Page 1

HIGH VOLTAGE RESONANT CONTROLLER

■

HIGH VOLTAGE RAIL UP TO 600V

■

dV/dt IMMUNITY±50V/ns IN FULL

TEMPERATURE RANGE

■

DRIVER CURRENT CAPABILITY:

250mA SOURCE

450mA SINK

■

SWITCHING TIMES 80/40ns RISE/FALL WITH

1nF LOAD

■

CMOS SHUT DOWN INPUT

■

UNDER VOLTAGE LOCK OUT

■

SOFT START FREQUENCY SHIFTING

TIMING

■

SENSE OP AMP FOR CLOSED LOOP

CONTROL OR PROTECTION FEATURES

■ HIGH ACCURACY CURRENT CONTROLLED

OSCILLATOR

■

INTEGRATED BOOTSTRAP DIODE

■

CLAMPING ON Vs

■

SO16, DIP16 PACKAGES

DESCRIPTION

The L6598 is manufactured with the BCD OFF LINE

L6598

DIP16 SO16N

ORDERING NUMBERS:

L6598 L6598D

technology, able to ensure voltage ratings up to

600V, making it perfectly suited for AC/DC Adapters

and wherever a Resonant Topology can be beneficial. The device is intended to drive two Power MOS,

in the classical Half Bridge Topology. A dedicated

Timing Section allows the designer to set Soft Start

Time, Soft Start and Minimum Frequency. An Error

Amplifier, together with the two Enable inputs, are

made available. In addition, the integrated Bootstrap

Diode and the Zener Clamping on low voltage supply, reduces to a minimum the external parts needed

in the applications.

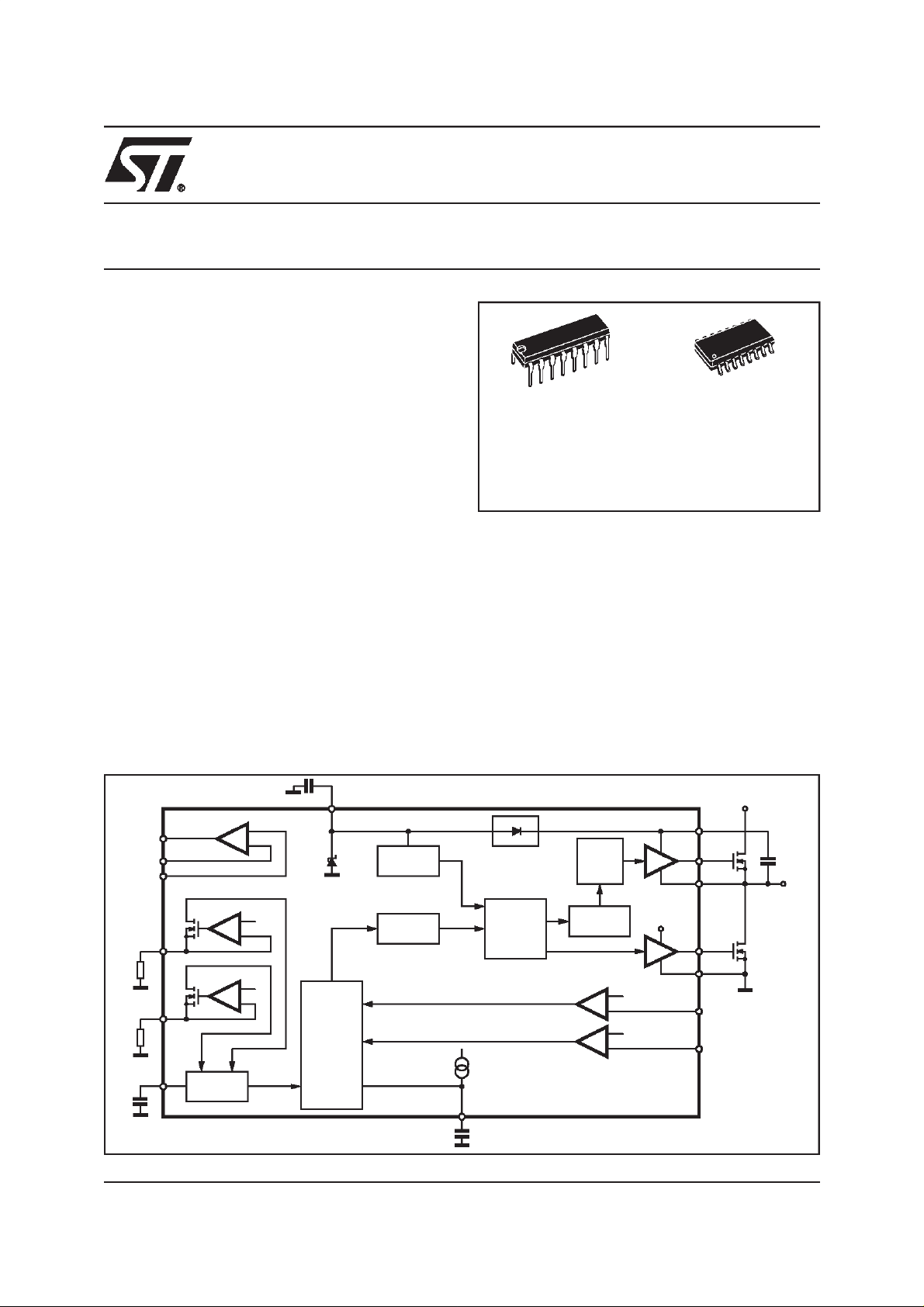

BLOCK DIAGRAM

OP

AMP

5

OPOUT

6

OPIN-

7

OPIN+

Ifmin

4

Rfmin

Rfstart

Cf

February 2000

Ifstart

2

3

VCO

V

S

+

-

V

REF

V

REF

12

CONTROL

LOGIC

UV

DETECTION

DEAD

TIME

Iss

BOOTSTRAP

1

Css

DRIVER

DRIVING

LOGIC

HVG

DRIVER

LEVEL

SHIFTER

LVG DRIVER

+

-

+

-

Vthe1

Vthe2

D98IN887A

16

15

14

Vs

11

10

8

9

V

BOOT

HVG

OUT

LVG

GND

EN1

EN2

H.V.

C

BOOT

LOAD

1/16

Page 2

L6598

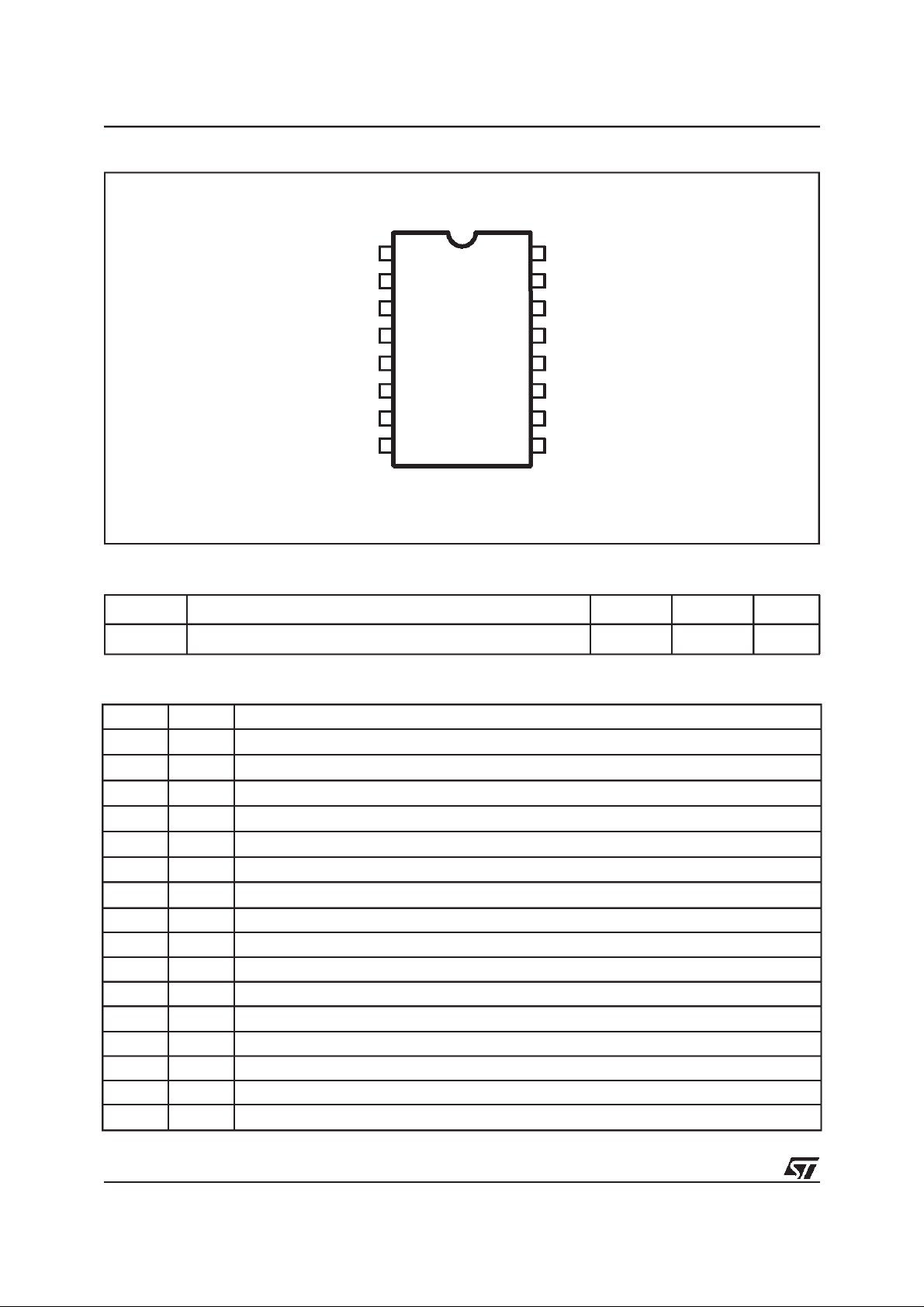

PIN CONNECTION

Css

Rfstart

Cf

Rfmin

OPOUT

OPIN-

OPIN+

1

2

3

4

5

6

7 GND

15

14

13

12

11

10

VBOOT16

HVG

OUT

N.C.

V

S

LVG

EN1 8 EN29

D98IN888

THERMAL DATA

Symbol Parameter SO16N DIP16 Unit

R

th j-amb

Thermal Resistance Junction to Ambient 120 80 °C/W

PIN FUNCTION

N. Name Function

1C

2R

3C

4R

5OP

6OP

7OP

8 EN1 Half Bridge Latched Enable

9 EN2 Half Bridge Unlatched Enable

10 GND Ground

11 LVG Low Side Driver Output

12 V

13 N.C. Not Connected

14 OUT High Side Driver Reference

15 HVG High Side Driver Output

16 V

Soft Start Timing Capacitor

SS

Soft Start Frequency Setting - Low Impedance VoltageSource - See also C

fstart

Oscillator Frequency Setting - see also R

f

Minimum Oscillation Frequency Setting - Low Impedance VoltageSource - See also C

fmin

Sense OP AMP Output - Low Impedance

out

Sense Op Amp Inverting Input - High Impedance

on-

Sense Op Amp Non Inverting Input - High Impedance

on+

Supply Volatge with Internal Zener Clamp

s

Bootstrapped Supply Voltage

boot

fmin,Rfstart

f

f

2/16

Page 3

ABSOLUTEMAXIMUM RATINGS

Symbol Parameter Value Unit

L6598

I

S

V

LVG

V

OUT

V

HVG

V

BOOT

dV

BOOT/dt

dV

OUT/dt

V

ir

V

ic

V

EN1,VEN2

I

EN1,IEN2

V

opc

V

opd

V

opo

T

stg

Supply Current at Vcl(*) 25 mA

Low Side Output 14.6 V

High Side Reference -1 to V

High Side Output -1 to V

-18 V

BOOT

BOOT

V

Floating Supply Voltage 618 V

VBOOT pin Slew Rate (repetitive) ±50 V/ns

OUT pin Slew Rate (repetitive) ±50 V/ns

Forced Input Voltage (pins Rfmin, Rfstart) -0.3 to 5 V

Forced Input Volatge (pins Css, Cf) -0.3 to 5 V

Enable Input Voltage -0.3 to 5 V

Enable Input Current ±3mA

Sense Op Amp Common Mode Range -0.3 to 5 V

Sense Op Amp Differential Mode Range -5 to5 V

Sense Op Amp Output Voltage (forced) 4.6 V

Storage Temperature -40 to +150 °C

T

T

amb

(*) The device is provided of an internal Clamping Zener between GND and the Vs pin, It must not be supplied by a low impedance voltage

source.

Note : ESD immunity for pins 14, 15 and 16 is guaranteed up to 900 (Human Body Model).

Junction Temperature -40 to +150 °C

j

Ambient Temperature -40 to +125 °C

RECOMMENDED OPERATINGCONDITIONS

Symbol Parameter Value Unit

V

V

out

V

boot

f

max

(*) If the condition Vboot - Vout < 18 is guaranteed, Vout can range from -3 to 580V.

Supply Voltage 10 to V

S

(*) High Side Reference -1 to Vboot-V

(*) Floating Supply Rail 500 V

Maximum Switching Frequency 400 kHz

cl

cl

V

V

3/16

Page 4

L6598

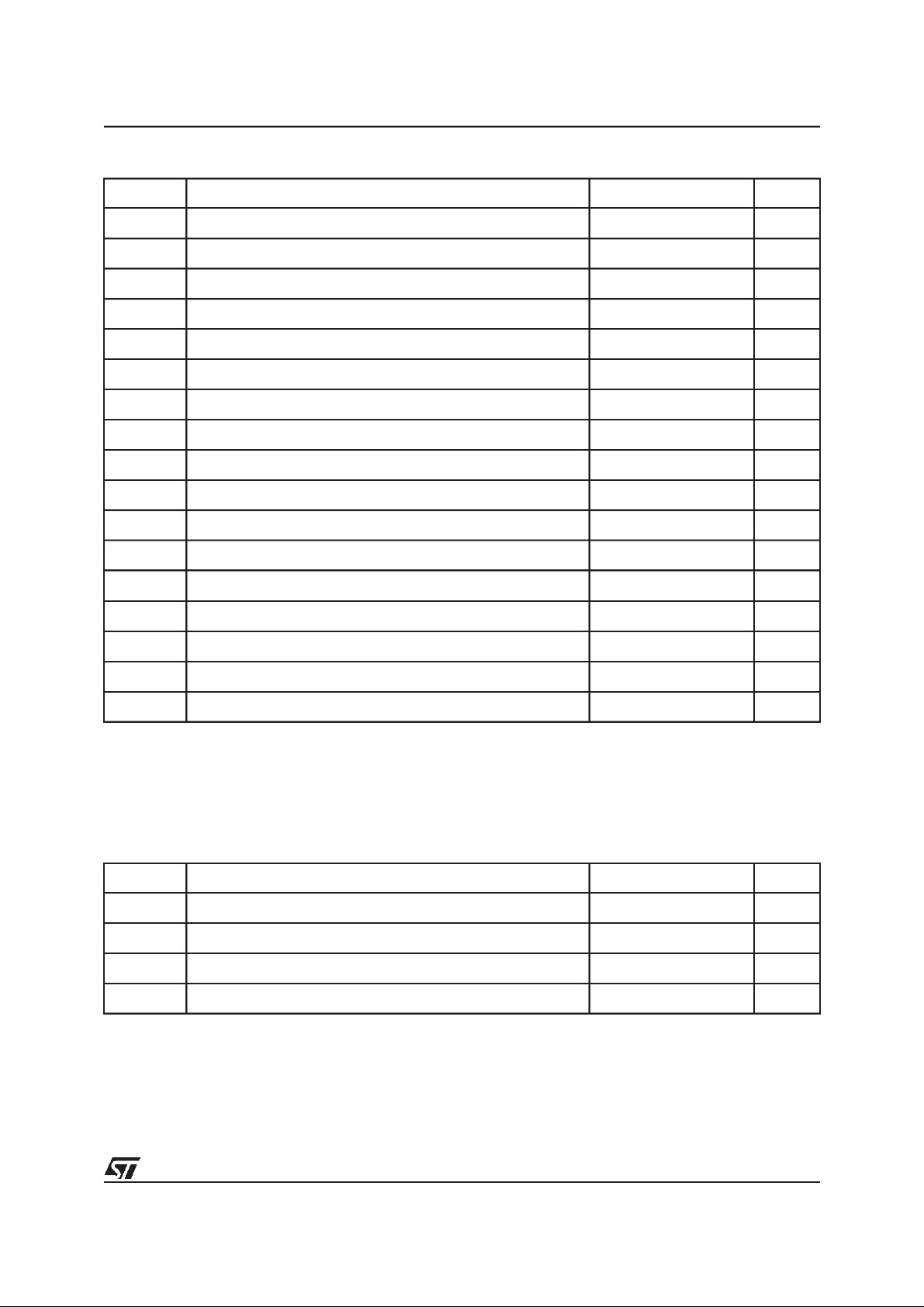

ELECTRICAL CHARACTERISTCS

(VS=12V;V

BOOT-VOUT

=12V;T

amb

=25°C)

Symbol Pin Parameter Test Condition Min. Typ. Max. Unit

SUPPLYVOLTAGE

V

V

V

suvp

suvn

suvh

12 VSTurnOn Threshold 10 10.7 11.4 V

VSTurnOff Threshold 7.3 8 8.7 V

Supply Voltage Under Voltage

2.7 V

hysteresis

V

cl

I

su

I

q

Supply Voltage Clamping 14.6 15.6 16.6 V

Start Up Current Vs<V

Quiescent Current, fout =

Vs>V

suvn

suvp

2mA

250 µA

60kHz, no load

HIGH VOLTAGESECTION

I

bootleak

I

outleak

R

don

16 BOOT pin Leakage Current V

14 OUT pin Leakage Current V

16 Bootstrap Driver On Resistance 150 Ω

= 580V 5 mA

BOOT

= 562V 5 mA

OUT

HIGH/LOW SIDE DRIVERS

I

hvgso

15 High Side Driver Source Current V

HVG-VOUT

= 0 170 250 mA

I

hvgsi

I

lvgso

I

lvgsi

t

rise

t

fall

15,11 Low/High Side Output Rise Time C

High Side Driver Sink Current V

11 Low Side Driver Source Current V

Low Side Driver Sink Current V

HVG-VBOOT

LVG-GND

LVG - VS

load

C

load

= 0 300 450 mA

= 0 170 250 mA

= 0 300 450 mA

= 1nF 80 120 ns

= 1nF 40 80 ns

OSCILLATOR

DC 14 Output Duty Cycle 48 50 52 %

f

min

Minimum Output Oscillation

Cf= 470pF; R

= 50k 58.2 60 61.8 kHz

fmin

Frequency

f

start

V

ref

Soft Start Output Oscillation

Frequency

2, 4 Voltageto Current Converters

Cf= 470pF; R

=47k

R

fstart

fmin

= 50k;

114 120 126 kHz

22

Threshold

t

d

14 Dead Time between Low and

0.2 0.27 0.35

High Side Conduction

TIMING SECTION

k

ss

1 Soft Start Timing constant Css= 330nF 0.115 0.15 0.185 s/µF

s

µ

4/16

Page 5

L6598

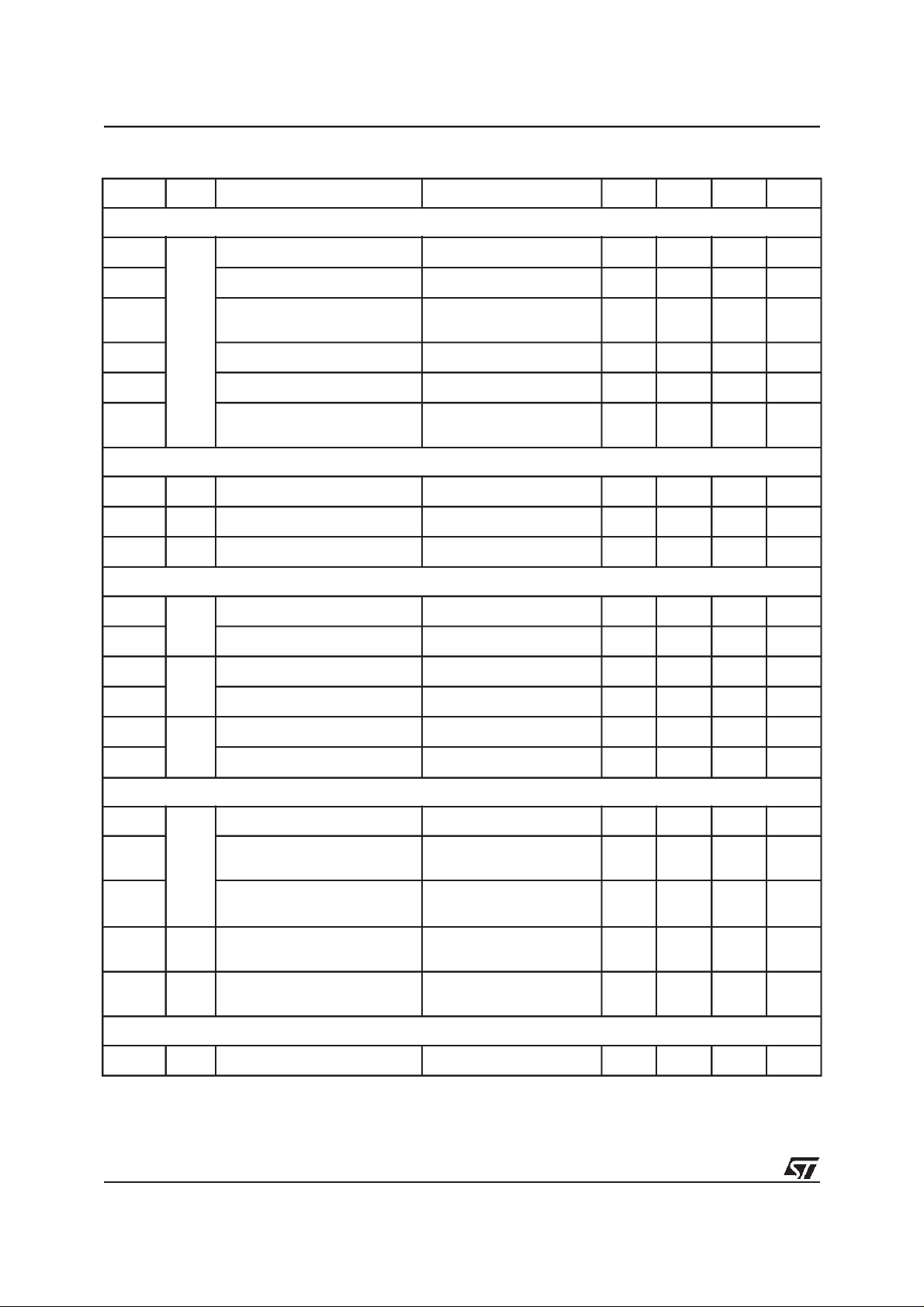

ELECTRICAL CHARACTERISTCS (continued)

Symbol Pin Parameter Test Condition Min. Typ. Max. Unit

SENSE OP AMP

l

IB

V

R

out

I

out-

I

out+

V

GBW Sense Op Amp Gain Band

G

COMPARATORS

V

the1

V

the2

t

pulse

6, 7 Input Bias Current 0.1 µA

io

ic

dc

Input Offset Voltage -10 10 mV

5 Output Resistance 200 300

Source Output Current V

Sink Output Current V

6,7 OP AMP input common mode

range

Width Product

DC Open Loop Gain 80 dB

8 Enabling Comparator Threshold 0.56 0.6 0.64 V

9 Enabling Comparator Threshold 1.05 1.2 1.35 V

8,9 Minimum Pulse lenght 200 ns

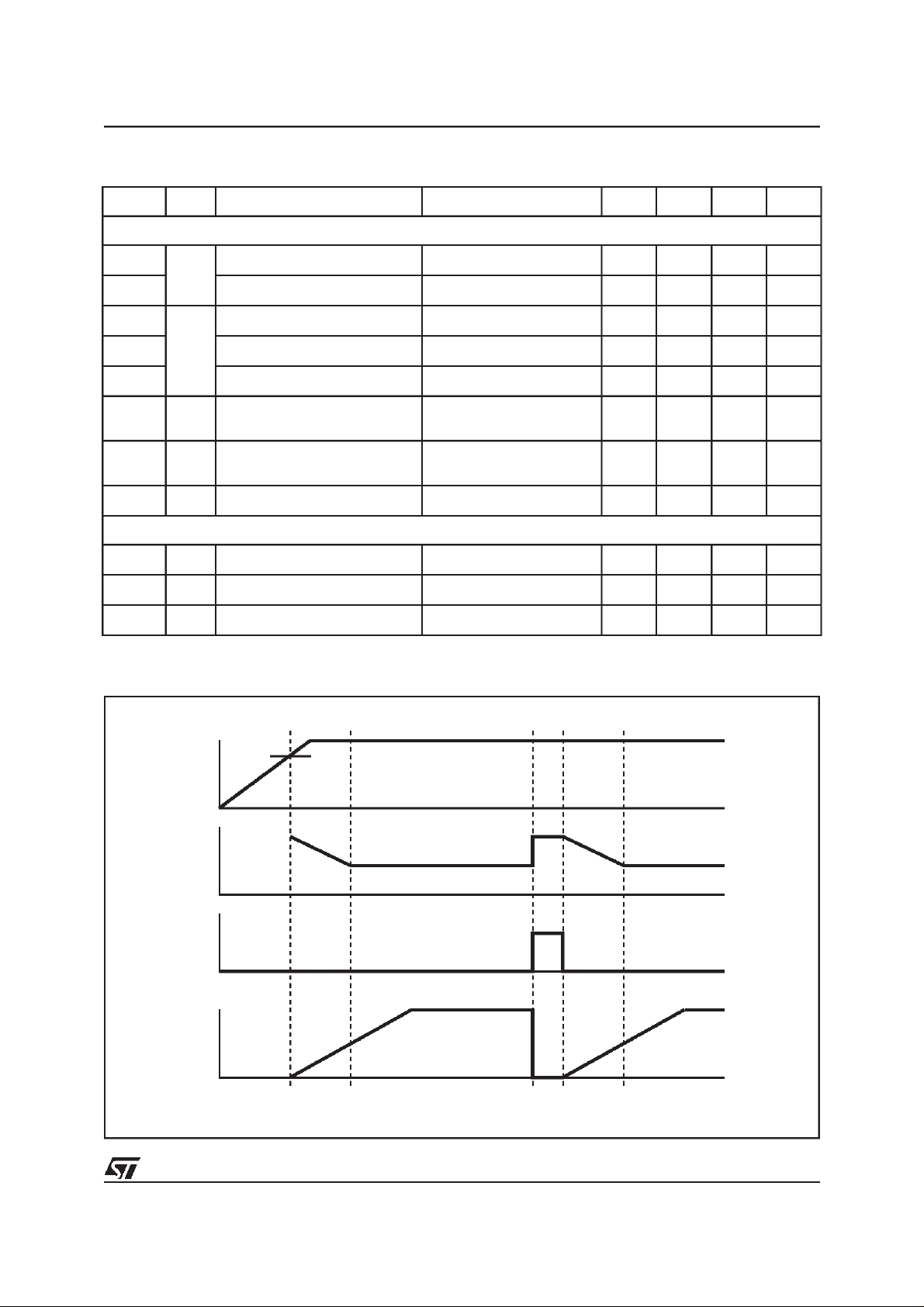

Figure 1. EN2 Timing Diagrams

= 4.5V 1 mA

out

= 0.2V 1 mA

out

-0.2 3 V

1MHz

Ω

V

S

f

OUT

EN2

V

Css

fstart

fmin

T

SS

T

SS

D98IN889

5/16

Page 6

L6598

Figure 2. EN1 Timing Diagrams

HVG

LVG

EN1

EN2

Figure 3. Oscillator/Output Timing Diagram

D98IN890

C

f

HVG

LVG

D98IN897

High/LowSide drivingsection

An High and Low Side driving Section provide the proper driving to the external Power MOS or IGBT. An high

sink/source driving current (450/250 mA typ)ensure fast switching times also when size4 Power MOS are used.

The internal logic ensures a minimum dead time to avoid cross-conduction of the power devices.

Timingand Oscillator Section

The L6598 isprovided of a soft start function. It consists in a period of time, TSS, in whichthe switching frequen-

to f

cy shifts from f

start

. This feature is explained in the following description (ref. fig.4 and fig.5).

min

6/16

Page 7

Figure 4. Soft Start and frequency shifting block

L6598

IfminIfstartIss

----------------+

R

1

fsta rt

Iosc

gmI

--------------

C

ss

[3]

ss

[1]

t–

gm OSC

Css

During the softstart time the currentISScharges the capacitor CSS, generating a voltage ramp which is delivered

to a transconductance amplifier, as shown in fig. 4. Thus this voltage signal is converted in a growing current

which issubtracted to I

start is equal to:

I

osc

At the start-up (t=0) the L6598 oscillates at f

. Therefore the current whichdrives the oscillator to set the frequency during the soft

fstart

I

fminIfstartgmVCss

V

REF

I

where [2]

I

osc

fmin

0() I

--------------

R

fmin

start

==

+

fminIfstart

t()–()+ I

,

I

fsart

, set by:

fminIfstart

V

REF

----------------

R

fstart

V

REF

+==

, 2V== =

V

REF

1

--------------

R

fmi n

At the end of soft start (t = T

only by I

Since the second term of eq.1 is equal to zero, we have:

Note that there is not a fixed threshold of the voltage across C

the frequency shifting), and T

the I

SS

In this way the soft start time depends only on the capacitor C

(i.e. R

min

current has been designed to be a fraction of I

I

SS

fmin

):

I

fstart

--------------

) the second term of eq.1 decreases to zero and the switching frequency is set

SS

I

()I

K

oscTss

gmI

ss

-------------- T

– 0T

I

fsta rt

SS

C

depends on CSS,I

TSS→

SS

ss

C

ssIfstart

--------------------------

gmI

fstart

fmin

→

fstart,gm

,so:

fstart

TSS→

K

SS

, and ISS(eq. 5). Making TSSindependent of I

V

REF

--------------==

R

SS

[4]

fmin

C

ssIfstart

------------------------==

gmI

in which the soft start finishes (i.e. the end of

C

ss

-----------

gmK

. The typical value of the kSSconstant (Soft

SS

[5]

ss

T

–→== =

SSkSSCSS

[6]

fstart

7/16

,

Page 8

L6598

Start Timing Constant) is 0.15 s/µF.

The current I

wave on the oscillator capacitor C

to compute an approximate value of the oscillator frequency in normal operation is:

The degree of approximation depends on the frequency value,butit remains very good inthe range from 30kHz

to 100kHz (figg.6-10)

Figure 5. Oscillator Block

is fed to the oscillator asshown infig. 5. It is twice mirrored (x4 and x8) generating the triangular

osc

. Referring to the internal structure of the oscillator (fig.5), a good relationship

f

1.41

f

min

--------------------=

R

fminCf

[7]

X4Iosc

Vth+

Vth-

+

S

R

+

X8

Cf

8/16

Page 9

L6598

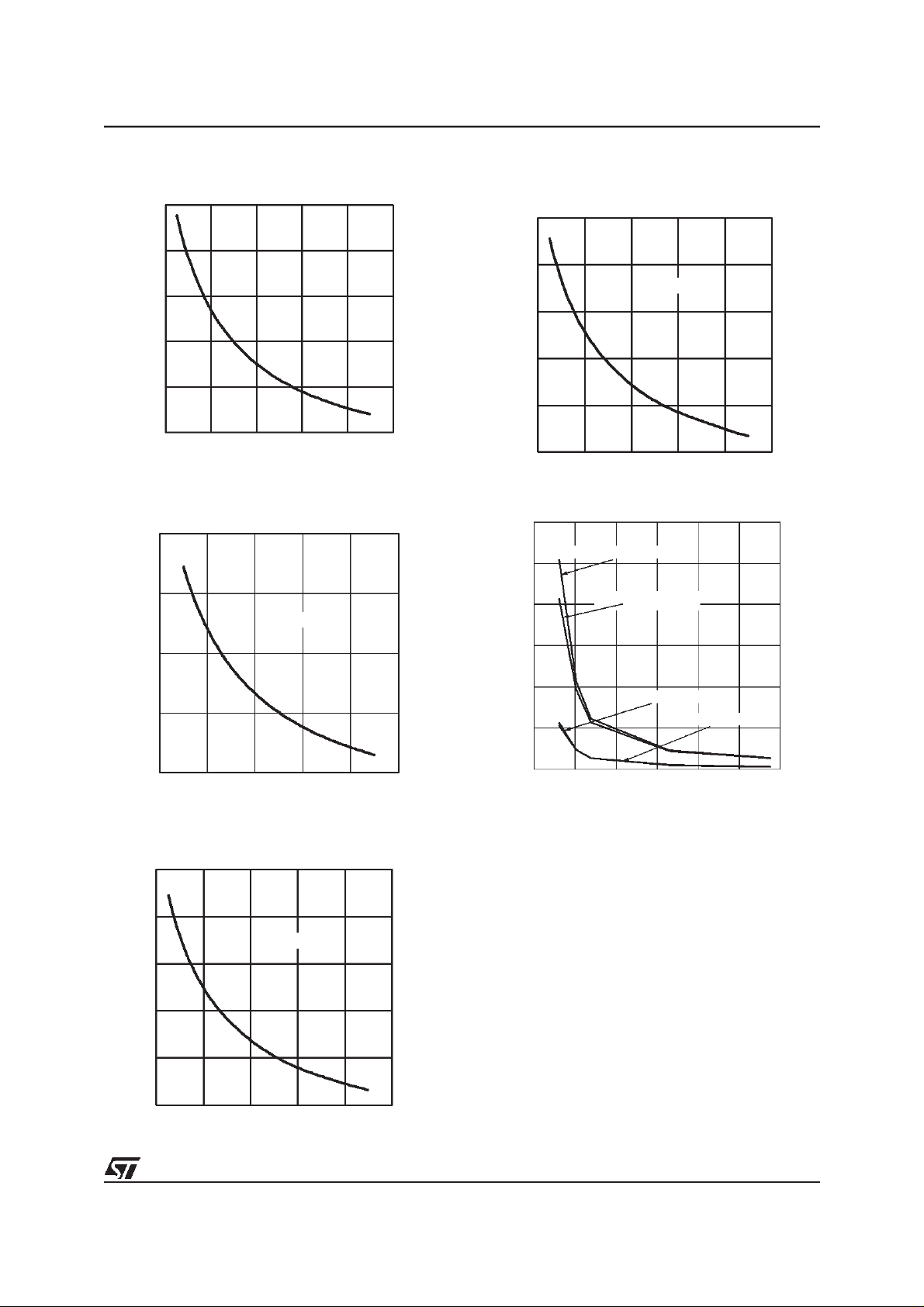

Figure 6. Typ. fmin vs. Rfmin @ Cf = 470pF

f

min

(KHz)

D98IN891

100

80

60

40

20

20 40 60 80 100 R

fmin

(KΩ)

Figure 7. Typ. (fstart-fmin) vs. Rfstar @

Cf = 470pF

∆

f

(KHz)

80

Rfmin=33KΩ

D98IN892

Figure 9. Typ. (fstart-fmin) vs. Rfstar @

Cf = 470pF

∆

f

(KHz)

100

Rfmin=100KΩ

80

60

40

20

20 40 60 80 100 R

D98IN894

fstart

Figure 10. fmin @ different Rf vs Cf

fmin

(KHz)

400

Rf=19.9Kohm - calc.

Rf=19.9Kohm- meas.

(KΩ)

60

40

20

20 40 60 80 100 R

fstart

Figure 8. Typ. (fstart-fmin) vs. Rfstar @

Cf = 470pF

f

∆

(KHz)

100

Rfmin=50KΩ

80

60

40

D98IN893

(KΩ)

200

0

0 200

Rf=90Kohm- meas.

Rf=90Kohm- calc.

400

Cf (pF)

20

20 40 60 80 100 R

fstart

(KΩ)

9/16

Page 10

L6598

BootstrapSection

The supply of the high voltage section is obtained by means of a bootstrap circuitry. This solution normally requires an high voltage fast recovery diode for charging thebootstrap capacitor (fig. 11a). In the L6568 a patented integrated structure, replaces this external diode. It is realised by means of a high voltage DMOS, driven

synchronously with the low side driver (LVG), with in series a diode, as shown in fig. 11b.

Figure 11. ootstrap driver

BOOT

D

VS VBOOT

CBOOT

VOUT

VS VBOOT

LVG

VOUT

C

BOOT

ab

To drive the synchronised DMOS it is necessary a voltage higher than the supply voltage Vs. This voltage is

obtained by means of an internal charge pump (fig. 11b).

The diode connected in seriesto the DMOS has been added to avoid undesirable turn on of it. The introduction

of the diode prevents any current can flow from the V

turned off when the internal capacitor of the pump is not fully discharged.

The bootstrap driver introduces a voltage drop during the recharging of the capacitor C

side driver is on), which increases with the frequency and withthe size of the external power MOS. It is the sum

of the drop across the R

and of the diode threshold voltage. At low frequency this drop is very small and

DSON

can be neglected. Anyway increasing the frequency it must be taken in to account. In fact the drop, reducing

the amplitude of the driving signal, can significantly increase the R

dissipation).

To be considered that in resonant power supplies the current which flows in the power MOS decreases increasing the switching frequency and generally the increases of R

is negligible. The following equation is useful to compute the drop on the bootstrap driver:

pin to the VSone in case that the supply is quickly

boot

(i.e. when the low

boot

of the external power MOS (and so the

DSON

is not a problem because power dissipation

DSON

Q

g

-------------------

T

ch earg

R

+==

dsonVdiode

[8]

is the on resistance of the bootstrap DMOS, and

where Q

T

charge

V

drop

isthe gate charge of the external power MOS, R

g

I

ch eargRdson

V

diode

V

→+

drop

dson

is the time in which the bootstrap driver remains on (about the semiperiod of the switching frequency

minus the dead time). The typical resistance value of the bootstrap DMOS is 150 Ohm. For example using a

power MOS with a total gate charge of 30nC the drop on the bootstrap driver is about 3V, at a switching frequency of 200kHz. In fact:

30nC

V

drop

------------------ 150Ω 0.6V~2.6V+=

2.23µs

To summarise, ifa significant drop on the bootstrap driver (at high switching frequency when large power MOS

are used) represents a problem, an external diode can be used, avoiding the drop on the R

10/16

DSON

of the DMOS.

Page 11

L6598

OP AMP Section

The integrated OP AMP is designed to offerLow Output Impedance, wide band,High input Impedance and wide

Common Mode Range. It can be readily used to implement protection features or a closed loop control. For this

purpose the OP AMP Output can be properly connected to R

Comparators

Two CMOS comparators are available to perform protection schemes. Short pulses (>= 200ns) on Comparators

Input are recognised. The EN1 input (active High), has a threshold of 0.6V (typical value) forces the L6598 in a

latched shutdown state (e.g. LVG Low, HVG low,Oscillator stopped), asin the Under Voltage Conditions. Normal Operating conditions are resumed after a power-off power-on sequence. The EN2 input (active high), with

a threshold of 1.2V (typical value) restarts a Soft Start sequence (see Timing Diagrams). In addition the EN2

Comparator, when activated, removes a latched shutdown caused by EN1.

Figure 12. Switching Time Waveform Definitions

pin to adjust the oscillation frequency.

fmin

90% 90%

HVG

90% 90%

LVG

10% 10%

t

r

10% 10%

t

r

t

f

Figure 13. Dead Time and Duty Cycle Waveform Definition

T

1

t

d

50%

HVG

t

50%

t

f

D98IN898

d

T

T

period

1

Dc =

LVG

50%

50%

T

period

50%

D98IN899

11/16

Page 12

L6598

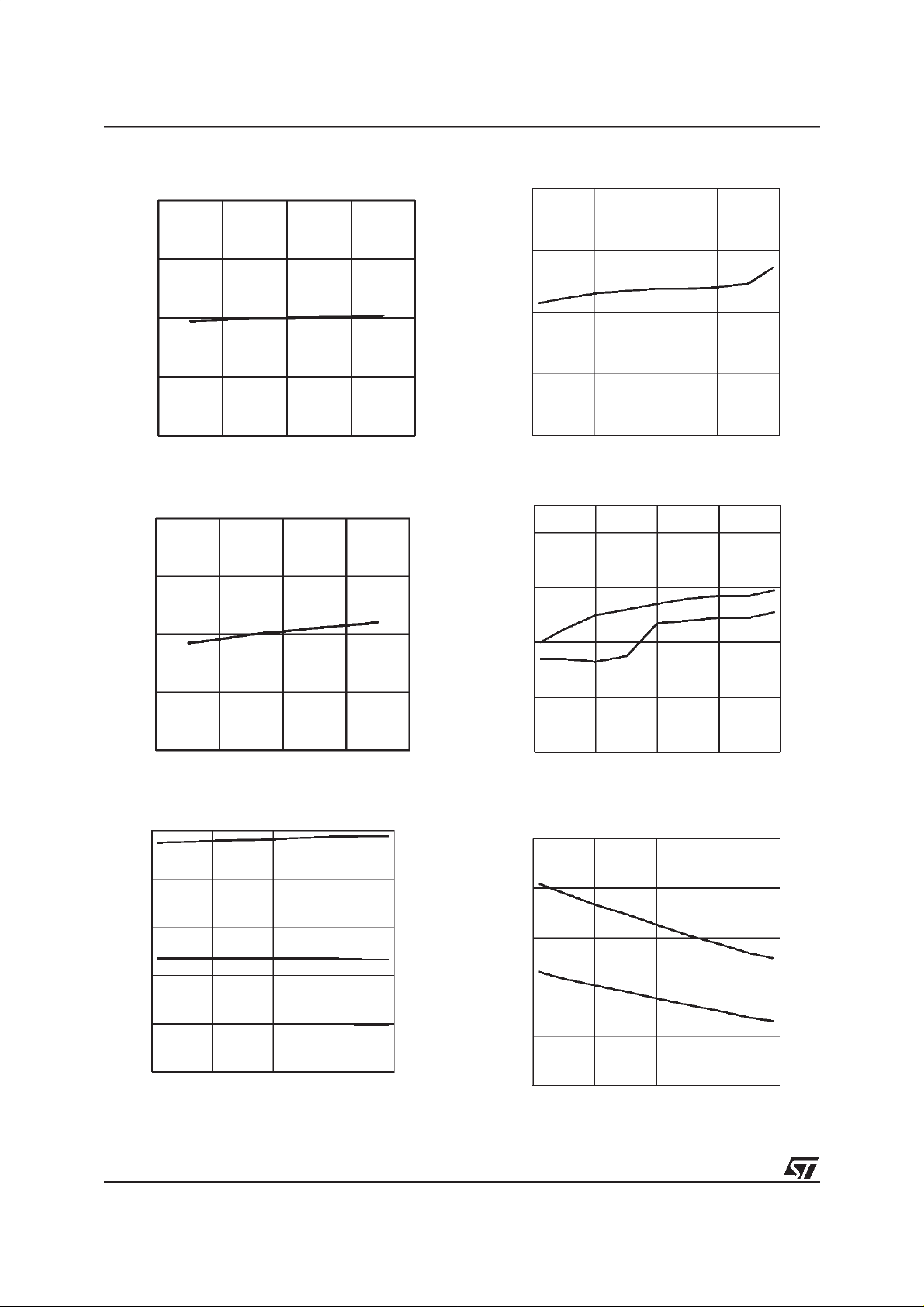

Figure 14. Typ. fmin vs. Temperature

f

min

(KHz)

70

60

50

40

-50 0 50 100

Figure 15. Typ. fstart vs. Temperature

f

fstart

(KHz)

130

D98IN896

D98IN895

T(°C)

Figure 17. Start Up Current vs Temperature

Isu

(µA)

200

150

100

50

-50

050

100

T(°C)

Figure 18. Quiescent Current vs Temperature

Iq

(mA)

2.3

2.1

Iq @Vclamp

120

110

100

-50 0 50 100

T(°C)

Figure 16. Vs thresholds and clamp vs temp.

Vs

(V)

14

12

10

8

6

-50 0 50

100

Vclamp

Vsuvp

Vsuvn

T(°C)

Iq @12V

1.9

1.7

1.5

-50

0

50

100

T(°C)

Figure 19. HVG Source and Sink Current vs.

Temperature

Ihvg

(mA)

500

400

Ihvg sinkcurr.

300

200

100

-50 0 50

Ihvg sourcecurr.

100

T(°C)

12/16

Page 13

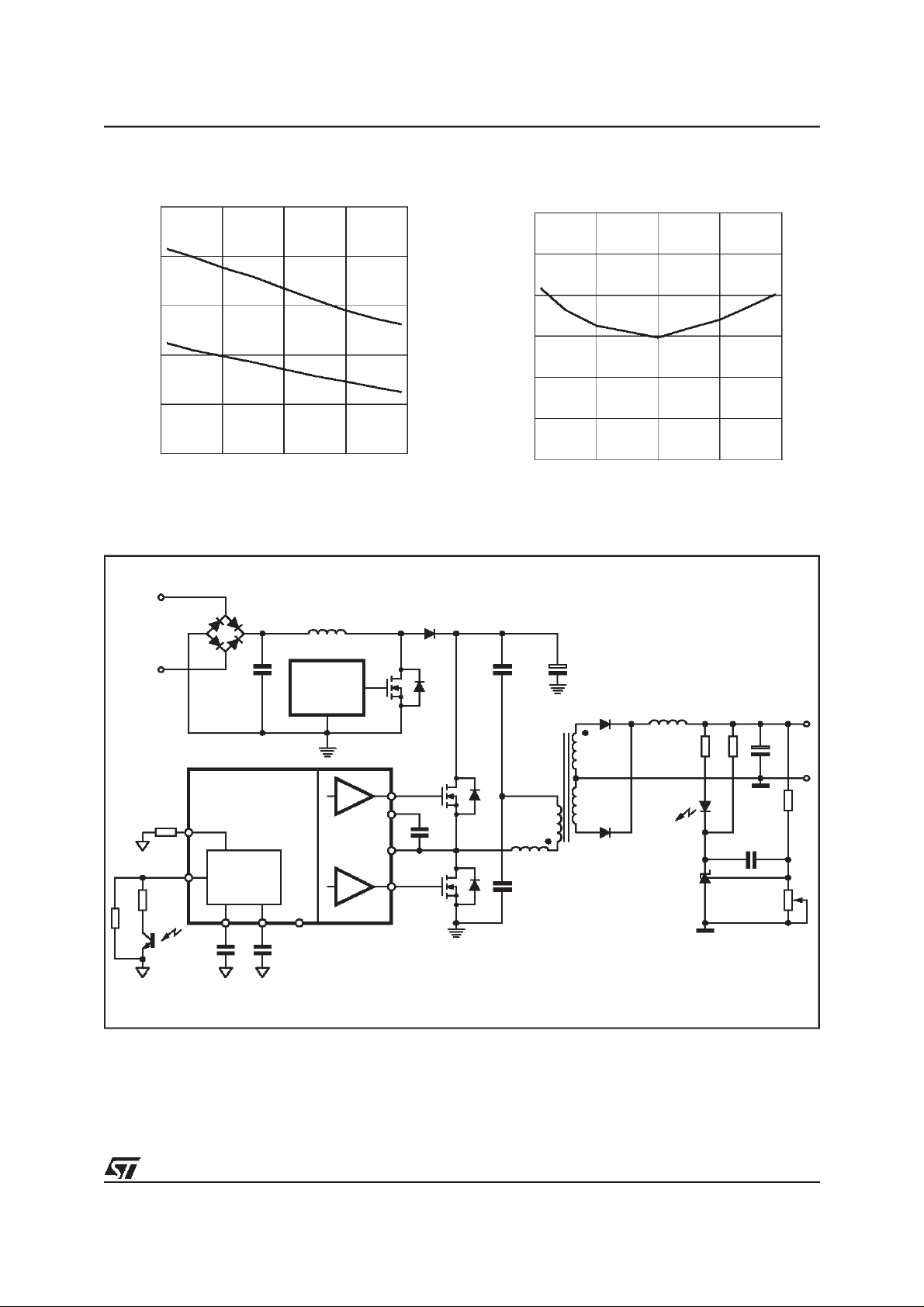

L6598

Figure 20. LVG Source and Sink Current vs.

Temperature

Ilvg

(mA)

500

400

Ilvg sink curr.

300

200

100

-50

0 50 100

Ilvg sourcecurr.

T(°C)

Figure 22. Wide Range AC/DC Adapter Application

Figure 21. Soft Start Timing Constant vs.

Temperature

kss

(s/µF)

0.16

0.14

0.12

-50

0 50 100

T(°C)

85 to

Vac

270

L6598

VCO

&

CONTROL

L6561

Vo

DRIVER

TL431

ENABLE

D98IN874A

13/16

Page 14

L6598

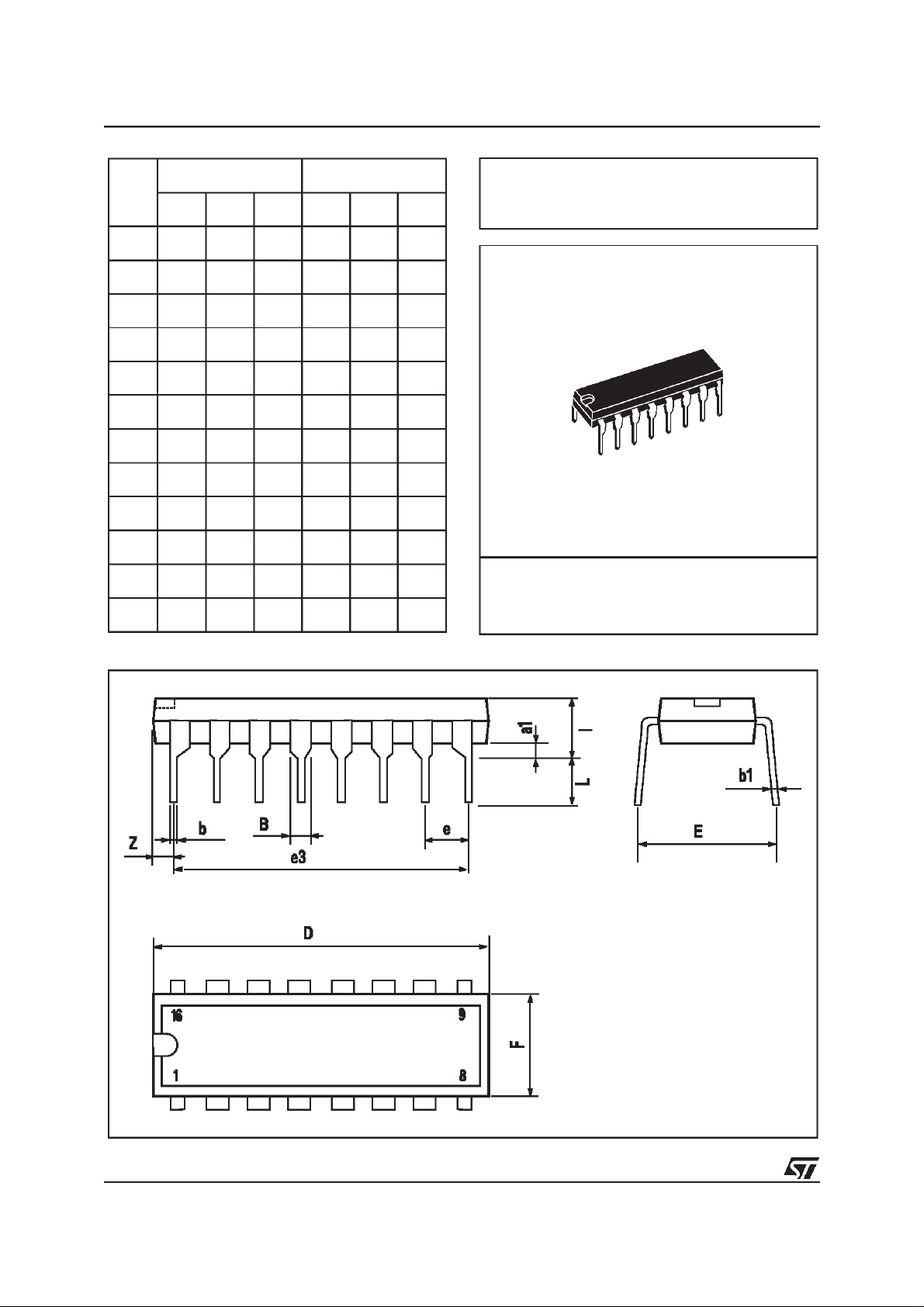

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

a1 0.51 0.020

B 0.77 1.65 0.030 0.065

b 0.5 0.020

b1 0.25 0.010

D 20 0.787

E 8.5 0.335

e 2.54 0.100

e3 17.78 0.700

F 7.1 0.280

I 5.1 0.201

L 3.3 0.130

Z 1.27 0.050

mm inch

OUTLINE AND

MECHANICAL DATA

DIP16

14/16

Page 15

L6598

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

A 1.75 0.069

a1 0.1 0.25 0.004

a2 1.6 0.063

b 0.35 0.46 0.014 0.018

b1 0.19 0.25 0.007 0.010

C 0.5 0.020

c1 45° (typ.)

D (1) 9.8 10 0.386 0.394

E 5.8 6.2 0.228 0.244

e 1.27 0.050

e3 8.89 0.350

F (1) 3.8 4 0.150 0.157

G 4.6 5.3 0.181 0.209

L 0.4 1.27 0.016 0.050

M 0.62 0.024

S

mm inch

0.009

8°(max.)

OUTLINE AND

MECHANICAL DATA

SO16 Narrow

(1) Dand F do not include mold flashor protrusions. Mold flash or potrusions shall not exceed0.15mm (.006inch).

15/16

Page 16

L6598

Information furnished is believed tobe accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of useof suchinformation nor for any infringement of patents or otherrights ofthird parties whichmayresult fromits use. No license isgranted

by implicationor otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

2000 STMicroelectronics - All Rights Reserved

Australia - Brazil -China - Finland - France - Germany - Hong Kong - India - Italy - Japan - Malaysia -Malta- Morocco - Singapore - Spain

STMicroelectronics GROUP OF COMPANIES

- Sweden - Switzerland - UnitedKingdom - U.S.A.

http://www.st.com

16/16

Loading...

Loading...