Page 1

Model A118 / D118

OPERATORS MANUAL

Manual No. 513715 Rev.0

Page 2

Page 3

This manual provides basic information about the machine. Instructions and suggestions are

given covering its operation and care.

The illustrations and specifi cations are not binding in detail. We reserve the right to make

changes to the machine without notice, and without incurring any obligation to modify or provide new parts for machines built prior to date of change.

DO NOT ATTEMPT to operate the machine until instructions and safety precautions in this

manual are read completely and are thoroughly understood. If problems develop or questions

arise in connection with installation, operation, or servicing of the machine, contact Stoelting.

stoeltingfoodservice.com

Stoelting Foodservice Equipment

502 Highway 67

Kiel, WI 53042-1600

U.S.A.

Main Tel: 800.558.5807

Fax: 920.894.7029

Customer Service: 888.429.5920

Fax: 800.545.0662

Email: foodservice@stoelting.com

© 2017 Stoelting

Page 4

A Few Words About Safety

Safety Information

Read and understand the entire manual before

operating or maintaining Stoelting equipment.

This manual provides the operator with information

for the safe operation and maintenance of Stoelting

equipment. As with any machine, there are hazards

associated with their operation. For this reason safety

is emphasized throughout the manual. To highlight

specifi c safety information, the following safety defi ni-

tions are provided to assist the reader.

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and

their explanations, deserve your careful attention

and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions

or warnings they give are not substitutes for proper

accident prevention measures.

If you need to replace a part, use genuine Stoelting

parts with the correct part number or an equivalent

part. We strongly recommend that you do not use

replacement parts of inferior quality.

Safety Alert Symbol:

This symbol Indicates danger, warning or caution.

Attention is required in order to avoid serious personal injury. The message that follows the symbol

contains important information about safety.

Signal Word:

Signal words are distinctive words used throughout

this manual that alert the reader to the existence and

relative degree of a hazard.

WARNING

The signal word “WARNING” indicates a potentially

hazardous situation, which, if not avoided, may result

in death or serious injury and equipment/property

damage.

CAUTION

The signal word “CAUTION” indicates a potentially

hazardous situation, which, if not avoided, may result

in minor or moderate injury and equipment/property

damage.

CAUTION

The signal word “CAUTION” not preceded by the

safety alert symbol indicates a potentially hazardous

situation, which, if not avoided, may result in equipment/property damage.

NOTE (or NOTICE)

The signal word “NOTICE” indicates information or

procedures that relate directly or indirectly to the

safety of personnel or equipment/property.

Page 5

TABLE OF

CONTENTS

Description and Specifi cations

1.1 Description ..................................................................................................1

1.2 Specifi cations .............................................................................................2

Installation Instructions

2.1 Safety Precautions .....................................................................................3

2.2 Shipment and Transit ..................................................................................3

2.3 Machine Installation ....................................................................................3

Initial Set-Up and Operation

3.1 Operator’s Safety Precautions ...................................................................5

3.2 Operating Controls and Indicators .............................................................5

3.3 Removing Mix from Machine ......................................................................6

3.4 Disassembly of Machine Parts ...................................................................6

3.5 Cleaning Disassembled Parts ....................................................................7

3.6 Cleaning the Machine .................................................................................7

3.7 Assembling the Machine ............................................................................7

3.8 Sanitizing ....................................................................................................8

3.9 Freeze Down and Operation ......................................................................9

3.10 Daily Defrost ...............................................................................................9

3.11 Consistency Adjustment .............................................................................9

3.12 Preventive Maintenance .............................................................................9

3.13 Extended Storage .......................................................................................10

Troubleshooting

4.1 Light Indicators ...........................................................................................11

4.2 Troubleshooting ..........................................................................................12

Replacement Parts

5.1 Decals and Lubrication ...............................................................................13

5.2 Auger and Door ..........................................................................................14

5.3 Spigot Assembly .........................................................................................15

5.4 Trays and Hopper Cover ............................................................................15

Page 6

Page 7

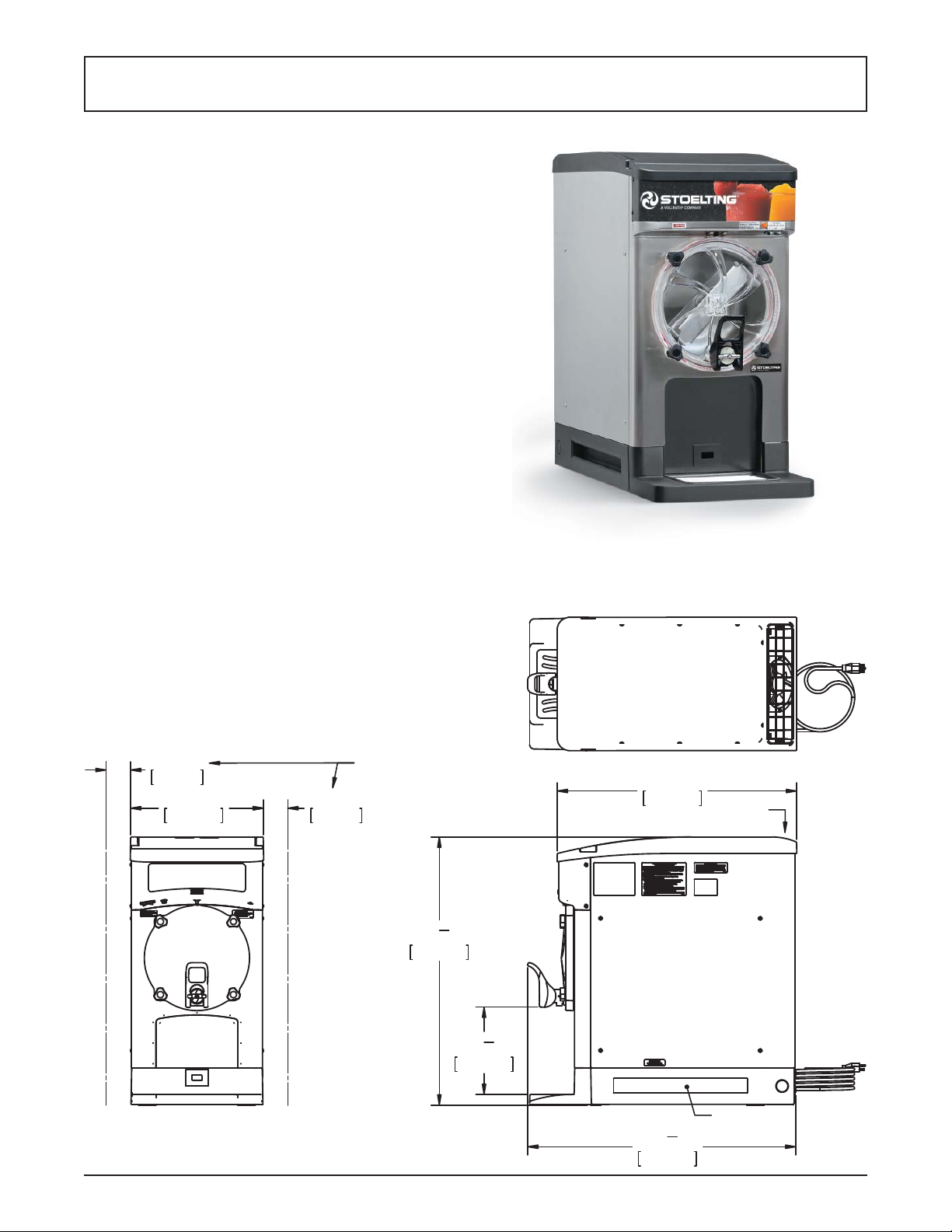

SECTION 1

DESCRIPTION AND SPECIFICATIONS

1.1 DESCRIPTION

Stoelting’s Frozen Uncarbonated Beverage Dispensers

mix and serve a variety of frozen beverages including

margaritas, slushes, coffee drinks, and dairy-based products. They are the ideal choice for bars and restaurants

looking for fl exibility, capacity and simple operation in a

compact footprint.

This manual is designed to help qualifi ed service per-

sonnel and operators with the installation, operation and

maintenance of the Stoelting A118 & D118 machines.

ALL HEIGHT

DIMENSIONS +/- 1/2"

DUE TO ADJUSTABLE

LEGS

3"

16"

40.79cm

7.54cm

Figure 1-1 Model D118

CLEARANCE REQUIRED

FOR AIRFLOW

(SIDES ONLY)

7.54cm

3"

1

"

82.44cm

32

2

73.61cm

29"

AIR OUT

5

"

26.86cm

10

8

AIR IN

(BOTH SIDES)

1

82.43cm

32

"

2

Owner’s Manual #513715 1 A118/D118 Model Machines

Page 8

1.2 SPECIFICATIONS

Model A1 18 Model D118

Dimensions Machine with crate Machine with crate

width 16’’ (40,6 cm) 20’’ (50,8 cm) 16’’ (40,6 cm) 20’’ (50,8 cm)

height 30-5/8’’ (77,8 cm) 39-3/4’’ (101,0 cm) 30-5/8’’ (77,8 cm) 39-3/4’’ (101,0 cm)

depth 28-7/8’’ (73,3 cm) 41-1/2’’ (105,4 cm) 28-7/8’’ (73,3 cm) 41-1/2’’ (105,4 cm)

Weight 210 lbs (95,2 kg) 240 lbs (108,8 kg) 210 lbs (95,2 kg) 240 lbs (108,8 kg)

Electrical

running amps

connection type

1 Phase,

115 VAC, 60Hz

10.2A 4.7A 13.6A 8.6A

NEMA5-20P power

cord provided

Compressor 4,250 Btu/hr 8,250 Btu/hr

Drive Motor 1/7 hp

Air Flow Air cooled units require 3” (7,6 cm) air space on both sides.

1 Phase,

208-240 VAC, 60Hz

NEMA6-20P power

cord provided

1 Phase,

115 VAC, 60Hz

NEMA L5-30P power

cord provided

208-240 VAC, 60Hz

NEMA6-20P power

cord provided

1 Phase,

Water cooled units require 1/2” N.P.T. water and drain fi ttings. Maximum water

Plumbing Fittings

pressure of 130 psi. Minimum water fl ow rate of 3 GPM per barrel. Ideal EWT

of 50°-70°F.

Hopper Volume 5 gallon (18,93 liters)

Freezing Cylinder

Volume

2 gallon (7,57 liters)

Owner’s Manual #513715 2 A118/D118 Model Machines

Page 9

SECTION 2

INSTALLATION INSTRUCTIONS

2.1 SAFETY PRECAUTIONS

Do not attempt to operate the machine until the safety

precautions and operating instructions in this manual are

read completely and are thoroughly understood.

Take notice of all warning labels on the machine. The labels have been put there to help maintain a safe working

environment. The labels have been designed to withstand

washing and cleaning. All labels must remain legible for

the life of the machine. Labels should be checked periodically to be sure they can be recognized as warning labels.

If danger, warning or caution labels are needed, indicate

the part number, type of label, location of label, and quantity

required along with your address and mail to:

STOELTING FOODSERVICE EQUIPMENT

ATTENTION: Customer Service

502 Hwy. 67

Kiel, Wisconsin 53042

2.2 SHIPMENT AND TRANSIT

The machine has been assembled, operated and inspected

at the factory. Upon arrival at the fi nal destination, the

entire machine must be checked for any damage which

may have occurred during transit.

With the method of packaging used, the machine should

arrive in excellent condition. THE CARRIER IS RESPONSIBLE FOR ALL DAMAGE IN TRANSIT, WHETHER

VISIBLE OR CONCEALED. Do not pay the freight bill

until the machine has been checked for damage. Have

the carrier note any visible damage on the freight bill. If

concealed damage and/or shortage is found later, advise

the carrier within 10 days and request inspection. The

customer must place claim for damages and/or shortages

in shipment with the carrier. Stoelting, Inc. cannot make

any claims against the carrier.

F. Place the CLEAN-ON-OFF switch in the OFF

position.

E. Connect the power cord to the proper power

supply . Refer to the nameplate on your machine

for proper supply . The unit must be connected to a

properly grounded receptacle. The electrical cord

furnished as part of the machine has a three prong

grounding type plug. The use of an extension cord

is not recommended. Do not use an adapter to

circumvent the grounding requirement.

F. Follow the steps in Section 3 for proper cleaning

and spigot assembly prior to operation.

2.3 MACHINE INSTALLATION

Installation of the machine involves moving the machine

close to its permanent location, removing all crating, setting in place, assembling parts, and cleaning.

A. Uncrate the machine.

B. Accurate leveling is necessary for correct drainage

of machine barrel and to insure correct overrun.

Place a bubble level on top of the machine at each

corner to check for level condition. If adjustment

is necessary, level the machine by turning the

bottom part of each leg in or out.

c. Correct ventilation is required. The machine

requires 3” clearance on both sides.

D. Install the drip tray support. Insert the pins on the

bracket into the holes on the bottom of the front

panel. Install the drip tray and drip tray grid.

Owner’s Manual #513715 3 A118/D118 Model Machines

Page 10

Owner’s Manual #513715 4 A118/D118 Model Machines

Page 11

SECTION 3

INITIAL SET-UP AND OPERATION

3.1 OPERATOR’S SAFETY PRECAUTIONS

SAFE OPERATION IS NO ACCIDENT; observe these

rules:

A. Know the machine. Read and understand the

Operating Instructions.

B. Notice all warning labels on the machine.

C. Wear proper clothing. Avoid loose fi tting garments,

and remove watches, rings or jewelry that could

cause a serious accident.

D. Maintain a clean work area. Avoid accidents by

cleaning up the area and keeping it clean.

E. Stay alert at all times. Know which switch, push

button or control you are about to use and what

effect it is going to have.

F. Disconnect power for maintenance. Never

attempt to repair or perform maintenance on the

machine until the main electrical power has been

disconnected.

G. Do not operate under unsafe operating conditions.

Never operate the machine if unusual or excessive

noise or vibration occurs.

3.2 OPERATING CONTROLS AND

INDICATORS

Before operating the machine, it is required that the operator know the function of each operating control. Refer

to Figure 3-1 for the location of the operating controls on

the machine.

WARNING

High voltage will shock, burn or cause death. The

OFF-ON switch must be placed in the OFF position

prior to disassembling for cleaning or servicing. Do

not operate machine with cabinet panels removed.

A. CLEAN-OFF-ON Switch

The CLEAN-OFF-ON switch is used to supply

power to the control circuit. When the switch is in

the OFF (middle) position, power is not supplied

to the control board or refrigeration system. When

the switch is in the ON position, the machine

operates in the freezing mode. When the switch

is in the CLEAN position, all refrigeration stops

and the auger starts rotating. If left in the CLEAN

position, defrost mode begins.

Add Mix

Clean/Off/

On Switch

Diagnostic

Light

Figure 3-1 Controls

Owner’s Manual #513715 5 A118/D118 Model Machines

Light

Page 12

B. ADD MIX Light

The ADD MIX light fl ashes to alert the operator

to a low mix condition. It does so by monitoring

the mix level in the hopper. When the ADD MIX

light is fl ashing, refi ll hopper immediately.

NOTE

Failure to refi ll hopper immediately may result in

operational problems.

C. Diagnostic Light

The Diagnostic Light is lit during defrost mode

and fl ashes if an error occurs. There are two quick

fl ashes if the drive motor is not sensed. Refer to

the troubleshooting section for details.

3.3 REMOVING MIX FROM MACHINE

If the machine is empty, go to Section 3.4.

A. Place the switch in the CLEAN position.

B. After about 5 minutes, place a container under

the spigot and drain the mix.

C. Fill the hopper with cool tap water.

D. Open the spigot to drain the water. If it is not clear

allow the cylinder to refi ll with water and drain it

again.

E. Place the switch in the OFF position.

3.4 DISASSEMBLY OF MACHINE PARTS

Before using the machine for the fi rst time, complete

machine disassembly, cleaning and sanitizing procedures

need to be followed. Routine cleaning intervals and

procedures must comply with the local and state health

regulations. Inspection for worn or broken parts should

be made at every disassembly of the machine. All worn

or broken parts should be replaced to ensure safety to

both the operator and the customer and to maintain good

machine performance and a quality product.

T o disassemble the machine, refer to the following steps:

A. Make sure the switch is in the OFF position and

remove the hopper cover.

C. Turn the inner spigot assembly counterclockwise

90° and pull the assembly out of the spigot housing.

D. Pull the lock tab forward and turn the spigot

housing counterclockwise 90°. Pull the assembly

out of the door.

NOTE

Use the optional spigot tool to assist pulling the

lock tab forward.

Pull lock tab forward

Pull lock tab forward

and turn housing

and turn housing

counterclockwise.

counterclockwise.

Figure 3-2 Removing Spigot Housing

E. On the inner spigot assembly , compress the valve

plug and retaining cap together and rotate the pin

90°.

F. Remove the pin, retainer cap, and spring from

the valve plug. Remove the spigot lock clip it by

squeezing it at the top and pulling downwards.

CAUTION

Hazardous Moving Parts.

Handle

Revolving auger shaft can grab and cause injury.

Place the switch in the OFF (middle) position before

disassembling for cleaning or servicing.

B. Hold the spigot handle and turn the handle

retaining pin. Pull the handle forward and remove

it.

Owner’s Manual #513715 6 A118/D118 Model Machines

Handle

Retaining

Retaining

Pin

Pin

Spring

Spring

Retaining Cap

Retaining Cap

Spigot Lock Clip

Spigot Lock Clip

Figure 3-3 Spigot Assembly

Valve Plug

Valve Plug

Page 13

Figure 3-4 Auger Assembly and Door

G Remove the o-rings from the spigot assemblies.

First wipe off the lubricant using a clean paper

towel. Then squeeze the o-ring upward with a dry

cloth. When a loop is formed, roll the o-ring out

of the groove.

H. Remove front door by unscrewing knobs and then

pulling the door off the studs. Remove the front

door o-ring.

I. Remove the square auger bushing.

J. Remove auger assembly from the freezing cylinder

and remove auger blades.

K. Remove rear seal and rear seal o-ring from the

auger.

3.5 CLEANING DISASSEMBLED PARTS

Disassembled parts require complete cleaning, sanitizing

and air drying before assembling. Local and state health

codes dictate the procedure required. Some state health

codes require a four sink process (pre-wash, wash, rinse,

sanitize, air dry), while others require a three sink process

(without the pre-wash step). The following procedures

are a general guideline only . Consult your local and state

health codes for the procedures required in your location.

A. Place all parts in 90° to 110°F (32°C to 43°C) mild

detergent water and wash thoroughly. Use the

brushes that shipped with the machine to clean

the parts.

B. Rinse all parts with clean 90° to 110°F (32°C to

43°C) water.

C. Place all parts in a sanitizing solution for at least

1 minute, then remove and let air dry completely

before assembling in machine.

3.6 CLEANING THE MACHINE

The exterior of the machine should be kept clean at all

times to preserve the luster of the stainless steel. A high

grade of stainless steel has been used on the machine to

ease cleanup. To remove spilled or dried mix, wash the

exterior with 90° to 110°F (32°C to 43°C) mild detergent

water and wipe dry.

Do not use highly abrasive materials, as they will mar the

fi nish. Use a soft cloth or sponge to apply the solution.

For best results, wipe with the grain of the steel.

A. Clean the rear seal surfaces on the inside of the

freezing cylinder.

B. Using sanitizing solution and the large barrel

brush provided, sanitize the freezing cylinder by

dipping the brush in the sanitizing solution and

brushing the inside of the freezing cylinder.

C. Wrap the brush in a clean sanitized cloth and

thoroughly dry the freezing cylinder.

D. Remove the drain tray, drip tray and drip tray grid

from the front of the machine. Clean and replace

them.

3.7 ASSEMBLING THE MACHINE

To assemble the machine, refer to the following steps:

NOTE

T otal Blend sanitary lubricant, or equivalent must be

used when lubrication of parts is specifi ed.

T otal Blend can be used to lubricate parts and also

as a spline lubricant. Do not use more than one

packet of Total Blend per freezing cylinder.

NOTE

The United States Department of Agriculture and

the Food and Drug Administration require that lubricants used on food processing equipment be certifi ed for this use. Use lubricants only in accordance

with the manufacturer’s instructions.

Owner’s Manual #513715 7 A118/D118 Model Machines

Page 14

Lubricate o-ring with

Lubricate o-ring with

Petrol Gel

Petrol Gel

Do not lubricate rear

Do not lubricate rear

of rear seal

of rear seal

Figure 3-5 Auger

A. Install the rear seal o-ring. Lubricate the outside

of the rear seal o-ring with a generous amount

of sanitary lubricant.

B. Install the rear seal onto the auger.

C. Lubricate the drive end of the auger with a small

amount of Total Blend lubricant.

D. Install the two plastic blades onto the auger and

insert the auger into the freezing cylinder. Position

the auger with the blade arms vertical and the

drive end inserted just enough to engage the

drive.

E. Apply a thin layer of sanitary lubricant to the

inside and back (side facing auger) of the square

auger support bushing. Install the bushing onto

the auger.

F. Fit the front door o-ring into the groove on the

rear of the front door.

G. Align square cutout on the front door with the

auger support bushing. Seat the bushing into the

front door then place the door onto the mounting

studs.

H. Secure the front door to the machine by placing

the knobs on the studs and tightening until fi nger

tight. Tighten in a crisscross pattern. Do not

overtighten. Proper o-ring seal can be observed

through the transparent front door.

I. Place the o-ring onto the spigot housing and

lubricate the o-ring with sanitary lubricant. Install

the housing into the front door.

Insert spigot housing into

Insert spigot housing into

door and rotate 90”

door and rotate 90”

Figure 3-7 Install Spigot Housing

J. Assemble the spigot assembly.

1. Install the spigot lock clip into the retaining

cap.

2. Place the o-rings onto the retaining cap

and valve plug. Lubricate the o-rings with a

generous amount of sanitary lubricant.

3. Put the spring and retaining cap onto the valve

plug.

4. Press the retaining cap against the plug so

that the retaining pin can be installed.

5. Install the pin onto the shaft and turn it 90°.

Handle

Handle

Retaining

Retaining

Pin

Pin

Figure 3-8 Spigot Assembly

Fit bushing onto auger then

Fit bushing onto auger then

align bushing with door cutout.

align bushing with door cutout.

Figure 3-6 Align Square Bushing

Owner’s Manual #513715 8 A118/D118 Model Machines

K. Install the assembly into the spigot housing and

rotate the assembly clockwise 90° to secure it.

Spring

Spring

Retaining Cap

Retaining Cap

Spigot Lock Clip

Spigot Lock Clip

Valve Plug

Valve Plug

Page 15

L. Install the spigot handle onto the spigot assembly.

1. Make sure the handle retaining pin is vertical.

Align the handle onto the pins in the spigot

housing.

2. Pull and rotate the retaining pin so that it locks

the handle in place.

3.8 SANITIZING

Sanitizing must be done after the machine is clean and

just before the machine is fi lled with mix. Sanitizing the

night before is not ensure sanitization the next day . However, you should always clean the machine and parts

after each use.

NOTE

The United States Department of Agriculture and

the Food and Drug Administration require that all

cleaning and sanitizing solutions used with food

processing equipment be certifi ed for this use.

When sanitizing the machine, refer to local sanitary regulations for applicable codes and recommended sanitizing

products and procedures. The frequency of sanitizing

must comply with local health regulations.

Mix sanitizer in quantities of no less than 2 gallons of 90°

to 110°F (32° to 43°C) water. Allow sanitizer to contact

the surfaces to be sanitized for 5 minutes. Any sanitizer

must be used only in accordance with the manufacturer’s

instructions and provide a 100 parts per million strength

solution.

A. Prepare 2 gallons of Stera-Sheen sanitizing

solution following the manufacturer’s instructions.

B. Pour the sanitizing solution into the hopper.

C. Place the switch into the CLEAN position to start

the auger rotating.

D. Check for leaks at the front door seals and in the

drain tray.

E. While the cylinder is being sanitized, use a

sanitized soft bristle brush dipped in sanitizing

solution to clean the hopper and hopper cover.

F. After 5 minutes, open the spigot to drain the

sanitizing solution.

G. When the solution has drained, place the switch

in the OFF position. Allow the freezing cylinder

to drain completely.

The machine is now sanitized and ready for adding mix.

3.9 FREEZE DOWN AND OPERATION

A. Sanitize immediately before use.

B. Fill the hopper with mix. Open the spigot and drain

a small amount of mix to remove any remaining

sanitizer.

D. Place the switch in the ON position.

NOTE

After the drive motor starts, there is a delay before

the compressor starts.

F. After 15 to 20 minutes the product will be at

consistency and will be ready to serve. Freeze

down time may vary depending on mix type and

ambient temperatures.

G. To dispense, pull or push the spigot handle. To

prevent from dispensing, push the spigot lock clip

upwards.

H. Do not operate the machine when the ADD MIX

light is on. Refi ll the hopper immediately.

3.10 DAILY DEFROST

The machine must be placed in defrost mode on a daily

basis to prevent large ice crystal buildup.

A. Place the switch in the CLEAN position.

B. The auger rotates continuously for 20 minutes.

After 20 minutes the defrost mode begins. The

auger rotates for 90 seconds every 7 minutes

and the diagnostic light is lit.

C. Keep the machine in defrost mode for at least 4

hours daily.

D. Place the switch in the ON position to return

to freeze down product and return to normal

operation.

3.11 CONSISTENCY ADJUSTMENT

The consistency adjustment screw is located behind the

access plug on the right side panel. Remove the plug to

access the screw.

To adjust consistency, use a fl at head screwdriver. Turn

clockwise for thicker product and counterclockwise for

Owner’s Manual #513715 9 A118/D118 Model Machines

Page 16

thinner product. Allow 15-30 minutes for the consistency

change to show up in the product.

3.12 PREVENTIVE MAINTENANCE

Stoelting recommends that a maintenance schedule be

followed to keep the machine clean and operating properly.

A. DAILY

1. The machine must be placed in defrost mode for

4 hours to prevent ice buildup (see Section 3.10)

2. The exterior should be kept clean at all times to

preserve the luster of the stainless steel. A mild

alkaline cleaner is recommended. Use a soft cloth

or sponge to apply the cleaner.

B. WEEKLY

1. Check o-rings and rear seal for excessive wear

and replace if necessary.

2. Remove and clean the drip tray:

a. Remove the drain tray

b. Gently lift the drip tray upwards to disengage

it from the support and pull it out.

c. Clean the drain tray and drip tray. Clean behind

the drip tray and at front of the machine with

a mild detergent.

d. Replace the drip tray and drain tray.

C. QUARTERLY

Air Cooled

The air-cooled condenser is a copper tube and aluminum

fi n type. Condensing is totally dependent upon airfl ow. A

plugged condenser fi lter, condenser , or restrictions in the

lower vented panels lowers the capacity of the system

and may cause damage to the compressor.

The condenser must be kept clean of dirt and grease.

The machine must have a minimum of 3” ventilation on

the right and left sides of the unit for free fl ow of air. Make

sure the machine is not pulling over 100° F (37° C) air

from other equipment in the area.

Press Tab to Remove FilterPress Tab to Remove Filter

The condenser and condenser fi lter require periodic clean-

ing. To clean, refer to the following procedures.

NOTE

The machine has a two fi lters. Both fi lters must be

cleaned.

A. Remove the drain tray. Gently lift the drip tray

upwards to disengage it from the support and

pull it out.

B. Remove the lower vented panels on the left and

right side of the machine by pulling the front of

the panel outward to unfasten it from the leg.

Then pull the panel forward to disengage it from

the pins.

B. Press the fi lter tab and pull the fi lter out.

C. Visually inspect the condenser fi lter for dirt.

D. If the fi lter is dirty, vacuum or brush clean, rinse

with clean water and allow to dry before replacing

on the machine.

NOTE

If the condenser is not kept clean, refrigeration effi ciency is lost.

Water Cooled

The water-cooled condenser is a tube and shell type. The

condenser needs a cool, clean supply of water to properly

cool the machine. Inlet and discharge lines must be 3/8”

I.D. minimum. Make sure the machine is receiving an

unrestricted supply of cold, clean water.

3.13 EXTENDED STORAGE

Refer to the following steps for storage of the machine

over any long period of shutdown time:

A. Place the CLEAN-OFF-ON switch in the OFF

(middle) position.

B. Disconnect (unplug) from the electrical supply

source.

C. Clean all parts that come in contact with mix

thoroughly with a warm water cleaning solution

Rinse in clean water and dry parts. Do not sanitize.

NOTE

Do not let the cleaning solution stand in the hopper or in the freezing cylinder during the shutdown

period.

D. Remove, disassemble and clean the front door,

spigot and auger parts.

E. In a water cooled machine, disconnect the water

lines and drain water. With a fl athead screwdriver,

hold the water valve open and use compressed

air to clear the lines of any remaining water.

Figure 3-10 Filter Removal

Owner’s Manual #513715 10 A118/D118 Model Machines

Page 17

SECTION 4

TROUBLESHOOTING

4.1 LIGHT INDICATORS

The machine has two lights that alert the user if a problem occurs: an ADD MIX light and a Diagnostic Light.

The ADD MIX light fl ashes to alert the operator to a low mix condition. It does so by monitoring the mix level in the

hopper. When the ADD MIX light is fl ashing, refi ll hopper immediately.

The Diagnostic Light is on during defrost mode and fl ashes if an error occurs. Refer to the chart below for details.

Indication On Two Blinks

Conditions Defrost Mode Drive current is not sensed

The machine attempts to sense drive current with a 3 second

Self Correction

Operation

Corrective

Action

N/A

Every 7 minutes the auger runs

for 90 seconds.

N/A Contact Service Technician

pre-stir. If current is sensed, the machine returns to normal

operation. If current is not sensed, the machine waits 7 minutes

and trys to sense current with another 3 second pre-stir. After

the third attempt, the compressor runs on timers.

Every 21 minutes the auger runs for 10 seconds.

Owner’s Manual #513715 11 A118/D118 Model Machines

Page 18

4.2 TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE REMEDY

1 Power to machine is off. 1 Supply power to machine.

Machine does not

run.

Machine does not

shut off.

Product has large

ice crystals.

Product is too fi rm.

Product is too thin.

2 Blown fuse or tripped circuit. 2 Replace or reset.

3 Freeze-up (auger does not turn). 3 Turn Clean/Off/On switch Off for 15 minutes,

then restart.

4 Front door not in place. 4 Assemble front door in place.

1 Consistency temperature setting is too

fi rm.

2 Refrigeration problem. 2 Check system. (Call distributor for service)

1 Machine was in freeze mode without

dispensing product for an extended

period.

1 Consistency temperature setting is too

fi rm.

1 No vent space for free fl ow of cooling

air.

2 Air temperature entering condenser is

above 100°F.

3 Condenser is dirty. 3 Clean. (See Section 3)

4 Consistency setting too soft. 4 Turn Consistency Adjustment knob clockwise.

1 Turn Consistency Adjustment knob counter-

clockwise.

1 Use defrost mode daily. To use defrost mode,

turn the switch to Clean. After 20 minutes,

defrost mode automatically begins. Allow to

remain in defrost mode for at least 4 hours.

1 Turn Consistency Adjustment knob counter-

clockwise.

1 A minimum of 3” of air space on both sides.

(See Section 2)

2 Change location or direct hot air away from

machine.

Product does not

dispense.

Rear auger seal

leaks.

Front door leaks.

5 Auger is assembled incorrectly. 5 Remove mix, clean, reassemble, sanitize and

freeze down.

6 Refrigeration problem. 6 Check system. (Call distributor for service)

1 No mix in hopper. 1 See Auto Fill Troubleshooting section.

2 Drive motor overload tripped. 2 Allow drive motor overload to auto-reset. (If

condition continues, call distributor for service.)

3 Freeze-up (auger does not turn). 3 Turn Clean/Off/On switch Off for 15 minutes,

then restart. Make sure brix is below 10%

4 Freeze-up (mix inlet tube frozen shut). 4 Turn machine off and unplug. Use a food safe

plastic spoon handle to poke the ice blockage

through the mix inlet into the freezing cylinder.

Connect power and turn machine on.

1 Outside surface of rear auger seal is

lubricated.

2 Rear seal missing or damaged. 2 Check or replace.

3 Seal o-ring missing, damaged or

installed incorrectly.

4 Worn or scratched auger shaft. 4 Replace auger shaft.

1 Front door knobs are loose. 1 Tighten knobs.

2 Spigot parts are not lubricated. 2 See Section 3.

3 Chipped or worn spigot o-rings. 3 Replace o-rings.

4 O-rings or spigot installed wrong. 4 Remove spigot and check o-ring.

5 Inner spigot hole in front door nicked

or scratched.

1 Clean lubricant from outside of rear seal, lubri-

cate inside of seal and reinstall.

3 Check. or replace.

5 Replace front door.

Owner’s Manual #513715 12 A118/D118 Model Machines

Page 19

5.1 DECALS AND LUBRICATION

Part Number Description Quantity

C-1000-26C Decal - Made In USA 1

324105 Decal - Caution Electrical Shock 3

324106 Decal - Caution Electrical Wiring Materials 1

324107 Decal - Caution Hazardous Moving Parts 2

324141 Decal - Caution Rotating Blades 1

324208 Decal - Attention Refrigerant Leak Check 2

324509 Decal - Cleaning Instructions 1

324566 Decal - Wired According To 1

324584 Decal - Adequate Ventilation 3” 3

324686 Decal - Danger Automatic Start 2

324803 Decal - Domed Stoelting Logo (Large) (Header Panel) 1

324852 Decal - Clean Condenser Filter 1

324865 Decal - Standby Light 1

324922 Decal - Assembly Check 1

490749 Leg - Front 2

490750 Leg - Rear (w/Suction Cup) 1

508053 Lubricant - Total Blend (50 Packets) 670547 Thread Sealant - Loctite 565 1

2183636 Spacer - Leg 4

2205934 Spigot Tool 1

SECTION 5

REPLACEMENT PARTS

Owner’s Manual #513715 13 A118/D118 Model Machines

Page 20

5.2 AUGER AND DOOR

625352

625352

2205308

2205308

624678

624678

2204983

2204983

666786

666786

2205002

2205002

2205672 or

2205672 or

2205707

2205707

482019

482019

Part Number Description Quantity

482019 Knob - Front Door (Black) 4

624678-5 O-Ring - Rear Seal - Black (5 Pack) 1

625352 O-Ring - Front Door - Black 1

666786 Seal - Rear Auger - Black 1

2204983 Auger 1

2205002 Blade - Scraper (Has 2) 2

2205308 Bushing - Front Auger Support (Square) 1

2205672 Door - Lighted 1

2205707 Door - No Light 1

Owner’s Manual #513715 14 A118/D118 Model Machines

Page 21

5.3 SPIGOT ASSEMBLY

Part Number Description Quantity

624595 O-Ring - Valve Plug (Inner) 1

624654 O-Ring - Valve Plug (Outer) 1

624663 O-Ring - Retaining Cap 1

624715 O-Ring - Spigot Housing 1

694248 Spring - Valve Plug Shaft 1

2205414 Retaining Cap - Spigot Valve 1

2205417 Housing - Spigot 1

2205369 Pin - Handle Retaining 1

2205621 Handle - Spigot Push/Pull 1

2205761 Valve Plug - Spigot 1

2205766 Lock Clip - Spigot 1

2205621

2205621

2205417

2205417

624715

624715

2205369

2205369

2205766

2205766

2205414

2205414

694248

694248

624663

624663

624595

624595

2206047

2206047

624654

624654

5.4 TRAYS AND HOPPER COVER

2205495

2205495

2205762

2205762

Part Number Description Quantity

744281 Tray - Drain (Front) 1

2205495 Cover - Hopper 1

2205497 Tray - Drip (Molded) 1

2205762 Grid - Drip Tray 1

2205497

2205497

744281

744281

Owner’s Manual #513715 15 A118/D118 Model Machines

Page 22

Owner’s Manual #513715 16 A118/D118 Model Machines

Loading...

Loading...