Page 1

F40 Avanti

Conventional Flue Coal Effect Stove

Instructions for Use,

Installation and Servicing

For use in GB, IE (Great Britain and Eire)

IMPORTANT

Do not attempt to burn rubbish in this appliance. This appliance must only be operated with the glass door secured firmly in

position. The front casing of this appliance will become hot whilst in operation, it is therefore recommended that a suitable

guard should be used for the protection of young children, the elderly or infirm.

Please read these Instructions carefully before installation or use.

Keep them in a safe place for future reference and when servicing the fire.

The commissioning sheet found on page 3 of these instructions should be completed by the Installer.

This appliance has been certified for use in countries other than those stated. To install this appliance in these countries, it is essential to

obtain the translated instructions and in some cases the appliance will require modification. Contact Gazco for further information.

PR0778 Issue 4 (February 2007)

Page 2

2

CONTENTS

COVERING THE FOLLOWING MODELS

8685MCSC - P8685MCSC

8685MMCSC - P8685MMCSC

8685HMCSC - P8685HMCSC

PAGE

APPLIANCE COMMISIONING CHECKLIST 3

USER INSTRUCTIONS 4

INSTALLATION INSTRUCTIONS 9

Technical Specifications 9

Site Requirements 10

Installation 11

Commissioning 14

SERVICING INSTRUCTIONS 15

Servicing Requirements 15

Fault Finding 16

How to replace parts 17

Basic spare parts list 20

Service Record 21

Page 3

3

APPLIANCE COMMISSIONING CHECKLIST

FLUE CHECK PASS FAIL

1. Flue is correct for appliance

2. Flue flow test

3. Spillage test

GAS CHECK

1. Gas soundness & let by test

2. Standing pressure test mb

3. Appliance working pressure (on High Setting) mb

NB All other gas appliances must be operating on full

4. Gas rate m3/h

5. Does ventilation meet appliance requirements

6. Has the remote hand set been tuned to the control box YES NO

Dealer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contact No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Date of Purchase. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gas Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Company. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engineer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contact No.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Corgi Reg No.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Date of Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IMPORTANT NOTICE

Explain the operation of the appliance to the end user, hand the completed instructions to them for safe keeping,

as the information will be required when making any guaranteed claims.

DEALER AND INSTALLER INFORMATION

This product is guaranteed for 2 years from the date of installation, as set out in the terms and conditions of sale between Gazco and your

local Gazco dealer. This guarantee will be invalid, to the extent permitted by law, if the above Appliance Commissioning Checklist is

not fully completed by the installer and available for inspection by a Gazco engineer. The guarantee will only be valid during the

second year, to the extent permitted by law, if the annual service recommended in the Instructions for Use has been completed by a

Corgi registered engineer, and a copy of the service visit report is available for inspection by a Gazco engineer.

Page 4

1.1 Installation and servicing must be carried out by a

competent person in accordance with Gas Safety

(Installation and Use) Regulations 1998, the relevant British

Standards for Installation, appropriate Codes of Practice and

in accordance with the manufacturers instructions. It is

recommended that a CORGI registered engineer be used

for this purpose as they are approved by the HSE under the

above regulations.

1.2 This appliance is suitable for use in G.B. and I.E. using

Natural Gas at a supply pressure of 20mbar or LPG at a

supply pressure of 28mbar (Butane) or 37mbar (propane).

1.3 The installation shall also be completed in accordance with:

The Building Regulations issued by The Department of The

Environment.

The Building Standards (Scotland) Regulations issued by the

Scottish Development Department.

For Republic of Ireland, reference should be made to the

relevant standards governing installations (IS813:1996)

1.4 Read all these instructions before commencing installation.

1.5 This appliance must be installed in accordance with the

rules in force and only used in a sufficiently ventilated

space.

1.6 Ensure that curtains are not positioned above the stove, and

that there is at least a clearance of 300mm between the

sides of the stove and any curtains.

1.7 The manufacturer considers the full outer casing of this

stove to be a working surface. Therefore it will become hot

whilst in operation. A suitable guard is recommended to

protect young children, the aged and the infirm.

1.8 This stove must only be operated with the door secured

firmly in position. If any cracks appear in the glass the

appliance must not be used until the glass panel is replaced.

1.9 Do not attempt to burn rubbish in this stove.

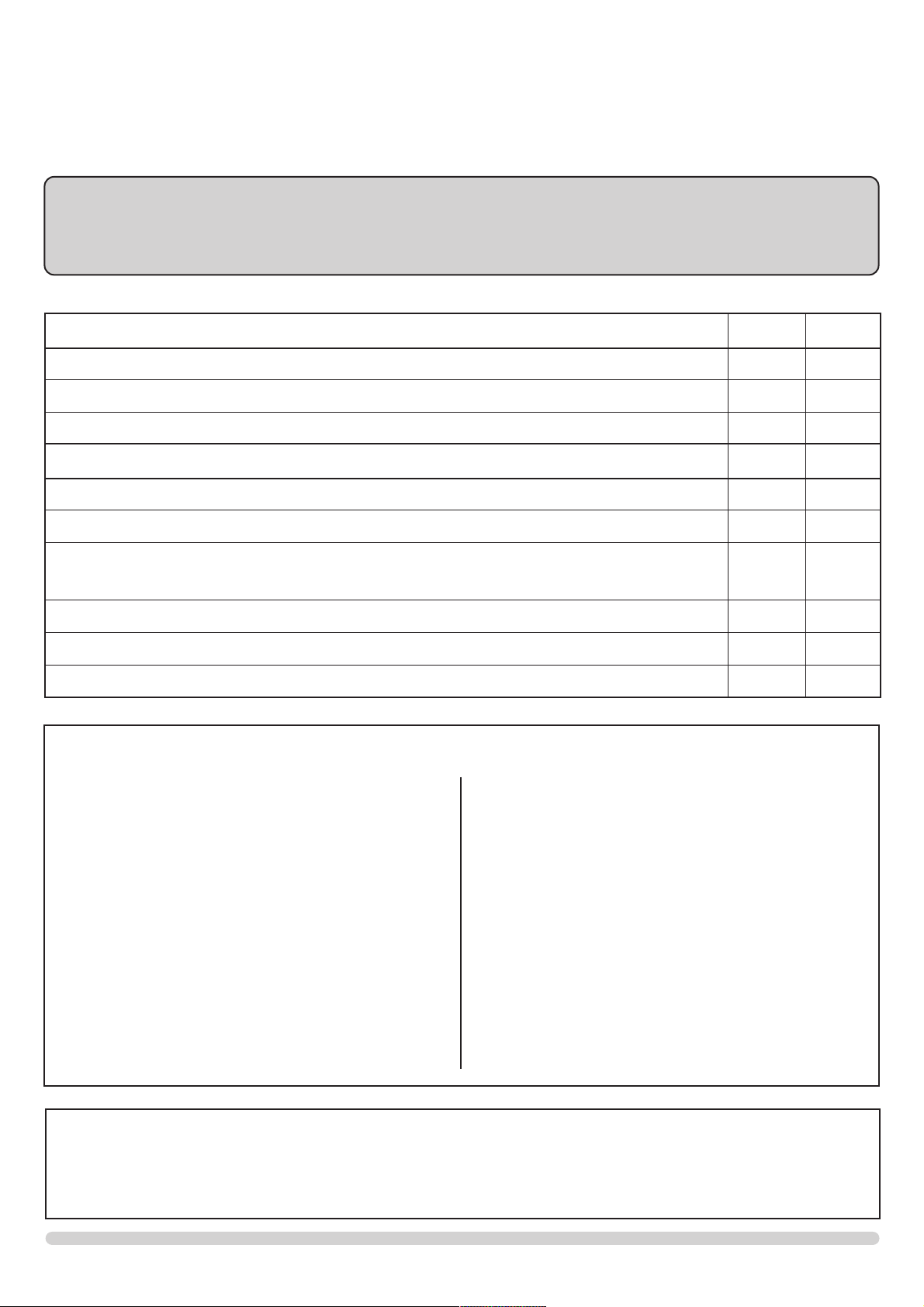

1.10 Any combustible shelves or surrounding furniture must only

be fitted in accordance with the minimum dimensions

detailed in diagram 1.

1.11 Contact a competent service engineer to carry out relevant

spillage checks etc. following home improvements carried

out after installation of this stove (e.g. the fitting of double

glazing).

1.12 In all correspondence, please quote the appliance type and

serial number which can be found on the databadge at the

rear of the stove.

1.13 This product is guaranteed for 2 years from the date of

installation, as set out in the terms and conditions of sale

between Gazco and your local Gazco dealer. Please consult

with your local Gazco dealer if you have any questions. In

all correspondence always quote the model No. and serial

No. Please ensure the commissioning checklist is

completed by your installer, as this is a requirement of

your Guarantee.

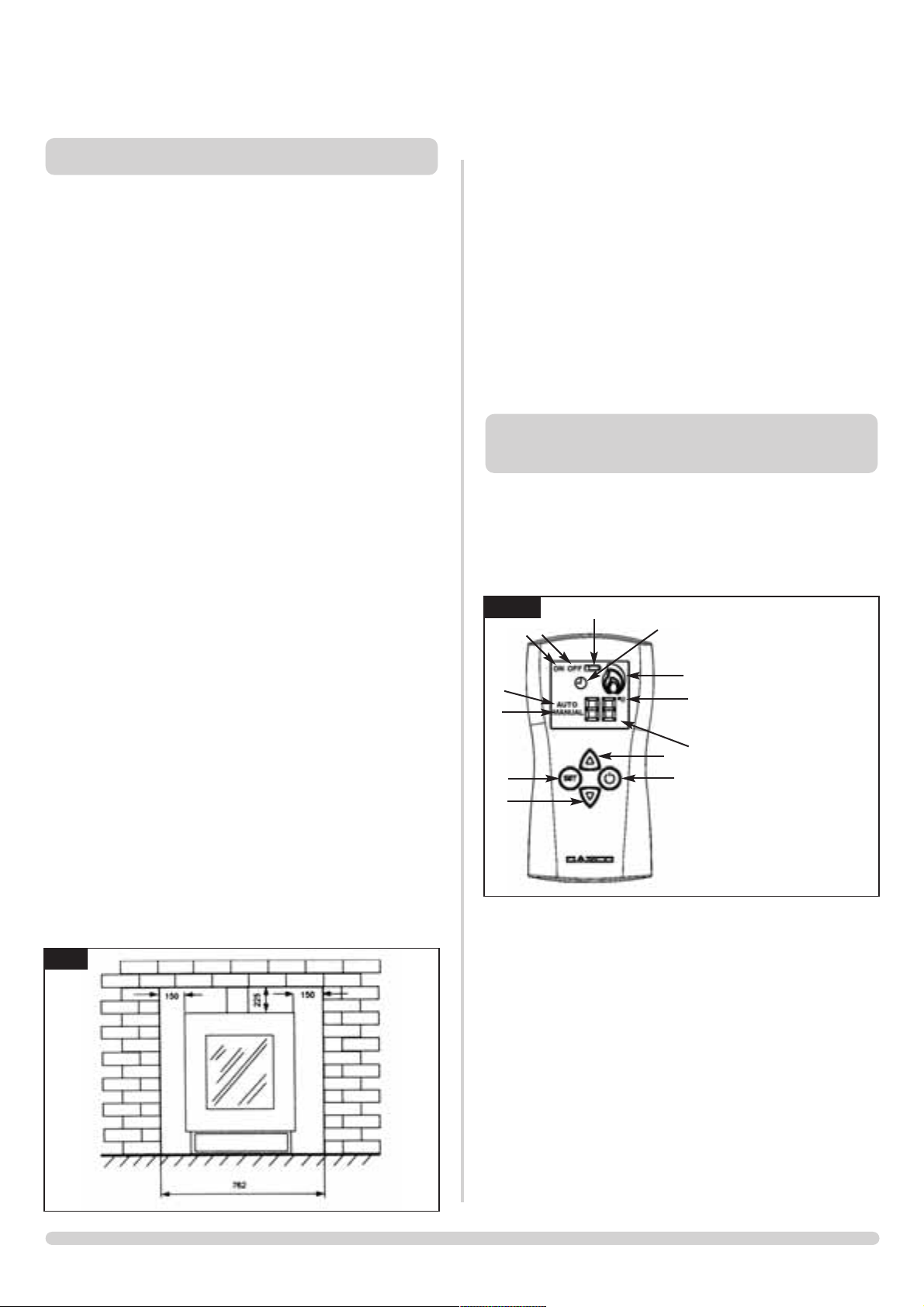

2.1

To ignite the F40 Avanti

The Gazco F40 Avanti has a fully automatic battery

operated gas control which can be lit using the hand set or

touch pad. The touch pad is located on the lower front

panel of the appliance, behind the main door.

2.1.1 Before the fire can be lit the remote control must be in the

manual mode. See diagram 2. Refer to section 2.6 to

change to manual mode.

2.1.2 Press the ON / OFF button (11). The word ON appears in

the display (4).

2.1.3 Press the SET button (12). The pilot light should now light.

This should take about 10 seconds.

If the pilot fails to light press the ON / OFF button (11) and

then the SET button (12) then repeat the above sequence.

2.1.4 A single flame will appear on the display (1). When this has

stopped flashing, an audible click is heard. You are now

ready to adjust the flame height.

2. LIGHTING THE F40 AVANTI

WITH HAND SET

1. GENERAL

4

USER INSTRUCTIONS

1

AR1468

2

1: Flame display

2: Celsius display

3: Temperature display

4: On display

5: Off display

6: Low battery display

7: Clock display

8: Auto display

9: Manual display

10: UP button

11: ON/OFF button

12: SET button

13: DOWN button

AR1665

1

2

3

10

11

5

6

7

4

8

9

12

13

Page 5

IF THE FIRE IS EXTINGUISHED OR GOES OUT IN USE,

WAIT 3 MINUTES BEFORE ATTEMPTING TO RELIGHT

THE FIRE. THE CONTROL VALVE HAS AN INTERLOCK

DEVICE AND THEREFORE CANNOT BE LIT UNTIL THE 3

MINUTES HAVE ELAPSED.

2.2 To adjust the flame height

Once the pilot has been lit the main burner can be lit and

adjusted.

2.2.1 Press the ( ) UP button (10). The flame symbol (1) will

show one extra flame. This is to indicate the burner is on its

lowest position.

2.2.2 Press the same button again and the burner will be in the

medium position.

2.2.3 Press the button again and the burner will be in the

maximum position.

2.2.4 Press the ( ) DOWN button (13) one step at a time and

this will reduce the burner from maximum to medium then

to minimum.

2.2.5 If the ( ) DOWN button is pressed once more, only the

pilot will remain alight.

2.3 To turn the F40 Avanti off

The F40 Avanti can be turned off with the flames in any

position, ie minimum, medium or maximum. It can also be

turned off from the pilot only position.

2.3.1 Press the ON / OFF button (11) the word OFF appears in

the display.

2.3.2 Press the SET button (12) and the fire will turn off.

NOTE: The pilot can be left on if so desired

2.4 To change from Manual to Automatic mode

2.4.1 The hand set display will show the word MANUAL (8)

2.4.2 Press the SET button (12) once and the word AUTO will

flash.

2.4.3 Press the SET button (12) again and the word AUTO will

stop flashing.

2.4.4 The room temperature display is now flashing and ready to

be set.

2.5 To set the room temperature

2.5.1 Following on from section 2.4, once the room temperature

is flashing on the display, it can be set.

2.5.2 Press either the ( ) button (10) or the ( ) button (13) to

either increase or decrease the temperature.

2.5.3 Press the SET button (12) once you have set the

temperature as desired.

If the SET button (12) is not pushed the temperature display

will stop flashing and remain unchanged.

2.6 To change from Automatic to Manual

mode.

2.6.1 The hand set display will show AUTO (8).

2.6.2 Press the SET button (12) once and the word MANUAL will

flash.

2.6.3 Press the SET button (12) again and the word

MANUAL will stop flashing.

You are now in Manual mode.

2.7 Low battery display (Hand Set)

The low battery symbol (6) will appear on the hand set

when the batteries require replacement.

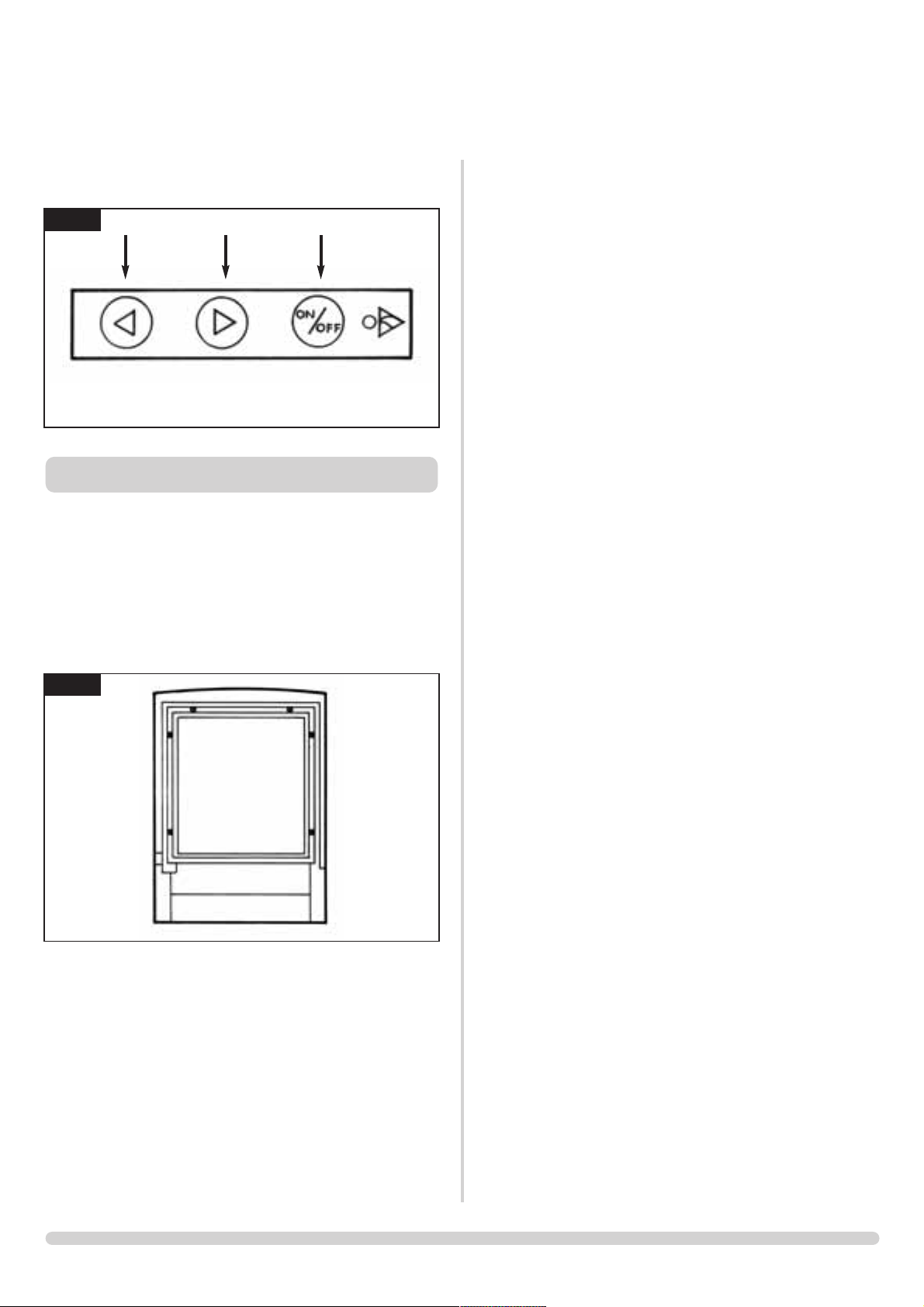

2.8 Lighting the F40 Avanti (Touch Pad)

2.8.1

The touch pad is located behind the main door. To open

the door, press the lower right hand corner of the door until

a click is heard, open the door and the touch pad can be

seen. See diagram 3.

2.8.2

Press the ON / OFF button (A) once and the red LED will

flash. The pilot will now light. This should take about 10

seconds. If the pilot does not light press the ON / OFF

button again to reset the control unit and repeat step 1

above. Before the burner can be lit wait for the audible

click. See diagram 4.

2.9 To adjust the flame height (Touch Pad)

2.9.1

Once the pilot has lit press the Up ( ) button (B) and the

burner will light. See diagram 4.

2.9.2

Press either of the ( ) buttons (B / C) to adjust the

height of the flames. See diagram 4.

5

USER INSTRUCTIONS

3

AR1466

Page 6

2.10 To turn the F40 Avanti off (Touch Pad)

2.10.1

Press the ON / OFF button (A) once and the F40 Avanti will

turn off. See diagram 4.

ENSURE THE APPLIANCE IS COLD BEFORE PROCEEDING.

3.1 The outside casing of the F40 Avanti should be cleaned

using a damp cloth.

3.2 To clean the glass frame, remove the front as detailed in the

installation instructions.

3.3 Remove the glass frame by unscrewing the six pozidrive

screws. See diagram 5.

3.4 To clean the glass surface, Gazco recommends you use a

ceramic glass product generally sold for cleaning ceramic

hobs.

3.5 Ensure that the fibreglass seal on the glass frame is intact.

Replace the six screws working from the top down. Tighten

the screws evenly.

NEVER OPERATE THE APPLIANCE WHEN THE GLASS

PANEL IS REMOVED OR BROKEN.

ADVICE ON HANDLING AND DISPOSAL OF FIRE

CERAMICS

The fuel effect and side panels in this appliance are made

from Refractory Ceramic Fibre (RCF), a material which is

commonly used for this application.

Protective clothing is not required when handling these

articles, but we recommend you follow normal hygiene

rules of not smoking, eating or drinking in the work area

and always wash your hands before eating or drinking.

To ensure that the release of RCF fibres are kept to a

minimum, during installation and servicing a HEPA filtered

vacuum is recommended to remove any dust accumulated

in and around the appliance before and after working on it.

When servicing the appliance it is recommended that the

replaced items are not broken up, but are sealed within

heavy duty polythene bags and labelled as RCF waste.

RCF waste is classed as stable, non-reactive hazardous

waste and may be disposed of at a licensed landfill site.

Excessive exposure to these materials may cause temporary

irritation to eyes, skin and respiratory tract; wash hands

thoroughly after handling the material.

3. CLEANING THE F40 AVANTI

6

USER INSTRUCTIONS

5

AR1454

4

AR1455

C

A

B

Page 7

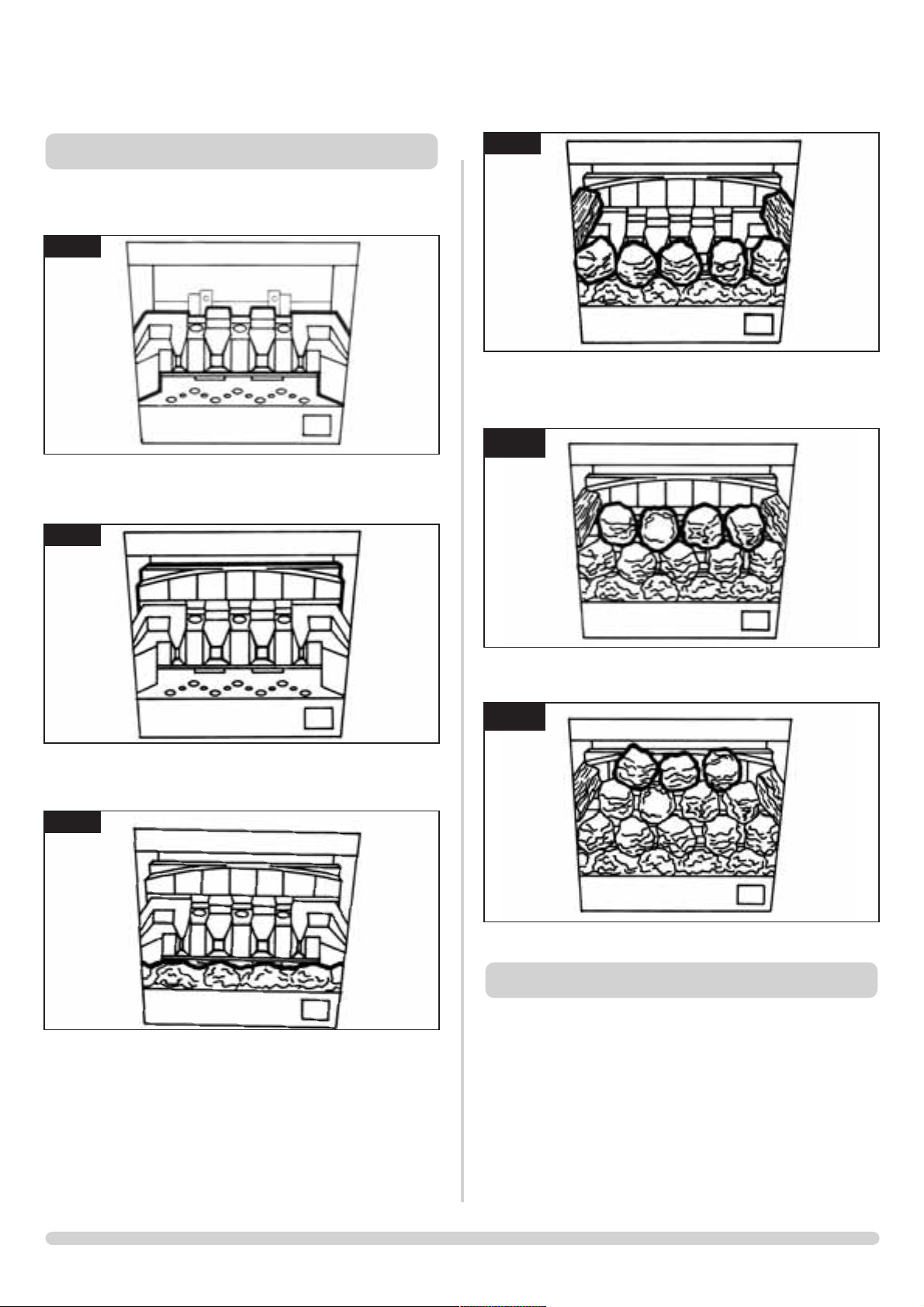

4.1 Place the flame baffle onto the burner and push against the

rear tray lip. See diagram 6

4.2 Locate the rear panel against the spacer brackets and slide

down so that it locates on the ledge of the flame baffle. See

diagram 7

4.3 Locate the front coal between the heat shield and the flame

baffle so its ends sit flat on the burner skin. See diagram 8

4.4 Place five of the loose round coals on the front coal so they

lean against the flame baffle, in between the fingers. Place

the two rectangular coals against the reflector panels, one

either side, behind the front row of loose coals. See

diagram 9

4.5 Place four of the loose round coals behind the first row so

that they sit on the fingers, the two outer ones should touch

the rectangular coals. See diagram 10

4.6 Place the three remaining coals behind the centre row so

that they touch the back panel. See diagram 11

5.1 The stove is fitted with the Gazco Flue Sure System, which

will act to cut off the gas supply to the burners in the event

of incorrect operation of the flue. If the system acts to cut

off the gas supply, this indicates that there is insufficient flue

pull. If this occurs a minimum of 10 minutes should be

allowed before trying to relight. Continued operation of this

safety device means there may be a serious problem with

the flue system. A qualified gas engineer should inspect this.

Do not use the stove until an engineer says it is safe to

do so.

5. GAZCO FLUE SURE SYSTEM

4. FUEL BED ARRANGEMENT

7

USER INSTRUCTIONS

6

9

8

10

11

AR0359

7

AR0360

AR0361

AR0362

AR0363

AR0364

Page 8

6.1 This is a safety feature incorporated in all GAZCO fires,

which automatically switches off the gas supply if the pilot

light goes out and fails to heat the thermocouple.

7.1 The surface coating on your GAZCO stove will ‘burn off’

during the first 24 hours of operation on high, producing a

harmless and temporary odour. If the odour persists ask

your Gazco dealer for advice

your retail for advice.

8.1 A qualified gas engineer must service the stove every 12

months. In all correspondence, always quote the appliance

type and the serial number that may be found on the data

badge on the appliance.

9.1 Any purpose provided ventilation should be checked

periodically to ensure that it is free from obstruction.

periodically to ensure that it is free from obstruction.

10.1 To assist in any future correspondence, your installer should

have completed the commissioning sheet, this records the

essential installation details of this appliance. In all

correspondence always quote the model No. and serial No.

11.1 Parts of this appliance become hot during normal use. It is

therefore recommended that a suitable fire guard be used

for protection of young children and the infirm. Indeed, all

parts of the appliance should be treated as a 'working

surface' except for the control touch pad area and access

panel.

12.1 Refer to the instructions supplied with the decorative front

and remove the front as detailed.

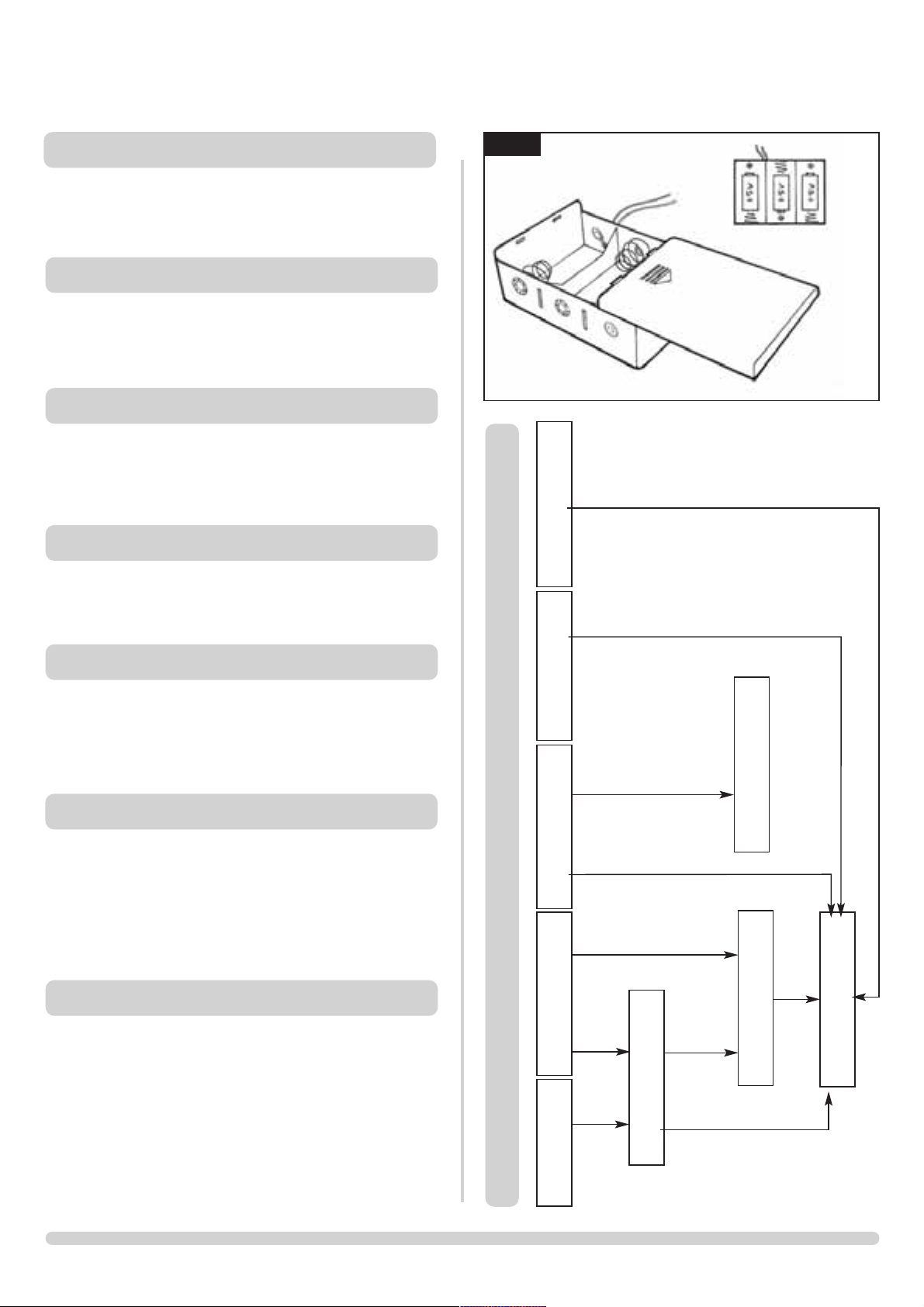

12.2 Locate the plastic battery holder situated to the right hand

side of the compartment and withdraw.

12.3 Replace the batteries ensuring they are in the correct

orientation. See diagram 12.

12.4 Push the battery holder back into its location and close the

door as detailed in the instructions supplied.

12. BATTERY REPLACEMENT

11. HOT SURFACES

10. INSTALLATION DETAILS

9. VENTILATION

8. SERVICING

7. ‘RUNNING IN’

8

USER INSTRUCTIONS

FIRE WILL NOT LIGHT

Does the pilot spark when

using the handset?

Does the pilot spark when

using the touch pad?

Is there any spark

at the pilot?

Does the appliance go

out during use?

Does pilot light then go

out immediately?

Is the low battery indicator

visible on the handset display?

Change the appliance

batteries

Change the handset

batteries

Does it spark only once or

twice and very slowly?

NO

NO

NO

NO

NOYES YES YESYES

6. FLAME FAILURE DEVICE

12

AR1664

Page 9

9

INSTALLATION INSTRUCTIONS

TECHNICAL SPECIFICATION

COVERING THE FOLLOWING MODELS

8685MCSC - P8685MCSC

8685MMCSC - P8685MMCSC

8685HMCSC - P8685HMCSC

MODEL GAS GAS WORKING NOX AERATION INJECTOR GAS RATE INPUT kW (Gross) COUNTRY

TYPE PRESSURE CLASS m

3

/h High Low

F40 Avanti I

2H

NG 20 mbar 5 1x7.5mm 1.7 0.515 5.4 3.5 GB, IE

8685 G20

F40 Avanti I3PLPG Propane 37 mbar 5 1x13.5mm 1.2 0.201 5.5 3.5 GB, IE

P8685 G31

Efficiency Class II

Flue Outlet Size 127mm (5”) ø

Gas Inlet Connection Size 8mm ø

Miminum flue specification T260 / N2 / O / D / 1

Maximum flue temperature 180°c

PACKING CHECKLIST

QTY Description

1 Stove

1 Flue infill plate

1 Front coal

1 Coal set

1 Rear Ceramic

1 Fixing kit containing:-

1 Instruction manual

2 Wood screws

2 Rawl plugs

1 Remote handset

3 ‘C’ cell batteries

3 ‘AAA’ cell batteries

AR1450

Page 10

1.1 The chimney or flue system must comply with the rules in

force, and must be a minimum of 127mm in diameter. (5").

1.2 The minimum effective height of the flue or chimney must

be 3 metres (10ft). Any horizontal flue run from the rear

outlet should not exceed 100mm from the back of the

appliance.

1.3 The chimney or flue must be free from any obstruction. Any

damper plates should be removed or secured in the fully

open position, and no restrictor plates should be fitted.

1.4 The chimney should be swept prior to the installation of the

appliance. However, where it can be seen that the chimney

is clean and unobstructed throughout its entire length, it

need not be swept.

NOTE: If it is intended to fit the stove into a existing brick

built chimney a 5" (127mm) liner must be used. Larger lined

flues may work, but in some instances could cause cold

start flue problems resulting in nuisance shutdown. Lined

flues above 7" (175mm) are not recommended.

Due to recent changes to European chimney standards,

new flue’s and chimney’s are now described by their

temperature, pressure and resistance to corrosion,

condensation and fire. To assist in identifying the correct

flue system, the minimum flue specification is shown in the

technical specification on page 8 of this book. Existing

chimney’s are not covered by this system.

2.1 Consult the rules in force.

Note: This appliance does not normally require any

additional ventilation when installed in G.B.

3.1 Before installation, ensure that the local distribution

conditions (identification of the type of gas and pressure)

and the adjustment of the appliance are compatible.

3.2 Ensure that the gas supply is capable of delivering the

required amount of gas, and is in accordance with the rules

in force.

3.3 Soft copper tubing and soft soldered joints can be used but

must not be closer than 50mm to the base of the tray.

3.4 A means of isolating the gas supply to the appliance must

be provided independent of any appliance control.

3.5 All supply gas pipes must be purged of any debris that may

have entered, prior to connection to the appliance.

4.1 This fire must stand on a non-combustible hearth that is at

least 12mm thick and projects 50mm minimum from the

base of the fire in all directions.

4.2 Do not install in a room that contains a bath or shower.

MINIMUM CLEARANCE

4.3 The fire is not suitable for installation against a combustible

wall. All combustible materials must be removed from

behind the fire.

4.4 Ensure you comply with all minimum clearance

measurements, whether or not to combustible materials.

See diagram 2 & 2A.

The above dimensions provide adequate clearance at the

side and rear of the fire so that controls can be reached.

4. APPLIANCE LOCATION

3. INSTALLATION OF THE GAS SUPPY

2. VENTILATION

1. FLUE AND CHIMNEY REQUIREMENTS

10

INSTALLATION INSTRUCTIONS

SITE REQUIREMENTS

1

A = 562mm

B = 431mm

C = 12mm

AR1468

AR1469

50

2

3

Page 11

ENSURE THAT THE APPLIANCE IS CORRECTLY

ADJUSTED FOR THE GAS TYPE AND CATEGORY

APPLICABLE IN THE COUNTRY OF USE. REFER TO THE

DATABADGE AND TECHNICAL SPECIFICATIONS ON

PAGE 9

FOR DETAILS OF CHANGING BETWEEN GAS TYPES

REFER TO SECTION 11 OF THE SERVICING

INSTRUCTIONS.

1.1 This appliance must be installed in accordance with the

rules in force, and used only in a sufficiently ventilated

space. Please read these instructions before installation and

use of this appliance.

1.2 These instructions must be left intact with the user.

1.3 Do not attempt to burn rubbish on this appliance.

1.4 In your own interest, and those of safety, this appliance

must be installed by competent persons in accordance with

local and national codes of practice. Failure to install the

appliance correctly could lead to prosecution.

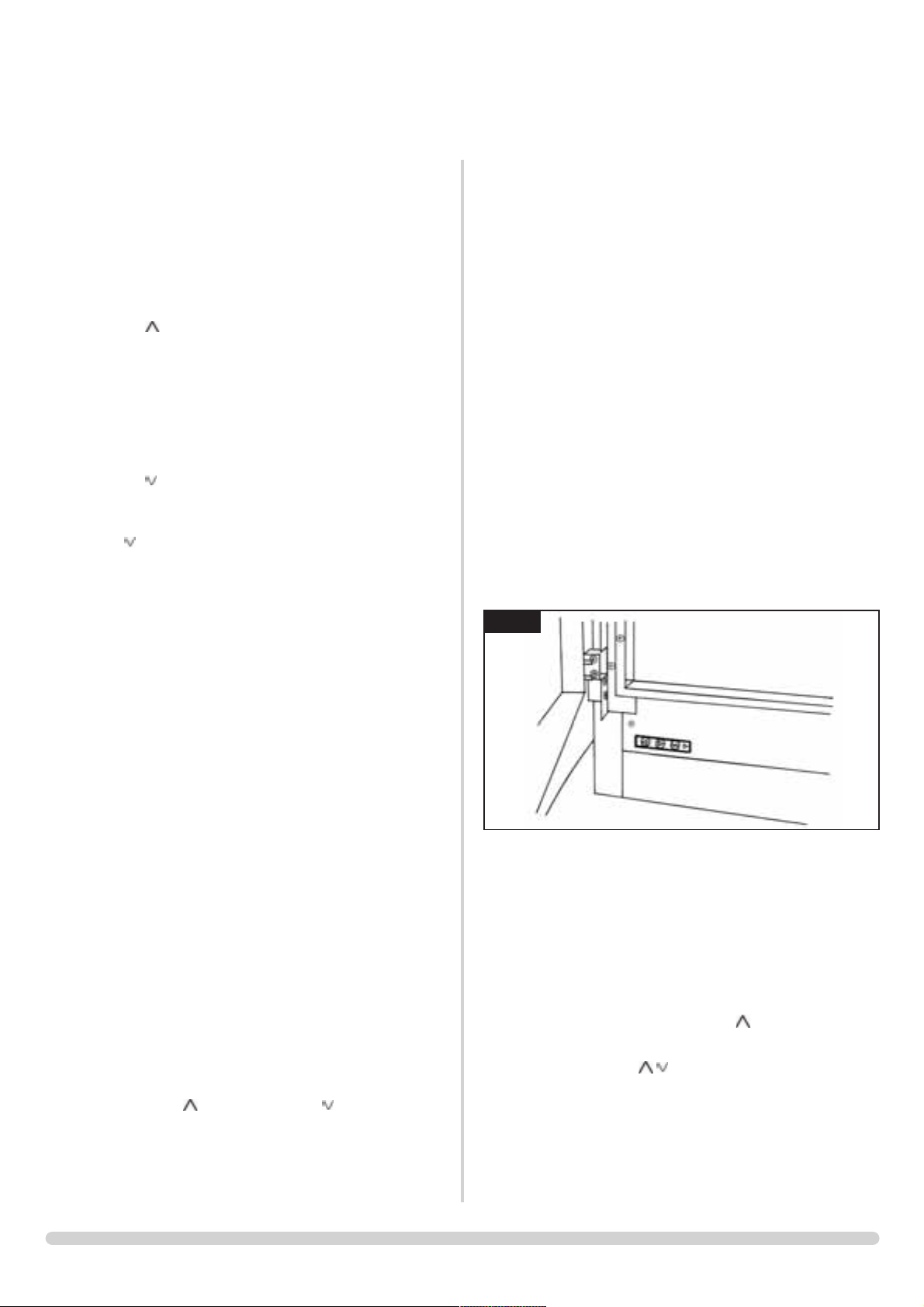

2.1 Remove the appliance from its packaging. It will now be

necessary to decide upon top or rear flue exit, the stove is

factory built for rear exit but is easily converted by swapping

the flue spigot with the blanking plate and putting the

blanking plate on the rear of the stove.

2.2 Open the lower door by pressing until a “click” is heard,

and gently lowering down.

2.3 Remove the glass frame by undoing the six pozidrive

screws. The four black screws are for removing the entire

firebox if required. Remove the ceramic components and

place carefully to one side. Remove the lower cover panel

by undoing the two pozidrive screws. See diagram 1.

2.3 Disconnect the lead for the touchpad and the two leads for

the TTB See Diagram 2.

2.4 Undo the two screws at the back of the firebox and gently

pull the burner unit forward. See diagram 3.

2.5 At the rear of the burner unit, undo the thermocouple and

disconnect the TTB leads. Now remove the burner unit

completely. See diagram 4.

2. INSTALLATION OF THE STOVE

1. SAFETY PRECAUTIONS

11

INSTALLATION INSTRUCTIONS

INSTALLATION

1

2

3

AR1454

AR1463

AR1457

4

AR1462

Page 12

2.6 Remove the four black screws in the firebox and lift the

firebox clear. See diagram 5.

2.7 For Midi and Highline versions of the F40, it will be

necessary to remove the base panel. This lifts up and

through the upper part of the carcass. See diagram 6.

2.8 It will now be possible to access the two tabs for bolting the

appliance down (if required). Position the stove ensuring all

appropriate clearances are observed. Using a pencil mark

the position of the holes in the fixing bracket. See diagram

7.

2.9 Remove the stove and drill the holes using a masonary drill.

Insert the rawlplugs.

2.10 Reposition the stove and level it using the three levelling

bolts in the base. Screw the stove down. Replace the

decorative base cover panel if fitted.

2.11 Refit the fire box and burner unit to the stove taking care to

reconnect the small TTB electrical connector to the left

hand terminal and the large TTB connector to the right

hand terminal. See diagram 8.

2.12 THE TTB CONNECTIONS IN THE INTERUPTOR BLOCK

MUST HAVE THE RED HIGHLIGHTED SPADE CLOSEST

THE VALVE. SEE DIAGRAM 9.

2.13 Having run the gas supply to the stove, PURGE THE

SUPPLY, this is essential to expel any debris that may block

the controls. Connect the gas supply to the 8mm test point

located at the lower right hand side of the stove. A gas

soundness check must be completed up to the gas inlet

connection. See diagram 10.

2.14 Check the pull of the flue system by applying a lighted

smoke pellet to the flue system opening. If there is a

definite flow into the chimney, proceed with the

installation, if not warm the chimney for a few minutes.

12

INSTALLATION INSTRUCTIONS

INSTALLATION

8

9

AR1472

AR1362

7

AR1456

6

AR1471

5

AR1470

10

AR1461

Page 13

IF THERE IS STILL NO DEFINITE FLOW, THE FLUE MAY

REQUIRE ATTENTION - SEEK EXPERT ADVICE.

2.15 The flue system may now be connected to the stove, ensure

that all joints are sealed with a suitable fire resistant sealant.

It is also recommended that a physical retention method be

used at the flue spigot joint, self-tapping screws being

favoured.

2.16 Connect a suitable pressure gauge to the test point located

on the inlet fitting, and turn the gas supply on. Light the

stove and check all gas joints for gas soundness. Turn the

stove to maximum and check that the supply pressure is as

stated on the data badge. Turn the gas off and replace the

test point screw, turn the gas on and check the test point for

gas soundness.

3.1 Place the flame baffle onto the burner and push against the

rear tray lip. See diagram 11.

3.2 Locate the rear panel against the spacer brackets and slide

down so that it locates on the ledge of the flame baffle. See

diagram 12.

3.3 Locate the front coal between the heat shield and the flame

baffle so its ends sit flat on the burner skin. See diagram 13.

3.4 Place five of the loose round coals on the front coal so they

lean against the flame baffle, in between the fingers. Place

the two rectangular coals against the reflector panels, one

either side, behind the front row of loose coals. See

diagram 14.

3.5 Place four of the loose round coals behind the first row so

that they sit on the fingers, the two outer ones should touch

the rectangular coals. See diagram 15.

3.6 Place the three remaining coals behind the centre row so

that they touch the back panel. See diagram 16.

4.1 After laying out the coals, replace the glass panel. Tighten

the six pozidrive screws, working from the top down. Do

not over tighten. Lower the front door on by holding at 90

degrees to the appliance and lowering down on to the two

hinge pins. See diagram 17.

3. FUEL BED ARRANGEMENT

13

INSTALLATION INSTRUCTIONS

INSTALLATION

12

13

14

15

16

AR0361

AR0362

11

AR0363

AR0364

AR0360

AR0359

4. DOOR REPLACEMENT

17

AR1363

Page 14

4.2 Close the door by pushing the lower right corner of the

door until a click is heard. The door will now have latched.

Opening is done by the lower right hand door, again until a

click is heard, and opening to its stop.

NOTE: THE HANDSET HAS BEEN FACTORY

PROGRAMMED TO OPERATE THIS APPLIANCE. IF THE

HANDSET OR CONTROL UNIT HAS BEEN REPLACED, IT

WILL BE NECESSARY TO FOLLOW THE PROGRAMMING

PROCEDURE.

PROGRAMMING THE HANDSET

Section 5 must be read in total before trying to programme

the handset! The sequence must be performed while the

ON/OFF on the display is still flashing.

5.1 Open the lower door by pressing until a ‘click’ is heard.

Now switch the button on the control unit to the Unlock

position . See diagram 18.

5.2 The remote handset must now be programmed. Push the ON /

OFF button (11), the ON or OFF display will start flashing. Then

press the ON / OFF button (11), and the

( )

(10) and

( )

(13) buttons at the same time.

Immediately after press the SET button (12) once. See diagram

19.

5.3 The clock (7) will appear on the display. After a few seconds this

will disappear.

5.4 Finally push the switch to the Lock position , towards the rear

of the appliance. The remote should now be tuned to the

control box.

5.5 Close the lower door untill a ‘click’ is heard.

5.6 Close all openable doors and windows in the room, ignite the

appliance and operate on maximum for 10 minutes. Remove

the plastic sight plug from the right hand side of the appliance.

Position a lighted smoke match just inside the draught diverter

opening and check that all smoke is drawn into the opening by

viewing through the sight hole. See diagram 20. If there is any

doubt, run the appliance for a further 10 minutes, and repeat

the test.

5.7 If there are any extractor fans in adjacent rooms, the test must

be repeated with the fans running on maximum and

interconnecting doors open.

IF SPILLAGE PERSISTS, DISCONNECT THE APPLIANCE

AND SEEK EXPERT ADVICE.

For future reference record the installation details on

commissionging sheet page 3 of these instructions.

5. COMMISSIONING

14

SERVICING INSTRUCTIONS

COMMISSIONING

18

20

AR1493

19

1: Flame display

2: Celsius display

3: Temperature display

4: On display

5: Off display

6: Low battery display

7: Clock display

8: Auto display

9: Manual display

10: UP button

11: ON/OFF button

12: SET button

13: DOWN button

AR1665

1

2

3

10

11

5

6

7

4

8

9

12

13

AR1676

Page 15

This appliance must be serviced at least once a year by a

competent person.

All tests must be serviced by best practice as described by the

current CORGI recommendations.

1.1 Before any test are undertaken on the appliance, conduct a

gas soundness test for the property to ensure that there are

no gas leaks prior to starting work.

1.2 Before any tests are undertaken on the applaince it is also

recommended to fully check the operation of the appliance.

1.3 Special checks

1.3.1 Clean any lint or fluff from the pilot - pay particular

attention to the aeration hole in the side of the pilot

1.3.2 Clean away any fluff or lint from under the burner

1.3.3 Check that the spark gap on the pilot is correct

1.4 Correct any faults found during the initial tests and then recommission the appliance conducting the usual safety checks.

1.5 Advise the customer of any remedial action taken.

15

SERVICING INSTRUCTIONS

SERVICING CHART

IGNITION FUNCTIONAL CHECK 1

PILOT WILL NOT LIGHT

Ensure there is no debris around the pilot assembly,

(e.g. soot, etc.) which could short the spark, clean the area.

Operate the valve.

Is there a spark?

Consult Section

2 and retry.

Check alignment of pilot

burner head, change the

ignition lead,

see diagram 1 on page 17.

Check isolation tap and

gas meter, retry.

Correct and

retry.

Purge the gas pipes

and retry.

SEE 'NO SPARK'

CHART

SYSTEM OK

There is a blockage in the system, check the inlet test point,

the mag seating, valve and pilot filter.

Is the gas turned on to the

appliance?

Is the gas pressure correct?

Has the system got

any air in it?

Does the pilot light?

Is the control being

operated correctly?

Will the pilot light

with a match?

No Yes

No

Yes

No

Yes

Yes

No

No

Yes

No

No

Yes

Yes

1. SERVICING REQUIREMENTS

Page 16

16

SERVICING INSTRUCTIONS

FAULT FINDING CHARTS

PILOT WILL NOT STAY LIT OR FIRE GOES OUT IN USE

Ensure there is no debris around the pilot assembly,

(e.g. soot etc.) Check for fluff in the pilot aeration hole.

See the diagram in Replacing Parts section.

Problem is with the

pipework or

fittings which lead

to the fire. Correct

and retry.

Is thermocouple

connection good

in back of valve?

Replace thermocouple.

Will pilot

stay alight?

Change mag

unit.

Is the pilot flame of the

correct length? Is the

thermocouple in its

correct postion in the

pilot bracket. See

diagram 5 in Replacing

Parts, section 2.3.

Change the

ODS unit.

Will pilot

stay alight?

With the pilot

running is the gas

pressure as stated on

the databadge?

With the fire running

on full is the gas at

the pressure stated

on the databadge?

Run for 3 mins,

turn off, time interval

until mag unit shuts

with a click. Is this

greater than 7

seconds?

Run for 3 mins, turn

off, time interval until

mag unit shuts with a

click. Is this greater

than 7 seconds?

Tighten the

connection and retry.

No

No

No

No

No

No

Yes

SYSTEM OK

Yes

Yes

Yes

Yes

No

Yes

Yes

No

Light the pilot using either the hanset or the touch pad.

FLAME FAILURE FUNCTIONAL CHECK 3IGNITION FUNCTIONAL CHECK 2

NO SPARK

Ensure there is no debris around the pilot assembly,

(e.g. soot etc.) which could short the spark, clean the area.

Consult the users

instructions, retry.

From Ignition Fault

Finding Chart 1

Is the gap between

electrode and

thermocouple 4.0mm?

Has ignition lead

become detached or is

connection poor?

Remove the electrode lead

and electrode. With insulated

pliers. Hold the tip 40mm from the

pilot pipework, is there a spark

when the system is operated?

Has the ignition lead

become detached from the

control box?

Replace the lead, retry.

Correct and retry.

Check hanset batteries are OK.

Replace if required. Check handset

is on manual. Check if handset lock

is off. Check batteries to the control

unit. Replace if required. Retry with

handset and touch pad.

Is the valve being

operated correctly?

Check tab on pilot burner

wood is not damaged. Either

repair tab or replace pilot

burner & retry

Yes

Yes

Yes

No

No

No

Yes

Yes

Yes

No

No

Replace the electrode.

Replace the electrode

lead and retry.

Yes

No

Page 17

1.1 All principle components can be replaced without removing

the appliance from its installation, although it is essential

that the gas supply to the appliance is turned off at the

isolation device before proceeding further.

1.2 ENSURE THAT THE APPLIANCE IS COLD BEFORE

COMENCING WORK ON IT.

1.3 Remove the batteries from the battery box.

1.4 If access to the components is restricted the burner and

control system is a self contained unit and can be removed

as a single unit for easy maintenance.

2.1 Remove the door from the stove, open the lower door, and

remove the lower panel. Remove the batteries from the

battery box, undo the six pozidriv screws and remove the

glass frame. See diagram 1

2.2 Carefully remove the ceramic components from the stove

and store safely. Remove the touchpad panel

2.3 Disconnect the TTB and the touchpad leads from the

control unit. See diagram 2

2.4 Undo the gas connection at the pressure test point, and

undo the two screws at the back of the firebox. See diagram

3

2.5 Carefully pull the burner unit forward until access to the

rear of the valve is possible. Undo the thermocouple lead

and remove the TTB wires. See diagram 4

2.5 The burner unit can now be removed to work on.

2.6 Reassemble in the reverse order, check for gas leaks. When

connecting the TTB wires in the back of the valve, it is

essential for the wire with the red highlight be closest the

valve. Note also, that the connectors for the TTB in the

control unit are different sizes.

3.1 Follow the steps 2.1 to 2.5 above, making sure that the gas

supply is isolated at the isolation point.

3.2 With the burner unit removed, undo the two screws and

remove the front aeration guide. See diagram 5

3. PILOT UNIT

2. MAIN BURNER

1. GENERAL

17

SERVICING INSTRUCTIONS

REPLACING PARTS

1

2

3

4

5

AR1454

AR1463

AR1457

AR1462

AR1443

Page 18

3.3 Remove the lint arrestor by folding the tabs back. See

diagram 6.

3.4 Undo the compression nut on the pilot unit, disconnect the

ignition lead from the electrode by pulling gently down on

the wire. Undo the two screws and the pilot unit can be

removed. See diagram 7

3.5 Reassemble in reverse order, check for gas leaks.

4.1 Follow steps 2.1 to 2.5 to remove the burner unit, making

sure that the gas supply is isolated at the isolation point.

4.2 Cut the cable tie, gently pull the lead out from the

electrode and the control unit.

4.3 Reassemble in reverse order, check for gas leaks. Take care

not to route the ignition lead too close to other electrical

leads.

5.1 Follow steps 2.1 to 2.5 above to remove the burner unit,

making sure the gas supply is isolated at the isolation point.

Turn the burner unit over, the aeration plate is accessible

from below.

5.2 Undo the M5 nyloc nut, and remove the aeration plate. See

diagram 8

5.3 Reassemble in reverse order with the correct aeration plate.

Check for gas leaks.

6.1 Follow steps 2.1 to 2.5 above, making sure the gas supply is

isolated at the isolation point. Turn the burner unit over and

disconnect the thermocouple lead. See diagram 9

6.2 Disconnect the TTB leads and unscrew the interrupter block

(A). Support the valve and undo the magnetic valve

retaining nut (B). See diagram 10

6.3 Remove the magnetic valve unit located inside. Reassemble

in reverse order, taking care to assemble the TTB leads with

the red highlighted one closest the valve. Check for gas

leaks.

6. MAGNETIC SAFETY VALVE

5. AERATION PLATE

4. IGNITION LEAD

18

SERVICING INSTRUCTIONS

REPLACING PARTS

7

8

9

10

AR1445

AR1448

AR1459

AR1458

B

A

6

AR1444

Page 19

7.1 Follow steps 2.1 to 2.5 to remove the burner unit. Making

sure the gas supply is isolated at the isolation point. Turn the

burner unit over to access the main injector pipe. Undo the

compression fittings both ends of the pipe and remove. See

diagram 11

7.2 Unscrew the injector and remove.

7.3 Reassemble in reverse order, the injector must NOT be

tightened into the burner but allowed to float to enable it to

line up with the pipe. Turn on the gas supply and check for

leaks.

8.1 Follow the steps 2.1 to 2.5 to remove the burner unit,

making sure the gas supply is isolated at the isolation point.

Undo the compression nuts on the injector pipe and inlet

pipe and remove these pipes. Undo the compression nut

on the pilot pipe, lift the pipe clear of the valve.

8.2 Disconnect the motor control wire, by pressing in the tab

and easing the connector out. See diagram 12

8.3 Undo the two M4 nuts holding the gas valve to the bracket

and remove the gas valve, taking care to remove the earth

connections.

8.4 Reassemble in reverse order, making sure that the earth

connections are between the gas valve and the bracket.

Check for gas leaks.

9.1 The control unit can be replaced without removing any

other components from the stove.

9.2 Open the front door and remove. Open the lower door and

remove the lower panel. Remove the batteries from the

battery box. See diagram 13

9.3 Carefully, disconnect the electrical connections. Undo the

two mounting screws for the unit and remove. See diagram

14

9.4 Remount control box, and replace electrical connections as

shown below. See diagram 15

9. CONTROL UNIT

8. GAS VALVE

7. MAIN INJECTOR

19

SERVICING INSTRUCTIONS

REPLACING PARTS

11

12

13

14

15

AR1458

AR1460

AR1463

AR1473

AR1474

1. Ignition lead - Red Cable.

2. Earth lead - Green/Yellow Cable.

3. Battery box - Cream Connector, Red and Black cables.

4. TTB1 - Small Spade Connector, Black Lead.

5. TTB2 - Large Spade Connector, Black Lead.

6. Touchpad - Cream Connector, Grey Ribbon Lead.

7. Gas Valve - Cream Connector, Multicoloured Leads.

Page 20

10.1 Open and remove the front door. Remove the glass frame.

Carefully remove the ceramic components and place to one

side. Undo the two screws at the back of the firebox and

carefully withdraw the bracket. See diagram 16

10.2 Disconnect the two sender wires. Undo the two taptite

screws and remove the sensor and the two plastic spacers.

See diagram 17

10.3 Refit the new sensor ensuring that the plastic spacers are

between the sensor and the bracket. Refit the leads. See

diagram 18

10.4 Feed the cable back through the hole as you replace the

bracket. When the bracket is located correctly it will sit

flush with the back panel without force required. If not

positioned correctly the bracket will sit at an angle. See

diagram 19

In order to change between gas types, it will be necessary

to change the following items

Pilot Unit

Control Valve**

Main Injector

Aeration Plate

Control Unit

Data Badge

The relevant parts can be ordered from Gazco, always

quote the appliance type and serial number when ordering

spare parts.

**NOTE: THE CONTROL VALVE IS FACTORY PRESET

FOR CORRECT GAS TYPE AND MODEL, A NEW UNIT

WILL NEED TO BE ORDERED WHEN CHANGING

BETWEEN GAS TYPES.

10. GAZCO FLUE SURE SYSTEM

20

SERVICING INSTRUCTIONS

REPLACING PARTS

16

17

11. CHANGING BETWEEN GAS TYPES

AR1442

AR1446

18

AR1452

AR1448AR1447

19

Page 21

13. SPARE PARTS LIST

21

SERVICING INSTRUCTIONS

REPLACING PARTS

Component NG LPG

PROPANE BUTANE

BURNER UNIT B0215 PB0215

MAIN INJECTOR IN0053 IN0052

PILOT ASSEMBLY PI0036 PI0037

TTB EL0001 EL0001

CONTROL BOX EL0359 EL0360

GAS VALVE* GC0107

MAG UNIT GC0109

IGNITION LEAD GC0013

CERAMIC REAR PANEL CE0530

FLAME BAFFLE CE0118

COAL SET CE0127

FRONT COAL CE0122

TTB LEADS EL0315

BATTERY BOX EL0274

VALVE MOTOR HARNESS EL0278

TOUCH PAD HARNESS EL0273

TOUCH PAD EL0272

HANDSET EL0275

EARTH LEAD EL0190

WINDOW FRAME ASSEMBLY GZ5227

*Gas Valve is pre-set for the correct gas type.

Page 22

22

SERVICE RECORDS

1ST SERVICE

Date of Service:...........................................................................

Next Service Due:.......................................................................

Signed:........................................................................................

Dealer's Stamp/CORGI Registration Number

3RD SERVICE

Date of Service:...........................................................................

Next ServiceDue:........................................................................

Signed:........................................................................................

Dealer's Stamp/CORGI Registration Number

5TH SERVICE

Date of Service:...........................................................................

Next Service Due:.......................................................................

Signed:........................................................................................

Dealer's Stamp/CORGI Registration Number

7TH SERVICE

Date of Service:...........................................................................

Next Service Due:.......................................................................

Signed:........................................................................................

Dealer's Stamp/CORGI Registration Number

9TH SERVICE

Date of Service:...........................................................................

Next Service Due:.......................................................................

Signed:........................................................................................

Dealer's Stamp/CORGI Registration Number

2ND SERVICE

Date of Service:...........................................................................

Next Service Due:.......................................................................

Signed:........................................................................................

Dealer's Stamp/CORGI Registration Number

4TH SERVICE

Date of Service:...........................................................................

Next Service Due:.......................................................................

Signed:........................................................................................

Dealer's Stamp/CORGI Registration Number

6TH SERVICE

Date of Service:...........................................................................

Next Service Due:.......................................................................

Signed:........................................................................................

Dealer's Stamp/CORGI Registration Number

8TH SERVICE

Date of Service:...........................................................................

Next Due:........................................................................

Signed:........................................................................................

Dealer's Stamp/CORGI Registration Number

10TH SERVICE

Date of Service:...........................................................................

Next Service Due:.......................................................................

Signed:........................................................................................

Dealer's Stamp/CORGI Registration Number

Page 23

23

Page 24

Gazco Limited, Osprey Road, Sowton Industrial Estate, Exeter, Devon, England EX2 7JG

Tel: (01392) 261999 Fax: (01392) 444148 E-mail: info@gazco.com

A member of the Stovax Group

Loading...

Loading...