Page 1

5050 & 5051 Stretcher Chair

OPERATIONS MANUAL

For Parts or Technical Assistance:

1-800-327-0770

Page 2

Table of Contents

Introduction

Specifications 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warning / Caution / Note Definition 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation Guide

Base Pedal Operation 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Raising And Lowering Litter Height 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Applying the Brake System 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating the Steer Caster 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trendelenburg/Reverse Trendelenburg Positioning 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Siderails 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Patient Transfer System 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating the Fowler 8, 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating the Adjustable Foot Rest 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating the Optional Independent Foot Section

Dependent (Chair Mode) Operation 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Independent Operation 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Resetting the Foot Section (Returning To Chair Mode) 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Positioning the Push Bar 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing And Reinstalling the Mattress 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating the Enhanced Clearance Head Piece 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Optional Inflatable Head Support Cushion 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Optional Wrist Rests 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Optional Tethered I.V. Pole 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preventative Maintenance

Cleaning 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checklist 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limited Warranty

Obtaining Parts and Service 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supplemental Warranty Coverage 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Return Authorization 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Freight Damage Claims 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 3

Introduction

INTRODUCTION

This manual is designed to assist you with the operation of the 5050 & 5051 Stretcher Chair. Read it thoroughly before using the equipment.

SPECIFICATIONS

Maximum Weight Capacity 400 pounds

Overall Stretcher Length/Width 76”/30”

Patient Surface Length/Width (Mattress) 74”/24”

Minimum/Maximum Stretcher Height (Floor to Litter Surface) 22”/33.5”

Foot Section Articulation 0_ to 80_

Fowler Articulation 0_ to 90_

Trendelenberg/Reverse Trendelenberg Articulation +18_/-18 _

Stryker reserves the right to change specifications without notice.

WARNING / CAUTION / NOTE DEFINITION

The words WARNING, CAUTION and NOTE carry special meanings and should be carefully reviewed.

WARNING

The personal safety of the patient or user may be involved. Disregarding this information could result in injury

to the patient or user.

CAUTION

These instructions point out special procedures or precautions that must be followed to avoid damaging the

equipment.

NOTE

This provides special information to make maintenance easier or important instructions clearer.

2

Page 4

Introduction

Before operating this stretcher, it is important to read and understand all information in this manual.

Carefully read and strictly follow the warnings listed on this page.

WARNING

Patient entry, egress and transfer from the Model 5050 & 5051 Stretcher Chair must always be done at the

center side locations with the siderail lowered. At no time should patients be allowed to enter or exit from

the ends of the Stretcher Chair, unless it is in the full chair position (back section up/foot section down). Improper entry, egress or transfer may cause the Stretcher Chair to tip or become unstable which may result

in patient injury.

To avoid risk of tipping resulting in patient injury, never leave the Stretcher Chair unattended in the horizontal

position. Always return the unit to the chair position when not in use. Warning labels are located at the head

and foot end of the Stretcher Chair frame stating: “DO NOT SIT ON END. TIPPING MAY OCCUR. KEEP

IN THE CHAIR POSITION WHEN NOT IN USE.”

Always apply the caster brakes when a patient is getting on or off the stretcher. Push on the stretcher to ensure the brakes are securely locked. Always engage the brakes unless the stretcher is being moved. Injury

could result if the stretcher moves while a patient is getting on or off the stretcher . I f brakes do not hold properly, refer to your stretcher maintenance manual for a brake adjustment procedure.

Be sure to remove any equipment that may be in the way before lowering the Stretcher Chair or damage could

occur to the equipment or the Stretcher Chair.

Be sure the siderail latching mechanism is working properly and the siderail is latching securely at all times

or patient injury could result. If the siderails are not latching properly, refer to your stretcher maintenance

manual for adjustment details.

To avoid having the siderail swing down freely when the latch is released, securely hold the siderail either

underneath or from the end when raising or lowering it. Failure to do so could cause damage to the Stretcher

Chair or injury to the user.

To avoid possible injury, patients should be appropriately restrained at all times.

When using the patient transfer system, always lock the brakes on all stretchers or beds being used and

always be sure the transfer surface is securely on the surface of the mating stretcher or bed. The Stretcher

Chair patient surface and the surface of the mating stretcher or bed must be at the same height before the

patient is transferred. Failure to follow these guidelines may result in an unstable surface and patient injury .

Be sure the brakes on both the Stretcher Chair and the mating bed or stretcher have been applied before

proceeding with the patient transfer.

Keep fingers/hands clear of the area between the frame and the Fowler when lowering the Fowler or injury

could result.

Hold the foot rest firmly while repositioning it to prevent it from falling to the lowest position and causing injury

or equipment damage.

Do not stand on the foot rest. Tipping may occur which could result in patient or user injury.

The foot section will release during the return to dependent operation (Chair Mode). Hold the end securely

and support it when repositioning.

The weight of the patient’s head is resting on the head piece and must be supported by the operator when

the latches are released and the head piece is being positioned. Failure to adequately support the head piece

while positioning the head could result in patient injury.

CAUTION

The dual articulating headpiece is designed to provide precision surgical positioning. Be sure to treat it with

care. The unit should be routinely checked to ensure optimal performance. In the event of any impact or

overload of the headpiece, be sure the unit is working properly and supports the intended load. Verify the

adjustment gears lock and release properly and, if necessary, refer to the adjustment procedure in the maintenance manual.

3

Page 5

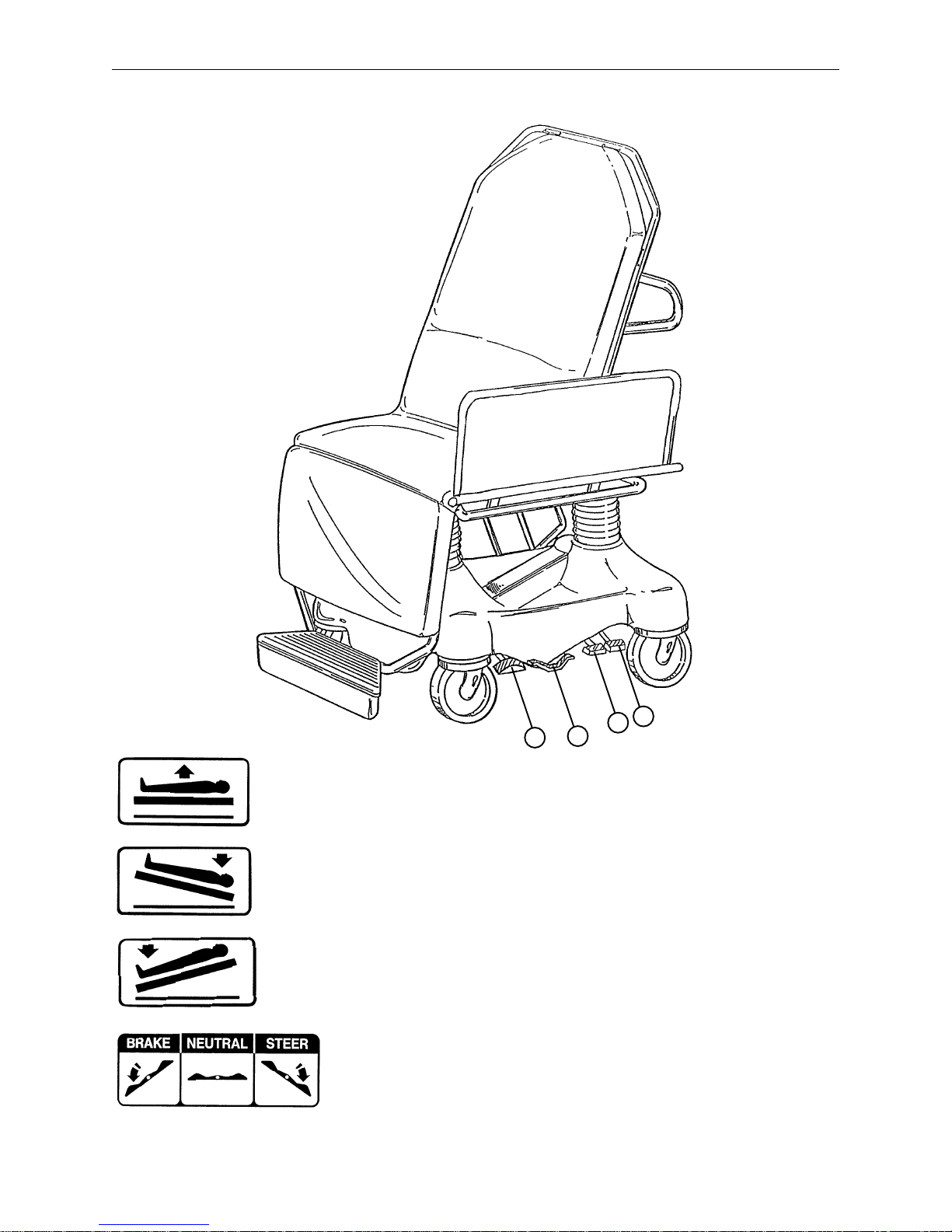

BASE PEDAL OPERATION

Operation Guide

B

C

D

A

(A)

Pump to raise litter.

(B) Depress to lower head end (Trendelenburg).

(C) Depress to lower foot end (Reverse Trendelenburg).

To lower both ends of the stretcher, depress

both Trendelenburg pedals at the same time.

(D) Brake and Steer functions

4

Page 6

Operation Guide

WARNING

Patient entry, egress and transfer from the Model 5050 Stretcher Chair must always be done at the center

side locations with the siderail lowered. At no time should patients be allowed to enter or exit from the ends

of the Stretcher Chair, unless it is in the full chair position (back section up/foot section down). Improper entry ,

egress or transfer may cause the Stretcher Chair to tip or become unstable which may result in patient injury .

RAISING AND LOWERING LITTER HEIGHT

NOTE

For user convenience, pump pedals and control pedals are located on both sides of the Stretcher Chair.

CAUTION

Be sure to move any equipment that may be in the way before raising or lowering the Stretcher Chair height

or damage could occur to the equipment or the Stretcher Chair.

To raise the litter height, pump foot pedal (A) repeatedly until desired height is achieved. (See illustration,

page 4).

To lower the litter height, activate both pedals (B) and (C) using the same foot. Depress pedal (B) to lower

the head end only and depress pedal (C) to lower the foot end only of the Stretcher Chair. (See illustration,

page 4).

WARNING

To avoid risk of tipping resulting in patient injury, never leave the Stretcher Chair unattended in the horizontal

position. Always return the unit to the chair position when not in use. Warning labels are located at the head

and foot end of the Stretcher Chair frame stating: “DO NOT SIT ON END. TIPPING MAY OCCUR. KEEP

IN THE CHAIR POSITION WHEN NOT IN USE.”

APPLYING THE BRAKE SYSTEM

To engage the brakes on the Stretcher Chair, push fully down on the side of pedal (D) closest to the head

end of the stretcher. (See illustration page 4).

WARNING

Always apply the caster brakes when a patient is getting on or off the stretcher. Push on the stretcher to ensure the brakes are securely locked. Always engage the brakes unless the stretcher is being moved. Injury

could result if the stretcher moves while a patient is getting on or off the stretcher . I f brakes do not hold properly, refer to your stretcher maintenance manual for a brake adjustment procedure.

NOTE

For user convenience, the Brake/Steer pedal is located on both sides of the Stretcher Chair.

OPERATING THE STEER CASTER

To engage the steer caster, push fully down on the side of pedal (D) closest to the foot end of the stretcher

(See illustration page 4). This will lock the steering caster (foot end, right). The Stretcher Chair will pivot

around it when cornering.

5

Page 7

Operation Guide

TRENDELENBURG/REVERSE TRENDELENBURG POSITIONING

NOTE

Litter height must be raised first in order to achieve a trend. or reverse trend. position.

CAUTION

Be sure to remove any equipment that may be in the way before lowering the Stretcher Chair or damage could

occur to the equipment or the Stretcher Chair.

For Trendelenburg positioning (head down), depress pedal (B). (See illustration, page 4).

For Reverse Trendelenburg positioning (foot down), depress pedal (C). (See illustration, page 4).

NOTE

The higher the litter is before pedals (B) or (C) are activated, the greater the trend. or reverse trend. angle

will be. (Maximum trend. angle is +18_. Maximum reverse trend. angle is -18_).

USING THE SIDERAILS

A

WARNING

Be sure the siderail latching mechanism is working properly and the siderail is latching securely at all times

or patient injury could result. If the siderails are not latching properly, refer to your stretcher maintenance

manual for adjustment details.

To avoid having the siderail swing down freely when the latch is released, securely hold the siderail either

underneath or from the end when raising or lowering it. Failure to do so could cause damage to the Stretcher

Chair or injury to the user.

To avoid possible injury, patients should be appropriately restrained at all times.

To raise the siderails, pull out the locking latch (A) while securely holding the siderail and raise the siderail

to the full up position until the latch engages.

To lower the siderails, pull out the locking latch (A) while securely holding the siderail and lower the siderail

to the full down position until the latch engages. The siderail will be partially tucked away under the litter.

6

Page 8

Operation Guide

USING THE PATIENT TRANSFER SYSTEM

C

B

A

WARNING

When using the patient transfer system, always lock the brakes on all stretchers or beds being used and

always be sure the transfer surface is securely on the surface of the mating stretcher or bed. The Stretcher

Chair patient surface and the surface of the mating stretcher or bed must be at the same height before the

patient is transferred. Failure to follow these guidelines may result in an unstable surface and patient injury .

Be sure the Stretcher Chair is as close to the mating surface as possible and at the same height or slightly

higher (not to exceed 1”).

Pull the release knob (A) and lower the siderail down onto the mating stretcher or bed. The siderail arm rest

(B) should be flat to serve as a lead to the transfer surface. If it is not, push the arm rest toward the foot end

of the stretcher to release the arm rest latch (C), then rotate the arm rest up so it is parallel with the siderail.

CAUTION

Be sure the brakes on both the Stretcher Chair and the mating bed or stretcher have been applied before

proceeding with the patient transfer.

Using a sheet, draw the patient onto the mating bed or stretcher.

7

Page 9

Operation Guide

OPERATING THE FOWLER (5050)

A

B

WARNING

Keep fingers/hands clear of the area between the frame and the Fowler when lowering the Fowler or injury

could result.

Squeeze red handle (A) toward the Fowler frame (not toward item (B) push bar) for pneumatic assist in raising

the Fowler. Remove hands from handle when desired height is achieved.

To lower the Fowler, squeeze red handle (A) toward the Fowler frame (not toward item (B) push bar) and push

down until the Fowler has reached the desired height. Remove hands from handle when desired height is

achieved.

8

Page 10

Operation Guide

OPERATING THE FOWLER (5051)

A

Squeeze red handle (A) toward the Fowler frame for pneumatic assist in raising the Fowler. Remove hands

from handle when desired height is achieved.

A

WARNING

Operation of the pneumatic Fowler is a manual procedure. Use caution when raising the Fowler while a patient is on the stretcher. Use proper lifting techniques and get additional assistance, if necessary. Failure

to use proper lifting techniques could cause injury to the operator.

To lower the Fowler, squeeze red handle (A) toward the Fowler frame and push down until the Fowler has

reached the desired height. Remove hands from handle when desired height is achieved.

WARNING

Keep fingers/hands clear of the area between the frame and the Fowler when lowering the Fowler or injury

could result.

9

Page 11

Operation Guide

OPERATING THE ADJUSTABLE FOOT REST

WARNING

Hold the foot rest firmly while repositioning it to prevent it from falling to the lowest position and causing injury

or equipment damage.

Do not stand on the foot rest. Tipping may occur which could result in patient or user injury.

NOTE

The leg section must be down in order to adjust the foot rest. The foot rest must be rotated halfway up to

the leg section in order to adjust the height.

To raise the foot rest:

Rotate the foot rest halfway up, then slide it toward the butt section until you reach the desired height. While

pulling the foot rest out toward you, rotate it down to a horizontal position. The foot rest will drop into the next

lower position.

To lower the foot rest:

While grasping the foot rest firmly , rotate it up and push back on it. When it clears its latch, it will drop down.

Rotate the foot rest down to a horizontal position.

10

Page 12

Operation Guide

OPERATING THE OPTIONAL INDEPENDENT FOOT SECTION

A

Dependent (Chair Mode) Operation

During dependent (Chair Mode) operation, the foot section will articulate with the Fowler when going from

the sitting to the supine position. In order for the foot section to be in Chair Mode, the red handle (A), located

on both sides of the foot section, must be pointing toward the head end of the Stretcher Chair.

Independent Operation

When the foot section is in the Independent Mode, it can articulate to any position independent of the Fowler.

To operate the foot section in the Independent Mode, rotate the red handle (A) so it is pointing toward the foot

end of the Stretcher Chair, as shown in the illustration above. The foot section is now locked into position,

independent of the Fowler. To reposition the foot section, hold the foot end securely , pull the red handle (A)

toward you and hold it in that position. Lift or lower the foot section to the desired position and release the

red handle to lock it in place.

Resetting the Foot Section (Returning to Chair Mode)

CAUTION

The foot section will release during the return to dependent operation (Chair Mode). Hold the end securely

and support it when repositioning.

While supporting the foot section, rotate the red handle (A) on the foot section so it is pointing toward the head

end of the Stretcher Chair. Lift or lower the foot section until it locks in place. Raise or lower the Fowler and

assure the foot section moves with it.

11

Page 13

POSITIONING THE PUSH BAR

Operation Guide

A

To lower the push bar, pull back the red release knob (A) while holding onto the push bar. Swing the push

bar into the full down position until the latch engages.

To raise the push bar, pull back the red release knob (A) while holding onto the push bar. Swing the push

bar into the full up position until the latch engages.

REMOVING AND REINSTALLING THE MATTRESS

When removing the mattress, it is important to start at the head end of the Stretcher Chair. Pull on the head

end of the mattress to release it from the Velcro on the Fowler and midsection. Once it is free of the Velcro,

pull the mattress toward the head end of the Stretcher Chair to disengage the mattress from the foot section

sliding tabs. (The tabs keep the foot section of the mattress close to the litter surface during articulation.)

To reinstall the mattress, slide the pockets on the foot end back over the sliding tabs. Place the mattress down

the length of the litter surface and press firmly on the Fowler and midsection to secure the Velcro strips.

12

Page 14

Operation Guide

OPERATING THE ENHANCED CLEARANCE HEAD PIECE

To operate the enhanced clearance head piece, grasp either handle under the

head section and squeeze. Handle (A) releases the latch and rotates the

head piece on axis ”A”. Handle (B) releases the other latch and rotates

(Cut-Away View)

the head section on axis ”B”. For ease of operation, it is recom-

mended that only one latch be released at a time.

AXIS

AXIS

WARNING

The weight of the patient’s head is resting on the head piece and must be supported by the operator when

the latches are released and the head piece is being positioned. Failure to adequately support the head piece

while positioning the head could result in patient injury.

CAUTION

The dual articulating headpiece is designed to provide precision surgical positioning. Be sure to treat it with

care. The unit should be routinely checked to ensure optimal performance. In the event of any impact or

overload of the headpiece, be sure the unit is working properly and supports the intended load. Verify the

adjustment gears lock and release properly and, if necessary, refer to the adjustment procedure in the maintenance manual.

USING THE OPTIONAL INFLATABLE HEAD SUPPORT CUSHION

The optional inflatable head support cushion has two internal air bladders. Squeeze the bulb (A) to inflate the bladders and provide more stability for the patient’s head. Press the release valve (B) to deflate the

bladders.

B

A

13

Page 15

Operation Guide

USING THE OPTIONAL WRIST RESTS

There are two optional wrist rests available; standard and temporal .

To use the wrist rest, insert the support

tube (A) into the socket in the Fowler head

piece assembly. Turn knob (B) clockwise

to secure the wrist rest assembly.

To adjust the height of the wrist rest, turn

knob (C) counterclockwise to loosen it.

Raise or lower the wrist rest to the desired

height, and turn the knob clockwise to

tighten it and hold the wrist rest in place.

The ”U” shaped rest (D) can be pivoted up

and away from the patient when the wrist

rest is not in use.

USING THE OPTIONAL TETHERED I.V. POLE

To use the tethered I.V. pole:

D

D

C

A

C

1

B

B

A

2

1. Remove the I.V. pole from the storage trough under the

litter and insert into the receptacle on the corner of the

litter frame.

2. To raise the height of the pole, turn knob (A) counterclockwise and pull up on the telescoping portion (B)

of the pole to raise it to the desired height.

3. Turn knob (A) clockwise to lock the telescoping portion

in place.

B

A

14

Page 16

Cleaning

Hand wash all surfaces of the stretcher with warm water and mild detergent. Dry thoroughly. DO NOT

STEAM CLEAN, PRESSURE WASH, HOSE OFF OR ULTRASONICALLY CLEAN. Using these methods

of cleaning is not recommended and may void this product’s warranty.

Clean Velcro AFTER EACH USE. Saturate Velcro with disinfectant and allow disinfectant to evaporate. (Appropriate disinfectant for nylon Velcro should be determined by the hospital.)

In general, when used in those concentrations recommended by the manufacturer, either phenolic type or

quaternary type disinfectants can be used. Iodophor type disinfectants are not recommended for use because staining may result. The following products have been tested and have been found not to have a harmful effect WHEN USED IN ACCORDANCE WITH MANUFACTURERS RECOMMENDED DILUTION.*

*MANUFACTURER’S

TRADE NAME DISINFECTANT

TYPE

A33 Quaternary Airwick (Professional Products Division) 2 ounces/gallon

A33 (dry) Quaternary Airwick (Professional Products Division) 1/2 ounce/gallon

Beaucoup Phenolic Huntington Laboratories 1 ounce/gallon

Blue Chip Quaternary S.C. Johnson 2 ounces/gallon

Elimstaph Quaternary Walter G. Legge 1 ounce/gallon

Franklin Pheno-

mysan F2500

Franklin Sentinel Quaternary Purex Corporation 2 ounces/gallon

Galahad Phenolic Puritan Churchill Chemical Company 1 ounce/gallon

Hi-Tor Quaternary Huntington Laboratories 1/2 ounce/gallon

LPH Phenolic Vestal Laboratories 1/2 ounce/gallon

Matar Phenolic Huntington Laboratories 1/2 ounce/gallon

Omega Quaternary Airwick (Professional Products Division) 1/2 ounce/gallon

Quanto Quaternary Huntington Laboratories 1 ounce/gallon

Sanikleen Quaternary West Chemical Products 2 ounces/ gallon

Sanimaster II Quaternary Service Master 1 ounce/gallon

Vesphene Phenolic Vestal Laboratories 1 1/4 ounce/ gallon

Phenolic Purex Corporation 1 1/4 ounce/gallon

MANUFACTURER

RECOMMENDED

DILUTION

Quaternary Germicidal Disinfectants, used as directed, and/or Chlorine Bleach products, typically 5.25% So dium Hypochlorite in dilutions ranging between 1 part bleach to 100 parts water, and 2 parts bleach

to 100 parts water are not considered mild detergents. These products are corrosive in nature and

may cause damage to your stretcher if used improperly. If these types of products are used to clean

Stryker patient handling equipment, measures must be taken to insure the stretchers are rinsed with clean

water and thoroughly dried following cleaning. Failure to properly rinse and dry the stretchers will leave a corrosive residue on the surface of the stretcher, possibly causing premature corrosion of critical components.

NOTE

Failure to follow the above directions when using these types of cleaners may void this product’s warranty.

REMOVAL OF IODINE COMPOUNDS

This solution may be used to remove iodine stains from mattress cover and foam footrest pad surfaces.

1. Use a solution of 1-2 tablespoons Sodium Thiosulfate in a pint of warm water to clean the stained area.

Clean as soon as possible after staining occurs. If stains are not immediately removed, allow solution to

soak or stand on the surface.

2. Rinse surfaces which have been exposed to the solution in clear water before returning bed to service.

15

Page 17

Preventative Maintenance

CHECKLIST

All fasteners secure (reference all assembly prints)

Siderails move and latch properly

All casters lock with brake pedal engaged

Steer function working properly

All casters secure and swivel properly

Body restraints intact and working properly

Oxygen bottle holder intact and operating properly

Fowler/leg articulation operating properly

Trendelenburg/Reverse Trendelenburg operating properly

Optional articulating head piece locking and releasing properly - check immediately if the head piece

is bumped on a door, wall or other obstacle while the stretcher is being moved

Transfer surface intact and working properly

No rips or cracks in mattress cover

No leaks at hydraulic connections

Hydraulic jacks holding properly

Hydraulic drop rate set properly

Hydraulic oil level sufficient

Lubricate where required, including the brake adjuster assembly and brake cam and the independent

foot section mechanisms

Serial No.______________

______________

______________

______________

______________

Completed By:_________________________________ Date:_____________

NOTE

Preventative maintenance should be performed at a minimum of annually. A preventative maintenance program should be established for all Stryker Medical equipment. Preventative maintenance may need to be

performed more frequently based on the usage level of the product.

16

Page 18

Warranty

Limited Warranty:

Stryker Medical Division, a division of Stryker Corporation, warrants to the original purchaser that its products

should be free from defects in material and workmanship for a period of one (1) year after date of delivery.

Stryker’s obligation under this warranty is expressly limited to supplying replacement parts and labor for, or

replacing, at its option, any product which is, in the sole discretion of Stryker, found to be defective. Stryker

warrants to the original purchaser that the frame and welds on its beds will be free from structural defects

for as long as the original purchaser owns the bed. If requested by Stryker, products or parts for which a

warranty claim is made shall be returned prepaid to Stryker’s factory. Any improper use or any alteration or

repair by others in such manner as in Stryker’s judgement affects the product materially and adversely shall

void this warranty. Any repair of Stryker products using parts not provided or authorized by Stryker shall void

this warranty. No employee or representative of Stryker is authorized to change this warranty in any way.

Stryker Medical stretchers are designed for a 10 year expected life under normal use conditions and appropriate periodic maintenance as described in the maintenance manual for each device.

This statement constitutes Stryker’s entire warranty with respect to the aforesaid equipment. STRYKER

MAKES NO OTHER WARRANTY OR REPRESENTATION, EITHER EXPRESSED OR IMPLIED, EXCEPT

AS SET FORTH HEREIN. THERE IS NO WARRANTY OF MERCHANTABILITY AND THERE ARE NO

WARRANTIES OF FITNESS FOR ANY PARTICULAR PURPOSE. IN NO EVENT SHALL STRYKER BE

LIABLE HEREUNDER FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING FROM OR IN ANY

MANNER RELATED TO SALES OR USE OF ANY SUCH EQUIPMENT.

To Obtain Parts and Service:

Stryker products are supported by a nationwide network of dedicated Stryker Field Service Representatives.

These representatives are factory trained, available locally, and carry a substantial spare parts inventory to

minimize repair time. Simply call your local representative, or call Stryker Customer Service at (800)

327-0770.

Service Contract Coverage:

Stryker has developed a comprehensive program of service contract options designed to keep your equipment operating at peak performance at the same time it eliminates unexpected costs. We recommend that

these programs be activated before the expiration of the new product warranty to eliminate the potential of

additional equipment upgrade charges.

A SERVICE CONTRACT HELPS TO:

S Ensure equipment reliability

S Stabilize maintenance budgets

S Diminish downtime

S Establish documentation for JCAHO

S Increase product life

S Enhance trade-in value

S Address risk management and safety

17

Page 19

Warranty

Stryker offers the following service contract programs:

SPECIFICATIONS GOLD SILVER PM* ONLY

Annually scheduled preventative maintenance X X

All parts,** labor, and travel X X

Unlimited emergency service calls X X

Priority one contact; two hour phone response X X X

Most repairs will be completed within 3 business days X X

JCAHO documentation X X X

On-site log book w/ preventative maintenance & emergency service records X

Factory-trained Stryker Service Technicians X X X

Stryker authorized parts X X X

End of year summary X

Stryker will perform all service during regular business hours (9-5) X X X

* Replacement parts and labor for products under PM contract will be discounted.

** Does not include any disposable items, I.V. poles (except for Stryker HD permanent poles), mattresses, or damage re-

sulting from abuse.

Stryker Medical also offers personalized service contracts.

Pricing is determined by age, location, model and condition of product.

For more information on our service contracts,

please call your local representative or call (800) 327-0770 (option #2).

Return Authorization:

Merchandise cannot be returned without approval from the Stryker Customer Service Department. An authorization number will be provided which must be printed on the returned merchandise. Stryker reserves the

right to charge shipping and restocking fees on returned items.

SPECIAL, MODIFIED, OR DISCONTINUED ITEMS NOT SUBJECT TO RETURN.

Damaged Merchandise:

ICC Regulations require that claims for damaged merchandise must be made with the carrier within fifteen

(15) days of receipt of merchandise. DO NOT ACCEPT DAMAGED SHIPMENTS UNLESS SUCH DAMAGE

IS NOTED ON THE DELIVERY RECEIPT AT THE TIME OF RECEIPT. Upon prompt notification, Stryker

will file a freight claim with the appropriate carrier for damages incurred. Claim will be limited in amount to

the actual replacement cost. In the event that this information is not received by Stryker within the fifteen

(15) day period following the delivery of the merchandise, or the damage was not noted on the delivery receipt

at the time of receipt, the customer will be responsible for payment of the original invoice in full.

Claims for any short shipment must be made within thirty (30) days of invoice.

International Warranty Clause:

This warranty reflects U.S. domestic policy. W arranty outside the U.S. may vary by country. Please contact

your local Stryker Medical representative for additional information.

18

Page 20

European Representative

Stryker France Phone: 33148632290

BP 50040-95946 Roissy Ch. de Gaulle Fax: 33148632175

Cedex-France

6300 Sprinkle Road, Kalamazoo, MI 49001-9799 (800) 327-0770

www.strykermedical.com

DH 8/02 5051-90-2 REV F

Loading...

Loading...