Page 1

Model 100FA / 100CA / 2217GA

OPERATORS MANUAL

Manual No. 513653 Mar. 2010

Page 2

Page 3

This manual provides basic information about the machine. Instructions and suggestions are

given covering its operation and care.

The illustrations and specifi cations are not binding in detail. We reserve the right to make

changes to the machine without notice, and without incurring any obligation to modify or provide new parts for machines built prior to date of change.

DO NOT ATTEMPT to operate the machine until instructions and safety precautions in this

manual are read completely and are thoroughly understood. If problems develop or questions

arise in connection with installation, operation, or servicing of the machine, contact Stoelting.

stoeltingfoodservice.com

Stoelting Foodservice Equipment

502 Highway 67

Kiel, WI 53042-1600

U.S.A.

Main Tel: 800.558.5807

Fax: 920.894.7029

Customer Service: 888.429.5920

Fax: 800.545.0662

Email: foodservice@stoelting.com

© 2014 PW Stoelting, LLC

Page 4

A Few Words About Safety

Safety Information

Read and understand the entire manual before

operating or maintaining Stoelting equipment.

This manual provides the operator with information

for the safe operation and maintenance of Stoelting

equipment. As with any machine, there are hazards

associated with their operation. For this reason safety

is emphasized throughout the manual. To highlight

specifi c safety information, the following safety defi ni-

tions are provided to assist the reader.

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and

their explanations, deserve your careful attention

and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions

or warnings they give are not substitutes for proper

accident prevention measures.

If you need to replace a part, use genuine Stoelting

parts with the correct part number or an equivalent

part. We strongly recommend that you do not use

replacement parts of inferior quality.

Safety Alert Symbol:

This symbol Indicates danger, warning or caution.

Attention is required in order to avoid serious personal injury. The message that follows the symbol

contains important information about safety.

Signal Word:

Signal words are distinctive words used throughout

this manual that alert the reader to the existence and

relative degree of a hazard.

WARNING

The signal word “WARNING” indicates a potentially

hazardous situation, which, if not avoided, may result

in death or serious injury and equipment/property

damage.

CAUTION

The signal word “CAUTION” indicates a potentially

hazardous situation, which, if not avoided, may result

in minor or moderate injury and equipment/property

damage.

CAUTION

The signal word “CAUTION” not preceded by the

safety alert symbol indicates a potentially hazardous

situation, which, if not avoided, may result in equipment/property damage.

NOTE (or NOTICE)

The signal word “NOTICE” indicates information or

procedures that relate directly or indirectly to the

safety of personnel or equipment/property.

Page 5

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

SECTION 1 INTRODUCTION .............................................................................................................. 1

1.1 Description ...................................................................................................................... 1

1.2 Specifications.................................................................................................................. 1

SECTION 2 INSTALLATION INSTRUCTIONS...................................................................................... 3

2.1 Safety Precautions.......................................................................................................... 3

2.2 Shipment and Transit ...................................................................................................... 3

2.3 Freezer Installation.......................................................................................................... 3

2.4 Adjusting Cup Dispensers ............................................................................................... 7

SECTION 3 INITIAL SET-UP AND OPERATION ................................................................................. 9

3.1 Operator's Safety Precautions ......................................................................................... 9

3.2 Operating Controls and Indicators.................................................................................... 9

3.3 Draining the Freezer For Disassembling and Cleaning..................................................... 10

3.4 Disassembly and Cleaning of Freezer Parts .................................................................... 10

3.5 Sanitizing The Freezers and Freezer Parts...................................................................... 15

3.6 Assembly of Freezer ....................................................................................................... 15

3.7 Mix Information................................................................................................................ 17

3.8 Freeze Down and Operation ............................................................................................ 17

3.9 Dispensing Product ......................................................................................................... 17

3.10 Routine Cleaning ............................................................................................................. 17

3.11 Preventative Maintenance ................................................................................................ 17

3.12 Extended Storage............................................................................................................ 18

SECTION 4 DECALS AND TAGS....................................................................................................... 21

4.1 How to Order Decals and Tags........................................................................................ 21

Page 6

LIST OF ILLUSTRATIONS

Figure Illustration Page

1 Model 100C - Front.................................................................................................................... 2

2 Model 100C - Side..................................................................................................................... 2

3 Model 100F/2217G - Front......................................................................................................... 2

4 Model 100F/2217G - Side.......................................................................................................... 2

5 Adjustable Leg .......................................................................................................................... 3

6 Warning Label Locations - 100C ................................................................................................ 4

7 Warning Label Locations - 100F/2217G ..................................................................................... 5

8 Space & Ventilation Requirements ............................................................................................ 6

9 Electrical Plug........................................................................................................................... 6

10 Installing Sani-tray and Cover .................................................................................................... 6

1 1 Adjusting Cup Dispensers ......................................................................................................... 7

12 Operating Controls..................................................................................................................... 9

13 Remove Sani-tray and Cover...................................................................................................... 11

14 Draining Product ........................................................................................................................ 11

15 Removing Spigot Assembly....................................................................................................... 12

16 Removing Spigot O-RIng from Spigot Body................................................................................ 12

1 7 Cut-away View of Spigot Assembly ........................................................................................... 12

18 Removing Drive Cap and O-Ring ................................................................................................ 13

19 Removing Sealer Ring ............................................................................................................... 13

2 0 Removing Agitator Assembly and Lower Bushing ...................................................................... 13

21 Removing Divider Plate from Agitator Fingers............................................................................. 14

22 Removing Drive Shaft ................................................................................................................. 14

2 3 Exploded View of Divider plate and Agitator Assembly .............................................................. 14

24 Lubricating Drive Shaft ............................................................................................................... 15

2 5 Installing Divider Plate and Agitator Assembly........................................................................... 16

2 6 Proper Installation of Sealer Ring............................................................................................... 16

2 7 Correct and Incorrect Alignment of Vertical Center Post Guide Hole .......................................... 16

2 8 External Parts To Be Cleaned ................................................................................................... 19

Page 7

SECTION 1

INTRODUCTION

1.1 DESCRIPTION

Models 100CA, 100FA, and 2217GA freezers are gravity

fed. The freezers are equipped with fully automatic controls

to provide a uniform product. The freezers are designed to

operate with Slush Puppie neutral bases and concentrated

flavors.

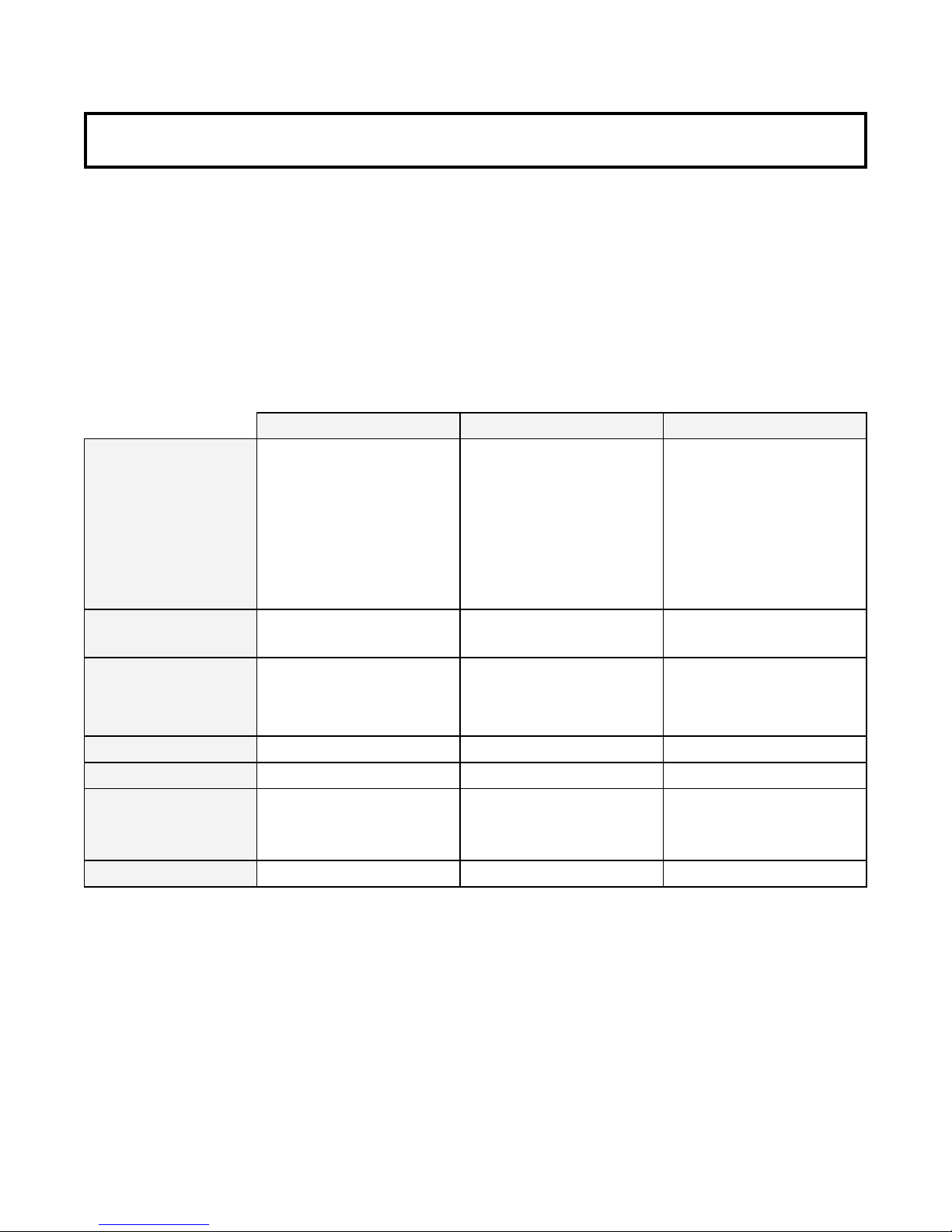

1.2 SPECIFICATIONS

This manual is designed to assist qualified service

personnel and operators in the installation, operation

and maintenance of the Models 100CA, 100FA, and

2217GA freezers.

Dimensions

width

height

depth

Weight

Electrical

running amps

connection type

Compressor

Drive Moto r

Cooling

Hopper Vol u m e

Model 100CA

Ma ch i n e w i th crate Ma chine wi th crate Ma ch i ne with cra te

15'' (38,1 c m ) 28'' (71,1 cm) 15'' (38,1 cm) 17'' (43,2 cm ) 15'' (38,1 c m ) 17'' (43,2 c m )

32'' (81,3 c m )

29-1/2'' (74,9

cm)

142 lbs (64, 4

kg)

40-1/4'' (102,2

cm)

35-1/2'' (90,2

cm)

200 lbs (90,7

kg)

Model 100FA Model 2217GA

58'' (147,3 c m ) 66'' (167,6 cm) 58'' (147, 3 cm ) 66'' (167,6 cm )

15'' (38,1 cm ) 21'' (53, 3 c m ) 15'' (38,1 cm ) 21'' (53,3 cm)

140 lbs (63,5

kg)

165 lbs (74,8

kg)

160 lbs (72, 5

kg)

185 lbs (83,9

kg)

1 Phase, 115 VAC, 60Hz1 Phase, 115 VAC, 60Hz 1 Phase, 115 VAC, 60Hz

approximate l y 7A

NEM A5- 15P included

2,250 Bt u/hr

1/12 hp

Air cool ed un its r equire 6"

(15, 2 cm ) air spa ce an

sides and back

10 gal l o n (37 , 85 liter s)

approximat el y 7A

NEM A5-15 P inc l uded NEMA5- 15P in cl uded

2,250 Btu/h r 2,250 Bt u/hr

1/12 h p

Air cool ed un it s r eq uire 6"

(15,2 cm) air space at

front an d back.

10 gallon ( 37, 85 l it er s)

approximately 9A

1/12 hp

Air cooled un its require 6"

(15, 2 cm ) air spa ce at

fr ont an d back .

10 gal l on (37,85 liters )

1

Page 8

AIR OUT

Figure 1

Model 100CA - Front

Figure 2

Model 100CA - Side

Figure 3

Model 100FA/2217GA - Front

NOTE: Figures in parenthesis are in centimeters.

Figure 4

Model 100FA/2217GA - Side

2

Page 9

SECTION 2

INSTALLATION INSTRUCTIONS

2.1 SAFETY PRECAUTIONS

Do not attempt to operate the freezer until the safety

precautions and operating instructions in this manual are

read and completely understood.

Take notice of all warning labels on the freezer (Figures 6

& 7). The labels have been put there to help maintain a safe

working environment. The labels have been designed to

withstand washing and cleaning. All labels must remain

legible for the life of the freezer. Labels should be checked

periodically to be sure they can be recognized as warning

labels.

If danger, warning, or caution labels are needed, indicate

the part number, type of label, location of label, and

quantity required along with your address and advise your

distributor.

2.2 SHIPMENT AND TRANSIT

The freezer has been assembled, operated and

inspected at the factory. Upon arrival at the final destination, the complete freezer must be checked for any

damage which may have occurred during transit.

With the method of packaging used, the freezer should

arrive in excellent condition. THE CARRIER IS

RESPONSIBLE FOR ALL DAMAGE IN TRANSIT,

WHETHER VISIBLE OR CONCEALED.

NOTICE

Accurate leveling is necessary to insure proper operation

and correct drainage of freezer barrel.

W ARNING

Lifting hazard

Do not attempt to lift freezer manually . Use proper lifting equipment such as a forklift, lift table, or pallet

jack, with lifting device positioned beneath the freezer’s

base. Ensure that personnel remain clear of suspended

load. Failure to do so may result in personal injury

and/or damage to the freezer that will void any factory

warranties.

Do not pay the freight bill until the freezer has been

checked for damage. Have the carrier note any visible

damage on the freight bill. If concealed damage and/or

shortage is found later, advise the carrier within 10 days

and request inspection. The customer must place claim

for damages and/or shortages in shipment with the carrier.

2.3 FREEZER INSTALLATION

Installation of the freezer involves moving the freezer close

to its permanent location, removing all crating, setting in

place, assembling parts, and cleaning.

A. Uncrate the freezer.

B. The floor model freezers must be placed in a

solid level position. To level the freezer, turn the bottom

part of each leg in or out. Place a level on top of the

hopper, with the cover removed, to check whether or not

the freezer islevel (Fig. 5).

Figure 5

Adjustable Leg

C. The counter model freezer must be placed on a solid

level surface. Place the rubber pad furnished under the

freezer to create a seal to that surface. The counter

model freezer is air-cooled and discharges at the top.

AL LOUVERED PANELS MUST have 3" of clearance

on sides of unit, 10" of clearance at the top, and 1"

clearance at rear of unit for proper cooling.

3

Page 10

IMPORTANT NOTICE TO OPERATOR

BEFORE INSTALLING EQUIPMENT, READ THE OWNER'S MANUAL CAREFULLY. TAKE NOTE OF ALL INSTRUCTIONS AND CAUTION

DECALS ON THIS EQUIPMENT.

GO OVER THE MANUAL THOROUGHLY AND POINT OUT ALL DECALS TO YOUR EMPLOYEES, SO THEY UNDERSTAND HOW TO SAFELY

OPERATE THIS EQUIPMENT.

DO NOT REMOVE, DEFACE, OR PAINT OVER ANY DECALS. THEY ARE THERE FOR YOUR SAFETY.

(Behind Sani-tray)

CAUTION

THIS DEVICE MUST BE PLUGGED INTO A PROPERLY GROUNDED

RECEPTACLE TO PREVENT ELECTRICAL SHOCK HAZARD.

TAMPERING WITH THE PLUG OR USING VOLTAGES OTHER THAN

THE SPECIFICATIONS ON I.D. PLATE WILL VOID YOUR WARRANTY.

REFER TO OWNER'S MANUAL FOR INSTALLATION

INSTRUCTIONS.

723529

Warning Label Locations - 100C

(Behind Sani-tray)

Figure 6

4

Page 11

IMPORTANT NOTICE TO OPERATOR

BEFORE INSTALLING EQUIPMENT, READ THE OWNER'S MANUAL CAREFULLY. TAKE NOTE OF ALL INSTRUCTIONS AND CAUTION

DECALS ON THIS EQUIPMENT.

GO OVER THE MANUAL THOROUGHLY AND POINT OUT ALL DECALS TO YOUR EMPLOYEES, SO THEY UNDERSTAND HOW TO SAFELY

OPERATE THIS EQUIPMENT.

DO NOT REMOVE, DEFACE, OR PAINT OVER ANY DECALS. THEY ARE THERE FOR YOUR SAFETY.

(Affixed to condenser shroud)

THIS DEVICE MUST BE PLUGGED INTO A PROPERLY GROUNDED

RECEPTACLE TO PREVENT ELECTRICAL SHOCK HAZARD.

TAMPERING WITH THE PLUG OR USING VOLTAGES OTHER THAN THE

SPECIFICATIONS ON I.D. PLATE WILL VOID YOUR WARRANTY.

REFER TO OWNER'S MANUAL FOR INSTALLATION

INSTRUCTIONS.

723529

Warning Label Locations - 100F/2217G

CAUTION

Figure 7

5

(Affixed to condenser shroud)

Page 12

D. The floor model freezers are equipped with air-cooled

condensers and require correct ventilation. The front of

the freezer is the air intake and must be unobstructed.

Air discharges out of the rear of the unit. Do not obstruct

the discharge. Allow a 6" (15.2 cm) clearance behind

the unit (Fig. 8).

CAUTION

Risk of product damage

Air cooled condenser requires proper ventilation. Failure to provide adequate ventilation will void factory

warranties.

W ARNING

Do not alter or deform electrical plug in any way.

Altering the plug to fit into an outlet of different configuration may cause fire, risk of electrical shock, product

damage and will void the warranty.

Figure 9

Electrical Plug

Figure 8

Space and Ventilation Requirements

E. Place the ON-OFF-STIR ONLY toggle switch in the

OFF position. This switch is located on the lower left of

the freezer, under the drip tray and cover.

F. Connect the power cord. The plug is designed for 115

volt/15 amp duty. The unit must be connected to a

properly grounded receptacle. The electrical cord

furnished as part of the freezer has a three prong

grounding type plug (Fig.9). The use of an extension

cord is not recommended. If one must be used, use one

with a wire, size 12 gauge or heavier, with a ground. Do

not use an adaptor to avoid grounding equipment.

G. Install the sani-tray, cover and miscellaneous

parts on the freezeer (Fig. 10).

Figure 10

Installing Sani-tray and Cover

6

Page 13

2.4 ADJUSTING CUP DISPENSERS

To adjust the cup dispensers, install the size cup

desired into the dispenser and turn the wing nut on the

dispenser mounting bracket until enough tension is

applied to the rim of the cup to keep it from dropping out

(Fig. 11). Do not overtighten the wing nuts.

WING NUTS

Figure 11

Adjusting Cup Dispensers

7

Page 14

8

Page 15

SECTION 3

INITIAL SET-UP AND OPERATION

3.1 OPERATOR'S SAFETY PRECAUTIONS

A. Know the freezer. Read and understand the Operating

Instructions.

B. Notice all warning labels on the freezer.

C. Wear proper clothing. Avoid loose fitting garments,

and remove watches, rings or jewelry which could

cause a serious accident.

D. Maintain a clean work area. Avoid accidents by

cleaning up the area and keeping it clean.

E. Stay alert at all times. Know which switch, push-

button or control you are about to use and what

effect it is going to have.

F. Disconnect electrical cord for maintenance. Never

attempt to repair or perform maintenance on the

freezer until the main electrical power has been

disconnected.

G. Do not operate under unsafe operating conditions.

Never operate the freezer if unusual or excessive

noise or vibration occurs.

3.2 OPERATING CONTROLS AND INDICATORS

Before operating the freezer, it is required that the operator

know the function of each operating control and indicator.

Refer to Figure 12 for the locations of the operating controls

and indicators.

WARNING

Hazardous Voltage

The stirring only-off-stirring & freezing switch must be

placed in the OFF position when disassembling for

cleaning or servicing. The freezer must be disconnected

from electrical supply before removing any access panels. Only a qualified service Technician may remove

access panels. Failure to disconnect power before servicing could result in death or serious injury.

STIRRING ONLY-OFFSTIRRING & FREEZING

TOGGLE SWITCH

RESET

SWITCH

24HR TIMER

BATTERY

BACKUP

Figure 12

Operating Controls

9

HIGH PRESSURE

MANUAL RESET SWITCH

Page 16

STIRRING ONLY-OFF-STIRRING & FREEZING SWITCH

A.

The STIRRING ONLY-OFF-STIRRING & FREEZ-

ING switch is a three-position toggle switch used to

control the operation of the refrigeration system and

agitator. When the switch is placed in the STIR-

RING ONLY position, the refrigeration system will

be off and the agitator will rotate for cleaning, or if

stirring is required when the store is closed. When the

switch is placed in the OFF position, the refrigeration

system and agitator will be off. The switch should be

placed in the STIRRING & FREEZING position for

normal operation.

B. RESET SWITCH

The reset switch is a two-position breaker switch. This

switch is used to protect the freezer from mechanical

damage. The switch must be in the NORMAL

OPERATING POSITION (up) before the freezer will

operate.

Any time a condition occurs which causes the

agitator drive motor to draw excessive current, the

reset switch will automatically switch to the

OVERLOAD CUT-OUT FREEZER NOT OPERAT-

ING position. This will shut down the freezing and

agitation action of the freezer to protect the agitator

drive motor from burning out.

Should the reset switch ever trip out, move the

STIRRING ONLY-OFF-STIRRING & FREEZING

toggle switch to the STIRRING ONLY position. Then

move the reset switch back to NORMAL OPERAT-

ING POSITION (up) and allow the freezer to stir,

without refrigeration, for five minutes. After five

minutes of stirring, return the STIRRING ONLY-OFF-

STIRRING & FREEZING switch to the STIRRING &

FREEZING position.

C. 24 HOUR TIMER

To program the timer, rotate program disc in the

direction of the arrows to align the correct day/time

with the time of day mark. Then pull out for Off time

or push in for On time. Each actuator is equivalent

to 15 minutes time. Check for AM/PM centered

between 12 and 12 on rotating disc. At a 6:00 setting the

indicator will point to AM or PM.

E. SPIGOT ASSEMBLY

Dispensing of frozen mix is done by the SPIGOT

ASSEMBLY. By pulling the spigot plunger out, mix

in the form of ice crystals is dispensed through the

port on the bottom of the SPIGOT ASSEMBLY. To

stop dispensing, push the spigot plunger in.

F. FLAVOR BOTTLES

The FLAVOR BOTTLES are operated by a spring

loaded, push-button pump. By pushing down, 1/4

ounce (7.39 ml) of flavor is dispensed.

3.3 DRAINING THE FREEZER FOR DISASSEMBLING

AND CLEANING

After installation and initial set-up, the freezer exterior

must be cleaned and the freezer parts must be disassembled, cleaned and sanitized. Cleaning and sanitizing

MUST be done before the initial freeze down and operation.

Subsequent cleaning and sanitizing, after the freezer has

been operated and product has been dispensed, will

require the freezer to be completely drained of all unused

mix. Perform the following steps to drain the freezer of any

unused mix:

A. Set the STIRRING ONLY-OFF-STIRRING &

FREEZING switch to the STIRRING ONLY position

well in advance of cleaning and sanitizing to assure

complete defrosting and draining of the product

cylinder.

B. While the freezer is in the STIRRING ONLY mode,

remove the unused flavoring from the flavor bottles.

All unused flavoring should be poured into the

containers from which they came.

C. Remove the Sani-tray and cover by gently pushing

up to disengage from the support pins and pulling

out and down (Fig. 13).

D. With a bucket placed below the drain spigot, pull the

spigot to dispense (Fig. 14).

E. When liquid product is completely drained, empty

the bucket into the sink. Any remaining ice can be

removed by circulating warm water through barrel.

3.4

DISASSEMBLY AND CLEANING OF FREEZER PARTS

WARNING

D. HIGH PRESSURE MANUAL RESET SWITCH

The HIGH PRESSURE MANUAL RESET SWITCH is a

safety switch designed to protect the compressor from

damage due to excessive head pressure. When tripped,

the lever will be out; push to reset.

Hazardous Voltage

The stirring only-off-stirring & freezing switch must be

placed in the OFF position when disassembling for

cleaning or servicing. The freezer must be disconnected

from electrical supply before removing any access panels. Only a qualified service Technician may remove

access panels. Failure to disconnect power before servicing could result in death or serious injury.

10

Page 17

Figure 13

Removing Sani-tray and Cover

Inspection for worn or broken parts should be made during

every disassembly of the freezer for cleaning or other

purposes. All worn or broken parts should be replaced to

ensure safety to both the operator and the customer, and

to maintain good freezer performance as well as a quality

product.

NOTICE

Frequency of cleaning MUST comply with local health

regulations.

The exterior of the freezer must be kept clean at all times

to preserve the luster of the stainless steel. A mild alkaline

cleanser is recommended. Use a soft cloth or sponge to

apply the cleanser.

NOTICE

Do not use acid cleaners, strong caustic compounds or

abrasive materials to clean any plastic or stainless steel

parts of the freezer exterior.

A. Remove the dispensers from the side of the freezer

by pulling straight up. Clean the cup dispensers

and dispenser lids with a mild alkaline cleanser and

soft cloth or sponge.

B. Remove the sani-tray and insert by gently pushing

up to disengage from the support pins and pulling

out and down. Clean the sani-tray in the same

manner as the cup dispenses.

Figure 14

Draining Product

C. Remove the two-piece cover and mix level probe

assembly and clean.

D. Remove the flavor pumps from the bottles and

pump warm soapy water through them. Then clean

the bottles and pumps normally.

E. To remove the upper and lower spigot assemblies,

remove the retaining clip and pull the spigot assemblies straight out of the product outlet (Fig.15).

11

Page 18

È

È

Figure 15

Removing Spigot Assembly

SPLASH DEFLECTOR

FOR SPIGOT

O-RING

SHAFT & PLUG

ASSEMBLY

SPRING

Figure 16

Removing Spigot O-Ring from Spigot body

SHAFT

KNOB

SPACER

RETAINER CAP

Figure 17

Cut-away View of Spigot Assembly

12

Page 19

1. With a clean, dry towel, wipe excess lubricant from the

spigot assembly and o-ring. Firmly grasp the spigot

assembly with both hands and squeeze the o-ring

upward (Fig 16). When a loop is formed, roll the o-ring

out of the groove toward the end of the spigot assembly.

(See Fig. 17 for a cutaway view of the spigot assembly.)

CAUTION

Do not use any type of sharp object to remove O-rings.

Sharp objects may damage spigot bodies.

2. Place all loose parts in a pan or container and take

them to the wash sink, filled with warm, soapy water, for

cleaning.

3. Wash the product outlet with warm soapy water

using the brush provided.

G. For removal and disassembly of the divider plate

and agitator assembly, refer to the following steps:

WARNING

Hazardous Voltage

The stirring Only-Off-Stirring & Freezing switch must be

placed in the OFF position when disassembling for

cleaning or servicing. The freezer must be disconnected

from electrical supply before removing any access panels. Only a qualified service technician may remove

access panels. Failure to disconnect power before servicing could result in death or serious injury.

1. Remove the drive cap and o-ring from the agitator

tube (Fig.18).

2. Remove the sealer ring by squeezing the looped

section and lifting out of the product cylinder (Fig. 19).

Figure 19

Removing Sealer Ring

3. To remove the divider plate and agitator assembly, the

divider plate must be first rotated counterclockwise to

unlock and lift out of the product cylinder.

4. Once the divider plate and agitator assembly are

lifted off the vertical product cylinder center post and

out of the product cylinder, remove the divider plate

assembly and anti-lift disc. Remove the plastic

agitator bushing from the bottom of the product

cylinder center post by lifting up and out of the

product cylinder (Fig. 20). - Refer to Figure 23 for an

exploded view.

Figure 18

Removing Drive Cap and O-Ring

Figure 20

Removing Agitator Assembly and Lower Bushing

13

Page 20

5. Unscrew the divider plate from the agitator fingers

and remove (Fig.21).

Figure 21

Removing Divider Plate from Agitator Fingers

6. Remove the drive shaft by pulling straight up and

out of the vertical center post (Fig.22).

Figure 22

Removing Drive Shaft

Figure 23

Exploded View of Divider Plate and Agitator

Assembly

7. Place all loose parts in a pan or container and take

them to the wash sink, filled with warm, soapy

water, for cleaning.

CAUTION

Do not damage parts be dropping or rough handling.

Mishandling parts will void factory warranties.

NOTICE

Do not attempt to wash the inside of the vertical product

cylinder center post.

8. Wash the inside of the product cylinder with warm,

soapy water, using the brush provided.

14

Page 21

3.5 SANITIZING THE FREEZER AND FREEZER

PARTS

After the freezer parts have been soaked and washed in

warm, soapy water, they should be rinsed thoroughly in

clean water.

All parts must be sanitized before assembling with a

USDA certified food grade sanitizing solution (50 parts per

million of free available chlorine or equivalent is acceptable).

CAUTION

Avoid prolonged contact of sanitizer with freezer parts.

Prolonged contact of sanitizer with freezer may cause

corrosion of stainless steel parts.

3.6 ASSEMBLY OF FREEZER

To assemble the freezer and freezer parts, refer to the

following steps:

A. Mix a sanitizing solution of 50 parts per million to

sanitize all loose parts before assembling.

B. Place all loose parts in this solution, then remove

and let air dry.

C. Using this sanitizing solution and the brushes pro-

vided, sanitize the product cylinder and product

outlet by dipping the brush in the sanitizing solution

and scrubbing these areas.

D. After assembling the freezer (Section 3.6), mix approx-

imately 3 gallons (11.3 liters) of sanitizing solution and

pour into the product cylinder. Brush the walls of the

cylinder above the divider plate, with brushes provided

to sanitize this reservoir area.

E. Set the STIRRING ONLY-OFF-STIRRING &

FREEZING switch in the STIRRING ONLY position

and allow to stir for five minutes. Drain the solution

in the same manner as draining the product.

F. Pour approximately one pint (1/2 liter) of mixed

neutral base into the product cylinder. Wait one minute,

then drain the neutral base and remaining sanitizing

solution through the drain spigot.

NOTICE

Petro-Gel sanitary lubricant or equivalent must be used

when lubrication of parts is specified.

NOTICE

The United States Department of Agriculture and the Food

and Drug Administration require that lubricants used on

food processing equipment be certified for this use. Use

lubricants only in accordance with manufacturers instructions.

A. Assemble the divider plate and agitator assembly as

follows:

1. Before installing the drive shaft, lubricate the

bottom with Petro-Gel or any other type of sanitary

lubricant. Enough lubricant must be applied to

create approximately a 1/8 inch bulge at the bottom

of the drive shaft (Fig.24).

Sanitizing must be done after the freezer is clean and just

before the product cylinder is filled with mixed neutral

base. Sanitizing the night before is not effective. However,

you should always clean the freezer and parts after use.

WARNING

The United States Department of Agriculture and the

Food and Drug Administration require that all cleaning

and sanitizing solutions used with food processing

equipment be certified for this use.

When sanitizing the freezer, refer to local sanitary regulations for applicable codes and recommended disinfecting

products and procedures. The frequency of sanitizing

must comply with local health regulations.

PETRO-GEL

Figure 24. Lubricating Drive Shaft

15

Page 22

2. Install the drive shaft into the center post by

rotating and pressing down lightly on the shaft until

the shaft drops down and engages with the gear

box shaft.

3. Replace the plastic lower bushing to the bottom of

the vertical center post.

4. Assemble the divider plate to the stationary fingers.

5. Assemble the anti-lift disc onto the agitator

(See Fig.23).

6. Slide the divider plate down from the top of the

agitator tube, until it is seated properly, allowing the

agitator fingers clearance for rotation.

BACK

7. Assemble the divider plate and agitator assembly

onto the vertical center post, making sure the

indicator arrow on the divider plate is in position to

line up with the upper spigot. Grasp the agitator

tube and slide the assembly down the vertical

center post and lock (Fig. 25).

Figure 26

Proper Installation of Sealer Ring

9. Roll the agitator tube o-ring completely down the

agitator tube until it seals tightly to the divider

plate.

10. Rotate the agitator tube clockwise until the guide hole

at the top of the agitator tube forms a complete circle

with the hole at the top of the vertical center post

(Fig.27).

Figure 25

Installing Divider Plate and Agitator Assembly

8. Install the sealer ring by squeezing the looped

section and sliding down into the product cylinder.

NOTICE

For proper operation of the freezer, the looped section of

the sealer ring MUST be positioned to the back of the

product cylinder (Fig.26).

Figure 27

Correct and Incorrect Alignment

of Vertical Center Post Guide Hole

11. Assemble the drive cap onto the agitator tube, aligning

the guide pin in the drive cap with the guide hole in

the vertical center post and pressing down.

16

Page 23

B. Assemble o-rings onto the spigot plungers without

lubricant. Then apply a thin film of sanitary lubricant

to the exposed surfaces of the o-rings.

1. Insert the spigot assembly into the product outlet.

2. Slide the spigot retaining clip into position.

C. Assemble the flavor bottles as follows:

1. Replace the bottles in the flavor rack.

3.8 FREEZE DOWN AND OPERATION

A. With mixed Slush Puppie neutral base in the product

cylinder, start the freezing process by setting the

STIRRING ONLY-OFF-STIRRING & FREEZING switch

in the STIRRING & FREEZING position.

B. Although servable product can be obtained after the

freezer has been run for 1 hour, the best quality ice

crystals will develop after the freezer has been

running for several more hours.

D. Install sani-tray and cover.

E. Replace the cup dispensers on the side of the

freezer by positioning the bracket on the dispenser

above the bracket on the side of the freezer and sliding

down.

3.7 MIX INFORMATION

It is essential to follow the mixing instructions on the

neutral base container carefully. The concentration of

ingredients in the product, which determines the "Brix"

(sugar level), is very important to the operation of the

freezer and the quality of the drink. When the proper

amount of neutral base is mixed with the proper amount of

water, the mixture should have a "Brix" reading between 11

and 13.

CAUTION

Follow proper mixing procedures. Do not pour the individual ingredients (water or neutral base) directly in the

freezer and depend of the agitator to do the mixing. This

does not provide for adequate mixing and may cause

damage to the freezer.

Refer to the following steps for filling the freezer:

A. Follow instructions on the Slush Puppie neutral base

containers to mix neutral base with water. Then pour

into the freezer.

3.9 DISPENSING PRODUCT

To dispense product correctly, refer to the following steps:

A. Select the desired cup size.

B. Dispense flavor concentrate into the cup first, by

pushing the flavor pump down. Use one squirt of

flavor for small cups, two squirts for medium cups and

three squirts for large cups.

C. Place cup under and against the spigot.

D. Pull the spigot out.

E. Fill the cup. The gravity flow from the spigot will

automatically mix the flavor concentrate with the

neutral base mixture as it is dispensed.

F. When the cup is full, push the spigot in.

3.10 ROUTINE CLEANING

To remove spilled or dried mix from the freezer exterior,

simply wash in the direction of the finish with warm soapy

water or a mild alkaline cleanser and a soft cloth or sponge.

Do not use abrasive materials as they will mar the finish of

the freezer.

Refer to Figure 28 for all external parts of the freezer to be

cleaned.

B. The product cylinder has a 10 gallon capacity, when

filled approximately 1" (2.54 cm) from the top of the

cylinder. When filling the cylinder, it is necessary to

remove all trapped air from below the divider plate.

Fill the product cylinder with mix to within 1" (2.54 cm)

from the top. Place a sanitary container under the

serving spigot and dispense small amounts of liquid by

pulling out and pushing in the spigot in a series of short

bursts. Each time the spigot is closed, bubbles will rise

to the top of the liquid in the product cylinder. When no

morebubbles rise to the top, the air trapped under the

divider plate has been removed. Pour the contents of the

container back into the product cylinder.

3.11 PREVENTATIVE MAINTENANCE

It is recommended that the following maintenance schedule be followed to keep the freezer clean and operating

properly.

WARNING

Hazardous Voltage

The stirring only-off-Stirring & Freezing switch must be

placed in the OFF position when disassembling for

cleaning or servicing. The freezer must be disconnected

from electrical supply before removing any access

panels. Only a qualified Service Technician may remove

access panels. Failure to disconnect power before

servicing could result in death or serious injury.

17

Page 24

A. DAILY

1. The exterior should be kept clean at all times to

preserve the lustre of the stainless steel. A mild

alkaline cleanser is recommended. Use a soft

cloth or sponge to apply the cleanser.

CAUTION

3.12 EXTENDED STORAGE

Refer to the following steps for storage of the freezer over

any long period of time:

A. Place the STIRRING ONLY-OFF-STIRRING &

FREEZING switch in the OFF position.

Acid-based cleaners, strong caustic compounds and

abrasive cleansers will damage plastic freezer parts and

exterior panels. Use mild, alkaline cleansers only.

2. Clean the sani-tray by lifting up,out,and rinsing and

replacing.

B. WEEKLY

1. Remove the sani-tray and cover. Clean behind the

drip tray with a soap solution.

2. Check all o-rings for excessive wear and replace if

necessary.

C. MONTHLY

CAUTION

The freezer has an air cooled condenser and must have

proper air circulation.

Do not place the floor model freezer any closer than six

(6) inches (15.2 cm) from the wall.

The counter model freezer requires a 3" (7.6 cm) clearance on the sides, a 1" (2.5 cm) clearance at the rear, and

a 10" (25.4 cm) clearance at the top.

B. Disconnect (unplug) the freezer from the electrical

supply source.

C. With a warm detergent solution, thoroughly clean all

parts that come in contact with neutral base mix or

flavors. Rinse in clear water and dry all parts. Do not

sanitize.

NOTICE

Do not let cleaning solution or products stand in the

product cylinder during shutdown period.

D. Remove, disassemble and clean the spigot assem-

blies and lower bushing. Place these parts in a

plastic bag with a moist paper towel to prevent them

from becoming brittle.

Failure to clean the condenser filter may result in serious

freezer damage and could void the warranty.

CONDENSER CLEANING

1.For the floor models, remove the sani-tray and

insert. Remove the two phillips head screws from

the lower front panel and pull panel down and out.

Blow the dirt out from the opposite side of the

condenser using an air tank, CO2 tank, or vacuum.

2.For the counter model, remove the six phillips head

screws from the back panel. Then clean the condenser using the same method as on the floor model.

18

Page 25

LIQUID LEVEL INDICATOR

CUP DISPENSERS AND LIDS

COVERS

FLAVOR BOTTLES

SANI-TRAY AND INSERT

ALL PANELS

Figure 28

External Parts To Be Cleaned

19

Page 26

20

Page 27

SECTION 4

DECALS AND TAGS

4.1 HOW TO ORDER DECALS AND TAGS

To assure receipt of the proper warning decals, supply your dealer or distributor with the following information:

A. Model number of equipment.

B. Serial number of model, stamped on nameplate.

C. Part number, decal description and quantity needed. Common warning decal names and numbers are

listed below.

ROFSGATDNASLACED

G7122&F001,C001SLEDOM

REBMUNTRAPNOITPIRCSED

501423KCOHSCIRTCELE:NOITUACLACED

701423STRAPGNIVOM:NOITUACLACED

311423GULPDEDNUORG:NOI

TUACLACED

531423HCTIWSYTEFAS&ELGGOTLACED

002423TESERLAUNAMLACED

393423LRIWSGNITLEOTSLACED

845423ledoMroolFF00

1-NOITALITNEVETAUQEDALACED

585423EGRAHCNOITAREGIRFERLACED

946423 ledoMretnuoC-C001-NOITALITNEVETAUQEDALAC

ED

615327REMITTES:NTTAGAT

625327LAUNAMDAERGAT

925327NOITUACGAT

735327NAELCYRATINASGAT

21

Page 28

22

Page 29

WARRANTY

MIX TRANSFER PUMPS / COCKTAIL / SLUSH

1. Scope:

Stoelting LLC warrants to the first user (the “Buyer”) that the evaporator assembly and compressor (if applicable)

of Stoelting mix transfer pump, cocktail and slush equipment will be free from defects in materials and workmanship under normal use and proper maintenance appearing within five (5) years (two (2) years for “Mirage” equipment), and that all other components of such equipment manufactured by Stoelting will be free from defects in

material and workmanship under normal use and proper maintenance appearing within twelve (12) months after

the date that such equipment is originally installed.

2. Disclaimer of Other Warranties:

THIS WARRANTY IS EXCLUSIVE; AND STOELTING HEREBY DISCLAIMS ANY IM-

PLIED W ARRANTY OF MERCHANT ABILITY OR FITNESS FOR P ARTICULAR PURPOSE.

3.

Remedies:

Stoelting’s sole obligations, and Buyer’s sole remedies, for any breach of this warranty shall be the repair or (at

Stoelting’s option) replacement of the affected component at Stoelting’s plant in Kiel, Wisconsin, or (again, at

Stoelting’s option) refund of the purchase price of the affected equipment, and, during the first ninety (90) days of

the warranty period, deinstallation/reinstallation of the affected component from/into the equipment. Those obligations/remedies are subject to the conditions that Buyer (a) signs and returns to Stoelting, upon installation, the

Warranty Registration Card for the affected equipment, (b) gives Stoelting prompt written notice of any claimed

breach of warranty within the applicable warranty period, and (c) delivers the affected equipment to Stoelting or its

designated service location, in its original packaging/crating, also within that period. Buyer shall bear the cost and

risk of shipping to and from Stoelting’s plant or designated service location.

4. Extensions:

The warranty period for deinstallation/reinstallation of the affected component from/into the equipment is extended

to twelve (12) months on the following models: SO218, SO318, SO328. The warranty period for the drive motor

to be free of defects in materials and workmanship extended to five (5) years on the following models: SO218,

SO318, SO328.

5. Exclusions and Limitations:

This warranty does not extend to parts, sometimes called “wear parts”, which are generally expected to deteriorate

and to require replacement as equipment is used, including as examples but not intended to be limited to o-rings,

hoses, seals and drive belts. All such parts are sold

AS IS.

Further, Stoelting shall not be responsible to provide any remedy under this warranty with respect to any component that fails by reason of negligence, abnormal use, misuse or abuse, use with parts or equipment not manufactured or supplied by Stoelting, or damage in transit.

THE REMEDIES SET FORTH IN THIS WARRANTY SHALL BE THE SOLE LIABILITY

STOELTING AND THE EXCLUSIVE REMEDY OF BUYER WITH RESPECT TO EQUIPMENT SUPPLIED BY STOELTING; AND IN NO EVENT SHALL STOELTING BE LIABLE

FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES, WHETHER FOR BREACH

OF WARRANTY OR OTHER CONTRACT BREACH, NEGLIGENCE OR OTHER TORT,

OR ON ANY STRICT LIABILITY THEORY.

File: Policy Manual/W arrantyslush1

Loading...

Loading...