Stoelting O212B Service Manual

Model O212B

OPERATORS MANUAL

Manual No. 513705 Rev.0

This manual provides basic information about the machine. Instructions and suggestions are

given covering its operation and care.

The illustrations and specifi cations are not binding in detail. We reserve the right to make

changes to the machine without notice, and without incurring any obligation to modify or provide new parts for machines built prior to date of change.

DO NOT ATTEMPT to operate the machine until instructions and safety precautions in this

manual are read completely and are thoroughly understood. If problems develop or questions

arise in connection with installation, operation, or servicing of the machine, contact Stoelting.

stoeltingfoodservice.com

Stoelting Foodservice Equipment

502 Highway 67

Kiel, WI 53042-1600

U.S.A.

White Glove Service Network

Phone: 888.319.9549

© 2017 Stoelting

A Few Words About Safety

Safety Information

Read and understand the entire manual before

operating or maintaining Stoelting equipment.

This manual provides the operator with information

for the safe operation and maintenance of Stoelting

equipment. As with any machine, there are hazards

associated with their operation. For this reason safety

is emphasized throughout the manual. To highlight

specifi c safety information, the following safety defi ni-

tions are provided to assist the reader.

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and

their explanations, deserve your careful attention

and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions

or warnings they give are not substitutes for proper

accident prevention measures.

If you need to replace a part, use genuine Stoelting

parts with the correct part number or an equivalent

part. We strongly recommend that you do not use

replacement parts of inferior quality.

Safety Alert Symbol:

This symbol Indicates danger, warning or caution.

Attention is required in order to avoid serious personal injury. The message that follows the symbol

contains important information about safety.

Signal Word:

Signal words are distinctive words used throughout

this manual that alert the reader to the existence and

relative degree of a hazard.

WARNING

The signal word “WARNING” indicates a potentially

hazardous situation, which, if not avoided, may result

in death or serious injury and equipment/property

damage.

CAUTION

The signal word “CAUTION” indicates a potentially

hazardous situation, which, if not avoided, may result

in minor or moderate injury and equipment/property

damage.

CAUTION

The signal word “CAUTION” not preceded by the

safety alert symbol indicates a potentially hazardous

situation, which, if not avoided, may result in equipment/property damage.

NOTE (or NOTICE)

The signal word “NOTICE” indicates information or

procedures that relate directly or indirectly to the

safety of personnel or equipment/property.

TABLE OF

CONTENTS

Section Description Page

1 Description and Specifi cations

1.1 Description ..................................................................................................1

1.2 Specifi cations .............................................................................................2

2 Installation Instructions

2.1 Safety Precautions .....................................................................................3

2.2 Shipment and Transit ..................................................................................3

2.3 Machine Installation ....................................................................................3

3 Initial Set-Up and Operation

3.1 Operator’s Safety Precautions ...................................................................5

3.2 Operating Controls and Indicators .............................................................5

3.3 Assembly of Machine .................................................................................6

3.4 Sanitizing ....................................................................................................7

3.5 Freeze Down and Operation ......................................................................8

3.6 Mix Information ...........................................................................................8

3.7 Removing Mix From Machine .....................................................................8

3.8 Cleaning the Machine .................................................................................8

3.9 Disassembly of Machine Parts ...................................................................8

3.10 Cleaning and Sanitizing The Machine Parts ...............................................9

3.11 Sanitize Machine ........................................................................................9

3.12 Routine Cleaning ........................................................................................9

3.13 Preventive Maintenance .............................................................................10

3.14 Extended Storage .......................................................................................10

4 Troubleshooting

4.1 Light Indicators ...........................................................................................11

4.2 Troubleshooting ..........................................................................................11

5 Replacement Parts

5.1 Brushes, Decals, and Lubrication ...............................................................13

5.2 Auger Shaft and Faceplate Parts ...............................................................14

5.3 Hopper Parts ..............................................................................................15

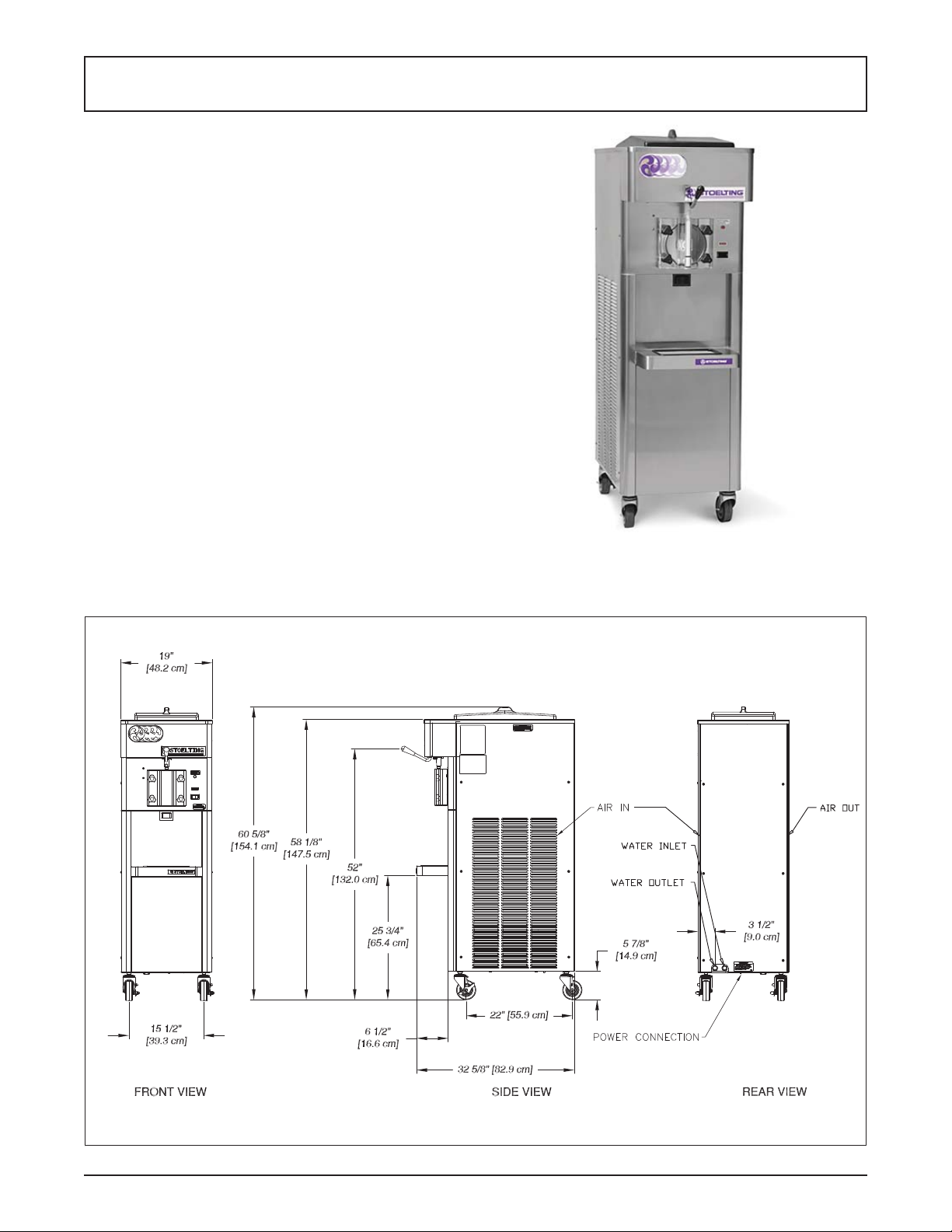

SECTION 1

DESCRIPTION AND SPECIFICATIONS

1.1 DESCRIPTION

The Stoelting O212B fl oor model machine is gravity fed.

The machine is equipped with fully automatic controls to

provide a uniform product. The machine will operate with

almost any type of shake mix. This manual is designed to

help qualifi ed service personnel and operators with the

installation, operation and maintenance of the Stoelting

O212B gravity machine.

Figure 1-1 Model O212B

Operators Manual #513705 1 O212B Model Machines

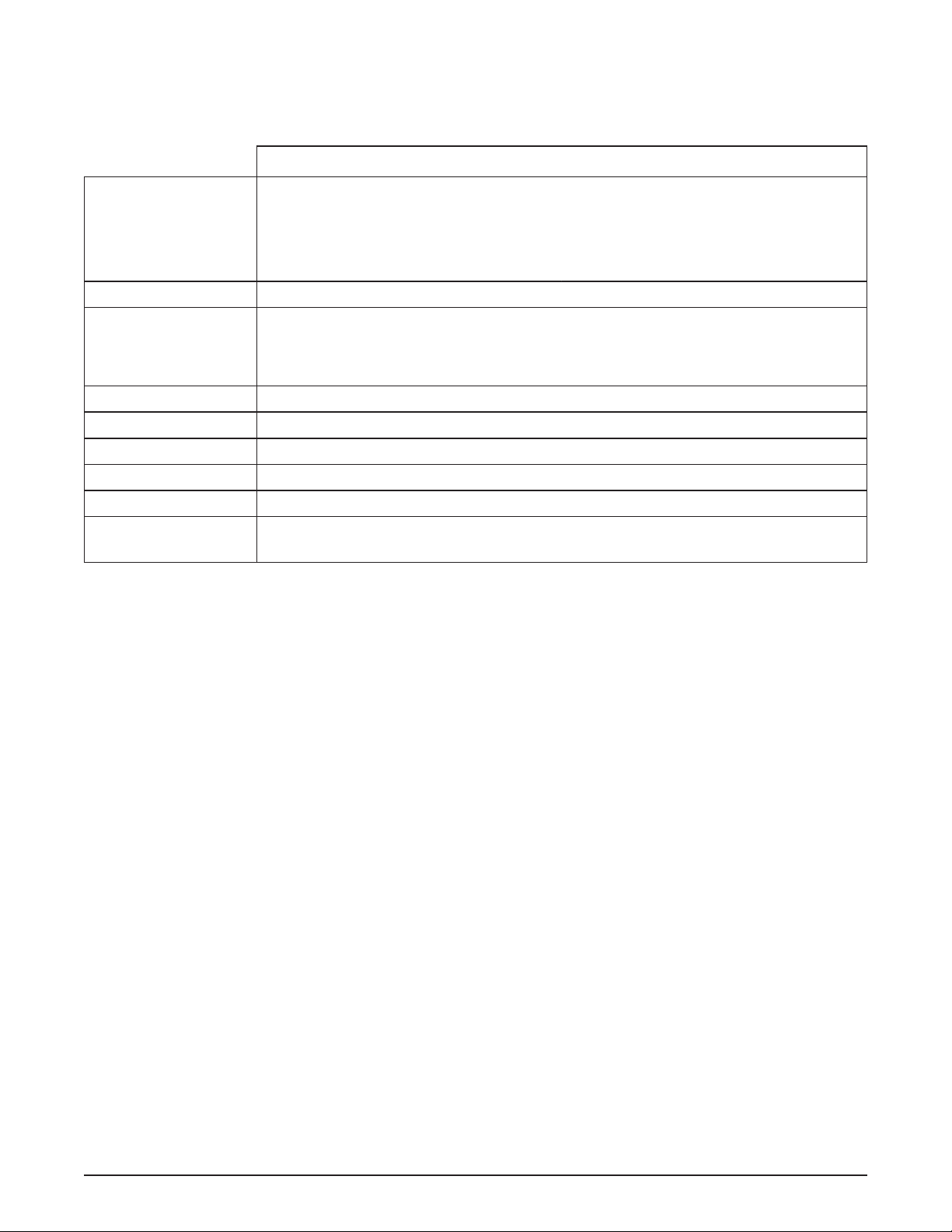

1.2 SPECIFICATIONS

Model O212B

Dimensions Machine with crate

width 19’’ (48,3 cm) 25’’ (63,5 cm)

height 60-5/8’’ (154,0 cm) 66’’ (167,6 cm)

depth 32-5/8’’ (82,9 cm) 51’’ (129,5 cm)

Weight 315 lbs (142,8 kg) 500 lbs (226,7 kg)

Electrical 1 Phase, 208-240 VAC, 60Hz

running amps 11A

connection type NEMA6-20P power cord provided

Compressor 12,000 Btu/hr

Drive Motor 3/4 hp

Air Flow Air cooled units require 3” (7,6 cm) air space on both sides

Plumbing Fittings Water cooled units require 3/8” N.P.T. water and drain fi ttings

Hopper Volume 6.5 gallon (24,61 liters)

Freezing Cylinder

Volume

2 gallon (7,57 liters)

Operators Manual #513705 2 O212B Model Machines

Loading...

Loading...