Page 1

■ 1A sink / 0.75A source min. gate drive

P

■ Active Miller clamp feature

■ Desaturation detection

■ Adjustable and accurate turn-on delay

■ UVLO protection

■ 2kV ESD protection

Description

TD352 is an advanced gate driver for IGBT and

power MOSFET. Control and protection functions

are included and allow the design of high reliability

systems.

Innovative active Miller clamp function avoids the

need of negative gate drive in most applications

and allows the use of a simple bootstrap supply

for the high side driver.

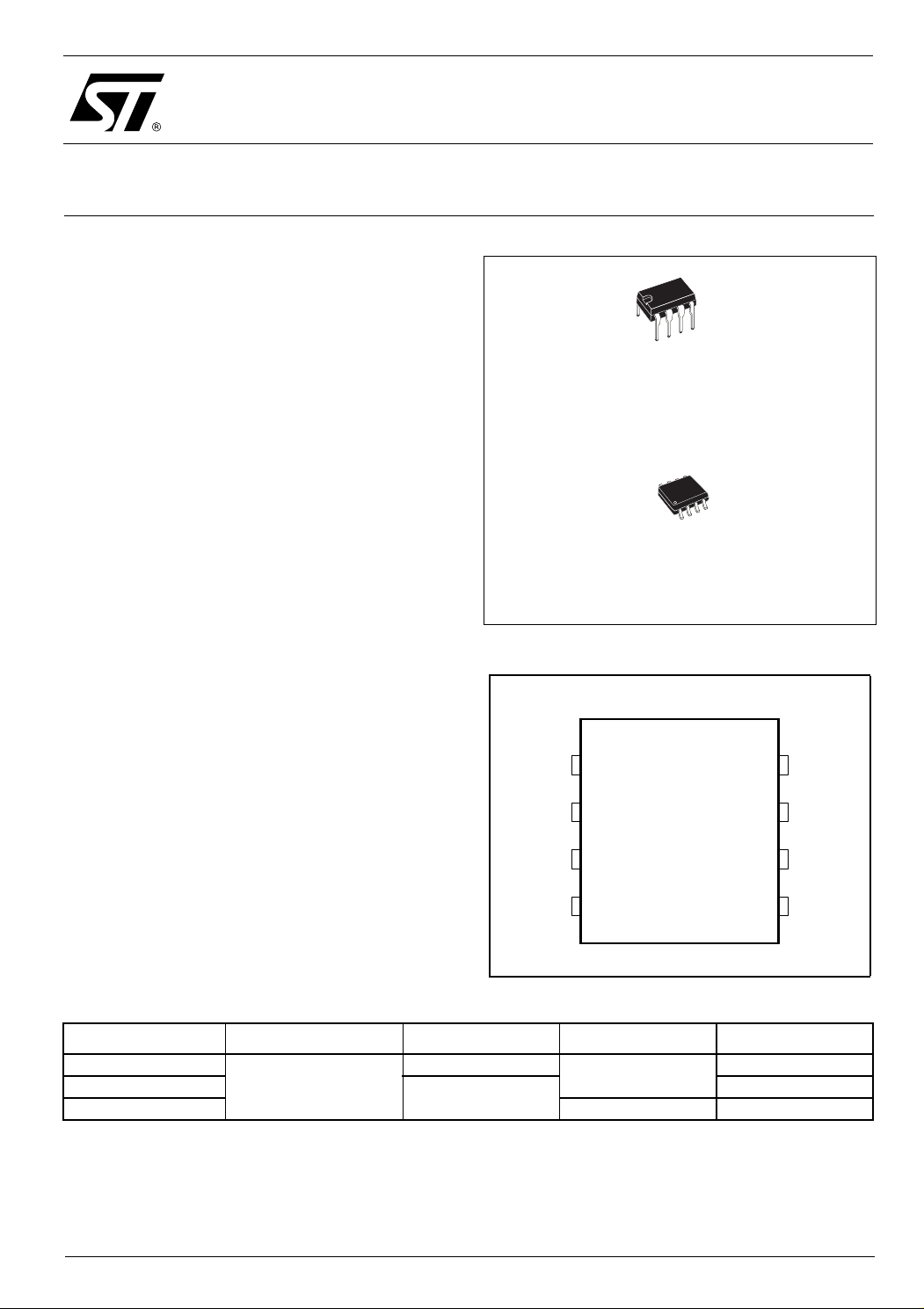

TD352

Advanced IGBT/MOSFET Driver

N

DIP-8

(Plastic Package)

D

SO-8

(Plastic Micropackage)

TD352 includes an adjustable turn-on delay. This

Pin Connections (top view)

feature can be used to implement reliable

deadtime between high and low sides of a half

bridge. External resistor and capacitor are used to

provide accurate timing.

Applications

■ 1200V 3-phase inverter

■ Motor control systems

■ UPS

VREF

TD352

CD VL

DESAT

Order Codes

Part Number Temperature Range Package Packaging Marking

TD352IN

TD352ID

TD352IDT Tape & Reel TD352I

-40°C, +125°C

DIP

SO

Tube

VHIN

OUT

CLAM

TD352I

TD352I

December 2004 Revision 1 1/13

Page 2

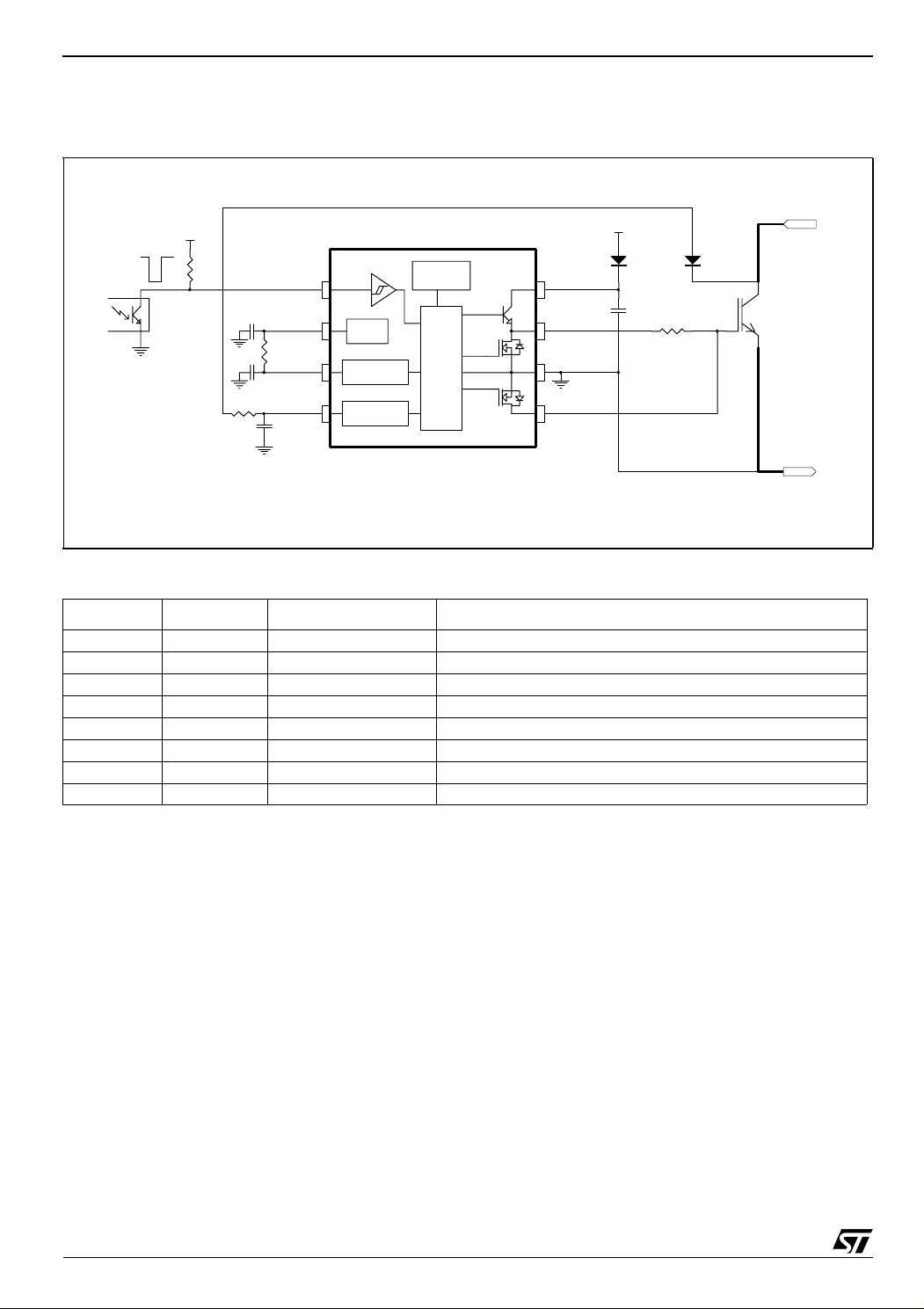

TD352 Block Diagram

1 Block Diagram

Figure 1. System and internal block diagram

VH

4.7k

IN VH

VREF

CD

DESAT

Vref

Delay

Desat

UVLO

OUT

VL

Control Block

CLAMP

16V

TD352

Table 1. Pin Description

Name Pin Number Type Function

IN 1 Analog input Input

VREF 2 Analog output +5V reference voltage

CD 3 Timing capacitor Turn on delay

DESAT 4 Analog input Desaturation protection

CLAMP 5 Analog output Miller clamp

VL 6 Power supply Signal ground

OUT 7 Analog output Gate drive output

VH 8 Power supply Positive supply

2/13

Page 3

Absolute Maximum Ratings TD352

2 Absolute Maximum Ratings

Table 2. Key parameters and their absolute maximum ratings

Symbol Parameter Value Unit

VHL Maximum Supply Voltage (VH - VL) 28 V

Vout Voltage on OUT, CLAMP, LVOFF pins VL-0.3 to VH+0.3 V

Vter Voltage on other pins (IN, CD, VREF) -0.3 to 7 V

Pd Power dissipation 500 mW

Tstg Storage temperature -55 to 150 °C

Tj Maximum Junction Temperature 150 °C

Rhja Thermal Resistance Junction-Ambient 150 °C/W

ESD Electrostatic discharge 2 kV

Table 3. Operating Conditions

Symbol Parameter Value Unit

VH Positive Supply Voltage vs. VL UVLO to 26 V

Toper Operating Free Air Temperature Range -40 to 125 °C

3/13

Page 4

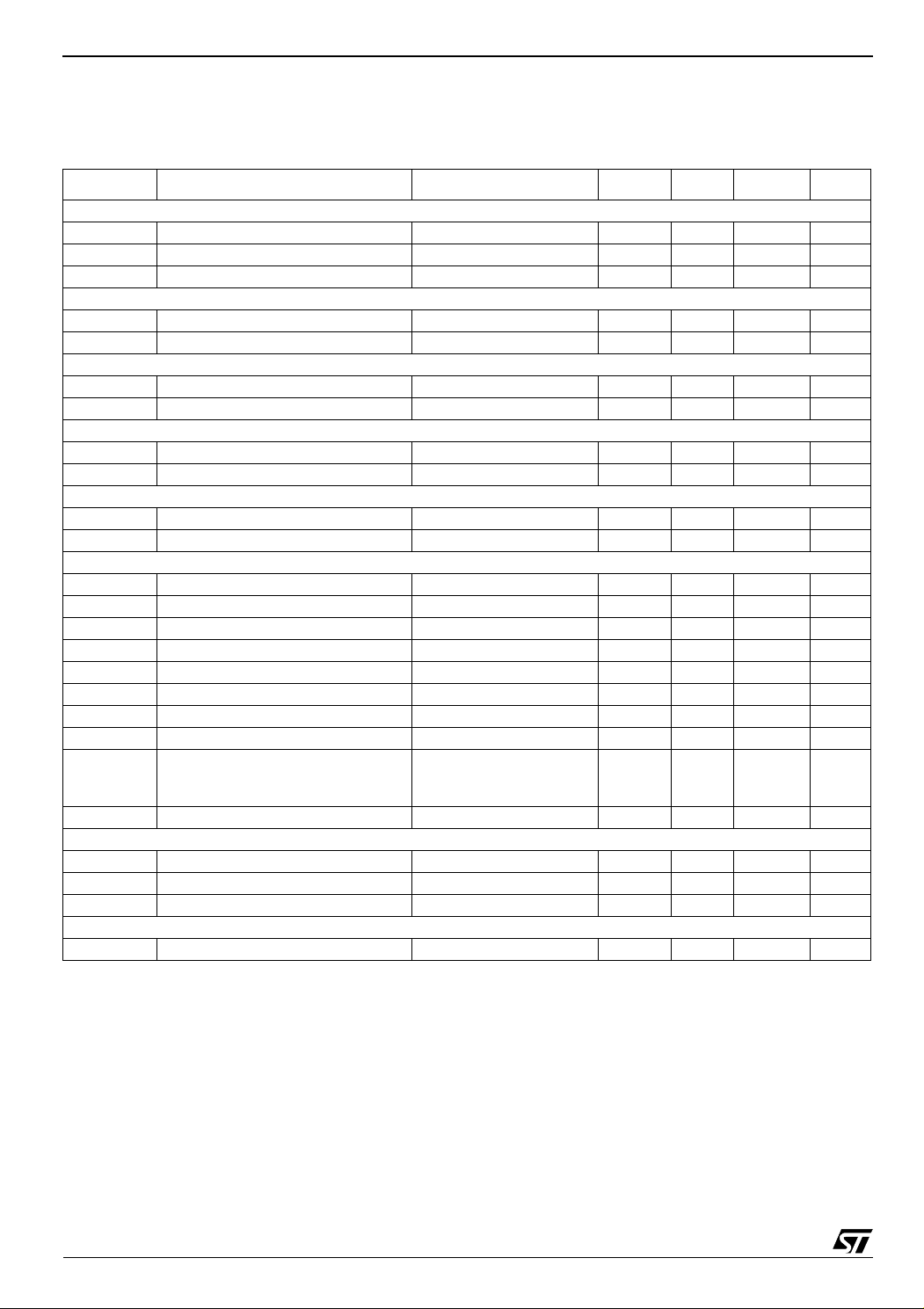

TD352 Electrical Characteristics

3 Electrical Characteristics

Table 4. T

Symbol Parameter Test Condition Min Typ Max Unit

Input

Vton IN turn-on threshold voltage 0.8 1.0 V

Vtoff IN turn-off threshold voltage 4.0 4.2 V

Iinp IN Input current IN input voltage < 4.5V 1

Voltage reference - Note 1

Vref Voltage reference T=25°C 4.85 5.00 5.15 V

Iref Maximum output current 10 mA

Clamp

Vtclamp CLAMP pin voltage threshold 2.0 V

VCL Clamp low voltage Icsink=500mA 2.5 V

Delay

Vtdel Voltage threshold 2.5 V

Rdel Discharge resistor I=1mA 500

Desaturation protection

Vdes Desaturation threshold VH-2

Ides Source current 250 µA

Outputs

Isink Output sink current Vout=6V 1000 1700 mA

Isrc Output source current Vout=VH-6V 750 1300 mA

VOL1 Output low voltage 1 Iosink=20mA 0.35 V

VOL2 Output low voltage 2 Iosink=500mA 2.5 V

VOH1 Output high voltage 1 Iosource=20mA VH-2.5 V

VOH2 Output high voltage 2 Iosource=500mA VH-4.0 V

tr Rise time CL=1nF, 10% to 90% 100 ns

tf Fall time CL=1nF, 90% to 10% 100 ns

tdon Turn on propagation delay

tdoff Turn off propagation delay 10% output change 400 ns

Under Voltage Lockout (UVLO)

UVLOH UVLO top threshold 10 11 12 V

UVLOL UVLO bottom threshold 9 10 11 V

Vhyst UVLO hysteresis Vhyst=UVLOH-UVLOL 0.5 1 V

Supply current

Iin Quiescent current input low, no load 2.5 mA

= -20 to 125°C, VH=16V (unless otherwise specified)

amb

10% output change:

Rd=4.7k, no Cd

Rd=11k, Cd=220pF 1.8 2.0

500

2.2

µA

Ω

ς

ns

µs

Note:1.Recommended capacitor range on VREF pin is 10nF to 100nF

4/13

Page 5

Functional Description TD352

4 Functional Description

4.1 Input stage

TD352 IN input is clamped at about 5V to 7V. The input is triggered by the signal edge. When using an

open collector optocoupler, the resistive pull-up resistor can be connected to either VREF or VH.

Recommended pull-up resistor value with VH=16V are from 4.7k to 22k.

4.2 Voltage reference

A voltage reference is used to create accurate timing for the turn-on delay with external resistor and

capacitor. The same circuitry is also used for the two-level turn-off delay.

A decoupling capacitor (10nF to 100nF) on VREF pin is required to ensure good noise rejection.

4.3 Active Miller clamp:

The TD352 offers an alternative solution to the problem of the Miller current in IGBT switching

applications. Instead of driving the IGBT gate to a negative voltage to increase the safety margin, the

TD352 uses a dedicated CLAMP pin to control the Miller current. When the IGBT is off, a low impedance

path is established between IGBT gate and emitter to carry the Miller current, and the voltage spike on

the IGBT gate is greatly reduced.

During turn-off, the gate voltage is monitored and the clamp output is activated when gate voltage goes

below 2V (relative to VL). The clamp voltage is VL+4V max for a Miller current up to 500mA. The clamp

is disabled when the IN input is triggered again.

The CLAMP function doesn’t affect the turn-off characteristic, but only keeps the gate to the low level

throughout the off time. The main benefit is that negative voltage can be avoided in many cases, allowing

a bootstrap technique for the high side driver supply.

4.4 Turn-on delay

Turn-on (Ta) delay is programmable through external resistor Rd and capacitor Cd for accurate timing. T

is approximately given by:

T

(µs) = 0.7 * Rd (kohms) * Cd (nF)

a

The turn-on delay can be disabled by connecting the CD pin to VREF with a 4.7k resistor.

Input signals with ON-time smaller than T

are ignored.

a

4.5 Desaturation protection

Desaturation protection ensures the protection of the IGBT in the event of overcurrent. When the DESAT

voltage goes higher than VH-2V, the TD352 OUT pin is driven low. The fault state is only exit after powerdown and power-up.

A programmable blanking time is used to allow enough time for IGBT saturation. Blanking time is

provided by an internal current source and external C

capacitor, the T

des

blanking time value is given

bdes

by:

= V

T

bdes

At VH=16V, T

(µs) = 0.056 * C

T

bdes

des

* C

/ I

des

des

is approximately given by:

bdes

des

(pF)

4.6 Output stage

The output stage is able to sink/source 1.7A/1.3A typical at 25°C and 1.0A/0.75A min. over the full

temperature range. This current capability is specified near the usual IGBT Miller plateau.

a

5/13

Page 6

TD352 Functional Description

4.7 Undervoltage protection

Undervoltage detection protects the application in the event of a low VH supply voltage (during start-up or

a fault situation). During undervoltage, the OUT pin is driven low (active pull-down for VH>2V, passive

pull-down for VH<2V.

Figure 2. Undervoltage protection

UVH

UVL

VH

Vccmin

OUT

FAULT

2V

6/13

Page 7

Functional Description TD352

Figure 3. Detailed internal schematic

UVLO

IN

VREF

D

ESAT

Comp_Input

7V

1V-4V

5V Vref

Comp_DelayOff

2.5V

S2

VH

250uA

Comp_Desat

VH-2V

S1

Control Block

Comp_Clamp

CLAMP

2V

VH

OUT

VL

rev. 2

7/13

Page 8

TD352 Timing Diagrams

5 Timing Diagrams

Figure 4. General turn-on and turn-off sequence

IN

CD

OUT

CLAMP

Vge

Vce

Ta

VL level

Twin

VH level

Twout

Open

VH level

Miller plateau

Figure 5. input and output waveform dynamic parameters

Twin

IN

(level mode)

IN

(edge mode)

Vton

VL level

Clamp threshold

Vtoff

Vtoff

OUT

Figure 6. Desaturation fault

IN

CD

OUT

DESAT

8/13

tdon

Vton

VH level

Twout

2.5V

Ta

VH-2V

Desat Blanking Time

tdoff

VH level

VL level

VL level

Page 9

Typical Performance Curves TD352

6 Typical Performance Curves

Figure 7. Quiescent current vs. temperature Figure 8. Low level output voltage vs.

temperature

2.5

2.0

1.5

In (mA)

1.0

0.5

0.0

- 50 -25 0 25 50 75 100 125

Temp (°C)

3.0

3.0

2.0

2.0

Iosink=500mA

Iosink=500mA

VOL -VL ( V)

VOL -VL ( V)

1.0

1.0

Iosink=20mA

Iosink=20mA

0.0

0.0

-50 -25 0 25 50 75 100 125

-50 -25 0 25 50 75 100 125

Temp (°C)

Temp (°C)

Figure 9. Sink current vs. temperature Figure 10. Rdel resistance vs. temperature

Isink (mA)

2000

1800

1600

1400

1200

500

400

300

200

Rdel (Ohms)

100

1000

-50 - 25 0 25 50 75 100 125

Temp (°C)

Figure 11. High level output voltage vs.

temperature

4.0

4.0

3.0

3.0

Iosource=500mA

Iosource=500mA

2.0

2.0

VH- VOH (V)

VH- VOH (V)

1.0

1.0

0.0

0.0

-50 -25 0 25 50 75 100 125

-50 -25 0 25 50 75 100 125

Temp (°C)

Temp (°C)

Iosource=20mA

Iosource=20mA

0

-50-250 255075100125

Temp (°C)

Figure 12. Source current vs. temperature

1600

1400

1200

Isrc (mA)

1000

800

-50 -25 0 25 50 75 100 125

Temp (°C)

9/13

Page 10

TD352 Application Diagrams

7 Application Diagrams

Figure 13. Single supply IGBT drive with active Miller clamp

VH

4.7k

IN VH

VREF

CD

DESAT

Vref

Delay

Desat

UVLO

Control Block

OUT

VL

CLAMP

TD352

Figure 14. Use of DESAT input for direct overcurrent detection

VH

Vref

4.7k

IN VH

VREF

CD

Vref

Delay

UVLO

OUT

VL

16V

16V

DESAT

Desat

Control Block

CLAMP

TD352

Figure 15. Large IGBT drive with negative voltage gate drive and optional current buffers

VH

16V

-10V

4.7k

IN VH

VREF

DESAT

CD

Vref

Delay

Desat

UVLO

Optional

OUT

VL

Control Block

TD352

CLAMP

Optional

10/13

Page 11

Package Mechanical Data TD352

8 Package Mechanical Data

8.1 DIP-8 Package

Plastic DIP-8 MECHANICAL DATA

DIM.

A 3.3 0.130

a1 0.7 0.028

B 1.39 1.65 0.055 0.065

B1 0.91 1.04 0.036 0.041

b 0.5 0.020

b1 0.38 0.5 0.015 0.020

D 9.8 0.386

E 8.8 0.346

e 2.54 0.100

e3 7.62 0.300

e4 7.62 0.300

F 7.1 0.280

I 4.8 0.189

L 3.3 0.130

Z 0.44 1.6 0.017 0.063

MIN. TYP MAX. MIN. TYP. MAX.

mm. inch

P001F

11/13

Page 12

TD352 Package Mechanical Data

8.2 SO-8 Package

SO-8 MECHANICAL DATA

DIM.

A 1.35 1.75 0.053 0.069

A1 0.10 0.25 0.04 0.010

A2 1.10 1.65 0.043 0.065

B 0.33 0.51 0.013 0.020

C 0.19 0.25 0.007 0.010

D 4.80 5.00 0.189 0.197

E 3.80 4.00 0.150 0.157

e 1.27 0.050

H 5.80 6.20 0.228 0.244

h 0.25 0.50 0.010 0.020

L 0.40 1.27 0.016 0.050

k ˚ (max.)

ddd 0.1 0.04

MIN. TYP MAX. MIN. TYP. MAX.

mm. inch

8

12/13

0016023/C

Page 13

Revision History TD352

9 Revision History

Date Revision Description of Changes

01 Dec. 2004 1 First Release

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

All other names are the property of their respective owners

© 2004 STMicroelectronics - All rights reserved

Australia - Belgium - Brazil - Canada - China - Czech Repubic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

STMicroelectronics group of companies

www.st.com

13/13

Loading...

Loading...