StorageWorks

SH043-SeriesCabinet

InstallationandUser’sGuide

Order Number: EK–SH043–IG. A01

This manual describes the concepts and procedures necessary to

install, configure, and use StorageWorks SH043-series cabinets. Both

mechanical cabinet configuration and power configuration are covered in

this manual. The configuration and connection of SCSI–2 signal busses

is covered in referenced StorageWorks documentation.

Digital Equipment Corporation

Maynard, Massachusetts

First Printing, October 1993

While Digital believes the information included in this publication is correct as of the date of

publication, it is subject to change without notice.

Digital Equipment Corporation makes no representations that the interconnection of its products

in the manner described in this document will not infringe existing or future patent rights, nor

do the descriptions contained in this document imply the granting of licenses to make, use, or sell

equipment or software in accordance with the description.

© Digital Equipment Corporation 1993.

All rights reserved.

Printed in the United States of America.

NOTE: This equipment generates, uses, and may emit radio frequency energy. The equipment has

been type tested and found to comply with the limits for a Class A digital device persuant to Part

15 of the FCC rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation.

Any changes or modifications made to this equipment may void the user’s authority to operate the

equipment.

Operation of this equipment in a residential area may cause interference in which case the user

at his own expense will be required to take whatever measures may be required to correct the

interference.

StorageWorks, CI, and the DIGITAL logo are trademarks of Digital Equipment Corporation.

This document was prepared using VAX DOCUMENT Version 2.1.

Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Manufacturer’s Declarations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

1 Introduction

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

1.2 Major Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

1.3 Power Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–7

1.3.1 Single Cabinet Power Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 1–7

1.3.2 Dual Shelf Power Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–8

1.3.3 Dual Cabinet Power Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–9

1.4 Cabinet Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–10

2 Site Preparation

2.1 General Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

2.2 Equipment Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

3 Unpacking and Installation

3.1 Unpacking the Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

3.2 Removing the Cabinet from the Pallet . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–3

3.3 Configuring the Cabinet Rack Space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–6

3.4 Placing the Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–6

3.5 Leveling the Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–7

3.6 Installing the Skirt Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–7

3.7 Inspecting the Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–8

3.8 Powering the Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–9

4 Configuring SH043 Storage-Only Cabinets

4.1 Cabinet Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

4.1.1 Shelf Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

4.1.2 TZLX-Series Tape Drive/Shelf Locations . . . . . . . . . . . . . . . . . . . . . . . 4–2

4.2 Filler and Air Separation Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–3

4.3 Power Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–4

4.4 Signal Cabling and Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–4

4.4.1 Shelf SCSI–2 Cable Selection and Connection . . . . . . . . . . . . . . . . . . . 4–4

4.4.2 SCSI–2 Cable Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–4

4.4.3 General Cable Routing Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–4

iii

5 Configuring SH043 Controller/Storage Cabinets

5.1 Cabinet Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

5.1.1 Shelf Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–2

5.1.2 TZLX-Series Tape Drive/Shelf Locations . . . . . . . . . . . . . . . . . . . . . . . 5–3

5.2 Filler and Air Separation Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–4

5.3 Power Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–4

5.4 Host SCSI–2 Signal Cabling and Routing . . . . . . . . . . . . . . . . . . . . . . . . . 5–4

5.4.1 Host SCSI–2 Signal Cable Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–4

5.5 Shelf Signal Cabling and Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–5

5.5.1 Shelf SCSI–2 Cable Selection and Connection . . . . . . . . . . . . . . . . . . . 5–5

5.5.2 SCSI–2 Cable Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–5

5.6 General Signal Cable Routing Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–6

6 Installing StorageWorks Shelves

6.1 General Shelf Mounting Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–1

6.2 Accessing the Cabinet Rack Space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–2

6.2.1 Removing the Exterior Cabinet Panels . . . . . . . . . . . . . . . . . . . . . . . . 6–2

6.3 Installing the Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–3

6.4 Filler Panel Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–6

6.5 Air Separation Panel Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–7

6.5.1 Installing the Front Air Separation Panel . . . . . . . . . . . . . . . . . . . . . . 6–7

6.5.2 Installing the Rear Air Separation Panel . . . . . . . . . . . . . . . . . . . . . . . 6–7

6.6 Reinstalling Exterior Cabinet Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–9

7 Installing TZLX-Series Tape Drives

7.1 General Installation Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–1

7.2 Accessing the Cabinet Rack Space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–2

7.2.1 Removing the Cabinet Side Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–3

7.3 Chassis Rail Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–4

7.3.1 Chassis Rail Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–4

7.3.2 Right Position Chassis Rail Assembly Installation . . . . . . . . . . . . . . . . 7–5

7.3.3 Left Position Chassis Rail Assembly Installation . . . . . . . . . . . . . . . . . 7–7

7.4 Mounting the TZLX-Series Tape Drive Enclosure . . . . . . . . . . . . . . . . . . . 7–9

7.5 Installing the Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–12

7.6 SCSI–2 Signal Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–13

7.7 Installing the Cabinet Door Tape Bezel Kit . . . . . . . . . . . . . . . . . . . . . . . . 7–13

7.8 Reinstalling Exterior Cabinet Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–14

8 Power Configuration

8.1 General Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–1

8.2 Cable Distribution Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–1

8.3 Utility Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–2

8.4 Single CDU Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–2

8.4.1 Single Cabinet Power Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 8–2

8.4.2 Dual Shelf Power Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–2

8.5 Dual Cabinet Power Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–3

iv

A Environmental Stabilization

A.1 Environmental Stabilization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–1

Glossary

Index

Figures

1–1 SH043-Series Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–2

1–2 Cabinet Major Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–5

1–3 TZLX-Series Tape Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–6

1–4 Single Cabinet Power Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 1–7

1–5 Dual Shelf Power Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–8

1–6 Dual Cabinet Power Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–9

2–1 Minimum Installation Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

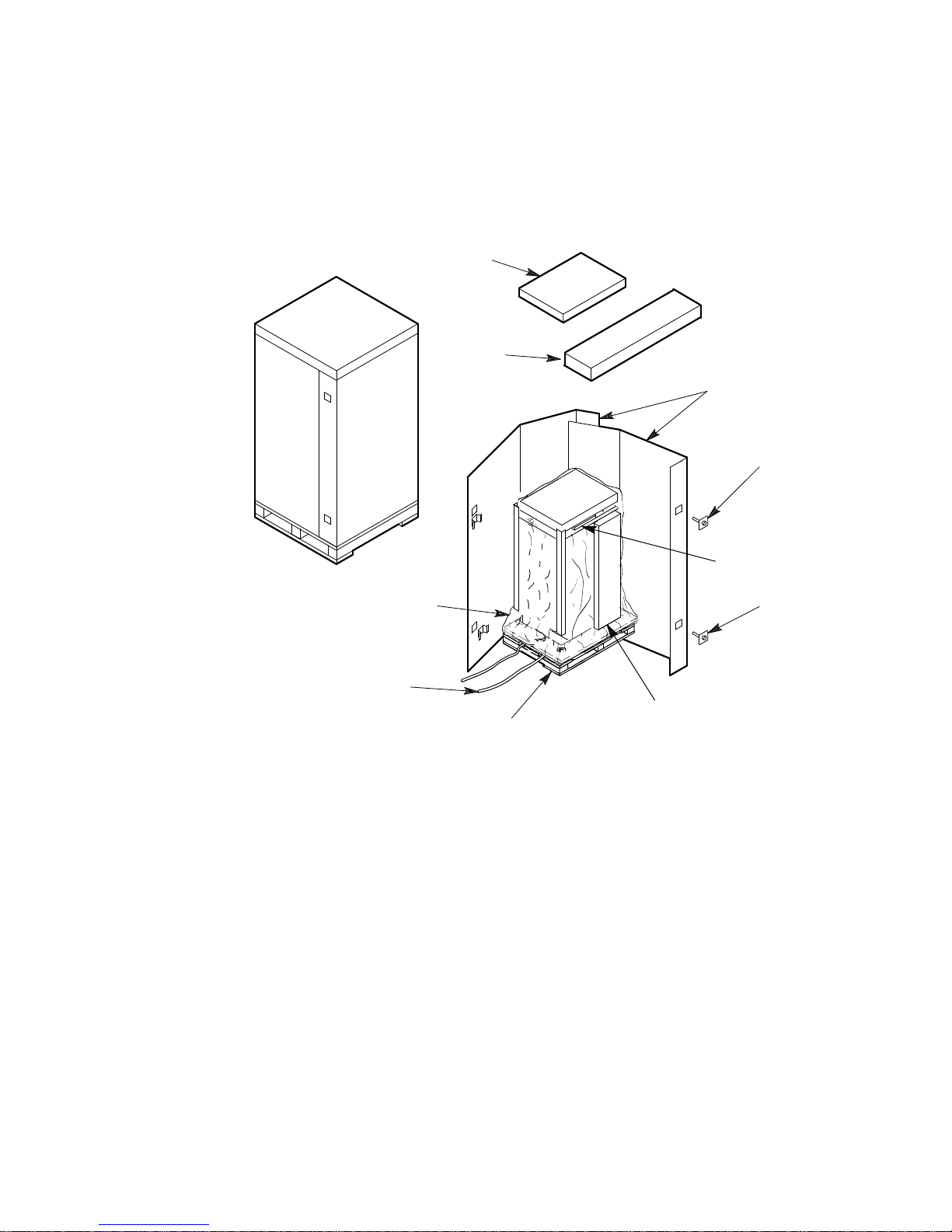

3–1 Shipping Container Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

3–2 Shipping Pallet Ramp Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–4

3–3 Shipping Bolts and Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–5

3–4 Removing the Cabinet from the Pallet . . . . . . . . . . . . . . . . . . . . . . . . . 3–6

3–5 Leveler Foot Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–7

3–6 Cabinet Skirt Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–8

4–1 SH043 Storage-only Cabinet Shelf Locations . . . . . . . . . . . . . . . . . . . . 4–2

4–2 SH043 Storage-only Cabinet Shelf and Tape Drive Locations . . . . . . . 4–3

5–1 SH043 Controller/Storage Cabinet Shelf Locations . . . . . . . . . . . . . . . 5–2

5–2 SH043 Controller/Storage Cabinet Shelf and Tape Drive Locations . . . 5–3

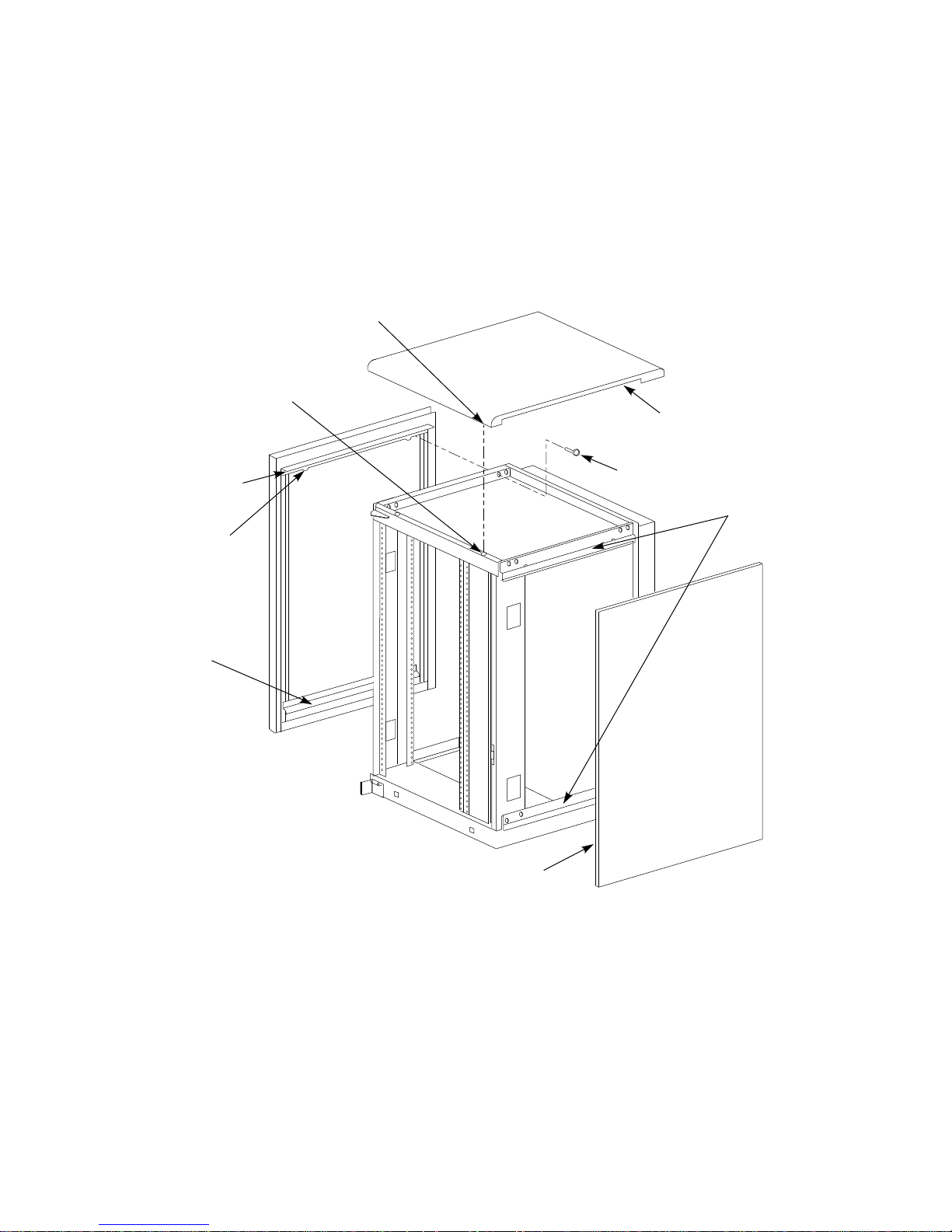

6–1 Exterior Cabinet Panel Removal and Installation . . . . . . . . . . . . . . . . 6–2

6–2 Horizontal Shelf Bracket Installation . . . . . . . . . . . . . . . . . . . . . . . . . 6–5

6–3 Rear Shelf Bracket Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–6

6–4 Front Air Separation Panel Installation . . . . . . . . . . . . . . . . . . . . . . . . 6–7

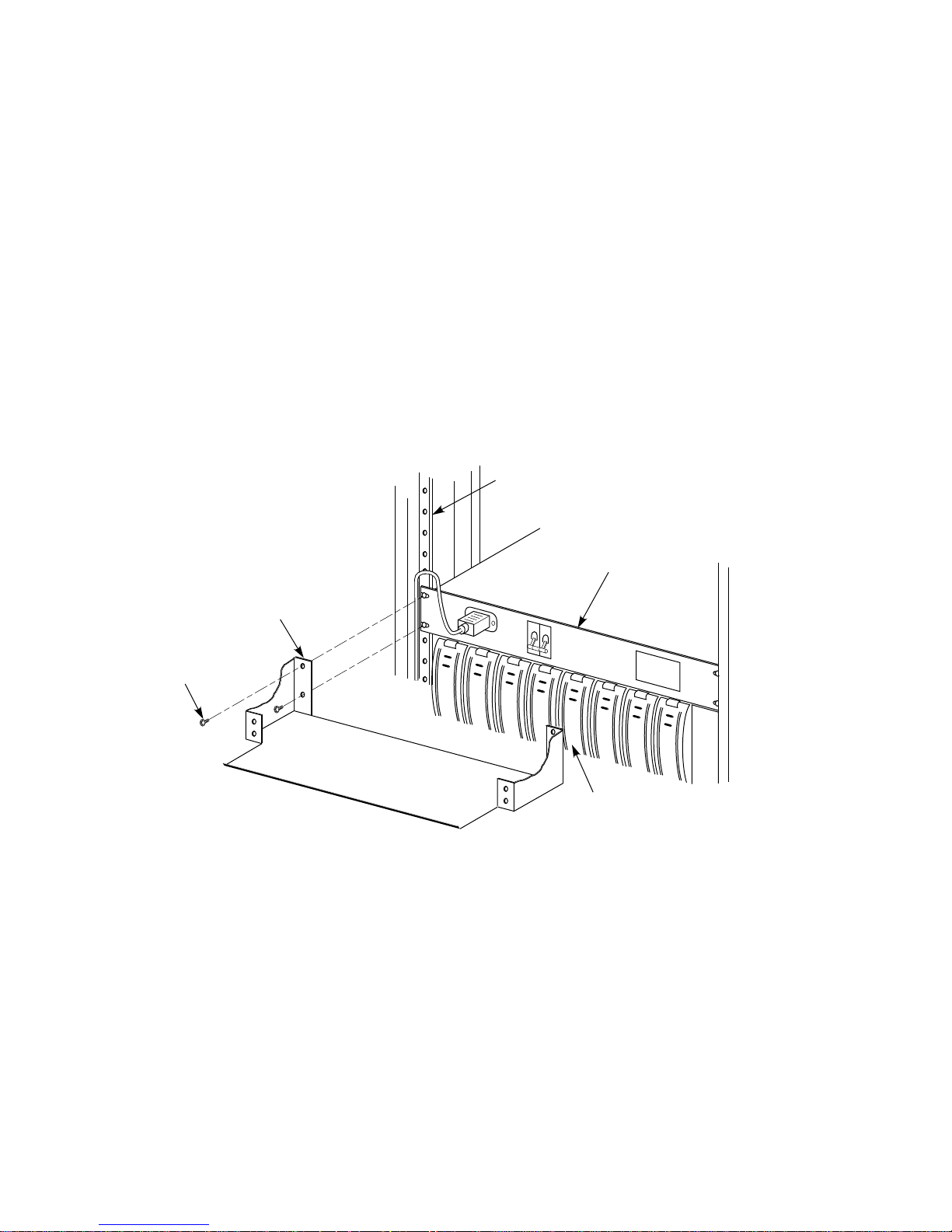

6–5 Rear Air Separation Panel Installation (Shelf installed directly below

CDU A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–8

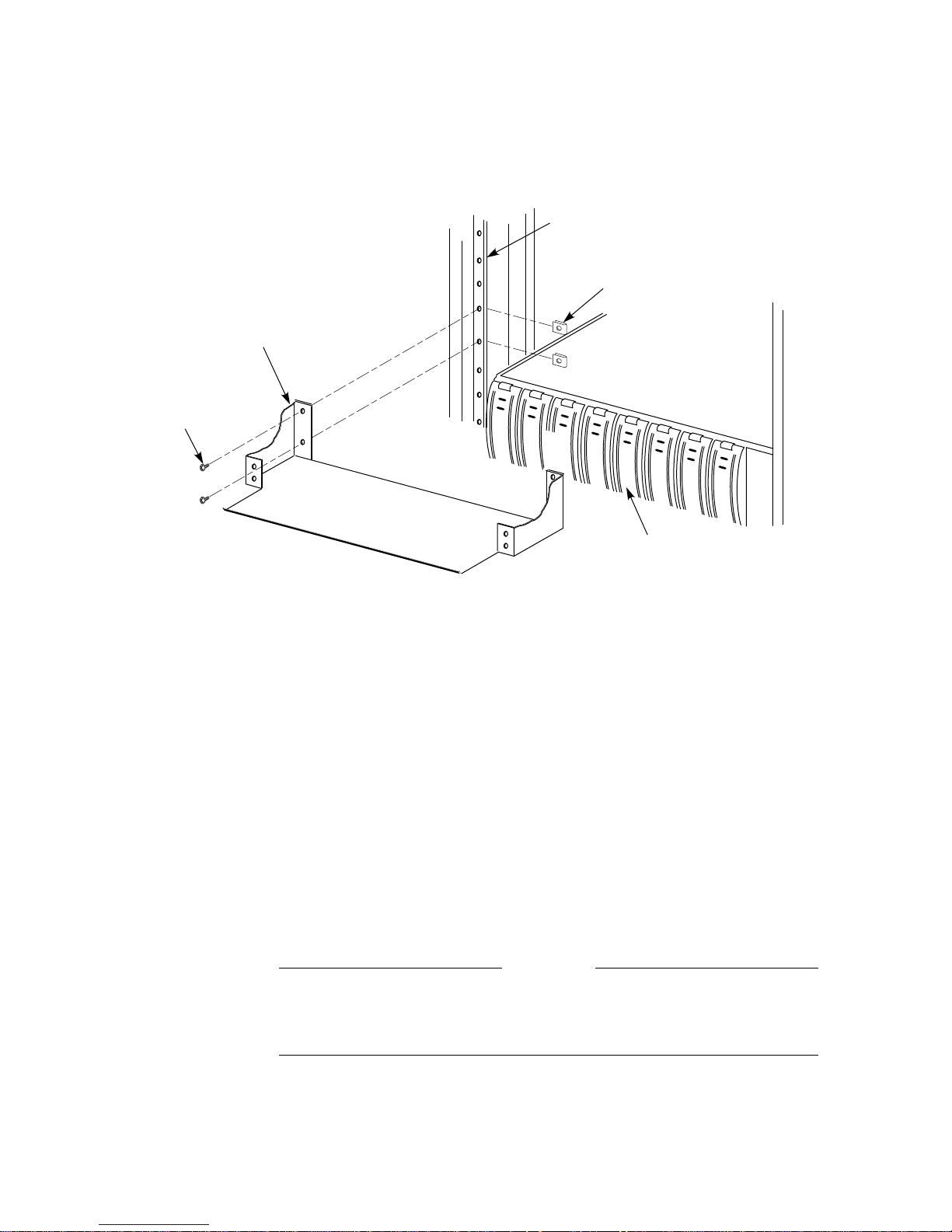

6–6 Rear Air Separation Panel Installation (Empty shelf position directly

below CDU A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–9

7–1 TZLX-Series Tape Drive Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 7–2

7–2 Cabinet Side Panel Removal and Installation . . . . . . . . . . . . . . . . . . . 7–3

7–3 Chassis Rail Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–5

7–4 Right Position Chassis Rail Assembly Installation . . . . . . . . . . . . . . . . 7–6

7–5 Left Position Chassis Rail Assembly Installation . . . . . . . . . . . . . . . . . 7–8

7–6 Right Position Tape Drive Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . 7–10

7–7 Left Position Tape Drive Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–11

7–8 TZLX-Series Tape Drive Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . 7–13

v

Tables

1 Equivalent StorageWorks Model Numbers . . . . . . . . . . . . . . . . . . . . . . vii

2 StorageWorks Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . viii

3 Acoustics—Preliminary Declared Values per ISO 9296 and ISO

7779 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

4 Schallemissionswerte—Vorläufige Werteangaben nach ISO 9296 und

ISO 7779/DIN EN27779 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

1–1 SH043-Series Cabinet Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

5–1 SH043 Controller/Storage Cabinet SCSI–2 Cable Lengths . . . . . . . . . . 5–5

6–1 Shelf Stop Bracket Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–4

6–2 Shelf Locking Bracket Part Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . 6–4

8–1 CDU Power Cable Variations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–2

A–1 Thermal Stabilization Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . A–1

vi

This document presents the concepts and procedures necessary to install,

configure, and use StorageWorks™ SH043-series cabinets. Both mechanical

cabinet configuration and power configuration are covered in this manual. The

configuration and connection of SCSI–2 signal busses is covered in referenced

StorageWorks documentation.

Intended Audience

This manual is intended for use by customers and Multivendor Customer

Services engineers responsible for installing, configuring, and using StorageWorks

SH043-series cabinets.

The procedures described in this guide are to be performed only by

qualified service personnel.

Model Numbers

Some equipment model numbers used in this manual are equivalent to those of

other StorageWorks equipment. Table 1 contains equivalent StorageWorks model

numbers for some of the equipment covered in this manual.

Preface

Note

Some documentation applicable to equipment covered in this manual is written

against the equivalent StorageWorks model number. Use Table 1 as a cross

reference to the appropriate documents.

Table 1 Equivalent StorageWorks Model Numbers

Document Model No. Equivalent StorageWorks Model No Description

SH043 SW500 Cabinet series

SHDZZ–ZZ BA350–SA Storage shelf

SHxzz–zz BA350–EA Controller/storage

shelf series

SHZ1Z–ZZ HSZ10 Controller

SHZ2Z–ZZ HSZ15 Controller

SHZBZ–ZZ RZ26–VA Disk drive

TZLX TZ8xx Tape loader series

(Tape drive series)

vii

Structure

This manual is organized as follows:

Chapter 1 Provides an overview of the SH043-series cabinet, a description of its

Chapter 2 Contains site preparation information.

Chapter 3 Describes the unpacking and installation of SH043-series cabinets.

Chapter 4 Describes the configuration of SH043-series storage-only cabinets.

Chapter 5 Describes the configuration of SH043 controller/storage cabinets.

Chapter 6 Describes the mounting of StorageWorks shelves within SH043-series

Chapter 7 Describes the mounting of TZ8xx-series tape drives within SH043-

Chapter 8 Describes the configuration of power within SH043-series cabinets.

Appendix A Provides information regarding the temperature stabilization of newly

Glossary The Glossary defines the acronyms and specialized terms used in this

Index The Index provides a cross-reference to subject matter in this

Related Documents

Table 2 lists the StorageWorks related user documents organized by use, system,

or product.

major components, and a discussion of the power options available for

it.

cabinets.

series cabinets.

unpacked equipment.

document.

document.

Table 2 StorageWorks Related Documentation

Document Title Order Number

StorageWorks Primary Publications†

StorageWorks Family Configuration Guide EK–BA350–CG

StorageWorks Family User’s Guide ‡ EK–BA350–UG

StorageWorks Family StorageWorks Building Blocks User’s Guide EK–SBB35–UG

StorageWorks RAID Array 110 Subsystem

BA350–EA Modular Storage Shelf User’s Guide EK–350EA–UG

BA35X–VA Vertical Mounting Kit User’s Guide EK–350SV–UG

DEC RAID Utilities User’s Guide EK–DECRA–UG

HSZ10–AA Controller Site Preparation Guide EK–HSZ10–IN

StorageWorks RAID Array 110 Subsystem User ’s Guide EK–SM2CA–UG

StorageWorks RAID Array 110 Utility for MS–DOS User’s Guide AA–Q0N5A–TE

†—Provided with each system

‡—Includes BA350–SA SBB shelf user’s guide

§—Available from Digital Account Representative

(continued on next page)

viii

Table 2 (Cont.) StorageWorks Related Documentation

Document Title Order Number

StorageWorks RAID Array 110 Subsystem

StorageWorks RAID Array 110 Utility for Novell Netware User ’s

Guide

StorageWorks RAID Array 110 Utility for SCO UNIX User ’s Guide AA–Q0N6A–TE

StorageWorks Array Controller 140-Series

AA–Q0N4A–TE

StorageWorks Array Controller HS Family of Array Controllers

EK–HSFAM–UG

User’s Guide

StorageWorks BA350–MA Controller Shelf User’s Guide EK–350MA–UG

DECraid+ Rackmount Storage Subsystem

HSC Intelligent I/O Servers

HSC Controller User’s Guide AA–PFSQA–TK

HSC Controller Installation Manual EK–HSCMN–IN

StorageWorks Enclosures

BA35X–VA Vertical Mounting Kit User’s Guide EK–350SV–UG

StorageWorks Family Desktop Expansion Unit User’s Guide EK–BA353–UG

StorageWorks Metric Shelf Bracket Kit Installation Guide EK–35XRD–IG

StorageWorks RETMA Shelf Rail Kit Installation Guide EK–35XRB–IG

StorageWorks SH043-Series Cabinet Installation and User’s

EK–SH043–IG

Guide

StorageWorks SH043-Series Cabinet Cable Distribution Unit

EK–SW43C–IG

Installation Guide

StorageWorks SW500-Series Cabinet Installation and User’s

EK–SW500–IG

Guide

StorageWorks SW500–Series Cabinet Cable Distribution Unit

EK–SW5CU–IG

Installation Guide

StorageWorks SW800-Series Data Center Cabinet Installation and

EK–SW800–IG

User’s Guide

StorageWorks SW800-Series Data Center Cabinet Cable

EK–SWCDU–IS

Distribution Unit Installation Guide

BA350–LA Modular Storage Shelf User’s Guide EK–350LA–UG

BA655 SCSI Disk and Tape PIU Installation Guide EK–BA655–IN

†—Provided with each system

‡—Includes BA350–SA SBB shelf user’s guide

§—Available from Digital Account Representative

Alpha AXP DEC 7000 and DEC 1000 Systems

(continued on next page)

ix

Table 2 (Cont.) StorageWorks Related Documentation

Document Title Order Number

Storage Devices

Installation Notice—RZ73 Bus Termination and Jumper

EK–RZ73X–IS

Installation Guide

RRD42 Disk Drive Owner’s Manual EK–RRD42–OM

RZ Series Disk Drive Installation Guide EK–DRZ01–IG

RZ Series Disk Drive Reference Manual EK–RZXXD–RM

RZ24 Hard Disk Drive Installation Guide EK–RZ24I–IS

RZ26B Disk Drive Installation Guide EK–RZ26B–IN

RZ2x Hard Disk Drive Upgrade Installation Instructions EK–RZ2XH–UG

RZ2x Series Drive Bracket Installation Sheet EK–RZ2XD–UG

SCSI Signal Converter DWZZA–AA EK–DWZZA–SV

SCSI Signal Converter DWZZA–MA EK–DWZZM–SV

SCSI Signal Converter DWZZA–VA EK–DWZAA–SV

TLZ06 Cassette Tape Drive Installation Guide EK–STEXP–AD

TLZ06 Cassette Tape Drive Owner’s Manual EK–TLZ06–OM

TZ30 Cartridge Tape Drive Operator’s Manual EK–OTZ30–OM

TZ30 Cartridge Tape Drive Reference Card EK–OTZ30–RC

TZ30 Cartridge Tape Drive Technical Manual EK–OTZ30–TM

General Reference Publications

Digital Systems and Options Catalog§

Small Computer System Interface, An Overview EK–SCSIS–OV

Small Computer System Interface, A Developer’s Guide EK–SCSIS–DK

†—Provided with each system

‡—Includes BA350–SA SBB shelf user’s guide

§—Available from Digital Account Representative

x

Documentation Conventions

The following conventions are used in this manual:

boldface type Boldface type indicates the first instance of terms being defined in text,

italic type Italic type indicates emphasis and complete manual titles. In the

in the glossary, or both.

glossary, italic type is also used to indicate cross-references.

xi

Manufacturer’s Declarations

Following are manufacturer’s declarations applicable to StorageWorks

SH043-series cabinets:

CAUTION

This is a class A product. In a domestic environment, this product may

cause radio interference, in which case the user may be required to take

adequate measures.

ACHTUNG !

Dieses ist ein Gerät der Funkstörgrenzwertklasse A. In Wohnbereichen

können bei Betrieb dieses Gerätes Rundfunkstörungen auftreten, in

welchen Fällen die Benutzer für entsprechende Gegenmaßnahmen

verantwortlich sind.

ATTENTION !

Ceci est un produit de Classe A. Dans un environment domestique, ce

produit risque de créer des interférences radiélectriques, il appartiendra

alors à l´utilisateur de prendre les mesures spécifiques appropriées.

The equipment described in this manual is listed by the Underwriters

Laboratories Incorporated and bears the UL Listing mark. SH043-series

cabinets are also certified by the Canadian Standards Association and

TÜV Product Service GmbH and bear both the CSA certification and

TÜV GS marks. The equipment also complies with the requirements for

CE-mark Class A.

Note

xiii

Note

Das in diesem Manual beschriebene Gerät wurde von TÜV Produkt

Service GmbH auf Sicherheit geprüft and trägt das GS Zeichen. Bitte

beachten Sie, daß Eingriffe in das Gerät, Reparaturen oder der Einbau

von Erweiterungen nur von Digital Personal erfolgen darf, da sonst die

GS Zulassung ungültig wird. Die Zulassung wird auch ungültig, wenn

nicht von Digital qualifizierte Speichererweiterungen eingebaut werden.

Das Gerät muß so aufgestellt werden, daß die Steckdose frei zugänglich

ist.

Table 3 Acoustics—Preliminary Declared Values per ISO 9296 and ISO 7779

Sound Pressure Level

Sound Power Level

, B‡

Product† Idle Operate Idle Operate

SH043 cabinet only 0.0 0.0 0.0 0.0

SH043 with 2 BA350–MA shelves,

7.0 7.0 50.0 51.0

each containing 2 HSJ40 controllers

and 8 SHDZZ-ZZ shelves, each

containing 6 SHZBZ-ZZ disk drives

, dBA

(Bystander Positions)

Per device when installed in SH043

SHDZZ-ZZ shelf containing

5.7 5.7 39 39

6 SHZBZ-ZZ disk drives

BA350–MA shelf with 2 HSJ40 controllers 5.6 5.6 39 39

Sound Pressure Level

Sound Power Level

, B‡

, dBA

(Operator Positions)

Product† Idle Operate Idle Operate

SH043 cabinet only 0.0 0.0 0.0 0.0

SH043 with 2 BA350–MA shelves,

7.0 7.0 50.0 51.0

each containing 2 HSJ40 controllers

and 8 SHDZZ-ZZ shelves, each

containing 6 SHZBZ-ZZ disk drives

Per device when installed in SH043

SHDZZ-ZZ shelf containing

5.8 5.8 46 46

6 SHZBZ-ZZ disk drives

BA350–MA shelf with 2 HSJ40 controllers 5.7 5.7 46 46

† Current values for specific configurations are available from Digital representatives.

‡ 1 B = 10 dBA

Note

Table 4 is a translation of the English language specifications in Table 3

into the German language.

xiv

Table 4 Schallemissionswerte—Vorläufige Werteangaben nach ISO 9296 und

ISO 7779/DIN EN27779

Schalldruckpegel

Schalleistungspegel

, B‡

Gerät† Leerlauf Betrieb Leerlauf Betrieb

nur SH043 Kabinett 0,0 0,0 0,0 0,0

SH043 mit 2 BA350–MA shelves,

7,0 7,0 50,0 51,0

jedes bestückt mit 2 HSJ40 controllers

und 8 SHDZZ-ZZ shelves, jedes

bestückt mit 6 SHZBZ-ZZ disk drives

Pro Gerät installiert im SH043

, dBA

(Beistehende Position)

SHDZZ-ZZ shelf mit

5,7 5,7 39 39

6 SHZBZ-ZZ disk drives

BA350–MA shelf mit 2 HSJ40 controllers 5,6 5,6 39 39

Schalldruckpegel

Schalleistungspegel

, B‡

, dBA

(Bediener Position)

Gerät† Leerlauf Betrieb Leerlauf Betrieb

nur SH043 Kabinett 0,0 0,0 0,0 0,0

SH043 mit 2 BA350–MA shelves,

7,0 7,0 50,0 51,0

jedes bestükt mit 2 HSJ40 controllers

und 8 SHDZZ-ZZ shelves, jedes

bestükt mit 6 SHZBZ-ZZ disk drives

Pro Gerät installiert im SH043

SHDZZ-ZZ shelf mit

5,8 5,8 46 46

6 SHZBZ-ZZ disk drives

BA350–MA shelf mit 2 HSJ40 controllers 5,7 5,7 46 46

† Aktuelle Werte für spezielle Ausrüstungsstufen sind über die Digital Equipment Vertretungen

erhältlich.

‡ 1 B = 10 dBA

xv

This chapter presents an overview, a description of major components, and a

discussion of power options for StorageWorks SH043-series cabinets.

1.1 Overview

The SH043-series cabinet, shown in Figure 1–1, is a member of Digital’s

StorageWorks family of modular enclosures. The 600 mm (23.62 inch) wide

cabinet provides an attractive enclosure with rackmount space and primary

power for up to 10 StorageWorks shelves of different types. Up to 8 StorageWorks

shelves can be used in conjunction with 2 TZLX-series tape drives. The cabinet

can accommodate both data storage and controller/data storage combinations.

The cabinet and its StorageWorks shelves can be configured with dual ac power

capability for power redundancy.

SH043-series cabinets offer a versatile, modular solution to array storage

problems. You may use them in both open-office and data center applications.

You may order the cabinet in a variety of preconfigured subsystem versions with

such options as mixed storage device types and storage, controller, or power

redundancy. You may also order custom configurations to meet your specific

needs. The modularity of the cabinet and its components offers efficient and

cost-effective upgrade paths.

1

Introduction

Specifications for SH043-series cabinets are shown in Table 1–1.

Introduction 1–1

Figure 1–1 SH043-Series Cabinet

1–2 Introduction

CXO-3897A-MC

Table 1–1 SH043-Series Cabinet Specifications

Characteristic Specification

Dimensions (nominal) 110.00 cm (43.31 in) height, 60.00 cm (23.62

in) width, 87.25 cm (34.35 in) depth

Weight

Empty cabinet (only 1 CDU installed)

140 kg (309 lb)

Empty cabinet with shipping

packaging

160 kg (353 lb)

Maximum configuration (2 BA350–

MA shelves, 8 SHDZZ–ZZ shelves

with 6 SHZBZ-ZZ disk drives in each,

2 CDUs)

290 kg (639 lb)

Agency compliance FCC, UL, CSA, TÜV, and CE-mark

Electrical rating

SW5xx–AC 100–120 volts, 60 Hz, single phase, 20

amperes

SW5xx–AD 100–120/200–240 volts, 50/60 Hz, single

phase, 20/16 amperes

Temperature +10°C to +35°C (+50°F to +95°F)

Reduce rating by 1.8°C for each 1000 m

altitude (1.0°F for each 1000 ft altitude)

Humidity 10 to 85 percent at maximum wet bulb

temperature of +32°C (+90°F) and minimum

dew point of +2°C (+36°F)

Recommended Environmental Limits†

Operating environment

Temperature 18°C to 24°C (64.4°F to 75.2°F) with an

average rate of change of 3°C/hour maximum

and a step change of 3°C or less

Relative humidity 40 to 60 percent (noncondensing) with a step

change of 10 percent or less (noncondensing)

Altitude Up to 2400 m (8000 ft)

Air quality

(maximum particle count)

Not to exceed 500,000 particles per cubic foot

of air at a size of 0.5 micron or larger

Nonoperating environment

Temperature –40°C to +66°C (–40°F to +151°F)

Relative humidity 10 to 80 percent noncondensing

Altitude 4900 m (16,000 ft)

†These limits are for optimum equipment performance and reliability.

Introduction 1–3

1.2 Major Components

The major components of the SH043-series cabinet are shown in Figures 1–2 and

1–3 and are as follows:

• Cabinet—The cabinet is a general-purpose enclosure that provides rackmount capability for standard 44.5 cm (17.5 inch) wide components. The

cabinet uses a standard metric rackmount bolt pattern with holes on 25 mm

(.98 inch) centers. Hinged front and rear doors and removable side panels

allow easy access to the cabinet interior. Casters and leveler feet are provided

to facilitate placement of the cabinet, and base trim skirts are provided to

enhance its appearance.

• Shelf brackets—Movable shelf brackets within the cabinet can be configured

to hold any of the StorageWorks shelf types. Six shelf positions may be used

in the front of the cabinet and four in the rear. Storage shelves may generally

be installed in any of the usable shelf positions, although some limitations

may be imposed by either weight or cable length restrictions. One shelf

position in the rear of the cabinet is reserved for power cable distribution

unit (CDU) installation, and one is left open for proper airflow.

• SBB shelves—StorageWorks building block (SBB) shelves are designed

to house any of the SBBs in the StorageWorks family. The shelves can accept

one or two power supply SBBs as well as a number of peripheral device SBBs.

SBB shelves provide the mechanical mounting, power, and signal interfaces

for the SBBs they house. The shelves are 445 mm (17.5 inch) in width and

are designed to slide into the shelf brackets.

• SBBs—StorageWorks building blocks (SBBs) are modular computer

peripheral devices or power units from the StorageWorks family. SBBs

may be disk drives, tape drives, shelf power supplies, battery backup units,

or other types of peripherals conforming to the Small System Computer

Interface 2 (SCSI–2) specification. They are housed in both 3½-inch and

5¼-inch wide modular carriers designed to plug into slots in SBB shelves.

Connectors on the rear of each SBB mate with connectors in the SBB shelf to

provide the electrical interface between the two units.

• Controller shelves—Controller shelves are StorageWorks shelves designed

specifically to house SCSI–2 peripheral controller and cache memory modules.

These shelves may also accept one or two power supply SBBs. Controller

shelves provide the mechanical mounting, power, and signal interfaces for

the units they house. The cabinet allows for the mounting of one controller

shelf in the front and one in the rear. Digital’s SHZ1Z-ZZ, and SHZ2Z-ZZ

controllers are both qualified for use with the SH043-series cabinet. In special

situations, different controller types can be installed within the same cabinet.

• CDUs—Cable distribution units (CDUs) provide the connections necessary

to distribute ac power to the shelves in the SH043 cabinet. CDUs also

provide surge and spike protection, along with a circuit breaker to control

the incoming ac power. As an option, two CDUs can be configured with an

auxiliary ac power source to provide redundant primary power within the

cabinet.

1–4 Introduction

Figure 1–2 Cabinet Major Components

SBB

SHELF

SBB

CABINET

CONTROLLER

SHELF

CDU

(INSTALLED

IN REAR)

SHELF

BRACKET

CXO-3896A-MC

Introduction 1–5

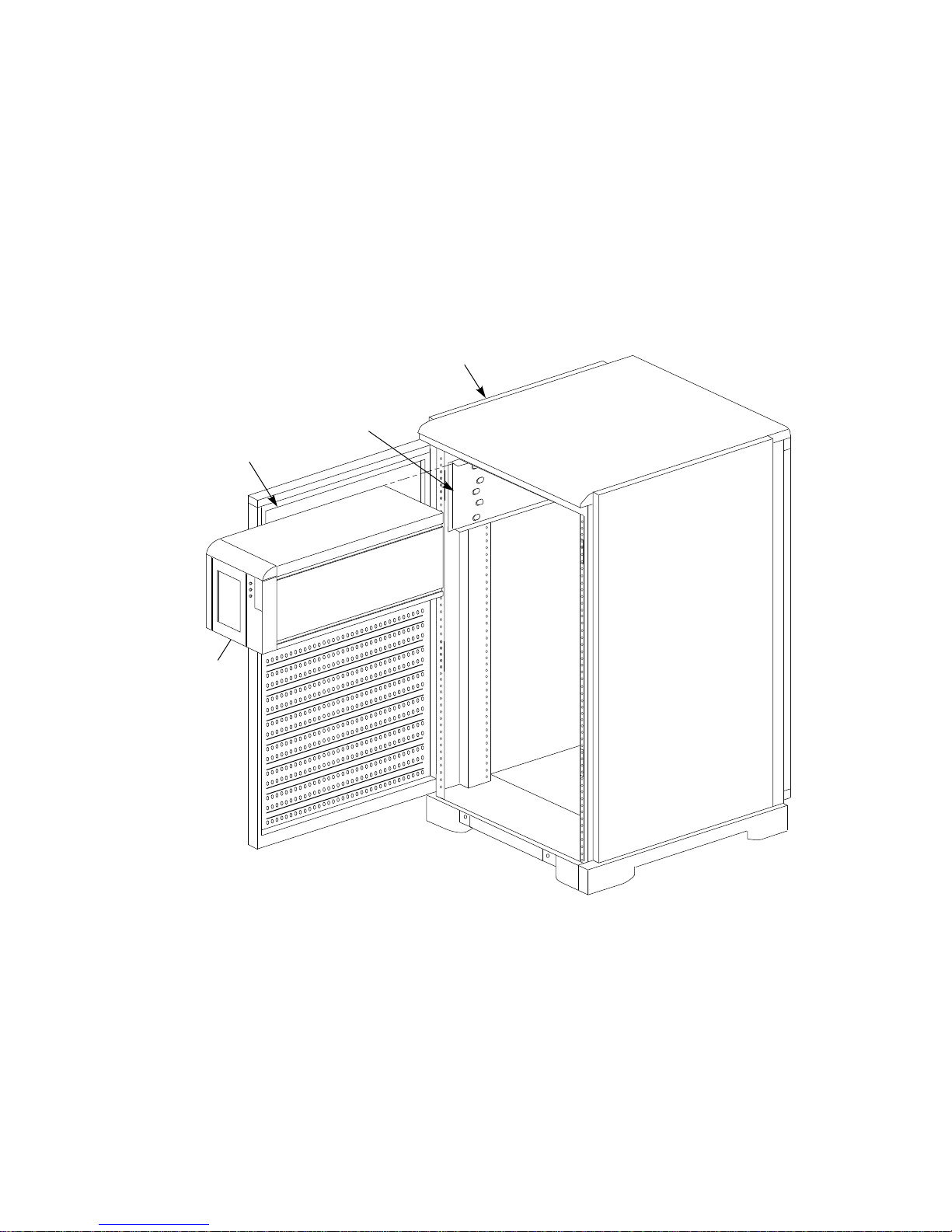

• TZLX-series tape drives—Up to two TZLX-series tape drives can be installed

in the upper area of the cabinet, as shown in Figure 1–3. A chassis rail is

used to support the tape drive from one side.

Figure 1–3 TZLX-Series Tape Drive

CHASSIS

TAPE

BEZEL

RAIL

CABINET

TZLx-SERIES

TAPE DRIVE

CXO-3954A-MC

1–6 Introduction

1.3 Power Configurations

The ac power distribution within the SH043-series cabinet can be configured in

one of the following three ways to provide the desired level of power redundancy

to the cabinet’s shelf-mounted peripheral devices:

• Single cabinet power configuration

• Dual shelf power configuration

• Dual cabinet power configuration

A description of each configuration option follows.

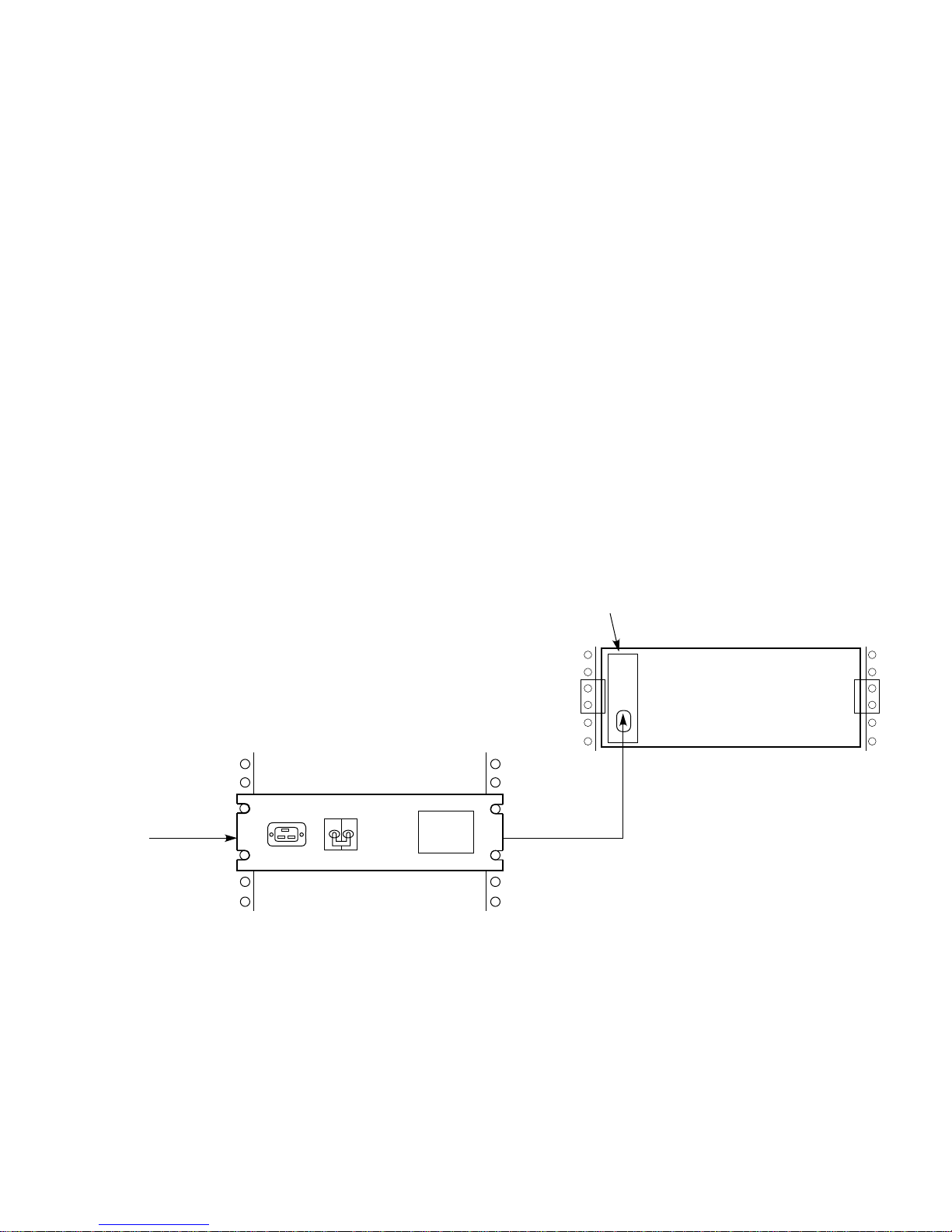

1.3.1 Single Cabinet Power Configuration

In the single cabinet power configuration, shown in Figure 1–4, a single ac power

source and CDU (A) are used to supply ac power to a single ac power supply

(A) in each shelf. This is the normal configuration for the cabinet, and it provides

no power redundancy to shelf peripheral devices.

Figure 1–4 Single Cabinet Power Configuration

AC POWER

SUPPLY A

PRIMARY

AC POWER

SOURCE

SBB SHELF

CDU A

PRIMARY

AC POWER

(BLACK

CABLE)

CXO-3937A-MC

Introduction 1–7

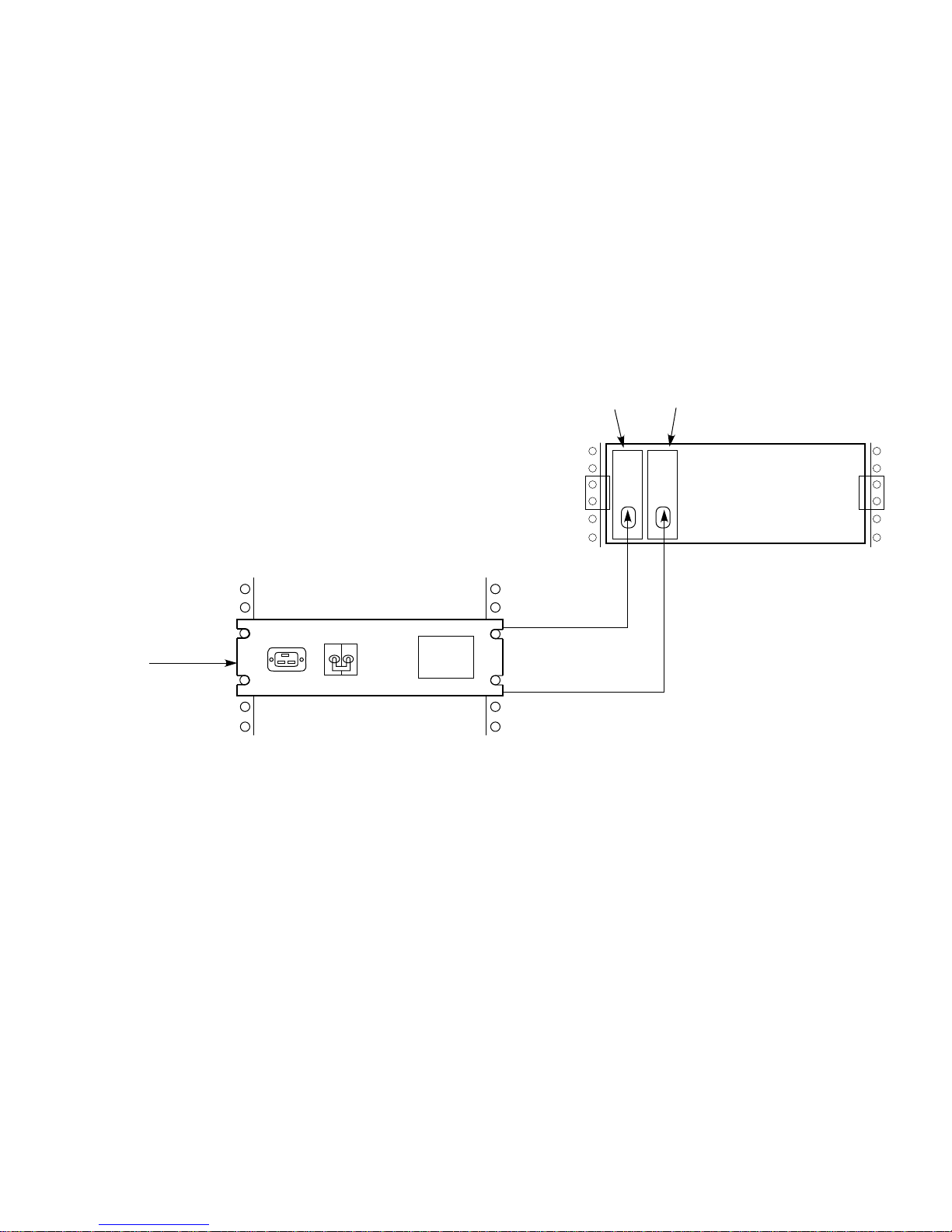

1.3.2 Dual Shelf Power Configuration

In the dual shelf power configuration, shown in Figure 1–5, a single primary

power source and CDU (A) are used to supply ac power to two ac power supplies

(A and B) in each shelf. If either power supply fails, the shelf remains powered

by the other supply. This configuration provides shelf power supply redundancy

to the shelf’s peripheral devices. The cabinet supports a maximum of six shelves

in the dual shelf power configuration.

Figure 1–5 Dual Shelf Power Configuration

PRIMARY

AC POWER

SOURCE

CDU A

AC POWER

SUPPLY A

PRIMARY

AC POWER

(BLACK OR

GRAY CABLE)

PRIMARY

AC POWER

(BLACK OR

GRAY CABLE)

AC POWER

SUPPLY B

SBB SHELF

CXO-3938A-MC

1–8 Introduction

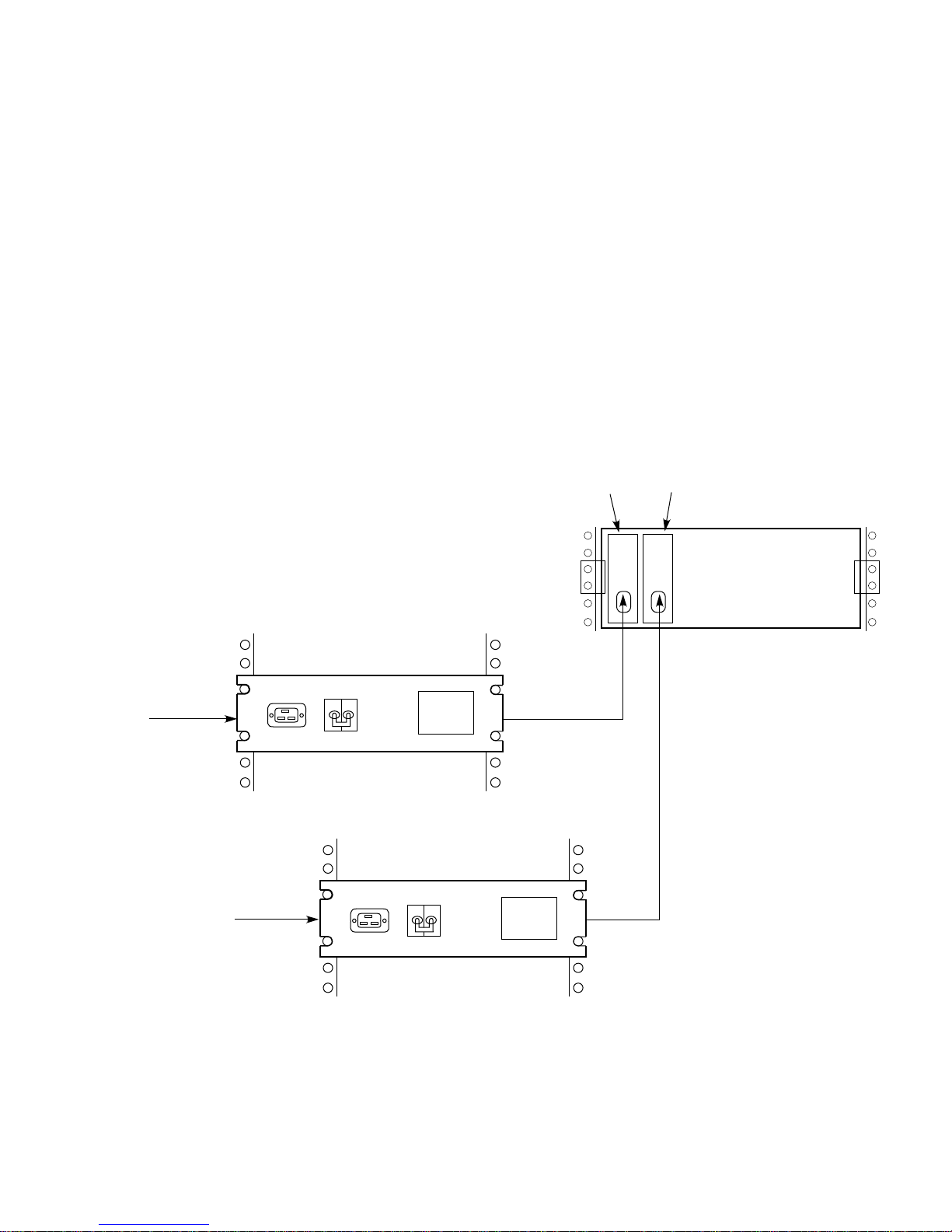

1.3.3 Dual Cabinet Power Configuration

In the dual cabinet power configuration, shown in Figure 1–6, an auxiliary power

source and a second CDU (B) are used to supply ac power to a second ac power

supply (B) in each shelf. If the primary power source, CDU A, or ac power supply

A fails, the shelf remains powered by ac power supply B. This configuration

provides complete power redundancy to the shelf’s peripheral devices.

Figure 1–6 Dual Cabinet Power Configuration

PRIMARY

AC POWER

SOURCE

AUXILLARY

AC POWER

SOURCE

CDU A

CDU B

AC POWER

SUPPLY A

PRIMARY

AC POWER

(BLACK

CABLE)

AC POWER

SUPPLY B

SBB SHELF

(GRAY

CABLE)

AUXILLARY

AC POWER

CXO-3936A-MC

Introduction 1–9

1.4 Cabinet Cooling System

Each StorageWorks shelf contains two rear-mounted blowers that move heat

from the shelf into the cabinet interior. The cabinet structure is such that heated

air moves from the cabinet interior up and out through the unused shelf positions

in the rear. It is then exhausted through the rear door. Logic signals allow the

status of the shelf blowers to be monitored by the host system.

Filler panels and air separation panels are used to properly route heated air

through the cabinet. Filler panels are flat plates that serve as covers for unused

shelf positions. Air separation panels are small baffles that mount just above

and outside the upper-most shelf in each side of the cabinet to prevent heated air

from being drawn down between the cabinet door and the shelf. Such air would

be drawn back into the shelf and would interfere with proper cooling.

1–10 Introduction

This chapter presents the information necessary to prepare a site for the

installation of the StorageWorks SH043-series cabinet.

2.1 General Considerations

SH043-series cabinets are intended for installation in Class A computer room

environments. Before installing the cabinet, make sure that the following

conditions have been met:

• The primary power source can supply the required amount of ac power, as

specified in Table 1–1.

• The site’s primary power receptacles are the correct versions for the power

plugs provided with the cabinet. The SH043-ZZ cabinet is supplied with a

power cable that has an IEC 309 plug.)

• The site floor can safely bear the weight of the cabinet, as specified in

Table 1–1. Keep in mind that the entire weight of the cabinet is borne by the

small surface area of the four leveler feet when the cabinet is installed in its

final position.

2

Site Preparation

• Adequate space is provided around the cabinet for opening the front and rear

doors, for accessing cables, and for adequate airflow. SH043-series cabinets

are not designed to be fastened to adjacent cabinets. See Figure 2–1 for

specific space requirements.

Site Preparation 2–1

Figure 2–1 Minimum Installation Clearances

31.50 in

600.0 mm

REAR

DOOR

SHO43-

SERIES

CABINET

FRONT

DOOR

29.33 in

60.0 cm

34.45 in

87.5 cm MAX

29.33 in

60.0 cm

CXO-3955A-MC

• The cabinet is positioned to allow external interface cables to reach to the

appropriate system units.

• If the cabinet is to be positioned next to other enclosures, there is sufficient

service loop in any connecting cables to allow the cabinet to be moved out for

access.

2.2 Equipment Grounding

SH043-series cabinets are normally connected to other equipment by one or

more interface buses. For both safety and reliable operation, proper grounding is

required between the cabinet and other equipment.

If enclosures are not connected to a common ground, there is a potential

for a personal injury as a result of electric shock.

When connecting a terminal to a controller within the cabinet, proper

grounding is required to prevent personnel injury and equipment damage.

For optimum safety and performance, it is recommended that the

terminal be powered by one of the two utility IEC outlets on the back of

each cable distribution unit (CDU). A spare power cord is furnished with

each cabinet for this purpose.

2–2 Site Preparation

WARNING

WARNING

If ground offset voltages generated in the power distribution system are excessive,

data transmission across interface buses can be affected. Significant performance

degradation or possible data corruption could result. SH043-series cabinets are

shipped with a ground strap (Digital part number 12–13756–A8) that is connected

to the rear of the unit. For optimum safety and performance, Digital recommends

that the ground strap be connected to the chassis of the host system.

Make sure that site power distribution systems meet local electrical codes prior to

the installation of SH043-series cabinets.

To make sure that the power distribution system will perform satisfactorily, a

power system survey should be done before installation. The following areas

should be investigated:

• Do all outlets have power ground connections?

• Do the power cables on all equipment at the site have grounding prongs?

• Are all power outlet neutral connections isolated from ground?

• Are the grounds for all outlets connected to the same power distribution

panel?

• Are all devices that are connected to the same breaker as the SH043

cabinet Underwriter’s Laboratories (UL) or International Electrotechnical

Commission (IEC) approved?

CAUTION

If there is a deficiency found in any area during the power survey, a

qualified electrician must correct it before installation may begin. Failure

to resolve power survey deficiencies before installing the equipment may

result in personnel injury as a result of electric shock.

If no problems are found during the survey, the site grounding system may be

considered to be adequate for personnel safety and reliable SH043-series cabinet

operation.

Site Preparation 2–3

This chapter describes the unpacking, installation, inspection, and powering of

StorageWorks SH043-series cabinets.

3.1 Unpacking the Cabinet

SH043-series cabinets are packed in a corrugated carton attached to a wooden

shipping pallet, as shown in Figure 3–1. Unpack the cabinet as follows:

Before unpacking the equipment, inspect the shipping carton for signs

of external damage. Report any damage to the local carrier and to

Multivendor Customer Services or your local Digital sales office.

Failure to thermally stabilize preconfigured storage subsystems may

damage drive media or associated electronics when the unit is turned on.

Environmental stabilization begins when the equipment is placed in the

room in which it is to be installed.

3

Unpacking and Installation

Note

CAUTION

1. Remove the cover, the fasteners, and the corrugated board from the pallet.

2. Remove the cartons containing the ramp set and skirt kit and set them aside.

3. Cut the shipping straps. Some cabinets are packaged in a plastic or barrier

bag. If the cabinet arrives in a plastic bag, leave the bag in place until

the cabinet has adjusted to the local temperature and humidity. Refer to

Appendix A for more information on environmental stabilization.

4. Once the cabinet is unpacked, examine the front and rear doors, right and left

side panels, top panel, and undercarriage for any apparent damage. Report

such problems immediately.

5. Retain the shipping container and all packing materials.

Unpacking and Installation 3–1

Figure 3–1 Shipping Container Contents

COVER

CARTON

CONTAINING

SKIRT KIT

CORRUGATED

BOARD

FASTENERS

MANUALS

PLASTIC OR

BARRIER BAG

SHIPPING

STRAPS

PALLET

FASTENERS

CARTON

CONTAINING

UNLOADING

RAMPS

CXO-3533A-TI

3–2 Unpacking and Installation

3.2 Removing the Cabinet from the Pallet

This section describes how to remove the cabinet from the pallet.

Use the following procedure to remove the cabinet from the shipping pallet:

1. Remove any packing material remaining on the pallet.

WARNING

Serious personal injury may result if correct safety precautions are not

taken during the unpacking procedure. All personnel should wear safety

glasses. The ramps, ramp side rails, and metal hardware should be

inspected for the following defects:

• Cracks more than 25 percent of the ramp depth, either across or

lengthwise on the ramp

• Knots or knotholes going through the thickness of the ramp and

greater than 50 percent of the ramp width

• Loose, missing, or broken ramp side rails

• Loose, missing, or bent metal hardware

If any of these defects exist, do not use the ramp. Investigate alternate

means of removing the cabinet or order a new ramp. (The part number

for the ramp set is 99–08897–05.)

2. Remove the two unloading ramps from the carton and inspect them.

3. Attach the ramps by fitting the metal prongs into the holes on the pallet, as

shown in Figure 3–2. Make sure that the arrows on the ramps match up with

the arrows on the pallet.

4. Extend the ramps to their full length.

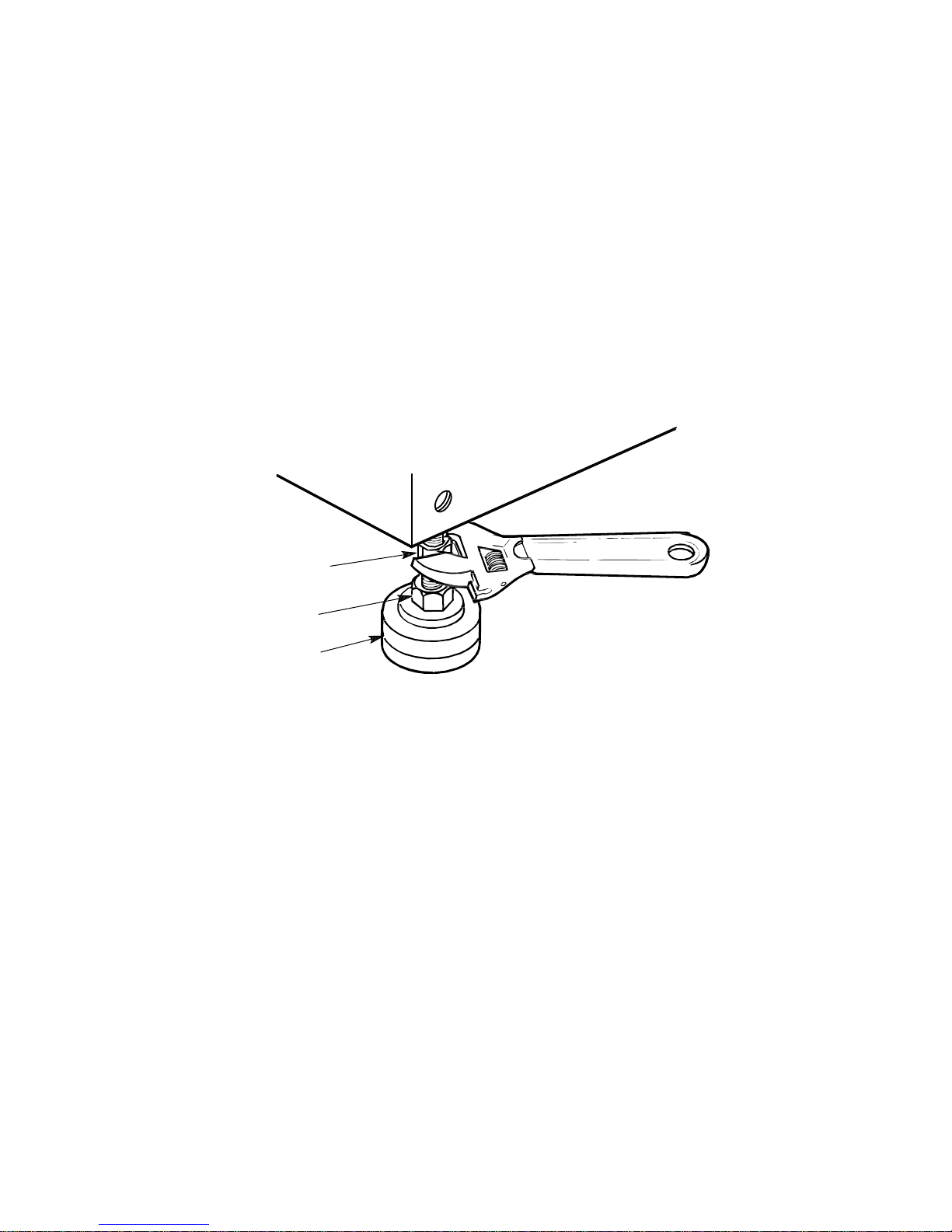

5. See Figure 3–3 for the location of the shipping bolts. Remove the bolts.

6. Remove the shipping brackets, shown in Figure 3–3, from the cabinet levelers

and set them aside.

Unpacking and Installation 3–3

Figure 3–2 Shipping Pallet Ramp Installation

LEFT

UNLOADING

RAMP

SHIPPING

PALLET

RIGHT RAMP

ATTACHES HERE

EXTEND RAMP TO

FULL LENGTH

RIGHT

UNLOADING

RAMP

CXO-688D_S

3–4 Unpacking and Installation

Figure 3–3 Shipping Bolts and Brackets

LEVELER

SHIPPING

BOLT

SHIPPING

BRACKET

SHR_X1102A_89_SCN

WARNING

The levelers must be raised fully for the cabinet to roll easily down the

unloading ramps. Failure to do so may result in personnel injury as a

result of the cabinet tipping off the pallet or ramp.

7. Loosen the leveler locking nuts and screw the four cabinet levelers all the

way up into the cabinet.

WARNING

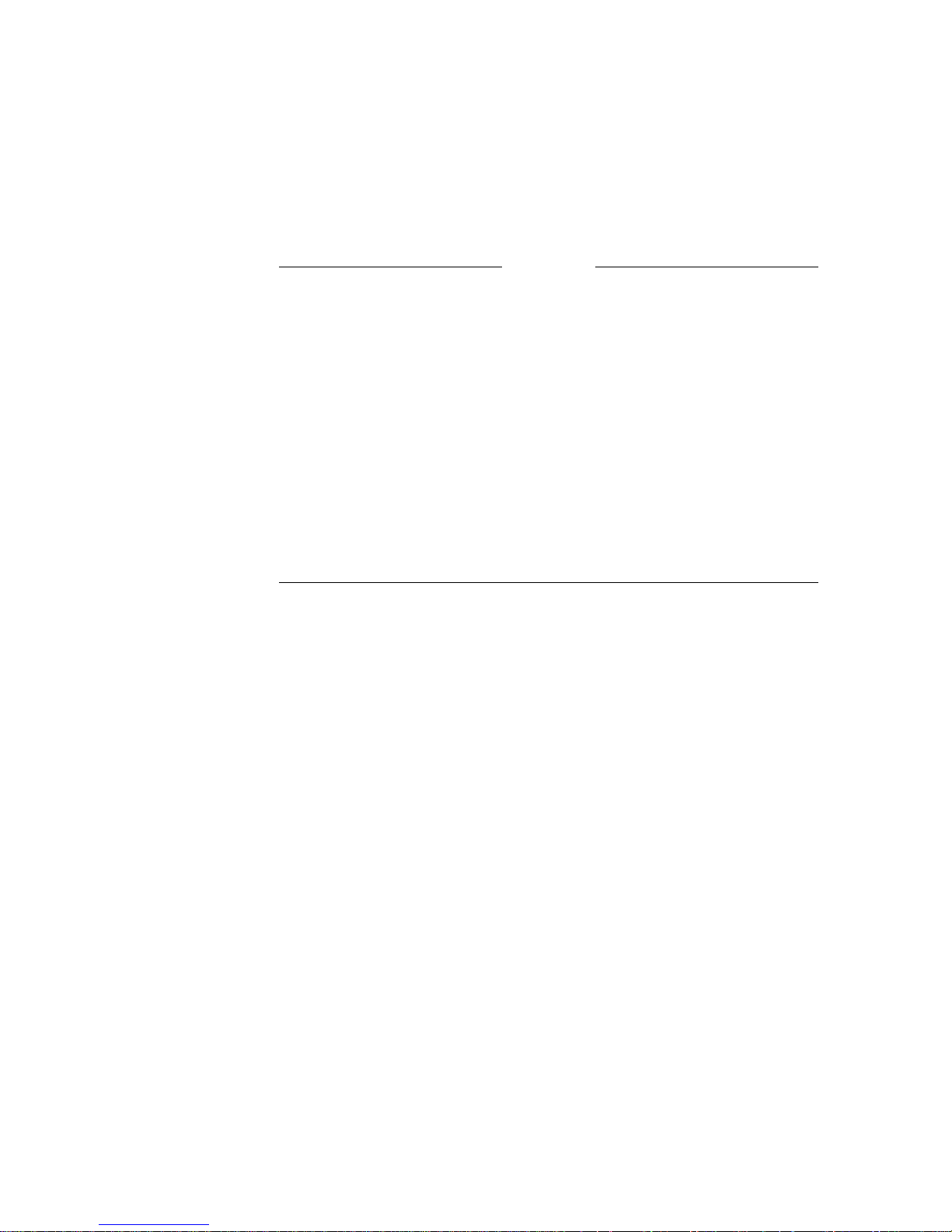

Three people are required to unload the cabinet from the shipping pallet.

Failure to use sufficient personnel may result in injury and equipment

damage.

8. Carefully roll the cabinet off the pallet and down the ramps to the floor as

shown in Figure 3–4.

Unpacking and Installation 3–5

Figure 3–4 Removing the Cabinet from the Pallet

3.3 Configuring the Cabinet Rack Space

Any shelves to be added to the cabinet should be installed before it is placed in its

permanent position. See the chapter in this document pertaining to your specific

cabinet configuration for the proper location of shelves. See Chapter 6 for detailed

information and procedures regarding shelf bracket and shelf installation.

3.4 Placing the Cabinet

WARNING

Use extreme caution when rolling the cabinet across the floor. Failure to

raise all leveler feet and to provide a clear path for the cabinet’s casters

may result in the cabinet tipping over and injury to personnel.

Once the cabinet rack space is configured as desired, the cabinet may be rolled to

its final installation position. Secure loose cabinet cables up and out of the way

when rolling the cabinet.

3–6 Unpacking and Installation

CXO-3808A

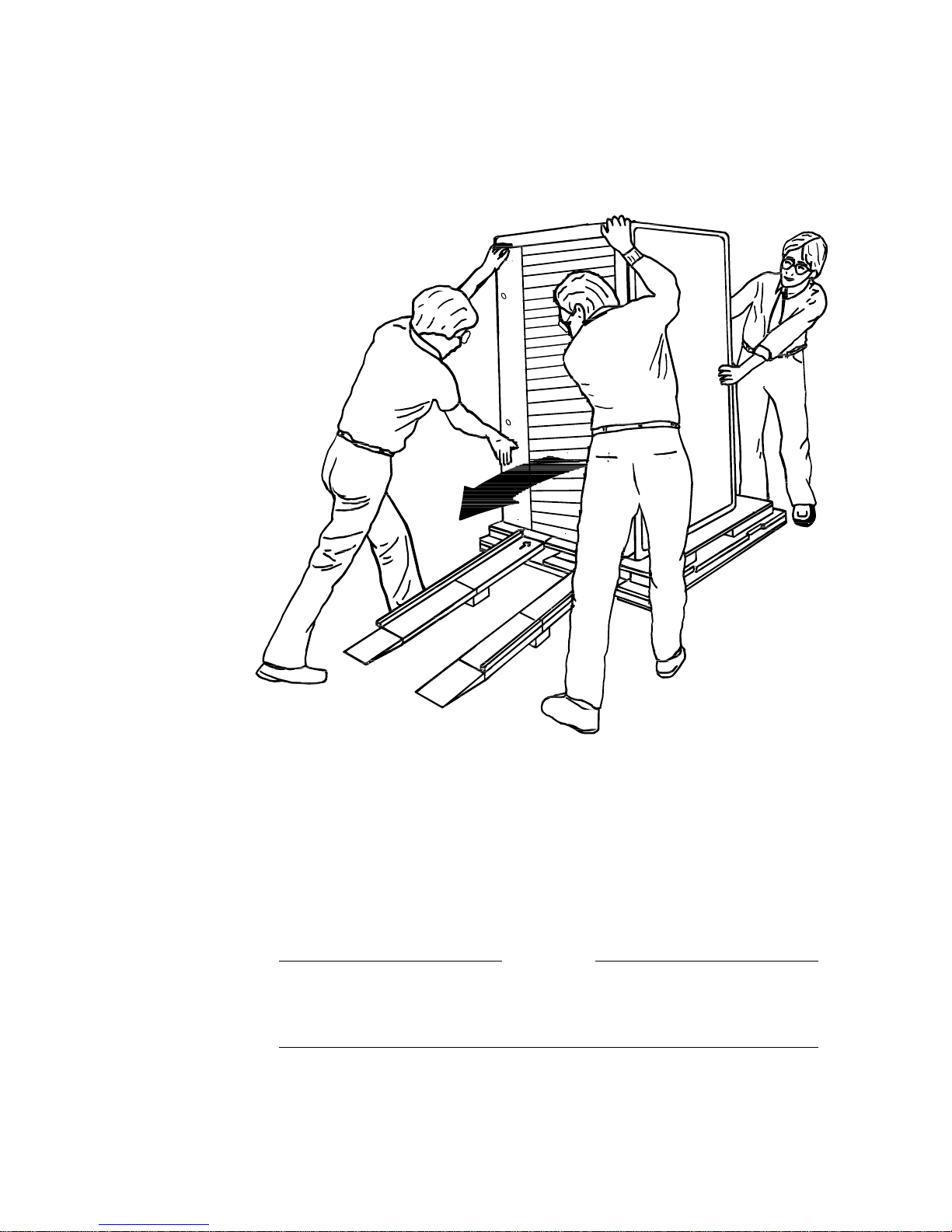

3.5 Leveling the Cabinet

Level the cabinet in its final position as follows:

1. Loosen the locknuts on all four leveler feet as shown in Figure 3–5.

2. Turn each leveler hex nut clockwise until the leveler foot contacts the floor.

3. Adjust all four leveler feet until the cabinet is level and the load is removed

from all casters. Verify that the casters spin freely.

4. Tighten the locknuts on all four leveler feet.

Figure 3–5 Leveler Foot Adjustment

LOCKNUT

LEVELER

HEX NUT

LEVELER

FOOT

3.6 Installing the Skirt Kit

The skirt kit is packaged separately inside the corrugated carton with the

cabinet. Installation of the skirt kit is optional. Install the skirt kit around the

base of the cabinet as follows:

1. Unpack the skirt kit carton and use Figure 3–6 to identify the right, left,

front, and rear skirts.

2. Position the skirts next to the cabinet, as shown in Figure 3–6.

3. The fasteners on the skirts consist of small pins with flat and barbed sides.

Using a Phillips screwdriver, turn the fasteners on each skirt until the flat

sides face up.

4. Position each skirt such that the fasteners mate with the receptacles on the

cabinet’s base.

5. Using a Phillips screwdriver, push each fastener straight into its mating

receptacle on the cabinet base.

(With the fasteners locked in place, a small amount of play allows the skirts

to be adjusted slightly up or down for proper alignment.)

CXO-3829A

Unpacking and Installation 3–7

Figure 3–6 Cabinet Skirt Installation

SIDE

SKIRT

REAR

SKIRT

3.7 Inspecting the Cabinet

Inspect the cabinet installation as follows:

1. Make sure that all hardware within the cabinet is fastened securely, and that

there are no loose pieces present in the cabinet interior.

2. Make sure that all four leveller feet are lowered to support the full weight of

the cabinet, and that the cabinet is level.

3. Make sure that there are no obstructions to the airflow from the shelf

blowers. (The side panels may need to be removed to check the shelf blowers.)

4. Check the identification label on the rear of the cabinet to verify that the

cabinet is configured to accept the power available at the site.

5. Make sure that all ac power cords connected from the shelves and cabinet

fans to the CDUs are firmly seated in their connectors at both ends.

6. Make sure that all signal cables internal to the cabinet are firmly seated in

their connectors at both ends.

SIDE

SKIRT

FRONT

SKIRT

CXO-3898A-MC

3–8 Unpacking and Installation

7. Make sure that all SBBs are seated firmly in their shelves.

8. Make sure that any necessary external interface cables are installed and

firmly seated in their connectors.

9. Make sure that the circuit breaker on each CDU is in the(OFF) position.

3.8 Powering the Cabinet

Once the cabinet has been inspected, power may be applied as follows:

1. Plug the primary power cables from each CDU into the appropriate site power

receptacles.

2. Switch the circuit breaker on each CDU to the(ON) position.

3. Verify that all shelf blowers are operating and that both status indicators

on each shelf power supply SBB are illuminated. Refer to the StorageWorks

Family User’s Guide for further information on shelf status indicators.

Failure to reduce the leakage current can result in equipment

performance degradation and personnel injury due to electric shock.

4. Measure the cabinet’s leakage current. If the leakage current exceeds 3.5 mA

after installation, Digital recommends that power cables with industrial type

B, IEC 950 connectors be installed.

WARNING

5. Initialize the storage subsystem. Procedures for initializing the cabinet’s

controller and storage devices are specific to the host system to which it is

connected. Refer to the appropriate system documentation for initialization

procedures.

Unpacking and Installation 3–9

4

Configuring SH043 Storage-Only Cabinets

This chapter describes the configuration of the SH043 storage-only cabinet. This

storage subsystem uses only the StorageWorks SHDZZ–ZZ shelf type. The Small

Computer Systems Interface 2 (SCSI–2) interface is used as the communications

path between the cabinet’s storage devices and their external controllers. SH043

storage-only cabinets can be configured with up to 10 storage shelves.

WARNING

While working in the cabinet interior, ac power must be removed from

cabinet components. Failure to do so may result in personnel injury as a

result of electric shock.

Prior to performing any of the procedures in this chapter, remove ac power from

the cabinet components. If the cabinet is installed and operating, spin down all

disk drives and halt all tape drives in the cabinet. Switch the circuit breaker on

the front panel of the cabinet’s cable distribution units (CDUs) to the(OFF)

position.

4.1 Cabinet Configuration

Failure to install cabinet components in the proper order could result in

cabinet instability, injury to personnel, and damage to equipment.

To maintain FCC compliance and proper airflow, filler panels and air

separation panels must be installed as specified for your particular

cabinet configuration. See Section 4.2 for further information.

The order of shelf installation in SH043 storage-only cabinets is predetermined to

allow for cabinet loading and cable length factors. Figures 4–1 and 4–2 show the

layout of both the front and rear of the storage-only cabinet. To prevent cabinet

instability, shelves must be installed in the order shown by the position numbers

in the illustrations.

WARNING

Note

Configuring SH043 Storage-Only Cabinets 4–1

4.1.1 Shelf Locations

Figure 4–1 shows the proper cabinet rail mounting holes for each shelf location

when TZLX-series tape drives are not installed. Shelf mounting hole numbers

are counted from the top of each rail. The hole number assignments shown in

the figure identify the mounting holes for each shelf’s top bracket screw. See

Chapter 6 for detailed procedures pertaining to the mounting of StorageWorks

shelves.

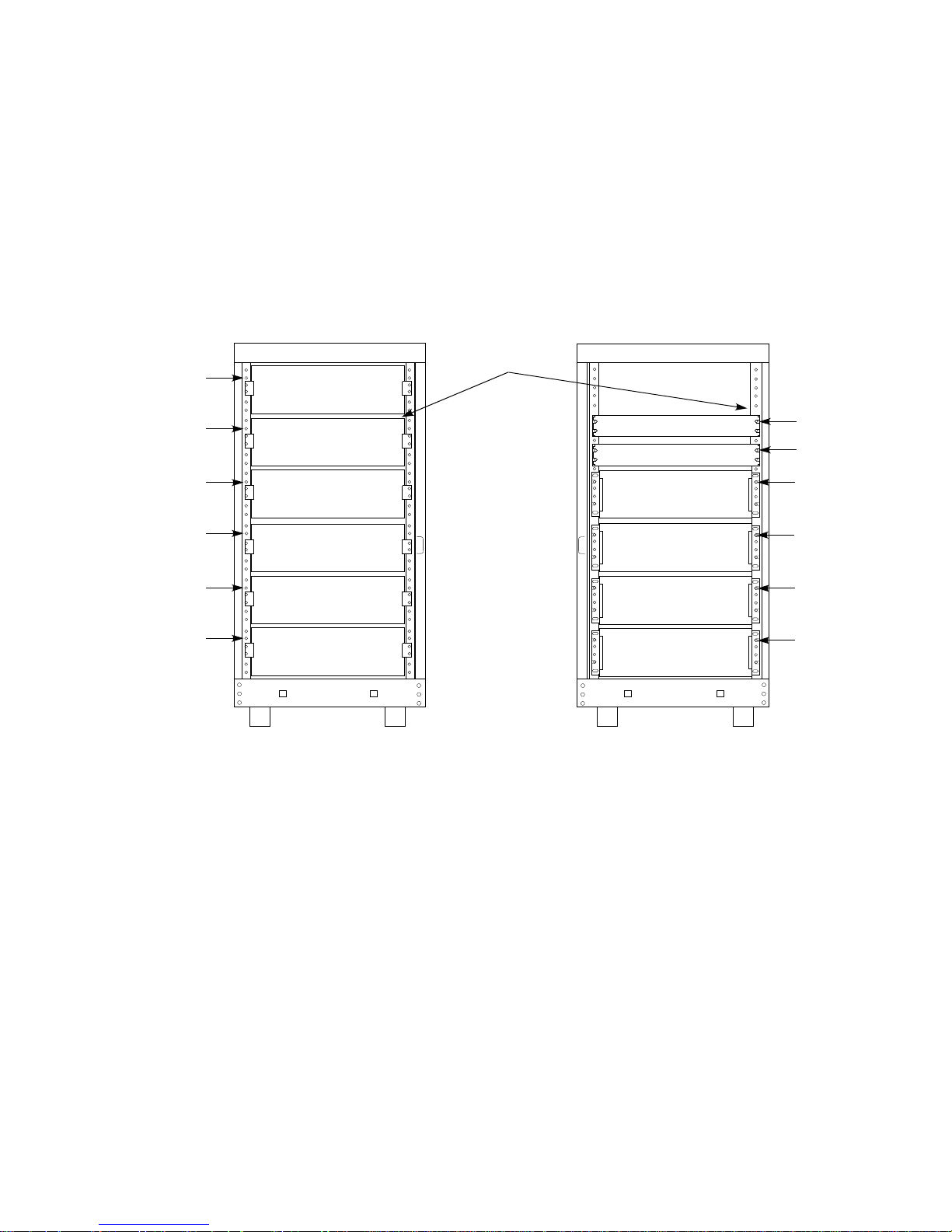

Figure 4–1 SH043 Storage-only Cabinet Shelf Locations

MOUNTING

LOCATIONS

HOLE

#2

HOLE

#8

HOLE

#14

HOLE

#20

HOLE

#26

HOLE

#32

STORAGE

POSITION S10

STORAGE

POSITION S5

STORAGE

POSITION S4

STORAGE

POSITION S1

STORAGE

POSITION S2

STORAGE

POSITION S3

CABINET FRONT

FRONT-TO-REAR

SCSI-2 CABLE

ROUTING POINTS

CDU B

CDU A

STORAGE

POSITION S9

STORAGE

POSITION S8

STORAGE

POSITION S7

STORAGE

POSITION S6

CABINET REAR

MOUNTING

LOCATIONS

HOLE

#7

HOLE

#10

HOLE

#14

HOLE

#20

HOLE

#26

HOLE

#32

CXO-3900A-MC

4.1.2 TZLX-Series Tape Drive/Shelf Locations

Figure 4–2 shows the proper cabinet rail mounting holes for each shelf location

when TZLX-series tape drives are installed. Mounting hole numbers are counted

from the top of each rail. The hole number assignments shown in the figure

identify the mounting holes for each shelf’s top bracket screw and for the round

standoff chassis rail locating hole for TZLX-series tape drives. See Chapter 6

for detailed procedures pertaining to the mounting of StorageWorks shelves. See

Chapter 7 for detailed procedures pertaining to the mounting of the tape drive.

Note that the TZLX-series tape drive extends from the front to the rear of the

SH043 cabinet and utilize the upper two shelf mounting positions on each side.

4–2 Configuring SH043 Storage-Only Cabinets

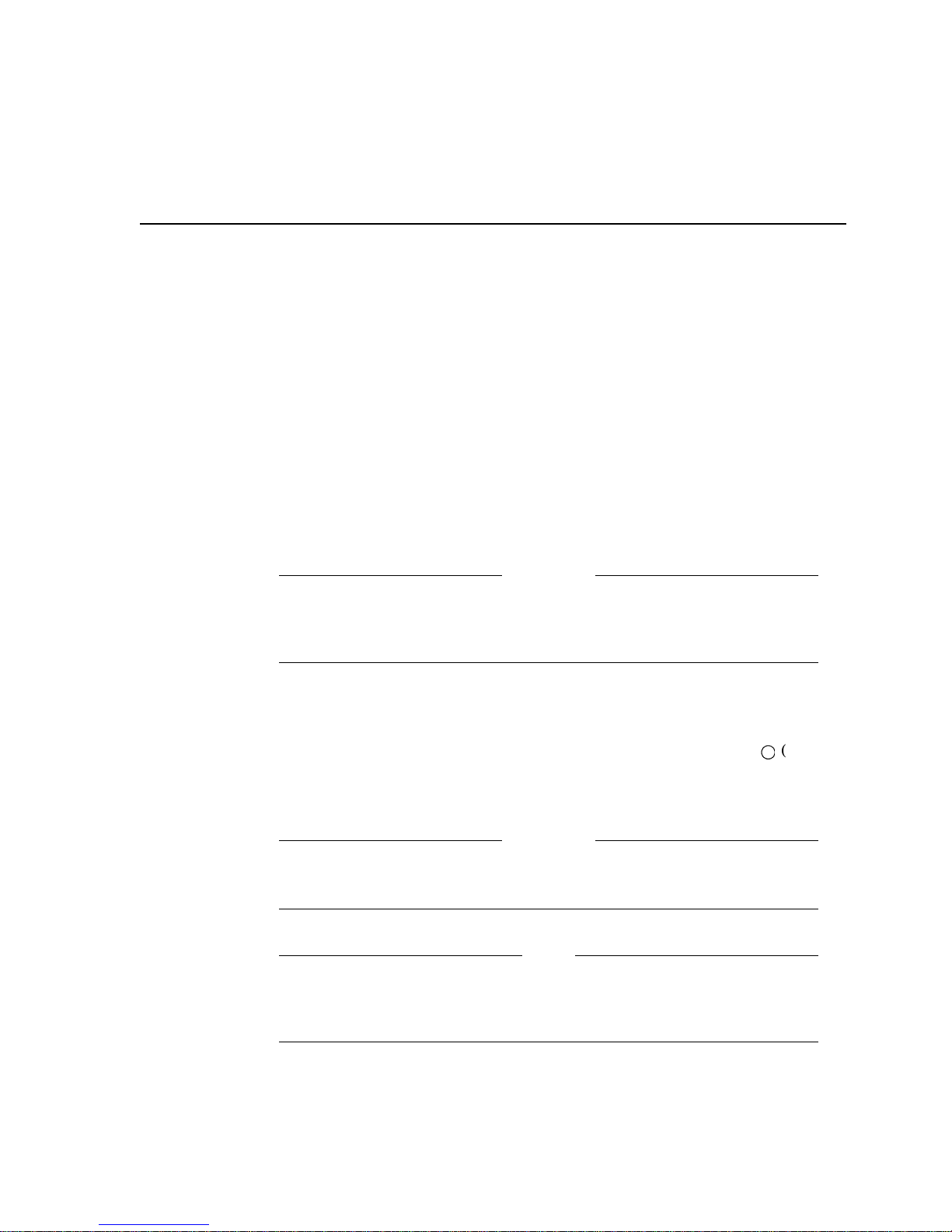

Figure 4–2 SH043 Storage-only Cabinet Shelf and Tape Drive Locations

MOUNTING

LOCATIONS

HOLE

#3

HOLE

#14

HOLE

#20

HOLE

#26

HOLE

#32

TZLx-SERIES

TAPE DRIVE

POSITION T2

STORAGE

POSITION S4

STORAGE

POSITION S1

STORAGE

POSITION S2

STORAGE

POSITION S3

CABINET FRONT

TZLx-SERIES

TAPE DRIVE

POSITION T1

FRONT-TO-REAR

SCSI-2 CABLE

ROUTING POINTS

TZLx-SERIES

TAPE DRIVE

POSITION T1

CDU B

CDU A

STORAGE

POSITION S6

STORAGE

POSITION S5

CABINET REAR

TZLx-SERIES

TAPE DRIVE

POSITION T2

MOUNTING

LOCATIONS

HOLE

#3

HOLE

#19

HOLE

#22

HOLE

#26

HOLE

#32

CXO-3956A-MC

4.2 Filler and Air Separation Panels

To maintain FCC compliance and proper airflow, filler panels and air

separation panels must be installed as specified for your particular

cabinet configuration and in accordance with the following guidelines.

Filler panels can be installed in empty shelf positions to control air flow and

electromagnetic emissions and for the purpose of cosmetics. Filler panels are

normally supplied and installed based on the specific configuration of the SH043

storage-only cabinet ordered. At least two filler panels are shipped with each

cabinet. Install filler panels using the following guidelines:

• If a particular filler panel configuration is specified for your cabinet, install

the panels exactly as specified.

• If a particular filler panel configuration is not specified for your cabinet, use

filler panels in all open slots below the highest shelf installed. Repeat for

each side of the cabinet.

• To ensure proper cooling air flow, never install filler panels above the highest

shelf installed in the cabinet.

See Chapter 6 for details on the installation of filler panels.

Note

Configuring SH043 Storage-Only Cabinets 4–3

Two air separation panels are supplied with each cabinet. Install an air

separation panel just above the upper-most shelf in each side of the cabinet. Air

separation panels are not required above TZLX-series tape drives. See Chapter 6

for details on the installation of air separation panels.

4.3 Power Configuration

The power in SH043 storage-only cabinets can be configured in any of the forms

described in Section 1.3. See Chapter 8 for detailed procedures on configuring

power within the cabinet.

4.4 Signal Cabling and Routing

Signal cabling in the SH043 storage-only cabinet consists of inter-shelf SCSI–2

cabling and shelf-host SCSI–2 controller cabling.

4.4.1 Shelf SCSI–2 Cable Selection and Connection

Refer to the StorageWorks Family Configuration Guide and the StorageWorks

Family User’s Guide for details on how to select and connect SCSI–2 cables to the

cabinet’s shelves.

4.4.2 SCSI–2 Cable Routing

SCSI–2 signal cables enter SH043 storage-only cabinets through openings in the

rear edges of the base pan of the cabinet. Cables destined for rear shelves are

normally routed along the base pan to the right-most vertical rail. They are then

routed to the the right-hand side of each rear shelf along the rail.

SCSI–2 cables destined for front shelves are routed along the base pan and up the

right-hand vertical cabinet rail to a point just above the CDUs (refer to Figures

4–1 and 4–2). They then pass into the interior of the cabinet and across to an

opening in the vertical chassis rail behind the two right-hand shelf brackets of

positions S5 and S10. They pass through the opening and out to the front of the

cabinet through the space between the S5/S10 shelf brackets. On the front of

the cabinet, cables are normally routed along the right vertical cabinet rail to

the right-hand side of each shelf along the rail. Half-meter, SCSI–2 cables are

normally used to link adjacent shelves to each other.

When TZLX-series tape drives are installed, there is a space between the bottom

of the drives and shelf position S4 (refer to Figure 4–2). This space is normally

used for the routing of SCSI–2 cables from the rear to the front of the cabinet.

4.4.3 General Cable Routing Rules

Cables should be routed and installed with the following rules in mind:

Cabinet rail edges may be sharp and can slice or abrade skin or cable

insulation.

• Cables should be routed in a manner that allows the shortest overall cable

length.

WARNING

• Signal cables should be kept away from power cables.

• Care should be taken to avoid sharp cable bends.

4–4 Configuring SH043 Storage-Only Cabinets

• Cables should be routed to allow StorageWorks building blocks (SBBs) and

controller modules to be freely inserted and removed from their shelves.

• Cables should not be routed tightly against the metal edges of the cabinet.

• Signal cable bundling along the outside of the cabinet rails should be done to

allow the doors to easily close.

• Cables should be fastened along cabinet rails using cable ties or nylon cable

clamps, U-nuts, and screws. Added cables should be included in existing

cable clamps where possible.

Configuring SH043 Storage-Only Cabinets 4–5

5

Configuring SH043 Controller/Storage Cabinets

This chapter describes the configuration of SH043 controller/storage cabinets.

These storage subsystems use StorageWorks HS-family array controllers

mounted in SHxzz–zz shelves. Storage devices are housed in SHDZZ–ZZ shelves.

StorageWorks HS-family array controllers use the Small Computer System

Interface 2 (SCSI–2) interface as the communication path with the host computer.

The SCSI–2 interface is used as the storage device bus in all subsystems. SH043

controller/storage cabinets can be configured with up to four controllers in

redundant pairs and with up to nine storage shelves.

Refer to the StorageWorks BA350–EA Modular Storage Shelf User’s Guide for

further information on HS-family array controllers and their installation.

WARNING

While working in the cabinet interior, ac power must be removed from

cabinet components. Failure to do so may result in personnel injury as a

result of electric shock.

Prior to performing any of the procedures in this chapter, remove ac power from

the cabinet components. If the cabinet is installed and operating, spin down all

disk drives and halt all tape drives in the cabinet. Switch the circuit breaker on

the front panel of the cabinet’s cable distribution units (CDUs) to the(OFF)

position.

5.1 Cabinet Configuration

Failure to install cabinet components in the proper order could result in

cabinet instability, injury to personnel, and damage to equipment.

To maintain FCC compliance and proper airflow, filler panels and air

separation panels must be installed as specified for your particular

cabinet configuration. See Section 5.2 for further information.

WARNING

Note

Configuring SH043 Controller/Storage Cabinets 5–1

The order of shelf installation in SH043 controller/storage cabinets is

predetermined to allow for cabinet loading and cable length factors. Figures

5–1 and 5–2 show the layout of both the front and rear of the controller/storage

cabinet. To prevent cabinet instability, shelves must be installed in the order

shown by the position numbers in the illustrations.

5.1.1 Shelf Locations

Figure 5–1 shows the proper cabinet rail mounting holes for each shelf location

when TZLX-series tape drives are not installed. Note that storage position

S7 may instead be used for the installation of a second controller shelf. Shelf

mounting hole numbers are counted from the top of each rail. The hole number

assignments shown in the figure identify the mounting holes for each shelf’s top

bracket screw. See Chapter 6 for detailed procedures pertaining to the mounting

of StorageWorks shelves.

Note

The SHxzz–zz controller/storage shelf consists of a controller shelf with an

attached storage shelf. In systems using SHxzz–zz shelves but not using

tape drives, storage positions S1 and S6 are physically attached to and

are dedicated to their respective controllers.

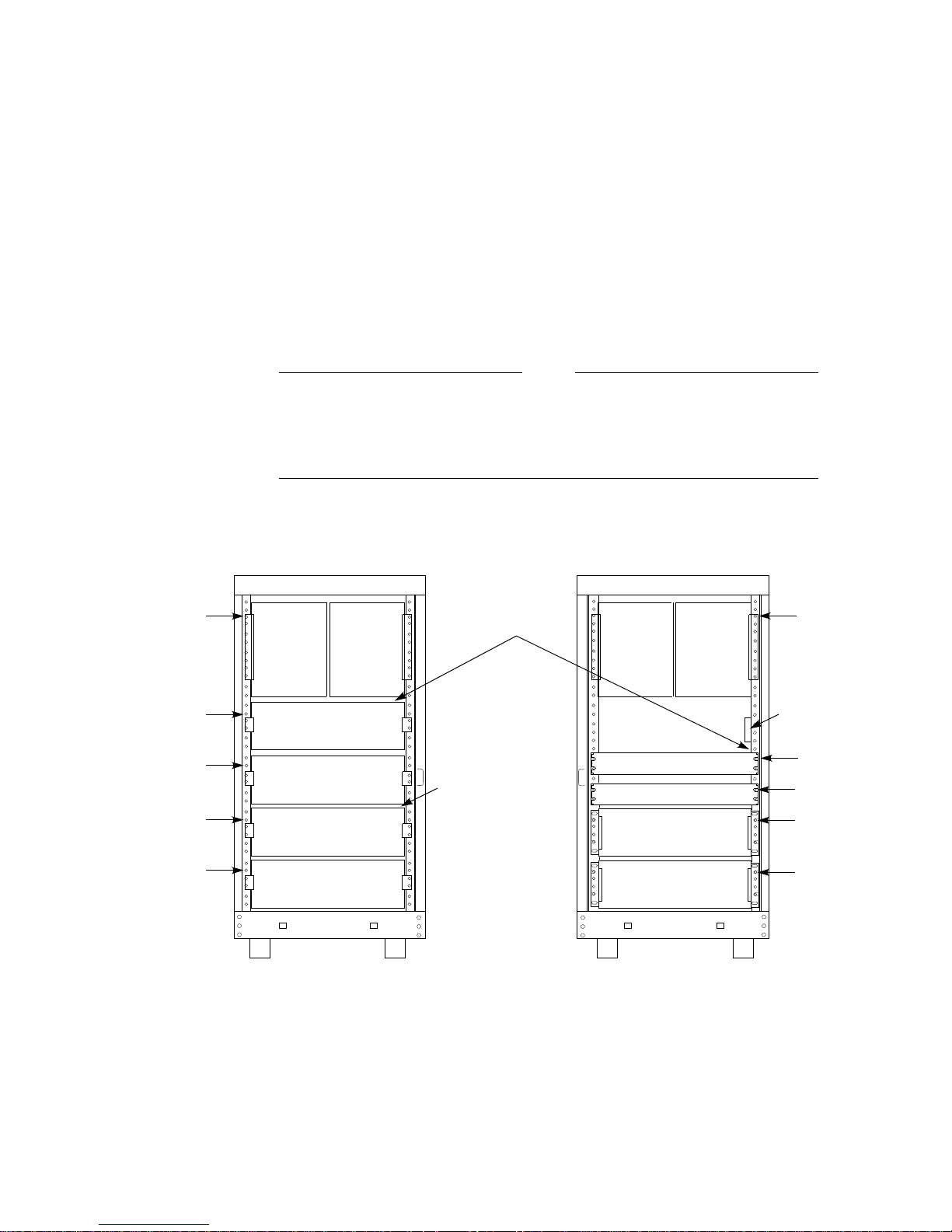

Figure 5–1 SH043 Controller/Storage Cabinet Shelf Locations

MOUNTING

LOCATIONS

HOLE

#2

HOLE

#8

HOLE

#14

HOLE

#20

HOLE

#26

HOLE

#32

STORAGE

POSITION S9

STORAGE

POSITION S4

STORAGE

POSITION S3

CONTROLLER

POSITION C1

STORAGE

POSITION S1

STORAGE

POSITION S2

CABINET FRONT

FRONT-TO-REAR

SCSI-2 CABLE

ROUTING POINTS

INTERNAL

CI CABLE

ROUTING

POINT

CDU B

CDU A

STORAGE

POSITION S8

STORAGE

POSITION S7

CONTROLLER

POSITION C2

STORAGE

POSITION S6

STORAGE

POSITION S5

CABINET REAR

MOUNTING

LOCATIONS

CI BULKHEAD

HOLE

#7

HOLE

#10

HOLE

#14

HOLE

#20

HOLE

#26

HOLE

#32

5–2 Configuring SH043 Controller/Storage Cabinets

CXO-3902A-MC

5.1.2 TZLX-Series Tape Drive/Shelf Locations

Figure 5–2 shows the proper cabinet rail mounting holes for each shelf location

when TZLX-series tape drives are installed. Mounting hole numbers are counted

from the top of each rail. The hole number assignments shown in the figure

identify the mounting holes for each shelf’s top bracket screw and for the round

standoff slide locating hole for the TZLX-series tape drives. Refer to Chapter 6 for

detailed procedures pertaining to the mounting of StorageWorks shelves. Refer to

Chapter 7 for detailed procedures pertaining to the mounting of TZLX-series tape

drives. Note that the TZLX-series tape drive extends from the front to the rear

of the SH043 cabinet and utilizes the upper two shelf mounting positions on each

side.

Note

The SHxzz–zz controller/storage shelf consists of a controller shelf with

an attached storage shelf. In systems using SHxzz–zz shelves and TZLXseries tape drives, storage positions S1 and S4 are physically attached to

and are dedicated to their respective controllers.

Figure 5–2 SH043 Controller/Storage Cabinet Shelf and Tape Drive Locations

MOUNTING

LOCATIONS

HOLE

#3

HOLE

#14

HOLE

#20

HOLE

#26

HOLE

#32

TZLx-SERIES

TAPE DRIVE

POSITION T2

STORAGE

POSITION S3

CONTROLLER

POSITION C1

STORAGE

POSITION S1

STORAGE

POSITION S2

CABINET FRONT

TZLx-SERIES

TAPE DRIVE

POSITION T1

FRONT-TO-REAR

SCSI-2 CABLE

ROUTING POINTS

INTERNAL

CI CABLE

ROUTING

POINT

TZLx-SERIES

TAPE DRIVE

POSITION T1

CDU B

CDU A

CONTROLLER

POSITION C2

STORAGE

POSITION S5

STORAGE

POSITION S4

CABINET REAR

TZLx-SERIES

TAPE DRIVE

POSITION T2

MOUNTING

LOCATIONS

HOLE

#3

CI BULKHEAD

HOLE

#19

HOLE

#22

HOLE

#26

HOLE

#32

CXO-3957A-MC

Configuring SH043 Controller/Storage Cabinets 5–3

5.2 Filler and Air Separation Panels

To maintain FCC compliance and proper airflow, filler panels and air

separation panels must be installed as specified for your particular

cabinet configuration and in accordance with the following guidelines.

Filler panels can be installed in empty shelf positions to control air flow and

electromagnetic emissions and for the purpose of cosmetics. Filler panels are

normally supplied and installed based on the specific configuration of the SH043

controller/storage cabinet ordered. At least two filler panels are shipped with

each cabinet. Install filler panels using the following guidelines:

• If a particular filler panel configuration is specified for your cabinet, install

the panels exactly as specified.

• If a particular filler panel configuration is not specified for your cabinet, use

filler panels in all open slots below the highest shelf installed. Repeat for

each side of the cabinet.

• To ensure proper cooling air flow, never install filler panels above the highest

shelf installed in the cabinet.

Refer to Chapter 6 for details on the installation of filler panels.

Two air separation panels are supplied with each cabinet. Install an air

separation panel just above the upper-most shelf in each side of the cabinet.

Air separation panels are not required above TZLX-series tape drives. Refer to

Chapter 6 for details on the installation of air separation panels.

Note

5.3 Power Configuration

The power in SH043 controller/storage cabinets can be configured in any of the

forms described in Section 1.3. Refer to Chapter 8 for detailed procedures on

configuring power within SH043 controller/storage cabinets.

5.4 Host SCSI–2 Signal Cabling and Routing

The SCSI–2 interface cables used to communicate with the host are routed

directly from the controller to the host. A intermediate bulkhead is not used.

5.4.1 Host SCSI–2 Signal Cable Routing

Route the host SCSI–2 interface cables as follows:

1. Route host SCSI–2 cables into SH043 controller/storage cabinets through the

openings in the rear edges of the base pan of the cabinet.

2. Route host SCSI–2 cables destined for rear controllers directly up the rear

right-hand vertical rail to the rear controller shelf.

3. Route host SCSI–2 cables destined for rear controllers along the base pan

to the rear right-hand vertical rail and upward to the pass-through location

shown in either Figure 5–1 or 5–2.

5–4 Configuring SH043 Controller/Storage Cabinets

4. Route the cables from the pass-through location to their respective controllers

as follows:

• Route the cable across the interior of the cabinet to an opening in the

vertical cabinet rail behind the two right-hand shelf brackets of positions

C1 and S3 (refer to Figures 5–1 and 5–2).

• Pass the cable through the opening and out to the front of the cabinet

through the space between the C1/S3 shelf brackets to the front controller

in position C1.

5.5 Shelf Signal Cabling and Routing

5.5.1 Shelf SCSI–2 Cable Selection and Connection

Refer to the StorageWorks Family Configuration Guide and the StorageWorks

BA350-EA Modular Storage Shelf User’s Guide for details on the selection of

SCSI–2 cables and their connection to the cabinet’s shelves.

5.5.2 SCSI–2 Cable Routing

SCSI–2 cables from the front controller to the controller’s associated front storage

shelves are normally routed along the right-hand vertical cabinet rail to the

right-hand side of each shelf. Half-meter, SCSI–2 cables are normally used to

link adjacent shelves or tape drives to each other.

SCSI–2 cables connecting front shelves to rear shelves pass to the rear of the

cabinet via the opening between the right-hand shelf brackets at positions S4 and

S9 (refer to Figure 5–1). They pass through this opening and into the interior

of the cabinet through the opening in the vertical cabinet rail behind the S4/S9

brackets. They then pass across the interior of the cabinet to the unused shelf

position above the CDUs. They pass through the right-hand side of the unused

shelf position and along the right-hand cabinet rail to the appropriate rear

shelves.

When TZLX-series tape drives are installed, there is a space between the bottom

of the drives and shelf position S3 (refer to Figure 5–2). This space is normally

used for the routing of SCSI–2 cables from the rear to the front of the cabinet.

Table 5–1 specifies the SCSI–2 cable length required to connect each controller

position with its companion shelves in SH043 controller/storage cabinets.

Table 5–1 SH043 Controller/Storage Cabinet SCSI–2 Cable Lengths

Controller Position Storage Shelf Position

C1 S1, S2, S3, S4, S9 1.00 m (3.28 ft)

C1 S5, S6, S7, S8 2.00 m (6.56 ft)

C1 T1, T2 2.00 m (6.56 ft)

C2 S5, S6, S8 1.00 m (3.28 ft)

Cable Length

Required

Configuring SH043 Controller/Storage Cabinets 5–5

Following are some standard SCSI–2 bus configurations:

Shelf connections for single-controller systems with no tape drives are as follow

(refer to Figure 5–1):

• Single storage shelf

C1–S1 C1–S2 C1–S3 C1–S4 C1–S5 C1–S6

• Serially cabled multiple storage shelves

C1–S1–S2 C1–S3–S4 C1–S5 C1–S6 C1–S7

Shelf connections for single-controller systems with tape drives are as follow

(refer to Figure 5–2):

C1–S1 C1–S2 C1–S3 C1–S4 C1–S5 C1–T1–T2

Shelf connections for dual-controller systems with single storage shelves are as

follows (refer to Figure 5–1):

C1–S1 C1–S2 C1–S3 C1–S4 C1–S9 C2–S6 C2–S8

5.6 General Signal Cable Routing Rules

Cables should be routed and installed with the following rules in mind:

WARNING

Cabinet rail edges may be sharp and can slice or abrade skin or cable

insulation.

• Cables should be routed in a manner that allows the shortest overall cable

length.

• Signal cables should be kept away from power cables.

• Care should be taken to avoid sharp cable bends.

• Cables should be routed to allow SBBs and controller modules to be freely

inserted and removed from their shelves.

• Cables should not be routed tightly against the metal edges of the cabinet.

• Signal cable bundling along the outside of the cabinet rails should be done to

allow the doors to easily close.

• Cables should be fastened along cabinet rails using cable ties or nylon cable

clamps, U-nuts, and screws. Added cables should be included in existing

cable clamps where possible.

5–6 Configuring SH043 Controller/Storage Cabinets

Installing StorageWorks Shelves

This chapter describes the details of the installation of StorageWorks shelves

into SH043-series cabinets. Procedures for front and rear shelf installation are

presented. The installation of filler panels and air separation panels in both the

front and rear of the cabinet are also covered.

6.1 General Shelf Mounting Considerations

Note

In the following descriptions and procedures, the terms front and rear

are references to locations in the cabinet. The terms inner and outer are

references to positions on the shelf brackets.

Each StorageWorks shelf is mounted in the cabinet with a bracket set (BA35x–

RB) (Refer to Figure 1–2.) Each bracket set consists of a pair of shelf brackets,

stop brackets, and locking brackets. (A typical bracket set is shown in

Figure 6–2.) The stops are attached to the inner portion of the shelf brackets to

position the shelf within the bracket. The locking brackets fix the shelf in place.

Various combinations of stop positions and locking bracket size are necessary to

situate a particular shelf for proper clearance from the cabinet doors.

6

The same shelf bracket and stop bracket parts are used to mount all types of

StorageWorks shelves in all locations. The bracket set for shelves mounted in

various positions in the cabinet differs only in that the locking brackets are

unique parts sized for specific cabinet positions.

Filler panels are installed in some unused shelf positions in the cabinet. Filler

panels are normally installed after shelf installation

An air separation panel is required in both the front and rear of the cabinet to

prevent the recirculation of heated air to the cabinet’s shelves. The air separation

panels are mounted just above the upper-most shelf in each side of the cabinet.

Air separation panels are normally installed after shelf installation.

WARNING

While working in the cabinet interior, ac power must be removed from

cabinet components. Failure to do so may result in personnel injury as a

result of electric shock.

Prior to performing any of the procedures in this chapter, remove ac power from

the cabinet components. If the cabinet is installed and operating, spin down all

disk drives and halt all tape drives in the cabinet. Switch the circuit breaker on

the front panel of the cabinet’s CDUs to the(OFF) position.

Installing StorageWorks Shelves 6–1

6.2 Accessing the Cabinet Rack Space

In maximum configurations where access to the interior of the cabinet is limited,

external cabinet panels may need to be removed before shelves can be installed

or reconfigured. Section 6.2.1 presents procedures for removing exterior cabinet

panels.

The front and rear cabinet doors are held closed by locks mounted near the top

and bottom of each door. The locks are released by turning them counterclockwise

with a 5/32-inch hex wrench.

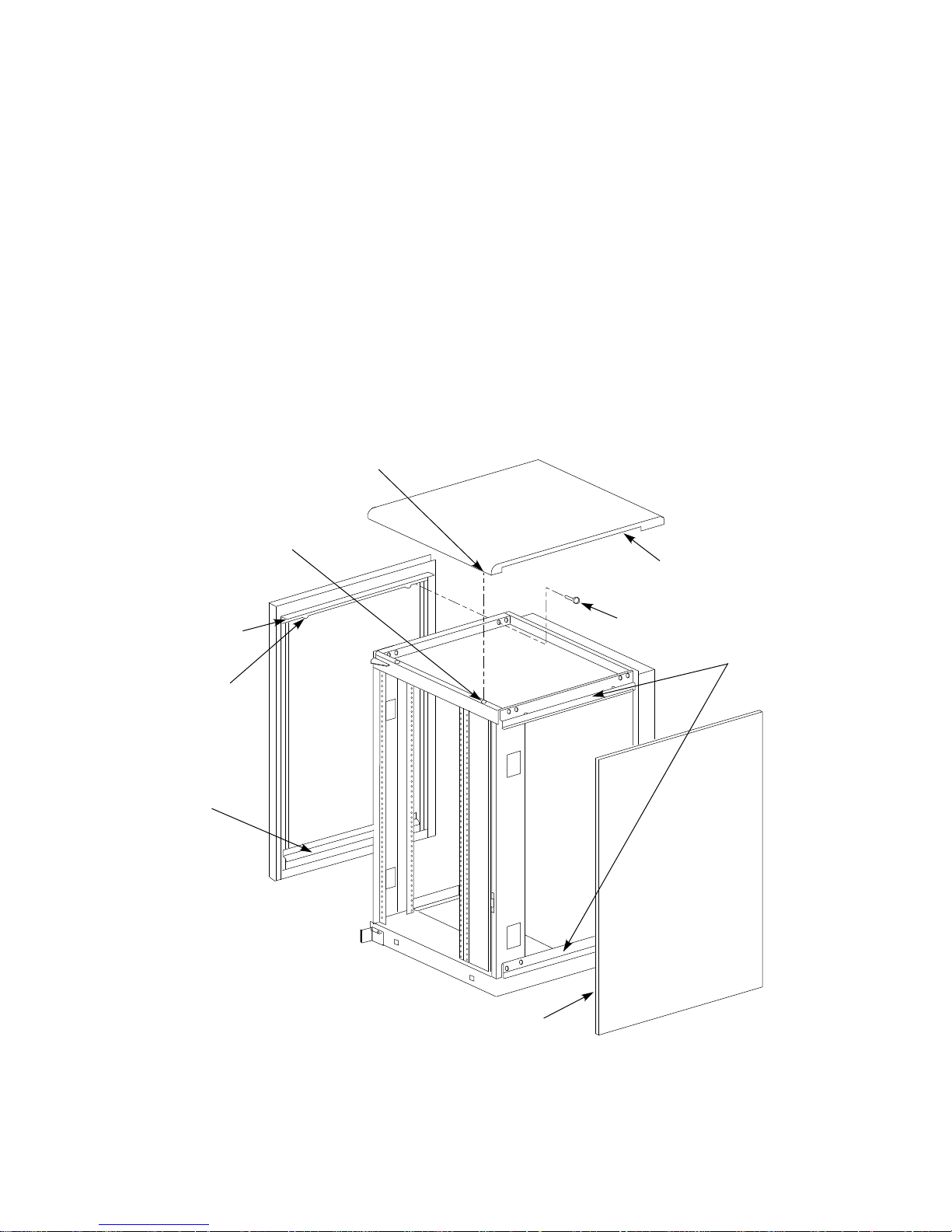

6.2.1 Removing the Exterior Cabinet Panels

As shown in Figure 6–1, there are two side panel hanger clips on each side of the

cabinet. A matching set of hanger clips are attached to each side panel. Remove

the side panels as follows:

Figure 6–1 Exterior Cabinet Panel Removal and Installation

FASTENER

PIN

(4 PLACES)

NYLON SNAP

FASTENER

(4 PLACES)

TOP COVER

UPPER

SIDE PANEL

HANGER

CLIP

LOWER

SIDE PANEL

HANGER

CLIP

LIP

M6x40mm BOLT

(4 PLACES)

SIDE PANEL

HANGER

CLIPS

CABINET

FRONT

SIDE PANEL

NOTE: FRONT AND REAR DOORS NOT SHOWN FOR CLARITY

6–2 Installing StorageWorks Shelves

CXO-3899A-MC

1. Move the cabinet away from adjacent enclosures as necessary.

2. Loosen the top cover by pushing up on its front and rear edges until it snaps

free of its fasteners.