Page 1

1288 HD Video Camera

User Guide

1288010000

1288010001

1288210105

1288710105

Page 2

Page 3

Contents

Warnings and Cautions ...................................... 3

Product Description and Intended Use .............. 6

Indications/Contraindications ......................................................7

The Camera Console ...................................................................8

The Camera Head ......................................................................10

The C-Mount Coupler ................................................................11

Setup and Interconnection ..............................12

Setting Up the Console ..............................................................12

Setting Up the Camera Head .....................................................17

Setting Up the Coupler ..............................................................18

Operation ........................................................ 20

Powering the Camera On/Off ....................................................20

Using the Camera Head Buttons ...............................................20

Using the Touchscreen Interface ...............................................22

Controlling Remote Video Accessories .....................................26

Using the SFB Serial Interface ...................................................26

Using the DVI Fiber Outputs ......................................................26

Operating the Camera with a Light Source ...... 27

Troubleshooting............................................... 28

Cleaning, Reprocessing, and Maintenance ...... 31

Cleaning the Camera Console ...................................................31

Reprocessing the Camera Head ................................................31

Using Sterile Drapes ..................................................................38

Replacing the Fuses ..................................................................39

Periodic Maintenance Schedule ................................................39

Electromagnetic Compatibility ........................ 42

Warranty and Return Policy ............................. 46

Page 4

Page 5

3

Warnings and Cautions

Please read this manual and follow its instructions carefully. e words warning,

caution, and note carry special meaning and should be carefully reviewed:

Warning Indicates risks to the safety of the patient or user. Failure to

follow warnings may result in injury to the patient or user.

Caution Indicates risks to the equipment. Failure to follow cautions

may result in product damage.

Note: Provides special information to clarify instructions or present additional

useful information.

An exclamation mark within a triangle is intended to alert the

user to the presence of important operating and maintenance

instructions in the manual.

A lightning bolt within a triangle is intended to warn of the

presence of hazardous voltage. Refer all service to authorized

personnel.

IMPORTANT SAFETY NOTICE: Before operating this device, please read

this operating manual thoroughly and carefully. When using this device

with a light source, re and/or severe injury may result to the patient, user,

or inanimate objects if the instructions in this manual are not followed.

All light sources can generate signicant amounts of heat at the scope tip,

the scope light post, the light cable tip, and/or near the light cable adapter.

Higher levels of brightness from the light source result in higher levels of

heat. Always adjust the brightness level of the camera and the monitor before

adjusting the brightness level of the light source. Adjust the brightness

level of the light source to the minimum brightness necessary to adequately

illuminate the surgical site. In addition, adjust the internal shutter of the

camera higher in order to run the light source at a lower intensity. Avoid

touching the scope tip or the light cable tip to the patient, and never place

them on top of the patient, as doing so may result in burns to the patient

or user. In addition, never place the scope tip, the scope light post, the light

cable adapter, or the light cable tip on the surgical drapes or other ammable

material, as doing so may result in re. Always place the light source in

standby mode whenever the scope is removed from the light cable or the

device is unattended. e scope tip, scope light post, light cable adapter,

and light cable tip will take several minutes to cool o aer being placed in

standby mode, and therefore may still result in re or burns to the patient,

user, or inanimate objects.

Page 6

4

Warnings

To avoid potential serious injury to the user and the patient and/or damage to

this device, please note the following warnings:

1. Carefully unpack this unit and check if any damage occurred during

shipment. If damage is detected, refer to the Warranty and Return Policy

section of this manual.

2. Read this operating manual thoroughly, especially the warnings, and be

familiar with its contents before connecting and using this equipment.

3. Be a qualied physician, having complete knowledge of the use of this

equipment.

4. Test this equipment prior to a surgical procedure. is unit was fully tested

at the factory before shipment. Never use this equipment in the presence of

ammable or explosive gases.

5. Avoid dissembling any part of the camera head, as doing so may break the

seals, causing leakage and/or electric shock.

6. Avoid removing covers on the control unit, as doing so may cause damage to

electronics and/or electric shock.

7. Attempt no internal repairs or adjustments not specically detailed in this

operating manual.

8. Pay close attention to the care and cleaning instructions in this manual. Any

deviation may cause damage.

9. Never sterilize the camera console, because the delicate electronics cannot

withstand this procedure.

10. Disconnect the control unit from the electrical outlet when inspecting the

fuses.

11. Before each use, check the outer surface of the endoscope to ensure that

there are no rough surfaces, sharp edges, or protrusions.

12. Avoid dropping the camera system. e camera system contains sensitive

parts that are precisely aligned.

13. Ensure that readjustments, modications, and/or repairs are carried out by

persons authorized by Stryker Endoscopy.

14. Ensure that the electrical installation of the relevant operating room complies

with the NEC and CEC guidelines.

15. To avoid the risk of electric shock, this equipment must only be connected to

a supply mains with protective earth.

16. Multiple portable socket-outlets shall not be placed on the oor.

e warranty is void if any of these warnings are disregarded.

Page 7

5

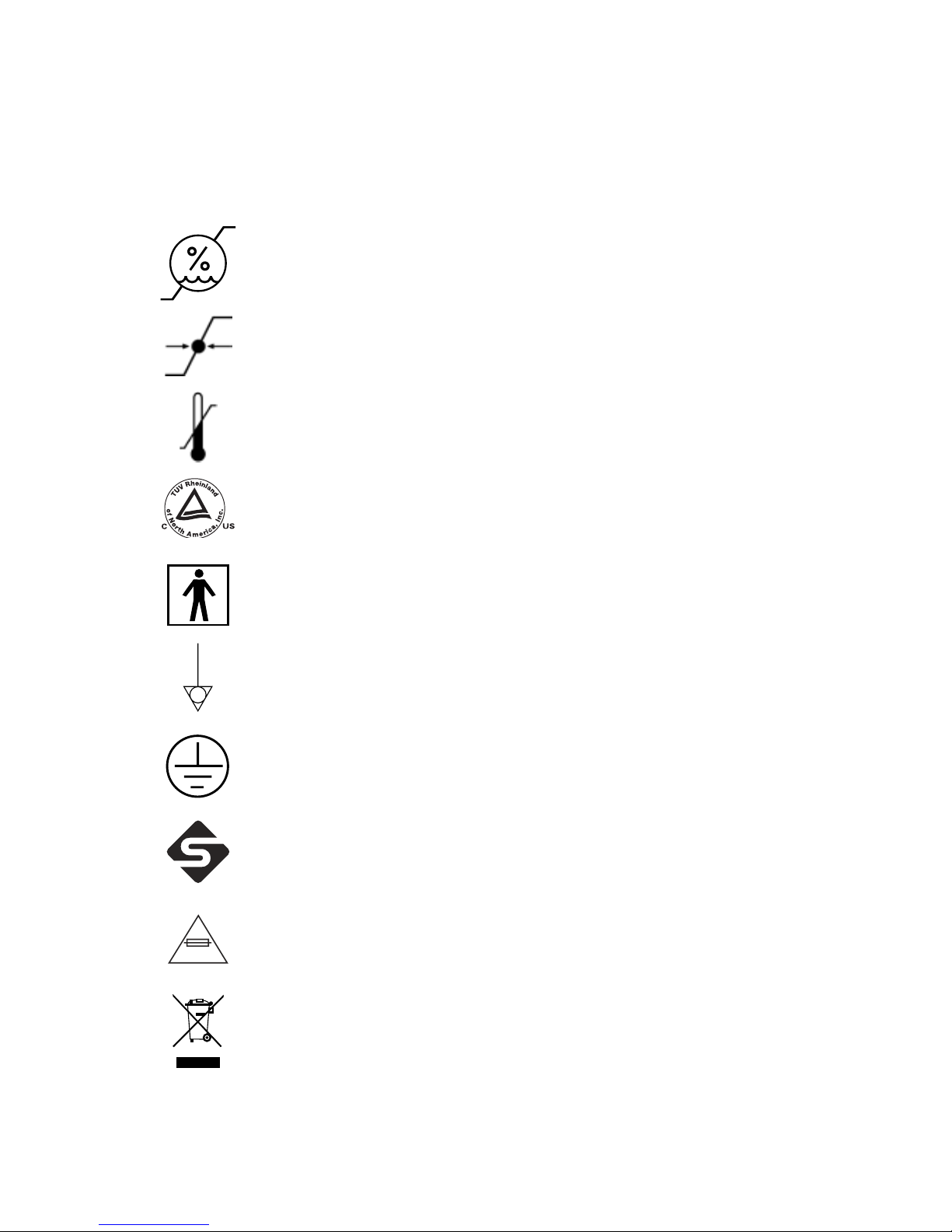

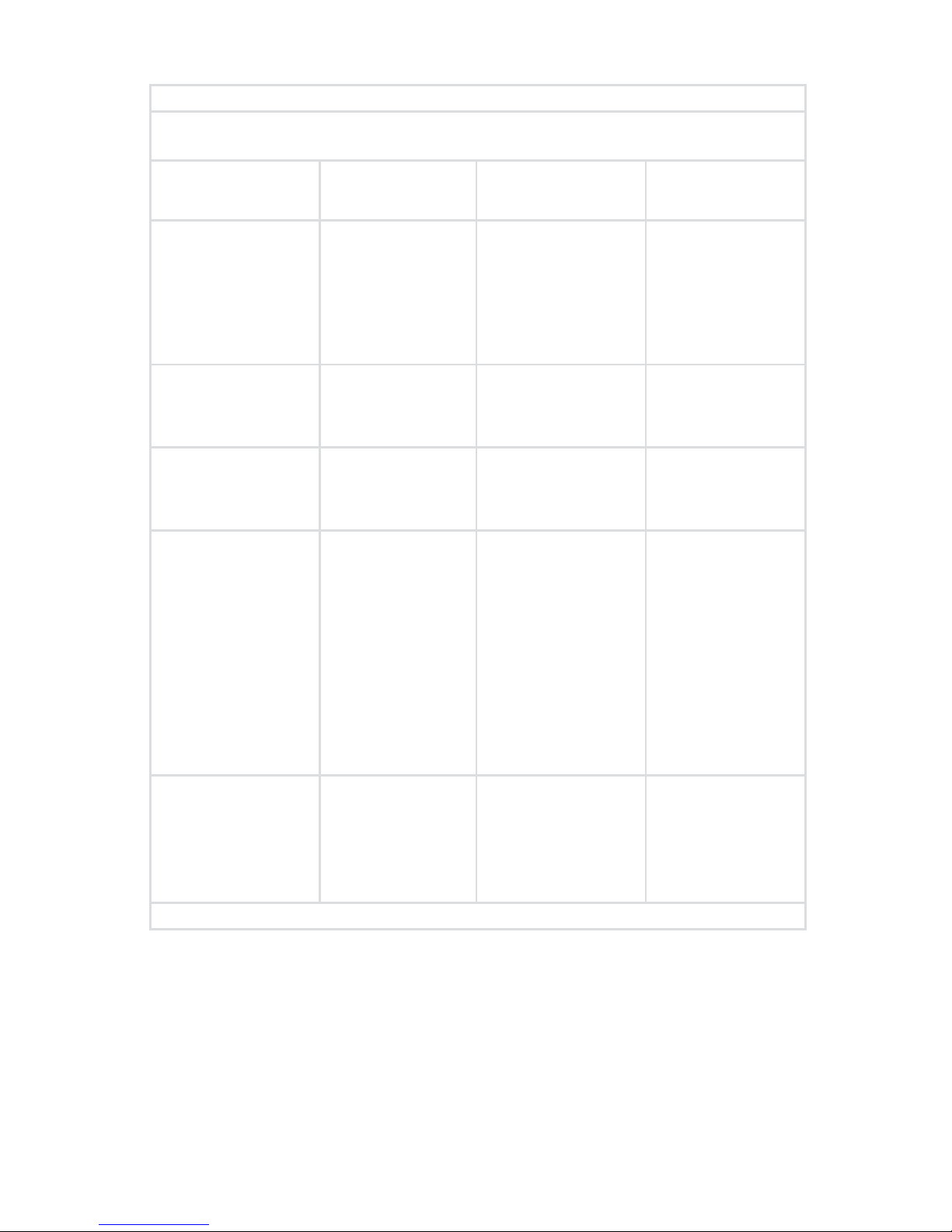

Symbol Definitions

In addition to the cautionary symbols already listed, other symbols found on

the 1288 HD Camera and in this manual have specic meanings that clarify the

proper use and storage of the 1288 HD Camera. e following list denes the

symbols associated with this product:

Operating humidity ratings

Operating pressure ratings

Operating temperature ratings

Denotes compliance to CAN/CSA C22.2 No601.1-M90

UL60601-1.

Type BF applied part

Equipotentiality

Protective Ground Earth

FireWire

Fuse rating

is symbol indicates that the waste of electrical and electronic

equipment must not be disposed as unsorted municipal waste

and must be collected separately. Please contact the manufacturer

or other authorized disposal company to decommission your

equipment.

Page 8

6

Product Description and Intended Use

e Stryker Endoscopy 1288 HD Medical Video Camera is a high-denition

camera used to capture still and video images of endoscopic surgical applications.

e 1288 HD Medical Video Camera consists of three main components:

Component Stryker Part Number

Camera console 1288010000; 1288010001

Camera head 1288210105, 1288710105

C-mount coupler 1288020122

e 1288 HD also comes with various connection cables which, like the other

components, can be purchased together or separately.

Federal law (United States of America) restricts this device to use

by, or on the order of, a physician.

Page 9

7

Indications/Contraindications

e 1288 HD Camera is indicated for use in general laparoscopy,

nasopharyngoscopy, ear endoscopy, sinuscopy, and plastic surgery wherevera

laparoscope/endoscope/arthroscope is indicated for use. A few examples of

the more common endoscopic surgeries are laparoscopic cholecystectomy,

laparoscopic hernia repair, laparoscopic appendectomy, laparoscopic pelvic

lymph node dissection, laparoscopically assisted hysterectomy, laparoscopic and

thorascopic anterior spinal fusion, anterior cruciate ligament reconstruction,

knee arthroscopy, shoulder arthroscopy, small joint arthroscopy, decompression

xation, wedge resection, lung biopsy, pleural biopsy, dorsal sympathectomy,

pleurodesis, internal mammary artery dissection for coronary artery bypass,

coronary artery bypass graing where endoscopic visualization is indicated

and examination of the evacuated cardiac chamber during performance of

valve replacement. e users of the camera are general surgeons, gynecologists,

cardiac surgeons, thoracic surgeons, plastic surgeons, orthopedic surgeons, ENT

surgeons and urologists.

ere are no known contraindications.

Page 10

8

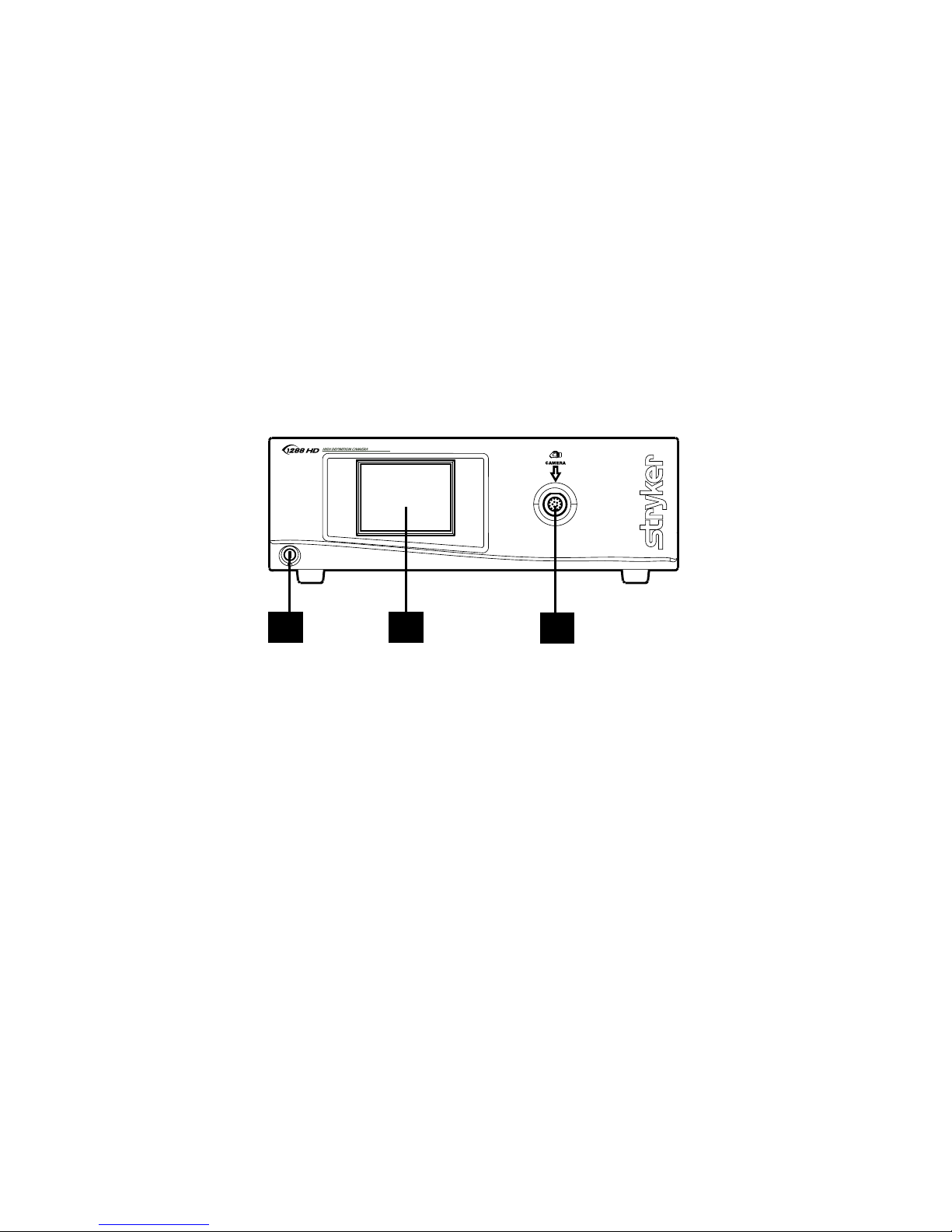

The Camera Console

e camera console or Camera Control Unit (CCU) is the control center for

the 1288 HD Medical Video Camera and processes the video and photographic

images captured during the surgical procedure. e console front panel features

a touch screen, where dierent menus can be accessed, including the controls

for adjusting the enhancement level, light level, zoom, and white balance, as

well as allows the selection of surgical specialty settings that optimize camera

performance for various, specic surgical procedures. e front panel also allows

activation of remote outputs. e rear panel provides ports for connecting the

1288 HD Camera to viewing and recording equipment, such as video monitors,

the SDC Ultra, or photo printers.

Front Panel

3

1 2

1. Power Switch Powers the camera ON and OFF

2. Touch Screen Allows navigation through dierent menus

for controlling the camera and adjusting the

system settings

3. Camera Connector Port Connects to the 1288 HD Camera Head

Page 11

9

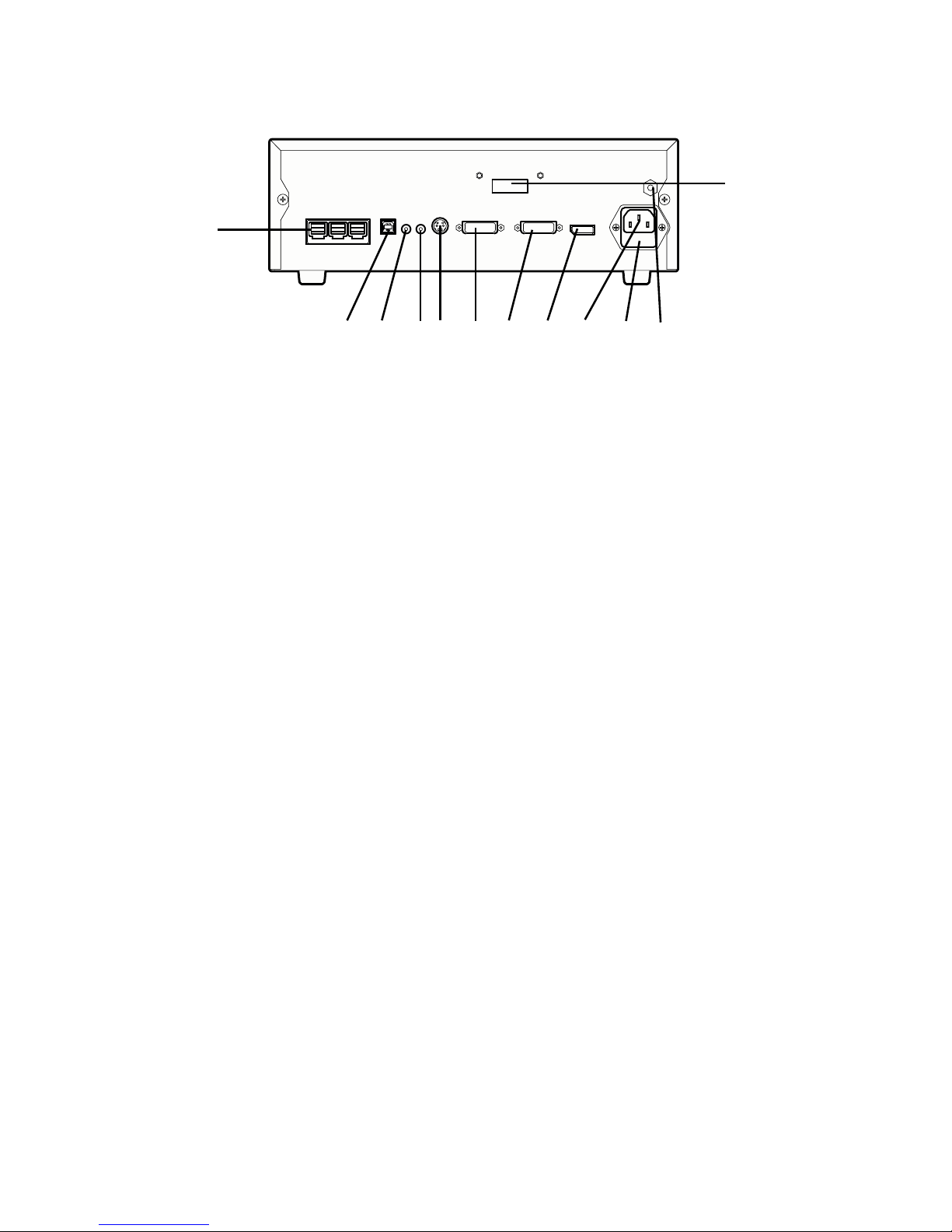

Rear Panel

213 64 5 7 8 9 10 11

12

1. SFB Connectors Enables FireWire connection with Stryker

FireWire devices; provides connection for remote

diagnoses and future soware upgrades

2. SIDNE® Port Connects to the SIDNE® Console to enable voice

operation and/or graphic tablet control

3. Remote Out 1 Connects to a video accessory remote switch

4. Remote Out 2 Connects to a video accessory remote switch

5. S-Video Out Analog video output

6. DVI Out 1 Digital video output

7. DVI Out 2 Digital video output

8. Display Port Digital video output

9. AC Power Inlet Connects to seperable power cord, which can be

used for mains isolation

10. Fuse Panel Contains two 0.63 A fuses

11. Equipotential

Ground Plug

12. Fiber Outputs

(optical)

DVI output for connection to Lucent connector

bers (optional: 1288010001)

Page 12

10

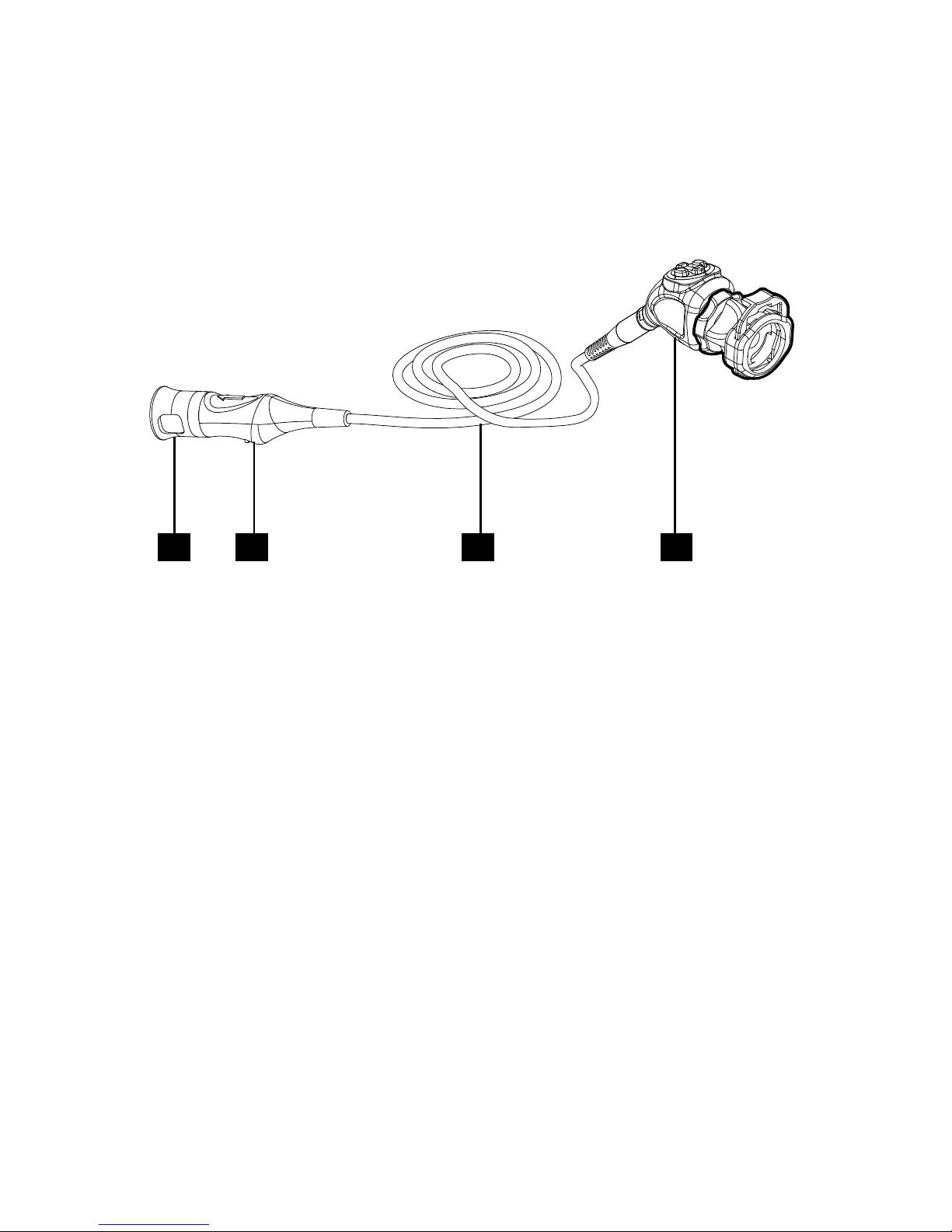

The Camera Head

e camera head connects to the camera console and captures video and

photographic images, which it relays to the camera console. It features several

controls that are accessible through a button keypad located on the top of the

camera head (see the “Operation Instructions” section of this manual).

1 42 3

1. Soaking Cap Protects the cable connector during cleaning and

sterilization

2. Cable Connector Connects the camera head to the camera console

3. Camera Cable

4. Camera Head Captures photographic and video images, provides

camera controls, and connects with a focusing

coupler

Page 13

11

The C-Mount Coupler

e C-Mount coupler threads onto the face of the camera head, enabling a

scope to be attached to the camera. It provides a focusing ring to adjust image

sharpness. e features of the coupler are listed in Figure 3 below. Additional

instructions are available in the “1288 C-Mount Coupler User Guide” (P/N

1000401152).

2

3

1

4

1. Rear Adapter reads onto the camera head

2. Focusing Ring Adjusts the coupler focus

3. Endobody Clamp Secures the scope to the coupler

4. Scope End Receives the endoscope

Page 14

12

Setup and Interconnection

Note: Stryker Endoscopy considers instructional training, or inservice, an

integral part of the 1288 HD Medical Video Camera. Your local Stryker

Endoscopy sales representative will perform at least one inservice at your

convenience to help set up your equipment and instruct you and your sta on its

operation and maintenance. To schedule an inservice, contact your local Stryker

Endoscopy representative aer your equipment has arrived.

Setting Up the 1288 HD Camera involves three steps:

1. Setting up the console

2. Setting up the camera head

3. Setting up the coupler

Setting Up the Console

Always connect the camera to an appropriate power source,

using a hospital-grade power cord. Loss of AC power will cause

the camera to shut down and the surgical image to be lost.

Only connect items to the camera that have been specied for

use with the camera. Connecting incompatible equipment may

cause unexpected results.

When the 1288 HD Camera is used with other equipment,

leakage currents may be additive. Ensure that all systems are

installed according to the requirements of IEC60601-1-1.

Caution Equipment which employs RF communications may

aect the normal function of the 1288 HD Camera. When

choosing a location for the 1288 HD Camera, consult the

“Electromagnetic Compatibility” section of this manual to

ensure proper function.

Always set up the console in a location that allows adequate

ventilation (airow) to the console. Insucient ventilation may

cause the console to overheat and shut down.

Page 15

13

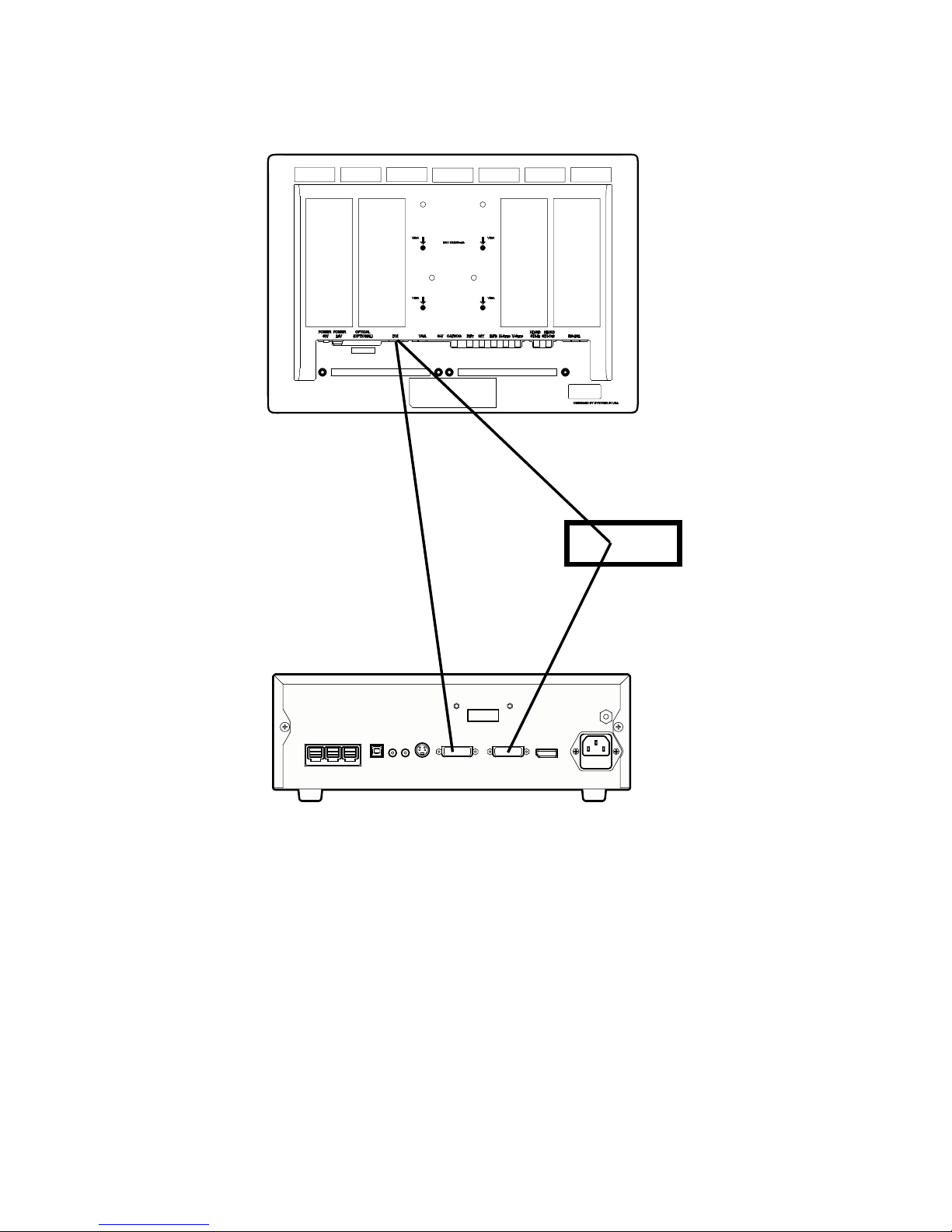

To set up the console, make the following connections:

1. Connect the AC power.

• Connect the AC power cord to the AC inlet on the rear console

panel.

• Connect the other end to a hospital-grade outlet.

2. Connect the video output.

• e rear panel provides one analog and three (or four with the

optional ber digital-video outputs, which can be used together or

independently:

Output Type Output Cable Connector

Analog *S-VHS 1 S-VHS 4 pin Mini-Din

(push-only connectors)

Digital **DVI-I1 DVI 29 pin (push-only

connectors, with two

tightening knobs)

**DVI-I2 DVI 29 pin (push-only

connectors, with

two tightening knobs)

Displayport Displayport 20 pin Displayport

(auto-locking connector)

Optional DVI over

optical Fiber

Fiber (×4) Lucent connector ber

(× 4) (push only)

* On some monitors, S-VHS inputs may be labeled Y/C.

** e DVI connectors can also output analog SXGA signals through a DVI-I

to VGA adapter.

Use the cables and outputs described above to connect the 1288 HD to other

operating-room equipment. Wiring Diagrams 1-3 describe typical set-ups.

• If desired, connect any remote outputs using the remote cables

supplied with the 1288 HD Camera. (See Wiring Diagram 2.)

Devices connected to the remote outputs of the 1288 HD Camera

can be operated using the P buttons on the camera head and/or

console. See the “Operation Instructions” section of this manual for

details.

• If desired, connect the SIDNE® interface as well. (See Wiring

Diagram 2.)

Page 16

14

Wiring Diagram 1: Camera and Flat-Panel Monitor

WiSe 26" HDTV Surgical Display

1288 HD Video Camera

DVI-I/VGA

Adapter

DVI

DVI

Page 17

15

Wiring Diagram 2: Camera, SDC, SIDNE®, and Flat-Panel Monitor

DVI

USB

DVI

Stryker European Rep. RA/QA Manager

ZAC Satolas Green Pusignan

Av. De Satolas Green

69881 MEYZIEU Cedex, France

WiSe 26" HDTV Surgical Display

1288 HD Video Camera

SIDNE®

SDC

DVI

REMOTE

Page 18

16

Wiring Diagram 3: Camera, Flat-Panel Monitor, and CRT Monitor

WiSe 26" HDTV Surgical Display

1288 HD Video Camera

DVI-I/VGA

Adapter

DVI

DVI

CRT Monitor

S-VHS

Page 19

17

Note: If you are using any device with unterminated analog video inputs, you

must connect a cable from the VIDEO OUT of that device to the VIDEO IN on

the monitor.

Note: An additional monitor may be connected using an open camera output.

Note: e camera console is shipped from the factory in NTSC video format.

If necessary, the video format can be changed to PAL by using the “Options”

submenu in the conguration menu. See the “Using the Conguration Menu”

section of this manual.

1. Power on the monitor.

2. Power on the camera.

Note: A color bar pattern will appear on the monitor when the camera head is

not connected to the camera console. Follow the instructions in the “Setting

Up the Camera Head” section of this manual to connect the camera head to the

console.

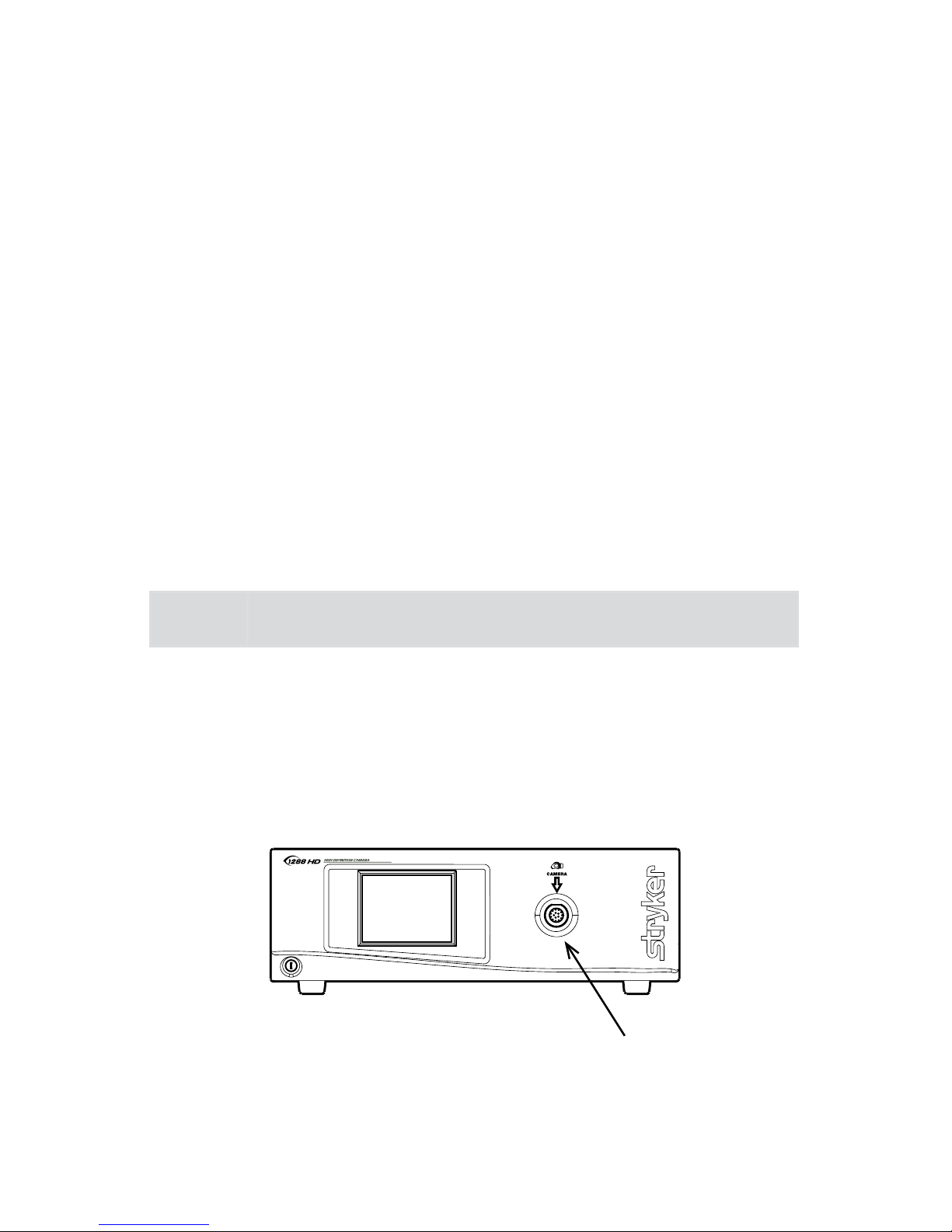

Setting Up the Camera Head

Caution Do not severely bend the camera cable or damage may result.

Note: To unplug the camera from the control unit, grasp the knobbed portion of

the connector and pull straight out.

1. Connect the camera head to the console.

• Unscrew the soaking cap from the cable connector if necessary.

• Align the blue arrow on the cable connector with the blue arrow on

the camera-connector port on the front console panel.

• Push in the connector until it locks in place.

Page 20

18

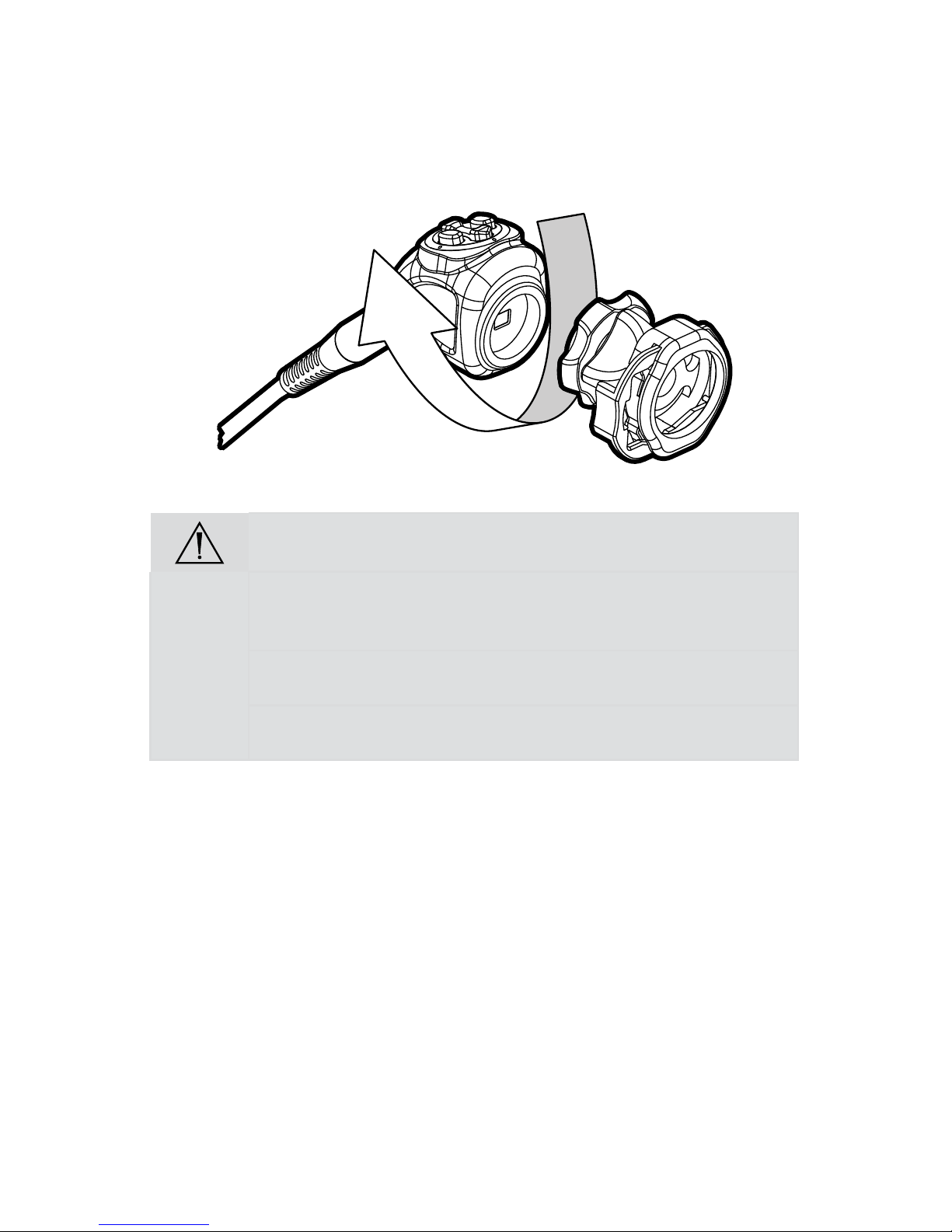

Setting Up the Coupler

1. Attach the coupler to the camera head.

• Grasping the rear adapter, screw the coupler onto the camera head

(clockwise) until it forms a tight seal.

Before each use, check the outer surface of the endoscope to

ensure there are no rough surfaces, sharp edges, or protrusions.

Caution When attaching or removing the coupler, grip only the rear

adapter, as twisting other parts of the coupler may result in

mechanical damage.

Do not overtighten the coupler, as this may damage the front

window of the camera.

Do not overtighten a direct-coupled C-mount scope, as this

may damage the front window of the camera.

Note: For direct-coupled C-mount scopes (scopes that require no coupler),

thread the endoscope directly into the camera head until it forms a tight seal.

Page 21

19

2. Attach an endoscope to the coupler.

• Remove the red dust cap if it is present.

• Push down on the endobody clamp (a) and insert the scope into the

scope end of the coupler (b).

• Release the endobody clamp.

(a)

(b)(c)

3. Attach a light cable from the light source to the light post on the endoscope (c).

Page 22

20

Operation

Warning: Before using the 1288 HD Camera in a surgical

procedure, test all components to ensure proper function.

Ensure that a video image appears on all video monitors before

beginning any procedure.

Note: Before operating the 1288 HD Camera, ensure all components have been

set up according to the instructions in the “Setup and Interconnection” section of

this manual.

Powering the Camera On/Off

Press the power switch on the console to power the camera on or o.

Using the Camera Head Buttons

e camera head features a cross-shaped, four-button keypad for controlling the

1288 camera. Shown below, these buttons are labeled P, W, Up, and Down.

WP

Page 23

21

P (Picture) Button

e P button controls up to two remote video accessories.

• Press the P button for less than two seconds to select Remote 1. One beep

will sound.

• Press the P button for more than two seconds to select Remote 2. Two beeps

will sound.

W (White Balance) Button

e W button activates the white-balance function or the light/zoom function.

e white balance function is used to correct slight color dierences that exist

between dierent light sources or endoscopes.

• Press the W button for less than two seconds to activate the white balance

function.

• Press the W button for more than two seconds to increase the light or zoom

level. e camera console can be set to “light” mode or “zoom” mode using

the Buttons submenu of the Conguration Menu. In “zoom” mode, each W

button press will raise the light level in four steps. In “light” mode, each press

will raise the zoom level in four steps. When either mode has reached its

maximum, pressing the W button again will cycle the level back to the lowest

setting.

Perform the white balance procedure before every surgical procedure.

Note: Ensure that a scope and light source are attached to the camera, and that

the camera, light source and monitor are powered on before adjusting the white

balance.

1. Point the scope at several stacked 4 × 4 white gauze pads, a white laparoscopic

sponge, or any clean white surface.

2. Look at the monitor and make sure that no glare is visible o of the white

surface.

3. Press and hold the W button until “WHITE BALANCE IN PROGRESS”

begins ashing on the video monitor.

4. Continue pointing the scope at the white surface until the video monitor

indicates that white balance is “WHITE BALANCE COMPLETE.” e video

picture may change color. If you cannot achieve an acceptable white balance,

refer to the “Troubleshooting” section of this manual.

Page 24

22

Up and Down Buttons

e up and down buttons work together to increase or decrease the light/zoom

level.

e camera console can be set to “light” mode or “zoom” mode using the Buttons

submenu of the Conguration Menu. In “light” mode, pressing the arrow buttons

will raise or lower the automatic-shutter light-level setting in 8 steps. In “zoom”

mode, pressing the arrow buttons will raise or lower the zoom level in 8 steps.

Press the arrow button once to adjust the light level by one step or hold down the

button for a quicker transition.

Using the Touchscreen Interface

e touchscreen interface on the console provides controls for operating the

camera and selecting system settings. Controls are located in a series of menus

shown below and described hereaer.

Home Menu

Language

ENGLISH

LANGUAGE

Page 25

23

Home Screen

e Home screen is the default screen. Use the buttons below to choose surgical

specialties, operate the camera head, and navigate to other menus.

Home Menu

Language

ENGLISH

LANGUAGE

Scroll through preset camera settings designed for

surgical specialties. Choose from:

• Arthroscopy

• Cystoscopy

• ENT

• Flexi-Scope

• Hysteroscopy

• Laparoscopy

• Laser

• Microscope

• Standard

Capture photo.

Press and hold button for two seconds before it

activates.

Capture video.

Press and hold button for two seconds before it

begins recording. Press again to stop.

Activate white balance.

Press and hold button for two seconds before it

activates.

• Press once to proceed to the Menu screen.

Page 26

24

Menu Screen

e Menu screen provides options for adjusting the camera picture.

Home Menu

Language

ENGLISH

LANGUAGE

• Press once to return to the Home screen.

• Hold for 5 seconds to proceed to the Language

screen.

Increase or decrease:

• Enhance (picture sharpness)

• Light (automatic-shutter light level)

• Zoom (magnication)

Enhance/Light/Zoom Meter

Appears on the monitor, indicating the selection level.

Page 27

25

Language Screen

e Language screen allows you to choose the default language for the user

interface.

Home Menu

Language

ENGLISH

LANGUAGE

ENGLISH

LANGUAGE

Scroll through available interface languages.

Choose from:

• Danish

• German

• Polish

• Dutch

• Greek

• Portuguese

• English

• Italian

• Simplied Chinese

• Finnish

• Japanese

• Spanish

• French

• Korean

• Swedish

• Norwegian

• Press the Home button to exit the language screen. Power

cycle the unit for the change to take eect.

• To initiate black balance, hold for 5 seconds until

“BLACK BALANCE” begins ashing on the video

monitor.

Page 28

26

Controlling Remote Video Accessories

e 1288HD Camera can remotely control up to two video accessories (such as

the SDC Ultra, a VCR, or a photo printer), enabling the user to capture images or

start and stop video recording by pressing the P button. (See also the “Using the

Camera Buttons” section of this manual.)

1. Connect the video accessory to one of the remote outputs on the rear console

panel. Use the provided remote cables. (See Wiring Diagram 2 in the “Setting

Up the Console” section of this manual.)

2. Press the P button for less than one second to select Remote 1. One beep will

sound.

3. Press the P button for more than one second to select Remote 2. Two beeps

will sound.

Using the SFB Serial Interface

e SFB serial connection on the console rear panel enables FireWire connection

to the Stryker Endoscopy Soware Management Site (SMS). Connect to the

L9000 Light Source for “Run/Standby” controls from the Camera Head.

Note: is system feature is not necessary for regular camera system operation.

is system feature requires an additional device (that is, a computer) to connect

to SMS.

Using the DVI Fiber Outputs

Using controls or adjustments or performing procedures

dierently than specied in this manual may result in

hazardous radiation exposure.

e 1288 HD Camera has the optional upgrade, the ber output, for model

1288010001. is upgrade contains four laser diodes to transmit a DVI output

over beroptic cables.

1. Connect four individual bers (terminated in Lucent connectors) to the red

(R), green (G), blue (B) and clock (C) laser diodes on the console rear panel.

2. Connect the four bers to a compatible beroptic DVI receiver.

• e four bers should be connected to the camera console in the labeled

order: RGBC

• e bers should be connected to the monitor in one of two

congurations: CBGR (reverse order) or BGRC (R/B switched).

3. Ensure the beroptic output is enabled (on) via the Options Submenu in the

Conguration Menu. (See the section “Using the Conguration Menu”.)

Note: e 1288 HD Camera model 1288010001 is a Class 1 laser product per IEC

60825-1 and 21CFR.

Page 29

27

Operating the Camera with a Light

Source

IMPORTANT SAFETY NOTICE: Before operating this device,

please read this operating manual thoroughly and carefully.

When using this device with a light source, re and/or severe

injury may result to the patient, user or inanimate objects, if the

instructions in this manual are not followed. All light sources

can generate signicant amounts of heat at the scope tip, the

scope light post, the light cable tip, and/or near the light cable

adapter. Higher levels of brightness from the light source result

in higher levels of heat. Always adjust the brightness level of the

camera and the monitor before adjusting the brightness level of

the light source. Adjust the brightness level of the light source

to the minimum brightness necessary to adequately illuminate

the surgical site. In addition, adjust the internal shutter of

the camera higher in order to run the light source at a lower

intensity. Avoid touching the scope tip or the light cable tip to

the patient, and never place them on top of the patient, as doing

so may result in burns to the patient or user. In addition, never

place the scope tip, the scope light post, the light cable adapter,

or the light cable tip on the surgical drapes or other ammable

material, as doing so may result in re. Always place the light

source in standby mode whenever the scope is removed from

the light cable or the device is unattended. e scope tip, scope

light post, light cable adapter, and light cable tip will take several

minutes to cool o aer being placed in standby mode, and

therefore may still result in re or burns to the patient, user, or

inanimate objects.

Page 30

28

Troubleshooting

Problem Possible Solution

“Restart

Camera

Console”

message

(Color bar

background)

• Camera head temporarily shut down due to overcurrent.

Turn o the console, wait 3 seconds, and turn it back on.

• Aer sterilization, ensure the camera head has cooled

down before connecting it to the console

“System Error”

message

(Light blue

background)

• No video detected.

• Aer sterilization, ensure the camera head has cooled

down before connecting it to the console

• Return the system for repair.

No color bar • Ensure the video-out from the console is connected to

the video-in on the monitor.

• Ensure all video systems are powered on.

• Ensure that the camera head is not connected to the

console.

• Turn o the console, wait 3 seconds, and turn it back on.

No color bar

(Optical DVI

only)

• Same as above.

• See the “Using the DVI Fiber Outputs” section of this

manual.

Incorrect

picture color

• Perform the white balance procedure. (See the “W

Button” section of this manual.)

• Check the color settings on the monitor.

White balance

(WB) quality

not good

• See the solution for “Picture is too dark.”

• See the solution for “Picture is too bright.”

• Perform the white-balance procedure with the light

source connected to the scope. Use metal-halide, xenon,

or LED lighting (no uorescent lighting).

Picture is too

dark

• Increase the camera light level with the camera head.

• Increase the light-source output.

• Check the ber-optic light cable for excessive broken

bers.

Picture is too

bright

• Decrease the camera light level.

• Decrease the light-source output.

• Ensure that Shutter submenu in the Conguration menu

has the following settings:

BRT CNTRL AUTO

Shutter On

Page 31

29

Noise or snow

on picture

when using

electrocautery

probes

• Plug the electrocautery generator into a separate

electrical outlet and separate the 1288 HD power cord

from the electrocautery power cord.

• Separate the camera cable from the electrocautery cable.

• Reposition the electrocautery grounding pad on the

patient.

Noise or snow

on picture

when not using

electrocautery

probes

• Reduce Enhancement.

• Check for and replace faulty video cables.

No video

picture when

the camera

head is plugged

in

• Check to ensure that all devices in the video system are

plugged in and powered on.

• Check the connector on the camera-head cable for

broken pins.

• Detach the camera head from console and reconnect

• Turn o the console, wait 3 seconds, and turn it back on.

Image is not

well centered

• Release the scope from the coupler and then reconnect

it. Make sure the scope is seated correctly in the coupler.

Variability

in color

reproduction

between

dierent light

sources or

peripherals

• Perform the white-balance procedure. (See the “W

Button” section of this manual.)

• Check the settings on video peripherals.

• Ensure the light source has a proper infrared lter (check

with manufacturer specications).

Foggy picture

(loss of

denition and

clarity)

• Refocus the camera.

• Refocus the coupler.

• Clean and dry both the scope and the coupler windows.

• Remove the coupler from the camera head and

remove any moisture that has built up between the two

components.

Page 32

30

Problem Possible Solution

Optics are

dirty

• Rotate the scope. If dust particles in the picture rotate,

the dust is located on the scope itself. Follow the

manufacturer’s instructions for cleaning the eyepiece

and negative lens.

• If particles in the picture do not move when you rotate

the scope, the particles are located on the coupler or

camera. Remove the scope and clean the window on the

front of the coupler with a dry or alcohol-tipped cotton

swab.

• If dust particles lie between the coupler and camera,

remove the coupler and clean the coupler and camera

windows.

• Ensure all components are completely dry before

reassembling them, or fogging may result.

Blurry picture • Ensure the coupler or C-Mount scope is in focus.

• Increase the enhancement.

• Ensure the specialty switch is not set to FLEXI-SCOPE

unless you are using a exible scope.

Note: If this troubleshooting guide does not resolve the problem, call Stryker

Technical Support at 1-877-478-7953 (inside the U.S.) or refer to the “Warranty

and Return Policy” section of this manual.

Page 33

31

Cleaning, Reprocessing, and

Maintenance

e camera console is not intended to come into contact with the patient. It may

be cleaned, but not sterilized. e camera head and coupler may contact the

patient and should both be cleaned and sterilized prior to every use.

Cleaning the Camera Console

Disconnect the console from the AC power source before

cleaning.

Caution Never immerse or sterilize the camera console as this will

damage the camera and void the warranty.

Should the camera console need cleaning, wipe it down with a sterile cloth and

mild cleaning solution.

Reprocessing the Camera Head

ese reprocessing instructions are provided in accordance with ISO 17664,

AAMI TIR12, AAMI ST79, and AAMI ST81. While they have been validated

by Stryker as being capable of preparing the device for re-use, it remains the

responsibility of the processor to ensure that the reprocessing as actually

performed, using equipment, materials, and personnel in the reprocessing

facility, achieves the desired result. is normally requires validation and

routine monitoring of the process. Stryker recommends users observe these

standards when reprocessing medical devices.

Warnings

• is device must be cleaned and sterilized prior to the rst use and aer

every subsequent use.

• Use only the sterilization cycles outlined in this document. Using

unspecied sterilization cycles may damage the device or result in

incomplete sterilization.

• Separate the camera head, coupler, and scope prior to cleaning,

disinfection, or sterilization. If the coupler and camera head are cleaned,

disinfected, or sterilized as a single unit, disconnecting the coupler

during use will compromise the sterility of the two products. (Refer to

the coupler and scope product manuals for reprocessing instructions.)

• Wear appropriate protective equipment: gloves, eye protection, etc.

Page 34

32

Cautions

• Always install the soaking cap prior to processing the camera. Failure

to properly tighten the soaking cap will corrode the connector pins and

void the warranty.

• Inspect the camera cable for cuts and breaks before soaking in any uid.

Return any damaged camera to Stryker for service.

• Never soak the camera in the same tray with sharp instruments.

• Do not use brushes or pads with metal or abrasive tips during manual

cleaning, as permanent scoring or damage could result.

• To minimize galvanic corrosion, avoid soaking dissimilar metals in close

proximity.

• Only camera heads marked can withstand steam

sterilization. Autoclaving camera heads that do not bear this marking

will result in product damage.

• Allow the camera head to cool before connecting it to the console.

Connecting the camera head while it is still hot may result in system

error.

Limitations on Reprocessing

• Do not cross-sterilize the device. Using multiple sterilization methods

may signicantly reduce the performance of the device.

• Do not leave the device in solutions longer than necessary. is may

accelerate normal product aging.

• Proper processing has a minimal eect on this device. End of life is

normally determined by wear and damage due to use.

• Damage incurred by improper processing will not be covered by the

warranty.

Instructions

Point of Use

• Wipe excess soil from the device using disposable paper towels.

• If an automated reprocessing method will be used, rinse any channels

inthe device with 50mL of sterile distilled water immediately aer use.

Containment and Transportation

• Reprocess the device as soon as reasonably practical following use1.

• Transport the device in a tray to avoid damage.

1

A 30 minute wait time was used during cleaning validation.

Page 35

33

Preparation for Cleaning

1. Disassemble the coupler from the scope and camera head.

2. Prepare an enzymatic detergent according to the manufacturer’s

recommendations (one ounce per gallon of tap water at 35 - 40°C)2.

3. Wipe the entire device with the detergent, using a clean cloth.

4. Immerse the device in the detergent. Using a syringe, inject any inside

regions of the device with 50mL of the detergent to ensure all parts of the

device are reached.

5. Soak the device in the detergent for a minimum of 15 minutes.

Cleaning: Manual

1. Brush

• Prepare a fresh solution of enzymatic detergent according to the

manufacturer’s recommendations (one ounce per gallon of tap water

at35 - 40°C)2.

• oroughly brush the exterior of the device with a so-bristled brush,

focusing on any mated or rough surfaces.

• Using a syringe, inject any lumen or mated surface a minimum

of5times with 50mL of the detergent.

• Brush any lumens a minimum of 5 times from each end, using

anappropriate bottle brush.

• Brush any movable parts in all extreme positions.

2. Rinse

• Rinse the device with reverse osmosis/de-ionized (RO/DI) water at

ambient temperature until all detergent residue is removed. Flush any

lumens or mated surfaces a minimum of 5 times. Once all detergent

residue is removed, continue to rinse for a minimum of 30 seconds.

• Drain excess water from the device and dry it using a clean cloth

orpressurized air.

• Visually inspect the device for cleanliness, paying close attention

tohard-to-reach areas. If visible soil remains, repeat steps 1 and 2.

3. Soak

• Prepare a non-enzymatic detergent according to the manufacturer’s

recommendations (0.25 ounces per gallon of tap water at 35 - 40°C)3.

• Fully immerse the device and use a syringe to inject any lumens and

mated surfaces with 50mL of the detergent.

• Soak the device for a minimum of 15 minutes.

Page 36

34

4. Brush

• oroughly brush the exterior of the device using a so-bristled brush.

• Using a syringe, inject 50mL of the detergent into any cannulae, lumens,

or mated surfaces a minimum of 5 times.

• Brush any lumens a minimum of 5 times from each end, using an

appropriate bottle brush.

• Actuate the device, brushing around any movable parts in all extreme

positions.

5. Rinse

• oroughly rinse the device with RO/DI water until all detergent

residue is removed. Flush any lumens or crevices a minimum of 5 times.

Once all detergent residue is removed, continue to rinse for a minimum

of 30 seconds.

• Drain the excess water from the device and dry it using a clean cloth

orpressurized air.

Cleaning: Automated

1. Brush

• Using a syringe, inject 50mL of the enzymatic detergent (from the

“Preparation for Cleaning” section) into any lumen and mated surface

aminimum of one time.

• Brush from both ends of any lumens a minimum of 1 time, using an

appropriate bottle brush.

2. Rinse

• Rinse the device with RO/DI water at ambient temperature until there

is no visible detergent residue. Continue to rinse for a minimum of

30seconds aer all detergent residue has been removed.

• Place the device in the washer on an incline to facilitate drainage.

Page 37

35

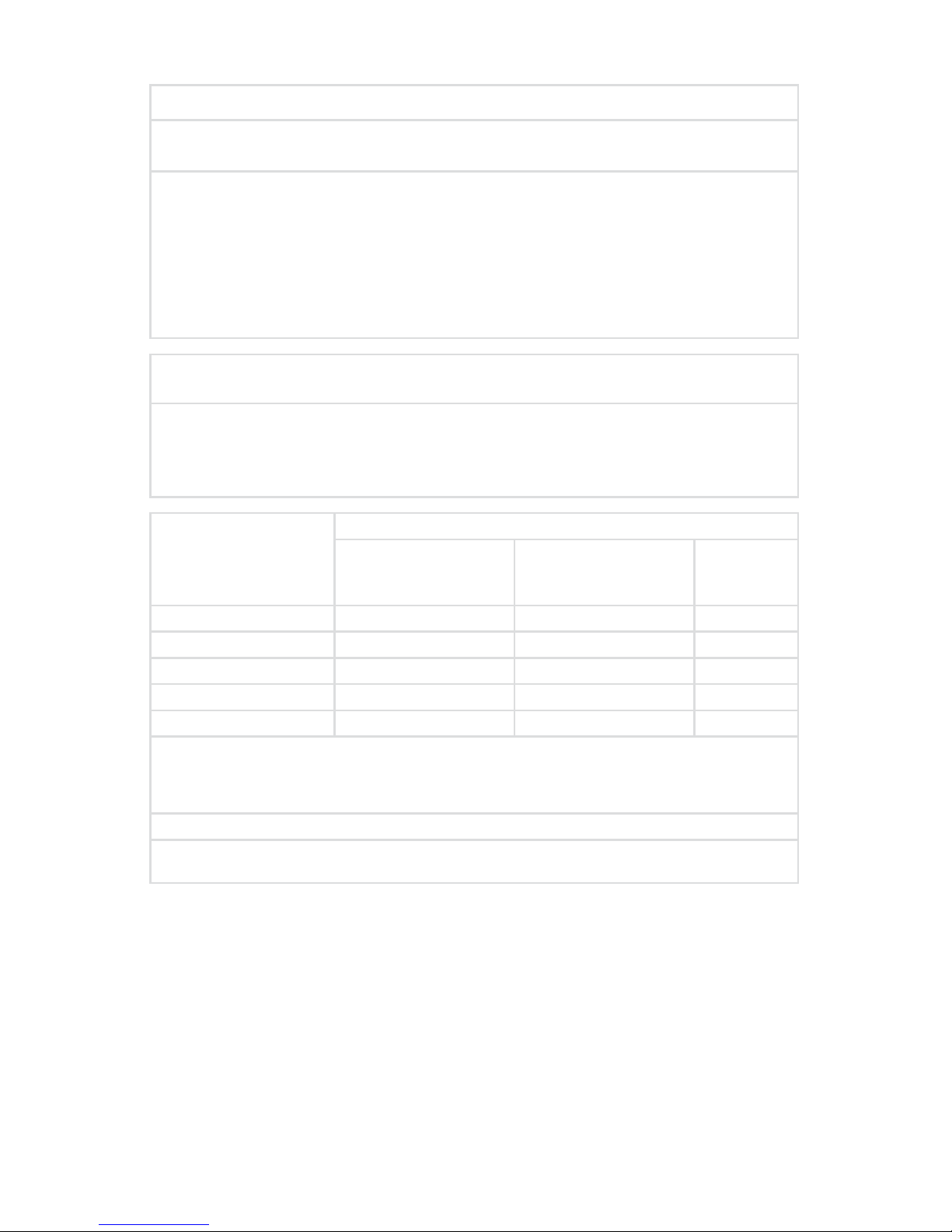

3. Automated wash

• Program the washer using the following parameters:

Phase Recirculation

Time

Water

Temperature

Detergent Type and

Concentration

(if applicable)

Pre Wash 2 minutes Cold tap

water

N/A

Enzyme

Wash

2 minutes Hot tap water Enzymatic Detergent

2

Wash 1 2 minutes Set point

(66˚C)

Non-enzymatic

Detergent

3

Rinse 1 2 minutes Hot tap water N/A

Dry Phase 7 minutes 115˚C N/A

• Upon completion of the draining phase aer Rinse 1, stop the cycle and

open the washer door.

• Remove the device from the washer during the thermal phase and place

the device back into the washer for the dry phase.

• If necessary, use pressurized air to aid in drying. Visually inspect each

device for cleanliness.

2

ENZOL® Enzymatic Detergent is validated for cleaning ecacy.

3

Renu-Klenz® is validated for cleaning ecacy.

Page 38

36

Low Level Disinfection (optional)

1. Disinfect the device in a disinfecting solution that has one of the following

active Ingredients:

• ≥ 2.4% glutaraldehyde4 with a minimum soaking time of 45 minutes at 25 °C

or

• >= 3.4% glutaraldehyde5 with a minimum soaking time of 20 minutes at 25 °C

or

• ≥ 0.55% ortho-phthalaldehyde6 with a minimum soaking time of 12minutes

at 25 °C.

2. Prepare the disinfecting solution according to the manufacturer’s instructions.

3. Per manufacturer’s recommendations, immerse the device, lling all lumens,

in the disinfecting solution for the required time at the appropriate temperature.

4. oroughly rinse and ush all parts and lumens with running,

demineralized water to remove the disinfectant.

5. Dry all parts with a lint-free towel immediately aer rinsing.

4

CIDEX Activated® is validated for disinfection ecacy.

5

CIDEX Plus® is validated for disinfection ecacy.

6

CIDEX® OPA is validated for disinfection ecacy.

Drying

• For automated drying, use the drying cycle provided with the washer/

disinfector.

• For manual drying, use a lint-free cloth.

• Dry any lumens with compressed air.

Maintenance, Inspection, and Testing

• Inspect the device on a continual basis. If a problem is observed or

suspected, the device should be returned for repair.

• Inspect all components for cleanliness. If uid or tissue buildup is

present, repeat the above cleaning and disinfection procedures.

• Inspect the camera cable for cuts and breaks. Return any damaged

camera to Stryker for service.

Packaging

N/A

Sterilization

Aer performing the cleaning instructions specied above, perform one of the

following sterilization cycles.

Page 39

37

Ethylene Oxide (EtO)

• Double wrap camera head and cable prior to sterilization.

Preconditioning parameters

Temperature 55°C (131°F)

Chamber Humidity 70% RH

Vacuum Set Points 1.3 psia

Time 30 minutes

Exposure

Concentration (100% EtO) 725 mg/L

Temperature 55 ± 2°C (131 ± 5°F)

Time 1 hour

Chamber Humidity 70% RH (50–80%) ± 5%

Aeration parameters

Aeration Time 12 hours

Temperature 35–54°C (95–129°F)

Steris® System 1

1. Clean and prepare the camera head and cable as recommended in the

Cleaning and Disinfection sections. Ensure the soaking cap is installed.

2. Sterilize the camera head and cable using Steris® System 1 with Steris®

Sterilant 20.

3. Allow the camera head, cable, coupler, and scope to completely dry before

reassembly. Any moisture on the threads will cause the camera and coupler

windows to fog during use.

Page 40

38

Sterrad®

1. Clean and prepare the camera head and cable as recommended in the

“Cleaning and Disinfection” section. Ensure the soaking cap is installed.

2. Double wrap the camera head and cable prior to sterilization.

3. Sterilize the camera head and cable following the instructions of the

manufacturer, using the STERRAD® 100S, 200, NX™, or 100NX™

Sterilization System. Select the standard cycle.

Warning: Not all sterilization trays are compatible with STERRAD® systems.

Using an incompatible tray may result in incomplete device sterilization.

Consult the instructions that came with your sterilization tray to determine

which sterilization method is compatible with your tray and devices.

Ifacompatible tray is not available, the devices can be double-wrapped

priortousing the STERRAD® system.

4. Allow the camera head, cable, coupler, and scope to completely dry before

reassembly. Any moisture on the threads will cause the camera and coupler

windows to fog during use.

Storage

Never store the device in a non-ventilated, humid environment such as a

carrying case. is may present an infection control risk.

Using Sterile Drapes

Using sterile drapes will ensure maximum longevity of your 1288 HD

Camera Head. For best results, follow the instructions provided by the drape

manufacturer.

Page 41

39

User Maintenance

Replacing the Fuses

To avoid the risk of re, use only fuses of the value specied on

the fuse label located on the rear panel of the transmitter.

1. Unplug the power cord from the wall outlet and remove the cord from the

transmitter console.

2. Unlatch the fuse holder above the AC inlet and remove it. (You may need

to press the tab on the fuse holder with a slender screwdriver to release the

latch.)

3. Replace the fuse with the same value and rating.

4. Reinstall the fuse holder until the tab snaps in place.

Periodic Maintenance Schedule

To ensure safe operation of the Model 1288 HD Video Camera

you should periodically perform the following procedure:

Every 12 months, check the earth leakage current to <500µA (<300µA in U.S.A.),

ground protective earth impedance to <0.1 ohms, and power consumption

less than or equal to rated power. Use a true RMS digital multimeter and safety

analyzer to perform this test.

Note: Refer calibration and operating diculties not detailed in this manual to

your Stryker Endoscopy sales representative.

Disposal

is product contains electrical waste or electronic equipment.

It must not be disposed of as unsorted municipal waste and

must be collected separately in accordance with applicable

national or institutional related policies relating to obsolete

electronic equipment.

e 1288 HD must be disposed of according to local laws and hospital practices.

Page 42

40

Technical Specifications

60Hz settings are displayed rst. (50Hz settings follow in parentheses.)

Imaging System 1/3” Progressive Scan CCDs

High Denition

Scanning System Horizontal: 64.00 kHz (60.00 kHz)

Vertical: 60.02 Hz (50.00 Hz)

Video Outputs Digital/

Analog:

Two Digital Video Interface

(DVI)/RGBHV

1280 × 1024 (HD), 720p, 1080p

(HDTV) format

Connector: 29-pin DVI-I

Y/C: One S-VHS

Connector: 4-pin mini-DIN

Digital Fiber: HD, HDTV (R, G, B, Clk)

Connector: Four Lucent ber connectors

with 1.25 mm ferrules

Digital One Displayport 1280 × 1024

(HD), 720p, 1080p (HDTV)

format

Connector 20 pin Displayport

Mounting Endoscope eyepiece used with C-mount coupler

C-mount camera head used with C-mount

scopes

(C-mount coupler/scope thread: 1-32" UN 2A)

Auto Shutter Range 1/60 (1/50) – 1/50,000 second

Operating Conditions Temperature: 5 – 40°C

Relative Humidity: 30 – 95%

Transport and Storage

Conditions

Temperature: -10 – 60°C

Relative Humidity: 10 – 75%

Atmospheric Pressure: 700 – 1060 hPa

Input Electrical Ratings 100 – 240VAC (0.6A) @ 50 – 60Hz

Page 43

41

Total Shipping Weight 13 lbs. (6.0 kg) Camera console

0.5 lbs. (0.226 kg) Coupler

1.5 lbs. (0.680 kg) Camera head

Dimensions Camera Console:

12.5” w × 4.0” h × 15.25” d

(31.8 cm w × 10.2 cm h × 38.7 cm d)

Camera Head Cable to Camera Console:

10.3 (3.15 m) sealed cable

20.7 (6.30 m) cable extension available

Enhancement 16 levels (switchable)

Classication Class I Equipment

Type BF Applied Part

Water Ingress Protection, IPX0—Ordinary

Equipment

Continuous Operation

Complies with Medical

Safety Standards

IEC 60601-1:1988 + A1:1991 + A2:1995

IEC 60601-2-18:1996 + A1:2000

CAN/CSA C22.2 No 601.1-M90

UL 60601-1:2003

AS/NZS 3200.1.0:1998

CSA 22.2.601.1.1:2002

CAN/CSA C22.2 No. 601.2.18:1990

Complies with Medical

EMC Standard

IEC 60601-1-2:2001 + A1:2004

Complies with Laser

Product Standards

Class 1 Laser Product

Contains four 850-nm laser diodes

is product complies with IEC 608251:1993+A1:1997+A2:2001.

is product complies with 21CFR, Subchapter

J, Parts 1040.10 and 1040.11, except for

deviations pursuant to Laser Notice No. 50,

dated July 26, 2001.

Please contact your local Stryker Endoscopy sales representative for information

on changes and new products.

Page 44

42

Electromagnetic Compatibility

Like other electrical medical equipment, the 1288 HD Camera requires special

precautions to ensure electromagnetic compatibility with other electrical medical

devices. To ensure electromagnetic compatibility (EMC), the 1288 HD Camera

must be installed and operated according to the EMC information provided in

this manual.

Note: e 1288HD Camera has been designed and tested to comply with

IEC60601-1-2:2001 requirements for EMC with other devices.

Do not use cables or accessories other than those provided

with the 1288 HD Camera, as this may result in increased

electromagnetic emissions or decreased immunity to such

emissions.

If the 1288 HD Camera is used adjacent to or stacked with other

equipment, observe and verify normal operation of the 1288

HD Camera in the conguration in which it will be used prior

to using it in a surgical procedure. Consult the tables below for

guidance in placing the 1288 HD Camera.

Caution Equipment which employs RF communications may aect the

normal function of the 1288 HD Camera.

Guidance and Manufacturer’s Declaration: Electromagnetic Emissions

1288 HD Camera is intended for use in the electromagnetic environment specied below. The

customer or the user of 1288 HD Camera should ensure that it is used in such an environment.

Emissions test Compliance Electromagnetic Environment -

guidance

RF emissions CISPR 11 Group 1 1288 HD Camera uses RF energy only

for its internal function; therefore, its

RF emissions are very low and are not

likely to cause any interference in nearby

electronic equipment.

RF emissions CISPR 11 Class B The 1288 HD Camera is suitable for

use in all establishments other than

domestic establishments and those

directly connected to the public low-

voltage power supply network that

supplies buildings used for domestic

purposes, provided the following warning

is heeded:

Warning: This system is intended

for use by health care professionals

only. This system may cause radio

interference or may disrupt the operation

of nearby equipment. It may be

necessary to take mitigation measures,

such as reorienting or relocating the

system or shielding the location.

Harmonic emissions

IEC61000-3-2

Class A

Voltage Fluctuations/ icker

emissions IEC61000-3-3

Complies

Page 45

43

Guidance and Manufacturer’s Declaration: Electromagnetic Immunity

1288 HD Camera is intended for use in the electromagnetic environment specied below.

The customer or the user of 1288HD Camera should ensure that it is used in such an environment.

Immunity Test IEC 60601 Test Level Compliance Level Electromagnetic

Environment:

Guidance

Electrostatic Discharge

(ESD) IEC61000-4-2

±6kV contact

±8kV air

±2,4,6kV contact

±2,4,8kV air

Floors should be

wood, concrete, or

ceramic tile. If oors

are covered with

synthetic material,

the relative humidity

should be at least

30%.

Electrical fast transient/

burst IEC61000-4-4

±2kV for power supply

lines

±1kV for input/output

lines

±2kV line to ground

±1kV line to line

Mains power quality

should be that of a

typical commercial or

hospital environment.

Surge

IEC61000-4-5

±1kV differential mode

±2kV common mode

±0.5, 1kV differential

mode

±0.5, 1, 2kV common

mode

Mains power quality

should be that of a

typical commercial or

hospital environment.

Voltage dips, short

interruptions and

voltage variations on

power supply input lines

IEC61000-4-11

<5% Ut (>95% dip in

Ut) for 0.5 cycle

40% Ut (60% dip in

Ut) for 5 cycles

70% Ut (30% dip in

Ut) for 25 cycles

<5% Ut (>95% dip in

Ut) for 5 sec.

<5% Ut (>95% dip in Ut)

for 0.5 cycle

40% Ut (60% dip in Ut)

for 5 cycles

70% Ut (30% dip in Ut)

for 25 cycles

<5% Ut (>95% dip in Ut)

for 5 sec.

Mains power quality

should be that of a

typical commercial or

hospital environment.

If the user of 1288

HD Camera requires

continued operation

during power mains

interruptions, it is

recommended that

1288 HD Camera

be powered from an

uninterruptible power

supply or a battery.

Power frequency

(50/60Hz) magnetic eld

IEC 61000-4-8

3 A/m N/A Power-frequency

magnetic elds

should be at levels

characteristic of a

typical location in a

typical commercial or

hospital environment.

NOTE: Ut is the AC mains voltage prior to application of the test level.

Page 46

44

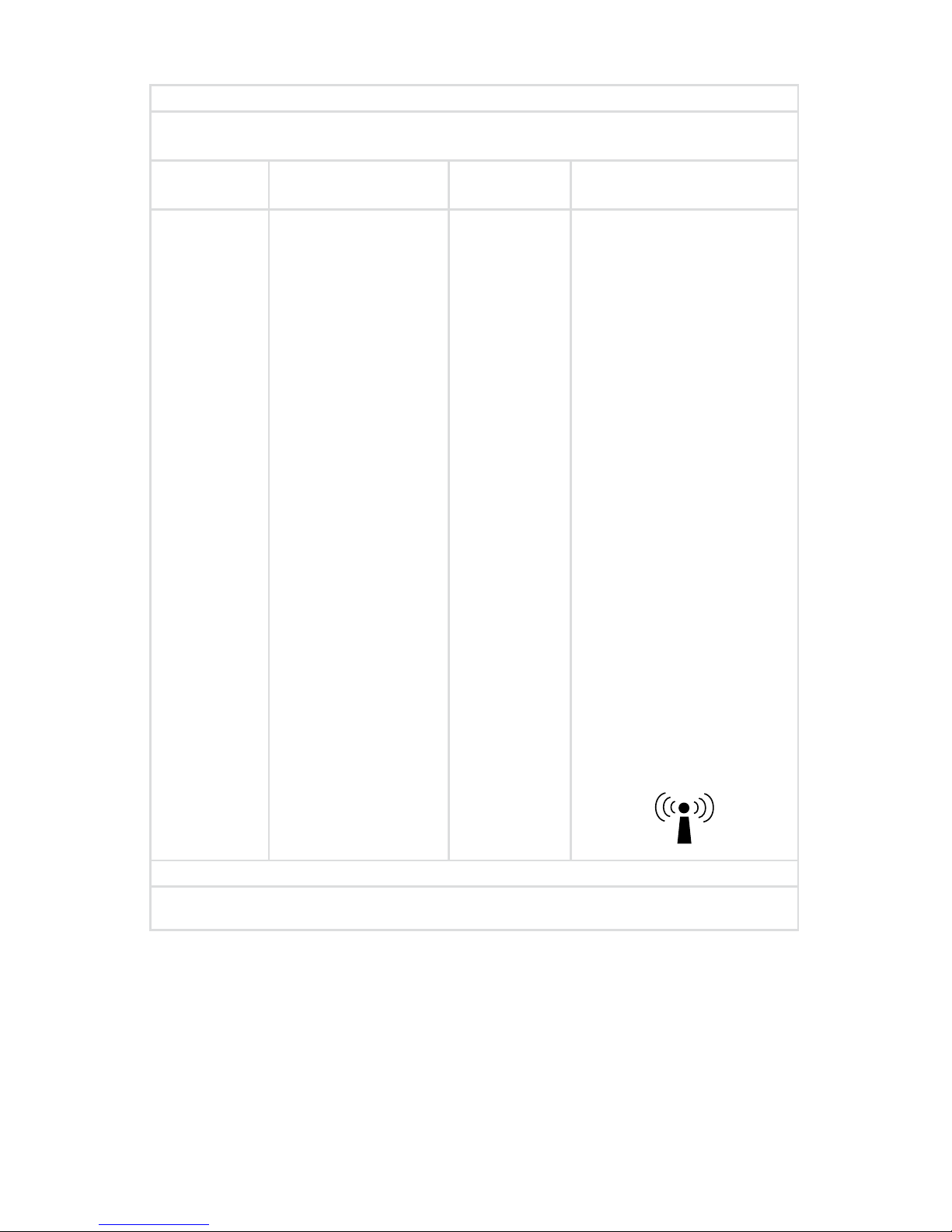

Guidance and Manufacturer’s Declaration: Electromagnetic Immunity

1288 HD Camera is intended for use in the electromagnetic environment specied below.

The customer or the user of 1288 HD Camera should ensure that it is used in such an environment.

Immunity Test IEC 60601 Test Level Compliance

Level

Electromagnetic Environment:

Guidance

Conducted RF

IEC 61000-4-6

Radiated RF

IEC 61000-4-3

3 Vrms

150 kHz to 80 MHz

3 V/m

80MHz to 2.5 GHz

3 V

3 V/m

Portable and mobile RF

communications equipment

should be used no closer to any

part of the 1288 HD Camera

system, including its cables, than

the recommended separation

distance calculated from the

equation applicable to the

frequency of the transmitter.

Recommended Separation

Distance

d = 1.17 √P

d = 1.17 √P 80 MHz to 800 MHz

d = 2.23 √P 800 MHz to 2.5

GHz

where P is the maximum output

power rating of the transmitter

in watts (W) according to the

transmitter manufacturer and d

is the recommended separation

distance in meters (m).

Field strengths from xed RF

transmitters, as determined

by an electromagnetic site

survey

(a)

, should be less than

the compliance level in each

frequency range

(b)

. Interference

may occur in the vicinity of

equipment marked with the

following:

NOTE 1: At 80 MHz and 800 MHz, the higher frequency range applies.

NOTE 2: These guidelines may not apply in all situations. Electromagnetic propagation is affected by

absorption and reection from structures, objects, and people.

Page 47

45

Guidance and Manufacturer’s Declaration: Electromagnetic Immunity

1288 HD Camera is intended for use in the electromagnetic environment specied below.

The customer or the user of 1288 HD Camera should ensure that it is used in such an environment.

(a) Field strengths from xed transmitters, such as base stations for radio (cellular/cordless)

telephones and land mobile radios, amateur radio, AM and FM radio broadcast, and TV broadcast,

cannot be predicted theoretically with accuracy. To assess the electromagnetic environment due to

xed RF transmitters, an electromagnetic site survey should be considered. If the measured eld

strength in the location in which the 1288 HD Camera system is used exceeds the applicable RF

compliance level above, the 1288 HD Camera system should be observed to verify normal operation.

If abnormal performance is observed, additional measures may be necessary, such as reorienting or

relocating the 1288 HD Camera unit.

(b) Over the frequency range 150 kHz to 80 MHz, eld strengths should be less than 3 V/m.

Recommended Separation Distances Between Portable and Mobile RF Communications

Equipment and the 1288 HD Camera System

The 1288 HD Camera system is intended for use in an electromagnetic environment in which

radiated RF disturbances are controlled. The user of the 1288 HD Camera system can help prevent

electromagnetic interference by maintaining a minimum distance between portable and mobile RF

communications equipment (transmitters) and the 1288 HD Camera system as recommended below,

according to the maximum output power of the communications equipment.

Rated maximum output

power (W) of transmitter

Separation distance (m) according to frequency of transmitter

150 kHz to 80 MHz

d = 1.17 √P

80MHZ to 800 MHz

d = 1.17 √P

800 MHz to

2.5 GHz

d = 2.33 √P

0.01 0.12 0.12 0.23

0.1 0.37 0.37 0.74

1 1.17 1.17 2.33

10 3.70 3.70 7.37

100 11.70 11.70 23.30

For transmitters rated at a maximum output power not listed above, the recommended separation

distance (d) in meters (m) can be estimated using the equation applicable to the frequency of the

transmitter, where P is the maximum output power rating of the transmitter in watts (W) according to

the transmitter manufacturer.

NOTE 1: At 80 MHz and 800 MHz, the separation distance for the higher frequency range applies.

NOTE 2: These guidelines may not apply in all situations. Electromagnetic propagation is affected by

absorption and reection from structures, objects, and people.

Page 48

46

Warranty and Return Policy

Product Warranty

Stryker Endoscopy warrants all products, subject to the exceptions provided

herein, to be free from defects in design, materials, and workmanship and

to substantially conform to the product specications contained in the

documentation provided by Stryker Endoscopy with the products for a period of

one year from the date of purchase (the “Warranty Period”). is warranty shall

apply only to the original end-user purchaser of products directly from Stryker

Endoscopy or a Stryker Endoscopy authorized distributor. is warranty may

not be transferred or assigned without the express written consent of Stryker

Endoscopy.

If a valid warranty claim is received within the Warranty Period, Stryker will, in

its sole discretion: (1) repair the product at no charge, (2) replace the product at

no charge with a product that is at least functionally equivalent to the original

product, or (3) refund the purchase price of the product. In any event, Stryker’s

liability for breach of warranty shall be limited to the replacement value of the

defective or non-conforming part or component.

is warranty does not apply to: (1) products that have been misused,

neglected, modied, altered, adjusted, tampered with, improperly installed or

refurbished; (2) products that have been repaired by any person other than

Stryker Endoscopy personnel without the prior written consent of Stryker

Endoscopy; (3) products that have been subjected to unusual stress or have not

been maintained in accordance with the instructions in the user manual or as

demonstrated by a Stryker Endoscopy representative; (4) products on which

any original serial numbers or other identication marks have been removed

or destroyed; or (5) products that have been repaired with any unauthorized or

non-Stryker components, including replacement lamps.

If Stryker determines in its reasonable discretion that the claimed defect or nonconformance in the product is excluded from warranty coverage as described

hereunder, it will notify the customer of such determination and will provide an

estimate of the cost of repair of the product. In such an event, any repair would

be performed at Stryker’s standard rates.

Products and product components repaired or replaced under this warranty

continue to be warranted as described herein during the initial Warranty Period

or, if the initial Warranty Period has expired by the time the product is repaired

or replaced, for thirty (30) days aer delivery of the repaired or replaced product.

When a product or component is replaced, the item provided in replacement will

be the customer’s property and the replaced item will be Stryker’s property. If a

refund is provided by Stryker, the product for which the refund is provided must

be returned to Stryker and will become Stryker’s property.

Page 49

47

e inspection, testing, acceptance, or use of the products and services furnished

hereunder shall not aect Stryker’s obligation under this warranty, and such

warranty shall survive inspection, test, acceptance, and use.

Notwithstanding the above, the following products are warranted for a period of

ninety (90) days from the date of purchase: Scopes, Associated Scope Hardware,

Fiber Optic Cables, Laparoscopic Instruments, VCRs, Monitors, and Printers;

replacement light bulbs are warranted for a period of sixty (60) days from the

date of purchase.

TO THE FULLEST EXTENT PERMITTED BY LAW, THE EXPRESS

WARRANTY SET FORTH HEREIN IS THE ONLY WARRANTY APPLICABLE

TO THE PRODUCTS AND IS EXPRESSLY IN LIEU OF ANY OTHER

WARRANTY BY STRYKER, EXPRESSED OR IMPLIED, INCLUDING, BUT

NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. EXCEPT AS SPECIFICALLY

PROVIDED IN THIS WARRANTY AND TO THE EXTENT PERMITTED

BY LAW, STRYKER IS NOT RESPONSIBLE FOR INDIRECT, SPECIAL,

INCIDENTAL OR CONSEQUENTIAL DAMAGES RESULTING FROM ANY

BREACH OF WARRANTY OR UNDER ANY OTHER LEGAL THEORY.

Return Policy

Stryker Endoscopy values customer relationships and strives for satisfaction in

purchases made by our customers. erefore, we oer a return policy for most

products. Under this policy, customers may return purchased products to Stryker

Endoscopy, within 90 days of customer’s receipt of the product, for a credit or

a refund of the purchase price paid, less shipping and handling and applicable

restocking fees. Products that fail aer the rst 90 days may be covered by and

are subject to the terms of applicable product warranty. Sterile products may

not be returned for credit or refund unless they are in their original, unopened

packaging or unless they are in breach of the applicable warranty.

Restocking Fees: Unless the product is defective or the return is the direct result

of a Stryker Endoscopy error, a restocking fee of 10% may be charged on all

returned products.

A Returned Merchandise Authorization (RMA) number must be obtained from

Stryker Endoscopy before returning product. To obtain an RMA number, please

contact Stryker Endoscopy Customer Service at 1.800.624.4422.

Please send any returned products to:

Stryker Endoscopy

Attn: Returns

5900 Optical Court

San Jose, CA 95138

Page 50

48

With the return, please include the following:

1. RMA number

2. Purchase order number

3. Original invoice number

4. Name, address, and account number (of the organization

returning the product)

5. Itemized list of the items being returned

6. Reason for the return

7. Product Experience Report/Complaint number, if applicable

Please carefully package the product being returned. Credit will not be given

foritems that are damaged in return shipment due to inadequate packaging.

Stryker Endoscopy does not accept any COD returns. Return shipping costs are

borne by the customer unless Stryker Endoscopy specically agrees otherwise.

Please clean and sterilize all potentially contaminated products prior to returning

them to Stryker Endoscopy. It is unlawful to transport bio-contaminated products

through interstate commerce, unless they are properly packaged and labeled as

such. Stryker Endoscopy reserves the right to destroy contaminated product at

the customer’s expense and charge the customer for a replacement unit.

If a return does not comply with these terms, Stryker Endoscopy reserves the

right to destroy the product at the customer’s expense. Any replacement would

be at the customer’s expense.

Page 51

Page 52

Stryker Endoscopy

5900 Optical Court

San Jose, CA 95138 USA

1-408-754-2000, 1-800-624-4422

www.stryker.com

European Representative:

Regulatory Manager, Stryker France

ZAC Satolas Green Pusignan

Av. De Satolas Green

69881 MEYZIEU Cedex, France

1000401140 D

2010/08

Products referenced with a ™ designation are trademarks of Stryker.

Products referenced with a ® designation are registered trademarks of Stryker.

STERRAD® is a registered trademark of Advanced Sterilization Products,

Division of Ethicon Inc., a Johnson and Johnson company.

STERRAD NX™ and STERRAD 100NX™ are trademarks of Advanced Sterilization

Products, Division of Ethicon Inc., a Johnson and Johnson company.

Loading...

Loading...