Stoelting 100CA Installation Manual

Model 100FA / 100CA / 2217GA

OPERATORS MANUAL

Manual No. 513653 Mar. 2010

This manual provides basic information about the machine. Instructions and suggestions are

given covering its operation and care.

The illustrations and specifi cations are not binding in detail. We reserve the right to make

changes to the machine without notice, and without incurring any obligation to modify or provide new parts for machines built prior to date of change.

DO NOT ATTEMPT to operate the machine until instructions and safety precautions in this

manual are read completely and are thoroughly understood. If problems develop or questions

arise in connection with installation, operation, or servicing of the machine, contact Stoelting.

stoeltingfoodservice.com

Stoelting Foodservice Equipment

502 Highway 67

Kiel, WI 53042-1600

U.S.A.

Main Tel: 800.558.5807

Fax: 920.894.7029

Customer Service: 888.429.5920

Fax: 800.545.0662

Email: foodservice@stoelting.com

© 2014 PW Stoelting, LLC

A Few Words About Safety

Safety Information

Read and understand the entire manual before

operating or maintaining Stoelting equipment.

This manual provides the operator with information

for the safe operation and maintenance of Stoelting

equipment. As with any machine, there are hazards

associated with their operation. For this reason safety

is emphasized throughout the manual. To highlight

specifi c safety information, the following safety defi ni-

tions are provided to assist the reader.

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and

their explanations, deserve your careful attention

and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions

or warnings they give are not substitutes for proper

accident prevention measures.

If you need to replace a part, use genuine Stoelting

parts with the correct part number or an equivalent

part. We strongly recommend that you do not use

replacement parts of inferior quality.

Safety Alert Symbol:

This symbol Indicates danger, warning or caution.

Attention is required in order to avoid serious personal injury. The message that follows the symbol

contains important information about safety.

Signal Word:

Signal words are distinctive words used throughout

this manual that alert the reader to the existence and

relative degree of a hazard.

WARNING

The signal word “WARNING” indicates a potentially

hazardous situation, which, if not avoided, may result

in death or serious injury and equipment/property

damage.

CAUTION

The signal word “CAUTION” indicates a potentially

hazardous situation, which, if not avoided, may result

in minor or moderate injury and equipment/property

damage.

CAUTION

The signal word “CAUTION” not preceded by the

safety alert symbol indicates a potentially hazardous

situation, which, if not avoided, may result in equipment/property damage.

NOTE (or NOTICE)

The signal word “NOTICE” indicates information or

procedures that relate directly or indirectly to the

safety of personnel or equipment/property.

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

SECTION 1 INTRODUCTION .............................................................................................................. 1

1.1 Description ...................................................................................................................... 1

1.2 Specifications.................................................................................................................. 1

SECTION 2 INSTALLATION INSTRUCTIONS...................................................................................... 3

2.1 Safety Precautions.......................................................................................................... 3

2.2 Shipment and Transit ...................................................................................................... 3

2.3 Freezer Installation.......................................................................................................... 3

2.4 Adjusting Cup Dispensers ............................................................................................... 7

SECTION 3 INITIAL SET-UP AND OPERATION ................................................................................. 9

3.1 Operator's Safety Precautions ......................................................................................... 9

3.2 Operating Controls and Indicators.................................................................................... 9

3.3 Draining the Freezer For Disassembling and Cleaning..................................................... 10

3.4 Disassembly and Cleaning of Freezer Parts .................................................................... 10

3.5 Sanitizing The Freezers and Freezer Parts...................................................................... 15

3.6 Assembly of Freezer ....................................................................................................... 15

3.7 Mix Information................................................................................................................ 17

3.8 Freeze Down and Operation ............................................................................................ 17

3.9 Dispensing Product ......................................................................................................... 17

3.10 Routine Cleaning ............................................................................................................. 17

3.11 Preventative Maintenance ................................................................................................ 17

3.12 Extended Storage............................................................................................................ 18

SECTION 4 DECALS AND TAGS....................................................................................................... 21

4.1 How to Order Decals and Tags........................................................................................ 21

LIST OF ILLUSTRATIONS

Figure Illustration Page

1 Model 100C - Front.................................................................................................................... 2

2 Model 100C - Side..................................................................................................................... 2

3 Model 100F/2217G - Front......................................................................................................... 2

4 Model 100F/2217G - Side.......................................................................................................... 2

5 Adjustable Leg .......................................................................................................................... 3

6 Warning Label Locations - 100C ................................................................................................ 4

7 Warning Label Locations - 100F/2217G ..................................................................................... 5

8 Space & Ventilation Requirements ............................................................................................ 6

9 Electrical Plug........................................................................................................................... 6

10 Installing Sani-tray and Cover .................................................................................................... 6

1 1 Adjusting Cup Dispensers ......................................................................................................... 7

12 Operating Controls..................................................................................................................... 9

13 Remove Sani-tray and Cover...................................................................................................... 11

14 Draining Product ........................................................................................................................ 11

15 Removing Spigot Assembly....................................................................................................... 12

16 Removing Spigot O-RIng from Spigot Body................................................................................ 12

1 7 Cut-away View of Spigot Assembly ........................................................................................... 12

18 Removing Drive Cap and O-Ring ................................................................................................ 13

19 Removing Sealer Ring ............................................................................................................... 13

2 0 Removing Agitator Assembly and Lower Bushing ...................................................................... 13

21 Removing Divider Plate from Agitator Fingers............................................................................. 14

22 Removing Drive Shaft ................................................................................................................. 14

2 3 Exploded View of Divider plate and Agitator Assembly .............................................................. 14

24 Lubricating Drive Shaft ............................................................................................................... 15

2 5 Installing Divider Plate and Agitator Assembly........................................................................... 16

2 6 Proper Installation of Sealer Ring............................................................................................... 16

2 7 Correct and Incorrect Alignment of Vertical Center Post Guide Hole .......................................... 16

2 8 External Parts To Be Cleaned ................................................................................................... 19

SECTION 1

INTRODUCTION

1.1 DESCRIPTION

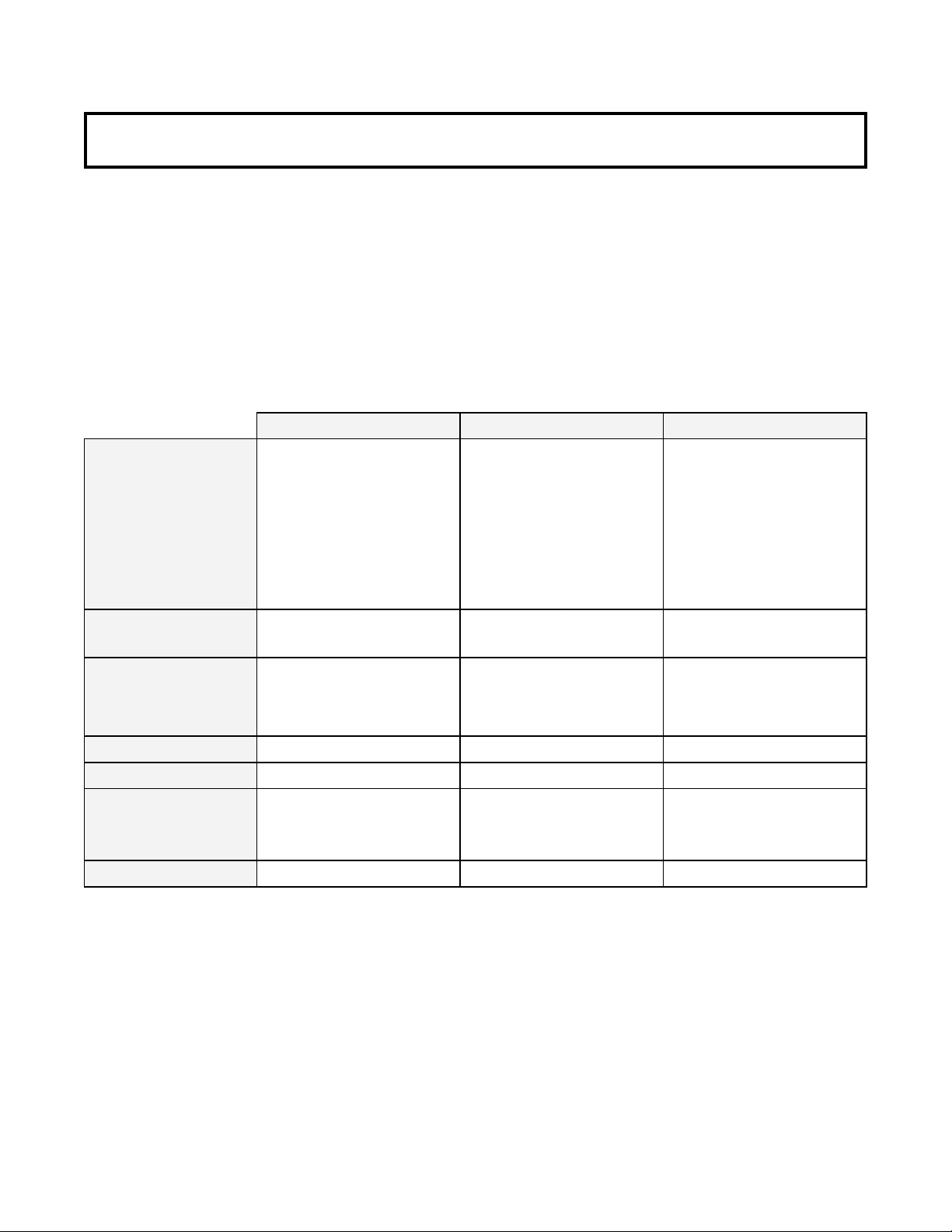

Models 100CA, 100FA, and 2217GA freezers are gravity

fed. The freezers are equipped with fully automatic controls

to provide a uniform product. The freezers are designed to

operate with Slush Puppie neutral bases and concentrated

flavors.

1.2 SPECIFICATIONS

This manual is designed to assist qualified service

personnel and operators in the installation, operation

and maintenance of the Models 100CA, 100FA, and

2217GA freezers.

Dimensions

width

height

depth

Weight

Electrical

running amps

connection type

Compressor

Drive Moto r

Cooling

Hopper Vol u m e

Model 100CA

Ma ch i n e w i th crate Ma chine wi th crate Ma ch i ne with cra te

15'' (38,1 c m ) 28'' (71,1 cm) 15'' (38,1 cm) 17'' (43,2 cm ) 15'' (38,1 c m ) 17'' (43,2 c m )

32'' (81,3 c m )

29-1/2'' (74,9

cm)

142 lbs (64, 4

kg)

40-1/4'' (102,2

cm)

35-1/2'' (90,2

cm)

200 lbs (90,7

kg)

Model 100FA Model 2217GA

58'' (147,3 c m ) 66'' (167,6 cm) 58'' (147, 3 cm ) 66'' (167,6 cm )

15'' (38,1 cm ) 21'' (53, 3 c m ) 15'' (38,1 cm ) 21'' (53,3 cm)

140 lbs (63,5

kg)

165 lbs (74,8

kg)

160 lbs (72, 5

kg)

185 lbs (83,9

kg)

1 Phase, 115 VAC, 60Hz1 Phase, 115 VAC, 60Hz 1 Phase, 115 VAC, 60Hz

approximate l y 7A

NEM A5- 15P included

2,250 Bt u/hr

1/12 hp

Air cool ed un its r equire 6"

(15, 2 cm ) air spa ce an

sides and back

10 gal l o n (37 , 85 liter s)

approximat el y 7A

NEM A5-15 P inc l uded NEMA5- 15P in cl uded

2,250 Btu/h r 2,250 Bt u/hr

1/12 h p

Air cool ed un it s r eq uire 6"

(15,2 cm) air space at

front an d back.

10 gallon ( 37, 85 l it er s)

approximately 9A

1/12 hp

Air cooled un its require 6"

(15, 2 cm ) air spa ce at

fr ont an d back .

10 gal l on (37,85 liters )

1

AIR OUT

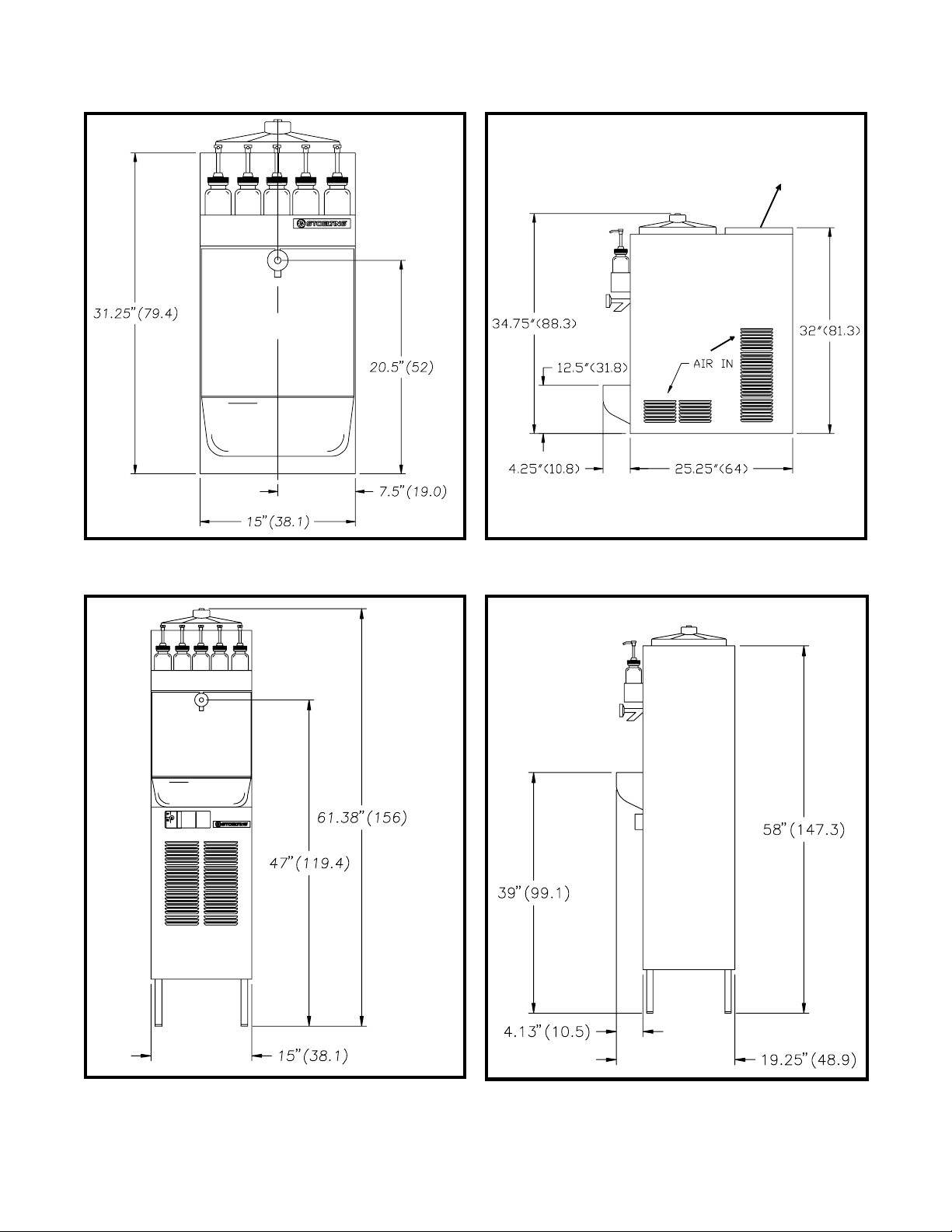

Figure 1

Model 100CA - Front

Figure 2

Model 100CA - Side

Figure 3

Model 100FA/2217GA - Front

NOTE: Figures in parenthesis are in centimeters.

Figure 4

Model 100FA/2217GA - Side

2

SECTION 2

INSTALLATION INSTRUCTIONS

2.1 SAFETY PRECAUTIONS

Do not attempt to operate the freezer until the safety

precautions and operating instructions in this manual are

read and completely understood.

Take notice of all warning labels on the freezer (Figures 6

& 7). The labels have been put there to help maintain a safe

working environment. The labels have been designed to

withstand washing and cleaning. All labels must remain

legible for the life of the freezer. Labels should be checked

periodically to be sure they can be recognized as warning

labels.

If danger, warning, or caution labels are needed, indicate

the part number, type of label, location of label, and

quantity required along with your address and advise your

distributor.

2.2 SHIPMENT AND TRANSIT

The freezer has been assembled, operated and

inspected at the factory. Upon arrival at the final destination, the complete freezer must be checked for any

damage which may have occurred during transit.

With the method of packaging used, the freezer should

arrive in excellent condition. THE CARRIER IS

RESPONSIBLE FOR ALL DAMAGE IN TRANSIT,

WHETHER VISIBLE OR CONCEALED.

NOTICE

Accurate leveling is necessary to insure proper operation

and correct drainage of freezer barrel.

W ARNING

Lifting hazard

Do not attempt to lift freezer manually . Use proper lifting equipment such as a forklift, lift table, or pallet

jack, with lifting device positioned beneath the freezer’s

base. Ensure that personnel remain clear of suspended

load. Failure to do so may result in personal injury

and/or damage to the freezer that will void any factory

warranties.

Do not pay the freight bill until the freezer has been

checked for damage. Have the carrier note any visible

damage on the freight bill. If concealed damage and/or

shortage is found later, advise the carrier within 10 days

and request inspection. The customer must place claim

for damages and/or shortages in shipment with the carrier.

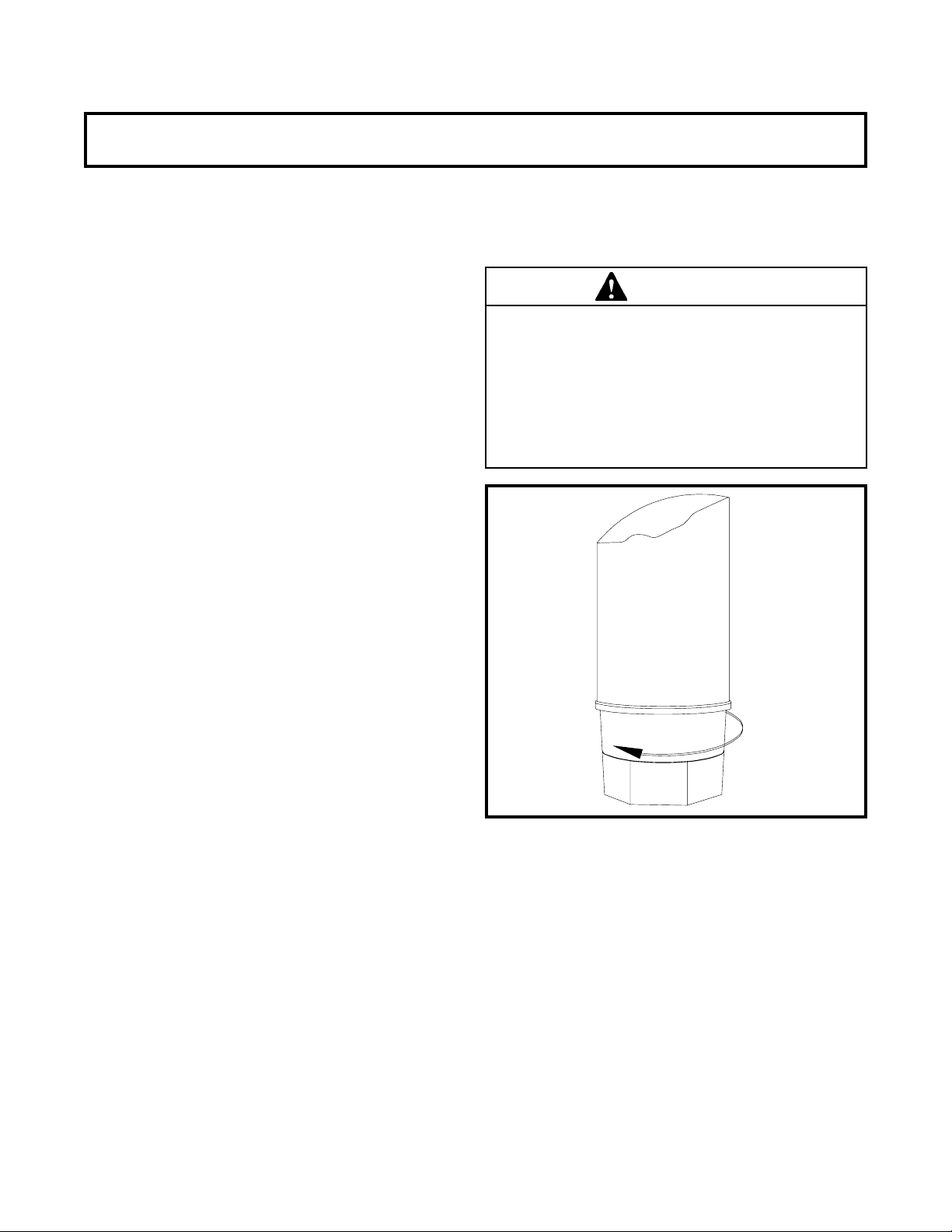

2.3 FREEZER INSTALLATION

Installation of the freezer involves moving the freezer close

to its permanent location, removing all crating, setting in

place, assembling parts, and cleaning.

A. Uncrate the freezer.

B. The floor model freezers must be placed in a

solid level position. To level the freezer, turn the bottom

part of each leg in or out. Place a level on top of the

hopper, with the cover removed, to check whether or not

the freezer islevel (Fig. 5).

Figure 5

Adjustable Leg

C. The counter model freezer must be placed on a solid

level surface. Place the rubber pad furnished under the

freezer to create a seal to that surface. The counter

model freezer is air-cooled and discharges at the top.

AL LOUVERED PANELS MUST have 3" of clearance

on sides of unit, 10" of clearance at the top, and 1"

clearance at rear of unit for proper cooling.

3

Loading...

Loading...