STM Products SCWR-D 1050-280 Manual

®

surfing evolution

INDUSTRIAL & PROFESSIONAL

WATER CHILLERS

STM PRODUCTS s.r.l.

Via Schiaparelli, 15 | 37135 VERONA | ITALY | Tel. +39 045 585700 | Fax +39 045 585730 | info@stm-products.com | www.stm-products.com

TRADITIONAL WATER CHILLERS

DIRECT CHILLERS WITH COIL INSIDE THE TANK

They cannot reach 2°C

The cooling process is very slow

The tank is difficult to clean

There is a sanitation risk being the tank normally over-dimensioned The output flow for a water delivery is slow being the pump installed normally under-dimensioned

Normally they are controlled by a simple thermostat

INDIRECT CHILLERS WITH DOUBLE COIL INSIDE THE TANK

They can deliver water at 2°C only at the beginning, but soon after the

temperature increases considerably

The output flow for a water delivery is very slow

STM WATER CHILLERS

THE HIGH TECHNOLOGY ADVANTAGES

The temperature is constantly kept at 2°C inside the tank

The temperature remains constant during the whole water delivery

After the end of each water delivery, the new incoming water is cooled again in few minutes therefore cool water will be available for the next batch

The evaporation process takes place inside a stainless steel plate heat exchanger. The high efficiency of this device speeds up the water cooling with the advantage of using not over-dimensioned tanks

The pump used for the water circulation through the heat exchanger is the same that is used to feed the doser-mixer with the result of a high rate flow

The STM chillers are controlled with an STM microprocessor control board with an LCD user interface

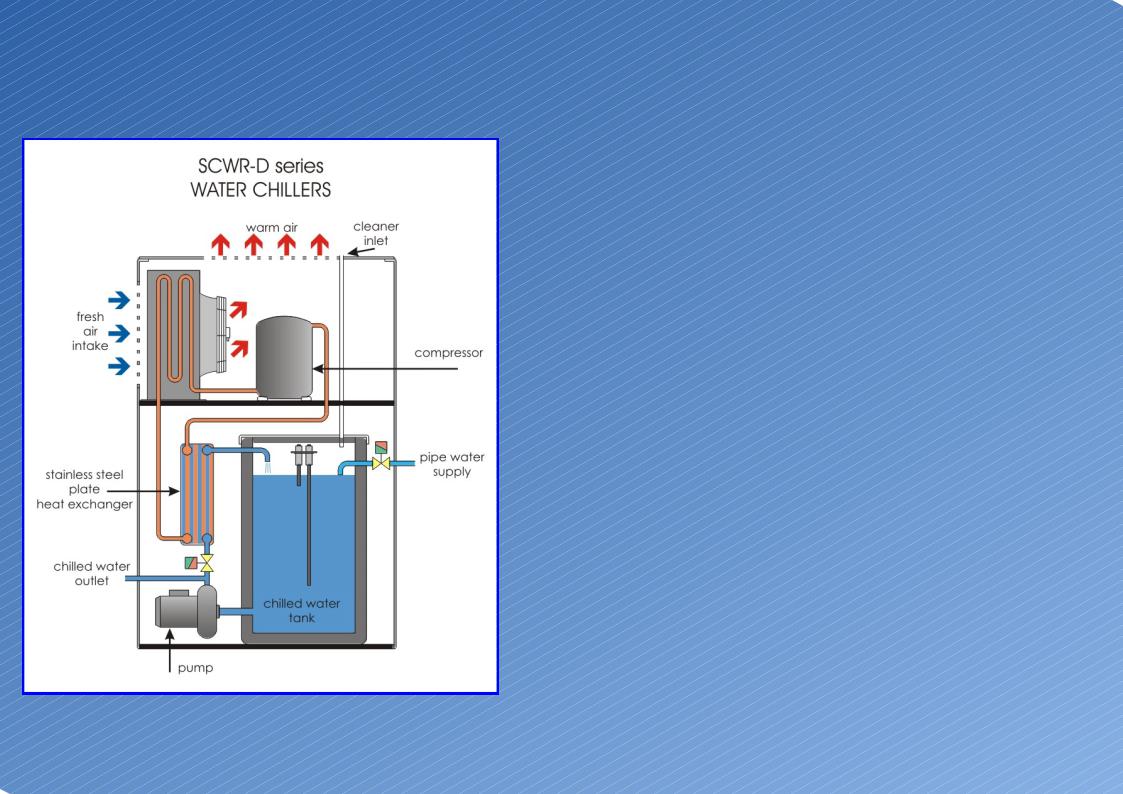

MACHINE CONCEPT

THERMODYNAMIC CIRCUIT

In the evaporator the refrigerant absorbes heat from the water to be cooled

The vapour coming out from the evaporator is compressed by the compressor increasing its temperature

The overheated vapour enters into the condenser where it transfers to the external ambient the heat absorbed from the evaporator and compressor

The liquid coming out from the condenser is laminated to low temperature by the thermostatic valve and returns to the evaporator

WATER CIRCUIT

Cooling phase: the pump circulates the tank water through the evaporator while the compressor is working Delivery phase: the pump sends the water to the doser Charging phase: at the end of a delivery, the charging valve opens till the tank is full. At the same time the

cooling phase starts too. Thermostating phase: an hysteresis parameter controls the start of the compressor to keep constant the tank temperature

Loading...

Loading...