Page 1

Prime™ Series Stretcher

1115

Big Wheel

Operations Manual

For parts or technical assistance call:

USA: 1-800-327-0770

2012/09 D.3 1115 -109 - 0 01 R EV D www.stryker.com

Page 2

Page 3

Table of Contents

Symbols and Definitions ....................................................................5

Symbols ............................................................................5

Warning/Caution/Note Definition ...........................................................6

Introduction .............................................................................7

Product Description ....................................................................7

Intended Use of Product.................................................................7

Intended Use of Product - Prime X Option ...................................................7

Specifications ........................................................................9

Specifications - Optional Scale System (Non-Electric Litter/Electric Litter Option) .....................11

Product Illustration - Electric Litter Option...................................................12

Product Illustration - Prime X Option.......................................................13

Contact Information ...................................................................14

Serial Number Location ................................................................14

Summary of Safety Precautions .............................................................15

Setup Procedures........................................................................20

Operation Guide.........................................................................21

Applying the Brake System..............................................................21

Operating the Base Controls - Side Control Hydraulics .........................................22

Operating the Base Controls - Optional Three-Sided and Four-sided Control Hydraulics.................23

Raising and Lowering the Litter Height - Optional Electric Lift ....................................24

Adjusting Trendelenburg/Reverse Trendelenburg Positions - Side Control Hydraulics ...................25

Adjusting Trendelenburg/Reverse Trendelenburg Positions - Optional Three-Sided or Four-Sided Control Hydraulics 25

Operating the Big Wheel®..............................................................26

Operating the Siderails.................................................................27

Operating the Siderail Patient Controls - Optional Electric Litter (Not Available With Prime X Option) .......28

Operating the Foot End Nursing Controls - Optional Electric Litter (Not Available With Prime X Option)......29

Using Patient Control Lockout - Optional Electric Litter (Not Available With Prime X Option)..............30

Operating the Optional Push Handles......................................................30

Operating the Pneumatic Fowler - Non-Electric...............................................31

Operating the Fowler - Optional Electric Litter (Not Available With Prime X Option) ....................32

Operating the Optional Gatch - Non-Electric (Not Available With Prime X Option)......................33

Operating the Gatch - Optional Electric Litter (Not Available With Prime X Option).....................34

Operating the Recovery Chair (Not Available With Prime X Option) ................................35

Using the Base Hood for Storage .........................................................36

Using the Optional Pump Rack...........................................................37

Using the Optional Retractable Cord Reel - Electric Lift/Litter Option...............................38

Operating the Optional Scale System......................................................39

Operating the Optional Scale System - Non-Electric Litter.......................................40

Replacing the Optional Scale System Batteries - Non-Electric Litter ...............................41

Operating the Optional Scale System - Electric Litter Option Without Chaperone (Not Available With Prime X Option) 42

Charging the Optional Scale System Battery Pack - Electric Litter Option (Not Available With Prime X Option) 43

Operating the Optional Scale System - Electric Litter Option With Chaperone (Not Available With Prime X Option) 44

www.stryker.com 1115 -10 9 - 0 01 R EV D 3

Page 4

Table of Contents

Operating the Chaperone (Stretcher Exit) Option (Not Available With Prime X Option) ..................45

Charging the Optional Scale System Battery Pack - Electric Litter Option with Chaperone (Not Available With

Prime X Option) ......................................................................45

Operating the Chaperone (Stretcher Exit) Option - Optional Setup (Not Available With Prime X Option) .....46

Using X-Ray Cassettes - Prime X Option ...................................................47

Using the Defibrillator Tray ..............................................................48

Using the Foot Extension/Defibrillator Tray ..................................................48

Using the Footboard/Chartholder .........................................................49

Using the I.V. Caddy ...................................................................49

Operating the Foot Supports (Not Available With Prime X Option) .................................50

Operating the Two-Stage Permanently Attached I.V. Pole .......................................52

Operating the Three-Stage Permanently Attached I.V. Pole .....................................53

Operating the Removable I.V. Pole ........................................................54

Installing the Siderail Pads ..............................................................54

Using the Upright Oxygen Bottle Holder ....................................................55

Using the Serving Tray .................................................................55

Using the Restraint Straps ..............................................................56

Using the Upright X-Ray Cassette Holder ...................................................57

Using the Lateral Cassette Holder ........................................................58

Cleaning...............................................................................59

Stretcher Cleaning....................................................................59

Mattress Cleaning ....................................................................60

Preventative Maintenance ..................................................................62

Checklist ..........................................................................62

Preventative Maintenance ..................................................................63

Checklist (Continued)..................................................................63

EMC Information.........................................................................64

Optional Electric Lift/Litter and Optional Scale System .........................................64

Warranty ..............................................................................68

Limited Warranty .....................................................................68

To Obtain Parts and Service ............................................................68

Service Contract Coverage .............................................................68

Service Contract Programs .............................................................69

Return Authorization...................................................................69

Damaged Merchandise ................................................................69

International Warranty Clause............................................................69

Recycling Passport ......................................................................70

4 1115 -10 9 - 0 01 R EV D www.stryker.com

Page 5

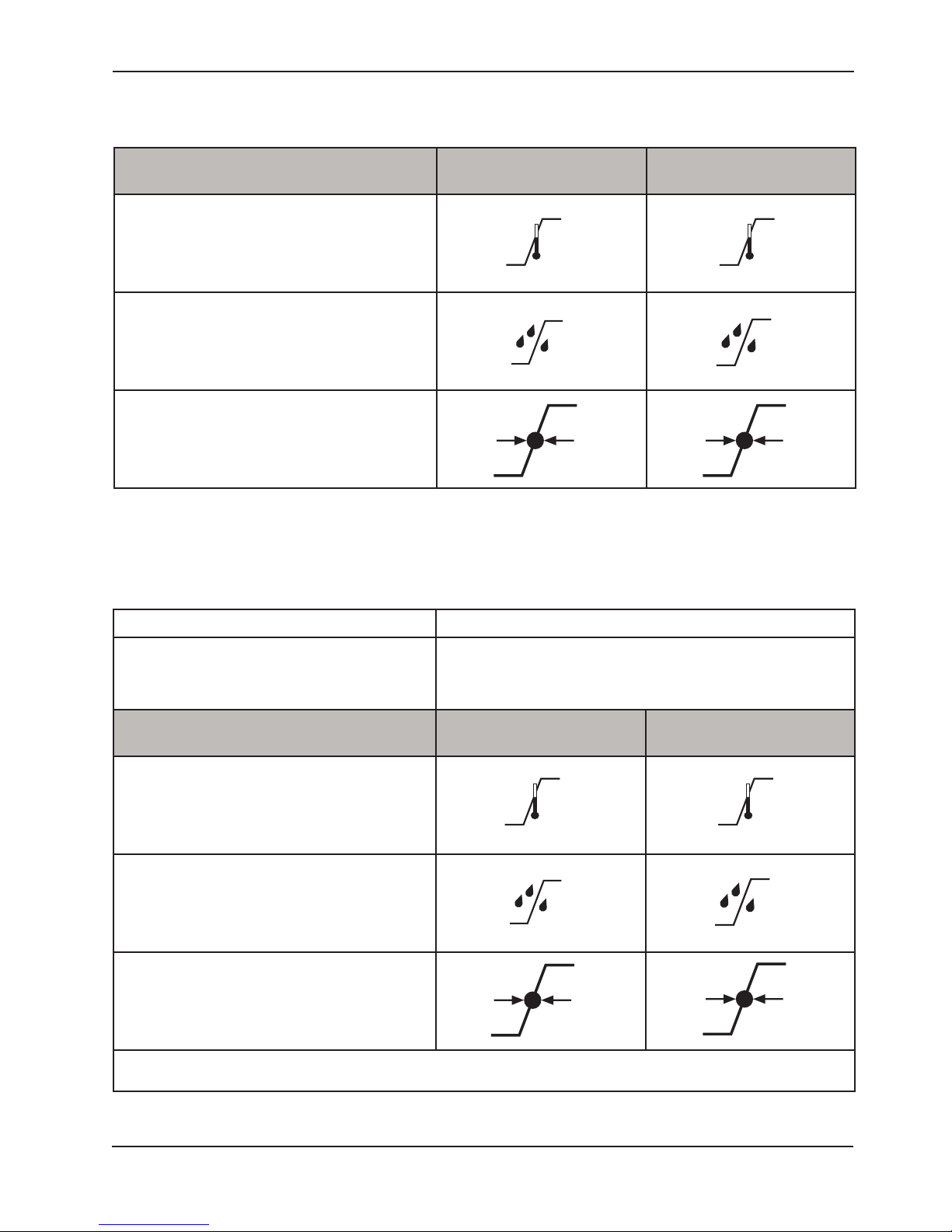

SYMBOLS

~

Symbols and Definitions

Warning/Caution: Consult accompanying documentation

Safe Working Load indicates the sum of the patient, mattress, and accessory weight

In accordance with European Directive 2002/96/EC on Waste Electrical and Electronic

Equipment, this symbol indicates that the product must not be disposed of as unsorted

municipal waste, but should be collected separately. Refer to your local distributor for

return and/or collection systems available in your country.

Manufacturer

Do not store oxygen bottle

Do not push/pull

IPX6

Alternating Current

Direct Current

Type B Equipment: equipment providing a particular degree of protection against electric

shock, particularly regarding allowable leakage current and reliability of the protective

earth connection.

Class 1 Equipment: equipment in which protection against electric shock does not rely on

basic insulation only, but which includes an additional safety precaution in that means are

provided for the connection of the equipment to the protective earth conductor in the fixed

wiring of the installation in such a way that accessible metal parts cannot become live in

the event of a failure of the basic insulation.

Dangerous Voltage

Protective Earth Terminal

Protection from Liquid Jet

www.stryker.com 1115 -10 9 - 0 01 R EV D 5

Return To Table of Contents

Page 6

Symbols and Definitions

Medical Equipment Classified by Underwriters Laboratories Inc. with Respect to Electric

Shock, Fire, Mechanical and Other Specified Hazards Only in Accordance with UL

87VL

MEDICAL

ELECTR ICAL

EQUIPMENT

UL 60601-1

CAN/CSA C 22.2

N0. 601.1

*IEC 60601-

2-32:1994

WARNING/CAUTION/NOTE DEFINITION

The words WARNING, CAUTION and NOTE carry special meanings and should be carefully reviewed.

60601-1 First Edition (2003) and CAN/CSA C22.2 No. 601.1.

*For Prime-X Option, Associated Equipment of X-Ray Equipment IEC 60601-2-32:1994

Non-Ionizing Radiation

WARNING

Alerts the reader about a situation which, if not avoided, could result in death or serious injury. It may also describe

potential serious adverse reactions and safety hazards.

CAUTION

Alerts the reader of a potentially hazardous situation which, if not avoided, may result in minor or moderate injury to the

user or patient or damage to the equipment or other property. This includes special care necessary for the safe and

effective use of the device and the care necessary to avoid damage to a device that may occur as a result of use or

misuse.

NOTE

Provides special information to make maintenance easier or important instructions clearer.

Return To Table of Contents

6 1115 -10 9 - 0 01 R EV D www.stryker.com

Page 7

Introduction

This manual is designed to assist you with the operation of Stryker Model 1115 Prime Series Stretcher. Read this

manual thoroughly before using the equipment or beginning maintenance on it. To ensure safe operation of this

equipment, it is recommended that methods and procedures be established for educating and training staff on the safe

operation of this stretcher.

PRODUCT DESCRIPTION

The Stryker Model 1115 Prime Series Stretcher with Big Wheel® decreases start-up force by 50 percent and steering

effort by 60 percent.

INTENDED USE OF PRODUCT

The Stryker Model 1115 Prime Series Stretcher is a wheeled device which consists of a platform mounted on a wheeled

frame that is designed to support patients in a horizontal position. The device has siderails and has the option available

to support the temporary or permanent placement of I.V. poles. A stretcher provides the caregiver a method of

transporting patients within a healthcare facility. The device has a two Big Wheels which reduces the required start-up

force to move the stretcher. Some stretchers may also be used for minor procedures and short-term stay (treatment

and recovery).

INTENDED USE OF PRODUCT - PRIME X OPTION

The Prime X option provides a platform for the short-term outpatient clinical evaluation and treatment of human patients

and additionally may be used for minor procedures and short-term outpatient stay (treatment and recovery). The Prime

X option provides an articulating radiographic patient support surface and a platform below the patient support surface

for X-Ray cassette placement to allow the capture of clinical X-Rays (AP Full Body, optional Full Body Lateral, and

optional Upright Chest) when used in conjunction with a medical X-Ray system. The Prime X option is a wheeled device

consisting of a platform mounted on a wheeled frame that is designed to transport patients in a horizontal position

within the interior of a healthcare facility by health professionals and/or trained representatives of the user facility. The

device has siderails and optional supports for fluid infusion equipment.

The Prime X option is intended to be used to transport patients to and from all departments within the interior of a

healthcare facility. The use of the Prime X option as a short-term outpatient clinical evaluation, treatment, minor

procedure, and short-term outpatient recovery platform may include use in, but not limited to, the Emergency Department

(ED), including the Trauma area, and Post-Anesthesia Care Unit (PACU). The Prime X option is not intended to be used

for long-term inpatient treatment and recovery. See the specification table in the operations manual of the device for

the intended environmental conditions.

The Prime X option has a safe working load up to 700 pounds (318 kg) and is intended to be used with all patients,

including those mildly to critically ill. The stretcher may also be used to transport deceased patients within an enclosed

healthcare facility.

The Prime X option has an optional scale system intended to measure and display weight in pounds or kilograms of

patients weighing 50 to 700 pounds (22.7 to 318 kg) and patients not exceeding the height of 75.25 inches (191 cm).

See the specification table for accuracy claims.

The Prime X option has an expected life of 10 years under normal use, conditions, and with appropriate periodic

maintenance as described in the maintenance manual for each device.

The Prime X option is not recommended for use with a Stryker Pioneer mattress or a mattress with a thickness

greater than four inches and is not compatible for use with a C-Arm. The Prime X option is intended for use in all

establishments other than home healthcare, domestic, and those directly connected to the public low voltage power

supply network that supplies buildings used for domestic purposes.

www.stryker.com 1115 -10 9 - 0 01 R EV D 7

Return To Table of Contents

Page 8

IntroductionIntroduction

INTENDED USE OF PRODUCT - PRIME X OPTION (CONTINUED)

The Prime X option has the following options available: three-sided brake/steer pedal controls, three-sided and foursided hydraulic lift controls, powered lift controls, dual siderail latch assembly, slider board assembly, pump bar, I.V.

pole(s), restraint straps, defibrillator tray, defibrillator tray/foot extender, footboard/chartholder, serving tray, serving tray

holder/footboard, siderail pads, upright oxygen bottle holder, and I.V. caddy and may include other options as described

in the operations manual.

Return To Table of Contents

8 1115 -10 9 - 0 01 R EV D www.stryker.com

Page 9

SPECIFICATIONS

IntroductionIntroduction

26” Width 30” Width Option

Safe Working Load

Note: Safe Working

Load indicates the sum

of the patient, mattress,

and accessory weight.

Overall Stretcher Length 85” (± .5”) 215.9 cm 85” (± .5”) 215.9 cm 85” (± .5”) 215.9 cm

Overall Stretcher Width

(Siderails Up)

Overall Stretcher Width

(Siderails Down)

Minimum/Maximum

Stretcher Height

Fowler Angle 0° to 90° (± 5°)

Gatch Height 5.5” (14 cm) minimum Not applicable

Trendelenburg/Reverse

Trendelenburg

Minimum UnderStretcher Clearance

Attenuation Equivalent

(Aluminum Equivalence)

700 lb 318 kg 700 lb 318 kg 700 lb 318 kg

34” (± 1”) 86.4 cm 38” (± 1”) 96.5 cm 38” (± 1”) 96.5 cm

30.25”

(± .5”)

20.75” /

34” (± 1”)

+17°/-17° (± 3 °)

2.5”

nominal

1.75”

under the

hydraulic

jacks and

fifth wheel

1” under

the Big

Wheel

Not applicable

76.8 cm

52.7 cm /

86.4 cm

6.4 cm

4.5 cm

2.5 cm

30.5”

(± .5”)

20.75” /

34” (± 1”)

2.5”

nominal

1.75”

under the

hydraulic

jacks and

fifth wheel

1” under

the Big

Wheel

77.5 cm

52.7 cm /

86.4 cm

6.4 cm

4.5 cm

2.5 cm

Prime X Option

30” Width

30.5”

(± .5”)

23.25” /

36.5” (± 1”)

2.5”

nominal

1.75”

under the

hydraulic

jacks and

fifth wheel

1” under

the Big

Wheel

Maximum Value

Allowed is 1.7 mm Al

77.5 cm

59.1 cm /

92.7 cm

6.4 cm

4.5 cm

2.5 cm

www.stryker.com 1115 -10 9 - 0 01 R EV D 9

Return To Table of Contents

Page 10

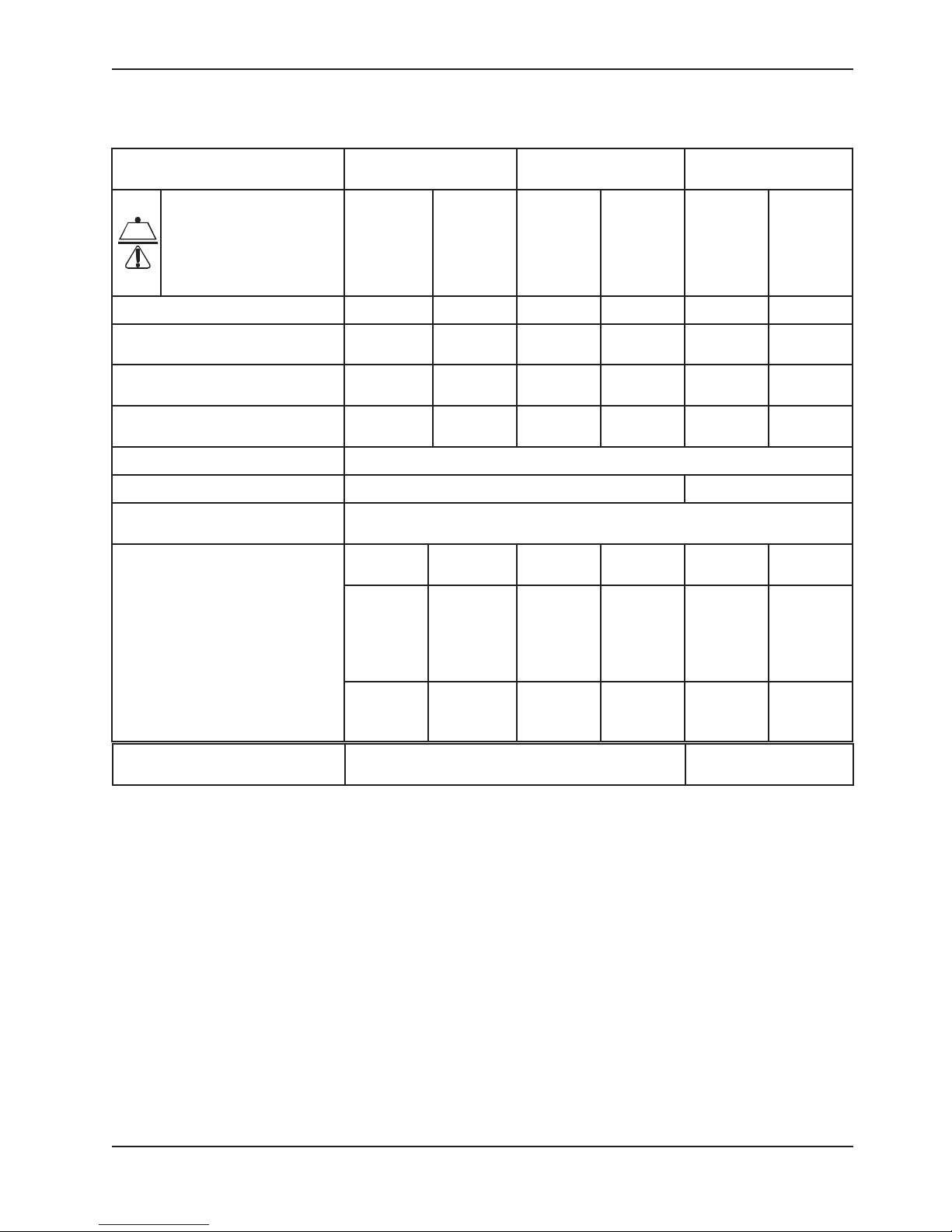

IntroductionIntroduction

SPECIFICATIONS (CONTINUED)

Electric Options Optional Electric Litter Optional Electric Lift

Electrical Requirements

Duty Cycle

Optional Scale System Non-Electric Litter Optional Electric Lift

Bat tery Type

Battery Voltage

Optional Scale System Optional Electric Litter Optional Electric Lift

Bat tery Type

Battery Voltage

Optional Scale System with

Chaperone (Stretcher Exit)

Bat tery Type

Battery Voltage

120V~, 60Hz, 10 A 120V~, 60Hz, 10 A

Continuous operation with intermittent loading is 1

min ON/20 min OFF

4 x AA Battery (4 X 1.5V ) Alkaline Type (LR6)

6.0V 6.0V

1 x Rechargeable Lithium Ion

Battery Pack (0058-135-000)

10.8V , 2.4Ah

Optional Electric Litter Optional Electric Lift

1 x Rechargeable Lithium Ion

Battery Pack (0058-134-000)

10.8V , 4.8Ah

Continuous operation

with intermittent loading

is 1 min ON/20 min OFF

4 x AA Battery (4 X 1.5V

) Alkaline Type (LR6)

Not applicable

Not applicable

Not applicable

Not applicable

Stryker reserves the right to change specifications without notice.

Note: Equipment not suitable for use in the presence of a flammable anesthetic mixture with air or with oxygen or

nitrous oxide.

Return To Table of Contents

10 1115 -10 9 - 0 01 R EV D www.stryker.com

Page 11

SPECIFICATIONS (CONTINUED)

Environmental Conditions Operation Storage and Transportation

IntroductionIntroduction

Temperature

0

50 F

0

(10 C)

0

100 F

0

(38 C)

75%

0

-4 F

0

(-20 C)

140 F

0

(60 C)

95%

0

Relative Humidity

30%

106 0 h Pa

10%

106 0 h Pa

Atmospheric Pressure

700 hPa

500 hPa

Specifications listed are approximate and may vary slightly from unit to unit or by power supply fluctuations.

SPECIFICATIONS - OPTIONAL SCALE SYSTEM (NON-ELECTRIC LITTER/ELECTRIC LITTER OPTION)

Optional Scale System Weight Operating Range 50 lb (22.7 kg) to 700 lb (318 kg)

Optional Scale System Accuracy

±3 lb (1.3 kg) for weights less than 100 lb (45 kg) and ±3% for

weights greater than or equal to 100 lb (45 kg) *

Environmental Conditions Operation Storage and Transportation

Temperature

0

61 F

0

(16 C)

0

79 F

0

(26 C)

75%

0

-4 F

0

(-20 C)

0

140 F

0

(60 C)

95%

Relative Humidity

30%

106 0 h Pa

10%

106 0 h Pa

Atmospheric Pressure

700 hPa

500 hPa

* To meet this accuracy claim, the patient surface must be in the flat position (fowler and gatch down) and the

stretcher cannot exceed 5 degrees of Trendelenburg/reverse Trendelenburg.

www.stryker.com 1115 -10 9 - 0 01 R EV D 11

Return To Table of Contents

Page 12

IntroductionIntroduction

PRODUCT ILLUSTRATION - ELECTRIC LITTER OPTION

Optional

Pop Up Push

Handle

Siderail

Push Pedal

Uni-Lower

Pedal

Brake/Steer

Control Pedal

Option

Integrated

Bumpers

Casters with

Integrated

Wheel Covers

Optional Siderail

Patient Controls

Gatch Release

Brake/Steer

Control Pedal

Optional

Handle

Siderail

Release

Siderail

Optional Patient

Control Lockout

Optional

Scale

System

Optional

Pump Rack

Optional Foot

End Nursing

Controls

Figure 1: Electric Litter Option

Return To Table of Contents

12 1115 -10 9 - 0 01 R E V D www.stryker.com

Page 13

IntroductionIntroduction

PRODUCT ILLUSTRATION - PRIME X OPTION

Optional

Pop Up Push

Handle

Cassette Tray

Patient

Surface with

Clear View

Technology

Pump Pedal

Uni-Lower

Pedal

Control Pedal

Brake/Steer

Option

Casters with

Integrated

Wheel Covers

Figure 2: Prime X Option

Integrated

Bumpers

Siderail

Release

Siderail

Brake/Steer

Control Pedal

Optional

Scale System

Optional

Pump Rack

www.stryker.com 1115 -10 9 - 0 01 R EV D 13

Return To Table of Contents

Page 14

Introduction

CONTACT INFORMATION

Contact Stryker Customer Service or Technical Support at: (800) 327-0770 or (269) 324-6500.

Stryker Medical

3800 E. Centre Avenue

Portage, MI 49002

USA

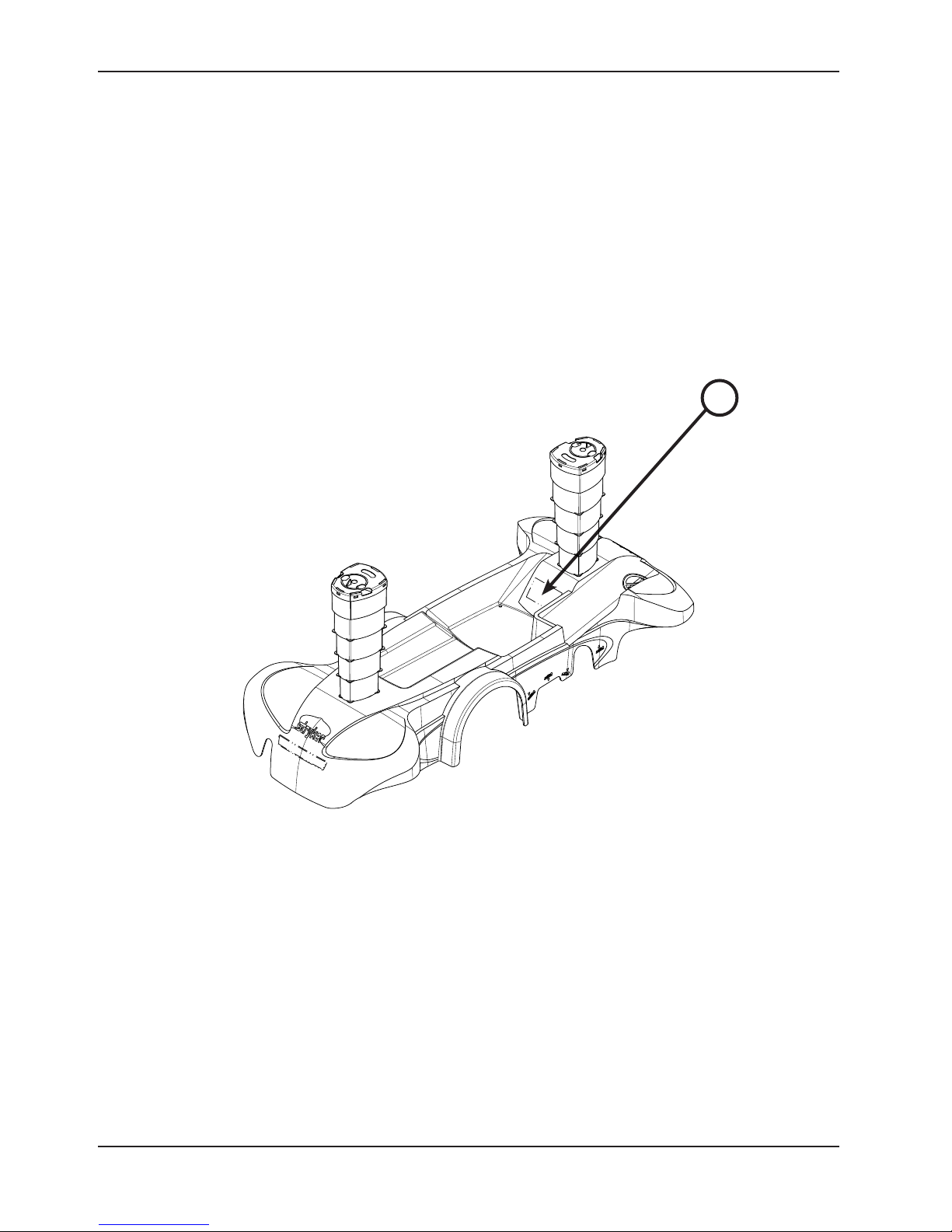

Please have the serial number (A) of your Stryker product available when calling Stryker Customer Service or Technical

Support. Include the serial number in all written communication.

SERIAL NUMBER LOCATION

A

Return To Table of Contents

14 1115 -10 9- 00 1 R E V D www.stryker.com

Figure 3: Serial Number Loction

Page 15

Summary of Safety Precautions

Carefully read and strictly follow the warnings and cautions listed on this page. Service only by qualified personnel.

See the maintenance manual for additional information.

WARNING

• This stretcher is equipped with a hospital grade plug for protection against electric shock hazard. It must be

plugged directly into a properly grounded three-prong receptacle. Grounding reliability can be achieved only when

a hospital grade receptacle is used.

• Always apply the brakes when a patient is getting on or off the stretcher. Push on the stretcher to ensure that the

brakes are securely locked. Always engage the brakes unless the stretcher is being moved. Injury could result if

the stretcher moves while a patient is getting on or off the stretcher.

• Patients should be discouraged from sitting directly on the ends of the stretcher. Excessive weight could cause

the litter surface to tip up, possibly causing patient injury.

• Leave the stretcher height in the lowest position when the patient is left unattended. Leaving the stretcher height

in a raised position could increase the chance of patient falls and injury.

• Make sure that the brakes are completely released before attempting to move the unit. Attempting to move the unit

with the brakes engaged could result in injury to the user and/or patient.

• After raising the siderails, pull firmly on the siderail to ensure that it is securely locked into the up position. Siderails

are not intended to serve as a patient restraint device to keep patients from exiting the unit. Siderails are intended

to keep a patient from inadvertently rolling off the unit. It is the responsibility of the attending medical personnel

to determine the degree of restraint necessary to ensure that a patient will remain in place. Failure to utilize the

siderails properly could result in patient injury.

• When lowering the siderail to the collapsed position, keep extremities of patients and staff away from the siderail

spindles or injury could occur.

• Powered stretcher mechanisms can cause serious injury. Operate stretcher only with persons clear of mechanisms.

• Operation of the fowler is a manual procedure. Use caution when raising the fowler while a patient is on the

stretcher. Use proper lifting techniques and get additional assistance, if necessary. Failure to use proper lifting

techniques could cause injury to the operator.

• Keep hands/fingers clear of the area around the fowler release handle and the fowler frame when lowering the

fowler. Injury could result if care is not taken when lowering the fowler.

• To avoid the risk of injury, ensure that the gatch prop rod is fully raised and securely placed into position.

• Use caution when operating the gatch while a patient is on the stretcher. Powered stretcher mechanisms can

cause serious injury. Operate stretcher only with persons clear of mechanisms.

• Use caution when operating the recovery chair while a patient is on the stretcher. Powered stretcher mechanisms

can cause serious injury. Operate stretcher only with persons clear of mechanisms.

• To avoid patient injury or equipment damage, all lines from any equipment stored on the pump rack must be

diverted away from the gatch handles.

• To avoid patient injury or equipment damage, do not lift the stretcher by the pump rack.

• To avoid equipment damage, remove any equipment from the pump rack that may be in the way before lowering

the litter.

• To avoid equipment damage while transporting the stretcher, verify that any equipment on the pump rack can

safely pass through door openings and under light fixtures.

• When using the Prime X option in conjunction with devices that generate X-radiation, the generating devices may

produce residual, stray, and/or scattered radiation. Users should refer to local, state, and federal use guidelines

as well as appropriate facility protocols for safety before use. Special attention should be given when performing

X-Rays with the stretcher’s fowler in the upright position and also when performing X-Rays using a lateral cassette.

www.stryker.com 1115 -10 9 - 0 01 R EV D 15

Return To Table of Contents

Page 16

Summary of Safety Precautions

WARNING (CONTINUED)

• The Prime X option is not recommended for use with a Stryker Pioneer mattress or a mattress with a thickness

greater than four inches and is not compatible for use with a C-Arm.

• To avoid the risk of injury to the patient or user or damage to the I.V. pole while transporting the stretcher, make

sure that the I.V. caddy is securely tightened on the I.V. pole.

• To avoid the risk of patient injury or equipment damage, do not sit on the foot support.

• Physical restraints, even if properly secured, may result in serious harm to patients and caregivers. The use of

restraint straps may potentially cause entanglement, entrapment, physical injury, and/or death. Caution must be

used in affixing restraint straps to avoid potential injury to both patients and caregivers.

• Restraint straps and/or devices must be attached only at the identified attachment points of the unit. Failure to do

so may result in patient or caregiver injury. Do not attach restraints straps to the siderail.

• This unit accommodates the use of ankle, chest, wrist, and body restraints. The use of restraint straps is regulated

by state and federal restrictions. Users, caregivers, and/or practitioners should refer to the applicable state and

federal restrictions and the appropriate facility protocols before using any restraint strap and/or device.

• If your unit is equipped with the optional electric lift/litter, unplug the power cord from the power outlet before

transporting or cleaning the unit. To unplug, grasp the mold near the outlet and pull the cord in a direction parallel

to the floor (not at an angle).

• This device does not offer any protection against X-Ray radiation.

• Do not steam clean the unit.

• Medical electrical equipment (such as the optional scale system or optional electric lift/litter) requires special

precautions regarding EMC and needs to be installed and put into service according to the EMC information

provided on page 64 to prevent equipment malfunction.

• Portable and mobile RF communication equipment can affect Medical Electrical Equipment (such as the optional

scale system or optional electric lift/litter).

• To avoid malfunction, the optional scale system or optional electric lift/litter should not be used adjacent to or

stacked with other equipment. If adjacent or stacked use is necessary, the optional scale system or optional

electric lift/litter should be observed to verify normal operation in the configuration in which it will be used.

• When using any mattress thicker than 2.5 inches or when using a mattress overlay with the Prime X option, extra

caution and operator supervision is recommended to reduce the risk of patient falls due to lesser siderail coverage.

CAUTION

• This stretcher is not intended for pediatric use or for patients under 50 lb. This stretcher is intended for use by

trained hospital personnel only.

• Do not modify this stretcher. Modifying the unit can cause unpredictable operation resulting in injury to the patient

or operator. Modifying the unit will also void its warranty.

• To avoid damage, remove any equipment that may be in the way before raising or lowering the litter height.

• Do not raise the unit (hydraulics on base) with a patient lift under the stretcher.

• To avoid injury or damage to the equipment, do not allow the siderail to lower on its own.

• The weight capacity of the gatch is 200 lb. Do not sit or stand on the gatch. Injury or damage to the equipment

could occur.

• To achieve recovery chair position, your stretcher must be equipped with the lift assist backrest and gatch options.

• The weight capacity of the base hood is 60 lb. Do not sit or stand on the base hood. Injury or damage to the

equipment could occur.

• Do not step on the base hood.

• Do not engage the steer pedal when the Big Wheel is resting on a threshold or other raised area. The force

required to engage the Big Wheel will be higher than normal, possibly causing damage.

• Do not use the cutout for the oxygen bottle holder on the base hood for the storage of oxygen bottles or patient

belongings.

Return To Table of Contents

16 1115 -10 9 - 0 01 R EV D www.stryker.com

Page 17

Summary of Safety Precautions

CAUTION (CONTINUED)

• The weight capacity of the pump rack is 40 lb.

• Do not use the pump rack as a push/pull device, because equipment damage could occur.

• To avoid damage, do not put items weighing more than 30 lb on the defibrillator tray.

• To avoid risk of patient or operator injury, ensure that all devices placed on the defibrillator tray are securely

strapped to the tray.

• Do not use the defibrillator tray as a push/pull device, because equipment damage could occur.

• If the stretcher is equipped with the optional foot end I.V. pole, the I.V. pole must be in the raised position when the

foot extension/defibrillator tray is installed. If the I.V. pole is not raised, the foot extension will not function properly

and injury could occur.

• The push handles were designed for use while transporting the stretcher. Avoid using other parts of the stretcher

as push/pull devices because damage could occur.

• To avoid damage, do not put items weighing more than 30 lb on the foot extender/defibrillator tray.

• Do not use the foot extension/defibrillator tray as a push/pull device, because equipment damage could occur.

• Do not use the footboard/chartholder as a push/pull device because equipment damage could occur.

• Always store the I.V. caddy when not in use to avoid damaging it when the unit is moved.

• To avoid the risk of equipment damage, do not use the foot support to store patient belongings or other items.

• To avoid injury to the operator, ensure that the operator’s fingers are clear of the mechanism when positioning the

foot support.

• Foot supports should be in the stored position when moving. The stretcher should be in brake position when foot

supports are in use.

• To avoid the risk of damage to the equipment, do not use the foot support as a push/pull device.

• To avoid injury to the patient or operator, ensure foot supports are tightened securely prior to use.

• If the stretcher is equipped with the scale system option, the scale should not be utilized while the foot supports

are in use because inaccurate readings may occur.

• If the stretcher is equipped with the chaperone option, the chaperone option should not be utilized while the foot

supports are in use because false readings may occur.

• To avoid damage to the removable I.V. pole, the weight of the I.V. bags should not exceed 40 lb.

• To avoid damage, the safe working load of the two-stage permanently attached I.V. pole is 40 lb.

• To avoid damage while transporting the stretcher, verify that the I.V. pole is at a low enough height to allow it to

safely pass through door openings and under light fixtures.

• Do not use the I.V. pole as a push/pull device because equipment damage could occur.

• To avoid damage, the weight of the I.V. bags should not exceed 12 lb while the weight of any one item attached to

each stage of the three-stage permanently attached I.V. pole should not exceed 9.3 lb.

• To avoid damage, do not put items weighing more than 40 lb in the upright oxygen bottle holder.

• Do not use the upright oxygen bottle holder as a push/pull device because equipment damage could occur.

• To avoid damage, do not put items weighing more than 30 lb on the serving tray.

• To avoid risk of user injury or damage to the equipment, ensure that the Upright X-Ray Cassette Holder is installed

correctly, following the instructions below.

• To avoid risk of user injury or damage to the equipment, ensure that the Lateral X-Ray Cassette Holder is installed

correctly, following the instructions below.

• Do not use the serving tray holder/footboard as a push/pull device because equipment damage could occur.

• Before returning the unit to service after cleaning, ensure that the unit is functioning properly by verifying that all

labels are intact, raise/lower the stretcher height, brake/steer pedal locks properly in both positions, latch/unlatch

the siderails, and raise/lower the fowler and gatch.

www.stryker.com 1115 -10 9 - 0 01 R EV D 17

Return To Table of Contents

Page 18

Summary of Safety Precautions

• Some cleaning products are corrosive in nature and may cause damage to the product if used improperly. If the

products suggested above are used to clean Stryker patient handling equipment, measures must be taken to ensure

that the stretcher is wiped with a damp cloth soaked in clean water and thoroughly dried following cleaning. Failure

to properly rinse and dry the stretcher will leave a corrosive residue on the surface of the stretcher, possibly causing

premature corrosion of critical components. Failure to follow the directions provided in the Cleaning section of this

manual (page 60) when using these types of cleaners may void this product’s warranty.

NOTE

• Equipment not suitable for use in the presence of a flammable anesthetic mixture with air or with oxygen or nitrous

oxide.

• The bottom of the brake pads should be cleaned regularly to prevent wax or floor remnant buildup.

• Clean the base hood storage area regularly.

• In lieu of specific requirments from IEC 60601-1 and IEC 60601-2-32:1994, equivalent means of safety were used

on the Prime-X series of products regarding accessory overloading, applied parts, and indications to the operator.

Return To Table of Contents

18 1115 -10 9 - 0 01 R EV D www.stryker.com

Page 19

Summary of Safety Precautions

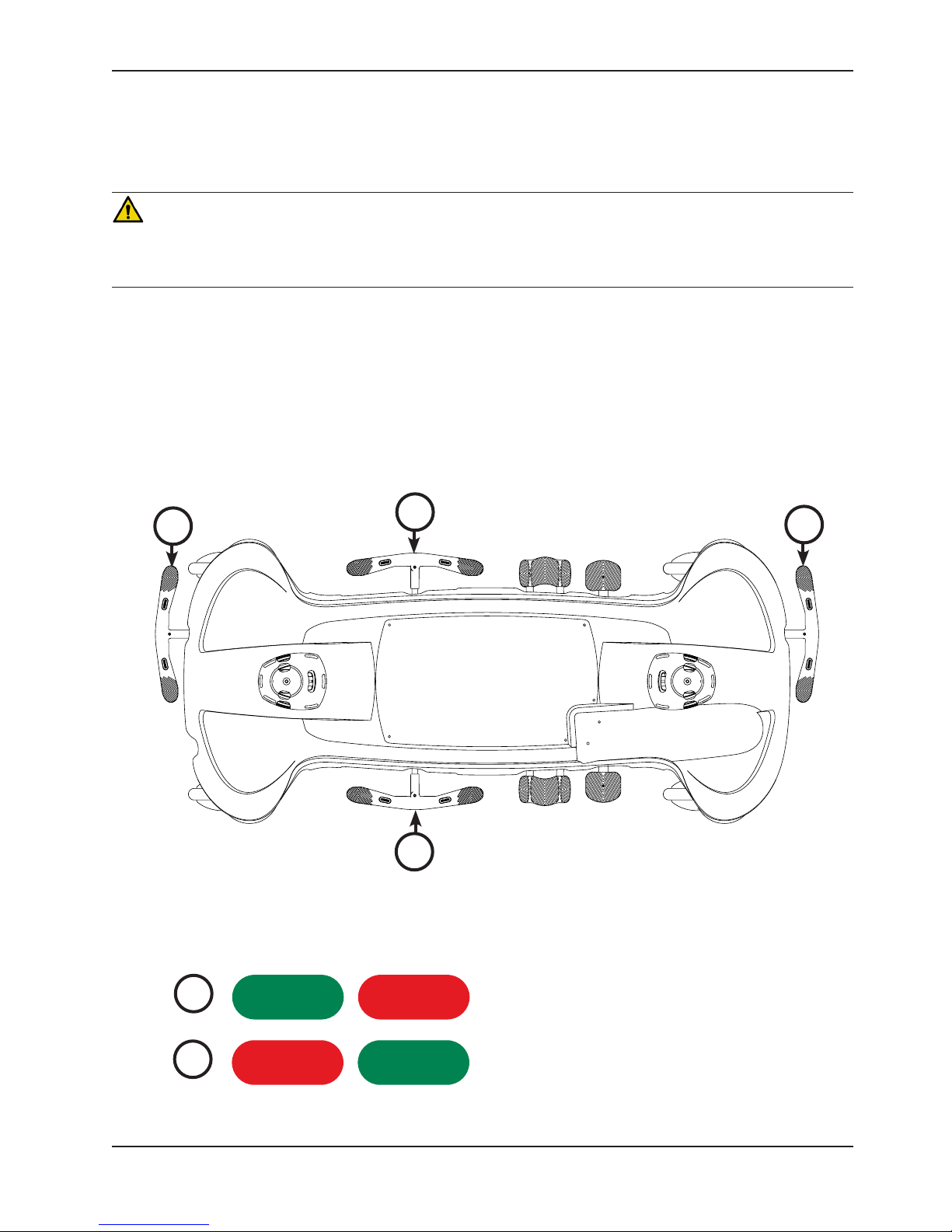

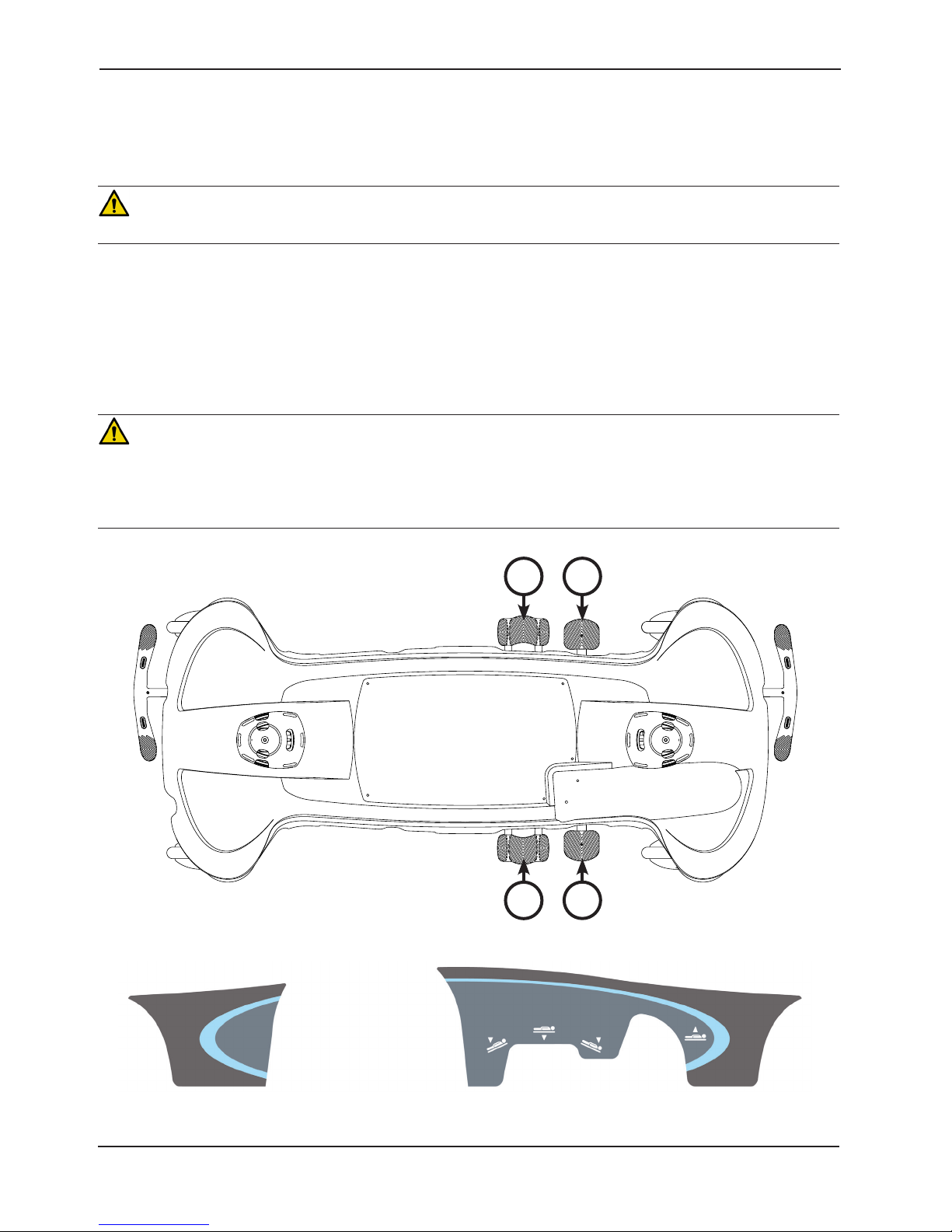

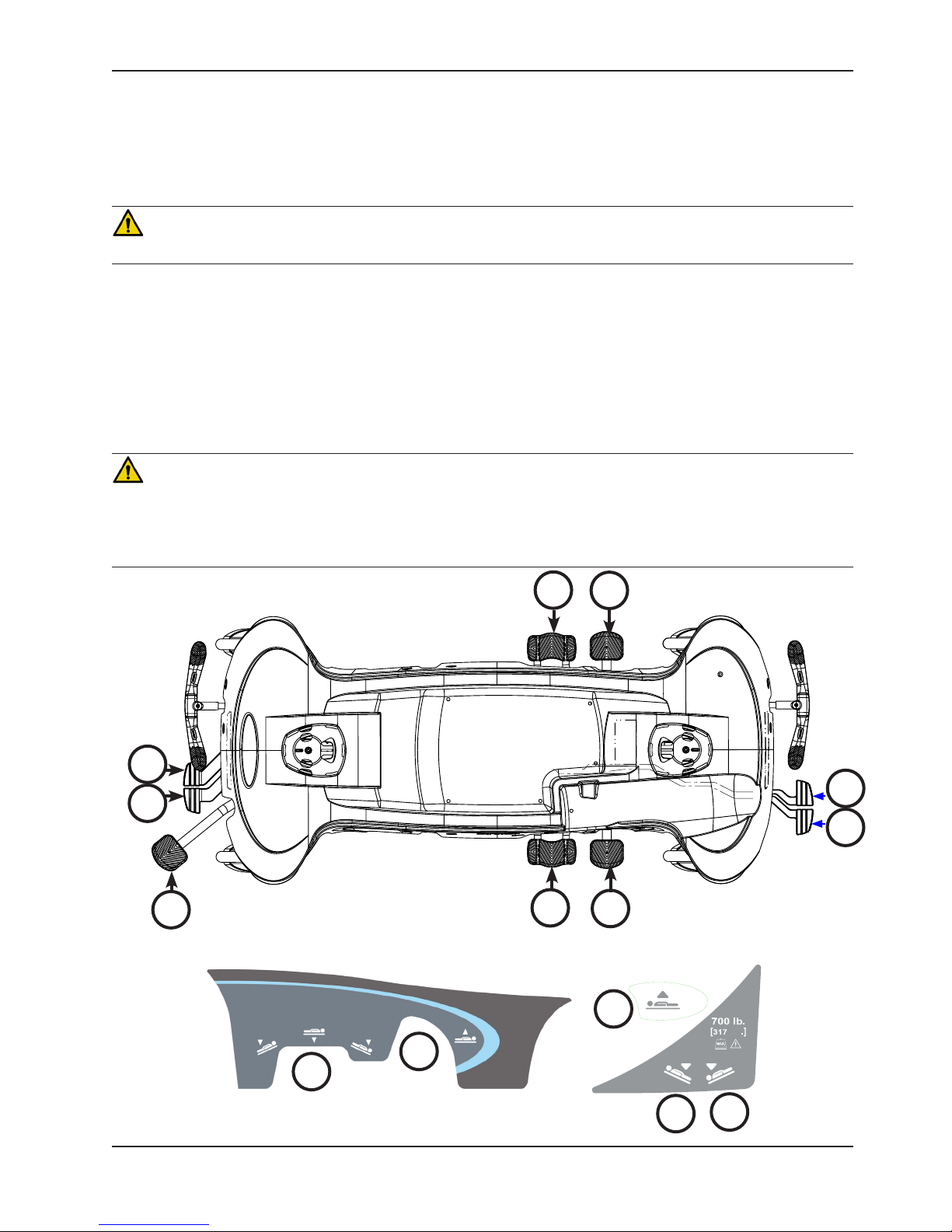

PINCH POINTS - PRIME X OPTION

Figure 4: Pinch Points - Prime X Option

Return To Table of Contents

www.stryker.com 1115 -10 9 - 0 01 R EV D 19

Page 20

Setup Procedures

If this unit is equipped with the optional electric lift/litter, the unit must reach room temperature prior to conducting

any setup and/or unit operations to prevent permanent damage to the unit.

Make sure that the unit is working properly before it is put into service. The following list will ensure that each part of

the unit is checked.

Stretcher checklist:

1. Depress the pedal at either end of the stretcher fully to set the four wheel brakes and verify that all of the four

casters are locked (page 21).

2. Raise and lower the hydraulic lift system (page 22 or page 23).

3. Raise the unit completely and activate the Trendelenburg function. Ensure that the head end lowers to the full

down position (page 25).

4. Raise the unit completely and activate the reverse Trendelenburg function. Ensure the foot end lowers to the full

down position (page 25).

5. Run through the operation of the Big Wheel to ensure that it is operating properly (page 26).

6. Ensure that the siderails raise and lower smoothly and lock securely in the full up position (page 27).

7. Raise and lower the fowler (head end) (page 31).

8. Raise and lower the gatch (foot end) (page 33).

If equipped with the optional electric lift/litter:

1. Check all items on the stretcher checklist above.

2. Plug the unit into a properly grounded, hospital grade wall receptacle and ensure that the LED lights illuminate on

the lockout keypad.

3. Raise and lower the hydraulic lift system (page 24).

4. Perform each function on the patient siderail controls to ensure that they are working properly (page 28).

5. Perform each function on the foot end nursing controls to ensure that they are working properly (page 29).

6. Raise and lower the fowler (head end) (page 32).

7. Raise and lower the gatch (foot end) (page 34).

If equipped with the optional scale - electric litter option (with or without chaperone option):

1. Check all items on the stretcher checklist above.

2. Plug the power cord into a properly grounded, hospital grade wall receptacle to charge the batteries.

Note: To charge the battery, see “Charging the Optional Scale System Battery Pack - Electric Litter Option (Not

Available With Prime X Option)” on page 43 or “Charging the Optional Scale System Battery Pack - Electric

Litter Option with Chaperone (Not Available With Prime X Option)” on page 45.

WARNING

This stretcher is equipped with a hospital grade plug for protection against electric shock hazard. It must be plugged

directly into a properly grounded three-prong receptacle. Grounding reliability can be achieved only when a hospital grade

receptacle is used.

CAUTION

• Do not modify this stretcher. Modifying the unit can cause unpredictable operation resulting in injury to the patient

or operator. Modifying the unit will also void its warranty.

• This stretcher is not intended for pediatric use or for patients under 50 lb. This stretcher is intended for use by

trained hospital personnel only.

Return To Table of Contents

20 1115 -10 9 - 0 01 R EV D www.stryker.com

Page 21

Operation Guide

APPLYING THE BRAKE SYSTEM

For user convenience, a brake/steer control pedal is located on both ends of the stretcher as shown in Figure 5.

WARNING

Always apply the brakes when a patient is getting on or off the stretcher. Push on the stretcher to ensure that the brakes

are securely locked. Always engage the brakes unless the stretcher is being moved. Injury could result if the stretcher

moves while a patient is getting on or off the stretcher.

To e ngage the brakes on the head end, push down on the brake (red) side of pedal (A).

To engage the brakes on the foot end, push down on the brake (red) side of pedal (B).

To release the brakes on the head end, push down on the steer (green) side of pedal (A).

To release the brakes on the foot end, push down on the steer (green) side of pedal (B).

Note: Your stretcher may be equipped with optional side control brake and steer functions (C) in addition to the

standard head end (A) and foot end (B) controls. The side control brakes operate the same as the head end and foot

end brakes.

B

C

C

Figure 5: Brake System

Note: The bottom of the brake pads should be cleaned regularly to prevent wax or floor remnant buildup.

A

Head End

A

B

www.stryker.com 1115 -10 9 - 0 01 R EV D 21

Steer/Brake functions (head end)

Brake/Steer functions (foot end)

Figure 6: Steer/Brake Functions

Return To Table of Contents

Page 22

Operation Guide

OPERATING THE BASE CONTROLS - SIDE CONTROL HYDRAULICS

To operate the base controls, see Figure 7 to locate which pedals are used for what operation.

CAUTION

To avoid damage, remove any equipment that may be in the way before raising or lowering the litter height.

To raise the litter height, pump pedal (A) repeatedly until the desired height is achieved.

To lower both ends of the litter together, depress the center of pedal (B).

To lower only the head end of the litter, depress the side of pedal (B) closest to the head end of the stretcher.

To lower only the foot end of the litter, depress the side of pedal (B) closest to the foot end of the stretcher.

WARNING

• Patients should be discouraged from sitting directly on the ends of the stretcher. Excessive weight could cause

the litter surface to tip up, possibly causing patient injury.

• Leave the stretcher height in the lowest position when the patient is left unattended. Leaving the stretcher height in

a raised position could increase the chance of patient falls and injury.

B A

B

Figure 7: Stretcher Base Controls - Side Control

A

Head End

Return To Table of Contents

22 1115 -10 9 - 0 01 R EV D www.stryker.com

A

B

Figure 8: Side Base Control Label

Page 23

Operation Guide

OPERATING THE BASE CONTROLS - OPTIONAL THREE-SIDED AND FOUR-SIDED CONTROL

HYDRAULICS

To operate the base controls, see Figure 9 to locate which pedals are used for what operation.

CAUTION

To avoid damage, remove any equipment that may be in the way before raising or lowering the litter height.

To raise the litter height, pump pedal (A) repeatedly until the desired height is achieved.

To lower both ends of the litter together, depress pedal (B) and pedal (D) together using the same foot or depress in

the center of pedal (C).

To lower the foot end of the litter, depress pedal (B) or the side of pedal (C) closest to the foot end.

To lower the head end of the litter, depress pedal (D) or the side of pedal (C) closest to the head end.

WARNING

• Patients should be discouraged from sitting directly on the ends of the stretcher. Excessive weight could cause

the litter surface to tip up, possibly causing patient injury.

• Leave the stretcher height in the lowest position when the patient is left unattended. Leaving the stretcher height in

a raised position could increase the chance of patient falls and injury.

B

D

A

C

C

Figure 9: Stretcher Base Controls - Optional Three-Sided and Four-Sided Control

A

A

A

A

C

C

A

B

D

Head End

kg

Figure 10 : Side Base Three-Sided or Four-Sided Control Label

www.stryker.com 1115 -10 9 - 0 01 R EV D 23

Figure 11:

Label A

B

D

Return To Table of Contents

Page 24

Operation Guide

RAISING AND LOWERING THE LITTER HEIGHT - OPTIONAL ELECTRIC LIFT

Ensure that the power cord is plugged into a properly grounded, hospital grade wall outlet before using the optional

electric lift.

CAUTION

To avoid damage, remove any equipment that may be in the way before raising or lowering the litter height.

To raise the litter height electrically, depress pedal (A) (see Figure 7 on page 22 or Figure 9 on page 23). The

litter will begin to raise. Hold the pedal down until the desired litter height is achieved. Release the pedal at any time

to stop the litter motion.

To lower the litter height manually, see the “Operating the Base Controls - Side Control Hydraulics” information on

page 22 or “Operating the Base Controls - Optional Three-Sided or Four-Sided Hydraulic Controls information” on

page 23. The litter height does not lower electrically.

WARNING

• Patients should be discouraged from sitting directly on the ends of the stretcher. Excessive weight could cause

the litter surface to tip up, possibly causing patient injury.

• Leave the stretcher height in the lowest position when the patient is left unattended. Leaving the stretcher height in

a raised position could increase the chance of patient falls and injury.

Return To Table of Contents

24 1115 -10 9 - 0 01 R EV D www.stryker.com

Page 25

Operation Guide

ADJUSTING TRENDELENBURG/REVERSE TRENDELENBURG POSITIONS - SIDE CONTROL

HYDRAULICS

Litter height must first be raised in order to achieve a Trendelenburg or reverse Trendelenburg position.

CAUTION

• To avoid damage, remove any equipment that may be in the way before raising or lowering the litter height.

• Do not raise the unit (hydraulics on base) with a patient lift under the stretcher.

For Trendelenburg positioning (head down), depress the side of pedal (B) closest to the head end (see Figure 7 on

page 22).

For reverse Trendelenburg positioning (foot down), depress the side of pedal (B) closest to the foot end (see Figure

7 on page 22).

To lower the stretcher from reverse Trendelenburg position, depress pedal (A) once to raise the foot end of the

stretcher, and then depress pedal (B) (see Figure 7 on page 22).

Note: The higher the litter is before pedal (B) is activated, the greater the Trendelenburg or reverse Trendelenburg

angle will be. (Maximum Trendelenburg angle is +17°. Maximum reverse Trendelenburg angle is -17°.)

ADJUSTING TRENDELENBURG/REVERSE TRENDELENBURG POSITIONS - OPTIONAL THREE-SIDED

OR FOUR-SIDED CONTROL HYDRAULICS

Litter height must first be raised in order to achieve a Trendelenburg or reverse Trendelenburg position.

CAUTION

• To avoid damage, remove any equipment that may be in the way before raising or lowering the litter height.

• Do not raise the unit (hydraulics on base) with a patient lift under the stretcher.

For Trendelenburg positioning (head down) (see Figure 8 on page 23):

• Depress pedal (D) at the foot end of the unit or

• Depress the side of pedal (C), located on the patient left or patient right side, closest to the head end of the unit.

For reverse Trendelenburg positioning (foot down) (see Figure 8 on page 23):

• Depress pedal (B) at the foot end of the unit or

• Depress the side of pedal (C), located on the patient left or patient right side, closest to the foot end of the unit.

To lower the stretcher from reverse Trendelenburg position, depress pedal (A) once to raise the foot end of the

stretcher, and then depress pedal (C) or (D) (see Figure 8 on page 23).

Note: The higher the litter is before pedal (B), (C), or (D) is activated, the greater the Trendelenburg or reverse

Trendelenburg angle will be. (Maximum Trendelenburg angle is +17°. Maximum reverse Trendelenburg angle is -17°.)

www.stryker.com 1115 -10 9 - 0 01 R EV D 25

Return To Table of Contents

Page 26

Operation Guide

OPERATING THE BIG WHEEL®

WARNING

• Make sure that the brakes are completely released before attempting to move the unit. Attempting to move the unit

with the brakes engaged could result in injury to the user and/or patient.

• If your unit is equipped with the optional electric lift/litter, unplug the power cord from the power outlet before

transporting or cleaning the unit. To unplug, grasp the mold near the outlet and pull the cord in a direction parallel

to the floor (not at an angle).

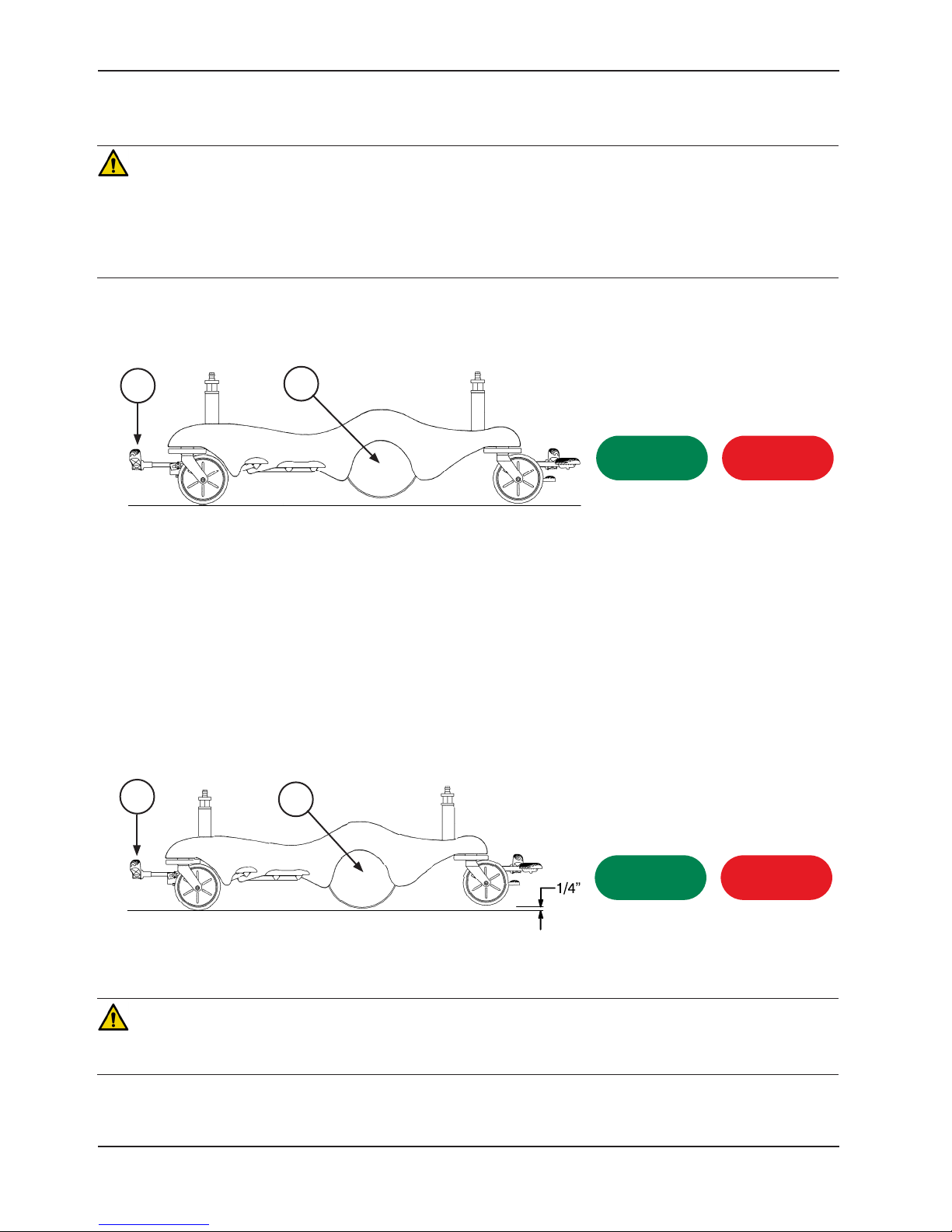

When the brake/steer pedal (A) is in the neutral or brake position, the Big Wheel (B) is elevated approximately 3/4”

and the stretcher rests on the four casters as shown in Figure 12. See page 21 for pedal operations.

A

B

Steer/Brake Label

Figure 12: Neutral or Brake Position

Note: The two Big Wheels (B) do not pivot. The stretcher cannot be moved directly sideways with the Big Wheel (B)

activated.

With the pedal (A) in the neutral position, the stretcher can be moved in any direction including sideways as shown

in Figure 12. See page 21 for pedal operations.

When the brake/steer pedal (A) is in the steer position, the foot end casters are elevated approximately 1/4” and the

stretcher rests on the two head end casters and the two Big Wheels (B) as shown in Figure 13. This provides increased

mobility and ease of steering the stretcher. See page 21 for pedal operations.

A

B

CAUTION

Do not engage the steer pedal when the Big Wheel is resting on a threshold or other raised area. The force required to

engage the Big Wheel will be higher than normal, possibly causing damage.

Return To Table of Contents

26 1115 -10 9 - 0 01 R EV D www.stryker.com

Steer/Brake Label

Figure 13: Steer Position

Page 27

Operation Guide

OPERATING THE SIDERAILS

Raising and lowering the siderails safely is a two-handed operation. Use one hand to hold and position the siderail and

the other hand to operate the siderail latch.

To raise the siderails, pull up on the siderail (A) and raise it to the highest position until the latch (B) engages as shown

in Figure 14.

WARNING

• After raising the siderails, pull firmly on the siderail to ensure that it is securely locked into the up position. Siderails

are not intended to serve as a patient restraint device to keep patients from exiting the unit. Siderails are intended

to keep a patient from inadvertently rolling off the unit. It is the responsibility of the attending medical personnel

to determine the degree of restraint necessary to ensure that a patient will remain in place. Failure to utilize the

siderails properly could result in patient injury.

• Leave the stretcher height in the lowest position when the patient is left unattended. Leaving the stretcher height

in a raised position could increase the chance of patient falls and injury.

• When using any mattress thicker than 2.5 inches or when using a mattress overlay with the Prime X option, extra

caution and operator supervision is recommended to reduce the risk of patient falls due to lesser siderail coverage.

A

B

Figure 14: Siderails

To lower the siderails, pull up on the latch (B) and guide the siderail to the lowest position as shown in Figure 14. The

latches (B) are colored yellow for easy identification.

WARNING

When lowering the siderail to the collapsed position, keep extremities of patients and staff away from the siderail spindles

or injury could occur.

Note: The foot end of the siderail top rail can be used as a push/pull handle.

CAUTION

To avoid injury or damage to the equipment, do not allow the siderail to lower on its own.

Note: There is a dual siderail latch option available with latches on both ends of the stretcher.

www.stryker.com 1115 -10 9 - 0 01 R EV D 27

Return To Table of Contents

Page 28

Operation Guide

OPERATING THE SIDERAIL PATIENT CONTROLS - OPTIONAL ELECTRIC LITTER (NOT AVAILABLE

WITH PRIME X OPTION)

Ensure that the power cord is plugged into a properly grounded, hospital grade wall outlet before using the optional

electric litter.

Each siderail has backlit controls to allow the patient to position the fowler and gatch as shown in Figure 15. The

power cord must be plugged into the wall socket for the patient controls to operate. When the stretcher is plugged in

(powered) and the controls are unlocked (see page 30), the white buttons are illuminated.

Note: The siderail patient controls are positioned in a staggered location on each side of the stretcher for easy patient

access.

WARNING

Powered stretcher mechanisms can cause serious injury. Operate stretcher only with persons clear of mechanisms.

34

Button Button Name Button Function

1 Gatch Down Press to lower the gatch (foot section)

2 Gatch Up Press to raise the gatch (foot section)

3 Fowler Up Press to raise the fowler (head section)

4 Fowler Down Press to lower the fowler (head section)

Return To Table of Contents

28 1115 -10 9 - 0 01 R EV D www.stryker.com

2 1

Figure 15: Siderail Patient Controls

21

3 4

Patient Right SiderailPatient Left Siderail

Page 29

Operation Guide

OPERATING THE FOOT END NURSING CONTROLS - OPTIONAL ELECTRIC LITTER (NOT AVAILABLE

WITH PRIME X OPTION)

Ensure that the power cord is plugged into a properly grounded, hospital grade wall outlet before using the optional

electric litter.

The foot end nursing controls allow the operator to position the fowler and gatch as shown in Figure 16. The power

cord must be plugged into the wall socket for the nursing controls to operate.

WARNING

Powered stretcher mechanisms can cause serious injury. Operate stretcher only with persons clear of mechanisms.

123 4

Figure 16: Foot End Nursing Controls - Optional Electric Litter

Button Button Name Button Function

1 Gatch Down Press to lower the gatch (foot section)

2 Gatch Up Press to raise the gatch (foot section)

3 Fowler Up Press to raise the fowler (head section)

4 Fowler Down Press to lower the fowler (head section)

www.stryker.com 1115 -10 9 - 0 01 R EV D 29

Return To Table of Contents

Page 30

Operation Guide

USING PATIENT CONTROL LOCKOUT - OPTIONAL ELECTRIC LITTER (NOT AVAILABLE WITH PRIME X

OPTION)

Ensure that the power cord is plugged into a properly

grounded, hospital grade wall outlet before using the

optional electric litter.

A

You can press the patient control lockout button to prevent

the patient from using the siderail patient controls to move

the fowler and gatch. The patient control lockout button is

located at the foot end of the stretcher.

B

To lock the siderail patient controls, press the Lock/

Unlock (A) button as shown in Figure 17. The lock icon (B)

is illuminated amber while the patient controls are locked.

The foot end nursing controls are not locked.

Note: When the siderail patient controls are locked, the

siderail patient controls are not backlit.

To unlock the siderail patient controls, press the Lock/Unlock (A) button as shown in Figure 17. The unlock icon (C)

is illuminated green when the patient controls are unlocked.

Figure 17: Patient Control Lockout

AC

OPERATING THE OPTIONAL PUSH HANDLES

To use the push handles, pivot the handles (A) up and push down until they are locked into position (Figure 18).

To store the push handles, lift the handles (B) up and pivot them down to store in the handle rests (Figure 19).

CAUTION

The push handles were designed for use while transporting the stretcher. Avoid using other parts of the stretcher as

push/pull devices because damage could occur.

A

Figure 18: Push Handles Open

Return To Table of Contents

30 1115 -1 09 - 0 01 REV D www.stryker.com

B

Figure 19: Push Handles Stored

Page 31

Operation Guide

OPERATING THE PNEUMATIC FOWLER - NON-ELECTRIC

To raise the fowler, squeeze either or both of the yellow fowler handles (A) for pneumatic assist until the fowler has

reached the desired angle (between 0 and 90 degrees) as shown in Figures 20 and 21.

To lower the fowler, squeeze either or both of the yellow fowler handles (A) and push down until the fowler has reached

the desired angle (between 90 and 0 degrees) as shown in Figures 20 and 21.

The drop seat/lift assist fowler uses the weight of the patient for additional assistance with raising the fowler. It also

helps keep the patient from sliding toward the foot end of the stretcher when the fowler is raised.

WARNING

• Operation of the fowler is a manual procedure. Use caution when raising the fowler while a patient is on the

stretcher. Use proper lifting techniques and get additional assistance, if necessary. Failure to use proper lifting

techniques could cause injury to the operator.

• Keep hands/fingers clear of the area around the fowler release handle and the fowler frame when lowering the

fowler. Injury could result if care is not taken when lowering the fowler.

A

Figure 20: Pneumatic Fowler - Prime Figure 21: Pneumatic Fowler - Prime X Option

A

www.stryker.com 1115 -10 9 - 0 01 R EV D 31

Return To Table of Contents

Page 32

Operation Guide

OPERATING THE FOWLER - OPTIONAL ELECTRIC LITTER (NOT AVAILABLE WITH PRIME X OPTION)

Ensure that the power cord is plugged into a properly grounded, hospital grade wall outlet before using the optional

electric litter.

To raise the fowler, press the UP (3) button on the patient siderail controls (A) or foot end nursing controls (B) until the

fowler has reached the desired angle (between 0 and 70 degrees) as shown in Figure 22.

To lower the fowler, press the DOWN (4) button until the fowler has reached the desired angle (between 70 and 0

degrees) as shown in Figure 22.

The drop seat/lift assist fowler uses the weight of the patient for additional assistance with raising the fowler. It also

helps keep the patient from sliding toward the foot end of the stretcher when the fowler is raised.

WARNING

• Keep hands/fingers clear of the area around the fowler release handle and the fowler frame when lowering the

fowler. Injury could result if care is not taken when lowering the fowler.

• Powered stretcher mechanisms can cause serious injury. Operate stretcher only with persons clear of mechanisms.

B

A

21

3 4

123 4

Return To Table of Contents

32 1115 -10 9 - 0 01 R EV D www.stryker.com

Figure 22: Fowler - Electric Option

Page 33

Operation Guide

OPERATING THE OPTIONAL GATCH - NON-ELECTRIC (NOT AVAILABLE WITH PRIME X OPTION)

To raise the gatch, pump handle (B) repeatedly to the left until the gatch has reached the desired height (5.5”/14 cm

minimum) as shown in Figure 23.

Note: You cannot raise the gatch manually if your unit is equipped with the optional electric litter.

To lower the gatch, pull handle (A) until the gatch has reached the desired height (5.5”/14 cm minimum) as shown in

Figure 23.

CAUTION

The weight capacity of the gatch

is 200 lb. Do not sit or stand on

the gatch. Injury or damage to the

equipment could occur.

A

A

Figure 23: Gatch - Foot End

To prop the foot end of the gatch up, lift up on the end of the gatch, allowing the prop rod to swing down and engage

in the bracket as shown in Figure 25.

To release the prop, lift up on the end of the gatch, swing the prop rod toward the head end of the unit to disengage

the bracket and lower the foot end as shown in Figure 25.

B

Figure 24: Gatch Label

WARNING

To avoid the risk of injury, ensure

that the gatch prop rod is fully

raised and securely placed into

position (Figure 25).

Figure 25: Gatch

www.stryker.com 1115 -10 9 - 0 01 R EV D 33

Return To Table of Contents

Page 34

Operation Guide

OPERATING THE GATCH - OPTIONAL ELECTRIC LITTER (NOT AVAILABLE WITH PRIME X OPTION)

Ensure that the power cord is plugged into a properly grounded, hospital grade wall outlet before using the optional

electric litter.

To raise the gatch, press the UP (2) button on the siderail patient controls (A) or foot end nursing controls (B) until the

gatch has reached the desired height (5.5”/14 cm minimum) as shown in Figure 26.

To lower the gatch, press the DOWN (1) button until the gatch has reached the desired height (5.5”/14 cm minimum)

as shown in Figure 26.

WARNING

Use caution when operating the gatch while a patient is on the stretcher. Powered stretcher mechanisms can cause

serious injury. Operate stretcher only with persons clear of mechanisms.

A

B

123 4

Figure 26: Gatch - Electric Option

21

3 4

CAUTION

The weight capacity of the gatch is 200 lb. Do not sit or stand on the gatch. Injury or damage to the equipment could

occur.

Return To Table of Contents

34 1115 -10 9 - 0 01 R EV D www.stryker.com

Page 35

Operation Guide

OPERATING THE RECOVERY CHAIR (NOT AVAILABLE WITH PRIME X OPTION)

CAUTION

To achieve recovery chair position, your stretcher must be equipped with the lift assist backrest and gatch options.

To place the stretcher into the recovery chair position as shown in Figure 27:

1. Raise the fowler to a seated position (for manual operation, see page 31; for the optional electric litter operation,

see page 32).

2. Fully raise the gatch (for manual operation, see page 33; for the optional electric litter operation, see page

34).

3. Raise the stretcher to its highest height (for side control, see page 22; for three-sided or four-sided controls, see

page 23; for optional electric litter operation, see page 24).

4. Place the stretcher into the full reverse Trendelenburg position (see page 25).

Figure 27: Recovery Chair

To lower the stretcher from the recovery chair position:

1. Raise the stretcher to its highest height (for side control, see page 22; for three-sided or four-sided controls, see

page 23; for optional electric litter operation, see page 24).

2. Lower the fowler from the seated position (for manual operation, see page 31; for the optional electric litter

operation, see page 32).

3. Lower the gatch (for manual operation, see page 33; for the optional electric litter operation, see page 34).

WARNING

Use caution when operating the recovery chair while a patient is on the stretcher. Powered stretcher mechanisms can

cause serious injury. Operate stretcher only with persons clear of mechanisms.

Return To Table of Contents

www.stryker.com 1115 -10 9 - 0 01 R EV D 35

Page 36

Operation Guide

USING THE BASE HOOD FOR STORAGE

You can store items in the base hood (A) as shown in Figure 28.

CAUTION

• The weight capacity of the base hood is 60 lb. Do not sit or stand on the base hood. Injury or damage to the

equipment could occur.

• Do not step on the base hood.

• Do not use the cutout for the oxygen bottle holder on the base hood for the storage of oxygen bottles or patient

belongings.

Note: Clean the base hood storage area regularly.

A

Figure 28: Base Hood Storage

Return To Table of Contents

36 1115 -1 0 9 - 0 01 R EV D www.stryker.com

Page 37

Operation Guide

USING THE OPTIONAL PUMP RACK

WARNING

• To avoid patient injury or equipment damage, all lines from any equipment stored on the pump rack must be

diverted away from the gatch handles.

• To avoid patient injury or equipment damage, do not lift the stretcher by the pump rack.

• To avoid equipment damage, remove any equipment from the pump rack that may be in the way before lowering

the litter.

• To avoid equipment damage while transporting the stretcher, verify that any equipment on the pump rack can safely

pass through door openings and under light fixtures.

CAUTION

• The weight capacity of the pump rack is 40 lb.

• Do not use the pump rack as a push/pull device, because equipment damage could occur.

Note: The pump rack is an option that may have been installed at the foot end of the stretcher. The choice was made

at the time that the stretcher was purchased.

The pump rack (A) can be used for the storage and transportation of stretcher equipment (Figure 29).

A

www.stryker.com 1115 -10 9 - 0 01 R EV D 37

Figure 29: Pump Rack

Return To Table of Contents

Page 38

Operation Guide

USING THE OPTIONAL RETRACTABLE CORD REEL - ELECTRIC LIFT/LITTER OPTION

The retractable cord reel (A) stores the stretcher power cord during transport as shown in Figure 30.

To use the retractable cord reel:

1. Pull the cord out of the reel to the desired length.

2. Plug the power cord into a properly grounded, hospital

grade wall outlet.

To store the power cord:

1. Unplug the plug by grasping the mold near the outlet and

pull the cord in a direction parallel to the floor (not at an

angle).

2. Tug and release the cord to retract the cord back into the

cord reel.

WARNING

If your unit is equipped with the optional electric lift/litter, unplug

the power cord from the power outlet before transporting or

cleaning the unit. To unplug, grasp the mold near the outlet and

pull the cord in a direction parallel to the floor (not at an angle).

A

Figure 30: Optional Retractable Cord Reel

Return To Table of Contents

38 1115 -1 09 - 0 01 REV D www.stryker.com

Page 39

Operation Guide

OPERATING THE OPTIONAL SCALE SYSTEM

The scale option (see page 40) is available for units without the optional electric litter.

The scale option (see page 42) is available for units with the optional electric litter. The scale system has a battery

backup option, so the standby icon indicates when the unit is unplugged and operating with battery backup.

The chaperone option (see page 44) is available for units with the optional electric litter scale option. The scale

system with chaperone (stretcher exit) has a battery backup option, so the standby icon indicates when the unit is

unplugged and operating with battery backup. The chaperone option also allows you to set zone controls to alert an

operator when a patient may be attempting to exit the stretcher.

www.stryker.com 1115 -10 9 - 0 01 R EV D 39

Return To Table of Contents

Page 40

Operation Guide

OPERATING THE OPTIONAL SCALE SYSTEM - NON-ELECTRIC LITTER

1

42 3

Figure 31: Scale System-Non-Electric Litter

Ref Icon/Button Description Action Display

1 Displays patient weight, unit of measurement and

battery status.

2 Push to toggle between patient weight in pounds

or weight in kilograms.

3 Push to weigh the patient. The display shows the

patient’s weight for approximately 40 seconds

before turning off.

4 Push and hold for 2 seconds to zero the scale

system before putting a patient on the stretcher.

If the display flashes “hold”, press and hold

the Zero button again until the display reads

“rel” (release). Release the Zero button. The

display flashes “000.0”, then displays “000.0”.

The system is not zeroed until the “000.0” stops

flashing. For the most accurate results, always

zero the scale system before putting a new

patient on the stretcher. The display shuts off

after approximately 40 seconds.

Note: Do not touch the stretcher while the scale system is weighing or zeroing. The patient must remain still while

the system is weighing. If the patient is moving, the system will try for 20 seconds to get a stable weight or zero value

before displaying the error message .

To convert the weight of

the patient to kilograms,

press and release lb/kg.

Repeat to return

to pounds.

Press and release

Weigh

Press and hold Zero

Release Zero

XXX.X kg

XXX.X lb

_ _ _ _

XXX.X lb

hold

rel

000.0 (flashing)

000.0 (solid)

If there is a loose connection or a malfunctioning component, the display will show “Err”. Attempt the function again.

If the system is functional, “Good” will display and the scale system is ready to use. If the malfunction is still present,

the display shows “Err” again. Call Stryker technical support at 800-327-0770.

To meet the accuracy claim as stated in the product specification on page 11, the patient surface must be in the flat

position (fowler and gatch down) and the stretcher cannot exceed 5 degrees of Trendelenburg/reverse Trendelenburg.

Return To Table of Contents

40 1115 -109 -001 RE V D www.stryker.com

Page 41

Operation Guide

REPLACING THE OPTIONAL SCALE SYSTEM BATTERIES - NON-ELECTRIC LITTER

To avoid completely draining the batteries and having the optional scale system shut down, replace the batteries

whenever only one of the charge indicator bars on the display (1) is black as shown on page 40.

To replace the scale system batteries:

1. Remove the Phillips head screws that hold the battery compartment cover to the display assembly.

2. Replace all four AA batteries.

• Install the positive and negative poles as indicated on the battery holder.

• Use only Alkaline type (LR6) batteries.

• Do not mix old and new batteries.

• Properly dispose of the old batteries in accordance with local regulations.

3. Reinstall the screws and the cover.

If the display is flashing “Lo batt”, then the batteries are drained and the scale system is disabled. Replace the batteries

with four new AA batteries as described above.

www.stryker.com 1115 -10 9 - 0 01 R EV D 41

Return To Table of Contents

Page 42

Operation Guide

OPERATING THE OPTIONAL SCALE SYSTEM - ELECTRIC LITTER OPTION WITHOUT CHAPERONE

(NOT AVAILABLE WITH PRIME X OPTION)

1

4

Figure 32: Scale System-Electric Litter Without Chaperone

Ref Icon/Button Description Action Display

1 Displays patient weight, unit of measurement and

battery status.

2 Push to toggle between patient weight in pounds

or weight in kilograms.

3 Push and hold for 2 seconds to zero the scale

system before putting a patient on the stretcher.

If the display flashes “hold”, press and hold

the Zero button again until the display reads

“rel” (release). Release the Zero button. The

display flashes “000.0”, then displays “000.0”.

The system is not zeroed until the “000.0” stops

flashing. For the most accurate results, always

zero the scale system before putting a new

patient on the stretcher. The display shuts off

after approximately 40 seconds.

4 When the scale system is unplugged and

operating with battery backup, the standby

indicator is amber. When the unit is plugged in,

the standby indicator is green.

5 Push to weigh the patient. The display shows the

patient’s weight for approximately 40 seconds

before turning off.

52 3

To convert the weight of

the patient to kilograms,

press and release lb/kg.

Repeat to return

to pounds.

Press and hold Zero

Release Zero

Press and release

Weigh

XXX.X kg

XXX.X lb

hold

rel

000.0 (flashing)

000.0 (solid)

_ _ _ _

XXX.X lb

Note: Do not touch the stretcher while the scale system is weighing or zeroing. The patient must remain still while

the system is weighing. If the patient is moving, the system will try for 20 seconds to get a stable weight or zero value

before displaying the error message .

If there is a loose connection or a malfunctioning component, the display will show “Err”. Attempt the function again. If

the malfunction is still present, the display shows “Err” again. Call Stryker technical support at 800-327-0770.

To meet the accuracy claim as stated in the product specification on page 11, the patient surface must be in the flat

position (fowler and gatch down) and the stretcher cannot exceed 5 degrees of Trendelenburg/reverse Trendelenburg.

Return To Table of Contents

42 1115 -10 9 - 0 01 R EV D www.stryker.com

Page 43

Operation Guide

CHARGING THE OPTIONAL SCALE SYSTEM BATTERY PACK - ELECTRIC LITTER OPTION (NOT

AVAILABLE WITH PRIME X OPTION)

To avoid completely draining the battery pack and having the optional scale system shut down, charge the battery pack

whenever only one of the charge indicator bars on the display (1) is black as shown on page 42.

The battery pack charges whenever the power cord is plugged into a properly grounded, hospital grade power source.

When the unit is stationary, you should plug the power cord into a power source whenever possible.

The optional scale system - electric litter option requires one 10.8V Li-Ion battery pack (0058-134-000). When fully

discharged, the battery pack requires approximately 3 hours of charging time to recharge.

www.stryker.com 1115 -10 9 - 0 01 R EV D 43

Return To Table of Contents

Page 44

Operation Guide

OPERATING THE OPTIONAL SCALE SYSTEM - ELECTRIC LITTER OPTION WITH CHAPERONE (NOT

AVAILABLE WITH PRIME X OPTION)

2 31

4

5 6 7

8

Figure 33: Scale Sysem-Electric Litter With Chaperone

Ref Icon/Button Description Action Display

1 Indicates when Zone 1 is armed. Allows the patient to move around

the stretcher freely, but cannot begin to exit the stretcher or the

alert with sound.

2 Displays patient weight, unit of measurement and battery status

3 Push to toggle between patient weight in pounds or weight in

kilograms

4 Indicates when Zone 2 is armed. Zone 2 is more restrictive than

Zone 1. When this zone is selected, the stretcher measures the

patient’s center of gravity. If the patient’s center of gravity moves

outside the preset boundary, an alert will sound.

5 Push once to arm Zone 1. Push twice to arm Zone 2. Once armed

or when alerting, press once to disarm.

To convert the weight of

the patient to kilograms,

press and release lb/kg.

Repeat to return to pounds.

Press and release Arm/Disarm On 1

XXX.X kg

XXX.X lb

On 2

Off

6 When the scale system is unplugged and operating with battery

backup, the standby indicator is amber. When the unit is plugged in,

the standby indicator is green.

7 Push to weigh the patient. The display shows the patient’s weight for

approximately 40 seconds before turning off.

8 Push and hold for 2 seconds to zero the scale system before putting

a patient on the stretcher. If the display flashes “hold”, press and

hold the Zero button again until the display reads “rel” (release).

Release the Zero button. The display flashes “000.0”, then displays

“000.0”. The system is not zeroed until the “000.0” stops flashing.

For the most accurate results, always zero the scale system before

putting a new patient on the stretcher. The display shuts off after

approximately 40 seconds.

Return To Table of Contents

44 1115 -1 09 - 0 01 REV D www.stryker.com

Press and release Weigh _ _ _ _

XXX.X lb

Press and hold Zero

Release Zero

hold

rel

000.0

(flashing)

000.0 (solid)

Page 45

Operation Guide

OPERATING THE OPTIONAL SCALE SYSTEM - ELECTRIC LITTER OPTION WITH CHAPERONE (NOT

AVAILABLE WITH PRIME X OPTION) (CONTINUED)

Note: Do not touch the stretcher while the scale system is weighing or zeroing. The patient must remain still while

the system is weighing. If the patient is moving, the system will try for 20 seconds to get a stable weight or zero value

before displaying the error message .