Page 1

1588 AIM Video Camera

1588-010-000

1588-210-105

1588-610-122

1588-710-105

Page 2

Page 3

Contents

Warnings and Cautions ........................................................................... 1

Cautions ......................................................................................................................1

Warnings: General ...................................................................................................2

Warnings: ENV Mode ..............................................................................................3

Operating the Camera with a Light Source ....................................................4

Product Description and Intended Use ................................................. 5

Indications ..................................................................................................................6

The Camera Console ...............................................................................................7

The Camera Head ....................................................................................................9

The C-Mount Coupler .......................................................................................... 10

Setup and Interconnection ................................................................... 11

Setting Up the Console ...................................................................................... 12

Wiring Diagram ..................................................................................................... 13

Setting Up the Camera Head ............................................................................ 14

Setting Up the Coupler ....................................................................................... 15

Installing the Soaking Cap ................................................................................ 17

Operation ............................................................................................... 18

Powering the Console On/O .......................................................................... 18

Controlling Remote Video Accessories ......................................................... 18

Using the Camera Head Buttons ..................................................................... 19

Programming Camera Head Buttons ............................................................ 22

Using the Touchscreen Interface..................................................................... 24

Using the Camera in ENV Mode ...................................................................... 27

Performing the White Balance Test ................................................................ 29

Advanced Features ............................................................................................... 29

Troubleshooting .................................................................................... 30

Reprocessing ..........................................................................................34

Cleaning the Console .......................................................................................... 34

Cleaning, Disinfecting, and Sterilizing the Camera Head ...................... 35

Materials and Equipment .................................................................................. 36

User Maintenance .................................................................................. 45

Inspection ................................................................................................................ 45

Using Sterile Drapes ............................................................................................ 45

Storage ..................................................................................................................... 45

Replacing the Fuses ............................................................................................. 45

Page 4

Periodic Maintenance Schedule ...................................................................... 46

Expected Service Life .......................................................................................... 46

Disposal and Recycling Information .............................................................. 46

Recycling Diagrams ............................................................................................. 47

Technical Specications ........................................................................ 49

Electromagnetic Compatibility ........................................................................ 51

Symbol Denitions ................................................................................ 55

Page 5

1

Warnings and Cautions

Please read this manual and follow its instructions carefully. The words

warning, caution, and note carry special meaning and should be carefully

reviewed:

Warning Indicates risks to the safety of the patient or user. Failure to

follow warnings may result in injury to the patient or user.

Caution Indicates risks to the equipment. Failure to follow cautions

may result in product damage.

Note: Claries the instructions or presents additional useful information.

An exclamation mark within a triangle is intended to alert the

user to the presence of important operating and maintenance

instructions in the manual.

A lightning bolt within a triangle is intended to warn of the

presence of hazardous voltage. Refer all service to authorized

personnel.

Cautions

To avoid potential damage to this device, please note the following cautions.

1. Carefully unpack this device and check if any damage occurred during

shipment. If damage is detected, refer to the standard warranty.

2. Never sterilize the camera console, because the delicate electronics

cannot withstand this procedure.

3. Ensure that the electrical installation of the relevant operating room

complies with the NEC and CEC guidelines.

4. Always treat the camera system with care. The camera system contains

sensitive parts that are precisely aligned and may suer damage if

dropped or mistreated.

5. Ensure that readjustments, modications, and/or repairs are carried out

by persons authorized by Stryker Endoscopy.

Page 6

2

Warnings: General

To avoid potential serious injury to the user and the patient and/or damage to

this device, please note the following general warnings.

1. Must be a qualied physician to use this equipment.

2. Read this operating manual thoroughly, especially the warnings, and be

familiar with its contents before connecting and using this device.

3. Test this equipment prior to a surgical procedure. This unit was fully

tested at the factory before shipment.

4. The camera head surface may exceed 41°C (106°F) in operating

conditions with high ambient temperatures and it should be handled

with caution.

5. The camera head and coupler are shipped non-sterile. You must sterilize

these devices before the rst use and after each use. To prevent device

damage and infection risk to the patient or user, follow all cleaning and

sterilization instructions in this manual.

6. Do not position the console so that it is dicult to disconnect the power

cord from the supply mains.

7. To avoid the risk of electric shock, this equipment must only be

connected to a supply mains with protective earth.

8. Multiple portable socket-outlets shall not be placed on the oor.

9. Never use the camera system in the presence of ammable or explosive

gases.

10. Disconnect the console from the electrical outlet when inspecting fuses.

11. Do not remove covers on the console, as doing so may cause damage to

electronics and/or electric shock.

12. Do not disassemble any part of the camera head; doing so may break the

seals, causing leakage and/or electric shock.

13. Attempt no internal repairs or adjustments not specically detailed in this

operating manual.

Page 7

3

Warnings: ENV Mode

IMPORTANT SAFETY NOTICE - LASER RADIATION:

Endoscopic Near-Infrared Visualization (ENV) mode controls a

Class1M laser emitted from the L10 LED Light Source with AIM

Technology (0220-220-300).

Use of controls or performance of procedures other than those

specied herein can result in hazardous laser radiation exposure

and can cause severe eye injury to the patient or user.

To avoid exposure to laser radiation, follow all warnings and

guidelines presented below and throughout this user manual.

1. Before using ENV mode, read and be familiar with all instructions

and warnings found in this user manual and in user manual P27006

(English) or P27009 (multilingual) for the L10 LED Light Source with AIM

Technology.

2. Protect the 1588AIM Video Camera against unqualied use.

3. Wear eye protection as appropriate. Refer to any applicable regional

regulations or standards for personal protective equipment.

4. Do not manipulate tissue while ENV mode is enabled. The camera is

intended to visualize tissue manipulation only while ENV mode is o.

5. When using ENV mode, do not view the light output with optical

instruments (for example, microscopes or magniers). Do not direct the

light output in ENV mode into an area where such instruments are likely

to be used.

6. Do not enable ENV mode when the endoscope is outside of the patient’s

body.

7. When ENV mode is enabled, never look into the following apertures or

direct the light emitted from the apertures toward another person:

• the light cable connection on the light source (if the cable is not

attached)

• the end of the light cable (if the SafeLight adapter is attached)

• the endoscope tip

8. When ENV mode is enabled, never leave a SafeLight adapter attached

to the light cable without an endoscope attached. Laser radiation can

continue to emit from the adapter.

9. Disconnect the light cable from the light source only when the light

source is powered o or in Standby mode.

Page 8

4

Operating the Camera with a Light Source

Please note the following warnings to avoid user or patient injury or product

damage when using the camera with a light source.

IMPORTANT SAFETY NOTICE - HIGH TEMPERATURES:

Before operating this device, please read this operating manual

thoroughly and carefully. When using this device with a light

source, re and/or severe injury may result to the patient, user

or inanimate objects if the instructions in this manual are not

followed.

All light sources can generate signicant amounts of heat

(exceeding 41°C/106°F) at the scope tip, the scope light post,

the light cable tip, and/or near the light cable adapter. Higher

levels of brightness from the light source result in higher levels

of heat. Always adjust the brightness level of the camera and the

monitor before adjusting the brightness level of the light source.

If the brightness level of the light source can be adjusted, set it to

the minimum brightness necessary to adequately illuminate the

surgical site.

In addition, adjust the internal shutter of the camera higher in order

to run the light source at a lower intensity. Avoid touching the

scope tip or the light cable tip to the patient, and never place them

on top of the patient, as doing so may result in burns to the patient

or user. In addition, never place the scope tip, the scope light post,

the light cable adapter, or the light cable tip on the surgical drapes

or other ammable material, as doing so may result in re.

Always place the light source in standby mode whenever the scope

is removed from the light cable or the device is unattended. The

scope tip, scope light post, light cable adapter, and light cable tip

will take several minutes to cool o after being placed in standby

mode, and therefore may still result in re or burns to the patient,

user, or inanimate objects.

The warranty is void if any of the above warnings or cautions are disregarded.

Page 9

5

Product Description and Intended Use

The Stryker 1588AIM (Advanced Imaging Modality) Video Camera with

Infrared Compatibility (or “1588AIM Camera”) is an endoscopic camera

system that is used to produce still and video images in the surgical eld

during surgical endoscopic procedures. The system is sensitive in the visible

and infrared spectrum. The optical image is transferred from the surgical

site to the camera head by a variety of rigid and exible scopes which are

attached to the camera head. The system consists of a camera control unit

(CCU) and a camera head with an integral cable that connects to the CCU.

A coupler is also available for attaching a scope to the camera head. The

available models for each part are listed below.

Note: For complete system requirements to use the camera’s Endoscopic

Near-Infrared Visualization (ENV) mode, see Stryker user manual P27006

(English) or P27009 (multilingual) for the L10 LED Light Source with AIM

Technology (0220-220-300).

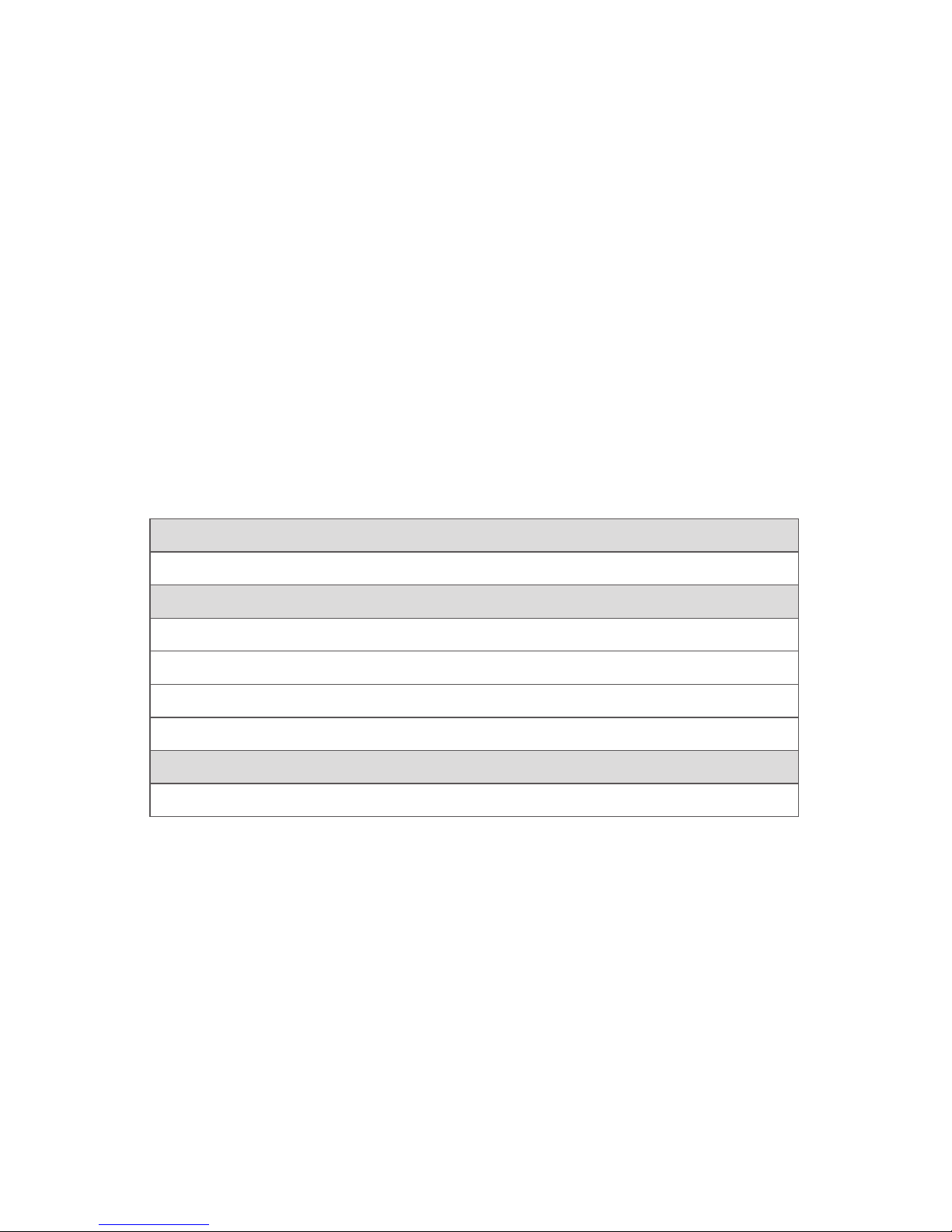

Console

1588-010-000 1588AIM Camera Control Unit

Camera Heads

1588-210-105 1588AIM Camera Head, C-Mount

1588-310-130 1588 Pendulum Camera Head with Integrated Coupler

1,2

1588-610-122 1588AIM Camera Head with Integrated Coupler

1588-710-105 1588AIM Inline Camera Head, C-Mount

Coupler

1588-020-122 AIM Coupler, 18 mm, C-Mount

3

1

Complete instructions are available in Stryker user manual P29925 (English) or P29926 (multilingual).

2

Not compatible with ENV mode when the camera is used with the L10 LED Light Source with AIM Technology.

3

Complete instructions are available in Stryker user manual P30104.

The 1588AIMconsole is also packaged with the following connection cables:

• Remote cables, 2.5 mm to 3.5 mm (Qty: 2)

• DVI-I cable (Qty: 1)

• Hospital-grade power cord (Qty: 1)

Contact your Stryker representative for availability of other cables that may be

required for alternate congurations.

Page 10

6

Indications

The Stryker 1588AIM (Advanced Imaging Modality) Video Camera

with Infrared Compatibility is indicated for use in general laparoscopy,

nasopharyngoscopy, ear endoscopy, sinuscopy, and plastic surgery wherever

a laparoscope/endoscope/arthroscope is indicated for use.

A few examples of the more common endoscopic surgeries are listed below.

• laparoscopic cholecystectomy

• laparoscopic hernia repair

• laparoscopic appendectomy

• laparoscopic pelvic lymph node dissection

• laparoscopically assisted hysterectomy

• laparoscopic and thorascopic anterior spinal fusion

• anterior cruciate ligament reconstruction

• knee arthroscopy

• shoulder arthroscopy

• small joint arthroscopy

• decompression xation

• wedge resection

• lung biopsy

• pleural biopsy

• dorsal sympathectomy

• pleurodesis

• internal mammary artery dissection for coronary artery bypass

• coronary artery bypass grafting where endoscopic visualization is

indicated

• examination of the evacuated cardiac chamber during performance of

valve replacement

The users of the Stryker 1588AIM Video Camera with Infrared Compatibility

are general surgeons, gynecologists, cardiac surgeons, thoracic surgeons,

plastic surgeons, orthopedic surgeons, ENT surgeons and urologists.

Page 11

7

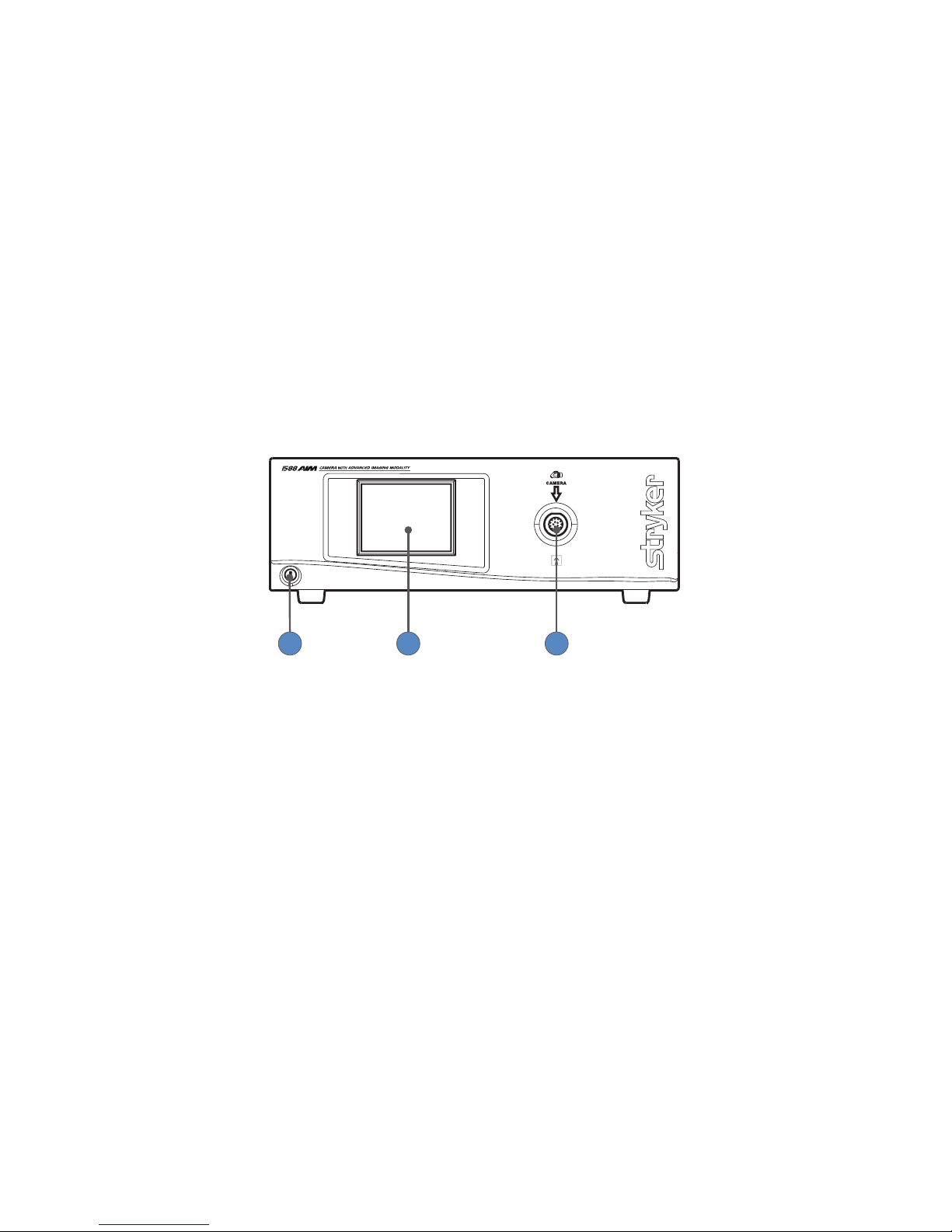

The Camera Console

The camera console—or Camera Control Unit (CCU)—is the control center for

the 1588AIM Camera, and it processes the video and photographic images

produced during the surgical procedure.

Front Panel

The console front panel features a touchscreen, where dierent menus can be

accessed, including the controls for adjusting the Light Level, Zoom Level, and

White Balance, as well as allowing the selection of Surgical Specialty settings

that optimize camera performance for specic surgical procedures. The

touchscreen also allows activation of remote outputs, which are commonly

used with a Stryker digital capture console to record images and video.

See the Operation section for more detail on using the front panel.

321

1. Power Switch Powers the camera ON and OFF

2. Touchscreen Allows navigation through dierent menus

for controlling the camera and adjusting

the video settings

3. Camera-Connector Port Connects to the 1588AIM Camera Head

Page 12

8

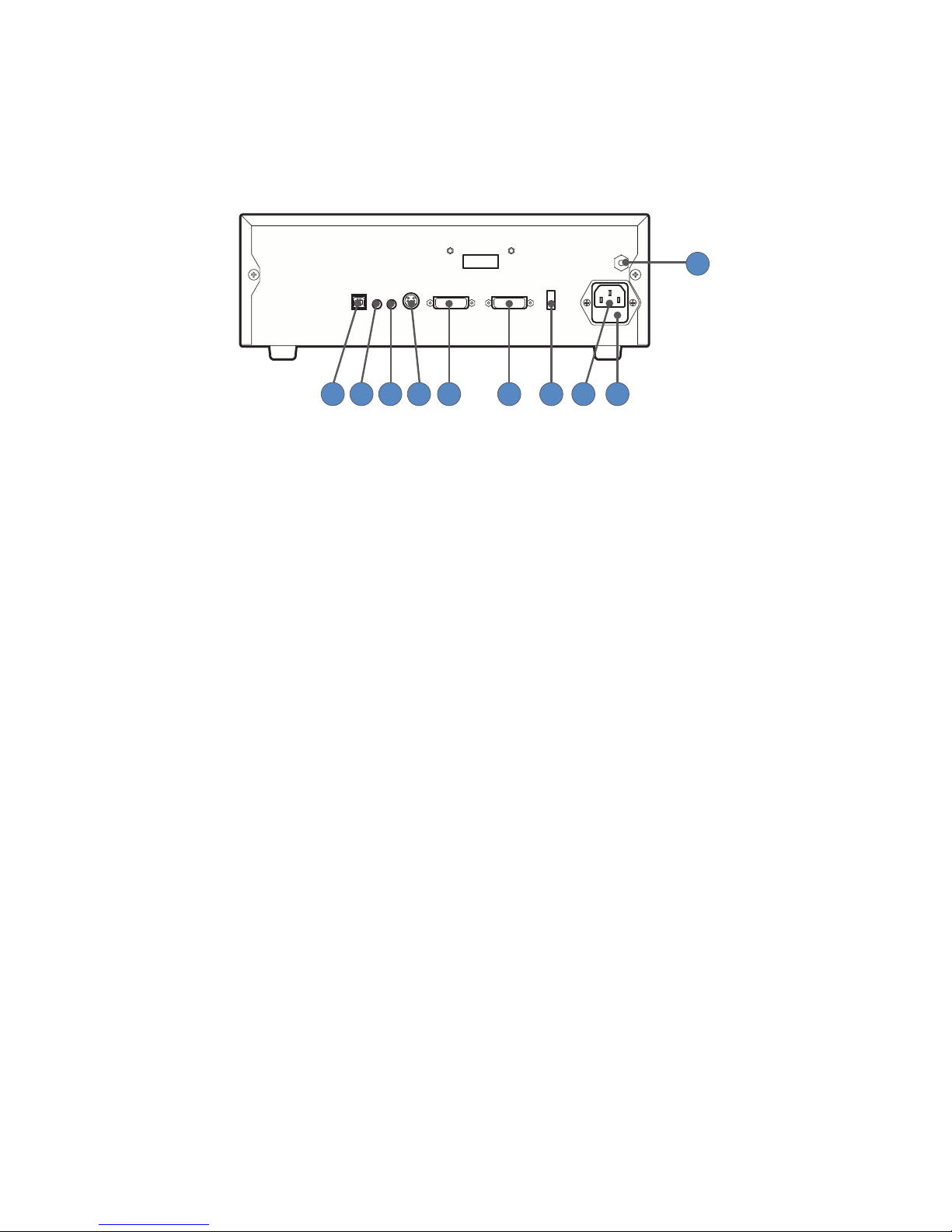

Rear Panel

The console rear panel provides ports for connecting the 1588AIM Camera to

viewing and recording equipment, such as video monitors and Stryker device

control consoles.

9

10

87654321

1. Device Control Port Connects to a Stryker device control console

(such as the SDC3 or SIDNE®) to enable voice

operation and/or graphic tablet control

2. Remote Out 1 Connects to a video accessory remote input

3. Remote Out 2 Connects to a video accessory remote input

4. S-Video Out Analog video output

5. DVI Out 1 Digital video output

6. DVI Out 2 Digital video output

7. Light Source Port Connects to Stryker light source

8. AC Power Inlet Connects to AC mains with separable power

cord

9. Fuse Panel Contains two 1.6A 250V fuses (slow blow, high

breaking capacity 1500A, size 5mm x 20mm)

10. Equipotential

Ground Plug

Connects to a potential equalization conductor.

The resulting medical electrical system shall

follow all applicable IEC 60601-1 requirements.

Page 13

9

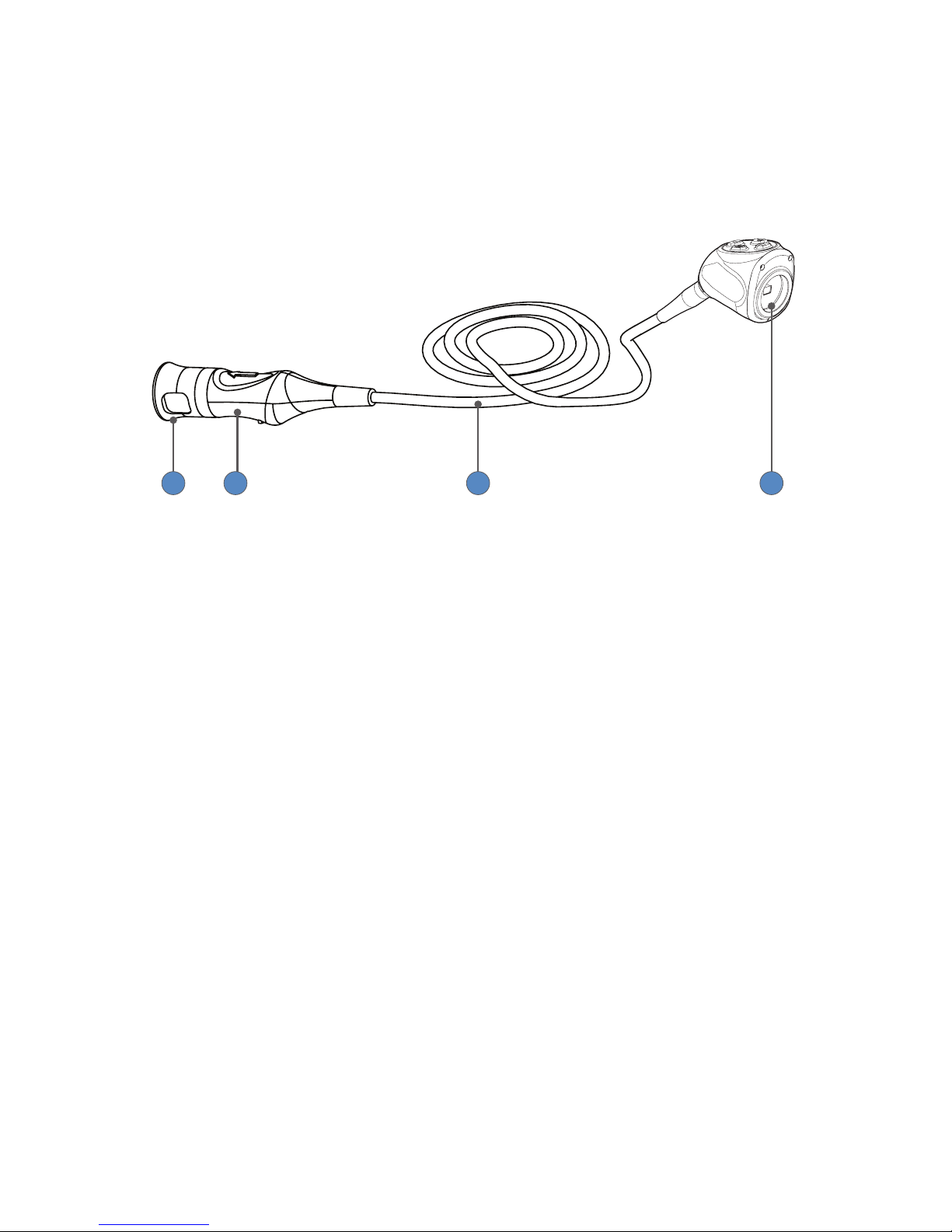

The Camera Head

The camera head connects to the camera console and produces video and

photographic images, which it relays to the camera console. Several controls

are accessible through a button keypad located on the top of the camera

head (see the Operation section).

41 2 3

1. Soaking Cap Protects the cable connector during cleaning,

disinfection, and sterilization

2. Cable Connector Connects the camera head to the camera console

3. Camera Cable The camera cable length is 10 feet (3.05 m)

4. Camera Head Produces photographic and video images,

provides camera controls, and connects with a

focusing coupler.

Page 14

10

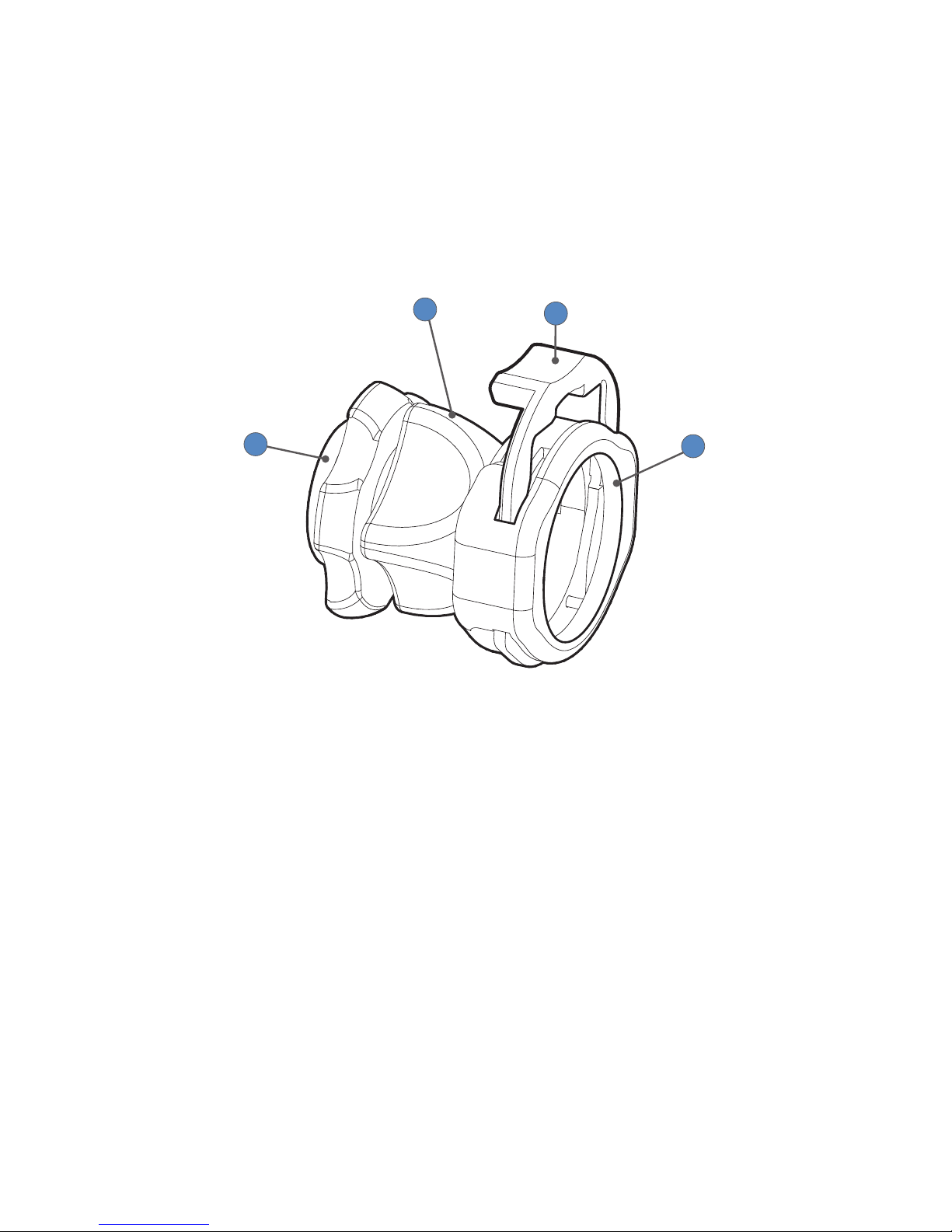

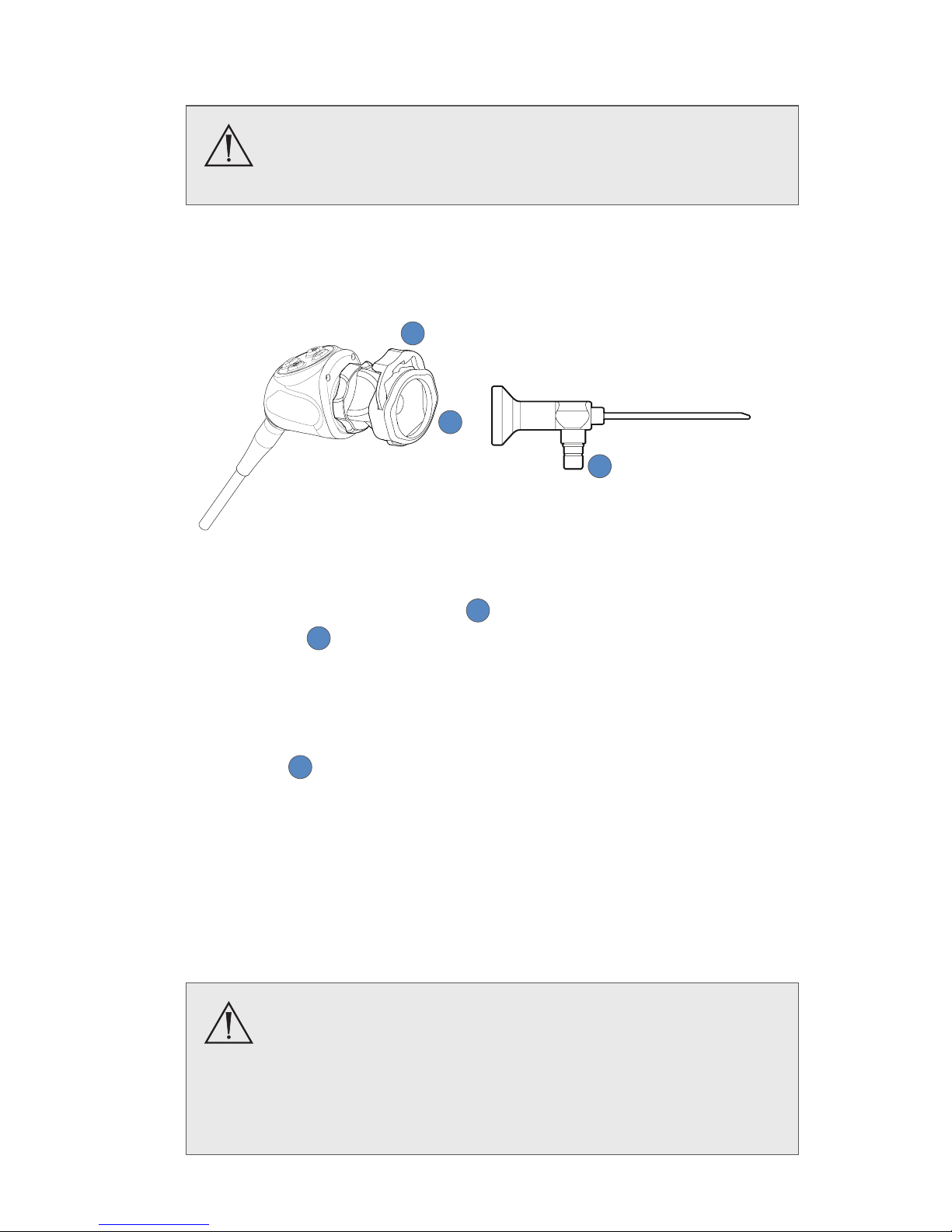

The C-Mount Coupler

The coupler threads onto the face of the camera head, enabling a scope to be

attached to the camera. It provides a focusing ring to adjust image sharpness.

It is recommended to use the camera with the AIM Coupler (1588-020-122).

The AIM Coupler enables use of ENV mode when the camera is connected to

the L10 LED Light Source with AIM Technology. Refer to Stryker user manual

P30104 for complete AIM Coupler instructions.

1

2

3

4

1. Rear Adapter Threads onto the camera head

2. Focusing Ring Adjusts the coupler focus

3. Endobody Clamp Secures the scope to the coupler

4. Scope End Receives the endoscope

Page 15

11

Setup and Interconnection

Stryker Endoscopy considers instructional training, or inservice, an

integral part of the 1588AIM Camera. Your local Stryker Endoscopy sales

representative will perform at least one inservice at your convenience to help

set up your equipment and instruct you and your sta on its operation and

maintenance. To schedule an inservice, contact your local Stryker Endoscopy

representative after your equipment has arrived.

Setting up the 1588AIM Camera involves three steps:

1. Setting up the console

2. Setting up the camera head

3. Setting up the coupler

• Always connect the console to an appropriate power

source, using a hospital-grade power cord. Loss of AC

power will cause the camera to shut down and the surgical

image to be lost.

• Only connect items to the 1588AIM Camera that have

been specied for use with the camera system. Connecting

incompatible equipment may cause unexpected results.

• When the camera system is used with other equipment,

leakage currents may be additive. Ensure that all systems

are installed according to the requirements of IEC60601-1.

• Equipment which employs RF communications may

aect the normal function of the 1588AIM Camera. When

choosing a location for the camera system, consult the

Electromagnetic Compatibility section to ensure proper

function.

• Always set up the console in a location that allows

adequate ventilation (airow) to the console. Insucient

ventilation may cause the console to overheat and shut

down.

Page 16

12

Setting Up the Console

Refer to the instructions below and the wiring diagram on the following page

for a typical 1588AIM Camera conguration.

1. Connect the console’s AC power to a hospital-grade outlet.

2. Connect one of the console’s DVI outputs to an available DVI input on a

Stryker digital capture console such as the SDC3.

• The 1588AIM console can also be connected to additional SDC video

inputs or directly to one or more display monitors; the rear panel

provides one analog and two digital-video outputs:

Output Type Output Cable Connector

Analog S-VHS 1* S-VHS 4 pin Mini-Din

(push-only

connectors)

Digital (standard) DVI-I1** and

DVI-I2**

DVI 29 pin (push-only

connectors, with two

tightening knobs)

* On some monitors, S-VHS inputs may be labeled Y/C.

** The DVI connectors can also output analog SXGA signals through a DVI-I to VGA adapter.

When using any device with unterminated analog video inputs, connect a cable from the VIDEO OUT of that

device to the VIDEO IN on the monitor.

3. Connect the DVI output from the Stryker digital capture console to the

DVI input on the display monitor.

4. Using the provided remote cables, connect remote outputs 1 and 2 from

the 1588AIM console to a Stryker digital capture console. (The remote

inputs should be connected to the same channel as the video input.)

• Devices connected to the remote outputs can be operated using the

console touchscreen or the P button on the camera head. See the

Operation section for details.

• Once connected to the 1588AIM Camera, the SDC3 (0240-060-100)

can control ENV, Dynamic Range Enhancement, and Strobe functions.

The user can also customize button congurations through the SDC3.

5. Connect a USB A-to-B cable (also available from Stryker, part 0105-187-

988) from the Light Source output on the 1588AIM console to the SDC

input on the Stryker L10 Light Source (220-220-000 or 220-220-300).

• To use ENV mode, the 1588AIM Camera requires a connection to the

L10 LED Light Source with AIM Technology (0220-220-300).

• The 1588AIM Camera Head can be programmed to toggle Run/

Standby controls on the L10 Light Source. Contact a Stryker

representative for more information about enabling this advanced

feature.

Page 17

13

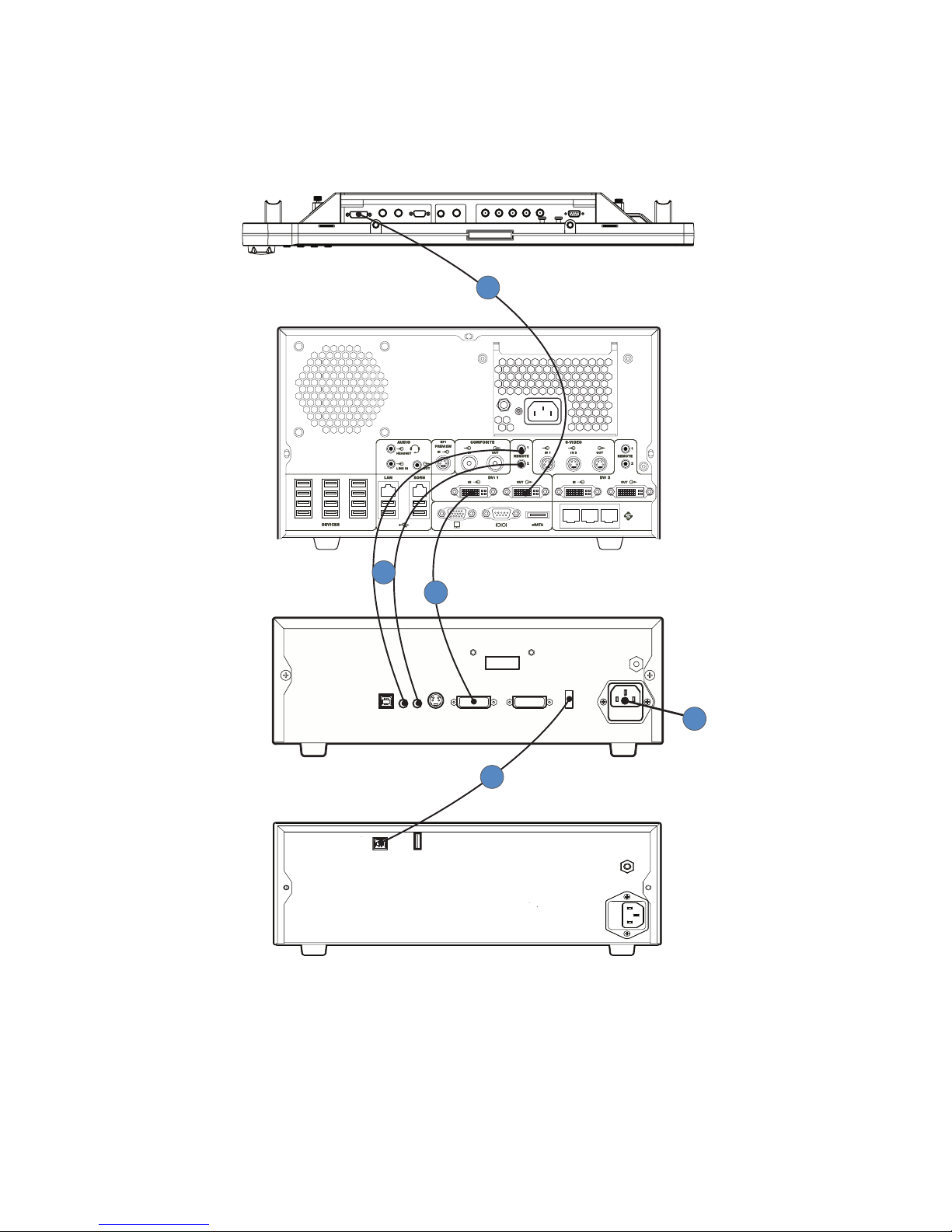

Wiring Diagram

SDC/SIDNE CCU

SDC3

1588AIM Camera

L10 Light Source

VisionPro 26" LED Surgical Display

(underside shown)

3

4

2

5

1

Page 18

14

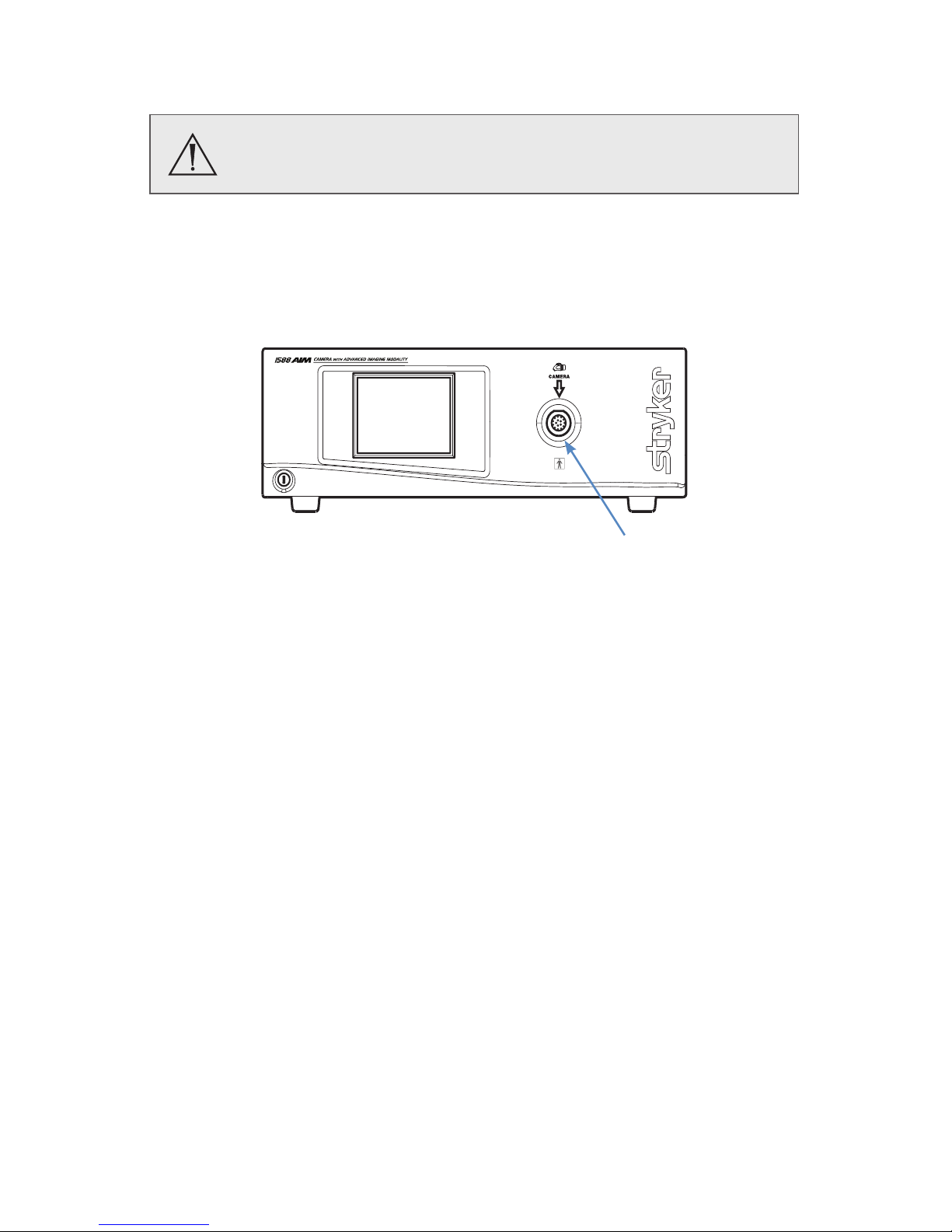

Setting Up the Camera Head

Do not severely bend the camera cable or damage may result.

1. Unscrew the soaking cap from the cable connector on the camera head.

2. Align the arrow on the cable connector with the arrow above the cameraconnector port on the front console panel.

3. Push in the connector until it locks in place.

Note: To unplug the camera from the console, grasp the knobbed portion of

the connector and pull straight out.

Page 19

15

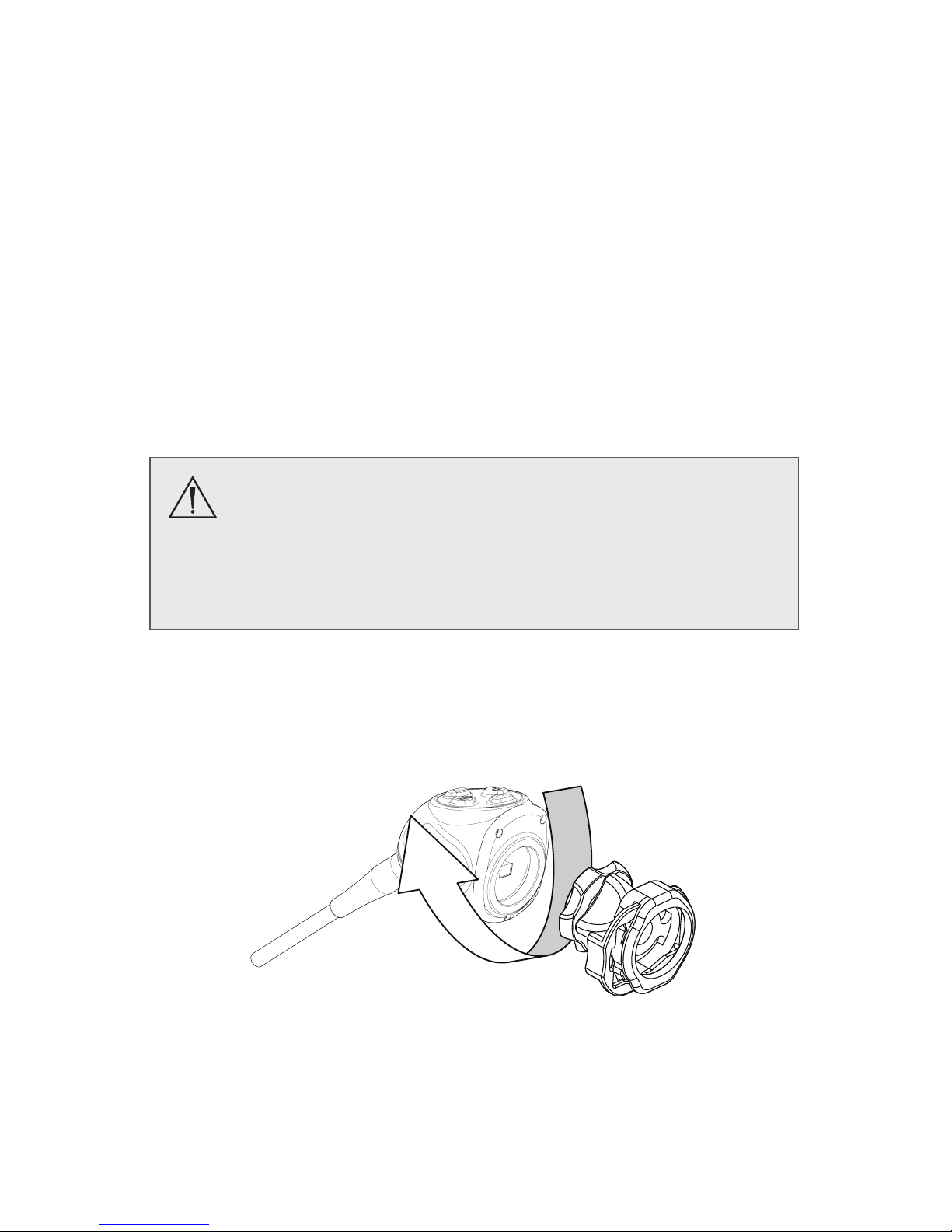

Setting Up the Coupler

Steps 1–3 below provide instructions for connecting 1588AIM Camera Heads

to the AIM Coupler, 18 mm, C-Mount (1588-020-122). Refer to the bullets

below for possible system variations:

• When using the 1588AIM Camera Head with Integrated Coupler

(1588-610-122), skip to step 2.

• When using the 1588 Pendulum Camera Head with Integrated

Coupler (1588-310-130), see Stryker user manual P29925 (English)

or P29926 (multilingual).

• When using a direct-coupled C-Mount endoscope (a scope that

requires no coupler), thread the endoscope directly into the

camera head until it forms a tight seal, and skip to step 3. (C-Mount

endoscopes are not compatible with camera heads that have an

integrated coupler.)

When attaching or removing the coupler, grip only the rear

adapter, as twisting other parts of the coupler with force may

result in mechanical damage.

Do not overtighten the coupler (or a direct-coupled C-mount

scope), as this may damage the front window of the camera.

1. Attach the coupler to the camera head.

• Gripping the rear adapter, screw the coupler clockwise onto the

camera head until it forms a tight seal (1588-210-105 and 1588-710105 only).

Note: To remove the coupler, grip the rear adapter and unscrew the

coupler counterclockwise from the camera head.

Page 20

16

2. Attach an endoscope to the coupler.

Before each use, check the outer surface of the endoscope

to ensure there are no rough surfaces, sharp edges, or

protrusions.

Note: For a list of endoscopes that are compatible with ENV mode, see

Stryker user manual P27006 (English) or P27009 (multilingual) for the L10

LED Light Source with AIM Technology.

1

2

3

• Remove the coupler dust cap if it is present.

• Depress the endobody clamp 1 and insert a scope into the

endobody

2

.

• Release the endobody clamp to secure the endoscope.

3. Attach a light cable from the light source to the light post on the

endoscope

3

.

Note: A scope adapter may be required to connect the cable to the

endoscope. See the light cable user manual for more detail.

Note: Only the Stryker AIM SafeLight™ cable (0233-050-300) is

compatible with ENV mode. ENV mode will not function if other cables

are used. Refer to the AIM SafeLight cable user manual (P27701) for

complete cable instructions.

When connecting an AIM SafeLight cable to the

endoscope, always connect the scope adapter to the

endoscope before connecting the adapter to the cable.

If ENV mode is enabled and the adapter is not connected

to the scope, laser radiation will emit from the adapter

that can cause severe eye injury to the patient or user.

Page 21

17

Installing the Soaking Cap

Before reprocessing the camera head, the soaking cap must be installed to

avoid damaging the cable connector.

Caution: Failure to properly tighten the soaking cap will corrode the

connector pins and void the warranty.

• To install the soaking cap, screw the cap onto the threads of the cable

connector until it forms a tight seal.

• To remove the soaking cap, unscrew the cap and pull it away from the

cable connector.

Page 22

18

Operation

Note: Before operating the 1588AIM Camera, ensure all system

components have been set up according to the instructions in the Setup and

Interconnection section.

Powering the Console On/O

Before using the 1588AIM Camera in a surgical procedure, test

all system components to ensure proper function. Ensure that

a video image appears on all video monitors before beginning

any procedure.

1. Power on the monitor.

2. Press the power switch on the console to power the console on or o.

Note: A color bar pattern will appear on the monitor if the camera head is not

connected to the camera console. If the color bar appears, refer to the Setting

Up the Camera Head section to connect the camera head.

Controlling Remote Video Accessories

The 1588AIM Camera can remotely control up to two functions of a video

accessory, such as a Stryker digital capture console. Commonly this enables

the user to capture images or start and stop video recording.

Remote video accessories can be controlled with the camera head’s P button

or the console touchscreen. See the following sections, Using the Camera

Head Buttons and Using the Touchscreen Interface.

Note: Controls for capturing photos or recording video require connecting a

video accessory to the console. See the Setup section for more detail.

Page 23

19

Using the Camera Head Buttons

The camera head features a four-button keypad for controlling the 1588AIM

Camera. The default button functions are described below.

Note: The camera head buttons can be customized dierently for each

surgical specialty. See the Programming Camera Head Buttons section for

more detail. The button conguration for the selected surgical speciality will

appear on the display monitor when the camera head is connected to the

console. The button conguration will disappear once the P button is pressed.

P (Picture) Button

The P button controls up to two functions of a remote video accessory.

Commonly this enables the user to capture images or start and stop video

recording. (See the Controlling Remote Video Accessories section for

connection requirements.)

• Press the P button for less than two seconds to select Remote 1. One beep

will sound. When the camera is connected to a Stryker digital capture

console, this will Capture a Photo.

• Press the P button for more than two seconds to select Remote 2. Two

beeps will sound. When the camera is connected to a Stryker digital

capture console, this will Start or Stop Video Recording.

W (White Balance) Button

The W button activates the White Balance function or the Zoom Cycle

function.

• Press the W button for less than two seconds to activate the Zoom Cycle

function. Each press raises the Zoom Level in eight steps. When the Zoom

Level reaches its maximum, pressing the button again cycles the level back

to the lowest setting.

• Press the W button for more than two seconds to activate the White

Balance function. White Balancing will correct slight color dierences that

exist between dierent light sources or endoscopes. See the Performing

the White Balance Test section below.

Page 24

20

Up and Down Buttons

The up and down buttons change functionality depending on the conditions:

Conditions Functionality of Up/Down buttons

• Default • Up and down buttons increase or decrease

the Automatic-Shutter Light Level in eight

steps.

• ENV mode is enabled

(see the ENV Mode

section for detail)

• Press the up button for less than two

seconds to activate the Backlight Cycle

function. Backlight aects the brightness of

surrounding anatomy that is not displayed as

uorescing green.

ü

Each press raises the Backlight Level in 10

steps. When the Backlight Level reaches

its maximum, pressing the button again

cycles the level back to the lowest

setting.

ü

The Backlight Level will appear on

the display monitor. (Note: Although

Backlight Level can be adjusted in 10

steps, the display monitor indicator will

only change every two button presses.)

• Press the down button for less than two

seconds to activate the ENV Gain Cycle

function. ENV Gain aects the uorescing

green appearance of the camera image.

ü

Each press raises the ENV Gain Level

in six steps. When the ENV Gain Level

reaches its maximum, pressing the

button again cycles the level back to the

lowest setting.

ü

The ENV Gain Level will appear on the

display monitor.

Page 25

21

Conditions Functionality of Up/Down buttons

• ENT/Skull Surgical

Specialty is selected1

(from the camera

console Home screen)

• Up button activates the Automatic-Shutter

Light Cycle function. Each button press

raises the Light Level in eight steps. When

the Light Level reaches its maximum,

pressing the up button again cycles the level

back to the lowest setting.

• Down button activates the Dynamic Range

Enhancement (DRE) Desaturation (Desat)

function. The DRE Desat function desaturates

red colors on the display monitor.

ü

Each button press toggles the function

on and o.

Note: DRE mode is on by default when the

ENT/Skull surgical specialty is selected. DRE

mode illuminates darker posterior cavities on

the display monitor.

1

The down button will also

activate the DRE Desat function

in the Arthroscopy, Cystoscopy,

and Laparoscopy surgical

specialties when DRE mode is

on. DRE mode can be turned on

via the touchscreen DRE menu

or by programming DRE Toggle

to another camera head button.

Contact a Stryker representative

for assistance with button

programming.

When DRE mode is on, a light bulb

icon appears in the top-left corner

of the display monitor.

When DRE Desat is on, an indicator

appears below the light bulb icon.

Page 26

22

Programming Camera Head Buttons

The camera head buttons can be customized dierently for each surgical

specialty. Contact a Stryker representative for assistance with button

programming.

The button conguration for the selected surgical speciality will appear on

the display monitor when the camera head is connected to the console. The

button conguration will disappear once the P button is pressed.

The following functions can be programmed to the buttons:

Function Name Function Description

NO FUNCTION No function

LIGHT UP Increase light level

LIGHT DOWN Decrease light level

LIGHT CYCLE Increase light until maximum level, then cycle back

to minimum level

ZOOM IN Increase zoom level

ZOOM OUT Decrease zoom level

ZOOM CYCLE Increase zoom until maximum level, then cycle back

to minimum level

ENHANCE UP Increase enhance level (sharpens camera image)

ENHANCE DOWN Decrease enhance level (sharpens camera image)

ENHANCE CYCLE Increase enhance until maximum level, then cycle

back to minimum level (sharpens camera image)

PICTURE Enable picture function on SDC3 / Activate

Remote1 cable

RECORD Enable record on SDC3 / Activate Remote2 cable

WB Enable White Balance

LS TOGGLE Toggle white light on/o from light source

INSFLTR TOGGLE Toggle insuator stop/start

DEV CNTRL MENU Edit device control menu on the SDC3

WINGMAN CNTRL Activate control of Wingman® Scope Holder (holding

button will allow Wingman to move)

DRE TOGGLE Toggle DRE mode on/o

ENV TOGGLE Toggle ENV mode on/o

Page 27

23

Function Name Function Description

STROBE TOGGLE Toggle strobe mode on/o.

Strobe mode is an optional mode that can be used

only in the Arthroscopy surgical specialty when the

camera is connected to a Stryker L10 light source.

When Strobe mode is on, this icon appears

in the top-left corner of the display

monitor.

Page 28

24

Using the Touchscreen Interface

The touchscreen interface on the console provides controls for adjusting or

capturing the video image. The menus are described below.

Home Screen

The Home Screen is the default screen. It displays the current camera mode

and it provides access to subsequent menus and common camera functions.

6

1. Use the arrows to scroll through preset camera settings designed for

Surgical Specialties. Choose from:

• Arthroscopy

• Cystoscopy

• ENT/Skull

• Flexi-Scope

• Hysteroscopy

• Laparoscopy

• Laser

• Microscope

• Standard

2. Press and hold the WB button for two seconds to activate the White

Balance function. See the Performing the White Balance Test section for

more detail.

ü

A checkmark appears on the button after White Balance is complete.

3. Press the camera button to Capture a Photo.

ü

A single beep will sound to indicate that a signal for capture/record

has been sent to the digital capture console.

4. Press the DRE button to navigate to the DRE mode screen. This button

will appear only when the Arthroscopy, Cystoscopy, ENT/Skull, or

Laparoscopy surgical specialty is selected.

5. Press the record button to Record a Video. Press again to stop recording.

ü

A double beep will sound to indicate that a signal for capture/record

has been sent to the digital capture console.

6. Press the Settings button to navigate to the Menu screen.

Page 29

25

Menu Screen

The Menu screen provides options for adjusting the camera picture.

1. Press the plus or minus button next to the brightness icon in order to

increase or decrease the Automatic-Shutter Light Level.

ü

The level is indicated by the lled bars under the icon and on the

display monitor.

2. Press the plus or minus button next to the zoom icon in order to increase

or decrease the Zoom Level (magnication).

ü

The level is indicated by the lled bars under the icon and on the

display monitor.

3. Press the Home button to return to the Home Screen.

Page 30

26

DRE Mode Screen

Dynamic Range Enhancement (DRE) Mode screen allows the user to turn

DRE functions on and o. This screen is accessible only when the ENT/Skull,

Arthroscopy, Cystoscopy, or Laparoscopy surgical specialty is selected.

1. Press the left button to turn on DRE mode. Press the button again to

turn o DRE mode. DRE mode illuminates darker posterior cavities on the

display monitor.

ü

When DRE mode is on, the bar at the bottom of the button will be

green. The right button for the DRE Desat function will also become

available.

Note: When the ENT/Skull surgical specialty is selected, by default DRE

mode is on and the DRE Desat function is available.

2. Press the right button to activate the DRE Desat function. Press the

button again to deactivate the function. DRE Desat desaturates red colors

on the display monitor.

ü

When DRE Desat is on, the bar at the bottom of the button will be

green.

Page 31

27

Using the Camera in ENV Mode

In Endoscopic Near-Infrared Visualization (ENV) mode, the camera can

visualize near-infrared light produced by the L10 LED Light Source with AIM

Technology (0220-220-300). Controls for ENV mode are accessible via the light

source or the camera console touchscreen and camera head buttons.

Before using ENV mode, be familiar with the warnings in

the Warnings: ENV Mode section of this user manual and all

warnings and instructions in the light source user manual

P27006 (English) or P27009 (multilingual). Failure to follow all

warnings can result in severe eye injury to the patient or user.

Note: For complete system requirements to use ENV mode, see Stryker user

manual P27006 (English) or P27009 (multilingual) for the L10 LED Light Source

with AIM Technology.

The ENV button will appear on the Home screen or Menu screen when the

following conditions are met:

• The camera console is connected to the L10 LED Light Source with AIM

Technology

• A camera head is connected to the camera console

• The Laparoscopy Surgical Specialty is selected on the camera console

• The L10 LED Light Source with AIM Technology is connected to an AIM

SafeLight cable (0233-050-300)

• A SafeLight scope adapter is connected to the SafeLight cable (see

cable user manual P27701 for compatible adapter part numbers)

1. To enable ENV mode, ensure the light source is in Active mode. If the light

source is not Active, the camera cannot enable ENV mode.

2. Press the ENV button at the bottom-right corner of the camera

touchscreen.

2

Page 32

28

ü

When ENV mode is enabled, the touchscreen and the ENV button

change to a green background.

Note: When ENV mode is enabled, the White Balance function is disabled

on the Home screen. The DRE button is also not available in ENV mode.

Note: When ENV mode is enabled, the brightness controls are disabled

on the Menu screen. Instead, the user can adjust the Backlight Level and

ENV Gain from the camera head up/down buttons. See the Using the

Camera Head Buttons section for more information.

3

3. Press the ENV button to turn o ENV mode. The touchscreen background

and ENV button will return to a gray color.

Page 33

29

Performing the White Balance Test

Before each surgical procedure, perform the White Balance test to adjust the

camera’s perception of white so it can display other colors correctly.

1. Ensure that a scope and light source are attached to the camera system,

and that the console, light source and monitor are powered on.

2. Point the scope tip at several stacked white gauze pads, a white

laparoscopic sponge, or any clean white surface.

3. Look at the monitor and make sure there is no visible glare o of the

white surface of the image.

4. Press and hold the camera head W button (or “WB” on the touchscreen)

until the monitor displays the message “WHITE BALANCE IN PROGRESS.”

5. Continue pointing the scope at the white surface until the video monitor

displays the message “WHITE BALANCE COMPLETE.” The image may

change color. If you cannot achieve an acceptable White Balance, refer to

the Troubleshooting section.

Advanced Features

The 1588AIM Camera has additional features that are not detailed in this

manual:

• Button programming

• Video image settings

• Touchscreen language settings

• Light source Run/Standby controls

• Other system settings

These advanced features require in-depth knowledge of the device and

should be performed only by trained personnel. For access to advanced

features, contact a Stryker representative.

Page 34

30

Troubleshooting

Problem Possible Solution

E1 error code • Turn o the console, wait 3 seconds, and turn

it back on.

E2 error code • Turn o the console, wait 3 seconds, and turn

it back on.

E3 error code • Turn o the console, wait 3 seconds, and turn

it back on.

E4 error code • Ensure vent holes on console are not

obstructed.

• Turn o the console, wait 3 seconds, and turn

it back on.

Touchscreen freezes • Turn o the console, wait 3 seconds, and turn

it back on.

“Restart Camera

Console” message

(Color bar background)

• Camera head temporarily shut down due

to overcurrent. Turn o the console, wait 3

seconds, and turn it back on.

• After sterilization, ensure the camera head

has cooled down before connecting it to the

console.

“System Error”

message (Light blue

background)

• No video detected.

• After sterilization, ensure the camera head

has cooled down before connecting it to the

console.

• Return the system for repair.

No color bar • Ensure the video-out from the console is

connected to the video-in on the monitor.

• Ensure all video systems are powered on.

• Ensure that the camera head is not

connected to the console.

• Turn o the console, wait 3 seconds, and turn

it back on.

Incorrect picture color • Perform the White Balance test. (See the

Performing the White Balance Test section.)

• Check the color settings on the monitor.

Page 35

31

Problem Possible Solution

White Balance quality

is not good

• See the solution for Picture is too dark.

• See the solution for Picture is too bright.

• Perform the White Balance test with the light

source connected to the scope. Use metalhalide, xenon, or LED lighting (no uorescent

lighting).

Picture is too dark • Increase the camera Light Level with the

camera head.

• Increase the light source output.

• Check the beroptic light cable for excessive

broken bers.

Picture is too bright • Decrease the camera Light Level.

• Decrease the light source output.

• Turn o the DRE Desaturation function.

Noise or snow on

picture when using

electrocautery probes

• Plug the electrocautery generator into a

separate electrical outlet and separate the

1588AIM console power cord from the

electrocautery power cord.

• Separate the camera cable from the

electrocautery cable.

• Reposition the electrocautery grounding pad

on the patient.

Noise or snow on

picture when not using

electrocautery probes

• Conrm all cable connectors are securely

attached.

• Check for and replace faulty video cables.

No video picture when

the camera head is

plugged in

• Check to ensure that all devices in the video

system are plugged in and powered on.

• Check the connector on the camera-head

cable for broken pins.

• Detach the camera head from the console

and reconnect.

• Turn o the console, wait 3 seconds, and turn

it back on.

Image is not well

centered

• Release the scope from the coupler and then

reconnect it. Make sure the scope is seated

correctly in the coupler.

Page 36

32

Problem Possible Solution

Variability in color

reproduction between

dierent light sources

or peripherals

• Perform the White Balance test. (See the

Performing the White Balance Test section.)

• Check the settings on video peripherals.

• Ensure the light source has a proper

infrared lter (check with manufacturer

specications).

Foggy picture (loss of

denition and clarity)

• Refocus the coupler.

• Disassemble the scope, coupler, and camera

head, and clean and dry all windows on the

components.

Optics are dirty • Rotate the scope. If dust particles in the

picture rotate, the dust is located on the

scope itself. Follow the manufacturer’s

instructions for cleaning the eyepiece and

negative lens.

• If particles in the picture do not move

when you rotate the scope, the particles are

located on the coupler or camera. Remove

the scope and clean the window on the front

of the coupler with a dry or alcohol-tipped

cotton swab.

• Disassemble the scope, coupler, and camera

head, and clean and dry all windows on the

components.

• Ensure all components are completely dry

before reassembling them, or fogging may

result.

Blurry picture • Ensure the coupler or C-mount scope is in

focus.

• On the Home screen, ensure the Surgical

Specialty is not set to FLEXI-SCOPE unless

you are using a exible scope.

• Disassemble the scope, coupler, and camera

head, and clean and dry all windows on the

components.

Page 37

33

Problem Possible Solution

Camera head button

error symbol appears

on display monitor:

• Return the camera head to Stryker for

service.

• If the symbol appears, the camera head

buttons are non-functional but the camera

head will still provide a video signal to the

console. The camera can be operated from

the console.

SIDNE device does not

recognize camera head

• Contact your Stryker representative for

compatibility settings.

ENV mode not enabled • Conrm the camera console is set to the

Laparoscopy Surgical Specialty.

• Conrm a USB A-to-A cable is connected

from the camera console to the L10 LED

Light Source with AIM Technology

• Conrm white light is activated on the light

source

Note: If this Troubleshooting section does not resolve the problem, call

Stryker Technical Support at 1-877-478-7953 (inside the U.S.) or refer to the

standard warranty.

Page 38

34

Reprocessing

The camera console is not intended to come into contact with the patient. It

may be cleaned, but not sterilized. The camera head and coupler may contact

the patient and should both be cleaned and sterilized prior to every use.

• For instructions on reprocessing the 1588 Pendulum Camera Head with

Integrated Coupler (1588-310-130), see user manual P29925 (English) or

P29926 (multilingual).

• For instructions on reprocessing the AIM Coupler (1588-020-122), see user

manual P30104.

Cleaning the Console

Should the camera console need cleaning, follow the warnings, cautions, and

instructions below. The user shall provide the mild detergent (or standard

disinfectant) and sterile cloth required for cleaning.

To avoid electric shock and potentially fatal injury, disconnect

the console from the AC power source before cleaning.

Observe the following cautions to avoid damaging the

console:

• Do not sterilize the console.

• Do not immerse the console in any liquid.

• Do not allow liquid to drip onto the console or collect on

any of its surfaces.

• Do not spray cleaning liquid directly onto the console,

power buttons, or connectors. Spray the cleaning liquid

onto a cloth, and use the cloth to wipe the console.

• Do not use corrosive cleaning solutions to clean the

console.

1. Spray a mild detergent or standard disinfectant onto a dry, sterile cloth.

Do not saturate the cloth.

2. Wipe the console. Do not allow liquid to drip from the cloth or collect on

the console.

3. When cleaning the front LCD screen, use extra care to prevent liquid from

dripping or pooling on the bottom of the screen. Excess liquid can enter

the console and cause product damage.

4. Visually inspect the external surface of the device for cleanliness, focusing

on hard-to-reach areas. If visible soil remains, repeat steps 1– 3.

Page 39

35

Cleaning, Disinfecting, and Sterilizing the Camera Head

These reprocessing instructions are provided in accordance with

ISO17664, AAMITIR12, AAMITIR30, AAMIST79, and AAMIST81. The

instructions have been validated by Stryker as being capable of preparing

the device for re-use. To achieve the desired result, the processor shall

ensure that the following instructions are performed as written in their

entirety and as appropriate in the processor’s facility. This normally

requires routine monitoring and validation of the facility’s reprocessing

procedures. Stryker recommends users observe these standards when

reprocessing medical devices.

Overview

Reprocessing the camera head involves manual or automated cleaning

with two dierent detergents, optional disinfection, and sterilization.

• Step 1 (required): Cleaning with Enzymatic Detergent

• Step 2 (required): Cleaning with Non-Enzymatic Detergent

• Step 3 (optional): Disinfection

• Step 4 (required): Sterilization

Warnings

• This device must be cleaned and sterilized prior to the rst use and

after every subsequent use.

• Separate the camera head, coupler (1588-210-105 and 1588-710-105

only), and scope prior to cleaning, disinfection, or sterilization. Failure

to follow this instruction will render the devices non-sterile. (Refer to

the coupler and scope product manuals for reprocessing instructions

for those devices.)

• Wear appropriate protective equipment: gloves, eye protection, etc.

• To avoid health risks from aerosol contamination, brush the device only

when it is submerged in liquid.

• Use only the sterilization cycles outlined in this document. Using

unspecied sterilization cycles may damage the device or result in

incomplete sterilization.

• Sterilize only one camera head per tray, or incomplete sterilization may

result. Follow any instructions provided with the sterilization tray or

system regarding tray setup and other devices that may be sterilized

within the same tray.

Page 40

36

Cautions

• Always install the soaking cap prior to processing the camera. Failure to

properly tighten the soaking cap will corrode the connector pins and

void the warranty. Refer to the Installing the Soaking Cap section for

more detail about installing the cap.

• Inspect the camera cable for cuts and breaks before soaking in any

uid. Return any damaged camera to Stryker for service.

• Never soak the camera in the same tray with sharp instruments.

• Do not use brushes or pads with metal or abrasive tips during manual

cleaning, as permanent scoring or damage could result.

• To minimize galvanic corrosion, avoid soaking dissimilar metals in close

proximity.

• The device cannot withstand an automated disinfection method.

• The 1588 camera heads are not autoclavable. Steam sterilizing camera

heads that are not marked AUTOCLAVE will result in product damage.

• Allow the camera head to cool before connecting it to the console.

Connecting the camera head while it is hot may result in system error.

• When using Steris® liquid chemical sterilization, remove the camera

head from the chamber once sterilization is complete, or moisture may

condense inside the camera head and cause display defects.

Limitations on Reprocessing

• Do not cross-sterilize the device. Using multiple sterilization methods

may signicantly reduce the performance of the device.

• Repeated sterilization via Ethlyene Oxide or Sterrad® 100NX® can

degrade the product’s cosmetic appearance.

• Do not leave the device in solutions longer than necessary. This may

accelerate normal product aging.

• Damage caused by improper processing is not covered by the

warranty.

Materials and Equipment

All materials and equipment required to reprocess the camera head shall be

supplied by the user unless otherwise noted

Item Description

All phases

Gloves, eye protection,

etc.

Wear protective equipment as required by the medical

facility and procedure.

Page 41

37

Cleaning

Water basin Large enough to accommodate camera head without

excessive bending of cable

Enzymatic detergent

1

Used in cleaning solution to remove surgical debris

Tap water To prepare cleaning solutions

Syringe

2

To inject detergent into hard-to-reach areas of device

Soft-bristle brush

3

To clean exterior of device or hard-to-reach areas of

device

Reverse osmosis/

deionized water

4

To rinse device

Clean cloth or ltered

pressurized air (≤40 psi)

To assist with drying

Non-enzymatic

detergent

5

Used in cleaning solution to remove surgical debris

Automated washer For using the automated cleaning procedure

Disinfection

Water basin Large enough to accommodate camera head without

excessive bending of cable

Disinfecting solution

6

≥ 2.4% glutaraldehyde

Tap water To prepare disinfecting solution

Reverse osmosis/

deionized water

4

To rinse the device

Clean cloth or ltered

pressurized air (≤40 psi)

To assist with drying

Sterilization

Sterilization system

7

· Sterrad 100S, 200, NX®, or 100NX

· Steris/Amsco® V-PRO® 1, V-PRO 1 Plus, or V-PRO maX

· SterisSystem1®, System1E®, System1Plus, or

System1Express

· Ethylene Oxide (EO)

Sterilization wrap

8,9

To maintain sterile barrier

Sterilization tray

9

Optional. Must be compatible with sterilization method.

1

Cleaning was validated using ENZOL® Enzymatic Detergent at 1 oz/gal. at 35°C.

2

Cleaning was validated using a 50mL syringe.

3

Recommend to clean with an M16 soft-bristle brush.

4

Cleaning was validated using reverse osmosis/deionized (RO/DI) water.

5

Cleaning was validated using Prolystica® 2x Neutral Detergent at 1/8oz/gal at 35°C.

6

Disinfection was validated using CIDEX® Activated at 25 °C with a soaking time of 45 minutes.

7

Steris System1, System1Plus, and System1Express are not intended for use in the United States.

8

Sterilization was validated using Kimberly-Clark® KC600 KIMGUARD sterilization wrap.

9

For United States users: when sterilizing the device, use only sterilization wraps and sterilization trays that have been cleared by

the FDA to use with the selected sterilization cycle.

Page 42

38

Instructions for Reprocessing

Point of Use

• Disassemble the camera head from the scope and coupler. To

disconnect the scope, depress the endobody clamp on the coupler and

remove the scope from the coupler. To disconnect the coupler, grip the

rear adapter of the coupler and unscrew it counterclockwise from the

camera head.

• Wipe any excess soil from the device using a clean sterile cloth.

• If an automated reprocessing method will be used, rinse any hardto-reach areas in the device with 50mL of sterile distilled water

immediately after use.

Containment and Transportation

• Reprocess the device as soon as reasonably practical following use.

Note: Cleaning was validated with a 30minute wait time.

• Transport the device in a tray to avoid damage. Follow the facility’s

internal procedures for the transportation of contaminated surgical

instruments and devices.

Cleaning

Manual Cleaning

Note: For necessary materials and equipment, see the Materials and

Equipment table.

1. Soak

• Disassemble the camera head from the scope and coupler.

• Ensure the soaking cap is installed. Refer to the Installing the

Soaking Cap section for more detail about installing the cap.

• Prepare an enzymatic detergent according to the manufacturer

instructions.

• Use a clean cloth to wipe the entire device with the detergent.

• Fully immerse the device in the detergent. Use a syringe to inject

50mL of the detergent into any crevices and mated surfaces to

remove loose debris.

• Soak the device in the detergent for 15minutes.

Page 43

39

2. Brush

• Thoroughly brush the exterior of the device with a soft-bristle

brush for 90seconds, focusing on any mated or rough surfaces.

• Use a syringe to inject 50mL of the detergent into any crevices and

mated surfaces 5times.

• When cleaning the 1588AIM Camera Head with Integrated

Coupler (1588-610-122), brush between all gaps and crevices while

pushing down on the endobody clamp. Continue brushing all gaps

and crevices while releasing the clamp to the initial position.

3. Rinse

• Remove the device from the prepared detergent. Rinse the device

with reverse osmosis/deionized water at ambient temperature for

90seconds or until all visible detergent residue is removed.

• Flush any crevices and mated surfaces 5times. After all visible

detergent residue is removed, continue to rinse for 30seconds.

• Drain excess water from the device and dry it with a clean cloth or

ltered pressurized air.

• Visually inspect the device for cleanliness, paying close attention to

hard-to-reach areas. If visible soil remains, repeat steps 1– 3.

4. Soak

• Prepare a non-enzymatic detergent according to the manufacturer

instructions.

• Fully immerse the device in the detergent. Use a syringe to inject

50mL of the detergent into any crevices and mated surfaces.

• Soak the device in the detergent for 15minutes.

5. Brush

• Thoroughly brush the exterior of the device with a soft-bristle

brush for 90seconds, focusing on any mated or rough surfaces.

• Use a syringe to inject 50mL of the detergent into any crevices and

mated surfaces 5times.

• When cleaning the 1588AIM Camera Head with Integrated

Coupler (1588-610-122), brush between all gaps and crevices while

pushing down on the endobody clamp. Continue brushing all gaps

and crevices while releasing the clamp to the initial position.

Page 44

40

6. Rinse

• Remove the device from the prepared detergent. Rinse the device

with reverse osmosis/deionized water at ambient temperature for

90seconds or until all visible detergent residue is removed.

• Flush any crevices and mated surfaces 5times. After all visible

detergent residue is removed, continue to rinse for 30seconds.

• Drain excess water from the device and dry it with a clean cloth or

ltered pressurized air.

• Visually inspect the device for cleanliness, paying close attention to

hard-to-reach areas. If visible soil remains, repeat steps 1– 6.

Automated Cleaning

Note: For necessary materials and equipment, see the Materials and

Equipment table.

1. Soak

• Disassemble the camera head from the scope and coupler.

• Ensure the soaking cap is installed. Refer to the Installing the

Soaking Cap section for more detail about installing the cap.

• Prepare an enzymatic detergent according to the manufacturer

instructions.

• Use a clean cloth to wipe the entire device with the detergent.

• Fully immerse the device in the detergent. Use a syringe to inject

50mL of the detergent into any crevices and mated surfaces to

remove loose debris.

• Soak the device in the detergent for 15minutes.

2. Brush

• Thoroughly brush the exterior of the device with a soft-bristle

brush for 90seconds, focusing on any mated or rough surfaces.

• Use a syringe to inject 50mL of the detergent into any crevices and

mated surfaces 5times.

• When cleaning the 1588AIM Camera Head with Integrated

Coupler (1588-610-122), brush between all gaps and crevices while

pushing down on the endobody clamp. Continue brushing all gaps

and crevices while releasing the clamp to the initial position.

Page 45

41

3. Rinse

• Remove the device from the prepared detergent. Rinse the device

with reverse osmosis/deionized water at ambient temperature for

90seconds or until all visible detergent residue is removed.

• After all visible detergent residue is removed, continue to rinse for

30seconds.

4. Automated Wash

• Place the device in the washer on an incline to facilitate drainage.

• Program the washer using the following parameters:

Pre-Wash

Recirculation Time 2 min

Water Temperature Cold tap water

Detergent Type n/a

Enzyme Wash

Recirculation Time 2 min

Water Temperature Hot tap water

Detergent Type Enzymatic detergent

Wash 1

Recirculation Time 2 min

Water Temperature Set point 66˚C

Detergent Type Non-enzymatic detergent

Rinse 1

Recirculation Time 2 min

Water Temperature Hot tap water

Detergent Type n/a

Dry Phase

Recirculation Time 7 min

Temperature 115 ˚C

Detergent Type n/a

• Filtered pressurized air can be used to aid in drying.

• Visually inspect the device for cleanliness, paying close attention to

hard-to-reach areas. If visible soil remains, repeats steps 1– 4.

Page 46

42

High-Level Disinfection (Optional)

The device must be sterilized after disinfection. Failure

to sterilize the device before reuse presents an acute

infection control risk to the patient.

Note: For necessary materials and equipment, see the Materials and

Equipment table.

The device can be disinfected using a disinfecting solution that has the

following active ingredient: ≥ 2.4% glutaraldehyde at 25°C.

1. Clean and prepare the device as recommended in this user manual.

Ensure the soaking cap is installed.

2. Prepare the disinfecting solution according to the manufacturer

instructions.

3. Immerse the device in the solution, lling all mated surfaces and

crevices.

4. Soak the device in the solution for 45minutes.

5. Thoroughly rinse and ush the device with running, reverse osmosis/

deionized water to remove the disinfectant.

6. Dry the device with a clean, lint-free cloth immediately after rinsing.

Sterilization

After performing the cleaning instructions specied above, perform one

of the following sterilization cycles. Note: For necessary materials and

equipment, see the Materials and Equipment table.

Sterrad

1. Clean and prepare the device as recommended in this user manual.

Ensure the soaking cap is installed.

2. If using a sterilization tray (optional), follow any additional

instructions provided with the tray. Use only trays that are compatible

with Sterrad.

3. Double wrap the device (or tray) prior to sterilization.

4. Sterilize the device following the instructions of the manufacturer,

using the Sterrad 100S, 200, NX, or 100NX Sterilization System. Select

the standard cycle.

5. After sterilization, allow the device to cool to room temperature

before reconnecting it to a coupler or the console. Otherwise, the lens

can fog during use or the console can produce a system error.

Page 47

43

Steris/Amsco V-PRO

1. Clean and prepare the device as recommended in this user manual.

Ensure the soaking cap is installed.

2. If using a sterilization tray (optional), follow any additional

instructions provided with the tray. Use only trays that are approved

for sterilization with V-PRO.

3. Double wrap the device (or tray) prior to sterilization.

4. Sterilize the device using one of the following V-PRO sterilization

systems:

• V-PRO 1 (Standard cycle)

• V-PRO 1 Plus (Non-Lumen or Standard cycle)

• V-PRO maX (Non-Lumen or Standard cycle)

5. After sterilization, allow the device to cool to room temperature

before reconnecting it to a coupler or the console. Otherwise, the lens

can fog during use or the console can produce a system error.

Steris System 1 / 1E / 1 Plus / 1 Express

Note: Steris System 1, System 1 Plus, and System 1 Express are not

intended for use in the United States.

1. Clean and prepare the device as recommended in this user manual.

Ensure the soaking cap is installed.

2. Following the instructions of the manufacturer, sterilize the device

using one of the Steris systems below with the appropriate sterilant:

• System 1 with Steris 20 Sterilant

• System 1E with S40™ Sterilant

• System 1 Plus with S40 Sterilant

• System 1 Express with S40 Sterilant

3. Remove the device from the Steris chamber once sterilization is

complete, or moisture may condense inside the device windows and

cause fogging.

4. After sterilization, allow the device to completely dry and cool to

room temperature before reconnecting it to a coupler or the console.

Otherwise, the lens can fog during use or the console can produce a

system error.

Page 48

44

Ethylene Oxide (EO)

1. Clean and prepare the device as recommended in this user manual.

Ensure the soaking cap is installed.

2. If using a sterilization tray (optional), follow any additional instructions

provided with the tray. Use only trays that are compatible with EO.

3. Double wrap the device (or tray) prior to sterilization.

4. Sterilize the device using the parameters below.

Preconditioning

Wrapping Double

Temperature 55 °C (131 °F)

Relative Humidity 70%

Vacuum Set Points 1.3 psia

Preconditioning Time 30 min

Exposure

Temperature 55 ± 2 °C (131 ± 5 °F)

Chamber Humidity 70% RH (50–80%) ± 5%

Concentration (100%

EO)

725 mg/L

Time 1 hour

Aeration

Aeration Time 12 hours

Temperature 35–39 °C (95–102 °F)

5. After sterilization, allow the device to cool to room temperature

before reconnecting it to a coupler or the console. Otherwise, the lens

can fog during use or the console can produce a system error.

Page 49

45

User Maintenance

Inspection

• Inspect the device on a continual basis for unacceptable deterioration such

as (but not limited to) corrosion, discoloration, pitting, cracked seals, or

abnormal noises. If a problem is observed or suspected, the device should

be returned for service.

• Inspect all components for cleanliness. If uid or tissue buildup is present,

repeat the above cleaning and sterilization procedures.

• Inspect the camera cable for cuts and breaks. Return any damaged camera

to Stryker for service.

Using Sterile Drapes

Using sterile drapes will ensure maximum longevity of your 1588AIM Camera.

For best results, follow the instructions provided by the drape manufacturer.

Storage

Store the device in a dry, clean, and dust-free environment at room

temperatures.

Replacing the Fuses

To avoid the risk of re, use only fuses of the value specied on

the fuse label located on the rear panel of the console.

1. Unplug the power cord from the wall outlet and remove the cord from

the transmitter console.

2. Unlatch the fuse holder above the AC inlet and remove it. (You may need

to press the tab on the fuse holder with a slender screwdriver to release

the latch.)

3. Replace the fuse with the same value and rating.

4. Reinstall the fuse holder until the tab snaps in place.

Page 50

46

Periodic Maintenance Schedule

To ensure safe operation of the 1588AIM Camera, you

should periodically perform the following procedure:

Every 12 months, check the earth leakage current to <500 µA (<300 µA

in USA), ground protective earth impedance to <0.1 ohms, and power

consumption less than or equal to rated power. Use a true RMS digital

multimeter and safety analyzer to perform this test.

Note: Refer calibration and operating diculties not detailed in this manual

to your Stryker Endoscopy sales representative.

Expected Service Life

The 1588AIM Camera Control Unit has an expected service life of 1540uses

(fouryears based on approximately two uses per day).

When camera heads 1588-210-105, 1588-610-122, and 1588-710-105 are

sterilized with V-PRO, Sterrad, or Steris System 1/1E/1 Plus/1 Express, the

expected service life is 280 reprocessing cycles (two years based on 140 cycles

per year).

When camera heads 1588-210-105, 1588-610-122, and 1588-710-105 are

sterilized with Ethylene Oxide, the expected service life is 140 reprocessing

cycles (two years based on 70 cycles per year).

Disposal and Recycling Information

This product contains electrical waste or electronic equipment.

It must not be disposed of as unsorted municipal waste and

must be collected separately in accordance with applicable

national or institutional related policies relating to obsolete

electronic equipment.

Dispose of the camera system according to local laws and hospital practices.

Refer to the diagrams below to identify components that must be recycled.

(The console is shown with the chassis cover removed for clarity.)

Page 51

47

Recycling Diagrams

Console

1

8910

2 3 4

5 6 7

Item Material Qty. Comments

1 Touchscreen LCD 1 Not shown above; on front panel

2 PC Board 1 —

3 PC Board 1 —

4 PC Board 1 —

5 Remote Cable 2 Cable length abbreviated above

6 AC Power Cord 1 Cable length abbreviated above

7 DVI Cable 1 Cable length abbreviated above

8 Power Supply 1 —

9 PC Board 1 —

10 PC Board 1 —

Page 52

48

Camera Head

Camera head model 1588-210-105 is shown below.

1 2

Item Material Qty. Comments

1 Cable 1 —

2 Camera Head Enclosure

(PC Boards)

1 The camera head enclosure that

contains PC Boards is sealed and

cannot be dismantled without

special equipment and training.

Page 53

49

Technical Specications

60 Hz settings are displayed rst. (50 Hz settings follow in parentheses.)

Imaging System 1/3″ Progressive Scan CMOS

High Denition

Scanning System Horizontal: 64.00 kHz (60.00 kHz)

Vertical: 60.02 Hz (50.00 Hz)

Video Outputs

Digital/Analog: Two Digital Video Interface (DVI)/RGBHV

1280 × 1024 (HD), 720p, 1080p (HDTV) format

Connector: 29-pin DVI-I

Y/C: One S-VHS

Connector: 4-pin mini-DIN

Mounting Endoscope eyepiece used with C-mount

coupler

C-mount camera head used with C-mount

scopes

(C-mount coupler/scope thread: 1-32″ UN 2A)

Auto Shutter Range 1/60 (1/50) – 1/50,000 second

Operating Conditions Temperature: 10–30 °C

Relative Humidity: 25–75%

Transport and Storage

Conditions

Temperature: -18–60 °C

Relative Humidity: 15–90%

Input Electrical Ratings 100–240 VAC (0.6 A) @ 50–60 Hz

Device Weight 10.8 lb (4.9 kg) Camera Console

1.0 lb (0.5 kg) Camera Head (approximate

weight)

Page 54

50

Dimensions Camera Console:

12.5″ w × 4.0″ h × 15.25″ d

(31.8 cm w × 10.2 cm h × 38.7 cm d)

Camera Head Cable:

10 ft (3.05 m) sealed cable

Classication Class I Equipment

Continuous Operation

Type BF Applied Part

Ingress Protection, IPX0—Ordinary Equipment

(1588AIM console)

Ingress Protection, IPX7—Protected against

the eects of temporary immersion in water

(1588AIM Camera Heads)

Page 55

51

Electromagnetic Compatibility

Like other electrical medical equipment, the 1588AIM Camera requires

special precautions to ensure electromagnetic compatibility with other

electrical medical devices. To ensure electromagnetic compatibility (EMC),

the camera system must be installed and operated according to the EMC

information provided in this manual.

Note: The 1588AIM Camera has been designed and tested to comply with

IEC60601-1-2 requirements for EMC with other devices.

• Do not use cables or accessories other than those provided

with the 1588AIM Camera, as this may result in increased

electromagnetic emissions or decreased immunity to such

emissions.

• If the 1588AIM Camera is used adjacent to or stacked with

other equipment, observe and verify normal operation of

the camera system in the conguration in which it will be

used prior to using it in a surgical procedure. Consult the

tables below for guidance in placing the 1588AIM Camera.

• Equipment which employs RF communications may aect

the normal function of the 1588AIM Camera.

Guidance and Manufacturer’s Declaration: Electromagnetic Emissions

The 1588 AIM Camera is intended for use in the electromagnetic environment specied below. The

customer or user of the camera system should ensure that it is used in such an environment.

Emissions test Compliance Electromagnetic Environment - guidance

RF emissions CISPR 11 Group 1 The 1588 AIM Camera uses RF energy only for

its internal function; therefore, its RF emissions

are very low and are not likely to cause any

interference in nearby electronic equipment.

RF emissions CISPR 11 Class B The 1588 AIM Camera is suitable for use

in all establishments other than domestic

establishments and those directly connected to

the public low-voltage power supply network that

supplies buildings used for domestic purposes,

provided the following warning is heeded:

Warning: This system is intended for use by

health care professionals only. This system

may cause radio interference or may disrupt

the operation of nearby equipment. It may be

necessary to take mitigation measures, such as

reorienting or relocating the system or shielding

the location.

Harmonic emissions

IEC61000-3-2

Class A