Stuart D4000/EURO, D4000 Instruction Manual

Distinction Water Still

D4000 & D4000/EURO

Instruction Manual

Manuel d’utilisation

700596 / 03 2017

water still Distinction D4000

ON

OFF

2

Before use

If the equipment is not used in the manner described in this

manual the protection provided by the equipment may be

impaired.

N.B. The Distinction Water Still is classified as “Permanently

Connected Equipment” and should be connected to the

electricity supply by a qualified electrician in the manner

described in the electrical installation section of this manual.

The Distinction Water Still is designed to operate under the

following conditions:

❖ For indoor use only

❖ Ambient temperature range +5°C to +40°C

❖ Altitude up to 2000m

❖ Relative humidity not exceeding 80%

❖ Mains supply voltage fluctuations not greater than

±10% of nominal

❖ Overvoltage category II IEC60364-4-443

❖ Pollution degree 2 IEC664

Distinction Water Still

D4000 & D4000/Euro

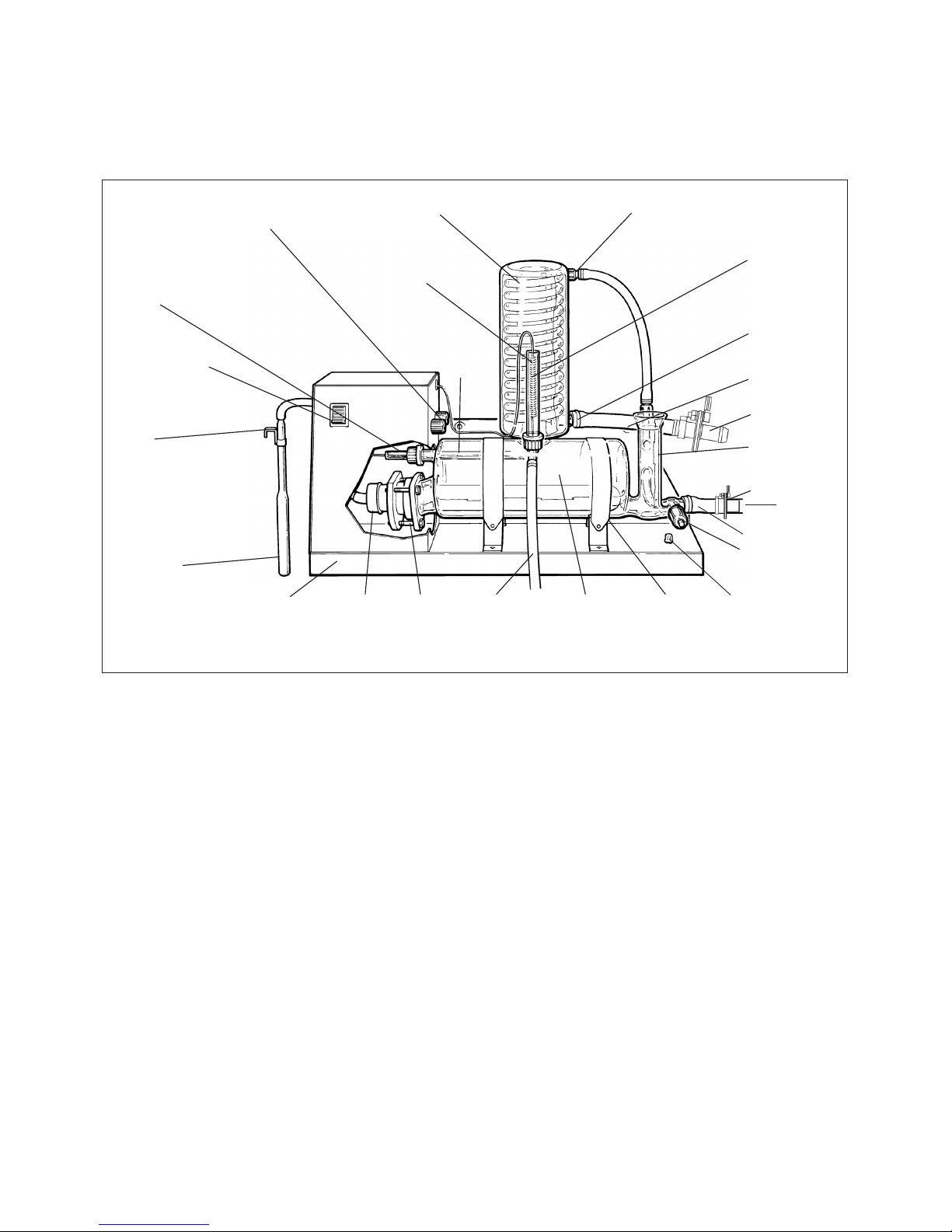

Figure 1 General assembly

Thermostat reset buttons

Boiler

thermostat

tube

On/Off switch

Clip

Reservoir

level

control

Heater Gaskets

and flange

Distillate

outlet tube

Boiler

Stand

Stopcock

To drain

Constant

level control

Wall mounting

screw holes

Condenser

cooling water

inlet

Condenser

thermostat tube

Condenser

outlet (upper)

Straps

Condenser

Condenser

thermostat

Boiler

thermostat

probe

ON

OFF

water still Dis

Hose assembly 2

Hose assembly 1

Outlet

Earth point for

earthed pipe straps

3

2. Remove the end cover from the electrical compartment by

undoing the retaining screws in the left hand panel.

3. Take the metal stand and place in the desired location. Note

that 2 screw holes are provided for wall mounting.

If wall mounting you must ensure you use appropriate

wall fixings that can hold a minimum weight of 80KG. If

you are in any doubt seek professional advice.

4. Take the boiler, the heater and the gasket kit and assemble as

shown in figure 2.

i) Place the bolts through the metal flange in the manner

shown and then place the metal flange over the tapered

glass tube of the boiler.

ii) Take the plastic insert and bend it round the glass tube

and into the metal flange. Pull the flange and insert

towards the open end of the glass tube until the insert

presses on the glass.

iii) Place the aluminium plate, followed by the silicone ring

over the heating element and locate approximately

40-45mm from the end with the electric cable, see fig. 2.

iv) Insert the heating element through the tapered glass tube

and into the boiler – ensure that there is clearance at the

inside end and no danger of the end of the element

pressing against the end of the boiler.

v) Insert the three bolts into the threaded holes in the

aluminium plate and evenly tighten. Check element is

secure and horizontal but do not over tighten bolts.

vi) Ensure the heating element is horizontal within the boiler

5. Take the two metal straps and attach the springs to the rear of

the “cradles” on the stand. Place the assembled boiler and

element onto the “cradle” of the stand. Slide the assembly

along until the protruding end of the element is located inside

the electrical compartment.

N.B. A “pip” on the bottom of the boiler locates in a hole in

the right-hand cradle.

Ensure that the boiler thermostat probe is located in the

thermostat tube.

Attach the free ends of the straps to the front of the cradle to

secure the boiler in place.

Location

The Distinction Water Still can be wall or bench mounted. Select a

convenient location which has access to the following services:-

Electricity Supply

Before connection please ensure that the line supply is suitable. The

Distinction Water Still is available in two models, model no. D4000

for supplies rated at 3kW, 220-240V 50/60 Hz single phase and

model no. D4000/EURO for supplies rated at 3kW, 200-230V,

50/60Hz, single phase. All units should be connected to the mains

supply via a double pole 30mA RCD isolating circuit breaker rated at

15A

Water Supply

A cold water supply capable of providing a minimum flow rate of

60 l/hr.

Drain

A waste water drain located below the level of the Still so that the

drain pipe can fall away straight without kinks or bends, to allow an

unimpeded flow. All water supplies and drainage systems should be

properly earth bonded.

Reservoir

A distillate collection reservoir should be located beneath the Still.

Assembly

1. Unpack the Still and identify the following components:-

Qty. Component Catalogue No.

1 Support Stand 1 Boiler D4000/B

1 Condenser WC48/M2

1 Heating element D240H for D4000

D220H for D4000/EURO

1 Hose kit W4000/HK

1 Gasket kit D4000/GK

1 Boiler thermostat tube WTT48

1 Condenser thermostat tube A515414

2 Plastic connecting caps QC18/11

2 Silicone rubber rings QR18/7 and QR18/10

1 P.T.F.E washer QW18/7

1 Reservoir level control WLS

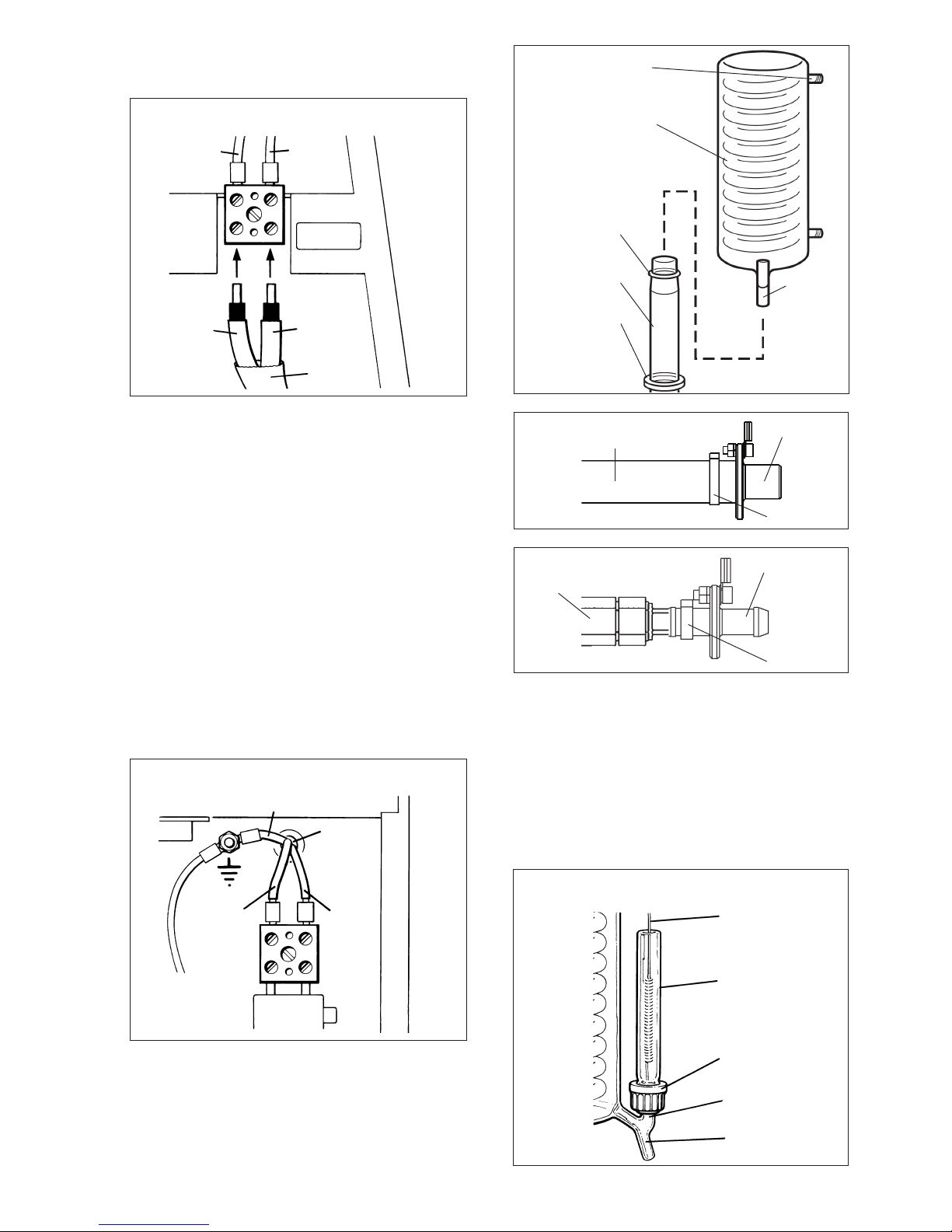

Figure 2 Heater and thermostat tube assembly

Heater

Aluminium

plate

Silicone

ring

Plastic

insert

Metal

flange

Bolts

Boiler

Screwcap

Tapered glass tube

Boiler

thermostat

tube

40-45mm

4

Identify the “condenser” thermostat and place the free end of

its probe into the thermostat tube. Carefully bend the capillary

to ensure that it does not obstruct access to the thermostat

reset buttons. - see figure 1.

13. Refer to fig. 3e. Connect the cooling water inlet of the

condenser to the connector of the 8mm bore hose of hose

assembly 2. Connect the free end of the earthed spigot of hose

assembly 2 to the cold water feed.

Select good quality tubing and secure all connections with hose

clips.

6. Connect the heater cable as shown in figure 3a.

- Push wires fully into block.

- Ensure screw terminations are tight.

7. Ensure that the sealing o-ring and stabilising o-ring are correctly

positioned, as shown in Figure 3c. Fit the condenser WC48/M2

by mounting it onto the vapour tube of the boiler. Ensure the

distillate outlet tube of the condenser faces the front and the

cooling outlet faces parallel to the unit.

8. From the hose kit take the length of 8mm bore hose fitted with

the plastic screwthread connectors at either end. Referring to

figure 1, screw one end of the hose to the condenser outlet

(upper) and the other end to the glass thread on the constant

level control.

09. Refer to fig. 3d. Carefully attach the end of the short 16mm

bore hose of hose assembly 1 to the outlet of the constant level

control. From the hose kit take the 1000mm length of 16mm

bore hose and attach to the free end of the earthed spigot. For

ease of connection, first warm the end of the hose with hot

water. Secure with the tie strap provided.

10. Lead the free end of the hose to drain, ensuring it falls away

from the Still with no kinks or bends to impede the water flow.

11. Ensure that the stopcock on the constant level control is closed.

12. Assemble the condenser thermostat tube A515414 connecting

cap QC18/11, silicone rubber ring QR18/7 as shown in figure 4a.

If the cap is left loose the assembly may now be carefully slid

over the air vent on the distillate outlet - see figure 4a.

Tighten up the cap once the tube is in place.

Figure 4a

Assembly of condenser thermostat tube

Condenser

thermostat

Condenser

thermostat

tube

Screwcap

Air vent

Distillate

outlet

Figure 3a

Heater electrical connections

Brown

Brown

Blue

Blue

Heater

cable

Heater

3kW 220/240V

Front

panel

Yellow/green

Mains

cable

Brown

Blue

N

L

Figure 3b

Figure 3c

Cooling water

outlet

Outlet

tube

Condenser

Sealing o-ring

Vapour tube

Stabilising o-ring

Figure 3d: Hose assembly 1

Connection to outlet of

constant level control

Free end

Tie-strap

Figure 3e: Hose assembly 2

Free end

Tie-strap

Connector

Mains electrical connections

5

14. Connect the distillate outlet of the condenser to a suitable

collection reservoir, using a suitable length of 9mm tubing.

A glass reservoir system is available from Cole-Parmer

(Catalogue No. WR20). Please contact the sales office for

details.

15. Replace the end panel on to the unit.

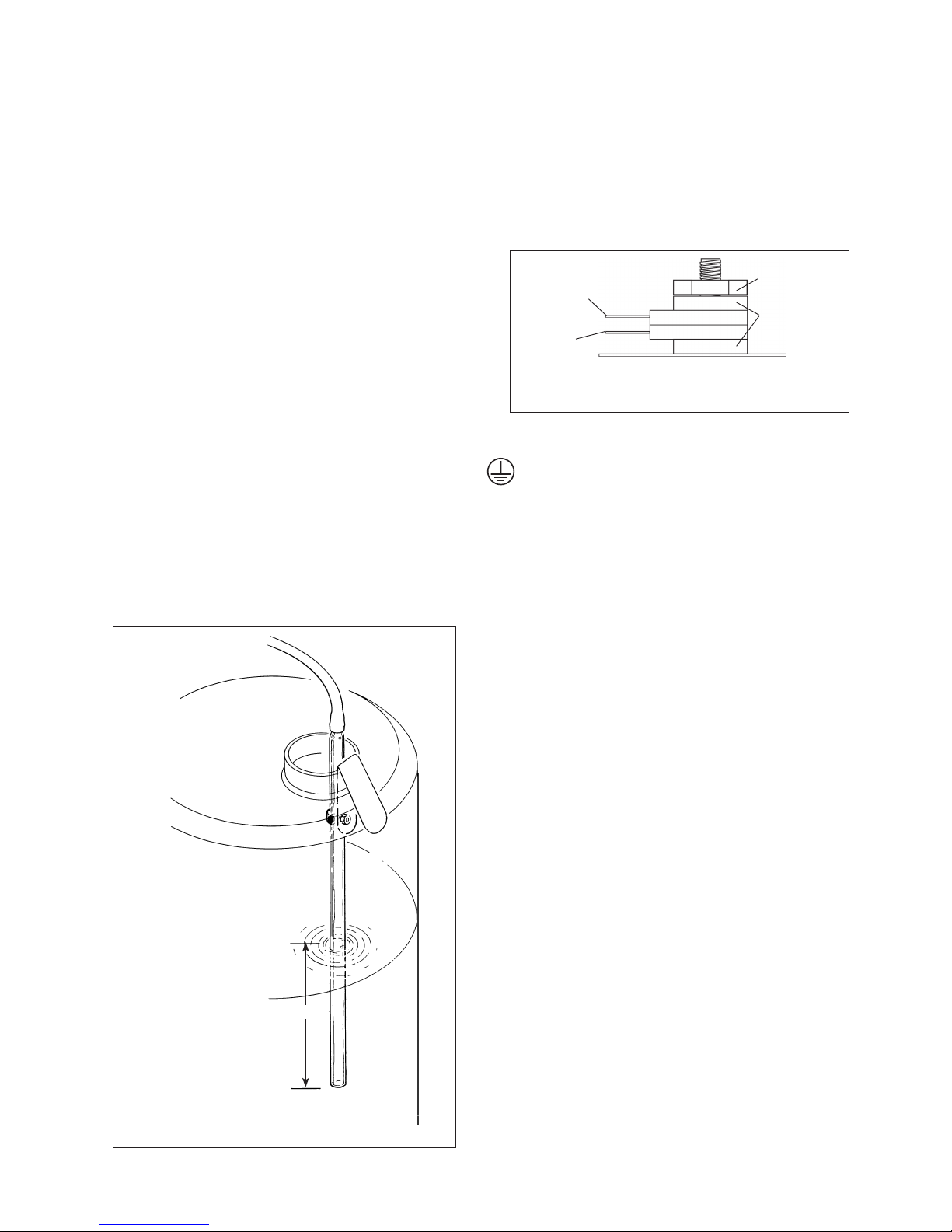

16. Take the reservoir control WLS and push the free end of the

rubber tubing onto the nozzle on the left hand end of the unit

- see figure 1.

Use the clip provided to mount the glass pressure bell in the

neck of the distillate reservoir.

Adjust the height of the pressure bell so that the open end is

approx. 140mm below the maximum distillate level.

Fitting the Reservoir Control WLS to Collection Vessels

- Position the distillate collection reservoir in a suitable location.

This should be below the water still so that the vinyl rubber

tubing transporting the distilled water from the still can fall

down to the reservoir without restrictions, kinks or U bends.

- Take the Reservoir Level Control WLS and connect the free end

of the rubber tubing to the nozzle, of the reservoir pressure

switch located on the side of the stand.

- Use the metal clip to fit the glass pressure bell inside the

distillate collection reservoir. Refer to fig. 4b.

- Position the bell so that the open end is 140mm below the

desired distillate level.

17. Ensure that the earthed spigot wires are connected to the earth

point see fig 1.

18. Turn on the water supply to fill boiler and check for leaks then

turn off the water supply.

Fig 4b

WLS Reservoir level control

140mm

Electrical installation

THIS EQUIPMENT MUST BE EARTHED!

The electrical installation should be carried out by a qualified

electrician. The following method is recommended.

The earthed spigots should pass a high current (i.e. >200mA) earth

continuity test.

The equipment is supplied with 1.5m of PVC/PVC flexible, triple

core, circular cable with the following specification, 1.5mm

2

to BS

6500 or equivalent and <HAR> or BASEC approved.

The cable gland is designed to accept cable whose diameter is

>7.0mm and <10.5mm. It is recommended that, at the connection

to the mains electrical supply, there is fitted a 30mA RCD circuit

breaker with a continuous current carrying capacity of 15 amps at

250V, and rated at an overcurrent protection level of 15A . These

devices should be sited near to the equipment and be clearly marked

“Disconnect device for ‘Distinction’ Water Still”.

NOTE: Do not connect to electricity supply with a 13 amp

plug.

Cable connections are shown in figures 3a and 3b. Connect to the

line supply noting that the wires in the instrument lead are coloured

in accordance with the following code:

Blue - Neutral

Brown - Live

Green & Yellow - Earth

Mains Cable Replacement

If the mains cable requires replacement, only cable with the

specification given above should be used.

For live and neutral leads use bootlace crimps, size 1.5mm, with a

performance conforming to BS 4G178 part 1, 1984 and part 2,

1986.

For the earth lead use 1.5mm, M4 eyelet crimps with a performance

conforming to BS 4G178 part 1, 1984 and part 2, 1986. A suitable

crimp tool should be used.

Operation

1. Turn on the cold water supply and adjust the flow to approx. 60 l/

hr. Observe that the water flows via the condenser and into the

boiler. Wait until the boiler has attained its correct operating level

and make sure that the excess water is flowing freely to drain.

1. For hose assembly 1 follow fitting instruction 9.

2. Ensure that the earth wire is connected correctly to the earth

post - see figs 1 and 4c.

3. For hose assembly 2, please follow fitting instruction 13.

4. Ensure that the earth wire is connected to the earth post - see

figs. 1 and 4c.

Replacing earthed hose

assemblies

Hose

assembly 2

Figure 4c Earth post connection

Nut

Hose

assembly 1

Shake

proof

washers

Loading...

Loading...