Page 1

Models 100F & C, 2217G

SERVICE MANUAL

Manual No. 513554

Page 2

Page 3

SERVICE MANUAL

MODELS 100 F & C AND 2217G SLUSH FREEZERS

This manual provides basic information about the freezer. Instructions and suggestions are given

covering its operation and care.

The illustrations and specifications are not binding in detail. We reserve the right to make

changes to the freezer without notice, and without incurring any obligation to modify or provide

new parts for freezers built prior to date of change.

DO NOT ATTEMPT to service or operate the freezer until instructions and safety precautions in

this manual are read completely and are thoroughly understood. If problems develop or questions

arise in connection with installation, operation or servicing of the freezer, contact your distributor.

STOELTING, LLC Tele: 920-894-2293

502 HWY. 67

KIEL, WI 53042-1600 Fax: 920-894-7029

Page 4

Page 5

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

SECTION 1 INTRODUCTION .............................................................................................................. 1

1.1 Descriptions .................................................................................................................... 1

1.2 Specifications.................................................................................................................. 1

SECTION 2 INSTALLATION INSTRUCTIONS...................................................................................... 3

2.1 Safety Precautions.......................................................................................................... 3

2.2 Shipment and Transit ...................................................................................................... 3

2.3 Freezer Installation .......................................................................................................... 3

2.4 Adjusting Cup Dispensers ............................................................................................... 7

SECTION 3 INITIAL SET-UP AND OPERATION ................................................................................. 9

3.1 Operator's Safety Precautions ......................................................................................... 9

3.2 Operating Controls and Indicators.................................................................................... 9

3.3 Draining the Freezer For Disassembling and Cleaning..................................................... 10

3.4 Disassembly and Cleaning of Freezer Parts .................................................................... 10

3.5 Sanitizing The Freezers and Freezer Parts...................................................................... 15

3.6 Assembly of Freezer ....................................................................................................... 15

3.7 Mix Information................................................................................................................ 17

3.8 Freeze Down and Operation ............................................................................................ 17

3.9 Dispensing Product ......................................................................................................... 17

3.10 Routine Cleaning ............................................................................................................. 17

3.11 Preventative Maintenance ................................................................................................ 17

3.12 Extended Storage............................................................................................................ 18

SECTION 4 DECALS AND TAGS....................................................................................................... 21

4.1 How to Order Decals and Tags........................................................................................ 21

SECTION 5 REFRIGERATION COMPONENTS AND ADJUSTMENTS ............................................... 23

5.1 Refrigeration System ....................................................................................................... 23

5.2 Compressor..................................................................................................................... 23

5.3 Condenser ....................................................................................................................... 23

SECTION 6 ELECTRICAL SYSTEM OPERATION AND ADJUSTMENTS ........................................... 27

6.1 24 Hour Timer.................................................................................................................. 27

6.2 Electronic Torque Control ................................................................................................ 27

SECTION 7 MAJOR COMPONENT REMOVAL AND INSTALLATION................................................. 29

7.1 Introduction ..................................................................................................................... 29

7.2 Condenser Fan Removal.................................................................................................. 29

7.3 Drive Motor Removal ........................................................................................................................... 29

7.4 Compressor Removal ...................................................................................................... 29

7.5 Compressor Installation ................................................................................................... 30

7.6 Drive Motor Installation .................................................................................................... 31

7.7 Condenser Fan Installation .............................................................................................. 31

SECTION 8 TROUBLESHOOTING ..................................................................................................... 33

8.1 Compressor Run Capacitor Open, Shorted or Blown........................................................ 34

8.2 Compressor Relay Defective or Burned Out ..................................................................... 34

8.3 Compressor Starts and Runs, But Short Cycles On Overload Protector .......................... 34

8.4 Compressor Runs Continuously ...................................................................................... 34

8.5 Unit Noisy ....................................................................................................................... 34

8.6 Compressor Will Not Start............................................................................................... 34

8.7 Compressor Will Not Start - Hums But Trips On Overload Protector................................ 35

8.8 Compressor Starts, But Does Not Switch Off of Start Winding ........................................ 35

Page 6

TABLE OF CONTENTS

8.9 Compressor Start Capacitor Open, Shorted or Blown ...................................................... 35

8.10 Freezer Will Not Start...................................................................................................... 35

8.11 Drive Motor Overload Trips (Freezer Shuts Down When Running) .................................... 35

8.12 Compressor Will Not Run, But Drive Motor Runs ............................................................. 35

8.13 Product Dispenses Incorrectly......................................................................................... 35

8.14 Product is Too Thin ......................................................................................................... 36

8.15 Agitator Does Not Rotate................................................................................................. 36

8.16 No Ice Crystals On Initial Freeze Down ........................................................................... 36

8.17 Excessive Ice Crystals Above Divider Plate ..................................................................... 36

8.18 Spigot Leaking or Stuck .................................................................................................. 36

SECTION 9 REPLACEMENT PARTS AND REFERENCE DRAWINGS .............................................. 37

9.1 How to Order Parts.......................................................................................................... 37

9.2 Spigot Assembly Parts.................................................................................................... 37

9.3 Model 100C Parts List..................................................................................................... 39

9.4 Model 100F Parts List ..................................................................................................... 41

9.5 Model 2217G Parts List................................................................................................... 43

Page 7

LIST OF ILLUSTRATIONS

Figure Title Page

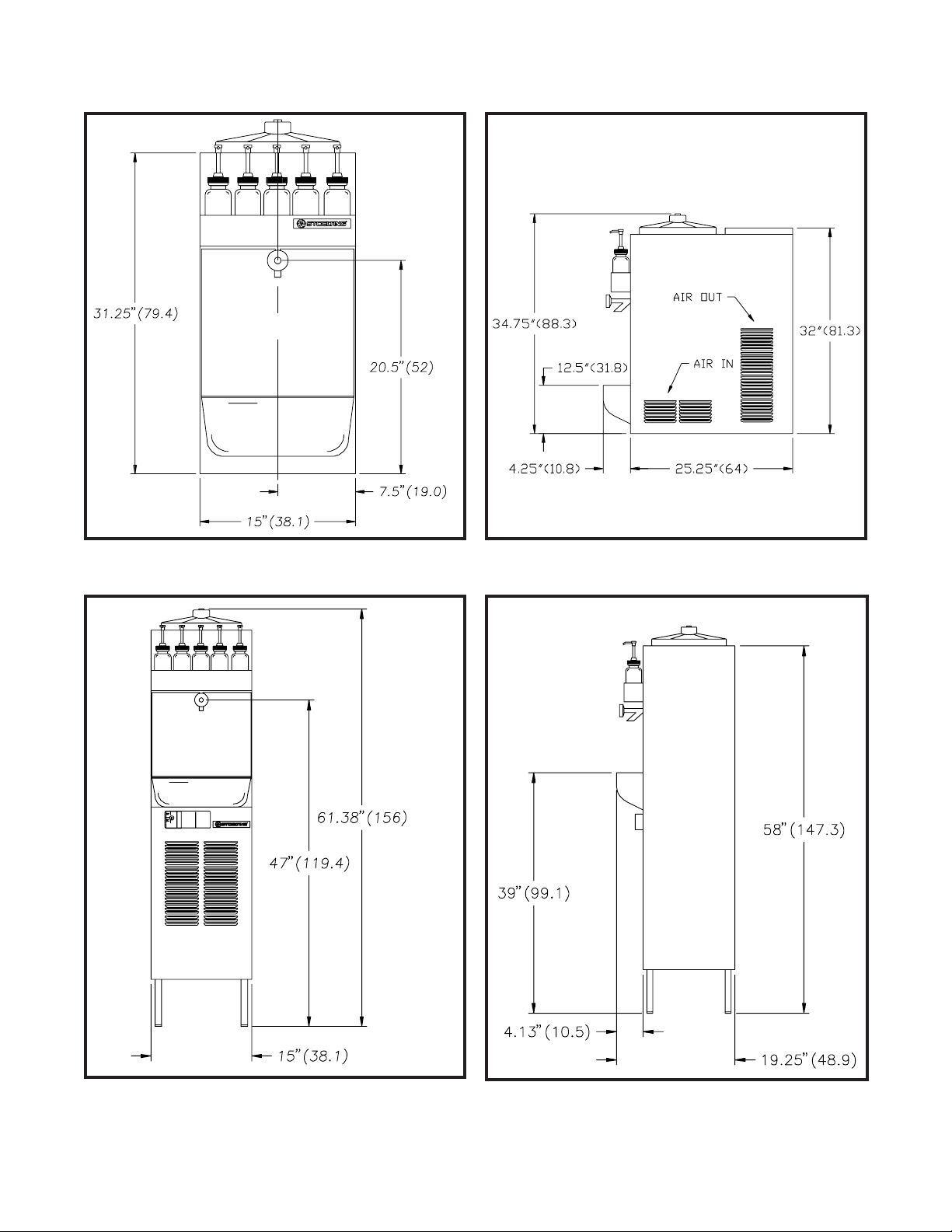

1 Model 100C - Front......................................................................................................................... 2

2 Model 100C - Side.......................................................................................................................... 2

3 Model 100F/2217G - Front.............................................................................................................. 2

4 Model 100F/2217G - Side............................................................................................................... 2

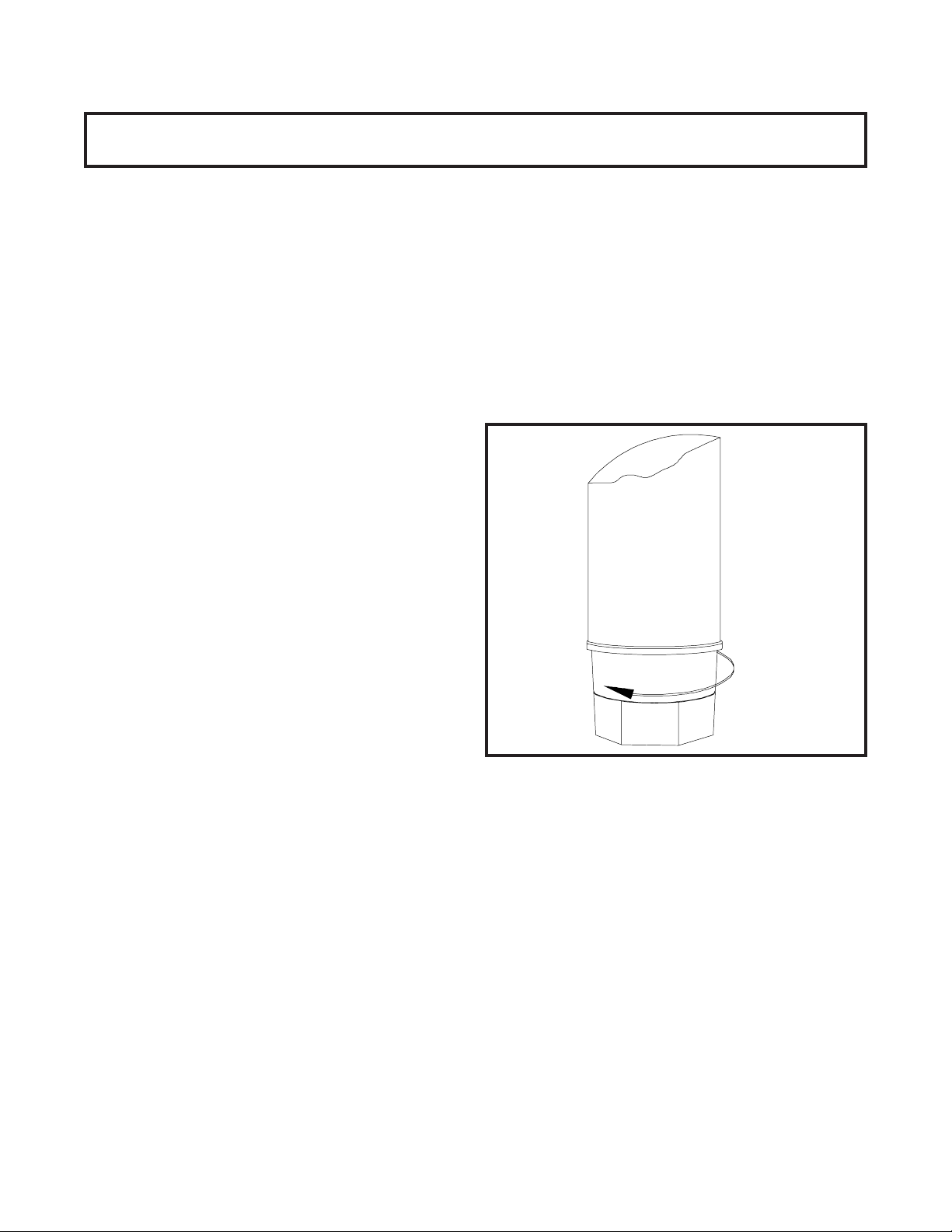

5 Adjustable Leg ............................................................................................................................... 3

6 Warning Label Locations - 100C..................................................................................................... 4

7 Warning Label Locations - 100F/2217G.......................................................................................... 5

8 Space & Ventilation Requirements ................................................................................................. 6

9 Electrical Plug................................................................................................................................ 6

10 Installing Sani-tray and Cover ......................................................................................................... 6

11 Adjusting Cup Dispensers .............................................................................................................. 7

12 Operating Controls ......................................................................................................................... 9

13 Remove Sani-tray and Cover........................................................................................................... 11

14 Draining Product............................................................................................................................. 11

15 Removing Spigot Assembly............................................................................................................ 12

16 Removing Spigot O-Ring from Spigot Body..................................................................................... 12

17 Cut-away View of Spigot Assembly ................................................................................................ 12

18 Removing Drive Cap and O-Ring ..................................................................................................... 13

19 Removing Sealer Ring .................................................................................................................... 13

20 Removing Agitator Assembly and Lower Bushing ........................................................................... 13

21 Removing Divider Plate from Agitator Fingers ................................................................................. 14

22 Removing Drive Shaft...................................................................................................................... 14

23 Exploded View of Divider plate and Agitator Assembly ................................................................... 14

24 Lubricating Drive Shaft.................................................................................................................... 15

25 Installing Divider Plate and Agitator Assembly................................................................................16

26 Proper Installation of Sealer Ring.................................................................................................... 16

27 Correct and Incorrect Alignment of Vertical Center Post Guide Hole............................................... 16

28 External Parts To Be Cleaned ........................................................................................................ 19

Page 8

LIST OF ILLUSTRATIONS

30 Removing Compressor Terminal Cover............................................................................................ 23

31 Check Winding............................................................................................................................... 23

32 Check Winding To Ground.............................................................................................................. 23

33 Check Condenser........................................................................................................................... 24

34 Remove Cap ................................................................................................................................... 24

35 Install Gauge .................................................................................................................................. 25

36 Adjust A.X.V. ................................................................................................................................. 25

37 Filter Drier Replacement................................................................................................................. 26

38 Torque Control ................................................................................................................................27

39 Tension Spring ............................................................................................................................... 27

40 Removing Torque Control ................................................................................................................ 28

41 Fan Removal .................................................................................................................................. 29

42 Disconnect Wire............................................................................................................................. 29

43 Drive Motor Removal....................................................................................................................... 29

44 Compressor Removal ..................................................................................................................... 30

45 Install Compressor ......................................................................................................................... 30

46 Remove Filter Drier......................................................................................................................... 31

47 Tension Spring ............................................................................................................................... 31

48 Fan Installation............................................................................................................................... 31

49 Exploded View of Spigot Assembly ................................................................................................ 37

50 Model 100C Exploded View............................................................................................................ 38

51 Model 100F Exploded View ............................................................................................................ 40

52 Model 2217G Exploded View.......................................................................................................... 42

Page 9

SECTION 1

INTRODUCTION

1.1 DESCRIPTION

Models 100C, 100F, and 2217G freezers are gravity fed.

The freezers are equipped with fully automatic controls to

provide a uniform product. The freezers are designed to

operate with most neutral bases and concentrated flavors.

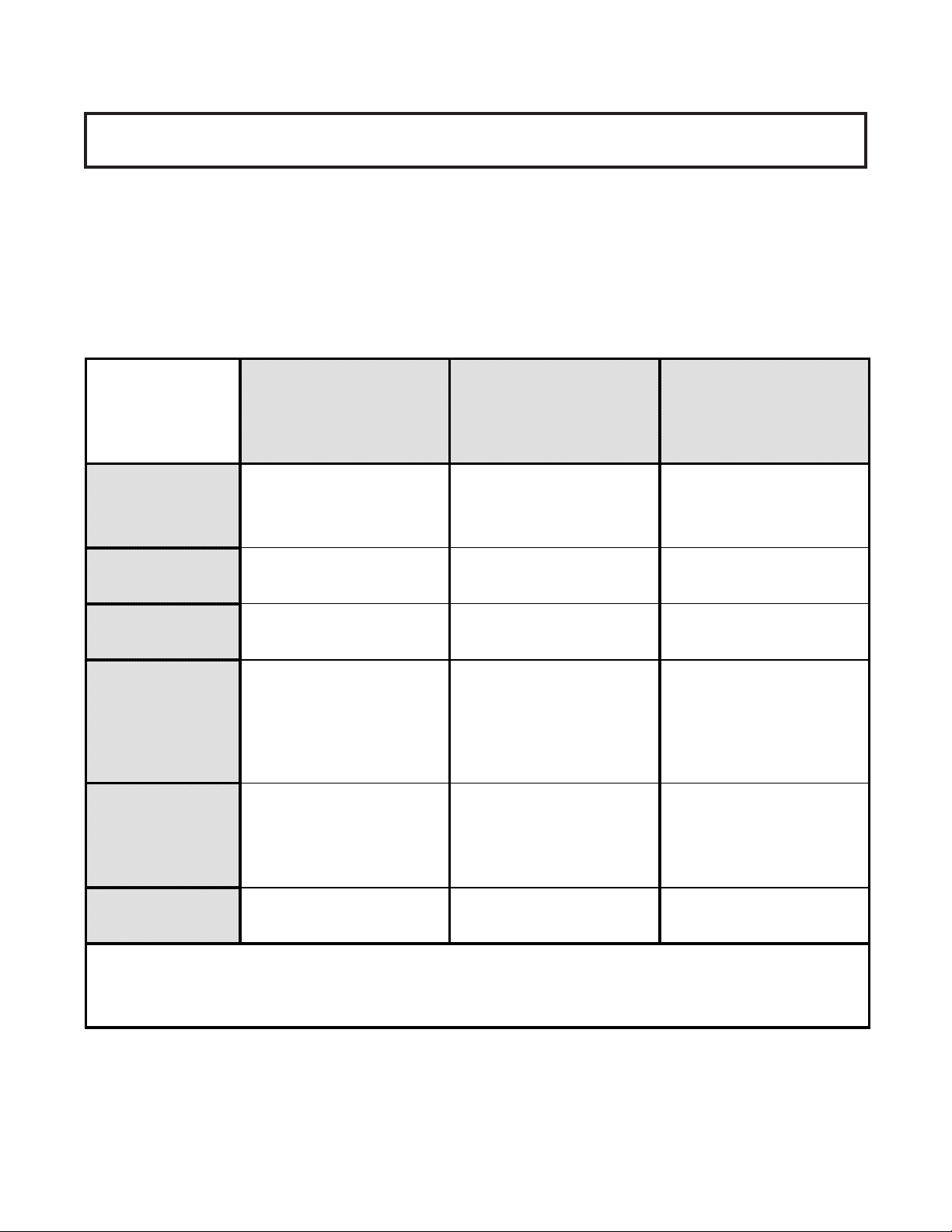

1.2 SPECIFICATIONS

This manual is designed to assist qualified service personnel and operators in the installation, operation and maintenance of the Models 100C, 100F, and 2217G freezers.

DIMENSIONS

WEIGHT

ELECTRICA L

COMPRESSOR

COOLING

100C COUNTER

MODEL FREEZER

widt h: 15" (38.1 cm)

depth: 29.5" (74.8 cm)

heig ht : 34. 75 " (88 . 3 cm)

130 lbs. (58.9 kg) 140 lbs. (63.5 kg) 140 lbs. (63.5 kg)

1 Phase, 115 VA C*

1/12 HP Drive Motor

2500 BTUH**

(frozen product output)

- Approx. 11 total running

amps. Use 15 A mp circuit breaker

Air cooled requires minimum

3" (7.6 cm) air clearance on

sides and 1" (2.5 cm) at rear

of unit.

100F FLOOR

MODEL FREEZER

width: 15" (38.1 cm)

depth: 19.25" (48.9 cm)

height: 61.38" (156 cm)

1 Phase, 115 VAC*

1/12 HP Dri v e M ot or

2500 BTUH**

(frozen product output)

- Approx. 11 total running

amps. Use 15 Amp circui t breaker

Requires unobstructed front

and 6" minimum (15.2 cm)

clearanc e at ba ck of uni t . No

clearance need ed on side of

unit.

2217G FLOOR

MODEL FREEZER

widt h: 15" (38.1 cm)

depth: 19.25" (48.9 cm)

height: 61.38" (156 cm)

1 Phase, 115 VA C*

1/12 HP Drive Motor

5200 BTUH**

(frozen product output)

- Approx. 9 total running

amps. Use 15 Amp cirucit breaker

Requires unobstructed front

and 6" mini mum (15.2 cm)

clearance at back of unit. No

clearance needed on side of

unit.

HOPPER

10 gallons (37.9 liters) 10 gallons (37. 9 li t er s ) 10 gallons (37.9 liters)

* A transformer is required if voltage is over 126.5 volts or under 103 volts.

** Under normal operating conditions.

1

Page 10

Figure 1

Model 100C - Front

Figure 2

Model 100C - Side

Figure 3

Model 100F/2217G - Front

NOTE: Figures in parenthesis are in centimeters.

Figure 4

Model 100F/2217G - Side

2

Page 11

SECTION 2

INSTALLATION INSTRUCTIONS

2.1 SAFETY PRECAUTIONS

Do not attempt to operate the freezer until the safety

precautions and operating instructions in this manual are

read and completely understood.

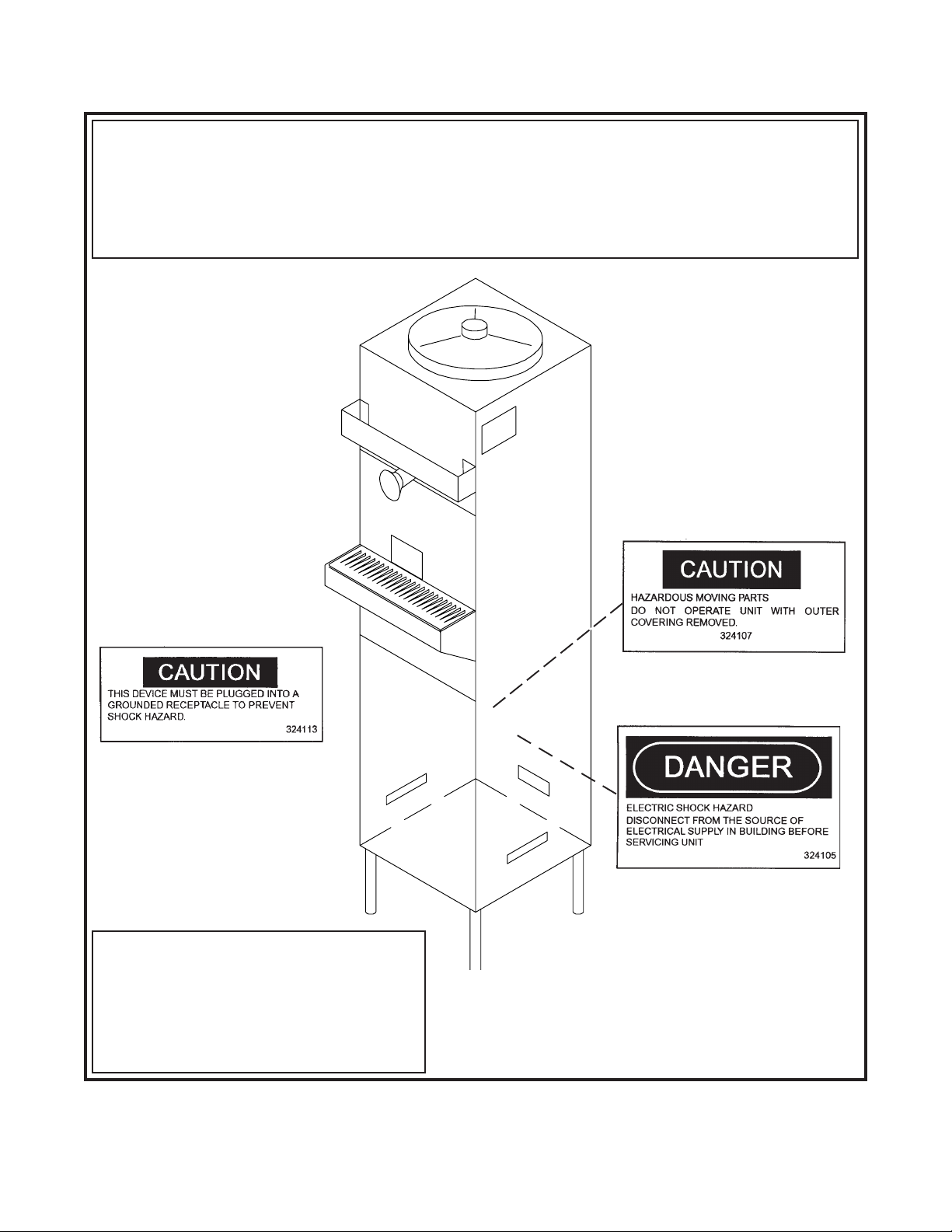

Take notice of all warning labels on the freezer (Figures 6

& 7). The labels have been put there to help maintain a safe

working environment. The labels have been designed to

withstand washing and cleaning. All labels must remain

legible for the life of the freezer. Labels should be checked

periodically to be sure they can be recognized as warning

labels.

If danger, warning, or caution labels are needed, indicate

the part number, type of label, location of label, and

quantity required along with your address and advise your

distributor.

2.2 SHIPMENT AND TRANSIT

The freezer has been assembled, operated and

inspected at the factory. Upon arrival at the final destination, the complete freezer must be checked for any

damage which may have occurred during transit.

With the method of packaging used, the freezer should

arrive in excellent condition. THE CARRIER IS

RESPONSIBLE FOR ALL DAMAGE IN TRANSIT,

WHETHER VISIBLE OR CONCEALED.

NOTE

Accurate leveling is necessary for correct

drainage of freezer barrel and to insure proper

operation.

C. The counter model freezer must be placed on a solid

level surface. Place the rubber pad furnished under the

freezer to create a seal to that surface. The counter

model freezer is air-cooled and discharges at the top.

AL LOUVERED PANELS MUST have 3" of clearance

on sides of unit, 10" of clearance at the top, and 1"

clearance at rear of unit for proper cooling.

Do not pay the freight bill until the freezer has been

checked for damage. Have the carrier note any visible

damage on the freight bill. If concealed damage and/or

shortage is found later, advise the carrier within 10 days

and request inspection. The customer must place claim

for damages and/or shortages in shipment with the carrier.

2.3 FREEZER INSTALLATION

Installation of the freezer involves moving the freezer close

to its permanent location, removing all crating, setting in

place, assembling parts, and cleaning.

A. Uncrate the freezer.

B. The floor model freezers must be placed in a

solid level position. To level the freezer, turn the bottom

part of each leg in or out. Place a level on top of the

hopper, with the cover removed, to check whether or not

the freezer islevel (Fig. 5).

Figure 5

Adjustable Leg

3

Page 12

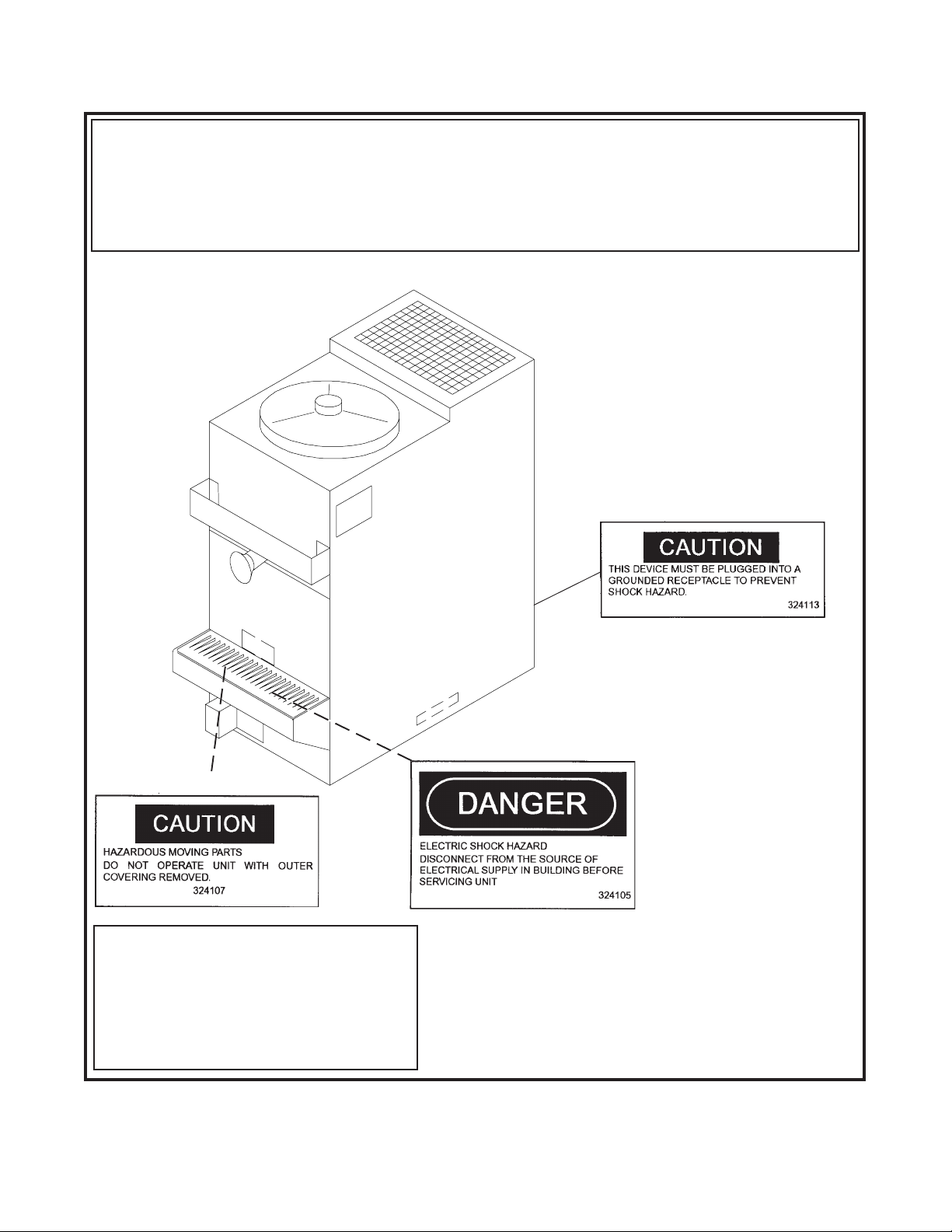

IMPORTANT NOTICE TO OPERATOR

BEFORE INSTALLING EQUIPMENT, READ THE OWNER'S MANUAL CAREFULLY. TAKE NOTE OF ALL INSTRUCTIONS AND CAUTION

DECALS ON THIS EQUIPMENT.

GO OVER THE MANUAL THOROUGHLY AND POINT OUT ALL DECALS TO YOUR EMPLOYEES, SO THEY UNDERSTAND HOW TO SAFELY

OPERATE THIS EQUIPMENT.

DO NOT REMOVE, DEFACE, OR PAINT OVER ANY DECALS. THEY ARE THERE FOR YOUR SAFETY.

(Behind Sani-tray)

CAUTION

THIS DEVICE MUST BE PLUGGED INTO A PROPERLY GROUNDED

RECEPTACLE TO PREVENT ELECTRICAL SHOCK HAZARD.

TAMPERING WITH THE PLUG OR USING VOLTAGES OTHER THAN

THE SPECIFICATIONS ON I.D. PLATE WILL VOID YOUR WARRANTY.

REFER TO OWNER'S MANUAL FOR INSTALLATION

INSTRUCTIONS.

723529

Warning Label Locations - 100C

(Behind Sani-tray)

Figure 6

4

Page 13

IMPORTANT NOTICE TO OPERATOR

BEFORE INSTALLING EQUIPMENT, READ THE OWNER'S MANUAL CAREFULLY. TAKE NOTE OF ALL INSTRUCTIONS AND CAUTION

DECALS ON THIS EQUIPMENT.

GO OVER THE MANUAL THOROUGHLY AND POINT OUT ALL DECALS TO YOUR EMPLOYEES, SO THEY UNDERSTAND HOW TO SAFELY

OPERATE THIS EQUIPMENT.

DO NOT REMOVE, DEFACE, OR PAINT OVER ANY DECALS. THEY ARE THERE FOR YOUR SAFETY.

(Affixed to condenser shroud)

THIS DEVICE MUST BE PLUGGED INTO A PROPERLY GROUNDED

RECEPTACLE TO PREVENT ELECTRICAL SHOCK HAZARD.

TAMPERING WITH THE PLUG OR USING VOLTAGES OTHER THAN THE

SPECIFICATIONS ON I.D. PLATE WILL VOID YOUR WARRANTY.

REFER TO OWNER'S MANUAL FOR INSTALLATION

INSTRUCTIONS.

723529

Warning Label Locations - 100F/2217G

CAUTION

Figure 7

5

(Affixed to condenser shroud)

Page 14

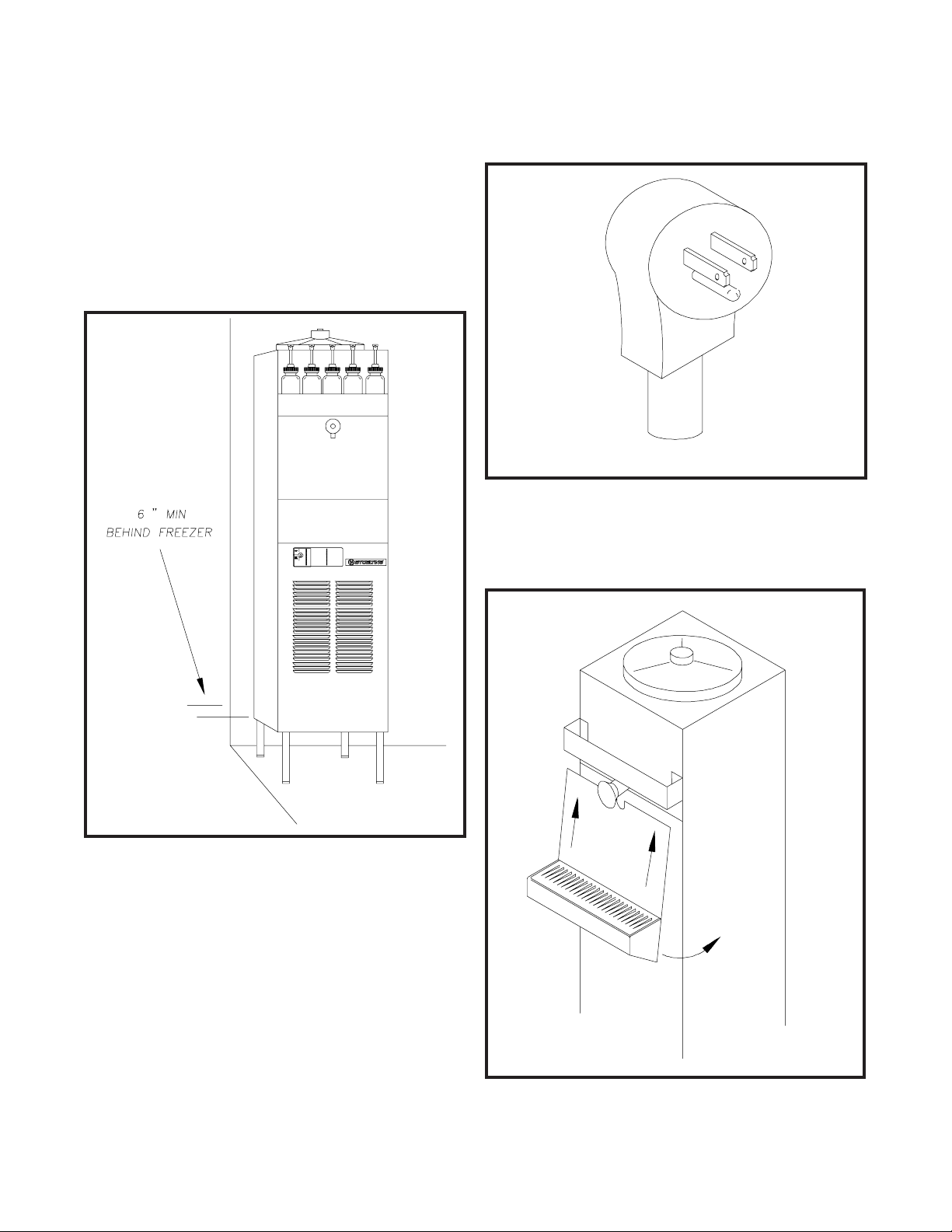

D. The floor model freezers are equipped with air-cooled

condensers and require correct ventilation. The front of

the freezer is the air intake and must be unobstructed.

Air discharges out of the rear of the unit. Do not obstruct

the discharge. Allow a 6" (15.2 cm) clearance behind

the unit (Fig. 8).

CAUTION

FAILURE TO PROVIDE ADEQUATE VENTILATION WILL

VOID WARRANTY!

CAUTION

DO NOT ALTER OR DEFORM PLUG IN ANY WAY!

Figure 9

Electrical Plug

G. Install the sani-tray, cover and miscellaneous parts

on the freezer (Fig. 10).

Figure 8

Space and Ventilation Requirements

E. Place the ON-OFF-STIR ONLY toggle switch in the

OFF position. This switch is located on the lower left of

the freezer, under the drip tray and cover.

F. Connect the power cord. The plug is designed for 115

volt/15 amp duty. The unit must be connected to a

properly grounded receptacle. The electrical cord

furnished as part of the freezer has a three prong

grounding type plug (Fig.9). The use of an extension

cord is not recommended. If one must be used, use one

with a wire, size 12 gauge or heavier, with a ground. Do

not use an adaptor to avoid grounding equipment.

Figure 10

Installing Sani-tray and Cover

6

Page 15

2.4 ADJUSTING CUP DISPENSERS

To adjust the cup dispensers, install the size cup desired

into the dispenser and turn the wing nuts on the dispenser

mounting bracket until enough tension is applied to the rim

of the cup to keep it from dropping out (Fig. 11). Do not overtighten the wing nuts.

WING NUTS

Figure 11

Adjusting Cup Dispensers

7

Page 16

8

Page 17

SECTION 3

INITIAL SET-UP AND OPERATION

3.1 OPERATOR'S SAFETY PRECAUTIONS

A. Know the freezer. Read and understand the Operating

Instructions.

B. Notice all warning labels on the freezer.

C. Wear proper clothing. Avoid loose fitting garments,

and remove watches, rings or jewelry which could

cause a serious accident.

D. Maintain a clean work area. Avoid accidents by

cleaning up the area and keeping it clean.

E. Stay alert at all times. Know which switch, push-

button or control you are about to use and what

effect it is going to have.

F. Disconnect electrical cord for maintenance. Never

attempt to repair or perform maintenance on the

freezer until the main electrical power has been

disconnected.

G. Do not operate under unsafe operating conditions.

Never operate the freezer if unusual or excessive

noise or vibration occurs.

3.2 OPERATING CONTROLS AND INDICATORS

Before operating the freezer, it is required that the operator

know the function of each operating control and indicator.

Refer to Figure 12 for the locations of the operating controls

and indicators.

WARNING

THE STIRRING ONLY-OFF-STIRRING & FREEZING

SWITCH MUST BE PLACED IN THE OFF POSITION

WHEN DISASSEMBLING FOR CLEANING OR SERVICING. THE FREEZER MUST BE DISCONNECTED FROM

ELECTRICAL SUPPLY BEFORE REMOVING ANY ACCESS PANELS. ONLY A QUALIFIED SERVICE TECHNICIAN MAY REMOVE ACCESS PANELS.

STIRRING ONLY-OFFSTIRRING & FREEZING

TOGGLE SWITCH

RESET

SWITCH

SEVEN DAY TIMER

Figure 12

Operating Controls

9

HIGH PRESSURE MANUAL

RESET SWITCH

Page 18

A. STIRRING ONLY-OFF-STIRRING & FREEZING

SWITCH

The STIRRING ONLY-OFF-STIRRING & FREEZING switch is a three-position toggle switch used to

control the operation of the refrigeration system and

agitator. When the switch is placed in the STIRRING ONLY position, the refrigeration system will

be off and the agitator will rotate for cleaning, or if

stirring is required when the store is closed. When the

switch is placed in the OFF position, the refrigeration

system and agitator will be off. The switch should be

placed in the STIRRING & FREEZING position for

normal operation.

B. RESET SWITCH

The reset switch is a two-position breaker switch. This

switch is used to protect the freezer from mechanical

damage. The switch must be in the NORMAL

OPERATING POSITION (up) before the freezer will

operate.

Any time a condition occurs which causes the

agitator drive motor to draw excessive current, the

reset switch will automatically switch to the

OVERLOAD CUT-OUT FREEZER NOT OPERATING position. This will shut down the freezing and

agitation action of the freezer to protect the agitator

drive motor from burning out.

Should the reset switch ever trip out, move

the STIRRING ONLY-OFF-STIRRING & FREEZING toggle switch to the STIRRING ONLY position.

Then move the reset switch back to NORMAL

OPERATING POSITION (up) and allow the freezer

to stir, without refrigeration, for five minutes. After

five minutes of stirring, return the STIRRING

ONLY-OFF-STIRRING & FREEZING switch to the

STIRRING & FREEZING position.

C. 24 HOUR TIMER

To program the timer, rotate program disc in the

direction of the arrows to align the correct day/time

with the time of day mark. Then pull out for Off time

or push in for On time. Each actuator is equivalent

to 15 minutes time. Check for AM/PM centered

between 12 and 12 on rotating disc. At a 6:00 setting the

indicator will point to AM or PM.

D. HIGH PRESSURE MANUAL RESET SWITCH

The HIGH PRESSURE MANUAL RESET SWITCH is a

safety switch designed to protect the compressor from

damage due to excessive head pressure. When tripped,

the lever will be out; push to reset.

E. SPIGOT ASSEMBLY

Dispensing of frozen mix is done by the SPIGOT

ASSEMBLY. By pulling the spigot plunger out, mix

in the form of ice crystals is dispensed through the

port on the bottom of the SPIGOT ASSEMBLY. To

stop dispensing, push the spigot plunger in.

F. FLAVOR BOTTLES

The FLAVOR BOTTLES are operated by a spring

loaded, push-button pump. By pushing down, 1/4

ounce (7.39 ml) of flavor is dispensed.

3.3 DRAINING THE FREEZER FOR DISASSEMBLING

AND CLEANING

After installation and initial set-up, the freezer exterior

must be cleaned and the freezer parts must be disassembled, cleaned and sanitized. Cleaning and sanitizing

MUST be done before the initial freeze down and operation.

Subsequent cleaning and sanitizing, after the freezer has

been operated and product has been dispensed, will

require the freezer to be completely drained of all unused

mix. Perform the following steps to drain the freezer of any

unused mix:

A. Set the STIRRING ONLY-OFF-STIRRING &

FREEZING switch to the STIRRING ONLY position

well in advance of cleaning and sanitizing to assure

complete defrosting and draining of the product

cylinder.

B. While the freezer is in the STIRRING ONLY mode,

remove the unused flavoring from the flavor bottles.

All unused flavoring should be poured into the

containers from which they came.

C. Remove the Sani-tray and cover by gently pushing

up to disengage from the support pins and pulling

out and down (Fig. 13).

D. With a bucket placed below the drain spigot, pull the

spigot to dispense (Fig. 14).

E. When liquid product is completely drained, empty

the bucket into the sink. Any remaining ice can be

removed by circulating warm water through barrel.

3.4 DISASSEMBLY AND CLEANING OF FREEZER

PARTS

CAUTION

PLACE THE ON-OFF-STIR ONLY SWITCH IN THE OFF

POSITION AND DISCONNECT THE FREEZER FROM

ELECTRICAL SUPPLY SOURCE BEFORE SERVICING

OR CLEANING.

10

Page 19

Figure 13

Removing Sani-tray and Cover

Inspection for worn or broken parts should be made during

every disassembly of the freezer for cleaning or other

purposes. All worn or broken parts should be replaced to

ensure safety to both the operator and the customer, and

to maintain good freezer performance as well as a quality

product.

NOTE

Frequency of cleaning MUST comply with local health

regulations.

The exterior of the freezer must be kept clean at all times

to preserve the luster of the stainless steel. A mild alkaline

cleanser is recommended. Use a soft cloth or sponge to

apply the cleanser.

NOTE

Do not use acid cleaners, strong caustic compounds or

abrasive materials to clean any plastic or stainless steel

parts of the freezer exterior.

A. Remove the dispensers from the side of the freezer

by pulling straight up. Clean the cup dispensers

and dispenser lids with a mild alkaline cleanser and

soft cloth or sponge.

B. Remove the sani-tray and insert by gently pushing

up to disengage from the support pins and pulling

out and down. Clean the sani-tray in the same

manner as the cup dispenses.

Figure 14

Draining Product

C. Remove the two-piece cover and mix level probe

assembly and clean.

D. Remove the flavor pumps from the bottles and

pump warm soapy water through them. Then clean

the bottles and pumps normally.

E. To remove the upper and lower spigot assemblies,

remove the retaining clip and pull the spigot assemblies straight out of the product outlet (Fig.15).

11

Page 20

È

È

Figure 15

Removing Spigot Assembly

O-RING

#624607

SPLASH DEFLECTOR

#1120918

SHAFT & PLUG

ASSEMBLY

#1147688

Figure 16

Removing Spigot O-Ring from Spigot body

SPRING

#694400

KNOB

#482024

RETAINER CAP

#232002

Figure 17

Cut-away View of Spigot Assembly

12

Page 21

1. With a clean, dry towel, wipe excess lubricant from the

spigot assembly and O-ring. Firmly grasp the spigot

assembly with both hands and squeeze the O-ring

upward (Fig 16). When a loop is formed, roll the O-ring

out of the groove toward the end of the spigot assembly.

(See Fig. 17 for a cutaway view of the spigot assembly.)

CAUTION

DO NOT USE ANY TYPE OF SHARP OBJECT TO

REMOVE ANY O-RINGS.

2. Place all loose parts in a pan or container and take

them to the wash sink, filled with warm, soapy water, for

cleaning.

3. Wash the product outlet with warm soapy water

using the brush provided.

G. For removal and disassembly of the divider plate

and agitator assembly, refer to the following steps:

WARNING

PLACE THE ON-OFF-STIR ONLY SWITCH IN THE OFF

POSITION AND DISCONNECT THE FREEZER

FROM ELECTRICAL SUPPLY SOURCE.

1. Remove the drive cap and O-ring from the agitator

tube (Fig.18).

Figure 19

Removing Sealer Ring

3. To remove the divider plate and agitator assembly, the

divider plate must be first rotated counterclockwise to

unlock and lift out of the product cylinder.

4. Once the divider plate and agitator assembly are

lifted off the vertical product cylinder center post and

out of the product cylinder, remove the divider plate

assembly and anti-lift disc. Remove the plastic

agitator bushing from the bottom of the product

cylinder center post by lifting up and out of the

product cylinder (Fig. 20). - Refer to Figure 23 for an

exploded view.

Figure 18

Removing Drive Cap and O-Ring

2. Remove the sealer ring by squeezing the looped

section and lifting out of the product cylinder (Fig. 19).

Figure 20

Removing Agitator Assembly and Lower Bushing

13

Page 22

5. Unscrew the divider plate from the agitator fingers

and remove (Fig.21).

Figure 21

Removing Divider Plate from Agitator Fingers

6. Remove the drive shaft by pulling straight up and

out of the vertical center post (Fig.22).

Figure 22

Removing Drive Shaft

Figure 23

Exploded View of Divider Plate and Agitator

Assembly

7. Place all loose parts in a pan or container and take

them to the wash sink, filled with warm, soapy

water, for cleaning.

CAUTION

DO NOT DAMAGE PARTS BY DROPPING OR ROUGH

HANDLING.

NOTE

Do not attempt to wash the inside of the vertical

product cylinder center post.

8. Wash the inside of the product cylinder with warm,

soapy water, using the brush provided.

14

Page 23

3.5 SANITIZING THE FREEZER AND FREEZER

PARTS

After the freezer parts have been soaked and washed in

warm, soapy water, they should be rinsed thoroughly in

clean water.

All parts must be sanitized before assembling with a

USDA certified food grade sanitizing solution (50 parts per

million of free available chlorine or equivalent is acceptable).

A. Mix a sanitizing solution of 50 parts per million to

sanitize all loose parts before assembling.

When sanitizing the freezer, refer to local sanitary regulations for applicable codes and recommended disinfecting

products and procedures. The frequency of sanitizing

must comply with local health regulations.

CAUTION

PROLONGED CONTACT OF SANITIZING SOLUTION

WITH FREEZER MAY CAUSE CORROSION OF STAINLESS STEEL PARTS.

3.6 ASSEMBLY OF FREEZER

To assemble the freezer and freezer parts, refer to the

following steps:

B. Place all loose parts in this solution, then remove

and let air dry.

C. Using this sanitizing solution and the brushes pro-

vided, sanitize the product cylinder and product

outlet by dipping the brush in the sanitizing solution

and scrubbing these areas.

D. After assembling the freezer (Section 3.6), mix approx-

imately 3 gallons (11.3 liters) of sanitizing solution and

pour into the product cylinder. Brush the walls of the

cylinder above the divider plate, with brushes provided

to sanitize this reservoir area.

E. Set the STIRRING ONLY-OFF-STIRRING &

FREEZING switch in the STIRRING ONLY position

and allow to stir for five minutes. Drain the solution

in the same manner as draining the product.

F. Pour approximately one pint (1/2 liter) of mixed

neutral base into the product cylinder. Wait one minute,

then drain the neutral base and remaining sanitizing

solution through the drain spigot.

Sanitizing must be done after the freezer is clean and just

before the product cylinder is filled with mixed neutral

base. Sanitizing the night before is not effective. However,

you should always clean the freezer and parts after use.

WARNING

THE UNITED STATES DEPARTMENT OF

AGRICULTURE AND THE FOOD AND DRUG ADMINISTRATION REQUIRE THAT ALL CLEANING AND SANITIZING SOLUTIONS USED WITH FOOD PROCESSING

EQUIPMENT BE CERTIFIED FOR THIS USE.

NOTE

Petro-Gel sanitary lubricant or equivalent must be

used when lubrication of parts is specified.

The United States Department of Agriculture and the

Food and Drug Administration require that lubricants

used on food processing equipment be certified for

this use. Use lubricants only in accordance with

manufacturers instructions.

A. Assemble the divider plate and agitator

assembly as follows:

1. Before installing the drive shaft, lubricate the

bottom with Petro-Gel or any other type of sanitary

lubricant. Enough lubricant must be applied to

create approximately a 1/8 inch bulge at the bottom

of the drive shaft (Fig.24).

PETRO-GEL

15

Figure 24. Lubricating Drive Shaft

Page 24

2. Install the drive shaft into the center post by

rotating and pressing down lightly on the shaft until

the shaft drops down and engages with the gear

box shaft.

3. Replace the plastic lower bushing to the bottom of

the vertical center post.

4. Assemble the divider plate to the stationary fingers.

5. Assemble the anti-lift disc onto the agitator

(See Fig.23).

6. Slide the divider plate down from the top of the

agitator tube, until it is seated properly, allowing the

agitator fingers clearance for rotation.

BACK

7. Assemble the divider plate and agitator assembly

onto the vertical center post, making sure the

indicator arrow on the divider plate is in position to

line up with the upper spigot. Grasp the agitator

tube and slide the assembly down the vertical

center post and lock (Fig. 25).

Figure 26

Proper Installation of Sealer Ring

9. Roll the agitator tube "O"-Ring completely down

the agitator tube until it seals tightly to the divider

plate.

10.Rotate the agitator tube clockwise until the guide hole

at the top of the agitator tube forms a complete circle

with the hole at the top of the vertical center post

(Fig.27).

Figure 25

Installing Divider Plate and Agitator Assembly

8. Install the sealer ring by squeezing the looped

section and sliding down into the product cylinder.

NOTE

For proper operation of the freezer, the looped

section of the sealer ring MUST be positioned to the

back of the product cylinder (Fig.26).

Figure 27

Correct and Incorrect Alignment

of Vertical Center Post Guide Hole

11. Assemble the drive cap onto the agitator tube, aligning

the guide pin in the drive cap with the guide hole in

the vertical center post and pressing down.

16

Page 25

B. Assemble O-rings onto the spigot plungers

without lubricant. Then apply a thin film of

sanitary lubricant to the exposed surfaces of the

O-rings.

1. Insert the spigot assembly into the product outlet.

2. Slide the spigot retaining clip into position.

divider plate has been removed. Pour the contents of the

container back into the product cylinder.

3.8 FREEZE DOWN AND OPERATION

A. With mixed Slush Puppie neutral base in the product

cylinder, start the freezing process by setting the

STIRRING ONLY-OFF-STIRRING & FREEZING switch

in the STIRRING & FREEZING position.

C. Assemble the flavor bottles as follows:

1. Replace the bottles in the flavor rack.

D. Install sani-tray and cover.

E. Replace the cup dispensers on the side of the

freezer by positioning the bracket on the dispenser

above the bracket on the side of the freezer and sliding

down.

3.7 MIX INFORMATION

It is essential to follow the mixing instructions on the

neutral base container carefully. The concentration of

ingredients in the product, which determines the "Brix"

(sugar level), is very important to the operation of the

freezer and the quality of the drink. When the proper

amount of neutral base is mixed with the proper amount of

water, the mixture should have a "Brix" reading between 11

and 13.

CAUTION

DO NOT POUR THE INDIVIDUAL INGREDIENTS (WATER OR NEUTRAL BASE) DIRECTLY INTO THE FREEZER

AND DEPEND ON THE AGITATOR TO DO THE MIXING.

THIS DOES NOT PROVIDE FOR ADEQUATE MIXING

AND MAY CAUSE DAMAGE TO THE FREEZER.

Refer to the following steps for filling the freezer:

A. Follow instructions on the Slush Puppie neutral base

containers to mix neutral base with water. Then pour

into the freezer.

B. The product cylinder has a 10 gallon capacity, when

filled approximately 1" (2.54 cm) from the top of the

cylinder. When filling the cylinder, it is necessary to

remove all trapped air from below the divider plate.

Fill the product cylinder with mix to within 1" (2.54 cm)

from the top. Place a sanitary container under the

serving spigot and dispense small amounts of liquid by

pulling out and pushing in the spigot in a series of short

bursts. Each time the spigot is closed, bubbles will rise

to the top of the liquid in the product cylinder. When no

morebubbles rise to the top, the air trapped under the

B. Although servable product can be obtained after the

freezer has been run for 1 hour, the best quality ice

crystals will develop after the freezer has been

running for several more hours.

3.9 DISPENSING PRODUCT

To dispense product correctly, refer to the following steps:

A. Select the desired cup size.

B. Dispense flavor concentrate into the cup first, by

pushing the flavor pump down. Use one squirt of

flavor for small cups, two squirts for medium cups and

three squirts for large cups.

C. Place cup under and against the spigot.

D. Pull the spigot out.

E. Fill the cup. The gravity flow from the spigot will

automatically mix the flavor concentrate with the

neutral base mixture as it is dispensed.

F. When the cup is full, push the spigot in.

3.10 ROUTINE CLEANING

To remove spilled or dried mix from the freezer exterior,

simply wash in the direction of the finish with warm soapy

water or a mild alkaline cleanser and a soft cloth or sponge.

Do not use abrasive materials as they will mar the finish of

the freezer.

Refer to Figure 28 for all external parts of the freezer to be

cleaned.

3.11 PREVENTATIVE MAINTENANCE

It is recommended that the following maintenance schedule be followed to keep the freezer clean and operating

properly.

CAUTION

NEVER ATTEMPT TO REPAIR OR PERFORM MAINTENANCE ON THE FREEZER UNTIL THE MAIN ELECTRICAL POWER HAS BEEN DISCONNECTED.

17

Page 26

A. DAILY

1. The exterior should be kept clean at all times to

preserve the lustre of the stainless steel. A mild

alkaline cleanser is recommended. Use a soft

cloth or sponge to apply the cleanser.

CAUTION

DO NOT USE ACID CLEANERS, STRONG CAUSTIC

COMPOUNDS OR ABRASIVE MATERIALS TO CLEAN

ANY PART OF THE FREEZER EXTERIOR OR PLASTIC

PARTS.

2. Clean the sani-tray by lifting up,out,and rinsing and

replacing.

3.12 EXTENDED STORAGE

Refer to the following steps for storage of the freezer over

any long period of time:

A. Place the STIRRING ONLY-OFF-STIRRING &

FREEZING switch in the OFF position.

B. Disconnect (unplug) the freezer from the electrical

supply source.

C. With a warm detergent solution, thoroughly clean all

parts that come in contact with neutral base mix or

flavors. Rinse in clear water and dry all parts. Do not

sanitize.

B. WEEKLY

1. Remove the sani-tray and cover. Clean behind the

drip tray with a soap solution.

2.Check all "O" Rings for excessive wear and replace if

necessary.

C. MONTHLY

CAUTION

THE FREEZER HAS AN AIR COOLED CONDENSER AND

MUST HAVE PROPER AIR CIRCULATION.

DO NOT PLACE THE E257 FLOOR MODEL FREEZER

ANY CLOSER THAN SIX (6) INCHES (15.2 CM) FROM

THE WALL.

THE COUNTER MODEL FREEZER REQUIRES A 3" (7.6

CM) CLEARANCE ON THE SIDES, A 1" (2.5CM) CLEARANCE AT THE REAR, AND A 10" (25.4 CM) CLEARANCE

AT THE TOP.

FAILURE TO CLEAN THE CONDENSER FILTER MAY

RESULT IN SERIOUS FREEZER DAMAGE AND COULD

VOID THE WARRANTY.

NOTE

Do not let cleaning solution or products stand in the

product cylinder during shutdown period.

D. Remove, disassemble and clean the spigot assem-

blies and lower bushing. Place these parts in a

plastic bag with a moist paper towel to prevent them

from becoming brittle.

CONDENSER CLEANING

1. For the floor models, remove the sani-tray and

insert. Remove the two phillips head screws from

the lower front panel and pull panel down and out.

Blow the dirt out from the opposite side of the

condenser using an air tank, CO2 tank, or vacuum.

2. For the counter model, remove the six phillips head

screws from the back panel. Then clean the condenser using the same method as on the floor model.

18

Page 27

LIQUID LEVEL INDICATOR

CUP DISPENSERS AND LIDS

COVERS

FLAVOR BOTTLES

SANI-TRAY AND INSERT

ALL PANELS

Figure 28

External Parts To Be Cleaned

19

Page 28

20

Page 29

SECTION 4

DECALS AND TAGS

4.1 HOW TO ORDER DECALS AND TAGS

To assure receipt of the proper warning decals, supply your dealer or distributor with the following information:

A. Model number of equipment.

B. Serial number of model, stamped on nameplate.

C. Part number, decal description and quantity needed. Common warning decal names and numbers are

listed below.

DECALS A ND TAGS FOR

MODELS 100C, 100F & 2217G

PA RT NUMBER DESCRI P TION

324105 DECAL CAUTI ON: ELEC TRIC SHOCK

324107 DECAL CAUTI ON: MOV I NG PA RTS

324113 DECAL CAUTION: GROUNDED PLUG

324135 DECAL TOGGLE & SAFETY SWITCH

324200 DECAL MANUAL RESET

324393 DECAL STOE LTING S WIRL

324548 DECAL ADEQUATE VENTILATION - 100F Floor Model

324585 DECAL REFRIGERATION CHARGE

324649 DECAL ADE QUAT E VE NTILA TI ON - 100C - Counte r Mod el

723516 TAG A TTN : S E T TI M E R

723526 TAG READ MANUAL

723529 TAG CAUTION

723537 TAG SANITARY CLEAN

21

Page 30

22

Page 31

SECTION 5

REFRIGERANT COMPONENTS AND ADJUSTMENTS

5.1 REFRIGERATION SYSTEM

This section is intended to provide qualified refrigeration

technicians with a general understanding of the refrigeration system, it's components and adjustments. It is recommended that any work done on the freezer be performed by

a qualified refrigeration technician.

5.2 COMPRESSOR

A. Winding Test

To test the compressor motor windings for possible problems, perform the following steps:

W ARNING

DISCONNECT FREEZER FROM ELECTRICAL

SUPPL Y BEFORE SERVICING.

ÅÅ

Å

ÅÅ

Meter Leads

ËË

Ë

ËË

Volt Ohm

1. Remove the two Philips head screws from the

bottom of the back panel and slide the side panel

down, back and out.

2. Remove the compressor terminal cover by inserting a standard screwdriver under the terminal

cover and retaining frame, pry out side then hold

with your hand while prying the other side. (Figure

30)

Figure 31. Check Windings

NOTE

Check your compressor handbook for proper values. (Available from compressor manufacturer. )

7. To check if windings are shorted to ground, connect one ohmmeter lead to a bare metal part on the

compressor and check terminals C, R, and S.

(Fig. 32)

ÇÇ

Ç

ÇÇ

Volt Ohm

Meter Leads

ËË

Ë

ËË

Figure 30. Removing Compressor Terminal Cover

3. Remove retaining clip and cover.

4. Remove the three wires from the compressor

terminals.

5. Set your ohmmeter at X1 and connect the ohmmeter to terminals C and R to check resistance

through run windings. Refer to Figure 31 for com-

pressor terminals.

6. Set your ohmmeter at X1 and connect the ohmmeter to terminals C and S to check resistance

through the start windings.

Figure 32. Check Winding to Ground

5.3 CONDENSER

The condenser is a air-cooled copper tube and aluminum

fin type. Condensing is totally dependent upon air flow. A

plugged condenser or restrictions in the louvered side

panel will restrict air flow.

23

Page 32

CAUTION

AIR RESTRICTIONS WILL LOWER THE CAP ACITY OF THE SYSTEM AND DAMAGE THE COMPRESSOR.

The condenser must be kept free of dirt and grease. The

freezer MUST have a minimum of 6" (15.2 cm) of ventilation

at all louvered panels for free flow of air. Make sure the

freezer is not pulling over 100°F (37°C) air from other

equipment in the area.

NOTE

Slush Freezers can not operate at temperatures over

120°F ambient.

The optional condenser filter and condenser require periodic cleaning. To clean, refer to the following procedures:

1. Remove the condenser filter from the lower front panel

and visually inspect for dirt. If the filter is dirty, shake or

brush excess dirt off the filter and wash in warm soapy

water. Once the filter is clean, rinse thoroughly in warm,

clean water and shake excess water out taking care not

to damage the filter in any way. Install the filter back

onto the front panel.

6. An alternative method of cleaning the condenser is to

use a condenser brush and vacuum.

NOTE

If the condenser is not kept clean, loss of refrigeration efficiency will result, causing extended run time

or inadequate product consistency .

7. For the Model 100C, remove the phillips head screws

from the back panel and remove the panel. Clean the

condenser following steps 4 - 6 above.

PRODUCT CYLINDER (EVAPORATOR)

An automatic expansion valve (A.X.V.) is used to control

the refrigerant flow to the freezing area of the product

cylinder. The adjustable A.X.V. is preset at the factory. If

the product is too thick or too thin, an A.X.V. adjustment

may be necessary.

A. A.X.V. Adjustment

To adjust the A.X.V., refer to the following procedures:

1. Remove the two philips head screws from the back side

panel and pull panel down and out (Model 100F).

Remove the left side and back panel (Model 100C).

2. For Model 100F, remove the sani-tray and insert.

Remove the two phillips head screws from the lower

front panel and pull panel down and out.

3. Visually inspect the condenser for dirt by shining a light

through the coil from the back of the condenser (Fig.

33.)

2. Remove the cap from the Schrader valve on the compressor (Fig. 34).

ÅÅ

Å Cap

ÅÅ

Figure 34. Remove Cap

3. Install a 0-100 P.S.I.G. gauge onto the Schrader valve

(Fig. 35).

4. Start the refrigeration cycle and read the pressure

Figure 33. Check Condenser

4. If the condenser is dirty, place a damp towel over the

condenser.

5. Using compressed air or CO2 tank, blow out the dirt

from the back of the condenser. Most of the dirt will cling

to the wet towel.

NOTE

Freezer must be full of product and past initial freeze

down.

24

Page 33

Figure 35. Install Gauge

5. Pressure gauge reading should be:

Model 100C 100F 100C 100F 2217 2217G

1. Assuming the side and rear panels have been removed,

perform the following procedures for removing the A.X.V.

Refrig. R12 R12 R22 R22 R502 R404A

Head 110 110 160 160 170 190

Pressure

Suction See See 33 33 28 42

Pressure Chart Chart

Below Below

6. If the pressure gauge reading does not fall within those

specifications, proceed with the following steps:

7. Remove the cap the the A.X.V. and, using a small

wrench, turn the adjusting screw 1/4 turn (90°) counterclockwise for more cooling or 1/4 turn (90°) clockwise

for less cooling (Fig. 36.)

8. Allow the system to level out for three to five minutes

before taking another pressure reading.

9. Should the reading still not fall within specifications,

repeat steps 8 and 9 until the correct reading is

obtained.

10.Once the correct reading is obtained, replace the cap.

Remove the pressure gauge from the Schrader valve

and replace the Schrader valve cap.

Figure 36. Adjust A.X.V.

WARNING

DISCONNECT FREEZER FROM ELECTRICAL SUPPL Y

SOURCE BEFORE SERVICING.

2. Recover the refrigerant charge, then leave a port open

to prevent pressure build-up during A.X.V. removal.

3. Remove foam insulation from surrounding lines.

4. Apply a heat sink (wet cloth) to the A.X.V.

5. Unsweat the A.X.V. from it s connecting lines.

6. Remove the A.X.V . with the heat sink.

C. T.X.V. Replacement

T o replace the A.X.V ., perform the following procedures:

CAUTION

WHEN REPLACING THE A.X.V., A HEAT SINK

(WET CLOTH) MUST BE USED TO PREVENT

DAMAGE TO THE V AL VE.

1. Position the A.X.V . with heat sink, so the refrigeration

line correspond with the proper valve ports.

11.Replace the rear panel.

B. A.X.V. Removal

CAUTION

IF IT IS NECESSARY T O REPLACE THE A.X.V ., A HEA T

SINK (WET CLOTH) MUST BE USED TO PREVENT

DAMAGE TO THE V AL VE.

2. Braze lines to the A.X.V . using the appropriate brazing

material.

3. Remove the heat sink from the A.X.V .

4. Replace any foam insulation to the surrounding lines.

5. Once the A.X.V . is installed, the refrigeration system

must be purged and evacuated to 50 microns of mercury for approximately 30 minutes.

25

Page 34

6. Break the vacuum to (0 P .S.I.G .) with dry nitrogen, then

with an open port, replace the filter drier using the

appropriate brazing material. (Fig.37).

7. Once the filter drier has been replaced, repeat the

evacuation and recharging procedures.

Open

ËË

Ë

ËË

Port

Figure 37. Filter Drier Replacement

26

Page 35

SECTION 6

ELECTRICAL SYSTEM OPERATION AND ADJUSTMENTS

6.1 24 HOUR TIMER

The 24 hr. timer is used to eliminate refrigeration during

non-use hours. When properly set it will prevent build-up of

large ice crystals and/or build-up of ice on the agitator. The

timer is located behind the lower front panel. To program

the timer, rotate program disc in the direction of the arrows

to align the correct time with the time of day. Then pull out

for OFF time or push in for ON time. Each actuator is

equivalent to 15 minutes. Check for AM/PM centered

between 12 and 12 on rotating disc. At a 6:00 setting, the

indicator will point to AM or PM.

6.2 ELECTRONIC TORQUE CONTROL

The electronic torque control is a time delay that controls

the operation of the compressor. The electronic torque

control operates in unison with two micro switches (ON

and OFF) and the agitator drive motor. If the control is

viewed from the back of the freezer while the freezer is

operating, the following conditions of normal operation will

be evident:

Left Hand Control

Bracket Arm

Left Hand (OFF)

Micro Switch

Ì

Right Hand Control

Å

Bracket Arm

Ê

É

Right Hand (ON)

Micro Switch

(Viewed from Back)

Figure 38. Torque Control

W ARNING

VIEWING THE FREEZER WITH ANY SIDE P ANEL REMOVED DURING OPERATION IS NOT RECOMMENDED, AS THE POSSIBILITY OF ELECTRICAL

SHOCK HAZARD IS GREA TL Y INCREASED. THIS PROCEDURE HAS BEEN ADDED ONL Y TO CLARIFY THE

THEORY OF OPERA TION.

1. When the right hand arm of the control bracket contacts

the right hand micro switch, the compressor will start.

2. As the compressor continues to run, ice crystals are

being formed in the product cylinder. As the drive motor

torque increases due to the formation of ice crystals,

the left-hand arm of the control bracket will gradually

move to the right and contact the left-hand micro

switch. The compressor will SHUT OFF approximately

71 to 81 seconds after the arm maintains contact with

the micro switch. This prevents eratic freeze down and

rapid recycling of the compressor.

See Figure 38 for a visual description of the components involved in this operation.

A. Consistency Adjustment

The tension spring (Fig.39), located on the right side of the

freezer, is used to adjust the product consistency. To

increase product consistency, increase the spring tension

by turning the eyebolt nut clockwise one turn. To decrease

product consistency, decrease the spring tension by

turning the eyebolt nut counterclockwise one turn.

3-1/16"

3-1/8"

(3-5/8" F257)

(Viewed from Right Side)

Figure 39. Tension Spring

NOTE

The tension spring is adjusted at the factory to

3-1/8 inches, (3-5/8 for the 2217G). If further adjustment is necessary , turn the eyebolt nut one turn at

a time in the desired direction.

B. Micro Switch Removal

Should either the right or the left micro switch be found to

be defective, either switch can be replaced by performing

the following procedures:

WARNING

DISCONNECT FREEZER FROM ELECTRICAL

SUPPL Y SOURCE BEFORE SER VICING .

27

Page 36

1. Remove the necessary panels. Model 100F back

panel, Model 100C left side panel.

2. Using a 5/16" wrench, remove the two nuts and star

washers from the torque control mounting bracket

(Fig.40).

Remove Nuts

ËË

Ë

ËË

ËË

Ë

ËË

Figure 40. Removing T orque Control

3. Remove the torque control from the mounting bracket

by pushing the assembly toward the left side of the

freezer until the mounting studs are clear of the mounting bracket. Then pull the assembly down and towards

you.

4. Using a 1/4" wrench, remove the two nuts from the rear

of the defective micro switch.

5. Remove the micro switch from the mounting studs and

disconnect from the connector.

C. Micro Switch Replacement

1. Connect a serviceable micro switch to connector.

2. Install micro switch onto the mounting studs and

fasten with the two hex nuts. Tighten nuts snugly with

1/4" wrench. Do not over tighten.

3. Position torque control behind the mounting bracket

and allow the two studs to be pushed through the holes

in the mounting bracket.

4. Install the two star washers and nuts onto the mounting studs. Tighten nuts snugly with a 5/16" wrench. Do

not over tighten.

5. Replace the back panel.

28

Page 37

SECTION 7

MAJOR COMPONENT REMOVAL AND INSTALLATION

7.1 INTRODUCTION

This section covers the removal and installation of the

condenser fan, drive motor and compressor. It is extremely

important to follow each step accurately and completely.

Failure to do so could result in further problems later.

7.2 CONDENSER FAN REMOVAL

To remove a condenser fan which has been found to be

defective, refer to the following procedures:

W ARNING

DISCONNECT FREEZER FROM ELECTRICAL

SUPPL Y SOURCE BEFORE SER VICING .

1. Remove the necessary panels: Model 100F back and

side panels, Model 100C back panel and back shroud.

2. Disconnect the condenser fan lead wires.

3. Using a 5/16" nut driver or a phillips screwdriver, remove

the four fastening screws from the fan mounting brackets (Fig.41).

2. Disconnect the lead wire from the drive motor capacitor.

3. Disconnect the wire leading from the drive motor to the

reset switch on the front of the freezer (Fig.42),

4. Remove the three socket head cap screws securing the

mounting flange to the bearing (Fig.43). Remove the

drive motor from either side.

ÅÅ

Å Connector

ÅÅ

Figure 42. Disconnect Wire

ÉÉ

É

ÉÉ

Fastening Screws

ËË

Ë

ËË

Figure 41. Fan Removal

4. Remove the fan and its supports through the side of the

freezer taking care not to damage the fan blade.

7.3 DRIVE MOTOR REMOVAL

To remove a defective drive motor, perform the following

procedures:

W ARNING

DISCONNECT FREZER FROM ELECTRICAL

SOURCE BEFORE SERVICING.

1. Remove the necessary panels. Model 100F back and

side panels. Model 100C front sides and bottom panels.

Socket

Head

Screws

Figure 43. Drive Motor Removal

If the drive motor failure is due to a defective drive motor

mount bearing, replace the bearing assembly as follows:

1. Remove snap ring.

2. Slide bearing down and off.

3. Slide new bearing on and replace snap ring. Bearing

must turn freely when assembled.

7.4 COMPRESSOR REMOVAL

To remove a defective compressor, perform the following

procedures:

29

Page 38

W ARNING

DISCONNECT FREEZER FROM ELECTRICAL

SUPPL Y SOURCE BEFORE SER VICING .

7.5 COMPRESSOR INSTALLATION

To install a serviceable compressor, perform the following

procedures:

1. Remove the necessary panels. Model 100F back and

side panels. Model 100C back panel and back shroud.

2. Disconnect lead wires at the compressor.

3. Recover refrigerant charge, then leave a port open to

prevent pressure build-up during compressor removal.

4. Unsweat the suction line and discharge line from the

compressor (Fig.44).

ÇÇ

Ç

ÇÇ

ÇÇ

Ç

ÇÇ

Suction Line

Discharge

Line

WARNING

DISCONNECT FREEZER FROM ELECTRICAL

SUPPL Y SOURCE BEFORE SER VICING .

ASSUMING THE SIDE AND BACK P ANELS HA VE

BEEN REMOVED FOR COMPRESSOR REMOV AL

AND THE ENTIRE REFRIGERATION SYSTEM

PURGED THOROUGHLY, YOU CAN BEGIN INST ALLING A NEW COMPRESSOR.

WARNING

IF ACID IS FOUND IN THE SYSTEM, CLEAN OUT

PER COMPRESSOR MANUFACTURER’S INSTRUCTIONS.

1. Install the four rubber compressor mounts on the

replacement compressor.

2. Remove all plugs from the replacement compressor.

3. Braze the access fitting line to the correct compressor

port, using the appropriate brazing material.

4. Install the compressor into the freezer, from the left

side, fitting the base over the four mounting studs.

Figure 44. Compressor Removal

5. Remove the four nuts and four washers from the base

of the compressor.

6. Remove compressor through left side of the freezer.

7. Remove the four rubber compressor mounts from the

old compressor.

NOTE

Rubber mounts are not always furnished with replacement compressors.

8. Unsweat the access fitting line from the compressor.

9. Check the compressor for a burn-out condition using an

acid test kit. If acid is found, clean out the system

per the compressor manufacturer’s instructions.

10.Sweat shut all open ports of the old compressor.

NOTE

A compressor returned to the company with any

open ports will void the warranty . ALWA YS plug any

open ports on a compressor that has been removed.

5. Install the four washers and four nuts onto the mounting

studs and tighten securely.

6. Leaving a port open to prevent pressure build-up, braze

the suction line and discharge line to the compressor

(Fig.45).

NOTE

Cap and valve must be removed.

Open

ËË

Ë

ËË

Port

Figure 45. Install Compressor

7. Connect the lead wires to the compressor. Replace the

terminal cover and retaining clip.

8. Evacuate the refrigeration system to 50 microns of

mercury for approximately 30 minutes.

30

Page 39

9. Break the vacuum (0 P.S.I.G.) through the Schrader

valve with the dry nitrogen.

10.Leaving a port open to prevent pressure build-up,

remove the filter drier and install a new filter drier using

the appropriate brazing material (Fig.46).

Filter Drier

3-1/16"

3-1/8"

(3-5/8" F257)

Figure 47. Tension Spring

6. Replace necessary panels.

7.7 CONDENSER FAN INST ALLA TION

T o install a serviceable condenser fan, perform the following procedures:

Figure 46. Remove Filter Drier

11.Purge and evacuate the refrigeration system to 50

microns of mercury for approximately 30 minutes.

12.Accurately charge the system with the amount and

type of refrigerant indicated on the freezer Model I.D.

plate.

13.Leak check all fittings and connections.

7.6 DRIVE MOTOR INSTALLATION

To install a serviceable drive motor, perform the following

procedures:

W ARNING

DISCONNECT FREEZER FROM ELECTRICAL

SUPPL Y SOURCE BEFORE SER VICING .

1. With the necessary panels removed for removal of a

defective drive motor, install the drive motor through

either side of the freezer and position mounting flange

over the bearing and line up the three holes.

2. Install the three socket head screws securing the

mounting flange to the freezer and tighten.

WARNING

DISCONNECT FREEZER FROM ELECTRICAL

SUPPL Y SOURCE BEFORE SER VICING .

1. Assuming the necessary panels have been removed

to remove a defective condenser fan, install a new condenser fan bracket through the side of the freezer and

align the holes in the fan brackets with the holes in the

condenser fan shroud attached to the freezer frame

(Fig.48).

Fastening Screws

3. Connect the wire leading from the drive motor to the

reset switch.

4. Connect the lead wire to the drive motor capacitor.

5. Connect tension spring and adjust to 3 1/16"-3 1/8"

(Fig.47).

Figure 48. Fan Installation

2. Using a 5/16" nut driver or a phillips head screwdriver,

install the four screws securing the fan supports to the

mounting brackets.

3. Connect the condenser fan lead wires.

31

Page 40

32

Page 41

SECTION 8

TROUBLESHOOTING

Troubleshooting can be difficult. The TROUBLESHOOTING INDEX on the preceding page gives a list of possible

problems. To make a repair to a problem, make reference to the cause and correction on the page indicated.

This list of problems causes and corrections will only give an indication of where a possible problem can be and what

repairs are needed. Normally, more or other repair work is needed beyond the recommendations in the list.

Remember that a problem is not normally caused by only one part, but by the relation of one part with other parts. This

list is only a guide and cannot give all possible problems and corrections. The technician must find the problem and its

source, then make the necessary repairs.

In the event the Troubleshooting Guide does not help to correct the service problem, the factory Service Department

should be contacted. Write or call:

STOELTING, INC. Tele: 920-894-2293

502 HWY. 67 800-558-5807

KIEL, WI 53042 Fax: 920-894-7029

INDEX

DESCRIPTION PAGE

8.1 Compressor run capacitor open, shorted or blown..................................................................................35

8.2 Compressor relay defective or burned out ..............................................................................................35

8.3 Compressor starts and runs, but short cycles on overload protector ......................................................35

8.4 Compressor runs continously.................................................................................................................35

8.5 Unit Noisy ..............................................................................................................................................35

8.6 Compressor will not start .......................................................................................................................35

8.7 Compressor will not start - hums but trips on overload protector ............................................................36

8.8 Compressor starts, but does not switch off of start winding ...................................................................36

8.9 Compressor start capacitor open, shorted or blown ...............................................................................36

8.10 Freezer will not start...............................................................................................................................36

8.11 Drive motor overload trips (freezer shuts down when running).................................................................36

8.12 Compressor will not run, but drive motor runs.........................................................................................36

8.13 Product dispenses incorrectly ................................................................................................................36

8.14 Product is too thin ..................................................................................................................................37

8.15 Agitator does not rotate..........................................................................................................................37

8.16 No ice crystals on initial freeze down ..................................................................................................... 37

8.17 Excessive ice crystals above divider plate..............................................................................................37

8.18 Spigot leaking or stuck...........................................................................................................................37

33

Page 42

8.1 COMPRESSOR RUN CAPACITOR OPEN, SHORTED, OR BLOWN

CAUSE CORRECTION

Improper capacitor ........................................................... Determine correct size and replace.

Excessively high line voltage ........................................... Contact your local power company

(1 10% of rated max.)

8.2 COMPRESSOR RELAY DEFECTIVE OR BURNED OUT

Incorrect relay .................................................................. Check and replace.

Incorrect mounting angle.................................................. Remount relay in correct position.

Line voltage too high or too low ........................................ Contact your local power company .

(+/- 10%)

Excessive short cycling ................................................... Determine reason and correct.

Relay being influenced by loose vibrating mounting ......... Remount rigidly.

Incorrect run capacitor ..................................................... Replace with proper capacitor.

8.3 COMPRESSOR STARTS AND RUNS, BUT SHORT CYCLES ON OVERLOAD PROTECTOR

Low voltage to unit ........................................................... Determine reason and correct.

Overload protector defective ............................................. Replace overload.

Excessive discharge pressure ......................................... Check ventilation, restrictions in cooling medium,

restrictions in refrigeration system.

Suction pressure too high ................................................ Check for overcharge. Adjust or replace expansion valve.

Compressor too hot - return gas hot ................................ Check refrigerant charge (fix leak), add refrigerant if

necessary.

Compressor motor has a winding shorted ........................ Replace compressor.

8.4 COMPRESSOR RUNS CONTINUOUSLY

Shortage of refrigerant...................................................... Fix leak, add refrigerant.

T orque control defective.................................................... Check and replace torque control.

Mix in hopper too warm.................................................... Refrigerant mix before adding to hopper .

T ension spring on torque .................................................. Spring length should be 3-1/8" long. Adjust if necessary.

Restriction in refrigeration system.................................... Determine location and remove.

Restricted air flow to freezer ............................................ Louvered panels require 6" (15.2 cm) clearance for air

intake and 10" (25.4 cm) clearance for discharge.

Filter dirty ........................................................................ Clean or replace filter.

Fan not running................................................................ Check fan and replace if necessary .

Dirty condenser ............................................................... Clean condenser.

Mix too rich...................................................................... Take "Brix" reading. Fill with properly mixed product.

8.5 UNIT NOISY

Drive cap will not stay in place......................................... Check locking pin inside of drive shaft and slot in agitator

for excessive wear and replace if necessary.

Loose parts or mountings ................................................ Find and tighten.

Agitator drive shaft not lubricated ..................................... Lubricate agitator drive shaft.

Tubing rattles ................................................................... Reform to be free of contact.

Mix too lean..................................................................... Fill product cylinder with properly mixed neutral base.

Bent fan causing vibration ................................................ Replace fan.

Fan motor bearings worn.................................................. Replace motor.

Agitator fingers are bent................................................... Realign or replace agitator and stationary fingers.

Internal compressor spring broken ................................... Replace compressor.

Lower agitator bushing is missing .................................... Install lower bushing.

8.6 COMPRESSOR WILL NOT ST ART

Line disconnect switch open............................................ Close start or disconnect switch

Overload protector tripped ................................................ Will reset after cooling.

T orque control defective.................................................... Check and replace torque control.

Contactor defective .......................................................... Replace contactor.