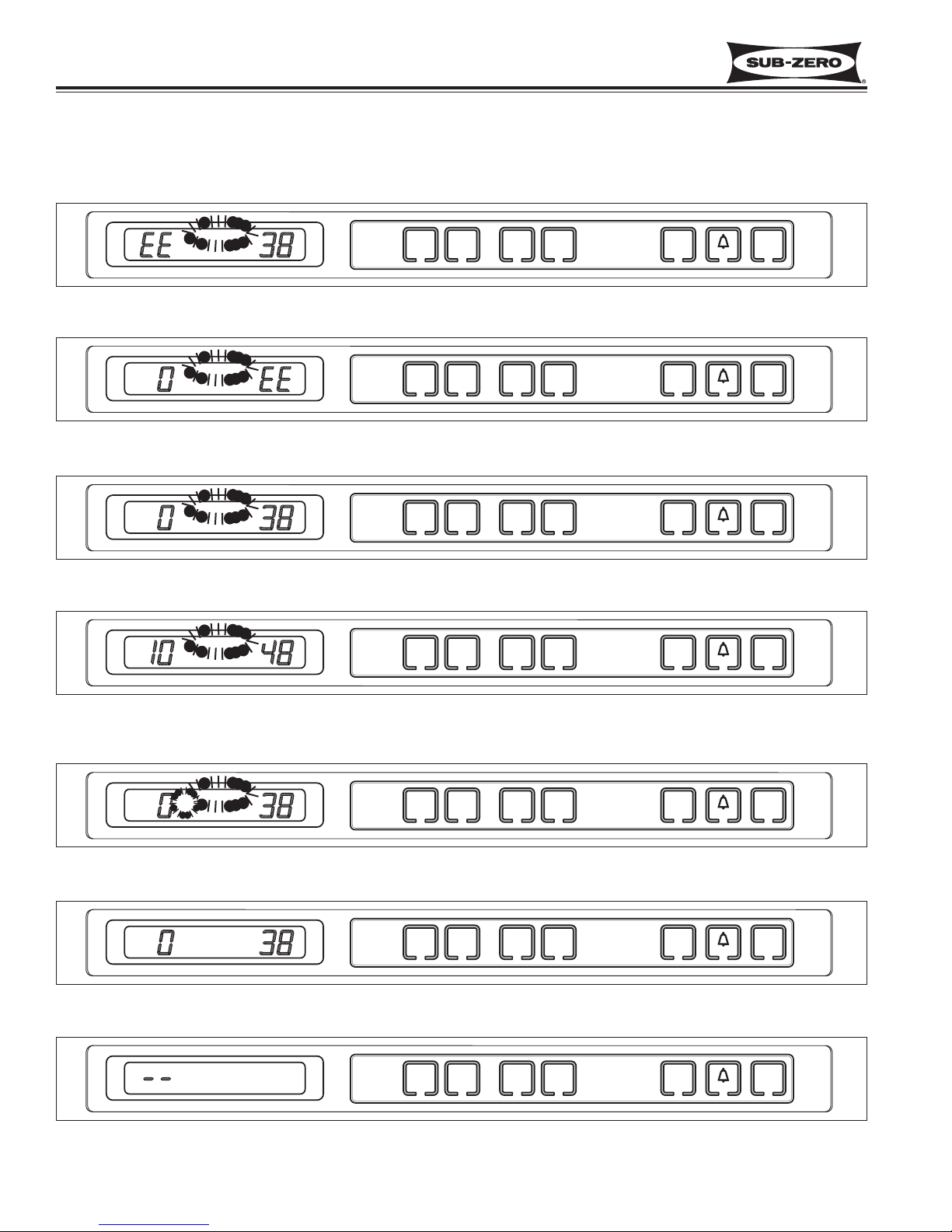

POSSIBLE ERROR INDICATORS

The diagrams on this page illustration what a customers may see on LCD if a problem/error exists with the unit.

NOTE: To clear indicators and error codes, problem must be corrected then press bell ON/OFF key for 15 seconds.

Figure 3-27.

“EE” Displayed at Right & “SERVICE” Flashing = Refrigerator Compartment Thermistor (or its Wiring) Fault

Figure 3-26.

“EE” Displayed at Left & “SERVICE” Flashing = Freezer Compartment Thermistor (or its Wiring) Fault

Figure 3-29.

Service Flashing = Several 100% run periods, a drawer was not open during last 100% run period, and zone

temperature not able to fall half way between set point and low off-set.

Figure 3-30.

“ICE” and “SERVICE” Flashing = Solenoid Energized 15 Seconds, Every 24 Hours, 5 Consecutive Times

Figure 3-31.

“SERVICE” Steady, not Flashing = Error Codes Observed in Diagnostic Mode, but not Cleared

Figure 3-28.

Service Flashing = Evaporator Thermistor (or its Wiring) Fault

Figure 3-32.

“- - ” Double Dashes Displayed = Model Configuration was not Performed

SERVICE

FREEZER

WARMERCOLDER

WARMERCOLDER

REFRIGERATOR

ON/OFF

ON/OFF

UNITICE

ON/OFF

SERVICE

FREEZER

WARMERCOLDER

WARMERCOLDER

REFRIGERATOR

ON/OFF

ON/OFF

UNITICE

ON/OFF

SERVICE

FREEZER

WARMERCOLDER

WARMERCOLDER

REFRIGERATOR

ON/OFF

ON/OFF

UNITICE

ON/OFF

SERVICE

FREEZER

WARMERCOLDER

WARMERCOLDER

REFRIGERATOR

ON/OFF

ON/OFF

UNITICE

ON/OFF

ICE

SERVICE

FREEZER

WARMERCOLDER

WARMERCOLDER

REFRIGERATOR

ON/OFF

ON/OFF

UNITICE

ON/OFF

SERVICE

FREEZER

WARMERCOLDER

WARMERCOLDER

REFRIGERATOR

ON/OFF

ON/OFF

UNITICE

ON/OFF

FREEZER

WARMERCOLDER

WARMERCOLDER

REFRIGERATOR

ON/OFF

ON/OFF

UNITICE

ON/OFF

Page 31

Electronic Control System

Integrated

(700-3BASE)

Series

3-19

#3758424 - Revision B - December, 2005

BR-3 Thermistor Code Table

THERMISTOR LOCATION CODE

Refrigerator Compartment r

Evaporator E

ELECTRONIC CONTROL TROUBLESHOOTING INPUT OPERATIONS

The following few pages explain troubleshooting input operations performed at the control panel. The input operations described are Diagnostic Mode, Manual Component Activation Mode and Temperature Log Recall.

Diagnostic Mode

Initiating Diagnostic Mode allows the Service Technician to observe real-time temperature readings from all thermistors without temperature averaging.

To initiate Diagnostic Mode, the unit must be ON, then press and hold either

COLDER key, and press the UNIT

ON/OFF key, then release both keys (See Figure 3-33). The left display area will show the real-time temperature of

the thermistor, the right display area will show the thermistor location code, and all LCD indicators will illuminate.

Pressing either

COLDER key while in Diagnostic Mode will toggle forward to the next thermistor location (See

Figures 3-34 & 3-35), while pressing either WARMER key while in Diagnostic Mode will toggle backward to the previous thermistor location.

NOTE: If the COLDER and UNIT ON/OFF keys are pressed and held for 10 seconds, Manual Component

Activation Mode will be initiated (this is covered later in the section).

NOTE: Diagnostic Mode will end 20 seconds after the last key stroke.

Figure 3-33. Initiate Diagnostic Mode - Press and Hold Either

COLDER Key, Then UNIT ON/OFF Key

(“F” Indicates Freezer Compartment)

Figure 3-34. Toggle Through Temperature Readings - Press Either COLDER Key

(“r” Indicates Refrigerator Compartment)

Figure 3-35. Toggle Through Temperature Readings - Press Either

COLDER Key

(“E” Indicates Evaporator)

BCI-3 Thermistor Code Table

THERMISTOR LOCATION CODE

Freezer Compartment F

Refrigerator Compartment r

Evaporator E

BFI-3 Thermistor Code Table

THERMISTOR LOCATION CODE

Freezer Compartment F

Evaporator E

SERVICE

ICE

OFF

FREEZER

WARMERCOLDER

WARMERCOLDER

REFRIGERATOR

ON/OFF

ON/OFF

UNITICE

ON/OFF

ICE

SERVICE

OFF

FREEZER

WARMERCOLDER

WARMERCOLDER

REFRIGERATOR

ON/OFF

ON/OFF

UNITICE

ON/OFF

SERVICE

ICE

OFF

FREEZER

WARMERCOLDER

WARMERCOLDER

REFRIGERATOR

ON/OFF

ON/OFF

UNITICE

ON/OFF

Page 32

Electronic Control System

Integrated

(700-3BASE)

Series

3-20

#3758424 - Revision B - December, 2005

Figure 3-36. “EE” Observed in Diagnostic Mode = Thermistor Fault in Location Indicated by Code

Figure 3-37. “Sr” Observed While in Diagnostic Mode = Unit is in Showroom Mode

If “Sr” is observed at left display area during Diagnostic Mode, the unit is in Showroom Mode, which was explained

earlier in this section (See Figure 3-37).

If “EC” is observed in the right display area during Diagnostic Mode, the numbers at left are “Error Codes” (See

Figure 3-38). Error Codes indicate problems registered by specific components. If error codes are registered, they

will appear before temperature readings and can be toggled through with the temperature readings as described on

the previous page. (See Error Code Table below and instructions on clearing Error Codes on next page.)

Figure 3-38. “EC” Observed While in Diagnostic Mode = Error Code

(See table below & how to clear Error Codes on next Page)

700BCI-3 Error Code Table

CODE INDICATION

05 Refrig. cabinet thermistor read open or shorted for 10+ seconds, or repeatedly read erratic temp’s

07 Freezer cabinet thermistor read open or shorted for 10+ seconds, or repeatedly read erratic temp’s

08 Freezer evaporator thermistor read open or shorted for 10+ seconds, or repeatedly read erratic temp’s

20 Defrost under-heat with no voltage feedback through Gray/White wire at defrost start

21 Defrost overheat

22 No voltage feedback through Gray/White wire at defrost start

23 Defrost overheat with no voltage feedback through Gray/White wire at defrost start

24 Defrost under-heat

30 Excessive Icemaker Water Valve Solenoid Activation (Exceeded 15 Seconds)

40 Excessive Freezer Compressor Run

50 Excessive Refrigerator Fan Run

Diagnostic Mode Indicators

If “EE” is observed in left display area during Diagnostic Mode, the thermistor in that location is open or shorted, or

there is a break in that thermistor’s wiring (See Figure 3-36).

ICE

SERVICE

OFF

FREEZER

WARMERCOLDER

WARMERCOLDER

REFRIGERATOR

ON/OFF

ON/OFF

UNITICE

ON/OFF

ICE

SERVICE

OFF

FREEZER

WARMERCOLDER

WARMERCOLDER

REFRIGERATOR

ON/OFF

ON/OFF

UNITICE

ON/OFF

ICE

SERVICE

OFF

FREEZER

WARMERCOLDER

WARMERCOLDER

REFRIGERATOR

ON/OFF

ON/OFF

UNITICE

ON/OFF

Page 33

Electronic Control System

Integrated

(700-3BASE)

Series

3-21

#3758424 - Revision B - December, 2005

If Error Codes are observed in Diagnostic Mode, a non-flashing SERVICE icon will appear on the LCD when

Diagnostic Mode ends, indicating error codes are still stored (See Figure 3-39). To clear a non-flashing SERVICE

icon and the error codes, the problem must be corrected and the unit must be ON, then the door ajar alarm bell

ON/OFF key must be pressed and held for 15 seconds. The control will emit a short “beep” when the SERVICE

icon and error codes are cleared. (See Figure 3-40)

Figure 3-40. Clear Non-flashing SERVICE - Press & Hold Bell ON/OFF Key for 15 Seconds

Figure 3-39. Non-flashing SERVICE after Diagnostic Mode = Error Codes are Stored

Press and hold for 15 seconds

BEEP!

Figure 3-41. Initiate Manual Component Activation Mode (Refrigerator Zone Shown) -

Press and Hold Desired COLDER Key and UNIT ON/OFF Key for 10 Seconds

Manual Component Activation Mode

Manual Component Activation Mode energizes the cooling system for 5 minutes, allowing a Service Technician to

check for proper voltage readings at activated components without having to wait for the zone to call for cooling.

To initiate Manual Component Activation Mode the unit must be ON, then press and hold the desired COLDER key

and the UNIT ON/OFF key for 10 seconds (See Figure 3-41). All cooling functions for that zone will begin and the