Page 1

Model F231

SERVICE MANUAL

Manual No. 513659 Rev.2

Page 2

Page 3

This manual provides basic information about the machine. Instructions and suggestions are

given covering its operation and care.

The illustrations and specifi cations are not binding in detail. We reserve the right to make

changes to the machine without notice, and without incurring any obligation to modify or provide new parts for machines built prior to date of change.

DO NOT ATTEMPT to operate the machine until instructions and safety precautions in this

manual are read completely and are thoroughly understood. If problems develop or questions

arise in connection with installation, operation, or servicing of the machine, contact Stoelting.

stoeltingfoodservice.com

Stoelting Foodservice Equipment

502 Highway 67

Kiel, WI 53042-1600

U.S.A.

Main Tel: 800.558.5807

Fax: 920.894.7029

Customer Service: 888.429.5920

Fax: 800.545.0662

Email: foodservice@stoelting.com

© 2014 PW Stoelting, LLC

Page 4

A Few Words About Safety

Safety Information

Read and understand the entire manual before

operating or maintaining Stoelting equipment.

This manual provides the operator with information

for the safe operation and maintenance of Stoelting

equipment. As with any machine, there are hazards

associated with their operation. For this reason safety

is emphasized throughout the manual. To highlight

specifi c safety information, the following safety defi ni-

tions are provided to assist the reader.

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and

their explanations, deserve your careful attention

and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions

or warnings they give are not substitutes for proper

accident prevention measures.

If you need to replace a part, use genuine Stoelting

parts with the correct part number or an equivalent

part. We strongly recommend that you do not use

replacement parts of inferior quality.

Safety Alert Symbol:

This symbol Indicates danger, warning or caution.

Attention is required in order to avoid serious personal injury. The message that follows the symbol

contains important information about safety.

Signal Word:

Signal words are distinctive words used throughout

this manual that alert the reader to the existence and

relative degree of a hazard.

WARNING

The signal word “WARNING” indicates a potentially

hazardous situation, which, if not avoided, may result

in death or serious injury and equipment/property

damage.

CAUTION

The signal word “CAUTION” indicates a potentially

hazardous situation, which, if not avoided, may result

in minor or moderate injury and equipment/property

damage.

CAUTION

The signal word “CAUTION” not preceded by the

safety alert symbol indicates a potentially hazardous

situation, which, if not avoided, may result in equipment/property damage.

NOTE (or NOTICE)

The signal word “NOTICE” indicates information or

procedures that relate directly or indirectly to the

safety of personnel or equipment/property.

Page 5

INTELLITEC2™ FIRMWARE

VERSION UPDATE LOG

The list below shows the history of the fi rmware versions in the IntelliTec2™ control. The information in this manual

refers to Version 20.39.

VERSION 20.52

Released on 8/22/11

• Motor Calibration screen now returns to the current status screen after pressing the left arrow.

• Refer Solenoid text changed to Storage Refrigeration.

• When exporting the error log data the fi le name is now the serial number of machine.

• Serial Number can now be changed in the Modify Contact Information screen.

• CutIn Offset changed to 20 (was 30)

• Default Offtime changed to 450 (was 300)

VERSION 20.39

Released on 3/2/11

• Added phase reversal detection for 3 phase machines

• Added Spigot Open Time error Error 21

• Added support for I/O update

• Changed High Torque Error 2 detection to be directly from motor amperage and not from a calculated factor

VERSION 20.27

Released on 12/28/10

• Added Unit Serial Number to Service Contact Information and Modify Contact Information

• Added Clean Warning to Clean Options

VERSION 20.15

Released 11/23/10

• Added Enable Control to Basic Settings

• Removed Enable CutOut Temp from Basic Settings

• Changed CutOut Consistency to CutOut Consistency Offset

• Added CutIn Consistency Offset

• Moved Sleep 1 Drive On and Sleep 1 Drive Off to Factory Settings from Advanced Settings

• Moved Stir On and Stir Off to Advanced Settings from Factory Settings

• Added Storage Refrigeration to Storage Settings

• Storage CutIn changed to 37.5°F (was 37°F)

• Moved Pressure Sensing and Liquid Sensing to Factory Settings

• Added Clean Options to Utilities page 1

• Moved Clean Lockout to Clean Options from Utilities page 1

• Added Clean History Log to Clean Options

Service Manual #513659 iii Model F231

Page 6

VERSION 17.19

Released on 9/8/10

Note: They are few initial machines with 15.19 (8/23/10) where cutout consistency was 70, then pulleys were

changed. T wo machines with 16.19 had 60 as cutout limit, then some minor internal reset timers were changed

and 17.19 released on 9/8/10

• Consistency Limit changed to 60 (was 110 for 1 phase / 80 for 3 phase)

• Moved Stir On and Stir Off to Factory Settings from Basic Settings

• Enable CutOut Temp and CutOut Temp moved to Basic Settings from Factory Settings

• Sleep 1 Drive Off changed to 600 seconds (was 300 seconds)

• Sleep 2 CutIn changed to 33°F (was 38°F)

• Sleep 2 CutOut changed to 30.5°F (was 30°F)

(continued on next page)

VERSION 17.19 (CONTINUED)

• Storage CutOut changed to 32°F (was 31°F)

• Storage Offset changed to 4°F (was 2°F)

• Storage Off Time changed to 13 min (was 2 min)

• Storage On Time changed to 130 sec (was 200 sec)

• Storage Max On changed to 3 min (was 10 min)

• Storage Recovery changed to 4 min (was 1 min)

• Clean Lockout Period moved to Factory Settings from Storage Settings

• Touchpad Lockup moved to Utilities from User Preferences

• Date Format added to Time and Date

• Added second Utilities page

• Changed Utilities page 1 to be accessible to Manager passcode

• Testing and Manual Operation, Restore Factory Defaults, Clear Error Log and Clear Statistics moved to

Utilities page 2 from page 1

• Added Product Selection, Export Machine Stats to Utilities page 1

• Removed Clear EEPROM Map from Utilities

• Added Motor Zero Load Calibration, Restore Motor Table Defaults and Reset Unit Confi guration to Utilities

page 2

Service Manual #513659 iv Model F231

Page 7

TABLE OF

CONTENTS

Section Description Page

1 Description and Specifi cations

1.1 Description .................................................................................................. 1

1.2 Specifi cations ............................................................................................. 2

2 Installation Instructions

2.1 Safety Precautions ..................................................................................... 5

2.2 Shipment and Transit .................................................................................. 5

2.3 Machine Installation .................................................................................... 5

2.4 Installing Permanent Wiring ........................................................................ 5

2.5 Initial Startup of IntelliTec2™ ......................................................................6

3 Initial Set-Up and Operation

3.1 Operator’s Safety Precautions .................................................................... 9

3.2 Operating Controls and Indicators .............................................................. 9

3.3 Disassembly of Machine Parts ................................................................... 10

3.4 Cleaning Disassembled Parts ....................................................................11

3.5 Sanitizing Machine Parts ............................................................................11

3.6 Cleaning the Machine ................................................................................. 11

3.7 Assembling the Machine ............................................................................12

3.8 Sanitizing ....................................................................................................12

3.9 Freeze Down and Operation ......................................................................13

3.10 Fine Consistency Adjustment ..................................................................... 13

3.11 Mix Information ........................................................................................... 14

4 Maintenance and Adjustments

4.1 Accessing Control Readings and Settings .................................................15

4.2 Navigation and Modifying Settings ............................................................. 15

4.3 User Interface Screens ............................................................................... 15

4.4 Performance Screens ................................................................................. 16

4.5 Settings Screens ........................................................................................ 16

4.6 Utilities Screens .......................................................................................... 18

4.7 Errors & Statistics Screens ......................................................................... 21

4.8 Updating Firmware .....................................................................................23

4.9 Drive Belt Tension Adjustment ....................................................................24

4.10 Condenser Cleaning ................................................................................... 25

4.11 Preventative Maintenance .......................................................................... 25

4.12 Extended Storage ....................................................................................... 25

Page 8

Section Description Page

5 Refrigeration System

5.1 Refrigeration System .................................................................................. 27

5.2 Refrigerant Recovery and Evacuation ........................................................ 27

5.3 Refrigerant Charging ..................................................................................28

5.4 Compressor ................................................................................................29

5.5 Condenser ..................................................................................................30

5.6 Valves ......................................................................................................... 30

A. Thermostatic Expansion Valve (TXV) ..................................................................30

B. Automatic Expansion Valve (AXV) .......................................................................31

C. Check Valve .........................................................................................................32

D. High Pressure Cutout ........................................................................................... 32

E. Hot Gas Bypass ...................................................................................................32

F. Evaporator Pressure Regulator (EPR) .................................................................33

G. Water Valve (Water Cooled Models Only) ............................................................ 34

5.7 Solenoid ...................................................................................................... 34

5.8 Filter Drier ................................................................................................... 36

5.9 Capillary Tube .............................................................................................36

6 Electrical and Mechanical Control Systems

6.1 IntelliTec2™ Control ................................................................................... 37

6.2 Contactors .................................................................................................. 37

6.3 Drive Motor .................................................................................................38

6.4 Capacitors .................................................................................................. 39

6.5 Gearbox ...................................................................................................... 39

6.6 Condenser Fan Motor (Air-Cooled Only) .................................................... 39

6.7 Spigot Switch .............................................................................................. 40

6.8 Temperature Control Sensor ......................................................................41

7 Troubleshooting

7.1 Error Codes ................................................................................................ 43

7.2 Troubleshooting .......................................................................................... 44

7.3 Troubleshooting - Machine .........................................................................46

8 Replacement Parts

8.1 Decals and Lubrication ...............................................................................47

8.2 Panels and Screws ..................................................................................... 47

8.3 Auger Shaft and Faceplate Parts ...............................................................48

8.4 Air Plenum Kit ............................................................................................. 49

8.5 Internal Components .................................................................................. 50

8.6 Spigot Assembly ......................................................................................... 52

8.7 Front ........................................................................................................... 52

8.8 Wiring Diagrams ......................................................................................... 53

Page 9

SECTION 1

INTRODUCTION

1.1 DESCRIPTION

The Stoelting F231 fl oor machine is gravity fed. The

machine is equipped with the IntelliTec2™ control which

provides a uniform product. The F231 is designed to

operate with almost any type of commercial soft serve or

non-dairy mixes available, including: ice milk, ice cream,

yogurt, and frozen dietary desserts.

This manual is designed to assist qualifi ed service per-

sonnel and operators in the installation, operation and

maintenance of the Stoelting F231 gravity machine.

Figure 1-1 Model F231

Service Manual #513659 1 Model F231

Page 10

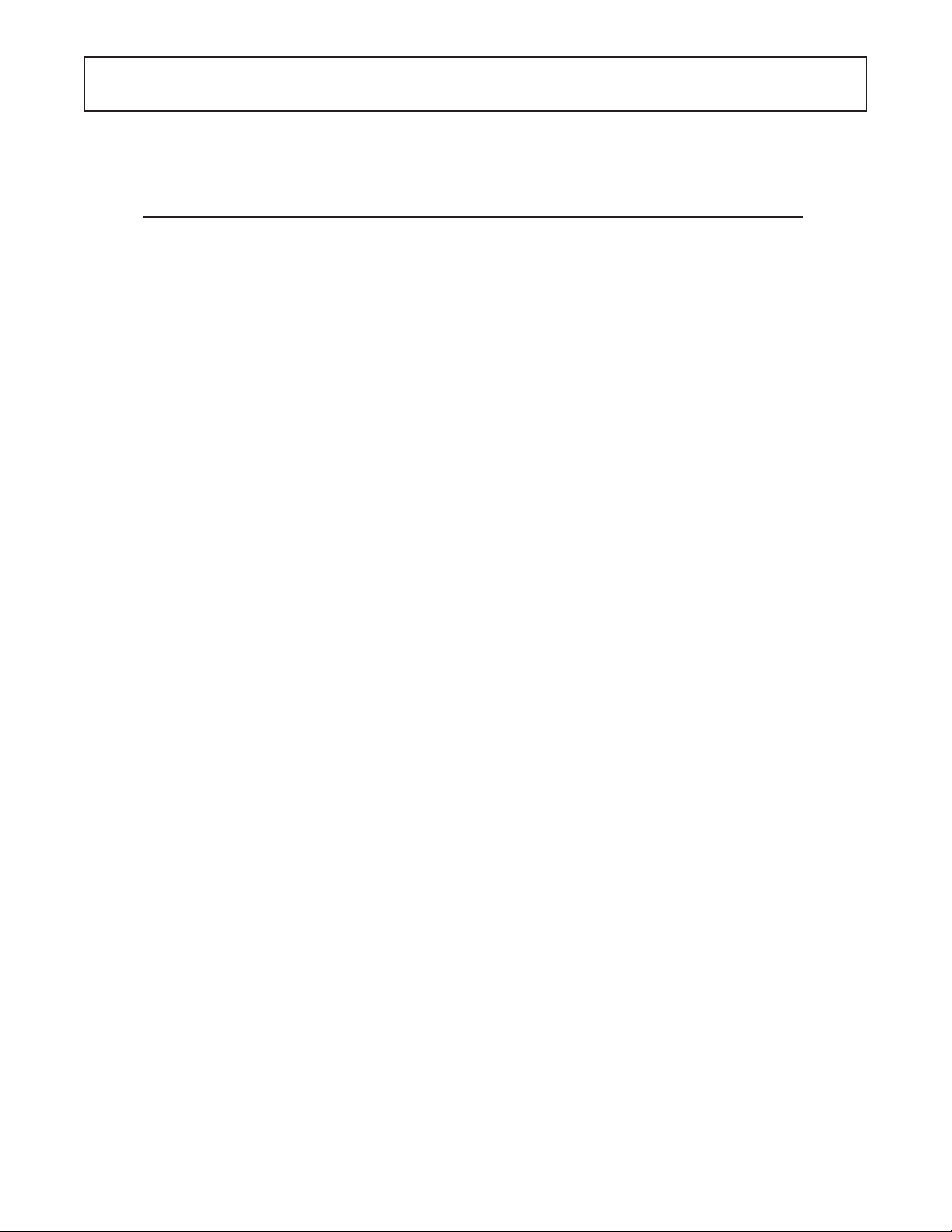

1.2 SPECIFICATIONS

Figure 1-2 Dimension Specifi cations (variations on spigot handles and casters available)

Model F231

Dimensions Machine as shipped

width 19-1/4’’ (48,9 cm) 32’’ (81,3 cm)

height 58-1/4’’ (148,0 cm) 60’’ (152,4 cm)

depth 28’’ (71,1 cm) 39’’ (99,1 cm)

Weight 400 lbs (181,4 kg) 470 lbs (213,1 kg)

Electrical 1 Phase, 208-240 VAC, 60Hz 3 Phase, 208-240 VAC, 60Hz

running amps 12A 10A

connection type NEMA 6-20P power cord provided NEMA L15-20P power cord provided

International Option 1 Phase, 220-240 VAC, 50Hz

Compressor 12,000 Btu/hr (R-404A)

Drive Motor Two - 3/4 hp

Air Flow Air cooled units require 3” (7,6 cm) air space on both sides

Water cooled units require 1/2” N.P.T. water and drain fi ttings.

Plumbing Fittings

Maximum water pressure of 130 psi. Minimum water fl ow rate of 3 GPM. Ideal

EWT of 50°-70°F

Hopper Volume Two - 3 gallon (11,35 liters)

Freezing Cylinder

Volume

Service Manual #513659 2 Model F231

Two - 0.85 gallon (3,22 liters)

Page 11

Menu Display F231

Basic Enable Control Consistency/Consistency

CutOut Consist Offset 7

CutIn Consist Offset 20

CutIn Temp 19.5 °F

CutOut Temperature 19 °F

Cycles In Serve Mode 20

Advanced Standby On Time 10 sec

Standby Off Time 360 sec

Standby Time 120 min

Stir On 15 sec

Stir Off 600 sec

Sleep 2 CutIn 33 °F

Sleep 2 CutOut 30.5 °F

Default Off Time 300 sec

Storage Storage Refrigeration Active

Storage CutIn 37.5 °F

Storage CutOut 32 °F

Storage Offset 4 °F

Storage Off Time 13 min

Storage On Time 130 sec

Storage Max On 3 min

Storage Recovery 4 min

Storage Too Warm 50 °F

Storage Too Warm 2 hr

F231

Refrigerant R-404A

Charge

Suction Pressure

(at 72°F)

Discharge Pressure 225-235 psig

Hot Gas Bypass

Pressure

EPR Valve 68-70 psig

Service Manual #513659 3 Model F231

One Cylinder 18-22 psig

Both Cylinders 22-27 psig

14 psig (only hopper running)

(W/C) 32 oz

(A/C) 42 oz

Hopper Only 14 psig

Page 12

Sleep 2 CutIn

y

Sleep 2 Cutout

PUSH TO FREEZE or Spigot Pull

PUSH TO FREEZE or Spigot Pull

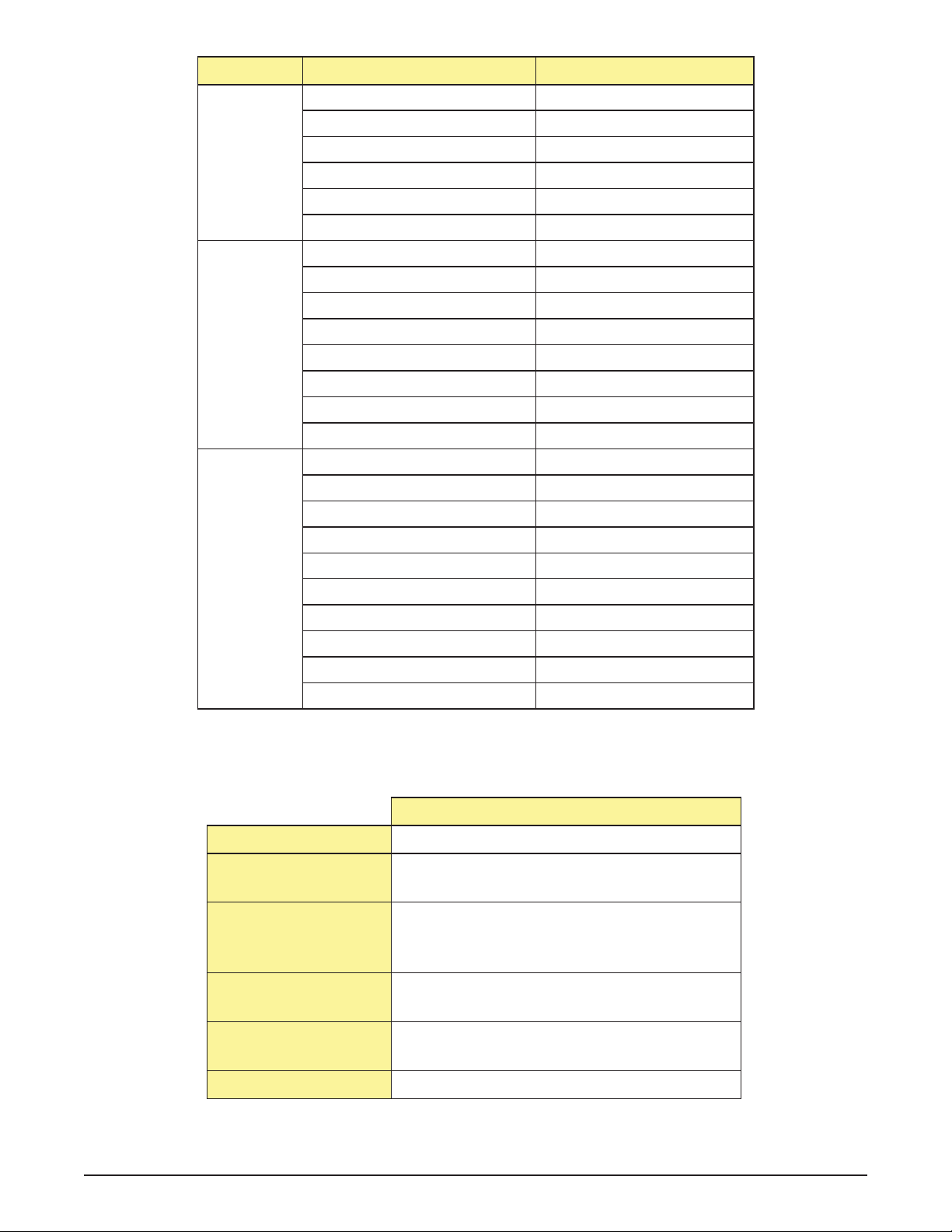

IntelliTec2™ Control Modes of Operation

Sleep 2 CutIn

Standby

Off Time

Standby Mode Sleep 1 Mode Serve Mode / Serve 2 Mode** Sleep 2 Mode

Standby

On Time

Standby

Time

Time* Sleep 2 CutIn*

or

PUSH TO FREEZE or Spigot Pull

CutIn

Consistency

Temperature

Freezing Cycle

CutOut

Consistency

Cycles Until Sleep* Standb

* Resets any time the PUSH TO FREEZE button is pressed or a spigot is pulled. In order for the mode to change, it has to go through its normal

the freezer will start up in the Serve mode.

1) A stir cycle will start in each mode. The cycle is independent of the freezing cycle.

2) Normal start up mode is Sleep 1 when the number of cycles is set below 99. When cycles are set higher than 99,

3) Sensor failure will keep the control in Serve and Standby modes only.

cycles without reset.

** After the Cycles Until Sleep number is met, Serve 2 Mode goes directly into Sleep 2 Mode.

Note:

active for the Consistency/Consistency setting and monitors CutIn Consistency. Both use CutOut Consistency.

4) A freeze cycle will reset the stir cycle.

5) Serve Mode is active for the Temperature/Consistency setting and monitors CutIn Temperature. Serve 2 Mode is

Temperature

Service Manual #513659 4 Model F231

Page 13

SECTION 2

INSTALLATION INSTRUCTIONS

2.1 SAFETY PRECAUTIONS

Do not attempt to operate the machine until the safety

precautions and operating instructions in this manual are

read completely and are thoroughly understood.

Take notice of all warning labels on the machine. The labels have been put there to help maintain a safe working

environment. The labels have been designed to withstand

washing and cleaning. All labels must remain legible for

the life of the machine. Labels should be checked periodically to be sure they can be recognized as warning labels.

If danger, warning or caution labels are needed, indicate

the part number, type of label, location of label, and quantity

required along with your address and mail to:

STOELTING

ATTENTION: Customer Service

502 Hwy. 67

Kiel, Wisconsin 53042

2.2 SHIPMENT AND TRANSIT

The machine has been assembled, operated and inspected

at the factory. Upon arrival at the fi nal destination, the

entire machine must be checked for any damage which

may have occurred during transit.

With the method of packaging used, the machine should

arrive in excellent condition. THE CARRIER IS RESPONSIBLE FOR ALL DAMAGE IN TRANSIT, WHETHER

VISIBLE OR CONCEALED. Do not pay the freight bill

until the machine has been checked for damage. Have

the carrier note any visible damage on the freight bill. If

concealed damage and/or shortage is found later, advise

the carrier within 10 days and request inspection. The

customer must place claim for damages and/or shortages

in shipment with the carrier. Stoelting, Inc. cannot make

any claims against the carrier.

2.3 MACHINE INSTALLATION

WARNING

Installation must be completed by a qualifi ed

electrician/refrigeration specialist.

Incorrect installation may cause personal injury,

severe damage to the machine and will void factory warranty.

A. Uncrate the machine.

B. Install the four casters. Turn the threaded end

into the machine until no threads are showing. To

level, turn out casters no more than 1/4” maximum,

then tighten all jam nuts.

C. The machine must be placed in a solid level

position.

NOTE

Accurate leveling is necessary for correct drainage

of freezing cylinder and to insure correct overrun.

D. Machines with air cooled condensers require a

minimum of 3” (7,5cm) of space on both sides

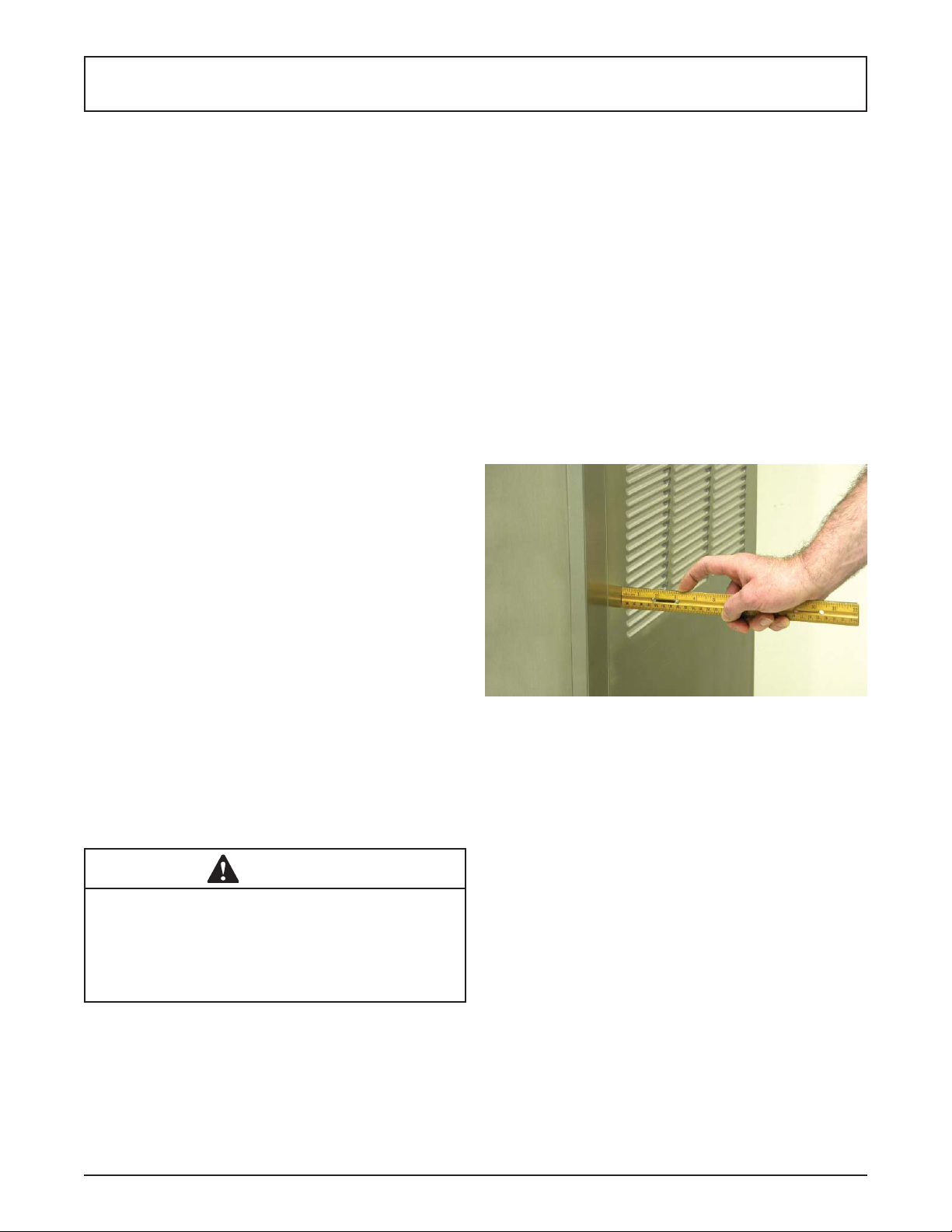

for proper circulation. (Fig. 2-1)

E. Machines that have a water cooled condenser

require 1/2” NPT supply and drain fi ttings.

Figure 2-1 Space and Ventilation Requirements

2.4 INSTALLING PERMANENT WIRING

To install wiring follow the steps below:

A. Refer to the nameplate on the side panel of the

machine for specifi c electrical requirements. Make

sure the power source in the building matches

the nameplate requirements.

B. Remove the back panel and the junction box

cover located at the bottom of the machine.

C. Install permanent wiring according to local code.

Installation of the machine involves moving the machine

close to its permanent location, removing all crating, setting in place, assembling parts, and cleaning.

Service Manual #513659 5 Model F231

Page 14

2.5 INITIAL STARTUP OF INTELLITEC2™

Before completing the following procedures, follow the

steps in Section 3 to disassemble, clean, lubricate and

sanitize the machine.

NOTE

IntelliT ec2™ startup must be completed by a trained

authorized service provider or Stoelting distributor.

A. Locate a copy of the latest fi rmware fi le (uezimage.

rom) and service contact fi le (info.txt).

B. Modify the info.txt fi le with information from the

service company using the instructions in the fi le.

C. Put the fi rmware fi le and service contact fi le onto

the root level of a USB fl ash drive (do not put the

fi les into any folder).

D. Insert the fl ash drive into the USB port of the

machine.

E. Fill the mix containers in the cabinet with mix.

F. Connect power to the machine and press the

Main Power On/Off button and the Pump On/Off

buttons.

SETTING CONTACT INFORMATION

A. When the Current Status screen is displayed,

press the left arrow button to access the passcode

selection screen. Press the right arrow, SET, then

the SEL button.

D. The screen will change and show “File Found” for

a quick second while it updates the information.

E. After updating the contact information, the screen

will show the Service Contact Information page.

Figure 2-4

F. Press the left arrow button to go back to the Current

Status screen. Then press the right arrow to go

to the Main Menu.

NOTE

If you press the left arrow from the Current Status

screen it will ask for the password. Press the right

arrow, SET, then the SEL button.

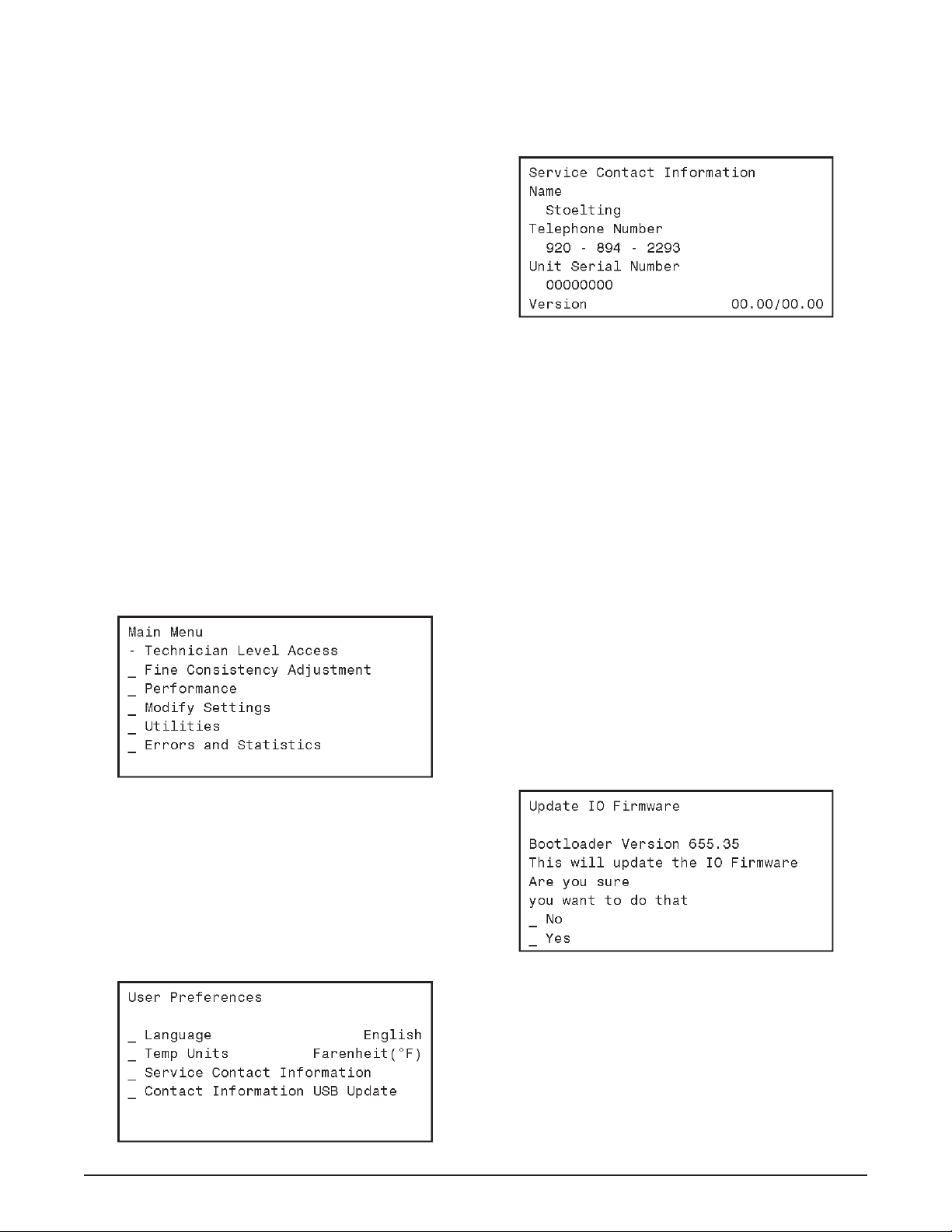

UPDATING FIRMWARE

If the control has the latest fi rmware, skip this section and

go to the Motor Calibration section.

A. Move the cursor to the Utilities option and press

the SEL button. Then move the cursor to the Next

Utilities Menu and press the SEL button.

B. On the Utilities (2 of 2) screen move the cursor

to the Update IO Firmware option and press the

SEL button.

C. On the Update IO Firmware screen select the

Yes option.

Figure 2-2

B. After the password is accepted, use the arrows to

move the cursor to the Modify Settings option and

press the SEL button. Then move the cursor to

the User Preferences and press the SEL button.

C. On the User Preferences screen move the cursor

to the Contact Information USB Update and press

the SEL button.

D. This process will take about 4 minutes. DO NOT

INTERRUPT this upload. The control will go

through several process steps and return to the

Main Menu when the update is completed.

Figure 2-3

Service Manual #513659 6 Model F231

Figure 2-5

Page 15

E. Press the left arrow button to go back to the Current

Status screen. Then press the right arrow to go

to the Main Menu.

NOTE

If you press the left arrow from the Current Status

screen it will ask for the password. Press the right

arrow, SET, then the SEL button.

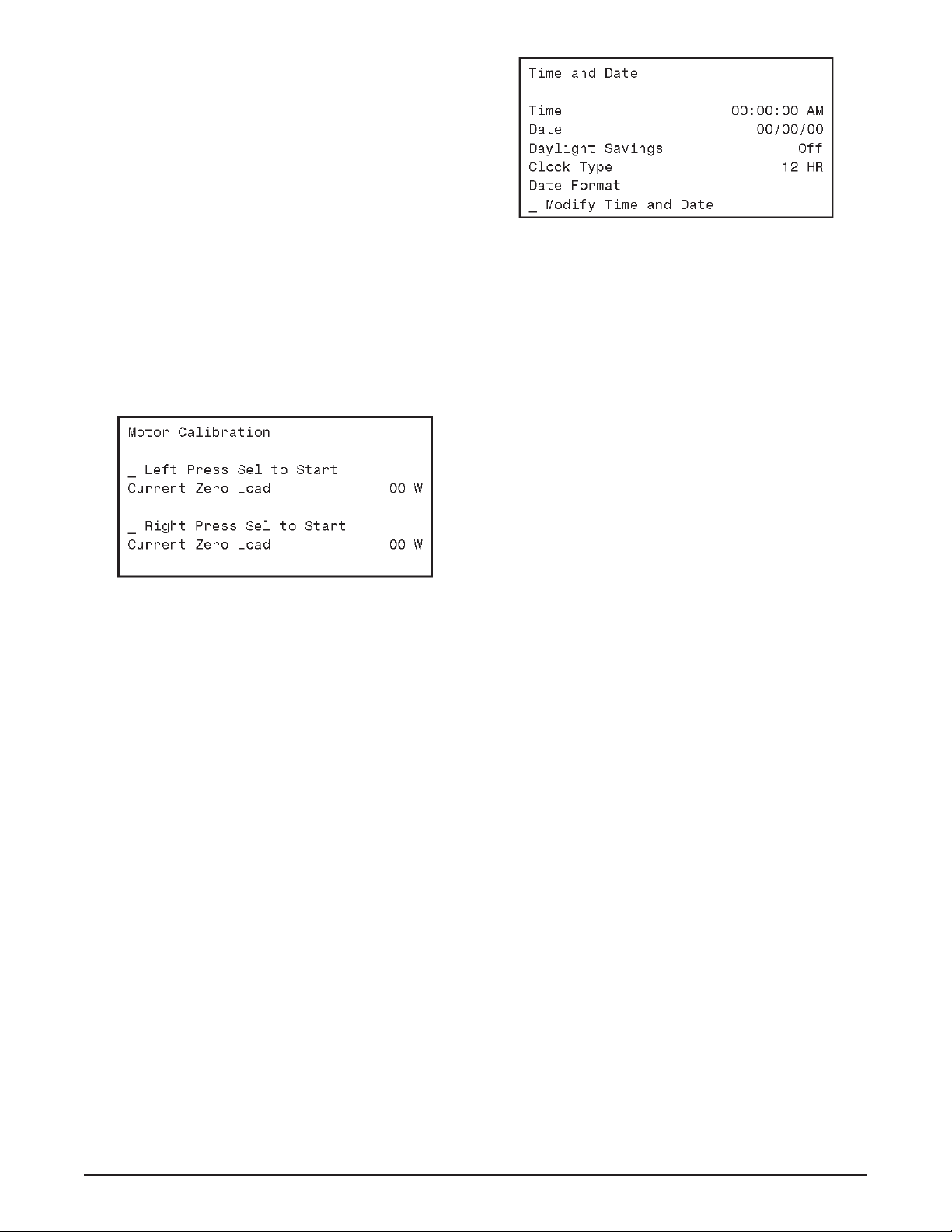

MOTOR CALIBRATION

Before starting the motor calibration, be sure there is liquid

mix in the freezing cylinder.

A. Select the Utilities option, then the Next Utilities

option. Select the Unit Calibration then the Motor

Calibration option.

B. Move the cursor over the Left side and press the

SEL button then move the cursor over the Right

side and press the SEL button.

Figure 2-6

NOTE

The motor calibration can be done for both sides

simultaneously.

C. After the calibration is complete, press the Main

Power On/Off button to turn the machine off and

remove the USB fl ash drive.

SETTING CONTROL

A. Press the Main Power On/Off button.

B. When the Current Status screen is displayed,

press the left arrow button to access the passcode

selection screen. Press the right arrow, SET, then

the SEL button.

C. Move the cursor to the Modify Settings option

and press the SEL button. Then move the cursor

to the Time and Date option and press the SEL

button and adjust the settings as required.

1. Press the SEL button to enter the Modify Time

and Date screen.

2. Move the cursor to the setting that needs to

be changed and press the SET button.

3. Use the arrow buttons to change the setting

and press the SET button to save the change.

Figure 2-7

D. Press the Push to Freeze button and let the

machine cycle 4-5 times.

E. Draw product from the barrel immediately after

the compressor cycles off after the fi fth time and

test the product for consistency and temperature.

F. Adjust the product consistency by increasing or

decreasing the CutIn Consist Offset setting.

G. If the machine short cycles (short on/off

compressor run times), change the settings as

follows:

1. If the product is too soft, increase the CutOut

Consist Offset.

2. If the product is too fi rm, decrease the CutIn

Consist Offset.

H. Allow the machine to cycle 3-4 more times after

making the adjustment.

I. After 3-4 cycles, draw product from the barrel

immediately after the compressor cycles on.

If the product is servable when the compressor

cycles on but it is too fi rm at the end of the cycle,

reduce the CutOut Consist Offset.

SETTING DISCHARGE PRESSURE ON WATER

COOLED MACHINES

A. Water cooled machines require the water

condenser valves to be adjusted to maintain

a discharge pressure of 225-235 psig. When

adjusting the discharge pressure the machine

must be under a full load with both cylinders

running and the hopper running (if applicable).

Service Manual #513659 7 Model F231

Page 16

Service Manual #513659 8 Model F231

Page 17

SECTION 3

INITIAL SET-UP AND OPERATION

3.1 OPERATOR’S SAFETY PRECAUTIONS

SAFE OPERATION IS NO ACCIDENT; observe these

rules:

A. Know the machine. Read and understand the

Operating Instructions.

B. Notice all warning labels on the machine.

C. Wear proper clothing. Avoid loose fi tting garments,

and remove watches, rings or jewelry that could

cause a serious accident.

D. Maintain a clean work area. Avoid accidents by

cleaning up the area and keeping it clean.

E. Stay alert at all times. Know which switch, push

button or control you are about to use and what

effect it is going to have.

F. Disconnect power for maintenance. Never

attempt to repair or perform maintenance on the

machine until the main electrical power has been

disconnected.

G. Do not operate under unsafe operating conditions.

Never operate the machine if unusual or excessive

noise or vibration occurs.

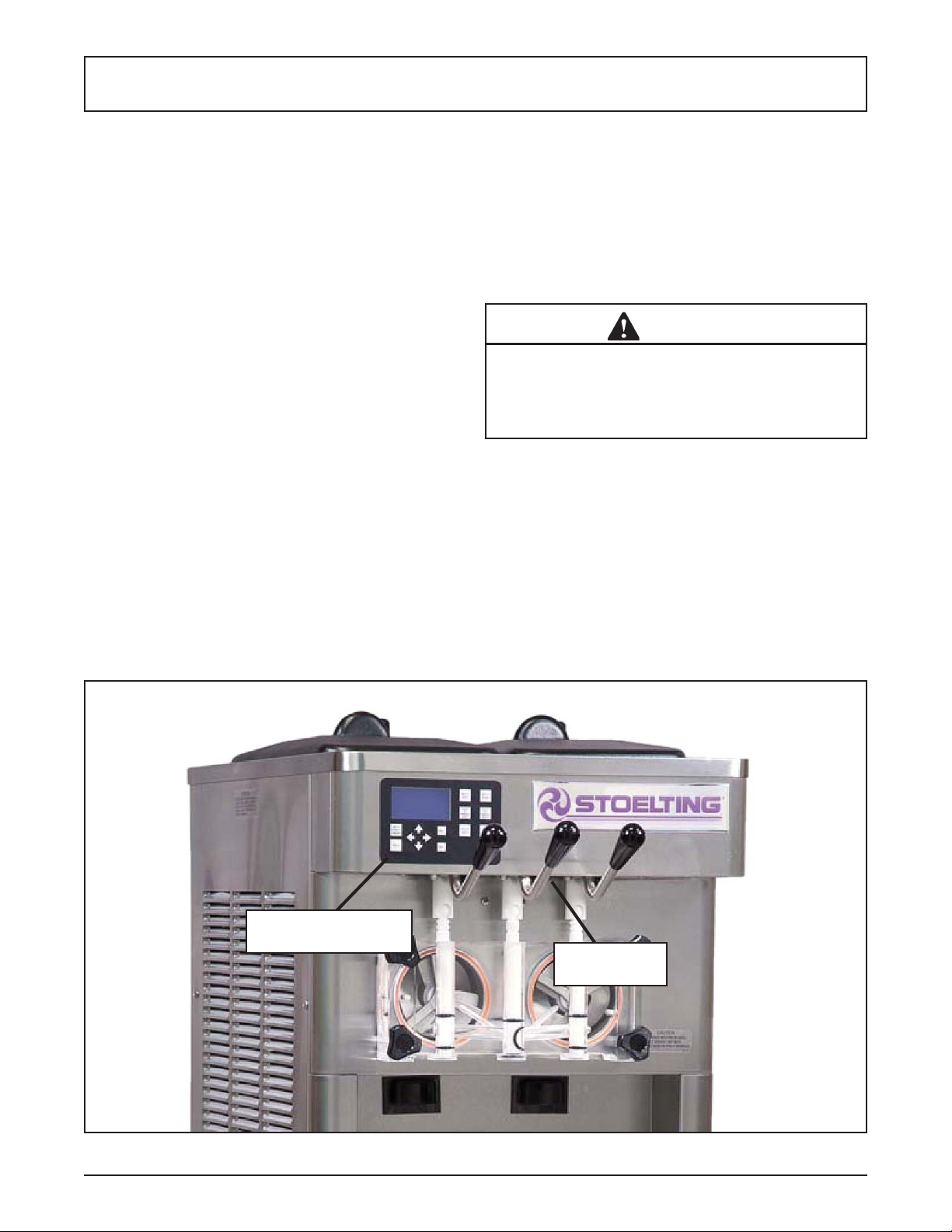

3.2 OPERATING CONTROLS AND INDICATORS

Before operating the machine, it is required that the operator know the function of each operating control. Refer

to Figure 3-1 for the location of the operating controls on

the machine. For the information regarding error codes

displayed on the control panel, refer to the troubleshooting

section of this manual.

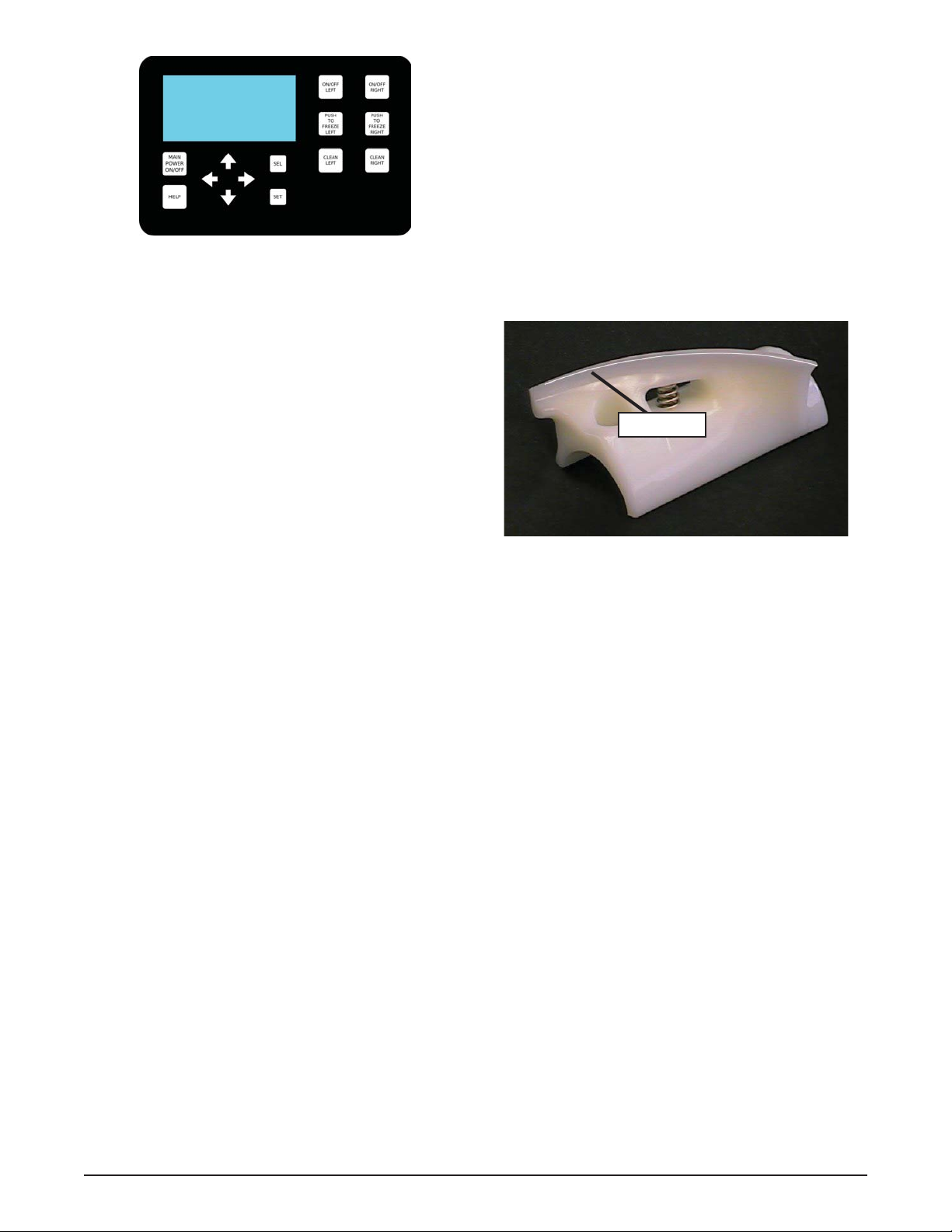

A. INTELLITEC2™ TOUCHPAD

WARNING

High voltage will shock, burn or cause death. The

OFF-ON switch must be placed in the OFF position

prior to disassembling for cleaning or servicing. Do

not operate machine with panels removed.

Main Power On/Off

The Main Power button is used to supply power to the

IntelliTec2™ control, the freezing cylinder circuits and

the storage refrigeration system. When the machine is

fi rst plugged in, the control defaults to the On status with

power to the hopper only. If the Main Power On/Off button

is pressed when the machine is on, the machine will turn

off and a status message will be displayed on the screen.

IntelliTec2™ Control

(See Figure 3-2)

Figure 3-1 Machine Controls

Service Manual #513659 9 Model F231

Dispense

Rate Adjustor

Page 18

Figure 3-2 IntelliTec2™ Control

Help

Pressing the Help button will display help information

dependant on the cursor’s location. Pressing the Help

button again will exit the help screen.

Selection Button (SEL)

The SEL button is used by technicians to select menu

options.

Set Button (SET)

The SET button is used by technicians to save changes

when modifying control settings.

On/Off Button

Power to the freezing cylinders can then be controlled

with the On/Off Left and On/Off Right switches.

Push to Freeze Button

Pressing the PUSH TO FREEZE button initiates “Serve

Mode”.

Clean Button

The CLEAN button initiates “Clean Mode”.

Arrow Buttons ()

The arrow buttons are used by technicians to navigate

through the control readings and settings.

B. SPIGOT SWITCH

The spigot switch is mounted to the spigot cam assembly

behind the header panel. When the spigot is opened to

dispense product, the spigot switch opens and the “Serve

Mode” begins.

C. DISPENSE RATE ADJUSTOR

The dispense rate adjustor is located under the header

panel, to the immediate right of the spigot handles. Turning

the knob counterclockwise will decrease the dispense rate.

D. MIX LOW LIGHTS

The mix low lights are located at the back of the F231.

There is a light for each freezing cylinder. A steady light

signifi es a low mix condition. A blinking light signifi es an

error. The light will automatically turn off when the condition has been resolved.

E. USB ACCESS PORT

The USB access port is located on the right side panel

of the machine. The port is used by technicians to import

fi rmware and export machine statistics.

3.3 DISASSEMBLY OF MACHINE PARTS

Before using the machine for the fi rst time, complete

machine disassembly, cleaning and sanitizing procedures need to be followed. Routine cleaning intervals

and procedures must comply with the local and state

health codes. Inspection for worn or broken parts should

be made at every disassembly of the machine. All worn

or broken parts should be replaced to ensure safety to

both the operator and the customer and to maintain good

machine performance and a quality product. Check the

wear line on the auger fl ights on a regular basis (Fig.

3-3) and replace as needed. Frequency of cleaning must

comply with the local health regulations.

Wear Line

Figure 3-3 Auger Flight Wear

To disassemble the machine, refer to the following steps:

A. REMOVING MIX

For the fi rst time cleaning the machine, skip to part B.

Disassembly of Front Door.

1. Press the Clean button. After mix has melted

(about 5 minutes) open the spigot to drain the

mix.

2 Fill the hopper with 2 gallons (8 liters) of cool tap

water.

3. Press the Clean button to run the machine. After

30 seconds press the Clean button again to stop

the auger.

4. Drain the water out of the machine.

NOTE

If the water does not drain clear, repeat steps 2-4.

5. Use Stera-Sheen or equivalent sanitizing solution

mixed according to manufacturer’s instructions to

provide a 100 parts per million strength solution.

Mix sanitizer in quantities of no less than 2

gallons of 90° to 110°F (32°C to 43°C) water. Any

sanitizer must be used only in accordance with

the manufacturer’s instructions.

6. Pour the sanitizer into the hopper.

7. Using brushes provided, scrub the hopper.

8. After 5 minutes, drain the sanitizer out of the

freezing cylinder.

Service Manual #513659 10 Model F231

Page 19

B. DISASSEMBLY OF FRONT DOOR

1. Turn the machine off by pressing the Main Freezer

Power Off/On button on the IntelliTec2™ control.

2. Remove the knobs on the front door.

3. Remove the front door by pulling it off the studs.

4. Remove the spigot through the bottom of the front

door.

5. Remove all o-rings from parts by fi rst wiping off

the lubrication using a clean towel. Then squeeze

the o-ring upward to form a loop (Fig. 3-4). Roll

the o-ring out of the groove.

Figure 3-4 Removing O-Ring

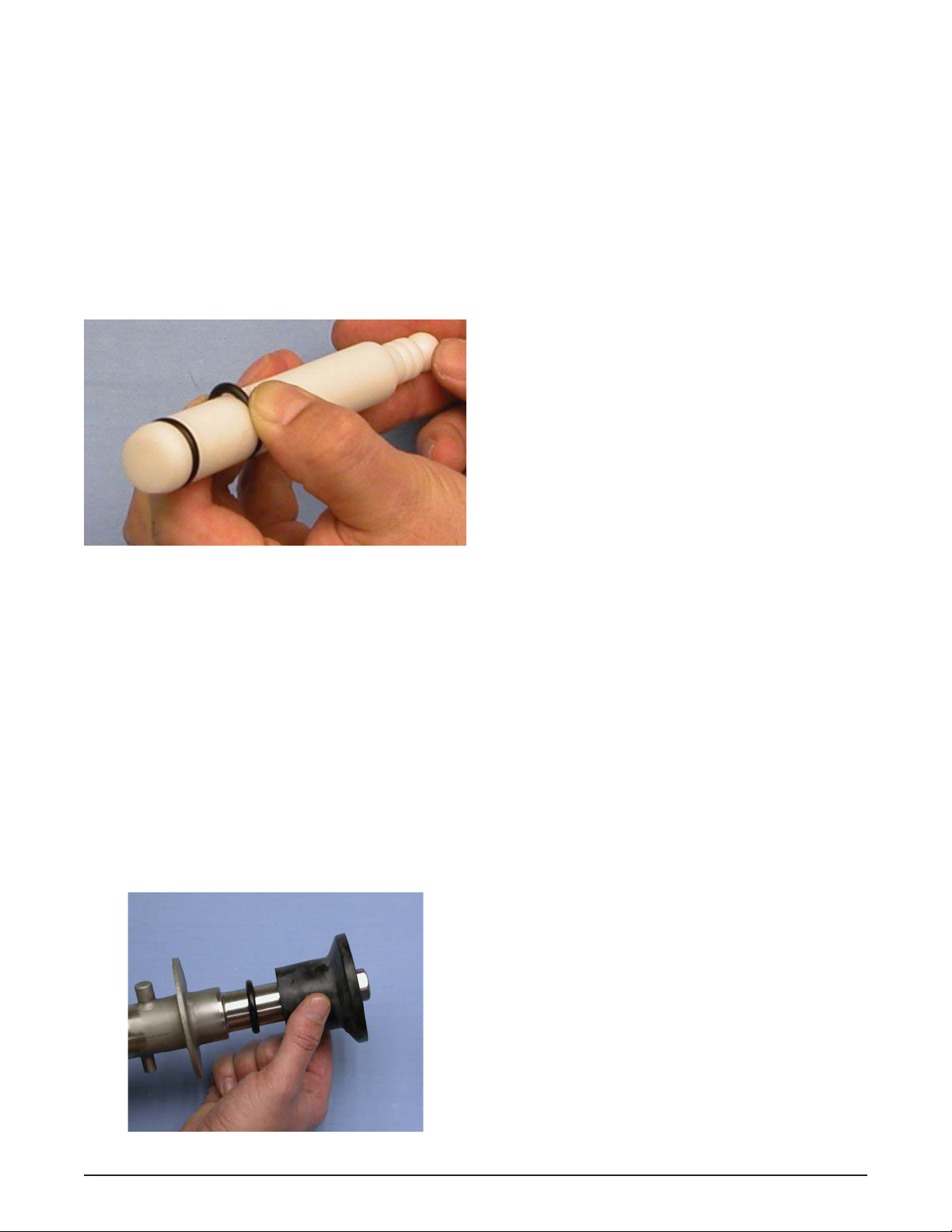

C. DISASSEMBLY OF AUGER

1. Remove the front auger support and bushing.

2. Remove the auger assembly from the machine.

Pull the auger out of the machine barrel slowly.

As the auger is being pulled out, carefully remove

each of the plastic fl ights with springs.

3. Keep the rear of the auger tipped up once it is

clear of the freezing cylinder to prevent the rear

seal assembly from dropping.

4. Wipe the spline lubricant off of the hex end of the

auger with a paper towel. Remove the rear seal

assembly (Fig. 3-5).

5. Unscrew the springs from the auger fl ights.

3.4 CLEANING DISASSEMBLED PARTS

Disassembled machine parts require complete cleaning,

sanitizing and air drying before assembling. Local and state

health codes will dictate the procedure required. Some

state health codes require a four sink process (pre-wash,

wash, rinse, sanitize, air dry), while others require a three

sink process (without the pre-wash step). The following

procedures are a general guideline only. Consult your

local and state health codes for the procedures required

in your location.

A. Prepare Stera-Sheen or equivalent cleaner in

2 gallons of 90° to 110°F (32° to 43°C) water

following manufacturers instructions. Place all

parts in the solution and clean with provided

brushes.

B. Rinse all parts with clean 90° to 110°F (32° to

43°C) water.

C. Wash the hopper and freezing cylinder with the

Stera-Sheen solution and brushes provided.

D. Clean the rear seal surfaces from the inside of the

freezing cylinder with the Stera-Sheen Solution.

3.5 SANITIZING MACHINE PARTS

A. Use Stera-Sheen or equivalent sanitizing solution

mixed according to manufacturer’s instructions to

provide a 100 parts per million strength solution.

Mix sanitizer in quantities of no less than 2

gallons of 90° to 110°F (32°C to 43°C) water. Any

sanitizer must be used only in accordance with

the manufacturer’s instructions.

B. Place all parts in the sanitizing solution for 5

minutes, then remove and let air dry completely

before assembling in machine.

3.6 CLEANING THE MACHINE

The exterior should be kept clean at all times to preserve

the luster of the stainless steel. A high grade of stainless

steel has been used on the machine to ease cleanup. To

remove spilled or dried mix, wash the exterior with 90° to

110°F (32°C to 43°C) Stera-Sheen solution or equivalent

cleaner and wipe dry.

Do not use highly abrasive materials, as they will mar the

fi nish. Use a soft cloth or sponge to apply the solution.

For best results, wipe with the grain of the steel.

A. Clean the rear seal surface from inside of the

freezing cylinder.

Figure 3-5 Rear Seal Assembly

Service Manual #513659 11 Model F231

Page 20

B. Using sanitizing solution and the large barrel

brush provided, sanitize the freezing cylinder by

dipping the brush in the sanitizing solution and

brushing the inside of the freezing cylinder.

NOTE

Do not let sanitizing solution sit overnight in the

freezing cylinder.

C. Remove the drip tray by pulling from the front

panel. Clean and replace the drip tray.

3.7 ASSEMBLING MACHINE

To assemble the machine parts, refer to the following steps:

NOTICE

Petrol-Gel sanitary lubricant or equivalent must be

used when lubrication of machine parts is specifi ed.

NOTICE

The United States Department of Agriculture and

the Food and Drug Administration require that lubricants used on food processing equipment be certifi ed for this use. Use lubricants only in accordance

with the manufacturer’s instructions.

A. Assemble all o-rings onto parts dry, without

lubrication. Then apply a thin fi lm of sanitary

lubricant to exposed surfaces of the o-rings.

B. Lubricate the rear seal area on the auger shaft

with a thin layer of sanitary lubricant. Install the

rear seal o-ring. Lubricate the outside of the rear

seal o-ring with sanitary lubricant.

C. Lubricate the inside metal surface of the rear

seal and install it onto the auger shaft. DO NOT

lubricate the outside of the rear auger seal (Fig.

3-6).

D. Lubricate the hex drive end of the auger with a

small amount of spline lubricant. A small container

of spline lubricant is shipped with the machine.

E. Screw the springs onto the studs in the plastic

fl ights. The springs must be screwed into the

fl ights completely to provide proper compression.

F. Install the two plastic fl ights onto the rear of the

auger and insert it part way into the freezing

cylinder.

G. Install the remaining plastic fl ights, push the auger

into the freezing cylinder and rotate slowly until

the auger engages the drive shaft.

H. Apply a thin layer of sanitary lubricant to the inside

and outside of the auger support bushing. Install

the bushing onto the auger support and install the

auger support into the front of the auger. Rotate

the auger support so that one leg of the support

points straight up.

I. Apply a thin layer of sanitary lubricant to the

o-rings on the spigot body and install the spigot

body through the bottom of the front door.

K. Apply a thin fi lm of sanitary lubricant to the door

seal o-ring and fi t it into the groove on the rear

of the front door.

M. Place the front door assembly on the mounting

studs and the push front door against the machine

carefully.

N. Secure the front door to the machine by placing

the knobs on the studs and tightening until fi nger

tight. Do not overtighten. A proper o-ring seal can

be observed through the transparent front door.

3.8 SANITIZING

Sanitizing must be done after the machine is clean and

just before the machine is fi lled with mix. Sanitizing the

night before is not effective. However, you should always

clean the machine and parts after using it.

NOTE

The United States Department of Agriculture and

the Food and Drug Administration require that all

cleaning and sanitizing solutions used with food

processing equipment be certifi ed for this use.

When sanitizing the machine, refer to local sanitary regulations for applicable codes and recommended sanitizing

products and procedures. The frequency of sanitizing

must comply with local health regulations. Mix sanitizer

according to manufacturer’s instructions to provide a 100

parts per million strength solution. Mix sanitizer in quantities of no less than 2 gallons of 90°F to 110°F (32°C to

43°C) water. Allow sanitizer to contact the surfaces to be

sanitized for 5 minutes. Any sanitizer must be used only

Figure 3-6 Lubricate Rear Seal

Service Manual #513659 12 Model F231

in accordance with the manufacturer’s instructions.

Page 21

A. Prepare 2 gallons of Stera-Sheen sanitizing

solution following the manufacturer’s instructions.

B. Install the mix inlet regulator into the hopper.

C. Pour the sanitizing solution into the hopper.

D. Make sure the display shows the freezing cylinder

is off. If it is not, press the On/Off Left or On/Off

Right button to turn it off.

NOTE

If the freezing cylinder is not off, the control will

not go into Clean mode. This is to protect from accidentally going into Clean mode.

E. Press the CLEAN button.

F. Check for leaks.

1. Check for leaks at the front door seals.

2. Check the drain tray located under the front

door for leaks coming from the rear of the rear

auger seal.

G. Using a sanitized soft bristle brush (or equivalent)

dipped in sanitizing solution, clean the hopper

sides, mix inlet regulator and underside of the

hopper cover.

H. After fi ve minutes, open the spigot to expel

sanitizing solution. Drain all of the solution from

the machine.

I. When the solution has drained, press the CLEAN

button to stop the auger. Allow the freezing cylinder

to drain completely.

The machine is now sanitized and ready for adding mix.

3.9 FREEZE DOWN AND OPERATION

A. Sanitize immediately before use.

B. Make sure the display shows the freezing cylinder

is off. If it is not, press the On/Off Left or On/Off

Right button to turn it off.

C. Fill the hopper with at least 2.5 gallons of mix.

D. Place a container under the spigot and open the

spigot to allow the mix to fl ush out about 8 ounces

(0.23 liters) of sanitizing solution and liquid mix.

E. Press the On/Off button for the cylinder.

F. Press the PUSH TO FREEZE button.

G. When the product is at 75% consistency, the

display will read “SERVE”. Open the spigot to

dispense product.

H. The machine dispenses product at a reasonable

draw rate. If the machine is overdrawn, the result

is a soft product or a product that will not dispense

at all. If this occurs, allow the machine to run for

approximately 30 seconds before dispensing more

product. A dispense rate adjustor is located under

the header panel, to the immediate right of the

spigot handle. Turning the knob counterclockwise

will decrease the dispense rate.

I. Do not operate the machine when the MIX LOW

message is displayed. Refi ll the mix container

immediately.

NOTE

The control has a standby mode for Serve 1 and

a sleep mode for Serve 1 and Serve 2. After a

preset number of freezing cycles in Serve 1, it will

enter the standby mode (followed by sleep mode)

and remain there until someone draws product or

presses the PUSH TO FREEZE button. In Serve 2

the control directly goes into the Sleep 2 mode. In

the sleep mode, the machine will keep the product

below 41°F (5°C). Sleep modes do not take the

place of cleaning and sanitizing. Federal, State,

and local regulatory agencies determine frequency

of cleaning and sanitizing.

3.10 FINE CONSISTENCY ADJUSTMENT

If the product consistency needs to be adjusted, use the

Fine Consistency Adjustment. To access the setting, the

Associate level password must be entered. Follow the

steps below for the Fine Consistency Adjustment.

A. Press the left arrow from the Current Status

screen.

B. Press the right arrow then the SEL button from

the Password screen. After the password is

accepted, move the cursor to the Fine Consistency

Adjustment option and press the SEL button.

C. On the Fine Consistency Adjustment screen, press

the SEL button and use the arrows to modify the

setting. Adjust the Fine Consistency higher to

increase the consistency or lower to decrease

the consistency.

D. Press the SET button to save the changes. Make

adjustments in increments of 5 for best results.

Service Manual #513659 13 Model F231

Page 22

3.11 MIX INFORMATION

Mix can vary considerably from one manufacturer to

another. Differences in the amount of butterfat content

and quantity and quality of other ingredients have a

direct bearing on the fi nished frozen product. A change

in machine performance that cannot be explained by a

technical problem may be related to the mix.

Proper product serving temperature varies from one

manufacturer’s mix to another. Mixes should provide a

satisfactory product in the 20°F to 24°F range. Diet and

low-carb mixes typically freeze to proper consistency at

higher temperatures.

When checking the temperature, stir the thermometer in

the frozen product to get an accurate reading.

Old mix, or mix that has been stored at too high a temperature, can result in a fi nished product that is unsatisfactory.

To retard bacteria growth in dairy based mixes, the best

storage temperature range is between 33° to 38°F (0.5°

to 3.3° C).

Service Manual #513659 14 Model F231

Page 23

SECTION 4

MAINTENANCE AND ADJUSTMENTS

This section is intended to provide maintenance personnel

with a general understanding of the machine adjustments.

It is recommended that any adjustments in this section

be made by a qualifi ed person.

4.1 ACCESSING CONTROL READINGS AND

SETTINGS

The readings and settings on the IntelliTec2™ control are

accessed by using a keypad sequence. Press the left arrow button from the Current Status screen to access the

passcode input screen.

The specifi c readings and parameters available depend

on the keypad sequence entered. The lowest level is

Associate and has limited access. The Manager level

has access to the majority of screens except Utilities (2

of 2). The Technician level has full access to the control

including the Associate and Manager level options.

Following are the keypad sequences for the three levels

available.

Associate Press the right arrow then the SEL button.

Manager Press the right arrow, up arrow then the

SEL button

Technician Press the right arrow, SET, then the SEL

button

4.2 NAVIGATION AND MODIFYING SETTINGS

Navigating through the IntelliTec2™ screens is done with

the arrow keys on the touchpad. After positioning the cursor on a desired menu, press the SEL button to select

that option. If the option is a setting, press the SET button

to change the value. Use the arrow keys to change the

value. Press the SET button to save the changes.

The SEL button changes the cylinder selection on screens

that show the cylinder.

Pressing the left arrow button from any menu will go back

one screen. Pressing the left arrow button at the Main

Menu screen goes to the Current Status screen.

4.3 USER INTERFACE SCREENS

A. Current Status

Current Status 01/01/01

12:34:56

Left Serve

Right Sleep 1

Storage Left On

Storage Right On

The Current Status screen gives an overview of the

machine's operation. It shows the mode of the freezing

cylinders and the storage refrigeration. If there is an error,

the error text description replaces the status information.

The Service Contact Information screen is accessed from

the Current Status screen. Move the cursor to the Service

Contact Information option and press the SEL button.

B. Service Contact Information

Service Contact Information

Name

Stoelting

Telephone Number

920 - 894 - 2293

Unit Serial Number

00000000

Version 00.00/00.00

The Service Contact Information screen provides the

name and telephone number for service. The default is

Stoelting Technical Customer Service. The Manager and

Technician levels can change the default by selecting

the Modify Contact Information option or by uploading

the info.txt fi le.

C. Main Menu

Main Menu

- Technician Level Access

_ Fine Consistency Adjustment

_ Performance

_ Modify Settings

_ Utilities

_ Errors and Statistics

The Main Menu screen provides access to all the readings and settings on the IntelliTec2™ control. To access

the Main Menu, use one of the keypad sequences from

Section 4.1. The example above shows the options available when entering the Manager or Technician keypad

sequence. The Associate will only see the Fine Consistency Adjustment option.

_ Service Company

Service Manual #513659 15 Model F231

Page 24

D. Fine Consistency Adjustment

B. Performance (2 of 2)

Fine Consistency Adjustment

Cylinder Right

Changing the fine consistency

change the firmness of the

product.

Consistency CutIn Limit 00

Consistency CutOut Limit 00

_ Fine Consistency 000

Product consistency can be adjusted by the Associate

level by using the Fine Consistency Adjustment screen.

Increasing the Fine Consistency number increases the

product consistency (fi rmer product).

The Consistency Limits show the Fine Consistency adjustment added to the Consistency number.

4.4 PERFORMANCE SCREENS

A. Performance (1 of 2)

Performance (1 of 2)

Cylinder Right

Consistency 000.00

Cylinder Temp -000.0°F

Motor Amps 00.000A

Input Voltage 000.0V

Performance (2 of 2)

Cylinder Right

Ambient Temp -000.0°F

Storage Temp -000.0°F

Number of Cycles 000

Error Status No Error

The Performance screens display the current status of

the machine. This screen shows the current ambient

temperature, storage temperature and number of cycles

since the Push to Freeze button was pressed or the spigot

was pulled. Press the left arrow to go to the fi rst screen.

4.5 SETTINGS SCREENS

A. Modify Operating Settings

Modify Operating Settings

_ Basic Settings

_ Advanced Settings

_ Storage Settings

_ User Preferences

_ Time and Date

The Performance screens display the current status of

the machine. These screens are available to the Manager

and Technician levels. Press the right arrow to go to the

second screen.

Cylinder

The performance information displayed is for the selected

cylinder. To change cylinders press the SEL button.

Consistency*

This is the current consistency number of the selected

cylinder. The consistency number represents how thick

or thin the product in the freezing cylinder is. A higher

number means the product is thicker. Go to the Modify

Operating Settings menu to change the operating setting.

Cylinder Temperature

This is the current suction line temperature of the selected

cylinder.

Motor Amps*

This is the current motor amps of the selected cylinder.

Input Voltage*

This is the current voltage of the selected cylinder.

* Only shown when the drive motor is running

This menu provides access to view and change the different operating settings on the machine. The Manager and

Technician levels have access to these screens.

B. Basic Settings

Basic Settings

Cylinder Right

_ Enable Control Consist-Consist

_ CutOut Consist Offset 000

_ CutIn Consist Offset 000

_ CutIn Temp 00.0°F

_ CutOut Temp 00.0°F

_ Cycles In Serve Mode 000

This menu contains settings for the control style, CutIn

and CutOut, cycles in serve mode and auger cycle times.

This screen is available to the Technician level.

Service Manual #513659 16 Model F231

Page 25

Cylinder can be changed by pressing the SEL button.

The Enable Control setting determines the cutin and

cutout style. The options are Consistency-Consistency,

Temperature-Consistency or Temperature-Temperature.

Setting the control to Consistency-Consistency enables

Serve 2 Mode (instead of Serve 1 Mode). Serve 2 Mode

extends the post stir to prevent short cycling the compressor and a possible misread of the consistency in the

freezing cylinder.

CutOut Consistency Offset is a number that represents

the point at which a freezing cycle will end in ConsistencyConsistency or Temperature-Consistency style. The

actual cutout value is the sum of this number, the Cutin

Consistency Offset and the Motor Zero Load numbers.

CutIn Consistency Offset is a number that represents

the point at which a freezing cycle will start in ConsistencyConsistency style. The actual cutout value is the sum of

this number and the Motor Zero Load number.

CutIn T emperature is the suction line temperature in the

cylinder when a freezing cycle will start in TemperatureConsistency or Temperature-Temperature style.

CutOut Temperature is the suction line temperature in the

cylinder when a freezing cycle will stop in TemperatureTemperature style.

Cycles In Serve Mode is a count of the number of freez-

ing cycles.

C. Advanced Settings (1 of 2)

Advanced Settings (1 of 2)

Cylinder Right

_ Standby On Time 0000 sec

_ Standby Off Time 0000 sec

_ Standby Time 000 min

_ Stir On 0000 sec

_ Stir Off 0000 sec

The Advanced Settings menu contains standby and

sleep mode adjustments and is available to the Manager

and Technician levels. Press the right arrow to go to the

second screen.

Cylinder can be changed by pressing the SEL button.

The Standby On Time setting determines the length of

the freezing cycle in Standby Mode.

The Standby Off Time setting determines the length

between freezing cycles in Standby Mode.

The Standby Time setting determines the total amount

of time in Standby Mode.

Stir On is the amount of time that the auger rotates during

the stir cycle. Stir cycles occur in Serve Mode, Standby

Mode and Sleep 2 Mode.

Stir Off is the amount of time between stir cycles. Stir

cycles occur in Serve Mode, Standby Mode and Sleep

2 Mode.

D. Advanced Settings (2 of 2)

Advanced Settings (2 of 2)

Cylinder Right

_ Sleep 2 CutIn -00.0°F

_ Sleep 2 CutOut -00.0°F

_ Default Off Time 0000 sec

The Advanced Settings menu contains standby and sleep

mode adjustments and is available to the Manager and

Technician levels. Press the left arrow to go to the fi rst

screen.

Sleep 2 CutIn is the temperature that a freezing cycle

starts in Sleep 2 Mode.

Sleep 2 CutOut is the temperature that a freezing cycle

stops in Sleep 2 Mode.

Default Off Time is the maximum time between freezing

cycles during Serve Mode or Serve 2 Mode.

E. Storage Settings (1 of 2)

Storage Settings (1 of 2)

_ Storage Refirgeration Active

_ Storage CutIn -00.0°F

_ Storage CutOut -00.0°F

_ Storage Degree Offset 00°F

_ Storage Off Time 00 min

_ Storage On Time 0000 sec

This Storage Settings menu contains storage refrigeration

parameters and is available to the Technician level. Press

the right arrow to go to the second screen.

Storage Refrigeration can be set to Active or Suspend.

Active is the normal setting. Suspend is used only for

troubleshooting and setting an AXV. Never have refrigeration set to Suspend during normal operation.

Storage CutIn is the temperature at which the storage

refrigeration cycle starts. This is how warm it will get before

starting a storage refrigeration cycle.

Storage CutOut is the temperature at which the storage

refrigeration cycle stops. This is how low the temperature

will get before ending the storage refrigeration cycle.

The Storage Offset value is added to the storage tem-

perature reading to determine if storage refrigeration

starts with a freezing cycle. This setting helps prevent

short cycling and saves energy.

The Storage Off setting determines the time between

storage refrigeration cycles during a sensor failure.

The Storage On setting determines the length of a stor-

age refrigeration cycle during a sensor failure.

Service Manual #513659 17 Model F231

Page 26

F. Storage Settings (2 of 2)

H. Time and Date

Storage Settings (2 of 2)

_ Storage Max On 00 min

_ Storage Recovery 0 min

_ Storage Too Warm 00.0°F

_ Storage Too Warm 000 min

This Storage Settings menu contains storage refrigeration

parameters and is available to the Manager and Technician levels. Press the left arrow to go to the fi rst screen.

The Storage Max On setting is the maximum time that

a storage refrigeration cycle will run.

The Storage Recovery setting is the minimum time

between storage refrigeration cycles if the Storage Max

On time ends the cycle.

The Storage Too Warm values are the temperature and

amount of time. When the temperature is above the set

temperature for the set period, the Storage too Warm

message will be displayed.

G. User Preferences

Time and Date

Time 00:00:00 AM

Date 00/00/00

Daylight Savings Off

Clock Type 12 HR

Date Format

_ Modify Time and Date

The Time and Date menu shows the time and date settings. The Manager and Technician levels can change the

time and date by using the Modify Time and Date option.

4.6 UTILITIES SCREENS

Utilities (1 of 2)

_ Adjust LCD Contrast

_ Touchpad Lockup

_ Export Machine Stats

_ Clean Options

Next Utilities Menu

User Preferences

_ Language English

_ Temp Units Farenheit(°F)

_ Service Contact Information

_ Contact Information USB Update

The User Preferences menu contains language options,

temperature units, service contact information and touchpad lockup. The screen is available to the Manager and

Technician levels.

The Language setting changes the language displayed.

English and Polish are the only languages currently

available.

The Temperature Units setting changes the units dis-

played to Fahrenheit or Celsius.

The Service Contact Information option is used to change

the service contact details including service company

name and number and machine serial number.

Utilities (2 of 2)

_ Testing and Manual Operation

_ Unit Calibration

_ Clear Log Data

_ Restore Factory Defaults

_ Restore Motor Table Defaults

_ Reset Unit Configuration

The Utilities menu gives access for various settings and

operations in the control. The Utilities menu is available

to the Technician and Manager levels. The Manager level

will only have access to the fi rst screen. The Technician

level has access to both screens.

NOTE

Entering the Utilities (2 of 2) screen automatically

shuts off the freezing cylinders.

A. Product Selection

Product Selection

Cylinder Right

_ Current Product Type 0

CutOut Consistency 000

CutIn Consistency 000

Press Set to change selection

Press Sel to accept selection

Service Manual #513659 18 Model F231

Page 27

The Product Selection screen changes CutIn Consistency and CutOut Consistency to a predetermined value

depending on the product type.

B. Adjust LCD Contrast

Adjust LCD Contrast

0123456789

ABCDEFGHIJKLMNOPQRSTUVWXYZ

ź to change

Press

Ÿ

E. Clean Options

Clean Options

Clean History Log

Clean Warning

Clean Lockout

The Clean Options Menu gives access to the Clean History Log and Clean Lockout options.

The Adjust LCD Contrast screen adjusts the contrast between the background lighting and the text on the screen.

C. Touchpad Lockup

Touchpad Lockup

Touchpad Status: Unlocked

Do you want to lock keys

_ No Unlock Touchpad

_ Yes Lock Touchpad

The Touchpad Lockup is used to lock and unlock the

keypad for self service locations.

D. Export Machine Stats

Export Machine Stats

This will export statistics

data to stats.txt file

Please insert USB flash memory

Are you sure you want to do that

_ No

_ Yes

The Export Machine Stats screen allows you to export

all the data and statistics stored in the control. Connect

a USB fl ash drive to the port on the side of the machine

and select the yes option.

Clean History Log (32 of 32)

Cylinder Right

Clean Log ID 0: 00/00/00

00:00:00

Clean Total Time 000 min

The Clean History Log screen shows the date, time and

duration of the last 32 clean cycles.

Clean Warning

Clean Warning Enabled

This option will

require cylinder cleaning

Are you sure you want to do that

_ No - Cancel Clean Warning

_ Yes - Enable Clean Warning

Clean Lockout

Clean Lockout Disabled

This option will

enforce cylinder cleaning

Are you sure you want to do that

_ No - Cancel Clean Lockout

_ Yes - Enable Clean Lockout

The Clean Warning and Clean Lockout screens are

used to enable the clean warning mode or the clean

lockout mode. When one of the modes is enabled and

the machine is not cleaned within a specifi ed period, the

machine will either display a warning (for warning mode)

or remain in sleep mode and not go into serve mode (for

lockout mode).

Service Manual #513659 19 Model F231

Page 28

F. Testing and Manual Operation

Testing and Manual Operation

Select below for testing

_ Left Output Control

_ Right Output Control

_ Left / Right Monitoring

The Testing and Manual Operation menu provides access

for individual components to be energized to assist with

troubleshooting. There are also test monitoring screens

that provide details of the machine status during testing.

Any energized component will deenergize after leaving

the Testing and Manual Operations menu.

Testing and Manual Ops, Left

_ Drive Motor Off

_ Fan Motor Off

_ Liquid Solenoid Off

_ Compressor Off

_ Refer Solenoid Off

_ Aux Solenoid Off

_ Pump Motor Off

Test Monitoring (1 of 3)

Cylinder Right

CRC Errors Dis/IO 0/6791

Motor Voltage 0.0 V

Motor Current 0.000

I/V Phase Angle 0.0°

Frequency 0.0 Hz

Consistency 0.0

Test Monitoring (2 of 3)

Cylinder Right

CRC Errors Dis/IO 0/12

Ambient Temp +00.0°F

Cylinder Temp +00.0°F

Hopper Temp +00.0°F

Pressure Sensor

Pressure Sw On

Test Monitoring (3 of 3)

Cylinder Right

CRC Errors Dis/IO 0/12

Cabinet Door Closed

Spigot Closed

Door Closed

Hi Pressure No

Liquid Level Low

Selecting Left or Right Output Control goes to a screen

that allows motors, solenoids or the compressor to be

individually activated. Activate by moving the cursor to

the desired component and press the SET button.

Selecting Left/Right Monitoring goes to screens that show

current statistics of the selected cylinder.

The Test Monitoring screens can be used for immediate

feedback when troubleshooting. For example the spigot

switch can be tested by opening the spigot and observing

if the status text changes from "Closed" to "Open".

G. Motor Calibration

Motor Zero Load Calibration

_ Left Press Sel to Start

Current Zero Load 00 W

_ Right Press Sel to Start

Current Zero Load 00 W

The Motor Calibration screen is used when a motor is

replaced or the control fi rmware is updated. Move the

cursor to the correct option and press the SEL button to

calibrate the motor to the control.

Service Manual #513659 20 Model F231

Page 29

I. Clear Log Data

K. Restore Unit Confi guration

Clear Log Data

This will clear the error log

and the statistics.

Are you sure

you want to do that

_ No

_ Yes

The Clear Log Data screen will clear all the errors and

statistics in memory.

J. Restore Factory Defaults / Restore Motor Table

Defaults

Restore Factory Settings

This will reset all machine

settings to the original

factory configurations. Are

you sure you want to do that

_ No

_ Yes

Reset Unit Configuration

This will reset the unit type

and motor types.

Are you sure you want to do that

_ No

_ Yes

The Restore Unit Confi guration screen allows you to

change the motor type default. See section 4.8 for details.

4.7 ERRORS & STATISTICS SCREENS

The Errors & Statistics menu gives the Technician access

to machine statistics and error history.

Errors and Statistics

_ Machine Statistics

_ Error History

Restore Motor Table Defaults

This will reset all motor

tables to the original

factory configurations. Are

you sure you want to do that

_No

_Yes

The Restore Factory Defaults and Restore Motor Table

defaults screens allow you to restore the control to the

factory confi gurations.

A. Machine Statistics (1 of 10)

Machine Statistics (1 of 10)

Cylinder Right

Time in Serve Mode 0000 hr

Last 24hrs 0000 min

Last 7days 0000 hr

Time in Off Mode 0000 hr

Last 24hrs 0000 min

Last 7days 0000 hr

The Machine Statistics screen 1 of 10 shows the time in

serve mode and time in sleep mode. The screen shows

a running total, the total for the previous day and the total

for the previous week for both statistics.

Service Manual #513659 21 Model F231

Page 30

B. Machine Statistics (2 of 10)

E. Machine Statistics (5 of 10)

Machine Statistics (2 of 10)

Cylinder Right

Total Low Mix Run 0000 hr

Last 24hrs 0000 min

Last 7days 0000 hr

The Machine Statistics screen 2 of 10 shows the low mix

running time. This is the total time, including serve mode

and sleep mode, that the freezing cylinder was operating

with a low mix error. The screen shows a running total,

the total for the previous day and the total for the previous week.

C. Machine Statistics (3 of 10)

Machine Statistics (3 of 10)

Cylinder Right

Last Clean Cycle 00/00/00

00:00:00 AM

Last Clean Total Time 0000 min

Machine Statistics (5 of 10)

Cylinder Right

Estimated Serve Amount 0000 gal

Last 24hrs 0000 gal

Last 7days 0000 gal

Last Serve Reset 00/00/00

00:00:00 AM

_ Reset Serve Amount

The Machine Statistics screen 5 of 10 gives the estimated

serve amount of the freezing cylinder based on the time

the spigot is open during serve mode. The estimation is

also calculated for the previous day and the previous week.

The screen gives an option to reset the serve amount and

shows when the last reset was done.

F. Machine Statistics (6 of 10)

Machine Statistics (6 of 10)

Cylinder Right

Compressor Run Time 0000 hr

Compressor Cycles 0000

Last Compressor Reset 00/00/00

00:00:00

_ Reset Compressor Time

The Machine Statistics screen 3 of 10 provides the time

and date that the freezing cylinder was last cleaned. This

value is recorded when the Clean button is pressed on

the touchpad. The screen also shows how long the most

recent clean mode lasted.

D. Machine Statistics (4 of 10)

Machine Statistics (4 of 10)

Cylinder Right

Spigot Open Total 0000 min

Last 24hrs 0000 min

Last 7days 0000 min

Spigot Total Cycles 0000

Average Spigot Open 0000 sec

The Machine Statistics screen 4 of 10 shows the total time

that the spigot has been open during serve mode. The

screen shows a running total, the total for the previous

day and the total for the previous week. The screen also

shows the total times that the spigot has been opened.

The Machine Statistics screen 6 of 10 shows the total

run time for the compressor and counts the total cycles.

There is an option to reset the timer and the screen shows

when the last reset was done. The reset should be used

if the compressor is changed.

G. Machine Statistics (7 of 10)

Machine Statistics (7 of 10)

Cylinder Right

Motor Run Time 0000 hr

Motor Cycles 0000

Last Motor Reset 00/00/00

00:00:00 AM

_ Reset Motor Time

The Machine Statistics screen 7 of 10 shows the total run

time for the drive motor and counts the total cycles. There

is an option to reset the timer and the screen shows when

the last reset was done. The reset should be used if the

drive motor is changed.

Service Manual #513659 22 Model F231

Page 31

H. Machine Statistics (8 of 10)

K. Error History

Machine Statistics (8 of 10)

Cylinder Right

Pump Run Time 0000 hr

Pump Cycles 0000

Last Pump Reset 00/00/00

00:00:00 AM

_ Reset Pump Time

The Machine Statistics screen 8 of 10 shows the total run

time for the pump and counts the total cycles. There is

an option to reset the timer and the screen shows when

the last reset was done. The reset should be used if the

pump is changed.

I. Machine Statistics (9 of 10)

Machine Statistics (9 of 10)

Cylinder Right

Current Hose Usage 0000 hr

Hose Service Limit 100 hr

Last Hose Reposition 00/00/00

00:00:00 AM

_ Reset Hose Service Time

The Machine Statistics screen 9 of 10 shows the amount

of time the pump hose has been in use and when the

last reposition was completed. There is also an option to

reset the hose timer.

J. Machine Statistics (10 of 10)

Machine Statistics (10 of 10)

Last Unit Power Up 00/00/00

00:00:00

Avg Power KWH/Day 0 Watts

The Machine Statistics screen 10 of 10 shows when the

machine was last powered on. The screen also gives an

average power consumption per day.

Error History 25 of 25

Type Cylinder Sensor

Date 00/00/00 00:00:00 AM

Cylinder Right

_ Status At Time of Error

_ Help

The Error History screen shows the last error that occurred.

The screen shows the type of error, the time and date and

the cylinder that had the error. Up to 25 errors are stored.

Press the up or down arrow to scroll through the errors.

Select the Status at Time of Error option to view data for

the time the error occurred. The Help option explains the

error and provides quick troubleshooting tips.

L. Status at Time of Error

Status at Time of Error

Operating Mode Off

Mix Levels Full Level

Consistency 000.00

Input Voltage 000.0V

Motor Amps 00.000A

Ambient Temp -000.0°F

Cylinder Temp -000.0°F

The Status at Time of Error screen gives data for the time

the error occurred.

4.8 UPDATING FIRMWARE

Before starting, make sure there is liquid mix or water in

the freezing cylinder. The calibration steps should not be

completed with frozen product in the freezing cylinders.

Firmware is contained in a .rom fi le which can be down-

loaded from the extranet website or sent via email. Download the .rom fi le onto the top level of a USB drive (don't

put the fi le in a folder and don’t change the name of the

fi le) and follow the instructions below.

A. Unplug the machine from electrical power.

NOTE

On a dual power supply machine, unplug both sides.

Service Manual #513659 23 Model F231

Page 32

B. Connect the USB fl ash drive to the port on the

machine. Depending on the model, the USB port

will be located:

1. On the side of the machine. Remove the plug.

2. Behind the header panel. Remove the panel

and locate the USB connector on the display

module.

E. Connect power to the machine. On a dual power

supply machine, only the left side needs to be

connected.

F. The display should say "Stoelting Foodservice

Equipment" in a large font and the new fi rmware

version will be displayed at the bottom.

NOTE

If the display does not show the "Stoelting Foodservice Equipment" text, make sure the .rom fi le

is in the top level of the USB fl ash drive. The .rom

fi le cannot be in any folders within the fl ash drive.

G. From the Current Status screen, press the left

arrow button to get to the passcode entry screen.

H. Enter the technician password to the control by

pressing the right arrow, SET, then the SEL button.

I. Navigate to the Utilities menu and select the Next

Utilities Menu.

J. Go to the Reset Unit Confi guration option and

press the SEL button.

K. On the Reset Unit Confi guration screen select

the Yes option and press the SEL button.

L. Confi rm the control settings are the same as the

values in the table below:

Machine Machine Type Motor Type

F231-18 2 2

F231-38 2 2

F231-109 2 3

F231-309 2 3

Q. Go to the Motor Zero Load Calibration option and

press the SEL button.

NOTE

Calibration must be done with water or liquid mix

in the freezing cylinder. Do not try to calibrate with

frozen mix in the freezing cylinder.

R. Press the SEL button to calibrate the motors for

both freezing cylinders.

NOTE

If the motors do not start, cycle the power and try

again.

S. Press the left arrow to exit the Utilities menu and

go the Main Menu screen.

T. Go to the Modify Settings screen, scroll to the

User Preferences option and press SEL at the

Service Contact Information screen.

U. Scroll to the serial number and press the SET

button. Enter the serial number for the machine by

scrolling through the numbers. The serial number

is found on the information plate located on the

side or back of the machine. If the last digit is a

blank, scroll past the “z” for the blank space.

4.9 DRIVE BELT TENSION ADJUSTMENT

To check belt tension, refer to Figure 4-1 and follow the

steps below:

WARNING

Hazardous voltage

Make sure the machine is off when disassembling

for servicing. The machine must be disconnected

from electrical supply before removing any access

panel. Failure to disconnect power before servicing

could result in death or serious injury.

Machine & Motor Types

M. Scroll the cursor down to the Accept option

and press the SEL button. The screen will read