Aquatron

Automatic Water Stills

A4000 A4000D & A8000

Assembly and

operating instructions

Version 2.3

Contents

Location and Services 3

A4000 - Components, Assembly, Operation & Spares 4

A4000D - Components, Assembly, Operation & Spares 9

A8000 - Components, Assembly, Operation & Spares 14

Distillate Collection & Reservoir System 19

Connection of Aquatron Stills to Deionised and Pre-treated Water Supplies 20

Cleaning 22

Fault Finding 23

Circuit & Wiring Diagrams 24

The Aquatron Water Still complies with the

following European Directives:

89/336/EEC - E.M.C. DIRECTIVE

Amended by 92/31/EEC and 93/68/EEC

73/23/EEC - L.V.D. Amended by 93/68/EEC

Limitations of use

This product meets the applicable E.C. harmonised

standards for radio frequency interference and may

be expected not to interfere with, or be affected by

other equipment with similar qualifications. We

cannot be sure that other equipment used in its

vicinity will meet these standards and we cannot

guarantee that interference will not occur in practice.

Where there is a possibility that injury, damage or loss

might occur if equipment malfunctions due to radio

frequency interference, or for general advice before

use, please contact the Technical Service Department

of Bibby Scientific Ltd.

Location & Services

In order to obtain the optimum performance from your new

Aquatron careful consideration should be given to the intended

location and the availability of services such as water, electricity

and drain.

Please study the following notes before commencing installation.

Before Use

If the equipment is not used in the manner described in this

manual then its performance and operation will be impaired.

Aquatron water stills are designed to operate under the following

conditions:

❖ For indoor use only.

❖ Ambient temperature +5°C to +40°C.

❖ Altitude up to 2000m.

❖ Relative humidity not exceeding 80%.

❖ Mains supply voltage fluctuates not greater than ±10% of normal.

❖ Over voltage Category II IEC60364-4-443.

❖ Polluting degree 2 IEC664.

1. Bench Wall Mounting

Aquatron models A4000 and A8000 can be either bench or

wall mounted and a bracket is provided for the latter purpose.

A gap of at least 50cm should be left at the right hand end of

the unit to allow access to the heating elements.

For reasons of weight, models A4000D and A8000 are best

bench mounted, but if it is desired to elevate the unit then a

stout shelf should be used.

2. Electricity Supply

N.B. The Aquatron Water Still is classified as

“Permanently Connected Equipment” and should be

connected to the electricity supply by a qualified

electrician in the manner described in the electrical

installation section of this manual.

The Aquatron stills are available in three models, A4000,

A4000D & A8000.

A suitable supply for the A4000 is rated at 3kW, 220-240v,

50/60Hz~ single phase. A suitable supply for the A4000D &

A8000 is rated at 6kW, 220-240v, 50/60Hz~ single phase.

A4000 units should be connected to the mains supply via a

double pole 30mA Residual Current Breaker with over current

protection (RCBO) isolating circuit breaker rated at 15A.

A4000D and A8000 units should be connected to the mains

supply via a double pole 30mA Residual Current Breaker with

over current protection (RCBO) isolating circuit breaker rated at

32A.

If you have any doubts about the suitability of your supply,

consult a qualified electrician before installing your Aquatron

still.

4. Drain

A waste water drain is required. It is important that the

distance between the drain and the water still is kept as short

as possible to reduce the possibility of pressure build-up.

Similarly, the drain pipe from the still should fall straight,

without any kinks or bends, to allow an unimpeded flow. It is

also recommended that the unit is connected to properly earth

bonded water supplies and drainage systems.

5. Storage Tank

A suitable reservoir, the WR20 for instance, is required for the

collection of the distillate. This should be positioned beneath

the still ensuring that the distillate can flow into the reservoir

without hindrance.

6. Maintenance

The location of the still should facilitate easy access for routine

cleaning and maintenance. With regards to the latter, it is

recommended that a space of at least 50cm be provided on the

right hand side of the water still cabinet. This is to allow the

removal of the side cover and replacement of the heating

element.

7. Warranty

Bibby Scientific Ltd warrants this instrument to be free from

defects in material and workmanship, when used under normal

laboratory conditions, for a period of three (3) years. In the

event of a justified claim Bibby Scientific will replace any

defective component or replace the unit free of charge.

This warranty does NOT apply if damage is caused by fire,

accident, misuse, neglect, incorrect adjustment or repair,

damage caused by incorrect installation, adaptation,

modification, fitting of non approved parts or repair by

unauthorised personnel.

This Warranty does not include the heater element which

is only guaranteed for 1 year.

3. Water Supply

A cold water supply is required for coolant and feed purposes.

This may be from the mains supply or a header tank having a

flow capacity of at least 1 litre/min. for the A4000 and 2 litres/

min. for the A8000 and A4000D. The pressure range should be

within 3-100 p.s.i. (0.2–7 x 105Nm-2).

If the feed water quality is poor and likely to contain particulate

matter, such as rust or silt, it is advisable to fit a pre-filter unit

before the still.

3

A4000

Fig. 1

5

4

6

7

Lid

8

9

10

3

1

2

20

22 21

24

23

19

18

End

Plate

11

12

13

14

15

16

17

List of Major Components – A4000

Item Description Part

no. number

1 Perspex Screen M484

2 Boiler WBA

3 Funnel WF48

4 Condenser WC48/M2

5 Wall Mounting Bracket M510G

6 Green ‘Mains On’ Indicator 700691 (S)

7 White ‘On/Off’ Switch 700988 (S)

8 Amber ‘Reservoir Full’ Indicator 700987

9 White ‘Clean’ Switch 700988 (S)

10 Reservoir Pressure Switch WPS

11 Heaters Connector Terminal A4000/HTB

12 Water Flow Sensor Assembly I/A4000HK/1

Item Description Part

no. number

13 Solenoid Assembly A4000/SA

14 Mains Water Mini Valve Assembly 7001059 (S)

15 Reservoir Water Level Sensor WLS

16 Distillate Outlet Pipe (Bench Mounted) –

17 Cooling Water Pipe to Drain (16mm) –

18 Heater Assembly A4000/HA

19 Thermostat WT4

20 Rotaflo Stopcock A4000/RCOCK

21 Distillate Outlet (Wall Mounted) –

22 Boiler Level Control WL48

23 Boiler Plastic Coupling WBC1

24 Boiler Retaining Spring 700007

4

A4000 Assembly

Your Aquatron A4000 has been designed with ease of assembly

specifically in mind. Please study the installation diagram and the

enclosed DVD before commencing the installation. Follow the

sequence of instructions and do not connect the mains electricity

supply until directed.

1. From the outer packaging remove all the components including

the metal cabinet containing the glass boiler.

2. Before unpacking the individual components, identify them on

the check list below:

A4000 Unit containing boiler.

Condenser – WC48/M2

Heater – W48H

Boiler Level Control – WL48

Funnel – WF48

Reservoir Water Level Sensor – WLS

Output Hose Assembly – I/A4000HK/2

Hose Kit – I/WH48/1/B

Wall Mounting Bracket – M510G

3. Remove the perspex viewing screen (Fig. 1, item 1) from the

unit by lifting it up using the finger recess. Remove the internal

packaging carefully. Snip the temporary ties holding the boiler

retaining springs (Item 24).

4. Remove the end plate and lid by removing the retaining screws.

5. Ensure that the sealing O ring and the stabilising O ring are

correctly positioned on the vapour tube of the boiler. Fit the

condenser (Fig. 1, item 4) to the vapour tube ensuring that the

distillate outlet faces the front and the two water connections

are parallel to the unit Fig 1a. When slight resistance is felt

when fitting the condenser, press down slightly on the top

of the condenser until a gap of approximately 19mm exists

between the condenser and the boiler.

Cooling water outlet

Condenser

Sealing o-ring

7. Take the boiler level control WL48 (Fig. 1, item 22). Remove the

end split nut and central part of the boiler plastic coupling (Item

23) leaving the other split nut in place, and the internal seal

in the boiler level control. Ensure the Rotaflo stopcock is fully

closed (screwed down).

8. Take the 16mm earth spigot located inside the A4000 and

place the 16mm tubing part of it into a beaker of hot water for

approximately 20 – 30 seconds; this will make the tubing more

supple. Connect the 16mm tubing to the boiler level control

(Item 22) drain connection (below the Rotaflo stopcock). Secure

with a tie wrap.

9. Take the 1m length of 16mm hose from hose kit I/WH48/1/B.

Place one end into a beaker of hot water for approximately

20 – 30 seconds. Thread the tube through hole (Fig. 1, item

17) until approximately 300mm of tubing is inside the cabinet.

Connect to the 16mm earth spigot and secure with a tie wrap.

10. Pull the 16mm hose back out of the cabinet until a gap of

approximately 5mm exists between the boiler level control and

the boiler connection.

11. Place the boiler plastic coupling split nut and central part onto

the boiler connection. Connect the boiler level control to

the boiler, ensuring that the internal seal of the boiler plastic

coupling is fitted inside the boiler connection and the boiler

level control connection. Tighten the boiler plastic coupling.

12. Loosen the black cap on top of the boiler level control. Fit the

funnel into the top of the boiler level control and tighten the

black cap.

13. Take the hose assembly I/A4000HK/2 and connect the end

marked ‘2’ to the top connection of the condenser. Connect

the other end marked ‘3’ to the boiler level control.

14. Identify the water flow sensor assembly (Fig. 1, item 12) inside

the cabinet. Connect the red connector marked ‘1’ to the

bottom connection of the condenser. It may be necessary to

slightly twist the condenser to release any kinks in the water

sensor assembly.

15. Remove the heater black cap and rubber ring from the boiler.

Place the black cap onto the heater until it is approximately

25mm from the electrical connectors end. Push the rubber ring

onto the heater and into the black cap.

16. Fit the heater into the boiler and screw on the black cap. When

the black cap is tight push the heater through the black cap

until the end of the heater sits in the nodule at the end of the

boiler.

Do not overtighten the screw cap as this may cause the

boiler to break, or push the heater in too far as this may

break the nodule.

Vapour tube

Distillate

Outlet

Stabilising o-ring

Fig. 1a

6. Take the 1m length of 8mm hose from hose kit I/WH48/1/B

and connect one end to the distillate outlet of the condenser

(Fig. 1a). Secure with a tie wrap. Pass the other end of the tube

through the cabinet hole, Fig. 1, item 21 if to be wall mounted,

or hole, Item 16 if bench mounted.

Relay

Fig. 1b

PCB

Thermostat

Heater

Terminal

Blocks

N

E

L

Heater

lead

5

17. Thread the two heater connectors through the hole into the

I/A4000HK/1

I/A4000HK/2

I/WH48/1/B

16mm tubing x 1m - I/WH48/1/B

Solenoid

Condenser

Thermostat &

Thermostat Glass

Heater

Boiler

Level

Control

Funnel

Rotaflo Stopcock

1

2

3

Water Flow Switch

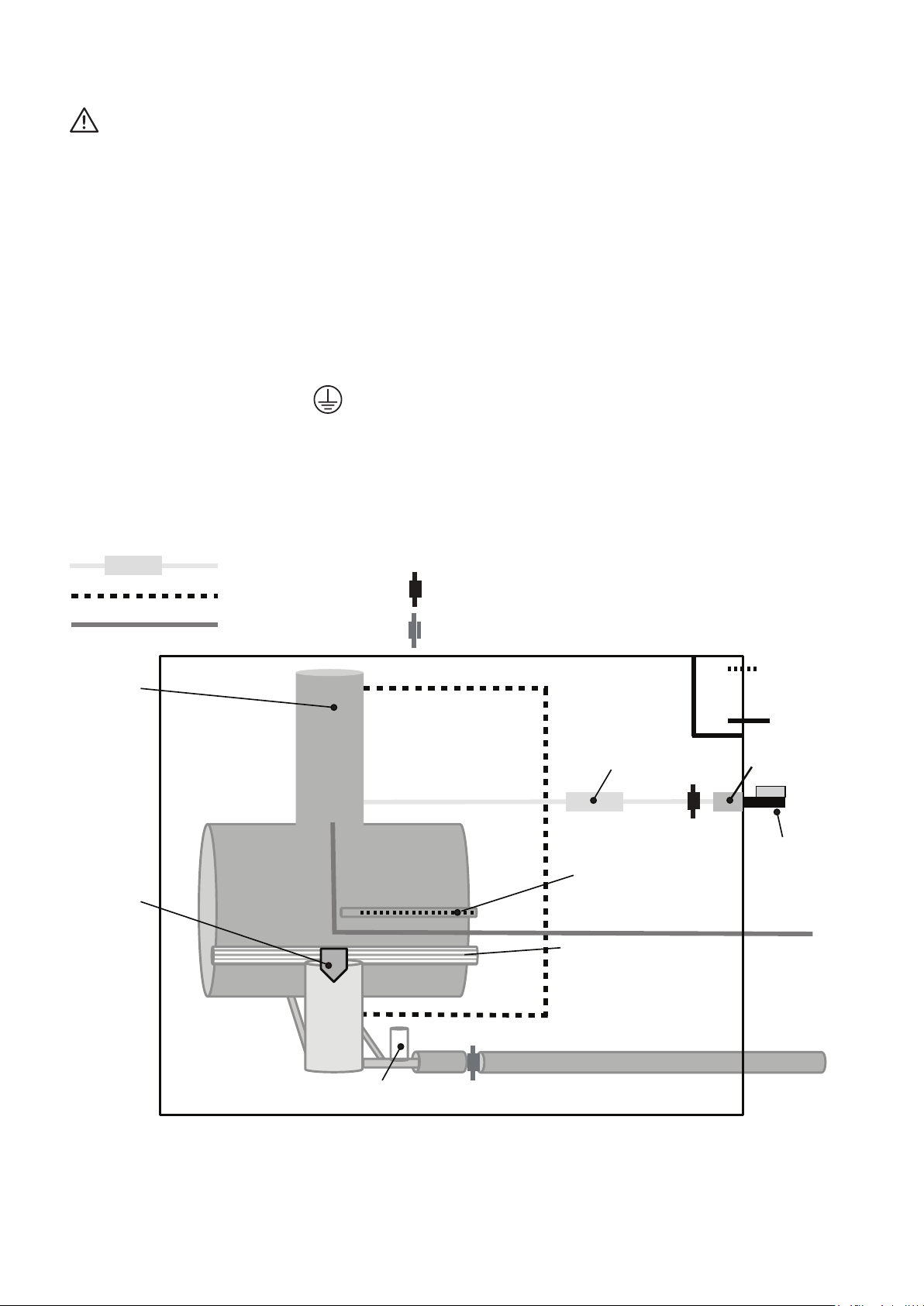

A4000 Installation Diagram

Boiler

Mains Water

Inlet Mini

Valve

Electrics

Reservoir

Water Level

Sensor

8mm Earth Spigot

16mm Earth Spigot

To Distillate

Reservoir

To Drain

electrical control compartment and connect to the heater

terminal block. Brown to Brown, Blue to Blue, (Fig. 1b).

SAFETY: It could be possible to mis-locate the heater

crimps on to the heater terminal block tags. Ensure

that the heater crimps are properly located onto

the heater terminal block tags and fully locked on.

Attempt to pull the crimp off the tag to ensure full

attachment.

18. Refit the end plate and lid.

19. Move the unit to its working location. If it is to be wall

mounted use the mounting bracket (Fig. 1, item 5). Ensure a

space of at least 50cm to the right of the unit to allow access.

20. Connect the cold water supply to the mains water inlet. The

tubing selected should have a safe working pressure of at

least equal to the pressure of the water supply and should be

adequately secured with hose clips.

DO NOT TURN ON WATER SUPPLY

21. THIS EQUIPMENT MUST BE EARTHED!

Carry out the electrical installation. This should only be carried

out by a suitably qualified electrician.

The A4000 is classed as permanently connected equipment. The

earth spigots should pass a high current (ie. >200mA).

The equipment is supplied with 1.5m of flexible, triple

core, circular cable to the following specification:

1.5mm², to BS 6500 or equivalent and <HAR> or BASEC

approved.

Connection to the mains electrical supply should be via a

double pole 30mA Residual Current Breaker with Overcurrent

protection (RCBO) isolating circuit breaker switch with a

continuous current carrying capacity of 15A at 250V and

overcurrent of 15A.

DO NOT SWITCH ON ELECTRICAL SUPPLY.

22. Connect the reservoir water level sensor WLS (Fig. 1, item 15) to

the A4000 and secure with a tie wrap.

Place the glass pressure bell in the collection reservoir, following

the instructions given on page 19.

23. Operate the A4000 Waterstill as per Operating Instructions and

check for leaks.

24. Fit the Perspex viewing screen

A4000 Installation Diagram

6

A4000 Operation

The following instructions apply to the A4000 water still where the

water feed to the boiler is via the mains supply or a header tank.

1. Before switching on either the mains electricity or water supply,

identify the control switches and indicator lights on the front of

the cabinet.

Green Light – When illuminated this shows that there is mains

supply voltage to the unit. Under no circumstances should the

cabinet end-panel be removed when this light is illuminated.

White ‘On/Off’ Switch – This is the primary switch for

controlling water and electricity inside the still. The switch

illuminates when pressed in the ON position.

Amber Light – When illuminated, this indicates that the

distillate collection reservoir is full as detected by the level

control.

White ‘Clean’ Light – This shuts off the heating element but

allows water to flow into the boiler when the still is being

commissioned or cleaned. When pressed in the CLEAN position

the switch illuminates.

2. Carefully check the following:

The appropriate electricity, water and drain services have been

provided. If in doubt, consult the LOCATION & SERVICES

SECTION of this manual.

The ON/OFF switch on the control panel is in the OFF position.

The CLEAN switch is pressed in the CLEAN position.

The Rotaflo stopcock on the boiler level control is closed.

The reservoir water level sensor is fitted to the distillate

collection vessel.

The dummy shorting plug is fitted to the boiler level control DIN

socket on the cabinet.

3. Ensure all earth leads are connected to the earth point.

4. Check all glassware for any damage.

5. Switch on the electricity supply – the green light illuminates.

6. Press the ON/OFF switch to the ON position – the switch will

illuminate.

7. Recheck that the CLEAN switch is in the CLEAN position and

illuminated.

8. Turn on the mains water supply and using the mini valve

assembly, adjust the flow rate to approximately 1 litre/min. This

can be achieved by observing the drain water from the boiler

level control and adjusting the mini valve assembly accordingly.

9. Check for water leaks.

10. Observe the boiler now filling with water to cover the heating

element. When water has reached the pre-set limit, the excess

will discharge to drain. Check the water drains freely and does

not back up into the boiler level control.

11. Switch the CLEAN button off by pressing it a second time. The

switch light goes out.

12. The heater will now warm up and eventually run at a red glow.

If the flow rate is insufficient, the heater will not switch on. This

will require adjustment of the mini valve assembly to be opened

further. After about 2 – 3 minutes of operation distilled water

will emerge from the outlet pipe falling into the collection

reservoir.

13. To avoid excess wastage of coolant water, make further

adjustments to the mini valve assembly. Slowly reduce the flow

rate until the flow control switch switches off the heater, then

increase the flow until the power is restored.

14. Refit the Perspex screen.

15. Safety Cut-Outs – All Aquatron water stills are protected by

the following safety devices.

Flow Control Switch – Monitors the flow of coolant water

into the still and shuts off the heating element if the flow is

insufficient.

Thermostat Cut-Out – In normal operation the water within

the glass will be at 100°C. In single fault conditions, i.e. in

the event of water supply failure, the content will increase

to 112°C where upon a resettable thermostat will operate.

Once switched, the thermostat has to be manually reset. This

is achieved by unscrewing the black knob located inside the

cabinet and pressing the reset button.

Reservoir Control – Is positioned in the collection reservoir

and switches off both the electricity and water supplies when

the reservoir is full of distillate water. The water supply is shut

off after around 7 minutes after the reservoir is full to allow the

heating element to cool.

It is recommended that the operation of the flow switch and

reservoir control is checked on a regular basis.

a. Simulation of Mains Water Supply Failure

Turn off the mains water supply at the tap. This should switch

off the heating element. Turning the tap on again will switch

the heater on.

b. Simulation of Reservoir Full Condition

Lower the glass pressure bell of the reservoir water level sensor

into the distillate to a depth of 150mm. This will switch off the

heating element immediately and the cooling water after 7

minutes. Raising the bell will cause both to be switched back

on.

16. Switching Off – Push the CLEAN switch to the ON position.

Wait until the residual heat contained in the heating element

has dispersed and no boiling is evident. Turn off water supply.

Push ON/OFF switch to OFF position. Isolate from mains

electricity supply.

7

A4000 Spares

Boiler WB4

Funnel WF48

Condenser WC48/M2

‘Mains On’ Green Indicator 700691(S)

‘On/Off’ White Switch 700988(S)

‘Reservoir Full’ Amber Indicator 700987

‘Clean’ White Switch 700988(S)

Reservoir Pressure Switch WPS

Heater Terminal Block A4000/HTB

Solenoid Assembly A4000/SA

Water Flow Sensor Assembly and Hoses I/A4000HK/1

Condenser to Boiler level control Hose (Output Hose Assembly) I/A4000HK/2

Reservoir Water Level Sensor WLS

Mains Water Mini Valve Assembly 7001059(S)

Thermostat Glass Tube WTT48

Thermostat WT4

Boiler Level Control WL48

Boiler Plastic Coupling WBC1

Heater Assembly A4000/HA

Heater Assembly 220V A4000/HA220

Boiler Retaining Spring 700007

Rotaflow Stop Cock Assembly A4000/RCOCK

6 Way Electrical Terminal Block A4000/ETB

Ceramic Terminal Block A4000/CTB

5 DIN Socket Assembly A4000/DIN

Boiler Vapour Tube Sealing O Ring I/M502

Boiler Vapour Tube Stabilising O Ring I/QR38/24

Relay Assembly A4000/RA

PCB 700804(ES)

Distillate Output and Boiler Level Control Drain Hose Kit I/WH48/1/B

Wall Mounting Bracket M510G

Black Phenolic Screw Cap I/QC38/25

8

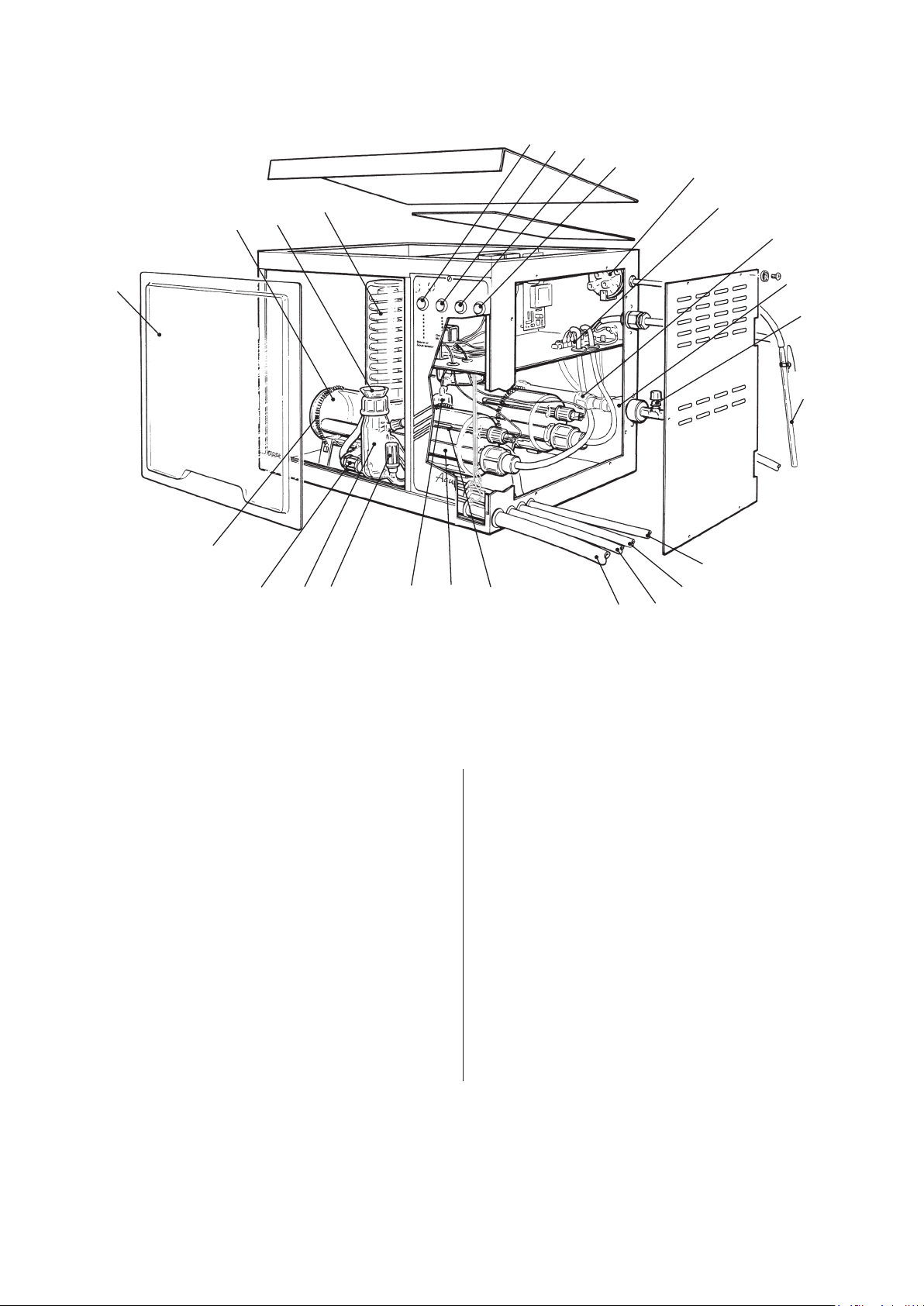

A4000D

Fig. 2

Lid

5

6

7

8

9

3

2

1

25

24

4

23 22 21

19

20

17

18

10

11

12

13

14

End

Plate

15

16

List of Major Components – A4000D

Item Description Catalogue

no. number

1 Perspex Screen M484

2 Boiler (2 off) WB4

3 Funnel WF48

4 Condenser (2 off) WC48/M2

5 Green ‘Mains On’ Indicator 700691(S)

6 White ‘On/Off’ Switch 700988(S)

7 Amber ‘Reservoir Full’ Indicator 700987

8 White ‘Clean’ Switch 700988(S)

9 Reservoir Pressure Switch WPS

10 Terminal Strip for Heaters A4000/HTB

11 Water Flow Sensor Assembly I/A4000DHK/1

12 Solenoid Assembly A4000/SA

13 Mains Water Inlet Valve Assembly 7001059(S)

Item Description Catalogue

no. number

14 Reservoir Water Level Sensor WLS

15 Distillate Outlet Pipe –

16 Drain Pipe from W4L2A –

17 Cooling Water Pipe to Drain (8mm) –

18 Cooling Water Pipe to Drain (16mm) –

19 Thermostat (2 required) WT4

20 Heater Assembly (2 required) A4000/HA

21 Boiler Level Control (rear) W4L2A

22 Rotaflo Stopcock A4000/RCOCK

23 Boiler Level Control (front) WL48

24 Boiler Plastic Coupling WBC1

25 Retaining Springs 7000007

9

A4000D Assembly

Your Aquatron A4000D has been designed with ease of assembly

specifically in mind. Please study the installation diagram and the

enclosed DVD before commencing the installation. Follow the

sequence of instructions and do not connect the mains electricity

supply until directed.

1. From the outer packaging remove all the components including

the metal cabinet containing the glass boiler.

2. Before unpacking the individual components, identify them on

the check list below:

A4000D Unit containing 2 boilers.

Condenser – WC48/M2 x2

Heater – W48H x2

Boiler Level Control (Front) – WL48

Boiler Level Control (Rear) – W4L2A

Funnel – WF48

Reservoir Water Level Sensor – WLS

Hose Kit – I/WH48/3/B

3. Remove the perspex viewing screen (Fig. 2, item 1) from the

unit by lifting it up using the finger recess. Remove the internal

packaging carefully. Snip the temporary ties holding the boiler

retaining springs (Item 25).

4. Remove the cabinet end plate and lid by removing the retaining

screws.

5. Withdraw the metal thermostat probe (Fig. 2, item 19) from the

glass tube inside the front boiler.

6. Remove the front boiler by releasing the retaining springs.

7. Ensure that the sealing O ring and the stabilising O ring are

correctly positioned on the vapour tube of the rear boiler

(Fig 2a).

Cooling water outlet

9. Fit the condenser to the vapour tube of the rear boiler ensuring

that the distillate outlet faces the front and the two water

connections are parallel to the unit. When slight resistance is

felt when fitting the condenser, press down slightly on the top

of the condenser until a gap of approximately 19mm exists

between the condenser and the boiler.

10. Pass the free end of the 8mm tubing through the hole (Fig. 2,

item 15).

11. Take the rear Boiler Level Control W4L2A and connect the 8mm

x 300mm vinyl tubing from hose kit I/WH48/3/B to the side arm

and tie wrap (Fig. 2b). Remove the end split nut and central

part of the boiler plastic coupling leaving the other split nut

on, and the internal seal in the boiler level control. Ensure the

Rotaflo stopcock is fully closed (screwed down).

12. Connect the tubing of the 8mm earth spigot hose assembly to

the drain of the rear boiler level control W4L2A and tie wrap.

13. Take the 8mm x 1m vinyl tubing from hose kit I/WH48/3/B and

connect to the 8mm earth spigot hose assembly in step 12 and

tie wrap. Pass the free end of the 8mm tubing through the hole

(Fig. 2, item 16).

14. Place the boiler plastic coupling split nut and central part onto

the rear boiler connection. Connect the boiler level control to

the boiler, ensuring that the internal seal of the boiler plastic

coupling is fitted inside the boiler connection and the boiler

level control connection. Tighten the boiler plastic coupling.

15. Connect the plug of the rear boiler level control to the DIN

socket connector.

Fig 2b: Rear

2

To boiler

level

socket

Water

flow

sensor

assembly

and hoses

Rotaflo

Stopcock

Vent pipe

Condenser

distillate

outlet tube

Side arm

3

1

Condenser

Sealing o-ring

Vapour tube

Distillate

Outlet

Stabilising o-ring

Fig. 2a

8. Select 8mm tubing x 1m from hose kit I/WH48/3/B and connect

one end to the distillate outlet connection (Bottom) of one of

the condensers (Fig. 2a). Secure with a tie wrap.

Lower drain

outlet

8mm Earth spigot

hose assembly

W4L2A

From distillate of first condenser

To drain

16. Refit the front boiler. Refit the thermostat probe removed in

step 5.

17. Fit the condenser to the front boiler vapour tube ensuring

that the distillate outlet faces the front and the two water

connections are parallel to the unit. When slight resistance is

felt when fitting the condenser, press down slightly on the top

of the condenser until a gap of approximately 19mm exists

between the condenser and the boiler.

18. Connect the free end of the 8mm x 300mm tubing connected

to the rear boiler level control side arm, to the distillate outlet of

the front condenser (Fig. 2c).

19. Take the front Boiler Level Control WL48, remove the end

split nut and central part of the boiler plastic coupling leaving

the other split nut on, and the internal seal in the boiler level

control. Ensure the Rotaflo stopcock is fully closed (screwed

down).

10

Fig. 2c

Front

Distillate

WBC1

WL48

3

4

Vent

pipe

1

To W4L2A

level control

Water flow

sensor

assembly

To drain

2

5

Outlet of

level control

Rotaflo

stopcock

16mm Earth spigot

hose assembly

To drain

20. Take the 16mm earth spigot and place the 16mm tubing part of

it into a beaker of hot water for approximately 20 – 30 seconds;

this will make the tubing more supple. Connect the 16mm

tubing to the front boiler level control drain connection (below

the Rotaflo stopcock). Secure with a tie wrap.

21. Take the 1m length of 16mm hose from hose kit I/WH48/3/B.

Place one end into a beaker of hot water for approximately

20 – 30 seconds. Thread the tube through the hole (Fig. 2, item

18) until approximately 300mm of tubing is inside the cabinet.

Connect to the 16mm earth spigot and secure with a tie wrap.

22. Pull the 16mm hose back out of the cabinet until a gap of

approximately 5mm exists between the boiler level control and

the boiler connection.

23. Place the boiler plastic coupling split nut and central part

onto the boiler connection. Connect the boiler level control to

the boiler, ensuring that the internal seal of the boiler plastic

coupling is fitted inside the boiler connection and the boiler

level control connection. Tighten the boiler plastic coupling.

24. Locate the tube assemblies inside the cabinet and connect the

numbered connectors as follows:

1 – Bottom connection of rear condenser.

2 – Bottom connection of front condenser.

3 – Top connection of rear condenser.

4 – Top connection of front condenser.

5 – Front Boiler Level Control.

25. Pass the remaining length of 8mm tubing through hole (Fig. 2,

item 17).

26. Loosen the black cap on the boiler level control. Fit the funnel

into the top of the boiler level control and tighten the black

cap.

27. Remove the heater black cap and rubber ring from the rear

boiler. Place the black cap onto one of the heaters until it is

approximately 25mm from the electrical connectors end. Push

the rubber ring onto the heater and into the black cap.

28. Fit the heater into the boiler and screw on the black cap. When

the black cap is tight push the heater through the black cap

until the end of the heater sits in the nodule at the end of the

boiler.

Do not overtighten the screw caps as this may cause the

boiler to break, or push the heaters in too far as this may

break the nodule.

29. Repeat steps 27 & 28 for front heater.

30. Pass the electrical cables of the heaters up into the electrical

control compartment via the two orifices. Push the spade

connections onto the heater terminal block. Brown to Brown,

Blue to Blue (Fig. 2d).

SAFETY: It could be possible to mis-locate the heater

crimps on to the heater terminal block tags. Ensure that

the heater crimps are properly located onto the heater

terminal block tags and fully locked on. Attempt to pull

the crimps off the tags to ensure full attachment.

N

E

Relay

Relay

PCB

Heater lead (back)

Heater

Terminal

Blocks

Thermostat

(Rear)

Thermostat

(Front)

L

Heater

lead

(front)

Fig. 2d

31. Refit the end plate and lid.

32. Move the unit to its working location. Ensure a space of at least

50cm to the right of the unit to allow access.

33. Connect the cold water supply to the mains water inlet. The

tubing selected should have a safe working pressure of at

least equal to the pressure of the water supply and should be

adequately secured with hose clips.

DO NOT TURN ON WATER SUPPLY

34. THIS EQUIPMENT MUST BE EARTHED!

Carry out the electrical installation. This should only be carried

out by a suitably qualified electrician.

The A4000D is classed as permanently connected equipment.

The earth spigots should pass a high current (ie. >200mA).

The equipment is supplied with 1.5m of flexible, triple

core, circular cable to the following specification:

4.0mm², to BS 6500 or equivalent and <HAR> or BASEC

approved.

Connection to the mains electrical supply should be via a

double pole 30mA Residual Current Breaker with Overcurrent

protection (RCBO) isolating circuit breaker switch with a

continuous current carrying capacity of 30A at 250V and

overcurrent of 30A.

These devices should be sited near to the equipment and clearly

marked ‘Disconnect device for Aquatron water still’

DO NOT SWITCH ON ELECTRICAL SUPPLY.

35. Connect the reservoir water level sensor WLS (Fig. 2, item 14) to

the A4000D and secure with a tie wrap. Place the glass pressure

bell in the collection reservoir, following the instructions given

on page 19.

36. Operate the A4000D Waterstill as per Operating Instructions

and check for leaks.

37. Fit the Perspex viewing screen.

11

Rotaflow Stopcock

3

I/A4000DHK/1

I/A4000DHK/2

I/WH48/3/B

Solenoid

Boiler

Level

Control

Rotaflo Stopcock

1

2

5

Water Flow Switch

Mains Water

Inlet Mini

Valve

Electrics

Reservoir

Water Level

Sensor

8mm Earth Spigot

8mm Earth Spigot

16mm Earth Spigot

To Distillate

Reservoir

To Drain

4

To Drain

16mm tubing x 1m - I/WH48/3/B

To Boiler

Level Socket

Funnel

Heater

Thermostat and

Thermostat Glass

Second Stage

Boiler Level Control

Front

Boiler

Rear

Boiler

I/WH48/3/B

8mm tubing x 1m - I/WH48/3/B

Restrictor

A4000D Installation Diagram

A4000D Operation

The following instructions apply to the A4000D water still where

the water feed to the boiler is via the mains supply or a header

tank.

1. Before switching on either the mains electricity or water supply,

identify the control switches and indicator lights on the front of

the cabinet.

Green Light – When illuminated this shows that there is mains

supply voltage to the unit. Under no circumstances should the

cabinet end-panel be removed when this light is illuminated.

White ‘On/Off’ Switch – This is the primary switch for

controlling water and electricity inside the still. The switch

illuminates when pressed in the ON position.

Amber Light – When illuminated, this indicates that the

distillate collection reservoir is full as detected by the level

control.

White ‘Clean’ Light – This shuts off the heating element but

allows water to flow into the boiler when the still is being

commissioned or cleaned. When pressed in the CLEAN position

the switch illuminates.

2. Carefully check the following:

The appropriate electricity, water and drain services have been

provided. If in doubt, consult the LOCATION & SERVICES

SECTION of this manual.

The ON/OFF switch on the control panel is in the OFF position.

12

The CLEAN switch is pressed in the ON position.

The Rotaflo stopcocks on the front and rear boiler level controls

are closed.

The float switch on the rear boiler level control W4L2A is set

at the factory. However, check that this has not been disturbed

during transit. A rough check is that the distance from the top

of the large screw cap of the W4L2A to the top of the glass

guide tube should be approximately 15-20mm (Fig 2e).

Fig 2e

Guide

tube

Float switch

15 - 20mm

To boiler level

socket

Distillate feed

from front still

Hose

assembly 2

To drain

The reservoir water level sensor is fitted to the distillate

collection vessel.

The dummy shorting plug is fitted to the boiler level control DIN

socket on the cabinet.

3. Ensure all earth leads are connected to the earth point.

4. Check all glassware for any damage.

5. Switch on the electricity supply – the green light illuminates.

6. Press the ON/OFF switch to the ON position – the switch will

illuminate.

7. Recheck that the CLEAN switch is in the ON position and

illuminated.

8. Turn on the mains water supply and using the mini valve

assembly, adjust the flow rate to approximately 2 litre/min.

This can be achieved by observing the drain water from the

boiler level control and adjusting the mini valve assembly

accordingly.

9. Check for water leaks.

10. Observe that the front boiler is now filling with water to cover

the heating elements. When the water has reached the pre-set

limit, the excess will discharge to drain. Check the water drains

freely and does not back up into the boiler level control.

11. Switch the CLEAN button off by pressing it a second time. The

switch light goes out.

The heater on the front boiler will now warm up and eventually

run at a red glow. After a short time distilled water will emerge

from the outlet pipe. This should feed into the empty rear boiler

via the rear boiler level control WL42A.

12. Allow the rear boiler to fill with single distilled water (for

approximately 20 – 30 minutes), keeping an eye on the level.

Note that the heater of the second stage only comes on when

the level of single distilled water in the rear boiler is at about

the equator. It may be necessary to adjust the level of the float

switch of the rear boiler level control (WL42A) to achieve this

condition.

Lifting the guide tube increases the level at which the heating

element will switch on.

Lowering the guide tube decreases the level at which the

element will switch on.

Double distilled water ultimately flows from outlet pipe (Fig.

2, item 15). This should fall away from the still with no kinks,

restrictions or U bends.

13. To avoid excess wastage of coolant water, make further

adjustments to the mini valve assembly. Slowly reduce the flow

rate until the flow control switch switches off the heater, then

increase the flow until the power is restored.

14. Safety Cut-Outs – All Aquatron water stills are protected by

the following safety devices.

Flow Control Switch – Monitors the flow of coolant water

into the still and shuts off the heating element if the flow is

insufficient.

Thermostat Cut-Out – In normal operation the water within

the glass will be at 100°C. In single fault conditions, i.e. in

the event of water supply failure, the content will increase to

112°C where upon a resettable thermostat will operate. Once

switched, the thermostat has to be manually reset. This is

achieved by unscrewing the black knob located inside the

cabinet and pressing the reset button.

Reservoir Control – Is positioned on the collection reservoir

and switches off both the electricity and water supplies when

the reservoir is full of distillate water. The water supply is shut

off around 7 minutes after the reservoir is full to allow the

heating element to cool.

It is recommended that the operation of the flow switch and

reservoir control is checked on a regular basis.

a. Simulation of Mains Water Supply Failure

Turn off the mains water supply at the tap. This should switch

off the heating element. Turning the tap on again will switch

the heater on.

b. Simulation of Reservoir Full Condition

Lower the glass pressure bell of the reservoir water level sensor

into the distillate to a depth of 150mm. This will switch off the

heating element immediately and the cooling water after 7

minutes. Raising the bell will cause both to be re-supplied.

16. Switching Off – Push the CLEAN switch to the ON position.

Wait until the residual heat contained in the heating element

has dispersed and no boiling is evident. Turn off water supply.

Push ON/OFF switch to OFF position. Isolate from mains

electricity supply.

A4000D Spares

Boiler WB4

Funnel WF48

Condenser WC48/M2

‘Mains On’ Green Indicator 700691(S)

‘On/Off’ White Switch 700988(S)

‘Reservoir Full’ Amber Indicator 700987

‘Clean’ White Switch 700988(S)

Reservoir Pressure Switch WPS

Heater Terminal Block A4000/HTB

Solenoid Assembly A4000/SA

Water Flow Sensor Assembly and Hoses I/A4000DHK/1

Reservoir Water Level Sensor WLS

Mains Water Mini Valve Assembly 7001059(S)

Thermostat Glass Tube WTT48

Thermostat WT4

Boiler Level Control (Front) WL48

Boiler Level Control (Rear) W4L2A

Boiler Plastic Coupling WBC1

Heater Assembly A4000/HA

Heater Assembly 220V A4000/HA220

Boiler Retaining Spring 700007

Condenser to Boiler Level Control Assembly I/A4000DHK/2

Rotaflow Stopcock Assembly A4000/RCOCK

Relay Assembly A4000/RA

PCB 700804(ES)

6 Way Electrical Terminal Block A4000/ETB

Ceramic Terminal Block A4000/CTB

5 DIN Socket Assembly A4000/DIN

Boiler Vapour Tube Sealing O Ring I/M502

Boiler Vapour Tube Stabilising O Ring I/QR38/24

4 DIN Socket Assembly A4000D/DIN

Distillate Output and Boiler Level

Control Drain Hose Kit I/WH48/3/B

Black Phenolic Screw Cap I/QC38/25

13

A8000

Fig. 3

5

4

6

Lid

3

2

8

7

9

10

11

12

1

25

24

23 22 20

21

List of Major Components – A8000

13

14

15

End

Plate

16

19

17

18

Item Description Catalogue

no. number

1 Perspex Screen M484

2 Boiler WB8

3 Funnel WF48

4 Condenser (2 off) WC48/M2

5 Wall Bracket M510G

6 Green ‘Mains On’ Indicator 700691(S)

7 White 'On/Off' Switch 700988(S)

8 Amber ‘Reservoir Full’ Indicator 700987

9 White ‘Clean’ Switch 700988(S)

10 Reservoir Pressure Switch WPS

11 Terminal Strip for Heaters A4000/HTB

12 Water Flow Sensor Assembly I/A8000HK/1

13 Solenoid Assembly A4000/SA

Item Description Catalogue

no. number

14 Mains Water Inlet Valve Assembly 7001059(S)

15 Reservoir Water Level Sensor WLS

16 Distillate Outlet Pipe (Bench Mounted) –

17 Cooling Water Pipe to Drain (8mm) –

18 Cooling Water Pipe to Drain (16mm) –

19 Thermostat WT8

20 Heater Assembly (2 Required) A4000/HA

21 Rotaflo Stopcock A4000/RCOCK

22 Distillate Outlet Pipe (Wall Mounted) –

23 Boiler Level Control WL48

24 Boiler Plastic Coupling WBC1

25 Retaining Springs 7000007

14

A8000 Assembly

Your Aquatron A8000 has been designed with ease of assembly

specifically in mind. Please study the installation diagram and the

enclosed DVD before commencing the installation. Follow the

sequence of instructions and do not connect the mains electricity

supply until directed.

1. From the outer packaging remove all the components

including the metal cabinet containing the glass boiler.

2. Before unpacking the individual components, identify them on

the check list below:

A8000 Unit containing boiler.

Condenser – WC48/M2 x2

Heater – W48H x2

Boiler Level Control – WL48

Funnel – WF48

Reservoir Water Level Sensor – WLS

Hose Kit – I/WH48/2/B

Wall Mounting Bracket – M510G

3. Remove the perspex viewing screen (Fig. 3, item 1) from the

unit by lifting it up using the finger recess. Remove the

internal packaging carefully. Snip the temporary ties holding

the boiler retaining springs (Item 25).

4. Remove the cabinet end plate and lid by removing the

retaining screws.

5. Ensure that the sealing O rings and the stabilising O rings are

correctly positioned on the vapour tubes of the boiler.

Cooling water outlet

Condenser

Sealing o-ring

Vapour tube

Distillate

Outlet

Stabilising o-ring

Fig. 3a

6. Fit one of the condensers (Fig. 3, item 4) to the left hand

vapour tube ensuring that the distillate outlet faces the front

and the two water connections are parallel to the unit. When

slight resistance is felt when fitting the condenser, press down

slightly on the top of the condenser until a gap of

approximately 19mm exists between the condenser and the

boiler (Fig. 3a).

7. Looking inside the cabinet, identify the vinyl tubing assemblies

fitted with numbered screw thread connectors. Make the

following connections:

Connect number 2 to the lower water inlet of the condenser.

Connect number 4 to the upper water outlet of the condenser

(Fig. 3b).

4

3

2

1

5

Fig. 3b

8. Fit the second condenser (Fig. 3, item 4) to the right hand

vapour tube ensuring that the distillate outlet faces the front

and the two water connections are parallel to the unit. When

slight resistance is felt when fitting the condenser, press down

slightly on the top of the condenser until a gap of

approximately 19mm exists between the condenser and the

boiler.

9. Looking inside the cabinet, identify the vinyl tubing assemblies

fitted with numbered screw thread connectors. Make the

following connections:

Connect number 1 to the lower water inlet of the condenser.

Connect number 3 to the upper water outlet of the condenser

(Fig. 3b).

10. From the hose kit I/WH48/2/B take the 1m length of 8mm

tubing fitted with the T piece.

11. Connect the 180mm length of tubing from the T piece to the

distillate outlet of the condenser on the left hand side. Secure

with a tie wrap.

12. Connect the 100mm length of tubing from the T piece to the

distillate outlet of the condenser on the right hand side.

Secure with a tie wrap.

13. Pass the free end of the tubing through:

The cabinet base (Fig. 3, item 22) if wall mounted.

The cabinet side (Fig. 3, item 16) if bench mounted.

14. Take the boiler level control WL48 (Fig. 3, item 23). Remove

the end split nut and central part of the boiler plastic coupling

(Item 24) leaving the other split nut on, and the internal seal

in the boiler level control. Ensure the Rotaflo stopcock is fully

closed (screwed down).

15. Take the 16mm earth spigot and place the 16mm tubing part

of it into a beaker of hot water for approximately 20 – 30

seconds; this will make the tubing more supple. Connect the

16mm tubing to the boiler level control (Item 23) drain

connection (below the Rotaflo stopcock). Secure with a tie

wrap.

16. Take the 1m length of 16mm hose from hose kit I/WH48/2/B.

Place one end into a beaker of hot water for approximately 20

– 30 seconds. Thread the tube through hole (Fig. 3, item 18)

until approximately 300mm of tubing is inside the cabinet.

Connect to the 16mm earth spigot and secure with a tie

wrap.

15

17. Pull the 16mm hose back out of the cabinet until a gap of

approximately 5mm exists between the boiler level control and

the boiler connection.

18. Place the boiler plastic coupling split nut and central part onto

the boiler connection. Connect the boiler level control to the

boiler, ensuring that the internal seal of the boiler plastic

coupling is fitted inside the boiler connection and the boiler

level control connection. Tighten the boiler plastic coupling.

19. Loosen the black cap on the boiler level control. Fit the funnel

into the top of the boiler level control and tighten the black

cap.

20. Connect the tubing connector number 5 to the boiler level

control (Fig 3b).

21. Take the remaining length of 8mm tubing from the 8mm earth

spigot and feed through the hole (Fig. 3, item 17).

22. Unscrew the two black plastic screw caps and rubber rings

from the boiler. Place the black caps onto the heaters until

they are approximately 25mm from the electrical connectors

end. Push the rubber ring onto the heaters and into the black

cap.

23. Fit the heaters into the boiler and screw on the black caps.

When the black caps are tight push the heaters through the

black caps until the end of the heaters sit in the nodules at the

end of the boiler.

Do not overtighten the screw caps as this may cause the

boiler to break, or push the heaters in too far as this

may break the nodule.

24. Thread the four heater connectors through the holes into the

electrical control compartment and connect to the heater

terminal blocks. Brown to Brown, Blue to Blue (Fig. 3c).

SAFETY: It could be possible to mis-locate the heater

crimps on to the heater terminal block tags. Ensure that

the heater crimps are properly located onto the heater

terminal block tags and fully locked on. Attempt to pull

the crimps off the tags to ensure full attachment.

N

E

28. THIS EQUIPMENT MUST BE EARTHED!

Carry out the electrical installation. This should only be carried

out by a suitably qualified electrician.

The A8000 is classed as permanently connected equipment.

The earth spigots should pass a high current (ie. >200mA).

The equipment is supplied with 1.5m of flexible, triple core,

circular cable to the following specification:

4.0mm², to BS 6500 or equivalent and <HAR> or BASEC

approved.

Connection to the mains electrical supply should be via a

double pole 30mA Residual Current Breaker with Overcurrent

protection (RCBO) isolating circuit breaker switch with a

continuous current carrying capacity of 30A at 250V and

overcurrent of 30A.

These devices should be sited near to the equipment and

clearly marked ‘Disconnect device for Aquatron water still’

DO NOT SWITCH ON ELECTRICAL SUPPLY.

29. Connect the reservoir water level sensor WLS (Fig. 3, item 15)

to the A8000 and secure with a tie wrap. Place the glass

pressure bell in the collection reservoir, following the

instructions given on page 19.

30. Operate the A8000 Waterstill as per Operating Instructions

and check for leaks.

31. Fit the Perspex viewing screen.

PCB

L

Heater lead (back)

Relay

Heater

Terminal

Blocks

Relay

Heater

lead

Thermostat

(front)

Fig. 3c

25. Refit the end plate and lid.

26. Move the unit to its working location. If it is to be wall

mounted use the mounting bracket Fig. 3 (Item 5). Ensure a

space of at least 50cm to the right of the unit to allow access.

27. Connect the cold water supply to the mains water inlet. The

tubing selected should have a safe working pressure of at least

equal to the pressure of the water supply and should be

adequately secured with hose clips.

DO NOT TURN ON WATER SUPPLY

16

I/A8000HK/1

I/A8000HK/2

I/WH48/2/B

16mm tubing x 1m - I/WH48/2/B

Solenoid

Condensers

Thermostat &

Thermostat Glass

Heaters

Boiler

Level

Control

Funnel

Rotaflo Stopcock

1

2

4

3

5

Water Flow Switch

Restrictor

Mains Water

Inlet Mini

Valve

Electrics

Reservoir

Water Level

Sensor

8mm Earth Spigot

16mm Earth Spigot

To Distillate

Reservoir

To Drain

To Drain

Boiler

A8000 Installation Diagram

A8000 Operation

The following instructions apply to the A8000 water still where the

water feed to the boiler is via the mains supply, or a header tank.

1. Before switching on either the mains electricity or water

supply, identify the control switches and indicator lights on the

front of the cabinet.

Green Light – When illuminated this shows that there is

mains supply voltage to the unit. Under no circumstances

should the cabinet end-panel be removed when this light is

illuminated.

White ‘On/Off’ Switch – This is the primary switch for

controlling water and electricity inside the still. The switch

illuminates when pressed in the ON position.

Amber Light – When illuminated, this indicates that the

distillate collection reservoir is full as detected by the level

control.

White ‘Clean’ Light – This shuts off the heating element but

allows water to flow into the boiler when the still is being

commissioned or cleaned. When pressed in the CLEAN

position the switch illuminates.

2. Carefully check the following:

The appropriate electricity, water and drain services have been

provided. If in doubt, consult the LOCATION & SERVICES

SECTION of this manual.

The ON/OFF switch on the control panel is in the OFF position.

The CLEAN switch is pressed in the CLEAN position.

The Rotaflo stopcock on the front boiler level control is closed.

The reservoir water level sensor is fitted to the distillate

The dummy shorting plug is fitted to the boiler level control

3. Ensure all earth leads are connected to the earth point.

4. Check all glassware for any damage.

5. Switch on the electricity supply – the green light illuminates.

6. Press the ON/OFF switch to the ON position – the switch will

7. Recheck that the CLEAN switch is in the CLEAN position and

8. Turn on the mains water supply and using the mini valve

9. Check for water leaks.

collection vessel.

DIN socket on the cabinet.

illuminate.

illuminated.

assembly, adjust the flow rate to approximately 2 litres/min.

This can be achieved by observing the drain water from the

boiler level control and adjusting the mini valve assembly

accordingly.

17

10. Observe the boiler now filling with water to cover the heating

elements. When water has reached the pre-set limit, the

excess will discharge to drain. Check the water drains freely

and does not back up into the boiler level control.

11. Switch the CLEAN button off by pressing it a second time. The

switch light goes out.

12. The heaters will now warm up and eventually run at a red

glow. If the flow rate is insufficient, the heaters will not switch

on. This will require adjustment of the mini valve assembly to

be opened further. After about 2 – 3 minutes of operation

distilled water will emerge from the outlet pipe falling into the

collection reservoir.

13. To avoid excess wastage of coolant water, make further

adjustments to the mini valve assembly. Slowly reduce the flow

rate until the flow control switch switches off the heaters,

then increase the flow until the power is restored.

14. Refit the Perspex screen.

15. Safety Cut-Outs – All Aquatron water stills are protected by

the following safety devices.

Flow Control Switch – Monitors the flow of coolant water

into the still and shuts off the heating element if the flow is

insufficient.

Thermostat Cut-Out – In normal operation the water within

the glass will be at 100°C. In single fault conditions, i.e. in the

event of water supply failure, the content will increase to

112°C where upon a resettable thermostat will operate. Once

switched, the thermostat has to be manually reset. This is

achieved by unscrewing the black knob located inside the

cabinet and pressing the reset button.

Reservoir Control – Is positioned on the collection reservoir

and switches off both the electricity and water supplies when

the reservoir is full of distillate water. The water supply is shut

off around 7 minutes after the reservoir is full to allow the

heating element to cool.

It is recommended that the operation of the flow switch and

reservoir control is checked on a regular basis.

a. Simulation of Mains Water Supply Failure

Turn off the mains water supply at the tap. This should switch

off the heating element. Turning the tap on again will switch

the heater on.

b. Simulation of Reservoir Full Condition

Lower the glass pressure bell of the reservoir water level

sensor into the distillate to a depth of 150mm. This will switch

off the heating element immediately and the cooling water

after 7 minutes. Raising the bell will cause both to be

re-supplied.

16. Switching Off – Push the CLEAN switch to the ON position.

Wait until the residual heat contained in the heating element

has dispersed and no boiling is evident. Turn off water supply.

Push ON/OFF switch to OFF position. Isolate from mains

electricity supply.

A8000 Spares

Boiler WB8

Funnel WF48

Condenser WC48/M2

‘Mains On’ Green Indicator 700691(S)

‘On/Off’ White Switch 700988(S)

‘Reservoir Full’ Amber Indicator 700987

‘Clean’ White Switch 700988(S)

Reservoir Pressure Switch WPS

Heater Terminal Block A4000/HTB

Solenoid Assembly A4000/SA

Water Flow Sensor Assembly and Hoses I/A8000HK/1

Condenser to Boiler Level Control Hose Assembly I/A8000HK/2

Reservoir Water Level Sensor WLS

Mains Water Mini Valve Assembly 7001059(S)

Thermostat Glass Tube WTT48

Thermostat WT8

Boiler Level Control WL48

Boiler Plastic Coupling WBC1

Heater Assembly A4000/HA

Heater Assembly 220V A4000/HA220

Boiler Retaining Spring 700007

Distillate Output and Boiler Level Control

Drain Hose Kit I/WH48/2/B

Rotaflow Stop Cock Assembly A4000/RCOCK

Relay Assembly A4000/RA

PCB 700804(ES)

6 Way Electrical Terminal Block A4000/ETB

Ceramic Terminal Block A4000/CTB

5 DIN Socket Assembly A4000/DIN

Boiler Vapour Tube Sealing O Ring I/M502

18

Boiler Vapour Tube Stabilising O Ring I/QR38/24

Black Phenolic Screw Cap I/QC38/25

Wall Mounting Bracket M510G

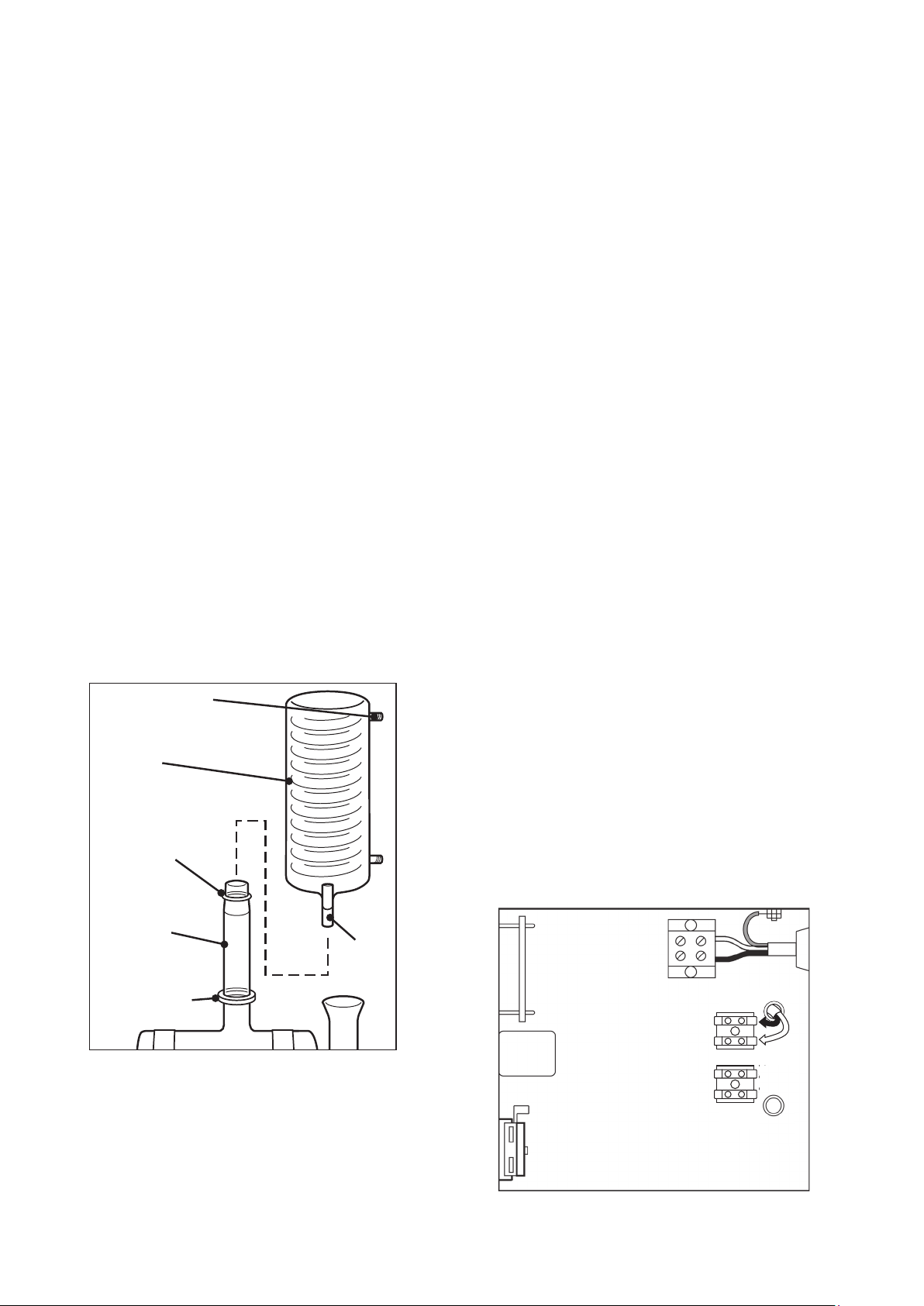

Distillate Collection

WR20 & WS20

& Reservoir System

Each Aquatron water still is supplied with a Reservoir Water Level

Sensor (WLS).

This automatically switches off the heating

elements and coolant water supply when

the distillate collection reservoir is filled

with distilled water.

Note that the control is fitted with a ‘delay

timer’ which switches off the coolant

water supply approximately 7 minutes after

the heating elements. This is to allow time

for the heaters to cool and for boiling to

cease.

The control also automatically switches on

the heating elements and coolant water

supply when the level of distillate in the

collection reservoir falls.

It is possible to fit the glass pressure bell of

the control to most types of reservoir and

container by means of a metal clip WFC/1

which is provided with the Reservoir Water

Level Sensor Assembly (WLS).

Alternatively, Bibby Scientific offer a purpose

designed reservoir collection system WR20 fitted with a special

adapter to hold the bell.

140mm

Reservoir System

To pressure switch

on Aquatron

Distillate

from

Metal

Clip

Reservoir

Water

Level

Sensor

Aquatron

50mm

Reservoir

water

level sensor

WR20

WR20

Reservoir

stand

Fitting the Reservoir Control WLS to Collection Vessels

1. Position the distillate collection reservoir in a suitable location.

This should be below the water still so that the vinyl rubber

tubing transporting the distilled water from the still can fall

down to the reservoir without restrictions, kinks or U bends.

2. Take the Reservoir Water Level Sensor WLS and connect the

free end of the rubber tubing to the nozzle of the pressure

switch located on the side of the Aquatron cabinet. Secure

with a tie wrap.

Nozzle of

Pressure

Switch

3. Use the metal clip to fit the glass pressure bell inside the

distillate collection reservoir.

4. Position the bell so that the open end is 140mm below the

desired distillate level.

Bibby Scientific offer a purpose designed reservoir system for the

collection of distilled water from your Aquatron.

WR20 – A 20 litre Pyrex glass reservoir complete with Rotaflo stop

cock and special lid.

WS20 – Reservoir stand, 43cm high for use with WR20.

The lid of the reservoir has a side arm for connection to the

distillate feed from the Aquatron and a vent fitted with a

bacteriological filter to maintain the purity of the water. A screw

thread fitting is also provided to support the Reservoir Water Level

Sensor (WLS).

Location & Assembly

1. Locate the reservoir in a position which is below the level of

the water still.

2. Fit the Rotaflo drain cock to the lower ground glass socket of

the reservoir and secure with the plastic joint clip.

3. Take the bacteriological filter and connect this to the top of

the glass feed-pipe using the vinyl tubing provided. Fit the

feed pipe and filter into the reservoir lid via the large screw

cap fitting.

4. Fit the Reservoir Water Level Sensor (WLS) to the lid via the

small screw cap fitting. Note that the system of the glass

pressure bell should extend approximately 50mm above the

screw cap.

5. Place the assembled lid into the socket of the reservoir.

6. Take the rubber tubing from the Reservoir Water Level Sensor

(WLS) and connect to the small plastic nozzle on the side of

the Aquatron cabinet.

7. Take the vinyl plastic tubing from the distillate outlet of the

water still and connect to the side arm of the feed pipe on

the reservoir lid. Ensure that the tubing falls down to the

reservoir without any restrictions, kinks or U bends.

19

Connection of Aquatron

stills to deionised and

pre-treated water supplies

Many laboratories prefer to feed their water stills with deionised or

pre-treated water to obviate the need for boiler cleaning and

descaling.

Your new Aquatron can be easily converted to a deionised water

feed by use of a simple accessory – the Water Feed Conversion

Kit, Part No A4000/WCK (A4000) or A4000D/WCK (A4000D &

A8000). This kit permits the still to operate with most types of

deioniser and also piped supplies of pre-treated water.

The sequence of operations to fit the kit is detailed below and

should be used in conjunction with the instructional video which

accompanies the kit. The video is also accessible on You Tube

(youtube.com/bibbyscientific) or http://www.stuart-equipment.

com/product.asp?dsl=131

A4000/WCK

Jubilee Clip

(700198)

Splice

(Sannar-004)

Straight

Connector

(700408)

A4000D/WCK

Jubilee Clip

(700198)

Float Switch

Assembly

(I/WCK/01(E))

Tubing

Assembly

(I/WCK/05)

Earthed Pipe

Deioniser Kit

(I/WCK/02)

Earthed Pipe

Deioniser Kit

(I/WCK/02)

A4000

1. Ensure the unit is isolated from the mains.

2. Remove the perspex viewing screen, cabinet roof and cabinet

end panel.

3. Lift out the front switch panel from the cabinet groove by

unscrewing the countersunk screw at the top of the panel.

This will allow better access to the plumbing system.

4. Unscrew the tubing connector marked ‘3’ from the boiler

level control as shown in the A4000 Installation Diagram on

page 6.

5. Connect the splice (Sannar-004) to the tubing connector

marked ‘3’ disconnected in step 4.

6. Connect tubing assembly (I/WCK/05) to the other end of the

splice in step 5.

7. Thread the earth cable from tubing assembly (I/WCK/05)

through the access hole in bottom of the electrical

compartment and connect to the main earth point.

8. Thread the tubing from tubing assembly (I/WCK/05) through

the last hole on the side of the cabinet to the drain.

9. Take tubing assembly (I/WCK/02) and connect to the

deionised / pre-treated water solenoid, and secure with a

jubilee clip.

10. Connect the other end of the tubing assembly (I/WCK/02) to

the boiler level control.

11. Thread the earth cable from tubing assembly (I/WCK/02)

through the access hole in bottom of the electrical

compartment and connect to the main earth point.

12. Unscrew the black cap from the boiler level control and

remove the funnel and seal.

13. Fit the boiler level control black cap over the float switch

assembly (I/WCK/01(E)) and fit to the boiler level control

ensuring that the end of the guide tube locates in the well at

the base.

14. Remove the dummy plug from the DIN connector and

connect the float switch assembly connector.

15. Remove the dummy cap from the deionised / pre-treated

water inlet and fit the straight hose connector (700408).

16. Connect the straight hose connector (700408) to the outlet

of the deionised / pre-treated water supply. Note the tubing

selected should have a safe working pressure of at least equal

to the pressure of the water supply and should be

adequately secured with hose clips.

17. Refit the front switch panel.

18. Refit the perspex viewing screen, cabinet side panel and

cabinet roof.

Straight

Connector

(700408)

20

Plug

(Sannar-002)

Float Switch

Assembly

(I/WCK/01(E))

A4000D

1. Ensure the unit is isolated from the mains.

2. Remove the perspex viewing screen, cabinet roof and cabinet

end panel.

3. Lift out the front switch panel from the cabinet groove by

unscrewing the countersunk screw at the top of the panel.

This will allow better access to the plumbing system.

4. Unscrew the tubing connector marked ‘5’ from the boiler

level control as shown in the A4000D Installation Diagram on

page 12.

5. Connect the plug (Sannar-002) to the tubing connector

marked ‘5’ disconnected in step 4.

6. Take tubing assembly (I/WCK/02) and connect to the

deionised / pre-treated water solenoid, and secure with a

jubilee clip.

7. Connect the other end of the tubing assembly (I/WCK/02) to

the boiler level control.

8. Thread the earth cable from tubing assembly (I/WCK/02)

through the access hole in bottom of the electrical

compartment and connect to the main earth point.

9. Unscrew the black cap from the front boiler level control and

remove the funnel and seal.

10. Fit the front boiler level control black cap over the float switch

assembly (I/WCK/01(E)) and fit to the front boiler level control

ensuring that the end of the guide tube locates in the well at

the base.

11. Remove the dummy plug from the DIN connector and connect

the float switch assembly connector.

12. Remove the dummy cap from the deionised / pre-treated

water inlet and fit the straight hose connector (700408).

13. Connect the straight hose connector (700408) to the outlet of

the deionised / pre-treated water supply. Note the tubing

selected should have a safe working pressure of at least equal

to the pressure of the water supply and should be

adequately secured with hose clips.

14. Refit the front switch panel.

15. Refit the perspex viewing screen, cabinet side panel and

cabinet roof.

A8000

1. Ensure the unit is isolated from the mains.

2. Remove the perspex viewing screen, cabinet roof and cabinet

end panel.

3. Lift out the front switch panel from the cabinet groove by

unscrewing the countersunk screw at the top of the panel.

This will allow better access to the plumbing system.

4. Unscrew the tubing connector marked ‘5’ from the boiler level

control as shown in the A8000 Installation Diagram on page

17.

5. Connect the plug (Sannar-002) to the tubing connector

marked ‘5’ disconnected in step 4.

6. Take tubing assembly (I/WCK/02) and connect to the deionised

/ pre-treated water solenoid, and secure with a jubilee clip.

7. Connect the other end of the tubing assembly (I/WCK/02) to

the boiler level control.

8. Thread the earth cable from tubing assembly (I/WCK/02)

through the access hole in bottom of the electrical

compartment and connect to the main earth point.

9. Unscrew the black cap from the boiler level control and

remove the funnel and seal.

10. Fit the boiler level control black cap over the float switch

assembly (I/WCK/01(E)) and fit to the boiler level control

ensuring that the end of the guide tube locates in the well at

the base.

11. Remove the dummy plug from the DIN connector and connect

the float switch assembly connector.

12. Remove the dummy cap from the deionised / pre-treated

water inlet and fit the straight hose connector (700408).

13. Connect the straight hose connector (700408) to the outlet of

the deionised / pre-treated water supply. Note the tubing

selected should have a safe working pressure of at least equal

to the pressure of the water supply and should be

adequately secured with hose clips.

14. Refit the front switch panel.

15. Refit the perspex viewing screen, cabinet side panel and

cabinet roof.

Operation

1. Before switching on either the mains electricity or water

supply, identify the control switches and indicator lights on the

front of the cabinet.

Green Light – When illuminated this shows that there is

mains supply voltage to the unit. Under no circumstances

should the cabinet end panel be removed if this light is

illuminated.

White ‘on/off’ Switch – This is the primary switch for

controlling water and electricty inside the still. The switch

illuminates when pressed in the ‘on’ position.

Amber Light – When illuminated this indicates that the

distillate collection reservoir is full as detected by the level

control.

White ‘Clean’ Switch – This shuts off the heating element

but allows water to flow into the boiler when the still is being

commissioned or cleaned. When pressed in the ‘Clean’

position the switch illuminates.

2. Carefully check:

i. the appropriate electricity, water and drain services have

been provided. If in doubt, consult the Location and Servces

section on page 3.

ii. the on/off switch on the control panel is in the off position.

iii. the clean switch is pressed in the clean position.

iv. the Rotaflo stopcock on the boiler level control is closed.

v. the reservoir pressure switch is fitted to the distillate

collection vessel.

vi. the dummy shorting plug has been removed from it’s socket

and replaced with the lead from the float switch assembly

(I/WCK/01(E)).

3. Switch on the electricity supply – the green indicator light will

illuminate.

4. Press the on/off switch to the on position – the switch will

illuminate.

5. Recheck that the clean switch is in the clean position and

illuminated.

6. Turn on the mains water supply and using the mini valve

assembly, adjust the flow rate to approximately 1 litre/min for

A4000 and 2 litres/min for A4000D and A8000. This can be

achieved by observing the drain water from the boiler

level control and adjusting the mini valve assembly accordingly.

Check the mains water flows to drain without restriction.

7. Turn on the supply of deionised or pre-treated water. Observe

that deionised water enters the boiler via the float switch

assembly in the boiler level control.

8. Allow deionised water to flow into the boiler until the heating

element(s) is covered by approximately 10mm of water. At this

level the flow of deionised water into the boiler should be

automatically cut off by the float switch assembly in the boiler

level control.

9. Switch off the clean button by pressing it for a second time –

the switch light extinguishes. The heater(s) will start to warm

up and eventually run at a red glow. (If heater(s) fails to glow,

check that the flow of mains water is adequate).

10. Allow distillation to commence and observe that the float

switch assembly allows fresh deionised water to enter the

boiler and maintain a satisfactory operating level. If the

deionised supply fails then the WCK kit fitted will switch off

the heater until it is restored.

21

Cleaning

When any of the Aquatron stills have been used to produce

distilled water directly from a mains water supply, there will

inevitably be a build up of scale in the boiler and on the heating

element(s). To obtain optimum performance from the still, the scale

should be removed on a regular basis. The time span between

cleaning depends entirely upon the hardness of the water supply.

In very hard water areas it may be necessary to clean the still once

a week, whereas in soft water areas several weeks may elapse

before cleaning is necessary.

It should not of course be necessary to de-scale the second stage

boiler on the A4000D or when the stills have been operated from

a deioniser.

Cleaning the still involves the use of 10% formic acid or kettle

descaler. As a safety precaution, protective clothing, gloves, mask

and goggles should be worn during cleaning.

Note – The cabinet and perspex screen should be cleaned using a

dilute detergent solution only.

It is possible to descale the Aquatron water still without

dismantling the glassware by following these instructions in

conjunction with Control of Substances Hazardous to Health

(COSHH) Regulations 2002.

Method

1. Push the CLEAN switch to the CLEAN position – the switch

illuminates.

2. Observe that the heating element(s) has switched off. Allow

boiling to stop and water to cool.

3. Push ON/OFF switch to OFF position.

4. Remove the perspex screen.

5. Open the Rotaflo stop cock on the boiler level control WL48,

allow the boiler to empty to ¾ of its full capacity, and close

the stop cock.

6. Carefully add about 100ml of 10% formic acid solution or

kettle descaler into the glass funnel of the WL48.

7. Push the ON/OFF switch to the ON position, the boiler will

refill to its operating level.

8. Push the ON/OFF switch to the OFF position.

9. Allow the chemical reaction within the boiler to continue until

all the deposits have been removed.

Note – If scale has built up above the operating level, the

boiler may be completely filled by either lifting the drain pipe

or restricting the flow of water to drain. This operation must

be carefully controlled so that the boiler does not over fill and

cause water to be forced over the funnel top.

10. Open the Rotaflo stop cock and allow contents of the boiler

to drain completely.

Note – If the acid added to the boiler has not been completely

neutralised, the liquid flowing to drain may be strongly acid.

Necessary safety precautions should be observed around the

drain position and any effluent control procedures followed.

11. Close Rotaflo stop cock.

12. Push ON/OFF switch to ON position and allow boiler to fill

with water. Again the boiler may be completely filled by

following procedure detailed in step 8.

13. Push ON/OFF switch to OFF position.

14. Drain the boiler by opening the Rotaflo stop cock.

15. Repeat steps 11-14 two or three times until the boiler has

been thoroughly flushed through.

16. The still is re-started by finishing the cleaning cycle at step 12.,

then pushing the CLEAN switch to the OFF position (switch is

not illuminated).

Before collecting the distillate the still should be allowed to

run for about 10 minutes with the distillate running to drain.

This will ensure that any residual acid is removed.

Note – The amount of acid required will depend upon the

degree of scaling. If after performing the cleaning cycle

deposits are left in the boiler, it may be necessary to repeat

the cleaning cycle using a fresh quantity of acid.

The benefits gained from regular cleaning cannot be over

emphasised.

22

Fault Finding

In the event of operating difficulties with your Aquatron, it is

suggested that the following basic checks are made. (Please note

that these checks should only be carried out by suitably qualified

personnel).

If these checks fail to identify and remedy the problem then you

are advised to seek the help of your supplier or the Service