Page 1

ULTRA 80

Xenon Lamphouse

Type 40001, 40002

Rev. 5/99

STRONG INTERNATIONAL

a division of Ballantyne of Omaha, Inc.

4350 McKinley Street

Omaha, Nebraska 68112 USA

Tel 402/453-4444 • Fax 402/453-7238

Page 2

Page 3

PREFACE

THE STRONG ULTRA 80 is a reflector type, direct current lamphouse for large format (70mm+) motion picture projection which uses a horizontally mounted xenon bulb as the light

source. Type 40001 is designed for use with the XH7000HS xenon bulb, and Type 40002, for the

XH10000V(H) bulb. Both type bulbs are manufactured by the Hanovia Division, ORC Lighting

Products, Azusa, California. The lamphouse reflector is a metal, deep ellipse type, with a “cold”

(dichroic) coating to reduce aperture heat and prolong bulb life. The reflector is designed to operate

in a fixed position 34½ to 35 inches from the projection film plane.

USE ONLY THE SPECIAL XENON POWER SUPPLIES manufactured by Strong

International. The 40001 lamphouse requires a power supply capable of providing 120-160 DC amperes at 43-49 V.DC. Nominal operating current for a 7000 watt bulb is 150 amperes; do not exceed

160 amperes. The xenon power supply used with the 40002 lamphouse must be capable of producing

135-200 DC amperes at 52-58 V.DC. The nominal operating current of a 10,000 watt bulb is 180

amperes; do not exceed 200 amperes. The xenon power supply must also include a 120 V.AC

lamphouse control circuit.

THE ADJUSTMENT CONTROL to position the xenon bulb in relation to the reflector is located on the rear of the lamphouse, behind the removable cover panel. This control permits

horizontal and vertical movement and focus control of the xenon bulb.

A TERMINAL STUD, located near the bulb anode support on the base pan of the

lamphouse, is provided as a connecting point for the lamphouse DC (+) lead and the anode lead

attached to the xenon bulb.

THE LAMPHOUSE CONTROL PANEL includes a DC ammeter to display the

operating current of the lamp. A pushbutton switch above the ammeter changes the reading to indicate the DC voltage at the arc. This capability permits calculation of the lamp power while the lamp

is operating (amperes x volts = wattage). Pressing the switch at ignition will also briefly display the

“no load” DC voltage.

AN ELAPSED TIME METER indicates the total number of hours the lamp has been

in service and provides a means of noting the number of hours each xenon bulb has operated. It is

advisable to replace the xenon bulb upon expiration of warranty hours. See the warranty information

provided by the manufacturer of the xenon bulb.

THE LAMP BLOWER(S), internally wired in the lamphouse, operate on AC voltage

and are required to maintain the seals of the bulb at a safe operating temperature. The top blower is

fused at 3 amperes. A second side-mounted blower is used on the T ype 40002 to cool the reflector for

10,000 watt operation. The blowers will operate continuously until control voltage is turned off at the

xenon power supply .

U80/001

Page 4

TWO AIR FLOW SWITCHES, mounted to the exhaust duct and the blower intake,

will prevent ignition of the lamp if the top blower is not operating, or the exhaust air flow is inadequate. The eight-inch lamphouse exhaust stack connects to an externally installed exhaust system.

The exhaust system must be capable of removing 700 cubic feet per minute (c.f.m.) of free air from the

lamphouse, as measured at the lamphouse exhaust outlet.

THE LAMPHOUSE has an interlock switch on the side access door and one under the

igniter cover on the top of the lamphouse. Opening the side door or removing the plastic igniter cover

will open the AC control circuit and prevent operation of the xenon lamp. The lamphouse door has a

viewing port to permit observation of the xenon arc.

THE IGNITER is equipped with an emergency ignition switch, located beneath the

plug button on the igniter access panel on the top of the lamphouse.

THE “MODE” rocker type switch on the rear of the lamphouse provides the means of

operating the equipment from a remote AUTO system, or when placed in the “MAN.” position, from

the lamphouse.

THE LAMP “ON - OFF” SWITCH on the lamphouse instrument panel is used for bulb

ignition when the MODE switch is in the “MAN.” position. For AUTO operation, the LAMP switch

remains in the “ON” position.

THE LAMPHOUSE DOUSER is provided to permit shutting off the light to the projector at changeover. The lamp should not be operated for any extended time with the douser closed.

The small intense spot of light on the douser plate may cause deterioration of the plate. An Electric

Douser Kit, connected to the projector motor, is available as an option. This option automatically

closes the douser when the projector motor is switched OFF.

THE ULTRA 80 is not designed for use with 35mm projection. The highly intense

radiant energy generated by high wattage xenon bulbs will damage 35mm prints.

IF AT ANY TIME you have a suggestion, or desire aid in securing anticipated results,

write STRONG INTERNATIONAL, 4350 McKinley Street, Omaha, Nebraska 68112.

U80/002

Page 5

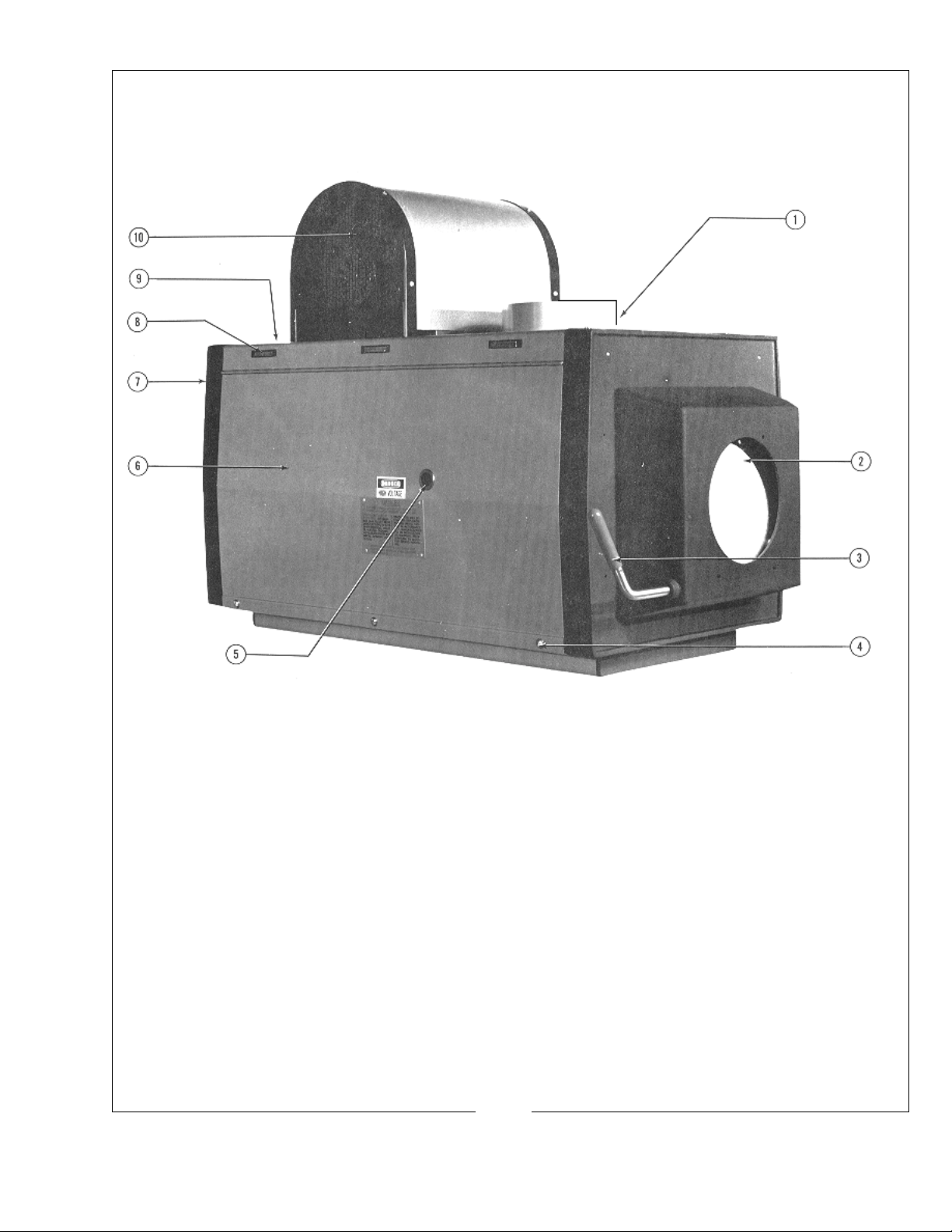

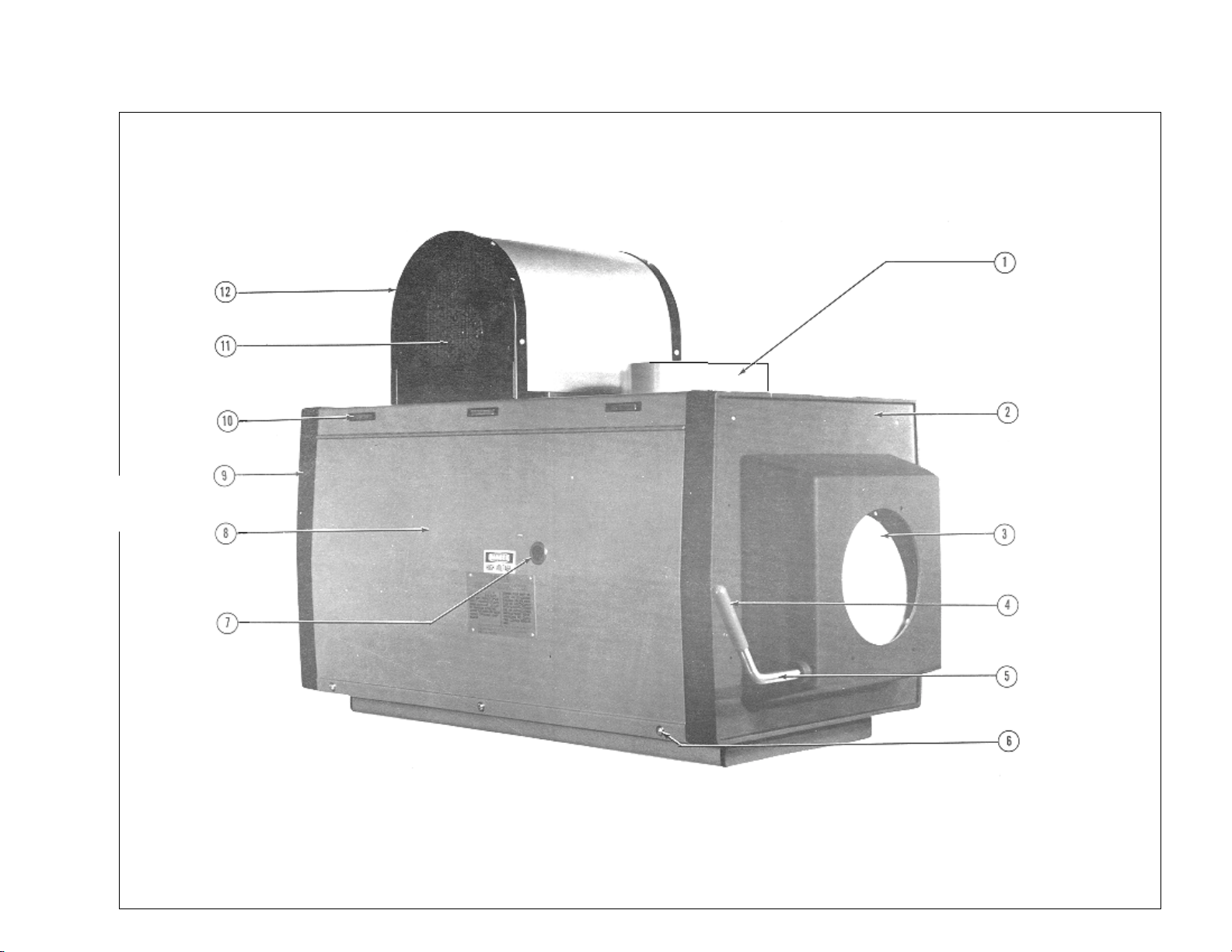

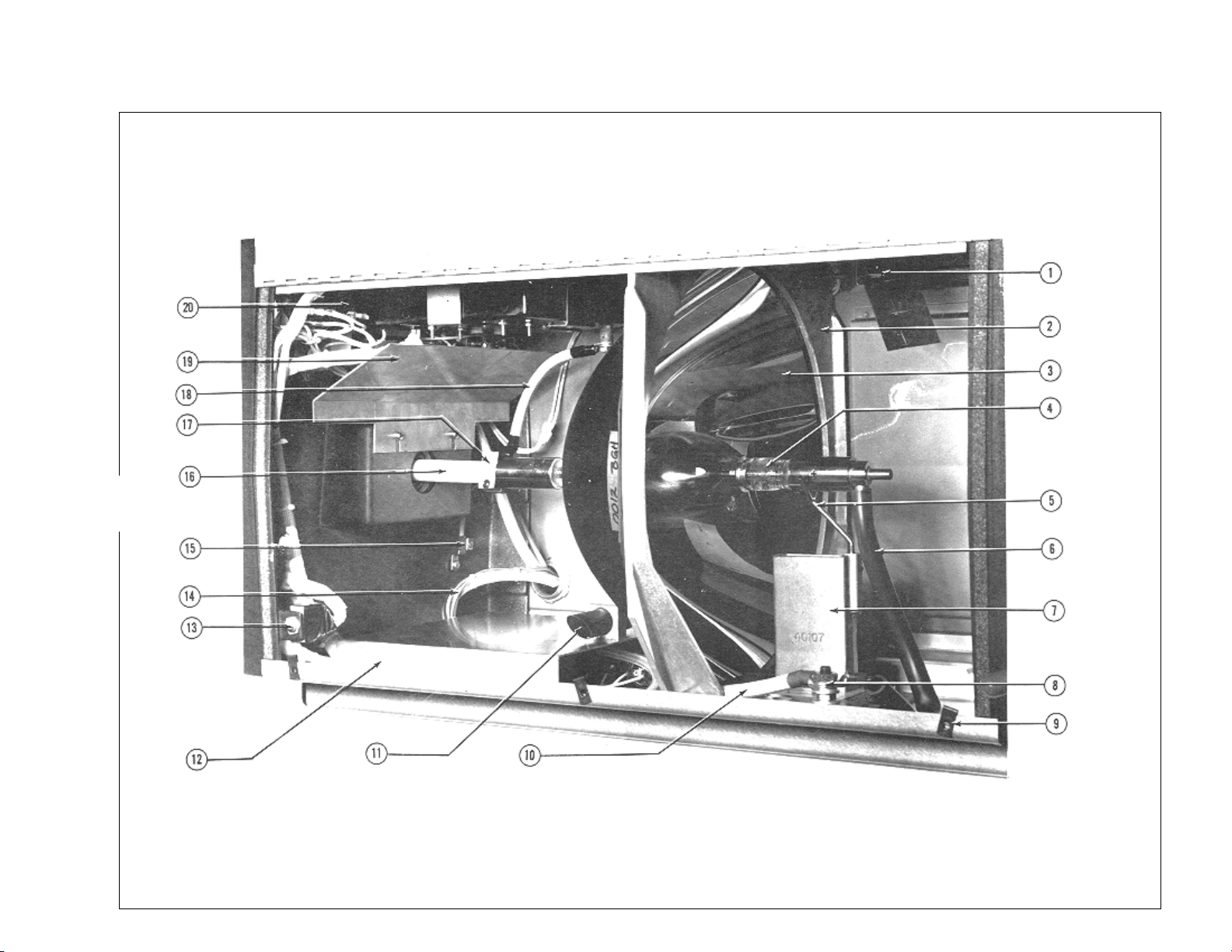

ULTRA 80 LAMPHOUSE

1. Exhaust Stack, 8 inch 6. Lamphouse Access Door

2. Douser Plate 7. Rear Casting & Instrument Panel

3. Douser Control Handle 8. Magnetic Door Catch (early models)

4. Tamperproof Screw 9. Emergency Ignition Switch*

5. Arc Viewing Port 10. Bulb Seal Blower

* Emergency Ignition Switch located below Plug Button on Access Plate.

U80/003

Page 6

MECHANICAL LAMPHOUSE ALIGNMENT

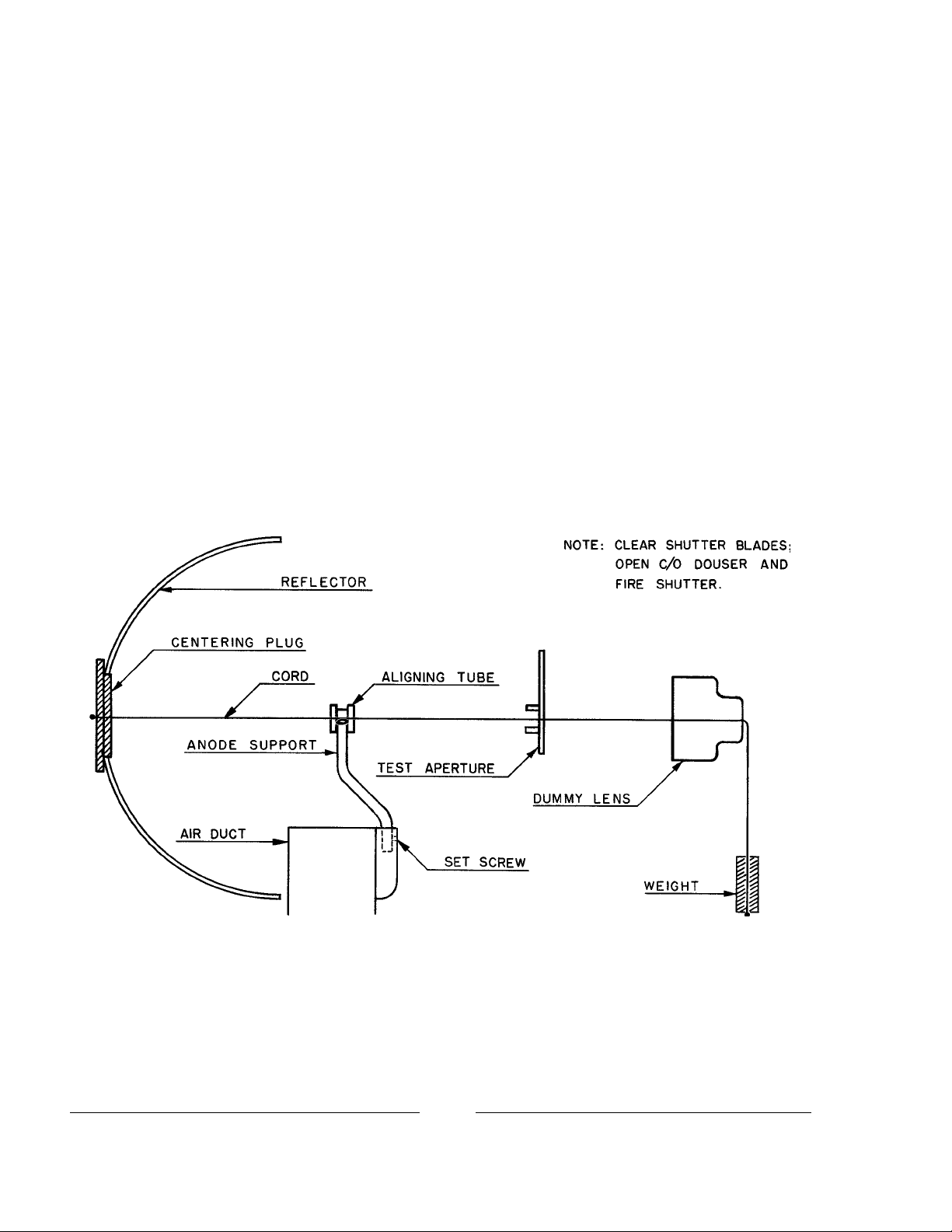

ONE ALIGNING KIT consisting of an aligning cord, aperture plate, dummy lens, and

centering plug is supplied with each lamphouse to provide an accurate and reliable method of optical

alignment of the lamphouse to the projector mechanism. Because of the relatively small arc produced

by the xenon bulb, good screen results can be obtained only by the careful use of this aligning kit.

PLACE THE LAMPHOUSE on the projection pedestal, making certain that it is centered between the ways. Open the side access door.

IF USING the optional Heat Filter, the filter holder bracket should be installed onto

the lamphouse before aligning the lamphouse to the projector. Do not insert the filter until the following aligning procedure has been completed.

POSITION THE LAMPHOUSE on the table so the center of the reflector measures as

near 34.5 inches from the projector aperture as the projector design will permit.

IN PREP ARATION for optical alignment, bolt the lamphouse temporarily to the pedestal table using the 5/16-18 cap screws shipped with the lamphouse accesssory kit.

U80/004

Page 7

INSERT THE CENTERING PLUG into the reflector opening, and secure the cord

behind it as illustrated. Place the aligning tube on the anode support yoke and run the cord through it.

Open the douser.

REMOVE THE PROJECTION LENS and pull the cord through the lens barrel. Pass

the cord through the dummy lens and tie the cord to an object of sufficient weight to hold the cord

taut. Position the test aperture as illustrated in the film trap of the projector. Close the film gate to

hold the test aperture in place.

MOST PROJECTOR BASES have adjustable lamphouse tables so the lamp can be

brought into optical alignment with the projector mechanism. If the lamphouse table is not adjustable,

use shims or washers at the front, rear, or at both ends of the lamphouse to obtain optical alignment to

the projector.

ALIGN THE LAMPHOUSE in relation to the projector so the cord passes through

the center of the hole in the test aperture, and the correct cord image is seen on the reflector. Set the

anode support yoke as illustrated and tighten the set screw in the air duct. DO NOT reposition the

reflector, as it is factory prealigned for maximum optical ef ficiency .

ONCE CORRECT ALIGNMENT is achieved, tighten the lamphouse mounting screws

to secure the lamphouse to the table. Remove the cord and associated fixtures and restore the operation of the fire shutter.

STORE THE ALIGNING KIT in a secure location in the projection booth. If the

Ultra 80 reflector is ever removed or replaced, it is necessary to repeat the entire cord alignment

procedure, Likewise, if a different type or wattage bulb is used in a subsequent relampment, it may be

necessary to re-align the anode yoke to position it for the optical center of the replacement bulb.

U80/005

Page 8

EXHAUST SYSTEM INSTALLATION

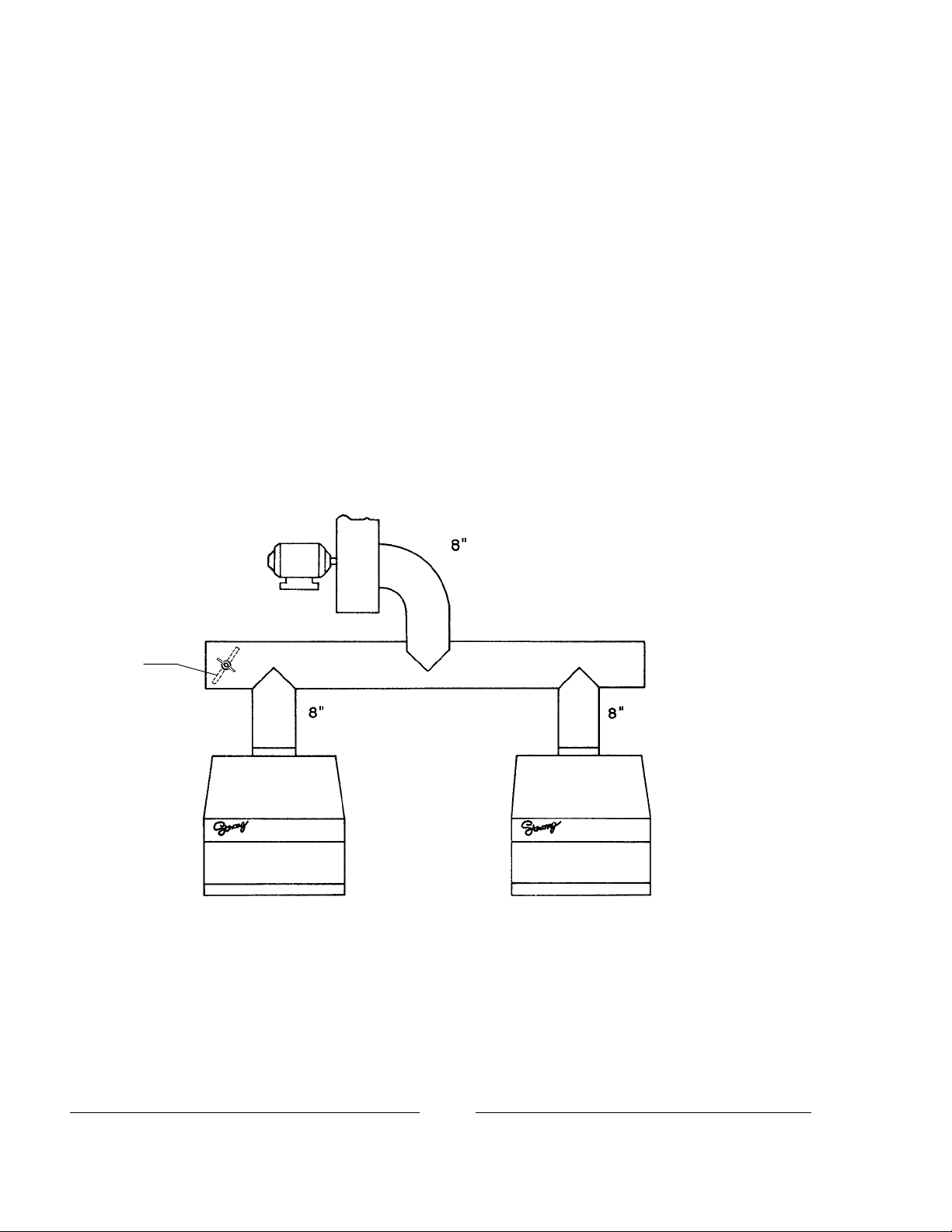

THE EXHAUST DUCT of the Ultra 80 is designed to fit an eight inch diameter

exhaust duct. This size ducting, either rigid or heat-resistant flexible, must be used throughout the

complete exhaust system. The exhaust system must be vented to outside air, and installed in such a

manner as to eliminate any possibility of downdraft or rain dripping into the lamphouse.

THE EXHAUST F AN must be capable of removing 700 cubic feet per minute (cfm) of

air, as measured at the exhaust outlet of the lamphouse. If more than one lamphouse is connected to

a common exhaust system, each individual lamphouse must meet the 700 cfm requirement.

IF THE EXHAUST AIR FLOW must be restricted for any reason, install bypasses

rather then dampers in the exhaust line.

Bypass

(as req’d.)

(700 cfm) (700 cfm)

CHECK EACH LAMPHOUSE for correct exhaust air flow . Insufficient exhaust draft

can severely shorten bulb life, and no credit will be allowed bulbs damaged in this manner . Inadequate

exhaust may also cause possible injury to personnel by overheating the lamphouse enclosure.

THE XENON BULBS approved for use in the Ultra 80 are designated as ozone free.

See “BULB INSTALLATION AND OPERATION.”

U80/006

Page 9

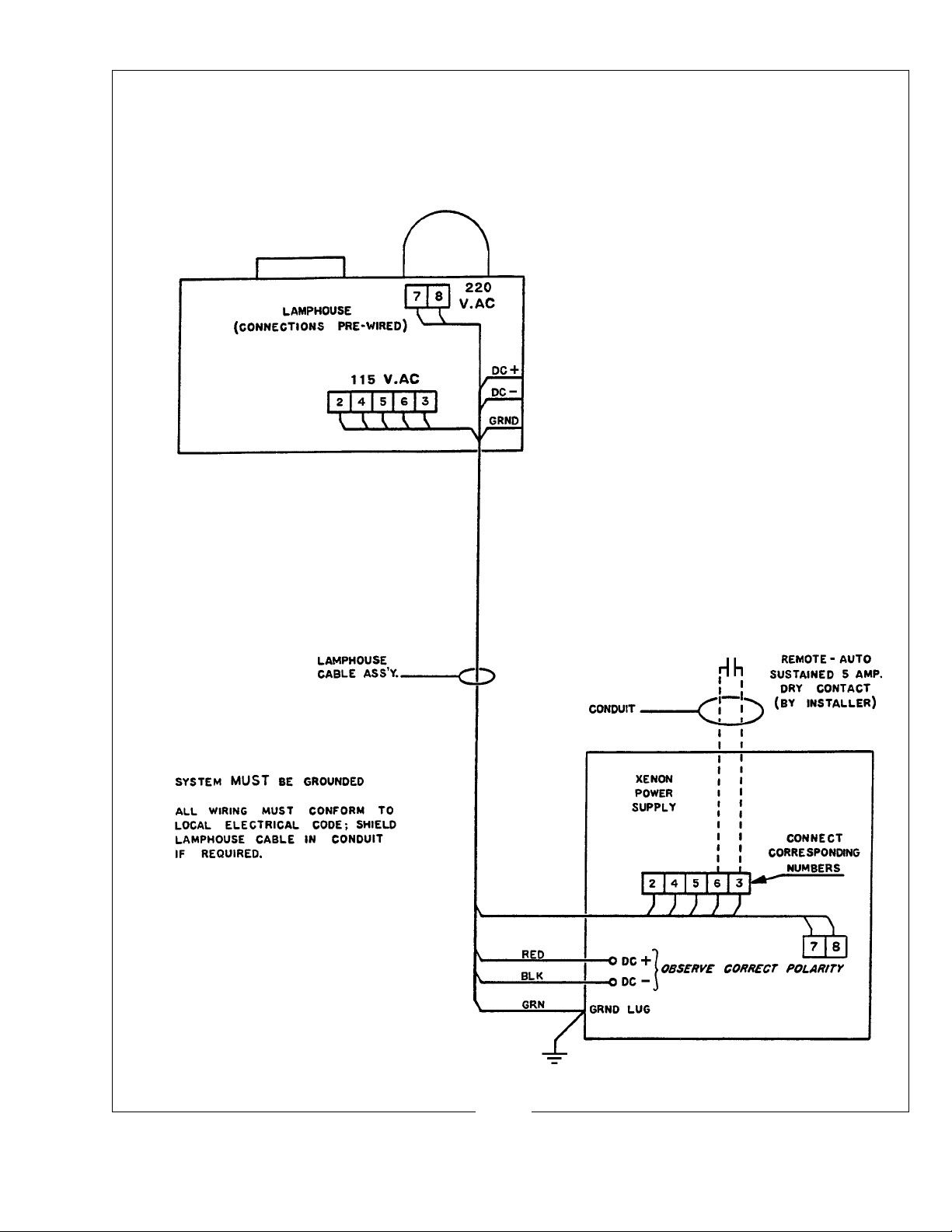

LAMPHOUSE - POWER SUPPLY INTERCONNECTION DIAGRAM

Ultra 80

U80/007

Page 10

WIRING INST ALLATION

THE LAMPHOUSE LEADS must be connected to the xenon power supply as illustrated on the Installation Diagram.

CONNECT THE TWO HEAVY FIBREGLASS INSULATED LEADS to the DC

outputs in the power supply. Observe correct polarity; red to positive (+), black to negative (-).

Tighten connections securely to prevent overheating. Leads 2, 4, 5, and 6 provide the 115 V.AC

control circuit between the lamphouse and power supply, and wires 7 & 8 (220 V.AC) power the

lamphouse blower. Connect them to their corresponding numbered terminals on the barrier strip in

the power supply cabinet.

COLOR CODE:

Brown #2

Red #3

Orange #4

Blue #5

Yellow #6

Grey #7

Black #8

BECAUSE OF HIGH VOLTAGES impressed during the ignition cycle, the xenon

lamphouse must be grounded. Connect the ground lead in the cable assembly (#8 AWG green) to the

terminal lug in the power supply cabinet. Make certain that the power supply is connected to an

adequate earth ground.

IF AUTOMATED or remote lamphouse switching is desired, it is generally more convenient to make such connections to the power supply barrier strip (3 & 6) as illustrated. See the

“AUTOMATION SYSTEMS” section following for detailed instructions.

ALL LEADS may be run in conduit or greenfield if desired, or if required by local

code. This may also be necessary as shielding to prevent electrical interference in the theatre sound

system.

IT IS RECOMMENDED to establish a routine of periodically checking all electrical

connections for tightness. Loose connections, particularly in the DC circuit, are subject to hazardous

overheating.

U80/008

Page 11

SAFETY PROCEDURES

THE XENON BULB is highly pressurized. When ignited, the normal operating temperature

of the bulb increases the pressure to a level at which the bulb may explode if not handled in strict accordance to

the manufacturer’s operating instructions. The bulb is stable at room temperature, but may still explode if

dropped or otherwise mishandled.

REFER bulb replacement and service to QUALIFIED PERSONNEL with adequate protective

clothing (face shield, clean cotton gloves, welder’s jacket). For routine lamphouse service, observe the following rules:

1. Allow the bulb to cool to room temperature before opening the lamphouse. Put on protective clothing

described above.

2. De-energize the xenon power supply at the AC source before opening the lamphouse compartment.

3. When possible, encase the bulb in its protective cover when cleaning or servicing the lamphouse inte-

rior. The bulb, when outside the lamphouse, must be encased in the cover.

4. Clean the bulb after it has cooled to room temperature. Do not touch the quartz envelope of the bulb;

fingerprints will burn in and create hot spots which may shorten bulb life. If fingermarks are made,

they should be carefully removed with methyl alcohol and cotton prior to bulb operation.

5. Never view an ignited bulb directly. BLINDNESS OR PERMANENT EYE DAMAGE MAY BE

INCURRED.

6. Use only xenon bulbs designated as OZONE FREE. When possible, vent the lamphouse exhaust to

outside atmosphere.

7. Maintain the lamphouse blower in good operating condition. Keep the blower inlet clean for unre-

stricted air flow .

8. To insure maximum bulb life, operate the lamphouse blower and the exhaust system for at least ten

minutes after extinguishing the bulb.

9. If returning a bulb for warranty adjustment, pack it in its original shipping container. Complete and

return all required warranty information.

10. Dispose of expired bulbs that are beyond warranty in the following manner: Wrap the bulb tightly in

several layers of canvas or heavy cloth. Place it on a hard surface and shatter the envelope with a sharp

hammer blow . DO NOT place an unshattered bulb in an ordinary refuse container.

11. DO NOT PERMIT UNAUTHORIZED PERSONNEL TO PERFORM OR A TTEMPT ANY PHASE

OF XENON BULB HANDLING OR SERVICE.

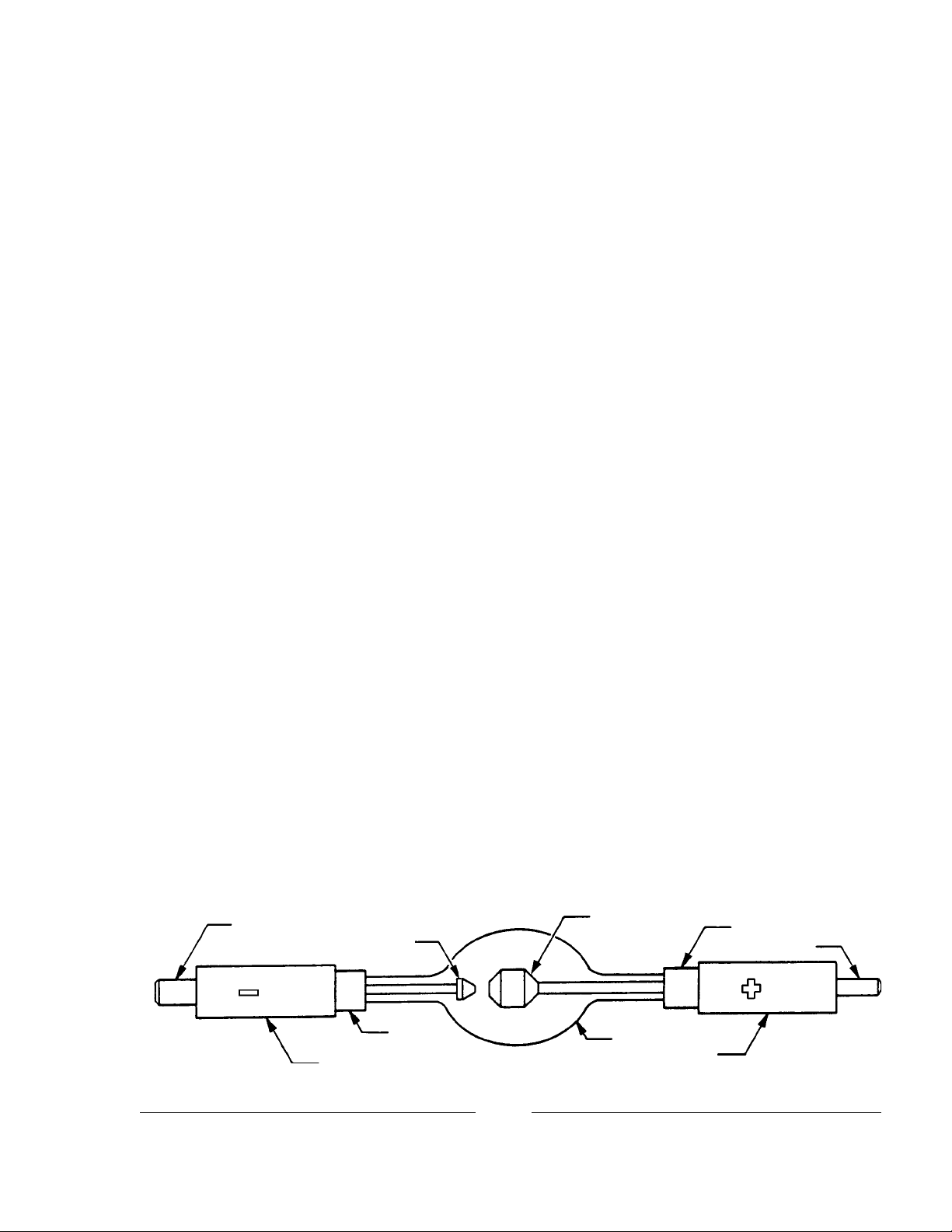

Cathode Pin

Cathode

Seal

Cathode End Cap

U80/009

Anode

Envelope

Anode End Cap

Seal

Anode Pin

Page 12

BULB INSTALLATION AND OPERATION

OBSERVE ALL SAFETY PROCEDURES. Bulb installation and replacement must

be performed by QUALIFIED PERSONNEL with protective clothing and face shield.

THE XENON BULB requires no adapters to mount in the Ultra 80. All bulb mounting fixtures and electrical connections are designed for use with the designated xenon bulb (7000 watt

for 40001; 10,000 watt for 40002). A silastic rubber tube is supplied with each lamp to permit insulating the bulb anode lead from the lamphouse base or other grounded metal components.

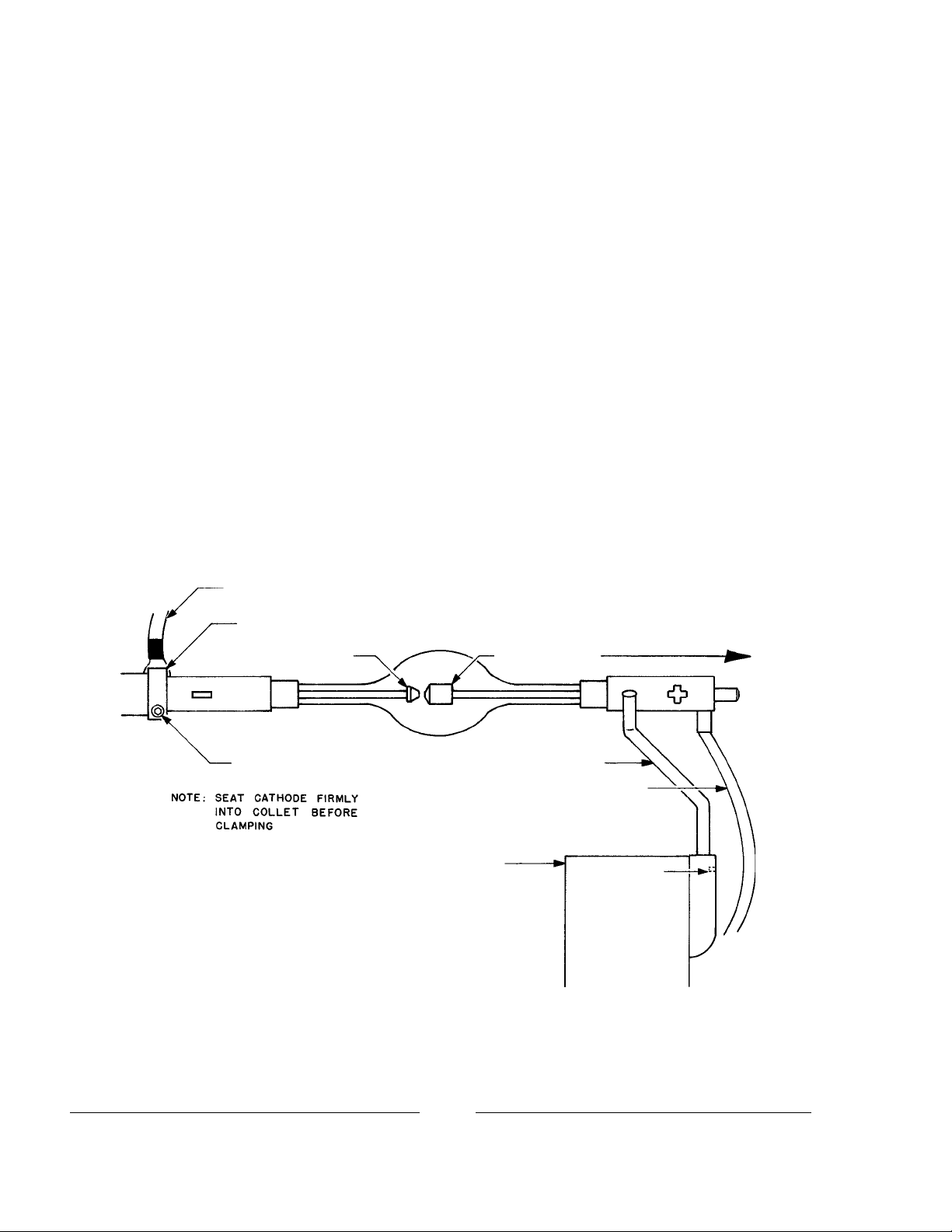

INSERT THE CATHODE (-) end of the bulb through the hole in the center of the

reflector. Seat the cathode pin into the cathode support collet as far as possible to permit full focus

travel of the bulb. Rest the anode (+) stem in the front support yoke and dress the anode lead directly

in front of the air duct. Securely tighten the socket head screw in the cathode clamp, taking care not

to apply any mechanical strain to the bulb vessel. Remove the hexnut, washer, and lockwasher from

the anode binding post in front of the reflector. Connect the anode lead to the binding post and tighten

securely .

Igniter Lead

Cathode Clamp

Cathode

Clamping Screw

Anode

Front Bulb Support Yoke

Bulb Anode Lead

Air Duct Casting

TOWARD

SCREEN

Set Screw

OBSER VE CORRECT POLARITY

REMOVE THE PLASTIC PROTECTIVE COVER (when applicable) from the bulb.

Close and secure the lamphouse door. Turn on the exhaust system. Place the MODE switch in the

“MAN.” position and close the douser.

U80/010

Page 13

TURN ON THE MAIN LINE SWITCH to energize the xenon power supply. The

POWER light on the lamphouse instrument panel will glow, the blower will start, and the air vane

switch will close to permit lamp operation. The lamphouse blower will operate continuously until the

main line switch to the power supply is opened.

PLACE THE LAMP SWITCH in the “ON” position and the bulb will ignite. Allow

the current to stabilize, and check the lamphouse ammeter. Set the power supply as required to supply

120-150 amperes to the 7000 watt bulb, or 150-180 amperes to the 10,000 watt bulb; DO NOT

exceed maximum rated current.

IF IGNITION does not occur, or the high voltage ignition pulse is not apparent, press

the emergency ignition switch located under the plug button on the top of the lamphouse. Do not hold

for more than one second; release immediately on bulb ignition. See the TROUBLESHOOTING

section following in this manual.

THE SMALL PUSHBUTTON SWITCH located directly above the ammeter may be

pressed while the lamp is operating to convert the meter reading to indicate the DC voltage at the arc.

This permits immediate calculation of the power at which the lamp is operating. Holding this switch

in at the ignition pulse will briefly display the “no load” voltage applied to the bulb for ignition.

REMOVE THE REAR COVER PANEL (two pull type knobs) to expose the bulb

position adjustment controls.

THE THUMB SCREWS on either side of the focusing control lock the horizontal and

vertical adjustment mechanism in position.

REMOVE THE PROJECTION LENS, start the projector, and open the douser. Do

not operate the lamp without the projector running.

TURN THE CENTER FOCUSING SECTION of the bulb position control until the

smallest black spot obtainable is focused on the projection screen. It may be best to run this adjustment both directions to permit positive identification of the spot. The position of the spot may be to

the right, left, top or bottom of the screen, and not necessarily in the center.

U80/011

Page 14

LOOSEN the two thumb

screws, one on either side of the focusing section, just enough to permit manual movement

of the complete assembly . The bulb adjustment

control will now move about these two thumb

screws, and as this control is shifted, the smooth

Support Y oke

Shadow

Anode

Shadow

Reflector

Hole

shadow of the electrode can be seen extending

beyond the projected hole in the reflector . The

electrode shadow must be centered inside the

projected hole of the reflector .

Projection Lens

removed

MOVE THIS CONTROL SECTION around the two thumb screws until the black

spot is as round as possible to project. It may be necessary to again adjust the focus control to define

a sharp spot. After the black spot is as even as possible to project, tighten the two thumb screws to

lock the adjustment section. This adjustment has now centered the projected image of the electrode

shadow and the hole in the reflector on the aperture and screen.

REPLACE THE PROJECTION LENS and rotate the focus adjustment until the

desired light distribution is projected to the screen. A void running the projector in this manner for an

extended period of time without frequently closing the lamphouse douser . W ithout film, the heat from

the xenon bulb can damage the projection lens.

THIS ADJUSTMENT should not be disturbed until it is necessary to replace or rotate

the xenon bulb. Then, only the bulb adjustments outlined above may have to be repeated; do not

disturb or adjust the optical alignment of the lamphouse on the projector table.

REPLACE THE REAR COVER PANEL over the bulb adjustment control mechanism. Press plungers into grommets to secure.

BECAUSE OF MANUF ACTURING TOLERANCES on the xenon bulb, and normal

aging, it may necessary to operate one lamp of a two-machine installation at slightly higher or lower

current to obtain equal light balance on the screen. This is done by adjusting the output of the xenon

power supply .

TO EXTINGUISH the arc, place the LAMP switch in the “OFF” position. The lamphouse blower will continue to operate until the main switch in the AC power line to the xenon power

supply is opened.

TO PROLONG BULB LIFE, leave the blower and exhaust fan operate for at least ten

minutes after turning off the lamp. Allow the bulb to cool to room temperature before opening the

lamphouse access door for any reason.

A PERMANENT MAGNET is mounted behind the reflector to stabilize the arc

between the electrodes of the ignited bulb. The magnet requires no adjustment. If the magnet is

removed for any reason, it must be replaced with the SOUTH pole nearest the lamphouse access door.

The south pole is stamped “S” and marked with paint.

U80/012

Page 15

AUTOMATION SYSTEMS

TO INTERCONNECT the lamp to an automation system, two #16 AWG wires (not

supplied by Strong) must be installed as illustrated on the Interconnection Diagram. These wires must

be shielded to prevent interference in the theatre sound system.

NOTE: Lamp ignition in “AUTO” mode is effected by a sustained dry contact closure between

terminals 3 and 6. DO NOT apply voltage to these terminals. Refer to instructions furnished by the

manufacturer of the automation controller.

TO OPERATE with an automation system, place the MODE switch in the “AUTO”

position, and the LAMP switch to “ON.” When the xenon power supply is energized, the lamphouse

POWER light will glow, and the blower will operate. The bulb will not ignite until provided a dry

contact between 3 and 6 by the automation controller . Opening this contact will extinguish the bulb,

and allow the POWER light and the blower to continue to operate.

IN THE EVENT of an automation failure, manual control of the lamp can be restored

by placing the MODE switch in “MAN.” and switching “ON or “OFF” with the LAMP switch.

U80/013

Page 16

MAINTENANCE

THE ULTRA 80 LAMPHOUSE requires very little maintenance to keep it in good

working order . Cleanliness is the most important element.

THE REFLECTOR should be cleaned periodically with a soft, clean, lint free cloth to

remove any dust from the reflecting surface. If excessively soiled, use of a mild commercial glass

®

cleaner (Windex

or equivalent) is acceptable; USE NO ABRASIVE CLEANERS.

THE XENON BULB should be checked occasionally for the presence of foreign material on the envelope. Any dirt or other foreign material should be removed promptly. Use only

alcohol and a clean cloth to clean the bulb; rinse with distilled water and dry carefully . DO NOT touch

the bulb with bare fingers, and observe all safety procedures when working around the bulb.

THE INSIDE OF THE LAMPHOUSE and the impeller blades of the blower should be

cleaned periodically, depending on the dust conditions at each installation. The grilles over the air

intakes can be removed for cleaning; do not allow dirt or dust to build up on the grille or in the fan

impeller.

THE XENON LAMPHOUSE does not require any lubrication other than at the

blower(s). Use two or three drops of non-detergent motor oil every four to six months. The oil holes

are located on the motor portion of the blower. Removing the blower covers will not affect the

mounting of the blowers.

CHECK ALL ELECTRICAL CONNECTIONS periodically for tightness, especially

the DC leads at the xenon bulb and at the shunt and igniter. Inspect crimped joints for oxidation, and

remake the connection if oxidized.

FOLLOW THE RECOMMENDATIONS of the xenon bulb manufacturer regarding

periodic bulb rotation. It is a general practice to rotate the bulb 180° at 50% of warranty life. After

rotating a bulb, increase current to the maximum allowable level, and operate the bulb at this elevated

level for three or four shows.

ALWAYS allow the lamphouse blower and the exhaust system to operate for at least

ten minutes after extinguishing the bulb. Failure to do so will shorten bulb life.

U80/014

Page 17

B2 Side Blower used on 10 kW Type 40002 only

5 & 6: 115 V.AC to Po wer Supply Contactor (K1)

3 & 6: 5 Amp. Dry Contact f or Remote-A uto Switching

(by Installer)

U80/015

Page 18

SCHEMATIC DIAGRAM

Parts List

Ref

Desig. Part No. Description

B1 40220 Bulb Seal Blower , 220 V.AC, 50/60 Hz.

B2 47944 Reflector Blower Assembly 115 V.AC, 50/60 Hz.

* B2 Used with 10,000 Watt Type 40002 ONLY *

C1,2 76132 Capacitor, .005 µf, 600 WVDC

C3 76133 Capacitor, .01 µf, 400 WVDC

C4A,B 76323 Capacitor, 1.0-1.0 µf, 600 WVDC

C5 81947 Capacitor, .05 µf, 500 WVDC

C6,7 88263 Capacitor, .05 µf, 600 WVDC

C8 39956 Capacitor, .05 µf, 2000 WVDC

DS1 78984 POWER Indicator Light, 1 15 V.AC

DS2 - Xenon Bulb, 7000 Watt; Order Hanovia XH7000HS

DS2 - Xenon Bulb, 10,000 Watt; Order Hanovia XH10000V(H)

E1 40987 Binding Post, DC Positive (+)

- 40131 Fibre Insulator

F1 40203 Fuse, 3 Amp. Slo-Blo

- 39199 Fuse Holder

M1 40971 Elapsed Time Meter, 60 Hz.

- 40963 Elapsed Time Meter, 50 Hz.

M2 40923 Ammeter , 0 - 300 Amp.

PCB 40913 Igniter Printed Circuit Board Assembly (Standard)

- 40984 Igniter PC Board (with High Reactance Power Supply)

R1 81247 Shunt, 50 mV.

R2 71283 Resistor, 90.9k Ohm, ¼ Watt, 1%

S1 80168 Door Interlock Switch

S2 81275 LAMP Switch, “ON - OFF”

S3 81276 MODE Switch, “AUTO - MAN.”

S4 39955 Air V ane Switch Assembly (Exhaust)

S5 85109 Air Vane Switch (Intake)

S6 72275 Voltage Test Switch

- 39999A Igniter Assembly

- 40902 Interconnect Cable, Lamphouse to Power Supply

Specify Equipment T ype and Serial Number when ordering replacement parts.

U80/016

Page 19

PRINCIPLE OF IGNITER OPERA TION

THE IGNITER is energized through the 115 V.AC control circuit when the LAMP

“ON-OFF” switch (S2) is depressed and all interlocks and air flow switches are closed.

CAUTION: Do not use the Emergency Ignition switch (S102) in the igniter until it is

determined that the polarity of the xenon bulb is correct. Use of the S102 switch bypasses the polarity

sensing diode (CR201) on the igniter printed circuit board; if polarity is not correct, the bulb will be

seriously damaged or destroyed. No credit is allowed on bulbs damaged by reversed polarity .

THE IGNITER supplies a high RF voltage pulse to the bulb, together with the high

“No Load” DC voltage from the xenon power supply, to ignite the xenon bulb. After the arc is

sustained, the AC circuit in the igniter is interrupted by the opening of K201 relay contacts on the

signal of the timer circuit on the PC board. The DC output of the xenon power supply is automatically

lowered to the power level required to maintain the arc. The DC power to the bulb is dependent upon

the bulb characteristics and the setting of the output of the xenon power supply .

DC VOLTAGE is applied to the printed circuit board from the xenon power supply,

energizing the 12 V.DC coil and closing the contacts of K201 relay , completing the AC circuit through

the igniter to the T102 high voltage (10 kV.) transformer. High voltage boost capacitor C107 is

charged to a voltage sufficient to cause breakdown across the E101 spark gap. Approximately 35 kV.

is supplied to the xenon bulb for ignition.

S101 is the igniter cover interlock switch and S102 is the Emergency Ignition switch,

which is a bypass for the K201 relay contacts and CR201 polarity sensing diode on the PC board.

Components C101, 102, and 103 function as RF bypass capacitors on the igniter . The C108 capacitor

serves as a coupling capacitor to the current coil.

THE PC BOARD operates on DC voltage from the xenon power supply. Capacitor

C201 across the positive #10 and negative #15 is an RF suppression capacitor. Resistor R201 and

zener diodes VR201 and 202 drop the DC voltage to 12 volts for the K201 relay coil. CR201 is the

polarity sensing diode. C204 is a polarized capacitor used for arc suppression at the K201 relay coil,

and CR202 functions as a transient protection diode.

THE FOLLOWING COMPONENTS are parts of the timing circuit on the PC board:

Timer chip U201, resistors R202, 203, and the polarized capacitor C203. The C203 capacitor functions as the timing control, and CR203 serves as the “ON” time control diode. C202 is the control

voltage isolation capacitor .

U80/017

Page 20

U80/018

IGNITER SCHEMATIC

Ref.

Desig. Part No. Description

C107 39110 Capacitor, 2400 pf, 20 kV.DC

C108 39110 Capacitor, 2400 pf, 20 kV.DC

E101 39923 Spark Gap Assembly

S101 80168 Cover Interlock Switch

S102 80168 Emergency Ignite Switch

T101 39937 High Voltage Transformer

- 39998 Case & Coil, Potted Assembly

Page 21

U80/019

Ref.

Desig. Part No. Description

C201 88263 Capacitor, .05 µf, 600 WVDC

C202 79127 Capacitor, .01 µf, 600 WVDC

C203 39156 Capacitor, 15 µf, 30/35 WVDC

C204 88249 Capacitor, .1 µf, 600 WVDC

CR201 85112 Diode, 2.5 A. 1000 PRV

CR202 85112 Diode, 2.5 A. 1000 PRV

CR203 85112 Diode, 2.5 A. 1000 PRV

K201 39154 Relay, P&B R10-E1-W2S800

- 39160 Relay Socket

- 39161 Relay Hold-Down Spring

R201 39157 Resistor, 1k Ohm, 12 Watt

R202 39158 Resistor, 100k Ohm, ½ Watt

IGNITER PRINTED CIRCUIT BOARD SCHEMATIC

WIRE MARKERS

A = 10

B = 15

C = 17

D = 38

Ref.

Desig. Part No. Description

R203 39159 Resistor, 200k Ohm, ½ Watt

U201 72185 Timer IC, Motorola MC11455P1

- 39164 IC Socket, (6) Pin

VR201 39211 Zener Diode, 1N5377A (40913*)

VR201 81519 Zener Diode, 1N5361 (40984*)

VR202 39162 Zener Diode, 1N4742

- 39145 PC Board (less Components)

* 40913 PCB Assembly, Standard

* 40984 PCB Assembly (Older Models using

High Reactance Power Supply)

Assembly Number written on Component Side of PCB.

Page 22

TROUBLE CHART

NOTE: When working inside the lamphouse, enclose the xenon bulb in its protective

covering and/or wear protective clothing and face shield. Do not touch the quartz envelope of the

bulb with bare fingers.

ALLOW THE LAMPHOUSE to cool, with all blowers operating, for at least (20)

minutes before opening the access door.

Normal Operation:

When the switch in the main AC supply line to the xenon power supply is placed in the “ON”

position, with the door interlock switch closed, the lamphouse POWER light will glow and the lamphouse blower(s) will operate. The top lamphouse blower will close the S4 air vane switch, and the

correct operation of the exhaust system will close the S5 air vane switch. These conditions complete

the circuit to the S2 LAMP “ON-OFF” switch.

Place the lamphouse MODE switch S3 in the “MAN.” position. When the lamphouse LAMP

switch S2 is in the “ON” position, the elapsed time meter will operate and the AC circuit (5 - 6) to the

xenon power supply will energize the circuitry necessary to supply DC voltage to the igniter and bulb.

There will be an audible high voltage arc ping at the spark gap in the igniter and at the xenon

bulb. The bulb should ignite immediately after one or two of these high voltage pulses, and the lamp

current will adjust to the sustaining level set at the xenon power supply. An aged or “warm” xenon

bulb may require repeated ignition cycles.

Troubleshooting:

If the xenon bulb does not ignite, observe the following operational sequences for assistance in

locating and isolating the trouble area.

When operating with a xenon power supply equipped with the red indicator light, and the light

is “ON,” the AC circuit in the power supply is trouble free up to the terminal block (L1, L2, L3) in the

power supply .

The blower(s) the lamphouse and the POWER light on the instrument panel should operate. If

this does not occur, the trouble is in either the door interlock switch, a blower motor, the indicator

lamp, a loose connection, a broken #2, #4, #7 or #8 lead, or a defective stepdown transformer in the

xenon power supply . The Ultra 80 has an in-line fuse in the 220 volt blower circuit; check the fuse and

replace if blown. Do not overfuse; use 3 A. slow blow .

U80/020

Page 23

CAUTION: To prevent bulb ignition when checking the AC control circuit, remove the #6

lead running from the igniter at the terminal post on the lamphouse base pan. Tape the exposed lead

to prevent shorting out the circuit.

Check the 115 V.AC control circuit in the lamphouse at the door switch, then the control leads

at terminals #9 and #12 (the “side” blower on 40002 lamp). The door interlock switch must be

manually actuated to energize this circuit.

The air flow from the top blower will move the actuating lever on switch S4, and the exhaust

draft should close switch S5. With the MODE switch in the “MAN.” position, and the LAMP switch

in the “ON” position, the elapsed time meter should start to indicate elapsed time. If this meter does

not operate, check for continuity at the LAMP and MODE switches. Check continuity of the air flow

switches; both should read 0 Ohms between “NO” and “COM” when actuated. A defective elapsed

time meter will not prevent bulb ignition. Replace lead #6.

With the LAMP switch in the “ON” position, a distinct high voltage arc ping at the igniter

spark gap should be heard, and a flash from the xenon bulb should be visible through the ammeter, as

DC voltage is applied to the bulb electrodes.

If the high voltage ping or the flash at the ammeter is not apparent, check the DC “No Load”

voltage between the lamphouse and power supply . Again disconnect lead #6 running from the igniter

at the terminal strip on the lamphouse base. Tape the end of the disconnected lead and close and

secure the lamphouse door.

Press the switch above the ammeter, and the meter will indicate the “No Load” DC voltage

supplied to the lamphouse when the LAMP switch is turned “ON.” This voltage will vary between

different types of power supplies. See your power supply manual for its correct “No Load” rating.

The standard 40913 igniter printed board in the Ultra 80 is designed for use with a Strong

switching power supply with high DC “No Load” voltage. Consult the factory if using an older high

reactance xenon power supply with normally lower DC “No Load” voltage.

If the correct voltage for the power supply being used is not indicated on the meter, the problem is in the lamphouse/power supply interconnecting cable, or in the power supply . See the troubleshooting guide in the power supply manual for additional instructions and tests. Replace lead #6 on

the terminal strip on the lamphouse base.

If the high voltage arc is audible at the lamphouse, and the bulb does not flash, replace the bulb

and attempt ignition with the new bulb.

Using the new bulb, if the high voltage arc is audible at the lamphouse, the flash of the bulb is

visible in the ammeter, and ignition is not sustained, the problem is in the power supply.

If the high voltage arc is not audible or the flash of the bulb visible, the trouble is in the igniter

or the igniter printed circuit board.

U80/021

Page 24

ULTRA 80 TROUBLESHOOTING

Bulb fails to ignite.

1. AC power not on to lamphouse. If 115 V.AC not read at 2 & 4, see power supply manual.

Check for loose 220 volt connection at 7 & 8.

2. Door interlock switch S1 open. Close and secure lamphouse access door. Tighten all three

screws; lock door and install security screw .

3. Faulty door interlock switch. Check for 115 V.AC at 9 & 12; replace switch if defective.

4. Air vane switch S4 not closing. Check for unobstructed operation; clean if required. Check

continuity between “NO” and “COM”; replace if defective.

5. Faulty S2 “ON-OFF” switch. Check for voltage at 3 & 5; check for loose wiring. Replace if

defective.

6. Automation fault. Override automation by switching MODE to “MAN.” and placing LAMP

switch in “ON.” See Automation Controller manual.

Bulb fails to ignite; ping audible, bulb flash visible.

1. Inadequate DC output from xenon power supply. Set power supply output to correct range

required for bulb wattage.

2. Faulty or expired xenon bulb. Replace as required.

Bulb fails to ignite; ping audible, no bulb flash.

1. Faulty xenon bulb. Check for cracked electrodes or darkened envelope. Replace if defective.

2. Ignition pulse shorting to ground. Inspect DC leads for burned insulation; dress leads away

from grounded metal components.

No high voltage ping audible; MODE switch in “MAN.” and LAMP switch in “ON.”

1. Loss of AC control voltage. Check xenon power supply for tripped circuit breaker or open

thermal switch. See power supply manual.

2. Little or no DC “No Load” voltage. Measure DC “No Load” voltage at 10 & 15. See power

supply manual.

3. Faulty igniter printed circuit board. If bulb ignites by pressing Emergency Ignition switch,

replace printed circuit board.

4. Faulty igniter. Check for 115 V.AC at 5 & 6; adequate DC “No Load” at 10 & 15. Replace

igniter if defective.

Bulb goes out during operation.

1. Xenon power supply overheated; thermal switch open. Check power supply blower(s), air

inlets and outlets unobstructed. See power supply manual.

U80/022

Page 25

Bulb goes out during operation (con’d.)

2. Lamphouse blower B1 failed or obstructed. Clean dust and dirt from blower inlet grille.

Check for 220 V.AC at 7 & 8; replace blower if defective.

3. Blower fuse F1 blown. Replace if defective (3 A. Slo-Blo).

4. Lamphouse air vane switch S4 or S5 faulty. Check for vane motion and switch continuity

(“NO” to “COM”); adjust or replace as required.

5. Backdraft from exhaust system. Check exhaust system installation; increase exhaust draft as

required.

6. Intermittent relay closure in automation controller. Override automation by switching MODE

to “MAN.” and check automation controller.

7 Phase loss or brown-out in xenon power supply AC source. Check AC input.

Power supply does not energize when actuated.

1. S1 door interlock switch, B1 blower, S4 air vane switch, S2 power switch, S3 MODE switch.

Check for correct voltage at each station; replace defective component.

2. Automation fault. Check for continuity between 3 & 6. See Automation Controller manual.

Use “MAN.” mode to override.

ALSO SEE POWER SUPPLY TROUBLESHOOTING

Noise in theatre sound as bulb ignites.

1. Faulty RF suppression capacitor(s). Remove and test C1, C2, C3, C4A or C4B. Replace if

defective.

2. Lamphouse, power supply, or sound system not properly grounded. Connect to adequate

earth ground.

3. Leads between lamphouse and automation contact not shielded. Shield leads in conduit.

Excessive light flicker .

1. Faulty or aged bulb. Check for cracked or sagging electrodes; replace if defective.

2. Arc stabilization magnet missing or reversed. Replace or correct (SOUTH pole toward access

door).

3. Excessive ripple in DC output. See power supply manual.

4. Projector shutter mistimed. See projector manual.

Reduced light output.

1. Normal bulb aging. Increase output current. DO NOT EXCEED MAXIMUM CURRENT

SPECIFIED BY BULB MANUFACTURER.

2. Bulb leakage. Check for high current and low voltage; discoloration of bulb envelope. Replace if defective.

3. Soiled reflector. Clean using commercial glass cleaner . USE NO ABRASIVES.

4. Soiled projection lens or port glass. Clean as required.

U80/023

Page 26

Extremely long duration between ignition pulses.

1. Low DC “No Load” from xenon power supply. Check “No Load” voltage; see power supply

manual.

2. Defective spark gap E101. A “Ping” sound is normal; excessive “Hissing” is abnormal. Replace if defective.

3. Low AC voltage to lamphouse. Check for 115 V.AC at 2 & 4; if below 95 volts, check

stepdown transformer in xenon power supply . See power supply manual.

4. Faulty K201 relay or U201 timer chip on igniter printed circuit board. Remove and test PCB;

replace if defective.

Igniter continues to fire after bulb ignites.

1. Faulty igniter printed circuit board. If defective, replace IMMEDIATELY to prevent bulb

damage.

U80/024

Page 27

U80/025

FIGURE 1

Page 28

FIGURE 1

Parts List

Item Part No. Description

1 40917 * Top Cover & Door Welded Assembly

2 40994 Front Casting Assembly (with Items 3, 4, 5)

- 40106 Front Casting (only)

- 40137 Front Heat Shield

3 81148 Douser Plate

- 81432 Shoulder Screw

- 81234 Bumper Stop

- 81187 Torsion Spring

- 00721 Set Screw, 10-32 x 3/8" Hex Head

4 45150A Handle Grip, Plastic

5 40115 Douser Shaft

6 01736-1 Tamperproof Screw, 10-32 x 1/2" Holt Head

7 48930 Arc Viewing Port Assembly

8 40917 * Top Cover & Door Welded Assembly (See Item 1)

- 71248 Cam Lock & Keys (not shown)

9 40105 Rear Casting

10 39139 Magnetic Door Catch

11 40220 Bulb Seal Blower , 220 V.AC, 50/60 Hz. (B1)

- 31-40002 Plug, Blower Motor

- 11-40019 Power Receptacle, Blower Motor

12 40920 Grille, Blower Cover (2 req’d.)

40194 Blower Cover

NOT SHOWN

- 40989 Instrument Panel Assembly (See Fig. 2 for components)

- 01423 Panel Mounting Screw, 10-32 x 5/16" Pan Head

- 39122 Ingiter Cover Access Plate

- 01304 Cover Mounting Screw, 8-32 x 5/16" Pan Head

- 00891A Lockwasher, #8

- 57275 Plug Button, Emergency Ignition Switch

- 40918 * Off-Operator Side Cover & Heat Shield W elded Assembly, 7 kW

(less Reflector Blower)

- 40903 * Off-Operator Side Panel Assembly , 10 kW (with Reflector Blower)

- 01345 Panel Mounting Screw, 10-32 x 1/2" Pan Head

- 00885 Lockwasher, #10

- 47944 Reflector Blower Assembly 115 V.AC, 50/60 Hz. (B2)

- 31-40002 Twistlock Plug

- 11-40019 Twistlock Receptacle

* Do not dismount Top Cover and Side Cover simultaneously; optical alignment may be affected.

U80/026

Page 29

U80/027

FIGURE 2

Page 30

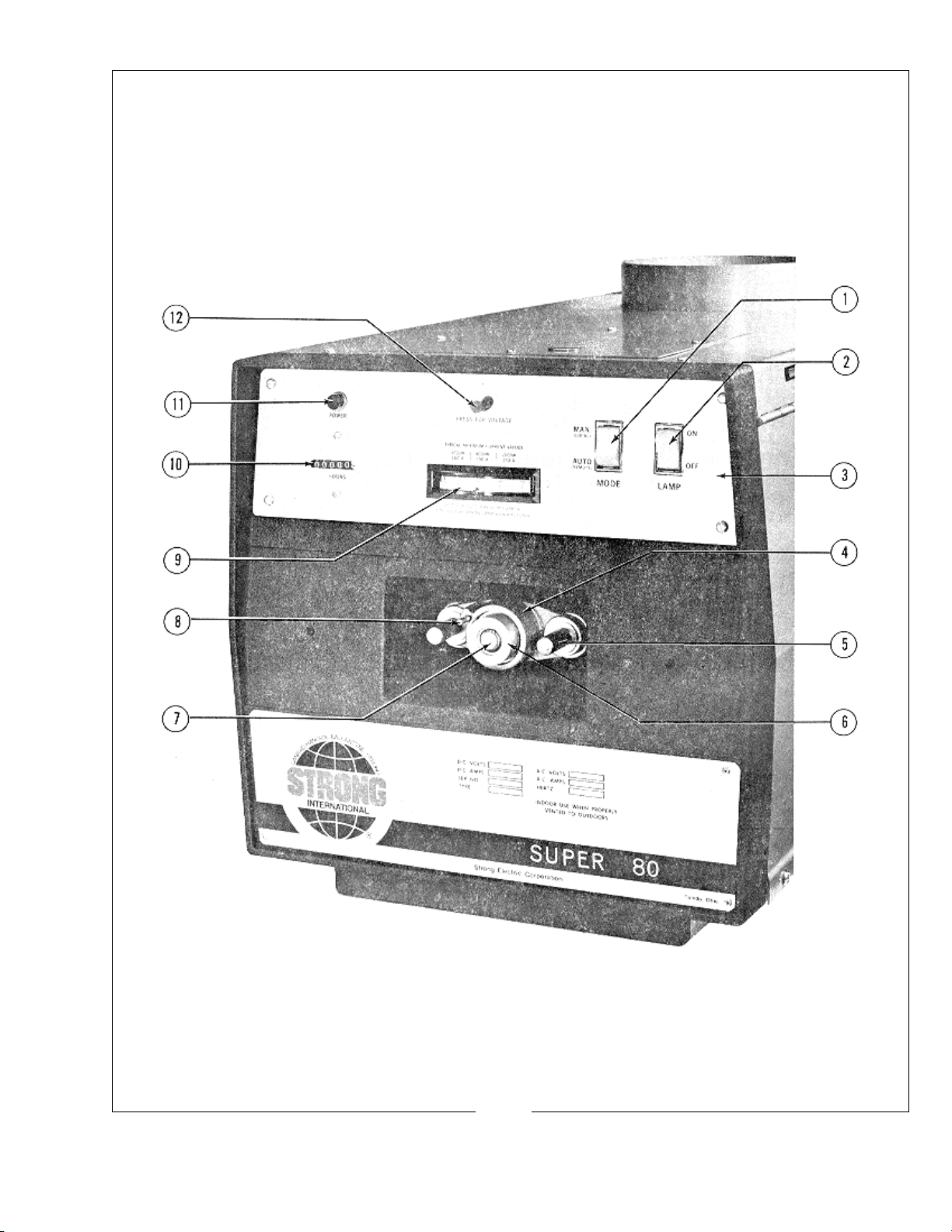

FIGURE 2

Parts List

Item Part No. Description

1 81276 MODE Switch (S3)

2 81275 LAMP Switch (S2)

3 40102 Plate, Instrument Panel (less Components)

- 01423 Screw, 10-32 x 5/16" Pan Head

4 65116 Casting, Bulb Adjustment Mechanism

- 65197 Fender Washer, Inner

5 37985 Thumb Screw

- 15010 Compression Spring

- 65150 Fender Washer, Outer

6 65959 Focus Screw & Bearing Assembly

7 40930 Bulb Collet, 7 kW (See Figure 3, Item 16)

7 40901 Bulb Collet, 10 kW (See Figure 3, Item 16)

- 21-48027 Collet Retaining Ring, “C” Clip

8 65153 Thumb Screw, Focus Lock

- 65154 Nylon Locking Ball

9 40923 Ammeter (M2)

10 40971 Elapsed Time Meter (M1) 60 Hz.

- 40963 Elapsed Time Meter (M1) 50 Hz.

Mounting Hardware supplied with Meter

11 78984 POWER Light (DS1)

12 72275 Voltage Test Switch (S6)

- 71283 Resistor (R2)

NOT SHOWN

- 40119 Cover Plate, Bulb Adjustment Controls

- 65166 Plunger, Black Plastic

- 65167 Grommet, Black Plastic

U80/028

Page 31

U80/029

FIGURE 3

Page 32

FIGURE 3

Parts List

Item Part No. Description

1 39955 Exhaust Air V ane Switch Assembly (S4)

2 40202 Reflector Bulkhead Casting

- 40142 Bulkhead Tie Rod

- 00805 Hex Nut, 1/4-20

3 23754 Reflector, 15" Dichroic Coated, Flanged

4 - Xenon Bulb, 10,000 Watt; Order Hanovia XH10000V(H)

4 - Xenon Bulb, 7000 Watt; Order Hanovia XH7000HS

5 40999 Bulb Support Yoke

- 00781 Set Screw, 8-32 x 1/4" Allen Head

6 81348 Insulator, Anode Lead (NOT USED in Ultra 80)

7 40107 Air Duct Casting

- 401 16 Air Duct Insulator Plate

- 01796 Screw, 5/16-18 x 3/4" Nylon

8 40987 Binding Post Assembly (E1)

- 40130 Block, Brown Phenolic

- 00642 Screw, 3/8-16 x 1-1/2" Flat Head

- 00809 Jam Nut, 3/8-16

- 00854 Flatwasher, 3/8"

- 40131 Fibre Insulator

- 00492 Screw, 1/4-20 x 3/4" Flat Head

- 00876 Split Lockwasher, 1/4"

- 00805 Hexnut, 1/4-20

10 40981 Anode Cable Assembly (R1 to E1)

1 1 M15315 Arc Stabilization Magnet

- 81137 Magnet Clamp

- 00781 Set Screw, 8-32 x 1/4" Allen Head

- 01710 Screw, 8-32 x 1/4" Hex Head

12 40120 Dust Cover

- 01742 Screw, 8-32 x 1/4" Pan Head

- 00891A Lockwasher, #8

13 80168 Door Interlock Switch (S1)

14 40902 Lamphouse/Power Supply Interconnect Cable Assembly

- 81143 Cable Connector, 90°

15 81274 Ground Lug

- 01423 Screw, 10-32 x 5/16" Pan Head

- 00891A Lockwasher, #8

U80/030

Page 33

FIGURE 3 Parts List (con’d.)

Item Part No. Description

16 24432 Bulb Support Collet, 5 kW*

16 40930 Bulb Support Collet, 7 kW

16 40901 Bulb Support Collet, 10 kW

17 24430 Collet Contact Clamp, 5 kW*

- 41-51213 Clamping Screw, 10-32 x 1" Socket Head

- 00685 Screw, 1/4-20 x 3/8" Hex Head

17 40111 Collet Contact Clamp, 7 & 10 kW

- 01532 Clamping Screw, 8-32 x 7/8" Socket Head

- 00685 Screw, 1/4-20 x 3/8" Hex Head

18 40979 Contact Clamp & Igniter Lead Assembly

19 40164 Light Baffle

- 01566 Screw, 10-24 x 5/16" Pan Head

- 00885 Lockwasher, #10

20 39999A Igniter Assembly (See Figure 5A)

* for 5 kW Osram with 18mm Cathode Pin. Other 5 kW bulbs

emulate 4 kW and 4.5 kW models. Consult bulb supplier .

NOT SHOWN

- 85109 Intake Air V ane Switch, Bulb Seal Blower (S5)

- 65158 Switch Mounting Bracket

U80/031

Page 34

FIGURE 4

U80/032

Page 35

FIGURE 4

Parts List

Item Part No. Description

1 - Not Used in Ultra 80; See Figure 1, Item 11

2 40136 Capacitor Clamp

- 01382 Screw, 8-32 x 3/16" Pan Head

- 00891A Lockwasher, #8

3 76323 Capacitor (C4A, C4B) 2 req’d.

4 40981 Anode Cable Assembly (R1 to E1)

5 40983 RF Capacitor Assembly (C1, C2, C3)

- 39153 Nylon Standoff

6 76133 Capacitor (C3)

7 76132 Capacitor (C1, C2)

8 40913 Igniter Printed Circuit Board Assembly

- 40984 Igniter PC Board (with High Reactance Power Supply)

- 39153 Nylon Standoff

- 39154 Relay (See PCB Schematic)

9 40974 Capacitor (C8)

10 40103 Barrier Strip, (14) T erminal

- 40138 Insulated Marker Strip

- 01799 Screw, 8-32 x 9/16", Round Head

- 00891A Lockwasher, #8

11 80168 Door Interlock Switch (S1)

12 81247 Shunt (R1)

- 01312 Screw, 8-32 x 1/2" Pan Head

- 00891A Lockwasher, #8

13 40973 RF Bypass Capacitor Assembly (C6, C7)

14 39199 Fuse Holder

- 40203 Fuse (F1)

15 81274 Ground Lug

- 01423 Screw, 10-32 x 5/16" Pan Head

- 00885 Lockwasher, #10

16 40902 Lamphouse/Power Supply Interconnect Cable Assembly

- 81143 Cable Connector, 90°

17 40901 Bulb Support Collet, 10 kW (See Figure 3, Item 16)

18 85109 Air Vane Switch (S5) Mounted to Top Blower in Ultra 80

- 65158 Switch Mounting Bracket

19 40164 Light Baffle (See Figure 3, Item 19)

U80/033

Page 36

FIGURE 5

U80/034

Page 37

FIGURE 5

Parts List

Item Part No. Description

- 39999A Igniter Assembly 115 V.AC, 50/60 Hz.

1 39260 Cover Interlock Switch (S101)

2 39113 Switch Bracket

- 00343 Screw, 10-32 x 1/4" Flat Head

3 39260 Emergency Ignition Switch (S102)

4 39110 High Voltage Capacitor (C107, C108)

- 00254 Screw, 8-32 x 1/4" Fillister Head

- 00891A Lockwasher, #8

- 39112 Capacitor Mounting Bracket

- 01752 Screw, 1/4-20 x 1" Hex Head Nylon

- 01754 Hex Nut, 1/4-20 Nylon

5 01742 Screw, 8-32 x 1/4" Pan Head

- 00981A Lockwasher, #8

6 39998 Case & Coil Potted Assembly

- 65353 DANGER Label

7 39201 * Spark Gap Body, Nylon

- 01567 Screw, 10-24 x 1/2" Pan Head

8 39107 * Contact Screw, Tungsten

- 39109 Terminal Tab (Order KT-74)

- 00831 Flatwasher, #10, Brass

- 00795 Hex Nut, 8-32

9 39937 High Voltage Transformer (T102)

- 01582 Flatwasher, #8

- 00795 Hex Nut, 8-32

10 39204 Transformer Spacer (4 req’d.)

* 39923 Spark Gap Assembly (Items 7 & 8, assembled and gapped)

NOT SHOWN

39101 Igniter Box Cover, Plastic

01305 Screw, 6-32 x 1/4" Pan Head

U80/035

Page 38

Page 39

Loading...

Loading...