Page 1

Planning Information

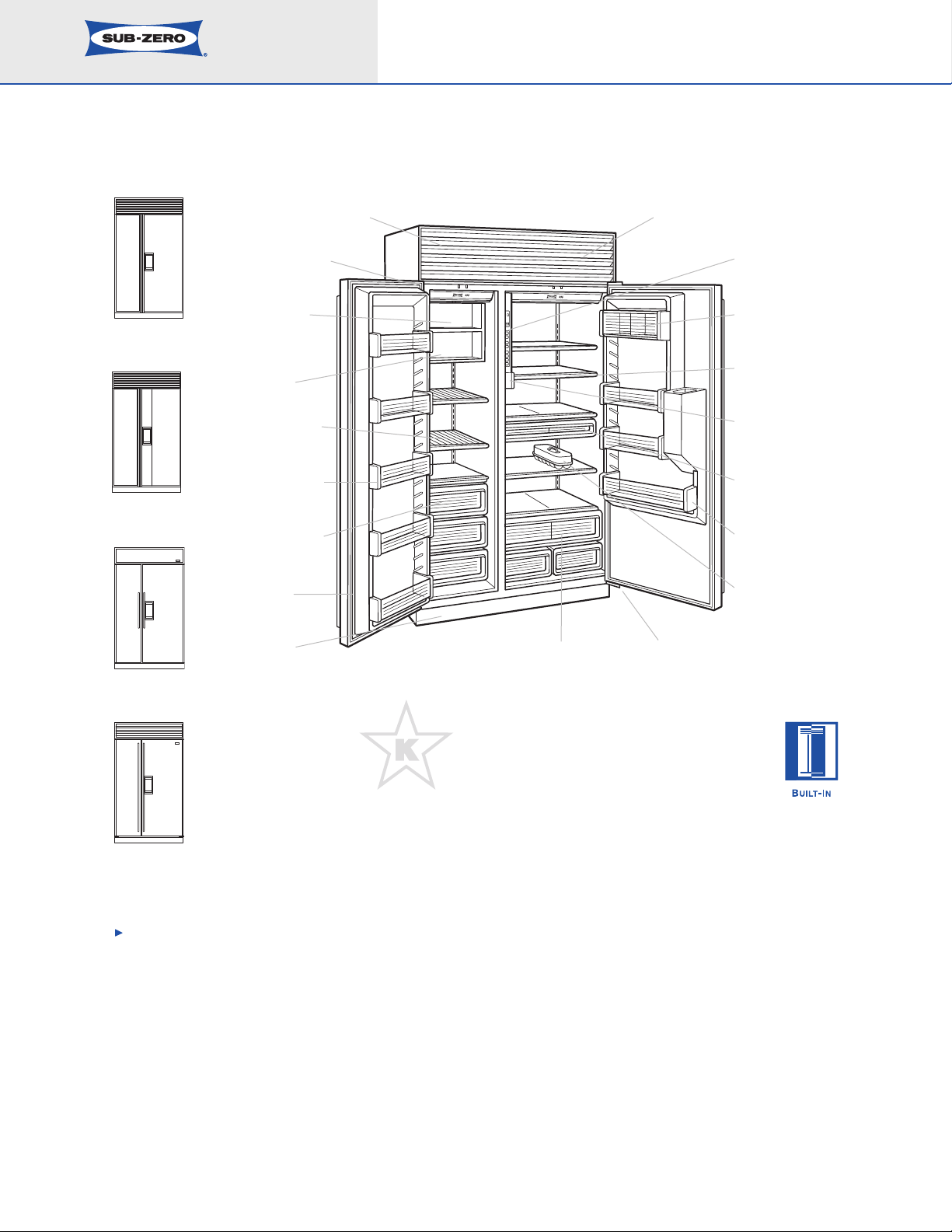

Built-In Model 695

Side-by-Side Refrigerator/ Freezer with Ice and Water Dispenser

odel 695/F

M

ramed

F

odel 695/F

M

Partial Framed

Model 695/O

Overlay

Front venting allows unit

to be completely built in

erial and model

S

umber plate

n

Automatic ice

aker

m

reezer

F

utility rack

djustable wire

A

helves

s

djustable door

A

shelves

Roll-out freezer

baskets

Four-sided

magnetic gaskets

Removable

kickplate

High humidity

crisper drawer

(Stainless steel design shown )

Hermetically sealed

refrigeration units

ighted electronic

L

ontrol panel

c

Adjustable dairy

ompartment

c

djustable spill-

A

proof glass shelves

ulk ice dispenser

B

djustable roll-out

A

utility basket

Adjustable door

shelves

Egg tray

Door closers

Model 695/S

Classic

Stainless Steel

The Sub-Zero Model 695 side-by-side

refrigerator/ freezer with ice and water

dispenser is available in your choice of the

framed, partial framed, overlay or stainless

steel design application. The stainless steel

model comes with classic stainless steel

wrapped doors.

Dimensions in parentheses are in

millimeters unless otherwise specified.

11/06

With the installa

appliances ar

religious regulations in conjunction with specific

instructions found on star-k.org. You may purchase

this harness kit through your Sub-Zero dealer.

To obtain local dealer information, visit the Locator

section of our website, subzero.com.

Sub-Zer

ice and w

tion of a harness kit, these

e Star-K compliant to meet strict

o offer

ater dispensing through the door

s two distinctive different models with

. This sideby-side unit is 48" (1219) wide and the dispenser is

placed on the refrigerator door to offer a sleek look and

most efficient use of interior storage space.

1

Page 2

Planning Information

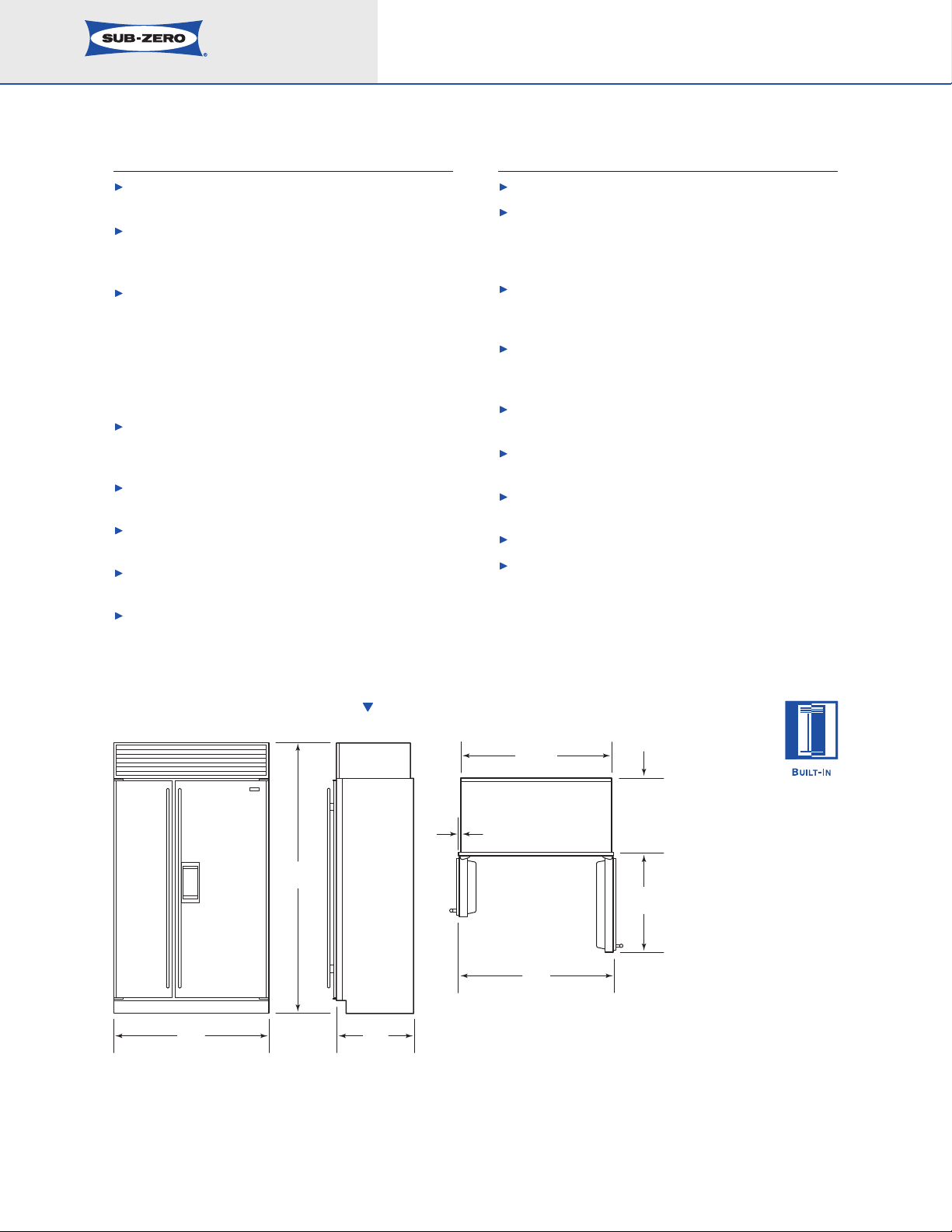

48"

(1219)

24"

(610)

84"

(2134)

237/8"

(606)

BEHIND

FRAME

291/4"

(743)

48"

(1219)

3

/8" (10)

FRAME EXTENSION

471/4"

(1200)

Built-In Model 695

FEATURES

48" (1219) wide side-by-side refrigerator/

freezer with ice and water dispenser

Framed, overlay and classic stainless steel

applications provide complete design

flexibility

If you choose not to use custom wood

panels above or below the glasswell, you

can order a partial framed accessory kit for

your framed unit – the kit includes molding

and a stainless steel panel that surrounds

the glasswell and runs the total height of the

refrigerator door

With the framed retrofit accessory kit,

existing Model 690 door panels can be used

on a new Model 695 framed unit

Sub-Zero's dual refrigeration system ensures

the freshest food and energy efficiency

Shallow-depth design means access is easy

to any area of the refrigerator

Electronic digital controls are up front and

easy to use

Bright interior lighting

Adjustable, spill-proof glass shelves

High-humidity crisper drawer is large and

deep with removable divider and smooth

sides for easy cleaning – there are even two

added storage drawers

Door alarm will let you know with an audible

beeping if your refrigerator or freezer door is

left ajar

Automatic ice maker provides an ample

s

upply of crescent-shaped ice – also has a

bulk ice dispenser

Solid core doors with magnetic gaskets and

door closers

Front venting allows unit to be completely

built in and serviced from the front

Meets strict Department of Energy requirements

UL listed for US and Canada

Two, five and twelve year residential

warranty – exclusions apply; warranty

information can be found on our website,

subzero.com

OVERALL DIMENSIONS

Stainless steel design shown.

1

±

y

ary b

Dimensions ma

Dimensions in parentheses are in

millimeters unless otherwise specified.

y v

/8" (3).

2

Page 3

Planning Information

Built-In Model 695

MODEL OPTIONS

Framed Design 695/F

Partial Framed Design 695/F

(accessory kit required)

Overlay Design 695/O

Classic Stainless Steel 695/S

ACCESSORIES

artial framed kit

FRAMP

includes molding and a stainless

steel insert panel for above and

below the glasswell on a framed

unit

FRAMRET – Framed retrofit kit

includes moldings and stainless

steel insert panels to accommodate existing Model 690 framed

door panels

Louvered, panel or stainless steel

grilles in 1" (25) increments from

10" (254) to 15" (381) high

Front and grille panels for framed

design in white

classic stainless steel

Side panels in white

classic stainless steel

Stainless steel and polished

chrome handles for overlay design

Gallon door shelf

Dozen egg container with lid

90˚ and 105˚ door stop kits

Accessories are available through your

Sub-Zero dealer. To obtain local dealer

information, visit the Locator section of

our website

AR – P

, subzer

, almond and

, almond and

o.com.

SPECIFICATIONS

M

odel 695 Side-by-Side Refrigerator/ Freezer

w

ith Ice and Water Dispenser

Overall Width 48" (1219)

Overall Height 84" (2134)

Overall Depth 24" (610)

Refrigerator Capacity 18.2 cu ft (515 L)

F

reezer Capacity 9.8 cu ft (278 L)

Minimum Height (levelers in) 83" (2108)

Door Swing Clearance 291/4" (743)

Electrical Requirements

Plumbing Requirements

115 V AC, 60 Hz, 15 amp circuit

1

/4" copper line

Water Supply 20–100 psi

Annual Energy Usage 747 kWh / $ 68

(based on 9.06 cents per kilowatt hour)

Shipping Weight Framed – 610 lbs (277 kg)

Overlay – 610 lbs (277 kg)

Stainless Steel – 656 lbs (298 kg)

Special Note Overlay design is now available

for this ice and water dispensing unit

Specifications are subject to change without notice.

Dimensions in parentheses are in

millimeters unless otherwise specified.

3

Page 4

Planning Information

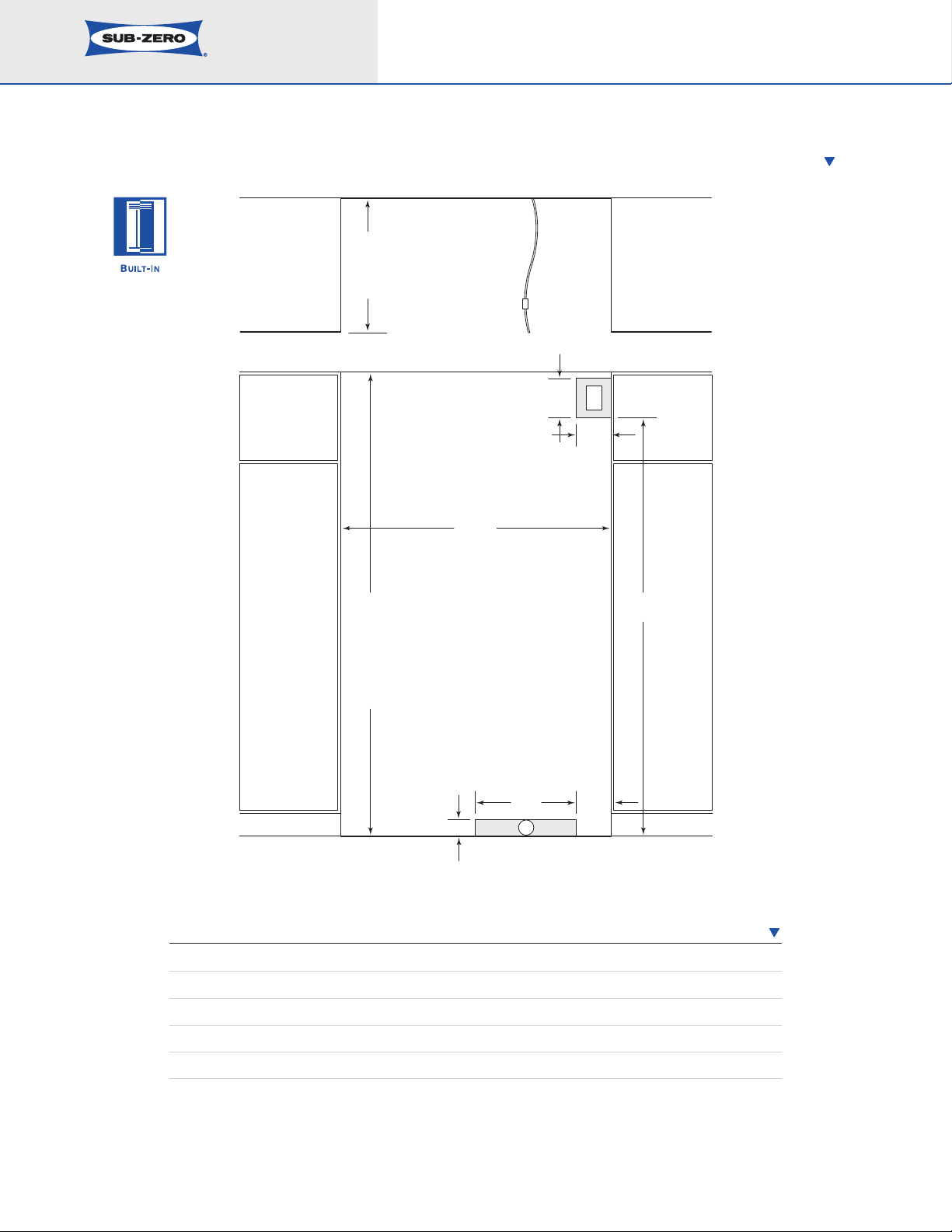

833/4"

(2127)

ROUGH

OPENING

HEIGHT

WITH

STANDARD

11" (279)

GRILLE

751/2"

(1918)

7"

(

178)

6"

(152)

471/2"

(

1207)

R

OUGH OPENING WIDTH

24"

(610)

ROUGH

OPENING

DEPTH

E

3"

(76)

18"

(457)

W

LOCATE WATER SUPPLY

WITHIN SHADED AREA

L

OCATE ELECTRICAL

W

ITHIN SHADED AREA

6"

(152)

SHUT-OFF

VALVE

E

XTEND WATER LINE

A

PPROX. 36" (914)

F

ROM BACK WALL

FRONT VIEW

TOP VIEW

Built-In Model 695

INSTALLATION SPECIFICATIONS

DIMENSIONS

Finished Rough Opening Width 471/2" (1207)

Finished Rough Opening Height 833/4" (2127)

Finished Rough Opening Depth 24" (610)

Location of Electrical Within upper shaded area

Location of W

ater Supply

See Installation Instructions shipped with unit for detailed specifications.

Refer to the Sub-Zero Design Guide pdf file for additional specifications.

Dimensions in parentheses are in

millimeters unless otherwise specified.

Within lower shaded area

4

Page 5

Planning Information

Built-In Model 695

INSTALLATION NOTES

R

efer to the illustrations and specifications

for overall dimensions, finished rough opening

dimensions and installation specifics.

A

llow the doors to open a minimum of 90˚ or

you'll have problems removing drawers. With

the doors opening at 90˚, you may have to

move drawers slightly to clear the door interior.

Refer to the minimum door swing clearances in

the specifications chart.

For corner installations, allow for a minimum

3" (76) filler so that the door can open to 90˚.

If you're using raised panels, consider using a

wider filler. A 90˚ door stop is available as an

accessory.

Be sure to add the filler strip width to your

finished rough opening dimension. In any sideby-side installation without a filler strip, add an

additional

This will allow for the proper width.

Refer to the full-scale illustrations at the end

of this section for specifics on door openings

and filler size alternatives.

If your client has chosen the stainless steel

design, the unit will be shipped complete with

wrapped stainless steel doors and handle

hardware. You will not have to install front

panels.

If your client has chosen the framed or

overlay design, you will be adding front panels

to give the unit the custom Sub-Zero look. The

overlay design also allows you to add your own

handles, or you may choose accessory handles

available through your Sub-Zero dealer. Refer to

pages 6– 12 for detailed information on adding

panels.

For Built-In models with an automatic ice

maker, rough in the water supply line. Connect

1

/4" OD copper line to the house supply, being

a

sure to use an easily accessible shut-off v

between the supply and the unit.

Do not use self-piercing valves. A saddle

alve kit (4200880) is av

v

Sub-Zero dealer. To obtain local dealer information, visit the Locator section of our website

subzero.com.

1

/2" (13) to your combined numbers.

alve

ailable from your

,

A

line filter is required when water conditions have a high sediment content. The ice

maker operates on water pressure of 20 psi

(1.4 bar) to 100 psi (6.9 bar). In some cases a

r

everse osmosis water filter system may not be

able to maintain the minimum water pressure

consistently.

The water line should be routed up through

1

the floor within

/2" (13) from the back wall and

no higher than 3" (76) off the floor. If you have

to come through the wall, make sure the water

line is no more than 3" (76) from the floor.

Locate water supply within the shaded area

shown in the installation illustration.

Regardless of the routing, allow 3' (.9 m) of

excess copper tubing to remain outside the wall

or floor for easy connection to the unit.

A 115 volt, 60 Hz, 15 amp electrical supply

is required. The supply circuit for this appliance

must be protected by a 15 amp fuse or circuit

breaker. It is recommended that a separ

ate

circuit, serving only this appliance, be provided.

All Built-In models are equipped with a 6'

(1.8 m) power supply cord with a 3

-prong

grounding plug which must be plugged into a

mating 3

-prong grounding type wall receptacle.

Locate electrical within the shaded area shown

in the installation illustration.

You must follow all National Electrical Code

regulations. In addition, be aware of local codes

and ordinances when installing your service.

To prevent the unit from tipping forward and

provide a stable installation, the unit must be

secured in place with an anti-tip blocking kit. If

there is a solid soffit a

bove the unit with clear

ance between the unit and the soffit of 1" (25)

or less, you won't need to block the unit.

For installations with clearances of more

than 1" (25), y

anti-tip bloc

ou must block the unit with the

king kit (wood bloc

k and hardw

are)

provided with each Built-In unit.

Refer to the

Built-In Installation Instructions

packed with the appliance, which provides

step-b

y-step pr

ocedures for making sure the

unit is installed properly.

Dimensions in parentheses are in

millimeters unless otherwise specified.

5

Page 6

Planning Information

PANELS

1

/4" (6) THICK OR LESS

1

/4" (6) Panel

Trim reveal

1

/4" (6) min

PANELS THICKER THAN

1

/4" (6)

Trim reveal

1

/4" (6) min

Rout to 1/4" (6)

thickness

Built-In Model 695

FRAMED PANELS

ADDING PANELS

In your plan for panels, be sure you are working with the

Sub-Zero panel design family called for in your design. If

you have chosen the stainless steel design, the unit will be

shipped complete with wrapped stainless steel doors and

handle hardware. You will not have to install front door

p

anels.

If you and your client have ordered a framed or overlay

design model, you will be adding panels to give the unit

the custom Sub-Zero look. Specifications on the following

pages provide installation considerations for framed and

overlay door panels.

Side panels can be used with the framed, overlay and

stainless steel design applications. Refer to specifications

on page 12.

Framed door panel 1/4" (6) thick or less

Framed door panel thicker than 1/4" (6)

FRAMED PANELS

If the thickness of the custom panels is less than 1/4"

(6), they must be backed up with a sheet of shim material

1

to build the total thickness to

1

than

/4" (6), an edge must be routed ar

/4" (6). If the panel is thicker

ound the panel to

ensure a proper fit. Refer to the illustrations on this page.

IMPORTANT NOTE: Routing, recessing or optional

extended handles may be required on raised panels for

finger clearance under the handle. Refer to the full-scale

illustrations on pages 13– 16.

IMPORTANT NOTE: The weight of each panel cannot

exceed 50 lbs (23 kg).

The traditional framed models come with an 11" (279)

louvered grille and elegant full-length handle. Optional

extended full-length handles that provide additional finger

ance for raised panels are available through your

clear

Sub-Zero dealer. To obtain local dealer information, visit

the Locator section of our website, subzero.com.

For framed door panel dimensions and dimensions for the

optional panel grille for the framed application, refer to

specifications on page 7.

To install framed panels, refer to the installation instructions shipped with each unit

. These instructions can also

be found on our website, subzero.com.

Dimensions in parentheses are in

millimeters unless otherwise specified.

6

Page 7

Planning Information

W

H

WW

H

B

A

12

7

/16"

(315)

57/8"

(150)

1

/4" (6) min

FLAT L ANDING

AREA FOR BEZEL

Built-In Model 695

FRAMED PANELS

For framed models, the refrigerator door panel must

include a cut-out to accommodate the glasswell and bezel.

The thickness of the panel in this area can range from

(6) to a maximum of 1

p

rovisions must be made to rout out a space to accommo-

1

/8" (29). If the panel is thicker,

1

/4"

date the decorative bezel surrounding the glasswell.

An 11" (279) louvered grille is standard on framed applications. Optional louvered grilles are available in 1" (25)

height increments from 10" (254) to 15" (381).

You may choose to use Sub-Zero's optional panel grille for

the framed application. Optional panel grilles are available

in 1" (25) height increments fr

om 10" (254) to 15" (381).

Refer to the chart below for panel dimensions.

FRAMED P ANEL DIMENSIONS

WIDTH HEIGHT

Framed Door Panels

Framed Grille Panel

Glasswell Cut-Out Location

(refrigerator door panel)

IMPORTANT NOTE: Panel thickness in

the glass

to a maximum of 1

thicker, you must rout out a minimum

(6) flat landing area to accommodate the

bezel surr

Dimensions in parentheses are in

millimeters unless otherwise specified.

well area can range from

ounding the glass

1

/8" (29). If the panel is

well.

1

/4" (6)

Refrigerator Door Panel 2711/16" (703) 6711/16"(1719)

Freezer Door Panel 1715/16" (456) 6711/16"(1719)

Maximum Weight (per panel) 50 lbs (23 kg)

Glasswell Cut-Out Location A – 19/16" (39)

(refrigerator door panel) B – 289/16" (726)

FRAMED GRILLE PANEL DIMENSIONS

WIDTH HEIGHT

10" (254) Grille 463/16" (1173) 815/16" (227)

11" (279) Grille 463/16" (1173) 915/16" (252)

12" (305) Grille 463/16" (1173) 1015/16" (278)

13" (330) Grille 463/16" (1173) 1115/16" (303)

14" (356) Grille 463/16" (1173) 1215/16" (329)

15" (381) Grille 463/16" (1173) 1315/16" (354)

1

/4"

7

Page 8

Planning Information

WW

H

Built-In Model 695

FRAMED PANEL ACCESSORY KITS

For framed models, the refrigerator door panel must

include a cut-out to accommodate the glasswell and bezel.

The thickness of the panel in this area can range from

(6) to a maximum of 1

p

rovisions must be made to rout out a space to accommo-

1

/8" (29). If the panel is thicker,

1

/4"

date the decorative bezel surrounding the glasswell.

If you choose not to use custom wood panels above or

below the glasswell for the framed application, a stainless

steel insert panel will be provided with the partial framed

accessory kit. This accessory kit includes partial framed

molding and classic stainless steel inset handle panel to

provide a spill-resistant finish above and below the glasswell on the refrigerator door only. Refer to the specifications for this option in the chart below. Grille panel dimensions will be the same as shown for framed panels.

Partial Framed Door Panels

(identical in size)

Partial framed kit

With the fr

amed retr

ofit accessory kit, existing Model 690

door panels can be used on a new Model 695 framed unit.

This accessory kit includes framed retrofit moldings and

classic stainless steel inset handle panels to accommodate

existing Model 690 framed refrigerator and freezer door

panels.

IMPORTANT NOTE: When using a partial framed or framed

1

retrofit kit, a

/2" (13) reveal must be maintained on the

bezel side of the panel.

Both accessory kits are available through your Sub-Zero

dealer. To obtain local dealer information, visit the Locator

section of our website, subzero.com.

PARTIAL FRAMED PANEL DIMENSIONS

WIDTH

Refriger

ator Door P

anel 17

15

/16" (456) 6711/16"(1719)

Freezer Door Panel 1715/16" (456) 67

HEIGHT

1

1

/16"(1719)

ramed retrofit kit

F

Dimensions in parentheses are in

millimeters unless otherwise specified.

8

Page 9

Planning Information

Door/Drawer/

Grille Trim

1

/16" (2)

5

/32" (4)

1

/4" (6) Backer Panel

5

/16" (8) min

.

10"

(3)

Spacer Panel

Overlay Panel

Spacer Panel

Overlay Panel

1

/4" (6)

Backer

Panel

.10"

(3)

~3/4"

(19)

Built-In Model 695

OVERLAY PANELS

OVERLAY PANELS

The overlay design allows decorative panels to cover the

door trim for a more seamless appearance that blends

with the design of the room. To achieve this look, the

most common way is to work with three panels—the

decorative overlay panel, a .10" (3) spacer panel and a

1

/4"

(6) backer panel. Depending on your cabinet manufacturer,

this could be one panel routed for different dimensions or

more likely, three different panels.

Regardless of the physical construction of the panels

(routing or three panel assembly), you will need to follow

the exact dimensions and panel placement to ensure a

proper fit.

The top illustration on this page is a cross section view of

the three panel assembly showing placement of the

door / drawer/ grille trim. The bottom illustration shows a

rear view of the three panel assembly and critical dimensions, standard for all overlay models.

Three panel assembly— cross section

Three panel assembl

y— rear view

Overlay models will come with no handle hardware,

because the beauty of this design is that you can match

the surr

ounding cabinetry hardware. These models will

come with an 11" (279) panel grille which will accept

decorative panel inserts to match the look of the door

panels. For overlay door and grille panel dimensions, refer

to specifications on page 10.

IMPOR

TANT NOTE:

Keep in mind that the Sub-Zero door

panels have the potential for hitting adjacent cabinets

and/or countertops when they are opened. You need to be

are of your surrounding cabinetry and space limitations

aw

when using the overlay models. Refer to the full-scale

illustrations on pages 15–16.

IMPORTANT NOTE: The weight of each door panel

-

assembly cannot exceed 50 lbs (23 kg). The total thic

k

ness of all panels for an overlay model must be at least

5

/8" (16) thick.

To install overlay panels, refer to the installation instructions shipped with each unit

. These instructions can also

be found on our website, subzero.com.

Do not exceed the dimensions listed for the overlay

grille panel. The decorative panel cannot be any larger

estrict the air flow to the compressor area

or it ma

y r

and cause problems with the operation of the unit.

Dimensions in parentheses are in

millimeters unless otherwise specified.

9

Page 10

Planning Information

WW

H

W

H

B

A

12

7

/16"

(315)

57/8"

(150)

1

/4" (6) min

FLAT L ANDING

AREA FOR BEZEL

Built-In Model 695

OVERLAY PANELS

An 11" (279) panel grille is standard on overlay applications. Optional panel grilles are available in 1" (25) height

increments from 10" (254) to 15" (381).

OVERLAY PANEL DIMENSIONS

WIDTH HEIGHT

Refrigerator Door Panel 28" (711) 68" (1727)

Refrigerator Door Spacer 271/16" (687) 671/16" (1703)

Refrigerator Door Backer 27

1

1

/16" (703) 67

1

1

/16" (1719)

Freezer Door Panel 181/4" (464) 68" (1727)

Freezer Door Spacer 175/16" (440) 671/16" (1703)

Freezer Door Backer 1715/16" (456) 6711/16" (1719)

Maximum Weight (per panel assembly) 50 lbs (23 kg)

Glasswell Cut-Out Location A – 111/16" (43)

(refrigerator door panel) B – 283/4" (730)

Glasswell Cut-Out Location A – 11/4" (31)

(refrigerator door spacer) B – 281/4" (718)

Overlay Door Panels

Overlay Grille Panel

Glasswell Cut-Out Location

(refriger

the glasswell area can range from

to a maximum of 1

thicker, you must rout out a minimum

(6) flat landing area to accommodate the

bezel surrounding the glasswell.

Dimensions in parentheses are in

millimeters unless otherwise specified.

ator door panel)

ANT NO

T

IMPOR

anel thic

TE: P

1

/8" (29). If the panel is

kness in

1

/4" (6)

1

/4"

Glasswell Cut-Out Location A – 19/16" (39)

(refrigerator door backer) B – 289/16" (726)

OVERLAY GRILLE PANEL DIMENSIONS

WIDTH HEIGHT

10" (254) Grille Panel 467/16"

10" (254) Grille Spacer 451/2"

10" (254) Grille Backer 461/8"

(1180)

(1156)

(1172)

815/16"

91/4"

85/16"

(235)

(211)

(227)

11" (279) Grille Panel 467/16" (1180) 101/4" (260)

11" (279) Grille Spacer 451/2" (1156) 95/16" (237)

11" (279) Grille Backer 461/8" (1172) 915/16" (252)

12" (305) Grille Panel 467/16" (1180) 111/4" (286)

12" (305) Grille Spacer 451/2" (1156) 105/16" (262)

12" (305) Grille Backer 461/8" (1172) 1015/16" (278)

13" (330) Grille Panel 467/16" (1180) 121/4" (311)

13" (330) Grille Spacer 451/2" (1156) 115/16" (287)

13" (330) Grille Backer 461/8" (1172) 1115/16" (303)

14" (356) Grille Panel 467/16" (1180) 131/4" (337)

14" (356) Grille Spacer 451/2" (1156) 125/16" (313)

14" (356) Grille Backer 461/8" (1172) 1215/16" (329)

15"

(381) Grille Panel 46

7

/16" (1180) 1

1

/4" (362)

4

15" (381) Grille Spacer 451/2" (1156) 135/16" (338)

15" (381) Grille Backer 461/8" (1172) 1315/16" (354)

10

Page 11

Planning Information

17/16" (37)

Width

of Stile

Adjacent

to Bezel

R

outing

Required

1

2

7

/8"

(327)

Height

o

f Bezel

111/16" (43)

Edge of

Panel to

Cut-Out

Glasswell

Cut-Out

1

Built-In Model 695

OVERLAY PANELS

For overlay models, the refrigerator door panel must

include a cut-out to accommodate the glasswell and bezel.

The thickness of the panel in this area can range from

(6) to a maximum of 1

1

/8" (29).

1

/4"

OVERLAY PANELS

Glasswell cut-out option

IMPORTANT NOTE: Regardless of the thickness of the

o

verlay panel for Model 695, you must plan for a flat

”landing” space for the decorative bezel surrounding the

glasswell area. Refer to page 10 for exact cut-out dimensions of the glasswell area in the overlay, spacer and

backer panels. This ”landing” area can be accomplished in

a number of different ways. We are showing two options

in the illustrations on this page.

The top illustration shows how you can recess the bezel

to the inset panel. You must rout out a space to accommodate the 12

7

/8" (327) height of the bezel. Also keep in

mind that the amount of material you will rout out of the

stile will vary because of the thickness of this element.

However, the width of the stile immediately adjacent to the

bezel must be 1

7

/16" (37). DO NOT cut the entire stile to

this dimension. In this illustration you can see that rails

above and below the bezel give this a finished look. Make

sure that the bezel is not supporting weight from the

panel.

The bottom illustration shows how you can box out a

landing space for the bezel using stiles and rails to create

this space. Again, keep in mind, that the total thickness of

the panel at this level must not exceed 1

1

/8" (29).

well cut-out option

Glass

Dimensions in parentheses are in

millimeters unless otherwise specified.

11

Page 12

Planning Information

131/4" (

337)

4" (102)

1

/4" (

6)

1

/4" (

6)

3"

(76)

3" (76)

237/8" (606)

BEHIND FRAME

1

2"

(51)

Glasswell

Profile

Handle

Profile

1"

(25)

Built-In Model 695

SIDE PANELS

SIDE PANELS

Side panels can be used with the framed, overlay and

stainless steel design applications. When planning for side

panels with the installation of the Built-In model, you need

to be aware of space configuration to achieve a pleasing

fit. Depending on the exact panel you are using with your

unit, the height of the panel will vary.

Cut-outs around the toe kick and grille area are required if

1

a

/4" (6) thick panel will be inserted into the main frame

channel. The panel will need to be 24" (610) deep. Refer to

the illustration on this page for placement of toe kick and

grille area cut-outs. If a

panel will abut the main frame and should be 23

3

/8" (10) thick panel is used, the

7

/8" (606)

deep. The toe kick area may or may not be cut out

depending on the look you want to achieve.

IMPORTANT NOTE: The use of side panels may change

the width of your rough opening.

Cut-outs for grille and toe kick area

HANDLE PROFILE

Handle and glasswell profile for

stainless steel Model 695

HARDWARE CONSIDERATIONS

Overlay models come without handle hardware. The

beauty of this design is that you can match the surrounding cabinet hardware. You or the cabinet manufacturer

must provide handle hardware to match the overall decorating scheme.

The handle hardware must be installed before installing

the panel assembly. Use larger D-style handles. If screws

with thick heads are used, the screws will need to be

countersunk into the door before the panel is put into

. Refer to the full-scale illustr

place

ations on pages 1

3–14

for handle hardware considerations.

IMPORTANT NOTE: Sub-Zero does not recommend using

single pull knobs on any of its Built-In models.

For overlay models, mounting placement of the refrigerator

door handle must assure pr

oper access to the glasswell

and adequate clearance under the handle. The illustration

at left shows placement of the refrigerator door handle in

relationship to the glasswell bezel on stainless steel

models.

Optional stainless steel handles are available in a variety of

diameters and lengths in the classic, platinum and carbon

stainless steel finishes and polished chrome. Contact

your Sub-Zero dealer for specifics. To obtain local dealer

information, visit the Locator section of our website,

subzero.com.

Dimensions in parentheses are in

millimeters unless otherwise specified.

12

Page 13

Planning Information

11/4"(

32) PANEL

1"(25) PANEL

1

/4"(6) P

ANEL

1

/2"(13) PANEL

3

/4"(19) PANEL

O

PTIONAL

EXTENDED

FULL-LENGTH

HANDLE

S

TANDARD

FULL-LENGTH

HANDLE

DOOR

1

/4"(

6)

FRAMED PANEL

1"

(25)

2"

(

51)

3"

(

76)

Built-In Model 695

HANDLE PROFILE – FRAMED APPLICATION

FULL-SCALE TEMPLATES

The following full-scale illustrations enable you

to under

stand some of the unique situations

you may face as you design the Built-In units

into homes. These templates can be easily

photocopied or used in y

Dimensions in parentheses are in

millimeters unless otherwise specified.

our tr

acings.

HANDLE PROFILE

The full-scale illustration above shows handle

placement for the fr

amed a

pplication standard

full-length handle and the optional extended

full-length handle shown in the dashed line.

13

Page 14

Planning Information

2" (

51)

1" (25)

S

TAINLESS STEEL

H

ANDLE PROFILE

GLASSWELL PROFILE

R

EFRIGERATOR DOOR PROFILE – TOP VIEW

DOOR

NOTE: FOR OVERLAY APPLICATIONS, OPTIONAL STAINLESS STEEL HANDLE

MUST BE MOUNTED ON PANEL MINIMUM 5/8" (16) THICK.

Built-In Model 695

HANDLE PLACEMENT MODELS – OVERLAY APPLICATION

HANDLE PLACEMENT

The full-scale illustration above shows proper

placement of the stainless steel handle for the

Model 695 refrigerator door in an overlay application.

Adequate clearance is required under the handle

to assure proper access to the glasswell.

IMPOR

TANT NOTE:For overlay applications,

the optional stainless steel handle must be

mounted on a panel at least

5

/8" (16) thick.

Dimensions in parentheses are in

millimeters unless otherwise specified.

14

Page 15

1

1

/

4

"

(32)

PA N

EL

1"

(25)

PA N

EL

*

1

/

4

"

(6)

PA N

EL

1

/

2

"

(13)

PA N

EL

3

/

4

"

(19)

PA N

EL

130˚ DOOR OPENING

WITH 2" (51) FILLER STRIP

(

TOP VIEW)

OPTIONAL

FRAMED EXTENDED

FULL-LENGTH HANDLE

STANDARD

FRAMED

FULL-LENGTH

HANDLE

D

OOR CLOSED

DOOR OPEN @ 130˚

HINGE

2" (51)

F

ILLER STRIP

MAIN FRAME

A

LLOW FOR FILLER LAP

BEHIND FLANGE

APPROX

PROFILE OF

STAINLESS

STEEL DOOR

AND HANDLE

OVERLAY PANEL

3/4" (19) THICK

(NOMINAL)

S

UB-ZERO UNITSUB-ZERO UNIT

Planning Information

Built-In Model 695

PANEL AND HANDLE PROFILE – 130˚ DOOR OPENING

The full-scale illustration above shows the panel

and handle profile of a 130˚ door opening with

2" (51) filler strip for framed applications.

Interference of door panels with handles at

maximum door s

optional 90˚ door stop available through your

Sub-Zero dealer.

Appr

*

stainless steel door

Dimensions in parentheses are in

millimeters unless otherwise specified.

oximate thic

wing ma

y require the use of an

kness of wr

.

pped

a

To obtain local dealer information, visit the

Locator section of our website, subzero.com.

The full-scale illustration on the following page

lets you see what considerations you need to

e for any overla

mak

how they may interact with adjacent cabinets

y panel applications, and

and/ or countertops.

15

Page 16

Planning Information

1

1

/4

"

(32)

PA N

EL

1"

(25)

PA N

EL

*

1

/4

"

(6)

PA N

EL

1

/2

"

(13)

PA N

EL

3

/4

"

(19)

PA N

EL

1

1

/4

"

(32)

1

1

/2

"

(38)

1

3

/4

"

(44)

0"

(0)

1"

(25)

2"

(51)

2

1

/4

"

(57)

2

1

/

2

"

(63)

2

3

/

4

"

(70)

3"

(76)

3

1

/4

"

(83)

3

1

/

2

"

(89)

1

/4

"

(6)

1

/2

"

(25)

3

/4

"

(19)

HINGE

OVERLAY PANEL

3/4" (19) THICK (NOMINAL)

DOOR CLOSED

DOOR OPEN @ 90˚

90˚ DOOR OPENING

(TOP VIEW)

M

AIN FRAME

NOMINAL OVERALL

WIDTH OF SUB-ZERO

S

UB-ZERO UNIT

237/8" (606) TO REAR

O

F SUB-ZERO

Built-In Model 695

OVERLAY PANEL APPLICATION – 90˚ DOOR OPENING

kness of wr

.

oximate thic

Appr

*

stainless steel door

Dimensions in parentheses are in

pped

a

millimeters unless otherwise specified.

16

Loading...

Loading...