Linea

Balanced Flue Convector Fire

Instructions for Use,

Installation and Servicing

For use in GB, IE (Great Britain and Eire)

PR0731 Issue 8 (September 2006)

IMPORTANT

Do not attempt to burn rubbish in this appliance. This appliance must only be operated with the glass door secured firmly in

position. The front casing of this appliance will become hot whilst in operation, it is therefore recommended that a suitable

guard should be used for the protection of young children, the elderly or infirm.

Please read these Instructions carefully before installation or use.

Keep them in a safe place for future reference and when servicing the fire.

The commissioning sheet found at the end of the Users Sections of these instructions should be completed by the Installer.

This appliance has been certified for use in countries other than those stated. To install this appliance in these countries, it is essential to

obtain the translated instructions and in some cases the appliance will require modification. Contact Gazco for further information.

2

CONTENTS

COVERING THE FOLLOWING MODELS

8651 P8651

PAGE

APPLIANCE COMMISSIONING CHECKLIST 3

USER INSTRUCTIONS 4

INSTALLATION INSTRUCTIONS 8

Technical Specifications 8

Site Requirements 9

Installation 12

Commissioning 14

SERVICING INSTRUCTIONS 15

Servicing Requirements 15

Fault Finding 15

How to replace parts 17

Basic spare parts list 23

Service Record 24

3

FLUE CHECK PASS FAIL

1. Flue is correct for appliance

2. Flue flow test N/A

3. Spillage test N/A

GAS CHECK

1. Gas soundness & let by test

2. Standing pressure test mb

3. Appliance working pressure (on High Setting) mb

NB All other gas appliances must be operating on full

4. Gas rate m3/h

5. Does ventilation meet appliance requirements N/A

6. Has the remote hand set been tuned to the control box YES NO

APPLIANCE COMMISSIONING CHECKLIST

Dealer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contact No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Date of Purchase. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gas Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Company. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engineer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contact No.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Corgi Reg No.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Date of Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IMPORTANT NOTICE

Explain the operation of the appliance to the end user, hand the completed instructions to them for safe keeping,

as the information will be required when making any guaranteed claims.

DEALER AND INSTALLER INFORMATION

This product is guaranteed for 2 years from the date of installation, as set out in the terms and conditions of sale between Gazco and your

local Gazco dealer. This guarantee will be invalid, to the extent permitted by law, if the above Appliance Commissioning Checklist

is not fully completed by the installer and available for inspection by a Gazco engineer. The guarantee will only be valid during the

second year, to the extent permitted by law, if the annual service recommended in the Instructions for Use has been completed by a

Corgi registered engineer, and a copy of the service visit report is available for inspection by a Gazco engineer.

4

USER INSTRUCTIONS

1.1 A competent person must carry out installation and

servicing.

1.2 In all correspondence, please quote the appliance type and

serial number, which can be found on the data badge

located on a plate under the control valve.

1.3 Ensure that curtains are not positioned above the appliance

and there is at least 300mm between the sides of the

appliance and any curtains.

1.4 If any cracks appear in the glass panel do not use the

appliance until the panel has been replaced.

1.5 If, for any reason, the flue has to be removed from the

appliance, the seals must be replaced in the inner spigot.

1.6 Do not obstruct the flue terminal in any way, i.e. by

planting flowers, trees, shrubs etc in the near vicinity, or by

leaning objects up against the terminal guard.

1.7 Do not use a garden sprinkler or hose near the terminal.

1.8 Do not stand or place objects on the terminal guard as this

will deform it.

This product is guaranteed for 2 years from the date of

installation, as set out in the terms and conditions of sale

between Gazco and your local Gazco dealer. Please consult

with your local Gazco dealer if you have any questions. In

all correspondence always quote the Model Number and

Serial Number.

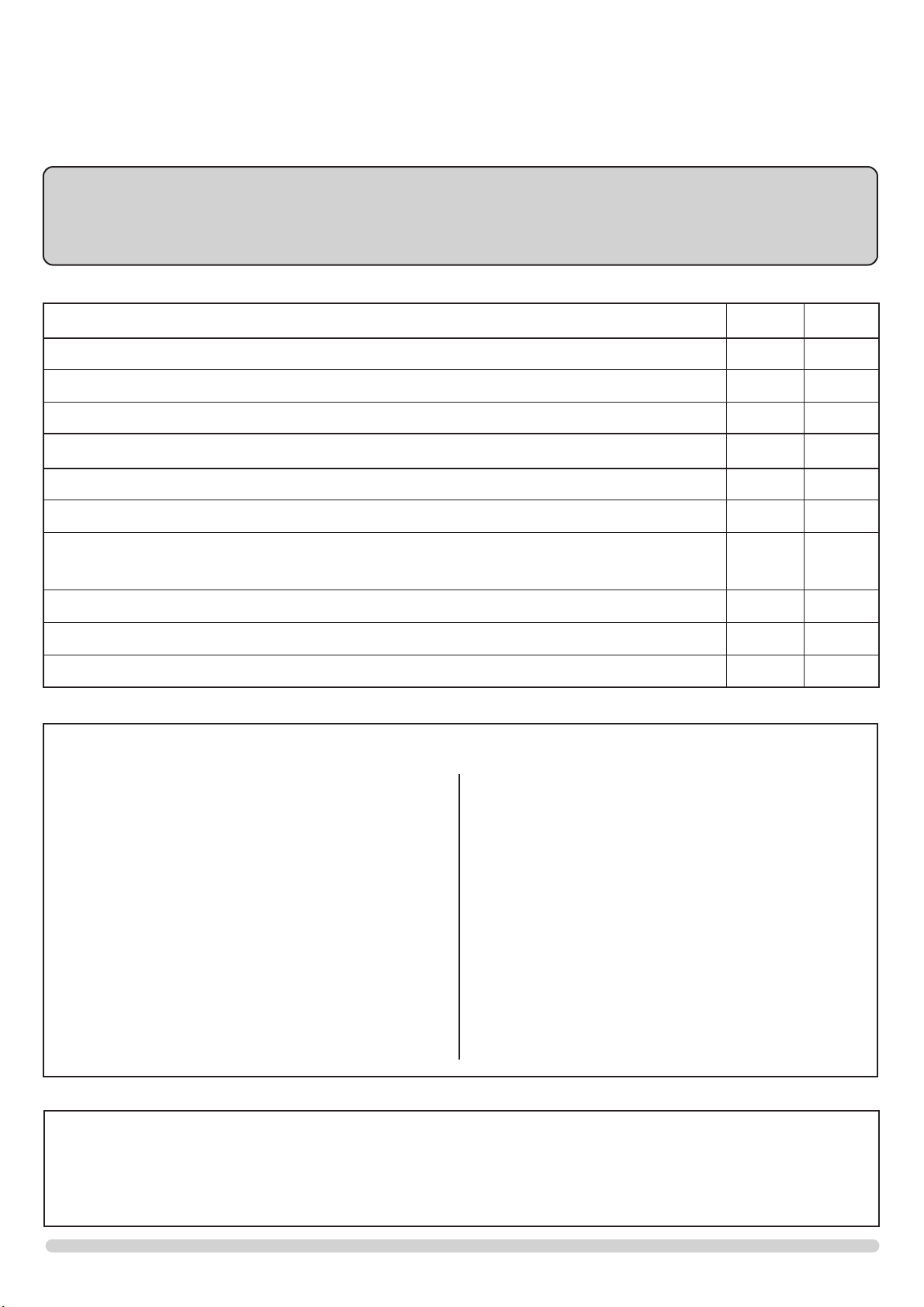

2.1

To ignite the Linea

The Gazco Linea has a fully automatic battery operated gas

control which can be lit using the hand set or touch pad.

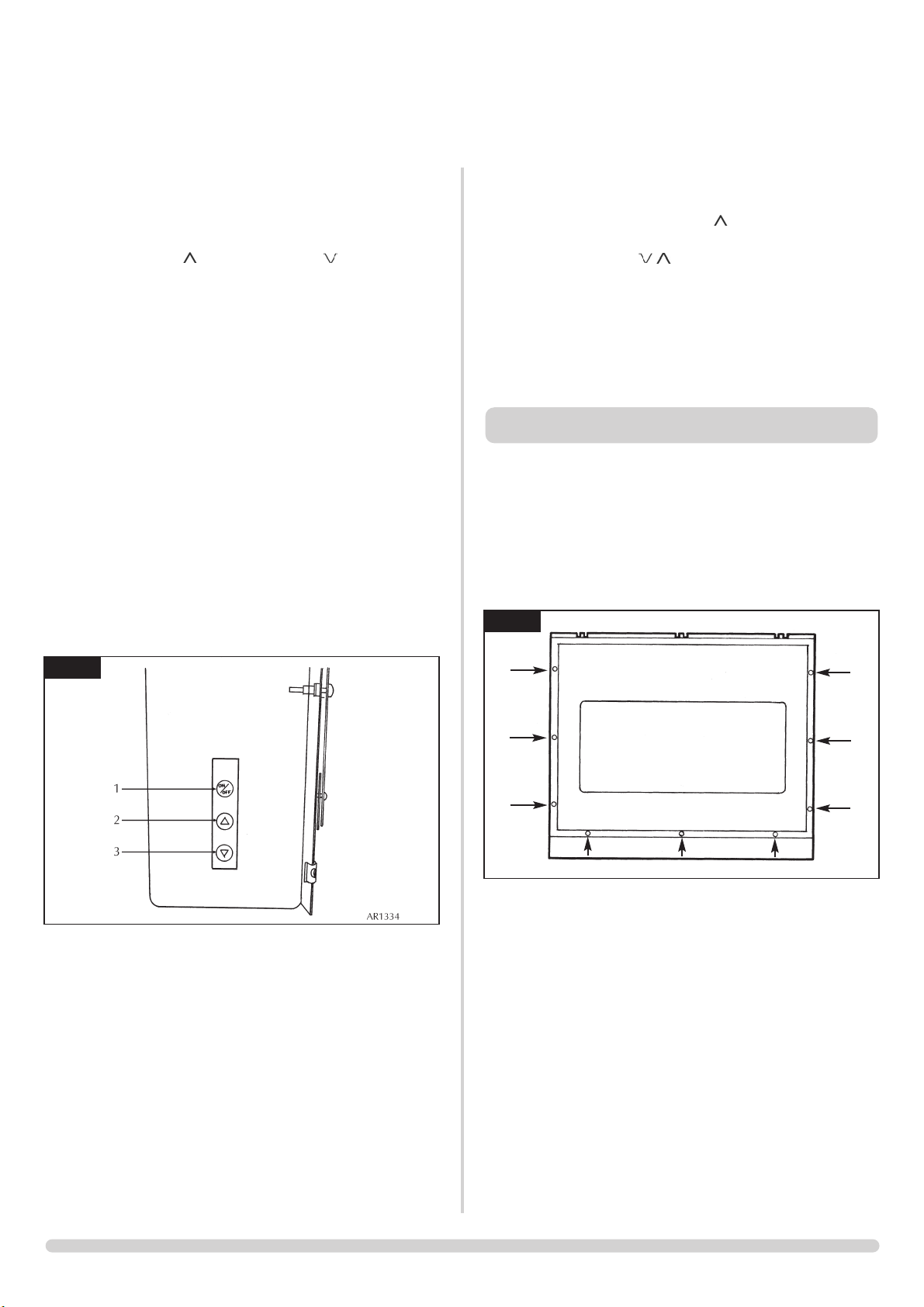

The touch pad is located on the lower left hand side of the

appliance.

2.1.1 Before the Linea can be lit the remote control must be in

the manual mode. See diagram 1. Refer to section 2.6 to

change to manual mode.

2. LIGHTING THE LINEA WITH HAND SET

1. GENERAL

2.1.2 Press the ON / OFF button (11). The word ON appears in

the display (4).

2.1.3 Press the SET button (12). The pilot light should now light.

This should take about 10 seconds.

If the pilot fails to light press the ON / OFF button (11) and

then the SET button (12) then repeat the above sequence.

2.1.4 A single flame will appear on the display (1). When this has

stopped flashing, an audible click is heard. You are now

ready to adjust the flame height.

IF THE FIRE IS EXTINGUISHED OR GOES OUT IN USE,

WAIT 3 MINUTES BEFORE ATTEMPTING TO RELIGHT

THE FIRE. THE CONTROL VALVE HAS AN INTERLOCK

DEVICE AND THEREFORE CANNOT BE LIT UNTIL THE 3

MINUTES HAVE ELAPSED.

2.2 To adjust the flame height

Once the pilot has been lit the main burner can be lit and

adjusted.

2.2.1 Press the ( ) UP button (10). The flame symbol (1) will

show one extra flame. This is to indicate the burner is on its

lowest position.

2.2.2 Press the same button again and the burner will be in the

medium position.

2.2.3 Press the button again and the burner will be in the

maximum position.

2.2.4 Press the ( ) DOWN button (13) one step at a time and

this will reduce the burner from maximum to medium then

to minimum.

2.2.5 If the ( ) DOWN button is pressed once more, only the

pilot will remain alight.

2.3 To turn the Linea off

The Linea can be turned off with the flames in any position, ie

minimum, medium or maximum. It can also be turned off from

the pilot only position.

2.3.1 Press the ON / OFF button (11) the word OFF appears in

the display.

2.3.2 Press the SET button (12) and the fire will turn off.

NOTE: The pilot can be left on if so desired

2.4 To change from Manual to Automatic mode

2.4.1 The hand set display will show the word MANUAL (8)

2.4.2 Press the SET button (12) once and the word AUTO will

flash.

2.4.3 Press the SET button (12) again and the word AUTO will

stop flashing.

2.4.4 The room temperature display is now flashing and ready to

be set.

1

1: Flame display

2: Celsius display

3: Temperature display

4: On display

5: Off display

6: Low battery display

7: Clock display

8: Auto display

9: Manual display

10: UP button

11: ON/OFF button

12: SET button

13: DOWN button

AR1665

1

2

3

10

11

5

6

7

4

8

9

12

13

5

2.5 To set the room temperature

2.5.1 Following on from section 2.4, once the room temperature

is flashing on the display, it can be set.

2.5.2 Press either the ( ) button (10) or the ( ) button (13) to

either increase or decrease the temperature.

2.5.3 Press the SET button (12) once you have set the

temperature as desired.

If the SET button (12) is not pushed the temperature display

will stop flashing and remain unchanged.

2.6 To change from Automatic to Manual

mode.

2.6.1 The hand set display will show AUTO (8).

2.6.2 Press the SET button (12) once and the word MANUAL will

flash.

2.6.3 Press the SET button (12) again and the word

MANUAL will stop flashing.

You are now in Manual mode.

2.7 Low battery display (Hand Set)

The low battery symbol (6) will appear on the hand set

when the batteries require replacement.

2.8 Lighting the Linea (Touch Pad)

2.8.1

Press the ON / OFF button (1) once and the red LED will

flash. The pilot will now light. This should take about 10

seconds.

If the pilot does not light press the ON / OFF button (1)

again to reset the control unit and repeat step 1 above.

Before the burner can be lit wait for the audible click.

2.9 To adjust the flame height (Touch Pad)

2.9.1

Once the pilot has lit press the ( ) button (2) and the

burner will light.

2.9.2

Press either of the ( ) buttons (2/3) to adjust the height

of the flames.

2.10 To turn the Linea off (Touch Pad)

2.10.1

Press the ON / OFF button (1) once and the Linea will turn

off.

ENSURE THE APPLIANCE IS COLD BEFORE PROCEEDING.

3.1 The outside casing of the Linea should be cleaned using a

damp cloth.

3.2 To clean the glass panel, remove the decorative front as

detailed in the instructions supplied with front.

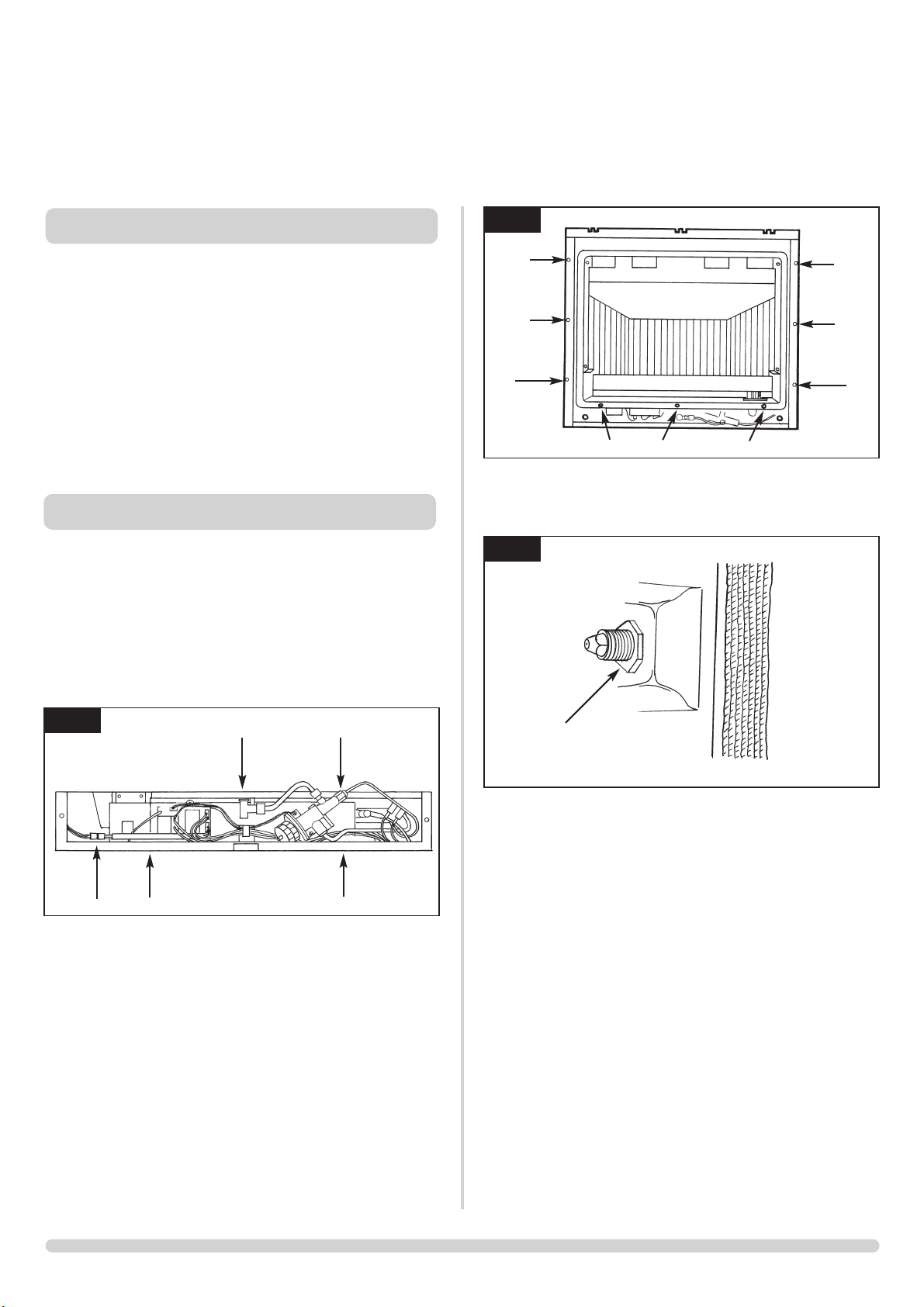

3.3 Remove the glass panel by unscrewing the nine pozidrive

screws. See diagram 3

3.4 Use a damp cloth and warm soapy water. Ensure the glass is

dry before re-assembling.

3.5 Ensure that the fibreglass seal on the firebox is intact then

hook the location tabs over the hooks on the top of the

firebox. Replace the nine screws working from the top

down, three long ones in the bottom holes. Tighten the

screws evenly.

NEVER OPERATE THE APPLIANCE WHEN THE GLASS

PANEL IS REMOVED OR BROKEN.

3. CLEANING THE LINEA

USER INSTRUCTIONS

2

3

AR1339

4.1 This is a safety feature incorporated on this appliance which

automatically switches off the gas supply if the pilot goes

out and fails to heat the thermocouple.

5.1 The surface coating on the ceramic panel used in your

GAZCO fire will "burn off" during the first few hours of use

producing a harmless and temporary odour. This will

disappear after a short period of use. If the odour persists,

ask your installer for advice.

6.1 The fire must be serviced every 12 months by a qualified

Gas Engineer. In all correspondence always quote the

Model number and the Serial number which may be found

on the data badge.

7.1 This appliance requires no additional ventilation.

8.1 To assist in any future correspondence, your installer should

have completed the commissioning sheet at the front of this

book, this records the essential installation details of the

appliance. In all correspondence always quote the Model

number and Serial number.

9.1 Parts of this appliance become hot during normal use. It is

therefore recommended that a suitable fire guard be used

for protection of young children and the infirm. Indeed, all

parts of the appliance should be treated as a 'working

surface' except for the control touch pad area and access

panel (Designio version only).

9. HOT SURFACES

8. INSTALLATION DETAILS

7. VENTILATION

6. SERVICING

5. RUNNING IN

4. FLAME FAILURE DEVICE

6

USER INSTRUCTION

7

USER INSTRUCTION

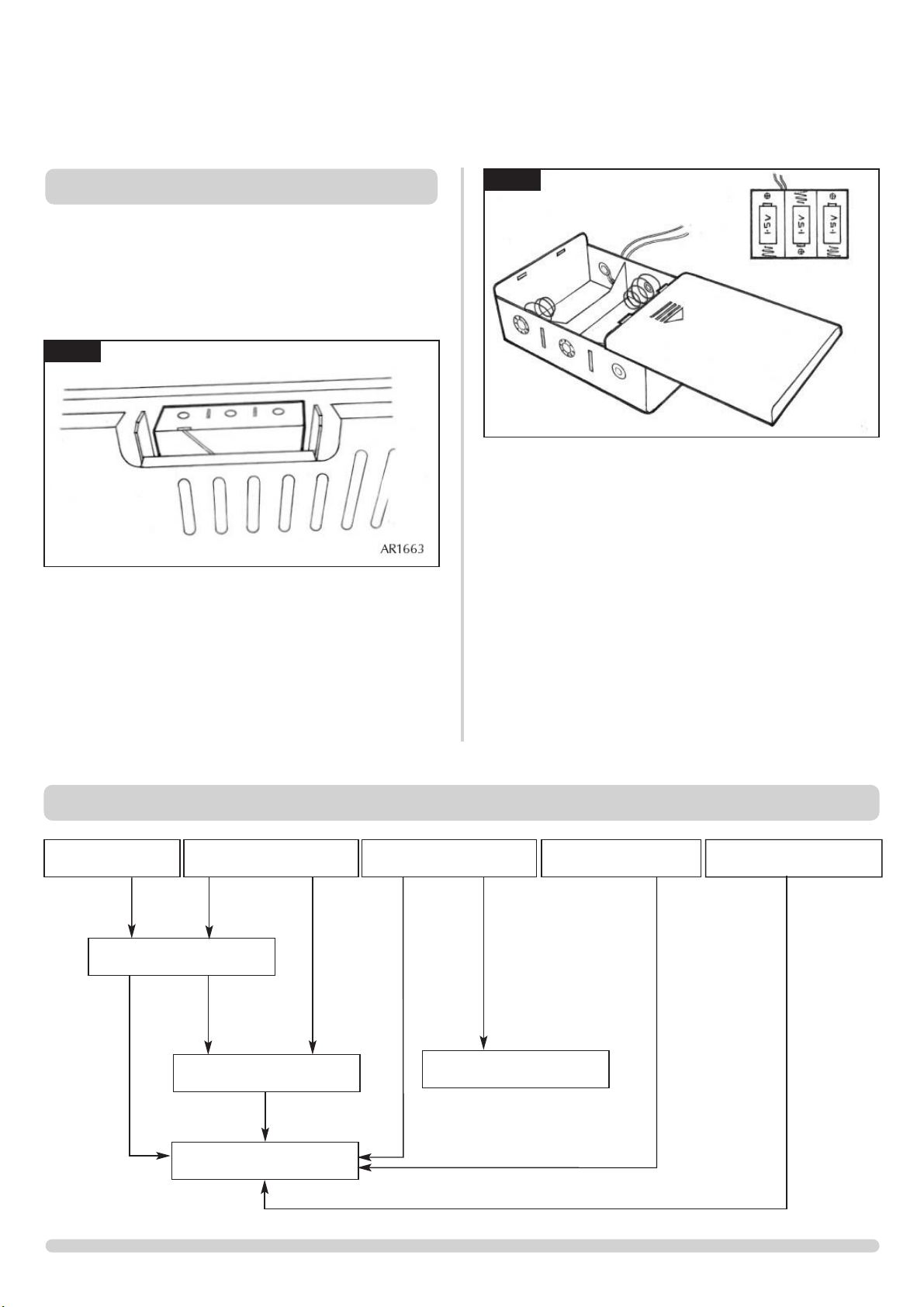

10.1 If the Linea is fitted with a Designio front, access to the

batteries can be achieved by simply dropping the lower

front access cover.

10.2 If the Linea is fitted with a Plano or Vetro front, access to

the batteries can be achieved through the access hole in the

casing below the unit. See diagram 4.

10.3 Remove the top from the plastic battery compartment by

gently depressing the top in the area with the indication

arrow and then sliding off in the direction of the arrow. See

diagram 5.

10.4 Replace the batteries with three "C" size cells ensuring they

are in the correct orientation as shown in the diagram in the

base of the plastic battery holder.

10.5 Replace the top of the battery holder and push back into its

location.

10. BATTERY REPLACEMENT

FIRE WILL NOT LIGHT

4

Does the pilot spark when

using the handset?

Does the pilot spark when

using the touch pad?

Is there any spark

at the pilot?

Does the appliance go

out during use?

Does pilot light then go

out immediately?

Is the low battery indicator

visible on the handset display?

Change the appliance

batteries

Change the handset

batteries

Does it spark only once or

twice and very slowly?

NO

NO

NO

NO

NOYES YES YESYES

INSUFFICIENT BATTERY POWER

The Copreci control system used on this appliance has a

built-in safety feature which will prevent the appliance from

lighting if there is insufficient battery power. This feature

will also act to turn the appliance off if the battery power

falls below a safe level.

When the battery power falls to a low level, this is indicated

by 10 audible beeps and 10 continuous flashes on the

touchpad LED indicator. This will occur when the ignition is

activated and the batteries should be replaced.

If the appliance will not light, please check the touchpad for

this warning before proceeding further. You may notice a

noise from the control valve when attempting to light the

appliance under these conditions. This is normal and should

not cause concern.

5

AR1664

8

INSTALLATION INSTRUCTIONS

TECHNICAL SPECIFICATION

COVERING THE FOLLOWING MODELS

8651 P8651

Efficiency Class I

Flue Outlet Size 100 Ø / 152mm Ø

Gas Inlet Connection Size 8mm Ø

Wall Thickness - Minimum = 100mm (4") Maximum = 500mm

Linea Replacement Batteries - 3 x 'C' Cells

Handset Replacement Batteries - 3 x 'AAA' Cells

Model

Gas Gas Working

Aeration Injector

Gas Rate Input kW (Gross) Nox

Country

CAT. Type Pressure m

3/

h High Low

Class

Linea NG I

2H

Natural (G20) 20mbar 2 x 8mm 1.7 0.50 5.25 3.5 4 GB, IE

Linea LPG I

3P

Propane (G31) 37mbar 1.2 0.20 5.25 3.5 4 GB, IE

PACKING CHECKLIST

Qty Description

1 Linea assembly including fixing bracket

1 Flue Pipe

1 Terminal Guard

1 Remote Hand Set

1 Terminal Guard Fixing Kit Containing:

4 Wood Screws 1

1

/4”

4 Red Rawlplugs

1 Linea Fixing Kit Containing:

4 Wood Screws 2

1

/2”

4 Brown Rawlplugs

1 Aluminium Tape

1 Sealing Ring

3 ‘C’ Cell Batteries

3 ‘AAA’ Batteries

1 Instruction Manual

1 x 7.5mm

2 x 10mm

AR1330

AR1331

9

INSTALLATION INSTRUCTIONS

SITE REQUIREMENTS

NOTE: This appliance can only be installed in conjunction

with the flue supplied.

1.1 The flue must be sited in accordance with BS5440: Part 1

(latest edition). See diagram 1.

1.2 Any terminal which is less than 2 metres above any access

(level ground, balcony or above a flat roof to which people

have access) is to be fitted with a guard.

1.3 The flue must be securely fixed and fire precautions

followed in accordance with local and national codes of

practice.

1.4 The horizontal terminal can be reduced in size. See diagram

2.

1. FLUE AND CHIMNEY REQUIREMENTS

2

AR0630

1

10

TIMBER FRAMED BUILDINGS

1.5 It will be necessary to provide additional clearance when

the flue passes through a wall containing any combustible

materials so as to prevent a fire hazard.

1.6 The hole through which the flue will pass, must have a steel

sleeve which is positioned so that an air gap of at least

25mm is maintained between the outer surface of the flue,

and any part of the sleeve.

1.7 For further guidance on the installation of gas appliances in

timber framed buildings, contact your local buildings control

authority.

2.1 Before installation, ensure that the local distribution

conditions (identification of the type of gas and pressure)

and the adjustment of the appliance are compatible.

2.2 Ensure that the gas supply is capable of delivering the

required amount of gas and is in accordance with the rules

in force.

2.3 Soft copper tubing can be used to install the appliance. Soft

soldered joints can be used externally of the appliance.

2.4 This appliance is supplied complete with a factory fitted

isolation device incorporated into the inlet connection, no

further isolation device is required.

2.5 All supply gas pipes must be purged of any debris that may

have entered, prior to connection to the appliance.

2.6 The gas inlet is located centrally at the bottom of the

appliance. The supply pipe may be installed using one of

three alternatives.

1) By drilling a hole straight through the outside wall. There

is a cutout in the back panel of the Linea and the fixing

bracket to allow the pipe to be concealed within the

appliance.

2) Surface mounting the pipe. For this option there is a pipe

cover kit 8654. This consists of

a) 1.4 Metre Cover

b) 2 Brackets

c) Screws and Rawlplugs

To fit the cover, measure the length required and cut down

accordingly. Fix the two brackets to the wall as required.

The magnets should be vertical. Fix pipe clips to the wall

and install the gas pipe. The cover can now be attached to

the magnets to cover the gas supply.

NOTE: There are three options of cover finishes. Black,

Metallic Alloy and primed finish which allows the customer

to finish any chosen colour.

3) The gas pipe can be concealed by cutting a channel in

the wall. All current regulations must be adhered to and no

pipe joint must be concealed in the wall.

2. GAS SUPPLY

INSTALLATION INSTRUCTIONS

SITE REQUIREMENTS

3.1 This appliance requires no additional ventilation.

IMPORTANT: DO NOT OBSTRUCT THE TOP AND BOTTOM

SLOTS IN THE LINEA OUTER CASE, THESE MUST BE

UNOBSTRUCTED. DO NOT RECESS THIS APPLIANCE

INTO A WALL, IT MUST BE SURFACE MOUNTED ON A

FLAT WALL USING THE WALL MOUNTING BRACKET

SUPPLIED.

4.1 This appliance does not require a hearth. It can only be

fitted on an outside wall with suitable clearances for the flue

terminal and guard (if required). As detailed in diagram 1.

4.2 All minimum clearances must be complied with. See

diagram 3. These clearances are to the outside edge of the

decorative frame and are therefore dependant on the frame

chosen.

4.3 The outer dimensions of the frames and their position

relative to the flue centre and Linea are detailed in

diagrams 4 and 5.

4. APPLIANCE LOCATION

3. VENTILATION

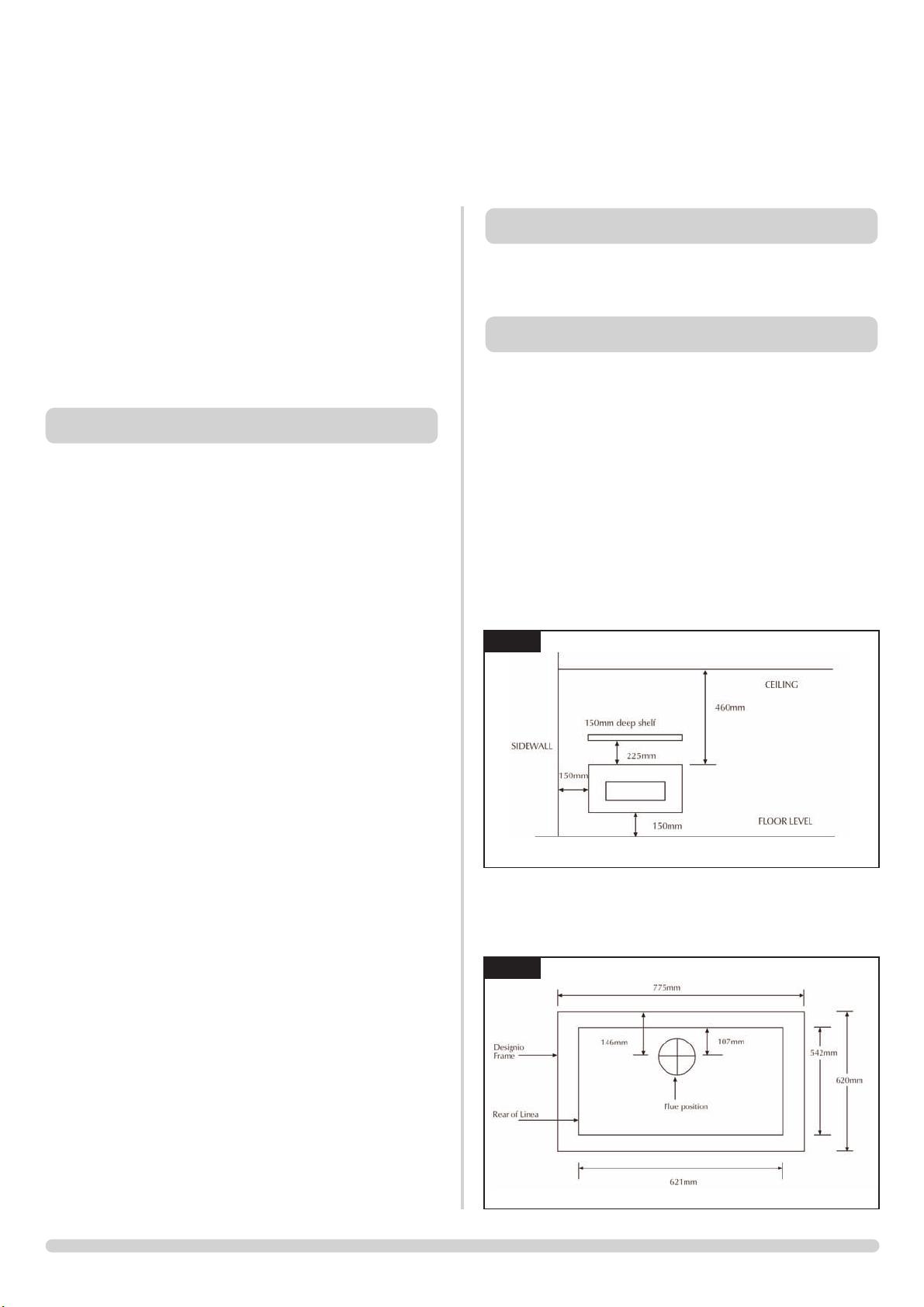

3

AR1325

4

AR1326

DESIGNO

11

INSTALLATION INSTRUCTIONS

SITE REQUIREMENTS

4.4 All combustible materials must be removed from behind the

appliance. See diagram 6.

4.5 The Linea may be mounted at any height, however, there

must be a minimum clearance of 150mm (6") between the

bottom edge of the appliance and the floor. To achieve this,

the minimum flue height for each front is shown in diagram

7.

5

AR1327

6

AR1328

7

AR1324

VETRO / PLANO DIMENSIONS

Combustible material to be removed around centre

line of flue. Shown as shaded area

MINIMUM HEIGHT OF FLUE FROM FLOOR LEVEL

VETRO / PLANO DESIGNIO

12

IMPORTANT: BEFORE THE APPLIANCE CAN BE

OPERATED THE REMOTE HANDSET MUST BE TUNED TO

THE CONTROL BOX SITUATED UNDER THE APPLIANCE.

IF THIS PROCEDURE IS OMITTED THE APPLIANCE CAN

ONLY BE LIT USING THE TOUCH PAD. SEE SECTION 3.

ENSURE THAT THE APPLIANCE IS CORRECTLY ADJUSTED

FOR THE GAS TYPE AND CATEGORY APPLICABLE IN THE

COUNTRY OF USE. REFER TO DATA BADGE AND

TECHNICAL SPECIFICATIONS ON PAGE 8.

FOR DETAILS OF CHANGING BETWEEN GAS TYPES REFER

TO SECTION 13 OF THE SERVICING INSTRUCTIONS.

1.1 This appliance must be installed in accordance with the

rules in force, and used only in a sufficiently ventilated

space. Please read these instructions before installation and

use of this appliance.

1.2 These instructions must be left intact with the user.

1.3 Do not attempt to burn rubbish on this appliance.

1.4 In your own interest, and those of safety, this appliance

must be installed by competent persons in accordance with

local and national codes of practice. Failure to install the

appliance correctly could lead to prosecution.

1.5 Keep all plastic bags away from young children.

2.1 Remove the appliance from the box and remove the two

screws, one from either side near the top of the black

surround. This will release the wall-fixing bracket.

2.2

Decide on the position of the Linea and Decorative front and

mark the intended position of the outer bottom edge of the

frame. Refer to diagram 4 and 5 in the site requirements for

overall dimensions of the decorative frames.

2.3 Having marked the position of the outer bottom edge,

position the template supplied ensuring that the line on the

wall aligns with the appropriate decorative frame bottom

edge on the template. See diagram 1.

2. INSTALLATION OF THE APPLIANCE

1. SAFETY PRECAUTIONS

2.4 Having ensured that the template is level, mark the centre

of the flue hole and the position of four fixing holes for the

wall-fixing bracket. See diagram 2.

Note: If a Vetro or Plano decorative front has been purchased, it

will also be necessary to mark the positions of the four

fixing holes for the front.

TAKE CARE WHEN MARKING OUT THE FLUE AS IT IS

VERY DIFFICULT TO MOVE AFTER INSTALLATION.

2.5 A 152mm (6") diameter hole is required to install the flue.

This can be achieved by either:

a) Core drill

b) Hammer and chisel

c) Drill small holes around the circumference, knock out

the centre and make good at both ends.

2.6 When the hole for the flue has been completed, insert the

four brown rawplugs supplied and attach the fixing bracket

using only the top two screws. See diagram 2a.

INSTALLATION INSTRUCTIONS

INSTALLATION

1

AR1332

2

AR1347

2a

AR1418

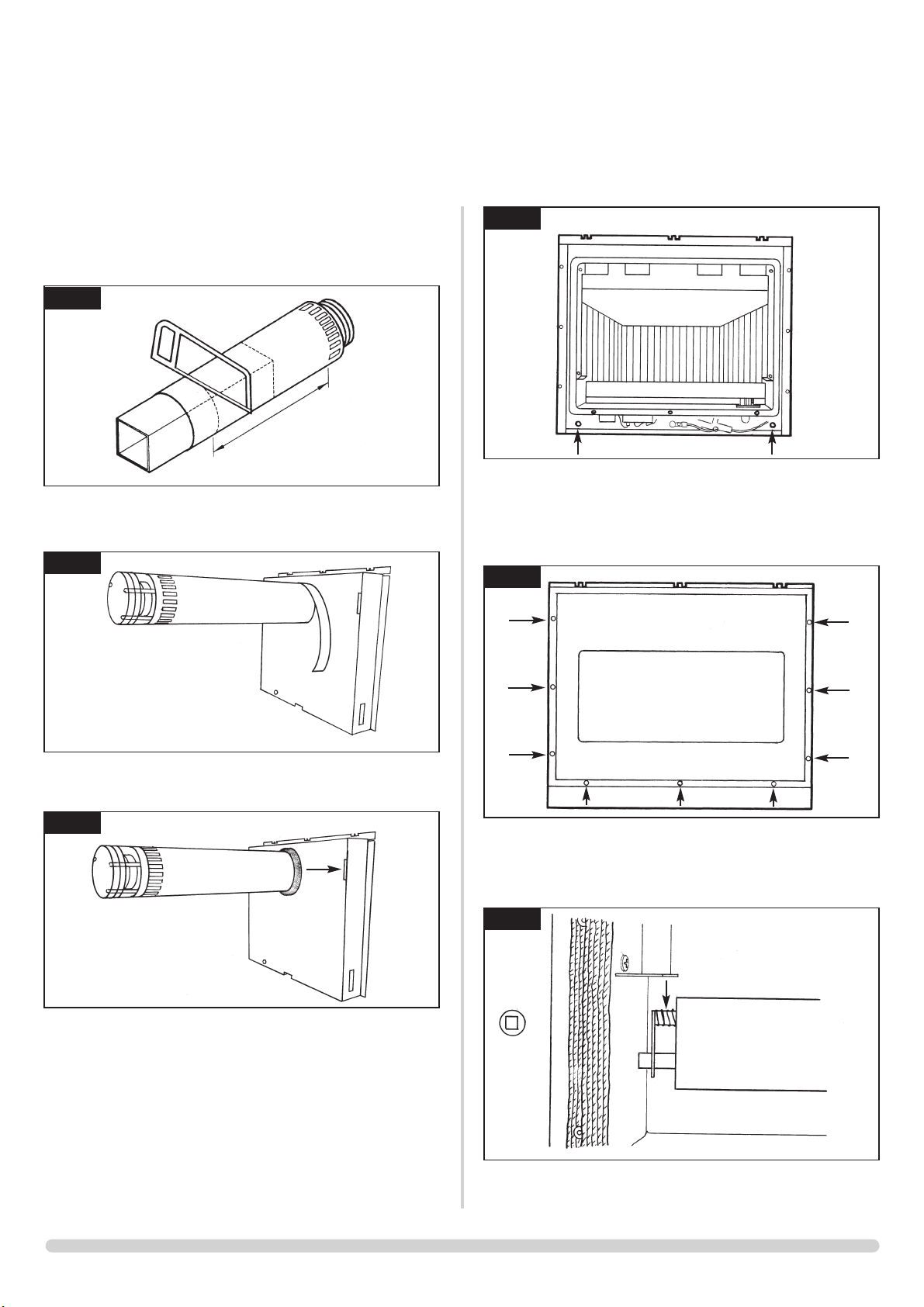

2.7 The flue can now be cut to size. Measure the thickness of

the wall, then deduct 12mm. This is the length required

when measuring from the line on the flue label. See

diagram 3.

2.8 Attach the flue to the appliance and seal using the

aluminium tape. See diagram 4.

2.9 Place the sealing ring over the flue and position it up against

the rear of the appliance. See diagram 5.

2.10 Fit the appliance on to the wall bracket by engaging the

arms on the bracket into the slots in the rear of the

appliance. See diagram 5.

2.11 Fit the appliance as far back as possible and refit the two

screws to secure the Linea to the wall bracket.

2.12 Fit the lower two wood screws through the rear of the

appliance and into the wall. See diagram 6 arrow A.

13

INSTALLATION INSTRUCTIONS

INSTALLATION

DO NOT OVER TIGHTEN. DO NOT DEFORM THE REAR

OF THE APPLIANCE.

2.13 Remove the nine screws retaining the glass frame, remove

the frame and store in a safe place. See diagram 7.

2.14 Remove the cardboard packaging from on top of the burner

and ensure the burner is fully engaged on the injector. Also

check the burner retention spring is located over the stud

and tab on the left hand side of the burner. See diagram 8.

5

AR1336

6

AR1338

7

AR1339

8

AR1340

4

AR1335

A

A

AR0630

3

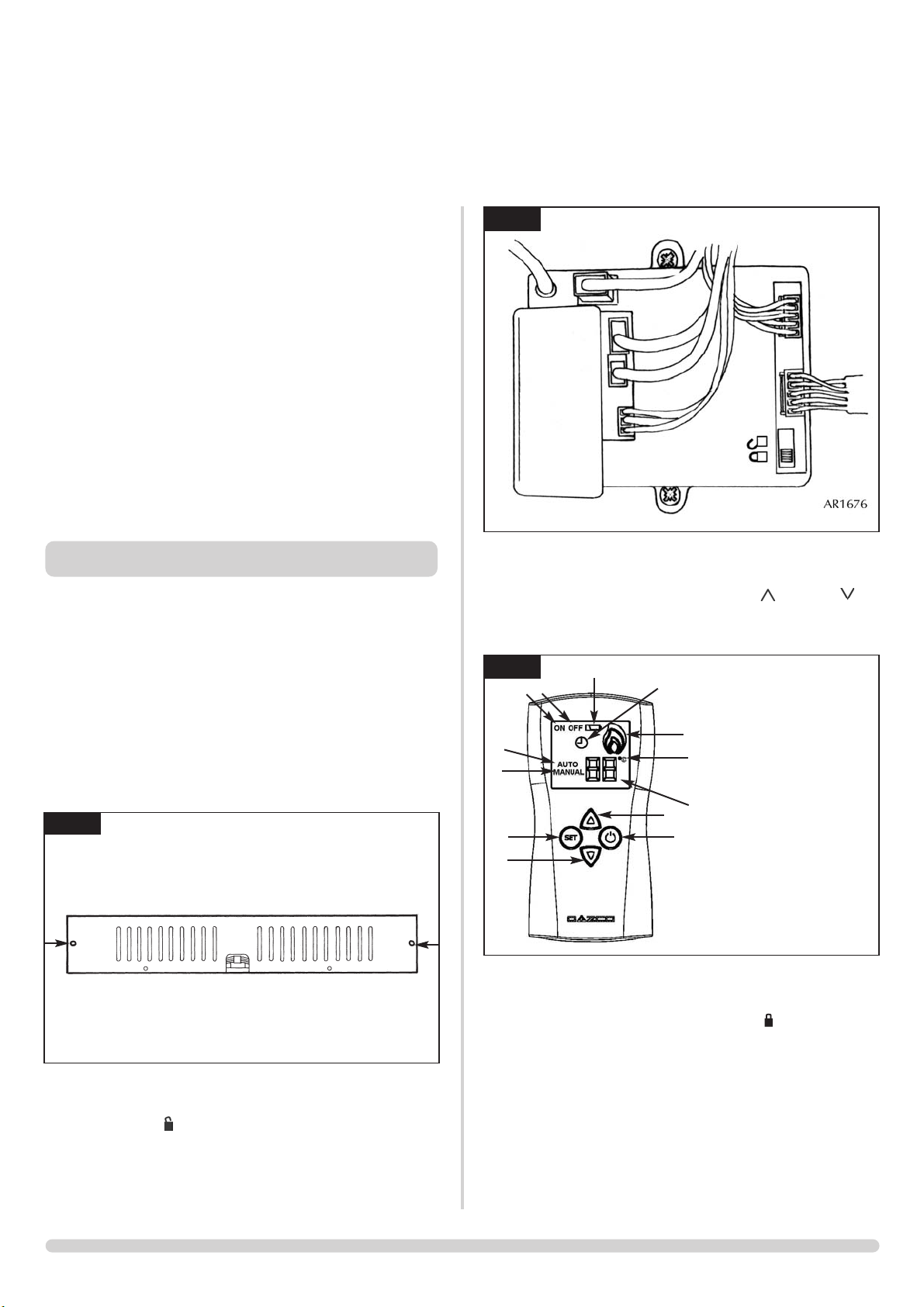

3.1.3 The remote handset must now be programmed. Push the ON /

OFF button (11), the ON or OFF display will start flashing. Then

press the ON / OFF button (11), and the

( )

(10) and

( )

(13) buttons at the same time.

Immediately after press the SET button (12) once. See diagram

11.

3.1.4 The clock (7) will appear on the display. After a few seconds this

will disappear.

3.1.5 Finally push the switch back to the Locked position, towards

the rear of the appliance. The remote should now be tuned to

the control box.

3.1.6 Replace the lower cover; ensure the tabs are located on the rear

flange. Engage the front tabs at the side of the appliance and

replace the two screws. Take extreme care as to not trap any

cables when replacing the cover.

NOTE: IF A NEW HANDSET IS PURCHASED THE ABOVE

PROCEDURE MUST BE REPEATED.

3.2 Check flame picture.

3.3 Check gas pressure.

14

INSTALLATION INSTRUCTIONS

INSTALLATION

NOTE: THE HANDSET HAS BEEN FACTORY

PROGRAMMED TO OPERATE THIS FIRE. IF

THE HANDSET OR CONTROL UNIT HAS

BEEN REPLACED, YOU MUST FOLLOW THE

PROGRAMMING PROCEDURE.

3.1 Programming the handset

Section 3 must be read in total before trying to program the

hand set. The sequence must be performed while the ON /

OFF on the display is still flashing.

3.1.1 Remove the two outer screws from the under side of the

appliance, pull the cover forward and remove. See diagram 9.

3.1.2 Working under the appliance the control box is located on the

left hand side. Using a pen or something similar push the switch

to the Unlock position. When viewed from underneath the

ON position is towards the front of the appliance. See diagram

10.

3. COMMISSIONING

9

AR1341

10

2.15 Replace the glass frame; ensure the top of the frame is

hooked on the tabs at the top of the appliance and replace

the nine screws with the three longest screws used in the

bottom fixing holes. Tighten from the top down.

HAVE YOU PURGED THE GAS SUPPLY?

2.16 Connect the gas supply to the isolation device using 8mm

pipe. Connect a suitable pressure gauge to the test point

and turn on the gas supply and check for leaks.

2.17 Light the appliance and set it to maximum. Check the

pressure corresponds to the data badge. Turn the gas off

and replace the test point screw. Turn the gas on and check

the screw for leaks.

THE YELLOW FLAMES WILL APPEAR WHEN THE FIRE

HAS GAINED SUFFICIENT HEAT - TYPICALLY 20

MINUTES.

26

1: Flame display

2: Celsius display

3: Temperature display

4: On display

5: Off display

6: Low battery display

7: Clock display

8: Auto display

9: Manual display

10: UP button

11: ON/OFF button

12: SET button

13: DOWN button

AR1665

1

2

3

10

11

5

6

7

4

8

9

12

13

15

IGNITION FUNCTIONAL CHECK 1

PILOT WILL NOT LIGHT

Ensure there is no debris around the pilot assembly,

(e.g. soot, etc.) which could short the spark, clean the area.

Operate the valve.

Is there a spark?

Consult User

Instructions and retry.

Check alignment of pilot

burner head, change the

ignition lead. Change the

electrode

See Replacing Parts, section 5.

Check isolation tap and

gas meter, retry.

Correct and

retry.

Purge the gas pipes and retry.

GO TO THE NEXT

CHART, IGNITION

FUNCTIONAL CHECK 2

SYSTEM OK

There is a blockage in the system, check the inlet test point, the

mag seating and valve. Check thermocouple leads for correct

orientation, condition and connection

Is the gas turned on to the

appliance?

Is the gas pressure correct?

Has the system got

any air in it?

Does the pilot light?

Is the control being

operated correctly?

Will the pilot light

with a match?

No Yes

No

Yes

No

Yes

Yes

No

No

Yes

No

No

Yes

Yes

SERVICING INSTRUCTIONS

SERVICING / FAULT FINDING CHARTS

This appliance must be serviced at least once a year by a

competent person.

All tests must be serviced by best practice as described by the

current CORGI recommendations.

1.1 Before any test are undertaken on the appliance, conduct a

gas soundness test for the property to ensure that there are

no gas leaks prior to starting work.

1.2 Before any tests are undertaken on the appliance it is also

recommended to fully check the operation of the

appliance.

1.3 Special checks

1.3.1 Clean any lint or fluff from the pilot - pay particular

attention to the aeration hole in the side of the pilot

1.3.2 Clean away any fluff or lint from under the burner

1.3.3 Check that the spark gap on the pilot is correct

1.4 Correct any faults found during the initial tests and then recommission the appliance conducting the usual safety

checks.

1.5 Advise the customer of any remedial action taken.

1. SERVICING REQUIREMENTS

16

PILOT WILL NOT STAY LIT OR FIRE GOES OUT IN USE

Ensure there is no debris around the pilot assembly,

(e.g. soot etc.) Check for fluff in the pilot aeration hole.

See the diagram in Replacing Parts section.

Problem is with the

pipework or

fittings which lead

to the fire. Correct

and retry.

Is thermocouple in

its correct position

in pilot bracket? See

diagram 4,

Replacing Parts.

Is the thermocouple

connection good in

back of valve?

Replace.

Is the pilot flame of the

correct length? See

diagram 4, Replacing

Parts.

Check, clean or

replace the pilot

injector.

Will pilot

stay alight?

With the pilot

running is the gas

pressure as stated on

the data badge?

With the fire running

on full is the gas at

the pressure stated

on the data badge?

Run for 3 mins,

turn off, time interval

until mag unit shuts with

a click. Is this greater

than 7 seconds?

Tighten the

connection and retry.

No

No

No

No

Yes

SYSTEM OK

Yes

Yes

Yes

Yes

No

Light the pilot using either the handset or the touch pad.

FLAME FAILURE FUNCTIONAL CHECK 3

SERVICING INSTRUCTIONS

FAULT FINDING CHARTS

IGNITION FUNCTIONAL CHECK 2

NO SPARK

Ensure there is no debris around the pilot assembly,

(e.g. soot etc.) which could short the spark, clean the area.

Consult the users

instructions, retry.

From Ignition Fault

Finding Chart 1

Is the gap between

electrode and

thermocouple 4.0mm?

Has ignition lead

become detached or is

connection poor?

Remove the electrode lead

and electrode. With insulated

pliers. Hold the tip 4.0mm from the

pilot pipework, is there a spark

when the system is operated?

Has the ignition lead

become detached from the

control box?

Replace the lead, retry.

Correct and retry.

Check handset batteries are OK.

Replace if required. Check handset

is on manual. Check if handset lock

is off. Check batteries to the control

unit. Replace if required. Retry with

handset and touch pad.

Is the valve being

operated correctly?

Check tab on pilot burner

wood is not damaged. Either

repair tab or replace pilot

burner & retry

Yes

Yes

Yes

No

No

No

Yes

Yes

Yes

No

No

Replace the electrode.

Replace the electrode

lead and retry.

Yes

No

No

Correct the position.

Yes

17

2.4 Raise the burner from the slot in the bracket, pull the

burner forward and slide to the left to clear the injector.

Take care not to lose the spring.

2.5 Replace in reverse order ensuring the spring is located over

the stud on the burner and the tab on the bracket.

The main frame, glass frame and main burner need only be

removed if the pilot burner is to be replaced. If only the

pilot injector, electrode or thermocouple is to be replaced

they can be accessed from under the appliance.

The pilot assembly consists of four components, which can

be individually changed, these are:

1) Pilot burner bracket.

2) Pilot injector

3) Electrode

4) Thermocouple.

4.1 Remove the main front by referring to the instructions

supplied with the decorative front.

4.2 Remove the glass frame from the appliance. See diagram 1

arrow C.

4.3 Remove the main burner by compressing the spring on the

lefthand side of the burner. See diagram 2. Raise the burner

forward and slide to the left to clear the injector. Take care

not to lose the spring.

4.4 Working underneath the appliance, remove the lower

cover. See diagram 3.

4.5 Remove the thermocouple, pilot pipe and electrode as

described in the sections 5 to 7.

4.6 Remove the two screws retaining the pilot burner. See

diagram 4.

3. PILOT UNIT

1.1 All principal components can be replaced without removing

the appliance from its installation, although it is essential

that the gas supply to the appliance is turned off at the

isolation device before proceeding further.

1.2 If for any reason the flue has to be removed from the

appliance, the seal must be replaced in the inner spigot.

1.3 If access to the controls is restricted, the whole control

assembly and wiring loom can be removed and serviced

outside the Linea, refer to section 14 for further details.

2.1 Remove the front from the appliance. (Refer to the

instructions supplied with the decorative front)

2.2 Remove the glass frame, note the orientation of the screws.

The three long silver screws locate only in the bottom of the

frame. See diagram 1, arrow C.

2.3 Compress the burner retaining spring towards the burner.

See diagram 2.

2. MAIN BURNER

1. GENERAL

SERVICING INSTRUCTIONS

REPLACING PARTS

4. PILOT BURNER

1

AR1338

3

AR1341

2

AR1340

C

C

C

C

C

C

C

C

C

18

4.7 Reassemble in reverse order and replace the pilot gasket

with a new one.

4.8 Check for gas leaks.

5.1 To gain access to the pilot pipe, it is easier if the

thermocouple is removed first. To do this follow section 7.

5.2 Undo the pilot pipe from the top of the gas valve and from

under side of the pilot burner. See diagram 5 arrow B.

5.3 Remove the pipe and the injector will drop out from the

burner. take care not to lose or damage the injector.

5.4 To replace the injector reverse the above procedure.

5.5 Check for gas leaks.

6.1 Remove the lower panel. See diagram 6.

SERVICING INSTRUCTIONS

REPLACING PARTS

6.2 Pull the ignition lead off the electrode and undo the

retaining nut. See diagram 7.

6.3 Replace with a new electrode. Do not over tighten the nut

as this could break the new component.

6.4 Replace the ignition lead and the lower cover.

7.1 Remove the lower panel. See diagram 6.

6. ELECTRODE

7. THERMOCOUPLE

4 6

AR1341

7

AR1349

5

AR1343

5. PILOT INJECTOR

B

x

X = LPG 10

NG 15

19

7.2 Disconnect the thermocouple from the gas valve. See

diagram 8 arrow C.

7.3 Undo the thermocouple nut in the back of the pilot burner

by half a turn. This will release the thermocouple.

7.4 Disconnect the two leads noting the orientation. The lead

with the red tape on is connected to the thermocouple

spade nearest the gas valve. See diagram 9.

WHEN REPLACING WITH A NEW THERMOCOUPLE

TAKE EXTREME CARE TO BEND THE NEW COMPONENT

TO THE EXACT SHAPE AND TO KEEP THE

CONNECTORS IN THE SAME ORIENTATION.

7.5 When replacing the thermocouple into the pilot burner

ensure the component is pushed fully into the hole. There

is a stop on the thermocouple to set the height.

7.6 Lock the retaining nut just enough to grip the

thermocouple.

7.7 Replace the lower panel.

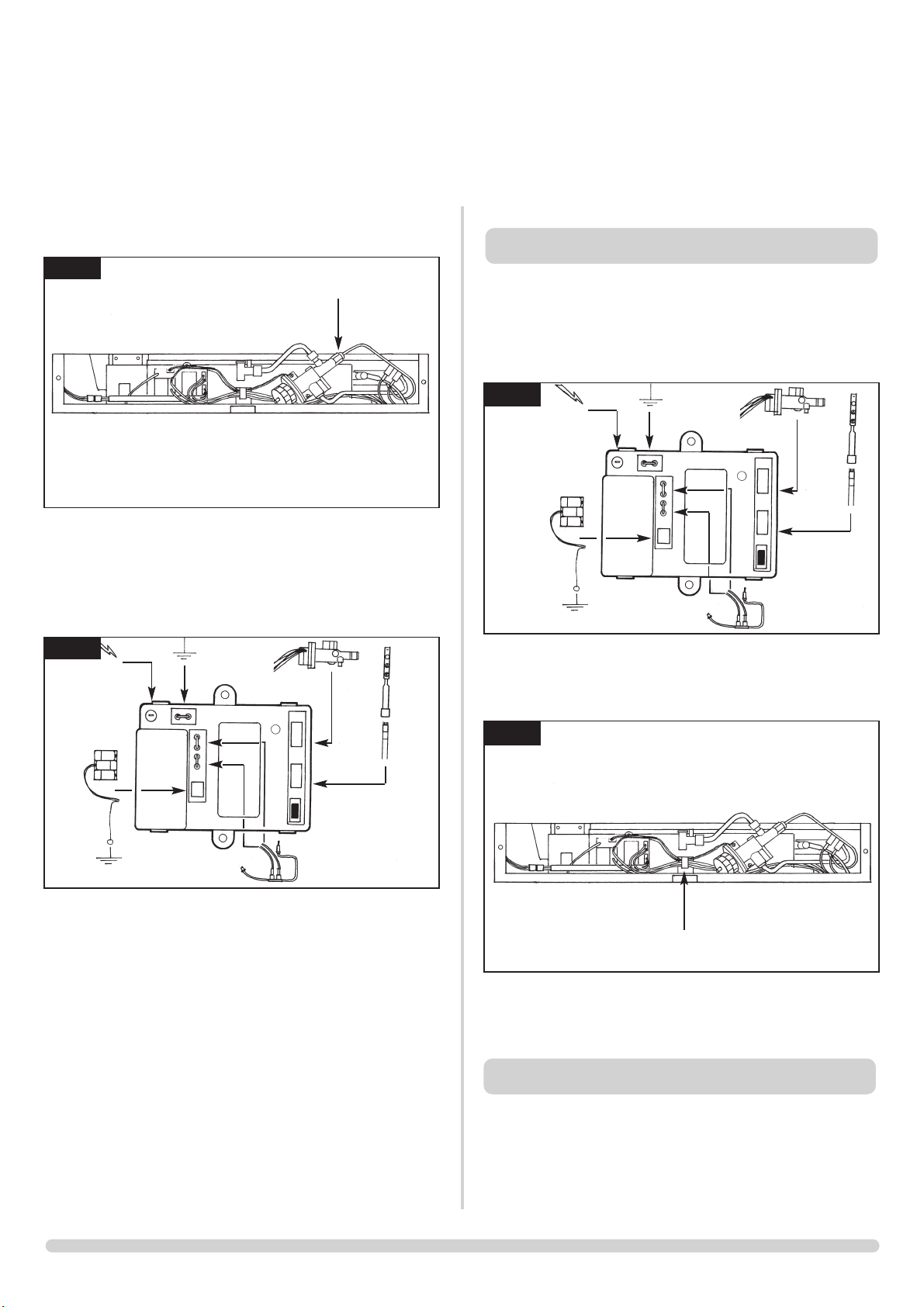

8.1 Remove the lower panel and pull the ignition lead off the

electrode.

8.2 Locate the ignition lead in the control box situated on the

left-hand side of the appliance and disconnect it. See

diagram 10

8.3 Release the wires from the central white clip and carefully

cut the cable ties. This will release the ignition lead. See

diagram 11.

8.4 Replace with a new lead, replace with new cable ties and

fit the wires back into the clip.

8.5 Fit the cover and ensure no wires are trapped.

9.1 Turn the gas off at the isolation device.

9.2 Remove the lower cover. See diagram 6

8. IGNITION LEAD

SERVICING INSTRUCTIONS

REPLACING PARTS

8

AR1344

10

AR1346

11

AR1344

9

AR1346

9. MAGNETIC SAFETY VALVE

C

4.5v

4.5v

10.3 Remove the main burner as described in section 2.

10.4 Remove the locknut from the injector. See diagram 15.

10.5 Remove the feed pipe from the gas valve. See diagram 16

arrow C.

10.6 Remove the feed pipe with the injector attached from the

appliance. Note the orientation of the injector on the pipe.

10.7 Reassemble in reverse order and check for gas leaks.

20

SERVICING INSTRUCTIONS

REPLACING PARTS

9.3 Remove the thermocouple from the rear valve. See diagram

12 Arrow c.

9.4 Support the valve and remove the magnetic valve retaining

nut. See diagram 13.

9.5 Reassemble in reverse order and check for gas leaks.

10.1 Remove the lower cover. See diagram 6.

10.2 Remove the glass frame. See diagram 14 arrow C.

10. MAIN INJECTOR

12

AR1344

13

AR1343

16

AR1343

14

AR1338

15

AR1345

C

C

C

C

C

C

C

C

C

C

C

21

SERVICING INSTRUCTIONS

REPLACING PARTS

11.1 Remove the lower cover. See diagram 6.

11.2 Locate the control box and remove all of the wires

connected to the box. NOTE THEIR POSITIONS.

11.3 Remove the two screws from the box. See diagram 17,

arrow A.

11.4 Replace in reverse order.

12.1 Turn off the gas supply at the isolation device.

12.2 Remove the lower cover. See diagram 6.

12.3 Remove the inlet pipe from the gas valve. See diagram 18

arrow D.

12.4 Disconnect the pilot pipe from the top of the gas valve. See

diagram 18 arrow B.

12.5 Undo the thermocouple from the rear of the gas valve. See

diagram 19 arrow C.

12. GAS VALVE

11. CONTROL BOX

17

AR1346

18

AR1343

12.6 Undo the feed pipe from the gas valve. See diagram 18

arrow C.

12.7 Release the wires from the clip and disconnect the valve

harness from the control box. See diagram 20.

12.8 Undo the two valve retaining nuts from the bracket. See

diagram 18 arrow A.

12.9 Cut the cable ties carefully and remove the valve.

12.10 Reassemble in reverse order and replace new cable ties.

DO NOT OVER TIGHTEN THE VALVE RETAINING NUTS.

12.11 Check for gas leaks.

19

AR1344

20

AR1346

C

C

A

B

D

A

A

4.5v

4.5v

22

SERVICING INSTRUCTIONS

REPLACING PARTS

In order to change between gas types it will be necessary to

change the following items.

Main Injector

Main Burner

Pilot Injector

Control Valve

Control Box

Thermocouple ( NG to LPG only).

LPG to NG no change).

Data Badge

NOTE: THIS ONLY NEEDS TO BE DONE IF ACCESS IS

TO THE CONTROLS IS RESTRICTED.

14.1 Remove the outer decorative front, refer to the instructions

supplied with the front.

14.2 Remove the lower cover. See diagram 6.

14.3 Disconnect the gas pipe at the isolation device. See diagram

21 arrow B.

14.4 Remove the glass frame. See diagram 22 arrow C.

13. CHANGING BETWEEN GAS TYPES

14. CONTROL BRACKET ASSEMBLY

21

AR1344

14.5 Remove the main burner as described in section 2.

14.6 Remove the injector locknut. See diagram 23.

14.7 Disconnect the touch pad from the harness. See diagram 21

arrow A.

14.8 Disconnect the ignition lead from the electrode.

14.9 Remove the thermocouple. See diagram 21 arrow C.

14.10 Remove the pilot pipe and ensure the pilot injector is kept

safe.

14.11 Remove the two screws securing the control bracket from

under the appliance. See diagram 21 arrow E.

14.12 Tilt the front edge of the bracket down slightly and move

the assembly to the right to disengage the injector. Rotate

the left hand side forward and down to allow the removal

of the injector from the side of the appliance. The assembly

should now be free of the appliance.

14.13 Reassemble in reverse order and check for gas leaks.

22

AR1338

23

AR1345

B

A

E

E

C

C

C

C

C

C

C

C

C

C

23

SERVICING INSTRUCTIONS

REPLACING PARTS

15. SHORT SPARES LIST

Component NG LPG

PROPANE BUTANE

BURNER UNIT GC0104 GC0105 GC0106

MAIN INJECTOR IN0053 IN0052

PILOT INJECTOR PI0069 PI0070

THERMOCOUPLE PI0071 PI0072

CONTROL BOX EL0276 EL0277

GAS VALVE* GC0107

MAG UNIT GC0109

IGN LEAD EL0267

SPARK ELECTRODE PI0073

CERAMIC REAR PANEL CE0474

T/C LEADS EL0271

BATTERY BOX EL0274

VALVE MOTOR HARNESS EL0278

TOUCH PAD HARNESS EL0273

TOUCH PAD ELO272

HANDSET EL0275

EARTH LEAD EL0190

WINDOW FRAME ASSEMBLY GZ3949

*Gas Valve is pre-set for the correct gas type.

24

SERVICE RECORDS

1ST SERVICE

Date of Service:...........................................................................

Next Service Due:.......................................................................

Signed:........................................................................................

Dealer's Stamp/CORGI Registration Number

3RD SERVICE

Date of Service:...........................................................................

Next ServiceDue:........................................................................

Signed:........................................................................................

Dealer's Stamp/CORGI Registration Number

5TH SERVICE

Date of Service:...........................................................................

Next Service Due:.......................................................................

Signed:........................................................................................

Dealer's Stamp/CORGI Registration Number

7TH SERVICE

Date of Service:...........................................................................

Next Service Due:.......................................................................

Signed:........................................................................................

Dealer's Stamp/CORGI Registration Number

9TH SERVICE

Date of Service:...........................................................................

Next Service Due:.......................................................................

Signed:........................................................................................

Dealer's Stamp/CORGI Registration Number

2ND SERVICE

Date of Service:...........................................................................

Next Service Due:.......................................................................

Signed:........................................................................................

Dealer's Stamp/CORGI Registration Number

4TH SERVICE

Date of Service:...........................................................................

Next Service Due:.......................................................................

Signed:........................................................................................

Dealer's Stamp/CORGI Registration Number

6TH SERVICE

Date of Service:...........................................................................

Next Service Due:.......................................................................

Signed:........................................................................................

Dealer's Stamp/CORGI Registration Number

8TH SERVICE

Date of Service:...........................................................................

Next Due:........................................................................

Signed:........................................................................................

Dealer's Stamp/CORGI Registration Number

10TH SERVICE

Date of Service:...........................................................................

Next Service Due:.......................................................................

Signed:........................................................................................

Dealer's Stamp/CORGI Registration Number

Gazco Limited, Osprey Road, Sowton Industrial Estate, Exeter, Devon, England EX2 7JG

Tel: (01392) 261999 Fax: (01392) 444148 E-mail: info@gazco.com

A member of the Stovax Group

Loading...

Loading...