Page 1

XENON GLADIATOR II

Follo w Spotlight

Type 47050

Rev. June 2001

STRONG

INTERNATIONAL

a division of Ballantyne of Omaha, Inc.

4350 McKinley Street

Omaha, Nebraska 68112 USA

Tel 402/453-4444 • Fax 402/453-7238

Page 2

Page 3

PREF ACE

THE STRONG INTERNATIONAL XENON GLADIATOR II Model 47050 is a direct current follow spotlight complete with a xenon lamphouse, power supply , optical system, color boomerang, and

base stand assembly. The spotlight assembly consists of the arc lamp, variable focus lens system, color boomerang, and base. The separate xenon power supply completes the installation.

ONLY THE SPECIAL XENON POWER SUPPLIES manufactured by Strong International

can be used with the Gladiator II. For installation and operation of the power supply , see the instruction manual

furnished separately .

THE XENON LAMPHOUSE utilizes a 2500 watt xenon bulb designed for horizontal operation, and a deep ellipse metal reflector as a light source. The reflector is designed to operate in a fixed position,

and is dichroic (“cold”) coated to reduce heat in the projected light. A lens blower and heat filters, mounted in

the spotlight optical system, further reduce heat at the projection lens and color media.

ONL Y XENON BULBS designed for horizontal operation should be used in this follow spot.

®

Those bulbs presently approved for the Gladiator II include the Hanovia

XH2500HS, the Osram

XBO2500W/HS OFR, and the ORC® XM2500HS. All required bulb cabling is provided in the xenon lamphouse, and bulb adapters are not required.

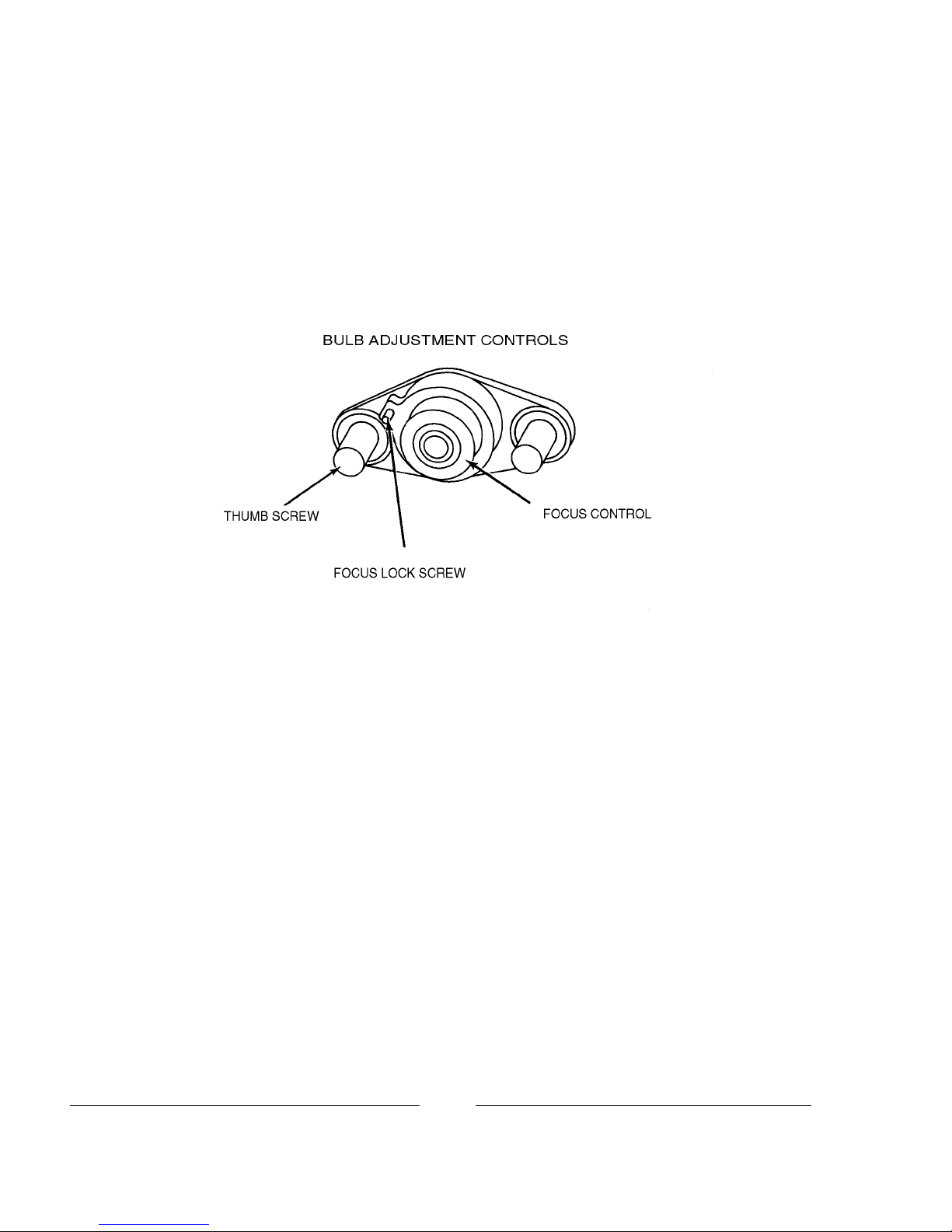

ADJUSTMENT CONTROL for the xenon bulb is located at the rear of the lamphouse behind

the access panel. The adjustments control the horizontal, vertical and focal movement of the bulb.

INSTRUMENTATION of the lamphouse includes a running time meter and a DC ammeter.

The running time meter indicates the number of hours the bulb has been in operation. The ammeter displays the

operating current of the lamp. A push button switch, located below the ammeter, changes the meter reading to

indicate the DC voltage at the arc.

THE LAMPHOUSE COOLING BLOWERS are internally wired and operate on AC voltage

derived from the xenon power supply . These blowers are required to maintain a safe operating temperature at

the bulb seals. The blowers operate continuously until the xenon power supply is de-energized. Air flow

interlock switches prevent operation of the lamp if the intake or exhaust blowers are not operating or failing to

move adequate air.

THE IGNITER is equipped with an emergency ignition switch, located on the top of the lamphouse below the plug button. Pressing this switch bypasses the relay contacts on the igniter printed circuit

board. DO NOT hold this switch for longer than one second to prevent transformer damage.

THE TWO ROCKER SWITCHES on the instrument panel are labeled MODE and LAMP.

The MODE switch permits operation of the lamphouse from a remote location when placed in the “AUTO”

position, or by the operator at the lamphouse when in “MAN.” The normal setting for this switch, in a follow

spot application, is in the “MAN.” position.

®

THE LAMP SWITCH is provided for manual bulb ignition when the MODE switch is in the

“MAN.” position. The LAMP switch must also be “ON” to complete the ignition circuit when operating from

a remote location.

XG2/001

Page 4

THE LAMPHOUSE is supplied with a 13 foot cable containing the DC leads, the AC control

wires, and the ground wire. The cable terminates in a multiple pin MS connector keyed to mate with the

receptacle on the power supply .

WHEN TRANSPORTING THE SPOTLIGHT, it is necessary to remove the xenon bulb and

place it in its original shipping container to prevent breakage. See the SAFETY PROCEDURES section

following, and permit only authorized personnel to handle the xenon bulb.

IF AT ANY TIME you have a suggestion, or desire aid in securing anticipated results, write

directly to STRONG INTERNATIONAL, 4350 McKinley Street, Omaha, Nebraska 68112.

XG2/002

Page 5

INSTALLATION AND SETTING UP SPOTLIGHT

THE XENON GLADIA TOR II is shipped in sections which must be assembled. Lifting straps

on the yoke assembly permit assembling the spotlight on the floor and later hoisting it to an elevated position.

ASSEMBLE THE FOUR BASE LEGS to the lower square section of the base column using

the 3/8-16 x 2-3/4 inch hex head cap screws and lockwashers provided. Insert a leveling foot and locknut in

each of the four leg brackets and level the base before continuing the installation.

WHEN INSTALLED in a permanent location, the leveling feet must be removed, and the

clearance holes in the base leg brackets used for hardware (user supplied) to bolt the base to the floor or

platform. If it is desired to have the unit portable, when operating, the leveling feet must be adjusted down until

the weight of the spotlight has been shifted from the casters to the leveling feet.

THE INNER TUBE and support yoke has three holes to permit adjusting the height of the

spotlight. The three holes are on four inch centers and will allow an optical height of approximately 53 inches,

57 inches, and 61 inches above floor level to the optical center of the lamphouse and lens system. The leveling

feet may be adjusted through an additional two inch range. Insert the height location pin through the hole in the

outer tube and one of the holes in the inner tube.

THE HORIZONT AL SWING and vertical tilt locking knobs are on the right hand (operating)

side of the yoke assembly . Tighten both of these locking devices securely before attempting to place the lamphouse and lens system on the support yoke.

PLACE THE LAMPHOUSE and lens system on the yoke assembly , with the spot size control

handle to the right hand (operating) side, the same as the locking controls on the yoke. Line up the four

mounting holes in the bottom of the base rail with the four mating holes in the support yoke and secure using the

four sets of 3/8-16 screws, nuts and washers.

A TTACH THE LAMPHOUSE CABLE CONNECTOR to the mating receptacle on the power

supply . The lamphouse and power supply connectors are keyed for correct pin alignment; make certain pins are

seated before tightening the locking ring. DO NOT energize the xenon power supply before the xenon bulb is

correctly installed into the lamphouse.

EARLIER MODELS of Strong xenon spotlights included a heavy-gauge green ground wire in

the lamphouse cable assembly . This ground wire was attached to a ground stud connected to the power supply

cabinet. Current models of Strong power supplies include a 1/4-20 stud in the cabinet adjacent to the MS

connector to allow ground termination of older spotlights.

XG2/003

Page 6

Conduit

LAMPHOUSE

(Connections Pre-wired)

Remote - Auto

Sustained 5 Amp.

Dry Contact

(by Installer

as req’d.)

LAMPHOUSE - PO WER SUPPLY

Interconnection Diagram

MS CONNECTOR

Pin Wire No,

A DC B DC+

C 2

D 3

E 4

F 5

G 6

I 7

J 8

M Grnd

Lamphouse

Cable Assembly

SYSTEM MUST BE GROUNDED

All wiring must conform to local

codes; shield lamphouse cable in

conduit if required.

XENON

POWER

SUPPLY

MS Connector (pre-wired)

DC+

DC-

XG2/004

Page 7

SAFETY PROCEDURES

READ CAREFULLY BEFORE INSTALLING XENON BULB

THE XENON BULB is highly pressurized. When ignited, the normal operating temperature

of the bulb increases the pressure to a level at which the bulb may explode if not handled in strict accordance to

the manufacturer’s operating instructions.

THE BULB is stable at room temperature, but may still explode if dropped or otherwise mishandled. Breakage resulting from transport and handling is not covered by the bulb manufacturer’s warrranty ,

and it is strongly recommended to dismaount the xenon bulb when transporting the spotlight.

REFER bulb replacement and service to QUALIFIED PERSONNEL with adequate protective

clothing (face shield, clean cotton gloves, welder’s jacket). For routine lamphouse service, observe the following rules:

1. Allow the bulb to cool to room temperature before opening the lamphouse. Put on protective clothing

described above.

2. De-energize the xenon power supply at the AC source before opening the lamphouse compartment.

3. When possible, encase the bulb in its protective cover when cleaning or servicing the lamphouse inte-

rior. The bulb, when outside the lamphouse, must be encased in the cover.

4. Clean the bulb after it has cooled to room temperature. Do not touch the quartz envelope of the bulb;

fingerprints will burn in and create hot spots which may shorten bulb life. If fingermarks are made,

they should be carefully removed with methyl alcohol and cotton prior to bulb operation.

5. Never view an ignited bulb directly. BLINDNESS OR PERMANENT EYE DAMAGE MAY BE

INCURRED.

6. Use only xenon bulbs designated as OZONE FREE. When possible, vent the lamphouse exhaust to

outside atmosphere.

7. Maintain the lamphouse blower in good operating condition. Keep the blower inlet clean for unre-

stricted air flow .

8. To insure maximum bulb life, operate the lamphouse blower and the exhaust system for at least ten

minutes after extinguishing the bulb.

9. If returning a bulb for warranty adjustment, pack it in its original shipping container. Complete and

return all required warranty information.

XG2/005

Page 8

10. Dispose of expired bulbs that are beyond warranty in the following manner: Wrap the bulb tightly in

several layers of canvas or heavy cloth. Place it on a hard surface and shatter the envelope with a sharp

hammer blow . DO NOT place an unshattered bulb in an ordinary refuse container.

11. DO NOT PERMIT UNAUTHORIZED PERSONNEL TO PERFORM OR A TTEMPT ANY PHASE

OF XENON BULB HANDLING OR SERVICE.

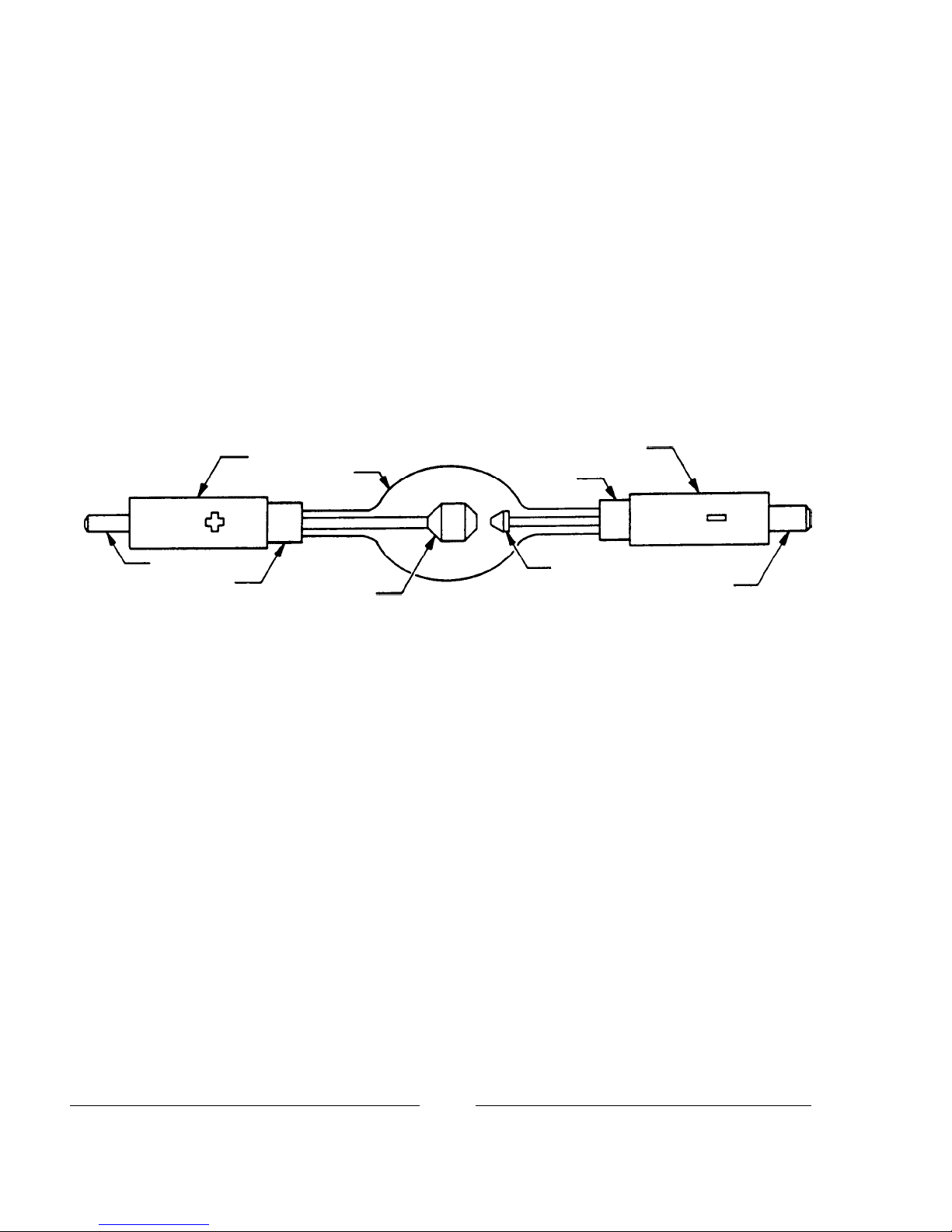

Anode Pin

Seal

Anode End Cap

Envelope

Anode

Cathode End Cap

Seal

Cathode

Cathode Pin

XG2/006

Page 9

BULB INSTALLATION

OBSER VE ALL SAFETY PROCEDURES when working around the xenon bulb. Open the

lamphouse access door by removing the tamperproof screws using the special screwdriver supplied. The igniter

lead and contact clamp are tied off for shipping. Free the clamp and slide it over the rear bulb support collet.

THE BULB SUPPORT YOKE in front of the reflector has three horizontal positioning holes

to permit setting the height of the yoke. The Gladiator II uses only the upper two holes. The spotlight is shipped

set up for use with the Hanovia XH2500HS bulb normally supplied with the unit, and the spring pin is through

the top hole. Because of a different end cap dimension, the bulb yoke must be raised and the pin installed in the

center hole if an Osram XBO2500W/HS bulb is used. The yoke may be repositioned by loosening the 8-32 set

screw in the support post. Tighten the set screw after setting the yoke position.

REMOVE THE PLASTIC PROTECTIVE COVER from the xenon bulb only if necessary.

Handle the bulb by the metal end caps only. Insert the bulb into the lamphouse, passing the anode (+) end cap

through the center hole of the reflector. Take care not to bump or scratch the surface of the reflector.

Clamping Screw 01532

Rear Clamp

39194

Rear Support Collet 39952

Xenon Bulb, Type 2500HS

Clamping Screw 01532

Front Bulb Support

Yoke 39975

Cathode Contact

Clamp 39953

Screw 00687

INSERT THE ANODE (+) PIN into the rear support collet and contact clamp. Rest the

cathode (-) end cap in the front bulb support yoke. Seat the anode (+) pin into the rear support collet as far as

possible for correct focus travel. Securely tighten the socket head clamping screw in the anode contact.

REST THE CATHODE END CAP in the “V” of the bulb yoke. Install the cathode contact

clamp over the cathode (-) pin. Firmly tighten the socket head clamping screw for a secure electrical contact.

Dress the negative DC lead attached to the contact clamp directly in front of the bulb support yoke to minimize

the projected shadow .

RECORD the bulb serial number, date, and lamphouse hours on the Xenon Bulb Record on the

inside back cover of this manual. This information will be needed in the event of a bulb warranty adjustment.

IT IS RECOMMENDED to use the above-mentioned lamphouse cables when installing the

xenon bulb. Anode leads supplied with bulbs are generally removable. If it is necessary to use the bulb anode

lead, remove the lamphouse igniter lead, and use the clamp to secure the bulb to the support collet. Attach the

bulb lead terminal to the igniter post; insulate the lead well and dress the lead away from grounded lamphouse

components.

XG2/007

Page 10

ESTABLISH A ROUTINE of periodically checking all electrical connections for tightness.

Loose contacts, particularly in the DC circuit, will cause overheating and damage the xenon bulb and other

components. Normal xenon bulb warranties allow no credit for bulb damage caused by overheating.

REFER TO THE BULB MANUFACTURER’S INSTRUCTIONS regarding bulb rotation.

Most bulb manufacturers recommend rotating the bulb 180° at 50% of warranty hours. After rotating the bulb,

operate at maximum allowable current for several hours, and then return to the nominal operating current.

IN THE EVENT of a bulb warranty claim, the bulb must be packaged in its original shipping

container, and returned with all required warranty forms completed. Contact the dealer through whom the bulb

was originally purchased for correct procedures and Return Authorizations.

IT IS A COMMON PRACTICE to replace the bulb at the expiration of its warranty period. If

a xenon bulb explodes in operation, the reflector and other lamphouse components are frequently damaged. The

xenon bulb manufacturer will extend no credit for a replacement reflector if the defective bulb is beyond warranty. Explosion-damaged reflectors are to be returned to the bulb supplier, NOT Strong International, unless

the bulb was supplied by Strong.

ARC STABILIZATION MAGNET

THE XENON BULB used in the Gladiator II lamphouse requires an arc stabilization magnet.

This magnet is located on the lamp base behind the reflector. This magnet is preset at the factory and should

not require adjustment. Should it become necessary to adjust the magnet, the following procedure must be

followed. Observe all bulb safety procedures when working in the lamphouse compartment.

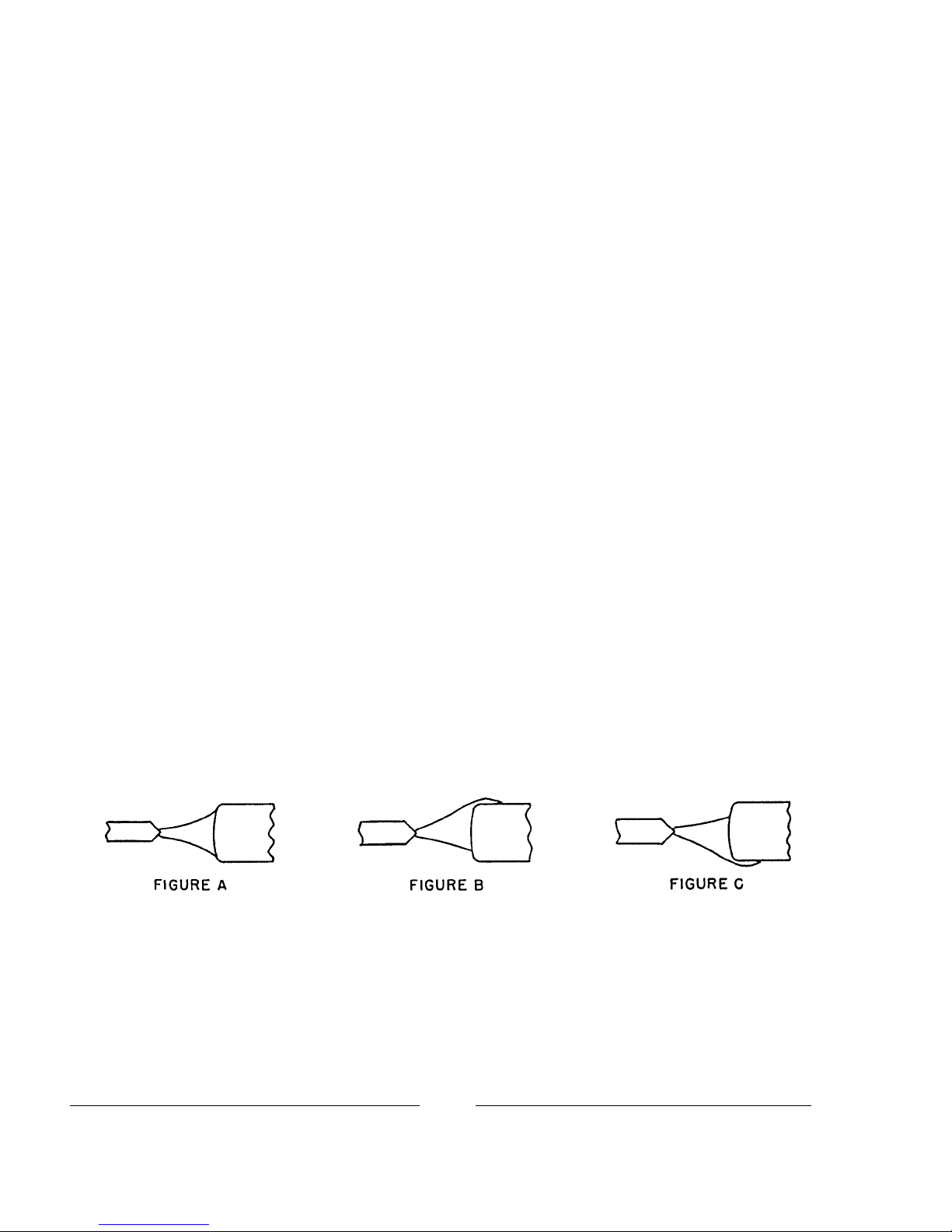

THE NORMAL ARC, when viewed through the arc viewing port, will appear as in Figure

“A.” This represents the correct magnet position. Figure “B” shows the position of the arc when the magnet

is too low . Raise the magnet on its adjustment bracket to lower the arc to the position illustrated in Figure “A.”

Figure “C” shows the position of the arc when the magnet is too high. Lower the magnet to raise the arc to

the position illustrated in Figure “A.”

THE MAGNET must always be installed with the longest portion of the magnet nearest the

bulb, and with the NORTH (N) pole pointing to the operator side access door. Reversing the magnet will

cause bulb flicker, and may inhibit bulb ignition. In new equipment, the magnet is normally in the center of the

adjustment range. Changes in the magnet position are required only to correct an improperly burning arc

(Figure “B” or “C”).

ANY REPLACEMENT MAGNET should first be installed in the center position of the

adjustment range. Raise or lower the magnet as required to center the arc as illustrated in Figure “A.”

XG2/008

Page 11

OPERATION

INSTALL THE GLASS HEAT FILTER into the bracket mounted on the rear of the fadeout

and douser support housing. NOTE: The coated side of the filter, with the XX or other marking, must be

facing the reflector. Reach through the side door and nose opening of the lamphouse, slide the filter into the slot

in the top angle bracket, and lower it into the bottom slotted bracket.

REMOVE THE PLASTIC COVER from the xenon bulb. DO NOT ignite the lamp with the

cover on the bulb. Store the cover for future re-use.

CLOSE AND SECURE the lamphouse door using the tamperproof screws and special screwdriver supplied with the lamphouse. Engage the cam lock and install the security screw. The door must be

completely secured to actuate the interlock switch and permit lamp ignition. Place the MODE switch in the

“MAN.” (manual) position.

TURN ON THE MAIN LINE SWITCH and/or circuit breaker to energize the xenon power

supply. The lamphouse blowers will start and the blower interlock switches will be actuated to permit lamp

ignition. The blowers will operate continuously until the xenon power supply is de-energized.

PLACE THE LAMP SWITCH in the “ON” position and the lamp will ignite. If ignition does

not occur, or the high voltage pulse is not apparent, press the emergency ignition switch on the top of the

lamphouse under the plug button. Do not hold more than one second; release immediately upon lamp ignition.

Use of the emergency ignition switch indicates an abnormal condition; see the TROUBLESHOOTING section

following.

CHECK THE READING on the lamphouse ammeter. Nominal current for the 2500 watt

xenon bulb is 90 amperes. DO NOT , AT ANY TIME, exceed 100 amperes. Output current is adjusted at the

power supply; see power supply manual for instructions. Operation of a new bulb is normally started at the

lower end of its range (80 A.), and current is gradually increased as the bulb ages to maintain light output.

PRESS THE SMALL PUSH BUTTON SWITCH located below the ammeter to read the DC

voltage at the arc. This permits immediate calculation of the power at which the lamp is operating (volts x

amperes = wattage). Holding this switch in during the ignition cycle will also briefly indicate the “no load”

(open circuit) DC voltage applied to the xenon bulb for ignition.

REMOVE THE REAR COVER PLATE below the instrument panel by withdrawing the two

plastic plungers. This exposes the bulb positioning controls in the lamphouse back casting.

TO FOCUS THE XENON BULB and obtain the best light on the stage, the two methods

outlined below are the most suitable.

MOVE THE SPOT SIZE CONTROL HANDLE (trombone) on the large lens carriage all the

way forward to project the smallest spot possible; place the iris, masking shutters (choppers) and the fadeout

douser blades in their full open positions. Project a spot to a wall or similar flat perpendicular surface opposite

the spotlight position.

XG2/009

Page 12

THE CENTER SECTION of the bulb positioning controls is a threaded member that focuses

the bulb in relation to the reflector. T urning this adjustment moves the bulb in only one plane, into or away from

the reflector. T urning this section clockwise moves the bulb away from the reflector . The small knurled screw

to the left of this section can be tightened to lock the focusing mechanism after the following procedures have

been completed.

THE LARGE THUMB SCREWS, on either side of the focusing control, lock the horizontal

and vertical adjustment mechanism in position.

TURN THE CENTER FOCUSING SECTION of the bulb positioning control counterclockwise until a small black spot is projected onto the wall. It may be best to run this adjustment both directions to

permit positive identification of the spot.

LOOSEN THE TWO THUMB SCREWS, one on either side of the center focusing section,

just enough to permit manual movement of the complete assembly. The bulb positioning control will now move

around these two thumb screws, and as this control is shifted, the smooth shadow of the bulb electrode can be

seen extending beyond the projected center hole in the reflector. The shadow of the electrode (black spot) must

be centered in the projected hole of the reflector (shaded, less dense dark area).

MOVE THE CONTROL SECTION around the two screws until the black spot is as round as

possible to project. It may be necessary to again turn the focus control to project a sharply defined black spot.

AFTER THE BLACK SPOT is as even around the outside as possible to project, and appears

centered in the shaded reflector center hole, tighten the two large thumb screws to lock the position of the

mechanism. Turn the center focus control to obtain the brightest light with the best light distribution. Rotate the

lens spot focus control knob, located at the extreme front of the lens mechanism, to obtain the sharpest edge

possible on the projected spot.

THE SECOND METHOD of focusing the xenon bulb is to project the spot to the stage, and

working with the above lamphouse controls, adjust these controls to obtain a “hot spot” on the projected spot.

Then center this “hot spot” on the projected light by moving the entire control section around the two thumb

screws. Once this “hot spot” is centered in the projected light, lock the control in position with the two thumb

screws and turn the center section to obtain a spot with an even distribution of light. Rotate the lens spot focus

control knob to obtain a sharp edge on the projected spot.

XG2/010

Page 13

THESE ADJUSTMENTS should not be disturbed until it is necessary to replace the xenon

bulb. At that time, the procedure on obtaining a smooth, round black spot, or “hot spot,” may have to be

repeated. Replace the cover plate over the bulb positioning controls.

BECAUSE OF NORMAL BULB AGING, and manufacturing tolerances between individual

xenon bulbs, it may be necessary to operate lamps at slightly higher or lower current settings to maintain

uniform light output when two or more spotlights are used in one installation. This entails a slight current

output adjustment at the xenon power supplies. See the power supply manual.

TO EXTINGUISH the arc, place the LAMP switch on the instrument panel to “OFF.” The

lamphouse blowers will continue to operate until the xenon power supply is de-energized. Allow the blowers to

operate for ten minutes before turning off the power supply; a forced-air bulb cooling cycle is required by all

bulb manufacturers.

DAILY OPERATION in the “Manual” mode requires only that the xenon power supply be

energized, the MODE switch be left in the “MAN.” position, and the lamp switched ON and OFF by means of

the LAMP switch. No bulb alignment or “warm up” are necessary. Always allow for the ten minute bulb

cooling cycle.

OPERA TION IN THE “AUT O” MODE is intended for use only if the spotlight is to be used as

a fixed spot without an operator at the equipment. Place the MODE switch in the “AUTO” position, and the

LAMP switch to “ON.” The lamp will ignite when a sustained dry contact is made between the automation

leads 3 and 6, and extinguish when the contact is opened. See the INST ALLATION DIAGRAM in the power

supply manual. The lamphouse blowers will operate until the xenon power supply is de-energized; allow for ten

minutes bulb cooling.

BEFORE OPENING the lamphouse enclosure for servicing, allow the blowers to operate for

twenty minutes, or until the bulb has cooled to room temperature.

HANDLING THE SPOTLIGHT

GENERALLY THE BEST POSITION for the operator to stand is hear the center of the spotlight on the right side. The angle of tilt, the size of the porthole, and the layout of the spotlight position may

dictate another location.

EACH OPERATOR will, after a few minutes of operation, generally develop his own system

and position for most convenient operation.

THE HORIZONTAL SWING and vertical tilt are individually adjustable to give the desired

degree of friction to suit the operator. The locking clamps are located on the right side of the yoke assembly.

THE EASE with which the spot size control handle (“trombone”) can be operated may be

adjusted by means of the nylon friction brake screw in the outrigger of the large lens carriage casting. T o access

this adjustment, open the color boomerang and remove the gel frames. Slide the large lens carriage to the

extreme rear position. Reach through the boomerang housing and loosen the nylon friction screw locknut. Turn

the nylon friction screw clockwise to increase drag, or counterclockwise to relieve. Tighten the locknut after the

desired adjustment is reached.

XG2/011

Page 14

OPERATION OF OPTICAL SYSTEM

THE IRIS CONTROL is the front lever which projects through the top of the optical system

housing. When this lever is to the left (as viewed from the rear of the unit), the largest aperture is provided.

Smaller apertures are obtained as the lever is moved to the right.

THE SPOT SIZE CONTROL HANDLE is located on the right hand side of the optical system

just above the base rail. A variation of spot sizes from full flood to small spot can be obtained by moving the

spot size control handle from one extreme to the other. Beam intensity is increased by this optical system when

reducing from flood to spot, and maximum intensity is reached when the spot size control handle is in the

extreme forward position.

THE MAXIMUM FLOOD SPOT is obtained with the iris control lever to the left (away from

operating side) for the largest aperture and with the spot size control handle moved as far to the rear as possible.

SMALLER SIZED SPOTS are projected as the spot size control handle is moved forward.

Most of the spot sizes needed will be produced with the iris in its maximum open position.

FOR A “HEAD SPOT,” or any spot smaller than can be obtained with the spot size control

handle in its extreme forward position, shift the iris control lever to the right (toward operating side) for a

smaller aperture. The iris control lever should always be returned to its extreme left position before the spot size

control handle is again moved to obtain larger spots.

THE MASKING SHUTTER (chopper) lever is the middle lever projecting through the top of

the optical system housing. The masking shutter blades are operated by this lever to shape the projected spot to

a rectangle, strip spot, or dousing.

THE DISENGAGED POSITION of the masking shutter lever is to the extreme right (toward

operating side) and varying degrees of masking to complete cutoff are obtained by moving the lever to the left

(away from operating side).

THE ANGLE of the masking shutter blades can be adjusted to compensate for the horizontal

projection angle. Remove the color boomerang and optical system housing, and loosen the screws holding each

of the masking shutter blades enough to allow adjustments. Ignite the bulb and adjust the angle of the bottom

blade by tapping with a screwdriver so its projected edge lies parallel to the footlights. Tighten the screw.

Operate the masking shutter lever to close the blades. Adjust the upper blade to close in line with the bottom

blade and tighten the screw .

THE FADEOUT MECHANISM AND DOUSER CONTROL is the rear lever projecting

through the top of the optical system cover. This lever controls the intensity of light from complete fadeout

when the lever is to the left, to full intensity when the lever is to the right.

THE SPOT FOCUSING CONTROL KNOB is located on the operating side of the optical

system at the forward end above the base rail. This control is used to adjust the optical system for the length of

throw . When making an adjustment, rotate the spot focusing control knob until the sharpest edge is obtained on

the projected spot.

XG2/012

Page 15

OPERATION OF COLOR BOOMERANG

THE COLOR BOOMERANG is equipped with six color holders and an ultraviolet filter.

Additional filter holders can be supplied by an authorized Strong International Dealer.

TO OPERATE INDIVIDUAL COLOR FILTERS, lower the desired filter selector lever. A

rocker catch located in the color disc housing holds the filter in position.

TO RELEASE A COLOR, push the filter release button or engage another color , thus releas-

ing the previous color automatically.

TO REPLACE A FIL TER HOLDER, open the hinged top of the color disc housing and lift out

the desired filter holder.

HIGH TEMPERATURE FILTERS (RoscoLux

®

or equivalent) cut to nine inch diameter are

required, and are secured in the filter holders with paper fasteners.

NOTE: WHEN PLACING COLOR FIL TERS in the boomerang, the less dense colors (pink,

amber) should be placed in the holders toward the rear of the boomerang (toward arc), and those of greater

density (red, green) should be placed in the holders toward the front of the boomerang (away from the arc).

COLOR TEMPERATURE REDUCTION FILTERS, required for use with television and

videotape, are available from theatrical supply dealers.

XG2/013

Page 16

MAINTENANCE

THE XENON GLADIATOR II SPOTLIGHT requires very little maintenance to keep it in

good working order.

THE REFLECTOR should be cleaned periodically with a soft, clean, lint-free cloth to remove

dust from the reflecting surface. If excessively soiled, the reflector may be cleaned with Windex

®

or an equivalent glass cleaner. DO NOT use abrasive cleaners of any kind. Clean the heat filter glass; replace with the

coated surface toward the lamphouse.

CHECK ALL ELECTRICAL CONNECTIONS for tightness on a regular basis. Loose con-

nections, particularly in the DC circuit, may cause premature bulb failure and damage lamphouse components.

LUBRICA TE the bulb seal blower and the lens blower with two or three drops of non-detergent

oil once every six months. The exhaust blower is permanently lubricated.

THE XENON BULB should be checked occasionally for the presence of dust or foreign materials. If necessary, clean the quartz envelope of the bulb with alcohol, and wipe dry with a clean, lint-free cloth.

Observe all safety procedures when working with the exposed bulb.

THE INSIDE OF THE LAMPHOUSE and the blower squirrelcages should be cleaned periodically, depending on the dust conditions at each installation. Keep the blower inlet and outlet grilles clean to

permit free air flow . Clean the actuator arms of the air flow switches to prevent dust build-up.

THE LENS SYSTEM should be kept clean to prevent any light reduction in the projected spot.

Tighten the horizontal swing and vertical tilt locking clamps. Remove the color gels to reach and clean the back

surface of the large lens. Remove the cover casting over the fadeout, chopper, and iris controls to remove the

small projection lens which is held in place with a large spring-type retainer ring at the front of the lens barrel.

CLEAN THE PROJECTION LENS and large lens with with any cleaner approved for use on

coated projection lenses. Replace the projection lens with the end with the FL marking ring toward the iris;

secure with the retainer ring.

BEFORE TRANSPOR TING the spotlight, remove the xenon bulb from the lamphouse. Place

the bulb in its plastic cover and original shipping container.

XG2/014

Page 17

Air Flow (Intake)

LAMPHOUSE SCHEMATIC

Access Door Interlock

Lens

Exhaust

Bulb Seal

Air Flow (Exhaust)

Lamp ON - OFF

A - BLK DC Neg.

B - RED DC Pos.

C - BRN No . 2

D - RED No . 3

E - ORN No. 4

F - BLU No. 5

G - YEL No. 6

I - GRY No. 7

J - BLK No. 8

M - GRN Ground

47050 - 4/00

XG2/015

Page 18

PARTS LIST

Lamphouse Schematic

Ref.

Desig. Part No. Description

B1 39938 Bulb Seal Blower Assembly, 1 15 V.AC, 50/60 Hz.

- 21-21015 Fuse, 1.5A. (F1)

B2 71220 Exhaust Blower, 115 V.AC, 50/60 Hz.

B3 47944 Lens Cooling Blower, 115 V.AC, 50/60 Hz.

C1,2 76132 Capacitior, .005 µf, 600WVDC *

C3 76133 Capacitor, .01 µf, 400 WVDC *

C4A, 4B 80177 Capacitor, 1.0+1.0 µf, 600 WVDC

C5 81947 Capacitor, .01 µf, 500 WVDC

C6,7 88263 Capacitor, .05 µf, 600 V.DC

C8 39956 Capacitor, .05 µf, 1200 V.DC

DS1 - Xenon Bulb

M1 39976 Elapsed Time Meter, 60 Hz.

- 39974 Elapsed Time Meter, 50 Hz.

M2 65142 Ammeter, 0-150 A.

R1 82167 Shunt, 150 A. 50 mV.

R2 39151 Resistor, 150k Ohm, ½ Watt (Order 21-46059)

S1 80168 Door Interlock Switch

S2 81275 LAMP Switch, Rocker Type

S3 81276 MODE Switch, Rocker Type

S4 78133 Air Flow Switch, Exhaust

- 81545 Air Vane Actuator, Exhaust Switch

S5 72275 VOLTAGE Switch, Pushbutton

S6 85109 Air Flow Switch, Intake Blower

- 39949A Igniter Assembly, Gladiator

- 40913 Igniter Printed Circuit Board Assembly

- 39939 MS Connector & Interconnect Cable Assembly

- 88318 MS Connector, 14 Pin Male

* 39933 RF Suppressor Assembly (C1, C2, C3)

XG2/016

Page 19

PRINCIPLE OF IGNITER OPERATION

THE IGNITER is energized through the 115 V.AC control circuit when the LAMP “ON-OFF”

switch (S2) is depressed and all interlocks and air flow switches are closed.

CAUTION: Do not use the Emergency Ignition switch (S102) in the igniter until it is determined that the polarity of the xenon bulb is correct. Use of the S102 switch bypasses the polarity sensing diode

(CR201) on the igniter printed circuit board; if polarity is not correct, the bulb will be seriously damaged or

destroyed. No credit is allowed on bulbs damaged by reversed polarity .

THE IGNITER supplies a high RF voltage pulse to the bulb, together with the high “No Load”

DC voltage from the xenon power supply , to ignite the xenon bulb. After the arc is sustained, the AC circuit in

the igniter is interrupted by the opening of K201 relay contacts on the signal of the timer circuit on the PC board.

The DC output of the xenon power supply is automatically lowered to the power level required to maintain the

arc. The DC power to the bulb is dependent upon the bulb characteristics and the setting of the output of the

xenon power supply .

DC VOL T AGE is applied to the printed circuit board from the xenon power supply , ener gizing

the 12 V.DC coil and closing the contacts of K201 relay, completing the AC circuit through the igniter to the

T102 high voltage (10 kV.) transformer. High voltage boost capacitor C107 is char ged to a voltage sufficient to

cause breakdown across the E101 spark gap. Approximately 35 kV. is supplied to the xenon bulb for ignition.

S101 is the igniter cover interlock switch and S102 is the Emergency Ignition switch, which is

a bypass for the K201 relay contacts and CR201 polarity sensing diode on the PC board. Components C101,

102, and 103 function as RF bypass capacitors on the igniter. The C108 capacitor serves as a coupling capacitor to the current coil.

THE PC BOARD operates on DC voltage from the xenon power supply. Capacitor C201

across the positive #10 and negative #15 is an RF suppression capacitor. Resistor R201 and zener diodes

VR201 and 202 drop the DC voltage to 12 volts for the K201 relay coil. CR201 is the polarity sensing diode.

C204 is a polarized capacitor used for arc suppression at the K201 relay coil, and CR202 functions as a

transient protection diode.

THE FOLLOWING COMPONENTS are parts of the timing circuit on the PC board: Timer

chip U201, resistors R202, 203, and the polarized capacitor C203. The C203 capacitor functions as the timing

control, and CR203 serves as the “ON” time control diode. C202 is the control voltage isolation capacitor.

XG2/017

Page 20

IGNITER ASSEMBLY, SCHEMATIC

Ref.

Desig. Part No. Description

C107 39110 Capacitor, 2400 pf, 20 kV.DC

C108 39110 Capacitor, 2400 pf, 20 kV.DC

E101 39923 Spark Gap Assembly

S101 80168 Cover Interlock Switch

S102 80168 Emergency Ignite Switch

T101 39937 High Voltage Transformer

- 39998 Case & Coil, Potted Assembly

XG2/018

Page 21

A = 10

B = 15

C = 17

D = 38

WIRE MARKERS

IGNITER PRINTED CIRCUIT BOARD

ASSEMBLY, SCHEMATIC

Ref.

Desig. Part No. Description

R203 39159 Resistor, 200k Ohm, ½ Watt

High Reactance Power Supply)

U201 72185 Timer IC, Motorola MC11455P1

- 39164 IC Socket, (6) Pin

VR201 39211 Zener Diode, 1N5377A (40913*)

VR201 39167 Zener Diode, 1N5369A (39966*)

VR202 39162 Zener Diode, 1N4742

- 39145 PC Board (less Components)

* 40913 PCB Assembly, Standard

* 39966 PCB Assembly (Older Models using

Assembly Number written on Component Side of PCB.

XG2/019

Ref.

Desig. Part No. Description

C201 88263 Capacitor, .05 µf, 600 WVDC

C202 79127 Capacitor, .01 µf, 600 WVDC

C203 39156 Capacitor, 15 µf, 30/35 WVDC

C204 88249 Capacitor, .1 µf, 600 WVDC

CR201 85112 Diode, 2.5 A. 1000 PRV

CR202 85112 Diode, 2.5 A. 1000 PRV

CR203 85112 Diode, 2.5 A. 1000 PRV

K201 39154 Relay, P&B R10-E1-W2S800

- 39160 Relay Socket

- 39161 Relay Hold-Down Spring

R201 39157 Resistor, 1k Ohm, 12 Watt

R202 39158 Resistor, 100k Ohm, ½ Watt

Page 22

TROUBLE CHART

NORMAL OPERATION

WHEN THE SWITCH in the main AC supply line to the xenon power supply is in the ON

position, and the 30 A. circuit breaker on the switching power supply is ON, the POWER light on the xenon

power supply will glow. The lamphouse and power supply blowers will start. NOTE: Early model Strong

Switching Power Supply blowers may not start until the LAMP switch has been closed.

OPERA TION OF THE LAMPHOUSE BLOWERS will close the (2) air flow interlock switches

(intake and exhaust), and if the lamphouse door is closed and correctly secured, the control circuit to the LAMP

switch will be completed.

THE MODE SWITCH, located on the lamphouse instrument panel, should be in the “MAN.”

(Manual) position. This enables ignition control from the instrument panel, and is the normal mode of spotlight

operation.

WHEN THE LAMP SWITCH is placed in the ON position, the AC control circuit in the

lamphouse will energize the power supply circuitry providing DC current to the igniter and bulb. If an early

model Strong switching type power supply is used, the power supply blowers will start at this point.

THERE WILL BE a distinctly audible high voltage arc ping at the igniter arc gap and across

the bulb electrodes. The bulb should ignite immediately after one or two of these high voltage pulses, and the

lamp current will adjust to the output setting of the xenon power supply . Multiple ignition pulses prior to bulb

ignition normally indicate a low DC output setting. See xenon power supply manual. A “warm” or aged xenon

bulb might also require multiple strikes.

TROUBLE SHOOTING

IF THE XENON BULB does not ignite, observe the following operational sequences for assistance in locating and isolating the trouble area.

WHEN THE F AN(S) and the indicator light on the power supply are on, the AC circuit in the

power supply is trouble free up to the terminal block in the power supply.

AT THIS TIME, the lamphouse blowers should operate. If this does not occur, the trouble is

in the cover interlock switch, the access panel interlock switch, the blower motor, a loose connection, a broken

#2 or #4 lead, or a blown F1 seal blower fuse. Check the 1.5 A. fuse in the in-line fuseholder.

CAUTION: T o

prevent bulb ignition when checking the AC control circuit in the lamphouse, remove lead #10 from the igniter

terminal strip.

CHECK AT THIS TIME for 115 V.AC Control Voltage at the access door interlock switch

(wires 2 & 4), and the blower terminals (9 & 12). The door interlock switch must be manually actuated to

energize the blowers. Replace #10 lead before proceeding.

XG2/020

Page 23

THE VANES on the air flow switches should raise. With the MODE switch in the “MAN.”

position and the LAMP switch in the “ON” position, the running time meter should start and indicate elapsed

time. If this meter does not operate, check for continuity at the MODE and LAMP switches.

A DEFECTIVE RUNNING TIME METER will not prevent bulb ignition.

WITH THE “LAMP” SWITCH in the “ON” position, a distinct high voltage arc ping should

be heard at the spark gap in the igniter, and the flash of the xenon bulb should be visible through the ammeter as

a high DC voltage pulse is applied across the bulb electrodes.

IF THE HIGH VOLTAGE PING or the flash at the ammeter is not apparent, check for 115

V.AC at terminals 5 & 6 at the terminal board. If 115 V.AC is present, and terminals are tight, check then the

“No Load” DC V oltage between the lamphouse and power supply . Remove either lead #5 or #6 at the terminal

board to prevent bulb ignition and defeat the door interlock switch. Check the DC voltage across terminals #10

(-) and #15 (+). A reading of 85 V.DC should be measured if using a high reactance power supply; 120-170

V.DC if using a switching type. If this voltage is not indicated, the problem is in the leads between the lamphouse and power supply, or in the power supply boost circuit. See the trouble shooting section of the power

supply manual for additional instructions. Replace lead #5 or #6 at the igniter before proceeding.

THE SWITCHING-TYPE XENON POWER SUPPLY furnished with the spotlight system

includes thermal overload switches and protection circuits to prevent damage resulting from high or low input

voltage. Loss of DC open circuit voltage, or an interruption of DC sustaining current, may be traced to these

circuits. See the power supply manual.

IGNITER PRINTED CIRCUIT BOARD 40913 is required for use with the switching type

xenon power supply . If the lamphouse is equipped with an older type, replace it with the 40913 board. If the

lamphouse ignites only by means of the emergency ignition switch, replace the igniter PC board.

IF THE HIGH VOL T AGE ARC is audible at the lamphouse and the bulb does not flash, check

for a lamphouse DC lead arcing to ground. If no ground fault is detected, replace the bulb and attempt ignition

with the new bulb.

IF THE HIGH VOL TAGE ARC is audible at the lamphouse, the flash of the bulb is visible in

the ammeter, but ignition of the bulb is not sustained, the problem area is in the power supply. See the trouble

shooting section of the power supply manual for additional instructions.

IF THE HIGH VOL T AGE ARC is not audible or the flash of the bulb visible, the problem is in

the igniter or igniter PC board assembly .

EXCHANGE of components (i.e. igniters, printed circuit boards) between two similar Strong

Xenon Gladiators to aid in diagnosis of a problem is encouraged. This will not lead to equipment damage, and

will not void equipment warranty .

XG2/021

Page 24

XENON GLADIATOR II TROUBLESHOOTING

Bulb fails to ignite.

1. MODE switch S3 set to “AUTO.” Place in “MAN.” position when not employing automated or remote

lamphouse operation.

2. AC power not on to lamphouse. Turn switching power supply 30 A. circuit breaker ON. If 115 V.AC

not read at 2 & 4, see power supply manual.

3. Door interlock switch (S1) open. Close and secure lamphouse door.

4. Faulty interlock switch(s). Check for 115 V.AC at 9 & 12; replace switch(s) if defective.

5. Air vane switches not closing. Check for unobstructed operation; clean if required. Check continuity

between “NO” and “COM;” replace if defective.

6. Faulty S2 “ON-OFF” switch. Check for voltage at 3 & 5; check for loose terminals or wiring. Replace

if defective.

7. Blower fuse F1 blown. Replace as required (1.5 A. Std.).

8. Low AC source voltage actuating “brownout” protection circuit in xenon power supply.

Bulb fails to ignite; ping audible, bulb flash visible.

1. Inadequate DC output from xenon power supply. Set power supply output to correct range required for

bulb wattage (90 A. nominal for 2500 watt).

2. If bulb flash is visible but faint, check for defective HV capacitor(s) in igniter. Replace if defective.

3. Faulty or expired xenon bulb. Replace as required.

Bulb fails to ignite; ping audible, no bulb flash.

1. Faulty xenon bulb. Check for cracked electrodes or darkened envelope. Replace if defective.

2. Ignition pulse shorting to ground. Inspect DC leads for burned insulation; dress leads away from

grounded metal components.

No high voltage ping audible; MODE switch in “MAN.” and LAMP switch in “ON.”

1. Loss of AC control voltage. Check xenon power supply for tripped circuit breaker or open thermal

switch. See power supply manual.

2. Little or no DC “No Load” voltage. Measure DC “No Load” voltage at 10 & 15. See power supply

manual.

3. Open fuse F1 (600 V.) on switching power supply. SEE POWER SUPPLY MANUAL. Allow (20)

minutes for capacitor discharge before replacing.

4. Faulty igniter printed circuit board. If lamphouse ignites immediately when emergency ignition switch

is pressed, replace printed circuit board.

5. Loose spark gap connections or terminals. Repair or replace as required.

7. Faulty igniter. Check for 115 V.AC at 5 & 6; adequate DC “No Load” at 10 & 15. If present, and

igniter does not fire, replace igniter.

XG2/022

Page 25

Bulb goes out during operation.

1. Xenon power supply overheated; thermal switch open. Check power supply blower(s), air inlets and

outlets unobstructed. See power supply manual.

2. Xenon bulb depressurizing. Check for envelope discoloration; replace if defective.

3. Lamphouse blower not moving adequate air. Clean; lubricate seal blower .

4. Lamphouse blower failed or obstructed. Clean dust and dirt from blower inlet grille. Check for 115

V.AC at 7 & 8; replace blower if defective.

5. Lamphouse air vane switches faulty. Check for vane actuation; adjust or replace as required.

6. Lamphouse exhaust obstructed. Clear obstruction; clean outlet grille.

7. Exhaust air flow switch reacting to backdraft. Adjust actuator to compensate for backdraft.

8. Fluctuating AC source voltage actuating brownout or spike protection circuits in xenon power supply.

See power supply manual.

Power supply does not energize when actuated.

1. Door interlock switch, B1 blower, F1 blower fuse, S4 air vane switch, S2 power switch, S3 MODE

switch. Check for 115 V.AC at each station; replace defective component.

SEE POWER SUPPLY TROUBLESHOOTING UNDER SAME HEADING.

Noise in theatre sound as bulb ignites.

1. Faulty RF suppression capacitor(s). Remove and test C1, C2, C3, C4A or C4B. Replace if defective.

2. Lamphouse, power supply, or sound system not properly grounded. Connect to adequate earth ground.

3. Leads between lamphouse and automation contact not shielded. Shield leads in conduit. (“AUTO”

Mode applications only .)

Excessive light flicker ..

1. Faulty or aged bulb. Check for cracked or sagging electrodes; replace if defective.

2. Excessive ripple in DC output. See power supply manual.

3. Arc stabilization magnet reversed. NORTH pole should point toward opertor’s side. Check with

compass if required.

Reduced light output.

1. Normal bulb aging. Increase output current. DO NOT EXCEED MAXIMUM CURRENT LEVEL

SPECIFIED BY BULB MANUF ACTURER.

2. Soiled reflector. Clean using commercial glass cleaner; USE NO ABRASIVES.

3. Soiled heat filter, projection lens, or large lens. Clean as required.

Extremely long duration between ignition pulses.

1. Low DC “no load” voltage from the xenon power supply. Check “no load” voltage; see power supply

manual.

2. Defective spark gap. A “Ping” sound is normal; excessive “Hissing” is abnormal. Replace if defective.

XG2/023

Page 26

Extremely long duration between ignition pulses (continued)

3. Low AC voltage to lamphouse. Check for 115 V.AC at 2 & 4; if below 95 volts, check stepdown

transformer in xenon power supply. See power supply manual.

4. Defective timer IC chip on igniter PC board. Replace if defective.

Igniter continues to fire after bulb ignites.

1. Faulty igniter printed circuit board. Replace circuit board IMMEDIATELY to prevent bulb damage.

Color gels burning or fading prematurely .

1. Bulb focused to “hot spot.” Refocus bulb to flat field with iris fully open and spot size control handle

(“trombone”) fully forward.

2. Heat filter glass reversed or peeled. Check for coated surface toward bulb; replace if coating peeled.

3. Reflector coating peeled. Replace if defective.

XG2/024

Page 27

1

2

3

4

6

5

7

8

13

12

11

XG2/025

10

9

FIGURE 1

Page 28

PARTS LIST

Figure 1

Item Part No. Description

1 39964 T op Cover & Door Welded Assembly

- 4100371 Screw, 10-32 x 3/8" Pan Head

- 00885 Lockwasher, #10

2 39139 Magnetic Door Catch (2 req’d.)

3 48930 Arc Viewing Port

4 65353 DANGER Label

5 81282 CAUTION Label

- 01639-5 Pop Rivet, 1/8"

6 39964 T op Cover & Door Welded Assembly

7 39995 Base Adapter Assembly

- 39125 Base Plate

- 39126 Base Channel, Right

- 39127 Base Channel, Left

- 39128 Front Shim

- 4110310 Screw, 10-24 x 5/16" Flat Head

- 39129 Shim, Rear & Center

- 4250623 Screw, 1/4-20 x 5/8" Hex Head

- 4257000 Lockwasher, 1/4" Split Ring

8 4100502 T amperproof Screw, 10-32 x 1/2" Holt Head

- 4107101 Flatwasher, #10

- 4108021 Tinnerman Nut, #10 (Clip-On)

- 65149A Screwdriver (for 4100502)

9 39219 Name & Data Plate, Super Lume-X

- 01639-2 Pop Rivet, 1/8"

10 65968 Cover Assembly, Bulb Adjust Controls

- 65140 Cover Plate

- 65166 Plunger, Black Plastic

- 65167 Grommet, Black Plastic

11 39954 Back Casting Assembly (see Fig. 3 & 4)

12 39982 Igniter Access Panel

- 4080310 Screw, 8-32 x 5/16" Pan Head

- 4087004 Lockwasher, #8

13 57275 Plug Button, Emergency Ignite Switch

71284 Cam Lock & Key, Lamphouse Access Door

25372 Cam Lock Security Screw , Special Hex Head

NOT SHOWN

XG2/026

Page 29

1

2

3

4

5

6

7

8

9

10

11

19

18

12

13

14

15

16

17

FIGURE 2

XG2/027

Page 30

PARTS LIST

Figure 2

Item Part No. Description

1 65111 Front Casting

2 - Douser Assembly not used on

3 - Gladiator Lamphouse

4 41-98034 Hole Plug, 1/2" (not shown)

5 39972 Lamphouse Base Pan

- 4100371 Screw, 10-32 x 3/8" Pan Head

- 4107001 Lockwasher, #10

- 4108021 Tinnerman Nut, #10

6 65948 Lead Assembly , Shunt to Binding Post

7 39953 Negative Lead & Contact Assembly

- 4250373 Screw, 1/4-20 x 3/8" Hex Head

- 4257001 Lockwasher, 1/4"

8 39931 Block & Post Assembly , Front Bulb Support

- 4250507 Mounting Screw , 1/4-20 x 1" Hex Head Nylon

9 39975 Bulb Support Yoke

- 01704 Spring Pin, Height Adjust

- 4080259 Set Screw, 8-32 x 1/4"

10 - Bulb Adapter not required in Gladiator Lamphouse

11 39978 Reflector Assembly, Potted Assembly (as shown)

11 39876 Flanged Reflector, 11" Dichroic (current production)

- 65435 Reflector Adapter Ring, Black Enamel (incl. with 39876)

- 21-58001 Compression Spring, Long

- 18194 Shoulder Bolt

- P-3055 Compression Spring, Short

- 4250870 Ring Mounting Screw, 1/4-20 x 7/8" Hex Head

12 65114 Reflector Bulkhead Casting

- 4250752 Mounting Screw, 1/4-20 x 3/4" Hex Head

- 39149 Tie Rod (to Front Casting)

- 4258001 Hexnut, 1/4-20

- 39179 Arc Stabilization Magnet

- 81137 Magnet Clamp

- 39178 Mounting Plate, Magnet Clamp

13 39939 Cable Assembly, Lamphouse to Power Supply

- 88318 MS Connector, (14) Pin (not shown)

14 39938 Lamphouse Blower Assembly , 1 15 V.AC, 50/60 Hz.

- 85109 Air Vane Switch (S6), 60 Hz.

- 39955 Air Vane Switch (S6), 50 Hz.

- 83131 Blower Inlet Grille

XG2/028

Page 31

P ARTS LIST, Figure 2 (continued)

Item Part No. Description

15 - Bulb Adapter not required in Gladiator Lamphouse

- 39194 Anode Clamp, Gladiator II

16 39933 RF Suppression Capacitor Assembly (C1,C2,C3)

17 39165 Shield, Printed Circuit Board

- 4080252 Screw, 8-32 x 1/4" Socket Head

- 4087000 Lockwasher, #8

18 39949A Igniter Assembly (see Figure 5)

19 39954 Back Casting Assembly (See Figures 3 & 4)

XG2/029

Page 32

1

3

2

4

5

6

13

12

FIGURE 3

11

10

9

XG2/030

8

7

Page 33

PARTS LIST

Figure 3

Item Part No. Description

1 65142 Ammeter (M2)

2 81276 MODE Switch (S3)

3 81275 LAMP Switch (S2)

4 65116 Casting, Bulb Adjust Mechanism

5 37985 Thumb Screw

- 15010 Compression Spring

- 65150 Fender Washer

6 65112 Rear Casting

7 65959 Focus Screw & Bearing Assembly

- 21-48027 Snap Ring, Bulb Collet

8 65153 Knurled Lockscrew

9 41-98013 Plug Button, 3/8"

10 39970 VOLTAGE Switch Assembly

- 72275 Switch, Pushbutton (S5)

- 39151 Resistor (R2)

- 39152 Label, “Press for Voltage”

11 39976 Elapsed Time Meter (M1), 60 Hz.

- 39974 Elasped Time Meter, 50 Hz. (Export)

- 4040500 Mounting Screw , 4-40 x 1/2" Round Head

- 4048003 Hexnut, 4-40

- 4047001 Lockwasher, #4

12 4080310 Screw, 8-32 x 5/16" Pan Head

- 4087004 Lockwasher, #8

13 65107 Instrument Panel (less Components)

XG2/031

Page 34

15

1

14

13

12

11

10

2

3

4

5

6

9

8

7

FIGURE 4

XG2/032

Page 35

PARTS LIST

Figure 4

Item Part No. Description

1 39969 Potentiometer Assembly (early models*)

2 79131 Ground Lug

- 4080311 Screw, 8-32 x 5/16" Socket Head

- 4087000 Lockwasher, #8

3 39143 Cable Clamp

4 40913 Igniter Printed Circuit Board

4 39966 Igniter Printed Circuit Board**

- 39154 Relay (K201)

- 39155 PCB Stand-Off, Nylon

5 81143 Strain Relief Cable Clamp

- 39939 Cable Assembly , Lamphouse to Power Supply

6 82167 Shunt (R1)

- 4101004 Mounting Screw, 10-32 x 1" Pan Head

- 4107000 Lockwasher, #10 Split Ring

7 39130 Barrier Strip, (15) Terminal

- 39153 Insulation & Marker Strip

8 39921 Wire Harness Assembly (incl. Item 7)

9 81947 Capacitor Assembly (C5)

- 41 10250 Grounding Screw, 10-24 x 1/4" Socket Head

- 4107000 Lockwasher, #10

10 39986 Capacitor Assembly

- 80177 Capacitor (C4A)

11 80168 Door Interlock Switch

- 39622 Bracket

- 4060501 Screw, 6-32 x 1/2" Flat Head

- 4067001 Lockwasher, #6

- 4098001 Hexnut, 6-32

12 39194 Anode (+) Clamp

- 4080870 Clamping Screw , 8-32 x 7/8" Socket Head

13 39952 Bulb Support Collet

14 39945 Igniter Cable & Clamp Assembly

- 4250373 Screw, 1/4-20 x 3/8" Hex Head

- 4257000 Lockwasher, 1/4"

15 72199 Wire Tie Mount, Self-Adhesive

* Used with Strong Type 88000 Power Supplies only

** Used with High Reactance Power Supplies (pre-1989) only

XG2/033

Page 36

IGNITER ASSEMBLY

2

1

3

4

5

6

10

9

7

8

FIGURE 5

XG2/034

Page 37

PARTS LIST

Figure 5

Item Part No. Description

1 80168 Cover Interlock Switch (S101)

2 39113 Switch Bracket

- 4100251 Screw, 10-32 x 1/2" Flat Head

3 80168 Emergency Ignite Switch (S102)

4 39110 High Voltage Capacitor (C107, 108)

- 4080252 Screw, 8-32 x 1/4" Socket Head

- 4087001 Lockwasher, #8

- 39112 Capacitor Mounting Plate

- 4251001 Screw, 1/4-20 x 1" Hex Head Nylon

- 4258015 Hex Nut, 1/4-20 Nylon

5 4080250 Screw, 8-32 x 1/4" Pan Head

- 4087001 Lockwasher, #8

6 39998 Case & Current Coil, Potted Assembly

- 65353 DANGER Label

7 39201 * Spark Gap Body, Nylon

- 4110501 Screw, 10-24 x 1/2" Pan Head

8 39107 * Contact Screw, Tungsten

- 39109 Terminal Tab

- 4107100 Flatwasher, #10 Brass

- 4088001 Hexnut, 8-32

* 39923 Spark Gap Assembly (Items 7 & 8, Gapped)

9 39937 High Voltage Transformer (T102)

- 4087101 Flatwasher, #8

- 4088001 Hexnut, 8-32

10 39204 Transformer Spacer

NOT SHOWN

39101 Cover, Igniter Box

4060250 Cover Mounting Screw , 6-32 x 1/4" Pan Head

XG2/035

Page 38

LAMPHOUSE EXHAUST BLOWER

Assembly No. 47935

72375

47936

71220

39173

78133

81545

Switch Location,

earlier models

Part No. Description

39173 Switch Bracket

47936 Blower Housing, Welded Assembly

71220 Blower (B2), 115 V.AC, 50/60 Hz.

40937 Plug & Cord Assembly

72375 Barrier Strip, (2) Terminal

78133 Air Flow Switch (S4)

81545 Actuator, Air Flow Switch

XG2/036

Page 39

FIGURE 6

XG2/037

Page 40

PARTS LIST

Figure 6

Item Part No. Description

1 49943 Lifting Strap

2 4377102 Flatwasher, 3/8"

3 49120 Tilt Axis Bolt

4 4378002 Locknut, 3/8-16 Hex

5 02411 Washer, .640" I.D. x 1-1/4" O.D.

6 49126 Clamp Plate

7 49125 Compression Spring, Tilt Clamp

8 49124 Spring Bushing

9 49223 Clamp Shaft

10 49130 Clamp Handle

11 10048A Knob, Round Plastic

12 49290 Swivel Clamp Shaft

- 49291 Stop Plate, Horizontal Swivel

- 4372500 Bolt, 3/8-16 x 2-1/2" Square Head

13 49130 Clamp Handle

14 83799 Base Column, Welded Assembly

15 83297 Mounting Bolt, Base Leg

- 4377001 Lockwasher, 3/8" Split Ring

16 83797 Base Leg, Welded Assembly

- 47238 Tandem Caster, Locking (not shown)

17 49226 Leveling Foot

- 4508001 Locknut, 1/2-13 Hex

18 83294A Height Adjustment Pin

19 83794 Tube & Collar Assembly

20 83113 Needle Bearing

21 83114 Race, Needle Bearing

22 49213 Swivel Clamp Collar

- 4250503 Screw, 1/4-20 x 1/2" Hex Head

- 4257000 Lockwasher, 1/4" Split Ring

23 83357 Y oke Cover Plate

- 4080375 Screw, 8-32 x 3/8" Pan Head

- 4087001 Lockwasher, #8

24 83112 Collar, Inner Tube

- 4260370 Set Screw, 1/4-28 x 3/8" Dog Point

25 47951 Yoke Assembly

26 4371120 Screw, 3/8-16 x 1"

- 4377001 Lockwasher, 3/8"

- 4377103 Flatwasher, 3/8"

- 4378001 Hexnut, 3/8-16

27 47958 Saddle & Quadrant Assembly

28 83341 Cable Clamp

- 4250623 Screw, 1/4-20 x 5/8" Hex Head

XG2/038

Page 41

FIGURE 7

XG2/039

Page 42

PARTS LIST

Figure 7

Item Part No. Description

1 49342 Hand Rail

- 4317000 Lockwasher, 5/16" Split Ring

- 4310500 Screw, 5/16-18 x 1/2" Hex Head

2 47944 Blower Assembly (B3), with Item 5

- 44191 Blower Motor & Squirrelcage, 115 V.AC

- 21-40011 Plug, (2) Pin Male

- 31-62007 Molex Pin, Male

- 21-40019 Receptacle, (2) Pin Female

- 31-62006 Molex Pin, Female

3 4080375 Screw, 8-32 x 3/8" Pan Head (as req’d.)

4 47177 Receptacle Bracket (not req’d. in current units)

5 21-71066 Cable, 18/2 T ype SJ (incl. with Item 2)

6 47965 Base Rail, Welded Assembly

XG2/040

Page 43

FIGURE 8

XG2/041

Page 44

PARTS LIST

Figure 8

Item Part No. Description

1 51417 Large Lens Retainer

2 51914 Lens Ring, Welded Assembly

3 51418 Rubber Gasket, Lens Mount

4 51408 Large Lens, 11" Diameter

5 4080250 Screw, 8-32 x 1/4" Pan Head

6 00919 Cotter Pin, 1/16" x 1/2"

- 4107100 Flatwasher, #10 Brass

7 51133 Adjusting Block, Lens Focus

- 4060253 Screw, 6-32 x 1/4" Socket Head

- 4067001 Lockwasher, #6

8 51352 End Casting, Front

9 47207 Stud, Lens Focus Adjust

- 4250508 Screw, 1/4-20 x 1/2" Pan Head

- 4257004 Lockwasher, 1/4"

10 51454 Adjusting Screw, Lens Focus

11 48127 Retaining Ring

12 4250508 Screw, 1/4-20 x 1/2" Pan Head

- 4257004 Lockwasher, 1/4"

13 4080120 Set Screw, Focus Adjust Knob

14 51168 Focus Adjust Knob

15 51114 Stop Collar, Slide Rod

- 4100180 Set Screw, 10-32 x 3/16"

16 51479 Rubber Bumper

17 51910 Ribbon Assembly, Lens Focus

18 4110371 Screw, 10-24 x 3/8" Socket Head

- 4107000 Lockwasher, #10 Split Ring

19 51509 Handle, Red Plastic

20 51441 Handle Shaft

- 51428 Retaining Ring

21 51350 Support Casting, Large Lens Carriage

22 4258015 Locknut, 1/4-20 Hex Nylon

23 4251001 Friction Brake Screw, 1/4-20 x 1" Hex Head Nylon

24 47968 Base Pan, Welded Assembly

25 51453 Slide Rod (Left & Right)

26 51160 Pulley Stud

- 4087100 Flatwasher, #8 Brass

27 47210 Large Pulley

XG2/042

Page 45

P ARTS LIST, Figure 8 (continued)

Item Part No. Description

28 51162 Expansion Spring, Ribbon Tension

29 51354 Support Bracket, Slide Rods

- 4250508 Screw, 1/4-20 x 1/2" Pan Head

- 4257004 Lockwasher, 1/4"

30 51120 Retaining Clip, Spring & Ribbon

- 4080310 Screw, 8-32 x 5/16" Pan Head

- 4087004 Lockwasher, #8

- 00919 Cotter Pin, 1/16" x 1/2"

31 4250508 Screw, 1/4-20 x 1/2" Pan Head

- 4257004 Lockwasher, 1/4"

32 51353 End Casting, Rear

33 83163 Small Pulley

34 51160 Pulley Stud

- 4087100 Flatwasher, #8 Brass

35 47967 Lens Mechanism Housing, Welded Assembly

- 23059A STRONG Insignia

- 47168 GLADIATOR Insignia

- 45237 Insignia, Roman Numeral “II”

- 47962 Rubber Light Baffle, for Item 20 Shaft

36 83160 Support Casting, Projection Lens

37 4080372 Screw, 8-32 x 3/8" Flat Head

38 83144 Mounting Tube, Projection Lens

39 44239A Projection Lens, Compound

40 83155 Retaining Ring, Projection Lens

41 47211 Pulley, Lar ge Lens Carriage

XG2/043

Page 46

58

59

FIGURE 9

Item 58 Bracket mounts to

back surface of Item 31.

XG2/044

Page 47

PARTS LIST

Figure 9

Item Part No. Description

1 10048A Knob, Red Plastic

2 51451 Iris Shaft

3 406037B Screw, 6-32 x 3/8" Pan Head

4 4067001 Lockwasher, #6

5 51978 Friction Spring & Button

- 51229 Friction Pad

6 4060621 Screw, 6-32 x 5/8" Socket Head

7 4067001 Lockwasher, #6

8 51979 Iris (as shown; see Fig. 9A for current configuration)

- 83181 Plate, 51979 Iris

- 83182 Retaining Clip, 51979 Iris

9 51226 Pivot Stud

10 83773 Aperture Support Plate

11 51160 Pulley Stud

12 83163 Large Pulley

13 4087100 Flatwasher, #8 Brass

14 47191 Masking Blade

15 47982 Slide Assembly, Masking Blade

16 4087000 Lockwasher, #8 Split Ring

17 4080375 Screw, 8-32 x 3/16" Pan Head

18 4257102 Flatwasher, 1/4"

19 51156 Friction Plate (Replace with 4507106 Friction Washer)

20 83134 Fadeout Pull Rod, Long

21 4257000 Lockwasher, 1/4" Split Ring

22 4258001 Hexnut, 1/4-20

23 4107100 Flatwasher, #10 Brass

24 4107001 Lockwasher, #10

25 4080250 Screw, 10-32 x 1/4" Pan Head

26 4080250 Screw, 10-32 x 1/4" Pan Head

27 4107001 Lockwasher, #10

28 4107100 Flatwasher, #10 Brass

29 83351 Retaining Strip, Fadeout Bracket

30 51226 Pivot Stud

31 83890 Fadeout Support Assembly

32 83892 Fadeout Blade, Lower

33 83891 Fadeout Blade, Upper

34 51153 Spacer Bushing

XG2/045

Page 48

P ARTS LIST, Figure 9 (continued)

Item Part No. Description

35 83133 Fadeout Pull Rod, Short

36 01704 Spring Pin

37 51357 Cover Plate Casting

38 4250508 Screw, 1/4-20 x 1/2" Pan Head

39 10048A Knob, Red Plastic

40 51155 Control Lever, Fadeout Mechanism

41 83143 Fadeout Lever Bracket

42 10048A Knob, Red Plastic

43 51452 Control Lever, Masking Blades

44 51498 Masking Blade Pull Rod, Short

45 51156 Friction Plate (Replace with 4507106 Friction W asher)

46 4317100 Flatwasher, 5/16"

47 4318004 Hexnut, 5/16-18 FlexLock

48 MAL-64 Spacer (early models only)

49 4257000 Lockwasher, 1/4" Split Ring

- 4257102 Flatwasher, 1/4"

50 4258001 Hexnut, 1/4-20

51 4318004 Hexnut, 5/16-18 FlexLock

52 48406 Bracket, Masking Blade Control Lever

53 51153 Spacer Bushing

54 51497 Masking Blade Pull Rod, Long

55 47170 Stop Bracket, Iris Lever

56 4087004 Lockwasher, #8 Split Ring

57 4080250 Screw, 8-32 x 1/4" Pan Head

58 47966 Mounting Bracket, Heat Filter Glass

- 4100371 Mounting Screw, 10-32 x 3/8" Pan Head

- 4107104 Lockwasher, #10

59 65122A Heat Filter Glass, Coated

83788 Aperture Plate, Masking Blades, and Iris

83790 Fadeout Mechanism and Blades

ASSEMBLIES

(Items 1-17, 42-50, & 52-57)

(Items 18-36, 39-41, & 51)

XG2/046

Page 49

Part No. Description

21-37001 Roll Pin, 3/32 x 9/16"

21-70029 Spring W asher

24369 Bell Crank

24372 Adapter Ring

24374 Iris

25017 Bushing (with 41-51530)

25034 Iris Clamp

406037B Screw, 6-32 x 3/8"

4080621 Screw, 8-32 x 5/8"

41-51530 Shoulder Bolt

51451 Iris Control Handle

81432 Shoulder Screw

72-00075 Link

41-51530,

25017

406037B

FIGURE 9A

51451

24369

406037B

24374

21-70029

21-37011

72-00075

83773

ref. Figure 9,

Item 10

81432

4080621

25034

24372

XG2/047

Page 50

47

FIGURE 10

XG2/048

Page 51

PARTS LIST

Figure 10

Item Part No. Description

1 51376 Cover Plate, Gel Frame

2 51928 Gel Frame & Slide Channel

3 01456 Paper Fastener

4 4068001 Hexnut, 6-32

5 4067001 Lockwasher, #6

6 51926 Plate & Slide Channel, Ultra Violet

7 51192 Ultra Violet Lens

8 51406 Clip, UV Lens

9 406037B Screw, 6-32 x 3/8" Pan Head

10 4088001 Hexnut, 8-32

11 4087000 Lockwasher, #8 Split Ring

12 51404 Support Arm

13 51396 Catch, Color Arm

14 4080754 Screw, 8-32 x 3/4" Pan Head

15 51379 Mounting Bracket, Right

16 4107000 Lockwasher, #10 Split Ring

17 4110501 Screw, 10-24 x 1/2" Pan Head

18 51398 Nylon Washer

19 51402 Torsion Spring, UV Filter

20 51927 UV Arm Assembly

21 408037A Screw, 8-32 x 3/8" Pan Head

- 4087000 Lockwasher, #8 Split Ring

22 51465 Torsion Spring, Color Arm

23 51929 Color Arm Assembly, 6-1 1/16"

24 51403 Pivot Shaft, Color Arms

25 00919 Cotter Pin, 1/16" x 1/2"

26 4107101 Flatwasher, #10 S.A.E.

27 51922 Rocker Catch Assembly, Short

- 51506 Rubber Pad, Short

28 17219 Compression Spring, Release Button

29 51923 Rocker Catch Assembly, Long

- 51505 Rubber Pad, Long

30 90473 Compression Spring, Release Button

31 00919 Cotter Pin, 1/16" x 1/2"

32 51467 W asher , Color Release Button

33 51397 Color Release Button

34 51395 Rocker Catch Shaft

XG2/049

Page 52

P ARTS LIST, Figure 10 (continued)

Item Part No. Description

35 01475 Cotter Pin, 1/16" x 3/8"

36 51356 Cover, Boomerang Housing

- 4080506 Screw, 8-32 x 1/2" Pan Head

37 51166 Retaining Screw, Boomerang Cover

38 51930 Color Arm Assembly, 6-3/16"

39 51931 Color Arm Assembly, 5-1 1/16"

40 51932 Color Arm Assembly, 5-3/16"

41 51933 Color Arm Assembly, 4-1 1/16"

42 51934 Color Arm Assembly, 4-3/16"

43 51378 Mounting Bracket, Left

44 51399 Spacer

45 51400 Stop Shaft

46 51401 Rubber Stop

47 19893 Boomerang Heat Filter Assembly

- 47231 Bracket

- 47232 Heat Filter Mounting Disc

- 47233 Heat Filter

- 46150 Assembly Clip

PARTS NOT SHOWN

51913 Boomerang Housing & Hinge

51471 Rubber Bumper Pad, 7" x 8"

4080310 Screw, 8-32 x 5/16" Pan Head

4088001 Hexnut, 8-32

4087004 Lockwasher, #8

51355 Boomerang Housing Support Casting, Rear

4080372 Screw, 8-32 x 3/8" Flat Head

51864 Auxiliary Color Holder (replaces UV Filter)

NOTE: Color temperature reduction filters, required for use with television and videotape, are available from

theatrical supply dealers.

XG2/050

Page 53

Page 54

Loading...

Loading...