Page 1

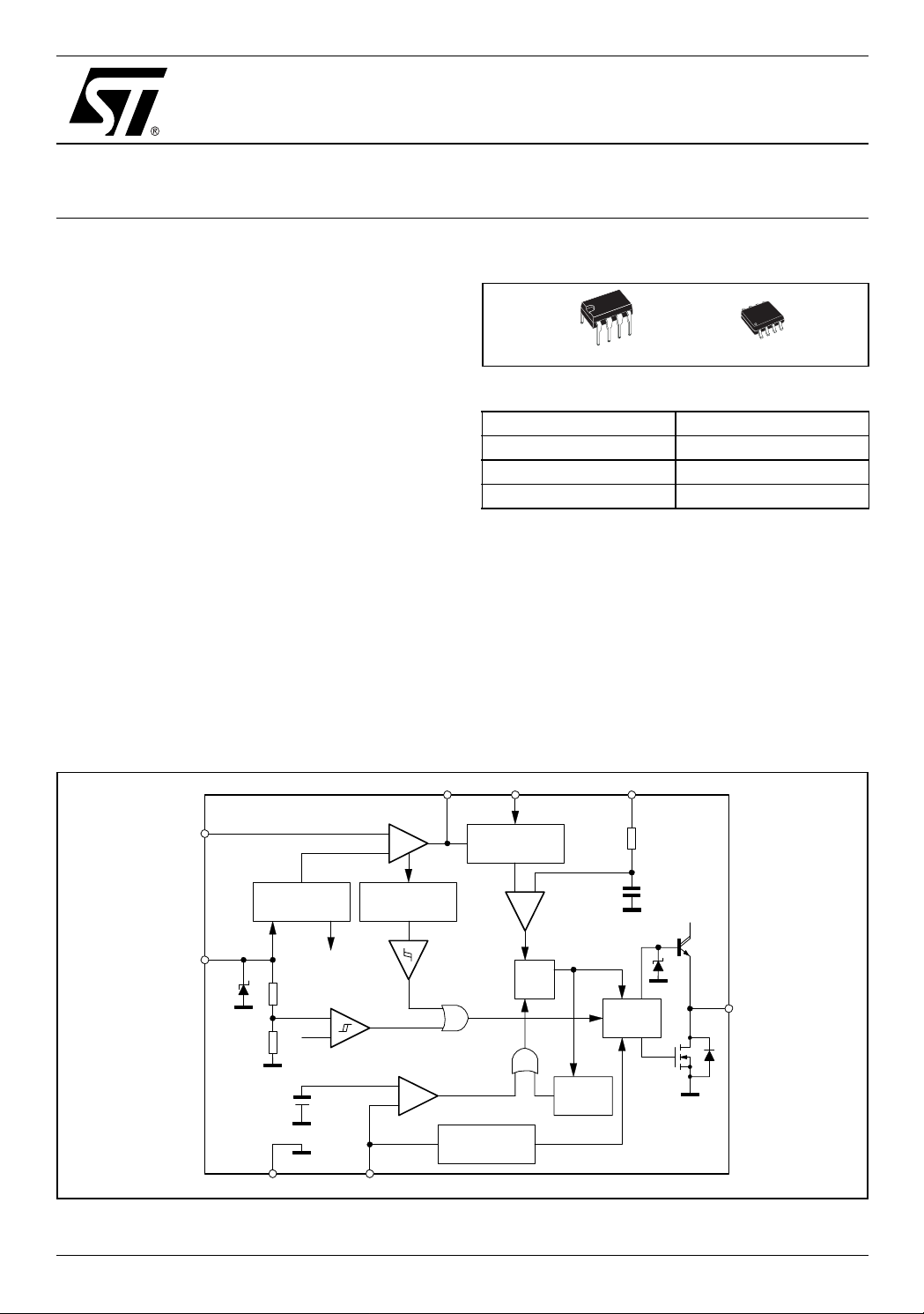

L6562

Fi

TRANSITION-MODE PFC CONTROLLER

1 FEATURES

■ REALISED IN BCD TECHNOLOGY

■ TRANSITION-MODE CONTROL OF PFC PRE-

REGULATORS

■ PROPRIETARY MULTIPLIER DESIGN F OR

MINIMUM THD OF AC INPUT CURRENT

■ VERY PRECISE ADJUSTABLE OUTPUT

OVERVOLTAGE PROTECTION

■ ULTRA-LOW (≤70µA) START-UP CURRENT

■ LOW (≤4 mA) QUIESCENT CURRENT

■ EXTENDED IC SUPPLY VOLTAGE RANGE

■ ON-CHIP FILTER ON CURRENT SENSE

■ DISABLE FUNCTION

■ 1% (@ Tj = 25 °C) INTERNAL REFERENCE

VOLTAGE

■

-600/+800mA TOTEM POLE GATE DRIVER WITH

UVLO PULL-DOWN AND VOLTAGE CLAMP

■ DIP-8/SO-8 PACKAGES

1.1 APPLICATIONS

■ PFC PRE-REGULATORS FOR:

– IEC61000-3-2 COMPLIANT SMPS (TV,

Figure 2. Block Diagram

1

INV

VOLTAGE

REGULATOR

-

+

2.5V

OVERVOLTAGE

DETECTION

gure 1. Packages

DIP-8

SO-8

Table 1. Order Codes

Part Number Package

L6562N DIP-8

L6562D SO-8

L6562DTR Tape & Reel

DESKTOP PC, MONITOR) UP TO 300W

– HI-END AC-DC ADAPTER/CHARGER

– ENTRY LEVEL SERVER & WEB SERVER

2 DESCRIPTION

The L6562 is a current-mode PFC controller operating in Transition Mode (TM). Pin-to-pin compatible with the predecessor L6561, it offers improved

performance.

COMP MULT CS

23 4

MULTIPLIER AND

THD OPTIMIZER

+

-

5pF

40K

CC

V

June 2004

8

CC

V

25 V

R2

6

2.1 V

1.6 V

GND

R1

INTERNAL

SUPPLY 7V

REF2

V

DRIVER

15 V

7

GD

RSQ

+

UVLO

-

ZERO CURRENT

DETECTOR

+

-

5

ZCD

DISABLE

Starter

stop

STARTER

REV. 6

1/16

Page 2

L6562

2 DESCRIPTION (continued)

The highly linear multiplier includes a special circuit, able to reduce AC input current distortion, that allows

wide-range-mains operation with an extremely low THD, even over a large load range.

The output voltage is contr olled by means of a voltage-mode er ror amplifier and a precise (1% @Tj =

25°C) internal voltage reference.

The device features extremely low consumption (≤70 µA before start-up and <4 mA running) and includes

a disable function s uitable for IC remo te ON/OFF, which makes it easier t o comply with energ y saving

norms (Blue Angel, EnergyStar, Energy2000, etc.).

An effective two-step OVP enab les to sa fely han dle overvol tages either occ urring at start-up or re sulti ng

from load disconnection.

The totem-pole output stage, capable of 600 mA source and 800 mA sink current, is suitable for big MOSFET or IGBT drive which, combined with the other features, makes the device an excellent low-cost solution for EN61000-3-2 compliant SMPS's up to 300W.

Table 2. Absolute Maximum Ratings

Symbol Pin Parameter Value Unit

V

CC

IGD 7 Output Totem Pole Peak Current ±0.8 A

--- 1 to 4 Analog Inputs & Outputs -0.3 to 8 V

IZCD 5 Zero Current Detector Max. Curre nt -50 (source)

P

tot

T

j

T

stg

8 IC Supply voltage (Icc = 20 mA) self-limited V

10 (sink)

Power Dissipation @Tamb = 50°C (DIP-8)

(SO-8)

Junction Temperature Operating range -40 to 150 °C

Storage Temperature -55 to 150 °C

1

0.65

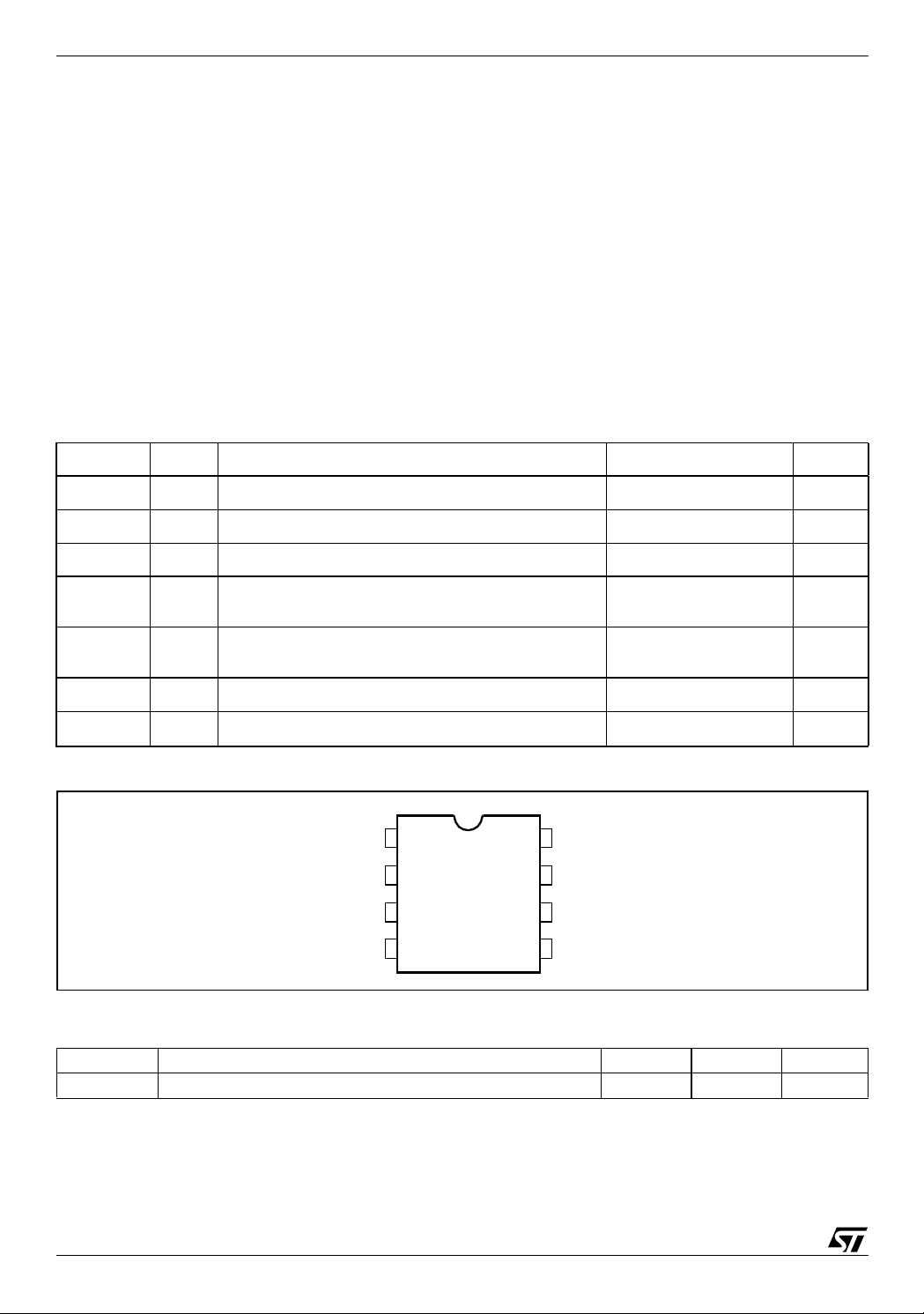

Figure 3. Pin Connection (Top view)

INV

COMP

MULT

CS

1

2

3

4

Vcc

8

7

GD

GND

6

ZCD

5

mA

W

Table 3. Thermal Data

Symbol Parameter SO8 Minidip Unit

2/16

R

th j-amb

Max. Thermal Resistance, Junction-to-ambient 150 100 °C/W

Page 3

Table 4. Pin Description

N° Pin Function

1 INV Inverting input of the error amplifier. The information on the output voltage of the PFC pre-

regulator is fed into the pin through a resistor divider.

2 COMP Output of the erro r amplifier. A compensation ne twork is placed be tween this pin and INV (pin

#1) to achieve stability of the voltage control loop and ensure high power factor and low THD.

3 MULT Main input to the multiplier. This pin is connected to the rect ified mains voltage via a resistor

divider and provides the sinusoidal reference to the current loop.

4 CS Inpu t to th e PW M co mparato r. The current fl owing in the M OSFE T is s ense d thro ugh a resis tor,

the resulting voltage is applied to this pin and compared with an internal sinusoidal-shaped

reference, generated by the multiplier, to determine MOSFET’s turn-off.

5 ZCD Boost inductor’s demagnetization sensing input for transition-mode operation. A negative-going

edge triggers MOSFET’s turn-on.

6 GND Ground. Current return for both the signal part of the IC and the gate driver.

7 GD G ate driver output. The to tem pole output stag e is able to drive power MOSFET’s and IGBT’s

with a peak current of 60 0 mA source and 800 mA sink. The high-level voltage of this pin is

clamped at abou t 12V to avoid excessive gate voltages in case the pin is supplied with a high

Vcc.

8 Vcc Supply Voltage of both the signal par t of the IC and the gate dr iver. The supply voltage upper

limit is extended to 22V min. to provide more he ad roo m for supply voltage cha ng es.

L6562

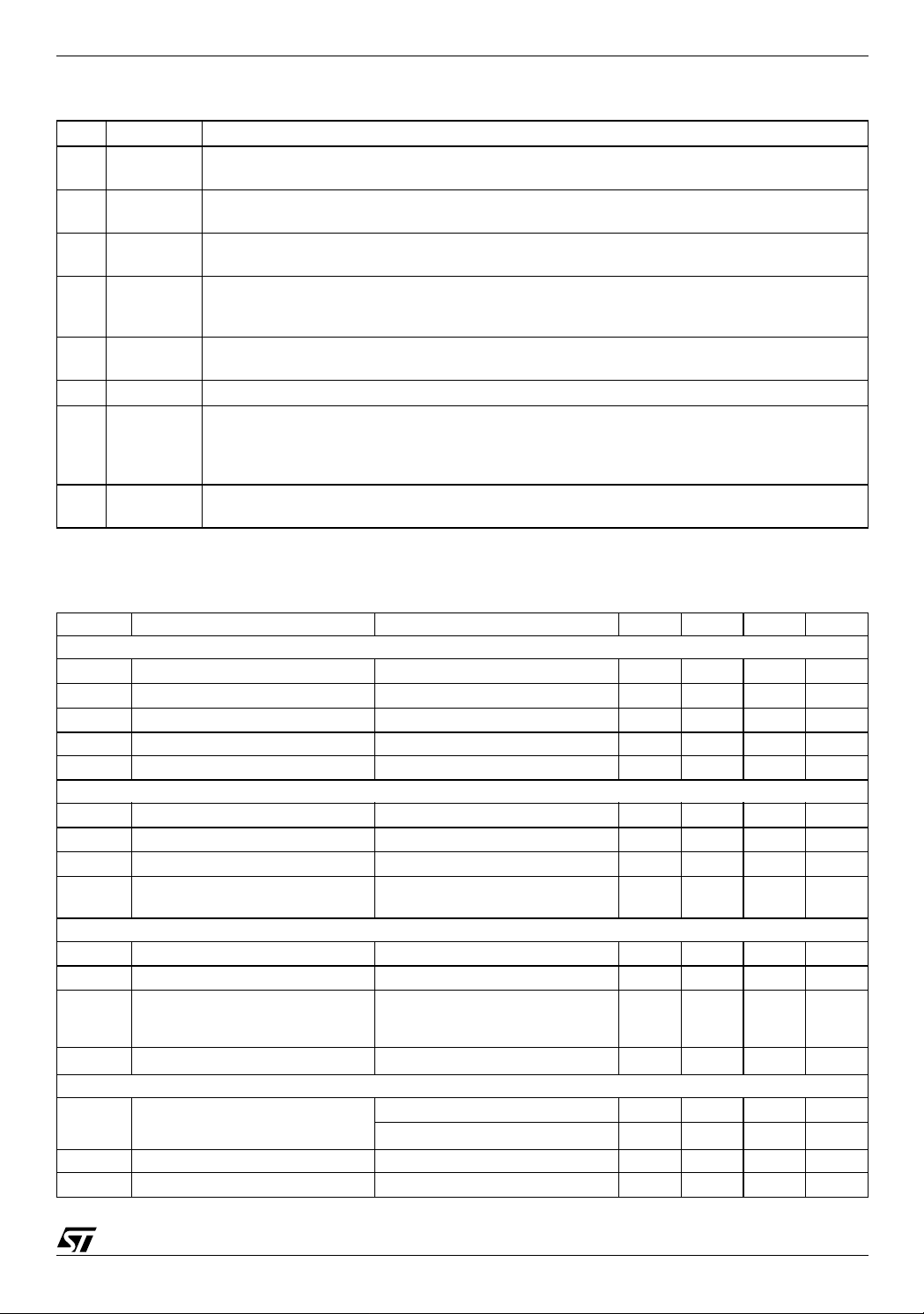

Table 5. Electrical Characteristics

(T

= -25 to 125°C, VCC = 12, CO = 1 nF; unless otherwise specified)

j

Symbol Parameter Test Condition Min. Typ. Max. Unit

SUPPLY VOLTAGE

V

V

CCon

V

CCOff

Hys Hysteresis 2.2 2.8 V

V

SUPPLY CURRENT

I

start-up

I

MULTIPLIER INPUT

I

MULT

V

MULT

VCS∆

---------------------

∆

V

MULT

ERROR AMPLIFIER

V

I

Operating range After turn-on 10.3 22 V

CC

Turn-on threshold

Turn-off threshold

Zener Voltage ICC = 20 mA 22 25 28 V

Z

(1)

(1)

11 12 13 V

8.7 9.5 10.3 V

Start-up Current Before turn-on, VCC =11V 40 70 µ A

I

Quiescent Current After turn-on 2.5 3.75 mA

q

Operating Supply Current @ 70 kHz 3.5 5 mA

CC

I

Quiescent Current During OVP (either static or

q

Input Bias Current V

dynamic) or V

= 0 to 4 V -1 µA

VFF

=150 mV

ZCD

Linear Operation Range 0 to 3 V

Output Max. Slope V

K

INV

(2)

Gain

Voltage Feedback Input

Threshold

MULT

V

COMP

V

MULT

= 0 to 0.5V

= 1 V, V

= Upper clamp

= 4 V 0.5 0.6 0.7 1/V

COMP

1.65 1.9 V/V

Tj = 25 °C 2.465 2.5 2.535 V

10.3 V < Vcc < 22 V

(1)

2.44 2.56

Line Regulation Vcc = 10.3 V to 22V 2 5 mV

Input Bias Current V

INV

= 0 to 3 V -1 µA

INV

2.2 mA

3/16

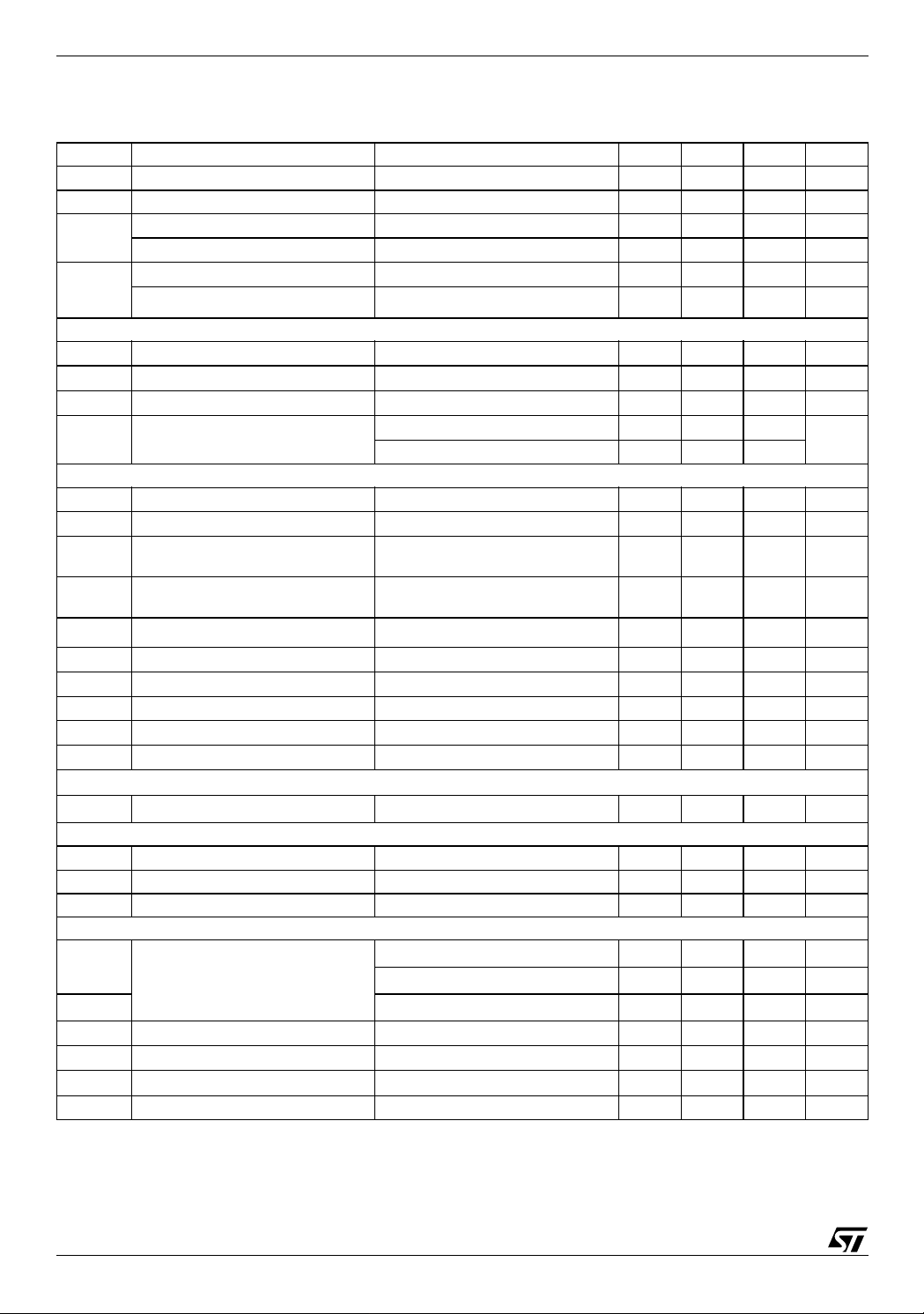

Page 4

L6562

Table 5. Electrical Characteristics (continu ed)

= -25 to 125°C, VCC = 12, CO = 1 nF; unless otherwise specified)

(T

j

Symbol Parameter Test Condition Min. Typ. Max. Unit

G

GB Gain-Bandwidth Product 1 MHz

I

COMP

V

COMP

CURRENT SENSE COMPARATOR

I

t

d(H-L)

V

CS clamp

V

CSoffset

ZERO CURRENT DETECTOR

V

ZCDH

V

ZCDL

V

ZCDA

V

ZCDT

I

ZCDb

I

ZCDsrc

I

ZCDsnk

V

ZCDdis

V

ZCDen

I

ZCDres

STARTER

t

START

OUTPUT OVERVOLTAGE

I

OVP

Hys Hysteresis

GATE DRIVER

V

V

V

Oclamp

(1) All param eters are in tr acking

(2) The multipl i er output is given by:

(3) Parameters guaranteed by design, functionality tested in production.

Voltage Gain Open loop 60 80 dB

v

Source Current V

Sink Current V

Upper Clamp Voltage I

Lower Clamp Voltage

Input Bias Current VCS = 0 -1 µA

CS

Delay to Output

Current sense reference clamp V

Current sense offset V

Upper Clamp Voltage I

Lower Clamp Voltage I

Arming Voltage

COMP

COMP

SOURCE

I

= 0.5 mA

SINK

= 4V, V

= 4V, V

= 0.5 mA 5.3 5.7 6 V

= 2.4 V -2 -3.5 -5 mA

INV

= 2.6 V 2.5 4.5 mA

INV

(1)

2.1 2.25 2.4 V

200 350 ns

= Upper clamp 1.6 1.7 1.8 V

COMP

= 0 30 mV

MULT

V

= 2.5V 5

MULT

= 2.5 mA 5.0 5.7 6.5 V

ZCD

= -2.5 mA 0.3 0.65 1 V

ZCD

(3)

2.1 V

(positive-going edge)

Triggering Voltage

(3)

1.6 V

(negative-going edge)

Input Bias Current

= 1 to 4.5 V

V

ZCD

2µA

Source Current Capability -2.5 -5.5 mA

Sink Current Capability 2.5 mA

Disable threshold 150 200 25 0 mV

Restart threshold 350 mV

Restart Current after Disable 30 75 µA

Start Timer period

75 130 300 µs

Dynamic OVP triggering current 35 40 45 µA

(3)

Static OVP threshold

OH

Dropout Voltage

OL

Voltage Fall Time 30 70 ns

t

f

t

Voltage Rise Time 40 80 ns

r

Output clamp voltage I

UVLO saturation V

VcsKV

(1)

I

GDsource

I

GDsource

I

= 200 mA

GDsink

GDsource

= 0 to V

CC

MULTVCOMP

= 20 mA

= 200 mA

= 5mA; Vcc = 20V

, I

CCon

2.5–()⋅⋅=

=10mA 1.1 V

sink

2.1 2.25 2.4 V

10 12 15 V

30 µA

22.6

2.5 3 V

0.9 1.9 V

4/16

Page 5

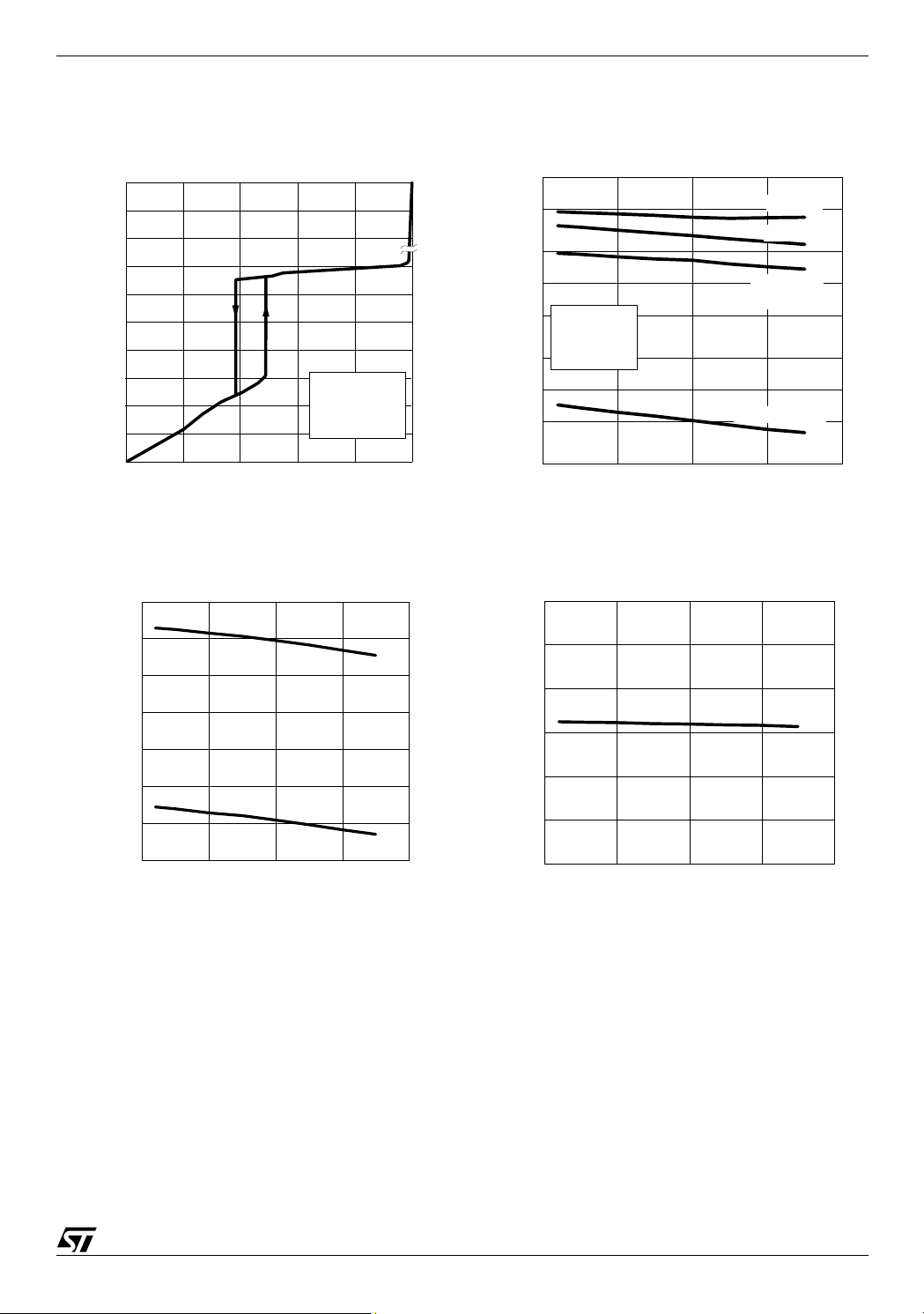

3 TYPICAL ELECTRICAL CHARACTERISTICS

L6562

Figure 4. Supply current vs. Supply voltage

I

CC

(mA)

10

5

1

0.5

0.1

0.05

0.01

0.005

0

0 5 10 15 20

V

cc(V)

Figure 5. Start-up & UVLO vs. T

12.5

V

CC-ON

12

(V)

Co = 1nF

f = 70 kHz

= 25°C

T

j

j

25

Figure 6. IC consumption vs. T

Icc

10

[mA]

5

j

2

1

0.5

Vcc = 12 V

Co = 1 nF

f = 70 kHz

0.2

0.1

0.05

0.02

-50 0 50 100 150

Before start-up

Tj (°C)

Figure 7. Vcc Zener voltage vs. Tj

Vcc

Z

28

(V)

27

Operating

Quiescent

Disabled or

during OVP

CC-OFF

V

(V)

11.5

11

10.5

10

9.5

9

-50 0 50 100 150

Tj (

°C)

26

25

24

23

22

-50 0 50 100 150

Tj (°C)

5/16

Page 6

L6562

Figure 8. Feedback reference vs. Tj

V

REF

2.6

(V)

2.55

2.5

2.45

2.4

-50 0 50 100 150

Tj (°C)

Figure 9. OVP current vs. T

I

OVP

41

(µA)

40.5

40

39.5

39

-50 0 50 100 150

Tj (°C)

j

Vcc = 12 V

Vcc = 12 V

Figure 11. Delay-to-output vs. T

t

D(H-L)

500

(ns)

400

300

200

100

0

-50 0 50 100 150

Tj (°C)

j

Figure 12. Multiplier characteristic

V

(pin 4)

CS

upper voltage

(V)

clamp

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0

0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5

5.0

4

5

.

4.0

V

MULT

(pin 3) (V)

Vcc = 12 V

V

COMP

(V)

3.5

3.2

3.0

2.8

2.6

(pin 2)

Figure 10. E/A output clamp levels vs. T

Vpin2

6

(V)

6/16

Upper clamp

5

4

3

Lower clamp

2

-50 0 50 100 150

Tj (°C)

Vcc = 12 V

j

Figure 13. Multiplier gain vs. T

K

1

0.8

j

Vcc = 12 V

=4 V

V

COMP

V

=1V

MULT

0.6

0.4

0.2

0

-50 0 50 100 150

Tj (°C)

Page 7

L6562

Figure 14. Vcs clamp vs. Tj

V

CSx

2

(V)

1.8

1.6

1.4

Vcc = 12 V

V

1.2

COMP = Upper clamp

1

-50 0 50 100 150

Tj (°C)

Figure 15. Start-up timer vs. T

Tstart

150

(µs)

140

130

Vcc = 12 V

Figure 17. ZCD source capability vs. T

I

ZCDsrc

0

(mA)

-2

-4

-6

-8

-50 0 50 100 150

Tj (°C)

j

Figure 18. Gate-drive output low saturation

pin7

V

[V]

4

Tj = 25 °C

Vcc = 11 V

SINK

Vcc = 12 V

= lower clamp

V

ZCD

j

3

120

110

100

-50 0 50 100 150

Tj (°C)

Figure 16. ZCD clamp levels vs. T

V

ZCD

7

(V)

6

5

4

3

2

1

0

-50 0 50 100 150

Tj (°C)

Upper clamp

I

ZCD = ±2.5 mA

Lower clamp

j

Vcc = 12 V

2

1

0

0 200 400 600 800 1,000

IGD[mA]

Figure 19. Gate-drive output high saturation

pin7

V

[V]

-1.5

Tj = 25 °C

Vcc - 2.0

-2.5

Vcc - 2.5

Vcc - 3.0

-3.5

Vcc - 3 .5

Vcc - 4.0

-4.5

-2

-3

-4

0 100 200 300 400 500 600 700

IGD[mA]

Vcc = 11 V

SOURCE

7/16

Page 8

L6562

Figure 20. Gate-drive clamp vs. T

clamp

Vpin7

15

(V)

14

13

12

11

10

-50050100150

Tj (°C)

j

Vcc = 20 V

Figure 21. UVLO saturation vs. T

Vpin7

1.1

(V)

1

0.9

0.8

0.7

0.6

0.5

-50 0 50 100 150

Tj (°C)

j

Vcc = 0 V

4 APPLICATION INFORMATION

4.1 Overvoltage protection

Under steady-state conditions, the voltage control loop keeps the output voltage Vo of a PFC pre-regulator

close to its nomina l v al ue, se t by th e r esi sto rs R1 an d R2 of the outp ut d iv id er. Neglecting ripple co mponents, the current through R1, I

the error amplifier is internally referenced at 2.5V, also the voltage at pin INV will be 2.5V, then:

, equals that through R2, IR2. Considering that the non-inverting input of

R1

I

R2

2.5

------- - I

R2

R1

Vo 2.5–

--------------------- -===

R1

.

If the output voltage experiences an abrupt change ∆Vo > 0 due to a load drop, the voltage at pin INV will

be kept at 2.5V by the loc al feedback of the error amplifier, a network co nnected be tween pins INV a nd

COMP that introduces a long time constant to achieve high PF (this is why ∆Vo can be large). As a result,

the current through R2 will remain equal to 2.5/R2 but that through R1 will become:

R1

Vo 2.5– Vo∆+

--------------------------------------- -=

R1

.

I'

The difference current ∆IR1=I'R1-IR2=I'R1-IR1=∆Vo/R1 will flow through the compensation network and enter the error amplifier output (pin COMP). This current is monitored inside the L6562 and if it reaches about

37 µA the output voltage of the mul tip li er is forced to dec reas e, th us smo othly red ucing the en er gy deliv ered to the output. As the curren t excee ds 40 µA , the O VP is triggered (Dynamic OVP): the ga te- dri ve is

forced low to switch off the external power transistor and the IC put in an idle state. This condition is maintained until the c urrent falls b elow ap prox imatel y 10 µA , w hich re -enab les the in ternal s tarte r and al lows

switching to restart. The output ∆Vo that is able to trigger the Dynamic OVP function is then:

Vo∆ R1 40 10

⋅⋅=

6–

.

An important advan tage of thi s technique is that th e OV le vel can be s et indepe ndently of the regu lated

output voltage: the latter depends on the ratio of R1 to R2, the former on the individual value of R1. Another

advantage is the precision: the tol erance of the detectio n current is 12%, that is 12% tolerance on ∆Vo.

Since ∆Vo << Vo, the tolerance on the absolute value will be proportionally reduced.

Example: Vo = 400 V, ∆Vo = 40 V. Then: R1=4 0V /40 µA=1MΩ; R2=1MΩ·2.5/(400-2.5)=6.289kΩ. The tolerance on the OVP level due to the L6562 will be 40·0.12=4.8V, that is 1.2% of the regulated value.

8/16

Page 9

L6562

When the load of a PFC pre-regulator is very low, the output voltage tends to stay steadily above the nominal value, which cannot be handled by the Dynamic OVP. If this occurs, however, the error amplifier output will saturate low; hence, when this is detected, the external power transistor is switched off and the IC

put in an idle state (Static OVP). Normal operation is resumed as the error amplifier goes back into its linear region. As a result, the L6562 will work in burst-mode, with a repetition rate that can be very low.

When either OVP is activa ted the quies cent co nsump tion of the IC is redu ced to minim ize the dischar ge

of the Vcc capacitor and increase the hold-up capability of the IC supply system.

4.2 THD optimizer circuit

The L6562 is equipped with a special circuit that reduces the conduction dead-angle occurring to the AC

input current near the zero-crossings of the line voltage (crossover distortion). In this way the THD (Total

Harmonic Distortion) of the current is considerably reduced.

A major cause of this distortion is the inability of the system to transfer energy effectively when the instantaneous line voltage is very low. This effect is magnified by the high-frequency filter capacitor placed after

the bridge rectifier, which retains some residual voltage that causes the diodes of the bridge rectifier to be

reverse-biased and the input current flow to temporarily stop.

Figure 22. THD optimization: standard TM PFC controller (left side) and L6562 (right side)

Input current Input current

Rectified mains voltage Rectified mains voltage

Imains

Input current

MOSFET's drain voltage

Vdrain

Imains

Input current

MOSFET's drain voltage

Vdrain

To overcome this issue the ci r cu it emb edd ed in the L656 2 for ce s the PF C pre-r eg ula tor to pr oc ess more

energy near the line voltage zero-crossings as compared to that commanded by the control loop. This will

result in both minimizin g the tim e int er val wher e en ergy tran sfe r is lack in g and ful ly dis c hargi ng the high frequency filter capacito r after the bridge. The effect of the circuit is show n in figure 23, where the key

waveforms of a standard TM PFC controller are compared to those of the L6562.

Essentially, the circuit artificially increases the ON-time of the power switch with a positive offset added to

9/16

Page 10

L6562

the output of the multiplier in the proximity of the line voltage zero-crossings. This offset is reduced as the

instantaneous line vol tage inc reases , so that it becomes neglig ible as the l ine vol tage mo ves towa rd the

top of the sinusoid.

To maximally benefit from the THD optimizer circuit, the high-frequency filter capacitor after the bridge rectifier should be minimi zed, comp atibly with EM I filter ing nee ds. A la rge capac itanc e, in fact, i ntrodu ces a

conduction dead-angle of the AC input current in itself - even with an ideal energy transfer by the PFC preregulator - thus making the action of the optimizer circuit little effective.

Figure 23. Typical application circuit (250W, Wide-range mains)

D3 1N5406

Ω

5

L6562

T

R50 10 kΩ

C3 2.2 µF

C23

680 nF

21

7

4

6

STTH5L06

R7

Ω

10

0.33

R9

1W

Ω

STP12NM50

7 °C/W heat sink

R10

0.33

1W

MOS

Ω

2.5 Ω

R13

9.53 k

Ω

NTC

D1

R11

750 k

R12

750 k

Ω

Ω

Vo=400V

Po=250W

C6

100 µF

450V

-

5A/250V

Vac

(85V to 265V)

FUSE

+

-

BRIDGE

STBR606

C1

1 µF

400V

22 k

R4

R5

D8

1N4150

D2

1N5248B

C5 12 nF

C4

100 nF

R14

100

R6

68 kΩ

8

3

180 kΩ

1.5 MΩ

1.5 M

10nF

R3

Ω

Ω

180 k

R1

R2

Ω

C2

C29

22 µF

25V

Boost Inductor Spec: EB0057-C (COILCRAFT)

Figure 24. Demo board (EVAL6562-80W, Wide-range mains): Electrical schematic

T

C23

330 nF

5

21

L6562

6

R50 12 kΩ

C3 680 nF

4

D1

STTH1L06

R7

33

Ω

7

R9

0.82

0.6 W

STP8NM50

Ω

MOS

R10

0.82

0.6 W

Ω

9.53 k

4A/250V

Vac

(85V to 265V)

FUSE

R4

180 kΩ

R1

750 kΩ

BRIDGE

DF06M

+

-

Boost Inductor Spec (ITACOIL E2543/E)

C1

0.47 µF

400V

R2

750 k

Ω

C2

10nF

R3

10 k

Ω

E25x13x7 core, 3C85 ferrite

1.5 mm gap for 0.7 mH primary inductance

Primary: 105 turns 20x0.1 mm

Secondary: 11 turns 0.1 mm

180 k

22 µF

R5

C29

25V

Ω

D8

1N4150

D2

1N5248B

C5 12 nF

C4

100 nF

R14

100 Ω

R6

68 kΩ

8

3

NTC

2.5 Ω

R13

Vo=400V

R11

Po=80W

750 k

Ω

R12

Ω

750 k

C6

47 µF

450V

Ω

-

10/16

Page 11

Figure 25. EVAL6562-80W: PCB and component layout (Top view, real size: 57 x 108 mm)

L6562

Table 6. EVAL6562N: Evaluation results at full load

Vin (VAC)

Pin (W)

85 86.4 394.79 12.8 80.16 92.8 0.998 3.6

110 84.6 394.86 12.8 80.20 94.8 0.996 4.2

135 83.8 394.86 12.8 80.20 95.7 0.991 4.9

175 83.2 394.87 15.5 80.20 96.4 0.981 6.5

220 82.9 394.87 15.7 80.20 96.7 0.956 7.8

265 82.7 394.87 15.9 80.20 97.0 0.915 9.2

Note: measurements done with the line filter shown in figure 23

Vo (VDC) ∆Vo(V

pk-pk

)

Po (W) η (%) PF THD (%)

Table 7. EVAL6562N: Evaluation results at half load

Vin (VAC)

Pin (W)

85 42.8 394.86 6.6 40.20 93.9 0.994 5.5

110 42.5 394.90 6.6 40.20 94.6 0.985 6.2

135 42.5 394.91 6.7 40.20 94.6 0.967 7.1

175 42.5 394.93 8.0 40.19 94.6 0.939 8.3

Vo (VDC) ∆Vo(V

pk-pk

)

Po (W) η (%) PF THD (%)

220 42.6 394.94 8.2 40.19 94.3 0.869 9.8

265 42.6 394.94 8.3 40.19 94.3 0.776 11.4

Note: measurements done with the line filter shown in figure 23

11/16

Page 12

L6562

Table 8. EVAL6562N: No-load measurements

Vin (VAC)

Pin (W)

Vo (VDC) ∆Vo(V

pk-pk

)

85 0.4 396.77 0.45 0

110 0.3 396.82 0.55 0

135 0.3 396.83 0.60 0

(*)

175

(*)

220

(*)

265

(*)

Vcc = 12V supplied externally

0.4 396.90 1.00 0

0.4 396.95 1.40 0

0.5 396.98 1.65 0

Figure 26. Line filter (not tested for EMI compliance) used for EVAL6562N evaluation

to the AC

source

B81133

470 nF, X2

EPCOS

B82732

47 mH, 1.3A

EPCOS

B81133

680 nF, X2

EPCOS

to

EVAL6562N

Po (W)

12/16

Page 13

Figure 27. DIP-8 Mechanical Data & Package Dimensions

L6562

DIM.

mm inch

MIN. TYP. MAX. MIN. TYP. MAX.

A3.32 0.131

a1 0.51 0.020

B 1.15 1.65 0.045 0.065

b 0.356 0.55 0.014 0.022

b1 0.204 0.304 0.008 0.012

D 10.92 0.430

E 7.95 9.75 0.313 0.384

e2.54 0.100

e3 7.62 0.300

e4 7.62 0.300

F 6.6 0.260

I 5.08 0.200

L 3.18 3.81 0.125 0.150

Z 1.52 0.060

OUTLINE AND

MECHANICAL DATA

DIP-8

13/16

Page 14

L6562

Figure 28. SO-8 Mechanical Data & Package Dimensions

DIM.

A 1.35 1.75 0.053 0.069

A1 0.10 0.25 0.004 0.010

A2 1.10 1.65 0.043 0.065

B 0.33 0.51 0.013 0.020

C 0.19 0.25 0.007 0.010

(1)

D

E 3.80 4.00 0.15 0.157

e 1.27 0.050

H 5.80 6.20 0.228 0.244

h 0.25 0.50 0.010 0.020

L 0.40 1.27 0.016 0.050

k 0˚ (min.), 8˚ (max.)

ddd 0.10 0.004

Note: (1) Dimensi ons D does not inclu de mold flash, pro tru-

mm inch

MIN. TYP. MAX. MIN. TYP. MAX.

4.80 5.00 0.189 0.197

sions or gate bur rs.

Mold flash , pot rus ions or ga t e burr s shall not exce ed

0.15mm (.006inch) in total (both side).

OUTLINE AND

MECHANICAL DA T A

SO-8

14/16

0016023 C

Page 15

Table 9. Revision History

Date Revision Description of Chan g es

January 2004 5 First Issue

L6562

June 2004 6 Modified the Style-look in compliance with the “Corporate Technical

Publications Design Guide ”.

Changed input of the power amplifier connected to Multiplier (Fig. 2).

15/16

Page 16

L6562

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infri ngement of patents or othe r rights of third parties whic h may result from its use. No license is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without no tice. This publication supersedes and replaces all information previously suppl ied. STMicroelectronics product s are not

authorized for use as criti cal components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics.

All other names are the property of their respective owners

© 2004 STMicroelectronics - All rights reserved

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States

STMicroelectronics GROUP OF COMPANIES

www.st.com

16/16

Loading...

Loading...