Page 1

Logic Hotbox & Convector Fire

With upgradable control valve

Instructions for Use,

Installation and Servicing

For use in GB, IE (Great Britain and Eire)

PR0696 Issue 2 (October 2003)

IMPORTANT

The chimney must be swept before installation. Do not attempt to burn rubbish on this fire. This fire has a naked flame.

A suitable guard should be used for the protection of young children, the elderly or infirm.

This appliance is intended for decorative purposes only.

Please read these instructions carefully and keep them in a safe place.

They will be needed when servicing the fire.

The commissioning sheet on page 3 MUST be completed by the Installer.

This appliance has been certified for use in countries other than those stated. To install this appliance in these countries, it is essential to obtain the translat-

ed instructions and in some cases the appliance will require modification. Contact Gazco for further information.

Page 2

2

CONTENTS

PAGE

APPLIANCE COMMISSIONING CHECKLIST 3

USER INSTRUCTIONS 4

INSTALLATION INSTRUCTIONS 8

Technical Specifications 8

Site Requirements 10

Installation 11

Commisioning 17

SERVICING INSTRUCTIONS 18

Servicing Requirements 18

Fault Finding 19

How to replace parts 21

Basic spare parts list 23

Covering the following models

Hotbox Convector

8306PBUC 8308PBUC

P80306PBUC P8308PBUC

8306MCUC 8308MCUC

P8306MCUC P8308MCUC

Page 3

3

FLUE CHECK PASS FAIL

1. Flue is correct for appliance

2. Flue flow test

3. Spillage test

GAS CHECK

1. Gas soundness & let by test

2. Standing pressure test mb

3. Appliance working pressure (on High Setting) mb

NB All other gas appliances must be operating on full

4. Gas rate m3/h

5. Does ventilation meet appliance requirements

6. Have controls been upgraded (Upgradeable models only) 8455 Standard YES NO

APPLIANCE COMMISSIONING CHECKLIST

Dealer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contact No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Date of Purchase. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gas Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Company. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engineer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contact No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Corgi Reg No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Date of Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IMPORTANT NOTICE

Explain the operation of the appliance to the end user, hand the completed instructions to them for safe keeping,

as the information will be required when making any guaranteed claims.

DEALER AND INSTALLER INFORMATION

Page 4

1. GENERAL

2. LIGHTING THE FIRE

3. TURNING THE FIRE OFF

4. LIGHTING THE FIRE WITH A MATCH

5. UPGRADING YOUR FIRE

USER INSTRUCTIONS

2

1

4

1.1 Installation and servicing must only be carried out by a

competent person.

1.2 In all correspondence, please quote the appliance type and

serial number, which can be found on the databadge

adjacent to the control knob.

1.3 Ensure that curtains are not positioned above the fire, and

that there is a 300mm minimum clearance between the sides

of the fire and any curtains.

1.4 This product is guaranteed for 12 months from the date of

installation, as set out in the terms and conditions of sale

between Gazco and your local Gazco dealer. Please consult

with your local Gazco dealer if you have any questions. In all

correspondence always quote the Model Number and

Serial Number.

1.5 Parts of this appliance become hot during normal use. It is

therefore recommended that a suitable fire guard be used for

protection of young children and the infirm.

2.1 Locate the control valve on the appliance. There are two

control knobs on the valve, the right hand knob controls the

pilot ignition and the left hand knob controls the main burner.

2.2 If your appliance has already been upgraded to battery

remote control, please refer to the instructions provided with

the upgrade to operate the remote control. The following

instructions will work for either situation.

2.3 Ensure that the left-hand control knob is pointing to off ( ).

2.4 Ensure that the right hand control knob is pointing to off ( ).

2.5 Press in the right hand control knob and rotate it anti-clockwise

until a click is heard (keep pressing in) and the knob is pointing

to pilot ( ). The pilot should now light. If the pilot has not lit,

repeat the procedure until it does.

2.6 Keep the control knob pressed for 10 seconds and then

release it, the pilot should stay alight. If the pilot goes out,

repeat the procedures until it does.

2.7 If the pilot will not light after repeated attempts, contact the

retailer or installer from whom the appliance was purchased.

2.8 Turn the right hand control to point to main burner ( ). The

appliance can now be controlled using the left hand control

knob.

2.9 Turn the left hand control knob to point to low fire ( ), the

main burner will light on low. The burner can now be

controlled between low and high settings. Turn the control

knob anticlockwise increase the flame height and clockwise to

decrease the flame height.

THE YELLOW FLAMES WILL APPEAR WHEN THE FIRE HAS

GAINED SUFFICIENT HEAT - TYPICALLY 10 TO 20 MINUTES.

3.1 To turn the fire off, locate the control valve, turn the left-hand

control knob until it points to off ( ). The main burner will go

out leaving the pilot burning.

3.2 To turn the pilot off, locate the control valve, turn the right

hand control knob until it points to off ( ), the pilot will

go out.

If the pilot does not ignite as described in Section 2,

please consult your GAZCO dealer to rectify the problem.

However, the appliance may be lit as a temporary measure

using the following procedure:

4.1 Press in the right hand control knob and rotate it anticlockwise until a click is heard (keep pressing in) and the

knob is pointing to pilot ( ), apply a lighted match to the

pilot hood, see diagram 2.

4.2 When the pilot is alight, extinguish the match and continue

to depress for 5 to 10 seconds.

4.3 The fire may now be controlled as previously described.

5.1 Your fire is fitted with a control valve that can easily be

upgraded to battery powered remote control. This upgrade

can be fitted by anyone capable of simple DIY jobs and

requires no special training. This upgrade can be obtained

through your local Gazco stockist.

5.2 STANDARD REMOTE CONTROL This remote control can

control the fire after the pilot has been lit. It can turn the

main burner on and regulate it from low through to high and

back again. It can turn the main burner off leaving the pilot

burning GAZCO PART NUMBER 8455.

5.3 IMPORTANT - there is a thermostatic version of the upgrade

but this is NOT SUITABLE for open flame fires like the Logic.

Page 5

6. CLEANING THE FIRE

USER INSTRUCTIONS

5

7. ARRANGEMENT OF FUEL BED

COMPONENTS

6.1 Remove the ceramic coals or pebblesand place on a dry,

clean surface. Remove the fuelbed and the burner cover

gasket.

6.2 Clean the burner and tray assembly using a vacuum cleaner

with soft brush attachment, ensure all debris is removed from

the burner ports.

6.3 Replace the ceramics by referring to section 7.

NOTE: CERAMIC PARTS ARE FRAGILE. THE SIDE AND

REAR PANELS ARE REVERSIBLE. ONE SIDE IS PLAIN, THE

OTHER SIDE IS REEDED. ASK THE CUSTOMER WHICH

SIDE IS PREFERRED AT THIS STAGE.

ONLY USE THE CORRECT TYPE AND QUANTITY OF

CERAMIC COMPONENTS. POINTS 7.1 TO 7.5 ARE

COMMON TO ALL FUEL TYPES AND LAYOUTS.

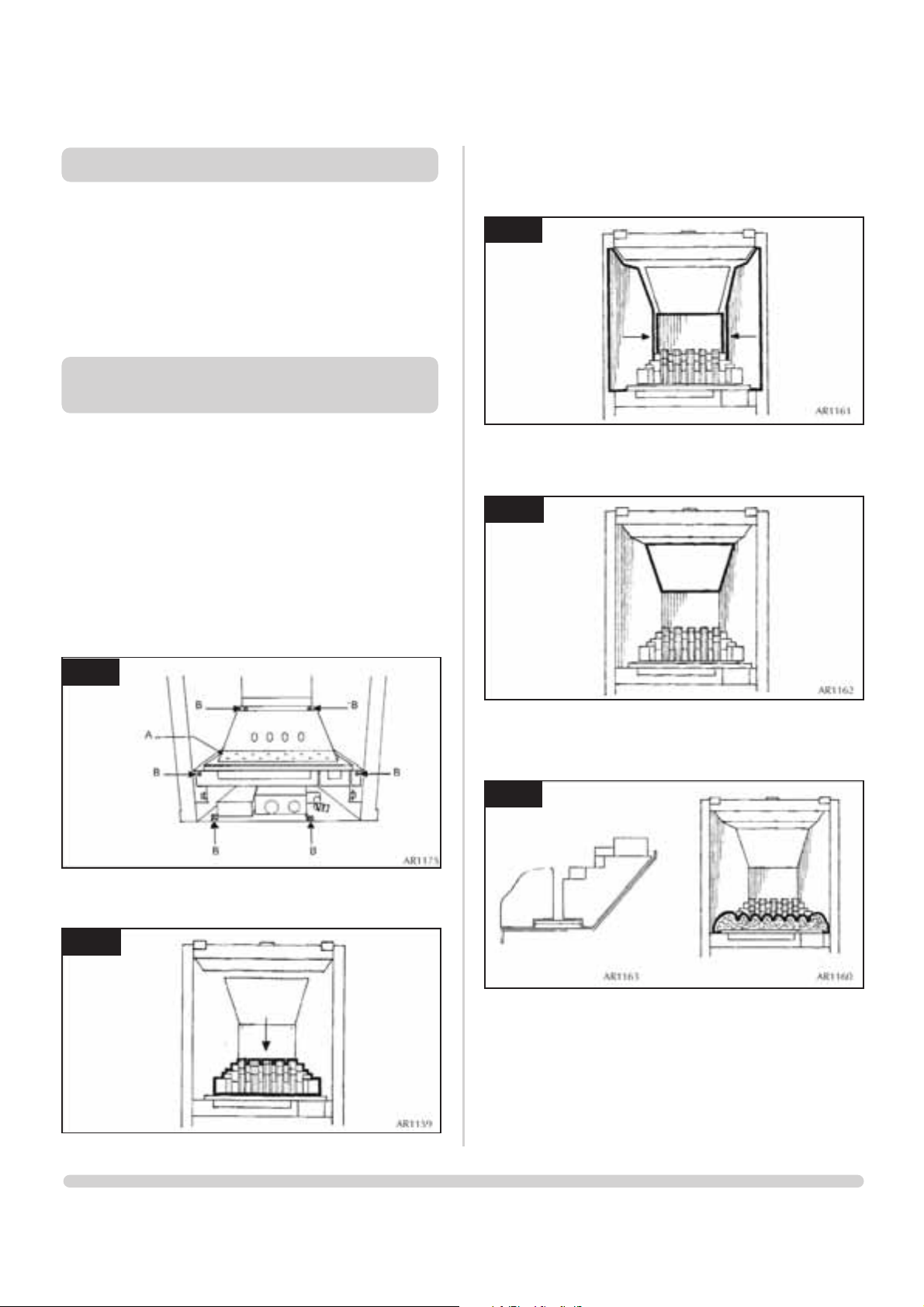

7.1 Position the burner cover gasket on the burner skin ensuring

the holes align with the ports. Take care as the front

left-hand hole is offset compared to the others.

See diagram 3, arrow A.

7.2 Position the flame baffle centrally on the tray and ensure the

stepped lower edge engages against the rear edge of the

burner skin. See diagram 4.

7.3 Place the rear panel against the rear of the box and slide

the side panels on either side of the flame baffle. Ensure they

locate in the brackets at the top of the firebox. DO NOT

SLIDE THEM ALL THE WAY BACK. See diagram 5.

7.4 Locate the top panel on top of the rear and side panels.

Finally push the sides fully towards the rear panel. This will

retain the top panel. See diagram 6.

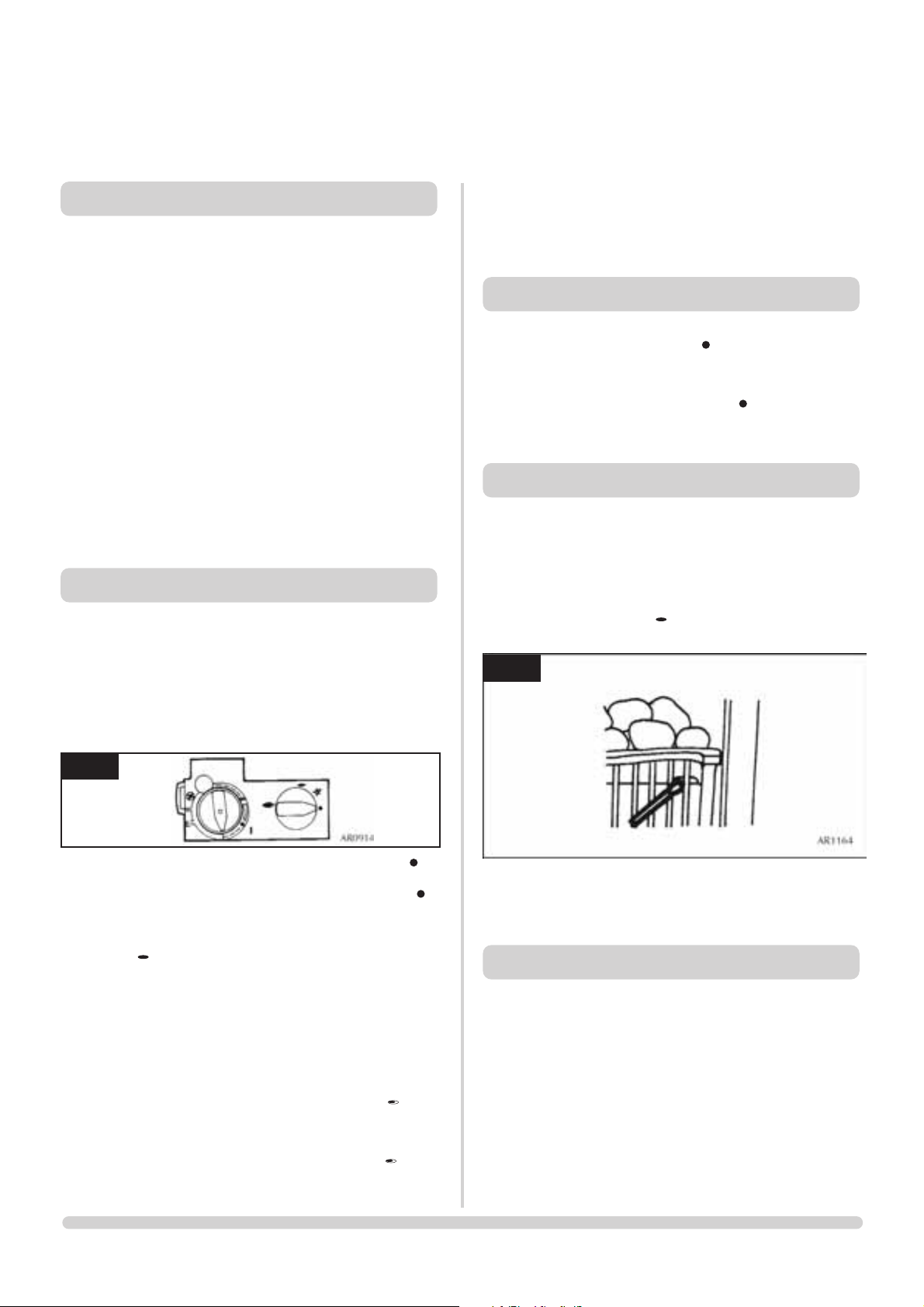

7.5 Place the front coal centrally in the channel at the front of

the tray. See diagram 7. The relationship between the front

coal and flame baffle is shown in diagram 7.

3

4

5

6

7

Page 6

USER INSTRUCTIONS

COAL LAYOUT

NOTE: THERE ARE TWO LARGE COALS IN A BAG INSIDE

THE MAIN BAG. THESE ARE ONLY TO BE USED WHEN A

CURVED FRONT SUCH AS THE HOLYROOD AND

RICHMOND ARE USED. DO NOT USE THE TWO LARGE

COALS WHEN USING A FLAT FRONTED FRAME.

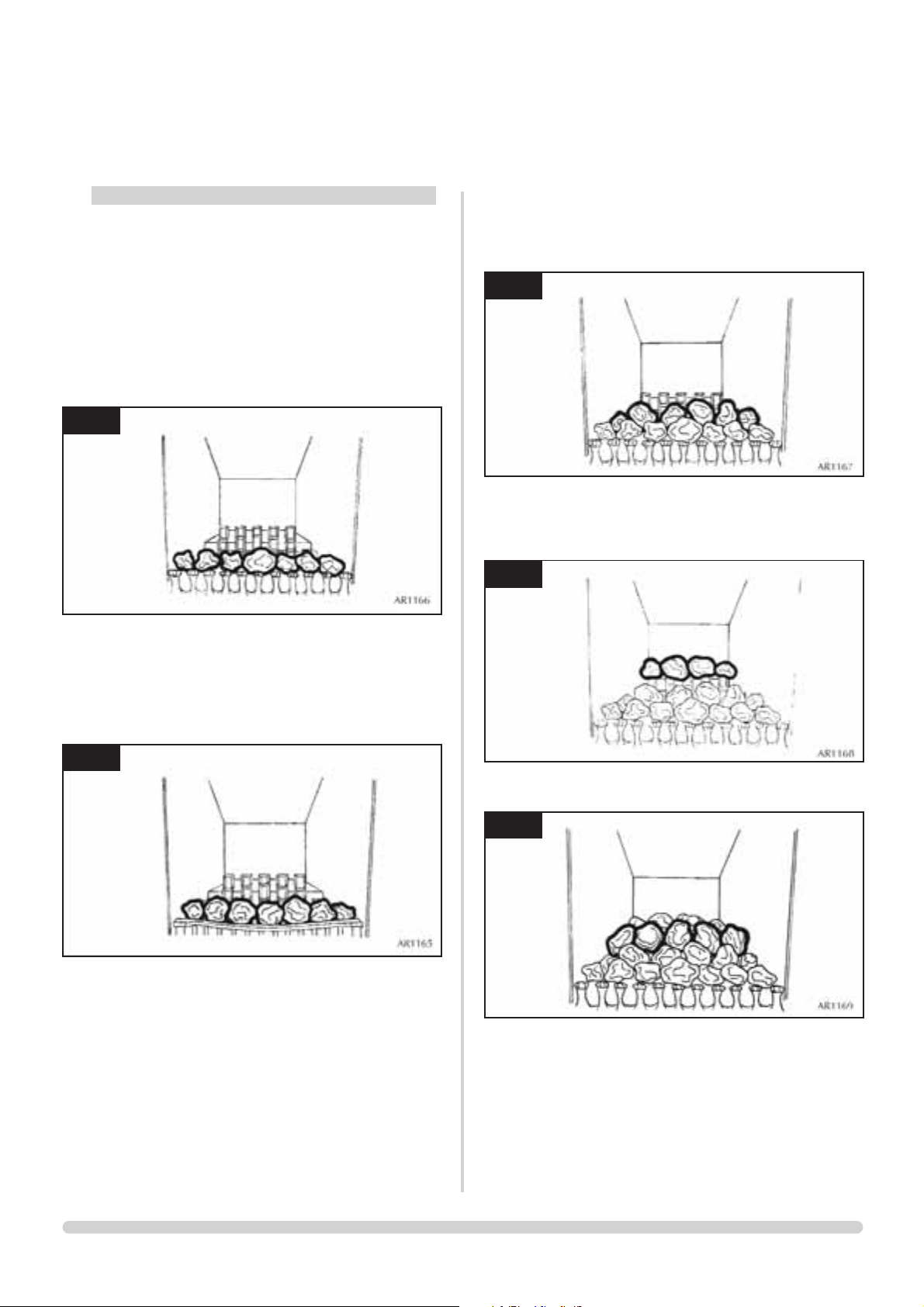

A) FRONT ROW COAL LAYOUT USING FLAT FIRE FRONTS

7.6 The front row is the only difference in coal layout. Place one

large coal centrally on the front coal resting against

the frame. Then place three small coals either side.

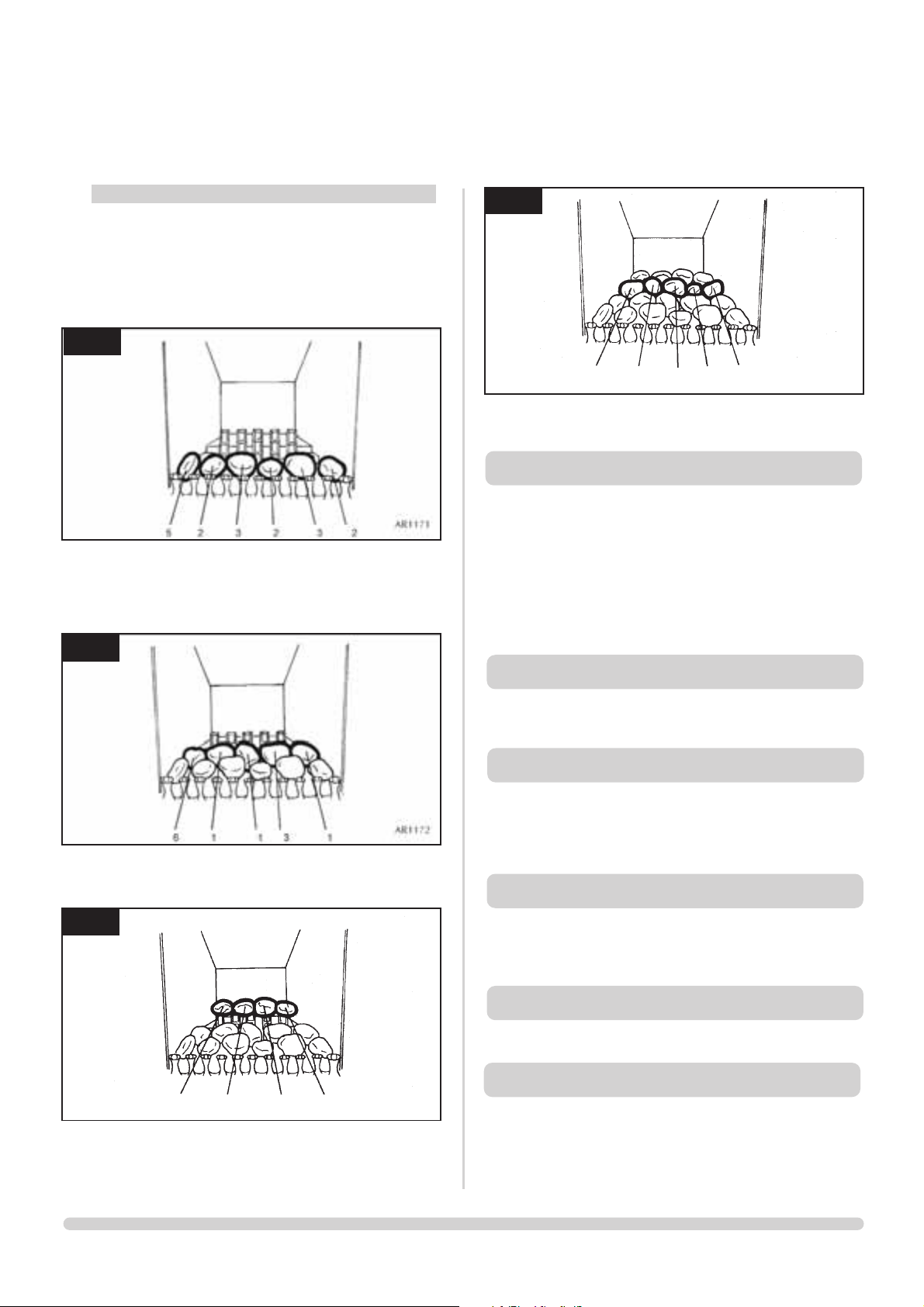

See diagram 8.

B) FRONT ROW COAL LAYOUT USING CURVED FIRE

FRONTS.

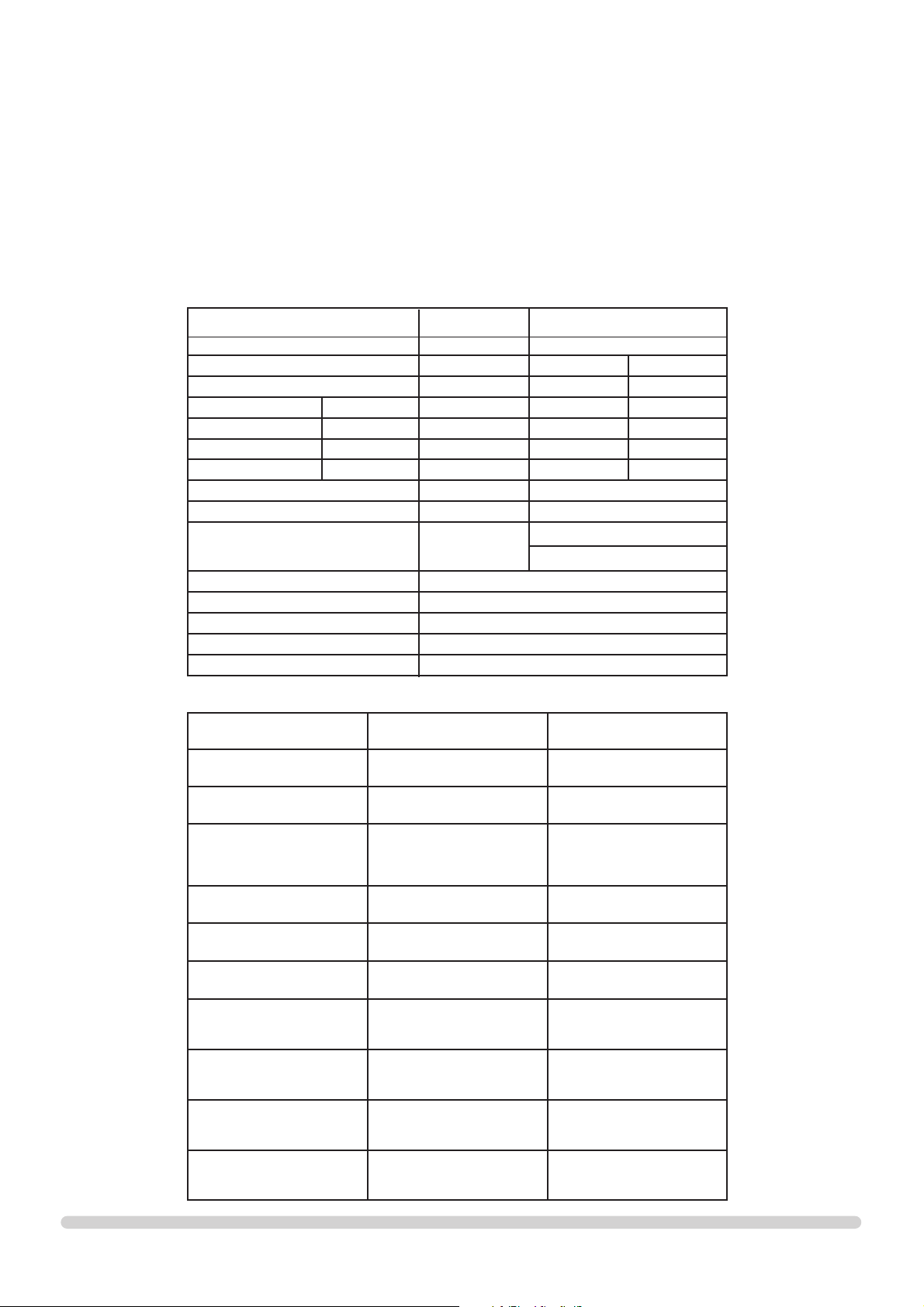

7.7 Place three large coals resting on top of the front coal and

against the front of the frame, then place two small coals

either side of the large ones. See diagram 9

C) COAL LAYOUT CONTINUED FROM FRONT ROW

7.7 Place four large coals behind the first row and one small

coal either end resting up against the side panels.

See diagram 10

7.8 Place one small coal either side on top of the flame baffle in

each rear corner. Then place two large coals in between the

two small coals. These coals should touch the rear panel.

See diagram 11.

7.9 Finally place five large coals between the second and rear

row of coals. See diagram 12.

7.10 It is essential that gaps are left between the coals to maximise

the performance of the appliance.

8

9

10

11

12

6

Page 7

7

PEBBLE LAYOUT - CURVED AND FLAT FRONTS

7.12 ALL THE PEBBLES HAVE AN IDENTIFICATION ON THE

UNDERSIDE. ENSURE THE PEBBLES ARE PLACED ONLY

IN THEIR CORRECT POSITIONS.

7.13 Place the first row of pebbles on top of the front coal resting

against the frame front. All the identifications are placed

face down so they cannot be seen. See diagram 13.

7.14 Working from the outside of the appliance, place the second

row of pebbles against the rear of the first row. Note the

orientation of each pebble, as this is important to the

performance of the fire. See diagram 14.

7.15 Place the rear row of pebbles on top of the flame baffle,

these must touch the rear panel. See diagram 15.

7.16 Place the remaining five pebbles between the second and

rear rows. See diagram 16.

13

14

15

8.1 The appliance is fitted with an oxygen sensitive pilot system

will act to cut off the gas supply to the fire should the

oxygen in the room fall below its normal level. If the fire is

turned off by this device, it usually indicates that there is a

problem with the flue system, and this should be inspected

by a qualified engineer. Do not attempt to use the fire

until an engineer says it is safe to do so.

This device is not a substitute for an independently

mounted carbon monoxide detector.

9.1 This is a safety feature incorporated in all GAZCO fires

which automatically switches off the gas supply if the pilot

light goes out and fails to heat the thermocouple.

10.1 The surface coating on the coals used in your GAZCO fire

will ‘burn off’ during the first few hours of use, producing a

harmless and temporary odour. This will disappear after a

short period of use. If the odour persists, ask your installer

for advice.

11.1 This fire must be serviced every 12 months by a qualified

Gas Engineer. In all correspondence, always quote the

appliance type and serial number, which may be found on

the databadge located on a chain beneath the control valve.

12.1 Any purpose provided ventilation should be checked

periodically to ensure that it is free from obstruction.

13.1 To assist in any future correspondence, your installer should

have completed this commissioning sheet, this records, the

essential installation details of the appliance. In all

correspondence always quote the Model Number and

Serial Number.

16

8. OXYGEN DEPLETION SENSOR

9. FLAME FAILURE DEVICE

11. SERVICING

10. ‘RUNNING IN’

12. VENTILATION

13. INSTALLATION DETAILS

USER INSTRUCTIONS

2 2 4 5

AR1173

6 5 4 5 2

AR1174

Page 8

INSTALLATION INSTRUCTIONS

TECHNICAL SPECIFICATION

Covering the following models

Hotbox Convector

8306PBUC 8308PBUC

P80306PBUC P8308PBUC

8306MCUC 8308MCUC

P8306MCUC P8308MCUC

GAS CATEGORY 1

2h

1

3+

Natural Butane Propane

Gas Type G20 G30 G31

Working Pressure 20 mb 29 mb 37 mb

Gross Input kW High 6.7 6.7 6.7

Low 3.0 3.0 3.0

Gas Rate m3/hr High 0.64 0.192 0.252

Low 0.29 0.086 0.113

Nox Class 1 1

Injector size 400 180

6x5 Rear

Aeration Size 6x15

23x15 Front

Min flue size 5” diameter

Min Flue size - Pre cast 90mm x 183 mm (16,500mm2min)

Min flue specifacation T160 / N2 / 0 /D / 1

Gas Inlet 8mm

Weight (Gross) 19Kg

APPLICABLE FRONTS

FRONT HOTBOX CONVECTOR

DESIGNIO 8251MA 8251MA

EVOLUTION 8255MB, 8255BS 8257MB, 8257BS

HOLYROOD

8391

8397

8150

8391

8397

8150

INFINITI 8249BS 8249BS

PROGRESS 8253BS 8253BS

RICHMOND N/A 8678

SPANISH 8382, 8385

8388, 8153

8382, 8385

8388, 8153

VICTORIAN

CONVECTOR

N/A 4262, 4263

ART NOUVEAU

CONVECTOR

N/A 4264, 4265

COMBINATION

CONVECTOR

N/A 4362, 4363

8

Page 9

INSTALLATION INSTRUCTIONS

TECHNICAL SPECIFICATION

OVERALL EXTERNAL

DIMENSIONS

SIDE VIEW

MINIMUM DEBRIS COLLECTION

SPACE REQUIREMENTS-

(EXISTING MASONRY CHIMNEYS ONLY)

OVERALL EXTERNAL

DIMENSIONS

PLAN VIEW

9

1

2

3

Page 10

10

INSTALLATION INSTRUCTIONS

SITE REQUIREMENTS

1.1 The chimney or flue system must comply with the rules in

force, and must be a minimum of 125mm (5”) in diameter.

Pre cast flues must conform to BS1289: 1986. The cross

sectional area of the flue must be 16500 mm

2

with a

minimum dimension of 90mm.

*When fitting the appliance to a pre cast flue, the total

minimum depth of fire opening necessary is (D) 215mm. This

allows a 25mm space behind the appliance for debris,

required on this type of flue system. This is achieved either by

using = (A) a 115mm deep starter block + (B) a 25mm

plasterboard and sealed space + (C) 75mm Gazco space

(part number 8315) with a marble slip or similar, inserted

behind the spacer front flange, see diagram 1.

Or the total dept can be achieved by using a deeper starter

block, remedial building work to the front of the fireplace

opening, and a marble slip or similar, or a combination of this.

NEVER PLASTER DIRECT TO THE FACE OF A PRECAST

FLUE. USE ADHESIVE TO FIX THE PLASTERBOARD TO THE

FACE OF THE FLUE AND FINALLY SKIM THE

PLASTERBOARD.

When fitting the Logic Convector fire and a Stovax Cast Iron

Convector fireplace to a pre-cast letterbox flue with a

standard starter block, the 8315 spacer kit will be required,

together with an extra deep 142mm rebate surround.

The Combination Convector breast. Fireplace requires a

75mm stud-work chimney breast.

The appliance can also be fitted into a metal fluebox with a

5” (125mm) diameter flexible liner. In this installation a 1”

(25mm) rebated fire surround must be used. Refer to

diagram 2 for dimensions.

Class 1 flues. Chimneys over 9” x 9” must be lined.

A flue restrictor is provided with the Logic convector. This

must be fitted when the flue is 9” x 9” or when the flue pull

is excessive. This is fitted from inside the appliance across the

outlet at the top of the convector box with two screws

provided.

1.2 The minimum effective height of the flue or chimney must

be 3 m (10ft).

1.3 The chimney or flue must be free from any obstruction.

Any damper plates should be removed or secured in the

fully open position, and no restrictor plates should be fitted.

1.4 The chimney should be swept immediately prior to the

installation of the appliance - unless it can be seen to be

clean and unobstructed throughout its entire length.

1.5 Ensure that there is a smooth taper transition from the

fireplace opening into the chimney or flue.

1.6 The flue pull should be checked prior to installation of the

appliance. Apply a smoke pellet to the flue or chimney

opening and ensure that the smoke is drawn into the

opening. If there is not a definite flow, pre-heat the chimney

for a few minutes and re-test the flow.

IF THERE IS STILL NO DEFINITE FLOW, THE CHIMNEY

MAY REQUIRE ATTENTION - SEEK EXPERT ADVICE.

2.1 This appliance must stand on a non-combustible hearth

that is at least 12mm thick and 50mm thick at least at the

periphery.

2.2 It must be fitted into a non-combustible opening.

2.3 These appliances must be hearth mounted into a fireplace

opening conforming to National Standards. The minimum

dimensions shall be as shown in diagram 2.

1. FLUE AND CHIMNEY REQUIREMENTS

1

A = Minimum precast flue starter block depth (115mm).

B = Plasterboard and adhesive seal all around fire opening.

C = Gazco spacer (8315)

D = Minimum total depth including 25mm for debris.

A

B

C

D

Hearth level

2. APPLIANCE LOCATION

AR1217

Page 11

11

INSTALLATION INSTRUCTIONS

SITE REQUIREMENTS

2.4 Ensure that no naked flame or incandescent part of the fire

bed projects beyond the vertical plane of the fireplace

opening.

2.5 The appliance must not be installed in any room that

contains a bath or shower.

2.6 Ensure clearances to combustible materials - see diagram 3

3.1 Before installation, ensure that the local distribution

conditions (identifaction of gas and pressure) and

the adjustment of the appliance are compatible.

3.2 Ensure that the gas supply is capable of delivering the

required amount of gas, and is in accordance with the rules

in force.

3.3 This appliance is supplied complete with a factory fitted

isolation device incorporated into the inlet connection, no

further isolation device is therefore required.

It is important to ensure that any national ventilation

requirements are taken into account during the

installation of this appliance.

4.1 This appliance has a norminal input not exceeding 7.0kw

and therefore does not normally require ant additional

permanent ventilation.

If, however, spillage is detected when commissioning the

appliance, there may be insufficient natural ventilation and

additional ventilation may be required.

For ventilation requirements im thr Republic of Ireland, it

will be necessary to refer to the relavant rules in force.

AIR VENTS MUST NOT BE RESTRICTED.

3

3. GAS SUPPLY

4. VENTILATION

2

215

Page 12

12

1.1 Remove the appliance from its packaging, and check that it

is complete and undamaged.

1.2 Put the loose ceramic parts to one side so that they are not

damaged during installation.

2.1 Your fire is fitted with a control valve that can be easily

upgraded to battery powered remote control. This upgrade

can be fitted by anyone capable of simple DIY jobs and

requires no special training. This upgrade can be obtained

through your local Gazco stockist.

2.2 STANDARD REMOTE CONTROL This remote control can

control the fire after the pilot has been lit. It can turn the

main burner on and regulate it from low through to high and

back again. It can turn the main burner off leaving the pilot

burning. GAZCO PART NUMBER 8455.

2.3 IMPORTANT - there is a thermostatic version of the upgrade

but this is NOT SUITABLE for open flame fires like the Logic.

3.1 This appliance must be installed in accordance with the rules

in force, and used only in a sufficiently ventilated space.

Please read all instructions before installation and use of this

appliance.

3.2 These instructions must be left intact with the user.

3.3 Do not attempt to burn rubbish on this appliance.

3.4 In your own interest, and those of safety, this appliance must

be installed by a competent person in accordance with local

and national codes of practice. Failure to install the appliance

correctly could lead to prosecution.

3.5 Keep all plastic bags away from young children.

NATURAL GAS @ 20mbar BUTANE @ 29mbar

PROPANE @ 37mbar

8306MCUC 8306PCUC P8306MCUC P8308MCUC

8308MCUC 8308PBUC P8308MCUC P8308PBUC

TO CHANGE FROM ONE GAS TYPE TO ANOTHER A

COMPLETE ENGINE ASSEMBLY WILL BE REQUIRED.

SEE SECTION 7 SERVICING INSTRUCTIONS.

4.1 Before installation, ensure that the local distribution

conditions (identification of the type of gas and pressure)

and the adjustment of the appliance are compatible. See

table above.

INSTALLATION INSTRUCTIONS

INSTALLATION

1. UNPACKING

2. CONTROL UPGRADE

3. SAFTEY PRECAUTIONS

4. INSTALLATION OF THE GAS SUPPLY

4.2 Ensure that the gas supply is capable of delivering the

required amount of gas, and is in accordance with the rules

in force. Please refer to the technical specification for the

correct working pressure for the gas used.

4.3 Soft copper tubing and soft soldered joints can be used but

must not be closer than 50mm (2”) to the underside of the

burner.

4.4 An isolation device is provided with the appliance.

4.5 All supply gas pipes must be purged of any debris that may

have entered, prior to connection to the appliance.

5.1 Remove the 6 burner retaining screws and withdraw the

burner unit from its location. See diagram 1, arrows B

5.2 Decide on the retention method. If cable fixings are to be

used, remove the two knockout holes on the rear of the

box, using a sharp hammer blow. See diagram 2.

5.3 Remove the backing from the self-adhesive silicone sealing

strip and apply to the rear flange of the firebox ensuring that

it is positioned as close to the outer edge as is practically

possible. See diagram 3.

5. PREPARING THE APPLIANCE

1

2

Page 13

13

5.4 Gas pipe entry must come through the right hand side of

the box. The rubber seal must be cut using a sharp knife to

allow the isolating elbow to pass through it. Ensure the

rubber is not damaged when doing this.

A means of isolation is provided with the appliance. This

must be fitted to the supply pipe prior to installing the

firebox.

6.4 Pass the cables vertically through the 2 sets of eyebolts and

thread the ends through the holes in the lower back of the

firebox. Pass the gas supply pipe through the hole in the

rubber seal (refer to section 5.2) and push the appliance into

place.

6.5 Thread the cables through the tensioner bolts and push the

threaded portions through the holes in the firebox so that

the lock nut sits against the back wall (ensure that the nut is

screwed fully up to the head of the tensioner to allow

maximum adjustment).

6.6 Slide the locking nipples onto the cables, pull the cables taut

and tighten the locking screw. Adjust the lock nuts using a

10mm spanner until the silicone sealing strip forms a tight

seal between the fireplace opening and the firebox flange.

See diagram 6.

6.7 Coil up the surplus cable and locate in the back of the

firebox.

NEVER SHORTEN THE CABLES, THEY WILL BE REQUIRED

WHEN SERVICING THE APPLIANCE.

INSTALLATION INSTRUCTIONS

INSTALLATION

3

6.INSTALLATION OF THE APPLIANCE

6.1 Ensure that the fireplace opening is in compliance with the

requirements of section 2 Site Requirements then proceed

as follows:

A) CABLE RETENTION METHOD

6.2 Mark the position of the 4 fixing holes on the rear of the

fireplace opening and drill the holes using a No. 12 masonry

drill bit. Insert the 4 fibre rawlplugs and screw the eyebolts

in as far as possible leaving the eye horizontal. See diagram 4.

6.3 Pass the 2 cables through the holes in the bracket on the

back of the firebox and pull taut so that the stop ends sit

tightly against the top of the bracket. See diagram 5.

4

5

6

Page 14

14

B) SCREW FIXING METHOD

6.8 Alternatively, this appliance can be secured back to the

fireplace opening using the screws and rawlplugs provided.

Place the firebox centrally in the opening and mark the

positions of the 4 fixing holes. Drill the holes and insert the 4

rawlplugs. See diagram 7.

6.9 Offer the firebox into the opening and ensure that the gas

supply pipe passes through the rubber seal.

6.10 Refit the burner assembly and secure the 6 pozidriv screws.

Connect the gas supply to the inlet connection on the

burner unit and tighten. It may be necessary to support the

inlet connection with another spanner whilst tightening this

joint. See diagram 8.

6.11 Turn on the gas supply to the appliance and check for leaks.

Light the fire and check all joints on the appliance for leaks.

6.12 Remove the sealing screw from the inlet connection and

connect a suitable “U” gauge manometer. Light the fire and

turn to the maximum position, refer to the databadge and

ensure that the running pressure is correct. If the pressure

varies significantly from that on the databadge, this may

indicate a supply problem and will require immediate

attention.

6.13 Turn the appliance off, disconnect the “U” gauge and

replace the sealing screw. Relight the appliance and check

the sealing screw for leaks.

INSTALLATION INSTRUCTIONS

INSTALLATION

7

8

NOTE: CERAMIC PARTS ARE FRAGILE. THE SIDE AND

REAR PANELS ARE REVERSIBLE. ONE SIDE IS PLAIN, THE

OTHER SIDE IS REEDED. ASK THE CUSTOMER WHICH

SIDE IS PREFERRED AT THIS STAGE.

ONLY USE THE CORRECT TYPE AND QUANTITY OF

CERAMIC COMPONENTS. POINTS 7.1 TO 7.5 ARE

COMMON TO ALL FULE TYPES AND LAYOUTS.

7.1 Position the burner cover gasket on the burner skin ensuring

the holes align with the ports. Take care as the front

left-hand hole is offset compared to the others.

See diagram 9, arrow A.

7.2 Position the flame baffle centrally on the tray and ensure the

stepped lower edge engages against the rear edge of the

burner skin. See diagram 10.

7. ARRANGEMENT OF FUEL BED

COMPONENTS

9

10

Page 15

15

INSTALLATION INSTRUCTIONS

INSTALLATION

7.3 Place the rear panel against the rear of the box and slide

the side panels on either side of the flame baffle. Ensure they

locate in the brackets at the top of the firebox. DO NOT

SLIDE THEM ALL THE WAY BACK. See diagram 11.

7.4 Locate the top panel on top of the rear and side panels.

Finally push the sides fully towards the rear panel. This will

retain the top panel. See diagram 12.

7.5 Place the front coal centrally in the channel at the front of

the tray. See diagram 13. The relationship between the front

coal and flame baffle is shown in diagram 13.

11

12

13

COAL LAYOUT

NOTE: THERE ARE TWO LARGE COALS IN A BAG INSIDE

THE MAIN BAG. THESE ARE ONLY TO BE USED WHEN A

CURVED FRONT SUCH AS THE HOLYROOD AND

RICHMOND ARE USED. DO NOT USE THE TWO LARGE

COALS WHEN USING A FLAT FRONTED FRAME.

FRONT ROW COAL LAYOUT USING FLAT FIRE FRONTS

7.6 The front row is the only difference in coal layout. Place one

large coal centrally on the front coal resting against

the frame. Then place three small coals either side.

See diagram 14.

FRONT ROW COAL LAYOUT USING CURVED FIRE

FRONTS.

7.7 Place three large coals resting on top of the front coal and

against the front of the frame, then place two small coals

either side of the large ones. See diagram 15.

COAL LAYOUT CONTINUED FROM FRONT ROW

7.8 Place four large coals behind the first row and one small

coal either end resting up against the side panels.

See diagram 16.

14

15

16

Page 16

16

INSTALLATION INSTRUCTIONS

INSTALLATION

7.9 Place one small coal either side on top of the flame baffle in

each rear corner. Then place two large coals in between the

two small coals. These coals should touch the rear panel.

See diagram 17.

7.10 Finally place five large coals between the second and rear

row of coals. See diagram 18.

7.11 It is essential that gaps are left between the coals to maximise

the performance of the appliance.

PEBBLE LAYOUT - CURVED AND FLAT FRONTS

7.12 ALL THE PEBBLES HAVE AN IDENTIFICATION ON THE

UNDERSIDE. ENSURE THE PEBBLES ARE PLACED ONLY

IN THEIR CORRECT POSITIONS.

7.13 Place the first row of pebbles on top of the front coal resting

against the frame front. All the identifications are placed

face down so they cannot be seen. See diagram 19.

17

18

19

7.14 Working from the outside of the appliance, place the second

row of pebbles against the rear of the first row. Note the

orientation of each pebble, as this is important to the

performance of the fire. See diagram 20.

7.15 Place the rear row of pebbles on top of the flame baffle,

these must touch the rear panel. See diagram 21.

7.16 Place the remaining five pebbles between the second and

rear rows. See diagram 22

20

6 5 4 5 2

AR1174

22

21

2 2 4 5

AR1173

Page 17

17

INSTALLATION INSTRUCTIONS

INSTALLATION / COMMISSIONING

11.1 Locate the control valve on the appliance. There are two

control knobs on the valve, the right hand knob controls

the pilot ignition and the left hand knob controls the main

burner.

11.2 If your appliance has already been upgraded to battery

remote control, please refer to the instructions provided

with the upgrade to operate the remote control. The

following instructions will work for either situation.

11.3 Ensure that the left-hand control knob is pointing to off ( ).

11.4 Ensure that the right hand control knob is pointing to off ( ).

11.5 Press in the right hand control knob and rotate it anti-

clockwise until a click is heard (keep pressing in) and the

knob is pointing to pilot ( ). The pilot should now light. If

the pilot has not lit, repeat the procedure until it does.

11.6 Keep the control knob pressed for 10 seconds and then

release it, the pilot should stay alight. If the pilot goes out,

repeat the procedures until it does.

11.7 If the pilot will not light after repeated attempts, contact the

retailer or installer from whom the appliance was purchased.

11.8 Turn the right hand control to point to main burner ( ). The

appliance can now be controlled using the left hand control

knob.

11.9 Turn the left hand control knob to point to low fire ( ), the

main burner will light on low. The burner can now be

controlled between low and high settings. Turn the control

knob anticlockwise increase the flame height and clockwise

to decrease the flame height.

THE YELLOW FLAMES WILL APPEAR WHEN THE FIRE HAS

GAINED SUFFICIENT HEAT - TYPICALLY 10 TO 20 MINUTES.

11. LIGHTING THE FIRE

1.1 Close all windows and doors to the room, check all controls,

and allow fire to burn on maximum for 5 minutes. Test for

spillage of flue products using a smoke match. Pass the

lighted smoke match along the top front edge just inside the

opening or canopy. See diagram 1.

1.2 If the fire spills, run for a further 10 minutes and re-check. If

the flue restrictor plate has been fitted to the fire this can be

removed to assist flue flow if required. ( Convector only)

1.3 If there are extractor fans in the room or adjacent rooms, the

spillage test must be repeated with the extractors running on

maximum.

IF SPILLAGE PERSISTS, DISCONNECT THE APPLIANCE

AND SEEK EXPERT ADVICE.

For future reference record the installation details on the

commissioning sheet on page 3 of these instructions.

1. COMMISSIONING

1

1

HOTBOX

Page 18

SERVICING INSTRUCTIONS

SERVICING

18

This appliance must be serviced at least once a year by a

competent person.

All tests must be serviced by best practice as described by

the current CORGI recommendations.

1.1 Before any tests are undertaken on the appliance, conduct a

gas soundness test for the property to ensure that there are

no gas leaks prior to starting work.

1.2 Before any tests are undertaken on the appliance it is also

recommended to fully check the operation of the appliance.

1.3 Special checks

1.3.1 Clean any lint or fluff from the pilot - pay particular

attention to the aeration hole in the side of the pilot.

1.3.2 Clean away any fluff or lint from under the burner

1.3.3 Check that the spark gap on the pilot is correct.

1.4 Correct any faults found during the initial tests and then

recommission the appliance conducting the usual safety

checks.

1.5 Advise the customer of any remedial action taken.

1.6 As part of the annual service, the space behind the firebox

must be inspected for any debris, which may have fallen

down the chimney.

1.7 Remove the gas fire from the firebox as detailed below.

1.8 Inspect the space behind the firebox for debris and the

condition of the chimney, the flue flow test should be carried

out now. Remove any debris and carry out any necessary

remedial work.

1. SERVICING REQUIREMENTS

Page 19

SERVICING INSTRUCTIONS

FAULT FINDING CHARTS

19

IGNITION FUNCTIONAL CHECK 1

PILOT WILL NOT LIGHT

Ensure there is no debris around the pilot assembly, e.g. coal, soot, etc

which could short the spark, clean the area. Check for fluff in the pilot

aeration hole. See diagram 7.

There is a blokage in the system, check the inlet test point, the mag

seating, valve and pilot filter

Operate the valve.

Is there a spark?

Does the pilot light?

Is the control being

operated correctly?

Will the pilot light

with a match?

Is the gas turned on to

the appliance?

Is the gas pressure

correct?

Has the system got

any air in it?

SYSTEM O.K

Consult users book

and retry

Check isolation tap

and gas meter, retry.

Correct and retry.

Purge the gas pipes

and retry

See “No Spark”

Chart *

Ensure gap between the

electrode and thermocouple

is as Dia. 8 and retry.

If gap is O.K then first

change the ignition lead and

retry.

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

IGNITION FUNCTIONAL CHECK 2

NO SPARK

Ensure there is no debris around the pilot assembly, e.g. coal, soot, etc

which could short the spark, clean the area.

Consult users

instructions, retry

Is the valve being

operated correctly?

Reset the pilot

burner

Correct and retry

Check for defective or

damaged control knob

spindle or cam operation.

Check for the correct

location of piezo

components. Correct and

retry.

Remove the electrode lead

from the piezo. Operate

the valve. Does a spark

jump from the piezo to

the valve body?

Operate the valve to

light the pilot, does the

valve ‘click’?

Has ignition lead become

detached or is connection

poor?

Remove the electrode lead

from electrode with

insulated pliers hold the tip

3.5mm from the pilot

pipework,is there a spark

when the valve ‘clicks’?

Is the electrode wire

detached from the piezo

valve?

Replace the ODA unit

Replace the electrode

lead and retry

Replace the

control valve

Is the gap between electrode

and thermocouple

as in Dia 7?

NO

NO

NO

YES

YES

YES

NO

YES

YES

YES

*

Page 20

SERVICING INSTRUCTIONS

FAULT FINDING CHARTS

20

FLAME FAILURE FUNCTIONAL CHECK

PILOT WILL NOT STAY LIT OR FIRE GOES OUT

If the appliance goes out in use continually, this may mean that the

oxygen depletion sensor has been activated. The appliance should not be used

untill the cause has been found and rectified.

Ensure there is no debris arounfd the pilot assembly, e.g. coal, soot, etc.

Check for fluff in the pilot aeration hole. See diagram 7.

Light the pilot and keep the control knob pushed in at least

10 seconds before letting go

With the pilot

running is the

gas pressure as

stated on the

datanadge?

Is the pilot

flame of the

correct length?

See diagram 7.

Is thermocouple

connection good

in back of valve

Replace

ODS unit

Change the

ODS unit

SYSTEM O.K

Tighten the

connection and

retry

With the fire

running on full is

the gas at the

pressure stated

on the datanadge

Problem is with

the pipework or

fittings which lead

to the fire. Correct

and retry

Run for 60 sec’s.,

turn off, time

interval until mag

unit shuts with a

click. Is this greater

than 7 seconds?

Run for 60 sec’s.,

turn off, time

interval until mag

unit shuts with a

click. Is this greater

than 7 seconds?

Will the pilot

stay lit?

Will the pilot

stay lit?

Change

mag unit

YES

NO

NO

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

Page 21

SERVICING INSTRUCTIONS

REPLACING PARTS

1. GENERAL

2. IGNITION LEAD

3. PIEZO

4. ODS PILOT UNIT

21

In order to service any of the following parts on the

appliance, it will be necessary to remove the burner unit

from the firebox. To remove the burner unit proceed as

follows.

1.1 Turn off the gas supply at the isolation device located under

the appliance.

1.2 Disconnect the gas supply pipe leaving the isolation device

on the supply pipe and not the appliance.

1.3 Remove the loose coals or pebbles and place on a dry clean

surface.

1.4 Remove the decorative frame, fret and ash cover. There are

two screws securing the frame to the appliance. Refer to

frame instructions.

1.5 Remove the front coal, flame baffle and all the ceramic liners.

All these items are very fragile so store them carefully.

1.6 Remove the six screws securing the burner unit to the fire

firebox. See diagram 1.

1.7 The burner unit can now be removed.

2.1 Remove the fire. Refer to section 1.

2.2 Undo the single screw that secures the left hand side of the

control cover. See diagram 2.

2.3 To release the right hand side of the control cover insert the

narrow blade screwdriver into the slot shown in diagram 3,

lever it gently and pull from the right hand side at the same

time. The cover will now come off, there is a small

cylindrical metal spacer inside the cover, this must be kept

and replaced on the fixing screw during re-assembly.

2.4 Disconnect the ignition lead from the gas valve and the pilot.

See diagram 4 arrow A.

2.5 Replace with a new ignition lead following the same route as

the old one. Replace the valve cover and the pilot assembly.

2.6 Check the operation of the new ignition lead.

2.7 Replace the fret.

3.1 The piezo assembly used on this appliance is not serviceable

and is unlikely to fail. If a new piezo is required it will be

necessary to change the gas valve, refer to section 5.

Note: The pilot unit on the appliance is a non serviceable

unit due to the complex nature of its manufacture.

Replacement of the complete unit must be carried out when

one of the following items becomes faulty:

Pilot injector

Ignition electrode

Thermocouple

1

2

3

4

Page 22

4.5 Replace with a new pilot assembly, set the spark gap. See

diagram 8.

4.6 After reassembly, check for gas soundness and carry out a

flame failure functional check details in the flow chart,

especially the mag drop out time.

5.1 Remove the fire, refer to section 1.

5.2 Disconnect the 2x8mm and 1x4mm gas pipe fittings at the

back of the gas valve and also disconnect the thermocouple,

see diagram 9 arrows B and E.

5.3 Disconnect the injector nut. See diagram 10 arrow D.

5.4 Undo the two bolts securing the gas valve to the appliance

and remove the valve.

5.5 Replace in reverse order.

5.6 Check all joints for gas leaks, check operation of the

thermocouple and ignition lead.

SERVICING INSTRUCTIONS

REPLACING PARTS

5. GAS VALVE

22

4.1 Remove the fire, refer to section 1.

4.2 Gently pull the ignition lead off the electrode. See diagram 5

arrow A.

4.3 Remove the two screws securing the pilot assembly. See

diagram 6 arrow B.

4.4 Undo the thermocouple connection at the back of the gas

valve and the pilot pipe at the pilot elbow. See diagram 7

arrows B and C.

5

6

7

8

9

10

B

B

C

E B

D

Page 23

6.1 Remove the fire, refer to section 1.

6.2 Under the thermocouple nut. See diagram 11 arrow B.

6.3 Undo the mag unit retaining nut at the back of the control

valve behind the thermocouple nut.

6.4 After removing the retaining nut, the mag unit can be tapped

out and a replacement fitted.

6.5 Replace the mag unit retaining nut and tighten. Note - this is

a gas-tight seal.

6.6 Replace the thermocouple and check for gas leaks.

6.7 After reassembly, carry out the flame failure functional check

as detailed in the flow chart, especially the mag unit drop out

time.

7.1 Remove the fire, refer to section 1.

7.2 With the fire removed, undo the injector compression nut

and valve nut (see diagram 12 arrows D and E), pull the pipe

clear of the injector body.

7.3 Rotate the injector until it is fully removed.

7.4 Replace with the correct replacement injector. When

ordering, always state the model, gas type and serial number.

7.5 Reassemble and turn the gas supply on, check for any leaks.

The following parts must be changed when converting an

appliance from one gas type to another:

Burner assembly NGA8306

LPGAP8306

Databadge PR0393L

Note: The control valve will be set for the particular

appliance and gas type. In all instances, when ordering new

parts, be sure to quote the appliance type and serial number.

Use only genuine Gazco replacement parts. Non-standard

components will invalidate the guarantee and may be

dangerous.

SERVICING INSTRUCTIONS

REPLACING PARTS

6. MAG UNIT

7. MAIN INJECTOR

8. CHANGING BETWEEN GAS TYPES

9. SPARES PART LISTS

23

CERAMIC PARTS

FRONT COAL. BLACK CE0400

FRONT COAL. GREY CE0401

FLAME BAFFLE. BLACK CE0402

FLAME BAFFLE. GREY CE0403

BURNER COVER GASKET CE0273

CONVECTOR SIDE LH CE0408

CONVECTOR SIDE RH CE0409

CONVECTOR REAR PANEL CE0410

CONVECTOR TOP PANEL CE0411

HOTBOX SIDE LH CE0404

HOTBOX SIDE RH CE0405

HOTBOX REAR PANEL CE0406

HOTBOX TOP PANEL CE0407

COAL SET CE0412

PEBBLE SET CE0455

NATURAL GAS PARTS

MAIN INJECTOR IN0007

PILOT ASSEMBLY PI0037

GAS VALVE GC0088

LPG PARTS

MAIN INJECTOR IN0025

PILOT ASSEMBLY PI0037

GAS VALVE GC0088

MISCELLANEOUS

IGNITION LEAD GC0090

MAG UNIT GC0092

CONTROL COVER GC0087

UPGRADE KIT 8445

11

B

12

D

E

Page 24

Gazco Limited, Osprey Road, Sowton Industrial Estate, Exeter, Devon, England EX2 7JG

Te l: (01392) 261999 Fax: (01392) 444148 E-Mail: info@gazco.com

Loading...

Loading...