Page 1

Power-PRO™ XT

6506

Operations Manual

2017/09 F.2 6506-209-001 REV F www.stryker.com

Page 2

sample text

Page 3

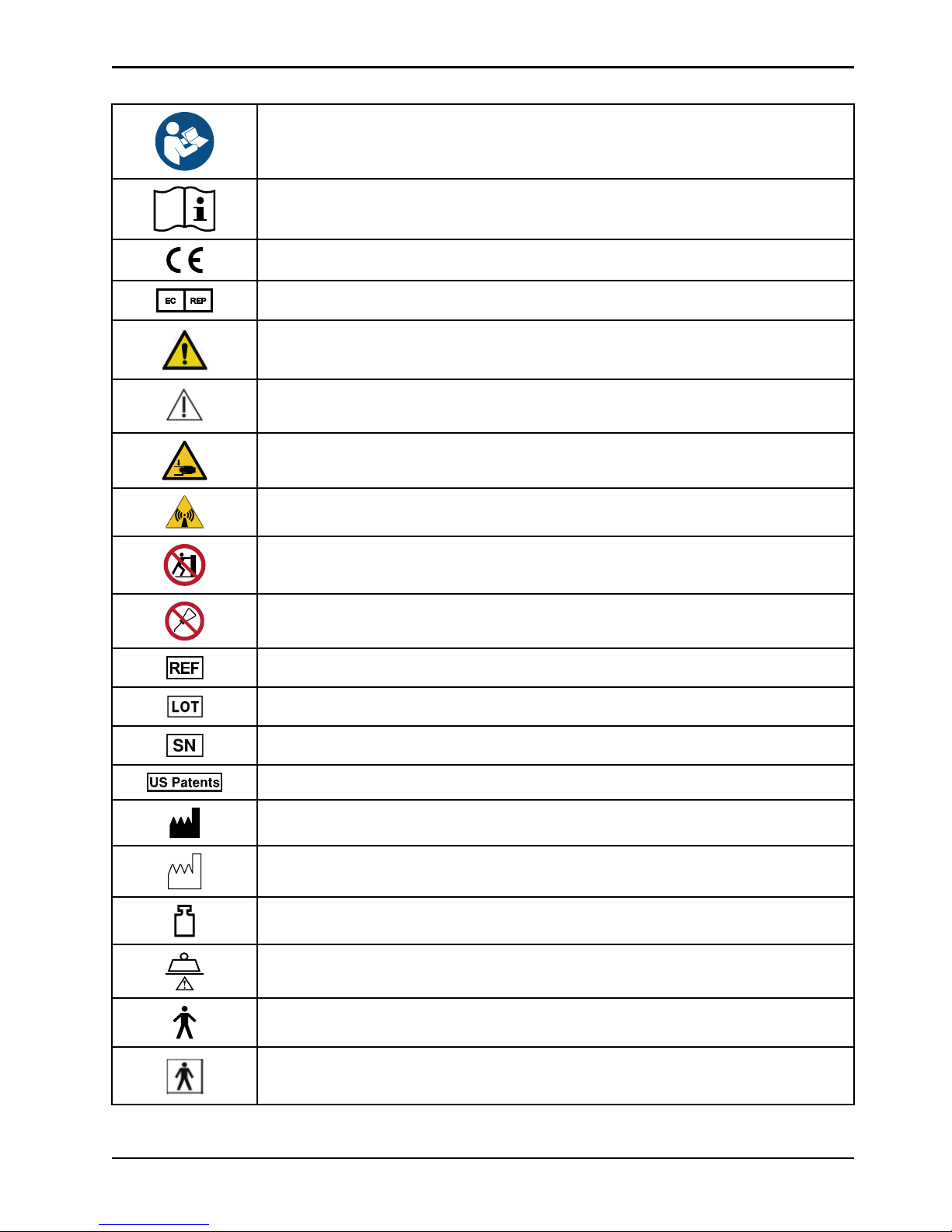

Symbols

Refer to instruction manual/booklet

Operating instructions

CE mark

European authorized representative

General warning

Caution

Warning; crushing of hands

Warning; non-ionizing radiation

No pushing

Do not lubricate

Catalogue number

Lot (batch) code

Serial number

For US Patents see www.stryker.com/patents

Manufacturer

Date of manufacture

Mass of equipment with safe working load

Safe working load

Type B applied part

Type BF applied part

www.stryker.com 6506-209-001 REV F

Page 4

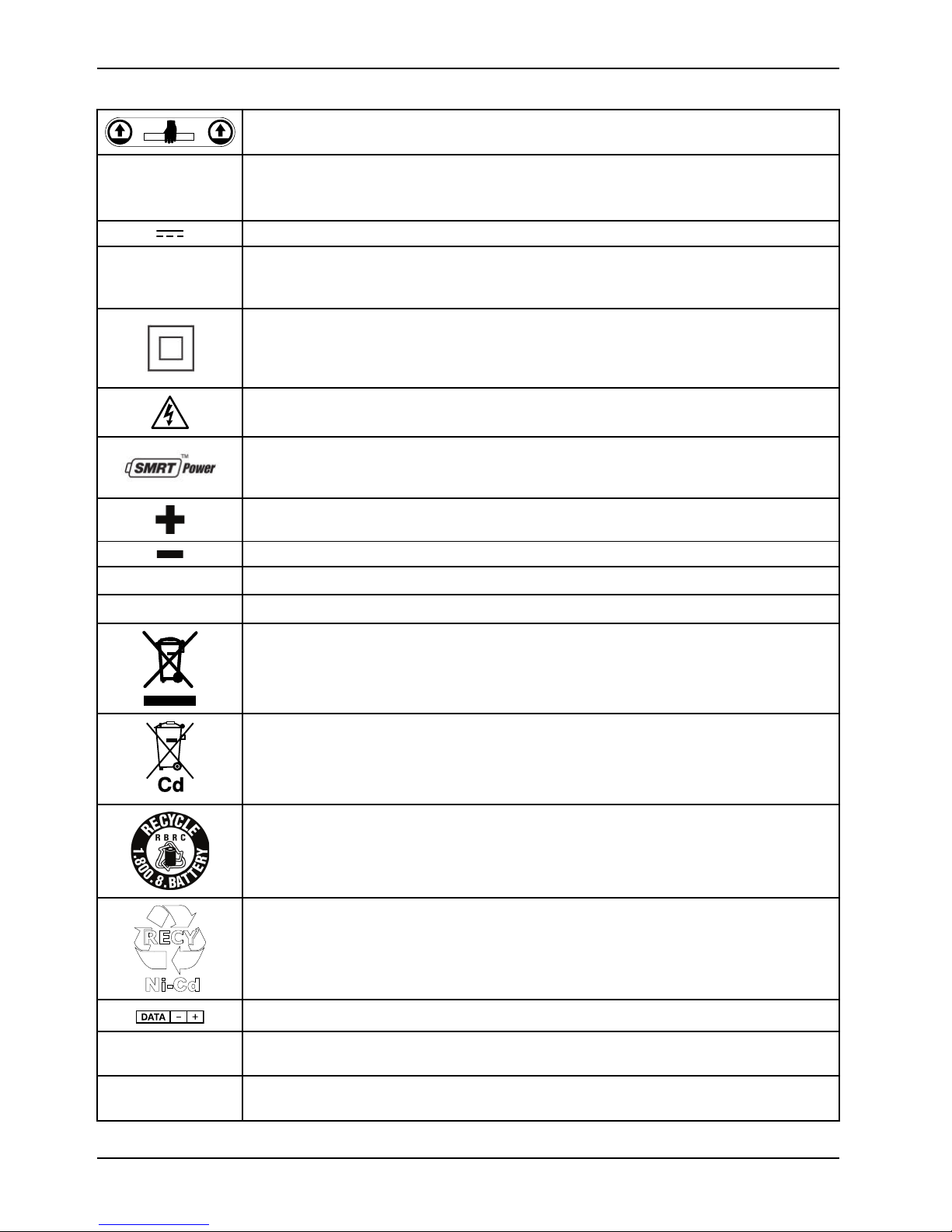

Symbols

~

Cd

DATA

_

+

Lift here

Medical Equipment Classified by Underwriters Laboratories Inc. With Respect to Electric Shock,

Fire, and Mechanical Hazards Only in Accordance with ANSI/AAMI ES60601-1:2012 and

CAN/CSA-C22.2 No. 60601-1:14.

Direct current

Alternating current

Class II electrical equipment: equipment in which protection against electric shock does not

rely on basic insulation only, but in which additional safety precautions such as double

insulation or reinforced insulation are provided, there being no provision for protective earthing

or reliance upon installation conditions.

Dangerous voltage

SMRT power system

IPX0

IPX6

Extend

Retract

Non-protected

Protection from powerful water jets

In accordance with European Directive 2002/96/EC on Waste Electrical and Electronic

Equipment, this symbol indicates that the product must not be disposed of as unsorted

municipal waste, but should be collected separately. Refer to your local distributor for return

and/or collection systems available in your country.

WEEE Directive (2012/96/EC). Contains cadmium.

The Rechargeable Battery Recycling Corporation (RBRC) is a non-profit, public service

organization that promotes the recycling of portable rechargeable batteries. Batteries must be

delivered to a battery collection site. Visit the RBRC website (www.rbrc.org) to find a nearby

collection site or call the phone number shown on the recycling symbol.

Contains nickel cadmium cells and should be recycled accordingly

Battery terminal identification (data line, negative, and positive)

KRX

23/44

2300 mAh

(1.2A/2h)

Ni-Cd cell identification per IEC 61951-1:20 03

Battery capacity, typical charge, and duration

6506-209-001 REV F www.stryker.com

Page 5

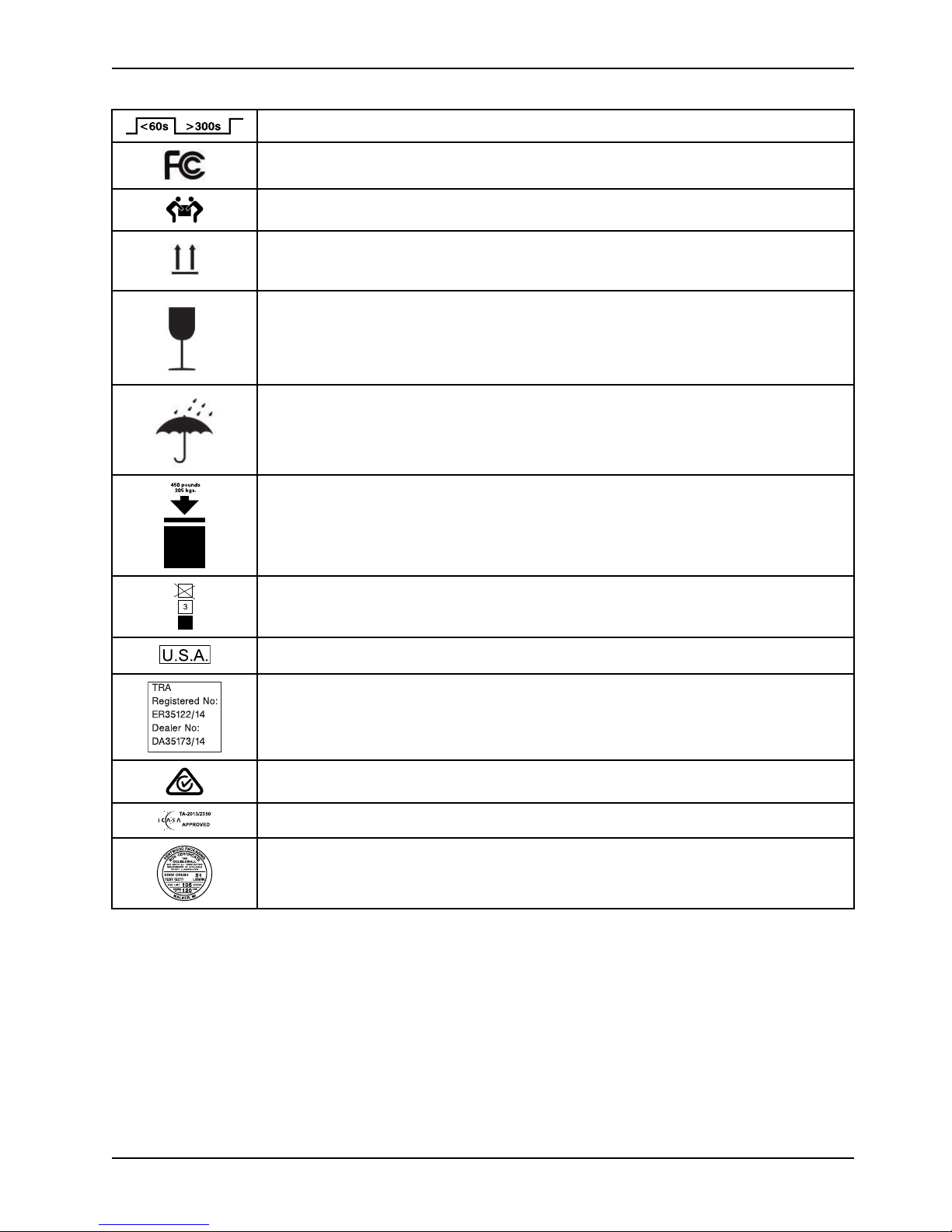

Symbols

< 60s > 300s

3

U.S.A.

TRA

Registered No:

ER35122/14

Dealer No:

DA35173/14

50

Cot duty cycle: 16.7% (less than 60 seconds on, more than 300 seconds off)

This device complies with Part 18 of the FCC rules

Two person lift

This way up

Fragile, handle with care

Keep dry

450 lb /205 kg weight capacity

Do not stack more than three high

English text below this symbol is intended for USA audiences only

Registered in United Arab Emirates by the Telecommunications Regulatory Authorities

Product complies with applicable EMC standards in Australia/New Zealand

Approved by independent communications authority of South Africa

Box manufacturer’s certificate - this packaging box has a minimum test value of 500 lb per sq.

in

www.stryker.com 6506-209-001 REV F

Page 6

sample text

Page 7

Table of Contents

Warning/Caution/Note Definition ...................................................................................................................4

Summary of safety precautions ....................................................................................................................5

Pinch points ....................................................................................................................................... 8

Mechanical stability .............................................................................................................................9

Introduction............................................................................................................................................ 11

Product description............................................................................................................................ 11

Indications for use ............................................................................................................................. 11

Expected service life .......................................................................................................................... 12

Contraindications............................................................................................................................... 12

Specifications - Power-PRO................................................................................................................. 12

Standards with required options............................................................................................................ 14

Specifications - SMRT ........................................................................................................................ 15

Product illustration - Power-PRO........................................................................................................... 16

Product illustration - SMRT .................................................................................................................. 17

Contact information............................................................................................................................ 17

Serial number location - Power-PRO...................................................................................................... 18

Serial number location - SMRT ............................................................................................................. 18

Date of manufacture .......................................................................................................................... 18

Setup.................................................................................................................................................... 19

Installation ............................................................................................................................................. 20

Installing the cot fastener .................................................................................................................... 20

Installing the in-fastener shut-off........................................................................................................... 20

Selecting the vehicle safety hook.......................................................................................................... 21

Vehicle configuration.......................................................................................................................... 22

Positioning of the vehicle safety hook, front to back .................................................................................. 23

Positioning of the vehicle safety hook, side to side .................................................................................... 24

Installing the vehicle safety hook........................................................................................................... 25

Operation .............................................................................................................................................. 27

Setting cot load height with jog function.................................................................................................. 27

Checking the battery power level .......................................................................................................... 27

Checking the hour meter and error display.............................................................................................. 28

Operating guidelines .......................................................................................................................... 29

Proper lifting techniques ..................................................................................................................... 29

Transferring the patient to the cot ......................................................................................................... 30

Rolling the cot with a patient ................................................................................................................ 30

Raising or lowering the cot................................................................................................................... 30

Raising, lowering, or releasing the cot with power ..................................................................................... 31

Raising or lowering the cot manually with the manual override..................................................................... 31

Expediting load with the high speed retract mode ..................................................................................... 32

Loading or unloading a cot with the Power-LOAD option............................................................................. 32

Loading a cot into a vehicle with an antler style cot fastener ....................................................................... 33

Unloading a cot from a vehicle with an antler style cot fastener ................................................................... 34

Positioning operators and helpers ......................................................................................................... 36

www.stryker.com 6506-209-001 REV F 1

Page 8

Table of Contents

Raising or lowering the backrest ........................................................................................................... 37

Raising or lowering the siderails ............................................................................................................ 37

Raising or lowering the siderails (XPS option) .......................................................................................... 37

Extending the retractable head section................................................................................................... 38

Retracting the retractable head section .................................................................................................. 38

Raising or lowering the footrest............................................................................................................. 39

Raising or lowering the optional knee gatch............................................................................................. 39

Applying or releasing a wheel lock......................................................................................................... 40

Applying or releasing the optional Steer-LOCK ......................................................................................... 40

Applying or releasing the optional kickstand for dialysis scale...................................................................... 40

Securing the patient with the G-rated restraint straps................................................................................. 41

Adjusting restraint straps ..................................................................................................................... 43

Securing a patient with the X-restraint/RUGGED™-X (6500-001-430/6506-001-430) restraint straps.................. 44

Adding a restraint strap extension ......................................................................................................... 47

Securing the patient with the Pedi-Mate® infant restraint system ................................................................. 48

Installing the child restraint with X-restraint package.................................................................................. 48

Installing the defibrillator platform.......................................................................................................... 50

Hanging equipment from the equipment hook .......................................................................................... 52

Installing the head extension with pillow.................................................................................................. 53

Positioning the two-stage IV pole........................................................................................................... 53

Positioning the optional three-stage IV pole ............................................................................................. 54

Attaching an oxygen bottle to the oxygen bottle holder............................................................................... 55

Attaching an oxygen bottle to the retractable head section oxygen bottle holder.............................................. 56

Installing the optional base storage net................................................................................................... 57

Installing the backrest storage pouch ..................................................................................................... 57

Installing the optional head end storage flat............................................................................................. 58

Transferring larger patients.................................................................................................................. 59

Attaching the mattress........................................................................................................................ 59

Installing a SMRT Pak ........................................................................................................................ 60

Removing a SMRT Pak from the cot ...................................................................................................... 60

Storing the battery ............................................................................................................................. 61

Charging the SMRT Pak...................................................................................................................... 61

Checking the SMRT Pak power level with the SMRT charger ...................................................................... 62

Electrical power installation requirements ............................................................................................... 63

Installing the SMRT charger................................................................................................................. 63

Installing the optional mounting bracket.................................................................................................. 63

Installing the charger onto the optional mounting bracket ........................................................................... 64

Powering the charger ......................................................................................................................... 65

Disconnecting the charger................................................................................................................... 66

Accessories ........................................................................................................................................... 67

Cleaning................................................................................................................................................ 68

Suggested cleaners........................................................................................................................... 68

Cleaning the charger.......................................................................................................................... 69

2 6506-209-001 REV F www.stryker.com

Page 9

Table of Contents

Cleaning the battery........................................................................................................................... 69

Preventive maintenance............................................................................................................................ 71

Lubrication....................................................................................................................................... 71

Regular inspection and adjustments ...................................................................................................... 71

Foot end fastener part replacement schedule.......................................................................................... 74

EMC information ..................................................................................................................................... 75

Warranty ............................................................................................................................................... 79

Warranty exclusion and damage limitations............................................................................................. 79

To obtain parts and service.................................................................................................................. 80

Return authorization........................................................................................................................... 80

Damaged product.............................................................................................................................. 80

International warranty clause ............................................................................................................... 80

www.stryker.com 6506-209-001 REV F 3

Page 10

Warning/Caution/Note Definition

The words WARNING, CAUTION , and NOTE carry special meanings and should be carefully reviewed.

WARNING

Alerts the reader about a situation which, if not avoided, could result in death or serious injury. It may also describe

potential serious adverse reactions and safety hazards.

CAUTION

Alerts the reader of a potentially hazardous situation which, if not avoided, may result in minor or moderate injury to the

user or patient or damage to the product or other property. This includes special care necessary for the safe and

effective use of the device and the care necessary to avoid damage to a device that may occur as a result of use or

misuse.

Note: Provides special information to make maintenance easier or important instructions clearer.

4 6506-209-001 REV F www.stryker.com

Page 11

Summary of safety precautions

Always read and strictly follow the warnings and cautions listed on this page. Service only by qualified personnel.

WARNING

• Always keep your hands clear of the red safety bar pivots when you load, unload, or change the height position of

the cot.

• Always use both hands when you transport the cot.

• Power-PRO with the Power-LOAD compatibility option operates primarily at these frequencies: 70 - 85 kHz for

inductive charging and 13.56 MHz±7 kHz, Amplitude Modulated (OOK), ERP: -82.37 dBm. The inductive charging

can operate between these frequencies: 70 - 125 kHz. Other equipment may interfere with the Power-LOAD system,

even if that other equipment complies with CISPR emission requirements.

• Always install the in-fastener shut-off system in any emergency vehicle that will be used with this cot if using an

antler style cot fastener.

• Install the cot fastener by qualified personnel only. Improper installation could result in injury to the patient or

operator.

• Always make sure that all cots meet the installation specifications for the Stryker cot fastener system.

• Always position the in-fastener shut-off before you place the cot into service.

• Do not attempt to operate the cot when it is loaded into a cot fastener.

• Always use the in-fastener shut-off to disable the electronic functionality only. Do not use the in-fastener shut-off for

any other purpose.

• Do not remove the battery when the cot is active.

• Always operate the cot only when all persons are clear of the mechanisms. Entanglement in powered cot

mechanisms can cause serious injury.

• Always inspect SMRT Paks for damage before every use.

• Do not allow untrained assistants to assist in the operation of the product.

• Do not ride on the base of the cot.

• Do not transport the cot sideways to avoid the risk of tipping. Always transport the cot in a lowered position, head end

or foot end first to minimize the risk of tipping.

• Always conduct patient monitoring when the cot is idle. If you hydraulically raise or lower the product you may

temporarily affect electronic patient monitoring equipment.

• Do not leave a patient unattended. Hold the product while a patient is on the product.

• Do not apply a wheel lock when a patient is on the product or when you move the product to avoid the risk of tipping.

• Do not use siderails as a patient restraint device.

• Always transport the cot at a lower height to reduce the risk of a cot tip. If possible, obtain additional assistance or

take an alternate route.

• Always avoid high obstacles, such as curbing, steps, or rough terrain to avoid the risk of the product tipping over.

• Always use Power-LOAD with the 6085/6086 Performance-PRO XT, 6500/6506 Power-PRO XT, and 6510/6516

Power-PRO IT cots with the Power-LOAD option only. In certain situations, you can use Power-LOAD as a standard

antler for most X-frame cots, but a rail clamp assembly is required for all cots without the Power-LO AD option.

• Always make sure that you use a Power-LOAD date of manufacture cot with the Stryker Model 6390 Power-LOAD

system to avoid the risk of injury.

• Always support the load of the patient, cot, and accessories after the weight is off of the ground.

• Do not pull or lift on the cot safety bar when you unload the cot.

• Always lock the head section into place before you operate the cot.

• Do not load the cot into a vehicle with the head section retracted when using a cot fastener. The cot may tip or not

connect with the cot fastener.

• Do not install or apply a wheel lock on a product with worn wheels that are less than 6 in. diameter.

www.stryker.com 6506-209-001 REV F 5

Page 12

Summary of safety precautions

WARNING (CONTINUED)

• Always use two people when using the kickstand.

• Always center the patient weight on the cot before you use the kickstand.

• Always apply the kickstand with your foot only.

• Always lower the cot height before you apply the kickstand for increased stability.

• Do not apply the kickstand during transport. Keep the kickstand in the retracted position.

• Do not use the kickstand as a brake.

• Do not apply the kickstand on a sloped surface.

• Always use all restraint straps to secure the patient on the cot. An unrestrained patient may fall from the cot.

• Do not attach restraint straps to the base tubes or cross tubes.

• Always use all restraint straps to secure the patient on the cot. An unrestrained patient may fall from the cot.

• Do not attach restraint straps to the base tubes or cross tubes.

• Always locate the buckle away from obstructions or accessories on the cot to avoid the risk of accidental release of

Pedi-Mate® infant restraint system and injury to the infant.

• Do not pinch your fingers between the fowler bracket and the oxygen bottle if your cot is equipped with the optional

retractable head section oxygen bottle holder.

• Do not remove the battery when the cot is activated.

• Do not attempt to open the battery pack for any reason, to avoid the risk of electric shock. If the battery pack case is

cracked or damaged, do not insert it into the charger. Return damaged battery packs to a service center for

recycling.

• Always avoid direct contact with a wet battery or battery enclosures. Contact may cause injury to the patient or

operator.

• Do not insert a cracked or damaged SMRT Pak into the SMRT charger. Return damaged SMRT Paks to a service

center for recycling.

• Always have a certified mechanic, familiar with ambulance vehicle construction, install the optional mounting bracket

and the SMRT charger.

• Always mount the SMRT charger to the optional mounting bracket in an enclosed cabinet and out of patient reach

during transport to comply with established crash test standards.

• Always make sure that the optional mounting bracket is securely attached to the surface.

• Always use any appropriate personal protective equipment while power washing to avoid inhaling contagion. Power

washing equipment may aerate contamination.

• Always wipe the product with clean water and dry after cleaning. Some cleaning products are corrosive in nature and

may cause damage to the product. Failure to properly rinse and dry the product leaves a corrosive residue on the

surface of the product and may cause premature corrosion of critical components.

• Always wear insulated rubber gloves, in addition to personal protective equipment, when cleaning the SMRT Pak to

reduce the risk of injury.

• Always disconnect the SMRT charger from the wall outlet before cleaning to avoid the risk of electrical hazards.

• Do not spray fluid directly onto the SMRT charger.

• Do not power wash the SMRT charger.

• Do not immerse the SMRT charger in water or allow water to collect on top of the SMRT charger to avoid the risk of

electric shock.

• Always use only non-conductive materials to wipe the SMRT Pak.

• Always refer to the disinfectant’s Material Safety Data Sheet (MSDS) to verify the pH range. Disinfectants with pH

levels higher than 10.5 may cause the SMRT Pak housing material to crack.

6 6506-209-001 REV F www.stryker.com

Page 13

Summary of safety precautions

WARNING (CONTINUED)

• Do not directly handle or make contact with the SMRT Pak terminals while cleaning to avoid the risk of injury.

• Do not immerse the SMRT Pak in liquid to reduce the risk of electric shock.

• Do not use solvents, lubricants, or other chemicals to clean the SMRT Pak unless otherwise directed.

• Always relieve pressure before you disconnect hydraulic or other lines. Escaping fluid under pressure can penetrate

the skin and cause serious injury. Tighten all connections before you apply pressure. If an accident occurs, see a

doctor immediately.

• Do not use bare hands to check for hydraulic leaks.

CAUTION

• Improper usage of the product can cause injury to the patient or operator. Operate the product only as described in

this manual.

• Do not modify the product or any components of the product. Modifying the product can cause unpredictable

operation resulting in injury to patient or operator. Modifying the product also voids its warranty.

• This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at their expense.

• Always set the cot load height to the proper stop height before operation.

• Always have a certified mechanic, familiar with ambulance vehicle construction, install the vehicle safety hook.

Consult the vehicle manufacturer before you install the vehicle safety hook. Make sure that the installation of the

vehicle safety hook does not damage or interfere with the brake lines, oxygen lines, fuel lines, fuel tank, or electrical

wiring of the vehicle.

• Always charge the battery before you place the product into service. An uncharged or depleted battery may cause

poor product performance.

• Always clear any obstacles that may interfere and cause injury to the operator or patient before operating the

product.

• Do not entangle the restraint straps in the base frame when you raise or lower the cot.

• Always secure the defibrillator platform to the product when you use the defibrillator platform.

• Always use and adjust the straps that are provided with the defibrillator platform to secure the defibrillator.

• Always change the installation location or adjust the straps for your specific defibrillator size or shape.

• Do not load the defibrillator platform above the safe working load of 30 lb (13.6 kg).

• Do not load the equipment hook above the safe working load of 35 lb (15.8 kg).

• Always remove all accessories or equipment from the equipment hook when in the vehicle.

• Do not load the oxygen bottle holder above the safe working load of 15 lb (6.8 kg).

• Do not use two oxygen bottle holders at the same time.

• Do not load the backrest storage pouch above the safe working load of 20 lb (9 kg).

• Do not allow the storage pouch to interfere with the operation of the retractable head section.

• Always remove the battery if the cot is not going to be used for an extended period of time (more than 24 hours).

• Always place the electrical SMRT charger power cord where it will not be stepped on, tripped over, or otherwise

subjected to damage or stress.

• Do not touch the SMRT Pak receptacle terminals with metal objects.

www.stryker.com 6506-209-001 REV F 7

Page 14

Summary of safety precautions

CAUTION (CONTINUED)

• Always grasp and pull the plug, not the cord, when you disconnect the SMRT charger to avoid the risk of damage to

the electrical plug and cord.

• Do not steam clean or ultrasonically clean the product.

• Do not exceed 180 °F (82 °C) as the maximum water temperature.

• Do not exceed 1500 psi (130.5 bar) as the maximum water pressure. If you are using a hand held wand to wash the

product, keep the pressure nozzle at a minimum of 24 in. (61 cm) from the product.

• Always allow to air dry.

• Always remove the battery before you wash the cot.

• Do not clean, service, or perform maintenance while the product is in use.

• Do not steam clean or ultrasonically clean the SMRT Pak.

• Always use authorized parts to avoid the risk of product damage.

• Always check hoses and lines regularly to avoid damage to the cot. Check and tighten loose connections. Hydraulic

lines, hoses, and connections can fail or loosen due to physical damage, kinks, age, and environment exposure.

• Do not tip the cot onto its load wheels and actuate the product as this will allow air to enter the hydraulic system.

• The use of accessories, transducers, and cables, other than those specified or provided by the manufacturer, could

result in increased electromagnetic emissions or decreased electromagnetic immunity and result in improper

operation.

• The emissions characteristics of this equipment make it suitable for use in industrial areas and hospitals (CISPR 11

class A). If it is used in a residential environment, for which CISPR 11 class B is normally required, this equipment

might not offer adequate protection to radio frequency communication services. The user might need to take

mitigation measures, such as relocating or reorienting the equipment.

• Avoid stacking or placing other equipment adjacent to Power-PRO and SMRT charger to prevent improper operation

of the products. If such use is necessary, carefully observe Power-PRO and SMRT charger and the other equipment

to make sure that they are operating properly.

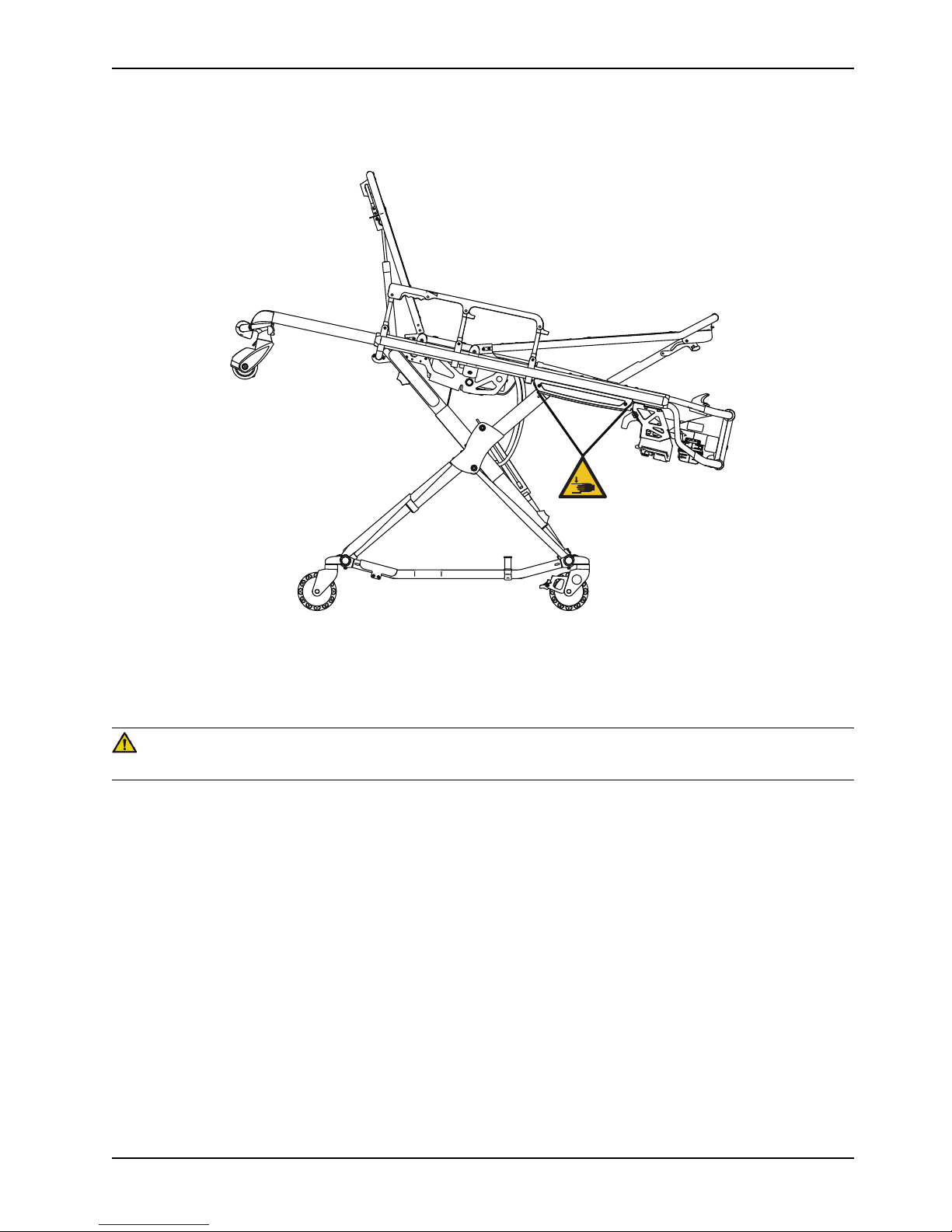

Pinch points

WARNING

Always keep your hands clear of the red safety bar pivots when you load, unload, or change the height position of the cot.

8 6506-209-001 REV F www.stryker.com

Page 15

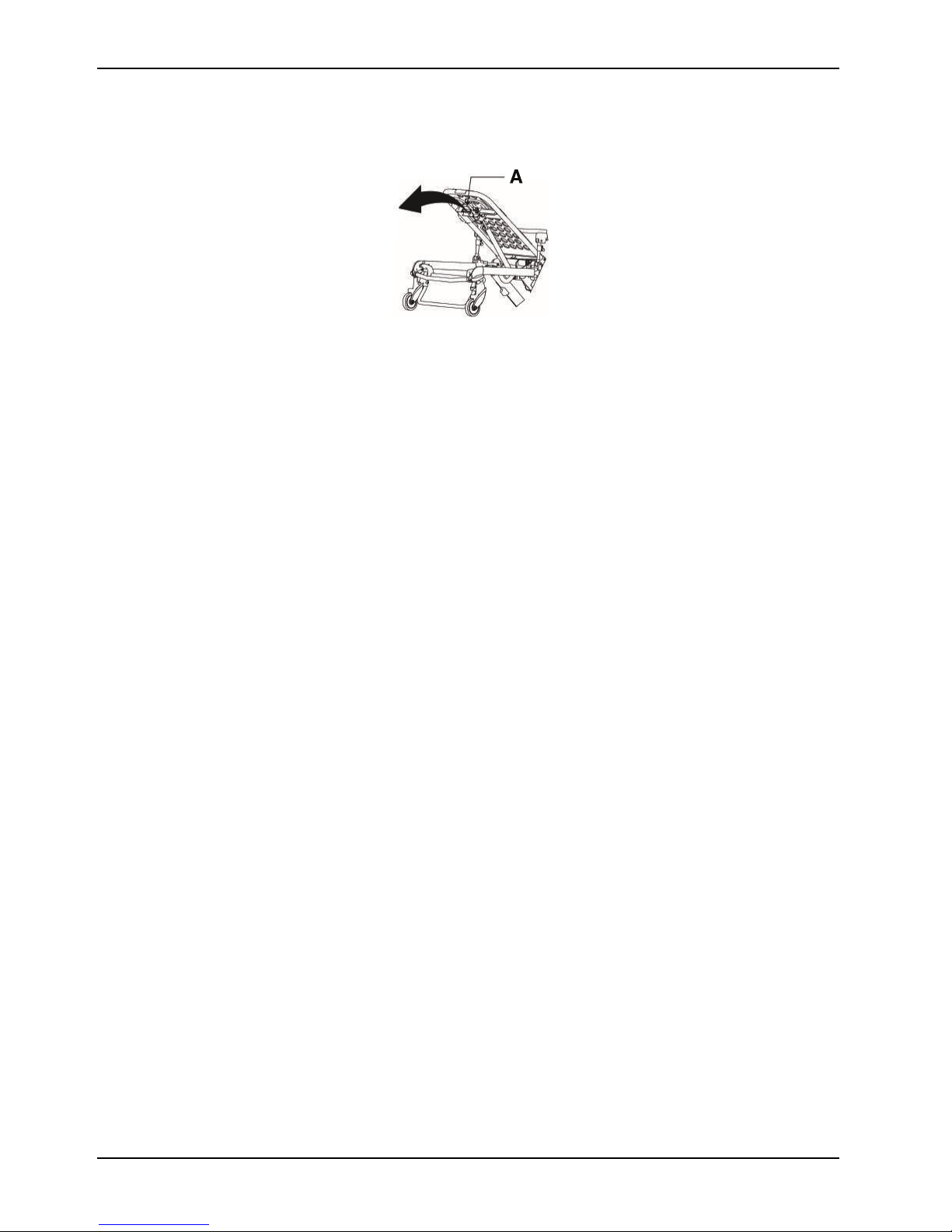

Summary of safety precautions

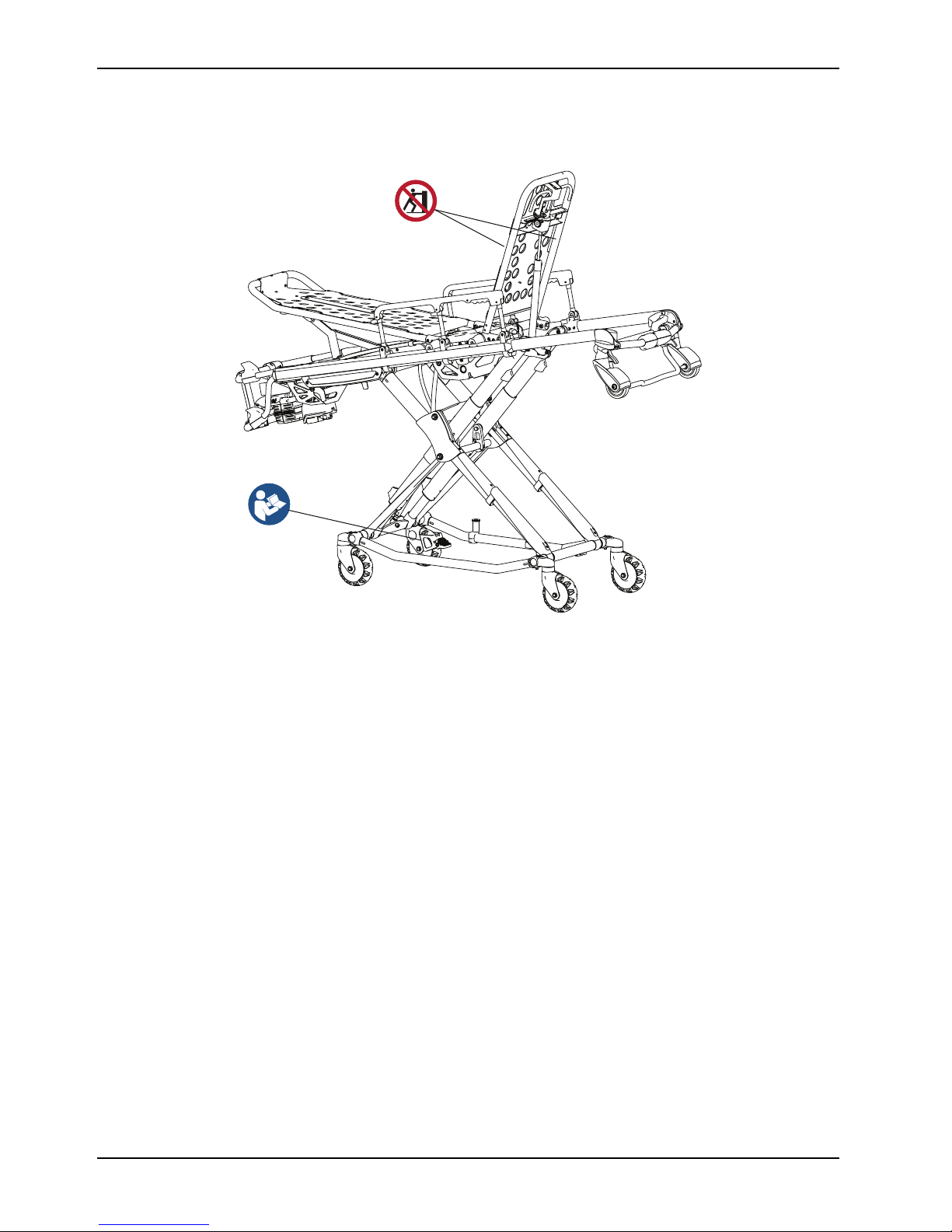

Pinch points (Continued)

Mechanical stability

WARNING

Always use both hands when you transport the cot.

Figure 1: Pinch points

www.stryker.com 6506-209-001 REV F 9

Page 16

Summary of safety precautions

Mechanical stability (Continued)

Figure 2: Mechanical stability

Notes

• If the cot is on a plane steeper than five degrees, place the cot in the lowest position.

• Do not use the defibrillator option and the foot end oxygen bottle holder option at the same time.

10 6506-209-001 REV F www.stryker.com

Page 17

Introduction

This manual assists you with the operation or maintenance of your Stryker product. Read this manual before operating or

maintaining this product. Set methods and procedures to educate and train your staff on the safe operation or

maintenance of this product.

CAUTION

• Improper usage of the product can cause injury to the patient or operator. Operate the product only as described in

this manual.

• Do not modify the product or any components of the product. Modifying the product can cause unpredictable

operation resulting in injury to patient or operator. Modifying the product also voids its warranty.

Notes

• This manual is a permanent part of the product and should remain with the product even if the product is sold.

• Stryker continually seeks advancements in product design and quality. This manual contains the most current

product information available at the time of printing. There may be minor discrepancies between your product and

this manual. If you have any questions, contact Stryker Customer Service or Technical Support at 1-800-327-0770.

Product description

The Stryker Model 6506 Power-PRO™ XT cot is a powered ambulance cot that consists of a platform mounted on a

wheeled X-frame designed to support and transport a maximum weight of 700 lb (318 kg) in pre-hospital and hospital

environments.

The device is collapsible for use in emergency vehicles and has an adjustable load height feature to allow the device to

be set to different ambulance deck heights for proper body mechanics during loading and unloading. The NiCd batterypowered hydraulic lift system allows operators to raise and lower the cot using the powered controls, while duplicate footend controls on the upper and lower lift bars accommodate different operator positions or sizes. The cot is equipped with

a manual back-up release handle to allow the operation of cot functions in the event of power loss. The device is

equipped with a retractable head section for 360-degree mobility in any height position, side rails, patient securement

straps, an adjustable pneumatic backrest, and various optional accessories that assist with the transport of a patient.

Maximum patient comfort is attainable with the three different litter positions of shock, flat leg, and optional knee gatch

positioning.

The SMRT™ power system consists of a SMRT charger and a SMRT Pak. The SMRT Pak powers the hydraulic lift

system of the Stryker powered ambulance cots.

Indications for use

The Stryker Power-PRO XT is a powered wheeled stretcher, which is intended to support and transport the entire body of

a traumatized, ambulatory, or non-ambulatory human patient (includes infants and adults).

The battery-powered hydraulic lift system is intended to help reduce the effort required by the operator to raise and lower

the cot. The device is designed to support patients in a supine (horizontal) or sitting position and facilitate the

transportation of associated medical equipment (such as oxygen bottles, monitors, or pumps) in emergency or transport

vehicles. This ambulance cot is intended to be used in pre-hospital and hospital environments, and in emergency and nonemergency applications. It is rated to a maximum capacity of 700 lb (318 kg) (sum of the patient, mattress, and

accessory weight) and the intended operators of the device are trained professionals including emergency medical

service and medical care center personnel, as well as medical first responders.

Power-PRO XT is not intended for extended stay or use as a hospital bed or in devices that modify air pressure, such as

hyperbaric chambers.

www.stryker.com 6506-209-001 REV F 11

Page 18

Introduction

Expected service life

Power-PRO has a seven year expected service life under normal use conditions and with appropriate periodic

maintenance.

The SMRT charger has a seven year expected service life under normal use conditions and with appropriate periodic

maintenance.

The SMRT Pak battery has a two year expected service life under normal use conditions.

Contraindications

None known.

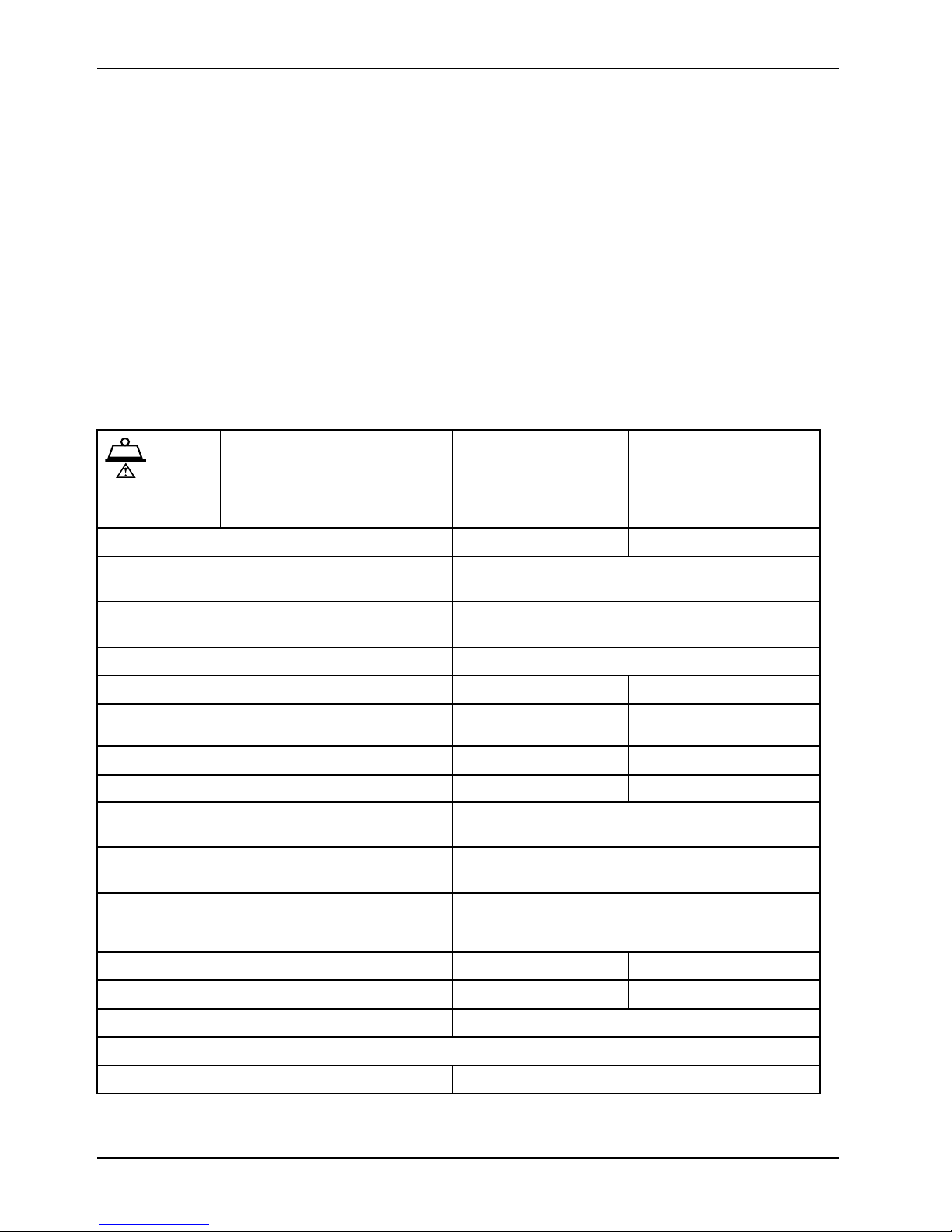

Specifications - Power-PRO

Safe working load

Note: Safe working load indicates

the sum of the patient, mattress,

and accessory weight.

Maximum unassisted lift capacity

Backrest articulation/shock position (standard fowler 6506-012-003)

Backrest articulation/shock position (1865 fowler

option - 6506-012-004)

Backrest articulation/shock position (6506-700-013) 6° to 73°/+15°

Overall length/minimum length/width

2

Height

Weight

Caster diameter/width

Minimum operators required for loading/ unloading an

occupied cot

Minimum operators required for loading/ unloading an

unoccupied cot

3

1

700 lb 318 kg

500 lb 227 kg

0° to 73°/+15°

0° to 75°/+15°

81 in./63 in./23 in. 206 cm/160 cm/58 cm

Adjustable from 14 in. to

41.5 in.

125 lb 57 kg

6 in./2 in. 15 cm/5 cm

2

1

Adjustable from 36 cm to

105 cm

Recommended fastener systems

Recommended loading height

Recommended working height (excluding mattress) 15.75 in. 40 cm

Hydraulic oil

Power system

Battery 24 VDC NiCd - SMRT power system

12 6506-209-001 REV F www.stryker.com

4

Model 6370 or 6377 Floor mount type, Model 6371 Wall

mount type, Model 6390 Power-LOAD, Model 6392

Performance-LOAD

Up to 36 in. Up to 91 cm

Stryker part number 6500-001-293

Page 19

Introduction

130 °F

(54 °C)

-30 °F

(-34 °C)

130 °F

(54 °C)

-30 °F

(-34 °C)

93%0%93%

0%

1060 hPa

700

1060 hPa

700

Specifications - Power-PRO (Continued)

Charger 100-240 VAC 1.20 A,

50/60 Hz or 12 VAC 4.16 A - SMRT power system

Cot duty cycle 16.7% (less than 60 seconds on, more than 300 seconds

off)

Standards (cots and chargers) ANSI/AAMI ES60601-1: 2012, CAN/CSA-C22.2 No. 60601-

1:14, KKK-A-1822

For standards that require specific options, see

Standards with required options on page 14.

1

Cot loads over 300 lb (136 kg) may require additional assistance to meet the set cot load height.

2

Height measured from bottom of mattress at seat section to ground level.

3

Cot is weighed with one battery and without mattress and restraints.

4

Set the cot height to any ambulance deck height that ranges from 26 in. to 36 in. (66 cm to 91 cm).

Stryker reserves the right to change specifications without notice.

Power-PRO XT is designed to conform to the Federal Specification for the Star-of-Life Ambulance (KKK-A-1822 ).

Power-PRO XT is designed to be compatible with some competitive cot fastener systems.

The yellow and black color scheme is a proprietary trademark of Stryker Corporation.

Hereby, Stryker declares that the radio equipment type short range device is in compliance with Directive 2014/53/EU.

The full text of the EU declaration of conformity is available at the following internet address: http://techweb.med.

strykercorp.com/EMS/EU%20Declaration%20of%20Conformity/index.html.

Labels may be unreadable from a viewing distance greater than 12 inches.

WARNING

Power-PRO with the Power-LOAD compatibility option operates primarily at these frequencies: 70 - 85 kHz for inductive

charging and 13.56 MHz±7 kHz, Amplitude Modulated (OOK), ERP: -82.37 dBm. The inductive charging can operate

between these frequencies: 70 - 125 kHz. Other equipment may interfere with the Power-LOAD system, even if that

other equipment complies with CISPR emission requirements.

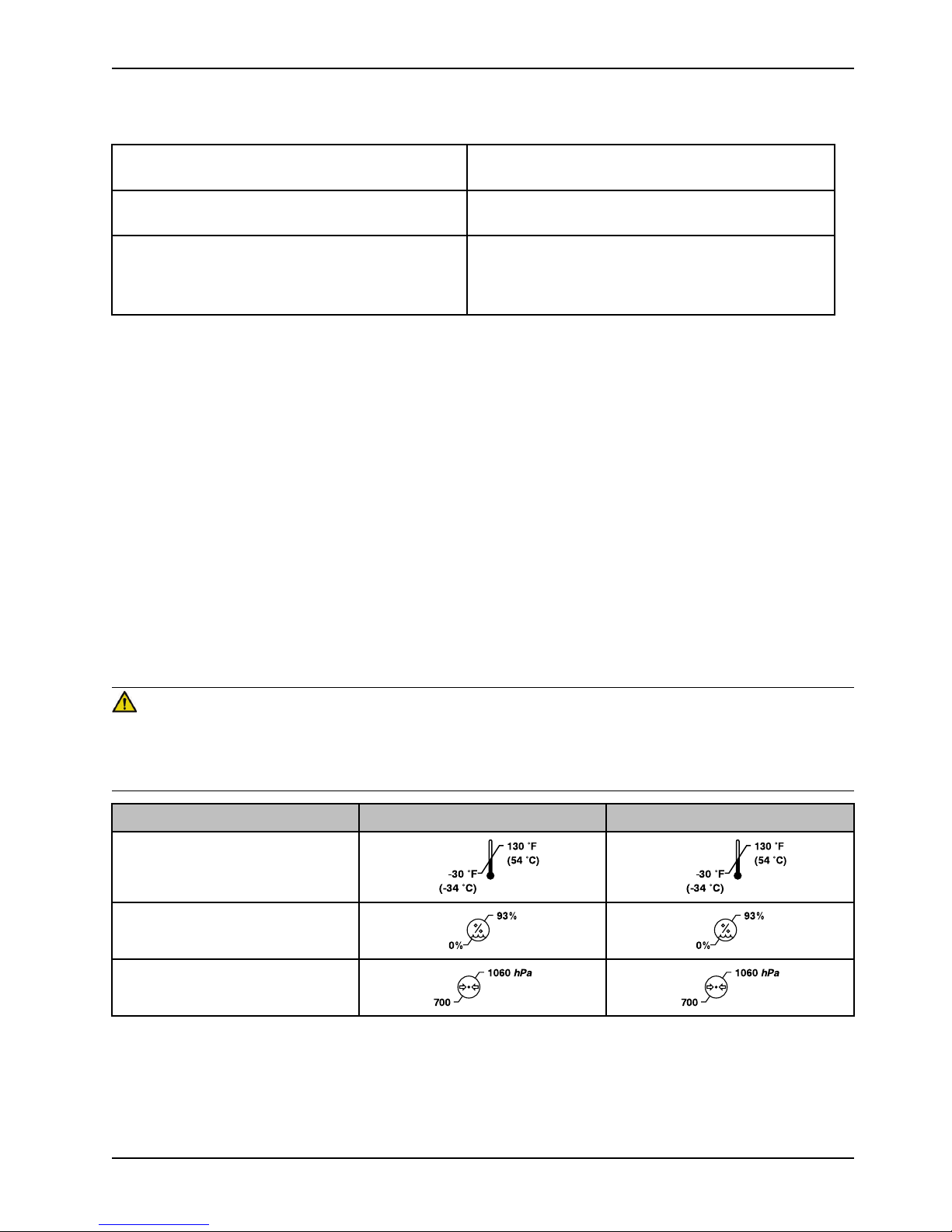

Environmental conditions

Temperature

Relative humidity

Atmospheric pressure

Operation Storage and transportation

www.stryker.com 6506-209-001 REV F 13

Page 20

Introduction

Specifications - Power-PRO (Continued)

CAUTION

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interferen ce when the equipment

is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and,

if not installed and used in accordance with the instruction manual, may cause harmful interferen ce to radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at their expense.

Note: In accordance with the European REACH regulation and other environmental regulatory requirements, the 6500001-210 and 6500-001-211 hydraulic hoses contain dibutyl phthalate (DBP).

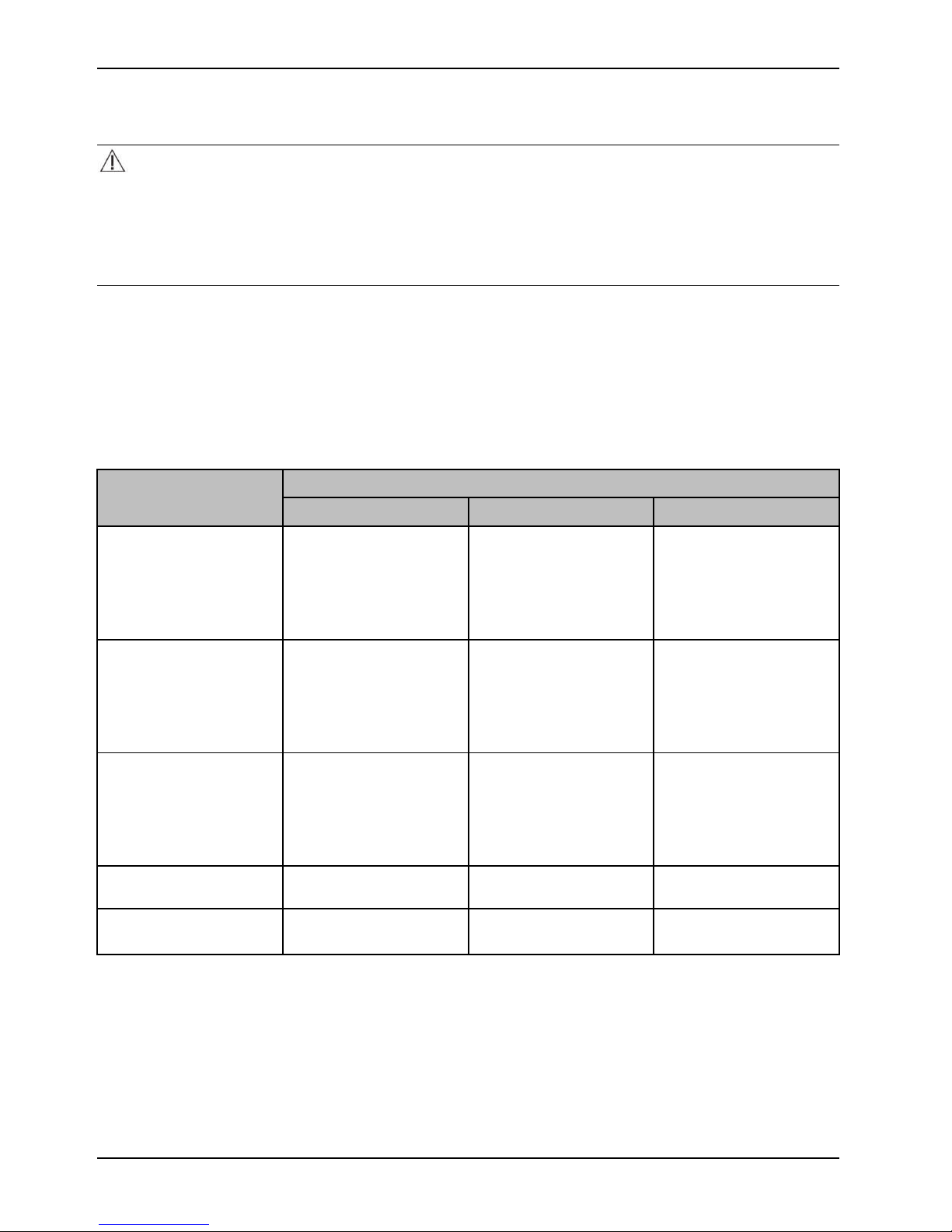

Standards with required options

To be compliant with the standards, you must install the following required options on your cot.

Note: Compatible cot is loaded into Power-LOAD in powered mode for crash testing.

Option selection

Standard

SAE J3027 crash-test

standards with the use of a

crash-rated fastener

AS/NZS-4535 crash-test

standards with the use of a

crash-rated fastener

BS EN 1789:2007+A2 :2014

crash-test standards with

the use of a crash-rated

fastener

BS EN 1865-3:2012

+A1:2015

BS EN 1865-2:2010

+A1:2015

Restraint package Mattress

X-restraint package (6500001-430) or RUGGED-X

restraint package (6506001-430)

X-restraint package (6500001-430)

G-rated restraint package

(6500-002-030), X-restraint

package (6500-001-430),

or RUGGED-X restraint

package (6506-001-430)

Knee gatch bolster

mattress (6500-002150/6506-002-150 ) or XPS

mattress (6500-003130/6506-003-130 )

(depending on cot siderail)

Knee gatch bolster

mattress (6500-002150/6506-002-150 ) or XPS

mattress (6500-003130/6506-003-130 )

(depending on cot siderail)

Knee gatch bolster

mattress (6500-002150/6506-002-150 ) or XPS

mattress (6500-003130/6506-003-130 )

(depending on cot siderail)

Option

XPS option (6506-040-000)

1865 fowler option (6506012-004)

The Britax Meridian SICT Series No. 7200/A/2010 Convertible Child Restraint with the X-restraint package (6500-001-

430) has been dynamically crash tested with a 10 kg crash dummy to 18.2 G forward and 10 G sideward per AS/NZS4535: 1999 crash-test standards.

14 6506-209-001 REV F www.stryker.com

Page 21

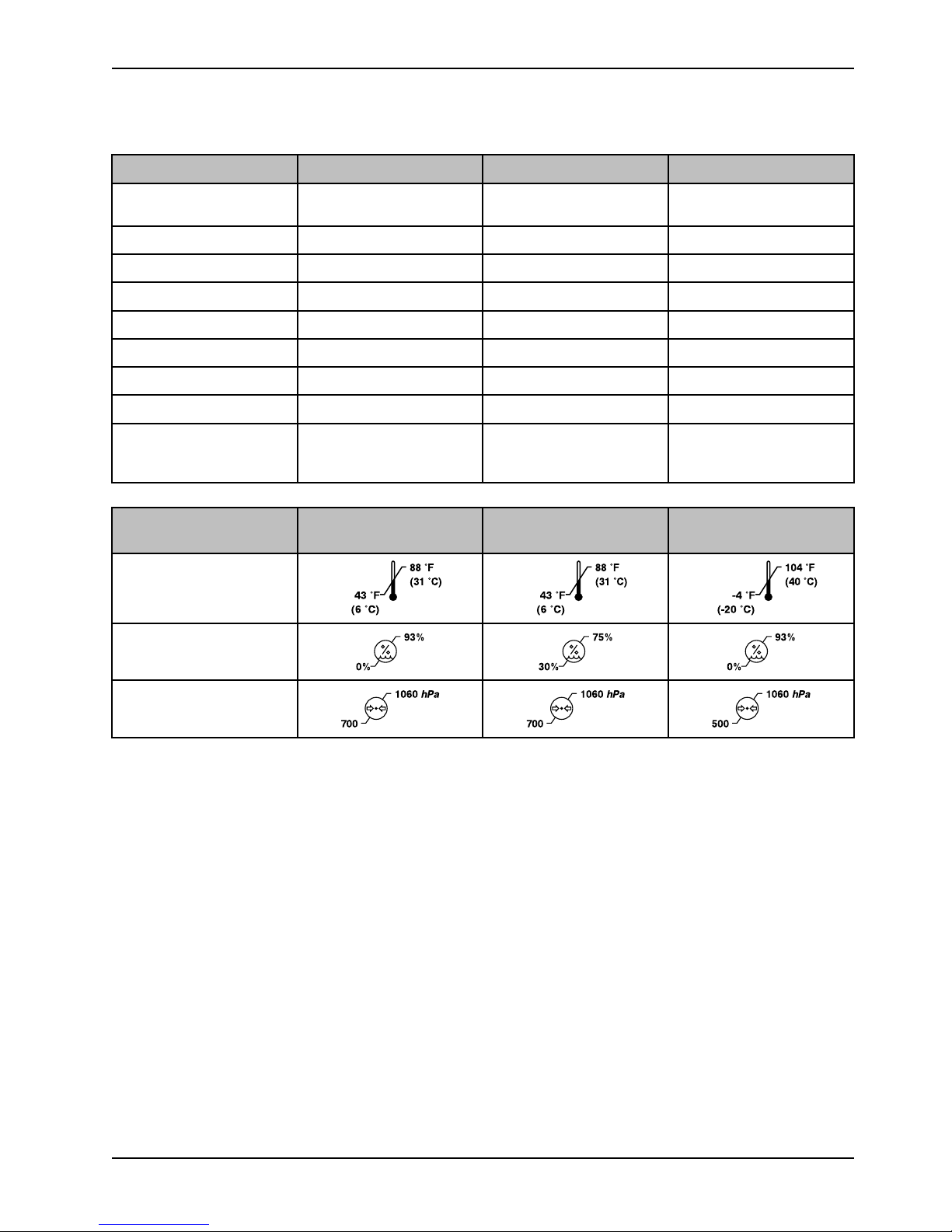

Specifications - SMRT

88 °F

(31 °C)

43 °F

(6 °C)

88 °F

(31 °C)

43 °F

(6 °C)

104 °F

(40 °C)

-4 °F

(-20 °C)

93%0%75%

30%

93%

0%

1060 hPa

700

1060 hPa

700

1060 hPa

500

Introduction

SMRT charger SMRT Pak AC power supply

Electrical input

13.9 VDC 4.16 A

Not applicable

100-240 VAC 1.20 A 50/60

Hz

Electrical output

Open circuit 40 VDC 1.20 A 24 VDC NiCd 12 VDC 4.16 A

Height 2.375 in. (60.325 mm) 3.25 in. (82.55 mm) 1.61 in. (40.89 mm)

Width 5.125 in. (130.175 mm) 4 in. (101.6 mm) 2.56 in. (65.02 mm)

Length 7 in. (177.8 mm) 5.75 in. (146.05 mm) 4.72 in. (119.89 mm)

Weight 1.3 lb (.59 kg) 3.8 lb (1.7 kg) .61 lb (.28 kg)

Enclosure protection IPX0 IPX6 IPX0

Equipment type Not applicable Not applicable

Approvals ANSI/AAMI ES60601-1:

Not applicable Not applicable

Class II

2012, CAN/CSA-C22.2 No.

60601-1:14

Environmental conditions

Operation Charging Storage and

transportation

Temperature

Relative

Atmospheric pressure

Specifications are approximate and may vary from unit to unit or as a result of power supply fluctuations.

Stryker reserves the right to change specifications without notice.

www.stryker.com 6506-209-001 REV F 15

Page 22

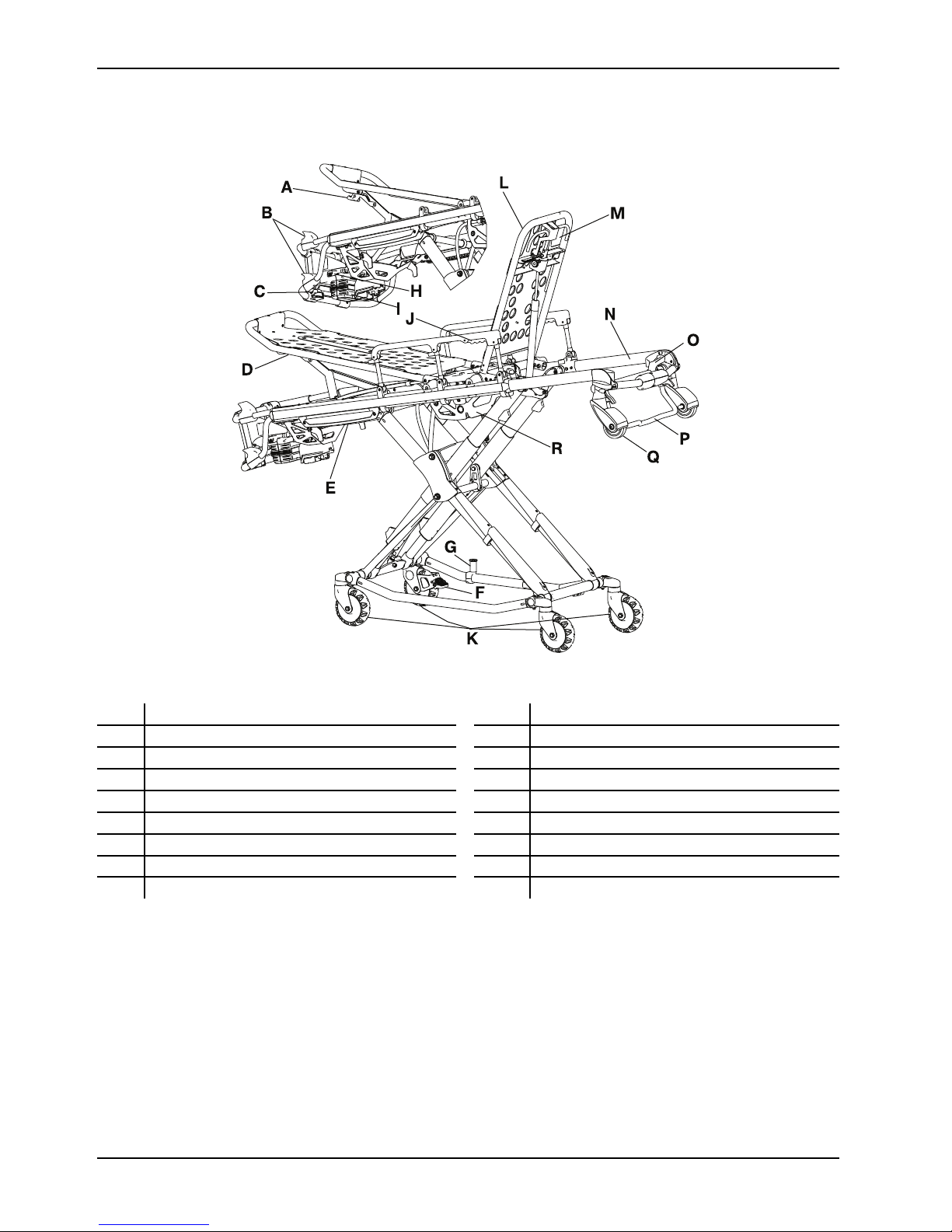

Product illustration - Power-PRO

A

B

C

D

E

F

G

H

I

K

L

M

N

O

P

Q

R

J

Introduction

Figure 3: Power-PRO XT

A Footrest release handle J Siderail release handle

B

C

D Footrest M

E

F Wheel lock O Head section release handle

G

H

I

Height adjustment switches

Manual back-up release handle

Height sensor housing (on other side)

Cot retaining post

Battery release

Battery

K

L Backrest

N Retractable head section

P

Q

R

Transport wheels

Backrest adjustment handle

Safety bar

Load wheel

Hydraulic unit

16 6506-209-001 REV F www.stryker.com

Page 23

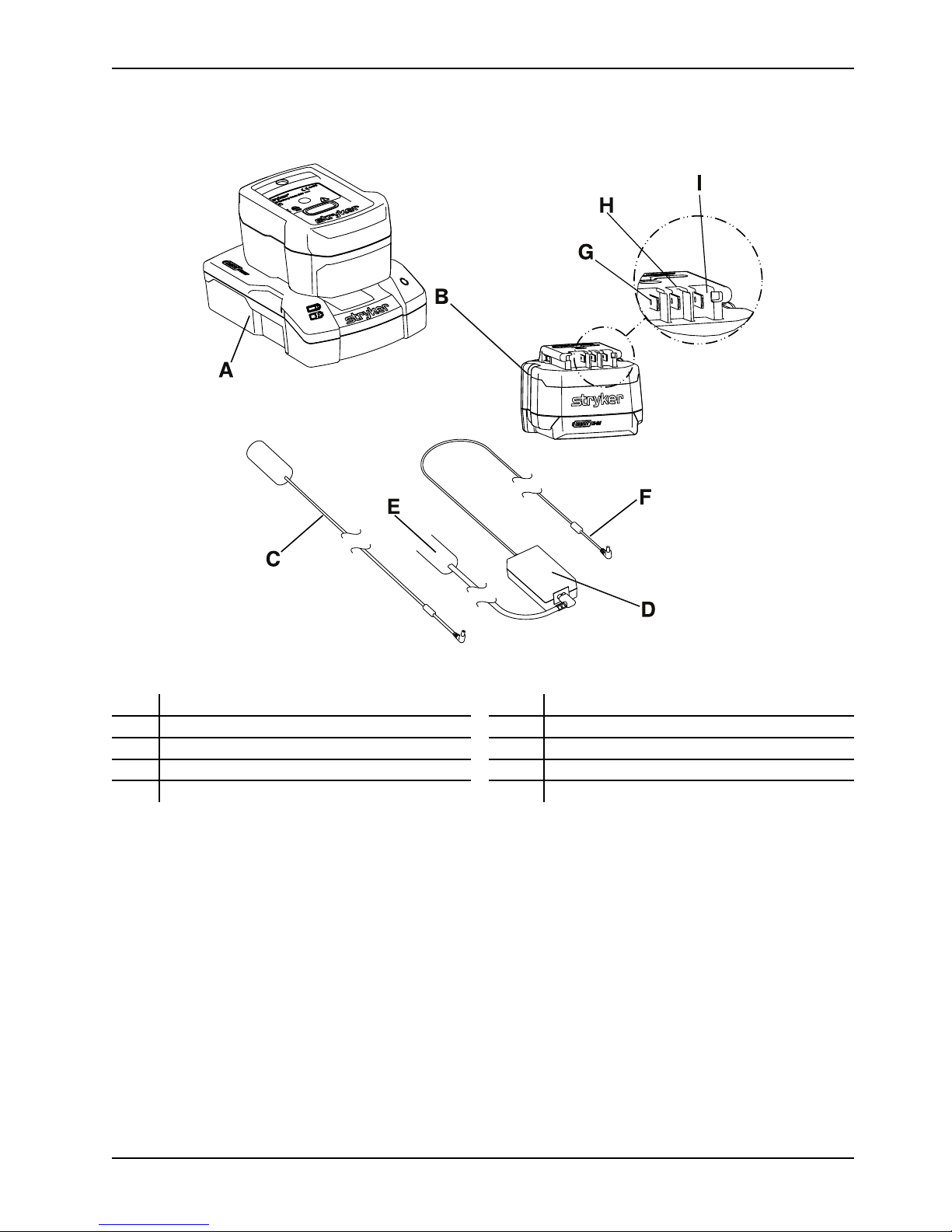

Product illustration - SMRT

A

C

D

E

F

H

I

G

B

Introduction

Figure 4: SMRT power system

SMRT charger

A

B SMRT Pak G Data

C DC cable H

AC power supply

D

AC power cord

E

F

I

Output cord

Power (-)

Power (+)

Contact information

Contact Stryker Customer Service or Technical Support at: 1-800-327-0770.

Stryker Medical

3800 E. Centre Avenue

Portage, MI 49002

USA

To view your operations or maintenance manual online, see https://techweb.stryker.com/.

Have the serial number (A) of your Stryker product available when calling Stryker Customer Service or Technical Support.

Include the serial number in all written communication.

www.stryker.com 6506-209-001 REV F 17

Page 24

Introduction

A

Serial number location - Power-PRO

Figure 5: Serial number location

Serial number location - SMRT

The serial number for the SMRT charger is located on the bottom of the unit. The lot number for the SMRT Pak is

located on the top of the SMRT Pak above the red release button.

Date of manufacture

The year of manufacture is the first 2 digits of the serial number for Power-PRO.

18 6506-209-001 REV F www.stryker.com

Page 25

Setup

During setup, unpack the cartons and check all items for proper operation. Make sure that the product operates before

you place it into service.

WARNING

Always install the in-fastener shut-off system in any emergency vehicle that will be used with this cot if using an antler

style cot fastener.

Remove all the shipping and packaging materials from the product before use.

The vehicle patient compartment where the product will be used must have a:

• Smooth rear edge for product loading

• Level floor large enough for the folded product

• Stryker cot fastener system

• Space to install the vehicle safety hook

• In fastener shut-off module installed, if using an antler style cot fastener

Note: Loose items or debris on the vehicle patient compartment floor can interfere with the operation of the vehicle

safety hook and product fastener. Keep the vehicle patient compartment floor clear.

Unpack the SMRT Paks and SMRT charger. Charge the SMRT Pak before use.

When necessary, modify the vehicle to fit the cot. Do not modify the cot.

www.stryker.com 6506-209-001 REV F 19

Page 26

Installation

Installing the cot fastener

The Stryker cot fastener systems are compatible only with cots that conform to the installation specifications.

WARNING

• Install the cot fastener by qualified personnel only. Improper installation could result in injury to the patient or

operator.

• Always make sure that all cots meet the installation specifications for the Stryker cot fastener system.

Note: You may need to adjust the rail clamp assembly to compensate for any variation in the cot retaining post position

depending on the cot manufacturer and model number.

These instructions are intended for cots with antler style cot fastener systems. For crash-rated cot fasteners, see the

appropriate Operations Manual for installation instructions.

Installing the in-fastener shut-off

These instructions are intended for cots with antler style cot fastener systems. For crash-rated cot fasteners, see the

appropriate Operations Manual for installation instructions.

WARNING

• Always position the in-fastener shut-off before you place the cot into service.

• Do not attempt to operate the cot when it is loaded into a cot fastener.

• Always use the in-fastener shut-off to disable the electronic functionality only. Do not use the in-fastener shut-off for

any other purpose.

• Always install the in-fastener shut-off system (if not using a crash-rated cot fastener) in any emergency vehicle that

will be used with this cot.

The cot and antler style cot fastener system have an integrated in-fastener shut-off function that disables the cot motor

when you secure the cot into the cot fastener. Tighten the bolts to secure the fastener before you install the shut-off

bracket. Install the shut-off bracket onto the rail clamp assembly before you place the cot into service.

1. Raise the base and push the cot into the vehicle patient compartment by following the appropriate loading

instructions.

2. Secure the extended head section of the cot into the cot fastener antler.

3. Secure the cot post into the fastener rail clamp.

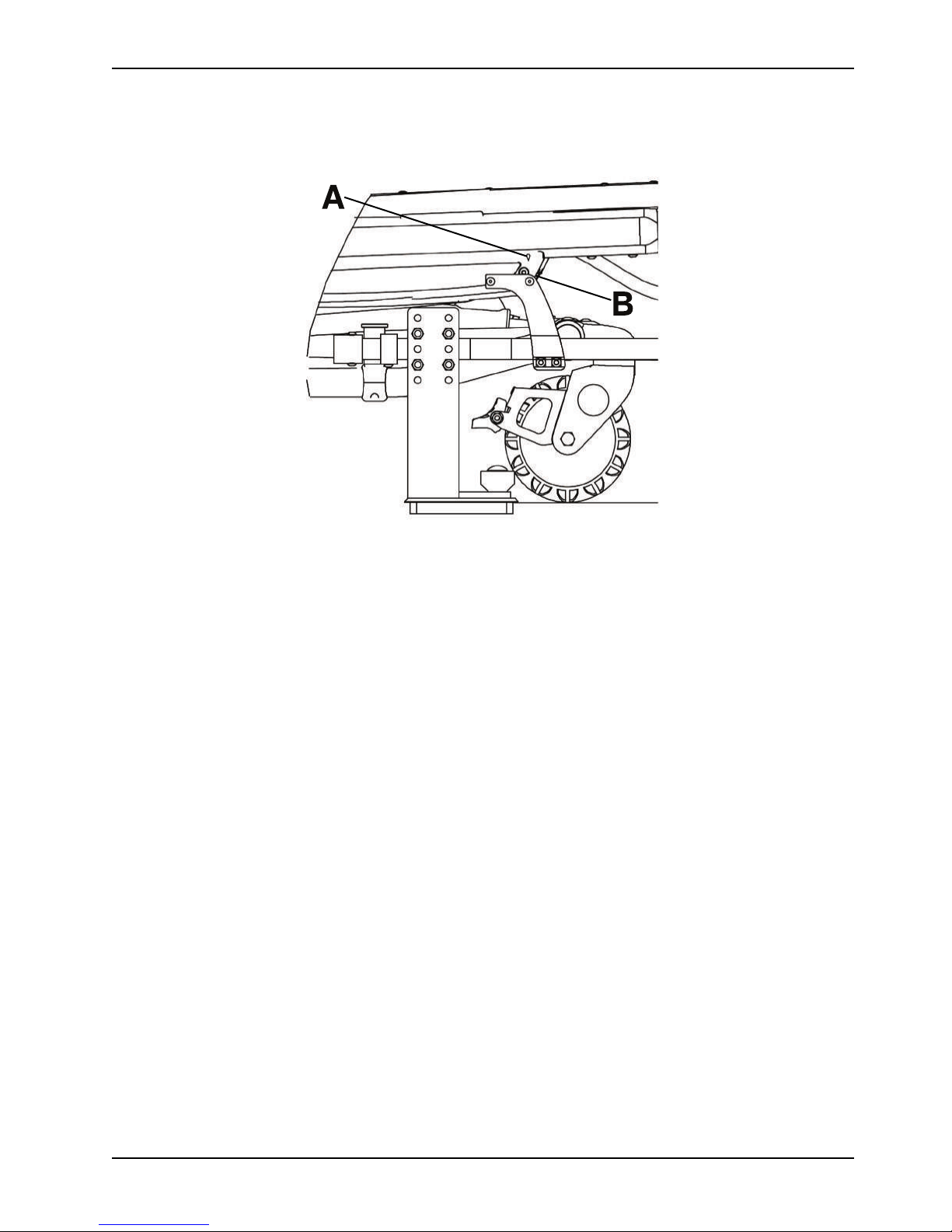

4. Adjust the shut-off bracket along the rail clamp until the diamond (A) on the sensor housing is lined up with the pop

rivet head (B).

Note: Align the diamond (A) on the sensor housing cover with the pop rivet head (B) on the in-ambulance shut-off.

5. Using a T27 Torx driver, securely fasten the bolts to attach the shut-off bracket to the rail clamp assembly.

6. Press the retract (-) button to make sure that the motor does not turn on while the cot is in the fastener. The cot

battery LED indicator will still illuminate. If the motor turns on, readjust the shut-off bracket.

20 6506-209-001 REV F www.stryker.com

Page 27

Installation

A

B

Installing the in-fastener shut-off (Continued)

Figure 6: Adjust shut-off bracket

Selecting the vehicle safety hook

The vehicle safety hook is a device that ships with the cot. The cot safety bar and vehicle safety hook keep the cot from

being accidentally removed from the vehicle and provide increased operator assurance and confidence when loading

and unloading.

Note: These instructions are intended for cots with antler style cot fastener systems. For crash-rated cot fasteners, see

the appropriate Operations Manual for installation instructions. Crash-rated cot fasteners are shipped and installed with

their own vehicle safety hook, thus no additional hook is needed.

The vehicle safety hook was designed for compatibility and proper operation when loading and unloading the cot from a

vehicle that is compliant with Federal Regulation KKK-A-1822. Stryker offers three different types of vehicle safety hooks

that are ordered and shipped with your cot. These vehicle safety hook types meet the needs of various emergency

vehicle configurations, specifically the length and location of the floor structure support that is located in the rear of the

vehicle.

To select which vehicle safety hook is appropriate for your vehicle configuration:

• Consider the location of the floor structure support where there is adequate room to mount the vehicle safety hook.

• Mount the vehicle safety hook into the back of the vehicle. Provide bumper clearance to allow the operators to load

and unload the cot from the vehicle.

• Note the differences in vehicle design. Each vehicle safety hook provides a different mounting location option to

maintain the appropriate distance between the face of the vehicle safety hook and the edge of the door sill.

Due to the differences in vehicle dimensions and the floor structure support locations, each vehicle safety hook allows

for a different mounting location. Select the correct position for your vehicle safety hook installation.

• Positioning of the vehicle safety hook, front to back on page 23

• Positioning of the vehicle safety hook, side to side on page 24

Note: When you replace an existing vehicle safety hook with a new style, adjust the mounting location to maintain the

proper position of the vehicle safety hook face.

www.stryker.com 6506-209-001 REV F 21

Page 28

Installation

6060-036-018

6092-036-018

6060-036-017

Selecting the vehicle safety hook (Continued)

Figure 7: Vehicle safety hook types

Vehicle configuration

CAUTION

• Always set the cot load height to the proper stop height before operation.

• Always have a certified mechanic, familiar with ambulance vehicle construction, install the vehicle safety hook.

Consult the vehicle manufacturer before you install the vehicle safety hook. Make sure that the installation of the

vehicle safety hook does not damage or interfere with the brake lines, oxygen lines, fuel lines, fuel tank, or electrical

wiring of the vehicle.

The cot is compatible with all vehicle deck heights that meet the Federal Specification for the Star-of-Life Ambulance

KKK-A-1822. See specifications for maximum load height.

According to Federal Specification for the Star-of-Life Ambulance KKK-A-1822:

• The rear of the ambulance shall be furnished with a sturdy, full-width, rear bumper, with step secured to the

vehicle’s chassis frame.

• The tread of the step shall have a minimum depth of 5 in. (13 cm) and a maximum depth of 10 in. (25 cm).

• If the step protrudes more than 7 in. (18 cm) from the rear of the vehicle, a fold-up step shall be furnished.

According to federal regulations (reference KKK-A-1822), the bumper height of the vehicle shall be installed equidistant

2 in. (± 5 cm) from the vehicle floor to the ground level, which is defined as the vehicle deck height. Installation of the

vehicle safety hook into any vehicle compliant with this federal specification provides adequate clearance for the cot

base to lower to its fully extended position.

22 6506-209-001 REV F www.stryker.com

Page 29

Installation

DH

2

2

A

B

C D

E

F

A

B

Vehicle configuration (Continued)

Figure 8: Deck and bumper height

A Deck height (DH)

B Bumper height

C Vehicle safety hook

D

E

F Bumper depth

Sill edge

Sill

Positioning of the vehicle safety hook, front to back

Check the front to back and side to side positioning when unloading and loading the cot to make sure that you install the

vehicle safety hook correctly.

To check the front to back positioning:

1. Select the appropriate vehicle safety hook (Selecting the vehicle safety hook on page 21).

2. Position the vehicle safety hook at least 3-3/4 in. from the leading edge of the door sill (A). The recommended

distance from the face of the safety hook to be no less than 3-3/4 in.

3. Make sure that you can secure the vehicle safety hook to the mount in the back of the vehicle.

4. Make sure that you have adequate bumper clearance to allow the cot to be loaded and unloaded from the vehicle.

5. Confirm the side to side placement of the vehicle safety hook (Positioning of the vehicle safety hook, side to side on

page 24).

www.stryker.com 6506-209-001 REV F 23

Page 30

Installation

6060-036-018

6060-036-017

6092-036-018

A

B

Positioning of the vehicle safety hook, front to back (Continued)

Figure 9: Vehicle safety hook placement

A

B Floor structure support

Sill

Positioning of the vehicle safety hook, side to side

Before you install the vehicle safety hook, check the front to back and side to side positioning, when you unload and load

the cot.

To check the side to side positioning:

1. Remove the cot from the cot fastener and unload it from the vehicle.

2. Note the position of the cot load wheels and the cot safety bar when you are remove the cot.

3. Mark the center of the cot safety bar on the vehicle floor.

4. Make sure that the position marked in step 3 is where the cot safety bar connects with the vehicle safety hook every

time when you unload the cot in a variety of positions (such as all the way to the left and all the way to the right).

24 6506-209-001 REV F www.stryker.com

Page 31

Installation

Positioning of the vehicle safety hook, side to side (Continued)

Notes

• If the cot safety bar does not connect with the vehicle safety hook in any of these positions (left, center, or right),

modify the vehicle. Do not modify the cot or the vehicle safety hook.

• If the cot safety bar connects with vehicle safety hook every time, install the vehicle safety hook.

Installing the vehicle safety hook

Before installing the vehicle safety hook, the certified mechanic should plan for the placement of the vehicle safety hook

in the rear of the vehicle patient compartment.

WARNING

• Failure to install the vehicle safety hook may cause injury to the patient or operator.

• Always have a certified mechanic, familiar with ambulance vehicle construction, install the safety hook.

• Always make sure that the cot safety bar connects with the vehicle safety hook before you remove the cot from the

vehicle patient compartment.

Hardware required (not supplied):

• (2) Grade 5, minimum 1/4”-20 socket head cap screws * for the short vehicle safety hook or long vehicle safety hook

• (2) Grade 5, minimum 1/4”-20 flat socket head cap screws * for the J vehicle safety hook

• (2) Flat washers

• (2) Lock washers

• (2) 1/4”-20 nuts

Note: The length of the socket head cap screws depend on the thickness of the vehicle floor. Use screws that are long

enough to go completely through the vehicle patient compartment floor, washer, and nut, with at least two full threads in

the nut.

1. Determine the correct vehicle safety hook front to back and side to side positioning, so the cot safety bar connects

to the vehicle safety hook every time.

• Positioning of the vehicle safety hook, front to back on page 23

• Positioning of the vehicle safety hook, side to side on page 24

2. Drill the holes for the screws.

3. Fasten the vehicle safety hook to the vehicle patient compartment floor.

4. Make sure that the cot safety bar connects with the vehicle safety hook before you remove the cot from the vehicle

patient compartment.

www.stryker.com 6506-209-001 REV F 25

Page 32

Installation

A

B

C

DE

Installing the vehicle safety hook (Continued)

Figure 10: Safety bar secured in the vehicle safety hook

A

B

C Squad bench

D Bumper

E Door frame

After installation, make sure that the cot legs lock into the load position without contacting the vehicle bumper.

26 6506-209-001 REV F www.stryker.com

Figure 11: Vehicle safety hook placement

Top view of vehicle

Vehicle safety hook

Page 33

Operation

Setting cot load height with jog function

The adjustable cot load height with jog function allows you to preset the height of the load wheels to meet the ambulance

deck height up to 36 in. The jog function assists operators when loading on an incline by jogging past the preset load

height. You can set the cot load height from 26 in. to 36 in. (66 cm to 91 cm) as measured from the ground to the bottom

of the load wheel.

To set the cot load height:

1. Locate the sensor housing on the patient right side of the cot.

2. Using a T27 Torx driver, remove the sensor housing cover by loosening the two screws (one on each end).

3. Adjust the left height sensor only inside the sensor housing: (Figure 12 on page 27):

a. Move the sensor toward the head end to increase the set load height or move the sensor toward the foot end to

decrease the set load height.

b. Press the retract (-) button to lower the cot to its lowest position, then press the extend (+) button to raise the

cot to its set load height position.

c. Measure the cot height from the bottom of the load wheels to the floor.

Note: Add an additional 1/2 in. (1,3 cm) to your deck height measurement to allow for variations in patient

weight or with other equipment that may be added to the cot.

d. Repeat steps 3a and 3b until you reach the desired cot load height.

4. Secure the height sensor cables. All cables should lie flat inside the housing between the sensors.

5. Using a T27 Torx driver, reinstall the two screws (removed in step 2) to replace the sensor housing cover.

Checking the battery power level

Use the cot battery LED indictor to check the SMRT Pak power level. A charged SMRT Pak, in working condition,

provides up to 25 calls with a 250 pound patient (actual results may vary). The 24 VDC Power-PRO system and the

SMRT Pak is rated for 2.4 amp-hours of electric energy.

WARNING

Do not remove the battery when the cot is active.

CAUTION

Always charge the battery before you place the product into service. An uncharged or depleted battery may cause poor

product performance.

www.stryker.com 6506-209-001 REV F 27

Figure 12: Adjust left sensor height

Page 34

Operation

B

A

A

6506/6516 6550

Checking the battery power level (Continued)

To check the battery power level, press the retract (-) button on the cot control switch to activate the cot battery LED

indicator. The cot battery LED indicator is located at the foot end control enclosure (shown as a battery symbol).

• The LED is solid green when the battery has a full charge or has an adequate battery power charge.

Note: For best results, use the SMRT Pak until the cot battery LED indicator changes from solid green to flashing

amber.

• The LED flashes amber when you need to charge or replace the battery

Note: The cot battery LED indicator does not have to flash amber before you remove and replace the SMRT Pak,

however, this is considered to be a best practice. You can remove and recharge the SMRT Pak at any time.

• The LED is a solid amber to indicate a battery error.

Notes

• Only use Stryker approved batteries.

• If equipped, the powered cot fastener automatically charges the SMRT Pak battery. Automatic charging occurs

when you lock the cot into the powered cot fastener (no cable or connectors required). The cot battery LED indicator

flashes green for a moment to signify that it is charging.

• Automatic charging will only occur with SMRT Pak batteries.

Checking the hour meter and error display

The hour meter indicates the amount of time (HHH.H hours) that the hydraulics were in use. The error display provides

error code information for troubleshooting.

Use the hour meter (A) (Figure 13 on page 28) to determine the frequency of preventive maintenance. Use the error

display (A) for troubleshooting. The error display overrides the hour meter display when an error occurs.

Figure 13: Checking the hour meter (A), error display (A), and battery status (B)

28 6506-209-001 REV F www.stryker.com

Page 35

Operation

Operating guidelines

WARNING

• Always operate the cot only when all persons are clear of the mechanisms. Entanglement in powered cot

mechanisms can cause serious injury.

• Always inspect SMRT Paks for damage before every use.

• Do not allow untrained assistants to assist in the operation of the product.

• Always follow proper hand placement on hand grips. Keep all hands clear of the red safety bar pivots when you load

or unload the cot or change cot height position.

• Do not ride on the base of the cot.

• Do not transport the cot sideways to avoid the risk of tipping. Always transport the cot in a lowered position, head end

or foot end first to minimize the risk of tipping.

• Always keep hands, fingers, and feet away from moving parts. Use caution when placing your hands and feet near

the base tubes while you raise or lower the cot.

• Always install the in-fastener shut-off system in any emergency vehicle that will be used with this cot if using an

antler style cot fastener.

• Always conduct patient monitoring when the cot is idle. If you hydraulically raise or lower the product you may

temporarily affect electronic patient monitoring equipment.

CAUTION

Always clear any obstacles that may interfere and cause injury to the operator or patient before operating the product.

• Operate the product only as described in this manual.

• Read all labels and instructions on the product before use.

• Practice changing height positions and loading the cot until you fully understand the operation of the product.

• Inspect the SMRT Pak housing and terminal area for any cracks or damage before first and every use.

• Always load or unload an occupied cot with a minimum of two trained operators. Two operators must be present

when a cot is occupied. Stryker recommends that both operators are at the foot end to reduce the load on each

operator. One or two operators can lift from the foot end of the cot.

• Do not adjust, roll, or load the cot into a vehicle without advising the patient. Stay with the patient and control the

product at all times.

• You can transport the cot in any position. Stryker recommends that the operators transport the patient in the lowest

comfortable position to maneuver the cot.

• Only use the wheel locks during patient transfer or without a patient on the product.

• Do not apply a wheel lock when an occupant is on the product or when moving the product to avoid the risk of tipping.

• Use properly trained helpers to control the cot, when necessary.

Proper lifting techniques

When you lift the product and occupant, follow these proper lifting techniques to avoid the risk of injury:

• Keep your hands close to your body

• Keep your back straight

• Coordinate all movement with your partner

• Lift with your legs

• Avoid twisting

www.stryker.com 6506-209-001 REV F 29

Page 36

Operation

Transferring the patient to the cot

WARNING

• Always use all restraint straps to secure the patient on the product. An unrestrained patient may fall from the product

and be injured.

• Do not leave a patient unattended. Hold the product while a patient is on the product.

• Do not apply a wheel lock when a patient is on the product or when you move the product to avoid the risk of tipping.

• Do not use siderails as a patient restraint device.

To transfer the patient to the product:

1. Roll the product to the patient (Rolling the cot with a patient on page 30).

2. Place the product beside the patient and raise or lower the product to the level of the patient.

3. Lower the siderails and open the restraint straps.

4. Transfer the patient to the product. Follow accepted EMS procedures.

5. Secure the patient to the product with all of the restraint straps.

6. Raise the siderails and adjust the backrest and footrest as necessary.

Note: Use the Transfer Flat (6005-001-001) to transfer larger patients.

Rolling the cot with a patient

WARNING

• Always transport the cot at a lower height to reduce the risk of a cot tip. If possible, obtain additional assistance or

take an alternate route.

• Always avoid high obstacles, such as curbing, steps, or rough terrain to avoid the risk of the product tipping over.

To roll the cot with a patient:

1. Position one operator at the foot end and one operator at the head end of the cot.

2. Make sure that the litter is perpendicular when you approach door sills or other low obstacles.

3. Lift each set of wheels over the door sill or obstacle separately.

Raising or lowering the cot

You can raise or lower an unoccupied cot with one operator. If a patient is on the cot, a minimum of two trained operators

(one located at each end of the cot) are required to raise or lower the cot.

WARNING

• Always keep hands, fingers, and feet away from moving parts. Use caution when placing your hands and feet near

the base tubes while you raise or lower the cot.

• Always follow proper hand placement on hand grips. Keep all hands clear of the red safety bar pivots when you load

or unload the cot or change cot height position.

CAUTION

Do not use the jog function to jog past the set cot load height after the cot safety bar connects with the vehicle safety

hook.

30 6506-209-001 REV F www.stryker.com

Page 37

Operation

A

B

C

Raising or lowering the cot (Continued)

To raise or lower the cot:

1. Operator 1 (foot end): Grasp the cot frame and press the:

• Extend (+) button to raise the cot to the desired height

• Retract (-) button to lower the cot to the desired height

2. Operator 2 (head end): Maintain a firm grip on the outer rail until the cot is at the desired height.

Notes

• Operator 2 is required to raise or lower the cot with a patient.

• If you press the extend (+) button on the cot control switch after the cot reaches the set cot load height, the motor

will remain halted until you release the button. After you release the button, press the extend (+) button again to jog

the cot height up higher.

Raising, lowering, or releasing the cot with power

There are two identical cot control switches located on the Power-PRO cots. Press the button on either of these switches

to raise (extend) the cot, lower (retract) the cot, or release the cot from Power-LOAD, if applicable (Figure 14 on page

31).

Reference Name Description

A Release

B Retract (-) Press and hold to lower the litter or

C

www.stryker.com 6506-209-001 REV F 31

Figure 14: Cot control switches

Press to unlock the cot (for use with

Power-LOAD only)

retract the cot undercarriage

Extend (+) Press and hold to raise the litter or

extend the cot undercarriage

Page 38

Operation

Raising or lowering the cot manually with the manual override

In the event of loss of electrical function, you can use the cot manual override. This allows manual operation of the

product until the restoration of the electrical, powered functions. Use the red manual back-up release handle to raise or

lower the cot.

The manual back-up release handle is located is along the patient left side of the lower lift bar at the foot end of the cot.

To raise or lower the cot with the manual back-up release handle:

1. Both operators: Lift the cot during the raise or lower operation to support the weight of the cot at each end.

2. Operator 1 (foot end):

a. Pull the manual back-up release handle toward the lift bar.

b. While pulling the manual back-up release handle, raise or lower the cot to the desired position.

c. Release the handle to lock the cot into position

Notes

• Both operators must lift the cot weight off of the wheels to use the manual extend or retract while a patient is on the

cot.

• Activation of the manual back-up release handle may cause the cot to lower at a slow rate if less than 50 lb (23 kg)

are on the cot.

• Hydraulic fluid will become more viscous when the cot is used for extended periods in cold temperatures. When

using the manual back-up release function to extend the base, while unloading in cold weather conditions, hold the

manual back-up release handle for approximately one second after the cot wheels touch the ground to minimize

sagging of the litter as you remove the cot from the vehicle patient compartment.

Expediting load with the high speed retract mode

When you press the retract (-) button, the cot will enter the high speed retract mode when the cot wheels are not

supporting the weight of the cot and patient.

The high-speed retract mode expedites loading of the cot into a vehicle. The undercarriage retracts toward the highest

position once the weight of the cot and patient is no longer supported by the wheels. Press the retract (-) button to

actuate the control switch.

Loading or unloading a cot with the Power-LOAD option

The cot is fully compatible with the Model 6390 Power-LOAD system if you ordered the cot with the Power-LOAD option

or upgraded your cot with the compatibility kit.

WARNING

• Always use Power-LOAD with the 6085/6086 Performance-PRO XT, 6500/6506 Power-PRO XT, and 6510/6516

Power-PRO IT cots with the Power-LOAD option only. In certain situations, you can use Power-LOAD as a standard

antler for most X-frame cots, but a rail clamp assembly is required for all cots without the Power-LO AD option.

• Always make sure that you use a Power-LOAD date of manufacture cot with the Stryker Model 6390 Power-LOAD

system to avoid the risk of injury.

32 6506-209-001 REV F www.stryker.com

Page 39

Operation

Loading or unloading a cot with the Power-LOAD option (Continued)

Cot Compatibility kit

Model 6506 Power-PRO XT

Model 6516 Power-PRO IT

Model 6086 Performanc e-PRO XT

For more information about using your Power-LOAD compatible cot, see the Power-LOAD Operations Manual.

6506-700-001

6516-700-001

6086-700-001

Loading a cot into a vehicle with an antler style cot fastener

Always load an occupied cot with a minimum of two trained operators. Two operators must be present when a cot is

occupied. Operators must be able to lift the total weight of the patient, cot, and any items on the cot.

WARNING

• Always support the load of the patient, cot, and accessories after the weight is off of the ground.

• Two operators must be present when a cot is occupied.

• Always follow proper hand placement on hand grips. Keep all hands clear of the red safety bar pivots when you load

or unload the cot or change cot height position.

• Do not load the cot into a vehicle with the head section retracted when using a cot fastener. The cot may tip or not

connect with the cot fastener.

Stryker recommends that both operators are at the foot end to reduce the load on each operator. One or two operators

can lift from the foot end of the cot. The higher an operator must lift the cot, the more difficult it may be to hold the weight.

The operator must be able to lift the cot high enough for the cot legs to extend when the cot is unloaded. An operator

may need help if they are too short or if the patient is too heavy to lift when unloading the cot. If you are a shorter

operator, you may need to raise your arms higher to allow the cot legs to extend.

Note: You can load an unoccupied cot into a vehicle with one operator.

To load the cot into a vehicle:

1. Extend and lock the retractable head section.

2. Place the cot in a loading position. A loading position is any position where the load wheels meet the vehicle floor

height.

3. Lift the vehicle bumper, if equipped, to the raised position.

4. Roll the cot to the open door of the vehicle patient compartment.

5. Push the cot forward until the load wheels are on the vehicle patient compartment floor and the cot safety bar

passes the vehicle safety hook.

6. Pull the cot back until the cot safety bar connects to the vehicle safety hook for maximum clearance to lift the base.

7. Make sure that the cot safety bar connects with the vehicle safety hook.

8. Load the cot.