Page 1

IMPORTANT

File in your

maintenance

records

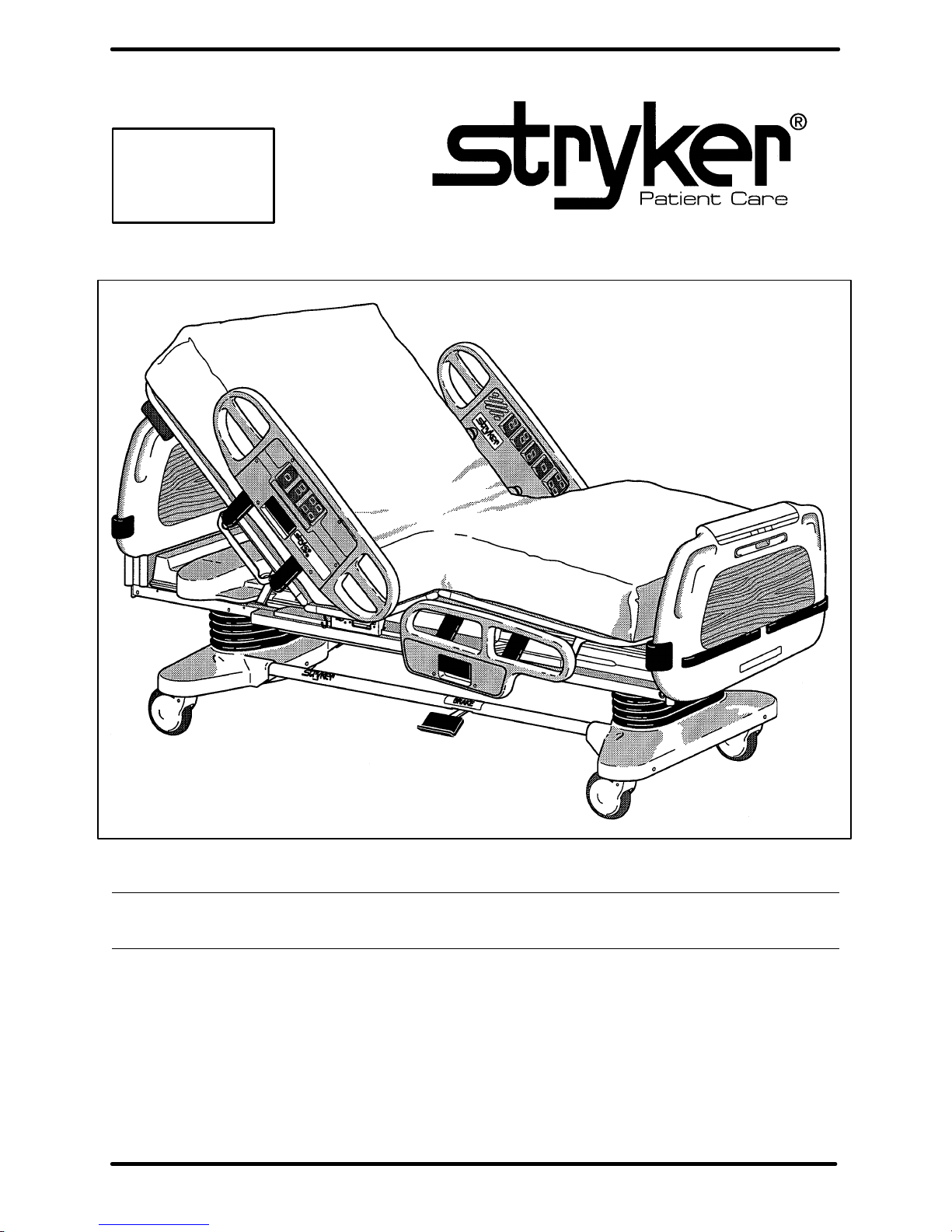

Modular Patient System (MPS) 3000 Bed

MAINTENANCE MANUAL

For Parts or Technical Assistance

1–800–327–0770

Page 2

Table of Contents

CHAPTER ONE – INTRODUCTION

S 1.1 Bed Specifications 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 1.2 Safety 9, 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 1.3 Warranty 11, 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 1.4 Recommended Parts Kits 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 1.5 Replacement Parts Kits 14, 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 1.6 Cleaning 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 1.7 Preventative Maintenance 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER TWO – MPS OPERATIONS

S 2.1 Set–Up Procedures 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 2.2 Bed Illustration 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 2.3 Base Operation Guide

Brake Pedal Operation 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steer Pedal Operation 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 2.4 Litter Operation Guide

CPR Emergency Release Usage 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foley Bag Hooks Usage 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot Prop Usage 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fracture Frame Usage 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I.V. Poles 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Night Light Usage (optional equipment) 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Patient Restraint Strap Locations 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 2.5 Foot Board/Head Board Operation Guide

Chart Rack Usage (optional equipment) 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CPR Board Usage (optional equipment) 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot Board Control Panel Guide 25, 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED Display Panel Guide 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 2.6 Siderail Operation Guide

Positioning Siderails 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Siderail Control Panel Lights 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inside Siderail Function Guide 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Outside Siderail Function Guide 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 2.7 Weigh System Operation Guide (optional equipment)

Weigh System Usage 31, 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Weigh System Control Panel Guide 33, 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 2.8 System Operation Guide

Bed Exit System Usage (optional equipment) 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dynamic Mattress System Usage (optional equipment) 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Function Lockout System Usage 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 3

Table of Contents

CHAPTER THREE – TROUBLESHOOTING

S 3.1 Mechanical Troubleshooting

Brakes engage at one end and release at the other when pedal is activated 36. . . . . . . . . . . . . . . . .

Brakes do not engage/release 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steer Wheel does not engage/release 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Siderail release latch does not engage/disengage 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CPR release does not disengage 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 3.2 Motion interrupt does not stop the movement of the bed 37. . . . . . . . . . . . . . . .

S 3.3 Trendelenberg/Reverse Trendelenberg does not position properly 38. . . . .

S 3.4 Bed does not raise/lower electrically 39, 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 3.5 Knee Gatch does not raise/lower electrically 41, 42. . . . . . . . . . . . . . . . . . . . . . . . . .

S 3.6 Fowler does not raise/lower electrically 43, 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 3.7 Siderail lockout controls will not activate/deactivate 45. . . . . . . . . . . . . . . . . . . . .

S 3.8 Siderail control lights do not turn on/off 46, 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 3.9 Bed Motion lock does not prevent bed motion 48. . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 3.9 Bed Motion lock LED does not light 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 3.10 Nurse call LED does not light 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 3.10 Nurse Call LED lights but Nurse Call does not activate 50. . . . . . . . . . . . . . . . .

S 3.10 Nurse call acknowledgement LED does not light 50, 51. . . . . . . . . . . . . . . . . . . .

S 3.11 TV/Radio does not turn on from siderail 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 3.12 Volume control button does not work 53, 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 3.12 Speaker volume not adequate 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 3.13 Room/Reading light control does not work 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 3.14 Bed Exit works but light does not illuminate 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 3.14 Bed Exit alarm does not sound when patient leaves bed 56. . . . . . . . . . . . . . .

S 3.14 Bed Exit lights indicate activation – beeper does not sound 57. . . . . . . . . . .

S 3.14 Bed Exit arms then disarms itself 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 3.15 Weigh System display will not turn on 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 3.15 Weigh System not weighing accurately 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 3.15 Weigh System functions do not work individually 59. . . . . . . . . . . . . . . . . . . . . .

S 3.16 Dynamic Mattress System does not work 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 3.16 Dynamic Mattress air loss light comes on 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 3.16 DMS firm or soft won’t adjust; rest of system functions properly 61. . . . .

S 3.16 DMS auto/manual won’t change; rest of system functions properly 61. .

S 3.17 Power On indicator does not light 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 3.18 Brake Not Set indicator does not flash 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 3.18 One or two Brake Not indicators not flashing when brake is set 64. . . . . . .

S 3.19 Night Light does not light 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 3.20 No Power at 110V Option Receptacle 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 4

Table of Contents

CHAPTER FOUR – MAINTENANCE PROCEDURES – BASE

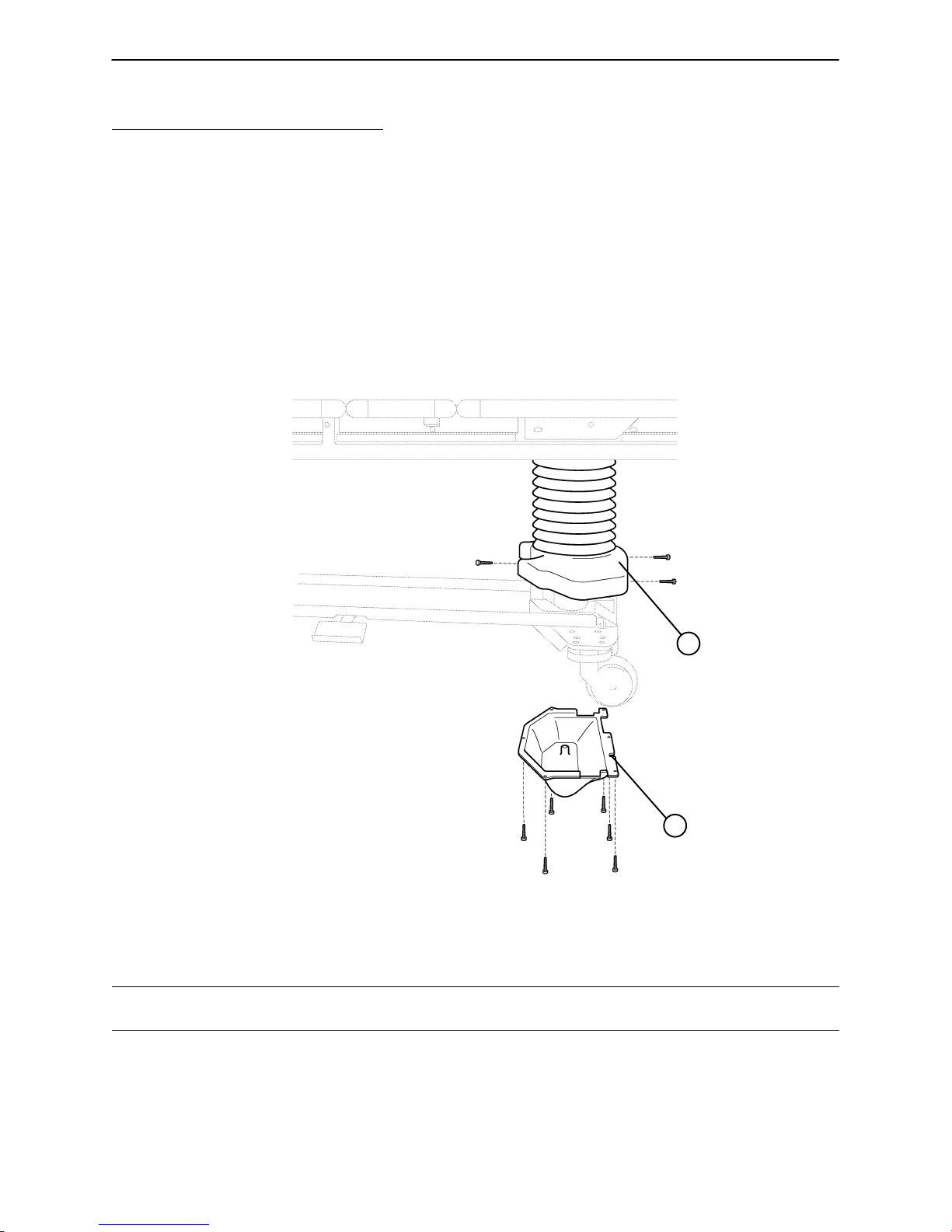

S 4.1 Base Cover Removal

Upper Lift Unit Cover 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lower Lift Unit Cover 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lowering Bellows 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 4.2 Brake System

Brake Ring (Pan) Assembly Removal 69, 70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brake Pedal Replacement 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brake Cam Replacement 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brake Sensor Replacement 72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 4.3 Steer Wheel Cable Replacement/Adjustment 73–75. . . . . . . . . . . . . . . . . . . . . . . . . .

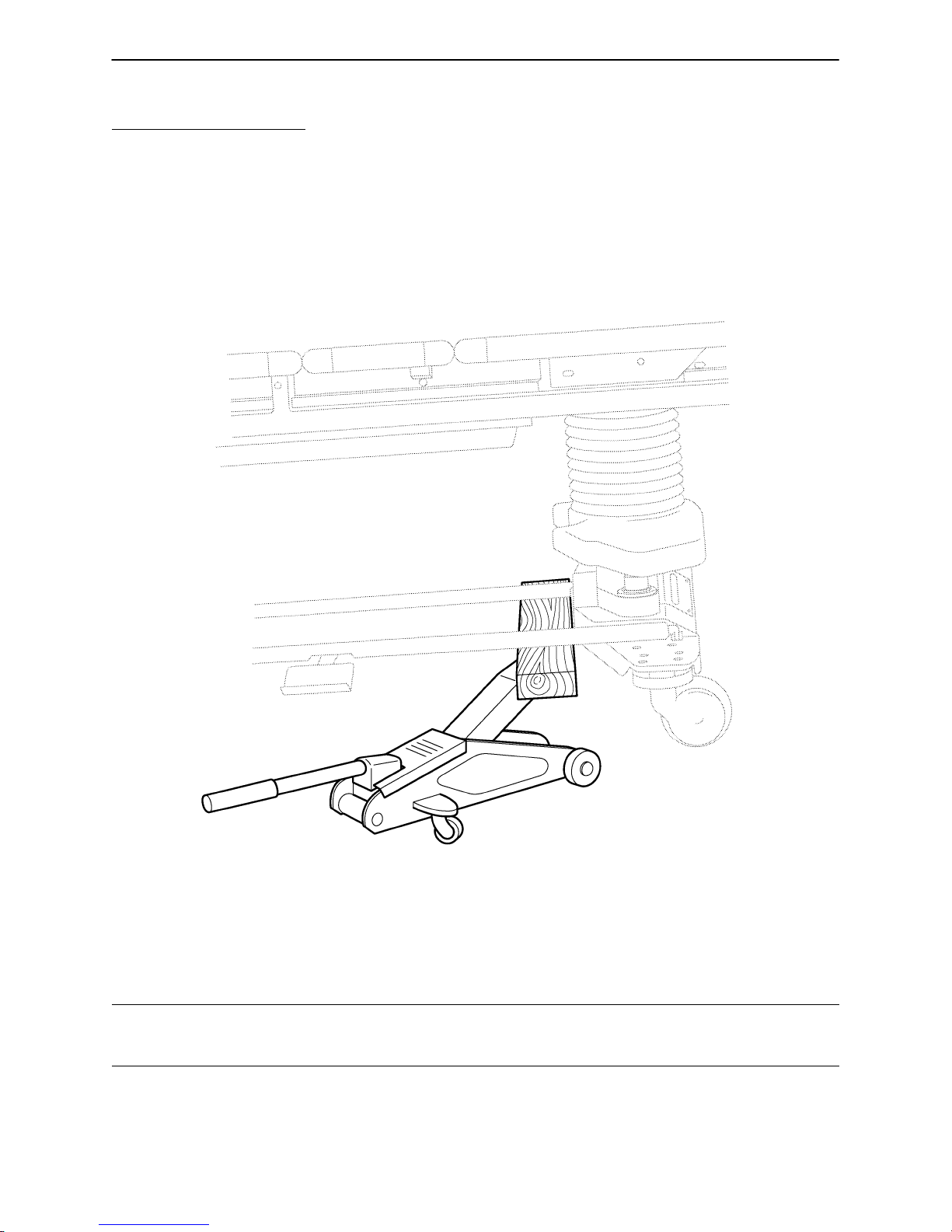

S 4.4 Caster Replacement 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 4.5 Lift Motor and Capacitor Replacement 77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 4.6 Lift Unit

Lift Motor Isolation Plate Replacement 79, 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lift Housing Removal and Replacement 81, 82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lift Gear Replacement 83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lift Drive Inner Screw and Upper Nut Replacement 84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lift Drive Outer Screw and Lower Nut Replacement 84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timing of Inner and Outer Drive Screws 84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Illustrations for Lift Unit Procedures 85, 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lift Motor Coupler Replacement 87, 88. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lift Potentiometer Adjustment/Replacement 89, 90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

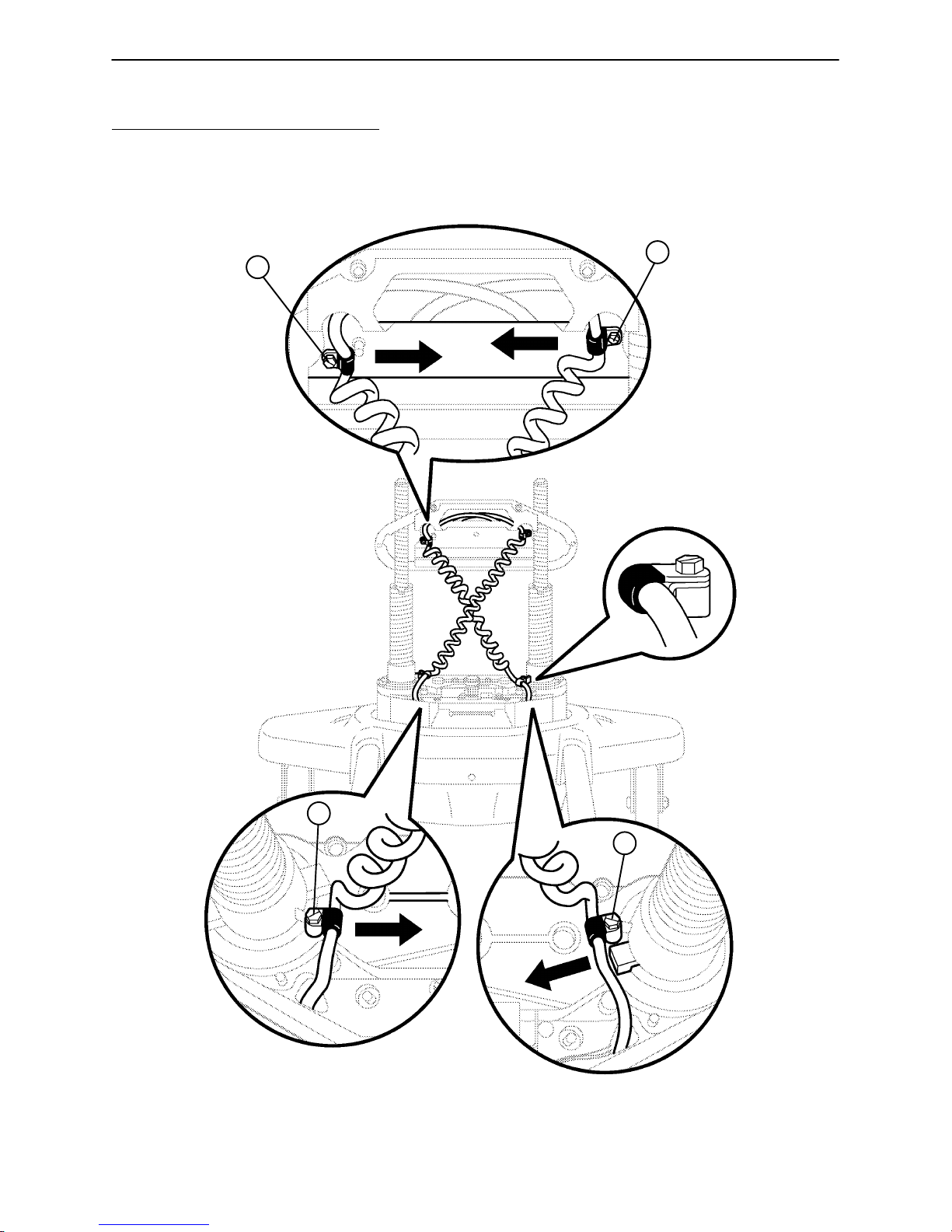

Power and Sensor Coil Cord Replacement 91, 92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER FIVE – MAINTENANCE PROCEDURES – LITTER

S 5.1 Removal of Litter Access Panels 93, 94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 5.2 Removal of Motion Interrupt Panel 95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 5.3 Motion Interrupt Switch Replacement 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 5.4 Knee Section

Knee Motor Limit Setting 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cam and Cam Guide Replacement (Knee and Head Motor) 98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Knee Motor Drive Screw and Nut Replacement 99, 100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Knee Motor Assembly Replacement 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 5.5 Head Section

Cam and Cam Guide Replacement (Head and Knee Motor) 98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Head Motor Limit Setting 102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Head Motor Removal and Replacement 103, 104. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Head Motor Drive Isolator and Decoupler Replacement 105. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Head Motor Drive Screw and Ball Nut Replacement 107, 108. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

Table of Contents

CHAPTER FIVE – MAINTENANCE PROCEDURES – LITTER (CONTINUED)

S 5.6 CPR

CPR Release Cable Adjustment/Replacement 109. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CPR Handle Assembly Replacement 109. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CPR Illustrations 110, 111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Litter Assembly, 110V Option 157. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 5.7 Weigh System Diagnostics and Repairs (Optional Equipment)

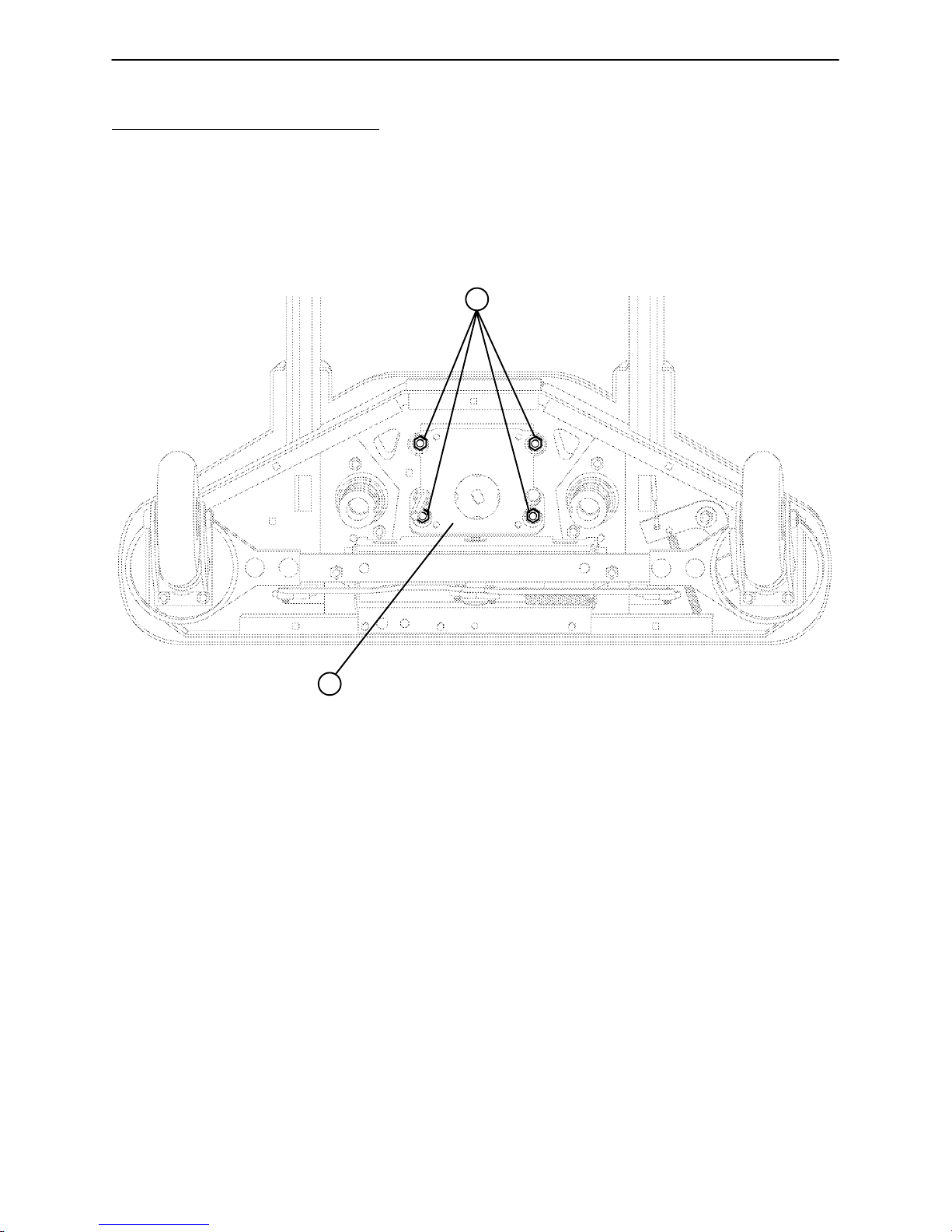

Weigh Diagnostic Procedure 1 12, 113. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Load Cell Replacement 114. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Weigh CPU Board Replacement 1 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 5.8 Litter CPU Board Replacement 115. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 5.9 Power Cord Replacement 116. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S 5.10 Litter Grease Points 116. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER SIX – MAINTENANCE PROCEDURES – SIDERAILS

S 6.1 Head and Foot End Siderail

Siderail Cover Removal 117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Molded Rail Replacement 118. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Siderail Latch Positioning Mechanism Replacement 119, 120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Siderail Cable Replacement 121, 122. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Siderail Assembly Removal 123, 124. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Siderail Module Replacement 125. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER SEVEN – MAINTENANCE PROCEDURES – FOOT BOARD

S 7.1 Foot Board

Foot Board Hinge Removal 126. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot Board Module Replacement 126. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot Board Interface Board Replacement 127. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot Board Interface Plug Replacement 128. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

APPENDIX A – ASSEMBLY DRAWINGS AND PARTS LISTS

S A.1 Base Drawings

Base Assembly 129–134. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lift Assembly, Common 135, 136. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lift Assembly, Head End 137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lift Assembly, Foot End 137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brake Assembly, Head 138. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brake Assembly, Foot 139, 140. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S A.2 Litter Drawings

Litter Assembly, Mechanical 141–144. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Litter Assembly, Electrical 145, 146. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Litter Cover Assembly 147, 148. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Litter Assembly 149–151. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Litter Assembly, Removable I.V. Pole Option 152. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Litter Assembly, Scale and/or Bed Exit Option 153, 154. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 6

Table of Contents

APPENDIX A – ASSEMBLY DRAWINGS AND PARTS LISTS (CONTINUED)

S A.2 Litter Drawings (Continued)

Litter Assembly, DMS Option 155. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mattress Assembly, DMS Option 154.1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hybrid Dynamic Mattress Litter Assembly 154.2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hybrid Dynamic Mattress Assembly 154.3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Litter Assembly, 90 Power Cord Option 154.4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Litter Assembly, Night Light Option 155. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Litter Assembly, Headwall IFC/Nurse Call/Bed Exit 156. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Litter Assembly, Pendant Port 157.1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Litter Assembly, Coil Cord Option 157.2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Litter Assembly, Bed Exit Option 157.3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Litter Accessory Adapter Frame Option Assembly 157.4, 157.5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Litter Roller Option Assembly 157.6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Litter Roller Assembly 157.7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Litter Telephone Option Assembly 157.8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phone Base Assembly 157.9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fowler Limit Switch Assembly 157.10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gatch Drive Assembly 158, 159. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fowler/CPR Drive Assembly 160, 161. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limit Switch Assembly 162. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot Lift Header Assembly 163. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot Lift Header Assembly, Option 164. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Head Lift Header Assembly 165. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Head Lift Header Assembly, Option 166. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CPR Release Assembly 167. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CPR Handle Assembly 167.1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Translation Cable Assembly 168. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Litter Foot/Prop Assembly 169. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removable I.V. Pole Assembly 170. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Permanent I.V. Pole Assembly 171. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Permanent I.V. Pole Mounting Assembly, Head End 172. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Permanent I.V. Pole Mounting Assembly, Foot End 173. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S A.3 Siderail Drawings

Head, Left Siderail 174, 175. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Head, Right Siderail 176, 177. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot, Left Siderail 178, 179. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot, Right Siderail 180, 181. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Siderail Motion Module Assemblies 182. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Siderail Lights Module Assemblies 183. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Siderail Nurse Call Module Assemblies 184, 185. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Siderail TV/Radio Module Assemblies 186. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Siderail DMS Module Assemblies 187. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 7

Table of Contents

APPENDIX A – ASSEMBLY DRAWINGS AND PARTS LISTS (CONTINUED)

S A.4 Head and Foot Board Drawings

Head Board Assembly 188. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CPR Board Assembly 189. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot Board Assembly 190, 191. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chart Holder Assembly 191.1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tape Switch Bed Exit Module Assembly 191.2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot Board Standard Module Assembly 192. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot Board Gatch/Fowler Module Assembly 193. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot Board DMS Module Assembly 194. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot Board Scale Module Assembly 195. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot Board Bed Exit Module Assembly 196. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S A.5 Overall Bed Assembly Drawing 197, 198. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

APPENDIX B – CIRCUIT BOARD LOCATIONS, BED WIRING DIAGRAMS

All board schematics are available, upon request, through Stryker Customer Service.

S B.1 Circuit Board Locations, Individual Board Drawings

Board Location Diagrams 199–202. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Individual Board Drawings 203–209. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S B.2 Wiring Diagrams

Bed, Siderail & Footboard Wiring Diagrams 210–218. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bed Wiring Block Diagram – Fully Loaded Bed 219–225. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S B.3 Voltage Charts 226–229. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 8

Chapter One – Introduction

DIRECTOR OF MAINTENANCE AND ENGINEERING

Thank you for your recent purchase of Stryker equipment. We believe that Stryker products are the

best designed, best manufactured, and best supported products on the market and we want you to

share this belief.

Attached is our MPS Service Manual with a recommended spare parts list to assist you in the maintenance of your new equipment. These are parts which our customers find convenient to have on hand

to facilitate maintenance and repairs. Parts damaged due to manufacturers defects in materials or

workmanship will be sent to you at no charge during the two year warranty period.

Stryker Customer Service is easily reached at (800) 327–0770. Our Customer Service Department

is staffed to facilitate replacement part orders, and we normally process and ship replacement parts

orders within twenty–four hours. Our goal, which we consistently achieve, is 95% of all replacement

parts or ders shipped within two days or less.

In addition to facilitating your parts orders, our customer service representatives can answer your

technical and troubleshooting questions, and have ready access to our staff of technical pr ofessionals who can provide any level of phone support required.

Finally, your customer service representative can put you in contact with your local field service r epresentative. This is a Stryker employee, not a third party subcontractor , who is always available for

on–site consultations, in–services, or maintenance.

As you can see, we have structured our service to offer you exactly the support you need. We offer

any level of service required, from basic phone support to full preventative maintenance and service

agreements, allowing you to better utilize your staff.

Thank you again for ordering Stryker products, and please do not hesitate to call Stryker Customer

Service for further assistance.

Sincerely,

Joseph P. Briggs

Vice President – Stryker Service

8

Page 9

Chapter One – Introduction

This manual is designed to assist you with the maintenance of the Modular Patient System (MPS) 3000 Bed.

Read it thoroughly before using the equipment. Keep the manual for future reference.

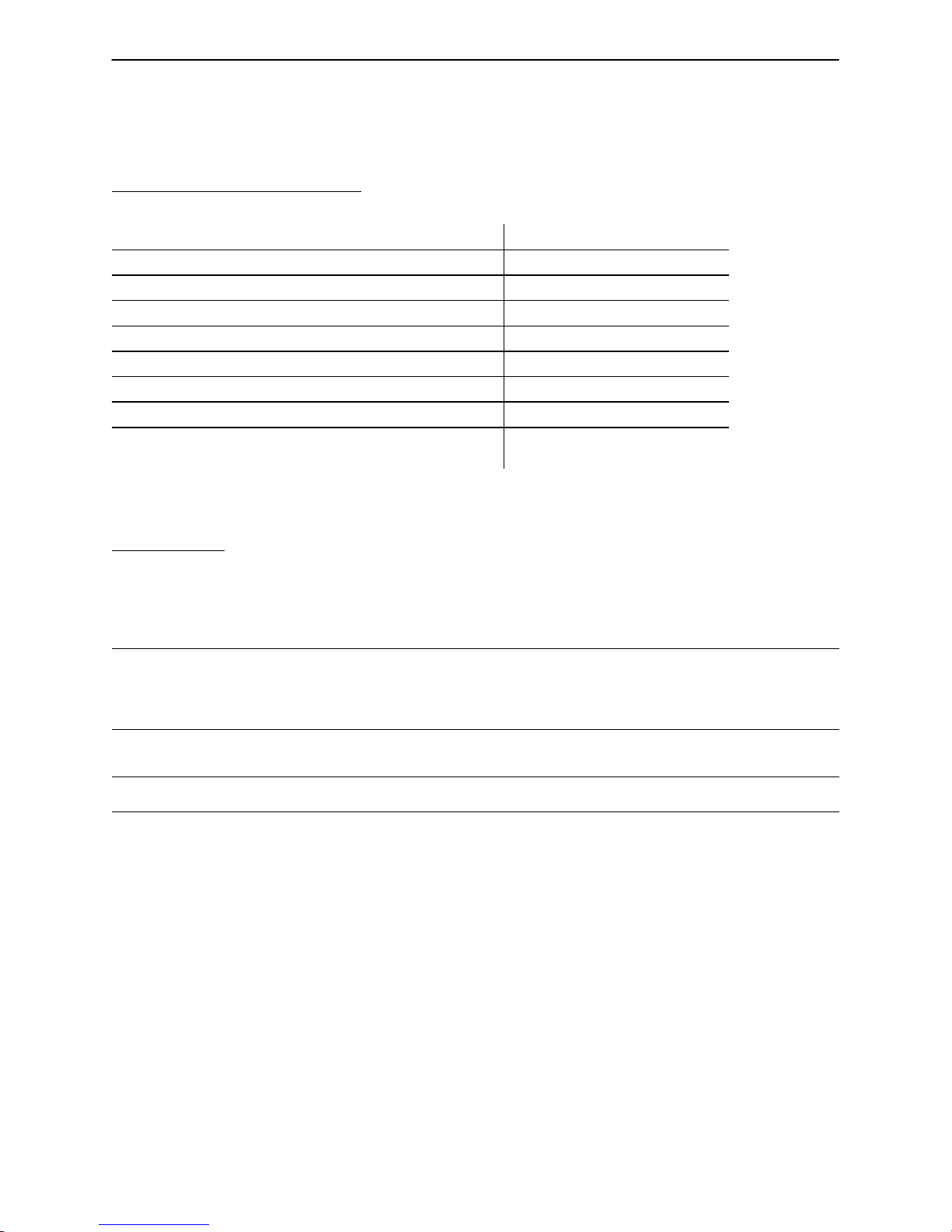

1.1 BED SPECIFICATIONS

Maximum Weight Capacity 500 pounds

Overall Bed Length/Width 93” / 41–1/2”

Patient Sleep Surface 84” / 35”

Minimum/Maximum Bed Height 15 3/8” / 31”

Knee Gatch Angle 0 to 40

Fowler Angle 0 to 60

Trendelenberg/Reverse Trendelenberg –12 to +12

Weigh System Accuracy (optional equipment) + / – 1% of total patient weight

Electrical Requirements – all electrical requirements

meet UL 544 specifications.

110 VAC, 60 Hz, 10.0 Amp

1.2 SAFETY

WARNING / CAUTION / NOTE DEFINITION

The words WARNING, CAUTION and NOTE carry special meanings and should be carefully reviewed.

WARNING

The personal safety of the patient or user may be involved. Disregarding this information could result in injury

to the patient or user.

CAUTION

These instructions point out special procedures or precautions that must be followed to avoid damaging the

equipment.

NOTE

This provides special information to make important instructions clearer.

9

Page 10

Chapter One – Introduction

1.2 SAFETY (CONTINUED)

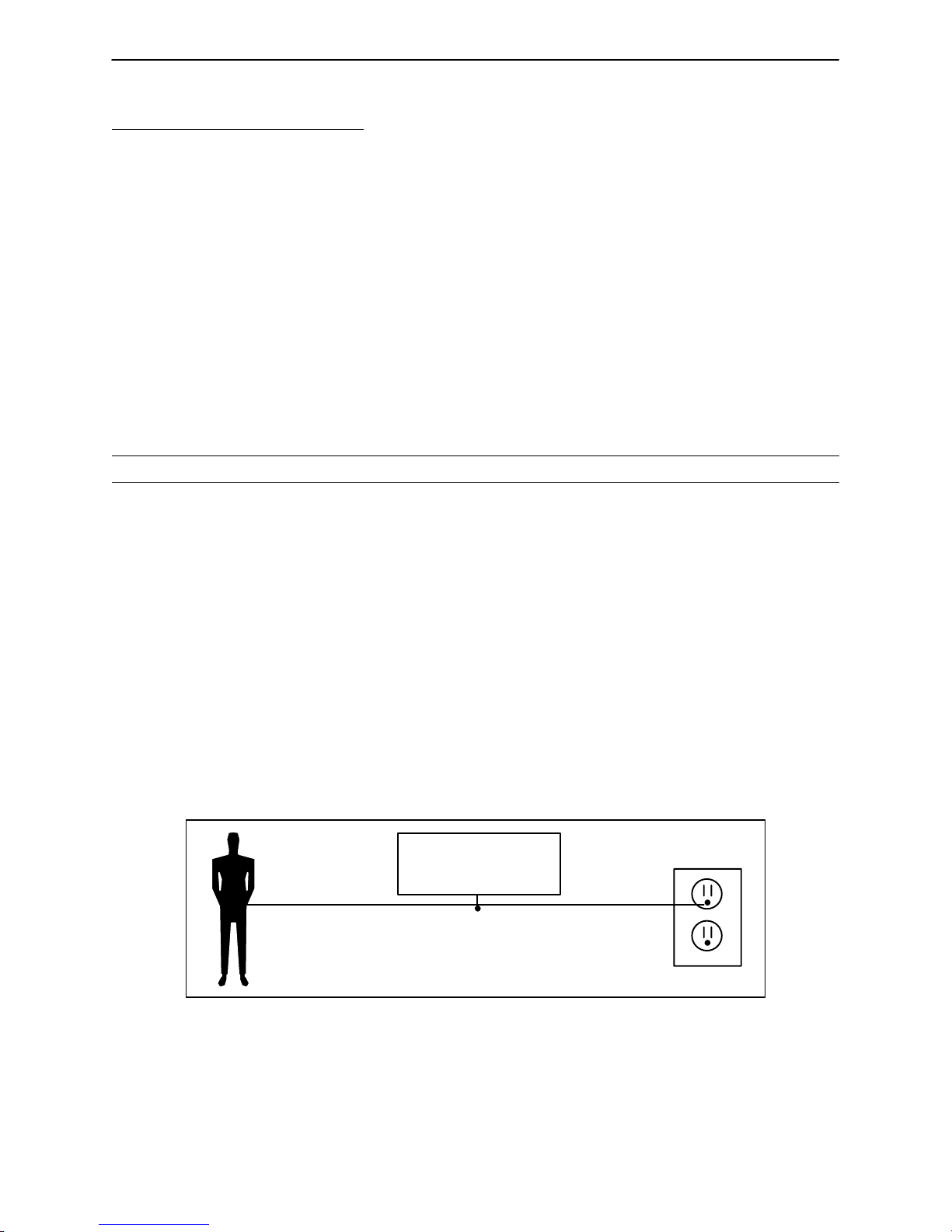

STATIC DISCHARGE PRECAUTIONS

The electronic circuits in the 3000 are completely protected from static electricity damage only while the bed

is assembled. It is extremely important that all service personnel always use adequate static protection when

servicing the electronic systems of the 3000. Whenever you are touching wires, you should be using static

protection.

Static Protection Equipment

The necessary equipment for proper static protection is:

1 static wrist strap; 3M part number 2214 or equivalent,

1 grounding plug; 3M part number 61038 or equivalent,

1 test lead with a banana plug on one end and an alligator clip on the other; Smith part number

N132B699 or equivalent.

CAUTION

All electronic service parts will be shipped in static shielding bags. Do not open the bags until you have completed steps 2 and 3 of the following procedure. Do not place unprotected circuit boards on the floor . All circuit

boards to be returned to Stryker Medical should be shipped in the static shielding bags the new boards were

shipped in.

Static Protection Procedure

1. Unplug the power cord from the wall receptacle.

2. Insert the grounding plug into a properly grounded hospital grade wall receptacle. Plug the banana plug

of the test lead into the receptacle on the grounding plug. Connect the alligator clip on the other end of

the test lead to a ground point on the bed.

3. Place the static control wrist strap on your wrist. Connect the alligator clip at the other end of the wrist strap

cord to a ground point on the bed.

BED

GROUNDING DIAGRAM

10

Page 11

Chapter One – Introduction

1.3 WARRANTY

Limited Warranty:

Stryker Patient Care Division, a division of Stryker Corporation, warrants to the original purchaser that the

MPS 3000 Bed should be free from defects in material and workmanship for a period of two (2) years after

date of delivery. Stryker’s obligation under this warranty is expressly limited to supplying replacement parts

for, or replacing, at its option, any product which is, in the sole discretion of Stryker, found to be defective.

Stryker warrants to the original purchaser that the frame and welds on its beds will be free from structural

defects for as long as the original purchaser owns the bed. If requested by Stryker, products or parts for which

a warranty claim is made shall be returned prepaid to Stryker’s factory. Any improper use or any alteration

or repair by others in such manner as in Stryker’s judgement affects the product materially and adversely shall

void this warranty. No employee or representative of Stryker is authorized to change this warranty in any way.

This statement constitutes Stryker’s entire warranty with respect to the aforesaid equipment. STRYKER

MAKES NO OTHER WARRANTY OR REPRESENTATION, EITHER EXPRESSED OR IMPLIED, EXCEPT

AS SET FORTH HEREIN. THERE IS NO WARRANTY OF MERCHANTABILITY AND THERE ARE NO

WARRANTIES OF FITNESS FOR ANY PARTICULAR PURPOSE. IN NO EVENT SHALL STRYKER BE

LIABLE HEREUNDER FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING FROM OR IN ANY

MANNER RELATED TO SALES OR USE OF ANY SUCH EQUIPMENT.

To Obtain Parts and Service:

Stryker products are supported by a nationwide network of dedicated Stryker Field Service Representatives.

These representatives are factory trained, available locally, and carry a substantial spare parts inventory to

minimize repair time. Simply call your local representative, or call Stryker Customer Service at (800)

327–0770.

Supplemental Warranty Coverage:

Stryker has developed a comprehensive program of extended warranty options designed to keep your equipment operating at peak performance at the same time it eliminates unexpected costs. We recommend that

these programs be activated before the expiration of the new product warranty to eliminate the potential of

additional equipment upgrade charges. Stryker offers the following Supplemental Warranties:

Extended (Parts and Labor)

All replacement parts (excluding mattresses and consumable items)

Labor and travel for all scheduled and unscheduled calls

Biannual Preventative Maintenance Inspections and repairs

JCAHO paperwork for preventative maintenance

Priority Emergency Service

Standard (Labor Only):

Labor and travel for all scheduled and unscheduled calls

Biannual Preventative Maintenance Inspections and repairs

JCAHO paperwork for preventative maintenance

Priority Emergency Service

Basic (Parts Only):

All replacement parts (excluding mattresses and consumable items)

Priority Emergency Service

Please call your local representative, or call (800) 327–0770 for further information

11

Page 12

Chapter One – Introduction

1.3 WARRANTY (CONTINUED)

Return Authorization:

Merchandise cannot be returned without approval from the Stryker Customer Service Department. An authorization number will be provided which must be printed on the returned merchandise. Stryker reserves the

right to charge shipping and restocking fees on returned items.

SPECIAL, MODIFIED, OR DISCONTINUED ITEMS NOT SUBJECT TO RETURN.

Damaged Merchandise:

ICC Regulations require that claims for damaged merchandise must be made with the carrier within fifteen

(15) days of receipt of merchandise. DO NOT ACCEPT DAMAGED SHIPMENTS UNLESS SUCH DAMAGE

IS NOTED ON THE DELIVERY RECEIPT AT THE TIME OF RECEIPT. Stryker Customer Service must be

notified immediately. Stryker will aid the customer in filing a freight claim with the appropriate carrier for damages incurred. Claim will be limited in amount to the actual replacement cost. In the event that this information

is not received by Stryker within the fifteen (15) day period following the delivery of the merchandise, or the

damage was not noted on the delivery receipt at the time of receipt, the customer will be responsible for payment of the original invoice in full.

Claims for any short shipment must be made within thirty (30) days of invoice.

12

Page 13

Chapter One – Introduction

1.4 RECOMMENDED PARTS KITS

MPS 3000 STARTER PACKAGE

Sensor Coil Cord Kit p/n 3000–200–741

Power Coil Cord Kit p/n 3000–200–743

Power Cord Kit p/n 3000–300–737

Lift Motor Kit p/n 3000–200–727

Fowler Motor Kit (includes clutch) p/n 3000–300–703

Gatch Motor Kit p/n 3000–300–711

Load Cell Kit (optional equipment) p/n 3000–307–701

Weigh CPU (optional equipment) p/n 3000–307–959

Caster Assembly p/n 3000–200–30 and 3000–200–16 (steer)

Main CPU Board Assembly p/n 3000–300–941

Junction Power Board Assembly p/n 3000–300–961

Interface Board Assembly p/n 3000–303–933

Lift Potentiometer Kit (Head) p/n 3000–200–929

Lift Potentiometer Kit (Foot) p/n 3000–200–731

Single Tube of Grease p/n 3000–200–700

Hardware Kit (reference p/n below)

MPS 3000 HARDWARE KIT – P/N 3000–000–700

Fuses (Variety)

Cover Fasteners (Variety) – siderails, bellows, lift covers, litter access, inner

shield

Snap Rings (Variety)

Sheet Metal Screws (Variety)

Cable Clamps (Variety)

Roll Pins (Variety)

Cotter Pins (Variety)

Steer Cable Retainer with Set Screw

Brake Pedal Bolt

Siderail Module Screws

Push Retaining Ring

Micro Switch (motion interrupt, brake)

13

Page 14

Chapter One – Introduction

1.5 REPLACEMENT PARTS KITS

BASE KITS

1. Steer Cable Kit – p/n 3000–200–701

2. Complete Lift Assembly Kit – p/n 3000–200–705

3. Idler Gear Kit – p/n 3000–200–707

4. Manual Idler Gear Kit – p/n 3000–200–709

5. Motor Pinion Gear Kit – p/n 3000–200–711

6. Outer Screw Kit – p/n 3000–200–713

7. Inner Screw Kit – p/n 3000–200–715

8. Single Tube of Grease – p/n 3000–200–700

9. Lift Motor Isolation Plate Kit – p/n 3000–200–723

10. Lift Motor Coupler Kit – p/n 3000–200–705

11. Lift Motor Kit – p/n 3000–200–727

12. Lift Potentiometer Kit (Head) – p/n 3000–200–729

13. Lift Potentiometer Kit (Foot) – p/n 3000–200–731

14. Brake Cam Kit – p/n 3000–200–733

15. Brake Sensor Switch Kit – p/n 3000–200–735

16. Brake Pedal Kit – p/n 3000–200–737

17. Steer Pedal Kit – p/n 3000–200–703

18. Upper Lift Cover Kit (Head) – p/n 3000–200–739

19. Upper Lift Cover Kit (Foot) – p/n 3000–200–749

20. Sensor Coil Cord Kit – p/n 3000–200–741

21. Power Coil Cord Kit – p/n 3000–200–743

22. Lift Capacitor Kit – p/n 3000–200–745

23. Lower Lift Cover Kit (Head or Foot) – p/n 3000–200–747

24. Manual Override Shaft Kit – p/n 3000–200–751

LITTER KITS

25. Load Cell Kit (Optional Equipment) – p/n 3000–307–701

26. Fowler Motor Kit (Includes Clutch) – p/n 3000–300–703

27. Fowler Decoupler/Isolator Kit – p/n 3000–300–705

28. Fowler Ball Screw Kit – p/n 3000–300–707

29. Fowler/Gatch Cam & Cam Guide Kit – p/n 3000–300–709

30. Gatch Motor Kit – p/n 3000–300–711

31. Gatch Coupler Kit – p/n 3000–300–713

32. Gatch Drive Screw Kit – p/n 3000–300–715

33. Translation Cable Kit – p/n 3000–300–717

34. CPR Handle Kit (Right) – p/n 3000–300–719

35. CPR Handle Kit (Left) – p/n 3000–300–739

36. Litter Electrical Cover #2 Kit – p/n 3000–300–721

14

Page 15

Chapter One – Introduction

1.5 REPLACEMENT PARTS KITS (CONTINUED)

LITTER KITS (CONTINUED)

37. Litter Mid Cover #5 Kit – p/n 3000–300–723

38. Fowler Motor Cover #4 Kit – p/n 3000–300–725

39. Head End Litter Cover #3 Kit – p/n 3000–300–727

40. Foot End Litter Cover #1 Kit – p/n 3000–300–729

41. Fowler Capactior Kit – p/n 3000–300–731

42. Gatch Capacitor Kit – p/n 3000–300–733

43. Litter Hinge Cover Kit – p/n 3000–300–735

44. Power Cord Kit – p/n 3000–300–737

SIDERAIL KITS

45. Foot End Siderail Kit (Right) – p/n 3000–400–701

46. Foot End Siderail Kit (Left) – p/n 3000–400–703

47. Head End Siderail Kit (Right) – p/n 3000–400–705

48. Head End Siderail Kit (Left) – p/n 3000–400–707

49. Siderail Head/Knee Module Kit (Inside/Right) – p/n 3000–400–709

50. Siderail Head/Knee Module Kit (Inside/Left) – p/n 3000–400–711

51. Siderail Head/Knee Module Kit (Outside/Right) – p/n 3000–409–713

52. Siderail Head/Knee Module Kit (Outside/Left) – p/n 3000–409–715

53. Siderail Nurse Call Module Kit (Inside/Right) – p/n 3000–403–717

54. Siderail Nurse Call Module Kit (Inside/Left) – p/n 3000–403–719

55. Siderail Nurse Call Module Kit (Outside/Right) – p/n 3000–403–721

56. Siderail Nurse Call Module Kit (Outside/Left) – p/n 3000–403–723

57. Siderail TV/Radio Module Kit (Inside/Right) – p/n 3000–404–723

58. Siderail TV/Radio Module Kit (Inside/Left) – p/n 3000–404–725

59. Siderail Dynamic Mattress System Module Kit (Inside/Right) – p/n 3000–402–727

60. Siderail Dynamic Mattress System Module Kit (Inside/Left) – p/n 3000–402–729

61. Siderail Lights Module Kit (Inside/Right) – p/n 3000–406–731

62. Siderail Lights Module Kit (Inside/Left) – p/n 3000–406–733

63. Siderail Bed Up/Down Module Kit (Outside/Right) – p/n 3000–400–735

64. Siderail Bed Up/Down Module Kit (Outside/Left) – p/n 3000–400–737

FOOT BOARD KITS

65. Foot Board Bed Position/Lockout Module Kit – p/n 3000–500–701

66. Foot Board Head/Knee Module Kit – p/n 3000–501–703

67. Foot Board Bed Exit System Module Kit – p/n 3000–508–705

68. Foot Board Dynamic Mattress System Module Kit – p/n 3000–502–707

69. Foot Board Scale Module Kit – p/n 3000–507–709

70. Foot Board Lid Kit – p/n 3000–500–711

71. C–Bumper Kit (Foot or Head Board) – p/n 3000–500–713

15

Page 16

Chapter One – Introduction

1.6 CLEANING

Hand wash all surfaces of the bed with warm water and mild detergent. Dry thoroughly.

CAUTION

Quaternary Germicidal Disinfectants, used as directed, and/or Chlorine Bleach products, typically 5.25% So dium Hypochlorite in dilutions ranging between 1 part bleach to 100 parts water, and 2 parts bleach to 100

parts water are not considered mild detergents. THESE PRODUCTS ARE CORROSIVE IN NATURE AND

MAY CAUSE DAMAGE TO YOUR BED IF USED IMPROPERLY. If these types of products are used to clean

Stryker patient care equipment, measures must be taken to insure the beds are wiped with clean water and

thoroughly dried following cleaning. Failure to properly rinse and dry the beds will leave a corrosive residue

on the surface of the bed, possibly causing premature corrosion of critical components. Failure to follow the

above directions when using these types of cleaners may void this product’s warranty.

CAUTION

Do not steam clean or hose off the MPS 3000 Bed. Do not immerse any part of the bed. Some of the internal

parts of the bed are electric and may be damaged by exposure to water.

16

Page 17

Chapter One – Introduction

1.7 PREVENTATIVE MAINTENANCE

BIANNUAL CHECKLIST

All fasteners secure (reference all assembly prints)

All casters lock with brake pedal engaged

”Brake Not Set” LED (on foot board) blinks when brakes are not engaged

Locking steer caster engages and disengages properly

Siderails move, latch and stow properly

CPR release working properly

Foot prop intact and working properly

I.V. pole working properly

Foley bag hooks intact

Optional chart rack intact and working properly

Optional CPR board not cracked or damaged and stores properly

No cracks or splits in head and foot boards

No rips or cracks in mattress cover

All functions on head end siderails working properly (including LED’s)

All functions on footboard working properly (including LED’s)

Motion Interrupt switches working properly

Optional night light working properly

Power cord not frayed

No cables worn or pinched

All electrical connections tight

All grounds secure to the frame

Ground impedence not more than 100 milliohms

Current leakage not more than 100 microamps

Apply grease to litter grease points

Bed Serial No. ______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

17

Page 18

Chapter Two – MPS Operations

2.1 SET–UP PROCEDURES

It is important that the MPS 3000 Bed is working properly before it is put into service. The following list will

help assure that each part of the bed is tested.

Plug the bed into a properly grounded, hospital grade wall receptacle and assure the ”Power” LED

light at the foot end of the bed comes on.

WARNING

The 3000 is equipped with a hospital grade plug for protection against shock hazard. It must be plugged directly into a properly grounded three–prong receptacle. Grounding reliability can be achieved only when a

hospital grade receptacle is used.

Plug the optional interface cable into the 37 pin connector under the litter frame at the head end of

the bed, and into the ”Patient Station”, ”Head Wall”, ”Docker Station”, or equivalent (whichever applies).

Assure the siderails raise, lower and store smoothly and lock in the up and intermediate positions

(page 28).

Assure that all four casters lock when the brake pedal is engaged (page 20).

NOTE

Assure that the ”Brake Not Set” LEDs located on the outside of the head end siderails and on the foot board

control panel come on when the brakes are disengaged.

Run through each function on the foot end control panel to assure that each function is working prop-

erly (page 25 & 26).

Run through each function on both head end siderails to assure that each is working properly (page

29 & 30).

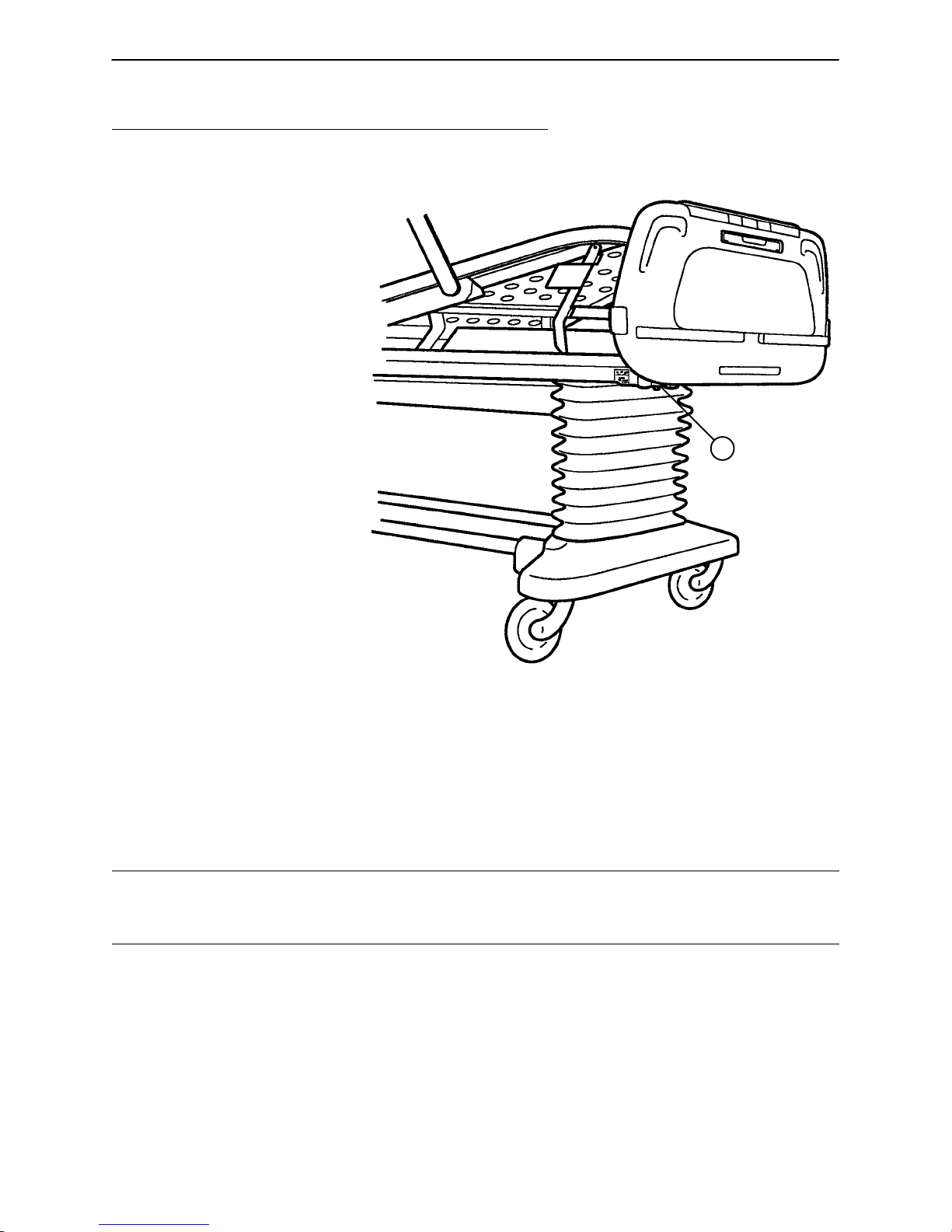

Activate the motion stop system to assure it is functioning properly: press and hold down the BED

DOWN key. As the bed lowers, lift up on each corner of the motion interrupt pan individually and assure the downward motion stops each time. Release the pan and allow the downward motion to continue.

NOTE

The bed’s upward motion or other functions are not disrupted by the motion stop system.

If any problems are found during bed set–up, contact Stryker Customer Service at 800–327–0770.

Damaged Merchandise

ICC Regulations require that claims for damaged merchandise must be made with the carrier within fifteen

(15) days of receipt of merchandise. DO NOT ACCEPT DAMAGED SHIPMENTS UNLESS SUCH DAMAGE

IS NOTED ON THE DELIVERY RECEIPT AT THE TIME OF RECEIPT. Stryker Customer Service must be

notified immediately. Stryker will aid the customer in filing a freight claim with the appropriate carrier for damages incurred. Claim will be limited in amount to the actual replacement cost. In the event that this information

is not received by Stryker within the fifteen (15) day period following the delivery of the merchandise, or the

damage was not noted on the delivery receipt at the time of receipt, the customer will be responsible for payment of the original invoice in full.

Claims for any short shipment must be made within thirty (30) days of invoice.

18

Page 19

Chapter Two – MPS Operations

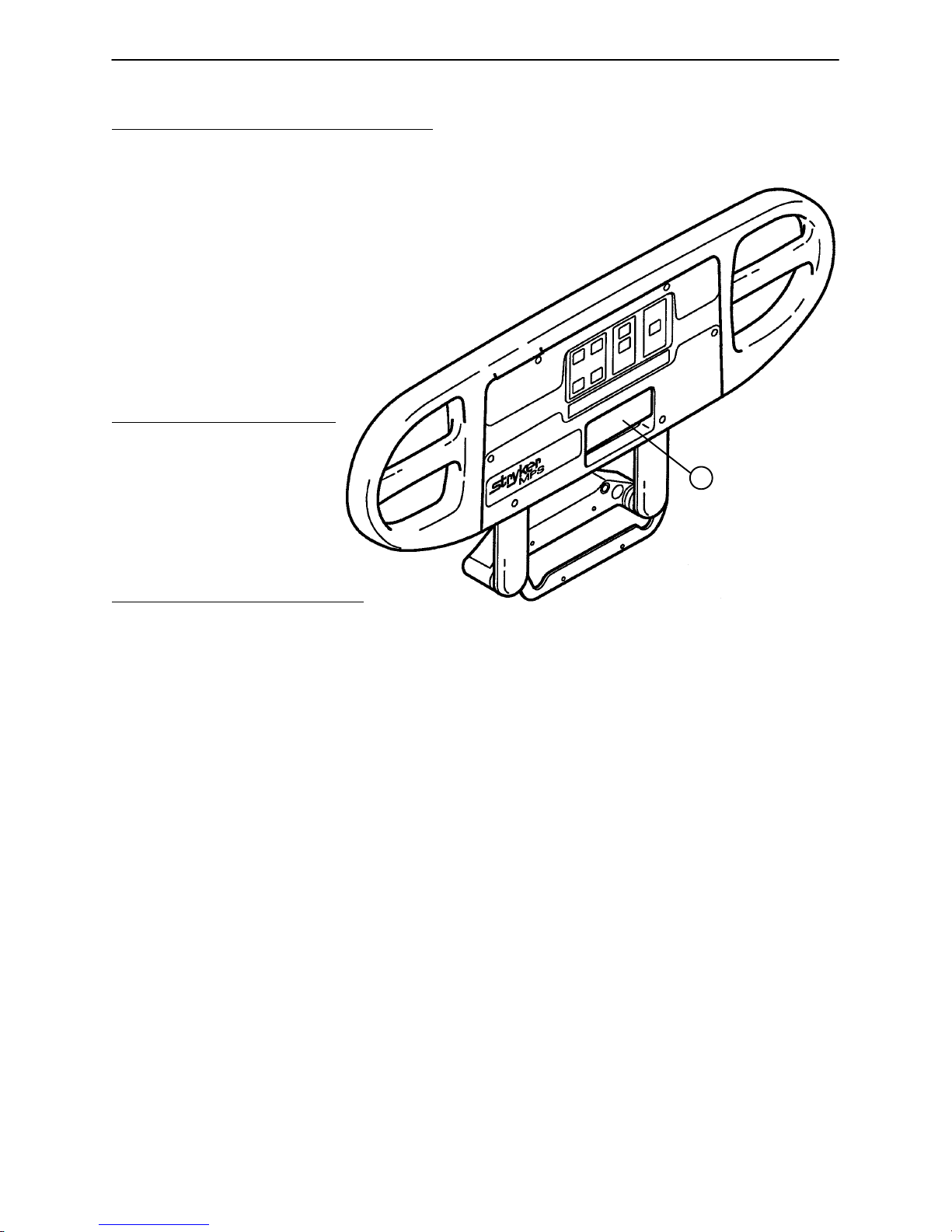

2.2 BED ILLUSTRATION

HEAD END

PATIENT’S

RIGHT

Steer

Pedal

I.V. and

Fracture Frame

Mount

CPR Release

Handle

Motion

Interrupt

Pan

Foley Bag Hooks

(Standard)

Siderail Release

Handle

Brake Pedal

PATIENT’S

LEFT

Foley Bag Hook

(Isolated)

(Optional Equip.)

Night

Light

I.V. and

Fracture Frame

Mount

Footboard

Control

Panel

Chart

Rack

(Optional Equip.)

FOOT END

19

Page 20

Chapter Two – MPS Operations

2.3 BASE OPERATION GUIDE

BRAKE PEDAL OPERATION

WARNING

Before putting a patient on the bed, be sure the brakes are fully engaged. Failure to set the brakes may allow

the bed to move, causing patient injury.

To activate the brakes, push down once on the pedal

identified by the label at right (located at both sides of

the bed). To disengage, push down once.

NOTE

There are LED lights on the outside of the head end siderails and on the foot end control panel that will blink

when the brakes are not engaged only if the bed is plugged into a wall socket (see pages 27 & 30). The brakes

will still operate properly when the bed is not plugged in.

STEER PEDAL OPERATION

The purpose of the steer caster is to help guide the bed along a straight line and to help with pivoting at corners

when the bed is moved.

To activate the steer caster, move the pedal located

at the head end of the bed to your left as shown on

the label.

NOTE

For proper ”tracking” of the steer caster, push the bed approximately 10 feet to allow the wheels to face the

direction of travel before engaging the steer pedal. If this is not done, proper ”tracking” will not occur and the

bed will be difficult to steer.

20

Page 21

Chapter Two – MPS Operations

2.4 LITTER OPERATION GUIDE

CPR EMERGENCY RELEASE USAGE

When quick access to the patient is needed, and the Fowler is raised, squeeze one of the two red release

handles (see illustration, page 19) and the Fowler can be lowered to a flat position.

NOTE

The handle can be released at any time to stop lowering the Fowler.

FOLEY BAG HOOKS USAGE, STANDARD AND ISOLATED (Isolated Optional Equipment)

The standard Foley bag hooks are found at two locations on both sides of the bed, under the frame rail below

the seat section and the extreme foot end of the bed.

NOTE

The patient weight reading on the bed scale system will be affected by using the standard Foley bag hooks.

The optional isolated Foley bag hooks are located under the litter frame at the top of the foot end bellows.

CAUTION

The Foley bag hooks move when the Fowler is raised or lowered. Fowler motion must be locked out when

using these hooks, and great care must be taken to avoid inadvertent movement of the hooks.

NOTE

The patient weight reading on the bed scale system will not be affected by usage of the isolated Foley bag

hooks.

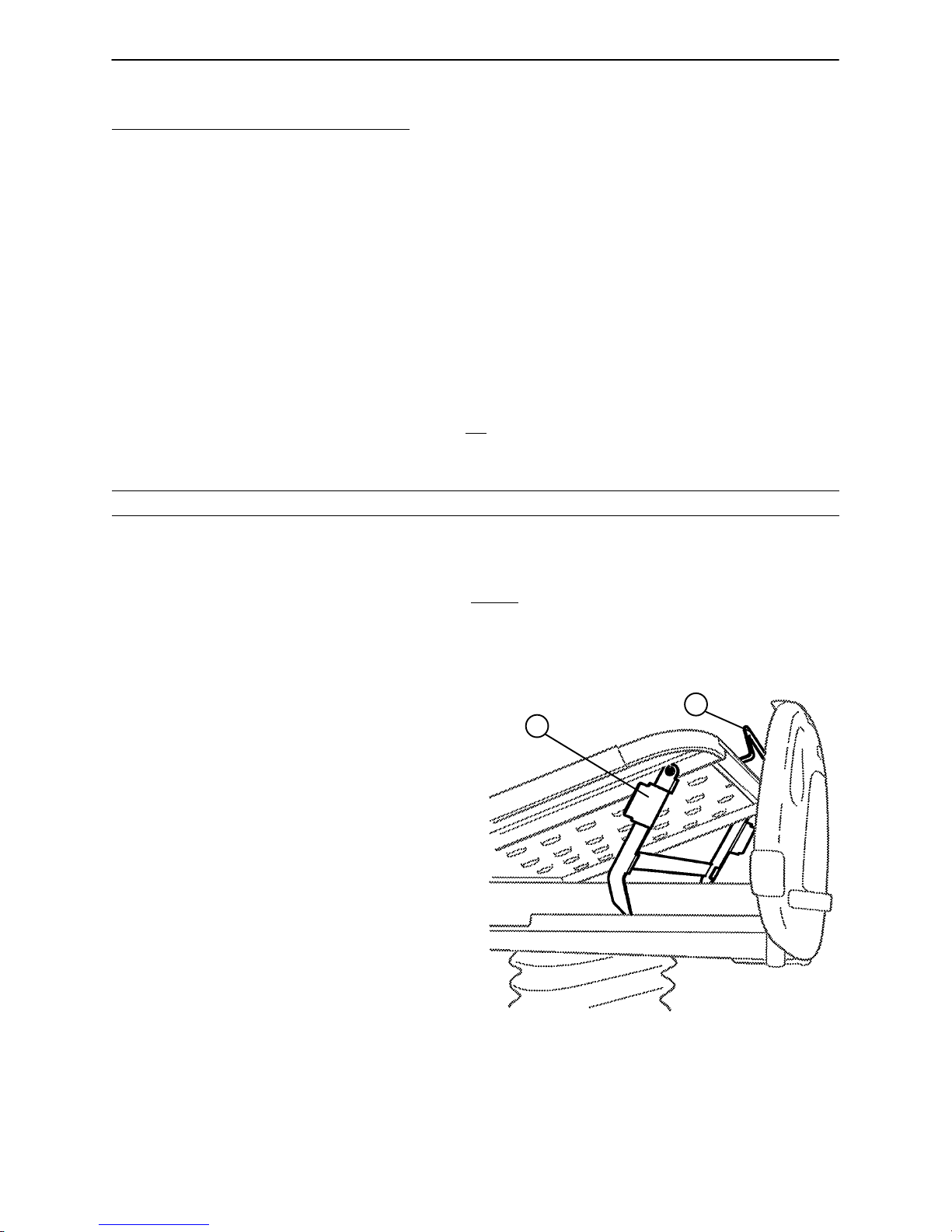

FOOT PROP USAGE

A

B

To prop the foot end of the Knee Gatch up, grasp

the handle (A) at the end of the Knee Gatch and

lift upward, allowing the latch arm to engage at the

desired height. To release the prop, lift up slightly

on the handle (A) and swing the foot prop handle

(B) toward the head end of the bed to disengage

the hinge and allow the foot end to lower.

FRACTURE FRAME USAGE

A standard fracture frame can be mounted on the bed using the I.V. sockets located on all four corners of

the bed. I.V. poles can be used in conjunction with a fracture frame if I. V . pole adaptor sockets are purchased.

FOOT END

21

Page 22

Chapter Two – MPS Operations

2.4 LITTER OPERATION GUIDE (CONTINUED)

I.V. POLES

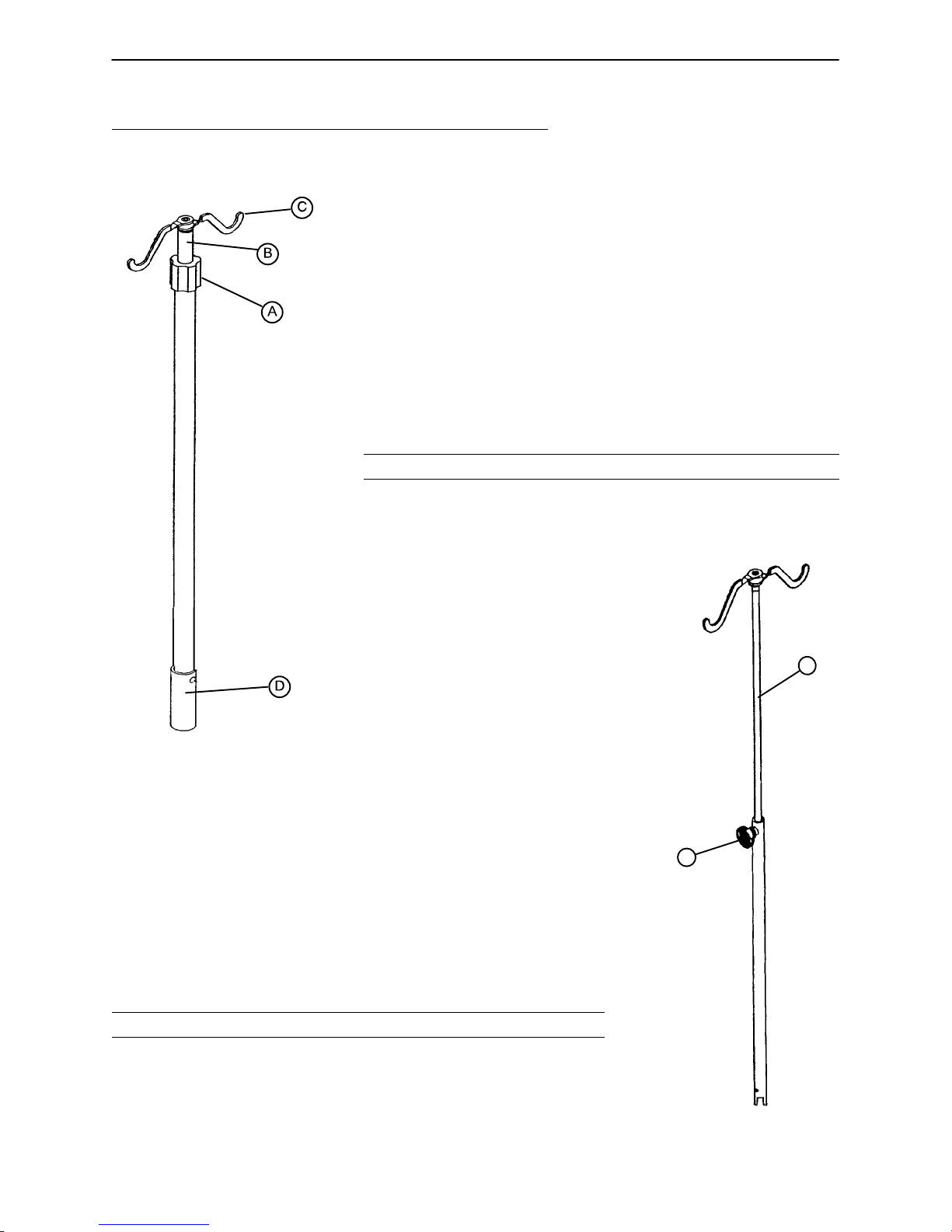

To use the Permanently Attached I.V. pole (optional equipment):

1. Lift and pivot the pole from the storage position and push down

until it is locked into receptacle (D).

2. To raise the height of the pole, turn the lock actuator (A) counter–

clockwise and pull up on the telescoping portion (B) of the pole to

raise it to the desired height.

3. Turn the lock actuator (A) clockwise to lock the telescoping portion

in place.

4. Rotate the I.V. hangers (C) to desired position and hang I.V. bags.

CAUTION

The maximum weight capacity of the I.V. pole is 40 pounds.

To use the ”Removable” I.V. pole:

1. Remove the pole from its storage position located at the foot end of the

bed, under the foot board.

2. Install the pole at any of the six receptacles on the bed top (located on

all four corners of the bed and halfway down the bed, on both sides.)

3. To raise the height of the pole, turn knob (A) counterclockwise and pull

up on the telescoping portion (B) of the pole and raise it to the desired

height.

4. Turn knob (A) clockwise to tighten the telescoping portion in place.

CAUTION

The maximum weight capacity of the I.V. pole is 40 pounds.

B

A

22

Page 23

Chapter Two – MPS Operations

2.4 LITTER OPERATION GUIDE (CONTINUED)

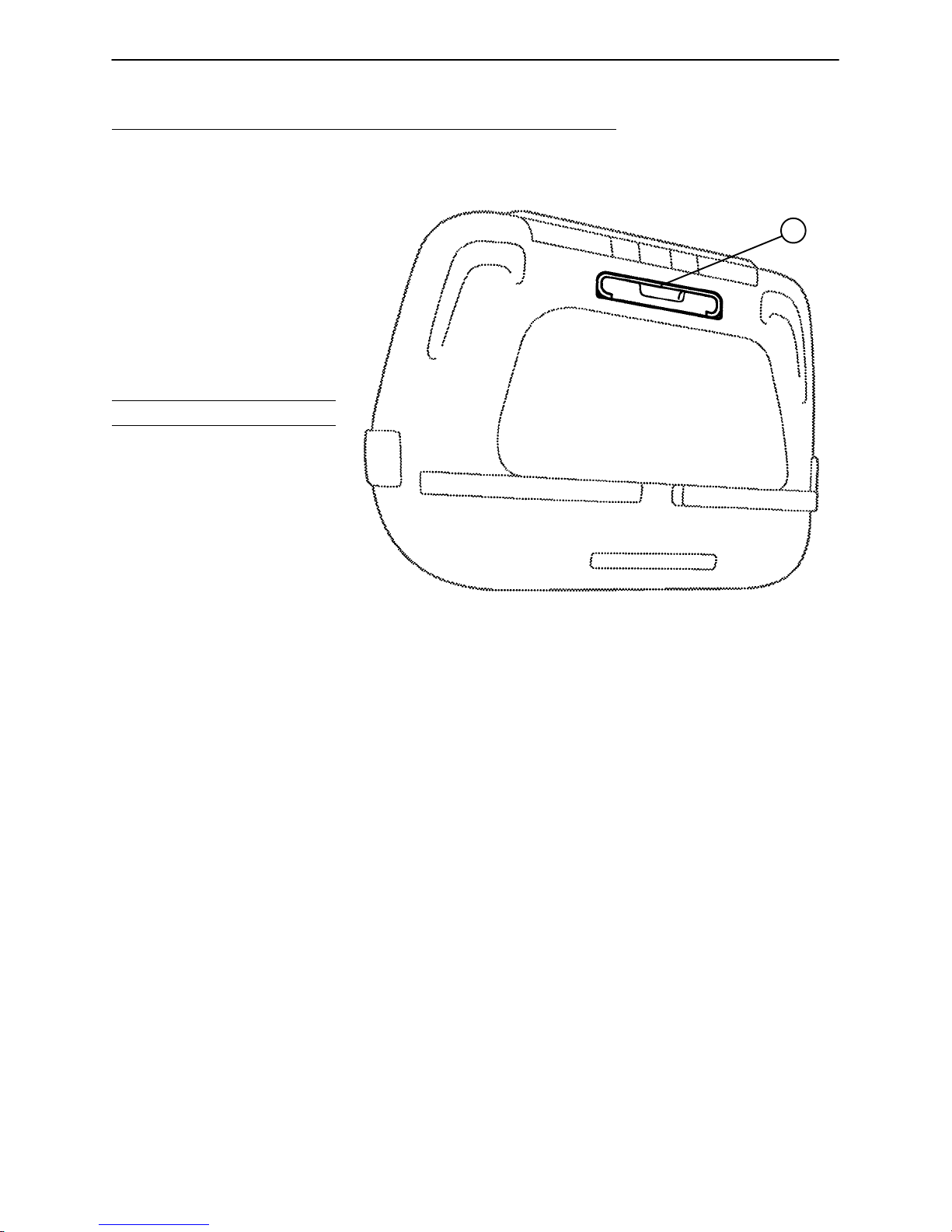

NIGHT LIGHT USAGE (Optional Equipment)

The bed may be equipped with

an optional night light (A) that will

illuminate the floor area around

the bed. The light has three set–

tings: LOW–OFF–HIGH.

A

FOOT END

PATIENT RESTRAINT STRAP LOCATIONS

The bed is equipped with 12 separate locations for installing patient restraint straps. The ”cutouts” in the bed

top are located directly across from each other (on both sides of the bed). When using restraint straps, attach

only to these locations. Never attach to mattress or bed rails.

WARNING

Restraints should be used only under the supervision of a licensed health care provider. Improperly adjusted

or improperly located restraint straps can cause serious injury to a patient.

23

Page 24

Chapter Two – MPS Operations

2.5 FOOT BOARD/HEAD BOARD OPERATION GUIDE

CHART RACK USAGE (Optional Equipment)

If the bed is equipped with the optional

chart rack, it is located on the foot

board. To use, pull handle rod (A)

downward. To store, push the handle

back to its storage position until it

locks in place.

CAUTION

Do not use handle rod (A) as a

device for pulling the bed. Doing

so may cause damage to the chart

rack and foot board.

A

FOOT END

CPR BOARD USAGE (Optional Equipment)

If the bed is equipped with the optional CPR board, it is stored on the bed’s head board. To remove, pull

away from the head board and lift out of storage position. If the CPR board option was not purchased,

the head board can be removed and used as an emergency CPR board.

24

Page 25

Chapter Two – MPS Operations

2.5 FOOT BOARD/HEAD BOARD OPERATION GUIDE (CONTINUED)

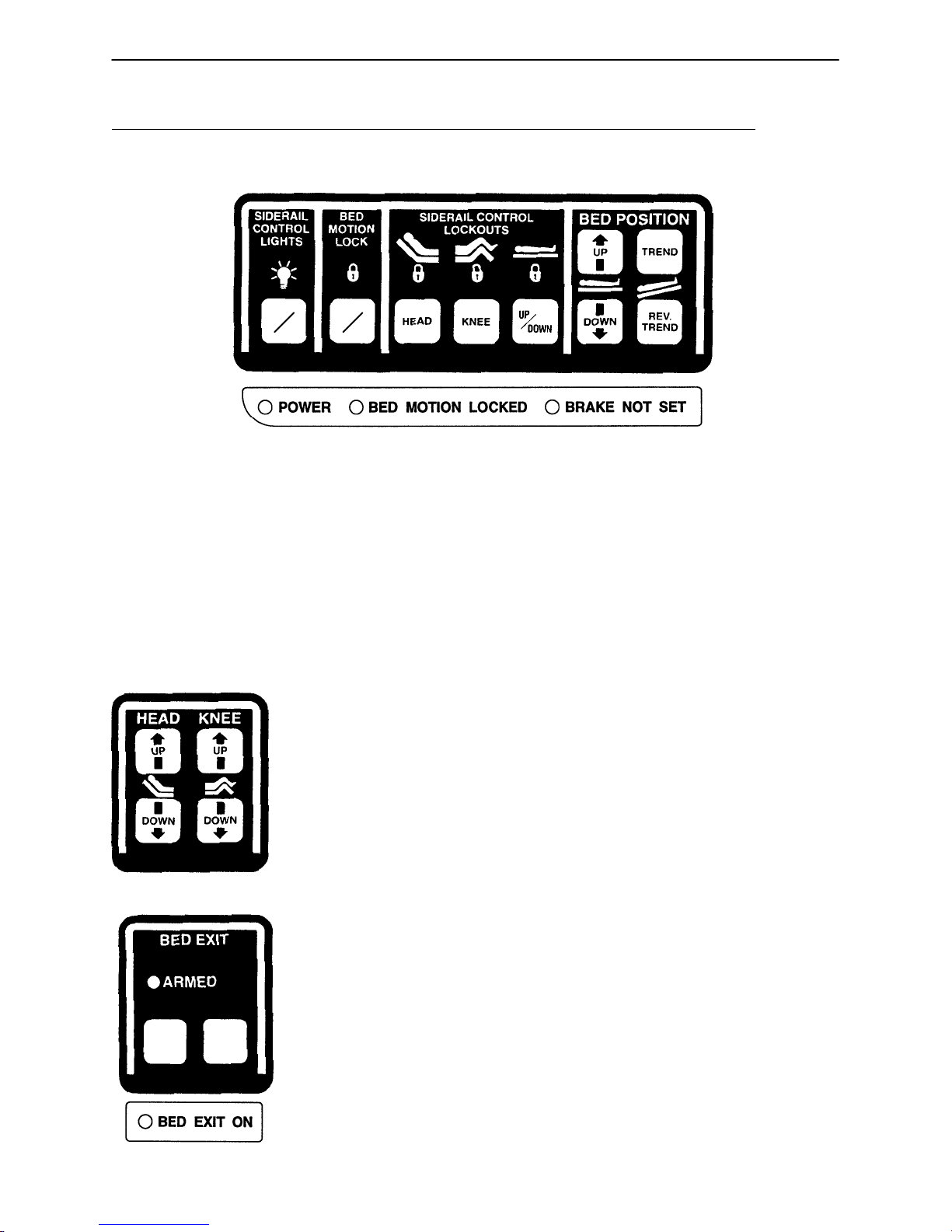

FOOT BOARD CONTROL PANEL GUIDE

8

ON

OFF

1234567

ON

OFF

9

1. Push to turn on siderail control panel lights. Push again to turn off (see page 28).

2. Push to lock out all bed motions. Push again to unlock (see page 35).

3. Push to lock out Fowler. Push again to unlock (see page 35).

4. Push to lock out Knee Gatch. Push again to unlock (see page 35).

5. Push to lock out bed height movement. Push again to unlock (see page 35).

6. Push to raise bed height.

7. Push to lower bed height.

8. Push to lower head end/raise foot end of bed (Trendelenberg position).

9. Push to lower foot end/raise head end of bed (Reverse Trendelenberg position).

1. Push to raise Fowler.

12

2. Push to raise Knee Gatch.

3. Push to lower Fowler.

4. Push to lower Knee Gatch.

34

This panel is optional equipment.

ARM DISARM

12

1. Push to activate Bed Exit function (see page 35).

2. Push to deactivate Bed Exit function (see page 35).

This panel is optional equipment.

25

Page 26

Chapter Two – MPS Operations

2.5 FOOT BOARD/HEAD BOARD OPERATION GUIDE (CONTINUED)

FOOT BOARD CONTROL PANEL GUIDE (Continued)

1. Push to turn the Dynamic Mattress system on or off (see page 35).

2. Push to activate automatic or manual modes (see page 35).

This panel is optional equipment.

1

ON

OFF

AUTO

MAN

2

1

23 4

SCALE

ON

567

1. LCD – displays patient weight.

2. Push to zero bed (see page 31 & 33).

3. Push when changing equipment on the bed (see page 31 & 33).

4. Push to change weight from pounds to kilograms or back (see page 32 & 33).

5. Push to turn weigh system on (see page 31 – 33).

6. Push to decrease numerical value of displayed weight (see page 32 & 34).

7. Push to increase numerical value of displayed weight (see page 32 & 34).

This panel is optional equipment.

NOTE

See page 27 for explanation of LED’s.

26

Page 27

Chapter Two – MPS Operations

2.5 FOOT BOARD/HEAD BOARD OPERATION GUIDE (CONTINUED)

LED DISPLAY PANEL GUIDE

The LED Display Panel is located at the foot end of the bed, under the Control Panel.

POWER BED MOTION LOCKED BRAKE NOT SET BED EXIT ON AIR LOSS

”POWER” – will light when the bed is plugged into the wall receptacle.

”BED MOTION LOCKED” – will light when the Bed Motion Lock has been activated.

”BRAKE NOT SET” – will blink when the brakes have not been set.

”BED EXIT ON” – will light when the Bed Exit function has been activated (optional equipment).

”AIR LOSS” – will light when there is a possible air leak in the Dynamic Mattress System (optional equipment).

27

Page 28

Chapter Two – MPS Operations

2.6 SIDERAIL OPERATION GUIDE

POSITIONING SIDERAILS

NOTE

The siderails can be locked at two heights (intermediate & full).

The siderails can be tucked away under the bed when not in use.

To remove the rail from the tucked position, grasp at the top of the

rail and pull outward.

To engage the siderail, grasp the rail and push it

upward until it rests in the ”intermediate” position.

To continue to the full height, pull the brown

release handle (A) until full height is

reached.

WARNING

Be sure rail is locked securely

into position. Siderails are not

intended to keep patients from

exiting the bed. They are

designed to keep a patient

from inadvertently rolling off the

bed. Always keep siderails in full–up

position when a patient is in the bed.

A

To disengage the rail, pull the brown release handle and pivot rail down to desired height. Tuck away siderails

by pushing the rails under the bed. Rails must be in the full down position before they can be tucked.

SIDERAIL CONTROL PANEL LIGHTS

The bed is equipped with lights that will illuminate the head end siderail control panel and can be activated

at the foot board control panel (see control panel guide page 25).

28

Page 29

Chapter Two – MPS Operations

2.6 SIDERAIL OPERATION GUIDE (CONTINUED)

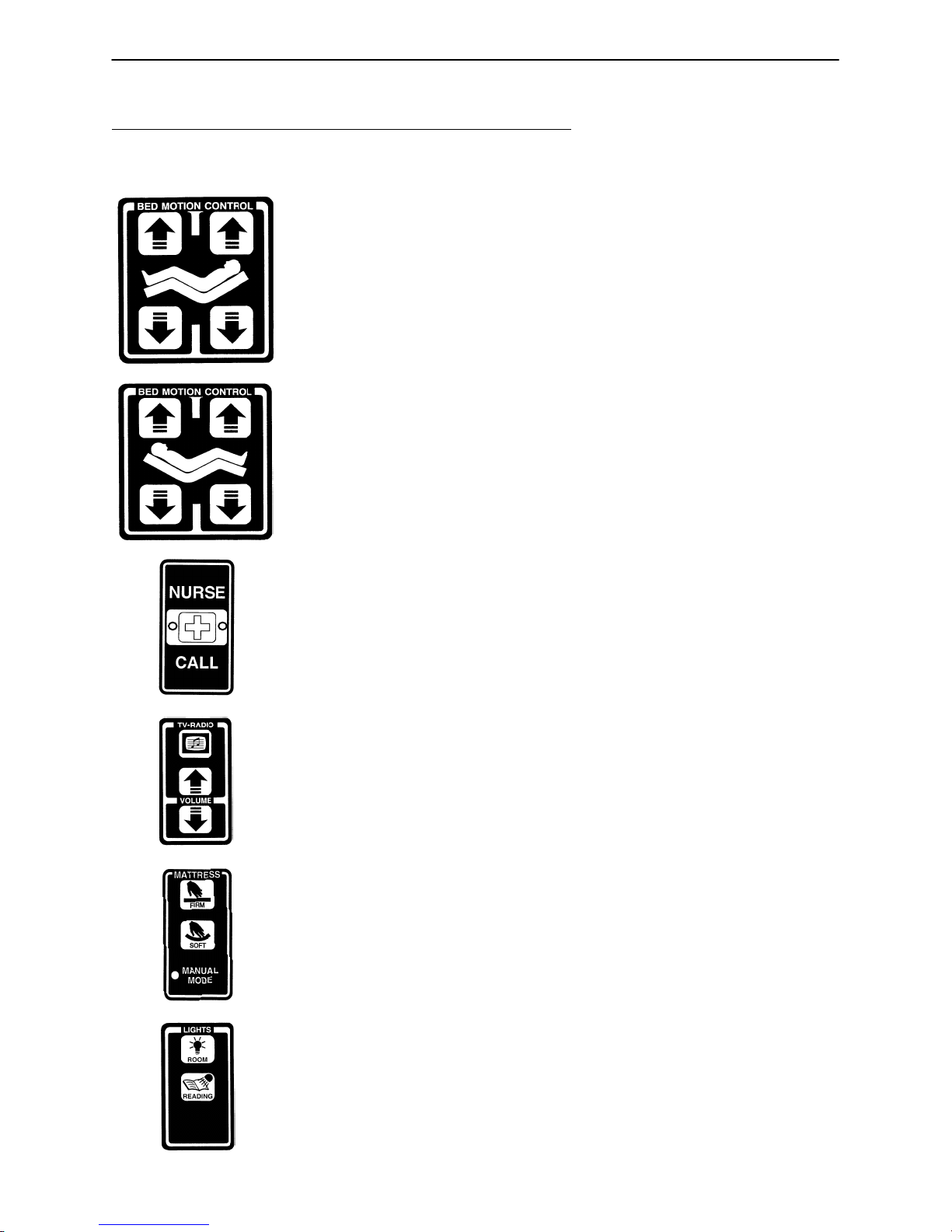

INSIDE SIDERAIL FUNCTION GUIDE

12

34

12

34

(Patient’s Right Rail)

1. Push to raise Knee Gatch.

2. Push to raise Fowler.

3. Push to lower Knee Gatch.

4. Push to lower Fowler.

(Patient’s Left Rail)

1. Push to raise Fowler.

2. Push to raise Knee Gatch.

3. Push to lower Fowler.

4. Push to lower Knee Gatch.

Push to activate Nurse Call.

NOTE

Yellow LED will light when button is pushed. Red LED will light with

Nurse Station acknowledgment.

This panel is optional equipment.

Push to turn TV or radio on and to select a channel.

Push to increase volume.

Push to decrease volume.

This panel is optional equipment.

Push to increase firmness of mattress.

Push to decrease firmness of mattress.

LED will light when the ”Manual” mode has been set at the foot

end of the bed.

This panel is optional equipment.

Push to turn the room light on.

Push to turn the bed overhead light on.

This panel is optional equipment.

29

Page 30

Chapter Two – MPS Operations

2.6 SIDERAIL OPERATION GUIDE (CONTINUED)

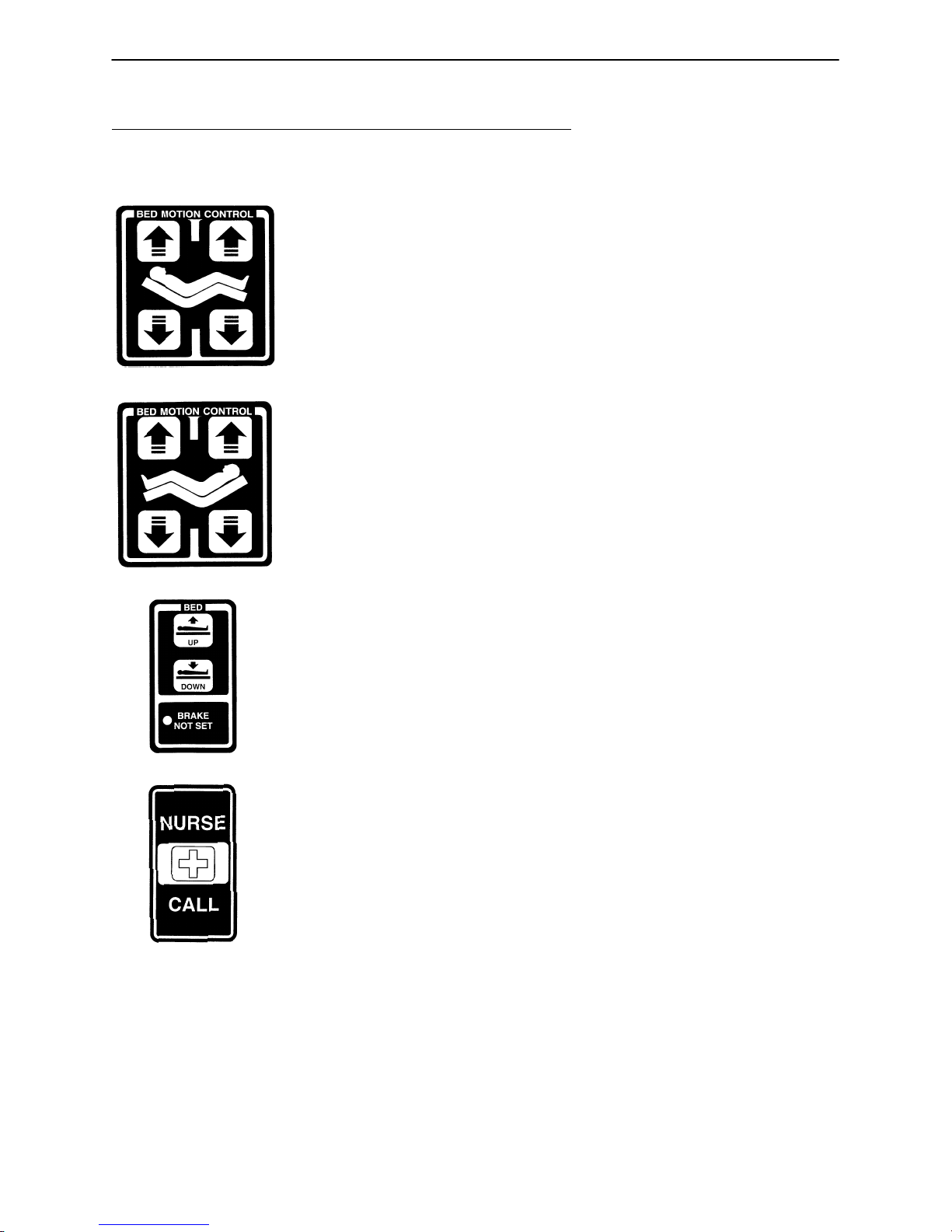

OUTSIDE SIDERAIL FUNCTION GUIDE

12

3

12

34

4

(Patient’s Right Rail)

1. Push to raise Fowler.

2. Push to raise Knee Gatch.

3. Push to lower Fowler.

4. Push to lower Knee Gatch.

This panel is optional equipment.

(Patient’s Left Rail)

1. Push to raise Knee Gatch.

2. Push to raise Fowler.

3. Push to lower Knee Gatch.

4. Push to lower Fowler.

This panel is optional equipment.

Push to raise bed height.

Push to lower bed height.

LED will blink when the brakes are not set.

Push to activate Nurse Call.

This panel is optional equipment.

30

Page 31

Chapter Two – MPS Operations

2.7 WEIGH SYSTEM OPERATION GUIDE

WEIGH SYSTEM USAGE

OPERATING THE SCALE BEFORE PUTTING A NEW PATIENT IN BED

Prepare bed for patient stay (linens, pillows, etc.).

Press and release ”SCALE ON”. The scale monitor will read:

”WEIGHING”

”XXX.X LB”

Press and hold ”ZERO”. The scale monitor will read:

”HOLD TO ZERO WT.”

”RELEASE TO ZERO”

Release ”ZERO”. The scale monitor will now read:

”DO NOT TOUCH BED”

”0.0 LB”

The bed is now ready for the patient.

NOTE

Do not zero the bed while a patient is in bed. If this should occur, remove the patient and zero the bed.

OPERATING THE SCALE IF PATIENT IS ALREADY IN BED

If it is necessary to add or remove special equipment (monitors, pumps, etc.) during the patient’s

stay, press and release ”SCALE ON” to activate the weigh system. After the scale monitor reads

”XXX.X LB”, press and hold . The scale monitor will read:

”HOLD TO START”

”RELEASE TO START”

Release . The scale monitor will read:

”DO NOT TOUCH BED”

”ADD/REMOVE EQUIP”

Add or remove the equipment and press . The scale monitor will read:

”RELEASE TO FIN.”

Release . The scale monitor will read:

The weight displayed will be that of the patient only.

”DO NOT TOUCH BED”

”XXX.X LB”

31

Page 32

Chapter Two – MPS Operations

2.7 WEIGH SYSTEM OPERATION (CONTINUED)

WEIGH SYSTEM USAGE (CONTINUED)

CONVERTING THE PATIENT’S WEIGHT

To convert the patient’s weight from pounds to kilograms, press and release ”SCALE ON” to activate

the weigh system. After the scale monitor reads ”XXX.X LB”, press and release the ”LBS/KGS” button. The scale monitor will read:

”WEIGHT NOW KGS”

”XXX.X KG”

Repeat the procedure to return to pounds. The display will read:

”WEIGHT NOW LBS”

”XXX.X LB”

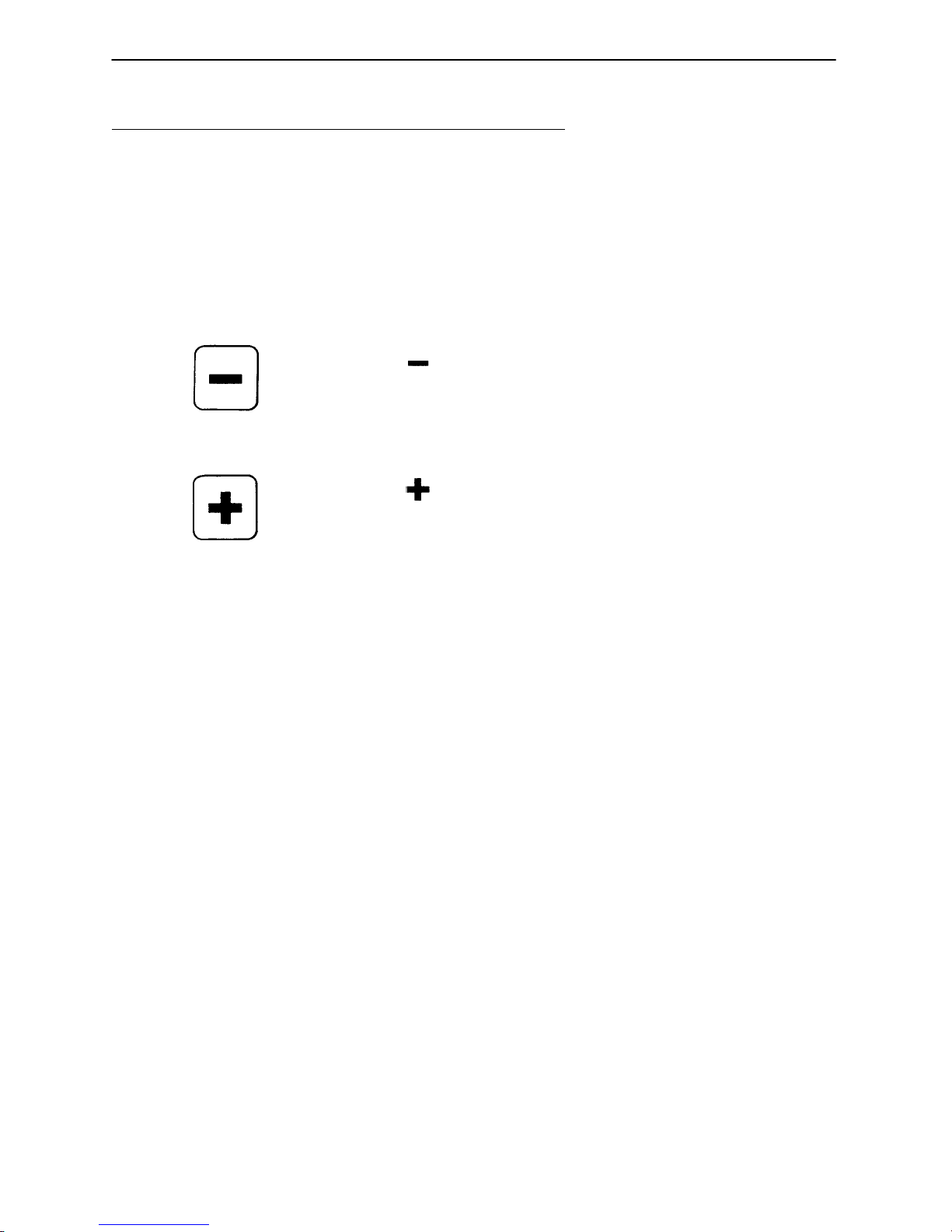

CHANGING THE NUMERICAL VALUE OF DISPLAYED WEIGHT

To decrease the numerical value of the displayed weight, press and hold ”–”. The scale monitor will

read:

”HOLD TO DEC. WT.”

”XXX.X LB”

Hold ”–” until desired value is achieved.

To increase the numerical value of the displayed weight, press and hold ”+”. The scale monitor will

read:

”HOLD TO INC. WT.”

”XXX.X LB”

Hold ”+” until desired value is achieved.

NOTE

The weigh system will shut off approximately one minute after a function has been used, if another function

is not activated. Display light will shut off and display will read ”SCALE OFF”.

The weigh system will retain all patient weight information in its memory even when the scale monitor is off

or when the bed is unplugged from the wall socket.

32

Page 33

Chapter Two – MPS Operations

2.7 WEIGH SYSTEM OPERATION (CONTINUED)

WEIGH SYSTEM CONTROL PANEL GUIDE

SYMBOL ACTION DISPLAY

To prepare bed for new patient:

SCALE

ON

to activate the scale system, begin ”XXX.X LB”

Press and release ”SCALE ON””WEIGHING...”

a new function and to display patient

weight.

ZERO

To add or remove equipment

Press and hold ”ZERO””HOLD TO ZERO WT.”

Release ”ZERO””DO NOT TOUCH BED”

during patient stay without

affecting registered patient

weight:

Press and release ”SCALE ON””WEIGHING...”

Press ”HOLD TO START”

Release ”DO NOT TOUCH BED”

Add or remove equipment.

Press ”RELEASE TO FIN.”

”RELEASE TO ZERO”

”0.0 LB”

”XXX.X LB”

”RELEASE TO START”

”ADD/REMOVE EQUIP.”

To convert the patient’s weight:

LBS.

KG.

Release ”DO NOT TOUCH BED”

”XXX.X LB”

To convert the patient’s weight ”WEIGHT NOW KGS”

to kilograms, press and release ”XXX.X KG”

”LBS./KG.”

Repeat the procedure to return to

pounds.

33

Page 34

Chapter Two – MPS Operations

2.7 WEIGH SYSTEM OPERATION (CONTINUED)

WEIGH SYSTEM CONTROL PANEL GUIDE (CONTINUED)

SYMBOL ACTION DISPLAY

To change the numerical value

of displayed weight:

Press and hold to scroll to ”HOLD TO DEC. WT.”

desired weight. ”XXX.X LB”

Press and hold to scroll to ”HOLD TO INC. WT.”

desired weight. ”XXX.X LB”

34

Page 35

Chapter Two – MPS Operations

2.8 SYSTEM OPERATION GUIDE

”BED EXIT” SYSTEM USAGE (Optional Equipment)

1. Before putting a new patient on the bed: prepare bed for patient stay by adding linens and equipment to

the bed. Press and hold ”DISARM” key for 5 seconds – ”ARMED” light will begin to flash. Release ”DISARM” key and do not touch the bed until ”ARMED” light stops flashing.

2. To arm Bed Exit: place patient on the bed, push ”ARM” key and release (”ARMED” light will come on).

3. To deactivate Bed Exit, push ”DISARM”. The ”ARMED” and ”BED EXIT ON” LED’s will turn off.

NOTE

If the scale system is active, it will switch to ”off” when Bed Exit is armed. Bed Exit will be temporarily disarmed

when the scale system is activated. When the bed is equipped with scales, the scales must be properly

zeroed for the Bed Exit System to function properly (see page 31 for scale system usage instructions).

WARNING

Bed Exit System does not prevent the patient from exiting the bed. It signals when a patient is about to exit.

Adding or subtracting objects from the bed after arming the bed exit system may cause a reduction in the

sensitivity of the bed exit system.

DYNAMIC MATTRESS SYSTEM USAGE (Optional Equipment)

1. Turn the mattress system on using the ”ON/OFF” switch in the ”Prevention Mattress” module on the foot

board control panel (see page 26 for Foot Board Control Panel Guide).

NOTE

Push this switch to turn the system both on and off. The ”AUT OMATIC” or ”MANUAL” LED on the foot board

will be on when the system is active.

2. The system can be set in either ”AUTOMATIC” or ”MANUAL” modes. The ”AUTO/MAN” switch is used

to activate both modes. When Automatic mode is selected, the ”AUTOMATIC” LED on the foot board

control panel will be on. When Manual mode is selected, the ”MANUAL” LED on the foot board control

panel and the ”MANUAL” LED on the inside siderail control panel will be on.

3. When the Automatic mode is selected, the firmness of the mattress will adjust automatically as needed.

When the Manual mode is selected, the firmness of the mattress can be adjusted by the patient or the

hospital clinical staff. The ”FIRM” and ”SOFT” switches are located on the control panels on the inside

of the head end siderails.

NOTE

The ”MANUAL” LED on the inside siderail will blink when the ”FIRM” or ”SOFT” switches are pressed while

in the manual mode.

4. If the ”AIR LOSS” LED is on, an air leak may exist.

FUNCTION LOCKOUT SYSTEM USAGE

1. To lock out the bed movement functions on the siderails and prevent the patient from changing the positioning of the bed, push the ”HEAD”, ”KNEE” and/or ”UP/DOWN” switches in the ”Siderail Control Lockouts”

module on the foot board control panel (see page 25).

NOTE

The foot board controls for these motions are not affected by the lockout switches.

The ”padlock” symbol on the control panel will be lighted when that function is locked out.

2. To lock out the entire bed motion for all switches on the bed, push the ”ON/OFF” switch in the ”Bed Motion

Lock” module on the foot board control panel (see page 25).

35

Page 36

Chapter Three – Troubleshooting

3.1 MECHANICAL TROUBLESHOOTING GUIDE

PROBLEM/SYMPTOM SOLUTION(S)

Brakes engage at one end and release at the other when pedal is activated.

Brakes do not engage when activated.

Brakes do not release.

Steer wheel does not engage when activated.

Steer wheel does not disengage.

Siderail release latch does not engage when activated.

Siderail release latch does not disengage.

CPR release does not disengage when activated. A. Check all applicable hardware and parts align-

Head section (Fowler) drifts down when weight is

added.

Head motor will not run Fowler down electrically –

motor hums momentarily when activated.

A. Brakes out of ”time”: slowly push down on

brake pedal until a spring release noise is heard.

Immediately release pedal then push pedal back

down entirely to set brakes.

B. Check all applicable linkage, hardware and

parts alignment. Replace parts as needed (reference brake assembly drawings, pages 138 & 139).

A. Check all applicable hardware and parts alignment. (See pages 73–75 for steer wheel cable adjustment and replacement.)

A. Check all applicable hardware and parts alignment. (See page 119 for siderail positioning

mechanism replacement.)

ment. (See pages 109 & 110 for CPR adjustments

and repairs.)

A. Back drive clutch has failed. Replace motor

and clutch assembly (see pages 103 & 104).

A. Refer to page 43, steps A & B to assure problem is not electrical. Replace motor and clutch

assembly if problem is mechanical (see pages 103

& 104).

36

Page 37

Chapter Three – Troubleshooting Guides

3.2 MOTION INTERRUPT TROUBLESHOOTING GUIDE

NOTE

Prior to replacing any circuit boards, ensure applicable cables and connections are intact (visually and mechanically). When measuring 110 VAC at any point, use only neutral (white) side of power line as a reference

point. DO NOT use digital ground as a reference point when measuring 110 VAC.

Visually and mechanically check for motion interrupt pan alignment and movement. Observe whether the

pan has been damaged. Any significant alteration in the shape of the pan may affect switch actuation. If the

pan’s shape is altered enough to affect the motion interrupt switches, replace the pan (p/n 3000–300–50) (see

page 95).

PROBLEM/SYMPTOM SOLUTION(S)

Motion interrupt does not disable the movement of

the bed when activated. (Motion of bed may be

prevented if the switch is constantly activated by a

foreign object.)

A. Check individual motion interrupt switches for

actuation and plunger travel. If switches appear to

be dismounted and/or damaged, replace as necessary (see page 96).

B. Using a voltmeter, check for +12 VDC at each

switch. Wire colors represent: red, +12 VDC,

black, ground reference. Replace switches as

necessary.

C. If +12 VDC is present at switches, verify the 2

pin plug from the motor stop cable is plugged into

P2 of the power junction board (p/n 3000–300–

961) (see page 199 for board location).

D. If +12 VDC is not present at the switches,

check connector P14, pin 5 of the litter CPU board

(p/n 3000–300–941). If voltage is not present,

check fuse F1 of the litter CPU board. Replace

fuse if necessary. If fuse is O.K. and voltage is not

present, check for 110 VAC at connector P1, pin

18. If 110 VAC is present, replace litter CPU

board (see page 115). If 110 VAC is not present,

check power junction board (p/n 3000–300–961) at

connector P1, pin 1 for 110 VAC. If voltage is not

present, check fuse F1. Replace as necessary. If

fuse is O.K., and 110 VAC is not present at connector P1, check connector J1, pin 2 for 110 VAC

input from power cord. If 110 VAC is present at

connector J1 but not at connector P1, replace

power junction board as needed (see page 199 for

board location).

37

Page 38

Chapter Three – Troubleshooting Guides

3.3 TRENDELENBERG/REVERSE TRENDELENBERG TROUBLESHOOTING

GUIDE

NOTE

Prior to replacing any boards, ensure applicable cables and connections are intact (visually and mechanically). To check for +5 VDC at various points called out in the troubleshooting, use digital ground as a reference

point (negative side of C18 on CPU litter board). When measuring 1 10 VAC at any point, use only the neutral

(white) side of the power line as a reference point. DO NOT use digital ground as a reference point when

measuring 110 VAC.

Assure the bed motion lock is not activated on the foot board. If bed motion will not unlock, see troubleshooting section 3.9 page 48. If any one part of Trendelenberg/Reverse Trendelenberg motion is not functioning,

see appropriate troubleshooting section (i.e. bed head end lift motor not functioning see section 3.4 page 40).

If the litter is at its lowest height when Trendelenberg or Reverse Trendelenberg is activated, the litter will raise

a few inches until the height is adequate. When this height is achieved, Trend. or Reverse Trend. will proceed.

PROBLEM/SYMPTOM SOLUTION(S)

Trendelenberg does not move into proper position

(head down, foot up).

Reverse Trendelenberg will not move into proper

position (head up, foot down). Note: connector

P2, pin 7 may be used for digital ground reference.

A. Check for +5 VDC at connector P1, pin 6 of the

foot board keyboard (p/n 3000–500–943) (see

page 202 for board location). If voltage is present,

use a voltmeter and verify switches are O.K. If

switches are defective, replace board.

B. Check foot board IFC (p/n 3000–500–955) for

+5 VDC at connector P2, pin 6 (see page 202 for

board location). If voltage is not present, check for

+8 VDC at connector P3, pin 5. If +8 VDC is present and +5 VDC is not present, replace foot board

IFC. If +8 VDC is not present, disconnect connector P3 and check for voltage at the cable connector. If +8 VDC is present at the cable but not at

the board, replace foot board IFC.

C. If Trend./Rev. Trend. motion is still uncontrollable, check the litter CPU board (p/n 3000–300–

941) for +8 VDC at connector P9, pin 5 (see page

199 for board location). If voltage is not present,

check fuse F1. If fuse is O.K. and the problem still

exists, check for 110 VAC at connector P1, pin 18.

If 110 VAC is present, replace litter CPU board. If

110 VAC is not present, check power junction

board (p/n 3000–300–961) at connector P1, pin 1

for 110 VAC. If voltage is not present, check fuse

F1. Replace fuse as necessary. If fuse is O.K.

and 110 VAC at connector P1 is not present,

check connector J1, pin 2 for 110 VAC input from

power cord. If 110 VAC is present at connector

P1, replace power junction board.

38

Page 39

Chapter Three – Troubleshooting Guides

3.4 BED MOTION TROUBLESHOOTING GUIDE

NOTE

Before proceeding, ensure the foot board is properly installed and electrical connections are made. Ensure

all bed motion lockouts are functioning properly and are turned off. Prior to replacing any boards, ensure all

applicable cables and connections are intact (visually and mechanically). Check for +5 VDC at various points

called out in the troubleshooting by using digital ground as a reference point (negative side of C18 on CPU

litter board). When measuring 110 VAC at any point, use only the neutral (white) side of the power lines as

a reference point. DO NOT use digital ground as a reference point when measuring 110 VAC.

If bed lift motion is not functioning properly, check Lift Lock Light on the foot board. If one of the lift potentiometers is disconnected, the Lift Lock Light in the foot board will flash constantly.

PROBLEM/SYMPTOM

Bed will not raise when switch is depressed.

Bed will not lower when switch is depressed.

SOLUTION(S)

A. Check switch keyboards in siderails for +5 VDC

at connector J1, pin 1 (see page 200 & 201 for

board locations). Use connector J2, pin 2 of the

inside Gatch/Fowler board (p/n 3000–400–901/

917) as a ref. point. If voltage is present and keyboards are not O.K., replace siderail keyboards