Page 1

Renaissance Series

2020 Critical Care Bed

OPERATIONS MANUAL

For Parts or Technical Assistance

1–800–327–0770

Page 2

Table of Contents

Introduction 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warning / Caution / Note Definition 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set–up Procedures 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation Guide

Operating Symbols 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Led Display 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Function Lockout/Scale System On/Off/Reset 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cardiac Chair 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Emergency Drop 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Emergency Stop 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Directional Steering Caster 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Optional Oxygen Bottle Holder 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the 110 Volt Outlet Option 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Optional Permanently Attached I.V. Pole 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Equipment Tray Options 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Optional X–Ray Cassette Holder 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Panel Guide 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Weigh System Usage 10,11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Weigh System Control Panel Guide 12,13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Patient Control/Nurse Control Guide 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Integrated Dynamic Mattress System Operation 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limited Warranty

Obtaining Parts and Service 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supplemental Warranty Coverage 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Return Authorization 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Freight Damage Claims 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 3

Introduction

INTRODUCTION

This manual is designed to assist you with the operation of the 2020 Renaissance Series Critical Care Bed.

Read it thoroughly before using the equipment.

SPECIFICATIONS

Maximum Weight Capacity 500 pounds

Overall Bed Length/Width 90”/38”

Minimum/Maximum Bed Height 22.5”/35”

Knee Gatch Angle 0 degrees to 35 degrees

Fowler Angle 0 to 90 Degrees

Trendelenberg/Reverse Trendelenberg –12 degrees to +12 degrees

Weigh System Accuracy (optional equipment) + / – 1% of total patient weight

Electrical Requirements 110 VAC, 60 Hz, 5.0 Amp

WARNING / CAUTION / NOTE DEFINITION

The words WARNING, CAUTION and NOTE carry special meanings and should be carefully reviewed.

WARNING

The personal safety of the patient or user may be involved. Disregarding this information could result in injury

to the patient or user.

CAUTION

These instructions point out special procedures or precautions that must be followed to avoid damaging the

equipment.

NOTE

This provides special information to make maintenance easier or important instructions clearer.

2

Page 4

Set–Up Procedures

SET–UP PROCEDURES

It is important that the 2020 Renaissance Series Critical Care Bed is working properly before it is put into

service. The following list will help assure that each part of the bed is tested.

S Depress the curved pedal at either end of the bed fully to set the four wheel brakes and assure all

four casters lock. Lift the pedal to the neutral position to release the brakes.

S Lift the pedal and assure the steering caster locks at the foot end of the bed (on the patient’s right

side only). Depress the pedal fully to set the brakes.

S Assure the bed will lower to the full down position by depressing both pedals at the foot end of the

bed.

S Raise the bed to the full up position by pumping the pedal identified by the ”bed up” label on the base

hood. Assure the head end lowers to the full down position by depressing the pedal identified by the

Trendelenberg (head down) label.

S Depress the pedal identified by the Reverse Trendelenberg (foot down) label and assure the foot end

lowers to the full down position.

S Raise the bed to the full up position. Pivot the manual override Fowler crank up into position. Push

in the crank and hold it in while turning it clockwise to raise the Fowler. Assure it will raise to at least

90 degrees. Hold the crank in and turn it counterclockwise to lower the Fowler. Assure it will lower to

flat.

S Pivot the manual override Knee Gatch crank up into position. Push in the crank and hold it in while

turning it clockwise to raise the Knee Gatch. Assure it will raise to 35 degrees. Hold the crank in and

turn it counterclockwise to lower the Knee Gatch. Assure it will lower to flat.

S Assure the siderails raise and lower smoothly and lock in the up and intermediate positions.

S Plug the bed into a properly grounded, hospital grade wall receptacle. Assure the ”BED ON” light on

the foot end keypad comes on.

WARNING

The 2020 is equipped with a hospital grade plug for protection against shock hazard. It must be plugged directly into a properly grounded three–prong receptacle. Grounding reliability can be achieved only when a

hospital grade receptacle is used.

S Push the scale system On/Off/Reset switch (under the foot end frame end, next to the function lock-

out switches) away from you to turn on the weigh system (see page 5 for diagram).

S Run through each function on the head end and foot end control panels and assure that each is work-

ing properly (see control panel guide page 9 and weigh system control panel guide page 12 & 13).

S Assure all functions are working properly on the patient controls or the in–rail nurse controls, if the

bed is equipped with them.

3

Page 5

Operation Guide

OPERATING SYMBOLS

Fowler Crank

T o raise the Fowler, push in the crank and hold it in while turning it clockwise.

To lower the Fowler, push in the crank and hold it in while turning it counter–

clockwise.

Knee Gatch Crank

To raise the Knee Gatch, push in the crank and hold it in while turning it

clockwise.

To lower the Knee Gatch, push in the crank and hold it in while turning it

counterclockwise.

Lift Pedal

Pump pedal to raise bed.

Trendelenberg Pedal

Depress pedal to lower head end.

Note: Depress both Trendelenberg pedals at the same time to lower litter.

Reverse Trendelenberg Pedal

Depress pedal to lower foot end.

Note: Depress both Trendelenberg pedals at the same time to lower litter.

Brake/Steer Pedal

Depress pedal fully to set four wheel brakes.

Lift pedal fully to engage steer caster.

4

Page 6

Operation Guide

LED DISPLAY

There is an optional LED display to show the angle of the Fowler and the angle of Trendelenberg/Reverse

Trendelenberg. The Fowler display lights will change as the Fowler is moved electrically by pressing the control panel button or manually by cranking. The bed must be plugged into a wall socket for the display lights

to work. The Fowler display is for 15 degree increments only . The Trendelenberg display lights will change

whenever the angle of T rendelenberg/Reverse Trendelenberg is changed electrically by pressing the control

panel button or manually by depressing the pedals. Again, the bed must be plugged in for the lights to work.

The Trendelenberg display is for 4 degree increments only.

FUNCTION LOCKOUT/SCALE SYSTEM ON/OFF/RESET

Under the foot end keypad, there are seven lockout switches. These switches are identified with symbols

(see below). Pull the switch toward you to individually lock out bed up/down, Fowler, Knee Gatch, Trendelenberg/Reverse Trendelenberg, cardiac chair (optional) and the patient controls (optional). If the keypad button

is pressed for a function that is locked out, a horn will sound and the bed will not respond. The seventh switch

at the far right of the group is the scale system on/off/reset switch. It is used to reset the scale system if an

unusual symbol or character is displayed on the scale monitor or if the scale system operates in any other

erratic manner. It will not clear the bed zero information stored in the scale system memory.

CARDIAC CHAIR

To activate the optional Cardiac Chair function, press and hold the button on the foot end control panel. The

Knee Gatch will raise, the Fowler will raise or lower to 51 degrees and the bed will tilt to –12 degrees Reverse

Trendelenberg. Release the button to stop bed movement: hold the button until movement stops to complete

the function.

EMERGENCY DROP

To activate the optional Emergency Drop function, press and hold the ”ON” button on the foot end control

panel for two seconds. The bed will level from Trendelenberg/Reverse Trendelenberg, the Fowler will lower

to flat, the Knee Gatch will lower to flat and the litter will lower to full down. Press the ”OFF” button when the

function is complete.

NOTE

Both the Cardiac Chair and the Emergency Drop functions are stopped by safety switches if there is an obstruction under the Fowler or Knee Gatch. To start Cardiac Chair after clearing the obstruction, press the

function button again. To start Emergency Drop after clearing the obstruction, press the start button again.

EMERGENCY STOP

Pressing the Emergency Stop button on the head end control panel will interrupt any downward motion.

Emergency Stop overrides both control panels and the patient or in–rail nurse controls.

5

Page 7

Operation Guide

OPERATING DIRECTIONAL STEERING CASTER

When transporting a patient, the steer caster helps to maintain the bed’s path along a straight line and aids

pivoting at corners.

Brake/Steer Pedal

Depress pedal fully to set four wheel brakes.

Lift pedal fully to engage steer caster.

For proper ”tracking” of the steer caster, push the bed approximately 10 feet to allow the wheels to face the

direction of travel before engaging the steer pedal. Without doing this, proper ”tracking” will not occur and

it will be difficult to steer the bed.

OPERATING OPTIONAL OXYGEN BOTTLE HOLDER

A

1. To use oxygen bottle holder, rotate (A) upward until it stops in an upright position, as shown.

2. To store, when not in use, rotate (A) downward until it stops (flat position).

USING THE 110 VOLT OUTLET OPTION

CAUTION

Only use equipment with the following electrical specifications: 125 VAC; 5A; 60Hz.

Maximum total load drawn by equipment used in this receptacle outlet must not exceed 10A.

The bed power cord must be plugged into a properly grounded three prong wall receptacle for the bed outlet

to work.

If the equipment plugged into the bed outlet is not receiving power, change the fuse located on the base assembly at the head end of the bed, near the serial number label.

CAUTION

To avoid risk of fire, replace fuse with a 3AB type, 250V, 10A Slow Blo fuse.

6

Page 8

OPERATING OPTIONAL PERMANENTLY ATTACHED I.V. POLE

C

Operation Guide

An optional permanently attached I.V. Pole

foot or both ends of the stretcher. The choice

desired height.

B

A

NOTE

may have been installed at either the head,

was made at the time the stretcher was pur–

chased.

To Use the I.V. Pole:

1. Lift the I.V. pole from the I.V. rest and hinge

downward into receptacle (A).

2. To increase the height of the pole, turn the lock

actuator (B) counterclockwise and pull up on the

telescoping portion (C). Raise the pole to the

3. Turn the lock actuator (B) clockwise to lock the

telescoping portion in place.

CAUTION

The weight of the I.V. bags should not exceed 40

pounds.

USING THE EQUIPMENT TRAY OPTIONS

CAUTION

Both the equipment (defibrillator) tray and the equipment

tray/footboard combination options have a 40 lb. limit.

To use the equipment tray/footboard combination option,

mount as shown in the illustration. The tray can be pivoted

out of the way when not in use by pulling knob (A) and ro–

tating tray to stored position.

NOTE

The equipment (defibrillator) tray and the equipment tray/

footboard combination are interchangeable between beds.

7

A

Page 9

Operation Guide

USING THE OPTIONAL X–RAY CASSETTE HOLDER

C

B

1. To access the Fowler x–ray cassette holder, raise the Fowler section.

A

D

C

B

2. Grasp handles (A) and squeeze, allowing locating pins (B) to disengage from mounting brackets (C).

3. Lower tray and install x–ray cassette.

4. Reverse steps 1 & 2 to engage loaded tray to Fowler mounting brackets (C).

NOTE

The tray position can be adjusted, from the patient’s head to the buttocks area, by loosening knob (D), sliding

the tray to the desired position, and re–tightening (D) to hold the position.

8

Page 10

SYMBOL BED ACTION

Litter will raise.

Litter will lower.

Fowler will raise.

Fowler will lower.*

Knee Gatch will raise.

Control Panel Guide

Knee Gatch will lower.*

Head end tilts down.**

Foot end tilts down.**

*There are individual safety switches to stop the movement of the Fowler and Knee Gatch if there is an ob–

struction under either one. The obstruction must be cleared before the function will continue.

**If the litter is at its lower limit when the Trendelenberg button is pressed, the foot end of the bed will raise

to achieve the desired angle for the bed. If the Reverse Trendelenberg button is pressed when the bed

is at its lower limit, the head end of the bed will raise to achieve the desired angle.

9

Page 11

Weigh System Usage

See Note Below

BEFORE PUTTING A NEW PATIENT ON THE BED

S There is a scale system on/off/reset switch under the frame end at the foot end of the bed along with

the function lockout switches. It is used to reset the scale system if an unusual symbol or character

is displayed on the scale monitor or if the scale system operates in any other erratic manner. It will

not clear the bed zero information stored in the scale system memory,

S Press and release ”PATIENT WEIGHT SYSTEM ON”. The scale monitor will read:

”WEIGHING”

”XXX.X LB GXX.X”

S Press and release ”LOCK/UNLOCK”. The scale monitor will read:

”LOCK/UNLOCK KEY?”

S Press and hold ”ZERO BED”. The scale monitor will read:

”KEY NOW UNLOCKED”

”HOLD TO ZERO WT.”

”RELEASE TO ZERO”

S Release ”ZERO BED”. The scale monitor will now read:

”DO NOT TOUCH BED”

”0.0 LB”

AFTER PUTTING A NEW PATIENT ON THE BED

S Press and release PATIENT WEIGHT SYSTEM ON”. After the scale monitor reads ”XXX.X LB”,

press and hold ”ZERO GAIN/LOSS”. The scale monitor will read:

”HOLD TO ZERO G/L”

”RELEASE TO ZERO”

S Release ”ZERO GAIN/LOSS”. The scale monitor will read:

”DO NOT TOUCH BED”

”XXX.X LB G00.0”

NOTE

If a negative sign (–) appears in the patient weight display, weight has been removed from the bed after the

”ZERO BED” function was completed. ”ZERO BED” must be completed again before patient weight readings

will be accurate.

10

Page 12

Weigh System Usage

AFTER PUTTING A NEW PATIENT ON THE BED (CONTINUED)

S If it is necessary to add or remove special equipment (monitors, pumps, etc.) during the patient’s

stay, press and release ”PATIENT WEIGHT SYSTEM ON” to activate the weigh system. After the

scale monitor reads ”XXX.X LB GXX.X”, press and hold ”CHANGE EQUIP.” The scale monitor will

read:

”HOLD TO START”

”RELEASE TO START”

S Release ”CHANGE EQUIP.” The scale monitor will read:

”DO NOT TOUCH BED”

”ADD/REMOVE EQUIP”

S Add or remove the equipment and press ”CHANGE EQUIP. END”. The scale monitor will read:

”RELEASE TO FIN.”

S Release ”CHANGE EQUIP. END”. The scale monitor will read:

”DO NOT TOUCH BED”

”XXX.X LB GXX.X”

NOTE

Do not remove the patient from the bed before completing the equipment change function or the patient’s

weight will stay in the memory and be added to the next patient’s weight reading. To remove the previous

weight reading from the memory, remove the patient from the bed and complete the ”ZERO BED” function

again.

S To convert the patient’s weight and weight gain/loss to kilograms, press and release ”PATIENT

WEIGHT SYSTEM ON” to activate the weigh system. After the scale monitor reads ”XXX.X LB

GXX.X”, press and release the ”LBS/KGS” button. The scale monitor will read:

”WEIGHT NOW KGS”

”XXX.X KG GXX.X”

S Repeat the procedure to return to pounds. The display will read:

”WEIGHT NOW LBS”

”XXX.X LB GXX.X”

S The display will turn off approximately one minute after a function is completed. The patient’s weight

and weight gain/loss will still be in the weigh system memory and will be displayed whenever the ”PA-

TIENT WEIGHT SYSTEM ON” button is pressed.

NOTE

If the ”EQUIPMENT CHANGE” function is started but not completed, the display will not turn off and will continue to read:

”ADD/REMOVE EQUIP”

11

Page 13

Weigh System Control Panel Guide

SYMBOL ACTION DISPLAY

To prepare bed for new patient:

Press and release ”PATIENT ”WEIGHING...”

WEIGHT SYSTEM ON” to activate ”XXX.X LB GXX.X”

the scale system, begin a new

function and to display patient weight.

Press and release ”LOCK/UNLOCK””LOCK/UNLOCK KEY?”

to begin the ”ZERO BED” function.

Press and hold ”ZERO BED”. ”KEY NOW UNLOCKED”

”HOLD TO ZERO WT.”

”RELEASE TO ZERO”

Release ”ZERO BED””DO NOT TOUCH BED”

”0.0 LB”

After putting new patient on bed:

Press and release ”PATIENT ”XXX.X LB”

WEIGHT SYSTEM ON”

Press and hold ”ZERO GAIN/LOSS””HOLD TO ZERO G/L”

”RELEASE TO ZERO”

Release ”ZERO GAIN/LOSS””XXX.X LB G00.0”

12

Page 14

Weigh System Control Panel Guide

SYMBOL ACTION DISPLAY

To add or remove equipment during

patient stay without affecting regis–

tered patient weight:

Press ”PATIENT WEIGHT ”XXX.X LB GXX.X”

SYSTEM ON”

Press ”CHANGE EQUIP. START””HOLD TO START”

”RELEASE TO START”

Release ”CHANGE EQUIP START””DO NOT TOUCH BED”

”ADD/REMOVE EQUIP”

Add or remove equipment.

Press ”CHANGE EQUIP. FINISH””RELEASE TO FIN.”

Release ”CHANGE EQUIP. FINISH””DO NOT TOUCH BED”

”XXX.X LB GXX.X”

To lockout any weigh system function

except ”PATIENT WEIGHT SYSTEM ON”

and ”LOCK/UNLOCK”:

Press and release ”LOCK/UNLOCK””LOCK/UNLOCK KEY?”

Press and release selected weigh ”KEY NOW LOCKED”

system button.

Multiple functions can be locked out

by repeating the above step. If a but–

ton is pressed for a function that has

been locked out, the display will read: ”KEY LOCKED OUT”

To unlock a function:

Press and release ”LOCK/UNLOCK””LOCK/UNLOCK KEY?”

Press and release selected button ”KEY NOW UNLOCKED”

To convert the patient’s weight to

kilograms, press and release ”WEIGHT NOW KGS”

”LBS/KGS””XXX.X KG GXX.X”

Repeat the procedure to return to

pounds.

13

Page 15

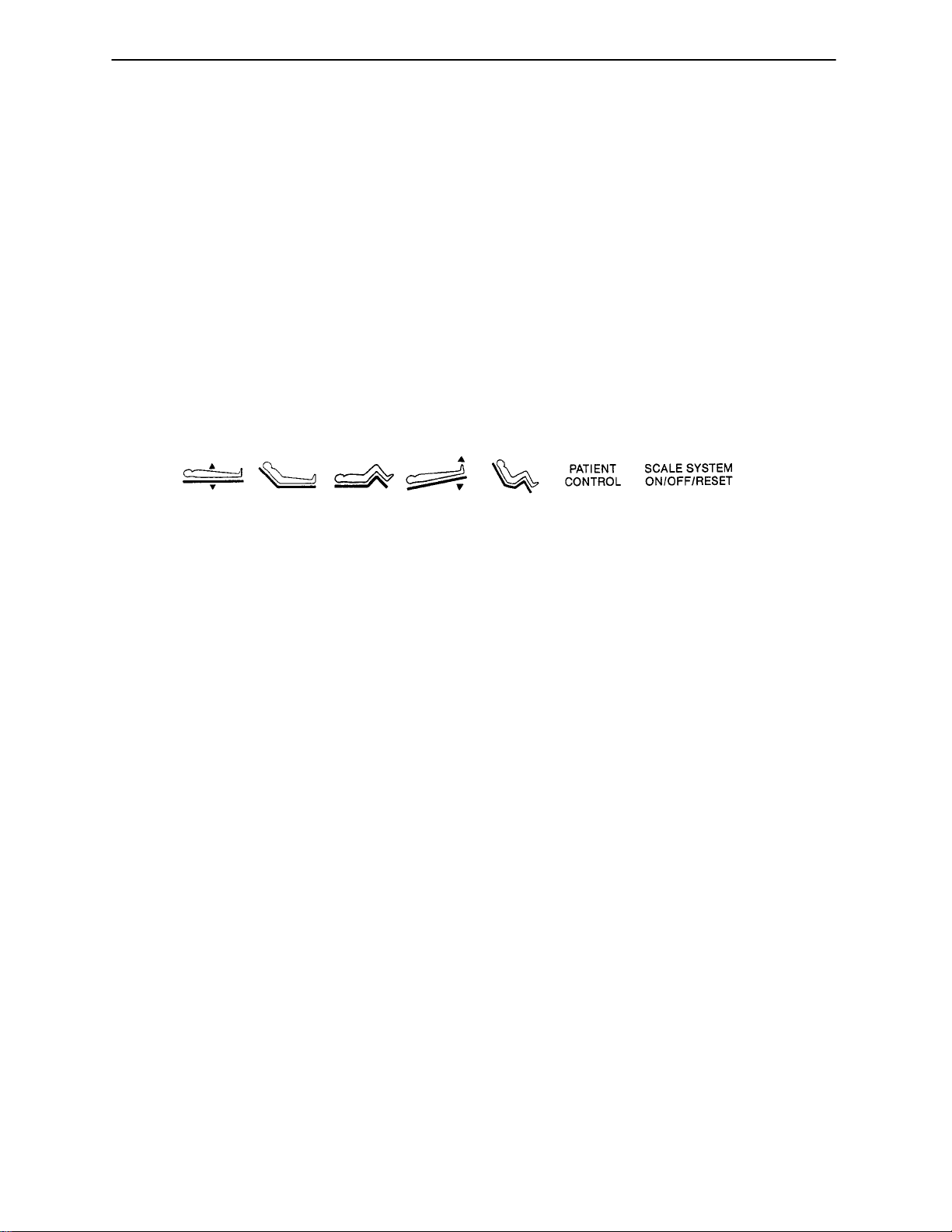

Patient Control/Nurse Control Guide

SYMBOL ACTION

Fowler will raise.

Fowler will lower.

Knee Gatch will raise.

Knee Gatch will lower.

Litter will raise.

Litter will lower.

Head end will lower/foot end will raise.

Foot end will lower/head end will raise.

14

Page 16

Integrated Dynamic Mattress System Operation

OPERATING OPTIONAL INTEGRATED DYNAMIC MATTRESS SYSTEM

NOTE

The Integrated Dynamic Mattress System will be active whenever the bed is plugged into the wall socket.

*When the lockout switch on the foot end frame end is not activated, the Dynamic Mattress System can be

operated in either the AUTOMA TIC or the MANUAL mode. When in the AUTOMATIC mode, the internal air

bladder will be inflated to a preselected pressure and the FIRM and SOFT buttons on the siderail control are

disabled. The system must be in MANUAL mode for the firmness of the mattress to be adjusted. To lockout

the mode that is not active, pull the lockout switch toward the foot end of the bed. This disables the AUTO/

MANUAL button on the siderail control and keeps the DMS operating in the mode currently active.

Dynamic Mattress Siderail Control

Press to change from automatic to manual operation mode or back.*

Press to make the mattress firmer (when in manual mode).

Press to make the mattress softer (when in manual mode).

LED indicates mattress is operating in AUTOMATIC mode.

LED indicates mattress is operating in MANUAL mode. Will blink when either the

FIRM or SOFT button is pressed to indicate the system is operating properly.

LED indicates possible air loss in mattress system.

15

Page 17

Warranty

Limited Warranty:

Stryker Medical Division, a division of Stryker Corporation, warrants to the original purchaser that its products

should be free from defects in material and workmanship for a period of one (1) year after date of delivery.

Stryker’s obligation under this warranty is expressly limited to supplying replacement parts and labor for, or

replacing, at its option, any product which is, in the sole discretion of Stryker, found to be defective. Stryker

warrants to the original purchaser that the frame and welds on its beds will be free from structural defects

for as long as the original purchaser owns the bed. If requested by Stryker, products or parts for which a

warranty claim is made shall be returned prepaid to Stryker’s factory. Any improper use or any alteration or

repair by others in such manner as in Stryker’s judgement affects the product materially and adversely shall

void this warranty. No employee or representative of Stryker is authorized to change this warranty in any way.

This statement constitutes Stryker’s entire warranty with respect to the aforesaid equipment. STRYKER

MAKES NO OTHER WARRANTY OR REPRESENTATION, EITHER EXPRESSED OR IMPLIED, EXCEPT

AS SET FORTH HEREIN. THERE IS NO WARRANTY OF MERCHANTABILITY AND THERE ARE NO

WARRANTIES OF FITNESS FOR ANY PARTICULAR PURPOSE. IN NO EVENT SHALL STRYKER BE

LIABLE HEREUNDER FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING FROM OR IN ANY

MANNER RELATED TO SALES OR USE OF ANY SUCH EQUIPMENT.

To Obtain Parts and Service:

Stryker products are supported by a nationwide network of dedicated Stryker Field Service Representatives.

These representatives are factory trained, available locally, and carry a substantial spare parts inventory to

minimize repair time. Simply call your local representative, or call Stryker Customer Service at (800)

327–0770.

Supplemental Warranty Coverage:

Stryker has developed a comprehensive program of extended warranty options designed to keep your equipment operating at peak performance at the same time it eliminates unexpected costs. We recommend that

these programs be activated before the expiration of the new product warranty to eliminate the potential of

additional equipment upgrade charges. Stryker offers the following Supplemental Warranties:

Extended (Parts and Labor)

S All replacement parts (excluding mattresses and consumable items)

S Labor and travel for all scheduled and unscheduled calls

S Biannual Preventive Maintenance Inspections and repairs

S JCAHO paperwork for preventive maintenance

S Priority Emergency Service

Standard (Labor Only):

S Labor and travel for all scheduled and unscheduled calls

S Biannual Preventive Maintenance Inspections and repairs

S JCAHO paperwork for preventive maintenance

S Priority Emergency Service

Basic (Parts Only):

S All replacement parts (excluding mattresses and consumable items)

S Priority Emergency Service

Please call your local representative, or call (800) 327–0770 for further information

16

Page 18

Warranty

Return Authorization:

Merchandise cannot be returned without approval from the Stryker Customer Service Department. An authorization number will be provided which must be printed on the returned merchandise. Stryker reserves the

right to charge shipping and restocking fees on returned items.

SPECIAL, MODIFIED, OR DISCONTINUED ITEMS NOT SUBJECT TO RETURN.

Damaged Merchandise:

ICC Regulations require that claims for damaged merchandise must be made with the carrier within fifteen

(15) days of receipt of merchandise. DO NOT ACCEPT DAMAGED SHIPMENTS UNLESS SUCH DAMAGE

IS NOTED ON THE DELIVERY RECEIPT AT THE TIME OF RECEIPT. Upon prompt notification, Stryker

will file a freight claim with the appropriate carrier for damages incurred. Claim will be limited in amount to

the actual replacement cost. In the event that this information is not received by Stryker within the fifteen

(15) day period following the delivery of the merchandise, or the damage was not noted on the delivery receipt

at the time of receipt, the customer will be responsible for payment of the original invoice in full.

Claims for any short shipment must be made within thirty (30) days of invoice.

International Warranty Clause:

This warranty reflects U.S. domestic policy. Warranty outside the U.S. may vary by country. Please contact

your local Stryker Medical representative for additional information.

17

Page 19

6300 Sprinkle Road, Kalamazoo, MI 49001–9799 (800) 327–0770

DH 11/93 2020–1–126 REV D

Loading...

Loading...