Page 1

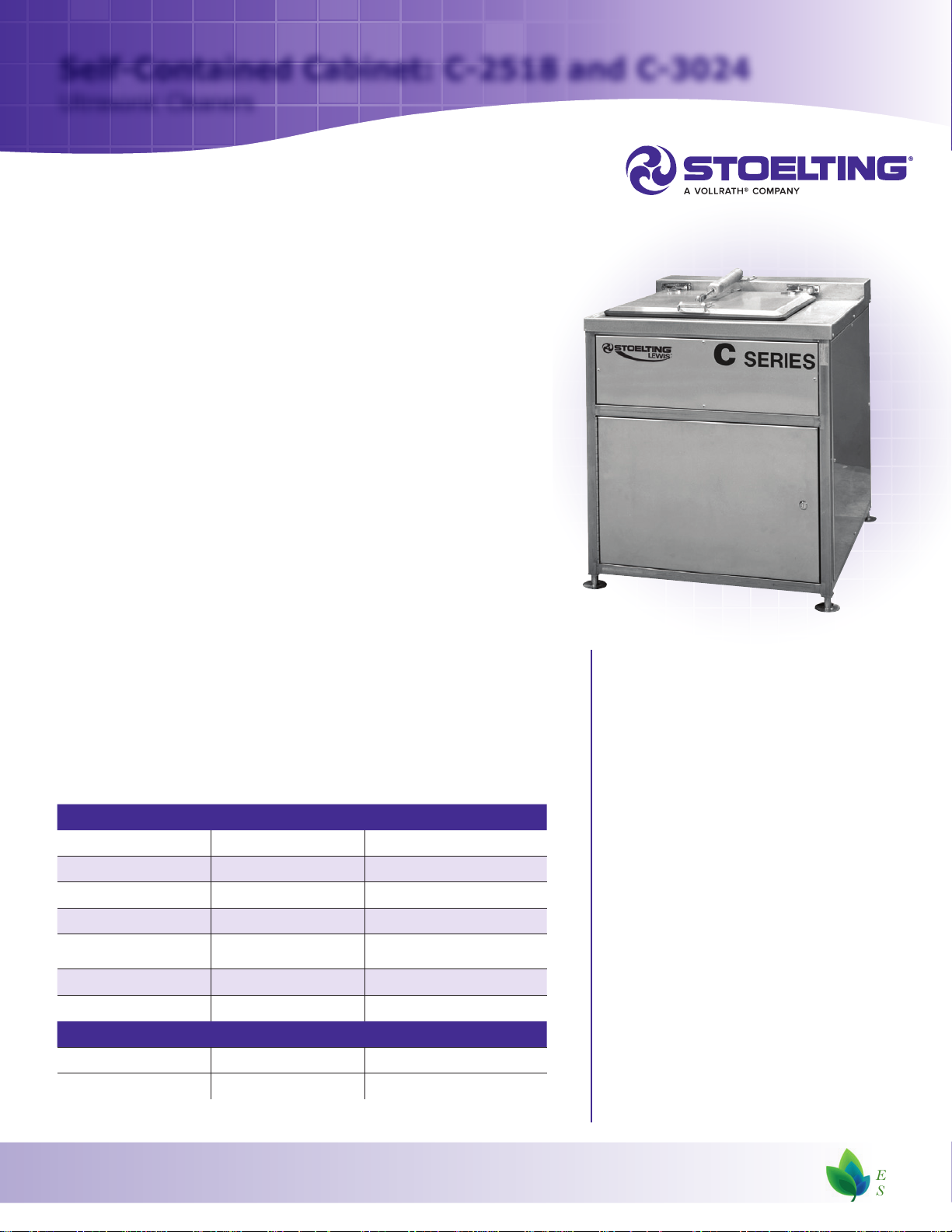

Self-Contained Cabinet: C-2518 and C-3024

Ultrasonic Cleaners

C-2518 Self-Contained Cabinet Cleaners provide all components

and accessories in one cabinet. Circuit breaker, timer, and all

controls are mounted on the control panel for operator

convenience. Access to the generator, pump, heaters, and other

accessories is through the latched front access door. Filter

housing is located externally at the rear. Units with 4000 watts of

ultrasonics have a separate NEMA 12 enclosure for generators

and controls. Matching Rinse and Drying Units are available to

give a complete Ultrasonic Wash, Rinse, and Dry operation.

CONTROLS

Controls include: Ultrasonic generator switch, ll button, heater

switch, pump mode selector switch, circuit breaker, 0-30 minute

interval timer, and thermostatic control.

TRANSDUCERS

Electronic Grade “A” nickel, silver brazed to a heavy, up to

1/4" thick, type 316L stainless steel radiating diaphragm

(tank bottom). Coils are wound with a high temperature magnet

wire. Unconditional 10 year warranty.

GENERATOR

All solid-state providing high efciency, and low maintenance.

Generators operate at 20 kHz. Synchronous operation, provides

2000 watts continuous power in each module. Meets FCC

requirements. Available to MIL-STD-461. Air lters are cleanable.

SPECIFICATIONS

Model C-2518 C-3024

Cleaning Tank Size 25" x 18" x 151/2" 30" x 24" x 20"

Liquid Depth 12" 15"

Liquid Capacity 23 Gallons 46 Gallons

Generator Output Power

Cabinet Size 35

Heater Size 4.5 kW 6 kW

ELECTRICAL REQUIREMENTS

Suffix - A 240 VAC,1 ph, 20 amps 240 VAC,1 ph, 30 amps

Suffix - E 480 VAC,1 ph, 20 amps 480 VAC,1 ph, 30 amps

2000 watts

(4000 watts optional)

1

/2" x 40" x 35" H 401/2" x 451/2" x 40" H

4000 watts (remotely mounted

generator enclosure)

Recirculatory System

Pump: Single Stage, centrifugal, sealless,

magnetically driven with all wetted parts of

ryton, ceramic, and stainless steel, 10 GPM

with 12 Ft. head.

Filter: Housing of stainless steel, 20"

disposable polypropylene lters. A variety of

elements can be used. Mounted on the

exterior rear for easy change.

Heaters: Constructed of Incoloy and 300

series stainless steel, immersion heater can

maintain 200°F. Low-level sensor protects

pump, heater, and transducers.

Plumbing and Fittings: Inlet plumbing and

ttings of copper. Recirculatory system is

stainless steel, Ryton and Neoprene.

Stainless drain valve with Teon seal is

provided. Recommend operating range of

110°F - 175°F.

Installation:

Electrical requirements noted in chart.

Plumbing: Fill water 1/2" NPT. Drain

1" CPVC drain (stainless steel available).

Gives a complete Ultrasonic Wash, Rinse, and Dry operation.

Enviro

Smart

Page 2

MATCHING CABINET CONSTRUCTION

CLEANER, RINSER, AND DRYER Each unit constructed of 16 gauge stainless steel, polished type

304 stainless steel countertop with drip-proof edge. Lid is insulated, double-pan type, stainless steel. Control

panel mounted in front countertop, opens out for servicing. Four anged adjustable leveling feet.

OPTIONS

TIMER

Optionally available for Rinser and Dryer

(0-30 minute)

STAINLESS STEEL PUMP on cleaner for high

caustics and high temperature operation

Rinser R-2518 and R-3024

These provide a matching rinse unit offering a clean

spray and/or immersion rinse system, a skim overow

weir and bottom drain. The electrically operated units

can be used in manual mode or operated automatically

by closing and opening the lid.

Water Spray Rate: 13 GPM @ 40 psi.

Plumbing: Inlet: 3/4" - NPT- Hot Water

Drain: 1-1/4" NPT

Available in 120 VAC, 240 VAC, 480 VAC, single phase

The nonelectrical unit has a manually operated valve.

Type F: Electrically operated suitable for tap water.

Type FS: Electrically operated for deionized water,

stainless steel inlet plumbing.

BASKETS

Stainless steel expanded metal

(4x4 or 8x8 mesh also available)

Lift lower platforms and rotating fixtures

OPTIONS FOR RINSER

Heater - for immersion mode

Pump and Filter - for immersion mode

Rinser R-2518 and R-3024

These provide a matching rinse unit offering a clean

spray and/or immersion rinse system, a skim overow

weir and bottom drain. The electrically operated units

can be used in manual mode or operated automatically

by closing and opening the lid.

Water Spray Rate: 13 GPM @ 40 psi.

Plumbing: Inlet: 3/4" - NPT- Hot Water

Drain: 1-1/4" NPT

Available in 120 VAC, 240 VAC, 480 VAC, single phase

The nonelectrical unit has a manually operated valve.

Type F: Electrically operated suitable for tap water.

Type FS: Electrically operated for deionized water,

stainless steel inlet plumbing.

Type M: Manually operated valve for tap water.

Type MS: Manually operated valve for deionized water.

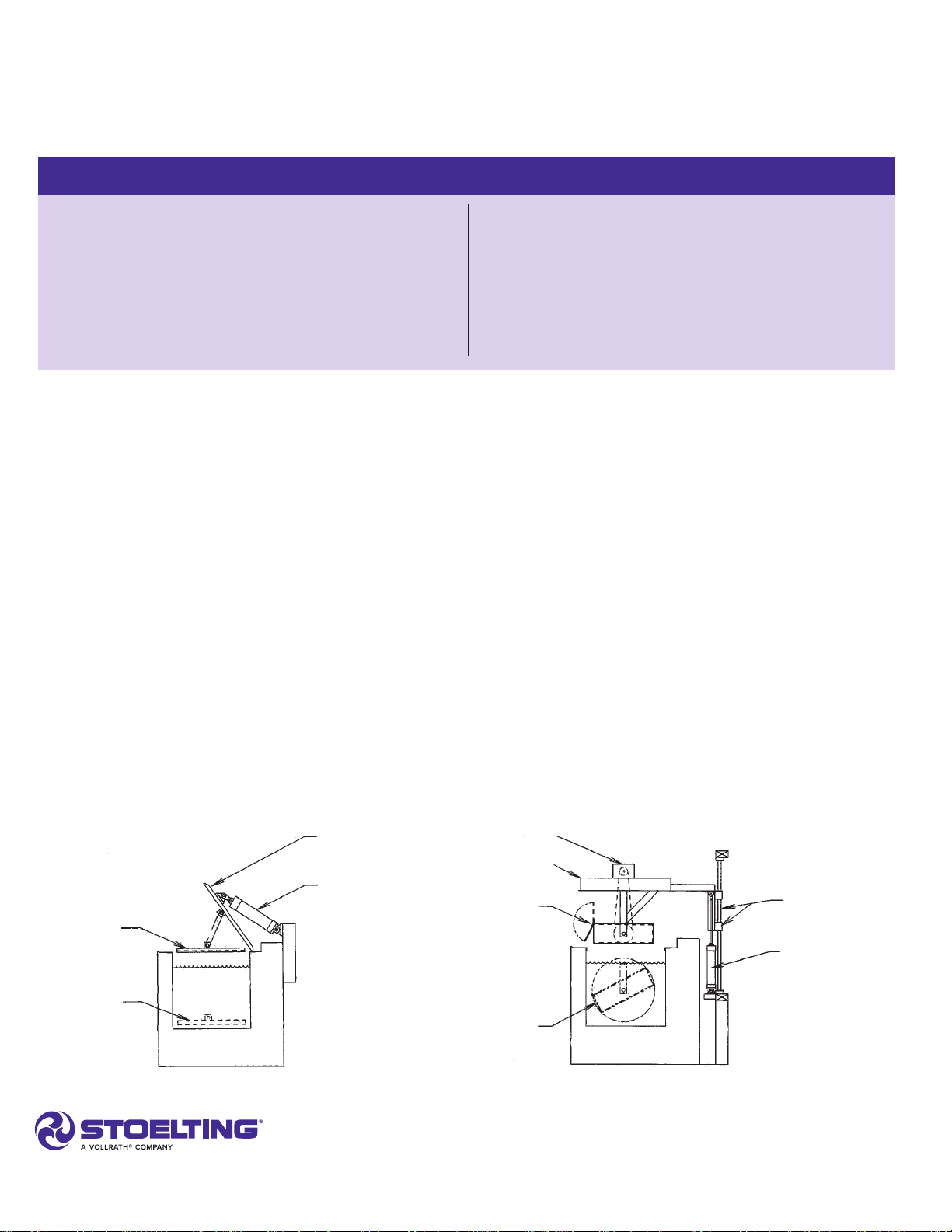

Acoustical Lid

Pneumatic

Cylinder

Platform in

Raised Position

Platform in

Lowered Position

stoeltingcleaning.com

800-545-0661 | (920) 894-2293 | Fax: (920) 894-7029 | E-mail: cleaning@stoelting.com

|

502 Highway 67 | Kiel, WI 53042-1600

Rotating Basket Carrier

in Raised Position

Rotating Basket Carrier

in Lowered Position

Type M: Manually operated valve for tap water.

Type MS: Manually operated valve for deionized water.

Rotation

Drive

Acoustical Lid

Linear Bearings

and Shafts

Pneumatic

Cylinder

ISO 9001:2008 Registered | STMC-209 4/13

Loading...

Loading...