Page 1

Model 4231G/H

OWNER'S MANUAL

Manual No. 513534 Apr. 2003, Rev. 3

Page 2

Page 3

Need Part s or Service?

We stock the parts you need.

Our Technicians are factory

trained and are certified in the

Stoelting Technicare program.

CALL

Distributor: _________________________

Phone No.: _________________________

(fill in or affix label)

Model No.: _______________________

Serial No.: _______________________

Purchase Date: ____________________

Start-Up Date:____________________

Page 4

Page 5

STOELTING OWNER'S MANUAL

FOR MODEL 4231G

STOELTING FLOOR GRAVITY FREEZER

SOFT-SERVE

This manual provides basic information about the freezer. Instructions and suggestions are given

covering its operation and care.

The illustrations and specifications are not binding in detail. We reserve the right to make changes

at any time without notice to the freezer without incurring any obligation to modify or provide new parts

for freezers built prior to date of change.

DO NOT ATTEMPT to operate the freezer until instructions and safety precautions in this manual are

read completely and are thoroughly understood. The freezer should be operated only by qualified

personnel. If problems develop or questions arise in connection with installation, operation or

servicing of the freezer, contact the company at the following location:

Stoelting, LLC Tele: 920-894-2293

502 Hwy. 67

Kiel, WI 53042-1600 Fax: 920-894-7029

Page 6

Page 7

TABLE OF CONTENTS

Section Description Page

1 INTRODUCTION .................................................................................................1

1.1 Description...........................................................................................................1

1.2 Specifications.......................................................................................................2

2 OPERATING INSTRUCTIONS............................................................................3

2.1 Safety Precautions...............................................................................................3

2.2 Shipment and Transit...........................................................................................4

2.3 Freezer Installation ..............................................................................................4

2.4 Electrical Connections .........................................................................................5

3 INTIAL SET-UP AND OPERATION ....................................................................7

3.1 Operator’s Safety Precautions .............................................................................7

3.2 Operating Controls and Indicators .......................................................................7

3.3 Sanitizing .............................................................................................................9

3.4 Freeze Down and Operation................................................................................10

3.5 Mix Information ....................................................................................................11

3.6 Removing Mix from Freezer.................................................................................11

3.7 Cleaning the Freezer ...........................................................................................12

3.8 Disassembly of Freezer Parts..............................................................................12

3.9 Cleaning the Freezer Parts ..................................................................................14

3.10 Sanitize Freezer and Freezer Parts .....................................................................14

3.11 Assembly of Freezer ............................................................................................14

3.12 Routine Cleaning .................................................................................................16

4 MAINTENANCE INSTRUCTIONS.......................................................................17

4.1 Preventative Maintenance ...................................................................................17

4.2 Freeze-up ............................................................................................................18

4.3 Condenser Service ..............................................................................................18

4.4 Extended Storage................................................................................................18

4.5 Troubleshooting ...................................................................................................19

5 REPLACEMENT PARTS ....................................................................................21

5.1 How to Order Parts..............................................................................................21

5.2 Push to Freeze Light/Switch Lamp Replacment...................................................21

5.3 Clean-Off-On Rocker Switch Replacement..........................................................21

5.4 Replacement Parts & Reference Drawings..........................................................22

Page 8

LIST OF ILLUSTRATIONS

Figure Description Page

1 Model 4231G Freezer ....................................................................................................... 1

2 Specifications.................................................................................................................... 1

3 Warning and Label Locations............................................................................................ 3

4 Space and Ventilation Requirements ................................................................................4

5 Leveling Freezer ...............................................................................................................5

6 Caster Adjustment ............................................................................................................ 5

7 Connecting Permanent Wiring ..........................................................................................5

8 Danger Decal.................................................................................................................... 5

9 Controls ............................................................................................................................7

10 Mix Inlet Regulator ............................................................................................................ 9

11 Sanitizing Procedure .........................................................................................................9

12 Clean Control.................................................................................................................... 9

13 Sanitizing Hopper.............................................................................................................. 9

14 Spigot Opened and Solution Draining ...............................................................................10

15 Pouring the Mix ................................................................................................................. 10

16 Dispensing Product...........................................................................................................10

17 Skimming the Foam .......................................................................................................... 11

18 Removing Mix Inlet Regulator ........................................................................................... 11

19 Draining Mix......................................................................................................................12

20 Auger Flight Wear & Front Auger Support Wear ...............................................................12

21 Removing Front Door........................................................................................................13

22 Removing Spigot...............................................................................................................13

23 Removing Auger Supports ................................................................................................ 13

24 Auger Shafts.....................................................................................................................13

25 Removing “O” Ring ...........................................................................................................13

26 Cleaning Freezer Barrel....................................................................................................14

27 Exploded View of Auger.................................................................................................... 15

28 Exploded View of Front Door ............................................................................................ 15

29 Installing Mix Inlet Regulators ........................................................................................... 16

30 Drain Trays .......................................................................................................................16

31 Skimming Hopper .............................................................................................................17

32 Sanitizing Mix Inlet Regulators (Carburetor)......................................................................17

33 Push to Freezer Light/Switch Assembly............................................................................ 21

34 Spigot, Front Door and Auger Assembly...........................................................................22

Page 9

SECTION 1

INTRODUCTION

1.1 DESCRIPTION

The Stoelting® 4231G freezer is gravity fed. The freezer

is equipped with fully automatic controls to provide a

uniform product. The freezer is designed to operate

with almost any type of commercial soft serve or nondairy mixes available, including ice milk, ice cream,

yogurt, and frozen dietary desserts.

This manual is designed to assist qualified service

personnel and operators in the insulation, operation

and maintenance of the Stoelting Model 4231 gravity

freezer.

Information Packet Location

Model 4231G . . . . . . . RIGHT SIDE

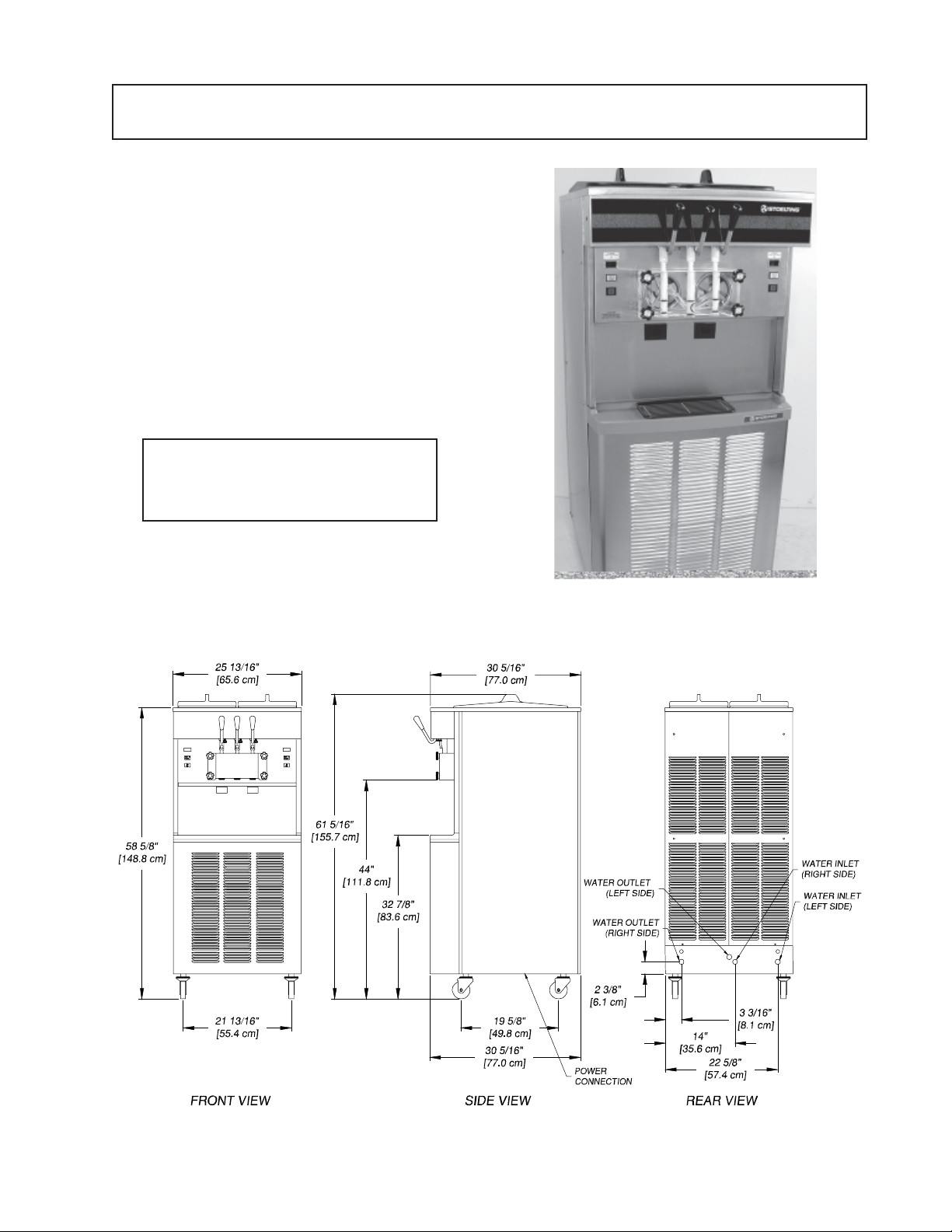

Figure 1. Model 4231G Freezer

Figure 2. Specifications

1

Page 10

1.2 SPECIFICATIONS

MODEL 4231G

FLOOR MODEL

GRAVITY FREEZER

DIMENSIONS

Freezer: 25.90” (65.81 cm) wide x 30.20” (76.7 cm)

deep x 60.80” (154.4 cm) high

Crated: 38.00” (96.5 cm) wide x 64.00” (162.5 cm) deep

x 70.00” (178.0 cm) high

WEIGHT

Freezer: 640 lbs. (291 kg)

Crated: 815 lbs. (370 kg)

ELECTRICAL

Refer to the nameplate located on the rear of the

Freezer.

COOLING

Air-cooled requires 3” (7.6 cm) clearance for all louvered

panels. Water-cooled requires ½” pipe or 5/8” inside

diameter copper water in be installed for adequate

water supply.

HOPPER CAPACITY

Two hoppers, 5.6 gallons (21 liters) each, refrigerated

and insulated.

2

Page 11

SECTION 2

INST ALLA TION INSTRUCTIONS

2.1 SAFETY PRECAUTIONS

Do not attempt to operate the freezer until the safety

precautions and operating instructions in this manual

are read completely and are thoroughly understood.

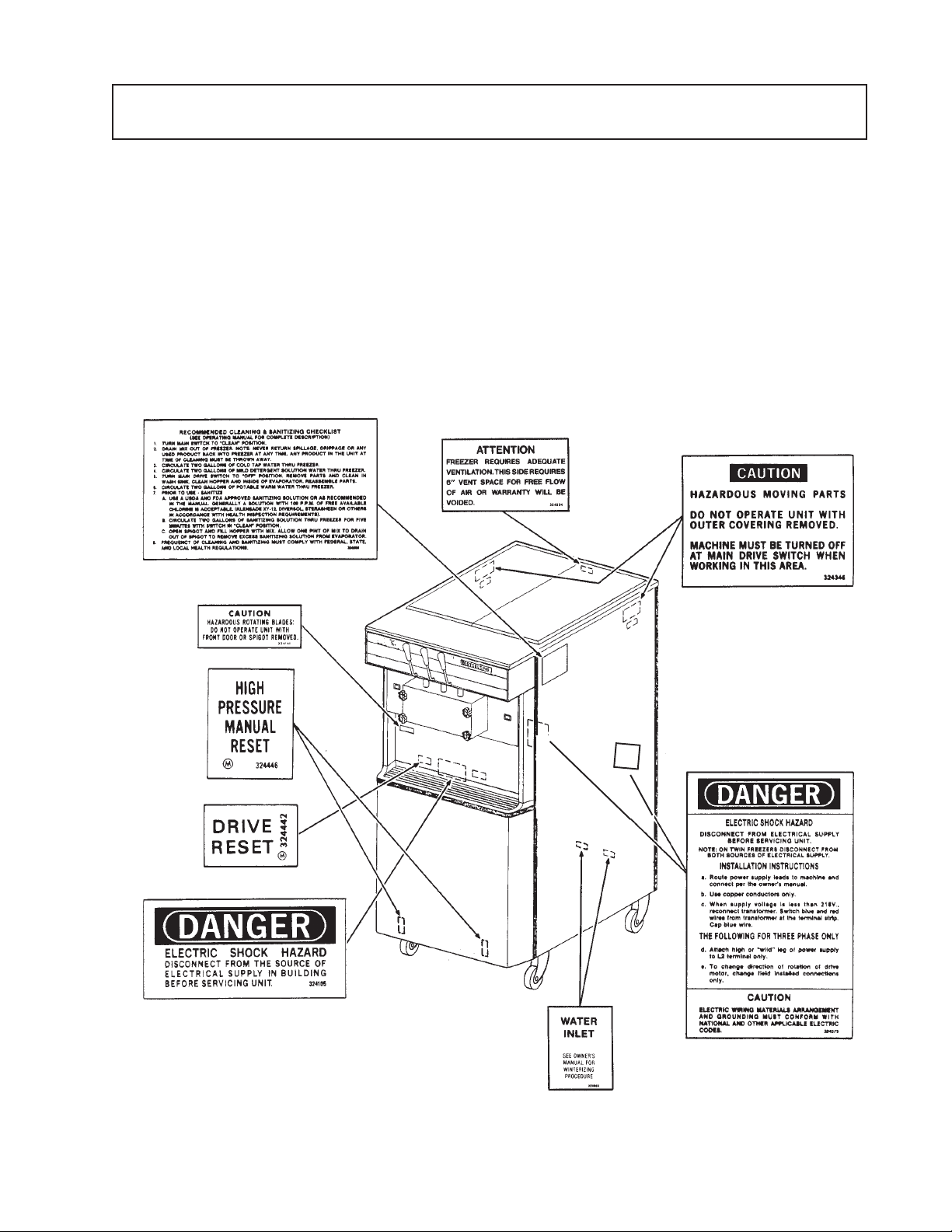

Take notice of all warning labels on the freezer (Fig. 3).

The labels have been put there to help maintain a safe

working environment. The labels have been designed

to withstand washing and cleaning. All labels must

remain legible for the life of the freezer.

Labels should be checked periodically to be sure they

can be recognized as warning labels.

If danger, warning or caution labels are needed, indicate

the part number, type of label, location of label, and

quantity required along with your address and mail to:

STOELTING, LLC

ATTENTION: Customer Service

502 HWY 67

Kiel, Wisconsin 53042-1600

Figure 3. Warning Label Locations

3

Page 12

2.2 SHIPMENT AND TRANSIT

The freezer has been assembled, operated and

inspected at the factory. Upon arrival at the final

destination, the freezer must be checked for any damage

that may have occurred during transit.

With the method of packaging used, the freezer should

arrive in excellent condition. THE CARRIER IS

RESPONSIBLE FOR ALL DAMAGE IN TRANSIT,

WHETHER VISIBLE OR CONCEALED. Do not pay the

freight bill until the freezer has been checked for damage.

Have the carrier note any visible damage on the freight

bill. If concealed damage and/or shortage are found

later, advise the carrier within 10 days and request

inspection. The customer must place claim for damages

and /or shortages in shipment with the carrier. Stoelting,

Inc. cannot make any claims against the carrier.

2.3 FREEZER INSTALLATION

NOTE

For Air Cooled Unit Only.

A rear block-off panel has been provided to prevent

recirculation of hot air beneath the freezer. The rear

block-off panel maximizes the efficiency of the freezer.

See the illustration for the installation instructions.

1. Remove both back panel mounting screws below

the bottom most louver.

2. Attach rear block-off panel to the back panel using

the same screws as shown.

ÅÅ

Å

ÅÅ

Bottom Most Louver Of Back Panel

ÅÅ

Å

ÅÅ

Back Panel Mounting Screw

ÇÇ

Ç

ÇÇ

Rear Blockoff Panel

CAUTION

FAILURE TO INST ALL THE FREEZER WITHIN

RECOMMENDED LIMITS WILL RESULT IN

POOR PERFORMANCE OF THE SYSTEM,

PREMATURE COMPONENT FAILURE AND

CANCELLATION OF WARRANTY.

Installation of the freezer involves moving the unit close

to its permanent location, removing all protective

packaging, setting in place and cleaning.

CAUTION

REMOVE LOWER FRONT PANEL BEFORE

REMOVING FREEZER FROM SKID.

A. The freezer requires adequate ventilation. A minimum

of 3” (7.6 cm) of vent space is required for free flow

of cooling air at the front and back (Fig. 4).

A water-cooled freezer requires an adequate water

supply, install 3/8 inch pipe or ½ inch inside diameter

copper water line to each side of the freezer. Connect

water outlet to a drain using a ½ inch inside diameter

line. Automatic washer hoses work well for final

connections. All water connections must comply with

local codes.

CAUTION

FLUSH ALL WATER LINES BEFORE

INSTALLATION. IN NEW STORES WITH

SEDIMENT WATER, ADD SUITABLE FILTER

OR STRAINER TO WA TER INLET.

CAUTION

FAILURE TO PROVIDE ADEQUATE

VENTILATION WILL VOID W ARRANTY .

Figure 4. Space and Ventilation Requirements

B. The unit is shipped without casters installed. To install

the casters, lift and support the unit while screwing

the four casters into the bottom of the frame at each

corner.

4

Page 13

Figure 5. Leveling Freezer

C. For location of proper electrical connections, refer

to Figure 7.

C. Accurate leveling is necessary for correct drainage

of freezer barrel to insure correct over-run and flow.

Place a spirit level on top of the freezer at each

corner to check for level condition (Fig. 5). If

adjustment is necessary , level the freezer by turning

the casters in or out (Fig. 6).

Figure 6. Caster Adjustment

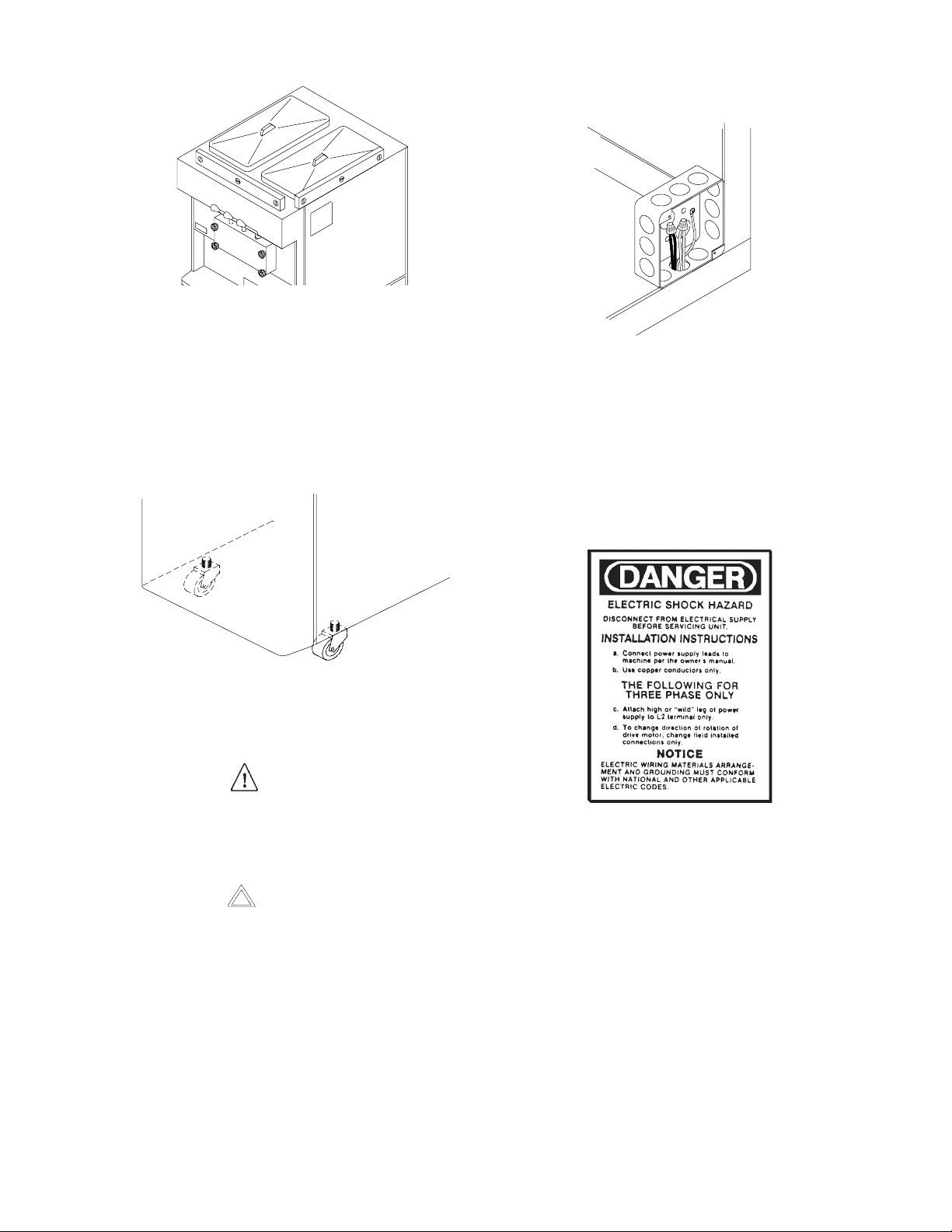

2.4 ELECTRICAL CONNECTIONS

WARNING

BEFORE INSTALLATION OF ANY CABLE IN

THE FREEZER, DISCONNECT THE FREEZER

FROM ITS ELECTRICAL SUPPLY SOURCE.

CAUTION

ROUTE ELECTRICAL CABLE SO THAT IT

CANNOT BE ACCIDENTALLY DAMAGED BY

PINCHING, CRUSHING, ETC.

Figure 7. Connecting Permanent Wiring

NOTE

When supply voltage is less than 218V , reconnect

transformer. Switch orange and red wires from

transformer at the terminal strip and cap blue wire.

D. Please read decal located on lower electrical box

cover (Fig. 8)

Figure 8. Danger Decal

The model 4231 freezer is two individual freezers in a

common enclosure. EACH SIDE MUST BE

CONNECTED INDIVIDUALLY. EACH SIDE MUST

HAVE ITS OWN ELECTRICAL SUPPLY. When making

the electrical supply connections, YOU MUST

MAINTAIN STRAIGHT POLARITY FROM SIDE TO

SIDE.

A. Connect freezer to a properly grounded 208/230 volt

(AC), source of electricity .

B. To access the electrical boxes, remove the two

Phillips head screws on the left and right side panels.

Then pull the panel down and out.

E. Check the auger shaft rotation by placing the MAIN

DRIVE switch in the CLEAN position. Auger shaft

rotation is clockwise as viewed through the clear

plastic front door. If the rotation is not clockwise, turn

the main electrical power OFF . Then reverse L1 and

L3 electrical power lines to the junction box (three

phase only). Re-check auger shaft rotation.

5

Page 14

6

Page 15

SECTION 3

INITIAL SET-UP AND OPERATION

3.1 OPERATOR’S SAFETY

PRECAUTIONS

SAFE OPERATION IS NO ACCIDENT; Observe these

rules:

A. Know the freezer. Read and understand the

Operating Instructions.

B. Notice all warning labels on the freezer.

C. W ear proper clothing. A void loose fitting garments,

and remove watches, rings or jewelry, which

could cause a serious accident.

D. Maintain a clean work area. Avoid accidents by

cleaning up the area and keeping it clean.

E. Stay alert at all times. Know which switch, push

button or control you are about to use and what effect

it is going to have.

Spigot Switch (behind panel)

Activated by Spigot Handles

F. Disconnect electrical cord for maintenance.

Never attempt to repair or perform maintenance on

the freezer until the main electrical power has been

disconnected.

G. Do not operate under unsafe operating

conditions. Never operate the freezer if unusual or

excessive noise or vibration occurs.

3.2 OPERATING CONTROLS AND

INDICATORS

Before operating the freezer, it is requires the operator

know the function of each operating control. Refer to

Figure 9 for the location of the operating controls on the

freezer.

WARNING

THE OFF-SERVE SWITCH MUST BE PLACED

IN THE OFF POSITION WHEN

DISASSEMBLING FOR CLEANING OR

SERVICING. THE FREEZER MUST BE

DISCONNECTED FROM ELECTRICAL SUPPL Y

BEFORE REMOVING ANY ACCESS PANEL.

Clean-Off-Serve Rocker Switch

Red Light (Push to Freeze)

Green Light (Ready to Serve)

Low Mix Light

Front Door Interlock Switch

Actuator (located between barrels behind stainless steel

panel)

Ì

Æ

Ê

Ì

Figure 9. Controls

È

Ê

7

Ë

ËË

Dispense Rate Adjusters

Ë

Ë

Å

É

Clean-Off-Serve Rocker Switch

Red Light (Push to Freeze)

Green Light (Ready to Serve)

Low Mix Light

High Pressure Reset Button (under lower front panel)

Water Cooled Only

Page 16

A. SPIGOT SWITCH

When the spigot handle is opened the SPIGOT

switch will start the auger drive motor and

refrigeration systems. When the spigot handle is

closed, the auger drive motor and compressor will

remain on until the product in the barrel reaches the

proper consistency.

NOTE

If the freezer shuts off and the PUSH TO FREEZE

light flashes, you have an error condition. Turn

the CLEAN-OFF-SERVE switch to the OFF

position, correct the problem and turn the freezer

back on.

GREEN LIGHT

B. CLEAN-OFF-SERVE SWITCH

The CLEAN-OFF-SERVE switch is a three-position

rocker switch used to control the operation of the

refrigeration system and auger. When the switch is

placed in the CLEAN position, the refrigeration

system will be off and the auger will rotate for

cleaning.

When the switch is placed in the OFF position, the

refrigeration system and auger will not operate.

When the switch is placed in the SERVE position,

the refrigeration system and auger will operate

automatically. The switch should be placed in the

ON position for normal operation.

C. PUSH TO FREEZE SWITCH

The illuminating PUSH TO FREEZE switch is used

to start the freezing cycle. During the initial freeze

down, the CLEAN-OFF-SERVE rocker switch is

placed in the SERVE position. Then the PUSH TO

FREEZE switch is pressed until the drive motor and

compressor comes “ON.”

NOTE

After the gearmotor starts, there is a 3-second

delay before the compressor starts.

The green lens is used to indicate that the product has

reached the proper consistency and is ready to be

dispensed.

NOTE

If the PUSH TO FREEZE lens is illuminated, push

the PUSH TO FREEZE switch and wait until the

green lens illuminates before dispensing.

MIX LOW LIGHT

The MIX LOW light is used to indicate when the hopper

is low on mix. When the light is illuminated fill the hopper

with mix.

CAUTION

FAILURE TO REFILL HOPPER IMMEDIATELY

MA Y RESULT IN OPERA TIONAL PROBLEMS.

D. DISPENSE RATE ADJUSTER

The dispense rate adjuster limits the opening of the

spigot.

To adjust product dispense rate, turn the adjusting

knob clockwise for slower flow and counterclockwise

for faster flow.

E. DOOR INTERLOCK SWITCH

During the normal operation, the red PUSH TO FREEZE

switch will illuminate after the freezer has been in idle for

the pre-set time. Before drawing product, press the red

PUSH TO FREEZE switch if it is illuminated. Wait until

the green lens is illuminated before dispensing.

When the door is securely fastened the freezer will

operate normally. When the door is removed, the

drive and compressor will not run.

8

Page 17

3.3 SANITIZING

Sanitizing must be done after the freezer is clean and

just before the hopper is filled with mix. Sanitizing the

night before is not effective. However, you should

always clean the freezer and parts after using it.

WARNING

THE UNITED STATES DEPARTMENT OF

AGRICULTURE AND THE FOOD AND DRUG

ADMINISTRATION REQUIRE THAT ALL

CLEANING AND SANITIZING SOLUTIONS

USED WITH FOOD PROCESSING EQUIPMENT

BE CERTIFIED FOR THIS USE.

B. Prepare 2 gallons (7.5 liters) of sanitizing solution

following manufacturer’s instructions. Pour into

hopper with mix inlet regulator in place (Fig. 11).

Figure 11. Sanitizing Procedure

When sanitizing the freezer, refer to local sanitary

regulations for applicable codes and recommended

sanitizing products and procedures. The frequency of

sanitizing must comply with local health regulations.

Mix sanitizer according to manufacturer’s instructions

to provide a 100 parts per million strength solution. Mix

sanitizer in quantities of no less than 2 gallons (7.5

liters) of 120°F water. Allow sanitizer to contact the

surfaces to be sanitized for 5 minutes. Any sanitizer

must be used only in accordance with the manufacturer’s

instructions.

CAUTION

PROLONGED CONTACT OF SANITIZER WITH

FREEZER MAY CAUSE CORROSION OF

ST AINLESS STEEL PARTS.

In general, sanitizing may be conducted as follows:

A. Push the mix inlet regulator fully into the hopper (Fig.

10).

C. Place the CLEAN-OFF-SERVE rocker switch in the

CLEAN position. Check for leaks around the front

door seal (Fig. 12).

Figure 12. Clean Control

D. Clean sides of hopper, mix inlet regulator and

underside of hopper cover using a sanitized soft

bristle brush dipped in the sanitizing solution (Fig.

13).

Figure 10. Mix Inlet Regulator

Figure 13. Sanitizing Hopper

9

Page 18

E. After five minutes, place the bucket under the spigots

and open all three spigots to drain the sanitizing

solution. When the solution has drained, place the

CLEAN-OFF-SERVE switch in the OFF position.

Allow the freezer barrel to drain completely (Fig. 14).

Figure 14. Spigot Opened and Solution Draining

3.4 FREEZE DOWN AND OPERATION

CAUTION

DO NOT OVERFILL THE HOPPER. MIX LEVEL

MUST NOT BE HIGHER THAN 2” (5CM) FROM

THE TOP OF THE AIR INLET TUBE ON THE

MIX INLET REGULA TOR.

E. The freezer barrel will automatically fill until it is about

½ full (about 3 min.) If the freezer barrel does not

fill, check for obstruction in the mix inlet regulator

“O” Ring, check for leaks at the mix inlet regulator

was installed correctly, or that the freezer is level.

F. Place the CLEAN-OFF-SERVE rocker switch in the

SERVE position, then press PUSH TO FREEZE

switch until the drive motor and compressor come

ON.

NOTE

After the gearmotor starts, there is a 3-second

delay before the compressor starts.

This section covers the recommended operating

procedures to be followed for the safe operation of the

freezer.

A. Sanitize just prior to use.

B. Place the CLEAN-OFF-SERVE switch in the OFF

position.

C. With spigots open, pour approximately 1 gallon (3.8

liters) of mix into the hopper. Allow the mix to flush

out about 8 ounces (0.23 liters) of sanitizing solution

and liquid mix. Close the spigot. (Fig.15)

G. After about 6 to 10 minutes the freeze will shut OFF

and the green lens will illuminate. The product is

ready to serve. Freeze down time may be longer for

some frozen diet dessert mixes.

H. For normal dispensing, move the spigot handle open

60° (Fig. 16).

Figure 15. Pouring the Mix

D. Fill hoppers with approximately 6-1/2 gallons (11.4

liters) of pre-chilled (40°F or 4°C) mix.

Figure 16. Dispensing Product

CAUTION

REFRIGERATION IS AUTOMATICALLY

ACTIV ATED WHEN THE SPIGOT IS OPENED.

CLOSE THE SPIGOT COMPLETELY AFTER

DISPENSING.

10

Page 19

I. The freezer is designed to dispense the product at

a reasonable draw rate. If the freezer is overdrawn,

the result is a soft product or a product the will not

dispense at all. If this should occur, allow the freezer

to run for approximately 30 seconds before

dispensing additional product. After a while the

operator will sense or feel the freezer is beginning

to fall behind, and will slow down the rate of draw so

as not to exceed the capacity.

J. Do not operate the freezer when the level indicator

shows the hopper is empty.

NOTE

The freezer has a standby mode sometimes

referred to as a sleep or energy conservation

mode. When the freezer is not used, after a preset

time, it will remain there until someone draws a

product or pushes the PUSH TO FREEZE switch.

In the standby mode, the freezer will keep the

product below 45°F. Standby modes are not to

be used in place of cleaning and sanitizing.

Federal, State, and Local regulatory agencies

determine frequency of cleaning and sanitizing.

Mix does not improve with age. Old mix, or mix that has

been stored at too high a temperature, can result in a

finished product that is less than satisfactory from the

appearance and taste standpoint. To retard bacteria

growth in dairy based mixes; the best storage

temperature range is between 36° to 40°F (2.2° to

4.4°C).

Some products tend to foam more than others do. If

excess foam should occur, skim off with a sanitized

utensil and discard (Fig. 17). Periodically, stir the mix in

the hopper with a sanitized utensil.

Figure 17. Skimming the Foam

3.5 MIX INFORMATION

Mix can vary considerably from one manufacturer to

another. Differences in the amount of butterfat content

and quantity and quality of other ingredients have a

direct bearing on the finished frozen product. A change

in freezer performance that cannot be explained by a

technical problem may be related to the mix. When

changing from one type of mix to another such a yogurt

to Vitari, you may have to change the mix inlet regulator

and/or control settings. Please call your distributor for

further information.

Proper product serving temperature varies from one

manufacturer’s mix to another. Mixes should provide a

satisfactory product in the 18° to 20°F (-7° to -6°C)

range.

When checking the temperature, stir the thermometer

in the frozen product to read the true temperature.

3.6 REMOVING MIX FROM FREEZER

To remove the mix from the freezer, refer to the following

steps:

A. Remove the mix inlet regulator from the hopper by

pulling straight up (Fig. 18).

Figure 18. Removing Mix Inlet Regulator

11

Page 20

B. Place the CLEAN-OFF-SERVE rocker switch in the

CLEAN position. Allow the mix to agitate in freezer

barrel until the mix has become a liquid.

C. Drain the liquid mix by opening the spigot. A bucket

or container should be placed under the spigot to

catch the liquid mix (Fig. 19).

Figure 19. Draining Mix

E. Repeat steps A through D using a mild detergent

solution.

3.8 DISASSEMBLY OF FREEZER

PARTS

CAUTION

PLACE THE CLEAN-OFF-SERVE ROCKER

SWITCHES IN THE OFF POSITION BEFORE

DISASSEMBLING FOR CLEANING OR

SERVICING.

Inspection for worn or broken parts should be made at

every disassembly of the freezer for cleaning or other

purposes. All worn or broken parts should be replaced

to ensure safety to both the operator and the customer

and to maintain good freezer performance and a quality

product. Two normal wear areas are the auger flights

and front auger support bearing (Fig. 20). Frequency of

cleaning must comply with the local health regulation.

D. Place the CLEAN-OFF-SERVE switch in the OFF

position.

3.7 CLEANING THE FREEZER

NOTE

The frequency of cleaning the freezer and freezer

parts must comply with local health regulations.

After the mix has been removed from the freezer, the

freezer must be cleaned. To clean the freezer, refer to

the following steps:

A. Close the spigot and fill the hoppers with 2 gallons

(7.5 liters) of cold tap water.

B. Place the CLEAN-OFF-SERVE switches in the

CLEAN position.

C. Allow the water to agitate for approximately five

minutes.

Figure 20. Auger Flight Wear and Front

Auger Support Wear

To disassemble the freezer, refer to the following steps:

A. Remove the mix inlet regulators from the hoppers

by pulling straight up.

D. Open the spigots to drain the water. Remember to

place a bucket or container under the spigots to catch

the water. When the water has drained, turn the

CLEAN-OFF-SERVE switches to the OFF position.

Allow the freezer barrel to drain completely.

B. Remove the front door by turning off the circular

knobs and then pulling the front door off the studs

(Fig. 21).

12

Page 21

Figure 21. Removing Front Door

C. Remove rosette cap. Push the spigot body through

the bottom of the front door and remove the spigot

body (Fig. 22).

E. Remove the auger assemblies from the freezer. Pull

the augers out of the freezer barrel slowly. As the

augers are being pulled out, carefully remove each

of the plastic flights with springs (Fig. 24).

Figure 24. Auger Shafts

F. Keep the rear of the auger shafts tipped up once

they are clear of the freezer barrels to avoid dropping

rear seals.

Figure 22. Removing Spigot

D . Remove the front auger supports and bearings (Fig.

23).

G. Remove the rear seals.

H. Wipe socket lubricant from the drive end (rear) of

the auger with a cloth or paper towel.

I. Remove all “O” Rings from parts by first wiping off

the lubricant using a clean paper towel. Then

squeeze the “O” Ring upward with a dry cloth. When

a loop is formed, roll out of the “O” Ring groove (Fig.

25).

Figure 25. Removing O-Ring

Figure 23. Removing Auger Supports

WARNING

DO NOT USE ANY TYPE OF SHARP OBJECT

TO REMOVE THE “O” RINGS.

13

Page 22

J. Remove drain trays.

3.9 CLEANING THE FREEZER PARTS

Place all loose parts in a pan or container and take to the

wash sink for cleaning. To clean freezer parts refer to

the following steps:

B. Place all parts in the sanitizing solution, then remove

and let air dry.

C. Using this sanitizing solution and the large barrel

brush provided, sanitize the rear of the barrel and

drive area by dipping the brush in the sanitizing

solution and brushing the rear of the barrel.

A. Place all parts in warm mild detergent water and

clean with brushes provided. Rinse all parts with

clean hot water.

CAUTION

DO NOT DAMAGE PARTS BY DROPPING OR

ROUGH HANDLING.

B. Wash the hopper and freezer barrel with warm

detergent water and brush provided (Fig. 26).

3.11 ASSEMBLY OF FREEZER

To assemble the freezer parts, refer to the following

steps:

NOTE

Petro-Gel sanitary lubricant or equivalent must

be used when lubrication of parts is specified.

NOTE

The United States Department of Agriculture and

the Food and Drug Administration require that

lubricants used on food processing equipment

be certified for this use. Use lubricants only in

accordance with the manufacturer’s instructions.

A. Assemble all “O” Rings onto parts dry, without

lubrication. Then apply a thin film of sanitary

lubrication to exposed surfaces of the “O” Rings.

Apply thin film of sanitary lubricant to metal part of

rear seal. Also apply a thin film of sanit ary lubricant

inside the hole on the front of the auger.

Figure 26. Cleaning Freezer Barrel

C. Clean the drip tray and insert with a soap solution.

Rinse with clean hot water.

3.10 SANITIZE FREEZER AND

FREEZER PARTS

A. Use a sanitizer mixed according to manufacturer’s

instructions to provide a 100 parts per million

strength solution. Mix sanitizer in quantities of no

less then two gallons (7.5 liters) of 120°F water. Allow

the sanitizer to contact the surface for 5 minutes.

Any sanitizer must be used only in accordance with

the manufacturer’s instructions.

B. Assemble the rear seals onto the augers with the

large end to the rear. Be sure the “O” Ring is in place

before installing the rear seal.

C. Lubricate the inside of the auger drive sockets (rear)

with a small amount of white socket lubricant. A small

container of socket lubricant is shipped with the

freezer.

D. Screw the springs onto the studs in plastic flights.

Springs must be screwed into the flights

completely to provide proper tension (Fig. 27).

14

Page 23

Figure 27. Exploded View of Auger

CAUTION

DO NOT PLACE THE MIX INLET REGULA TOR

INTO THE HOPPER BEFORE INST ALLING THE

AUGER.

E. Install the two plastic flights onto rear of the auger

and insert part way into freezer barrel.

F. Install the remaining plastic flights, push the auger

into the freezer barrel and rotate slowly until the

auger engages the drive shaft.

G. Install the auger support and bearing into the front

of the augers with one leg of the support at 9 o’clock.

NOTE

Apply a small amount of Petro-Gel to the surface

of the cam on the spigot handle prior to assembly

of handle to the spigot body.

H. Install the spigot bodies with ”O” Rings into the front

door from the bottom (Fig. 28). Push straight up until

the spigots are in place. Install rosette cap.

I. Install the front door on the freezer.

J. Install the circular knobs on the freezer studs.

Figure 28. Exploded View of Front Door

CAUTION

FINGER TIGHTEN THE CIRCULAR KNOBS

EVENL Y. DO NOT OVERTIGHTEN KNOBS.

Look for the proper seal between the freezer barrel, “O”

Ring, and front doors.

K. Install the mix inlet regulators into the hopper with

the air inlet (long) tube toward the front of the freezer

(Fig. 29).

15

Page 24

Figure 29. Installing Mix Inlet Regulators

NOTE

Refer to Section 3.3 for sanitizing the

assembled freezer before filling with mix.

Figure 30. Drain Trays

L. Install the drain trays (Fig. 30).

CAUTION

DRAIN TRAYS MUST BE IN PLACE BEFORE

OPERATING FREEZER TO PREVENT

DAMAGE FROM POSSIBLE AUGER SEAL

LEAKS.

3.12 ROUTINE CLEANING

To remove spilled or dried mix for the freezer exterior,

simply wash in the direction of the finish with warm

soapy water and wipe dry. Do not use highly abrasive

materials, as they will mar the finish.

16

Page 25

SECTION 4

MAINTENANCE INSTRUCTIONS

4.1 PREVENTIVE MAINTENANCE

It is recommended that a preventive maintenance

schedule be followed to keep the freezer clean and

operating properly. The following steps are suggested

as a preventive maintenance guide.

WARNING

NEVER ATTEMPT TO REPAIR OR PERFORM

MAINTENANCE ON FREEZER UNTIL THE

MAIN ELECTRICAL POWER HAS BEEN

DISCONNECTED.

The United States Department of Agriculture and the

Food and Drug Administration require that lubricants

used on food processing equipment be certified for this

use. Use lubricants only in accordance with the

manufacturer’s instructions.

A. DAILY

3. Run a sanitized brush down mix inlet regulator

(carburetor) tubes (Fig. 32).

Figure 32. Sanitizing Mix Inlet Regulator

(Carburetor)

NOTE

When sanitizing, the skimmer, brush and the hand

that holds the mix inlet regulator (carburetor) must

also be sanitized.

1. The exterior should be kept clean at all times

to preserve the luster of the stainless steel. A

mild alkaline cleanser is recommended. Use a

soft cloth or sponge to apply the cleanser.

2. Using a sanitized one-pint aluminum overrun

container, skim the mix in the hopper to remove

any foam buildup (Fig. 31).

Figure 31. Skimming Hopper

4. Note any unusual noises or operating

conditions upon startup. Repair or rectify

immediately if problems exist.

NOTE

Do not use acid cleaners, strong caustic

compounds or abrasive materials to clean any

part of the freezer exterior or plastic parts.

CAUTION

INSPECTION FOR WORN OR BROKEN PARTS

SHOULD BE MADE AT EACH DISASSEMBLY

OF THE FREEZER.

B. WEEKLY

1. Check all “O” Rings for excessive wear and

replace if necessary .

2. Check scraper blades, front bearing and rear

bearing for wear damage (paragraph 3.8).

17

Page 26

C. MONTHLY

1. Check drive belt for wear.

2. Check condenser for dirt.

D. Blow out the dirt from the back of the condenser.

Most of the dirt will cling to the wet towel.

CAUTION

THIS PROCEDURE EMITS A LOUD NOISE.

4.2 FREEZE-UP

If a freeze-up does occur, use the following steps to

thaw the mix in the freezer barrel:

CAUTION

IF THE DRIVE BELT SQUEALS WHEN THE

CLEAN-OFF-SERVE SWITCH IS PLACED IN

THE SERVE POSITION, OR WHEN THE

SPIGOT IS OPENED TO DISPENSE PRODUCT ,

TURN THE CLEAN-OFF-SERVE SWITCH TO

THE OFF POSITION.

A. Check to make sure the spigot handle is closed

completely, spigot switch is functioning properly,

there is mix in the hopper, or the mix inlet regulator

(carburetor) is not plugged.

B. If drive motor overload was tripped, remove the

middle front panel and push the reset button. If it

will not reset wait 5 minutes and try again.

E. An alternative method is to clean with a condenser

brush and vacuum.

4.4 EXTENDED STORAGE

Refer to the following steps for winterizing the freezer

for winter lay-up or any extended period of storage.

A. Clean thoroughly with a warm mild detergent all

parts that come in contact with mix. Rinse in clear

water and dry all parts. Do not sanitize as prolonged

exposure of metal parts to some sanitizers can

cause corrosion.

NOTE

Do not let cleaning solution stand in freezer barrel

or hopper during the shutdown period.

B. Remove, disassemble, and clean the front door,

auger and mix inlet regulator (carburetor). Leave

disassembled during the shutdown period.

C. Place the CLEAN-OFF-SERVE switch in the SERVE

position and push the PUSH TO FREEZE switch.

D. The product will be ready to serve when the green

light illuminates.

E. If the freezer continues to freeze-up, contact a

qualified refrigeration service technician, local

distributor, or Stoelting, Inc.

4.3 CONDENSER SERVICE

A. Visually inspect the condenser for dirt by shining a

light through the louvers.

B. If the condenser is dirty, vacuum all loose dirt.

C. If using compressed air or CO-2 tank to blow out

the dirt, first place a wet towel over the front of the

condenser.

C. Place plastic auger flights, rear bearing and front

bearing in a plastic bag with a moist paper towel.

This will prevent parts from becoming brittle if

exposed to dry air over an extended period of time

(over 30 days).

CAUTION

BARREL MUST BE EMPTY FOR FOLLOWING

PROCEDURE.

D. On water cooled freezers, shut off and disconnect

water supply at rear of freezer; run compressor for

2 to 3 minutes to open water valve, and blow out all

water first through inlet, then outlet line, using air or

carbon dioxide.

E. Disconnect the freezer from the electrical supply in

the building.

18

Page 27

4.5 TROUBLESHOOTING

WARNING

NEVER ATTEMPT TO REPAIR OR PERFORM MAINTENANCE ON FREEZER UNTIL THE MAIN

ELECTRICAL POWER HAS BEEN DISCONNECTED.

Problem Possible Cause Remedy

Freezer does not run 1. Power to freezer is off. 1. Supply power to freezer

2. Fuse or circuit breaker is blown or tripped. 2. Replace or reset. (If condition continues

See note 1 or 2)

3. Freeze-up 3. See paragraph 4.3.

4. High-pressure cutout tripped 4. Correct problem and reset.

5. Drive motor OFF ON Timer. 5. Place the CLEAN-OFF-SERVE switch to

the OFF position the reset.

Freezer shuts off on error 1. Low or no mix in hopper. 1. Add mix.

2. Low or no overrun. 2. Check mix inlet regulator.

3. Refrigeration problem. 3. Check system. (See note 1.)

Product is too soft 1. No vent space for free flow of cooling air. 1. A minimum of 6 inches of vent space

required. (See paragraph 2.2).

2. Air temperature entering condenser is 2. Change location or direct hot

above 100°F. (Air cooled.) air away from freezer.

3. Condenser is dirty. (Air-cooled) 3. Clean (See paragraph 4.6).

4. Consistency setting too soft 4. Readjust (See paragraph 4.2).

5. Stabilizers in mix are broken down. 5. Remove mix, clean, sanitize and freeze

down with fresh mix.

6. Refrigeration problem. 6. Check system. (See note 1.)

Product is too firm. 1. Consistency setting too firm 1. Readjust. (See paragraph 4.2.)

2. Spigot not fully closed. 2. Fully close spigot.

Product does not 1. No mix in hopper 1. Fill hopper with mix.

Dispense. 2. Mix inlet regulator (carburetor) mix inlet 2. Unplug, using a small sanitized

tube is plugged. brush.

3. Special mix inlet regulator (carburetor) 3. Order special mix inlet

needed for mix being used. regulator (carburetor). (See note 2.)

4. Capacity of freezer is being exceeded. 4. Slow up on the draw rate.

5. Drive motor overloaded. 5. Place reset lever in the ON position. (If

condition continues see note 1 or 2.)

6. Drive belt failure. 6. See paragraph 4.4.

7. Freeze-up 7. See paragraph 4.3.

Drive belt slipping 1. Worn drive belt. 1. Replace drive belt. (See paragraph 4.4.)

2. Freeze-up 2. See paragraph 4.3.

19

Page 28

Low overrun 1. Mix inlet regulator (carburetor) missing. 1. Replace mix inlet regulator (carburetor).

2. Mix inlet regulator (carburetor) “O” Ring 2. Replace mix inlet regulator

missing. (carburetor) “O” Ring.

3. Mix inlet regulator (carburetor) air tube 3. Clean with sanitizer brush.

blocked.

Front door leaks. 1. Front door knobs are loose. 1. Tighten knobs.

2. Spigot parts are not lubricated. 2. See paragraph 3.11.

3. Chipped or worn spigot “O” Rings. 3. Replace “O” Rings.

4. “O” Rings or spigot installed wrong. 4. Remove spigot and check “O” Rings.

5. Spigot hole in front door nicked or 5. Replace front door.

scratched.

Hopper will not 1. EPR valve needs to be adjusted. 1. (See note 1.)

Maintain mix 2. Temperature control failure. 2. Replace. (See notes 1 or 2.)

temperature below 3. Refrigeration problem. 3. Check system. (See note 1.)

45°F (7°C).

1. Must be performed by a qualified service person.

2. The local dealer, distributor or Stoelting, LLC, Service Department should be contacted. Write or call:

Stoelting, LLC

502 Hwy. 67,

Kiel, WI 53042

Phone (920) 894-2293.

20

Page 29

SECTION 5

REPLACEMENT PARTS

5.1 HOW TO ORDER PARTS

To assure receipt of the proper replacement parts, supply

your dealer or distributor with the following information:

A. Model number of equipment.

B. Serial number of model, stamped on nameplate.

Part Number Description

324014 Decal Black Arrow

324141 Decal Caution Rotating Blades

324509 Decal Cleaning

324548 Decal Ventilation

324346 Decal Caution

324393 Decal – Drip Tray

324803 Decal – Header Panel (Stoelting Logo)

324804 Decal - Header Panel (Stoelting Swirl)

324806 Decal - Header Panel (A & W Logo)

324798 Decal – CLEAN/OFF/SERVE

324125 Decal – Elec. Shock Hazard

C. Part number, part name and quantity needed.

Common part names and numbers are listed in this

manual.

5.2 PUSH TO FREEZE LIGHT/SWITCH

LAMP REPLACEMENT

B. Remove the faulty lamp by pulling out the lamp puller

(See Fig. 33).

Figure 33. Push To Freeze Light/Switch Assembly

C. T o install the new lamp, line up the lamp end with the

receptacle and push fully in.

D. Reinstall the lens by pushing firmly in. When installed

“PUSH TO” might be right side up.

NOTE

LED light bulbs require correct polarity . If the bulb

does not illuminate, remove the bulb, turn 180°

and replace.

5.3 CLEAN-OFF-SERVE ROCKER

SWITCH REPLACEMENT

A. Remove side panel.

To change a lamp in the PUSH TO FREEZE switch/light

follow these simple steps:

A. Grasp the lens with your thumb and forefinger and

pull out.

WARNING

DISCONNECT FREEZER FROM ELECTRICAL

SUPPL Y SOURCE BEFORE SERVICING .

21

Page 30

22

Page 31

1 2177428 1 Door w/pins

Item Stoelting PN Qty Description

2 3159696 2 Spigot, Outside

3 3158086 1 Spigot, Center

4 624598 4 O-Ring, 7/8 OD x 1/8 CS

5 624664 1 O-Ring 1-5/16 OD x 1-1/16 ID x 1/8 CS

6 625133 2 O-Ring 4.00" OD x .1875" CS

7 508135 As Reqd Lube, Petro-Gel

8 482019 4 Knob with 3/8-16 (Black)

9 624614 2 O-Ring, 1 OD x ¾ ID x 1/8 CS

10 482004 3 Knob

11 644094 6 Screw, Cap ¼-20 x 3/8 Hex Hd

12 4158215 3 Glide Bracket Weldment

13 2158260 3 Handle

14 570961 3 Pin, Cotterless Clevis

15 428045 3 Knob, Black Plastic

16 2158082 3 Glide

23

17 1158080 3 Adjusting Bar

18 647995 3 Screw, Machine ¼-20 x 3.50" Long

19 718773 4 Switch

20 647055 8 Screw, Machine #4-40 x .625" Long

21 538235 8 Nut, Hex #4-40

22 766917 8 Washer, Shakeproof #4

23 696048 2 Spring, Torsion (Outside Spigot)

23 696044 1 Spring Torsion (Center Spigot)

24 694247 3 Spring

25 1145194 2 Mix Inlet Reg. (1/4" Hole, Std Length)

25A 1146231 2 Mix Inlet Reg. (5/16" Hole, Std Length)

25B 1150832 2 Mix Inlet Reg. (1/4" Hole, Ext. Length)

25C 1150807 2 Mix Inlet Reg. (5/16" Hole, Ext. Length)

26 232734 3 Rosette Cap

Page 32

242526

Page 33

Page 34

Page 35

29 2172761 2 Water Valve Bracket (W/C Only)

30 644024 4 Screw Mach 8-32 x 1/4 Hx (W/C Only)

31 766941 4 Washer Shakeproof #8 (W/C Only)

32 2172763 2 Pressure Switch Bracket (W/C Only)

Item Stoelting PN Qty Description

33 538335 4 Nut Hex 1/4-20 x 7/16 Stl Zp

34 766456 4 Washer Round 5/8 x 9/32 Steel

35 647393 4 Screw Mach 6-32 x 3/8 Rd Hd Ph

36 766933 4 Washer Shakeproof 6 x 5/16

37 644106 4 Screw Cap 1/4-20 x 5/8 Hx Hd

38 522833 2 Fan Motor (A/C Only)

39 3171824 2 Bracket, Condenser (A/C Only)

40 4154716 1 Condenser Shroud (A/C Only)

41 162067 2 Blade, Fan (A/C Only)

42 284044 1 Condenser (A/C Only)

43 538280 8 Nut, Hex #8-32 (A/C Only)

44 766948 8 Washer, Shakeproof #10 (A/C Only)

45 538297 8 Nut, Hex #10-24 (A/C Only)

46 649000-37 4 Screw, Self Tap 10-24 (A/C Only)

47 732133 2 Wire Nut (Crimp) (A/C Only)

48 524075 4 Mount Motor Ring

49 524074 6 Mount Motor Bushing

50 221637 4 Bushing Support (Shaft End)

51 766566 8 Washer .406 ID x 2.5 OD x 14 GA

52 1145141 2 Motor Adjusting Stud

53 538344 2 Nut Hex 5/16-18 x 1/2 Stl Zp

54 1150893 2 Bushing Support (Opposite Shaft End)

55 649109 4 Screw Tap 10-16 x 1/2 Ind. Hx

56 538395 2 Nut Hex 1/2-13 x 3/4 x 5/16 Zp

57 538360 4 Nut Hex Full 3/8-16 Zp

58 538356 4 Nut Hex Locking Flange Zp

59 231083 2 Start Capacitor

60 231082 2 Run Capacitor

1 152294 4 Belt V, 39.2 O.L. x 38.3 P.L.

2 282021-SV 2 Compressor (4231-18G, -38G)

Item Stoelting PN Qty Description

2A 282020-SV 2 Compressor (4231-109G, -309G)

2B 282030 2 Compressor (4231-102G, -302G)

3 422156 2 Grommet Kit with sleeves

4 644371 8 Screw Cap 5/16-18 x 1-3/4 Hx

5 767211 8 Washer Flat 5/16, 7/8 x 3/8 x 14GA

6 522844 2 Motor, 2HP (1 PH & 3 PH, 60 HZ) (SER.#0 - 16068)

6 522856 2 Motor, 2 HP (1 PH & 3 PH, 60 HZ) (SER.#16069 Plus)

6A 523082 2 Motor, 2HP (50 HZ)

7 1145153 2 Pulley (1 PH & 3 PH, 60 HZ)

7A 1147928 2 Pulley (50 HZ)

8 614232 2 Speed Reducer 5:2:1 Reduction

9 628046 16 Rivet Blind 1/4

10 644091 4 Screw Cap 1/4-20 x 1/2 Hx Hd

11 644605 8 Screw Cap 3/8-6 x 2 Hx Hd Zp

12 714006 36” 1” x 100’ Roll/Rubber

13 766964 4 Washer Shakeproof 1/4 Zinc

14 766982 8 Washer Shakeproof 3/8 Zinc

15 M820072 .001 Sealant-White Adhesive

16 2147034 2 Pulley, 7.00 PD Machined

27

17 4172774 1 Hopper & Evap. Foamed

18 119421 4 Angle (Vertical Extrusion)

19 628038-04 16 Rivet 3/16 Dia. x .62 Lg.

20

21 284104 2 Condenser (W/C Only)

22 644307 8 Screw Cap 5/16-18 x 3/4 (W/C Only)

23 538351 2 Nut Hex 5/16-18 Locking (W/C Only)

24 766073 6 Washer Lock 5/16 (W/C Only)

25 2172762 1 Condenser Joining Bracket (W/C Only)

26 767205 6 Washer Flat 1/4 x 3/4 x 5/16 (W/C Only)

Page 36

28

Page 37

25 718750 2 Switch, Rocker

Item Stoelting PN Qty Description

26 732118 16 Terminal Panel Mount (Red)

27 732119 2 Terminal Housing (Red)

28 223007 4 Bushing Snap 5/8ID 3/4 Mtg.

29 295109 4 Contactor Mag 3-Pole 24V

30 766948 8 Washer Shakeproof 10 Zinc Plate

31 644048 8 Screw Mach 10-24 x 1/2 Hx Hd

32 538913 8 Nut Speed 10-24 x 37/64 x 5/8

33 231084 2 Capacitor, Run (4231-18G,-38G)

34 231079 2 Capacitor, Start (4231-18G,-38G)

35 647513 8 Screw Mach 8-32 x 3/8 Rd Hd Ph

36 2141450 2 Capacitor Bracket 50 HZ

37 766940 34 Washer Shakeproof 8 Zinc Plate

38 618157 2 Relay, Motor Start (4231-18G,-38G)

39 647529 10 Screw Mach 8-32 x 1/2 Rd Hd PH

40 744142 2 Transformer Assy

41 647536 4 Screw Mach 8-32 x 5/8 Rd Hd Ph

42 732019 2 Terminal Block 5 Contacts

43 1141398 2 Varistor Assy 24 Volt

44 4177141 1 Power Box Weldment

45 739527 2 Timer, Interval 24 Vac

46 1170811 1 Decal Clean Timer

47 732020 2 Terminal Block 8 Pole

1 649109 4 Screw Tap 10-16 x 1/2 Ind. Hx

Item Stoelting PN Qty Description

2 524091 2 Mount Adhesive Back 1 x 1 Plastic

3 647885 2 Screw Mach 1/4-20 x 1/2 Trs Hd

4 538922 2 Nut Speed 1/4-20

5 766964 6 Washer Shakeproof 1/4 Zinc

6 644195 4 Screw Cap 1/4-20 x 2 Hx Hd

7 1172773 4 Spacer, 1.47 Long

8 2158124-SV 1 Door Interlock Switch Assy

9 766949 2 Washer Shakeproof #10 Cntsink

10 647671 2 Screw Mach 10-24 x 1/2 Fl Hd

11 458105 2 Indicator, Mix Low

12 1154882 2 Switch, Push-To-Freeze Assembly

13 296179 2 Control Liquid Level 24V

14 524087 8 Mount Dual Lock Circuit Spacer

15 538296 4 Nut Hex #10-24 x 3/8 SS

16 538912 4 Nut Speed 10-24 x 47/64 x 9/16

29

17 2172828 2 Mix Probe Assembly

18 766430 2 Washer Round

19 1157996 2 Spacer

20 3158218 2 Control Board Bracket

21 521721 2 Module, Control Power Board

22 521554 2 Module, Control-Logic Board 608

23 647376 16 Screw, Machine #6-32 x 1/4”Lg.

24 766933 16 Washer, Shakeproof #6

Page 38

12, 13, 14

..

..

.

77

77

7

3

,,

,,

,

15

7

//

//

/

2

22

22

55

55

5

16

,,

,,

,

12, 13, 14

6

00

00

0

4A

..

..

.

77

77

7

9

0

00

00

10

00

00

0

11

00

00

0

.

..

..

1, 2A, 2B

15

,,

,,

,

8

8

00

00

0

9

..

..

.

3

..

..

.

16

22

22

2

0

00

00

10

0

00

00

11

1

11

11

6

,,

,,

,

12, 13, 14

..

..

.

4A

.

..

..

33

33

3

1, 2A, 2B

77

77

7

12, 13, 14

00

0000

0000

7

30

Page 39

Item Stoelting PN Qty Description

1 282021-SV 2 Compressor (4231-18G, -38G)

2A 282020-SV 2 Compressor (4231-109G, -309G)

2B 282030 2 Compressor (4231-102G, -302G)

3 4172774 1 Hopper & Evaporator Assembly

4 284104 2 Condenser (W/C Only)

4A 284044 1 Condenser (A/C Only)

5 718686 2 Switch Pressure (W/C Only)

6 342008 2 Drier, Filter

7 762277 2 Check Valve (Magni-Chek)

8 762445 2 Expansion Valve

31

9 342020 2 Drier Refrigeration

10 458010 2 Indicator, Sight Glass

11 763455 2 Valve Solenoid

12 375813 6 Access Fitting Assembly

13 282085 6 Cap Quick Seal

14 762359 6 Valve Core

15 231101-SV 2 Capillary Tube

16 1158278 2 Valve, EPR

Page 40

12, 13, 14

..

..

.

55

55

5

16

7

//

//

/

2

22

22

,,

,,

,

12, 13, 14

.

..

..

1, 2A, 2B

15

15

,,

,,

,

,,

,,

,

6

..

..

11

00

00

0

0

00

00

11

.

77

77

7

3

77

77

7

9

0

00

00

8

8

00

00

0

9

..

..

.

00

00

0

0

00

00

10

10

22

22

2

5

4

..

..

.

17

..

..

.

2

22

22

17

1

11

11

3

..

..

.

77

77

7

12, 13, 14

22

22

2

16

00

0000

0000

4

1

11

11

6

,,

,,

,

12, 13, 14

..

..

.

7

32

66

6

66

5

33

33

3

1, 2A, 2B

Page 41

Item Stoelting PN Qty Description

1 282021-SV 2 Compressor (4231-18G, -38G)

2A 282020-SV 2 Compressor (4231-109G, -309G)

2B 282030 2 Compressor (4231-102G, -302G)

3 4172774 1 Hopper & Evaporator Assembly

4 284104 2 Condenser (W/C Only)

4A 284044 1 Condenser (A/C Only)

5 718686 2 Switch Pressure (W/C Only)

6 342008 2 Drier, Filter

7 762277 2 Check Valve (Magni-Chek)

8 762445 2 Expansion Valve

33

9 342020 2 Drier Refrigeration

10 458010 2 Indicator, Sight Glass

11 763455 2 Valve Solenoid

12 375813 6 Access Fitting Assembly

13 282085 6 Cap Quick Seal

14 762359 6 Valve Core

15 231101-SV 2 Capillary Tube

16 1158278 2 Valve, EPR

Page 42

Page 43

WARRANTY

SOFT SERVE / SHAKE FREEZERS

1. Scope:

Stoelting, LLC warrants to the first user (the “Buyer”) that the freezer cylinders, hoppers, compressors, drive motors,

speed reducers, auger and auger flights of Stoelting soft serve / shake freezers will be free from defects in materials

and workmanship under normal use and proper maintenance appearing within five (5) years, and that all other

components of such equipment manufactured by Stoelting will be free from defects in material and workmanship

under normal use and proper maintenance appearing within twelve (12) months after the date that such equipment is

originally installed.

2. Disclaimer of Other Warranties:

THIS W ARRANTY IS EXCLUSIVE; AND STOEL TING HEREBY DISCLAIMS ANY IMPLIED W ARRANTY OF MERCHANTABILITY OR FITNESS FOR PA RTICULAR PURPOSE.

3.

Remedies:

Stoelting’s sole obligations, and Buyer’s sole remedies, for any breach of this warranty shall be the repair or (at

Stoelting’s option) replacement of the affected component at Stoelting’s plant in Kiel, Wisconsin, or (again, at

Stoelting’ s option) refund of the purchase price of the affected equipment, and, during the first twelve (12) months of

the warranty period, deinstallation/reinstallation of the affected component from/into the equipment. Those obligations/remedies are subject to the conditions that Buyer (a) signs and returns to Stoelting, upon installation, the

Checklist/Warranty Registration Card for the affected equipment, (b) gives Stoelting prompt written notice of any

claimed breach of warranty within the applicable warranty period, and (c) delivers the affected equipment to Stoelting

or its designated service location, in its original packaging/crating, also within that period. Buyer shall bear the cost

and risk of shipping to and from Stoelting’ s plant or designated service location.

4. Exclusions and Limitations:

This warranty does not extend to parts, sometimes called “wear parts”, which are generally expected to deteriorate

and to require replacement as equipment is used, including as examples but not intended to be limited to o-rings,

auger seals, auger support bushings and drive belts. All such parts are sold

AS IS.

Further, Stoelting shall not be responsible to provide any remedy under this warranty with respect to any component

that fails by reason of negligence, abnormal use, misuse or abuse, use with parts or equipment not manufactured or

supplied by Stoelting, or damage in transit.

THE REMEDIES SET FORTH IN THIS W ARRANTY SHALL BE THE SOLE LIABILITY STOEL TING

AND THE EXCLUSIVE REMEDY OF BUYER WITH RESPECT TO EQUIPMENT SUPPLIED BY

STOEL TING; AND IN NO EVENT SHALL STOEL TING BE LIABLE FOR ANY INCIDENT AL OR

CONSEQUENTIAL DAMAGES, WHETHER FOR BREACH OF W ARRANTY OR OTHER CONTRACT BREACH, NEGLIGENCE OR OTHER T ORT, OR ON ANY STRICT LIABILITY THEORY .

Loading...

Loading...