Page 1

MASTERGAN4

Datasheet

High power density 600V half-bridge driver with two enhancement mode GaN

HEMT

Features

• 600 V system-in-package integrating half-bridge gate driver and high-voltage

GaN power transistors:

– QFN 9 x 9 x 1 mm package

– R

– I

• Reverse current capability

• Zero reverse recovery loss

• UVLO protection on low-side and high-side

• Internal bootstrap diode

• Interlocking function

• Dedicated pin for shut down functionality

• Accurate internal timing match

• 3.3 V to 15 V compatible inputs with hysteresis and pull-down

• Over temperature protection

• Bill of material reduction

• Very compact and simplified layout

• Flexible, easy and fast design.

DS(ON)

DS(MAX)

= 225 mΩ

= 6.5 A

Product status link

MASTERGAN4

Product label

Applications

Switch-mode power supplies

Chargers and adapters

High-voltage PFC, DC-DC and DC-AC Converters

Description

The MASTERGAN4 is an advanced power system-in-package integrating a

gate driver and two enhancement mode GaN power transistors in half bridge

configuration. The integrated power GaNs have 650 V drain-source blocking voltage

and R

easily supplied by the integrated bootstrap diode.

The MASTERGAN4 features UVLO protection on both the lower and upper

driving sections, preventing the power switches from operating in low efficiency

or dangerous conditions, and the interlocking function avoids cross-conduction

conditions.

The extended range of the input pins allows easy interfacing with microcontrollers,

DSP units or Hall effect sensors.

The MASTERGAN4 operates in the industrial temperature range, -40°C to 125°C.

The device is available in a compact 9x9 mm QFN package.

of 225 mΩ, while the high side of the embedded gate driver can be

DS(ON)

DS13686 - Rev 1 - April 2021

For further information contact your local STMicroelectronics sales office.

www.st.com

Page 2

1 Block diagram

Driver

Driver

Logic,

interlocking,

overtemp

Level Shifter

Level Shifter

VCC UVLO

UVLO

Vbo

PGNDPVCC

OUTbBOOT

GL

GH

VCC

HIN

LIN

SD/OD

GND

OUT

VS

SENSE

HON

HOFF

LON

LOFF

R

BLEED

RGOFF

H

RGON

H

RGON

L

RGOFF

L

MASTERGAN4

Block diagram

Figure 1. Block diagram

DS13686 - Rev 1

page 2/27

Page 3

2 Pin descriptions and connection diagram

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

24

23

22

21

20

19

18

17

16

31

30

29

28

27

26

25

GND

SENSE

OUT

EP1

EP2

EP3

SENSE

OUT

OUT

OUT

SENSE

SENSE

SENSE

SENSE

SENSE

VS

VS

VS

VS

VS

GH

OUTb

BOOT

PGND

GL

PVCC

N.C.

VCC

GND

LIN

HIN

SD/OD

N.C.

N.C.

N.C.

Figure 2. Pin connections (top view)

MASTERGAN4

Pin descriptions and connection diagram

2.1 Pin list

Table 1. Pin descriptions

Pin Number Pin Name Type Function

15, 16, 17, 18, 19 VS Power Supply High voltage supply (high-side GaN Drain)

12, 13, 14, EP3 OUT Power Output Half-bridge output

4, 5, 6, 7, 8, 9, 10, 11, EP2 SENSE Power Supply Half-bridge sense (low-side GaN Source)

22 BOOT Power Supply Gate driver high-side supply voltage

21 OUTb Power Supply

27 VCC Power Supply Logic supply voltage

1 PVCC Power Supply Gate driver low-side supply voltage

28, EP1 GND Power Supply Gate driver ground

3 PGND Power Supply

26 HIN Logic Input High-Side driver logic input

24 LIN Logic Input Low-Side driver logic input

25 SD/OD Logic Input-output Driver Shut-Down input and Fault Open-Drain

2 GL Output Low-Side GaN gate.

20 GH Output High-Side GaN gate.

23, 29, 30, 31 N.C. Not Connected Leave floating

Gate driver high-side supply voltage, used only for Bootstrap

capacitor connection. Internally connected to OUT.

Gate driver low-side buffer ground. Internally connected to

SENSE.

DS13686 - Rev 1

page 3/27

Page 4

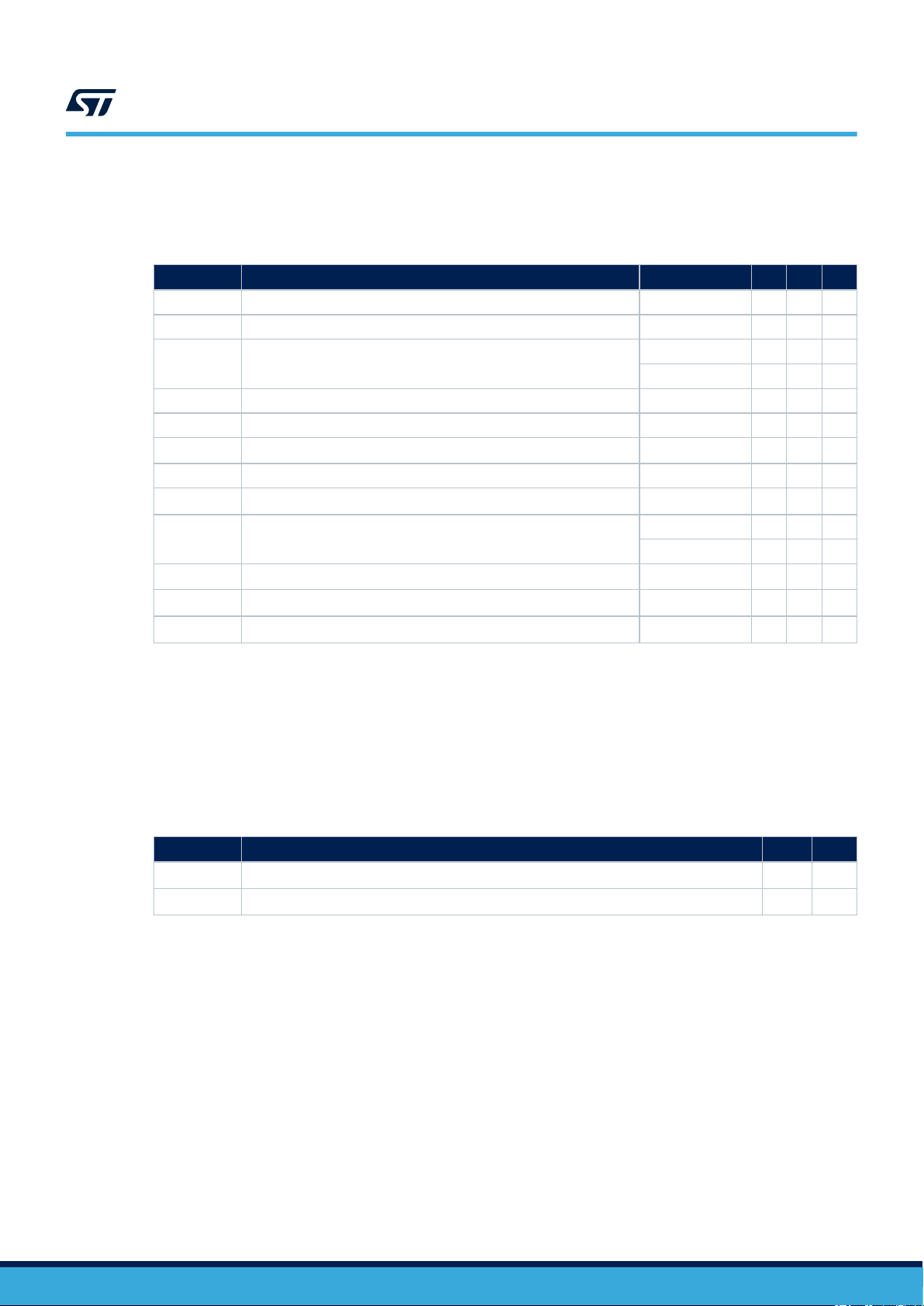

3 Electrical Data

3.1 Absolute maximum ratings

Each voltage referred to GND unless otherwise specified

Symbol Parameter Test Condition Value Unit

V

DS

VCC Logic supply voltage - -0.3 to 11 V

PVCC-PGND

VCC-PGND Logic supply vs Low-side driver ground - -0.3 to 18.3 V

PVCC Low-side driver supply vs logic ground - -0.3 to 18.3 V

PGND Low-side driver ground vs logic ground - -7.3 to 11.3 V

V

BO

BOOT Bootstrap voltage - -0.3 to 620 V

CGL, CGH

RGL, RGH

I

D

SR

V

T

T

1. PGND internally connected to SENSE.

2. OUTb internally connected to OUT

3. CGx < 0.08/(Pvcc^2*Fsw)-(330*10-12)

4. TCB is temperature of case exposed pad

5. Range estimated by characterization, not tested in production

6. Value specified by design factor, pulse duration limited to 50 µs and junction temperature

GaN Drain-to-Source Voltage

Low-side driver supply voltage

BOOT to OUTb voltage

(2)

Maximum external capacitance between GL and PGND and

between GH and OUTb

Minimum external pull down resistance between GL and

PGND and GH and OUTb

Drain current

Half-bridge outputs slew rate (10% - 90%) - 100 V/ns

out

Logic inputs voltage range - -0.3 to 21 V

i

Junction temperature - -40 to 150 °C

J

Storage temperature - -40 to 150 °C

s

Table 2. Absolute maximum ratings

TJ = 25 °C

(1)

FSW = 500 kHz

DC @ TCB = 25 °C

DC @ TCB = 100 °C

Peak @ TCB = 25 °C

MASTERGAN4

Electrical Data

620 V

- -0.3 to 7 V

- -0.3 to 7 V

(3)

- 6.8 kΩ

(4) (5)

(4) (5)

(4) (5) (6)

3.9 nF

6.5 A

4.6 A

12 A

DS13686 - Rev 1

page 4/27

Page 5

3.2 Recommended operating conditions

Table 3. Recommended operating conditions

Each voltage referred to GND unless otherwise specified

Symbol Parameter Note Min Max Unit

VS High voltage bus - 0 520 V

VCC Supply voltage - 4.75 9.5 V

PVCC-PGND

PVCC to PGND Low side supply

PVCC Low-side driver supply - 3 8.5 V

VCC-PVCC VCC to PVCC pin voltage - -3 3 V

PGND

Low-side driver ground

(1)

DT Suggested minimum dead time - 5 - ns

T

IN_MIN

V

BO

Minimum duration of input pulse to obtain undistorted output pulse

BOOT to OUTb pin voltage

BOOT BOOT to GND voltage -

V

T

J

Logic inputs voltage range - 0 20 V

i

Junction temperature - -40 125 °C

1. PGND internally connected to SENSE

2. See Section 6.1 Logic inputs for more detail

3. OUTb internally connected to OUT

4. 5 V is recommended during High Side turn-on

(1)

(3)

MASTERGAN4

Recommended operating conditions

- 4.75 6.5 V

Best performance 5 6.5 V

- -2 2 V

(2)

Best performance 5 6.5 V

- 120 - ns

- 4.4 6.5 V

(4)

0

530 V

3.3

Thermal data

Table 4. Thermal data

Symbol Parameter Value Unit

R

th(J-CB)_HS

R

th(J-A)

The junction to ambient thermal resistance is obtained simulating the device mounted on a 2s2p (4 layer) FR4

board as per JESD51-5,7 with 6 thermal vias for each exposed pad. Power dissipation is uniformly distributed

over the two GaN transistors.

Thermal resistance of each transistor’s junction to relevant exposed pad, typical 2.8 °C/W

Thermal resistance junction-to-ambient(1) 17.8 °C/W

DS13686 - Rev 1

page 5/27

Page 6

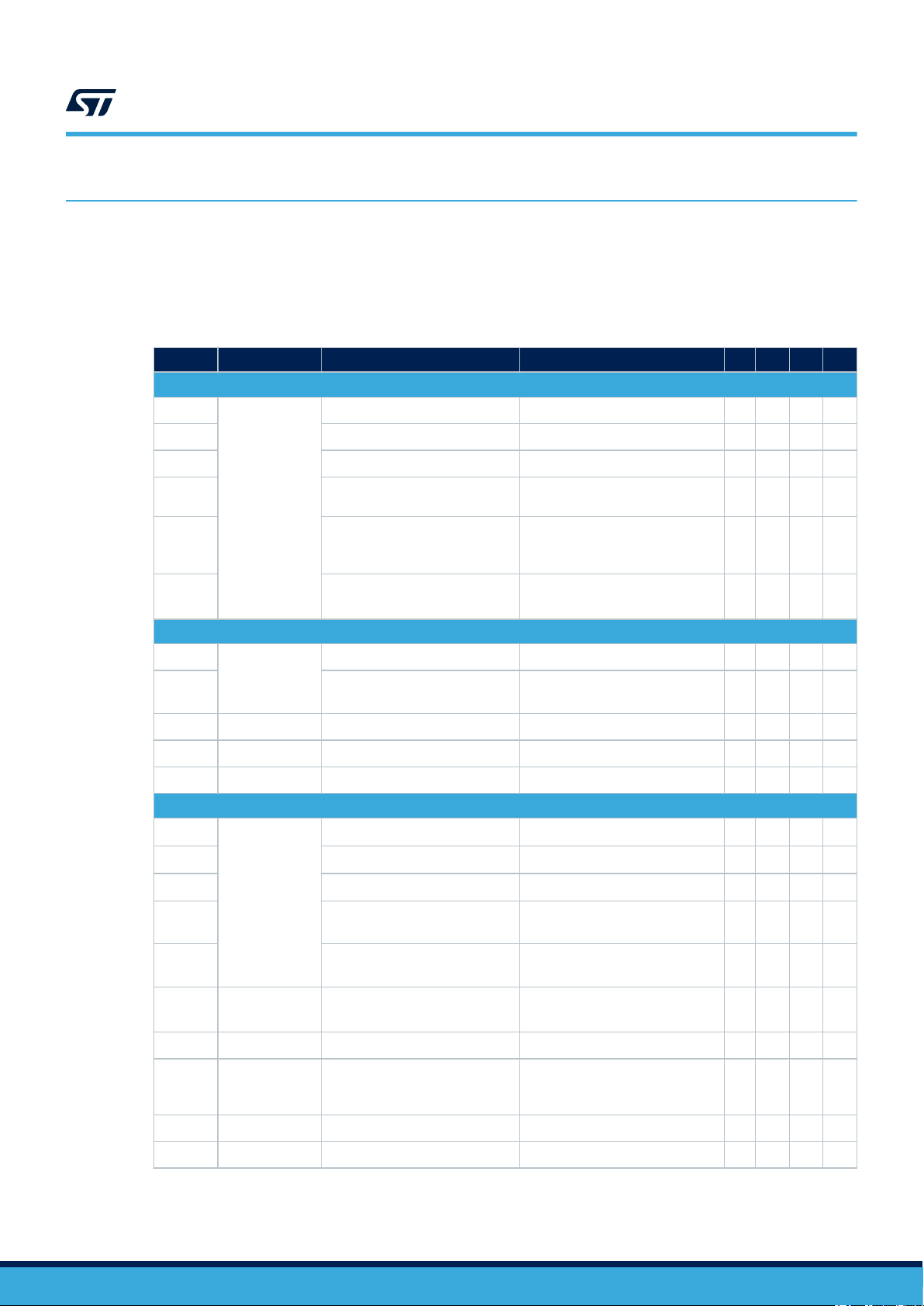

4 Electrical characteristics

4.1 Driver

Table 5. Driver electrical characteristics

VCC = PVCC = 6 V, SENSE = GND, TJ = 25 °C, unless otherwise specified

Each voltage referred to GND unless otherwise specified

Symbol - Parameter Test condition Min Typ Max Unit

VCC

VCC

VCC

I

QVCCU

I

I

thON

thOFF

hys

VCC vs. GND

QVCC

SVCC

VCC UV turn ON threshold

VCC UV turn OFF threshold

VCC UV hysteresis

VCC undervoltage quiescent

supply current

VCC quiescent supply current

VCC switching supply current

Logic section supply

(1)

(1)

(1)

VCC = PVCC = 3.8 V - 320 410 μA

SD/OD = LIN = 5 V;

HIN = 0 V;

BOOT = 7 V

SD/OD = 5 V; VBO = 6.5 V;

VS = 0 V; FSW = 500 kHz

MASTERGAN4

Electrical characteristics

- 4.2 4.5 4.75 V

- 3.9 4.2 4.5 V

- 0.2 0.3 0.45 V

- 680 900 μA

- 0.8 - mA

I

QPVCC

I

SPVCC

R

BLEED

RON

ROFF

V

BOthON

V

BOthOFF

V

BOhys

I

QBOU

I

QBO

I

SBO

I

R

DBoot

RON

ROFF

Low-side driver section supply

PVCC quiescent supply current SD/OD = LIN = 5 V - 150 - μA

PVCC vs. PGND

PVCC switching supply current

VS = 0 V

FSW = 500 kHz

- 1.0 - mA

GL vs. PGND Low side gate bleeder PVCC = PGND 75 100 125 kΩ

L

L

-

-

Low side turn on resistance

Low side turn off resistance

(2)

(2)

I(GL) = 1 mA (source) - 77 - Ω

I(GL) = 1 mA (sink) - 2 - Ω

High-side floating section supply

VBO UV turn ON threshold

VBO UV turn OFF threshold

VBO UV hysteresis

BOOT vs. OUTb

VBO undervoltage quiescent

supply current

(3)

VBO quiescent supply current

BOOT BOOT switching supply current

BOOT vs. SGND High voltage leakage current BOOT = OUT = 600 V - - 11 μA

LK

VCC vs. BOOT

Bootstrap diode on-resistance

(3)

(3)

(3)

VBO = 3.4 V

VBO = 6 V; LIN = GND;

(3)

SD/OD = HIN = 5 V;

VBO =6 V; SD/OD = 5 V;

VS = 0 V; FSW = 500 kHz

SD/OD = LIN = 5 V;

(4)

HIN = GND = PGND

- 3.6 4.0 4.4 V

- 3.4 3.7 4.0 V

- 0.1 0.3 0.5 V

- 140 200 μA

- 217 - μA

- 1.9 - mA

- 140 175 Ω

VCC – BOOT = 0.5 V

H

H

-

-

High side turn on resistance

High side turn off resistance

(2)

I(GH) = 1 mA (source) - 77 - Ω

(2)

I(GH) = 1 mA (sink) - 2 - Ω

DS13686 - Rev 1

page 6/27

Page 7

MASTERGAN4

Driver

Symbol - Parameter Test condition Min Typ Max Unit

Logic inputs

V

R

PD_IN

I

I

R

PD_SD

V

R

ON_OD

V

V

ihys

I

INh

I

INl

SDh

SDl

TSD

il

ih

TJ = 25 °C

LIN, HIN, SD/OD

Low level logic threshold voltage

Full Temperature range

TJ = 25 °C

High level logic threshold voltage

Full Temperature range

(5)

(5)

Logic input threshold hysteresis 0.7 0.96 1.2 V

Logic ‘1’ input bias current LIN, HIN = 5 V 23 33 55 μA

LIN, HIN

Logic ‘0’ input bias current LIN, HIN = GND - - 1 μA

Input pull-down

resistor

LIN, HIN = 5 V 90 150 220 kΩ

SD/OD Logic “1” input bias current SD/OD = 5 V 11 15 20 μA

SD/OD Logic “0” input bias current SD/OD = 0 V - - 1 μA

SD/OD Pull-down resistor

SD/OD

Thermal shutdown unlatch

threshold

SD/OD Open drain ON resistance

SD/OD = 5 V

OpenDrain OFF

TJ = 25 °C

(6)

TJ = 25 °C;

IOD = 400 mV

(6)

1.1 1.31 1.45

V

0.8 - -

2 2.17 2.5

V

- - 2.7

250 330 450 kΩ

0.5 0.75 1 V

8 10 18 Ω

I

OL_OD

T

d_GL

T

d_GH

SD/OD Open Drain low level sink current

LIN, GL Prop. delay from LIN to GL

HIN, GH Prop. delay from HIN to GH

TJ = 25 °C;

VOD = 400 mV

(6)

(6)

(6)

Over temperature protection

T

TSD

T

HYS

- Shut down temperature

- Temperature hysteresis

(5)

(5)

1. VCC UVLO is referred to VCC - GND

2. Turn on and turn off total resistances include the values of the gate resistors and the driver Rdson

3. VBO = V

4. R

BD(on)

R

BD(on)

Where: Ia is BOOT pin current when V

- V

BOOT

OUT

is tested in the following way

= [(VCC - V

BOOTa

) - (VCC - V

BOOTb

BOOT

)] / [Ia - Ib]

= V

BOOTa

; Ib is BOOT pin current when V

BOOT

= V

BOOTb

5. Range estimated by characterization, not tested in production

6. Tested at wafer level

22 40 50 mA

- 46 - ns

- 46 - ns

- 175 - °C

- 20 - °C

DS13686 - Rev 1

page 7/27

Page 8

4.2 GaN power transistor

Table 6. GaN power transistor electrical characteristics

VGS = 6 V; TJ = 25 °C, unless otherwise specified.

Symbol Parameter Test condition Min Typ Max Unit

V

(BR)DS

Drain-source blocking voltage

GaN on/off states

I

< 13.3 µA

DSS

VGS = 0 V

MASTERGAN4

GaN power transistor

(1)

650 - - V

VDS = 600 V

VGS = 0 V

VDS = V

ID = 1.7 mA

VDS = 0 V

I

D =

I

DSS

V

GS( th )

I

GS

R

DS( on)

Zero gate voltage drain current

Gate threshold voltage

Gate to source current

Static drain-source on-resistance

1. Tested at wafer level

2. Range estimated by characterization, not tested in production

2.2 A

GS

- 0.5 - µA

(1)

(2)

T

25°C

J =

125°C

(2)

T

J =

- 1.7 - V

- 40 - µA

- 225 300

mΩ

- 495 -

DS13686 - Rev 1

page 8/27

Page 9

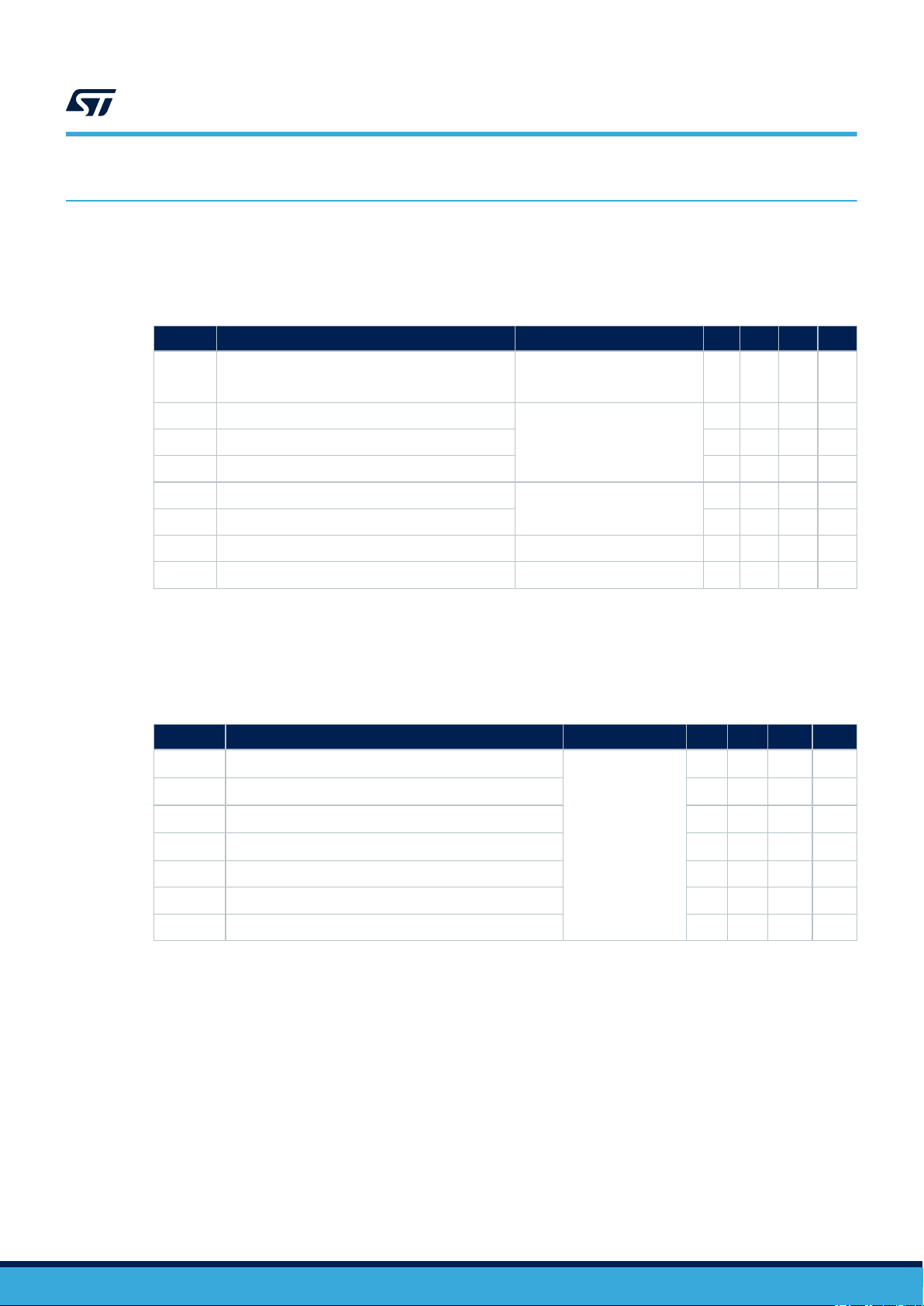

5 Device characterization values

The information in Table 7 and Table 8 represent typical values based on characterization and simulation results

and are not tested in production.

Table 7. GaN power transistor characterization values (each transistor)

Symbol Parameter Test condition Min Typ Max Unit

Q

Total gate charge

G

Q

E

C

C

C

I

1. C

2. C

Q

Output charge

OSS

Output Capacitance stored energy - 1.7 - µJ

OSS

Output capacitance - 14.2 - pF

OSS

Effective output capacitance energy related

O(ER)

Effective output capacitance time related

O(TR)

Reverse recovery charge - - 0 - nC

RR

Reverse recovery current - - 0 - A

RRM

is the fixed capacitance that would give the same stored energy as C

O(ER)

V

DS

is the fixed capacitance that would give the same charging time as C

O(TR)

V

DS

(2)

MASTERGAN4

Device characterization values

V

6 V, TJ = 25 °C

GS =

V

0 to 400 V

DS =

VGS = 0 V, VDS = 400 V

(1)

VGS = 0 V, VDS = 0 to 400 V

while VDS is rising from 0 V to the stated

OSS

while VDS is rising from 0 V to the stated

OSS

- 1.5 - nC

- 14 - nC

- 21 - pF

- 34 - pF

Symbol

t

(on)

t

C(on)

t

(off)

t

C(off)

1. t

2. tC

t

SD

E

E

(on)

Table 8. Inductive load switching characteristics

Parameter Test condition Min Typ Max Unit

(1)

Turn-on time

(2)

Crossover time (on) - 25 - ns

(2)

Turn-off time - 70 - ns

(1)

Crossover time (off) - 10 - ns

Shutdown to high/low-side propagation delay - 70 - ns

Turn-on switching losses - 10 - µJ

on

Turn-off switching losses - 2.5 - µJ

off

and t

(on)

include the propagation delay time of the internal driver and GaN Turn on time

(off)

and tC

are the switching times of GaN transistor itself under the internally given gate driving conditions

(off)

VS = 400 V,

VGS = 6 V,

ID = 3.2 A

See Figure 3

- 70 - ns

DS13686 - Rev 1

page 9/27

Page 10

Figure 3. Switching time definition

I

D

I

D

V

DS

V

DS

V

IN

V

IN

t

(ON)

t

(OFF)

t

C(ON)

t

C(OFF)

10%I

D

10%V

DS

10%I

D

10%V

DS

(a) turn-on

(b) turn-off

VDS (V)

I

D

(A)

VGS=6V

TJ=25°C

VGS=5V

0

1 2 3 4 5

0

2

4

6

8

10

12

14

16

18

20

VGS=4V

VDS (V)

I

D

(A)

VGS=6V

TJ=125°C

VGS=5V

0

1 2 3 4 5

0

1

2

3

4

5

6

7

8

9

10

VGS=4V

MASTERGAN4

Device characterization values

DS13686 - Rev 1

Figure 4. Typ ID vs VDS at TJ=25°C

Figure 5. Typ ID vs VDS at TJ=125°C

page 10/27

Page 11

0

2

10 18 20

0.22

0.24

0.26

0.28

0.30

0.32

0.34

0.36

0.38

TJ=25°C

ID (A)

R

DS(on)

(Ω)

4V

5V

6V

16

14124

86

0

1

5 9 10

0.45

0.48

0.51

0.54

0.57

0.60

0.63

0.66

0.69

TJ=125°C

ID (A)

R

DS(on)

(Ω)

4V

5V

6V

8

762

43

VDS (V)

I

D

(A)

VGS=6V

TJ=25°C

0

1 2 3 4 5

0

2

4

6

8

10

12

14

16

18

20

TJ=50°C

TJ=75°C

TJ=100°C

TJ=125°C

Normalized R

DS(on)

(1 at 25°C)

0

1.0

0.5

1.5

2.0

2.5

3.0

Temperature (°C)

-50

-10

30

70

110

150

MASTERGAN4

Device characterization values

Figure 6. Typ R

Figure 8. Typ I

vs ID at TJ=25°C

DS(ON)

D(ON)

vs V

DS

Figure 7. Typ R

Figure 9. Typ R

DS(ON)

DS(ON)_x

vs ID at TJ=125°C

vs TJ, normalized at 25°C

DS13686 - Rev 1

page 11/27

Page 12

VSD (V)

I

S

(A)

VGS=6V

TJ=25°C

VGS=0V

0

1 2 3 4 5 6 7 8 9 10

0

4

8

12

16

20

24

28

32

36

40

VSD (V)

I

S

(A)

VGS=6V

TJ=125°C

VGS=0V

0

1 2 3 4 5 6 7 8 9 10

0

2

4

6

8

10

12

14

16

18

20

1

10

100

1000

0.01

0.1

1

10

DC

50 μs

0.2 μs

Id (A)

Vds (V)

0 0.5

1

1.5

2

2.5

QG (nC)

V

GS

(V)

0

2

1

3

4

5

6

400 V

100 V

7

MASTERGAN4

Device characterization values

Figure 10. Typ ISD vs VSD, at TJ=25°C

Figure 12. Safe Operating Area at TJ=25°C

Figure 11. Typ ISD vs VSD, at TJ=125°C

Figure 13. Typ Gate Charge at TJ=25°C

DS13686 - Rev 1

page 12/27

Page 13

0

25

50

75

100

125

TCB (°C)

0

150

10

20

30

40

50

60

70

P

DISS

(W)

R

DBoot

(ohm)

0

100

50

150

200

250

300

Temperature (°C)

-50

-10

30

70

110

150

MASTERGAN4

Device characterization values

Figure 14. Derating Curve

Figure 15. Typ R

Dboot

vs T

J

DS13686 - Rev 1

page 13/27

Page 14

6 Functional description

6.1 Logic inputs

The MASTERGAN4 features a half-bridge gate driver with three logic inputs to control the internal high-side and

low-side GaN transistors.

The devices are controlled through following logic inputs:

• SD/OD: Shut-down input, active low;

• LIN: low-side driver inputs, active high;

• HIN: high-side driver inputs, active high.

Table 9. Inputs truth table (applicable when device is not in UVLO)

Input pins GaN transistors status

SD/OD LIN HIN LS HS

L

H L L OFF OFF

H L H OFF ON

H H L ON OFF

1. X: Don’t care

2. Interlocking

H

(1)

X

(2)

H

MASTERGAN4

Functional description

(1)

X

(2)

H

OFF OFF

OFF OFF

6.2

The logic inputs have internal pull-down resistors. The purpose of these resistors is to set a proper logic level in

case, for example, there is an interruption in the logic lines or the controller outputs are in tri-state conditions.

If logic inputs are left floating, the gate driver outputs are set to low level and the corresponding GaN transistors

are turned off.

The minimum duration of the on time of the pulses applied to LIN is T

either extended to T

or blanked, if shorter than 30ns (typ). Minimum duration of the off time of the pulses

IN_MIN

= 120ns; shorter pulses could be

IN_MIN

applied to LIN is 60ns or could be blanked if they are shorter.

The minimum duration of the off time of the pulses applied to HIN is T

either extended to T

or blanked, if shorter than 30ns (typ). Minimum duration of the on time of the pulses

IN_MIN

= 120ns; shorter pulses shall be

IN_MIN

applied to HIN is 60ns or could be blanked if they are shorter.

Interlocking feature interrupts running T

to avoid unexpected cross-conduction.

IN_MIN

Matched, short propagation delay between low side and high side are there.

Bootstrap structure

Bootstrap circuitry is typically used to supply the high-voltage section. MASTERGAN4 integrates this structure by

means of a patented integrated high-voltage DMOS to reduce the external components.

The Boostrap integrated circuit is connected to VCC pin and is driven synchronously with the low-side driver.

The use of an external bootstrap diode in parallel to the integrated structure is possible, especially when the

operating frequency is generally higher than 500kHz.

DS13686 - Rev 1

page 14/27

Page 15

6.3 VCC supply pins and UVLO function

VCC = PVCC

VCC

thON

VCC

thOFF

UVLO VCC

0V

0V

VCC rise

LIN

GL-PGND

0V

PVCC

The VCC pin supplies current to the logic circuit, level-shifters in the low-side section and the integrated bootstrap

diode.

The PVCC pin supplies low-side output buffer. During outputs commutations the average current used to provide

gate charge to the high-side and low-side GaN transistors flow through this pin.

The PVCC pin can be connected either to the same supply voltage of the VCC pin or to a separated voltage

source. In case the same voltage source is used, it is suggested to connect VCC and PVCC pins by means of

a small decoupling resistance. The use of dedicated bypass ceramic capacitors located as close as possible to

each supply pin is highly recommended.

The MASTERGAN4 VCC supply voltage is continuously monitored by under-voltage lockout (UVLO) circuitry that

turns the high-side and low-side GaN transistors off when the supply voltage goes below the V

The UVLO circuitry turns on the GaN, accordingly to LIN and HIN status, approximately 20µs (typ) after the

supply voltage goes above the V

voltage. A V

CCthON

Figure 16. VCC UVLO and Low Side

MASTERGAN4

VCC supply pins and UVLO function

CC_thOFF

hysteresis is provided for noise rejection purposes.

CChys

threshold.

DS13686 - Rev 1

page 15/27

Page 16

6.4 VBO UVLO protection

VCC

VCCthON

VCCthOFF

HIN

UVLO VBO

0V

0V

VBOrise

(GH-OUTB)

VBO

0V

V

BOthON

VBOthOFF

0V

VBO

Dedicated under-voltage protection is available on the bootstrap section between BOOT and OUTb supply pins.

In order to avoid intermittent operation, a hysteresis set the turn-off threshold with respect to the turn-on threshold.

When the VBO voltage falls below the V

Approximately 5µs (typ) after the VBO voltage reaches the V

operation and the output remains off until the next input pin transition that requests the high-side to turn on.

BOthOFF

Figure 17. VBO UVLO and High Side

threshold, the high-side GaN transistor is switched off.

threshold, the device returns to normal

BOthON

MASTERGAN4

VBO UVLO protection

DS13686 - Rev 1

page 16/27

Page 17

6.5 Thermal shutdown

THERMAL SHUTDOWN CIRCUIT

GH/GL

OD gate

(internal)

Fast shut down

the driver outputs are switched off

disable time

SD/OD

T

TSDTHYSTTSD -

VihV

0 V

TSDVOD

TJ

t1t

2

VPU

SD/OD

FROM / TO

CONTROLLER

C

OD

THERMAL

SHUTDOWN

LOGIC

R

ON_ODRPD_SD

R

OD_ext

2

1

immediately after overtemperature

The integrated gate driver has a thermal shutdown protection.

When junction temperature reaches the T

leaving the half-bridge in 3-state and signaling the state forcing

junction temperature is below T

GaN are driven again according to inputs when

The thermal smart shutdown system gives the possibility to increase the time constant of the external RC network

(that determines the disable time after the overtemperature event) up to very large values without delaying the

protection.

temperature threshold, the device turns off both GaN transistors

TSD

SD/OD pin low. SD/OD pin is released when

TSD-THYS

and SD/OD is below V

TSD

.

SD/OD rise above Vih.

Figure 18. Thermal Shutdown timing waveform

MASTERGAN4

Thermal shutdown

DS13686 - Rev 1

page 17/27

Page 18

7 Typical application diagrams

+

C

PVCC

FROM/TO CONTROLLER

H.V.

C

R

CBOOT

CVCC

C

R

COD

R

VCC

VCC

VPU

CbuS

FROM/TO CONTROLLER

FROM/TO CONTROLLER

VOUT

Driver

Driver

Logic,

interlocking,

overtemp

Level Shifter

Level Shifter

VCC UVLO

UVLO

Vbo

PGNDPVCC

OUTbBOOT

GL

GH

VCC

HIN

LIN

SD/OD

GND

OUT

VS

SENSE

HON

HOFF

LON

LOFF

R

BLEED

RGON

L

RGOFF

L

RGOFF

H

RGON

H

+

C

PVCC

FROM/TO CONTROLLER

H.V.

C

R

CBOOT

CVCC

C

R

COD

R

VOUT

VCC

VCC

VPU

CC

CbuS

FROM/TO CONTROLLER

FROM/TO CONTROLLER

TO CONTROLLER

Driver

Driver

Logic,

interlocking,

overtemp

Level Shifter

Level Shifter

VCC UVLO

UVLO

Vbo

PGNDPVCC

OUTbBOOT

GL

GH

VCC

HIN

LIN

SD/OD

GND

OUT

VS

SENSE

HON

HOFF

LON

LOFF

R

BLEED

RGON

L

RGOFF

L

RGOFF

H

RGON

H

Figure 19. Typical application diagram – Resonant LLC converter

MASTERGAN4

Typical application diagrams

Figure 20.

Typical application diagram – Active clamp flyback

DS13686 - Rev 1

page 18/27

Page 19

8 Package information

In order to meet environmental requirements, ST offers these devices in different grades of ECOPACK packages,

depending on their level of environmental compliance. ECOPACK specifications, grade definitions and product

status are available at: www.st.com. ECOPACK is an ST trademark.

8.1 QFN 9 x 9 x 1 mm, 31 leads, pitch 0.6 mm package information

Table 10. QFN 9 x 9 x 1 mm package dimensions

MASTERGAN4

Package information

Symbol

A

A3 - 0.10 -

b 0.25 0.30 0.35

D 8.96 9.00 9.04

E 8.96 9.00 9.04

D1 3.30 3.40 3.50

E1 2.06 2.16 2.26

D2 1.76 1.86 1.96

E2 3.10 3.20 3.30

D3 1.70 1.80 1.90

E3 3.10 3.20 3.30

e - 0.60 -

K - 0.24 -

L 0.35 0.45 0.55

N 31

aaa 0.10

bbb 0.10

ccc 0.10

ddd 0.05

eee 0.08

Min. Typ. Max.

0.90 0.95 1.00

Dimensions (mm)

Note: • Dimensioning and tolerances conform to ASME Y14.5-2009

• All dimensions are in millimeters

• N total number of terminals

• Dimensions do not include mold protrusion, not to exceed 0.15 mm

• Package outline exclusive of metal burr dimensions

DS13686 - Rev 1

page 19/27

Page 20

Figure 21. QFN 9 x 9 x 1 mm package dimensions

TOP VIEW

SIDE

VIEW

BOTTOM VIEW

MASTERGAN4

QFN 9 x 9 x 1 mm, 31 leads, pitch 0.6 mm package information

DS13686 - Rev 1

page 20/27

Page 21

9 Suggested footprint

TOP VIEW

Dimensions in mm

The MASTERGAN4 footprint for the PCB layout is usually defined based on several design factors as assembly

plant technology capabilities and board component density. For easy device usage and evaluation, ST provides

the following footprint design, which is suitable for the largest variety of PCBs.

The following footprint indicates the copper area which should be free from the solder mask,

while the copper area shall extend beyond the indicated areas especially for EP2 and EP3. To aid thermal

dissipation, it is recommended to add thermal vias under these EPADs to transfer and dissipate device heat to the

other PCB copper layers. A PCB layout example is available with the MASTERGAN4 evaluation board.

Figure 22. Suggested footprint (top view drawing)

MASTERGAN4

Suggested footprint

DS13686 - Rev 1

page 21/27

Page 22

10 Ordering information

Order code Package Package Marking Packaging

MASTERGAN4 QFN 9 x 9 x 1 mm MASTERGAN4 Tray

MASTERGAN4TR QFN 9 x 9 x 1 mm MASTERGAN4 Tape and Reel

MASTERGAN4

Ordering information

Table 11. Order codes

DS13686 - Rev 1

page 22/27

Page 23

Revision history

MASTERGAN4

Table 12. Document revision history

Date Version Changes

02-Apr-2021 1 Initial release.

DS13686 - Rev 1

page 23/27

Page 24

MASTERGAN4

Contents

Contents

1 Block diagram .....................................................................2

2 Pin descriptions and connection diagram ..........................................3

2.1 Pin list ........................................................................3

3 Electrical Data .....................................................................4

3.1 Absolute maximum ratings.......................................................4

3.2 Recommended operating conditions ..............................................5

3.3 Thermal data ..................................................................5

4 Electrical characteristics...........................................................6

4.1 Driver ........................................................................6

4.2 GaN power transistor ...........................................................8

5 Device characterization values .....................................................9

6 Functional description ............................................................14

6.1 Logic inputs ..................................................................14

6.2 Bootstrap structure ............................................................14

6.3 VCC supply pins and UVLO function .............................................15

6.4 VBO UVLO protection ..........................................................16

6.5 Thermal shutdown.............................................................17

7 Typical application diagrams......................................................18

8 Package information..............................................................19

8.1 QFN 9 x 9 x 1 mm, 31 leads, pitch 0.6 mm package information ......................19

9 Suggested footprint ..............................................................21

10 Ordering information .............................................................22

Revision history .......................................................................23

DS13686 - Rev 1

page 24/27

Page 25

MASTERGAN4

List of figures

List of figures

Figure 1. Block diagram ....................................................................2

Figure 2. Pin connections (top view) ............................................................3

Figure 3. Switching time definition ............................................................ 10

Figure 4. Typ ID vs VDS at TJ=25°C............................................................ 10

Figure 5. Typ ID vs VDS at TJ=125°C........................................................... 10

Figure 6. Typ R

Figure 7. Typ R

Figure 8. Typ I

Figure 9. Typ R

Figure 10. Typ ISD vs VSD, at TJ=25°C .......................................................... 12

Figure 11. Typ ISD vs VSD, at TJ=125°C ......................................................... 12

Figure 12. Safe Operating Area at TJ=25°C ....................................................... 12

Figure 13. Typ Gate Charge at TJ=25°C .........................................................12

Figure 14. Derating Curve ...................................................................13

Figure 15. Typ R

Figure 16. VCC UVLO and Low Side ........................................................... 15

Figure 17. VBO UVLO and High Side ........................................................... 16

Figure 18. Thermal Shutdown timing waveform .................................................... 17

Figure 19. Typical application diagram – Resonant LLC converter ....................................... 18

Figure 20. Typical application diagram – Active clamp flyback ..........................................18

Figure 21. QFN 9 x 9 x 1 mm package dimensions ................................................. 20

Figure 22. Suggested footprint (top view drawing) .................................................. 21

vs ID at TJ=25°C ......................................................... 11

DS(ON)

vs ID at TJ=125°C ........................................................ 11

DS(ON)

vs VDS................................................................. 11

D(ON)

DS(ON)_x

Dboot

vs TJ, normalized at 25°C ................................................. 11

vs TJ.................................................................. 13

DS13686 - Rev 1

page 25/27

Page 26

MASTERGAN4

List of tables

List of tables

Table 1. Pin descriptions.....................................................................3

Table 2. Absolute maximum ratings .............................................................4

Table 3. Recommended operating conditions.......................................................5

Table 4. Thermal data.......................................................................5

Table 5. Driver electrical characteristics ..........................................................6

Table 6. GaN power transistor electrical characteristics................................................ 8

Table 7. GaN power transistor characterization values (each transistor) ....................................9

Table 8. Inductive load switching characteristics.....................................................9

Table 9. Inputs truth table (applicable when device is not in UVLO)....................................... 14

Table 10. QFN 9 x 9 x 1 mm package dimensions ................................................... 19

Table 11. Order codes ...................................................................... 22

Table 12. Document revision history .............................................................23

DS13686 - Rev 1

page 26/27

Page 27

MASTERGAN4

IMPORTANT NOTICE – PLEASE READ CAREFULLY

STMicroelectronics NV and its subsidiaries (“ST”) reserve the right to make changes, corrections, enhancements, modifications, and improvements to ST

products and/or to this document at any time without notice. Purchasers should obtain the latest relevant information on ST products before placing orders. ST

products are sold pursuant to ST’s terms and conditions of sale in place at the time of order acknowledgement.

Purchasers are solely responsible for the choice, selection, and use of ST products and ST assumes no liability for application assistance or the design of

Purchasers’ products.

No license, express or implied, to any intellectual property right is granted by ST herein.

Resale of ST products with provisions different from the information set forth herein shall void any warranty granted by ST for such product.

ST and the ST logo are trademarks of ST. For additional information about ST trademarks, please refer to www.st.com/trademarks. All other product or service

names are the property of their respective owners.

Information in this document supersedes and replaces information previously supplied in any prior versions of this document.

© 2021 STMicroelectronics – All rights reserved

DS13686 - Rev 1

page 27/27

Loading...

Loading...