Stropuva DOMESTIC SOLID FUEL BOILER, S7, S10, S20, S40 Operating Manual

...

DOMESTIC SOLID FUEL BOILER

STROPUVA

INSTALLATION AND MAINTENANCE

MANUAL

CERTIFICATE NO. SPSC-672

CONTENT

1. DIMENSIONS AND CHARACTERISTICS ......................................................................................... 4

1.1 WOOD-FIRED BOILERS .............................................................................................................. 4

1.2 COAL-FIRED BOILERS ................................................................................................................ 5

2. DESCRIPTION OF A STRUCTURE .................................................................................................... 6

3. TRANSPORTATION AND WAREHOUSING .................................................................................... 7

4. BOILER FITTING ................................................................................................................................. 7

4.1. FIRE REQUIREMENTS ................................................................................................................ 8

4.2. REQUIREMENTS FOR THE CHIMNEY FLUE .......................................................................... 8

4.3. REQUIREMENTS FOR CONNECTING TO THE HEATING SYSTEM .................................... 9

4.4 MOUNTING PICTURE OF SOLID FUEL BOILER STROPUVA S40 NODE WITH THE

LOST OF PARTS .................................................................................................................................... 10

4.5. DESCRIPTION OF HEATING SYSTEM SCHEME OPERATION .......................................... 12

4.6 MOUNTING PICTURE OF SOLID FUEL BOILER STROPUVA S40 NODE WITH THE

LOST OF PARTS .................................................................................................................................... 13

4.7. DESCRIPTION OF SCHEME OPERATION WITHOUT ADDITIONAL BOILER AND

FLOOR HEATING .................................................................................................................................. 15

5. BOILER BURNING AND KINDLING ............................................................................................... 16

5.1. THE MOST ECONOMICALLY FUEL BURNS DOWN IN THE BOILER WHEN IT IS

FULLY LOADED ................................................................................................................................... 16

5.2. SETTING OF THE BI-THERMAL DRAUGHT REGULATOR ................................................ 18

5.3. EVALUATION OF THE BOILER OPERATION ....................................................................... 20

5.4. BOILER CLEANUP AND MAINTENANCE ............................................................................. 20

6. ACCIDENT PREVENTION REQUIREMENTS ................................................................................ 21

7. RISK ASSESSMENT .......................................................................................................................... 22

7.1. HEAT HAZARDS ........................................................................................................................ 22

7.2. PRESSURE HAZARDS ............................................................................................................... 23

7.3. POSSIBLE INTOXICATION ....................................................................................................... 23

7.4. REQUIREMENTS FOR CONNECTING OF ELECTRIC PARTS ............................................. 23

DEAR CUSTOMER,

We are delighted that you have put your trust in us.

We present the domestic solid fuel boiler, in the mouth of

which the burning time of one load is measured in days. With one

load of wood, peat and sawdust briquettes the boiler burns for

about 30 hours and with coal, the burning time is about 7 days.

Exceptional characteristics of the manufactured products, which

prolong the burning time of the solid fuel boiler, are the distribution

of air from the top and the solid fraction burning in the candle

principle.

Before installing and using it, we would ask that you read this

Manual carefully and follow the Instruction closely, as this will

guarantee better results when using the appliance.

Keep this Instruction Manual in a safe place so that you can

refer to it easily and thus abide by the guarantee conditions.

You should keep the Guarantee Certificate or, where relevant,

the technical datasheet, together with the Instruction Manuak for the

duration of the useful life of the appliance. It has important technical

information about the appliance.

Solid fuel heating boilers STROPUVA (hereinafter referred to as “the boiler”) are intended for

various premises/rooms where a central heating system is installed with radiators, heat water boiler for

domestic purposes or floor coils or heaters, or all together for heating. The system can be both with

natural and forced circulation, closed or opened.

1. DIMENSIONS AND CHARACTERISTICS

1.1 WOOD-FIRED BOILERS

Table 1.1. Dimensions and characteristics for wood-fired boilers.

Solid fuel: firewood logs, timber waste,

sawdust briquettes.

(Recommended moisture - ≤30%)*

MODEL

PARAMETRES

S7

S10

S20

S40

Power (kW)

7

10

20

40

Heated area (m2)

20-80

50-100

100-250

200-450

Fuel capacity (dm3)

150

200

350

500

Amount of firewood (kg)

15

25

50

80

Length of firewood (cm)

30-35

30-35

35-45

45-55

Water amount in the boiler (l)

26

34

45

58

Water temperature in the boiler (°C)

70

70

70

70

Coefficient of useful operation (%)

91,6

Flow of heated water (m3/h)

0,2

0,25

0,5

1,0

Dimension of load opening (mm)

250x210

250x210

260x220

280x240

Height (mm)

1250

1900

1900/2100

1900/2100

Diameter (mm)

450

450

560

680

Mass (kg)

100

185

231

315

* - Firewood containing more than 30 % moisture shall not burn at all and if burn – shall not endure

the required temperature, the burning shall be unstable. Combustion duration of fuel loading depend on its

quality, outside and inside temperature, building quality and other factors.

Table 1.2. Information for adjusters.

MODEL

Distance

between

floor and

chimney

(mm)

Chimney

diameter

(mm)

Distance

between

floor and

lower muff Ø

32 (mm)

Distance

between

floor and

upper muff Ø

32 (mm)

Pressure

valve (bar)

Water

pressure no

more than

(bar)

S7

1010

140

27.5

1187.5

1,5

2

S10

1430

160

12.5

1717.5

1,5 2 S20

1550

180

23.5

1936.5

1,5

2

S20 (1.9m)

1410

180

27.5

1727.5

1,5 2 S40

1550

200

38

1913

1,5

2

S40 (1.9 m)

1400

200

40

1710

1.5

2

1.2 COAL-FIRED BOILERS

Table 1.3. Dimensions and characteristics for coal-fired boilers.

Solid fuel: firewood logs, timber waste,

sawdust and peat briquettes, coal.

(Recommended moisture - ≤30%)*

MODEL

PARAMETRES

S10 U

S20 U

S40 U

Power (kW)

10

20

40

Heated area (m2)

50-100

100-200

180-400

Fuel capacity (dm3)

200

350

500

Amount of coal (kg)

Amount of firewood (kg)

75

25

130

50

220

80

Length of firewood (cm)

30-35

35-45

45-55

Water amount in the boiler (l)

34

45

58

Water temperature in the boiler (°C)

85

85

85

Coefficient of useful operation (%)

91,6

Flow of heated water (m3/h)

0,25

0,5

1,0

Dimension of load opening (mm)

250x210

260x220

280x240

Height (mm)

1900

1900/2100

1900/2100

Diameter (mm)

450

560

680

Mass (kg)

196

246

333

* - Firewood containing more than 30 % moisture shall not burn at all and if burn – shall not endure the

required temperature, the burning shall be unstable. Combustion duration of fuel loading depend on its

quality, outside and inside temperature, building quality and other factors.

Table 1.4. Information for adjusters.

MODEL

Distance

between

floor and

chimney

(mm)

Chimney

diameter

(mm)

Distance

between

floor and

lower muff Ø

32 (mm)

Distance

between

floor and

upper muff Ø

32 (mm)

Pressure

valve (bar)

Water

pressure no

more than

(bar)

S10 U

1550

160

57.5

1737.5

1.5

2

S20 U

1695

160

57.5

1947.5

1.5

2

S20 U

(1.9m)

1530

160

57.5

1747.5

1.5

2

S40 U

1675

180

57.5

1947.5

1.5

2

S40 U

(1.9 m)

1520

180

57.5

1747.5

1.5

2

6

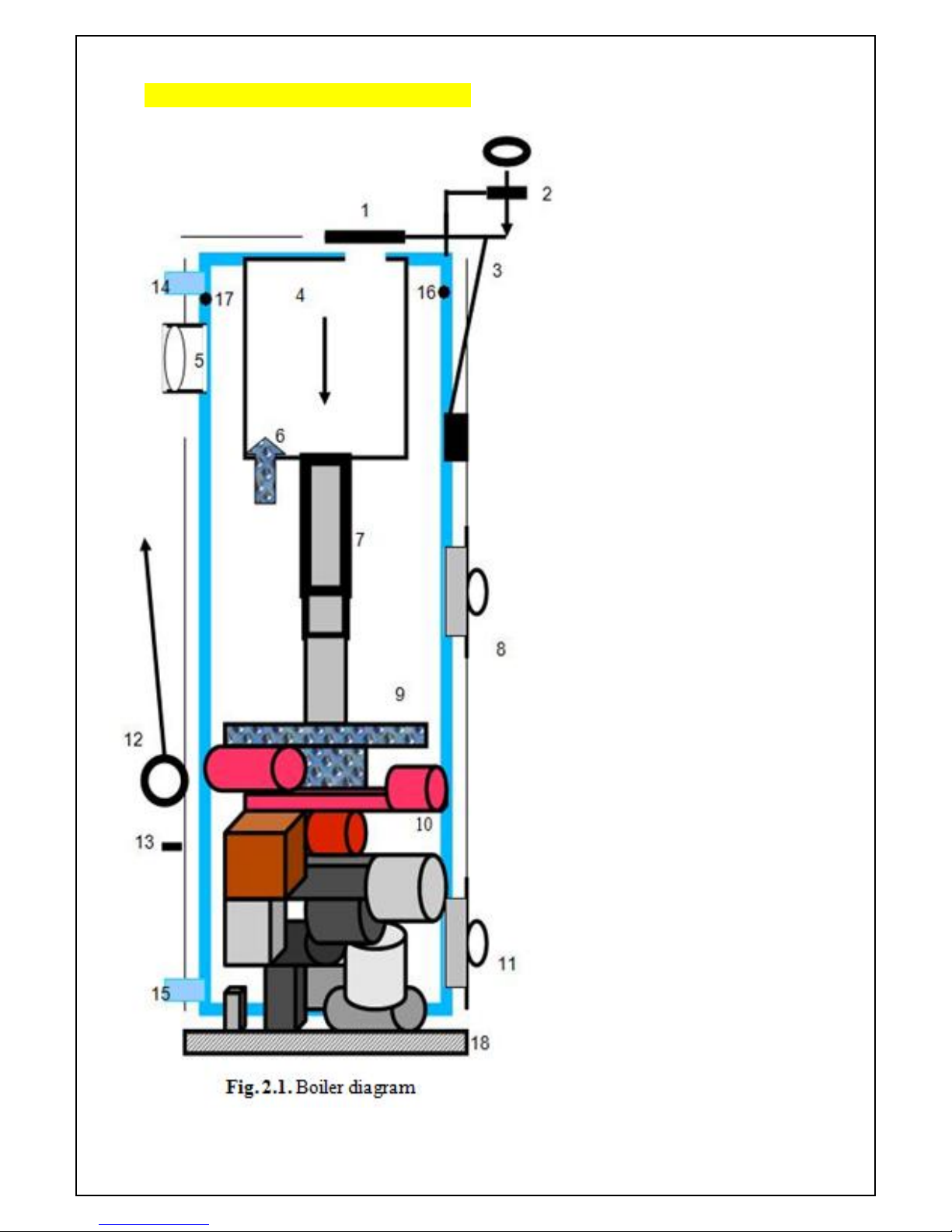

2. DESCRIPTION OF A STRUCTURE

The boiler (see figure 2.1.) is a

steel cylinder covered by a steel

cylinder of a bigger diameter, a

structure isinsulated. Bi-thermal

draught regulator (2) with wooden

stick (3) is at the front side of the

boiler (see for details item No. 5.2.).

Heated water is between the cylinders.

A structure has openings for loading

(8) of solid fuel (10), ash removal (11)

and smoke extraction flue (5). There

are also openings for water supply (14

- 15), thermometer (16) and pressure

safety valve (17). Air heating

compartment (4) for the improvement

of combustion quality and heating

transmission is mounted on the upper

part of a combustion compartment.

The boiler can be configured with grid

bars and switching valve (6) for

burning with peat or coal.

There is a gap between a

heating compartment and boiler

walls through which smoke pours so

that the heat would be better

transmitted. A telescope air feeding

pipe (7) fits into a compartment at the

end of which the air distributor is

fixed (9).

7

An opening for air injection and regulating valve (1) is at the upper part of a compartment. Upon

request, a concrete bottom with an insulating band is configured with the boiler (18). Lift cable (12) with

a ring of the air feeding mechanism is placed at the right side of the boiler in front of the door (a fixing

hook (13).

The purpose of the air distributor is to distribute correctly the air in the generation zones

below and near the air distributor, at the combustion zone near and above the distributor. Air

distributor leans upon the side firewood logs which do not get heated up to a high temperature.

It is no allowed to move a distributor during the combustion: after moving the air distributor up and

down, it turns and sinks deep into the combustion place and then the boiler operation is uneconomic, its

parts worn out more.

3. TRANSPORTATION AND WAREHOUSING

Boilers are allowed to be transported unfastened only in a horizontal position. If it does not rain, it is

allowed to transport with an open transport, in other cases it must be transported with a covered transport.

When transporting in a vertical position additional protection measures must be taken so that the boilers

won„t fall and scratch. Boilers can be stored in dry premises free of chemical active agent steam.

4. BOILER FITTING

The boiler is fitted in the premises corresponding to the state requirements established for the

premises of boiler houses. Premises where a boiler will be fitted must be at least 215 m in height and with

concrete flooring (at least in that place where the boiler will be erected). Premises must be made

watertight and protected from heated residential rooms and would have a vertical ventilation channel and

window or opening in the outside wall so that he air from outside would pass into the boiler and

ventilation channel. Using a mirror examine the inside of the chimney flue through the chimney flue

cleanup opening. The chimney flue must be clean. There must be no fittings nor bird nests and unsealed

openings leading to cavity ceilings and adjacent mines. It is verified whether the chimney flue does not

have openings or cracks in the outside through which the parasitic air can pass which will cool the

chimney flue and reduce its draught. Cracks, openings and a place where the boiler is connected to the

chimney flue must be sealed. If there are inner openings in the chimney flue leading to ceilings or adjacent

mines/shafts and there is no possibility to repair them, an oval or cylinder insert of stainless steel must be

fitted in. (Rectangular inserts are not reliable due to cracks formed in connection places due to

temperature changes). The boiler is erected straight on concrete floor; any cracks between the floor and

the boiler are sealed with heat resistant silicone or lime-cement solution with sand or other materials. The

boiler can be erected on a concrete bottom intended for fitting with an insulation rope.

8

During carrying sometimes parts of the boiler get deformed therefore when it is fitted into the

chimney flue and after closing all the doors and also the opening of the chimney flue cleanout opening,

check the operation of the upper valve, its nestling against surface of the air intake opening and doors

insulation using the flame of a candle or match.

4.1. FIRE REQUIREMENTS

The boiler is erected on a non flammable base. Metal connection of the boiler near the chimney

must be produced from metal not thinner than 1,5 mm and coated with heat insulation materials. The

condition of the chimney flue must be checked once per month (by examining it during the day time

through the cleanup opening with a mirror), in the event of necessity – clean it since soot and tars build up

in the chimney flue can ignite, throw the sparks, cause fire hazard, overheat or damage the insert. Using

branded chimney flues (of stainless steel or ceramic), study the users‟ manual and fulfill the requirements,

cleaning periodicity in particular. When the chimney flue is cleaned up, a horizontal flue between the

boiler and chimney flue must be cleaned up either.

4.2. REQUIREMENTS FOR THE CHIMNEY FLUE

The cross-width of the chimney flue opening can be 10 percent less as it is specified in the main

technical requirements but not bigger. The boiler requires an individual chimney flue; any other devices

cannot be connected to it. So that the formed condensate in the chimney flue would not get into the boiler,

a flue from the boiler to the chimney flue must be horizontal and not longer than 1.5 m and not shorter

than 0.20 m, well sealed and insulated with a heat insulation material in the connection places. Flue and

chimney flue is periodically cleaned up considering the mentioned above fire requirements.

It is recommended:

to fit in the chimney the insert of stainless steel; an orderly and correctly fitted insert protects

the chimney against the effect of condensate or moister;

an insert must not minimize significantly the cross section of the chimney opening; parts of

the insert must be tightly interconnected (with stainless steel rivets);

ash collector must be mounted below, collector must be mounted 15-20 cm below the flue

connection to the chimney flue; then the flue can be easily cleaned up through it;

the gap of the chimney between an insert and chimney walls, at least outside the chimney, fill

with inflammable insulation materials. At the top a crack must be hermetically plastered and tin

coated with a slope (from the opening to the chimney side);

the chimney at the cold loft must be sealed with inflammable insulation materials.

Loading...

Loading...